In the face of climate change and environmental degradation, the global community has recognized the imperative to transition from fossil fuels to renewable energy sources. Renewable energy, derived from natural processes that are constantly replenished, offers a promising solution to mitigate greenhouse gas emissions and secure a sustainable future for generations to come. This comprehensive discussion explores the significance, benefits, challenges, and future prospects of renewable energy.

Significance of Renewable Energy: Renewable energy encompasses a diverse array of sources, including solar, wind, hydroelectric, geothermal, and biomass energy. Unlike finite fossil fuels, renewable energy is inexhaustible and abundant, offering a sustainable alternative to traditional energy sources. By harnessing the power of renewable resources, nations can reduce their reliance on fossil fuels, mitigate air pollution, and combat climate change.

Renewable Energy

Benefits of Renewable Energy: The transition to renewable energy offers numerous economic, environmental, and social benefits. Economically, investing in renewable energy technologies stimulates job creation, fosters innovation, and enhances energy security by reducing dependence on imported fuels. Moreover, renewable energy projects often generate local revenue and attract investment, revitalizing communities and bolstering economic resilience.

Environmentally, renewable energy production produces minimal greenhouse gas emissions and pollutants compared to fossil fuels, mitigating air and water pollution and safeguarding ecosystems. Furthermore, renewable energy technologies have a smaller ecological footprint, with solar panels and wind turbines occupying relatively small land areas and causing minimal disruption to natural habitats.

Socially, renewable energy democratizes energy production by empowering communities to generate their own electricity, fostering energy independence and resilience. Additionally, renewable energy infrastructure enhances energy access in remote and underserved regions, bridging the energy gap and improving quality of life for millions worldwide.

Challenges Facing Renewable Energy: Despite its immense potential, renewable energy deployment faces several challenges, including intermittency, grid integration, storage limitations, and upfront costs. The intermittent nature of solar and wind power necessitates reliable storage solutions and grid flexibility to ensure consistent energy supply. Moreover, integrating renewable energy into existing grids requires substantial infrastructure upgrades and regulatory reforms to accommodate variable generation and optimize system reliability.

Additionally, while the long-term costs of renewable energy have declined significantly in recent years, upfront capital costs remain a barrier to widespread adoption, particularly in developing countries with limited financial resources. Overcoming these challenges requires concerted efforts from policymakers, industry stakeholders, and the research community to drive technological innovation, improve energy storage, streamline permitting processes, and facilitate financing mechanisms.

Future Prospects and Opportunities: Despite the challenges, the future of renewable energy appears promising, driven by ongoing technological advancements, policy support, and increasing public awareness of the urgency to address climate change. Rapid advancements in energy storage, smart grid technologies, and digitalization are enhancing the reliability and efficiency of renewable energy systems, enabling greater grid integration and flexibility.

Moreover, the growing momentum towards decarbonization and the Paris Agreement’s targets are spurring ambitious renewable energy targets and investments worldwide. Governments, corporations, and international organizations are increasingly committing to transition to renewable energy sources, recognizing the economic, environmental, and social benefits of a clean energy future.

Furthermore, emerging trends such as community-owned renewable energy projects, offshore wind farms, and renewable hydrogen production hold immense potential to accelerate the transition to a low-carbon economy and create sustainable, resilient energy systems.

Conclusion: Renewable energy represents a transformative force in addressing the dual challenges of climate change and energy sustainability. By harnessing the abundant power of nature, we can transition towards a clean, resilient, and equitable energy future. To realize this vision, concerted efforts are needed to overcome technological, regulatory, and financial barriers, while leveraging innovation, collaboration, and political will to accelerate the global energy transition. Together, we can embrace the power of renewable energy and pave the way towards a more sustainable world for current and future generations.

Solar Power

Solar power, often referred to as solar energy, is the conversion of sunlight into electricity using photovoltaic (PV) cells or solar thermal systems. It is a renewable and sustainable source of energy that has gained significant attention due to its environmental benefits and decreasing cost of technology. Solar power harnesses the abundant energy emitted by the sun, providing an inexhaustible and clean energy source.

Photovoltaic cells, commonly known as solar panels, convert sunlight directly into electricity through the photovoltaic effect. When sunlight strikes the surface of a solar panel, it excites electrons within the semiconductor material, creating an electric current. Solar panels can be installed on rooftops, ground-mounted arrays, or integrated into building materials, enabling decentralized power generation and reducing reliance on centralized grid infrastructure.

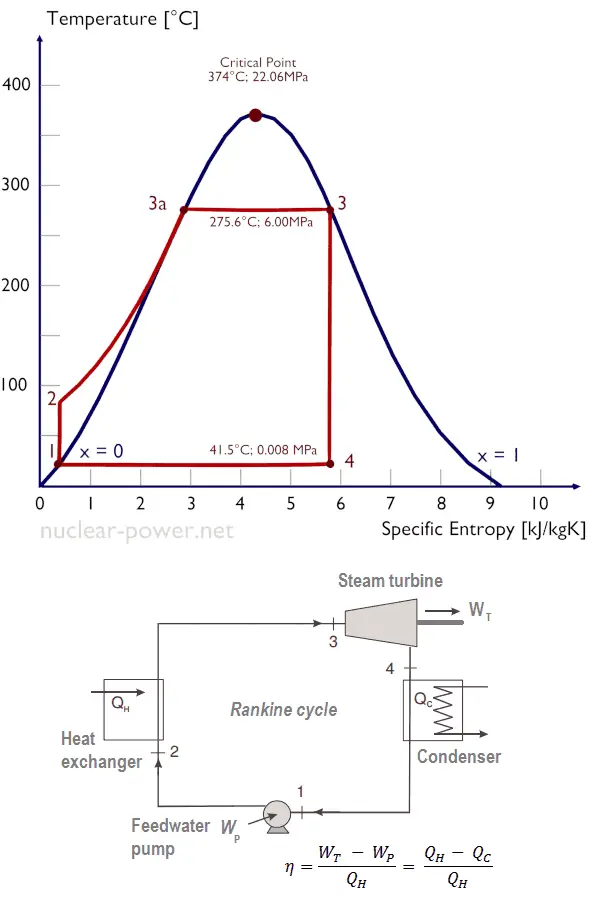

Solar thermal systems utilize mirrors or lenses to concentrate sunlight onto a receiver, where it is converted into heat energy. This thermal energy can be used for heating water, space heating, or generating electricity through steam turbines. Concentrated solar power (CSP) plants employ large-scale solar thermal technology to produce electricity, typically in regions with abundant sunlight and suitable land availability.

One of the key advantages of solar power is its environmental sustainability and minimal impact on ecosystems. Solar energy systems produce no greenhouse gas emissions or air pollutants during operation, reducing carbon footprint and mitigating climate change impacts. Solar power also contributes to energy independence and security by diversifying energy sources and reducing dependence on fossil fuels.

However, solar power also faces challenges such as intermittency, variability, and energy storage limitations. Solar energy generation is dependent on weather conditions and daylight availability, leading to fluctuations in output and grid integration challenges. Energy storage technologies such as batteries, pumped hydro, or thermal storage are essential for balancing supply and demand and ensuring grid stability.

Despite these challenges, solar power continues to expand rapidly worldwide, driven by technological advancements, policy support, and increasing consumer demand for clean energy. Governments, utilities, and businesses are investing in solar energy projects, incentivizing rooftop solar installations, and implementing renewable energy targets to accelerate the transition towards a sustainable energy future powered by the sun.

Wind Energy

Wind energy is a renewable and sustainable source of power derived from the kinetic energy of wind. It is harnessed through the use of wind turbines, which convert the motion of the wind into mechanical energy that can be used to generate electricity. Wind energy has emerged as one of the fastest-growing sources of renewable energy globally, offering numerous environmental, economic, and social benefits.

Wind turbines consist of large blades mounted on a tower, which rotate when exposed to wind. The rotation of the blades drives a generator, producing electricity. Wind turbines can vary in size and capacity, from small-scale turbines used for residential or rural applications to utility-scale turbines installed in wind farms for commercial power generation.

One of the key advantages of wind energy is its abundance and widespread availability. Wind is a naturally occurring resource found in many regions around the world, making wind energy a viable option for electricity generation in diverse geographic areas. Wind power is also considered a clean and environmentally friendly energy source, as it produces no greenhouse gas emissions or air pollutants during operation, unlike fossil fuel-based power plants.

Wind energy has the potential to significantly reduce reliance on fossil fuels, mitigate climate change impacts, and improve air quality by displacing conventional electricity generation sources. It offers energy security and independence by diversifying the energy mix and reducing dependence on imported fuels. Additionally, wind energy projects can stimulate economic growth, create jobs, and revitalize rural communities through investment, development, and local procurement opportunities.

Despite its many benefits, wind energy also faces challenges and limitations. Wind power generation is intermittent and variable, depending on weather conditions and wind patterns, which can lead to fluctuations in electricity output and grid integration challenges. Energy storage technologies, grid infrastructure upgrades, and demand-side management strategies are essential for balancing supply and demand and ensuring grid stability in wind-dominated power systems.

Furthermore, wind energy projects may encounter opposition from local communities due to concerns about visual impact, noise pollution, wildlife disruption, and land use conflicts. Effective stakeholder engagement, environmental impact assessments, and land use planning are critical for addressing these concerns and ensuring the sustainable development of wind energy projects.

Despite these challenges, wind energy continues to play a crucial role in the global energy transition towards a low-carbon and sustainable future. Technological advancements, cost reductions, and supportive policies have accelerated the deployment of wind power worldwide, making it a leading renewable energy source capable of meeting growing energy demand while mitigating climate change and advancing energy security goals.

Hydropower

Hydropower, also known as hydroelectric power, is a renewable energy source that harnesses the energy of flowing or falling water to generate electricity. It is one of the oldest and most widely used forms of renewable energy, with a long history of providing reliable and sustainable power for various applications, including electricity generation, irrigation, and industrial processes.

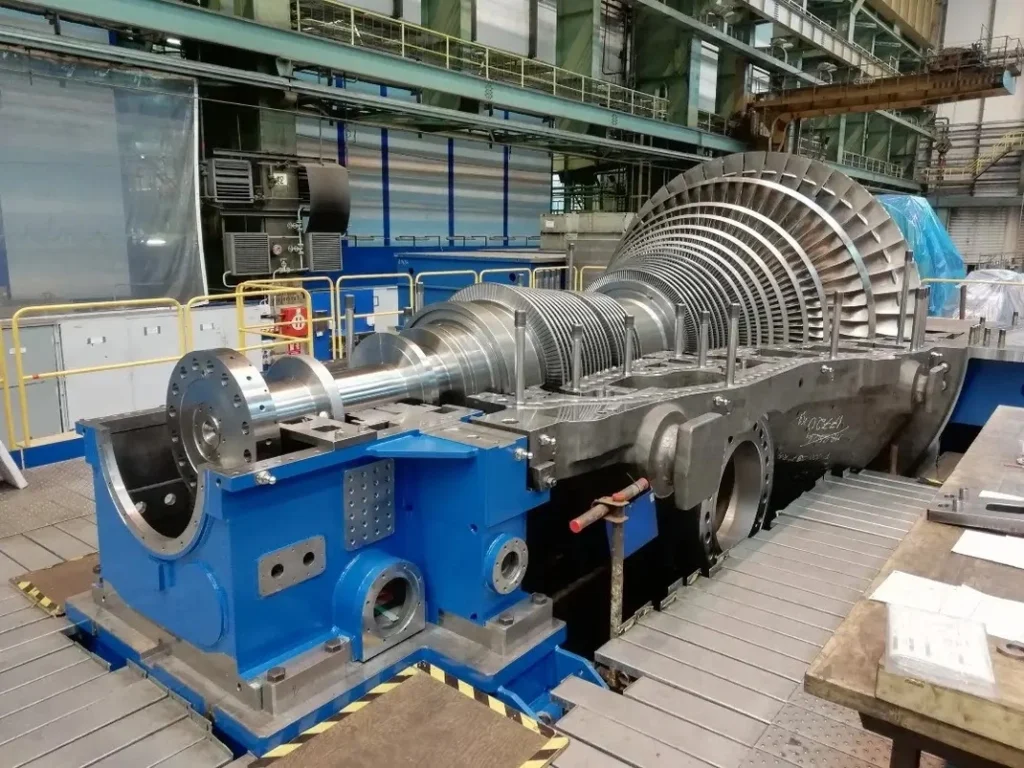

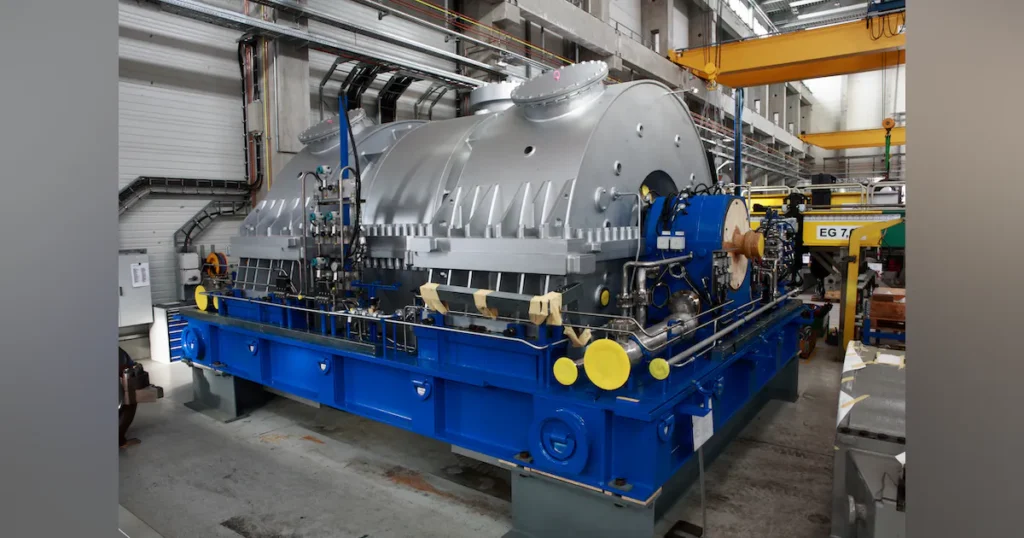

Hydropower systems typically involve the construction of dams, reservoirs, and water turbines to capture the energy of flowing water and convert it into mechanical or electrical energy. The potential energy stored in the water is released as it flows through turbines, which are connected to generators that produce electricity. Hydropower plants can vary in size and capacity, from small-scale run-of-river installations to large-scale dams and reservoirs.

One of the key advantages of hydropower is its reliability and predictability as a renewable energy source. Unlike solar and wind energy, which are intermittent and variable, hydropower can provide continuous and dispatchable power generation, making it a valuable asset for grid stability and energy balancing. Hydropower reservoirs also serve multiple purposes, including flood control, water supply, and recreational activities, enhancing their socio-economic value.

Hydropower offers numerous environmental benefits, including zero greenhouse gas emissions during operation and minimal air pollution compared to fossil fuel-based power plants. It contributes to climate change mitigation by displacing carbon-intensive energy sources and reducing reliance on non-renewable fuels. Hydropower projects can also provide ecosystem services such as habitat restoration, water quality improvement, and biodiversity conservation when properly managed and operated.

However, hydropower also presents environmental and social challenges, particularly related to habitat alteration, ecosystem disruption, and community displacement associated with dam construction and operation. Large-scale hydropower projects can have significant impacts on river ecosystems, fish migration patterns, and downstream water flow, leading to biodiversity loss and habitat fragmentation. Reservoir-induced seismicity and methane emissions from decomposing organic matter in reservoirs are also environmental concerns associated with hydropower development.

In recent years, there has been growing interest in small-scale and low-impact hydropower technologies such as micro-hydro systems, run-of-river projects, and pumped storage hydropower for grid stabilization and energy storage applications. These technologies offer opportunities for decentralized energy generation, community empowerment, and sustainable development while minimizing environmental and social impacts.

Overall, hydropower remains a critical component of the global energy mix, providing clean, renewable, and reliable electricity generation for meeting growing energy demand and advancing sustainable development goals. With careful planning, environmental stewardship, and stakeholder engagement, hydropower can continue to play a vital role in the transition towards a low-carbon and resilient energy future.

Biomass

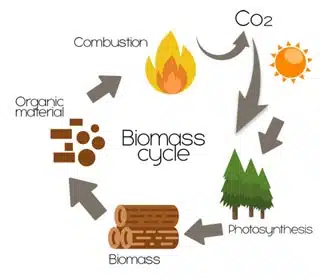

Biomass refers to organic materials derived from living or recently living organisms, which can be used as a renewable energy source for various applications, including heat, electricity, and transportation fuels. Biomass is composed of a wide range of organic materials, including wood, agricultural residues, municipal solid waste, animal manure, and dedicated energy crops such as switchgrass and miscanthus.

One of the key advantages of biomass is its abundance and availability as a renewable energy resource. Biomass materials are abundant and widely distributed across the globe, making them accessible and cost-effective for energy production in many regions. Biomass can be sustainably harvested, cultivated, or collected from agricultural, forestry, and waste management activities, reducing dependence on finite fossil fuel resources and promoting sustainable land management practices.

Biomass can be converted into energy through various thermochemical, biochemical, and mechanical processes, depending on the feedstock and desired end products. Common biomass conversion technologies include combustion, gasification, pyrolysis, fermentation, and anaerobic digestion, each offering unique advantages in terms of energy efficiency, fuel flexibility, and environmental performance.

- Combustion: Biomass combustion involves burning organic materials such as wood chips, crop residues, or municipal solid waste to produce heat energy. Biomass combustion can be used for residential heating, industrial process heat, or power generation in biomass-fired boilers, stoves, or power plants. Combustion emits carbon dioxide (CO2) and air pollutants such as particulate matter (PM), nitrogen oxides (NOx), and sulfur dioxide (SO2), but can be mitigated through proper combustion technology and emission controls.

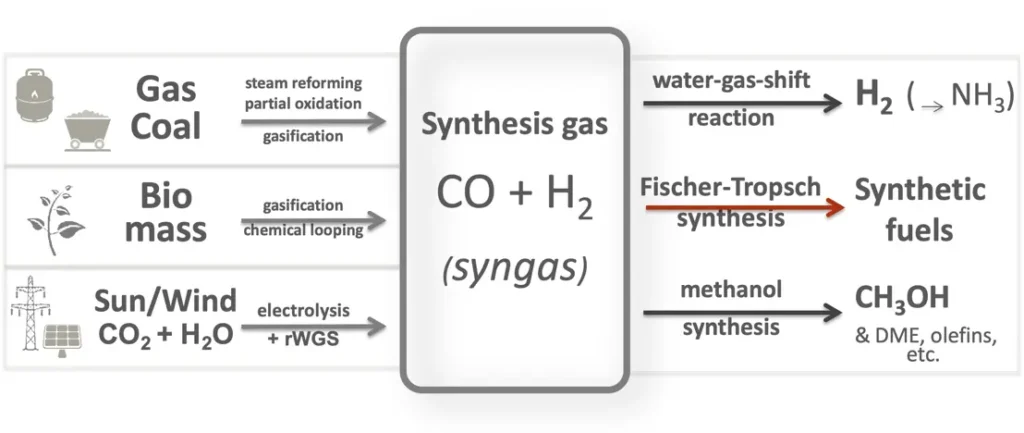

- Gasification: Biomass gasification is a thermochemical process that converts biomass into syngas (synthetic gas) by reacting it with a controlled amount of oxygen or steam at high temperatures (>700°C) in a gasifier. Syngas can be used as a fuel for power generation, combined heat and power (CHP) systems, or as a precursor for producing biofuels such as synthetic natural gas (SNG) or bio-based chemicals. Gasification offers high energy efficiency, fuel flexibility, and potential for carbon capture and utilization (CCU) technologies.

- Pyrolysis: Biomass pyrolysis involves heating organic materials in the absence of oxygen to produce biochar, bio-oil, and syngas. Pyrolysis can be used to convert lignocellulosic biomass into biofuels, biochar for soil amendment, and syngas for power generation or bio-based chemicals. Pyrolysis offers potential benefits for carbon sequestration, soil fertility enhancement, and waste valorization, but requires careful process control and optimization to maximize energy yield and product quality.

- Fermentation: Biomass fermentation utilizes microorganisms such as bacteria, yeast, or algae to convert sugars, starches, or cellulose into biofuels such as ethanol, biodiesel, or biogas. Fermentation can be used to produce biofuels from agricultural crops, food waste, or dedicated energy crops through anaerobic digestion, alcoholic fermentation, or microbial conversion processes. Biofuels derived from biomass fermentation offer renewable alternatives to fossil fuels, reduce greenhouse gas emissions, and promote sustainable bioenergy production.

- Anaerobic Digestion: Biomass anaerobic digestion involves the decomposition of organic materials in the absence of oxygen by anaerobic bacteria, resulting in the production of biogas (methane and carbon dioxide) and digestate. Anaerobic digestion can be used to treat organic waste streams such as animal manure, food waste, or wastewater sludge while simultaneously generating renewable biogas for heat, power, or vehicle fuel. Anaerobic digestion offers environmental benefits such as waste diversion, odor reduction, and nutrient recovery, contributing to circular economy principles and resource efficiency.

Despite its many benefits, biomass energy also faces challenges and limitations, including feedstock availability, competition with food and feed production, land use conflicts, and environmental impacts such as deforestation, biodiversity loss, and air pollution. Sustainable biomass production and utilization practices, integrated resource management, and advanced conversion technologies are essential for realizing the full potential of biomass as a renewable energy source while minimizing its environmental footprint and maximizing its socio-economic benefits.

Geothermal Energy

Geothermal energy is a renewable and sustainable energy source derived from the heat stored beneath the Earth’s surface. It harnesses the natural heat energy generated from the Earth’s core, mantle, and crust to produce electricity, heat buildings, and provide hot water for various applications. Geothermal energy has been utilized for thousands of years for bathing, heating, and cooking purposes and is now increasingly being used for electricity generation and district heating systems.

There are several types of geothermal resources that can be tapped for energy production:

- Geothermal Hot Springs: These are natural springs where groundwater is heated by geothermal heat sources and rises to the surface. Hot springs have been used for centuries for bathing, relaxation, and therapeutic purposes. In some cases, the heat from hot springs can be used directly for district heating or greenhouse heating without the need for additional equipment.

- Geothermal Wells: Geothermal wells are drilled deep into the Earth’s crust to access high-temperature reservoirs of steam or hot water. These reservoirs are typically found in regions with volcanic activity, tectonic plate boundaries, or geothermal gradients. The steam or hot water extracted from geothermal wells can be used to drive turbines and generate electricity in geothermal power plants.

- Enhanced Geothermal Systems (EGS): EGS involves engineering techniques to stimulate and enhance the permeability of hot rock formations deep underground where there is no naturally occurring geothermal reservoir. By injecting water or other fluids into the rock formations under high pressure, fractures are created, allowing for the circulation of fluids and heat exchange. EGS has the potential to significantly expand the geographic range of geothermal energy production beyond traditional volcanic areas.

Geothermal power plants typically use one of three main technologies to generate electricity:

- Dry Steam Power Plants: In dry steam power plants, high-pressure steam from underground reservoirs is directly fed into turbines to generate electricity. After passing through the turbines, the steam is condensed back into water and reinjected into the reservoir to maintain pressure and sustain production.

- Flash Steam Power Plants: Flash steam power plants are the most common type of geothermal power plants. They use high-pressure hot water from underground reservoirs to generate steam by reducing pressure through a flash tank. The steam is then used to drive turbines and generate electricity, similar to dry steam plants.

- Binary Cycle Power Plants: Binary cycle power plants use lower-temperature geothermal fluids to heat a secondary fluid with a lower boiling point, such as isobutane or isopentane. The secondary fluid vaporizes at a lower temperature and is used to drive turbines and generate electricity. Binary cycle power plants are suitable for geothermal resources with lower temperatures and are more widely applicable than dry steam or flash steam plants.

Geothermal energy offers several advantages as a renewable energy source:

- Reliability: Geothermal energy is available 24/7, providing a constant and reliable source of baseload power, unlike solar or wind energy, which are intermittent.

- Low Emissions: Geothermal power plants emit minimal greenhouse gases and air pollutants compared to fossil fuel-based power plants, contributing to climate change mitigation and improving air quality.

- Longevity: Geothermal reservoirs can sustain energy production for decades to centuries with proper management and reinjection practices, providing long-term energy security and stability.

- Local Economic Benefits: Geothermal energy projects create jobs, stimulate local economies, and provide revenue streams for landowners and communities through royalties, taxes, and lease payments.

However, geothermal energy also faces some challenges and limitations:

- Location Constraints: Geothermal resources are concentrated in specific regions with tectonic activity, volcanic geology, or high geothermal gradients, limiting their widespread availability and accessibility.

- High Upfront Costs: The initial capital investment required to drill geothermal wells and construct power plants can be significant, although operational costs are relatively low once the facilities are operational.

- Resource Sustainability: There is a risk of reservoir depletion or thermal decline over time if geothermal fluids are extracted at rates faster than they can be replenished by natural processes. Sustainable management practices, reinjection of spent fluids, and reservoir engineering are essential for maintaining long-term resource sustainability.

In conclusion, geothermal energy offers a reliable, sustainable, and environmentally friendly alternative to conventional energy sources for electricity generation, heating, and cooling applications. With ongoing technological advancements, cost reductions, and supportive policies, geothermal energy has the potential to play a significant role in the global energy transition towards a low-carbon and resilient future.

Tidal Energy

Tidal energy is a renewable and sustainable form of energy derived from the gravitational forces exerted by the moon and the sun on the Earth’s oceans. It harnesses the kinetic energy of tidal currents and tidal fluctuations to generate electricity through various technologies and systems. Tidal energy has the potential to provide a predictable and reliable source of power, with minimal environmental impact compared to conventional energy sources.

There are several methods for capturing tidal energy:

- Tidal Stream Systems: Tidal stream systems, also known as tidal turbines or underwater turbines, operate similarly to wind turbines but are submerged underwater to capture the kinetic energy of tidal currents. As the tide flows in and out, the underwater turbines rotate, driving generators to produce electricity. Tidal stream systems can be deployed individually or in arrays in areas with strong tidal currents, such as channels, straits, or coastal regions.

- Tidal Barrages: Tidal barrages are large dams or barriers built across estuaries, bays, or tidal rivers to capture and store tidal energy. As the tide rises and falls, water flows through sluice gates or turbines installed in the barrage, generating electricity. Tidal barrages can have a significant impact on the local ecosystem, including changes in water levels, sedimentation, and wildlife habitat, but they can also provide flood protection, navigation, and recreational benefits.

- Tidal Lagoon Systems: Tidal lagoon systems are similar to tidal barrages but are constructed as enclosed circular or horseshoe-shaped walls in coastal areas. As the tide enters and exits the lagoon through gates or turbines, water levels rise and fall, creating a pressure differential that drives turbines and generates electricity. Tidal lagoons can be designed to minimize environmental impacts and provide opportunities for marine habitat enhancement and recreational activities.

Tidal energy offers several advantages as a renewable energy source:

- Predictability: Tidal energy is highly predictable and reliable, with regular and consistent patterns of tidal cycles that can be accurately forecasted years in advance. This predictability enhances grid stability and energy planning, making tidal energy a valuable asset for meeting peak demand and reducing dependence on fossil fuels.

- High Energy Density: Tidal currents are dense and carry a significant amount of kinetic energy, allowing for efficient power generation using relatively small-scale infrastructure. Tidal energy systems can be deployed in areas with strong tidal flows to maximize energy capture and output.

- Low Environmental Impact: Tidal energy systems have minimal greenhouse gas emissions and air pollutants compared to fossil fuel-based power plants, reducing carbon footprint and mitigating climate change impacts. Tidal energy projects can also have low visual and noise impact, especially if deployed offshore or underwater, minimizing conflicts with other marine activities.

However, tidal energy also faces challenges and limitations:

- Site-specific Nature: Tidal energy resources are location-dependent and limited to coastal areas with strong tidal currents or suitable topography for tidal barrage construction. Identifying suitable sites for tidal energy projects requires comprehensive resource assessment and environmental impact studies to evaluate feasibility and minimize risks.

- High Capital Costs: The upfront capital costs of tidal energy infrastructure, including turbine installation, barrage construction, and grid connection, can be substantial. Tidal energy projects often require significant investment and long payback periods, making them less economically competitive compared to other renewable energy sources such as wind or solar.

- Environmental Concerns: Tidal energy projects can have environmental impacts on marine ecosystems, including changes in water flow, sediment transport, and wildlife behavior. Proper siting, monitoring, and mitigation measures are essential for minimizing adverse effects on marine habitats, migratory routes, and biodiversity.

In conclusion, tidal energy represents a promising and untapped resource for clean, renewable electricity generation with the potential to contribute significantly to the global energy mix. With continued technological advancements, cost reductions, and supportive policies, tidal energy can play a vital role in the transition towards a sustainable and resilient energy future, harnessing the power of the tides to meet growing energy demand while protecting the environment and enhancing energy security.

Wave Energy

Wave energy is a renewable and sustainable form of energy derived from the kinetic energy of ocean waves. It harnesses the natural motion of waves to generate electricity through various technologies and devices deployed offshore or near the coastline. Wave energy has the potential to provide a predictable and reliable source of power, with minimal environmental impact compared to conventional energy sources.

There are several methods for capturing wave energy:

- Oscillating Water Columns (OWCs): OWCs are offshore or nearshore structures that contain a chamber partially submerged in the water, open to the sea at the bottom, with a roof or air turbine on top. As waves enter the chamber, the water level rises and falls, causing the air trapped inside to oscillate. The oscillating air drives a turbine or generator, producing electricity.

- Point Absorbers: Point absorbers are floating or submerged devices that capture wave energy using buoyant or oscillating components. These devices move up and down or back and forth in response to wave motion, driving hydraulic pumps, linear generators, or oscillating bodies to generate electricity.

- Overtopping Devices: Overtopping devices are shore-based or nearshore structures designed to capture the potential energy of waves as they break over a barrier or ramp. The incoming waves are directed into a reservoir or basin, where the water level rises and falls, driving turbines or hydroelectric generators to produce electricity.

- Attenuators: Attenuators are long, segmented structures that float or submerge parallel to the direction of wave propagation. As waves pass along the length of the attenuator, they cause the segments to flex or oscillate, generating mechanical motion that can be converted into electricity using hydraulic systems or power take-off mechanisms.

Wave energy offers several advantages as a renewable energy source:

- Predictability: Wave energy is highly predictable and reliable, with regular and consistent patterns of wave activity that can be forecasted days or weeks in advance. This predictability enhances grid stability and energy planning, making wave energy a valuable asset for meeting peak demand and reducing dependence on fossil fuels.

- High Energy Density: Ocean waves carry a significant amount of kinetic energy, especially in regions with strong winds and wave climates. Wave energy systems can capture this energy using relatively small-scale devices or arrays, offering high energy density and efficiency compared to other renewable energy sources such as solar or wind.

- Low Environmental Impact: Wave energy systems have minimal greenhouse gas emissions and air pollutants compared to fossil fuel-based power plants, reducing carbon footprint and mitigating climate change impacts. Wave energy projects can also have low visual and noise impact, especially if deployed offshore or in remote coastal areas, minimizing conflicts with other marine activities.

However, wave energy also faces challenges and limitations:

- Technology Development: Wave energy conversion technologies are still in the early stages of development and demonstration, with limited commercial deployment and operational experience. Further research, innovation, and testing are needed to improve technology performance, reliability, and cost-effectiveness.

- Environmental Concerns: Wave energy projects can have environmental impacts on marine ecosystems, including changes in water flow, sediment transport, and wildlife behavior. Proper siting, monitoring, and mitigation measures are essential for minimizing adverse effects on marine habitats, migratory routes, and biodiversity.

- Resource Variability: Wave energy resources vary spatially and temporally, depending on factors such as ocean geography, wave climate, and seasonal weather patterns. Identifying suitable sites for wave energy projects requires comprehensive resource assessment and modeling to evaluate feasibility and optimize energy capture potential.

In conclusion, wave energy represents a promising and untapped resource for clean, renewable electricity generation with the potential to contribute significantly to the global energy mix. With continued technological advancements, cost reductions, and supportive policies, wave energy can play a vital role in the transition towards a sustainable and resilient energy future, harnessing the power of the oceans to meet growing energy demand while protecting the environment and enhancing energy security.

Biofuels

Biofuels are liquid or gaseous fuels derived from organic materials such as biomass, agricultural crops, algae, or waste streams. They are considered renewable energy sources because they can be produced from organic matter that can be replenished over time through natural processes. Biofuels are used primarily for transportation, either as standalone fuels or as blends with conventional fossil fuels, and they offer potential environmental and economic benefits compared to petroleum-based fuels.

There are several types of biofuels, including:

- Bioethanol: Bioethanol is an alcohol fuel derived from fermenting sugars or starches found in biomass feedstocks such as sugarcane, corn, wheat, or cellulosic materials. It is commonly used as a gasoline additive to increase octane levels and reduce greenhouse gas emissions. Bioethanol can be produced through fermentation and distillation processes using microorganisms such as yeast or bacteria.

- Biodiesel: Biodiesel is a renewable diesel fuel made from vegetable oils, animal fats, or recycled cooking oils through a process called transesterification. It can be used in diesel engines with little or no modification and is typically blended with petroleum diesel to reduce emissions of particulate matter, sulfur oxides, and hydrocarbons. Biodiesel production can utilize a variety of feedstocks, including soybean oil, rapeseed oil, palm oil, and waste cooking oil.

- Biogas: Biogas is a renewable natural gas produced by the anaerobic digestion of organic matter such as agricultural residues, animal manure, sewage sludge, or organic waste. It consists primarily of methane (CH4) and carbon dioxide (CO2) and can be used as a fuel for heating, electricity generation, or vehicle fuel in compressed natural gas (CNG) vehicles. Biogas production reduces methane emissions from organic waste decomposition and provides a renewable alternative to fossil fuels.

- Syngas: Syngas, or synthesis gas, is a mixture of hydrogen (H2) and carbon monoxide (CO) produced by gasification or pyrolysis of biomass feedstocks such as wood, agricultural residues, or municipal solid waste. Syngas can be used as a fuel for power generation, heating, or chemical synthesis processes, or it can be converted into liquid fuels such as synthetic diesel or jet fuel through Fischer-Tropsch synthesis.

Biofuels offer several advantages as renewable energy sources:

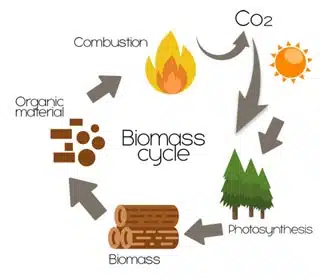

- Carbon Neutrality: Biofuels are considered carbon-neutral because the carbon dioxide (CO2) emitted during combustion is offset by the carbon dioxide absorbed by the plants during photosynthesis. This closed carbon cycle helps mitigate climate change by reducing net greenhouse gas emissions compared to fossil fuels.

- Energy Security: Biofuels reduce dependence on imported oil and fossil fuels, enhancing energy security and resilience against supply disruptions and price volatility. Domestic production of biofuels supports rural economies, creates jobs, and reduces reliance on foreign oil imports.

- Renewable Feedstocks: Biofuels can be produced from a wide range of renewable feedstocks, including agricultural crops, forestry residues, algae, and organic waste streams. This diversity of feedstocks reduces competition with food production and promotes sustainable land use practices, biodiversity conservation, and waste valorization.

However, biofuels also face challenges and limitations:

- Feedstock Availability: The availability and sustainability of biomass feedstocks for biofuel production are influenced by factors such as land availability, land use competition, water resources, and environmental impacts. Sustainable biomass production practices, land-use planning, and resource management are essential for ensuring the long-term viability of biofuel feedstocks.

- Resource Efficiency: Biofuel production processes require significant inputs of land, water, energy, and nutrients, which can lead to competition with food production, deforestation, soil degradation, and water pollution if not managed sustainably. Improving resource efficiency, crop productivity, and supply chain logistics are critical for minimizing environmental impacts and optimizing biofuel production systems.

- Technological Challenges: Biofuel production technologies face technical and economic challenges related to feedstock logistics, conversion efficiency, process scalability, and cost competitiveness compared to conventional fossil fuels. Research and development efforts are needed to advance biofuel technologies, reduce production costs, and improve performance, reliability, and environmental sustainability.

In conclusion, biofuels represent a promising and versatile renewable energy source with the potential to reduce greenhouse gas emissions, enhance energy security, and promote sustainable development. With continued investment, innovation, and policy support, biofuels can play a significant role in the global energy transition towards a low-carbon and resilient future, providing clean and renewable alternatives to conventional fossil fuels for transportation, heating, and power generation.

Solar Energy

Solar energy is a renewable and sustainable source of power derived from the sun’s radiation. It is one of the most abundant and widely available sources of renewable energy, offering a clean, inexhaustible, and environmentally friendly alternative to conventional fossil fuels. Solar energy can be harnessed and converted into electricity or heat using various technologies, including photovoltaic (PV) systems, concentrating solar power (CSP) plants, and solar thermal collectors.

- Photovoltaic (PV) Systems: Photovoltaic systems, commonly known as solar panels, convert sunlight directly into electricity using semiconductor materials such as silicon. When sunlight strikes the solar cells, photons of light are absorbed, releasing electrons and generating an electric current. The generated electricity can be used immediately, stored in batteries for later use, or fed into the grid for distribution. PV systems can be installed on rooftops, building facades, or ground-mounted arrays, making them suitable for both residential and commercial applications.

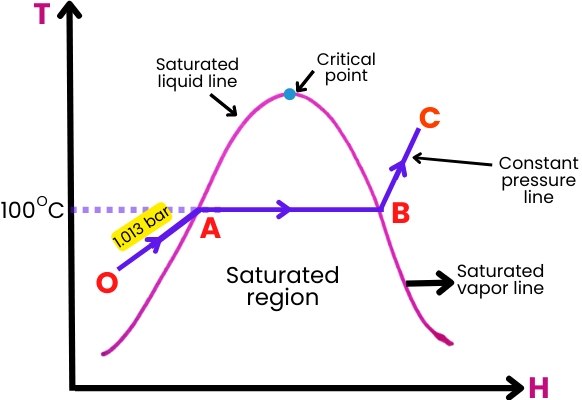

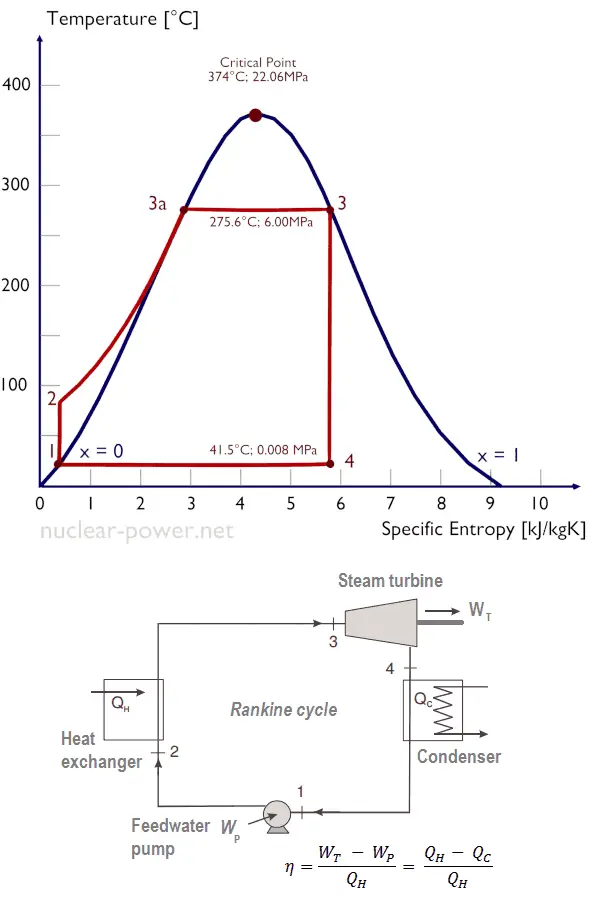

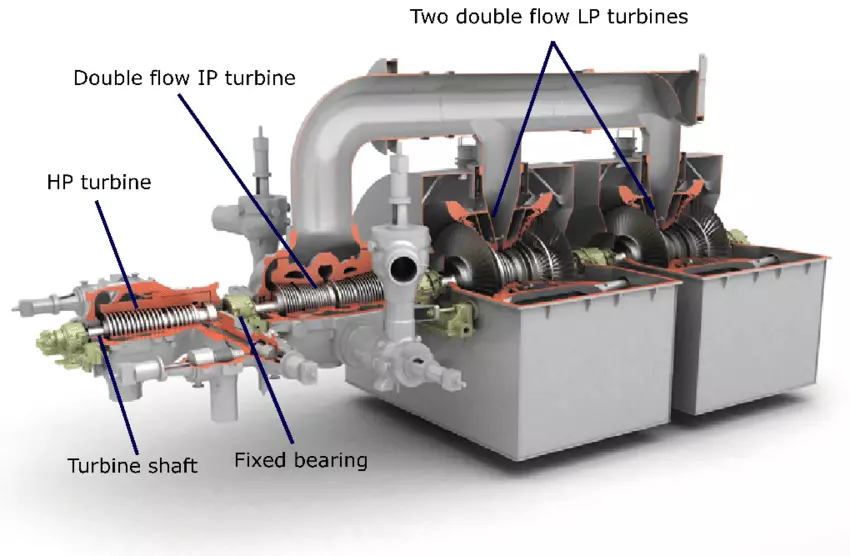

- Concentrating Solar Power (CSP) Plants: Concentrating solar power plants use mirrors or lenses to concentrate sunlight onto a receiver, where it is converted into heat energy. The concentrated heat is used to generate steam, which drives a turbine to produce electricity. CSP plants can incorporate various technologies such as parabolic troughs, solar power towers, or dish/engine systems, depending on the concentration method and receiver design. CSP plants are typically deployed in utility-scale power plants located in regions with high solar irradiance and suitable land availability.

- Solar Thermal Collectors: Solar thermal collectors capture sunlight to heat a fluid, typically water or a heat transfer fluid, for direct use in heating applications or for generating electricity through steam turbines. Solar thermal collectors can be flat-plate collectors, evacuated tube collectors, or concentrating collectors, depending on the concentration method and application. Solar thermal systems are used for water heating, space heating, industrial process heat, and solar cooling applications in residential, commercial, and industrial settings.

Solar energy offers several advantages as a renewable energy source:

- Abundance: Solar energy is abundant and widely distributed, with vast potential for power generation in regions around the world. The amount of solar energy reaching the Earth’s surface in one hour exceeds global energy demand for an entire year, making solar energy a virtually limitless resource.

- Clean and Sustainable: Solar energy produces no greenhouse gas emissions or air pollutants during operation, contributing to climate change mitigation and improving air quality. Solar power plants have minimal environmental impact compared to fossil fuel-based power plants, reducing land degradation, water consumption, and habitat disruption.

- Cost-Competitive: The cost of solar energy has declined significantly in recent years due to technological advancements, economies of scale, and policy incentives. Solar photovoltaic (PV) systems and solar thermal technologies are now cost-competitive with conventional energy sources in many regions, making solar energy an attractive investment for homeowners, businesses, and utilities.

- Modularity and Scalability: Solar energy systems are modular and scalable, allowing for flexible deployment and expansion according to energy demand and available space. Solar panels can be installed on rooftops, building facades, or ground-mounted arrays, making efficient use of urban and rural land areas.

Despite its many benefits, solar energy also faces challenges and limitations:

- Intermittency: Solar energy is intermittent and variable, depending on weather conditions, time of day, and seasonal changes. Cloud cover, shading, and night-time hours can affect solar energy generation, requiring energy storage, grid integration, and backup power systems for reliable electricity supply.

- Energy Storage: Energy storage technologies such as batteries, pumped hydro storage, or thermal storage are needed to store excess solar energy for use during periods of low sunlight or high energy demand. Energy storage enhances grid stability, load balancing, and energy resilience in solar-dominated power systems.

- Land Use and Environmental Impacts: Large-scale deployment of solar energy systems can have land use implications, including habitat fragmentation, land conversion, and visual impact. Proper land-use planning, environmental assessments, and stakeholder engagement are essential for minimizing adverse effects and maximizing co-benefits of solar energy projects.

In conclusion, solar energy represents a promising and rapidly growing renewable energy source with the potential to transform the global energy landscape. With continued technological innovation, supportive policies, and investment in infrastructure, solar energy can play a central role in the transition towards a sustainable, low-carbon future, powering communities, industries, and economies with clean, affordable, and resilient energy solutions.

Wind Energy

Wind energy is a renewable and sustainable source of power derived from the kinetic energy of wind. It is one of the fastest-growing forms of renewable energy globally, offering a clean, abundant, and environmentally friendly alternative to conventional fossil fuels. Wind energy can be harnessed and converted into electricity using wind turbines, which are designed to capture the kinetic energy of moving air and convert it into mechanical or electrical energy.

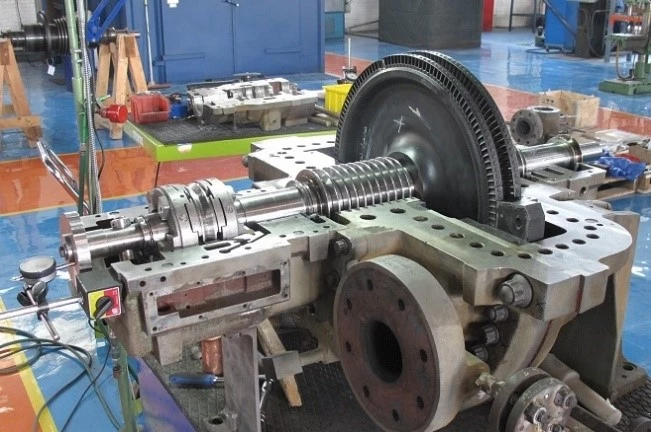

- Onshore Wind Turbines: Onshore wind turbines are installed on land, typically in open areas with consistent wind patterns such as plains, hills, or coastal regions. They consist of tall towers with rotor blades mounted on a hub, which are connected to a gearbox and generator. When the wind blows, the rotor blades spin, turning the generator to produce electricity. Onshore wind farms can range in size from small-scale installations to large utility-scale projects, supplying electricity to local communities or feeding into the grid.

- Offshore Wind Turbines: Offshore wind turbines are installed in bodies of water, such as oceans or lakes, to capture the strong and consistent wind resources available offshore. Offshore wind turbines are larger and more complex than onshore turbines, with taller towers, longer blades, and specialized foundation structures designed to withstand harsh marine environments. Offshore wind farms can be located near the coast or in deeper waters using floating platforms, providing opportunities for larger-scale deployment and higher energy production potential.

Wind energy offers several advantages as a renewable energy source:

- Abundance: Wind energy is abundant and widely distributed, with vast potential for power generation in regions around the world. Wind resources are strongest in coastal areas, plains, mountain passes, and offshore locations, providing ample opportunities for wind energy development and deployment.

- Clean and Sustainable: Wind energy produces no greenhouse gas emissions or air pollutants during operation, contributing to climate change mitigation and improving air quality. Wind power plants have minimal environmental impact compared to fossil fuel-based power plants, reducing land degradation, water consumption, and habitat disruption.

- Cost-Competitive: The cost of wind energy has declined significantly in recent years due to technological advancements, economies of scale, and policy incentives. Onshore and offshore wind projects are now cost-competitive with conventional energy sources in many regions, making wind energy an attractive investment for utilities, developers, and investors.

- Modularity and Scalability: Wind energy systems are modular and scalable, allowing for flexible deployment and expansion according to energy demand and available wind resources. Wind turbines can be installed individually or in arrays, ranging from small-scale turbines for residential use to large utility-scale wind farms for commercial power generation.

Despite its many benefits, wind energy also faces challenges and limitations:

- Intermittency: Wind energy is intermittent and variable, depending on weather conditions, time of day, and seasonal changes. Calm winds or gusty conditions can affect wind energy generation, requiring energy storage, grid integration, and backup power systems for reliable electricity supply.

- Grid Integration: Integrating large amounts of wind energy into the electricity grid can pose challenges related to grid stability, load balancing, and transmission infrastructure. Grid upgrades, smart grid technologies, and energy storage solutions are needed to manage variability and ensure the reliable operation of wind-dominated power systems.

- Land Use and Visual Impact: Large-scale deployment of wind turbines can have land use implications, including habitat fragmentation, land conversion, and visual impact. Proper siting, environmental assessments, and stakeholder engagement are essential for minimizing adverse effects and maximizing co-benefits of wind energy projects.

In conclusion, wind energy represents a promising and rapidly growing renewable energy source with the potential to play a significant role in the global energy transition. With continued technological innovation, supportive policies, and investment in infrastructure, wind energy can help reduce greenhouse gas emissions, enhance energy security, and promote sustainable development, powering communities, industries, and economies with clean, affordable, and resilient energy solutions.

Hydropower

Hydropower, also known as hydroelectric power, is a renewable and sustainable source of energy derived from the gravitational force of flowing water. It is one of the oldest and most widely used forms of renewable energy, with a long history of human use for mechanical power, irrigation, and electricity generation. Hydropower harnesses the energy of flowing water to generate electricity through various technologies and systems, including dams, turbines, and hydroelectric power plants.

- Run-of-River Hydropower: Run-of-river hydropower systems generate electricity by diverting a portion of a river’s flow through a turbine without the need for large storage reservoirs or dams. These systems utilize the natural flow and elevation drop of the river to drive turbines and generate electricity. Run-of-river hydropower plants have minimal environmental impact compared to conventional dams and reservoirs and can be deployed in remote or environmentally sensitive areas.

- Reservoir Hydropower: Reservoir hydropower systems, also known as storage hydropower, utilize dams and reservoirs to store water and regulate the flow of rivers for electricity generation. Water is stored in the reservoir during periods of low demand and released through turbines during periods of high demand to meet electricity needs. Reservoir hydropower plants provide grid stability, energy storage, and flood control benefits but can have significant environmental and social impacts, including habitat disruption, displacement of communities, and alteration of river ecosystems.

- Pumped Storage Hydropower: Pumped storage hydropower plants use surplus electricity during off-peak hours to pump water from a lower reservoir to a higher reservoir, storing energy in the form of gravitational potential energy. During periods of high demand, water is released from the upper reservoir through turbines to generate electricity and meet peak load requirements. Pumped storage hydropower plants provide grid balancing, load-shifting, and energy storage services, enhancing the reliability and resilience of the electricity grid.

Hydropower offers several advantages as a renewable energy source:

- Reliability: Hydropower is a reliable and dispatchable source of electricity, providing baseload power and grid stability in regions with abundant water resources. Hydropower plants can respond quickly to changes in electricity demand and provide ancillary services such as frequency regulation and voltage control.

- Energy Storage: Pumped storage hydropower plants serve as large-scale energy storage systems, storing surplus electricity during periods of low demand and releasing it during periods of high demand to balance supply and demand on the grid. Hydropower reservoirs can also provide seasonal energy storage for drought mitigation and water management.

- Low Operating Costs: Once constructed, hydropower plants have low operating and maintenance costs compared to fossil fuel-based power plants, making them economically competitive and financially attractive over the long term. Hydropower projects can also generate revenue through water sales, flood control, irrigation, and recreation.

- Environmental Benefits: Hydropower produces no greenhouse gas emissions or air pollutants during operation, contributing to climate change mitigation and improving air quality. Hydropower reservoirs can provide habitat for aquatic species, recreational opportunities, and water storage for agriculture, municipal, and industrial use.

However, hydropower also faces challenges and limitations:

- Environmental and Social Impacts: Large-scale hydropower projects can have significant environmental and social impacts, including habitat destruction, displacement of communities, alteration of river ecosystems, and loss of cultural heritage. Proper planning, stakeholder engagement, and environmental mitigation measures are essential for minimizing adverse effects and maximizing co-benefits of hydropower development.

- Climate Vulnerability: Hydropower generation can be affected by climate variability and change, including changes in precipitation patterns, snowmelt timing, and river flow regimes. Climate adaptation measures, reservoir management strategies, and operational adjustments are needed to mitigate climate risks and ensure the resilience of hydropower systems.

- Siltation and Sedimentation: Hydropower reservoirs can accumulate sediment over time, reducing storage capacity, affecting water quality, and impairing downstream ecosystems. Sediment management, reservoir flushing, and sediment bypass systems are needed to mitigate the effects of siltation and sedimentation on hydropower operations and ecosystem health.

In conclusion, hydropower represents a valuable and versatile renewable energy source with the potential to contribute significantly to the global energy transition. With careful planning, sustainable management, and inclusive governance, hydropower can help meet growing energy demand, support economic development, and promote environmental stewardship, providing clean, reliable, and resilient energy solutions for communities, industries, and economies around the world.

Geothermal Energy

Geothermal energy is a renewable and sustainable source of power derived from the heat stored beneath the Earth’s surface. It harnesses the natural heat flux from the Earth’s interior to generate electricity or provide heating and cooling for various applications. Geothermal energy is abundant and widely distributed, offering a reliable, baseload source of power with minimal environmental impact compared to conventional fossil fuels.

- Geothermal Power Plants: Geothermal power plants use hot water or steam from underground reservoirs to drive turbines and generate electricity. There are several types of geothermal power plants, including:

- Dry Steam Power Plants: Dry steam power plants use steam directly from underground reservoirs to drive turbines and generate electricity.

- Flash Steam Power Plants: Flash steam power plants utilize high-pressure hot water from underground reservoirs, which is flashed into steam at the surface and used to drive turbines.

- Binary Cycle Power Plants: Binary cycle power plants transfer heat from underground reservoirs to a secondary fluid with a lower boiling point, such as isobutane or pentane. The secondary fluid vaporizes and drives turbines to generate electricity.

- Direct-Use Applications: Geothermal energy is used directly for heating and cooling in various applications, including district heating systems, greenhouses, aquaculture, and industrial processes. Direct-use geothermal systems circulate hot water or steam from underground reservoirs through heat exchangers to provide space heating, hot water, or process heat without combustion or emissions.

- Geothermal Heat Pumps: Geothermal heat pumps, also known as ground-source heat pumps, utilize the relatively constant temperature of the Earth’s subsurface to provide heating, cooling, and domestic hot water for buildings. Geothermal heat pumps circulate fluid through a closed-loop system of underground pipes, transferring heat to or from the ground to maintain desired indoor temperatures efficiently and cost-effectively.

Geothermal energy offers several advantages as a renewable energy source:

- Reliability: Geothermal energy is a reliable and dispatchable source of electricity, providing baseload power and grid stability in regions with significant geothermal resources. Geothermal power plants operate continuously and can complement intermittent renewable energy sources such as wind and solar.

- Low Emissions: Geothermal power plants produce minimal greenhouse gas emissions and air pollutants during operation, contributing to climate change mitigation and improving air quality. Geothermal energy has one of the lowest life-cycle carbon footprints of all energy sources, making it an environmentally friendly alternative to fossil fuels.

- Longevity: Geothermal power plants have long operational lifetimes, with some plants operating for decades with minimal maintenance. Once a geothermal reservoir is developed, it can sustain power production for many years, providing a stable and long-term source of energy for local communities and industries.

- Local Economic Benefits: Geothermal energy development creates jobs, stimulates economic growth, and generates revenue for local communities through direct investment, employment opportunities, and royalty payments. Geothermal projects can also enhance energy security, reduce dependence on imported fuels, and promote sustainable development in rural areas.

However, geothermal energy also faces challenges and limitations:

- Resource Limitations: Geothermal resources are location-dependent and limited to regions with active tectonic activity, volcanic activity, or high geothermal gradients. Identifying suitable sites for geothermal development requires comprehensive exploration, drilling, and reservoir engineering to assess resource potential and mitigate risks.

- High Upfront Costs: The upfront capital costs of geothermal power plants and exploration drilling can be substantial, particularly for deep or high-temperature reservoirs. Geothermal projects often require significant investment and long payback periods, making them less economically competitive compared to other renewable energy sources such as wind or solar.

- Environmental Impacts: Geothermal energy development can have environmental impacts on land use, water resources, and ecosystems, including habitat disruption, land subsidence, and induced seismicity. Proper siting, environmental assessments, and mitigation measures are essential for minimizing adverse effects and ensuring sustainable development of geothermal resources.

In conclusion, geothermal energy represents a valuable and underutilized renewable energy source with the potential to play a significant role in the global energy transition. With continued investment, innovation, and supportive policies, geothermal energy can help meet growing energy demand, reduce greenhouse gas emissions, and promote sustainable development, providing clean, reliable, and resilient energy solutions for communities, industries, and economies around the world.

Tidal Energy:

Tidal energy is a renewable and sustainable source of power derived from the gravitational forces of the moon and the sun, which cause the ocean tides to rise and fall cyclically. It harnesses the kinetic energy of tidal currents and flows to generate electricity using various technologies and devices deployed in coastal or estuarine environments. Tidal energy is predictable, reliable, and highly concentrated, offering a consistent and renewable source of power with minimal environmental impact compared to conventional fossil fuels.

- Tidal Stream Turbines: Tidal stream turbines, also known as tidal turbines or underwater turbines, are submerged devices that resemble underwater wind turbines and operate in a similar manner. They capture the kinetic energy of tidal currents and flows to drive rotating blades connected to generators, producing electricity. Tidal stream turbines can be installed individually or in arrays on the seabed or mounted on floating platforms in tidal channels, straits, or coastal waters.

- Tidal Barrages: Tidal barrages are large-scale structures built across estuaries or tidal rivers to harness the potential energy of tidal range, the difference in water level between high tide and low tide. Tidal barrages consist of a series of sluice gates or turbines that open and close to control the flow of water through the barrage, generating electricity as water flows in and out of the tidal basin. Tidal barrages can provide baseload power and energy storage capabilities, but they can have significant environmental and social impacts, including habitat disruption and sedimentation.

- Tidal Lagoons: Tidal lagoons are impoundment structures built in coastal areas to capture and store tidal energy in enclosed reservoirs or basins. Tidal lagoons use the rise and fall of the tide to fill and empty the lagoon through sluice gates or turbines, generating electricity as water flows in and out of the lagoon. Tidal lagoons can provide reliable and predictable power generation with minimal environmental impact compared to tidal barrages, but they require suitable coastal topography and hydrological conditions for construction and operation.

Tidal energy offers several advantages as a renewable energy source:

- Predictability: Tidal energy is highly predictable and reliable, with regular and consistent patterns of tidal currents and flows that can be forecasted years in advance. Tidal energy systems can provide baseload power and grid stability, complementing intermittent renewable energy sources such as wind and solar.

- High Energy Density: Tidal currents and flows carry a significant amount of kinetic energy, especially in regions with strong tidal ranges and currents. Tidal energy systems can capture this energy using relatively small-scale devices or arrays, offering high energy density and efficiency compared to other renewable energy sources such as wind or solar.

- Low Environmental Impact: Tidal energy systems have minimal greenhouse gas emissions and air pollutants compared to fossil fuel-based power plants, reducing carbon footprint and mitigating climate change impacts. Tidal energy projects can also have low visual and noise impact, especially if deployed offshore or in remote coastal areas, minimizing conflicts with other marine activities.

However, tidal energy also faces challenges and limitations:

- High Costs: The upfront capital costs of tidal energy projects can be substantial, including site survey, device design, manufacturing, installation, and grid connection. Tidal energy technologies are still in the early stages of development and demonstration, with limited commercial deployment and operational experience, which can increase investment risks and project financing challenges.

- Environmental Concerns: Tidal energy projects can have environmental impacts on marine ecosystems, including changes in water flow, sediment transport, and wildlife behavior. Proper siting, monitoring, and mitigation measures are essential for minimizing adverse effects on marine habitats, migratory routes, and biodiversity.

- Resource Variability: Tidal energy resources vary spatially and temporally, depending on factors such as coastal geography, tidal range, and bathymetry. Identifying suitable sites for tidal energy projects requires comprehensive resource assessment and modeling to evaluate feasibility and optimize energy capture potential.

In conclusion, tidal energy represents a promising and emerging renewable energy source with the potential to contribute significantly to the global energy mix. With continued technological advancements, cost reductions, and supportive policies, tidal energy can play a vital role in the transition towards a sustainable and resilient energy future, harnessing the power of the tides to meet growing energy demand while protecting the environment and enhancing energy security.

Wave Energy:

Wave energy is a renewable and sustainable source of power derived from the kinetic energy of ocean waves. It harnesses the motion of waves to generate electricity using various technologies and devices deployed in coastal or offshore environments. Wave energy is abundant, predictable, and widely distributed, offering a clean and environmentally friendly alternative to conventional fossil fuels for electricity generation.

- Wave Energy Converters (WECs): Wave energy converters (WECs) are devices designed to capture and convert the kinetic energy of ocean waves into mechanical or electrical energy. There are several types of wave energy converters, including:

- Point Absorbers: Point absorbers are buoyant devices that move up and down with the motion of waves, driving mechanical or hydraulic systems to generate electricity.

- Oscillating Water Columns (OWCs): Oscillating water columns use the rise and fall of waves to compress and decompress air within a chamber, driving turbines or generators to produce electricity.

- Overtopping Devices: Overtopping devices capture the potential energy of waves as they flow over a structure, filling a reservoir or basin with water, which is then released through turbines to generate electricity.

- Surface Following Devices: Surface following devices utilize the motion of waves to drive floating or submerged structures, such as articulated rafts or flap gates, which are connected to power take-off systems to extract energy.

- Submerged Pressure Differentials: Submerged pressure differential systems harness the pressure differentials created by wave motion between submerged chambers or structures to generate electricity. As waves pass over the submerged device, pressure changes within the chambers drive fluid flow through turbines or generators, producing electricity.

- Terminators: Terminator devices are shoreline or seabed-mounted structures that absorb the energy of incoming waves and convert it into mechanical or electrical energy using hydraulic or pneumatic systems. Terminator devices can be installed in coastal areas or offshore environments to capture wave energy near the shore or in deeper waters.

Wave energy offers several advantages as a renewable energy source:

- Abundance: Wave energy is abundant and widely distributed, with significant potential for power generation in coastal areas and offshore environments around the world. Waves are generated by wind energy transferred to the ocean surface, making wave energy a renewable and inexhaustible resource.

- Predictability: Wave energy is predictable and follows consistent patterns based on factors such as wind speed, direction, and fetch. Wave forecasting models and oceanographic data can be used to predict wave conditions and optimize wave energy capture, enabling reliable and efficient power generation.

- Low Environmental Impact: Wave energy projects have minimal environmental impact compared to conventional fossil fuel-based power plants, producing no greenhouse gas emissions or air pollutants during operation. Wave energy devices can be deployed offshore or in remote coastal areas, minimizing visual and noise impact and preserving marine ecosystems.

- Energy Security: Wave energy can enhance energy security and resilience by diversifying the energy mix and reducing dependence on imported fossil fuels. Wave energy projects can provide reliable and locally sourced electricity to coastal communities, islands, and remote regions with limited access to conventional power sources.

However, wave energy also faces challenges and limitations:

- Technological Maturity: Wave energy technologies are still in the early stages of development and demonstration, with limited commercial deployment and operational experience. Technical challenges such as device reliability, survivability in harsh marine environments, and cost-effectiveness need to be addressed to scale up wave energy deployment and reduce costs.

- High Capital Costs: The upfront capital costs of wave energy projects can be substantial, including device design, manufacturing, installation, and grid connection. Financing wave energy projects can be challenging due to investment risks, regulatory uncertainty, and the lack of established markets and incentives for wave energy deployment.

- Resource Variability: Wave energy resources vary spatially and temporally, depending on factors such as ocean geography, wave height, period, and direction. Identifying suitable sites for wave energy projects requires comprehensive resource assessment and modeling to evaluate feasibility and optimize energy capture potential.

In conclusion, wave energy represents a promising and emerging renewable energy source with the potential to contribute significantly to the global energy transition. With continued research, development, and investment in wave energy technologies, supportive policies, and market incentives, wave energy can help meet growing energy demand, reduce greenhouse gas emissions, and promote sustainable development, providing clean, reliable, and resilient energy solutions for coastal communities, industries, and economies worldwide.

Bioenergy

Bioenergy is a renewable and sustainable source of power derived from organic materials, such as biomass, agricultural residues, organic waste, and biofuels. It harnesses the chemical energy stored in biological matter through processes such as combustion, fermentation, or conversion to produce heat, electricity, or transportation fuels. Bioenergy plays a vital role in the global energy mix, providing a versatile and flexible source of renewable energy for various applications.

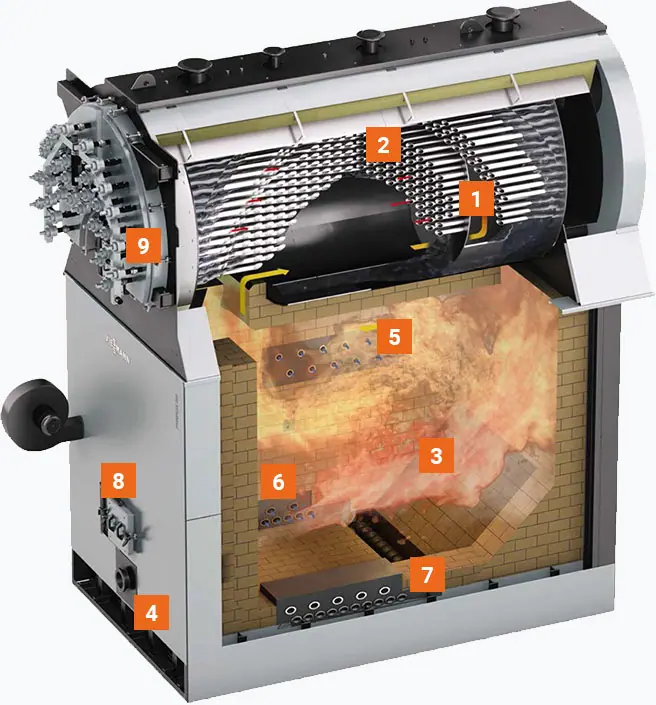

- Biomass Combustion: Biomass combustion involves burning organic materials, such as wood, agricultural residues, or energy crops, to produce heat or electricity. Biomass combustion systems range from traditional wood stoves and biomass boilers to modern biomass power plants equipped with advanced combustion technologies, such as fluidized bed boilers or gasification systems. Biomass combustion releases carbon dioxide (CO2) emissions, but it is considered carbon-neutral when sustainably managed, as the carbon emitted is offset by the carbon absorbed during the growth of biomass feedstocks.

- Biogas Production: Biogas production involves anaerobic digestion of organic materials, such as animal manure, sewage sludge, food waste, or energy crops, to produce biogas, a mixture of methane (CH4) and carbon dioxide (CO2), along with other trace gases. Biogas can be used directly as a renewable fuel for heating, cooking, or electricity generation, or upgraded to biomethane for injection into natural gas pipelines or use as a transportation fuel. Biogas production also generates nutrient-rich digestate, which can be used as fertilizer for agriculture or soil amendment.

- Bioethanol and Biodiesel: Bioethanol and biodiesel are liquid biofuels produced from renewable feedstocks, such as corn, sugarcane, wheat, soybeans, or lignocellulosic biomass. Bioethanol is produced through fermentation and distillation of sugars or starches, while biodiesel is produced through transesterification of vegetable oils or animal fats. Bioethanol is commonly blended with gasoline to reduce greenhouse gas emissions and enhance octane ratings, while biodiesel is blended with diesel fuel to improve lubricity and reduce emissions of particulate matter and nitrogen oxides.

- Pyrolysis and Gasification: Pyrolysis and gasification are thermochemical conversion processes that transform biomass into biochar, syngas, and bio-oil through heating in the absence of oxygen. Pyrolysis involves heating biomass at high temperatures (300-800°C) in a low-oxygen environment to produce biochar and bio-oil, which can be used as soil amendments or bioenergy feedstocks, respectively. Gasification involves reacting biomass with steam or oxygen at high temperatures (>700°C) to produce syngas, a mixture of hydrogen (H2) and carbon monoxide (CO), which can be used for heat, power, or biofuel production.

Bioenergy offers several advantages as a renewable energy source:

- Resource Availability: Biomass feedstocks for bioenergy production are abundant and widely available, including agricultural residues, forestry residues, energy crops, and organic waste. Bioenergy can be produced locally, reducing dependence on imported fossil fuels and promoting energy security and self-sufficiency.

- Carbon Neutrality: Bioenergy is considered carbon-neutral or even carbon-negative when sustainably managed, as the carbon emitted during combustion is offset by the carbon absorbed during the growth of biomass feedstocks. Biomass production and utilization can contribute to carbon sequestration, soil fertility, and ecosystem restoration, mitigating climate change and enhancing environmental sustainability.

- Energy Diversity: Bioenergy diversifies the energy mix and reduces reliance on fossil fuels, providing a flexible and dispatchable source of renewable energy for heat, power, and transportation. Bioenergy complements intermittent renewable energy sources such as wind and solar, providing baseload power and grid stability in integrated energy systems.

- Rural Development: Bioenergy production promotes rural development, job creation, and economic growth in agricultural and forestry regions, supporting local economies and livelihoods. Bioenergy value chains, including biomass supply chains, biorefineries, and biofuel distribution networks, create opportunities for small-scale farmers, entrepreneurs, and communities to participate in sustainable bioenergy markets.

However, bioenergy also faces challenges and limitations:

- Feedstock Availability: The sustainable supply of biomass feedstocks for bioenergy production depends on factors such as land availability, land use competition, biomass yield, and environmental sustainability. Competition for land between food production, bioenergy crops, and conservation can raise concerns about land-use change, deforestation, and biodiversity loss.

- Resource Efficiency: Bioenergy systems require efficient conversion technologies, feedstock logistics, and energy utilization practices to maximize energy output, minimize resource consumption, and optimize overall system efficiency. Improving the energy and carbon balances of bioenergy production and utilization is essential for enhancing resource efficiency and environmental performance.

- Technology Costs: The costs of bioenergy technologies, including biomass conversion, biorefining, and biofuel production, can be high compared to conventional fossil fuel-based technologies, particularly for emerging and innovative processes. Research, development, and demonstration efforts are needed to reduce technology costs, improve performance, and increase market competitiveness of bioenergy systems.

- Environmental Impacts: Bioenergy production can have environmental impacts on land, water, and ecosystems, including soil degradation, water pollution, and habitat fragmentation. Sustainable biomass management practices, environmental regulations, and certification schemes are essential for mitigating adverse effects and ensuring the environmental sustainability of bioenergy projects.

In conclusion, bioenergy represents a versatile and renewable energy source with the potential to contribute significantly to the global energy transition. With careful planning, sustainable management, and integrated approaches, bioenergy can help meet growing energy demand, reduce greenhouse gas emissions, promote rural development, and enhance environmental stewardship, providing clean, reliable, and resilient energy solutions for communities, industries, and economies worldwide.

Hydrogen Fuel:

Hydrogen fuel is a versatile and sustainable energy carrier derived from hydrogen gas (H2) that can be used for various applications, including transportation, electricity generation, heating, and industrial processes. It is considered a promising alternative to fossil fuels due to its high energy density, zero carbon emissions when used in fuel cells, and compatibility with existing infrastructure for storage, distribution, and utilization.

- Hydrogen Production: Hydrogen fuel can be produced from various feedstocks and energy sources through several methods, including:

- Steam Methane Reforming (SMR): SMR is the most common method of hydrogen production, utilizing natural gas or methane as a feedstock. It involves reacting methane with steam at high temperatures (>700°C) and pressures to produce hydrogen and carbon monoxide.

- Water Electrolysis: Electrolysis is a process that splits water molecules (H2O) into hydrogen (H2) and oxygen (O2) using electricity. It can be powered by renewable energy sources such as solar, wind, or hydroelectric power, resulting in zero-carbon hydrogen production.

- Biomass Gasification: Biomass gasification involves converting organic materials such as agricultural residues, forestry waste, or energy crops into synthesis gas (syngas), which can be further processed to produce hydrogen through water-gas shift reactions.

- Thermochemical Water Splitting: Thermochemical water splitting uses heat from concentrated solar energy, nuclear reactors, or fossil fuel combustion to split water molecules into hydrogen and oxygen through thermochemical reactions, such as metal oxide reduction or sulfur-iodine cycles.

- Hydrogen Storage and Distribution: Hydrogen fuel can be stored and transported in various forms, including compressed gas, liquid hydrogen, and solid-state materials, such as metal hydrides or carbon-based materials. Compressed hydrogen gas is typically stored in high-pressure tanks or cylinders for transportation and distribution to fueling stations. Liquid hydrogen is cryogenically cooled to temperatures below -253°C and stored in insulated tanks for long-term storage and space-constrained applications.

- Fuel Cell Technology: Fuel cells are electrochemical devices that convert hydrogen fuel and oxygen from the air into electricity through a chemical reaction. Fuel cells operate silently and efficiently, with higher energy conversion efficiencies compared to internal combustion engines, and produce only water vapor as a byproduct. Fuel cell systems are used in various applications, including vehicles, buses, trucks, trains, ships, stationary power generation, and backup power systems.

Hydrogen fuel offers several advantages as a clean and sustainable energy carrier:

- Zero Emissions: Hydrogen fuel produces no greenhouse gas emissions or air pollutants when used in fuel cells, offering significant environmental benefits and contributing to climate change mitigation and air quality improvement. Hydrogen fuel cells can help reduce dependence on fossil fuels and transition towards a low-carbon and sustainable energy future.

- Energy Security: Hydrogen fuel diversifies the energy mix and reduces dependence on imported fossil fuels, enhancing energy security and resilience to supply disruptions. Hydrogen can be produced from a variety of domestic sources, including natural gas, renewable electricity, biomass, and nuclear power, providing flexibility and self-sufficiency in energy supply.

- Versatility: Hydrogen fuel is a versatile energy carrier that can be used in various applications, including transportation, stationary power generation, industrial processes, and energy storage. Hydrogen fuel cells can power electric vehicles with long driving ranges and fast refueling times, providing a viable alternative to conventional internal combustion engines and battery electric vehicles.