Innovative Power Generation with Sand Battery and Steam Turbine Integration: Sand battery technology is an emerging energy storage solution that uses heated sand as a thermal reservoir. When integrated with steam turbines, this system can provide a sustainable and efficient way to generate electricity. Here’s how it works:

1. Understanding Sand Battery Technology

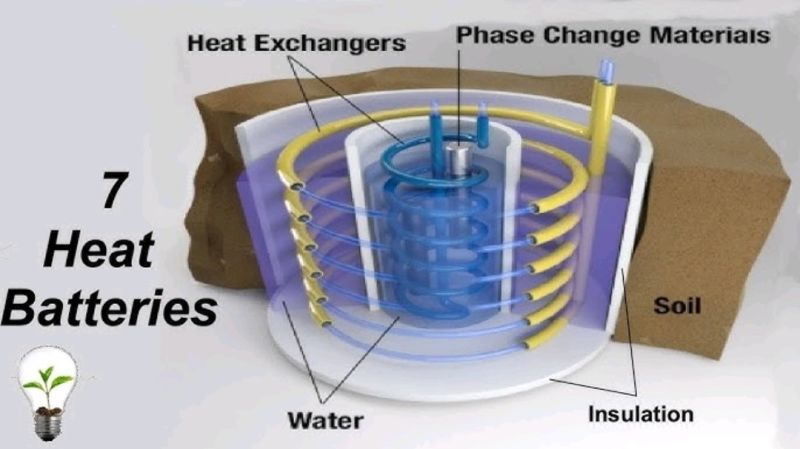

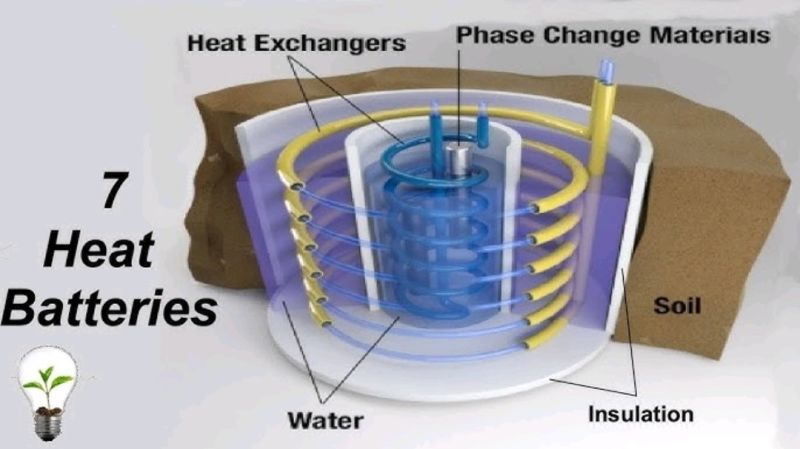

A sand battery stores energy in the form of heat. It consists of:

- Resistive heating elements powered by surplus electricity (e.g., from renewable sources).

- Insulated sand storage to retain high temperatures (500–1,000°C) for long durations.

- Heat exchangers to extract stored energy when needed.

2. Integrating Sand Batteries with Steam Turbines

To use a sand battery for steam turbine operation:

- Charging Phase

- Excess renewable electricity (solar, wind, etc.) heats the sand via resistive heating.

- The sand retains heat for days or weeks.

- Energy Extraction (Discharging) Phase

- The stored heat is transferred to a working fluid (e.g., water) via heat exchangers.

- The heated water turns into steam, which drives a steam turbine.

- The steam expands and generates mechanical energy, which is converted into electricity.

3. Applications

- Grid Stabilization: Acts as a buffer for renewable energy fluctuations.

- Industrial Use: Supplies process heat and steam for manufacturing.

- District Heating: Can provide heat to residential and commercial buildings.

- Off-grid Power: Supports remote areas with limited grid access.

4. Benefits

- Long-term heat retention (days to weeks).

- Low operational costs compared to batteries like lithium-ion.

- High efficiency when integrated with optimized steam turbines.

- Environmental sustainability with no hazardous chemicals.

5. Challenges

- Heat transfer efficiency: Losses occur during heat exchange.

- System scaling: Requires large storage to match grid-scale needs.

- Material constraints: Sand insulation and containment must withstand high temperatures.

Sand battery technology offers a promising way to store and utilize renewable energy by converting excess electricity into heat stored in sand. This stored heat can be used to generate steam, which in turn drives a steam turbine to produce electricity. The system works by using resistive heating elements to heat the sand to temperatures between 500 and 1,000°C. Sand, with its excellent heat retention properties, can store this thermal energy for extended periods, making it a reliable backup for intermittent renewable sources like wind and solar.

When electricity is needed, the stored heat is transferred to a working fluid, such as water, through heat exchangers. The heated water then turns into steam, which expands through a turbine to generate electricity. This approach has several advantages, including grid stabilization, industrial steam generation, district heating, and off-grid power applications. The system is cost-effective in the long run due to its low maintenance needs and long lifespan compared to chemical batteries.

However, challenges remain, such as optimizing heat transfer efficiency, ensuring minimal thermal losses, and scaling the system to meet large-scale energy demands. Proper insulation and advanced heat exchanger designs can improve overall efficiency, making sand batteries a viable option for integrating renewable energy with steam turbine technology. Would you like to explore potential design improvements or real-world case studies?

Sand battery technology presents an innovative solution for energy storage, particularly in applications where surplus renewable electricity needs to be converted into a reliable and dispatchable energy source. By leveraging the high heat retention properties of sand, this system provides an efficient way to store excess power from renewable sources like wind and solar. Instead of relying on conventional lithium-ion batteries, which degrade over time and have limited storage durations, sand batteries can hold heat for days or even weeks, offering a cost-effective and sustainable alternative.

The concept revolves around heating a large volume of sand using resistive heating elements powered by excess electricity. Once heated, the sand acts as a thermal reservoir, maintaining temperatures in the range of 500 to 1,000 degrees Celsius due to its excellent insulating properties. This stored heat can then be extracted when needed by using heat exchangers to transfer thermal energy to a working fluid, such as water. The heated water turns into steam, which expands through a steam turbine, generating mechanical energy that is converted into electricity.

The integration of sand batteries with steam turbines opens up a range of possibilities, especially for grid stabilization, industrial heat applications, and decentralized energy systems. One of the key advantages of this approach is its ability to decouple energy generation from consumption. Renewable energy sources like solar and wind are inherently intermittent, producing electricity when sunlight and wind are available rather than when demand is high.

A sand battery helps bridge this gap by storing excess energy during peak generation periods and releasing it when required, ensuring a steady and controllable power supply. Additionally, in industrial settings where high-temperature heat is needed for processes such as metalworking, food production, and chemical manufacturing, sand battery systems can provide an efficient way to supply heat and steam without relying on fossil fuels. By replacing traditional natural gas or coal-fired boilers with a sand-based thermal storage system connected to a steam turbine, industries can significantly reduce carbon emissions while maintaining a stable and reliable energy source.

District heating is another promising application for sand battery technology. In many regions, centralized heating networks supply heat to residential and commercial buildings using large-scale boilers fueled by natural gas or biomass. A sand battery integrated with a steam turbine could serve as a zero-emission alternative, storing excess renewable electricity as thermal energy and using it to generate steam when heating demand is high. This could be particularly beneficial in colder climates, where seasonal variations in heating needs make energy storage an essential component of an efficient heating system. By using locally available sand as a storage medium, communities can reduce reliance on imported fuels and enhance energy security.

Despite its many benefits, the implementation of sand battery systems for powering steam turbines presents certain technical and economic challenges. One major consideration is the efficiency of heat transfer between the stored thermal energy and the working fluid. Heat exchanger designs must be optimized to minimize losses and ensure that as much stored energy as possible is converted into usable steam. Additionally, while sand itself is an abundant and inexpensive material, the construction of large-scale insulated storage units and high-efficiency heating elements requires upfront investment. Proper insulation is critical to prevent heat dissipation over time, as even small thermal losses can reduce the overall efficiency of the system. Advanced insulation materials, along with innovative storage designs that minimize surface area exposure, can help improve performance.

Scalability is another important factor to consider. While small-scale sand battery prototypes have demonstrated promising results, expanding the concept to utility-scale energy storage requires careful engineering to balance storage capacity, heat retention, and energy extraction efficiency. Large-scale systems must be designed to withstand prolonged thermal cycling without degradation, ensuring long-term reliability. Moreover, integration with existing power grids and industrial processes requires smart control systems that can efficiently manage energy input and output based on demand fluctuations. Automated control systems that regulate heat charging and discharging cycles in response to real-time energy needs can enhance the effectiveness of sand battery-powered steam turbines.

Real-world implementations of sand battery technology are beginning to emerge, demonstrating its potential for large-scale deployment. In Finland, for example, researchers have developed sand-based thermal storage systems capable of storing renewable energy for extended periods, providing both electricity and heat on demand. Similar initiatives are being explored in other countries where the need for long-duration energy storage is growing. As advancements in materials science, heat transfer engineering, and thermal storage design continue to evolve, the feasibility of using sand batteries to power steam turbines is expected to improve. Governments and industries looking to achieve carbon neutrality targets may find this technology an attractive option for reducing reliance on fossil fuels while maintaining energy resilience.

Overall, the integration of sand battery technology with steam turbines represents a transformative approach to sustainable energy storage and generation. By harnessing the thermal properties of sand, excess renewable electricity can be efficiently stored and later converted into steam to drive turbines, enabling continuous and reliable power production. This technology has the potential to revolutionize not only electricity generation but also industrial heat applications and district heating systems. While challenges remain in terms of efficiency optimization, scalability, and cost reduction, ongoing research and development efforts are likely to unlock new possibilities for making sand batteries a mainstream component of future energy infrastructure. As the world transitions toward a low-carbon economy, innovative storage solutions like this will play a crucial role in ensuring a sustainable and resilient energy supply. Would you like me to focus on specific engineering aspects, economic feasibility, or case studies in future discussions?

Focusing on the engineering aspects, economic feasibility, and real-world case studies of sand battery technology integrated with steam turbines, it is essential to analyze the key factors that influence its efficiency and viability for large-scale energy storage and power generation. The engineering design of sand battery systems revolves around three critical components: heat storage, heat exchange, and energy conversion. Each of these elements must be optimized to maximize performance while minimizing losses.

Engineering Aspects of Sand Battery-Driven Steam Turbines

The first major engineering challenge is the heat storage system. Sand is an excellent thermal storage medium due to its high heat capacity and stability at elevated temperatures. However, to achieve practical efficiency, the sand must be contained within an insulated environment that minimizes heat loss over time. State-of-the-art thermal insulation materials, such as aerogels or vacuum-insulated panels, can be used to enhance storage efficiency. Additionally, the shape and configuration of the storage system must be optimized to ensure uniform heating and thermal retention. Large-scale storage units may use layered or compartmentalized designs to control heat distribution and prevent localized overheating or cooling.

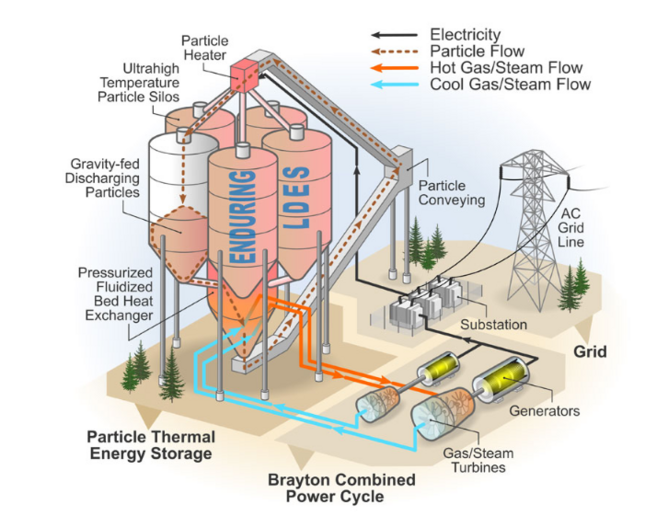

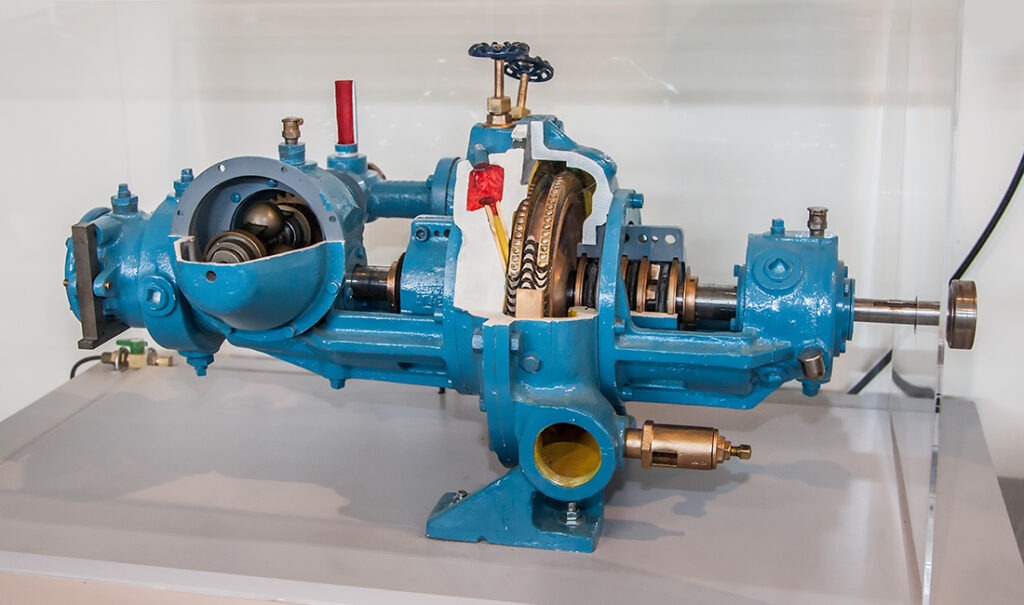

The second critical component is the heat exchanger system, which transfers the stored thermal energy to a working fluid. Conventional heat exchangers, such as shell-and-tube or plate-type systems, may not be fully optimized for high-temperature sand-based storage. Instead, advanced heat exchanger designs using molten salt or metal-based conduction systems could improve efficiency. The rate of heat transfer must be carefully controlled to match the energy demands of the steam turbine, avoiding excessive temperature fluctuations that could impact turbine performance. Computational fluid dynamics (CFD) simulations can be employed to model heat flow patterns and optimize exchanger geometries.

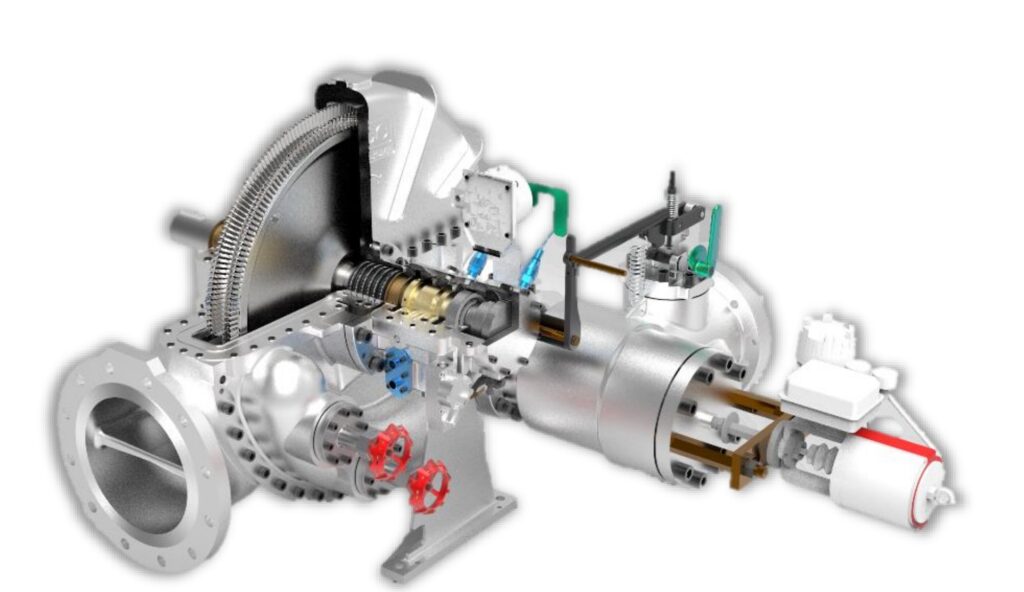

The third aspect is the energy conversion process, where the stored heat is used to generate steam and drive a turbine. Steam turbine selection depends on the desired application, with back-pressure turbines being suitable for combined heat and power (CHP) systems and condensing turbines being ideal for electricity generation. The efficiency of the steam cycle depends on parameters such as steam temperature, pressure, and expansion ratios. Superheated steam turbines can significantly improve efficiency by increasing the temperature differential between the heat source and the condenser. Additionally, the system may incorporate a Rankine cycle with regenerative heating to enhance overall performance.

Economic Feasibility of Sand Battery Technology

The economic viability of sand battery-powered steam turbines depends on multiple factors, including capital investment, operational costs, and return on investment. Compared to traditional battery storage solutions like lithium-ion or pumped hydro storage, sand batteries offer several cost advantages. The raw material (sand) is abundant and inexpensive, reducing the initial material costs. Additionally, sand batteries have a long operational lifespan with minimal degradation, unlike chemical batteries, which experience capacity loss over time.

However, the major cost drivers are the construction and insulation of the thermal storage unit, the integration of efficient heat exchangers, and the turbine setup. A well-designed system can achieve a levelized cost of storage (LCOS) competitive with other energy storage technologies. Estimates suggest that sand batteries could provide long-duration energy storage at costs lower than lithium-ion batteries if deployed at scale. The return on investment is particularly attractive in regions with high renewable energy penetration, where excess power needs to be stored and dispatched when demand rises.

For industries and district heating applications, sand battery systems can replace fossil-fuel-based boilers, reducing fuel costs and emissions. Government incentives, carbon credits, and subsidies for green energy projects further improve economic feasibility. Additionally, sand battery installations can generate revenue through capacity markets, where stored energy can be sold when electricity prices peak.

Real-World Case Studies and Implementation

In Finland, the first large-scale sand battery prototype has been successfully deployed by Polar Night Energy. This system stores surplus renewable electricity as heat in a sand reservoir, later used for district heating applications. The technology has demonstrated high thermal retention efficiency, with the ability to store energy for months. While this system primarily focuses on heat applications, scaling it up for electricity generation with steam turbines is a logical next step.

Other research initiatives are exploring sand-based energy storage for industrial use, where steam turbines can be driven by stored heat. In Germany, experimental projects are investigating the feasibility of integrating sand-based thermal storage with existing coal-fired power plants to enable a transition toward renewables without dismantling existing infrastructure. By retrofitting coal plants with sand storage and steam turbines, utilities can reduce emissions while maintaining grid stability.

In desert regions, where sand is abundant, large-scale sand battery projects could be deployed to store excess solar energy and generate electricity during the night. Countries like the United Arab Emirates and Saudi Arabia, with significant solar capacity, could use sand batteries to provide baseload power, reducing reliance on natural gas peaker plants.

The combination of engineering optimization, economic feasibility, and successful real-world implementations suggests that sand battery-powered steam turbines could play a crucial role in the global energy transition. As technology advances and costs decline, this approach could become a mainstream solution for integrating renewable energy into existing power grids, industrial heat applications, and district heating networks. Would you like to explore specific design models or energy efficiency comparisons with other storage technologies?

Using a sand battery for sustainable steam turbine energy generation presents a highly promising method for storing and utilizing renewable energy in a way that addresses intermittency issues while reducing reliance on fossil fuels. The core principle involves converting surplus electricity—typically from renewable sources like wind and solar—into heat, which is stored in sand at high temperatures. This stored thermal energy can then be used on demand to produce steam, which drives a turbine to generate electricity.

Principles of Sand Battery Storage

A sand battery system works by using resistive heating elements to raise the temperature of a large mass of sand, which serves as a thermal reservoir. Sand is an ideal storage medium due to its high specific heat capacity, thermal stability, and low cost. Advanced insulation materials are used to minimize heat loss, allowing the stored energy to be retained for days or even weeks. When energy is required, the stored heat is transferred to a working fluid—typically water—via heat exchangers, producing high-pressure steam that powers a steam turbine.

Advantages of Sand Battery-Powered Steam Turbines

- Long-Term Heat Storage – Unlike chemical batteries that have limited charge durations, sand can retain heat for extended periods, making it suitable for seasonal energy storage.

- Low Cost and Sustainability – Sand is abundant and inexpensive, and unlike lithium-ion batteries, it does not degrade over time.

- Grid Stability – By acting as a thermal energy buffer, sand batteries can help balance supply and demand in energy grids dominated by intermittent renewables.

- Industrial and District Heating Applications – Beyond electricity generation, the stored heat can be used for industrial processes and district heating, further increasing system efficiency.

- Reduced Carbon Emissions – By replacing fossil-fuel-based heat generation, sand batteries contribute to decarbonization efforts.

Challenges and Considerations

While sand batteries offer numerous benefits, their implementation faces several challenges:

- Heat Transfer Efficiency – Optimizing the heat exchanger system is crucial to minimize losses and ensure efficient energy conversion.

- Scalability – Large-scale deployment requires careful engineering to balance heat storage capacity, insulation effectiveness, and turbine efficiency.

- Integration with Existing Infrastructure – Retrofitting existing power plants with sand-based thermal storage requires investment in new heat exchangers and control systems.

Real-World Applications and Future Potential

Recent developments, such as Finland’s pioneering sand battery projects, demonstrate the feasibility of this technology for district heating. Scaling it up for electricity generation through steam turbines is the logical next step. Countries with abundant renewable energy sources could deploy sand batteries to store excess generation and use it for stable power output, reducing dependence on fossil-fuel peaker plants.

Advancements in materials science, heat exchanger design, and automated control systems will further enhance the efficiency and viability of sand battery-powered steam turbines. As the world moves toward a more sustainable energy future, this innovative storage solution could play a critical role in ensuring reliable and carbon-free electricity generation.

Detailed Design and Engineering of Sand Battery-Powered Steam Turbines

Harnessing sand battery technology for sustainable steam turbine energy generation requires careful engineering of the thermal storage system, heat transfer mechanisms, and energy conversion process. The effectiveness of this system depends on optimizing each component to maximize efficiency while ensuring long-term operational stability. Below is a comprehensive breakdown of the key design elements involved in integrating sand batteries with steam turbines.

1. Thermal Storage System Design

The core of a sand battery is its thermal storage system, where sand is heated to high temperatures (500–1,000°C) and retained for later energy use. To make this process efficient, the following factors must be considered:

- Material Selection: Sand is chosen for its high heat capacity, thermal stability, and availability. However, different sand compositions vary in their ability to retain heat. Quartz-based sand is commonly used due to its excellent thermal properties.

- Storage Configuration: The thermal storage unit is designed as a large, insulated container, which can be cylindrical, rectangular, or modular, depending on space constraints and scalability requirements. A vertical design can improve natural heat stratification, while a horizontal layout might be easier to integrate with existing power plants.

- Insulation: Advanced insulation materials such as aerogels, vacuum panels, and ceramic fibers are used to minimize heat loss. Multilayer insulation with reflective coatings can further enhance thermal retention.

- Charging Mechanism: The sand is heated using resistive heating elements powered by surplus renewable electricity. High-efficiency heating coils embedded within the sand ensure even heat distribution, while control systems regulate temperature to prevent overheating.

2. Heat Transfer and Exchange Mechanism

Once the sand has been heated, extracting and utilizing the stored thermal energy efficiently is crucial. Heat exchangers play a vital role in transferring heat from sand to water, converting it into steam for turbine operation.

- Heat Extraction Process: When electricity is needed, air or another heat transfer fluid (such as molten salts or high-temperature oil) is circulated through the sand storage unit, absorbing heat and transferring it to a heat exchanger.

- Heat Exchanger Design: Various types of heat exchangers can be used, including:

- Fluidized Bed Heat Exchangers, where hot sand particles interact with a circulating fluid to maximize heat transfer.

- Shell-and-Tube Heat Exchangers, in which a high-temperature fluid passes over water-filled tubes to generate steam.

- Direct Heat Exchange Systems, where pressurized steam pipes run through the sand bed to directly extract heat.

- Temperature Regulation: A controlled release of heat ensures that steam is generated at the optimal temperature and pressure for turbine efficiency. Superheated steam, rather than saturated steam, is preferred to maximize turbine power output.

3. Steam Turbine Integration and Power Generation

The final stage in the energy conversion process is using the extracted heat to generate steam and drive a turbine.

- Steam Generation: Water is heated to produce high-pressure steam, which expands through the turbine, converting thermal energy into mechanical work. Depending on the system requirements, the steam may be:

- Superheated (for higher efficiency): Achieved by passing steam through additional heat exchangers before entering the turbine.

- Saturated (for district heating applications): Used in cases where both electricity and heat are needed.

- Turbine Selection: The choice of turbine depends on the application:

- Condensing Steam Turbines are suitable for maximizing electricity generation by expanding steam to low pressure.

- Back-Pressure Steam Turbines are used when combined heat and power (CHP) applications are required, where the remaining heat is utilized for district heating or industrial processes.

- Energy Recovery Systems: To improve efficiency, regenerative heat exchangers and condensers can be added to recover waste heat and preheat feedwater before it enters the steam generator.

4. Control Systems and Automation

Efficient operation of a sand battery-powered steam turbine requires advanced control systems that manage heat charging, extraction, and turbine operation in response to electricity demand.

- Automated Heating Control: Ensures that sand reaches and maintains the target temperature without excessive energy use.

- Smart Energy Management: Uses predictive algorithms to optimize energy release based on electricity demand forecasts.

- Thermal Monitoring: Real-time sensors monitor heat distribution within the sand battery to prevent uneven cooling and optimize heat extraction.

5. System Scalability and Deployment Strategies

For sand battery-powered steam turbines to be deployed effectively, scalability and integration with existing energy systems must be considered.

- Modular Storage Units: Multiple smaller sand batteries can be combined to scale up storage capacity as needed.

- Integration with Existing Power Plants: Retrofitting coal or natural gas plants with sand battery thermal storage can enable a transition to renewables without major infrastructure overhauls.

- Grid-Level Applications: Large-scale sand battery installations can act as peak-load power plants, discharging stored energy when demand is high.

- Industrial and District Heating Applications: In addition to electricity generation, waste heat from the system can be used for industrial processes and district heating, improving overall efficiency.

Conclusion and Future Prospects

The integration of sand battery technology with steam turbines offers a sustainable, cost-effective, and long-duration energy storage solution. By leveraging the thermal stability of sand and the efficiency of steam turbines, this system can provide a stable and controllable power supply, mitigating the intermittency challenges of renewable energy sources. While challenges remain in optimizing heat transfer, improving scalability, and reducing capital costs, ongoing advancements in materials science, heat exchanger design, and automation will further enhance the feasibility of sand batteries as a mainstream energy storage technology.

Economic Feasibility of Sand Battery-Powered Steam Turbines

The economic viability of integrating sand battery technology with steam turbines depends on multiple factors, including capital investment, operational costs, system efficiency, and long-term financial returns. Compared to traditional energy storage methods like lithium-ion batteries, pumped hydro, or molten salt thermal storage, sand batteries offer several cost advantages, particularly in terms of material availability, longevity, and scalability. However, challenges such as heat transfer efficiency, infrastructure development, and integration with existing power grids must be addressed to achieve widespread adoption.

1. Capital Investment and Infrastructure Costs

The upfront costs for a sand battery-powered steam turbine system primarily include:

- Thermal Storage Construction – The cost of constructing a well-insulated sand storage unit depends on its size, insulation material, and containment structure. While sand itself is inexpensive, high-temperature insulation and structural containment must be carefully designed to minimize thermal losses.

- Heating System Installation – Resistive heating elements or induction heaters must be installed to efficiently convert surplus electricity into heat. These systems must be robust and capable of sustaining long-duration heating cycles.

- Heat Exchange System – High-efficiency heat exchangers are necessary to transfer thermal energy from the sand to the working fluid. Advanced designs, such as molten salt or direct sand-to-steam heat exchangers, may require additional R&D investment.

- Steam Turbine and Power Generation Unit – The cost of the turbine depends on the desired output capacity, efficiency, and whether it is a back-pressure or condensing turbine.

- Automation and Control Systems – Smart energy management systems optimize heat charging and discharging to align with grid demands, requiring investment in sensors, AI-driven controls, and predictive analytics.

While initial capital costs are significant, sand battery systems have a long lifespan and require minimal maintenance compared to chemical batteries, leading to a favorable total cost of ownership (TCO) over time.

2. Operational Costs and Maintenance

Operational expenses are relatively low compared to other storage technologies:

- Minimal Degradation – Unlike lithium-ion batteries, which degrade after thousands of charge cycles, sand does not chemically degrade, resulting in a much longer lifespan (potentially several decades).

- Low Maintenance Requirements – The system mainly requires periodic checks on heating elements, insulation integrity, and turbine components.

- Energy Efficiency Losses – Heat losses during storage and transfer must be minimized through insulation improvements and optimized heat exchanger designs. The round-trip efficiency (input electricity to output electricity) is currently estimated at 40–50%, which is lower than lithium-ion batteries but comparable to other thermal storage solutions.

To further improve cost efficiency, excess heat from the system can be repurposed for district heating or industrial applications, effectively increasing the system’s overall energy efficiency.

3. Levelized Cost of Storage (LCOS) Comparison

The levelized cost of storage (LCOS) is a key economic metric that assesses the cost per unit of energy stored and later discharged. Sand battery systems are expected to have an LCOS of $10–$30 per MWh, which is significantly lower than lithium-ion batteries ($130–$250 per MWh) and competitive with pumped hydro storage ($50–$150 per MWh).

Factors contributing to the low LCOS of sand batteries include:

- Cheap raw materials (sand is abundant and inexpensive).

- Long operational lifespan with minimal degradation.

- Scalability for large-scale energy storage without major geographical constraints.

For applications where long-duration storage is needed (e.g., seasonal energy storage for winter heating or grid balancing over weeks), sand batteries are more cost-effective than chemical batteries, which are optimized for shorter-duration storage (4–8 hours per cycle).

4. Revenue Streams and Financial Incentives

The financial feasibility of sand battery-powered steam turbines can be enhanced through multiple revenue streams:

- Grid Stabilization Services – Providing dispatchable power during peak demand periods can generate revenue from capacity markets.

- Renewable Energy Integration – Storing excess wind and solar energy for later use helps renewable energy providers optimize their generation capacity.

- District Heating and Industrial Steam Sales – Surplus heat from the system can be sold to industries or municipal heating networks, improving overall system profitability.

- Carbon Credits and Government Subsidies – Many governments offer incentives, tax breaks, and subsidies for energy storage projects that contribute to decarbonization efforts.

5. Market Adoption and Future Cost Reduction

While sand battery technology is still in its early stages, economies of scale and technological advancements are expected to drive costs down over time. Key areas for cost reduction include:

- More efficient heat exchangers to reduce energy losses.

- Advanced insulation materials to minimize thermal dissipation.

- Improved automation and AI-based optimization for better energy management.

- Integration with existing coal-fired power plants to repurpose infrastructure for clean energy storage.

As countries increase their renewable energy penetration, long-duration energy storage solutions like sand batteries will become essential for ensuring grid reliability. Countries with high renewable energy capacity, such as Germany, the United States, and China, are already exploring alternative thermal storage technologies, and sand batteries could emerge as a cost-competitive option.

Conclusion

From an economic perspective, sand battery-powered steam turbines present a highly promising solution for long-duration energy storage. With low material costs, minimal maintenance requirements, and multiple revenue opportunities, the technology has the potential to outperform traditional chemical batteries in terms of cost-effectiveness for large-scale energy storage. While initial investment costs are significant, the long operational lifespan and integration with existing infrastructure can make this a financially viable alternative for utilities, industrial users, and district heating networks. Future advancements in heat exchanger technology, automation, and system efficiency will further improve the economic case for widespread adoption.

Real-World Applications and Case Studies of Sand Battery-Powered Steam Turbines

The integration of sand battery technology with steam turbines is still in the early stages of large-scale deployment, but several pioneering projects and research initiatives demonstrate its potential. Countries with significant renewable energy capacity and a need for long-duration energy storage have started exploring the feasibility of using sand batteries to provide grid stability, industrial heat, and sustainable power generation. Below are key real-world applications and case studies that highlight the growing role of sand battery-powered steam turbines in the energy transition.

1. Polar Night Energy (Finland) – First Large-Scale Sand Battery Prototype

One of the most well-known implementations of sand battery technology is the project developed by Polar Night Energy in Finland. This system is primarily designed for thermal energy storage rather than direct electricity generation, but it serves as a crucial foundation for future steam turbine applications.

Key Features:

- Stores excess renewable energy (wind and solar) as heat in a 100-ton sand reservoir.

- Operates at temperatures up to 600°C.

- Designed to supply district heating rather than electricity, providing heat to local residential and commercial buildings.

- Uses simple resistive heating elements to charge the battery with surplus renewable energy.

Lessons for Steam Turbine Applications:

- The system demonstrates high thermal retention efficiency, with minimal heat loss over time.

- Scaling up this concept to higher temperatures (800–1,000°C) would enable direct steam generation for turbines.

- Future modifications could include integrated heat exchangers to extract energy more efficiently for power production.

2. Germany – Sand-Based Thermal Energy Storage for Industrial Heat

Germany, a global leader in renewable energy adoption, is exploring sand battery storage for industrial heat applications. One pilot project involves using sand-based thermal storage to replace fossil-fuel-based industrial heating.

Key Features:

- Aims to decarbonize high-temperature industrial processes (e.g., steel, cement, and chemical industries).

- Uses fluidized bed heat exchangers to efficiently transfer heat to industrial steam systems.

- Demonstrates the feasibility of retrofitting existing industrial boilers with sand battery storage.

Lessons for Steam Turbines:

- Industries requiring high-temperature steam can directly integrate sand battery technology with existing steam-based processes.

- Waste heat from industrial operations can be recycled back into the sand battery, improving overall energy efficiency.

3. United Arab Emirates & Saudi Arabia – Large-Scale Sand Battery for Solar Energy Storage

Desert regions, particularly in the Middle East, have a unique advantage in adopting sand battery technology due to the abundance of both solar energy and sand. The UAE and Saudi Arabia are exploring large-scale thermal storage solutions to store excess solar power and provide stable electricity output during nighttime.

Key Features:

- Solar PV and CSP (Concentrated Solar Power) integration – excess electricity is converted into stored heat in sand.

- High-temperature storage at 900–1,000°C, suitable for generating superheated steam.

- Potential to replace natural gas-based peaker plants for stable grid power.

Lessons for Steam Turbines:

- High-temperature storage makes direct steam turbine integration highly efficient.

- Large-scale storage can provide grid-scale baseload power, reducing reliance on fossil fuels.

- Decentralized energy systems using sand batteries could supply off-grid communities or industrial zones.

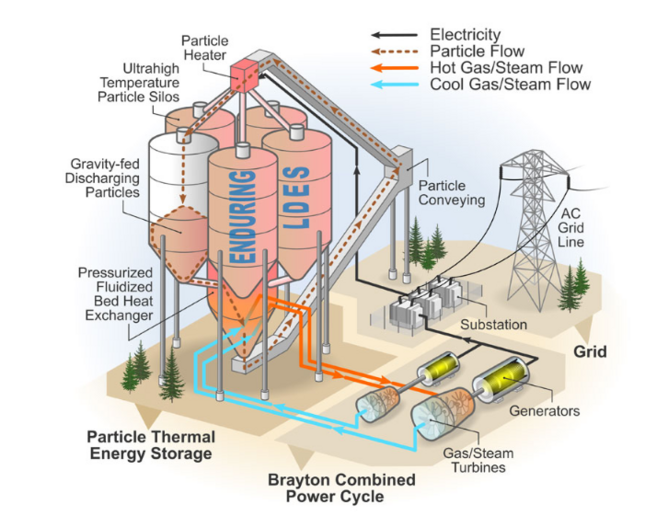

4. United States – Research into Long-Duration Thermal Storage for Power Plants

The U.S. Department of Energy (DOE) has been funding research into long-duration thermal energy storage, including sand-based solutions. These projects aim to repurpose existing coal and natural gas plants into clean energy storage and generation facilities.

Key Features:

- Evaluates using sand or other granular materials as a retrofit solution for decommissioned fossil fuel power plants.

- Investigates fluidized bed heat exchangers for improving heat transfer efficiency.

- Focuses on integrating with steam Rankine cycles for electricity generation.

Lessons for Steam Turbines:

- Transitioning existing power infrastructure to thermal storage can reduce costs and speed up deployment.

- High-capacity storage could enable seasonal energy shifting, storing excess renewable energy for months.

- Combining with other renewable energy sources (wind, geothermal, hydro) could create a hybrid energy system for grid resilience.

Future Prospects and Scaling Up Sand Battery-Steam Turbine Systems

The increasing interest in thermal storage solutions suggests that sand battery-powered steam turbines could become a mainstream energy storage technology within the next decade. Several key developments will influence the future of this technology:

1. Advances in Heat Exchanger Design

- More efficient direct-contact heat exchangers could improve the speed and effectiveness of heat transfer from sand to steam.

- Molten salt hybrid systems could enhance temperature control and thermal retention.

2. Policy and Investment in Clean Energy Storage

- Governments worldwide are introducing energy storage mandates and financial incentives for long-duration storage solutions.

- Increased funding for pilot projects and commercial-scale deployment will accelerate market adoption.

3. Large-Scale Grid Applications

- Integrating sand batteries with offshore wind farms could provide a reliable backup energy source.

- Utility-scale projects could stabilize renewable-heavy grids, reducing the need for fossil fuel backup power.

4. Hybrid Energy Solutions

- Combining sand battery storage with geothermal energy could create a fully renewable baseload power source.

- Hybrid systems using hydrogen production alongside sand storage could further enhance energy security.

Conclusion: The Road Ahead for Sand Battery-Powered Steam Turbines

The successful implementation of sand battery storage in district heating (Finland), industrial heat applications (Germany), solar energy storage (Middle East), and power plant retrofits (U.S.) demonstrates that this technology has real-world viability. The next logical step is scaling up these systems to drive steam turbines for sustainable electricity generation.

As the world transitions toward net-zero carbon energy systems, long-duration thermal storage will play a crucial role in balancing renewable power supply with demand. Sand battery-powered steam turbines could emerge as a key solution for large-scale energy storage, offering cost-effectiveness, durability, and scalability in ways that traditional battery storage cannot match.

Integrating Sand Battery Storage with Steam Turbine Power Plants

The integration of sand battery thermal storage with steam turbine power plants offers a transformative approach to energy storage and dispatchable renewable power generation. This hybrid system leverages the strengths of both technologies: the long-duration thermal storage capability of sand batteries and the high efficiency of steam turbines in converting thermal energy into electricity. The result is a sustainable, cost-effective solution for mitigating renewable energy intermittency and stabilizing power grids.

1. System Architecture and Components

A sand battery-steam turbine hybrid system consists of the following key components:

A. Sand Battery Thermal Storage Unit

- A large insulated container filled with high-temperature sand, heated up to 800–1,000°C using surplus renewable electricity (solar, wind, or grid power).

- Resistive heating elements or induction heating systems convert electrical energy into thermal energy.

- Advanced insulation materials (e.g., aerogels, ceramic fibers) minimize heat loss over extended storage periods.

- Heat transfer fluids (air, molten salts, or direct steam pipes) extract stored energy when needed.

B. Heat Exchange and Steam Generation System

- High-temperature heat exchangers transfer stored heat to a working fluid (typically water) to generate steam.

- Superheated steam at optimal pressure and temperature is fed into the steam turbine to produce electricity.

- Various heat exchanger configurations include:

- Fluidized bed heat exchangers (high-efficiency heat transfer from sand to air/water).

- Direct-contact steam pipes running through the sand bed.

- Molten salt hybrid systems to improve heat retention and transfer rates.

C. Steam Turbine and Power Generation Unit

- The steam turbine converts thermal energy into mechanical energy, which is then converted into electricity via a generator.

- The turbine type depends on application:

- Condensing steam turbines for maximum power generation.

- Back-pressure turbines for combined heat and power (CHP) applications.

- After expansion, steam is condensed and recycled back into the system, improving efficiency.

D. Control and Automation Systems

- Smart energy management software monitors and optimizes heat charging/discharging.

- Real-time thermal monitoring ensures even heat distribution and prevents overheating or energy loss.

- Demand-based operation allows dynamic adjustment of power output based on grid demand.

2. Operational Integration: Retrofitting vs. New Plant Design

A. Retrofitting Existing Steam Power Plants

Many traditional coal and natural gas power plants can be retrofitted with sand battery storage, replacing fossil fuel combustion with clean, renewable heat storage.

- Existing steam turbines and generators remain operational, reducing capital investment.

- Boiler modifications are needed to switch from fossil fuel combustion to heat exchangers connected to the sand battery.

- Lower operational costs as sand battery storage eliminates fuel costs and reduces maintenance.

B. New Sand Battery-Powered Steam Plants

- Designed from the ground up to optimize thermal efficiency and minimize heat losses.

- Modular and scalable, with multiple sand battery units for continuous power output.

- Potential for hybrid operation, integrating with solar thermal plants, geothermal, or waste heat recovery.

3. Advantages of Sand Battery-Steam Turbine Integration

A. Long-Duration and High-Capacity Storage

- Unlike lithium-ion batteries, sand battery storage retains heat for weeks or months, making it ideal for seasonal energy storage.

- Scalable for large-scale grid applications, capable of providing continuous baseload power.

B. Cost-Effectiveness

- Lower capital costs than lithium-ion and molten salt storage.

- Sand is an inexpensive and abundant material, reducing raw material costs.

- Minimal degradation over time, resulting in lower maintenance costs.

C. Renewable Grid Integration

- Absorbs surplus solar and wind energy when supply exceeds demand, preventing curtailment losses.

- Provides dispatchable power during peak demand periods, improving grid reliability.

- Enables 100% renewable energy systems by filling in supply gaps without fossil fuel backup.

D. Decarbonization of Industry and District Heating

- Excess heat can be supplied for industrial processes (e.g., cement, steel, chemical industries).

- Waste heat from the steam cycle can be used for district heating, improving overall efficiency.

4. Challenges and Engineering Considerations

A. Heat Transfer Efficiency

- Maximizing heat extraction efficiency from sand storage to steam generation is critical.

- New heat exchanger designs (fluidized beds, molten salts, phase-change materials) are needed for improved performance.

B. Thermal Expansion and Structural Stability

- High-temperature fluctuations can cause material stress in containment structures and heat exchangers.

- Advanced refractory materials and thermal expansion mitigation strategies must be implemented.

C. Scalability and Modular Deployment

- Large-scale deployment requires careful design to balance storage capacity, discharge rates, and turbine efficiency.

- Modular sand battery units could enable flexible scalability for different energy demands.

D. Policy and Investment Support

- Governments and utilities must provide financial incentives to support research, development, and deployment.

- Clear energy storage regulations are needed to integrate sand battery technology into national energy strategies.

5. Case Study: Potential Implementation in Decommissioned Coal Plants

A potential use case is repurposing retired coal power plants by replacing their coal-fired boilers with sand battery thermal storage.

Example: Repurposing a 500 MW Coal Plant

- Replace coal boilers with high-temperature sand battery storage.

- Retrofit existing steam turbines and generators for clean power production.

- Store excess renewable electricity in sand during off-peak hours.

- Discharge stored heat on demand to produce steam and generate electricity.

- Provide grid stability and baseload power without fossil fuel emissions.

This approach leverages existing infrastructure, significantly reducing costs and accelerating the transition to clean energy.

6. Future Prospects and Market Potential

A. Global Deployment Potential

- Europe: Ideal for grid-scale renewable energy storage and district heating.

- United States: Can replace fossil fuel peaker plants and stabilize renewables-heavy grids.

- Middle East & Africa: Enables solar energy storage for reliable nighttime power.

- Asia (India, China): Supports large-scale coal-to-renewable transitions.

B. R&D and Technological Advancements

- Higher-efficiency heat exchangers will improve conversion rates.

- AI-driven predictive controls will optimize energy release for grid stability.

- Hybrid sand battery-molten salt systems could push efficiency beyond 60%.

C. Economic and Policy Support

- Governments need to subsidize pilot projects and offer tax incentives for long-duration storage solutions.

- Carbon pricing and emission reduction targets will drive investment in fossil-free thermal storage.

Conclusion: A Sustainable Energy Storage Breakthrough

Integrating sand battery thermal storage with steam turbine power plants presents a game-changing solution for long-duration energy storage, grid stability, and industrial heat applications. With low-cost materials, high thermal efficiency, and potential for retrofitting existing power plants, this hybrid system could play a pivotal role in the transition to 100% renewable energy.

Economic Feasibility and Cost-Benefit Analysis of Sand Battery-Steam Turbine Integration

The integration of sand battery thermal storage with steam turbine power plants presents a promising economic case, balancing low capital investment, minimal operational costs, and long-term financial returns. Compared to conventional energy storage solutions, sand batteries offer superior cost efficiency, especially for long-duration energy storage (LDES).

This section evaluates the economic feasibility of sand battery-steam turbine systems, covering capital costs, operational expenses, return on investment (ROI), and comparative cost analysis with alternative energy storage technologies.

1. Capital Investment and Infrastructure Costs

The upfront costs for implementing a sand battery-steam turbine system depend on several factors, including storage capacity, heat transfer efficiency, and power plant size. The primary capital cost components include:

A. Sand Battery Construction

- Storage Unit Costs: A 100 MW sand battery system requires an insulated containment structure, costing between $30–$50 per kWh of thermal capacity.

- Sand Material Costs: Sand itself is abundant and inexpensive, with costs as low as $5 per ton, making it significantly cheaper than lithium-ion battery materials.

- High-Temperature Insulation: Advanced insulation (ceramics, aerogels) can increase upfront costs but reduces heat losses over time.

B. Heating System

- Resistive Heating Elements: The cost of electric heaters depends on capacity and efficiency, typically $10–$20 per kW.

- Induction or Joule Heating Alternatives: More efficient heating systems could lower long-term costs, though initial installation is higher.

C. Heat Exchange and Steam Generation

- Heat Exchanger System: The most expensive component, costing $200–$500 per kW depending on technology (fluidized beds, molten salts, or direct steam).

- Steam Turbine Modifications: If retrofitting an existing power plant, boiler modifications may cost $100–$300 per kW, far lower than installing a new steam turbine system.

D. Automation and Smart Grid Integration

- Control Systems and AI Optimization: Requires investment in real-time monitoring, predictive analytics, and automation, adding approximately $50,000–$500,000 depending on scale.

Total Estimated Capital Cost:

- New Sand Battery Storage for a 100 MW Plant: $50–$100 million.

- Retrofitting an Existing Steam Plant: $30–$60 million.

These costs are 50–70% lower than new pumped hydro storage projects and far cheaper than lithium-ion battery farms for similar large-scale storage.

2. Operational Costs and Maintenance

A. Minimal Fuel Costs

- Unlike fossil fuel power plants, sand battery systems eliminate fuel costs, which make up 40–60% of traditional power plant OPEX.

B. Low Degradation and Maintenance

- Sand does not degrade, meaning zero material replacement costs over decades.

- Heating elements and insulation may require periodic maintenance every 5–10 years, costing $5,000–$50,000 per cycle.

C. Energy Efficiency and Round-Trip Losses

- Current sand battery round-trip efficiency is 40–50% (electricity to stored heat to electricity).

- Losses can be minimized through heat recovery systems, increasing overall energy efficiency to 60% or more when used for district heating or industrial processes.

Annual O&M Costs Estimate:

- $1–$3 million per 100 MW facility, 75% lower than fossil fuel plants due to the absence of fuel costs and minimal component wear.

3. Revenue Streams and Return on Investment (ROI)

A sand battery-steam turbine system can generate revenue from multiple sources:

A. Energy Arbitrage

- Charges when electricity prices are low (e.g., surplus solar/wind generation).

- Discharges electricity when prices peak, generating higher revenues.

- Potential profits: $20–$80 per MWh depending on market conditions.

B. Grid Ancillary Services

- Provides frequency regulation, peak shaving, and load balancing.

- Revenue from grid operators: $5–$30 per MWh.

C. Industrial Heat and District Heating Sales

- Waste heat from steam turbines can be sold to district heating networks or industrial users.

- Revenue potential: $10–$50 per MWh of thermal energy.

D. Government Incentives and Carbon Credits

- Many governments offer tax credits for long-duration storage and renewable integration.

- Carbon credit earnings: $10–$40 per ton of CO₂ offset.

ROI Analysis:

- Investment Payback Period: 5–10 years, depending on electricity market conditions.

- IRR (Internal Rate of Return): 12–20%, making it competitive with other renewable energy storage projects.

4. Comparative Cost Analysis with Alternative Energy Storage Technologies

| Storage Technology | Capital Cost ($/kWh) | Efficiency (%) | Lifespan (Years) | LCOS ($/MWh) | Suitable for Long-Duration Storage? |

|---|---|---|---|---|---|

| Sand Battery | $30–$50 | 40–50% | 30–50 | $10–$30 | Yes |

| Lithium-Ion Battery | $200–$400 | 85–95% | 10–15 | $130–$250 | No |

| Pumped Hydro Storage | $150–$300 | 70–85% | 50–100 | $50–$150 | Yes |

| Molten Salt Storage | $50–$100 | 60–75% | 20–40 | $20–$70 | Yes |

| Hydrogen Storage | $150–$300 | 30–40% | 10–30 | $80–$200 | Yes |

Key Takeaways:

- Sand battery storage is the lowest-cost option for long-duration storage.

- Lower efficiency than lithium-ion, but far superior in cost and lifespan.

- Comparable to pumped hydro in economics, but does not require specific geography.

- Competitive with molten salt thermal storage, but using cheaper raw materials.

5. Scaling Up and Future Cost Reductions

A. Mass Production and Standardization

- Large-scale adoption will reduce capital costs through improved manufacturing and economies of scale.

B. Advanced Heat Exchanger Materials

- More efficient heat exchangers (ceramics, graphene coatings) will improve efficiency, reducing energy losses and LCOS.

C. AI and Automation for Energy Optimization

- AI-driven predictive models will enhance energy dispatch strategies, increasing revenue potential.

D. Policy and Investment Support

- Government-backed funding for long-duration storage will accelerate commercial deployment.

Conclusion: A Cost-Effective and Scalable Solution

Sand battery-steam turbine integration presents a highly competitive economic case for renewable energy storage and grid stabilization.

- Lower capital costs than lithium-ion and pumped hydro.

- Minimal O&M expenses and zero fuel costs.

- Diverse revenue opportunities from grid services, energy arbitrage, and industrial heat.

- Fast payback periods and high ROI, making it an attractive investment.

With continued technological advancements and policy support, sand battery storage could become a dominant long-duration energy storage solution worldwide.

Scaling Up Sand Battery-Steam Turbine Systems for Global Energy Transition

The large-scale deployment of sand battery-steam turbine systems has the potential to revolutionize energy storage and sustainable power generation, providing a reliable alternative to fossil fuel-based baseload electricity. The ability to store vast amounts of thermal energy in sand and convert it into electricity via steam turbines makes this technology a key enabler for the transition to a fully renewable-powered grid. However, the challenge lies in scaling up the technology from pilot projects to gigawatt-scale deployments that can support entire cities, industrial hubs, and national power grids. This expansion requires a coordinated approach involving engineering advancements, financial investments, policy support, and integration into existing and future energy infrastructures.

A major factor in scaling up sand battery technology is the optimization of thermal storage capacity, heat transfer efficiency, and steam turbine integration to maximize energy output while maintaining economic feasibility. Unlike conventional battery storage, where capacity is often limited by raw material availability and manufacturing constraints, sand battery storage is inherently scalable due to the abundance and low cost of sand as a heat storage medium. The primary challenge in scaling is not the storage material itself but the engineering systems required to efficiently transfer heat from the sand to the steam cycle without excessive energy losses. Advanced heat exchanger designs, such as fluidized bed systems, direct-contact heat pipes, or hybrid molten salt interfaces, will be essential in improving thermal transfer rates while minimizing degradation over time.

The construction of large-scale sand battery facilities will require modular designs that allow for incremental expansion based on energy demand. Instead of a single massive thermal storage unit, multiple sand battery modules could be interconnected, allowing for flexible scaling and redundancy in case of maintenance or operational issues. Each module could be optimized for specific applications, such as short-term peak demand management or seasonal energy storage, ensuring that energy is released precisely when it is needed most. Additionally, co-location of sand battery storage with existing steam turbine power plants or industrial heat users can significantly reduce costs by leveraging pre-existing infrastructure. Retrofitting coal-fired power plants, for instance, provides an opportunity to transition to clean energy without the need for entirely new power generation systems, making it a more cost-effective and politically viable solution in regions still reliant on fossil fuels.

One of the most promising large-scale applications of sand battery storage is in supporting national and regional power grids that increasingly depend on variable renewable energy sources such as solar and wind. In many countries, grid stability remains a major challenge as renewable penetration increases. Excess electricity generated during periods of high solar or wind availability often goes unused or is curtailed, leading to economic losses and wasted potential. By absorbing this excess energy and storing it as high-temperature heat in sand, power grids can operate with much greater flexibility, ensuring that electricity is available even when renewable generation fluctuates. In essence, sand battery storage enables renewable energy to function as a true baseload power source, replacing coal, natural gas, and nuclear energy in a cost-effective manner.

Beyond electricity generation, the large-scale deployment of sand battery technology can drive a transformation in industrial energy use by providing a reliable source of high-temperature heat. Many industries, including steel production, cement manufacturing, and chemical processing, rely on fossil fuels to generate process heat, making them some of the hardest sectors to decarbonize. With the ability to store and discharge heat at temperatures exceeding 800°C, sand batteries can directly replace fossil fuel combustion in industrial furnaces, kilns, and reactors. The advantage of using stored thermal energy rather than electricity for industrial processes lies in efficiency—converting electricity into heat and then back into electricity results in energy losses, whereas using stored heat directly avoids unnecessary conversion steps. This application not only reduces emissions but also stabilizes industrial energy costs by allowing companies to purchase and store energy during off-peak hours when electricity prices are low.

The economic viability of scaling up sand battery storage depends on both technological cost reductions and supportive policy frameworks. While initial deployment costs may still be higher than fossil fuel alternatives in some cases, economies of scale will play a crucial role in bringing down costs over time. As more sand battery projects are developed, improvements in manufacturing processes, materials science, and automation will drive down installation and operational costs, making the technology increasingly competitive. Government policies, including subsidies for long-duration energy storage, tax incentives for renewable heat adoption, and carbon pricing mechanisms, will further accelerate investment in sand battery infrastructure. Energy markets must also adapt to recognize the value of long-duration storage solutions, allowing sand battery operators to monetize their ability to provide grid stability, peak demand management, and industrial heat supply.

In addition to cost reductions, the successful deployment of large-scale sand battery systems will require significant advancements in energy dispatch and grid management technologies. Smart grid integration, powered by artificial intelligence and real-time energy forecasting, will ensure that sand battery storage is charged and discharged at optimal times based on electricity demand, renewable generation forecasts, and market pricing. AI-driven control systems will continuously monitor heat storage levels, adjust steam generation rates, and predict future energy requirements to maximize efficiency and revenue generation. This level of automation will be crucial in ensuring that sand battery plants operate seamlessly alongside variable renewable energy sources, enhancing overall grid reliability and energy security.

Another key factor in scaling up sand battery deployment is site selection and infrastructure development. Unlike pumped hydro storage, which requires specific geographical conditions such as mountains and reservoirs, sand battery storage can be deployed in virtually any location with sufficient space and access to renewable electricity. This flexibility allows for installation in urban areas, industrial zones, and remote regions that lack suitable sites for traditional energy storage methods. However, infrastructure such as transmission lines, grid interconnections, and district heating networks must be developed or upgraded to ensure efficient energy distribution. In regions with cold climates, integrating sand battery storage with district heating systems could provide dual benefits, supplying both electricity and thermal energy for residential and commercial heating, further improving overall efficiency.

The global market potential for sand battery-steam turbine integration is vast, with opportunities spanning diverse geographic regions and energy markets. In Europe, where energy storage is a critical component of achieving net-zero emissions targets, sand battery systems could complement existing renewable energy investments, reducing reliance on imported fossil fuels and enhancing energy security. In the United States, where large-scale energy storage is needed to support growing wind and solar capacity, sand battery deployment could help stabilize the grid while providing economic opportunities for repurposing retired coal and natural gas plants. In developing countries, where electrification and industrialization are rapidly expanding, sand battery storage could provide a low-cost, sustainable solution for managing energy demand growth while minimizing environmental impact. The Middle East and North Africa, with abundant solar resources, could use sand battery storage to harness and store excess solar energy, enabling 24/7 renewable electricity generation.

Ultimately, the large-scale implementation of sand battery-steam turbine systems represents a paradigm shift in energy storage, offering an affordable, scalable, and environmentally sustainable alternative to conventional fossil fuel-based power generation. With the right combination of technological advancements, policy support, and strategic investments, sand battery technology could play a central role in the global transition to renewable energy, eliminating reliance on polluting and finite resources while ensuring a stable and resilient energy supply for future generations. The path forward requires collaboration between governments, industry leaders, and researchers to accelerate deployment, optimize efficiency, and establish the necessary regulatory and financial mechanisms to support widespread adoption. As energy markets continue to evolve, sand battery storage stands as a breakthrough innovation capable of reshaping the future of sustainable power generation and long-duration energy storage at an unprecedented scale.

Future Innovations and Technological Advancements in Sand Battery-Steam Turbine Systems

As sand battery technology gains traction in the global energy landscape, continued research and development efforts are essential to unlocking its full potential. Future innovations will focus on increasing efficiency, optimizing heat transfer mechanisms, reducing capital costs, and expanding integration with renewable energy sources. Advancements in materials science, thermal engineering, and smart energy management will play a crucial role in making sand battery-steam turbine systems more competitive, reliable, and scalable. The convergence of artificial intelligence, automation, and next-generation heat exchange technologies will further enhance performance and economic viability, driving widespread adoption across diverse energy markets.

One of the primary areas of technological advancement lies in improving the heat retention and discharge efficiency of sand battery systems. While current designs achieve round-trip efficiencies in the range of 40–50%, future innovations could push these figures significantly higher. One promising approach involves the development of nanostructured insulating materials that minimize thermal losses while maintaining high heat conductivity for efficient energy extraction. Advanced ceramics, aerogels, and vacuum-insulated containment systems could be employed to achieve near-zero heat dissipation, allowing stored energy to be preserved for extended periods without degradation. Additionally, phase-change materials (PCMs) and latent heat storage techniques could be integrated with sand-based systems to enhance heat absorption and controlled discharge, improving the overall energy conversion efficiency.

The evolution of next-generation heat exchangers will be critical in optimizing the energy transfer process between stored heat in sand and working fluids used in steam turbines. Traditional heat exchangers rely on conduction-based thermal transfer, which can lead to inefficiencies and energy losses. Future designs may incorporate fluidized bed heat exchangers, in which sand particles are suspended in a controlled airflow or liquid medium to maximize heat transfer surface area. This approach significantly improves thermal exchange rates, allowing for faster and more efficient energy extraction. Other emerging solutions include graphene-coated heat exchangers, which leverage the exceptional thermal conductivity of graphene to enhance heat transfer performance while minimizing material wear and degradation.

Another major breakthrough on the horizon is the development of direct sand-to-steam systems, which eliminate intermediate heat transfer fluids and reduce energy conversion losses. In such systems, superheated sand particles could be directly exposed to pressurized water or other working fluids, instantly generating high-temperature steam for turbine operation. This method bypasses conventional heat exchangers, reducing complexity, cost, and energy losses associated with indirect thermal transfer. Experimental research is already underway to explore the feasibility of supercritical CO₂ cycles as a replacement for traditional steam cycles, where sand batteries provide the required thermal energy to drive CO₂-based turbines. Supercritical CO₂ power cycles offer higher efficiency, reduced turbine size, and lower cooling water requirements, making them an attractive option for future sand battery integration.

Artificial intelligence and machine learning will play a transformative role in optimizing sand battery operation and energy dispatch strategies. AI-driven predictive models can analyze real-time energy demand, weather forecasts, and electricity market trends to determine the optimal charging and discharging schedules for sand battery storage. By leveraging big data analytics, AI systems can continuously fine-tune heat storage parameters, adjust steam turbine load profiles, and predict future energy price fluctuations to maximize revenue generation. Additionally, machine learning algorithms can be used to detect early signs of wear and degradation in heat exchange components, enabling predictive maintenance strategies that reduce downtime and operational costs.

The integration of sand battery technology with hybrid renewable energy systems will also be a focal point of future developments. Rather than functioning as a standalone energy storage solution, sand batteries could be combined with other storage technologies to create multi-layered energy storage networks that balance short-term and long-term energy needs. For example, lithium-ion batteries could be used for rapid response grid balancing, while sand batteries provide long-duration thermal storage for sustained power generation. Similarly, coupling sand battery storage with hydrogen production facilities could create synergistic energy systems where excess renewable electricity is stored both as thermal energy and as hydrogen fuel, enhancing grid flexibility and energy security.

A significant area of research is the potential to leverage alternative heating methods to improve the efficiency of sand battery charging. Currently, resistive heating elements are the primary method for converting surplus electricity into thermal energy, but future systems may incorporate microwave heating, induction heating, or concentrated solar thermal heating to achieve higher efficiency and lower energy losses. Microwave heating, for instance, can penetrate sand particles at a molecular level, resulting in uniform and rapid heat distribution, while induction heating can provide highly controlled and targeted energy transfer without direct contact with the heating elements.

The application of sand battery technology is also expanding beyond electricity generation into high-temperature industrial process heat. Advanced designs may enable direct integration with industrial furnaces, metallurgy plants, and chemical processing units that require continuous high-temperature heat sources. Hydrogen production via thermochemical cycles could also benefit from sand battery heat storage, where stored energy is used to drive high-temperature chemical reactions for efficient hydrogen extraction. This opens up opportunities for decarbonizing sectors that have traditionally been difficult to transition to renewable energy sources.

On the policy and regulatory front, governments and international organizations are beginning to recognize the potential of long-duration thermal storage solutions such as sand batteries. Future regulatory frameworks will need to establish incentive structures, energy storage mandates, and investment tax credits to accelerate the deployment of large-scale sand battery projects. The establishment of standardized grid interconnection protocols will also be essential in ensuring seamless integration of sand battery systems into existing electricity markets. As nations strive to meet their carbon neutrality goals, policy-driven investments in research, pilot projects, and large-scale deployments will be critical in unlocking the full potential of this technology.

Looking ahead, the future of sand battery-steam turbine systems is poised for rapid evolution as technological breakthroughs, economic factors, and policy frameworks align to drive large-scale adoption. With ongoing advancements in materials science, energy conversion efficiency, AI-driven optimization, and hybrid system integration, sand batteries have the potential to emerge as a dominant energy storage technology, ensuring reliable, sustainable, and cost-effective power generation for future generations. The transition to a clean energy future will depend on scalable, innovative storage solutions, and sand battery technology is well-positioned to play a central role in this transformation.

Enhancing Steam Turbine Efficiency with Sand Battery Thermal Storage

The integration of sand battery thermal storage with steam turbine systems presents a groundbreaking opportunity to enhance efficiency, increase flexibility, and optimize power generation in renewable and hybrid energy systems. As global energy demands grow and the transition away from fossil fuels accelerates, finding efficient and cost-effective energy storage solutions is critical. Sand battery technology, with its ability to store vast amounts of thermal energy at high temperatures, provides a unique approach to addressing intermittency challenges in renewable energy while significantly improving the overall performance of steam turbines.

A key advantage of sand battery thermal storage is its ability to stabilize steam turbine operation by providing a steady and controllable heat supply. Traditional steam power plants rely on consistent fuel input—whether from coal, natural gas, or biomass—to generate high-temperature steam for turbine operation. However, with the shift towards renewables, power plants face challenges due to the variable nature of solar and wind energy. By integrating sand battery storage, excess renewable electricity can be converted into thermal energy and stored in sand for later use. This stored heat can then be used to generate steam on demand, ensuring continuous and efficient turbine operation even when solar or wind power output fluctuates.

One of the main factors affecting steam turbine efficiency is the quality and consistency of steam supply. Fluctuating temperatures and pressure levels can reduce turbine efficiency, increase wear and tear, and lead to frequent cycling, which shortens the lifespan of turbine components. Sand battery storage allows for precise thermal energy management, ensuring that steam is consistently produced at optimal temperatures and pressures, reducing energy losses and improving overall turbine performance. Unlike traditional energy storage solutions such as lithium-ion batteries, which degrade over time, sand can store heat for extended periods with minimal losses, making it a highly reliable option for long-duration energy storage (LDES).

In addition to stabilizing steam production, sand battery storage can enhance the efficiency of combined heat and power (CHP) systems, where both electricity and useful heat are generated simultaneously. CHP plants, widely used in industrial processes and district heating, require a reliable and steady heat supply to maximize efficiency. By storing surplus thermal energy and releasing it when needed, sand batteries enable CHP plants to operate at higher efficiency levels, reduce fuel consumption, and lower greenhouse gas emissions. This is particularly beneficial in industries with high heat demands, such as steel manufacturing, cement production, and chemical processing, where waste heat from sand battery systems can be effectively utilized.

The integration of sand battery storage also reduces the need for steam turbine load cycling, a common issue in conventional power plants. Frequent load variations lead to inefficiencies and increased maintenance costs due to thermal stress and mechanical fatigue in turbine components. With sand battery storage acting as a buffer, steam turbines can run at their optimal efficiency point, reducing wear and tear, extending operational lifespan, and minimizing maintenance requirements. This is particularly advantageous in hybrid power plants that combine renewable energy sources with traditional thermal power generation, where energy supply fluctuations can otherwise disrupt turbine efficiency.

From an economic perspective, sand battery thermal storage significantly lowers operational costs for steam turbine power plants. By storing and dispatching heat strategically, power plant operators can optimize electricity generation based on market demand and price fluctuations. During periods of low electricity prices or excess renewable generation, surplus energy can be stored in sand, preventing curtailment and ensuring that valuable renewable electricity is not wasted. When electricity prices peak, the stored heat can be converted into steam, allowing turbines to generate electricity at the most profitable times. This energy arbitrage capability improves revenue potential and enhances the financial viability of power plants utilizing sand battery storage.

Another key advantage of sand battery storage in steam turbine systems is its ability to enable off-grid and remote energy solutions. Many industrial sites, military bases, and rural communities lack stable grid connections and rely on expensive and polluting diesel generators for power. By integrating sand battery storage with steam turbine systems, these locations can establish independent, renewable-based energy solutions that provide reliable power without dependence on fossil fuels. Sand battery storage can be charged using locally available solar or wind energy, ensuring a continuous power supply for critical infrastructure and industrial applications.

Technological advancements in heat exchangers and steam generation systems will further enhance the efficiency of sand battery integration with steam turbines. Future developments in high-efficiency heat transfer materials, such as graphene-enhanced coatings and advanced ceramics, will improve thermal conductivity and minimize energy losses during heat exchange. Additionally, innovations in direct sand-to-steam systems, where sand directly heats water to generate steam, could eliminate intermediate heat transfer steps and boost overall efficiency. The incorporation of supercritical steam cycles, which operate at higher pressures and temperatures than traditional steam cycles, could further maximize efficiency and reduce energy losses in sand battery-powered steam turbine systems.