HRSG Economizer Evaporator Superheater: A heat exchanger is a device that transfers heat from one fluid (liquid or gas) to another without mixing them. It’s commonly used in heating, cooling, and energy recovery processes across various industries.

Heat Exchanger

- Purpose: To efficiently transfer thermal energy between fluids.

- Fluids: Can be gas or liquid on either side.

- No direct contact: The fluids typically stay separated by a solid wall to prevent mixing.

Common Types of Heat Exchangers:

- Shell and Tube:

- One fluid flows through tubes, and the other flows around the tubes within a shell.

- Widely used in power plants, oil refineries.

- Plate Heat Exchanger:

- Thin, corrugated plates stacked together; fluids flow in alternate layers.

- Compact and highly efficient; used in HVAC and food processing.

- Air Cooled Heat Exchanger:

- Uses air to cool fluid flowing through finned tubes.

- Common in remote or dry locations.

- Double Pipe Heat Exchanger:

- One pipe inside another; fluids flow in opposite directions.

- Simple design, used for small-scale applications.

Applications:

- Power plants (e.g., condenser in steam cycle)

- Refrigeration and air conditioning systems

- Chemical processing

- Automotive radiators

- Boilers and heating systems

A heat exchanger is a device used to transfer heat between two or more fluids without allowing them to mix. One fluid may be hot and the other cold, and the goal is to either heat up the cooler fluid or cool down the hotter one. The fluids can be liquids, gases, or a combination of both, and they remain separated by a solid barrier like metal to prevent contamination. Heat exchangers are found in a wide range of applications, such as in power plants, air conditioning systems, refrigeration units, car engines, chemical plants, and boilers.

There are many designs of heat exchangers. A common type is the shell and tube heat exchanger, where one fluid flows through a set of tubes and the other flows around them inside a larger shell. This setup allows efficient heat transfer over a large surface area. Another common design is the plate heat exchanger, which consists of multiple thin, flat plates stacked together with narrow gaps between them; fluids flow across alternate plates, which allows very effective heat transfer in a compact space. Some systems use air as one of the fluids—such as air-cooled heat exchangers, which use fans to blow air across finned tubes carrying the process fluid. In simpler systems, like a double pipe heat exchanger, one pipe carries one fluid while a second, larger pipe surrounds it carrying the other fluid in the opposite direction.

Heat exchangers play a critical role in thermal energy management. For example, in a steam power plant, the condenser is a type of heat exchanger that condenses exhaust steam from the turbine into water by transferring its heat to cooling water. In cars, the radiator cools the engine coolant by transferring its heat to the air. In HVAC systems, they help regulate temperature and humidity by transferring heat between indoor air and refrigerant or outside air. Because of their versatility, heat exchangers are essential components in many industries where heating or cooling is required.

Heat exchangers operate on the basic principle of thermodynamics, where heat naturally flows from a hotter object to a cooler one. By arranging the flow paths and surface areas effectively, heat exchangers are able to maximize the rate of heat transfer. The performance of a heat exchanger depends on factors like temperature difference between the fluids, the surface area available for heat transfer, the type of materials used, and the flow arrangement of the fluids.

There are different flow arrangements used in heat exchangers. In counterflow, the two fluids move in opposite directions, which generally allows for the highest efficiency because the temperature gradient is maintained across the entire length of the exchanger. In parallel flow, both fluids move in the same direction, but this usually results in lower efficiency since the temperature difference decreases along the length. In crossflow, the fluids move perpendicular to each other, which is common in applications like air-conditioning coils and radiators.

Material selection is important as well, since the heat exchanger must withstand pressure, temperature, and possibly corrosive fluids. Metals like stainless steel, copper, aluminum, and titanium are common due to their good thermal conductivity and durability. In some cases, non-metallic materials like graphite or special polymers are used for highly corrosive environments.

To maintain performance and efficiency, heat exchangers require regular maintenance. Over time, fouling can occur, where deposits like scale, sludge, or biological growth build up on the heat transfer surfaces. This reduces heat transfer efficiency and increases pressure drop. Cleaning, either mechanically or chemically, and proper water treatment can help prevent or manage fouling.

In energy-intensive industries, heat exchangers are also used for heat recovery, capturing waste heat from one process to preheat another stream, improving overall energy efficiency. This is especially common in chemical plants, refineries, food processing, and even in residential buildings with systems like heat recovery ventilation (HRV).

Shell and tube heat exchanger

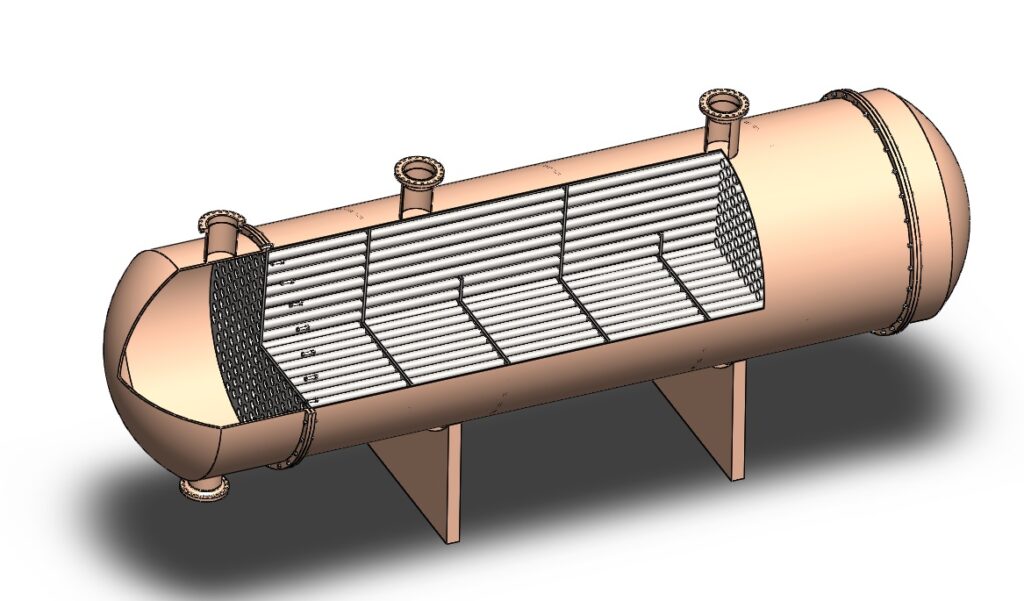

A shell and tube heat exchanger is one of the most common and widely used types of heat exchangers, especially in industries like power generation, petrochemical plants, and oil refineries. It consists of a series of tubes, one set carrying one fluid and another fluid flowing over or around them within a larger cylindrical shell. The purpose is to allow heat to transfer between the two fluids without them mixing.

Inside the heat exchanger, one fluid flows through the tubes—this is called the tube side. The other fluid flows over the tubes and around them inside the shell—this is called the shell side. The tubes are usually held in place by tube sheets and may be arranged in straight or U-shaped patterns. Baffles are placed inside the shell to direct the flow of the shell-side fluid back and forth across the tubes, which increases turbulence and improves heat transfer.

Shell and tube heat exchangers can be designed for single-pass or multi-pass flow, depending on the desired temperature change and space constraints. In a single-pass exchanger, the fluids make one trip through the system, while in a multi-pass design, the fluids may reverse direction and pass through several times for better heat exchange.

There are many configurations, but a typical example might involve hot steam flowing through the shell side while cooler water circulates through the tubes. As the steam gives up its heat to the water, it condenses, and the water heats up, all without the fluids mixing.

Advantages of shell and tube heat exchangers include:

- High pressure and temperature handling

- Modular and scalable design

- Easy to maintain and clean (especially if designed with removable tube bundles)

- Suitable for both liquids and gases on either side

However, they tend to be bulkier and heavier than other types like plate heat exchangers, and they usually require more space. Still, their reliability and flexibility make them a go-to choice for many heavy-duty thermal applications.

A shell and tube heat exchanger works by allowing two fluids at different temperatures to exchange heat without mixing. It consists of a large cylindrical shell that contains a bundle of tubes. One fluid flows inside the tubes, and the other fluid flows around the outside of the tubes within the shell. Heat is transferred through the tube walls from the hotter fluid to the cooler one. The direction of flow can be arranged in different ways, but a counterflow arrangement—where the fluids flow in opposite directions—is generally the most efficient.

The tubes are held in place by tube sheets at both ends, and the shell often contains baffles—metal plates that direct the flow of the shell-side fluid across the tubes multiple times. These baffles increase turbulence, which improves heat transfer by reducing the thickness of the fluid boundary layer on the tube surfaces. The number and placement of baffles can be adjusted depending on the application, balancing pressure drop and heat transfer performance.

The entire assembly is designed to handle high pressures and temperatures, making it suitable for demanding industrial processes. The materials used for construction depend on the fluids involved. For example, if the fluids are corrosive, stainless steel or special alloys might be used. In applications with non-corrosive water or steam, carbon steel or copper alloys may suffice. The tube bundle itself can be fixed or removable; removable designs are often used when regular cleaning or maintenance is required, especially in services prone to fouling.

Shell and tube heat exchangers can be found in a variety of systems, from power plants where they act as condensers for steam turbines, to refineries where they handle crude oil heating and cooling. In chemical plants, they’re used to regulate temperatures in reactions and product streams. The size, tube arrangement (like triangular or square pitch), number of passes, and flow rates are all tailored to specific heat duty requirements.

Over time, these exchangers may suffer from fouling, corrosion, or erosion, which can reduce efficiency. To maintain performance, they are often equipped with monitoring tools and require periodic inspections. Cleaning can be done mechanically using brushes or high-pressure water jets, or chemically using cleaning solutions that dissolve deposits.

The overall efficiency of a shell and tube heat exchanger depends on good design, material selection, and maintenance practices. Its robust construction and versatility in handling large volumes and extreme conditions make it a fundamental component in thermal systems across the globe.

In operation, the performance of a shell and tube heat exchanger is heavily influenced by several key design parameters. One of the most important is the log mean temperature difference (LMTD), which is used to calculate the effective driving force for heat transfer. The greater the temperature difference between the two fluids, the more efficiently heat can be exchanged. Engineers use this value, along with the overall heat transfer coefficient and heat transfer area, to determine how much heat the exchanger can handle.

Another crucial aspect is pressure drop, which refers to the loss of fluid pressure as it passes through the exchanger. A well-designed exchanger aims to maximize heat transfer while keeping pressure drop within acceptable limits. Too much pressure loss can reduce system efficiency and increase pumping or operational costs. Baffles, while enhancing turbulence and heat transfer, can also contribute to pressure drop, so their placement must be carefully optimized.

Flow arrangements also play a significant role in performance. A one-pass configuration might be simple and compact, but a two-pass or multi-pass arrangement can allow better temperature control and higher heat recovery in a smaller footprint. In such cases, the fluid is directed back through the exchanger more than once using partition plates, enhancing heat transfer without needing additional equipment.

Tube layout patterns—such as triangular, square, or rotated square—impact not only how many tubes can fit into the shell but also the ease of cleaning and the amount of turbulence created in the shell-side fluid. A triangular pitch provides more surface area and higher turbulence, improving heat transfer but making mechanical cleaning harder. A square pitch, on the other hand, allows easier access for cleaning but might be less efficient thermally.

In some applications, thermal expansion can become an issue, especially when the two fluids are at very different temperatures. This can cause stress on the tubes and shell. To deal with this, designs may include features like expansion joints or floating tube sheets, which allow parts of the exchanger to expand and contract independently without causing damage.

Shell and tube heat exchangers are also highly customizable. For example, the tube diameter, length, wall thickness, and number of tubes can all be adjusted based on the thermal duty and space constraints. In highly corrosive environments, titanium, nickel alloys, or even graphite may be used instead of conventional materials. For high-pressure applications, thicker walls and more robust tube supports are necessary.

Despite their large size compared to other exchanger types, shell and tube exchangers are chosen when reliability, capacity, and flexibility matter most. Their simple but effective design has stood the test of time, and they continue to be a cornerstone in both traditional and advanced industrial systems. Whether cooling compressed gases, condensing steam, recovering waste heat, or regulating temperature-sensitive chemical reactions, shell and tube exchangers are designed to perform under demanding conditions with consistent, long-term results.

Steam Generator

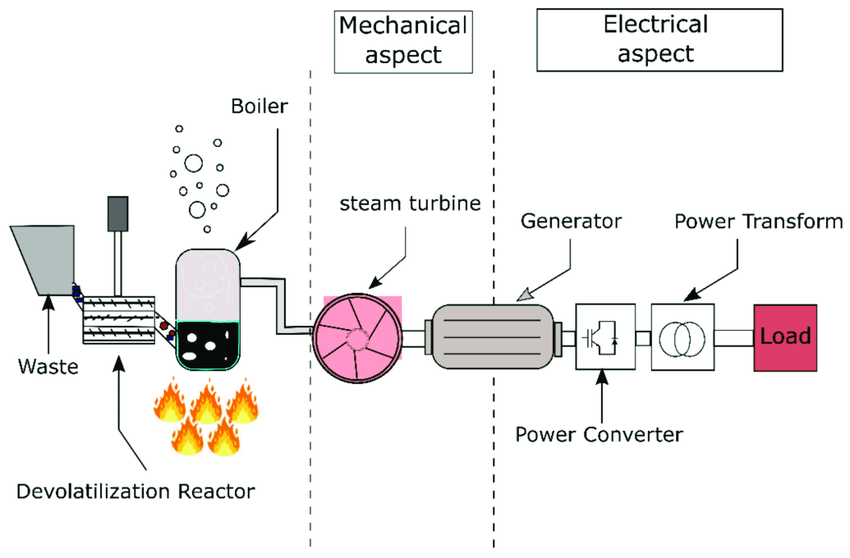

A steam generator is a device that produces steam by heating water, typically using fuel combustion, electrical energy, or nuclear reactions as the heat source. It plays a critical role in many industrial systems, especially in power generation, chemical processing, and heating systems. The basic function is to convert liquid water into high-pressure steam, which can then be used to drive turbines, heat equipment, or perform mechanical work.

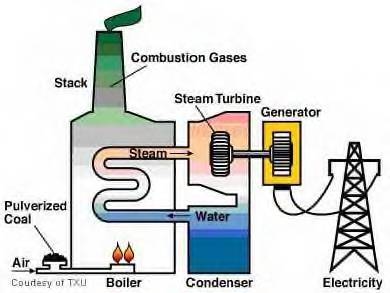

In a conventional thermal power plant, the steam generator is often referred to as a boiler. Water is fed into the system, where it’s heated inside tubes or drums until it reaches its boiling point. As the water absorbs heat, it turns into steam and exits the generator under high pressure. This steam then flows to a turbine, where it expands and spins the blades, converting thermal energy into mechanical energy, and then to electrical energy via a generator.

The design of a steam generator depends on the application and operating conditions. In fire-tube boilers, hot gases from combustion pass through tubes that are surrounded by water. In water-tube boilers, water flows through tubes that are heated externally by combustion gases. Water-tube boilers are preferred in high-pressure, high-capacity systems because they offer better heat transfer and pressure handling.

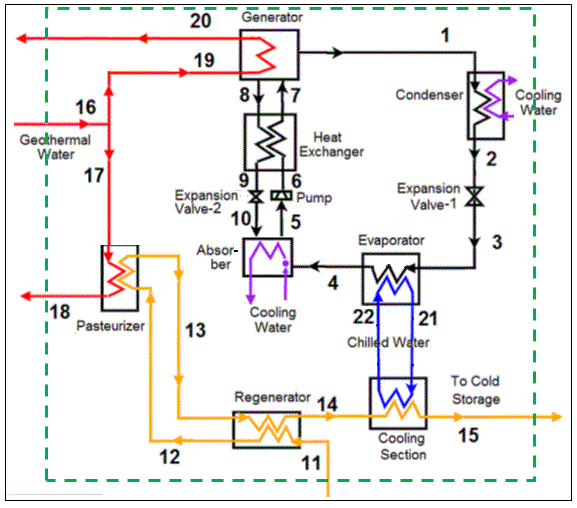

In nuclear power plants, the steam generator operates differently. The reactor core heats up a primary coolant (usually pressurized water), which flows through a heat exchanger. In this exchanger, heat is transferred to a secondary loop containing water that turns into steam. This steam then powers turbines, just like in a fossil-fuel plant, but without direct contact with the radioactive material.

Steam generators also appear in smaller-scale systems like laundry machines, medical sterilizers, or steam baths, where compact electric steam generators are used. These rely on electrical heating elements to rapidly boil water and produce steam in a controlled environment.

Key components of a typical steam generator system include the economizer (preheats feedwater using exhaust gases), drum or steam separator (separates steam from water), superheater (raises the temperature of the steam beyond saturation point for increased efficiency), and blowdown systems (remove sludge and impurities from the system to maintain performance).

Efficient steam generation depends on careful control of pressure, temperature, fuel combustion, water quality, and heat transfer surfaces. Poor water treatment can lead to scaling, corrosion, and reduced efficiency. Modern steam generators often include sensors, automation, and feedback controls to optimize performance and safety.

A steam generator operates on the simple principle of converting water into steam using a heat source, but the way it’s implemented can vary widely depending on the application. In large-scale power plants, the steam generator is the heart of the energy conversion process. Water is fed into the system and heated in multiple stages, often starting with preheating in the economizer, where heat from flue gases is used to raise the water temperature before it enters the main boiler section. Once inside the boiler, the water circulates through a network of tubes exposed to high-temperature combustion gases. As the water absorbs heat, it begins to boil and generate steam. In advanced systems, this steam is then directed through a superheater, which further increases its temperature beyond the boiling point to produce what’s known as superheated steam. This form of steam carries more energy and is better suited for doing mechanical work, such as turning the blades of a steam turbine.

Steam generators are designed to handle high pressures and temperatures, so the materials and construction must meet strict safety and performance standards. Boiler tubes, drums, and pressure parts are usually made from special steel alloys that can withstand prolonged exposure to heat and pressure without deforming or failing. In high-efficiency modern plants, the entire process is monitored and controlled through advanced instrumentation systems that adjust fuel flow, air supply, feedwater rate, and other parameters in real-time to ensure optimal steam production and fuel usage.

In smaller applications, steam generators take on a much simpler form. For instance, in laboratories, hospitals, or steam rooms, compact electric steam generators are often used. These systems consist of a water reservoir, electric heating elements, and a pressure vessel. When turned on, the heating elements rapidly bring the water to a boil, producing steam almost instantly. These generators are typically easier to maintain and install but are only practical for lower-volume needs.

In nuclear power plants, steam generation takes place without any combustion at all. Instead, the reactor core heats a primary loop of water that never boils because it’s kept under extremely high pressure. This superheated water passes through a heat exchanger called the steam generator, where it transfers its heat to a secondary loop containing lower-pressure water. This second loop does boil, producing steam that drives turbines. Because the primary and secondary loops are separate, radioactive material stays isolated, improving safety.

One of the major operational concerns in any steam generation system is the quality of the feedwater. Impurities in the water can cause scale, corrosion, and deposits inside the tubes and other heat transfer surfaces. These issues not only reduce efficiency but can also lead to equipment failure over time. That’s why feedwater treatment—through filtration, chemical dosing, and demineralization—is critical. Many systems also include a blowdown process to remove accumulated solids from the water inside the boiler.

The efficiency of a steam generator depends on how well it captures and uses the energy from its heat source. Improvements like air preheaters, economizers, and better insulation all help reduce heat loss and fuel consumption. Over the years, steam generation technology has evolved from simple coal-fired boilers to highly advanced, computer-controlled systems using natural gas, biomass, solar thermal energy, and even nuclear fusion in experimental setups. Despite these advancements, the fundamental idea remains the same—use heat to turn water into steam, and steam into power.

As steam generators evolve, their design and operation become increasingly sophisticated to meet the growing demand for efficiency, safety, and environmental sustainability. The main challenge in steam generation remains optimizing heat transfer while minimizing fuel consumption and emissions. Modern designs integrate advanced heat recovery systems that recycle waste heat to preheat water or air, thereby reducing the overall energy needed for steam production. This not only enhances efficiency but also lowers the carbon footprint of steam generation systems, especially in industrial settings.

For instance, in combined heat and power (CHP) systems, also known as cogeneration plants, steam generators produce steam for power generation while simultaneously using the waste heat for heating purposes. This dual-purpose utilization of energy drastically increases the system’s efficiency, with overall energy use reaching up to 80–90% in some cases, compared to traditional power plants where the efficiency may only reach 30–40%.

In some industries, like chemical processing or refining, the demand for steam can fluctuate rapidly depending on the operational cycles of reactors or distillation columns. To address this, steam accumulator systems are used. These systems temporarily store excess steam when demand is low and then release it when demand spikes, ensuring a constant supply without the need to constantly adjust the steam generator’s output.

Another notable advancement in steam generation involves the integration of automation and monitoring systems. Modern steam generators are equipped with sensors and control systems that measure temperature, pressure, and flow rate in real-time. These systems can adjust the fuel feed, air intake, and water flow based on demand and operational conditions. The use of machine learning algorithms is starting to gain traction in predicting maintenance needs, optimizing fuel efficiency, and preventing issues like scaling or overheating before they occur. This predictive approach can significantly reduce downtime and improve the overall lifespan of the steam generator.

In nuclear steam generators, there has been an ongoing push for safer, more efficient designs. Advanced reactors, such as small modular reactors (SMRs), are being developed with smaller, more compact steam generation systems that are easier to monitor and control. These reactors also aim to be more cost-effective and flexible, allowing for steam generation on a smaller scale that is ideal for decentralized power production, such as supplying power to remote or industrial locations that are not connected to a central grid.

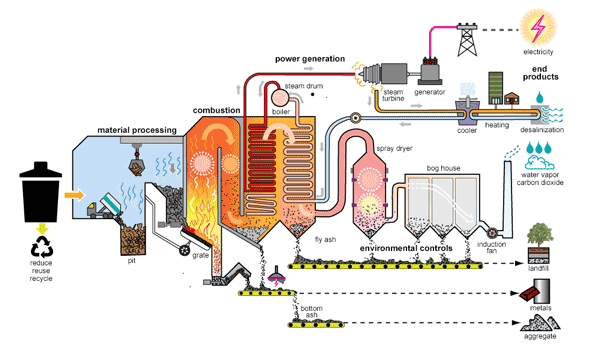

In the biomass power generation sector, steam generators are being adapted to burn organic materials like wood pellets, agricultural waste, or even municipal solid waste. These renewable sources of fuel require different combustion systems and heat management strategies compared to traditional fossil fuels. Steam generators in biomass plants are designed to handle variable fuel quality, moisture content, and combustion characteristics, making the design and operation more complex but ultimately more sustainable.

The environmental aspect is also a major focus. With the global push for carbon-neutral and sustainable energy solutions, steam generators are increasingly being paired with carbon capture and storage (CCS) technologies. These systems capture carbon dioxide emissions from the combustion process and store them underground or use them for other industrial purposes. This combination of steam generation and carbon management helps mitigate the environmental impact of fossil fuel-powered plants, while still meeting the need for reliable steam production.

Overall, while the fundamental operation of steam generators remains the same—producing steam through heat exchange—the technology continues to evolve in response to environmental pressures, economic factors, and technical advancements. Whether in large power plants or smaller industrial applications, the quest for more efficient, cleaner, and smarter steam generation systems is ongoing, shaping the future of energy production across the globe.

How does a Steam Generator Work

A steam generator works by converting water into steam using heat. This process is at the core of many industrial systems, including power plants, chemical processing, and heating systems. The basic operation is relatively simple, but various configurations exist depending on the application, the heat source, and the intended use of the steam.

The process typically starts with feedwater (cold water) being pumped into the steam generator or boiler. The water enters the system through the economizer, a heat exchanger that preheats the feedwater using waste heat from the exhaust gases of combustion. This helps reduce the amount of energy required to bring the water to a boil.

Once the water enters the boiler (or steam generator), it flows through a series of tubes or a large chamber where it is exposed to a heat source. The heat source can vary:

- In fossil fuel plants, burning coal, oil, or natural gas generates heat. The combustion gases flow over or through the tubes, heating the water inside.

- In nuclear power plants, heat is generated by the nuclear reaction in the reactor core. The heat is transferred to the primary coolant loop, which then heats water in a secondary loop to produce steam, without the two fluids mixing.

- In solar thermal plants, mirrors or lenses focus sunlight onto a receiver that heats the fluid (typically water or oil) to produce steam.

As the water absorbs heat, it begins to boil, and steam starts to form. The steam rises and is collected at the top of the generator, while the remaining water continues to absorb heat until it turns into steam as well. To ensure the steam is dry and usable for power generation or other purposes, the water-steam mixture often passes through a steam separator. This device removes excess water droplets, producing dry steam for use in turbines or other systems.

In many large-scale systems, the steam is passed through a superheater. The superheater raises the temperature of the steam above its saturation point, making it superheated steam. Superheated steam carries more energy and is more efficient for driving turbines, as it avoids condensation, which would otherwise reduce the efficiency of energy transfer.

Once the steam is generated and superheated (if necessary), it is directed through pipes to the intended process, whether it’s powering turbines, heating a building, or being used in industrial processes. The steam may pass through a turbine, where its thermal energy is converted into mechanical energy. After performing work in the turbine, the steam loses much of its energy and is cooled down, often in a condenser, where it turns back into water. This water is then pumped back into the steam generator to repeat the cycle, making the process continuous.

Throughout this process, the steam generator must maintain controlled conditions—pressure, temperature, and flow rates—because these factors determine how efficiently steam is produced and whether the system operates safely. For example, pressure relief valves and temperature controls are essential safety features to prevent dangerous overpressure or overheating.

The working cycle of a steam generator is typically based on the Rankine cycle in power plants, which involves the evaporation of water, expansion of steam, condensation, and recompression of the water. This cycle is a key principle behind many steam-based power generation systems.

A steam generator continues its operation by maintaining the water and steam in a controlled environment to ensure efficiency and safety. After the steam is produced, it typically travels through pipes and is directed to a turbine where its thermal energy is converted into mechanical energy. The pressure and temperature of the steam are key factors in ensuring that the turbine operates efficiently. In a turbine, steam expands rapidly, causing the blades to spin, which then drives a generator to produce electricity in power plants or performs mechanical work in other applications.

Once the steam has passed through the turbine and its energy has been extracted, it needs to be cooled and condensed back into water so it can be reused in the cycle. This is done in a condenser, which typically uses cool water from a nearby source, such as a river or ocean, to absorb the heat from the steam. As the steam cools down in the condenser, it condenses into water, which is then pumped back into the steam generator to be reheated.

Throughout this entire process, maintaining the appropriate water chemistry is vital to prevent issues like scaling, corrosion, and fouling within the steam generator. The quality of the feedwater must be monitored and treated to ensure it is free from impurities that could damage the heat exchange surfaces or affect the efficiency of steam production. For example, in larger plants, demineralization and deoxygenation processes are used to ensure the water remains clean and free from minerals that can form scale deposits inside the boiler tubes.

The efficiency of a steam generator also depends on its ability to maintain optimal pressure and temperature. Too much pressure can cause mechanical failure, while too little pressure can prevent steam from having enough energy to drive turbines effectively. Temperature controls ensure the steam does not lose too much heat as it moves through the system, which could reduce the energy efficiency of the entire process.

Additionally, modern steam generators often incorporate automation and control systems that continuously monitor and adjust key parameters like pressure, temperature, water flow, and fuel consumption. These systems ensure that the steam generator operates at peak efficiency and can automatically shut down or make adjustments in case of operational issues, improving both safety and performance.

The cycle of producing steam, expanding it in a turbine, and condensing it back into water is a continuous process. This cycle repeats over and over, creating a reliable source of steam for various industrial processes, electricity generation, or heating applications. The overall performance of a steam generator is heavily dependent on the design, the materials used, and the maintenance practices in place, which together ensure that the system operates efficiently and safely over its lifetime.

In a steam generator system, maintaining thermal efficiency is crucial to ensure minimal fuel consumption while maximizing the amount of steam produced. The more efficiently the system can transfer heat to the water, the less fuel is required to produce steam, which is particularly important in large-scale operations like power plants. As a result, designs often include features such as heat recovery systems to capture waste heat from exhaust gases and recycle it to preheat incoming water. This not only conserves energy but also reduces the environmental impact of steam generation by lowering the demand for fuel.

In larger facilities, like combined-cycle power plants, the efficiency can be further enhanced by integrating gas turbines with steam generators. In such systems, natural gas is burned in a turbine, which generates electricity. The exhaust gases from the turbine, still containing substantial heat, are then used to generate steam in a heat recovery steam generator (HRSG). The steam produced from this system drives a steam turbine, further increasing the overall efficiency of power generation by utilizing what would otherwise be wasted energy. This approach can bring the efficiency of the power generation process to as high as 60% or more, compared to the typical 30–40% efficiency seen in conventional coal-fired plants.

For industrial applications, steam generators are often used in processes where consistent and reliable heat is needed, such as in chemical manufacturing, food processing, and oil refining. In these contexts, steam is used to heat reactors, distillation columns, sterilizers, or other equipment. The steam’s pressure and temperature must be carefully controlled to meet the specific requirements of the process. For example, some processes require low-pressure steam for gentle heating, while others need high-pressure steam for mechanical work or for driving turbines.

Safety is a paramount concern in steam generator operation, especially due to the high pressures and temperatures involved. Boilers and steam generators are designed with numerous safety features such as pressure relief valves, temperature sensors, and automatic shutdown systems that protect against over-pressurization, overheating, or other operational failures. Many systems also have redundant safety systems to ensure that if one fails, others can take over and prevent catastrophic damage. These safety mechanisms are regularly tested and must meet industry standards and regulations.

Regular maintenance is also key to the continued efficient operation of steam generators. Over time, the heat exchange surfaces inside the system can become coated with scale from minerals in the water, or even accumulate soot and ash from combustion, which reduces the system’s ability to transfer heat. For this reason, boiler cleaning is necessary to remove these deposits and restore heat transfer efficiency. Additionally, corrosion can be an issue, especially if water treatment is inadequate, and specific maintenance procedures are employed to detect and prevent it, such as periodic inspections, tube replacements, and chemical treatments for corrosion inhibition.

Technological advancements in automation and digital monitoring are also playing an increasingly important role in steam generator operation. Using sensors to continuously monitor parameters like steam pressure, flow rates, fuel consumption, and emissions helps operators make real-time adjustments to maintain optimal performance. In some systems, predictive maintenance algorithms powered by machine learning can anticipate when components might fail or require servicing, reducing unexpected downtime and optimizing the lifespan of the equipment.

Additionally, the future of steam generation is moving toward greener technologies. One such development is the use of biomass as a fuel source instead of traditional fossil fuels. Biomass, such as wood chips, agricultural residues, or waste materials, can be burned in steam generators to produce steam in an environmentally friendly way, as it is considered carbon-neutral (the carbon dioxide released during combustion is offset by the carbon absorbed by the plants during their growth). However, the use of biomass requires specially designed boilers and steam generators, as the fuel burns at different rates and produces more ash than conventional fossil fuels.

In the context of nuclear power, advancements in small modular reactors (SMRs) are reshaping the future of steam generation. SMRs are compact, scalable nuclear reactors designed to be safer and more cost-effective than traditional large-scale nuclear plants. These reactors produce heat that is used to generate steam for electricity generation, and their small size allows them to be deployed in areas where traditional large reactors would not be feasible. Additionally, SMRs are designed to be more resilient in terms of safety and can operate in remote locations or alongside other industrial processes where consistent and reliable steam is needed.

Ultimately, the function of a steam generator—whether for power production, industrial heating, or process applications—remains central to countless energy systems across the globe. As technological and environmental demands evolve, steam generation continues to adapt, improving in efficiency, safety, and sustainability.

Steam Generator and Boiler Difference

The terms steam generator and boiler are often used interchangeably, but there are subtle differences between them, especially in the context of how they are used and their specific functions in various industries.

1. Basic Definition:

- A boiler is a general term for any closed vessel designed to heat water to produce steam. It is used in a variety of industries for heating, power generation, or processing purposes. Boilers can be fueled by a variety of sources, such as natural gas, coal, oil, or biomass.

- A steam generator, on the other hand, is a more specific term often used to describe a system that produces steam in a controlled environment through the use of heat. While a steam generator can technically be considered a type of boiler, it typically refers to a system designed for high-efficiency, high-pressure, or high-temperature steam production, particularly in power generation systems or nuclear applications.

2. Design and Operation:

- Boilers can come in several designs, such as fire-tube, water-tube, or electric boilers, and they function by heating water to a boiling point. In the case of fire-tube boilers, hot gases pass through tubes immersed in water; in water-tube boilers, water passes through tubes heated by combustion gases. Boilers are primarily used in industrial processes, space heating, and smaller-scale power generation.

- Steam generators, particularly in nuclear power plants, are used to generate steam from heated water, often in a two-loop system. The primary loop carries heat generated by the reactor to the steam generator, where it heats water in the secondary loop to produce steam. The steam generated is then used to drive turbines for power production. Steam generators used in these applications must be capable of handling very high pressures and temperatures.

3. Pressure and Temperature:

- Boilers generally operate at lower pressures and temperatures compared to steam generators, especially when used for heating purposes in industrial or residential applications. For example, a residential boiler might operate at pressures around 1–2 bar, while industrial boilers can reach higher pressures but are still typically lower than the steam generators used in power generation.

- Steam generators, especially in power plants or nuclear reactors, operate at much higher pressures and temperatures. The steam produced in these generators is typically superheated to increase its energy content and efficiency in driving turbines.

4. Use Cases:

- Boilers are used in many industries for generating steam to power turbines, heat buildings, or for use in various industrial processes like chemical manufacturing, food processing, and oil refining. Boilers are also found in steam-based heating systems like district heating.

- Steam generators, in contrast, are often associated with power generation (especially in large-scale systems), nuclear reactors, and marine propulsion systems. They are typically used where high-pressure, high-temperature steam is required for efficient energy production or propulsion.

5. Size and Complexity:

- Boilers tend to be smaller and simpler than steam generators, designed for localized or industrial-scale use. They may be standalone units in a factory or power plant.

- Steam generators, especially those used in nuclear power plants, tend to be much larger, more complex, and operate under more stringent safety protocols. They are usually designed for continuous high-performance operations in large-scale industrial systems or power stations.

6. Efficiency:

- Boilers typically focus on providing a reliable, continuous heat source and may not always be as efficient as steam generators when it comes to power generation. They are optimized for low-cost, effective steam production but not necessarily for maximizing energy efficiency in power generation.

- Steam generators, particularly in combined-cycle or nuclear power plants, are designed to maximize energy efficiency, often using advanced heat recovery methods and superheating to convert heat into high-efficiency steam for turbines.

7. Component Variations:

- A boiler often includes basic components such as a burner, heat exchanger, water drum, feedwater pump, and flue gas stack. It can be a simpler design, especially in residential or small industrial applications.

- A steam generator typically includes more complex components, particularly in nuclear or high-pressure steam systems, such as primary and secondary loops, steam separators, superheaters, and pressure relief systems. The design needs to handle much higher pressures and safety standards, particularly in nuclear or high-efficiency power plants.

Conclusion:

While both steam generators and boilers are designed to produce steam, a steam generator is typically a more specialized, higher-pressure system used in power generation or nuclear applications, where efficiency and safety are crucial. A boiler, on the other hand, is a broader term that refers to a device used in many industries for heating and power generation at relatively lower pressures and temperatures. The distinction lies in the application, pressure, temperature, and complexity of the system, with steam generators often being a more specialized subset of the broader category of boilers.

A steam generator, while sharing similarities with a boiler in terms of producing steam, is designed specifically for high-efficiency, high-temperature, and high-pressure applications, especially in larger-scale or more complex operations. In power plants, especially those that use nuclear or combined-cycle technology, steam generators are essential for ensuring that the steam produced can be used efficiently in turbines for electricity generation. These systems often feature sophisticated heat exchange processes, with components designed to handle the extreme conditions of pressure and temperature that are common in large-scale energy production. In nuclear plants, for example, steam generators are critical for transferring heat from the nuclear reactor’s primary loop to the secondary loop, where water is heated to produce steam without mixing the radioactive coolant from the reactor with the steam used to drive turbines.

On the other hand, a boiler is a more general term that can apply to a broad range of systems designed to produce steam for industrial processes, heating, or power generation at lower pressures. Boilers come in a variety of designs, such as fire-tube or water-tube types, and they can operate on various fuel sources, including natural gas, coal, or biomass. Boilers are commonly found in industrial settings where they serve to provide steam for heating, chemical processes, or even smaller power generation applications. While they also operate at high temperatures, their steam is often not superheated, and they typically function at lower pressures compared to steam generators used in power plants.

The key difference between the two lies in the application and the operating conditions. Steam generators are specialized for producing steam in environments where energy efficiency and high-performance steam are required, such as in turbines for electricity generation. Boilers, while capable of producing steam, are more versatile and commonly used in industries for heating and process applications where extreme pressure and temperature conditions are not as critical.

Additionally, steam generators often feature more advanced systems for monitoring and controlling pressure, temperature, and flow to ensure that the steam produced is suitable for the high-demand applications, such as turbine operation in power plants. In contrast, boilers, especially those used in smaller-scale or industrial applications, may focus more on maintaining a steady steam supply for heating or processing needs without necessarily prioritizing the same level of efficiency or energy recovery.

In short, while both steam generators and boilers function to produce steam, the difference lies in the scale, application, pressure, and temperature at which they operate. Steam generators are high-performance systems typically used for large-scale, high-pressure applications, such as in power plants, while boilers are versatile and widely used in a broader range of industries at varying levels of pressure and efficiency.

The distinction between steam generators and boilers extends into their operational lifecycles, design complexities, and the way they are integrated into larger systems. For example, in large-scale power generation, particularly in combined-cycle plants, steam generators play a vital role in ensuring that the system operates as efficiently as possible. These plants use both gas turbines and steam generators to maximize energy output. Gas turbines generate electricity directly, but the exhaust gases still have significant heat energy. This waste heat is captured by the steam generator to produce steam, which then drives a steam turbine to generate even more electricity. This process, known as combined heat and power (CHP) or cogeneration, significantly improves the overall efficiency of the plant.

In contrast, boilers in industrial settings typically focus on the generation of steam for specific processes. These may include district heating systems, chemical plants, or food processing facilities, where steam is needed for heating, sterilization, or as a reactant in certain chemical processes. The steam produced in these systems does not always need to be at the high pressures or temperatures required by turbines. As such, these systems are often simpler in design and operation, focusing more on delivering consistent and reliable steam rather than optimizing for energy recovery or maximum efficiency.

Another important difference is the maintenance and operating costs associated with steam generators and boilers. Steam generators, particularly in power plants, require more rigorous maintenance protocols due to the high pressures, temperatures, and the critical nature of the systems they serve. For example, in nuclear steam generators, constant monitoring is required to ensure the integrity of pressure boundaries, to prevent leaks, and to maintain high levels of operational safety. In these high-demand environments, regular inspections and upgrades to the system’s components are essential to prevent failure and extend the life of the equipment. Additionally, because these systems are so complex, they often rely on highly specialized maintenance teams, and parts are often bespoke, which can increase the cost of operation.

Boilers, being simpler and generally operating at lower pressures, typically have lower maintenance costs but require regular cleaning to ensure efficiency. Over time, scale buildup, soot accumulation, and corrosion can reduce their heat transfer efficiency, which is why maintenance often involves cleaning and checking the system for damage. The overall life expectancy of a boiler can be longer than that of a steam generator, depending on the environment and its usage, but maintaining its efficiency still requires constant attention to the quality of water, combustion processes, and pressure settings.

In the case of fossil fuel boilers, environmental considerations have become increasingly important. Modern regulations require these systems to be more energy-efficient and to meet stricter emissions standards. This has led to advancements in boiler technology, such as low-NOx burners, flue gas recirculation, and scrubbing technologies that reduce the environmental impact. The use of biomass boilers, which burn organic materials, has also gained traction as an environmentally friendly alternative to coal and oil. These types of systems are often designed for industries that need both heat and power from a sustainable source.

Additionally, both steam generators and boilers face safety challenges due to the high pressures and temperatures involved. While boilers typically operate at lower pressures, the potential for overpressure, explosions, or leakages is always a concern. As such, both types of systems are equipped with pressure relief valves, safety shut-off mechanisms, and automatic monitoring controls to maintain safe operational conditions. For steam generators in power plants, especially those used in nuclear or high-efficiency power generation, these safety protocols are even more stringent. In these settings, the consequences of failure are far more serious, which is why their design incorporates multiple layers of redundancy and fail-safes.

The emergence of digital technologies is also playing a role in the evolution of both steam generators and boilers. The integration of sensor technology, real-time data collection, and machine learning algorithms is enabling more sophisticated control of both types of systems. This allows for better predictive maintenance, real-time performance adjustments, and the optimization of fuel consumption. In steam generators, for example, digital controls can adjust the heat input based on real-time steam demand, improving both efficiency and response times to fluctuating power loads. Similarly, boilers can be equipped with systems that automatically adjust combustion processes to reduce emissions or optimize heat transfer.

Finally, as industries around the world work towards becoming carbon-neutral or adopting more sustainable practices, both steam generators and boilers are part of a larger push for cleaner energy production. For steam generators, this may involve the integration of carbon capture and storage (CCS) technologies to reduce the carbon dioxide emissions associated with fossil fuel combustion. Meanwhile, boilers are increasingly designed to operate on renewable fuels like biomass or biogas, and waste-to-energy systems are becoming more common as a way to both generate power and reduce landfill waste.

Ultimately, the evolution of both steam generators and boilers reflects a broader trend towards efficiency, safety, and sustainability. The systems themselves may differ in their scale, complexity, and applications, but they both serve the crucial function of producing steam, which remains an essential component of modern industry and energy production. As technology advances, the boundary between steam generators and boilers will continue to blur, with innovations that make both systems more efficient, adaptable, and environmentally friendly.

Low Pressure Steam Generator

A low-pressure steam generator is designed to produce steam at relatively lower pressures compared to high-pressure systems used in power generation. Typically, low-pressure steam generators operate at pressures below 15 bar (approximately 220 psi), though this can vary depending on the specific application. These systems are commonly used in industrial processes where steam is needed for heating, sterilization, or other non-turbine applications, as well as for smaller-scale power generation.

In a low-pressure steam generator, the basic principle of operation remains the same as in high-pressure systems: water is heated by a heat source until it boils and produces steam. However, since the pressure is lower, the temperature of the steam will also be lower, which means the steam will not have as much energy as higher-pressure steam, and it is not typically used for driving turbines or other high-energy applications. Instead, it is generally used for heating purposes or as a source of mechanical energy in simpler industrial processes.

Low-pressure steam generators are often designed to be simpler and more cost-effective compared to high-pressure systems, and they can be fueled by a variety of sources, including natural gas, oil, or even renewable biomass. They are commonly found in industries such as food processing, chemical manufacturing, textiles, and district heating systems, where steam is needed for a wide range of applications but at lower pressure and temperature.

One of the key advantages of low-pressure steam generators is their operational simplicity. Since they operate at lower pressures, they do not require the same level of safety features and maintenance procedures as high-pressure steam generators, which can handle the more demanding conditions found in power plants. As a result, low-pressure steam systems tend to be more cost-effective to install and maintain.

Additionally, low-pressure steam generators are often more energy-efficient for applications where high-pressure steam is not necessary. For example, in a district heating system, where steam is used to heat buildings, the demand for high-pressure steam is minimal. A low-pressure steam generator provides an adequate supply of steam for these applications while consuming less fuel and requiring less sophisticated controls compared to high-pressure alternatives.

Although they may not be suitable for power generation or large-scale industrial applications that require high-pressure steam, low-pressure steam generators play a critical role in smaller industrial systems. They are especially valuable in operations where consistent, reliable steam is needed but at lower temperatures and pressures, ensuring efficiency and cost-effectiveness.

Low-pressure steam generators are essential in many industrial applications where steam is needed for processes like heating, sterilization, humidification, and other tasks that do not require high energy levels. These systems provide a reliable and efficient means of generating steam at lower temperatures and pressures, which is ideal for specific industries. For instance, in the food processing industry, steam is used for cooking, sterilization, and cleaning, but high pressure is not necessary. Similarly, in textiles, steam is used for dyeing and finishing processes, where low-pressure steam is sufficient.

The design of low-pressure steam generators is relatively simpler compared to their high-pressure counterparts. They often consist of a burner, heat exchanger, and boiler drum, where water is heated and converted into steam. In these systems, since the pressure is lower, the system doesn’t have to handle the intense structural demands required by high-pressure systems. This makes low-pressure steam generators more straightforward to maintain and more cost-effective to operate. The materials used in their construction are also less demanding in terms of strength and durability, which helps keep the initial cost of installation lower.

While these systems are generally not used in electricity generation, they still play a key role in smaller-scale energy production, such as in combined heat and power (CHP) systems, where the steam can be used for heating or mechanical work. In a CHP setup, low-pressure steam may be used for heating purposes, while any excess can be used for generating electricity in a small-scale turbine or mechanical engine. This makes low-pressure steam systems more versatile for localized or decentralized energy needs, offering a more environmentally friendly and efficient alternative to purely combustion-based heating systems.

Another advantage of low-pressure steam generators is their fuel flexibility. They can run on a variety of fuel sources such as natural gas, propane, biomass, or even waste oils. This flexibility allows industries to choose the most cost-effective or sustainable fuel source depending on availability and environmental considerations. In some cases, renewable fuels like biomass are becoming more popular, as they provide an environmentally friendly option while reducing reliance on fossil fuels.

In addition, low-pressure steam generators often incorporate modern control systems that allow for automated operation, optimizing the use of fuel and water while maintaining consistent steam output. These control systems can include pressure sensors, temperature controllers, and flow regulators, ensuring that the system operates efficiently and safely. Because the steam produced is at a lower pressure, safety concerns are typically less critical than in high-pressure systems, but safety protocols are still in place to prevent overheating, leaks, or system malfunctions.

In summary, low-pressure steam generators serve a critical role in various industries by providing steam for heating, sterilization, and other essential processes without the need for high energy input. They are simple, cost-effective, and versatile systems that can run on different types of fuel, offering a sustainable solution for smaller-scale or localized steam requirements. These systems are an integral part of many industrial operations, contributing to efficiency and productivity without the need for complex, high-pressure steam generation.

Low-pressure steam generators are not only advantageous due to their simplicity and cost-effectiveness but also for their adaptability to various operating conditions. For example, in a chemical manufacturing plant, low-pressure steam is often required for reaction vessels or distillation columns where a gentle, consistent heat source is necessary. These processes typically don’t require the high temperatures or pressures that come with a high-pressure steam generator, making low-pressure systems the ideal choice.

In district heating systems, low-pressure steam generators also have a significant role. These systems provide heat to residential, commercial, or industrial buildings in urban areas, often via steam distributed through a network of pipes. Since the steam’s primary purpose here is for space heating and not for driving turbines, low-pressure steam is more than sufficient. These systems tend to operate at lower pressures to maximize energy efficiency and reduce operational costs, while still ensuring that the heat transferred to buildings is adequate to meet their heating needs.

Additionally, as energy efficiency and sustainability become increasingly important, low-pressure steam generators can be adapted to integrate with renewable energy sources. For instance, solar thermal energy or geothermal energy can be used to heat the water that is converted into steam in these systems, further reducing the environmental impact of steam generation. The use of combined heat and power (CHP) systems can also be an attractive option, especially in cogeneration plants, where low-pressure steam is generated alongside electricity, allowing both forms of energy to be used efficiently and sustainably.

Another area where low-pressure steam generators are gaining popularity is in the biopharmaceutical industry, where they are used to sterilize equipment and materials. Since the sterilization process requires steam at specific temperatures to be effective, but not necessarily at high pressures, low-pressure steam generators fit the requirements well. They offer a reliable and controlled environment for sterilization without the complexity of handling high-pressure steam systems, ensuring both operational efficiency and safety.

While low-pressure steam generators are well-suited for various industries, they are not entirely free from limitations. One challenge is that the steam produced at lower pressures has a relatively lower thermal energy content, meaning it cannot be used for high-energy tasks like driving turbines in large power plants. Additionally, while maintenance costs are lower compared to high-pressure systems, regular monitoring and care are still needed to ensure efficiency. Issues such as corrosion, scaling, or sediment buildup can affect the performance of the system over time, requiring regular cleaning and water treatment to maintain optimal heat transfer.

Despite these challenges, the long-term reliability and low operational costs of low-pressure steam generators make them an attractive choice for a wide range of applications. They provide a cost-effective, flexible, and environmentally friendly solution for industries that require steam at lower temperatures and pressures, and their efficiency and adaptability to various fuel sources ensure that they will continue to play a significant role in both industrial processes and energy production. The ongoing development of smart monitoring technologies and predictive maintenance systems is also expected to enhance the performance of low-pressure steam generators, allowing operators to further optimize their energy use and minimize downtime, improving both economic and environmental outcomes.

Portable Steam Generator Industrial

A portable steam generator in an industrial context is a compact and mobile unit designed to generate steam for various applications, such as cleaning, sterilization, or power generation, and can be easily moved from one location to another within a facility or between different sites. These units are particularly useful for industries where steam is needed on a temporary or mobile basis, such as in construction, oil and gas, food processing, manufacturing, or maintenance operations.

Unlike fixed steam generators, portable units are designed for ease of transportation and can be used in remote or temporary work environments. They typically come in skid-mounted or trailer-mounted designs, allowing them to be moved by trucks or cranes. This makes them ideal for projects or operations that need flexible steam supply but don’t have access to stationary steam systems or where fixed installations aren’t feasible due to space or logistical constraints.

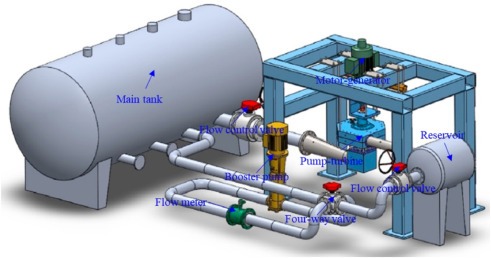

The operation of a portable steam generator is similar to that of fixed steam systems. Water is heated by a fuel source—such as natural gas, diesel, propane, or even electricity—to produce steam, which is then supplied to the required location via hoses or pipes. The unit typically includes a boiler, burner, water pump, and heat exchanger, and it is equipped with pressure controls and safety mechanisms to ensure safe operation under varying load conditions.

In the oil and gas industry, for example, portable steam generators are commonly used for steam cleaning of equipment and machinery, drilling operations, or enhanced oil recovery (EOR). Steam is injected into reservoirs to increase pressure and make oil extraction easier, and portable steam generators can be brought in to support these processes in the field. Similarly, in the food processing industry, portable steam generators are used for cleaning and sterilizing equipment, ensuring sanitation without requiring the installation of a permanent steam system.

One of the key benefits of portable steam generators is their flexibility. These units can be moved to where steam is required, and they can easily be relocated as project needs change. This is particularly advantageous for industries where operations are temporary or scattered across different locations. Portable systems also allow for rapid deployment, which is essential in urgent situations such as emergency shutdowns or maintenance work, where quick access to steam is necessary.

Another advantage is the cost-effectiveness of portable steam generators. Since they are designed for mobility, they can be rented, reducing the need for industries to invest in permanent steam systems if their steam requirements are temporary or infrequent. Renting a portable steam generator also allows companies to scale up or down depending on their needs, and it eliminates the long-term maintenance and installation costs associated with fixed steam generation systems.

Portable steam generators are also well-suited for industries that operate in areas with limited infrastructure. For instance, in remote mining sites or construction projects where utilities like electricity or water supply may be inconsistent, a portable steam generator can be brought in to provide the necessary steam for operations such as cleaning, sterilization, or pressure testing without relying on fixed infrastructure.

However, while portable steam generators offer many advantages, they do come with some challenges. Due to their mobile nature, they are generally smaller in capacity compared to large fixed steam generators. This limits their use in large-scale power generation or heavy industrial processes that require continuous, high-volume steam production. The size and capacity of portable units typically make them more suitable for intermittent or low to medium volume steam demands.

Additionally, the maintenance of portable steam generators can be more challenging since they are designed to be moved and operated in diverse environments. These units are exposed to rough handling, varying weather conditions, and potential misuse, which can lead to wear and tear. As a result, regular inspection, servicing, and preventive maintenance are necessary to keep them operating efficiently and safely.

In conclusion, portable steam generators are a versatile solution for industries that require steam on a temporary or flexible basis. They are ideal for operations that need mobility, cost-effective steam production, and ease of deployment. While they may not be suitable for all applications—particularly those that demand high, continuous steam output—they offer significant advantages in terms of flexibility, mobility, and convenience, especially in industries where operations are spread across multiple sites or are short-term in nature.

Portable steam generators provide a valuable solution for industries needing mobile steam supply, especially when fixed steam systems aren’t practical or available. These units are versatile, cost-effective, and easy to deploy, offering the ability to quickly supply steam in remote locations or on temporary worksites. Their primary advantage lies in their flexibility and mobility, making them ideal for applications where steam is required intermittently or for short durations.

In industries such as construction, portable steam generators are often used for cleaning, heating, or sterilization tasks. For example, they can be used to sterilize equipment or clean surfaces that need high temperatures but don’t have direct access to a permanent steam system. In construction sites, where work areas may constantly change, these portable units allow steam to be brought to various parts of the site without the need to install a fixed steam boiler or heating system. Similarly, in mining or remote oil rigs, portable steam generators can be used for steam-assisted extraction processes, cleaning machinery, or even providing steam for workforce accommodations in the form of hot water or space heating.

Another key aspect of portable steam generators is their ability to be rented, which offers a significant cost-saving option for industries that don’t need continuous steam production. Renting allows companies to access steam generation on-demand without investing in expensive equipment that would remain unused when not required. This is especially beneficial for seasonal operations or temporary projects that last only a few months.

Portable units also provide value in maintenance and emergency situations. For example, if a fixed steam generator fails in a critical operation, a portable unit can be quickly brought in to provide the necessary steam for ongoing work, minimizing downtime. In situations where rapid steam production is needed for a particular task or equipment, portable steam generators can be deployed much faster than installing or waiting for a fixed solution.

However, there are some limitations. The primary drawback is the capacity. Because portable steam generators are designed to be mobile, they tend to have a smaller output than stationary systems, limiting their use to applications with lower or intermittent steam demand. They are best suited for tasks such as cleaning, sterilization, or small-scale production rather than large industrial processes requiring constant steam production.

Moreover, due to the nature of portable systems, they can be exposed to harsher conditions during transportation or operation in the field. This can lead to wear and tear, requiring more frequent maintenance or repairs. Portable steam generators may also require regular monitoring and inspections to ensure their continued safe operation, especially when used in challenging environments where reliability is critical.

Despite these limitations, portable steam generators continue to be an indispensable tool across various industries. Their ability to bring steam to areas that otherwise would not have access to steam systems makes them highly effective for temporary or mobile operations. As industries continue to prioritize flexibility, cost-efficiency, and speed, portable steam generators are expected to remain a crucial part of operations that require immediate and mobile steam supply.

Portable steam generators also offer an advantage when it comes to fuel versatility. Depending on the specific model, they can be powered by a variety of fuels such as diesel, natural gas, propane, or even electricity, allowing industries to select the most appropriate fuel type based on cost, availability, or environmental concerns. This fuel flexibility can be particularly important in remote or off-grid locations, where a steady supply of electricity or natural gas may not be feasible. Diesel-powered units, for example, are ideal for construction or mining operations where access to the power grid is limited, and propane-powered units may be used for more environmentally conscious operations in certain regions.

Another advantage of portable steam generators is their compact design. These units are built to be easily transportable, often featuring wheels or trailers that allow them to be towed behind vehicles or lifted by cranes. Their smaller footprint means they can be moved easily around a worksite or to different locations without the need for significant logistical support. This mobility is particularly useful for projects that span large areas or for operations that require steam to be deployed across multiple zones, without the need to install a permanent steam system at each location.

For industries dealing with emergency response, portable steam generators are invaluable. Whether it’s for disaster relief, firefighting, or chemical spills, these systems can quickly provide steam for decontamination, cleaning, or other urgent operations. In such situations, the rapid availability of steam can aid in disinfecting areas, cleaning equipment, or sterilizing materials, all of which are crucial tasks when responding to an emergency.

Moreover, portable steam generators can be integrated with advanced monitoring and automation systems. Modern units often come equipped with digital control panels, remote monitoring capabilities, and safety features like pressure relief valves, temperature sensors, and automated shutoff systems. This allows for precise control over the steam production process, ensuring safe and efficient operation even in challenging environments. Remote monitoring can be particularly valuable for operations that are located in remote areas, as it allows operators to check performance and make adjustments without needing to be physically present at the generator.

One consideration, however, is the water treatment involved in portable steam generation. To maintain the efficiency of the unit and prevent damage from scale buildup or corrosion, water used in the generator must often be treated to remove impurities. This is particularly important in industries that use hard water or have high levels of minerals, which can cause scaling inside the boiler. Some portable steam generators come with built-in water filtration systems, while in other cases, a separate portable water treatment unit may be required. Proper water treatment ensures that the generator operates smoothly, extends the life of the equipment, and maintains the quality of the steam produced.

For greenfield projects or areas where the infrastructure for steam generation is not yet established, portable steam generators are often the solution that fills the gap. In the early phases of large projects like oil extraction or construction of large facilities, these units can provide the necessary steam for initial operations, testing, or heating without the need for extensive infrastructure investment. Once the need for steam becomes more permanent, a larger, more fixed system can be installed, but the portable units allow for flexibility and smooth transition during the project’s development.

Despite these benefits, portable steam generators do face operational challenges. Since they are smaller and mobile, their energy efficiency might not be as high as that of stationary, large-scale steam generation systems. This means they might consume more fuel per unit of steam produced compared to larger, more efficient fixed systems, which can lead to higher operational costs if used for prolonged periods. Additionally, while the size and mobility make these units ideal for temporary use, they may not be able to meet the demands of continuous high-volume steam needs over long durations.

In summary, portable steam generators are highly effective, flexible, and cost-efficient solutions for industries that require temporary or mobile steam supplies. Their ability to be easily transported, fuel flexibility, and adaptability to various operational conditions make them invaluable for applications ranging from construction to emergency response, maintenance, and cleaning operations. While they might not replace large stationary systems for high-demand, long-term steam needs, portable steam generators provide a crucial tool for industries that prioritize mobility, cost-effectiveness, and speed in their steam generation requirements. As technology advances, these units are likely to become even more efficient, eco-friendly, and integrated with digital systems for better performance and monitoring, enhancing their value in a wide range of industrial sectors.

Industrial Steam Generator

An industrial steam generator is a large-scale device used to generate steam for industrial applications, such as power generation, process heating, sterilization, cleaning, and various other uses in industries like chemical manufacturing, refining, food processing, textiles, and pharmaceuticals. Industrial steam generators are designed to produce significant amounts of steam, typically at high pressures and temperatures, to meet the operational needs of large-scale industries.

These generators work on the basic principle of heating water to its boiling point, transforming it into steam, which can then be used to drive turbines, power equipment, or provide thermal energy for processes. The steam is typically produced in a boiler (a key component of the steam generator) and is then distributed to where it is needed in the plant via a network of pipes and valves.

The fuel used to generate steam can vary, and industrial steam generators are available in various types based on the fuel source: natural gas, coal, oil, biomass, and even electricity can all serve as energy sources. The choice of fuel depends on factors such as availability, cost, environmental regulations, and the operational requirements of the plant. In some cases, industrial steam generators are designed to work in cogeneration systems, where the waste heat is used for electricity generation in addition to steam production.

Key components of industrial steam generators include the boiler, burner system, heat exchangers, control systems, and safety mechanisms. The boiler is where the water is heated, typically using the heat from burning fuel. Inside the boiler, water tubes or fire tubes (depending on the type of boiler) transfer heat to the water to create steam. Once steam is produced, it can be sent to a turbine for power generation or directly to industrial processes.

Modern industrial steam generators also incorporate advanced control systems that monitor and adjust various parameters, such as pressure, temperature, and flow rates, to ensure safe and efficient operation. Automated controls help optimize fuel use, improve energy efficiency, and maintain system stability, making industrial steam generation more cost-effective and environmentally friendly.

In terms of efficiency, industrial steam generators are designed to operate at a high level of performance. High-efficiency units are designed to recover and reuse heat, which reduces the amount of fuel required to produce steam. This can be achieved through features like economizers, which recover heat from flue gases before they are released into the atmosphere, or condensing economizers that capture even more heat.

One of the key advantages of industrial steam generators is their capacity. These systems can generate large volumes of steam to meet the needs of heavy-duty industrial processes. Whether used for power generation, heating, or chemical reactions, industrial steam generators are capable of operating 24/7 in demanding environments, providing reliable steam supply for continuous production.

Safety is a critical aspect of industrial steam generators. Given the high pressure and temperature at which they operate, these systems must be equipped with safety valves, pressure relief systems, over-temperature protection, and automatic shutdown features to prevent accidents. Regular maintenance and inspection are also crucial to ensure safe operation, as failure to maintain the system properly could lead to equipment damage, energy inefficiency, or even hazardous situations.

Applications of industrial steam generators are diverse. In power plants, they are used to generate steam that drives turbines to produce electricity. In chemical plants, steam is often required for distillation, drying, or heating processes. In the food industry, steam is used for cooking, pasteurizing, sterilizing, and cleaning equipment. Similarly, in industries like pharmaceuticals and textiles, steam plays an important role in sterilizing equipment and controlling humidity levels.

Industrial steam generators are also a critical component in district heating systems, where they provide centralized heating to residential and commercial buildings. In these systems, steam is generated in a central location and distributed through a network of pipes to provide space heating, hot water, and sometimes even cooling. These systems can be more efficient than individual heating solutions because they can generate and distribute heat from a central point, often using waste heat from other industrial processes.

However, industrial steam generators are not without challenges. Fuel costs can be a significant operational expense, particularly when using non-renewable fuels like coal or oil. The high energy demand and operational complexity of large industrial steam systems mean that efficiency is crucial to reduce costs and minimize environmental impact. As a result, many industries are increasingly turning to alternative energy sources, like biomass or solar thermal energy, to reduce reliance on fossil fuels and decrease carbon emissions.