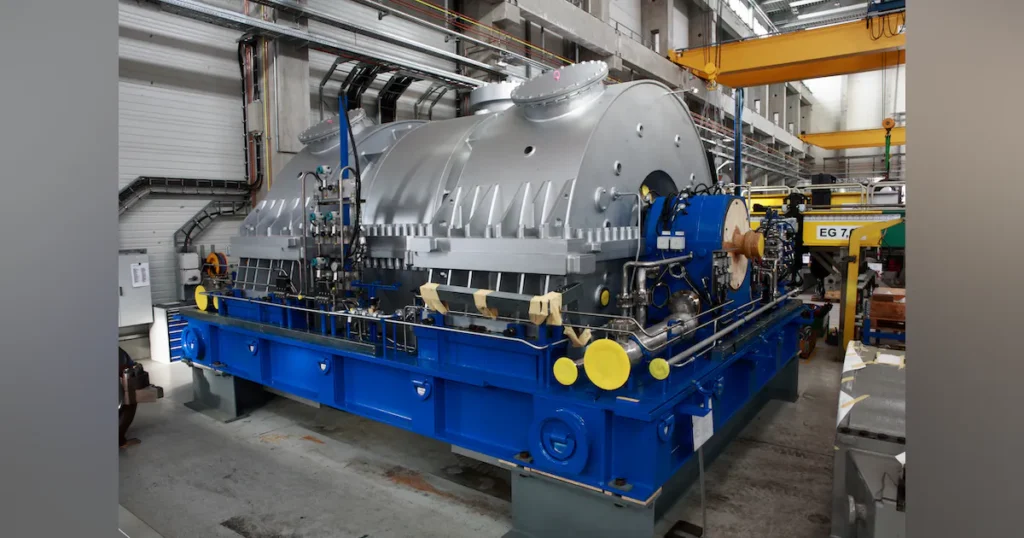

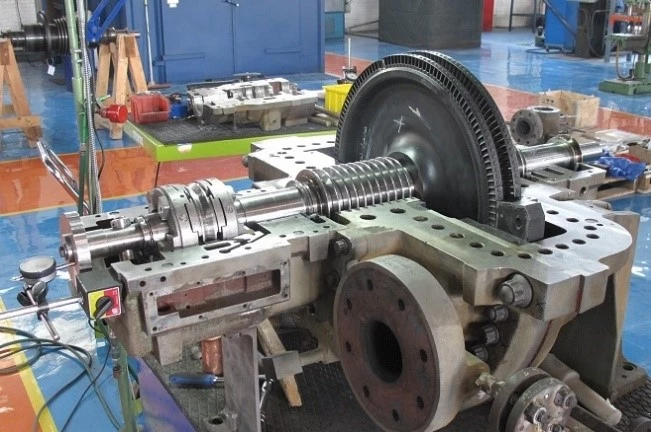

A single-stage steam turbine consists of several key components that work together to convert high-pressure steam into mechanical work. While the specific design and components may vary depending on the manufacturer and application, here are the fundamental parts commonly found in a single-stage steam turbine:

- Rotor (Turbine Wheel): The rotor is the central rotating component of the steam turbine. It typically consists of a shaft and a set of rotor blades or buckets. When steam is directed over the rotor blades, it causes the rotor to rotate, generating mechanical work. The rotor is connected to the machine or generator that utilizes the mechanical energy produced.

- Stator (Nozzle Block): The stator is the stationary component that directs high-pressure steam onto the rotor blades. It consists of fixed nozzles or guide vanes that control the flow and direction of steam as it enters the rotor blades. The stator’s design plays a critical role in optimizing steam flow and turbine efficiency.

- Rotor Blades (Buckets): The rotor blades are mounted on the rotor shaft and are responsible for capturing the kinetic energy of the steam as it flows over them. The shape and arrangement of these blades are crucial for efficiently converting the energy of the expanding steam into rotational motion.

- Bearings: Bearings support and allow the rotor shaft to rotate freely. They help minimize friction and wear within the turbine, ensuring smooth operation. Bearings are often lubricated to reduce friction and dissipate heat generated during operation.

- Governor: The governor is a control system that regulates the speed and output of the steam turbine. It monitors the turbine’s speed and adjusts the steam flow to maintain the desired operating speed. The governor helps stabilize the turbine’s operation under varying load conditions.

- Lubrication System: Steam turbine components, particularly bearings, require lubrication to reduce friction and prevent wear. Lubricating oil is supplied to critical parts of the turbine to ensure proper operation and longevity.

- Sealing System: Steam turbines require effective sealing to prevent steam leaks and maintain operational efficiency. Seals are used at various points within the turbine to contain steam and maintain the pressure difference between stages.

- Exhaust System: The exhaust system is responsible for directing the exhaust steam out of the turbine after it has passed over the rotor blades. In a back-pressure turbine, the exhaust steam is released at a pressure higher than atmospheric, and the exhaust system routes it to the intended application or industrial process.

- Control and Instrumentation: Modern steam turbines are equipped with advanced control and instrumentation systems that monitor and manage various parameters, including temperature, pressure, and speed. These systems help optimize turbine performance and safety.

- Casing: The casing encloses and protects the internal components of the turbine. It also helps direct steam flow and maintains structural integrity.

- Cooling System: Steam turbines generate significant heat during operation, and cooling systems, such as air coolers or water cooling, are used to dissipate this heat and maintain safe operating temperatures.

- Steam Inlet and Outlet Connections: The turbine has connections for steam inlet and outlet, allowing the high-pressure steam to enter the turbine and the exhaust steam to exit.

The design and arrangement of these components may vary based on the specific application and the manufacturer’s design choices. Single-stage steam turbines are relatively simple compared to multi-stage turbines, making them suitable for certain smaller-scale and specialized applications.

Single Stage Steam Turbine Parts

A single-stage steam turbine consists of several essential components that work together to convert the thermal energy of steam into mechanical energy. These components can be categorized into four main groups:

- Rotating Components:

- Turbine Blade: The turbine blade is the primary component that extracts energy from the steam. It is typically made of high-strength, heat-resistant materials like stainless steel or nickel alloys. The blade’s shape and orientation are crucial for efficient energy transfer.

- Turbine Disc: The turbine disc serves as the hub for the turbine blades. It is a solid rotating component that attaches the blades to the turbine shaft. The disc is made of a strong material that can withstand the high rotational speeds and centrifugal forces.

- Turbine Shaft: The turbine shaft is the central axis of rotation for the turbine. It transmits the mechanical energy generated by the turbine blades to the generator or other mechanical equipment. The shaft is made of a high-strength, durable material that can withstand the torque and rotational stresses.

- Stationary Components:

- Nozzle: The nozzle directs the steam flow onto the turbine blades at the optimal angle and velocity. The nozzle shape is designed to accelerate the steam and increase its kinetic energy.

- Casing: The casing encloses the rotating components and provides a pressurized environment for the steam flow. It is typically made of a strong, corrosion-resistant material like cast iron or stainless steel.

- Gland: The gland seals the gap between the rotating and stationary components to prevent steam leakage and maintain pressure. Glands are typically made of soft, resilient materials like graphite or Teflon.

- Auxiliary Components:

- Governor: The governor regulates the turbine speed by adjusting the steam flow. It ensures that the turbine operates within safe and efficient operating parameters.

- Bearings: Bearings support the rotating components and minimize friction. They are typically made of durable materials like bronze or babbitt metal.

- Sensors: Sensors monitor various parameters, such as steam pressure, temperature, and vibration, to provide feedback for control and safety systems.

- Additional Components:

- Condenser: A condenser is used in condensing turbines to remove the heat from the exhaust steam and create a vacuum, which increases the turbine’s power output.

- Generator: The generator converts the mechanical energy from the turbine shaft into electrical energy. It consists of coils of wire rotating within a magnetic field.

These components, working in unison, enable the single-stage steam turbine to efficiently convert steam energy into useful work, providing power for various applications.

Turbine Blade

A turbine blade is a crucial component of a steam turbine, responsible for converting the kinetic energy of the expanding steam into mechanical energy. These blades are carefully designed to optimize the interaction between the steam and the turbine blades, maximizing energy extraction and efficiency.

Blade Shape and Design:

The shape and angle of the turbine blades play a critical role in determining their performance. Blades can be designed with a variety of profiles, including aerofoils, twisted blades, and labyrinth blades.

- Aerofoil Blades: These blades have a curved cross-section similar to an airplane wing. The curvature of the blade helps to accelerate the steam as it flows over the blade, increasing its kinetic energy.

- Twisted Blades: These blades rotate around their longitudinal axis as they move downstream, gradually changing their angle of attack. This twisting action helps to maintain the optimal angle of interaction between the steam and the blade throughout the expansion process.

- Labyrinth Blades: These blades have complex internal passages that help to seal the gap between the blade and the casing, preventing steam leakage and maintaining pressure.

Material Selection for Turbine Blades:

The materials used for turbine blades must be able to withstand the extreme conditions of the steam environment, including high temperatures, high pressures, and corrosion from steam impurities.

- Stainless Steel: Stainless steel is a common material for turbine blades due to its strength, corrosion resistance, and relatively low cost.

- Nickel Alloys: Nickel alloys, such as Inconel and Hastelloy, offer better corrosion resistance and higher temperature capabilities than stainless steel.

- Ceramic Materials: Ceramic materials, such as alumina and zirconia, are extremely resistant to corrosion and heat, but they are also more brittle and difficult to manufacture.

Factors Affecting Turbine Blade Performance:

Several factors influence the performance of turbine blades, including:

- Steam Pressure: Higher steam pressure leads to increased kinetic energy of the steam, allowing the blades to extract more power.

- Steam Temperature: Higher steam temperature increases the steam’s enthalpy, which further enhances energy extraction.

- Blade Angle: The angle of attack between the steam and the blade is crucial for optimal energy transfer. A too-shallow angle results in reduced efficiency, while a too-steep angle can lead to blade erosion.

- Blade Vibration: Excessive vibration can cause blade fatigue and premature failure. Proper blade design, support structures, and vibration monitoring systems are essential for preventing blade damage.

In summary, turbine blades are critical components that enable steam turbines to efficiently convert steam energy into mechanical energy. Their careful design, material selection, and operating conditions are essential for ensuring optimal performance and maximizing turbine efficiency across a wide range of applications.

Calculating the back pressure in a steam turbine involves considering the properties of the exhaust steam and the specific conditions at the turbine outlet. The back pressure is typically expressed in pressure units such as pounds per square inch (psi), pascals (Pa), or bar. Here are the steps to calculate the turbine back pressure:

- Determine the Steam Properties:

- Gather information about the properties of the steam entering the turbine, including its pressure (P_in) and temperature (T_in). These values can be obtained from the steam source or the steam cycle.

- Understand the Turbine Characteristics:

- Familiarize yourself with the design and specifications of the steam turbine, including any extraction points (if applicable) and the desired back pressure level. Extraction points allow for the extraction of steam at various pressures for specific processes.

- Calculate the Isentropic Expansion:

- Determine the isentropic efficiency (η_isentropic) of the turbine, which represents how efficiently the turbine converts the enthalpy of the incoming steam into mechanical work. This efficiency is usually provided by the turbine manufacturer or can be estimated based on the type and design of the turbine.

- Calculate the enthalpy (h_out_isentropic) at the turbine outlet if the expansion were isentropic (adiabatic and reversible). This can be calculated using the steam tables or software tools specific to steam properties.

- Calculate the Actual Outlet Enthalpy:

- Use the isentropic efficiency to calculate the actual outlet enthalpy (h_out_actual) of the steam from the turbine:h_out_actual = h_in – η_isentropic * (h_in – h_out_isentropic)

- h_in is the enthalpy of the incoming steam.

- h_out_isentropic is the enthalpy at the outlet if the expansion were isentropic.

- Determine the Back Pressure:

- Based on the desired outlet pressure or back pressure (P_back_pressure) for your specific application, you can calculate the corresponding enthalpy at that pressure. This can be done using the steam tables or thermodynamic software.

- Ensure that the desired back pressure is within the operational capabilities of the turbine.

- Verify the Actual Back Pressure:

- Compare the calculated enthalpy at the desired back pressure to the actual outlet enthalpy (h_out_actual) from the turbine. The actual outlet pressure (P_out_actual) should match the desired back pressure as closely as possible.

- Calculate the actual back pressure (P_back_actual) using the enthalpy obtained at the desired back pressure.

Keep in mind that this calculation assumes ideal conditions and does not account for factors like mechanical losses or other losses in the turbine. It provides an approximate back pressure value based on the properties of the incoming steam and the turbine’s isentropic efficiency. Additionally, it’s important to consult the manufacturer’s specifications and guidelines for accurate calculations and operational limits specific to your turbine.

Turbine back pressure is the pressure of the steam exiting the turbine’s outlet. It is a crucial parameter that determines the efficiency and utilization of the steam turbine system.

Factors Affecting Turbine Back Pressure:

- Steam Supply Pressure: The pressure of the steam entering the turbine directly influences the backpressure level. Higher steam supply pressure generally results in higher backpressure.

- Steam Flow Rate: The amount of steam flowing through the turbine affects the backpressure. Increased steam flow can lead to a rise in backpressure.

- Turbine Design: The design of the turbine, including blade geometry, stage configuration, and exhaust piping, influences the backpressure level.

- Downstream Steam Utilization: If the exhaust steam from the turbine is utilized for other purposes, such as heating or process applications, the backpressure level is typically maintained at a specific value to provide the required steam pressure for those downstream applications.

Calculating Turbine Back Pressure:

The backpressure of a turbine can be calculated using various methods, including:

- Steam Cycle Analysis: By analyzing the steam cycle of the turbine system, including the properties of steam at different stages, the backpressure can be determined using mathematical equations and thermodynamic principles.

- Empirical Correlations: Empirical correlations based on experimental data and turbine design parameters can be used to estimate the backpressure level.

- Manufacturer’s Data: Turbine manufacturers often provide backpressure curves or tables for their specific turbine models, which can be used to determine the backpressure for different operating conditions.

- Turbine Instrumentation: In some cases, direct measurements of backpressure may be available from instrumentation installed on the turbine’s exhaust piping.

Optimizing Turbine Back Pressure:

The optimal backpressure level for a steam turbine system depends on the specific application and the balance between electricity generation and exhaust steam utilization. In cogeneration systems, the backpressure level is carefully selected to maximize both electricity production and steam availability for industrial processes.

Conclusion:

Turbine back pressure plays a critical role in steam turbine systems, influencing both energy extraction and exhaust steam utilization. By carefully calculating and optimizing the backpressure level, steam turbine systems can achieve optimal efficiency, provide valuable steam for various industrial applications, and contribute to energy conservation efforts.

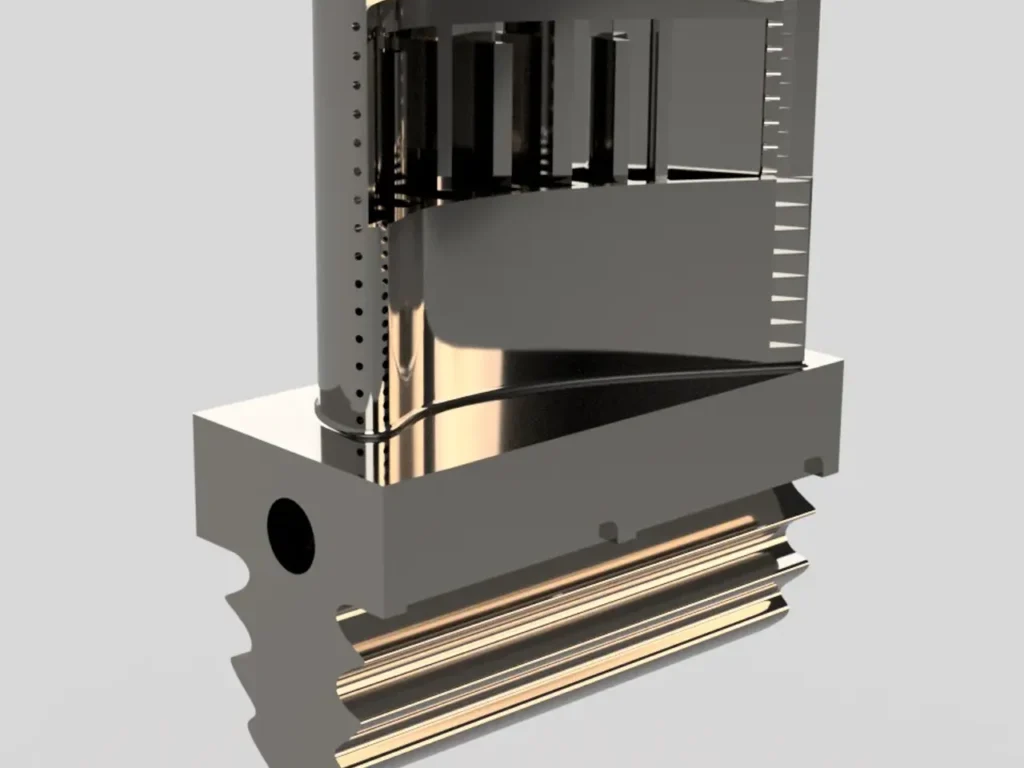

Turbine Disc

A turbine disc, also known as a rotor disc or impeller disc, is a crucial component in a steam turbine, gas turbine, or other rotary machinery. It serves as the central hub for mounting the turbine blades and transmitting the mechanical energy generated by the blades to the turbine shaft.

Key Characteristics of Turbine Discs:

- High Strength and Durability: Turbine discs must withstand immense rotational forces, high temperatures, and pressure fluctuations. They are typically made from high-strength materials like forged steel, nickel-based superalloys, or titanium alloys.

- Precise Manufacturing and Inspection: Turbine discs are manufactured to extremely tight tolerances to ensure their balance, stability, and integrity. They undergo rigorous inspections, including ultrasonic testing, to detect any imperfections that could compromise their structural integrity.

- Cooling Mechanisms: Turbine discs operate in high-temperature environments, requiring effective cooling mechanisms to prevent overheating and material degradation. Internal cooling passages or external cooling jets are often employed to dissipate heat and maintain optimal operating temperatures.

Function of Turbine Disc:

- Blade Mounting: The turbine disc provides the mounting surface for the turbine blades. The blades are carefully positioned and secured to the disc to ensure optimal alignment and blade-to-blade clearance.

- Centrifugal Force Management: The turbine disc rotates at high speeds, generating significant centrifugal forces. The disc’s design and material properties must withstand these forces to prevent deformation or failure.

- Mechanical Energy Transmission: The mechanical energy generated by the turbine blades is transferred to the turbine shaft through the turbine disc. The disc’s rotational motion drives the turbine shaft, which can then be used to generate electricity or drive other machinery.

Applications of Turbine Discs:

Turbine discs are found in a wide range of applications, including:

- Steam Turbines: Steam turbines use turbine discs to extract energy from steam, generating electricity or providing mechanical power for various industrial processes.

- Gas Turbines: Gas turbines employ turbine discs to convert the energy from hot compressed gas into mechanical energy, powering aircraft engines, power generation systems, or industrial turbines.

- Turbochargers: Turbochargers in internal combustion engines utilize turbine discs to enhance engine performance by increasing air intake.

- Turbomachinery: Turbine discs are essential components in various turbomachinery applications, including pumps, compressors, and expanders.

Conclusion:

Turbine discs play a critical role in converting the energy of steam, gas, or other fluids into mechanical energy. Their ability to withstand extreme conditions and transmit high rotational forces makes them indispensable components in a wide range of applications, powering machinery and generating electricity across various industries.

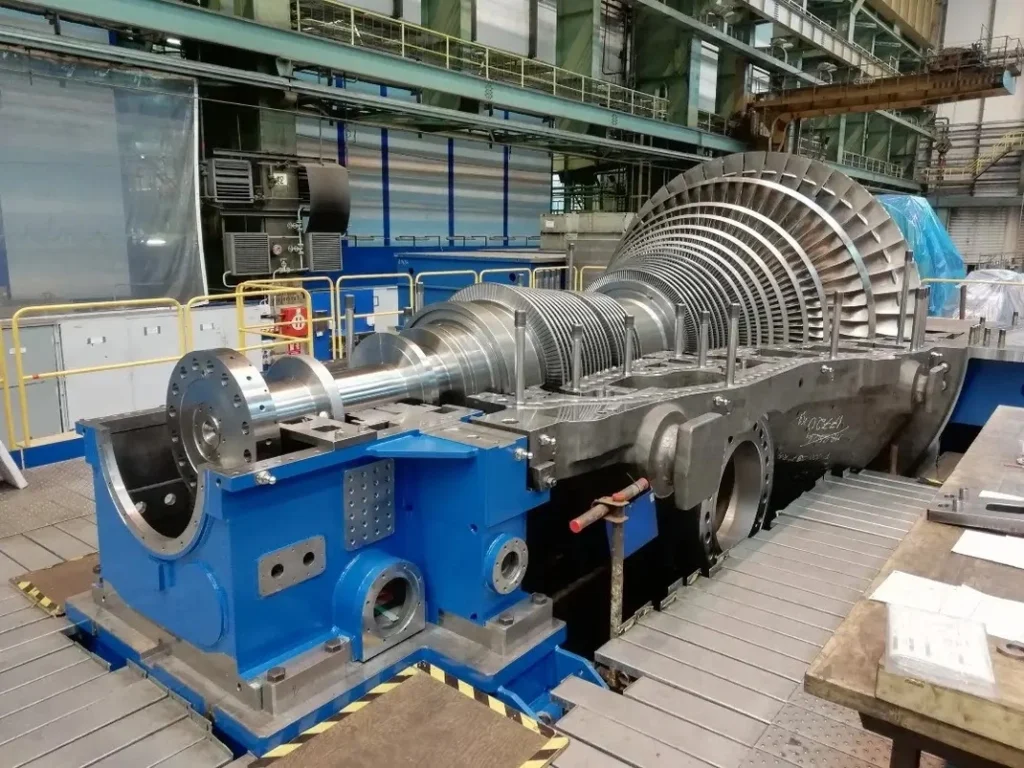

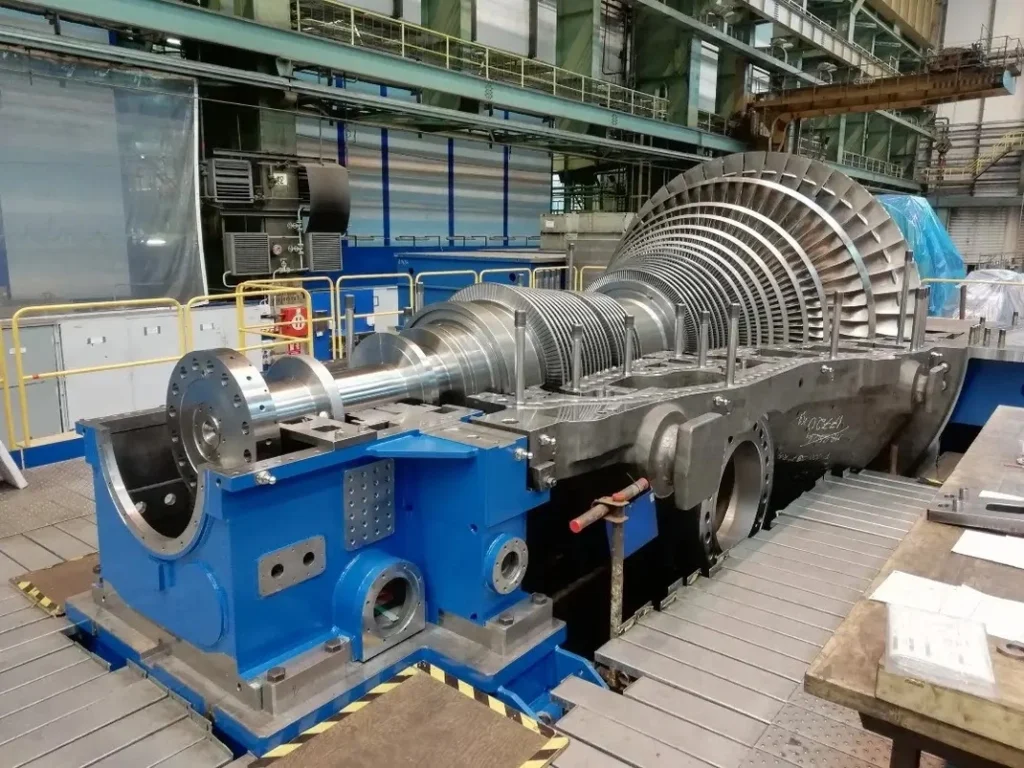

Turbine Shaft

The turbine shaft is a critical component in a steam turbine, gas turbine, or other rotary machinery that connects the turbine blades to the generator or other machinery. It serves as the central axis of rotation, transmitting the mechanical energy generated by the turbine blades to the output device.

Characteristics of Turbine Shafts:

- High Strength and Durability: Turbine shafts must withstand immense torque, rotational forces, and vibrations. They are typically made from high-strength materials like forged steel, nickel-based superalloys, or titanium alloys to ensure their integrity under demanding operating conditions.

- Precise Manufacturing and Balancing: Turbine shafts are manufactured to extremely tight tolerances to ensure their balance and stability. They undergo rigorous balancing procedures to minimize vibrations and prevent damage to the turbine and connected machinery.

- Surface Hardness and Wear Resistance: Turbine shafts operate in environments with potential wear and tear. Their surfaces are often treated with hardening processes or coated with wear-resistant materials to enhance their durability and extend their lifespan.

Function of Turbine Shaft:

- Mechanical Energy Transmission: The turbine shaft receives the mechanical energy generated by the turbine blades through the turbine disc. It rotates at high speeds, transmitting this energy to the generator or other machinery.

- Power Output Transmission: In steam turbines, the turbine shaft drives the generator, producing electricity. In gas turbines, the shaft can directly drive machinery or connect to a generator for electricity production.

- Speed Regulation: The turbine shaft’s speed is regulated by control systems to ensure optimal performance and prevent damage to the turbine and connected machinery.

Applications of Turbine Shafts:

Turbine shafts are found in a wide range of applications, including:

- Steam Turbines: Steam turbines use turbine shafts to generate electricity or provide mechanical power for various industrial processes.

- Gas Turbines: Gas turbines employ turbine shafts to convert the energy from hot compressed gas into mechanical energy, powering aircraft engines, power generation systems, or industrial turbines.

- Turbochargers: Turbochargers in internal combustion engines utilize turbine shafts to enhance engine performance by increasing air intake.

- Turbomachinery: Turbine shafts are essential components in various turbomachinery applications, including pumps, compressors, and expanders.

Conclusion:

Turbine shafts play a crucial role in converting the energy of steam, gas, or other fluids into mechanical energy and transmitting it to the output device. Their ability to withstand extreme conditions, transmit high torque, and maintain precise rotation makes them indispensable components in a wide range of applications, powering machinery and generating electricity across various industries.

Nozzle

A nozzle is a device that accelerates a fluid to a high velocity by constricting its passage. Nozzles are used in a wide variety of applications, including steam turbines, jet engines, rockets, and fluid spray systems.

How Nozzles Work:

- Fluid Constriction: A nozzle works by constricting the passage through which the fluid flows. This constriction increases the fluid’s velocity and decreases its pressure.

- Energy Conversion: As the fluid’s velocity increases, its kinetic energy increases. This increase in kinetic energy comes at the expense of the fluid’s pressure energy.

- Velocity Optimization: The shape of the nozzle is designed to optimize the fluid flow and achieve the desired velocity at the nozzle exit. This optimization is crucial for maximizing energy transfer and achieving the desired performance.

Types of Nozzles:

There are two main types of nozzles: convergent nozzles and convergent-divergent nozzles.

- Convergent Nozzles: Convergent nozzles have a continuously decreasing cross-sectional area from the inlet to the outlet. They are used in applications where a high velocity is required at the nozzle exit, such as steam turbines and jet engines.

- Convergent-Divergent Nozzles: Convergent-divergent nozzles have an initial convergent section followed by a divergent section. The convergent section accelerates the fluid, while the divergent section allows the fluid to expand and maintain a high velocity while its pressure decreases further. Convergent-divergent nozzles are used in applications where a high exit velocity and a low exit pressure are required, such as rockets and supersonic aircraft engines.

Applications of Nozzles:

Nozzles are used in a wide variety of applications, including:

- Steam Turbines: Nozzles in steam turbines accelerate steam to a high velocity, allowing the steam to transfer its energy to the turbine blades and generate electricity.

- Jet Engines: Nozzles in jet engines accelerate air to a high velocity, creating thrust that propels the aircraft forward.

- Rockets: Nozzles in rockets accelerate hot gas to a very high velocity, generating thrust that propels the rocket into space.

- Fluid Spray Systems: Nozzles in fluid spray systems create fine droplets of fluid for applications such as irrigation, cleaning, and painting.

- Venturi Meters: Nozzles are used in Venturi meters to measure fluid flow rate by constricting the flow path and measuring the pressure difference upstream and downstream of the nozzle.

Conclusion:

Nozzles are versatile and essential components in various engineering applications. Their ability to accelerate fluids efficiently and achieve desired flow characteristics makes them crucial for power generation, propulsion systems, fluid control, and measurement applications. The design and optimization of nozzles play a significant role in the performance and efficiency of these systems.

Casing

In the context of steam turbines and gas turbines, a casing is a critical component that encloses and supports the rotating turbine blades and other internal components. It provides a structural framework, ensures the containment of high-pressure fluids, and maintains a controlled environment for efficient operation.

Purpose and Functions of a Casing:

- Structural Support: The casing provides a rigid structure to support the turbine blades, shaft, and other rotating components. It withstands the immense centrifugal forces and vibrations generated during turbine operation.

- Fluid Containment: The casing ensures the containment of high-pressure steam or gas within the turbine. It prevents leaks and maintains a controlled pressure environment for optimal performance.

- Heat Management: The casing plays a role in heat management by providing thermal insulation and facilitating cooling mechanisms. It helps prevent excessive heat transfer and maintain the integrity of internal components.

- Lubrication and Sealing: The casing may incorporate passages or seals to allow for lubrication and sealing of rotating components. It ensures that the turbine operates efficiently with minimal friction and leakage.

- Access for Inspections: The casing may include access ports or removable sections to allow for inspections, maintenance, and repair of internal components.

Design Considerations for Turbine Casings:

- Material Selection: The casing material must be able to withstand high temperatures, pressures, and corrosive environments. Materials like forged steel, nickel-based superalloys, or cast iron are commonly used.

- Shape and Size: The casing shape and size are carefully designed to optimize flow patterns, minimize stress concentrations, and accommodate internal components.

- Manufacturing Precision: The casing is manufactured to tight tolerances to ensure its structural integrity, prevent leaks, and maintain proper alignment of internal components.

- Inspection and Monitoring: Casings undergo rigorous inspections and may incorporate sensors to monitor pressure, temperature, and vibration levels during operation.

Applications of Turbine Casings:

- Steam Turbines: Steam turbines employ casings to enclose the steam flow path, blades, and rotating components. They provide a pressure-tight environment for efficient steam expansion and power generation.

- Gas Turbines: Gas turbines use casings to contain the hot, pressurized gas flow and protect the rotating components from extreme temperatures and pressures.

- Turbochargers: Turbochargers in internal combustion engines utilize casings to house the turbine blades and provide a controlled environment for air compression.

- Turbomachinery: Casings are essential components in various turbomachinery applications, including pumps, compressors, and expanders.

Conclusion:

Turbine casings play a fundamental role in the safe and efficient operation of steam turbines and gas turbines. Their ability to withstand extreme conditions, maintain pressure integrity, and provide a controlled environment is crucial for maximizing energy conversion and ensuring the longevity of these critical power generation systems.

Gland

In the context of steam turbines and gas turbines, a gland is a device that seals the clearance between rotating and stationary components to prevent leakage of pressurized fluids. Glands play a critical role in maintaining the pressure and efficiency of these turbines.

Purpose and Functions of Glands:

- Leakage Prevention: Glands prevent the leakage of steam or gas from the high-pressure side of the turbine to the low-pressure side. This leakage can reduce the turbine’s efficiency and potentially cause damage to internal components.

- Pressure Maintenance: By preventing leakage, glands help maintain the pressure differential necessary for efficient turbine operation. This pressure difference is crucial for generating power or providing mechanical work.

- Contaminant Exclusion: Glands also prevent contaminants, such as dust or moisture, from entering the turbine and causing damage to internal components. They maintain a clean and controlled environment within the turbine.

- Lubrication and Cooling: Some glands incorporate lubrication and cooling mechanisms to reduce friction and heat generation between rotating and stationary surfaces. This ensures smooth operation and extends the lifespan of these components.

Types of Glands:

There are two main types of glands used in steam turbines and gas turbines:

- Labyrinth Glands: Labyrinth glands consist of a series of interlocking grooves or ridges that create a tortuous path for leakage. This design increases the frictional resistance to leakage and effectively prevents fluid escape.

- Brush Glands: Brush glands utilize a dense array of fine wires or bristles that make contact with the rotating shaft or disc. The bristles act as a barrier to leakage and provide a wiping action to remove contaminants.

Materials for Glands:

The materials used for glands must withstand high temperatures, pressures, and wear from constant contact with rotating components. Common materials include:

- Graphite: Graphite is a self-lubricating material with excellent wear resistance and thermal properties. It is commonly used for labyrinth glands.

- Babbitt Metal: Babbitt metal is a soft, white alloy with good embedding properties. It is used in conjunction with rotating shafts or discs to conform to their surface and provide a tight seal.

- Teflon: Teflon is a synthetic fluoropolymer with excellent chemical resistance and low friction characteristics. It is used for brush glands and other applications where minimal wear and contamination are critical.

Applications of Glands:

Glands are used in a variety of applications, including:

- Steam Turbines: Glands seal the clearance between the turbine blades and the casing, preventing steam leakage and maintaining pressure for efficient power generation.

- Gas Turbines: Glands seal the clearance between the rotating compressor and turbine blades and the casing, preventing gas leakage and maintaining pressure for efficient power production.

- Pumps and Compressors: Glands seal the clearance between rotating shafts and stationary components in pumps and compressors, preventing fluid leakage and maintaining pressure for fluid transfer or compression.

- Turbomachinery: Glands are essential components in various turbomachinery applications, ensuring efficient operation and preventing fluid leakage and contamination.

Conclusion:

Glands play a crucial role in maintaining the pressure integrity, efficiency, and longevity of steam turbines, gas turbines, and other rotating machinery. Their ability to seal clearances, prevent leakage, and maintain a controlled environment is essential for safe and reliable operation across various applications.

Back Pressure Steam

Back pressure steam is steam that is exhausted from a steam turbine at a lower pressure than the boiler’s operating pressure. This steam is still available for use in various applications, such as industrial processes, heating, and district heating systems.

Characteristics of Back Pressure Steam:

- Lower Pressure: Back pressure steam exits the turbine at a lower pressure than the boiler’s operating pressure. This lower pressure is a result of the expansion of the steam as it passes through the turbine’s stages.

- Still Contains Thermal Energy: Despite the lower pressure, back pressure steam still contains significant thermal energy that can be utilized for various purposes.

- Suitability for Downstream Applications: Back pressure steam can be used in a variety of downstream applications, such as process steam, heating, and district heating systems.

Factors Affecting Back Pressure:

- Turbine Design: The design of the steam turbine, particularly the blade configuration and stage spacing, influences the back pressure generated.

- Boiler Pressure: The operating pressure of the boiler dictates the maximum pressure of the steam entering the turbine.

- Turbine Load: The load on the turbine affects the back pressure, as higher loads result in lower back pressures due to increased steam flow.

- Condensate Return: Effective condensate return helps maintain the boiler’s water level and prevents overpressurization, which can affect back pressure.

Optimization of Back Pressure:

- Matching Demand and Supply: Balancing the supply of back pressure steam with the demand for downstream applications is crucial for efficient utilization.

- Pressure Control: Controlling the back pressure can be achieved through adjusting the turbine’s control valves or adjusting the boiler’s operating pressure.

- Stream Conditioning: In some cases, back pressure steam may require conditioning to remove impurities or adjust its temperature for specific downstream applications.

- Waste Heat Recovery: Back pressure steam can be used as an input for waste heat recovery systems, further extracting useful energy from the steam.

Benefits of Back Pressure Steam Utilization:

- Energy Efficiency: Utilizing back pressure steam for downstream applications enhances overall energy efficiency by extracting additional useful energy from the steam before it is discharged.

- Reduced Fuel Consumption: Redirecting back pressure steam to downstream uses can reduce the need for direct fuel combustion in boilers, leading to lower fuel consumption and cost savings.

- Environmental Benefits: Minimizing fuel consumption and utilizing waste heat from steam turbines contribute to reducing greenhouse gas emissions and minimizing the environmental impact of industrial processes.

- Water Savings: In some cases, back pressure steam can be used for process steam production, reducing the demand for fresh water, conserving water resources.

- Versatility: Back pressure steam can be used in a wide range of industrial processes and heating applications, making it a versatile and valuable energy source.

Conclusion:

Back pressure steam plays a significant role in optimizing energy efficiency and reducing environmental impact in steam turbine systems. By effectively utilizing back pressure steam for various downstream applications, industries can conserve fuel, reduce emissions, and extract additional value from their steam-generating processes.

Steam Supply Pressure

Steam supply pressure refers to the pressure of steam entering the turbine. It is a crucial parameter that affects the efficiency, performance, and overall operation of the steam turbine system.

Factors Affecting Steam Supply Pressure:

- Boiler Design and Capacity: The design and capacity of the boiler directly influence the maximum steam supply pressure that can be achieved. Larger boilers with more powerful pumps can generate steam at higher pressures.

- Fuel Type and Quality: The type and quality of fuel used in the boiler can affect the steam supply pressure. Higher-quality fuels, such as natural gas or oil, can produce steam at higher pressures compared to lower-quality fuels, such as coal.

- Boiler Efficiency: Boiler efficiency plays a role in determining the steam supply pressure. A more efficient boiler can generate steam at a higher pressure without excessive energy consumption.

- Condensate Return System: The effectiveness of the condensate return system, which collects and recycles condensed steam, can influence the steam supply pressure. Proper condensate return reduces the load on the boiler and allows for higher steam pressure generation.

Impact of Steam Supply Pressure:

- Turbine Efficiency: Higher steam supply pressure generally leads to higher turbine efficiency, as the steam molecules have more kinetic energy and can expand more effectively in the turbine stages.

- Power Generation: Higher steam supply pressure can increase the power output of the turbine, allowing for greater electricity generation.

- Heat Transfer Efficiency: Higher steam pressure can enhance heat transfer efficiency in steam-driven heat exchangers, improving their ability to transfer heat to various processes.

- Process Steam Production: In cogeneration systems, higher steam supply pressure can lead to increased production of high-pressure steam for industrial processes.

Optimizing Steam Supply Pressure:

The optimal steam supply pressure for a specific application depends on the desired balance between power generation, heat transfer, and exhaust steam utilization. In cogeneration systems, the steam supply pressure is adjusted to maximize both electricity production and steam availability for industrial processes.

Conclusion:

Steam supply pressure is a critical parameter that significantly impacts the performance and efficiency of steam turbine systems. By optimizing the steam supply pressure, steam turbine systems can achieve higher power generation, improve heat transfer efficiency, and maximize the utilization of exhaust steam for various industrial applications.

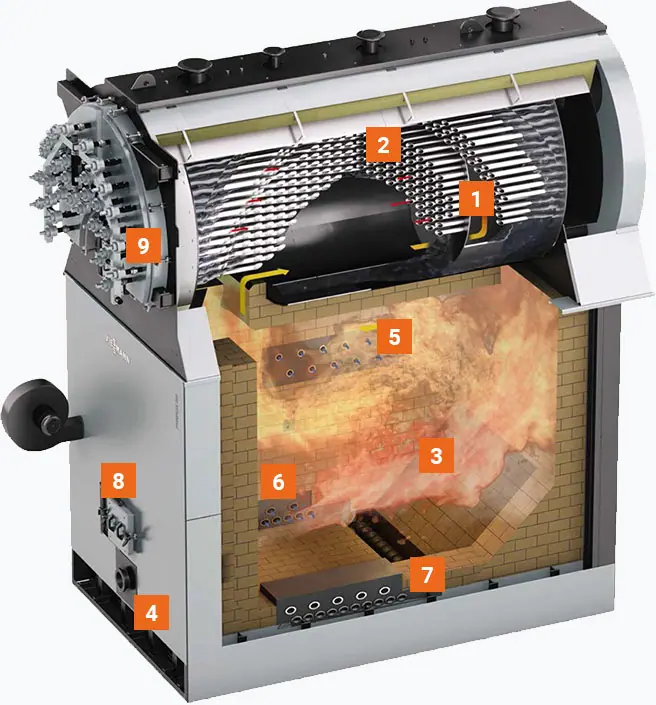

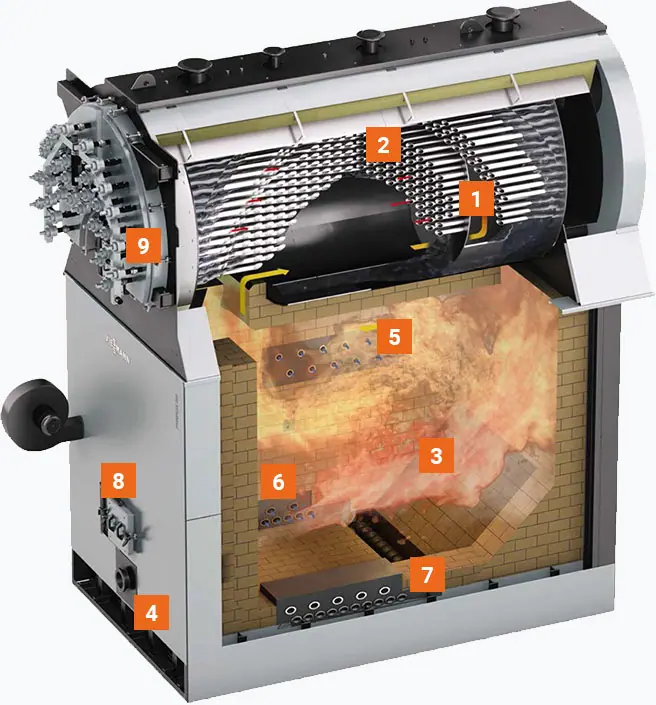

Boiler Design and Capacity

Boiler design and capacity play a crucial role in determining the efficiency, performance, and overall operation of steam turbine systems. The type and size of boiler selected must be carefully matched to the specific requirements of the steam turbine and the application it serves.

Factors Affecting Boiler Design:

- Steam Turbine Power Output: The steam turbine’s power output is a primary determinant of the boiler’s required capacity. Larger turbines with higher power ratings demand larger boilers capable of generating sufficient steam.

- Steam Pressure and Temperature: The desired steam pressure and temperature levels influence the boiler’s design parameters, such as the combustion chamber size and heat transfer surface area. Higher steam pressure and temperature requirements generally necessitate larger and more sophisticated boilers.

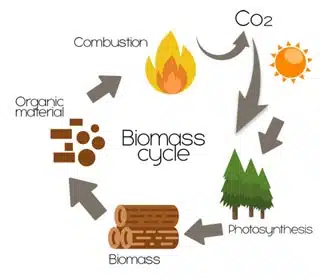

- Fuel Type and Efficiency: The type of fuel used in the boiler influences its design and operating characteristics. Boilers designed for certain fuel types, such as natural gas or oil, may have different combustion chambers, heat exchangers, and pollution control systems compared to boilers for coal or biomass.

- Condensate Return System: The effectiveness of the condensate return system, which collects and recycles condensed steam, can impact boiler design. Efficient condensate handling reduces the load on the boiler and allows for a smaller boiler size.

Impact of Boiler Design:

- Steam Production Efficiency: Boiler design significantly affects steam production efficiency. A well-designed boiler can minimize heat losses and maximize steam generation for a given amount of fuel input.

- Turbine Efficiency: Efficient steam production can directly impact turbine efficiency. Adequate steam pressure and temperature levels, along with minimizing impurities and contaminants in the steam, contribute to higher turbine efficiency.

- Reliability and Durability: Boiler design plays a crucial role in ensuring the reliability and durability of the boiler. Proper materials selection, corrosion protection measures, and effective maintenance practices can extend boiler lifespan and reduce downtime.

- Emissions Control: Boiler design can incorporate emissions control technologies to minimize harmful pollutants emitted during combustion. These technologies, such as flue gas desulfurization and Selective Catalytic Reduction, help protect the environment and meet environmental regulations.

Optimizing Boiler Design:

The optimal boiler design for a specific application depends on the desired steam pressure, temperature, and power output, as well as the fuel type and emission control requirements. By carefully considering these factors, boiler designers can select the most appropriate boiler type and size to meet the application’s needs and operate efficiently and sustainably.

Conclusion:

Boiler design and capacity are critical aspects of steam turbine systems, influencing their performance, efficiency, emissions control, and overall operation. By optimizing boiler design, steam turbine systems can maximize energy production, minimize environmental impact, and operate reliably for extended periods.

Fuel Type and Quality

Fuel type and quality play a significant role in the performance and efficiency of steam turbine systems. The appropriate selection and utilization of fuel can directly impact the steam production process, turbine operation, and overall energy generation.

Factors Affecting Fuel Selection:

- Steam Supply Requirements: The steam supply pressure, temperature, and flow rate requirements of the steam turbine determine the type of fuel that can be utilized effectively. Higher steam pressure and temperature demands may necessitate specific fuel types or blends.

- Fuel Availability and Cost: The availability and cost of different fuel sources in the region or locality influence the fuel selection process. Economic viability and supply chain considerations play a role in fuel choice.

- Environmental Regulations: Environmental regulations and emission standards can restrict the use of certain fuels or impose limits on pollutant emissions. Adherence to environmental norms is essential in fuel selection.

- Fuel Handling and Storage: The type of fuel also influences handling, storage, and transportation requirements. Some fuels, such as natural gas, require specialized infrastructure for transport and storage, while others, such as coal, can be handled using conventional methods.

Impact of Fuel Quality:

- Steam Production Efficiency: Fuel quality directly impacts steam production efficiency. High-quality fuels, such as natural gas or low-sulfur coal, produce cleaner and more efficient combustion, leading to higher steam generation rates for a given amount of fuel.

- Turbine Performance: Fuel quality can affect turbine performance by influencing steam purity and the presence of contaminants. Impurities in the steam, such as ash or sulfur compounds, can erode turbine blades and reduce efficiency.

- Emissions Control: Fuel quality plays a role in emissions control. Low-sulfur fuels produce fewer sulfur oxides (SOx), while low-nitrogen fuels reduce nitrogen oxide (NOx) emissions. Fuel choice can contribute to environmental compliance.

- Maintenance Requirements: Fuel quality can impact maintenance requirements. High-quality fuels generally lead to less fouling and corrosion in boilers and turbines, reducing maintenance frequency and costs.

Optimizing Fuel Selection and Quality:

- Fuel Analysis and Evaluation: Conducting regular fuel analysis and evaluation helps identify fuel quality variations and potential issues. This information can inform fuel selection decisions and optimize fuel blending strategies.

- Fuel Pre-Treatment: Pre-treatment processes, such as coal washing or fuel oil purification, can improve fuel quality and reduce impurities, leading to more efficient steam generation and cleaner emissions.

- Advanced Combustion Technologies: Utilizing advanced combustion technologies, such as fluidized bed combustion or staged combustion, can enhance fuel utilization and minimize pollutant formation.

- Fuel Management Systems: Implementing fuel management systems can optimize fuel usage, monitor fuel quality, and provide real-time data for fuel selection and blending decisions.

Conclusion:

Fuel type and quality are crucial aspects of steam turbine systems, influencing their efficiency, environmental performance, and overall operation. By selecting appropriate fuels, ensuring fuel quality, and implementing fuel management strategies, steam turbine systems can operate more effectively, reduce environmental impact, and contribute to sustainable energy production.

Boiler Efficiency

Boiler efficiency is a measure of how effectively a boiler converts the chemical energy in fuel into heat energy in steam. It is calculated by dividing the useful heat output by the total energy input. Boiler efficiency is typically expressed as a percentage, and can range from as low as 50% to as high as 98%.

Factors Affecting Boiler Efficiency:

- Boiler Design: The design of the boiler, including its combustion chamber, heat exchangers, and insulation, plays a significant role in determining its efficiency. Well-designed boilers minimize heat losses and maximize heat transfer to the water or steam being heated.

- Fuel Type and Quality: The type of fuel used in the boiler can affect its efficiency. Higher-quality fuels, such as natural gas or low-sulfur coal, produce cleaner and more efficient combustion, leading to lower heat losses and higher steam generation rates for a given amount of fuel.

- Combustion Control: Efficient combustion is crucial for maximizing boiler efficiency. Proper combustion control ensures that the correct amount of fuel and air is mixed, resulting in complete combustion and minimal heat losses.

- Boiler Maintenance: Regular maintenance and cleaning of the boiler, including its heat exchangers, burners, and tubes, are essential for maintaining efficiency. Fouling and corrosion can reduce heat transfer and lower efficiency.

- Water Treatment: The quality of the water used to generate steam can also impact boiler efficiency. Impurities in the water can lead to scale formation, which reduces heat transfer and increases energy consumption.

Improving Boiler Efficiency:

- Upgrade to High-Efficiency Boilers: Replacing old boilers with newer, more efficient models can significantly improve efficiency. Modern boilers incorporate advanced technologies and design features that minimize heat losses and enhance steam generation.

- Conduct Regular Boiler Maintenance: Implement a regular boiler maintenance schedule to ensure optimal performance and prevent efficiency losses. Maintenance should include cleaning, inspection, and replacement of worn or damaged components.

- Optimize Combustion Control: Employ advanced combustion control systems to ensure the precise mixing of fuel and air, leading to complete combustion and reduced heat losses.

- Utilize Efficient Fuel Blending: Blending different fuel types can optimize combustion and improve boiler efficiency. For instance, blending low-sulfur coal with higher-sulfur coal can reduce sulfur oxide emissions while maintaining efficiency.

- Implement Water Treatment Systems: Install appropriate water treatment systems to remove impurities from the boiler feedwater, preventing scale formation and maintaining heat transfer efficiency.

- Utilize Waste Heat Recovery Systems: Implement waste heat recovery systems to capture and utilize the heat lost in flue gases or other exhaust streams, increasing overall energy efficiency.

Conclusion:

Boiler efficiency is a critical parameter that directly influences the performance and cost-effectiveness of steam turbine systems. By optimizing boiler design, fuel selection, combustion control, and maintenance practices, steam turbine systems can achieve higher efficiency, reduce fuel consumption, and contribute to sustainable energy production.

Condensate Return System

A condensate return system is an integral part of a steam turbine system, responsible for collecting and returning condensed steam back to the boiler feedwater tank. This process plays a crucial role in improving steam turbine efficiency and reducing energy consumption.

Purpose of Condensate Return System:

The primary purpose of a condensate return system is to recover the thermal energy contained in the condensed steam and reuse it in the steam generation process. By recycling condensed steam, the boiler requires less energy to produce the same amount of steam, leading to significant fuel savings.

Working Principle of Condensate Return System:

- Condensate Collection: Condensate is collected from various points in the steam system, such as steam traps, heat exchangers, and process equipment. These collection points are typically located at low-pressure areas of the system.

- Condensate Transfer: The collected condensate is transported back to the boiler feedwater tank using pumps and piping. Condensate pumps provide the pressure differential required to overcome frictional losses and elevate the condensate to the desired pressure level.

- Condensate Treatment: Before being fed back to the boiler, the condensate may undergo treatment to remove impurities and contaminants that could cause corrosion or scale buildup in the boiler. This treatment may involve filtration, demineralization, or chemical conditioning.

- Condensate Storage: The treated condensate is stored in the boiler feedwater tank, where it is preheated by steam extraction or other means before being fed to the boiler. Preheating the condensate further reduces the boiler’s energy consumption.

Benefits of Condensate Return System:

- Improved Steam Turbine Efficiency: Reusing condensed steam reduces the energy required to generate steam, leading to higher steam turbine efficiency. This, in turn, improves overall power generation efficiency and reduces fuel consumption.

- Reduced Water Consumption: By recycling condensate, the need for fresh water for boiler feed is minimized. This conserves water resources and reduces the environmental impact of water extraction and treatment.

- Lower Operating Costs: The combination of improved efficiency and reduced water consumption leads to lower operating costs for the steam turbine system.

- Extended Boiler Life: By minimizing the introduction of impurities into the boiler, condensate return systems help protect the boiler from corrosion and scale buildup, extending its lifespan and reducing maintenance costs.

- Environmental Sustainability: Recycling condensate contributes to a more sustainable approach to steam turbine operation, reducing energy consumption, water usage, and environmental impact.

Conclusion:

A condensate return system is an essential component of a steam turbine system, playing a critical role in improving efficiency, reducing energy costs, and promoting environmental sustainability. By effectively collecting, treating, and reusing condensed steam, steam turbine systems can minimize their environmental footprint and contribute to a more sustainable energy future.

Turbine Efficiency

Turbine efficiency is a measure of how effectively a turbine converts the kinetic energy of a fluid, such as steam, water, or gas, into mechanical energy. It is typically expressed as a percentage, with higher values indicating better performance.

Factors Affecting Turbine Efficiency:

- Turbine Design: The design of the turbine, including the shape and size of the blades, the number of stages, and the overall geometry, plays a significant role in determining its efficiency. Well-designed turbines minimize energy losses and maximize energy conversion.

- Fluid Properties: The properties of the fluid flowing through the turbine, such as its density, pressure, and temperature, can affect efficiency. Higher density, pressure, and temperature generally lead to higher efficiency.

- Turbine Speed: The rotational speed of the turbine can also influence efficiency. Too slow a speed can reduce energy conversion, while too high a speed can lead to increased friction and energy losses.

- Fluid Entrance Conditions: The conditions at the turbine inlet, such as the uniformity and turbulence of the fluid flow, can affect efficiency. Smooth and uniform flow contributes to higher efficiency.

- Blade Erosion and Corrosion: Over time, turbine blades can experience erosion and corrosion due to the continuous exposure to high-velocity fluids. These degradations can reduce blade efficiency and overall turbine performance.

Improving Turbine Efficiency:

- Advanced Blade Design: Utilizing advanced blade designs, such as twisted or tapered blades, can improve fluid flow and reduce energy losses, leading to higher efficiency.

- Material Selection: Selecting materials with superior strength, erosion resistance, and corrosion resistance for turbine blades can extend their lifespan and maintain efficiency over time.

- Optimized Turbine Geometry: Optimizing the overall geometry of the turbine, including the blade angles, stage spacing, and flow path, can enhance energy conversion and reduce losses.

- Advanced Flow Control Systems: Implementing advanced flow control systems, such as variable inlet guide vanes or nozzle control mechanisms, can regulate the fluid flow and optimize turbine performance for different operating conditions.

- Regular Maintenance and Inspection: Regular maintenance and inspection of the turbine, including blade cleaning, surface repair, and component replacement, can prevent efficiency losses due to wear, erosion, or corrosion.

Conclusion:

Turbine efficiency is a crucial parameter that directly impacts the performance and cost-effectiveness of various power generation and industrial applications. By employing advanced design techniques, selecting appropriate materials, optimizing turbine geometry, implementing control systems, and conducting regular maintenance, turbine efficiency can be improved, leading to increased power output, reduced fuel consumption, and lower operating costs.

Back Pressure Steam Flow Rate

Steam flow rate, also known as steam mass flow rate, is a critical parameter that determines the power output and efficiency of steam turbine systems. It refers to the mass of steam passing through a specific point or section of the steam system per unit time. Steam flow rate is typically measured in kilograms per second (kg/s) or pounds per second (lb/s).

Importance of Steam Flow Rate:

- Power Output Determination: Steam flow rate is a primary input in calculating the power output of a steam turbine. The amount of steam passing through the turbine directly influences the kinetic energy available for conversion into mechanical energy.

- Efficiency Assessment: Steam flow rate is also used to assess the efficiency of steam turbine systems. By comparing the actual power output to the theoretical power output for a given steam flow rate, the efficiency of the turbine can be determined.

- Steam System Control: Steam flow rate is a crucial parameter for controlling and optimizing the performance of steam systems. By regulating the steam flow rate, various aspects of the system, such as turbine power output, steam pressure, and temperature, can be controlled.

- Process Steam Utilization: In cogeneration systems, where steam is used for both power generation and industrial processes, steam flow rate is important for ensuring adequate steam supply for both power generation and process needs.

- Boiler Operation: Steam flow rate is also relevant for boiler operation, as it impacts the boiler’s ability to generate steam at the desired pressure and temperature. Monitoring steam flow rate helps maintain proper boiler operation and prevent overproduction or underproduction of steam.

Methods of Measuring Steam Flow Rate:

- Venturi Meter: A Venturi meter is a device that measures the differential pressure between two tapered sections of a pipe. By knowing the pressure difference and the pipe diameter, the steam flow rate can be calculated.

- Orifice Plate: An orifice plate is a device that creates a localized constriction in a pipe, causing a pressure drop. By measuring the pressure drop and the pipe diameter, the steam flow rate can be determined.

- Turbine Inlet Nozzle Pressure: In some cases, the steam flow rate can be estimated based on the pressure at the turbine inlet nozzle. This method is less accurate than direct flow measurement but can be used for monitoring and control purposes.

- Ultrasonic Flowmeters: Ultrasonic flowmeters utilize the principle of Doppler shift to measure the velocity of steam flowing through a pipe. By knowing the velocity and the pipe diameter, the steam flow rate can be calculated.

- Coriolis Mass Flowmeters: Coriolis mass flowmeters measure the mass flow rate of a fluid based on the principle of Coriolis force. These meters are highly accurate and can be used for measuring steam flow rate in various applications.

Conclusion:

Steam flow rate is a fundamental parameter in steam turbine systems, influencing power output, efficiency, process steam utilization, and boiler operation. By accurately measuring and controlling steam flow rate, steam turbine systems can operate efficiently, produce the desired power output, and provide adequate steam for various industrial processes.

Turbine Design

Turbine design is a critical aspect of steam turbine systems, influencing their performance, efficiency, and overall operation. The design of a steam turbine encompasses various aspects, including blade geometry, stage configuration, flow path optimization, and material selection.

Key Elements of Turbine Design:

- Blade Design: The shape and size of turbine blades play a crucial role in efficiently converting the kinetic energy of steam into mechanical energy. Different blade designs, such as twisted or tapered blades, can be employed to optimize fluid flow and maximize energy extraction.

- Stage Configuration: The number of stages in a turbine determines the pressure drop and efficiency. Multi-stage turbines typically exhibit higher efficiency compared to single-stage turbines.

- Flow Path Optimization: The flow path through the turbine should be designed to minimize losses and maximize energy transfer. This includes optimizing blade angles, stage spacing, and the overall geometry of the turbine passages.

- Material Selection: Turbine materials must be carefully chosen to withstand the high temperatures, pressures, and corrosive effects of steam. Stainless steels, nickel alloys, and other high-performance materials are commonly used for turbine components.

Factors Influencing Turbine Design:

- Steam Parameters: The properties of the steam, such as its pressure, temperature, and flow rate, significantly impact turbine design. Higher steam pressure and temperature generally allow for higher efficiency and power output.

- Power Requirements: The desired power output of the turbine is a primary factor in determining its design. Larger turbines with more stages can produce higher power outputs.

- Application: The specific application of the steam turbine, such as power generation, process steam production, or marine propulsion, influences design considerations.

- Operational Conditions: The expected operating conditions, such as continuous or intermittent operation, load variations, and environmental factors, also influence turbine design.

Advanced Turbine Design Techniques:

- Computational Fluid Dynamics (CFD): CFD software allows for the simulation of fluid flow through the turbine, providing insights into aerodynamic performance and optimizing blade design.

- Additive Manufacturing (3D Printing): Additive manufacturing enables the fabrication of complex turbine components with intricate geometries, enhancing performance and material utilization.

- Smart Materials and Sensors: Embedded sensors and smart materials can provide real-time data on turbine performance and operating conditions, enabling predictive maintenance and optimized operation.

- Numerical Control (NC) Machining: Highly precise NC machining techniques allow for the production of turbine components with tight tolerances, ensuring efficient energy conversion and reducing losses.

Conclusion:

Turbine design is an intricate and evolving field, with advancements in materials, computational techniques, and manufacturing processes leading to more efficient, durable, and optimized steam turbine systems. By carefully considering the operating conditions, application requirements, and material properties, turbine designers can create turbines that meet the demands of various industries and contribute to sustainable energy production.

Back Pressure Downstream Steam Utilization

Downstream steam utilization refers to the use of steam that has already passed through a steam turbine and exited the turbine at a lower pressure. This exhaust steam, while no longer suitable for direct power generation, still contains significant thermal energy that can be utilized for various purposes in industrial processes and heating applications.

Applications of Downstream Steam Utilization:

- Process Steam: Exhaust steam can be used as process steam in various industrial applications, such as papermaking, textile processing, food production, and chemical manufacturing. Process steam provides heat for drying, sterilization, and other process steps.

- Heating and Space Conditioning: Exhaust steam can be employed for heating buildings, providing hot water, and maintaining comfortable temperatures in industrial facilities. This reduces the reliance on direct combustion of fossil fuels for heating purposes.

- Steam Recompression: In cogeneration systems, low-pressure exhaust steam can be recompressed using a booster compressor to elevate its pressure, enabling its reuse in higher-pressure processes or for power generation.

- Steam Jet Refrigeration: Exhaust steam can be used to drive steam jet ejectors, which create a vacuum and can be used for refrigeration or other vacuum applications.

- Steam Desalination: In desalination plants, exhaust steam can be used to heat seawater and facilitate the evaporation process, producing freshwater from seawater.

Benefits of Downstream Steam Utilization:

- Improved Energy Efficiency: Utilizing exhaust steam for downstream applications enhances overall energy efficiency by extracting additional useful energy from the steam before it is discharged.

- Reduced Fuel Consumption: By utilizing exhaust steam for process heating or other purposes, the need for direct fuel combustion is reduced, leading to lower fuel consumption and cost savings.

- Environmental Benefits: Minimizing fuel consumption and utilizing waste heat from steam turbines contribute to reducing greenhouse gas emissions and minimizing the environmental impact of industrial processes.

- Water Conservation: In cogeneration systems, utilizing exhaust steam for process steam production can reduce the demand for fresh water, conserving water resources.

- Diverse Applications: Exhaust steam can be used in a wide range of industrial processes and heating applications, making it a versatile and valuable energy source.

Challenges of Downstream Steam Utilization:

- Steam Quality: Exhaust steam may contain impurities, such as moisture or dissolved solids, that need to be removed before it can be utilized in certain applications.

- Steam Pressure Requirements: The pressure of the exhaust steam may not always be suitable for all downstream applications, requiring additional pressure boosting or steam conditioning.

- Piping and Distribution: Efficient distribution of exhaust steam to various downstream locations may require extensive piping networks and proper insulation to minimize energy losses.

- Condensation Management: Condensate generated from downstream steam utilization needs to be properly collected and returned to the boiler feedwater system to maintain water balance and optimize cycle efficiency.

- Matching Supply and Demand: Balancing the availability of exhaust steam with the demand from downstream applications requires careful planning and coordination.

Conclusion:

Downstream steam utilization plays a crucial role in maximizing energy efficiency and reducing the environmental impact of steam turbine systems. By effectively utilizing exhaust steam for various industrial processes and heating applications, industries can conserve fuel, reduce emissions, and extract additional value from their steam-generating processes.

Steam Turbines

Steam turbines are a fundamental component of modern power generation and various industrial processes. They convert thermal energy from steam into mechanical energy, which can then be used to generate electricity or drive machinery. The concept of harnessing steam power dates back to ancient times, with early attempts to use steam for mechanical purposes seen in the aeolipile, a simple steam-powered device invented by Hero of Alexandria in the 1st century AD. However, it wasn’t until the 19th century that steam turbines, as we know them today, began to take shape.

The breakthrough in steam turbine technology came in the late 19th century with the work of Sir Charles Parsons and Gustaf de Laval. Sir Charles Parsons is often credited with inventing the modern steam turbine in 1884, when he developed a prototype capable of driving an electrical generator. This invention marked a significant leap in efficiency compared to earlier steam engines. Parsons’ steam turbine quickly became the preferred method for generating electricity, and its design principles are still used in modern turbines.

Gustaf de Laval, a Swedish engineer, made significant contributions to the development of steam turbines, particularly in high-speed turbines. His work in the 1880s and 1890s led to the creation of impulse turbines, which use the kinetic energy of steam to drive the turbine blades. These developments laid the foundation for the widespread adoption of steam turbines in various industries.

Importance in Modern Industry

Today, steam turbines play a crucial role in the global energy landscape. They are used in thermal power plants to generate a significant portion of the world’s electricity. In a typical thermal power plant, steam is produced by burning fossil fuels such as coal, natural gas, or oil, or by utilizing nuclear energy. The steam is then directed into the turbine, where it expands and drives the turbine blades, converting thermal energy into mechanical energy. This mechanical energy is then used to rotate an electrical generator, producing electricity.

Steam turbines are also integral to various industrial processes. They are used in the petrochemical industry to drive compressors and pumps, in the steel industry for mechanical drives, and in the paper industry to generate electricity and drive machinery. Additionally, steam turbines are employed in marine propulsion systems, particularly in large vessels like aircraft carriers and submarines, where their reliability and efficiency are highly valued.

The versatility and efficiency of steam turbines make them indispensable in both traditional and modern energy systems. They are compatible with a wide range of energy sources, including fossil fuels, nuclear power, and renewable sources such as biomass, geothermal, and concentrated solar power. This adaptability ensures that steam turbines will continue to play a vital role in the global energy mix as the world transitions towards more sustainable energy solutions.

Fundamentals of Steam Turbines

Basic Principles

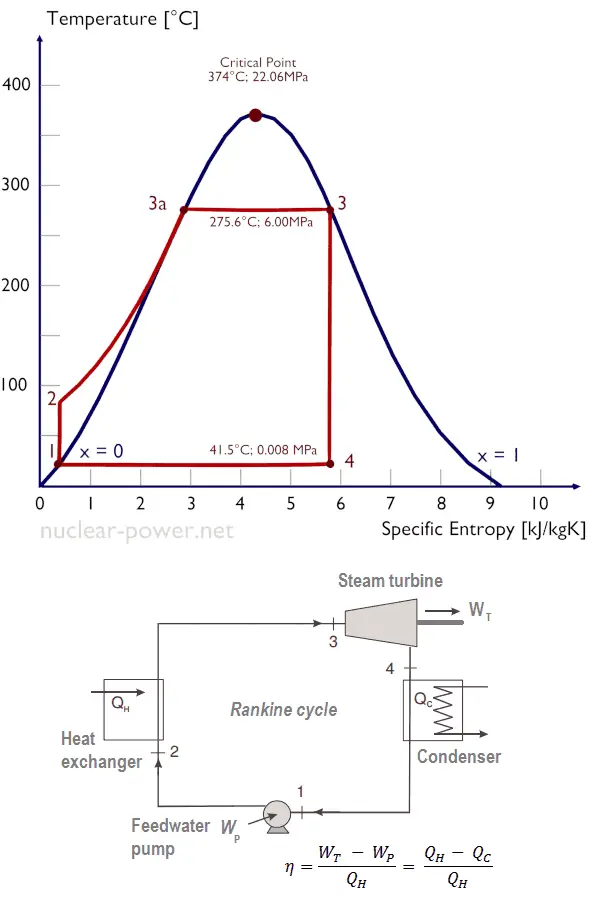

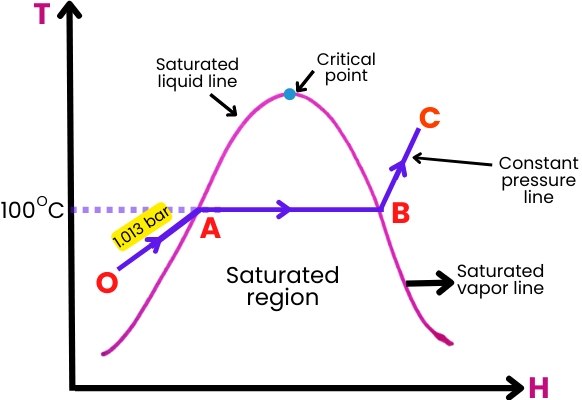

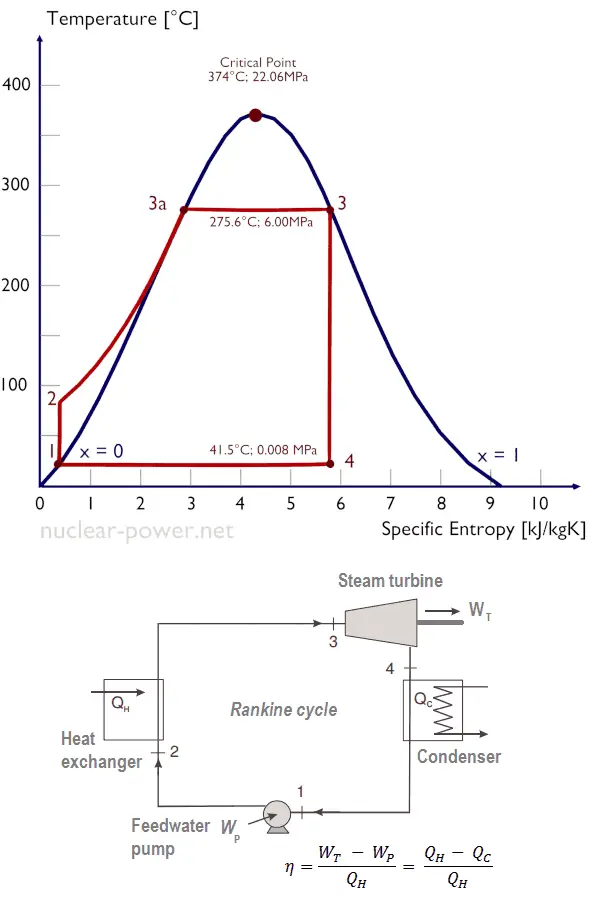

At the core of a steam turbine’s operation is the conversion of thermal energy from steam into mechanical energy. This process is grounded in the principles of thermodynamics, specifically the Rankine cycle, which is the fundamental thermodynamic cycle used in steam turbine operations.

In simple terms, the Rankine cycle involves four main processes:

- Heat Addition: In a boiler, water is heated at constant pressure, transforming it into steam. This high-pressure steam contains a significant amount of thermal energy.

- Expansion: The high-energy steam is directed into the turbine, where it expands. As the steam expands, its pressure and temperature drop, and it imparts kinetic energy to the turbine blades, causing them to rotate. This rotational energy is then transferred to a shaft connected to an electrical generator or mechanical equipment.

- Condensation: After passing through the turbine, the steam is exhausted into a condenser, where it is cooled and condensed back into water.

- Pumping: The condensed water is then pumped back to the boiler to begin the cycle again.

The efficiency of a steam turbine is determined by how effectively it converts the thermal energy in the steam into mechanical energy. Factors such as steam pressure, temperature, and the design of the turbine blades play crucial roles in determining this efficiency.

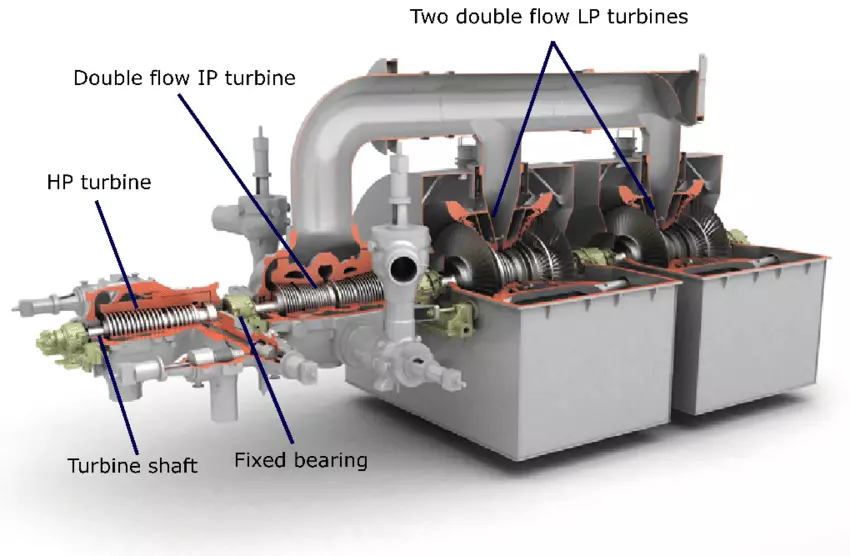

Key Components

Steam turbines consist of several critical components, each playing a specific role in the turbine’s operation:

- Rotor: The rotor is the rotating part of the turbine and consists of a shaft and attached blades. As steam passes through the turbine, it causes the rotor to spin, converting thermal energy into mechanical energy.

- Stator: The stator is the stationary part of the turbine that surrounds the rotor. It contains fixed blades that direct the flow of steam onto the rotor blades in an efficient manner.

- Casing: The casing encases the entire turbine, providing structural support and containing the steam within the turbine. It also protects the internal components from external elements.

- Blades: The turbine blades are crucial for the conversion of energy. There are two main types of blades: fixed blades (attached to the stator) and moving blades (attached to the rotor). The design and arrangement of these blades are critical for the efficient operation of the turbine.

- Steam Supply System: This system includes the pipes, valves, and other components that deliver steam to the turbine at the required pressure and temperature. It also controls the flow of steam into the turbine.

- Condenser: The condenser cools the exhaust steam from the turbine, converting it back into water to be reused in the cycle. It is typically a heat exchanger that removes the latent heat of vaporization from the steam.

- Governor: The governor is a control mechanism that regulates the turbine’s speed by adjusting the steam flow. It ensures that the turbine operates at the desired speed and can respond to changes in load demand.

Types of Steam Turbines

Steam turbines are classified based on their design, method of steam expansion, and application. The main types include:

- Impulse Turbines: In impulse turbines, high-pressure steam is directed onto the turbine blades through nozzles. The steam jets strike the blades, causing them to move, but the steam pressure remains constant as it passes over the blades. The rotor’s motion is purely due to the impulse force from the steam. Impulse turbines are often used in high-speed applications and are suitable for driving generators in power plants.

- Reaction Turbines: Unlike impulse turbines, reaction turbines utilize both the impulse of steam and the reaction force generated as steam expands and accelerates through the moving blades. The steam pressure drops as it passes through the blades, and this pressure drop is what drives the rotor. Reaction turbines are commonly used in lower-speed applications and are often found in industrial settings.

- Condensing Turbines: These turbines are designed to exhaust steam at a lower pressure, usually into a condenser, where the steam is condensed into water. Condensing turbines are widely used in power generation, where maximum efficiency is required.

- Non-Condensing Turbines: Also known as back-pressure turbines, these turbines exhaust steam at a pressure higher than atmospheric pressure. The exhaust steam can be used for heating or other industrial processes. Non-condensing turbines are commonly used in cogeneration systems where both electricity and process steam are needed.

- Extraction Turbines: Extraction turbines are designed to extract steam at one or more points along the turbine for industrial processes or heating. The remaining steam continues through the turbine for power generation. These turbines provide flexibility in applications where steam at different pressures is required.

- Reheat Turbines: In reheat turbines, steam is expanded through a high-pressure stage of the turbine, reheated in the boiler, and then expanded further in a lower-pressure stage. Reheating improves the efficiency of the cycle and reduces the moisture content of the steam, which can help to reduce blade erosion.

- Industrial Turbines: These are designed for specific industrial applications, such as driving compressors, pumps, or fans. Industrial turbines can be either impulse or reaction types, depending on the specific application requirements.

- Marine Turbines: Used in naval vessels and large commercial ships, marine turbines are designed to be highly reliable and capable of operating under the challenging conditions at sea. They are typically reaction turbines and are designed to drive propellers or generators for propulsion.

Thermodynamics and Fluid Mechanics

Thermodynamic Cycles

The operation of steam turbines is fundamentally based on thermodynamic cycles, with the Rankine cycle being the most important for understanding how these machines work. The Rankine cycle, named after William John Macquorn Rankine, is a closed-loop cycle that converts heat into work, making it the backbone of steam turbine operations in power plants and industrial settings.

- The Rankine Cycle: The Rankine cycle consists of four main processes:

- Isentropic Compression: The working fluid (water) is pumped from a low pressure to a high pressure. This process requires work input, typically provided by a pump.

- Isobaric Heat Addition: The high-pressure water is heated in a boiler at constant pressure, turning it into high-pressure steam.

- Isentropic Expansion: The high-pressure steam is expanded in the turbine, doing work by turning the turbine’s rotor. As the steam expands, its pressure and temperature drop.

- Isobaric Heat Rejection: The expanded steam is condensed at constant pressure back into water, completing the cycle.

- Reheat Cycle: In a reheat cycle, steam is expanded in a high-pressure turbine, reheated in the boiler, and then expanded again in a low-pressure turbine. This process increases the thermal efficiency of the cycle by allowing the steam to expand through a greater pressure range, reducing the moisture content at the turbine’s exhaust, which in turn minimizes turbine blade erosion.

- Regenerative Cycle: The regenerative cycle improves efficiency by preheating the feedwater entering the boiler using steam extracted from various stages of the turbine. This reduces the amount of fuel needed to heat the water to the desired temperature, thereby improving overall efficiency.

- Combined Cycle: The combined cycle is a modern approach that combines a gas turbine cycle with a steam turbine cycle. The exhaust gases from the gas turbine are used to generate steam in a heat recovery steam generator (HRSG), which then powers a steam turbine. This setup allows for very high overall efficiency, often exceeding 60%.

Fluid Dynamics in Steam Turbines

Fluid dynamics plays a crucial role in the operation of steam turbines, as the efficient conversion of steam energy into mechanical work depends on the controlled flow of steam through the turbine.

- Steam Flow and Velocity Triangles: The flow of steam through a turbine is characterized by velocity triangles, which are geometric representations of the velocity of steam relative to the blades of the turbine. These triangles help in analyzing the energy conversion process as the steam flows through both the stationary (stator) and moving (rotor) blades.

- Absolute Velocity: This is the velocity of the steam relative to the stationary components of the turbine.

- Relative Velocity: This is the velocity of the steam relative to the moving blades of the rotor.

- Blade Velocity: The velocity at which the turbine blades move.

- Impulse and Reaction Principles: Steam turbines operate on either impulse or reaction principles, or a combination of both.

- Impulse Turbines: In impulse turbines, steam is expanded through nozzles, converting its pressure energy into kinetic energy before it hits the rotor blades. The rotor blades are designed to absorb this kinetic energy, causing the rotor to spin.

- Reaction Turbines: In reaction turbines, the steam undergoes a pressure drop as it passes through the rotor blades, which are shaped to act as nozzles. The pressure drop results in a reactive force that turns the rotor. This principle is similar to how a jet engine works.

- Expansion and Losses: As steam expands through the turbine, it loses energy due to several factors, including friction, heat losses, and mechanical losses. These losses reduce the overall efficiency of the turbine. Understanding and minimizing these losses is crucial for optimizing turbine performance.

- Frictional Losses: Occur due to the friction between steam and the turbine blades and internal surfaces.

- Heat Losses: Result from the heat exchange between steam and the turbine casing or the environment.

- Mechanical Losses: Include losses in bearings, seals, and other mechanical components of the turbine.

Heat Transfer Mechanisms

Heat transfer is a critical aspect of steam turbine operation, influencing both efficiency and performance. The primary heat transfer mechanisms involved are conduction, convection, and radiation.

- Conduction: Conduction is the transfer of heat through a solid material, such as the turbine casing or blades. In steam turbines, conduction occurs when heat flows through the metal components from the high-temperature steam to cooler regions. The thermal conductivity of the materials used in turbine construction is an important factor, as it affects the rate of heat transfer and the temperature distribution within the turbine.