Biomass refers to organic materials derived from plants and animals, which can be used as a renewable energy source. It encompasses a wide range of organic matter, including wood, agricultural residues, crop waste, animal manure, and dedicated energy crops. Biomass is a versatile resource that can be converted into various forms of energy, including heat, electricity, and biofuels, through different conversion processes such as combustion, gasification, and anaerobic digestion.

Biomass Gasification

One of the key advantages of biomass is its abundance and widespread availability. It can be sustainably harvested and cultivated, making it a reliable and renewable source of energy. Biomass can also serve as a valuable alternative to fossil fuels, helping to reduce greenhouse gas emissions and mitigate climate change. By utilizing biomass for energy production, we can minimize our dependence on finite fossil fuel resources and transition towards a more sustainable and environmentally friendly energy system.

In addition to its energy potential, biomass offers several other benefits. For example, it can provide economic opportunities for rural communities by creating jobs in biomass production, harvesting, and processing. Biomass energy projects can also support local economies by providing revenue streams for farmers, foresters, and bioenergy producers.

However, it’s essential to consider the environmental and social implications of biomass utilization. While biomass can offer significant environmental benefits compared to fossil fuels, such as lower carbon emissions and reduced air pollution, it’s crucial to ensure that biomass is sourced and managed sustainably to avoid negative impacts on ecosystems, biodiversity, and food security. Sustainable biomass management practices, such as agroforestry, land-use planning, and waste-to-energy initiatives, can help maximize the benefits of biomass while minimizing its environmental footprint.

Overall, biomass represents a valuable renewable energy resource with the potential to play a significant role in our transition to a more sustainable energy future. By harnessing the power of biomass and investing in research, innovation, and infrastructure development, we can unlock its full potential as a clean, renewable, and environmentally friendly energy source.

Gasification:

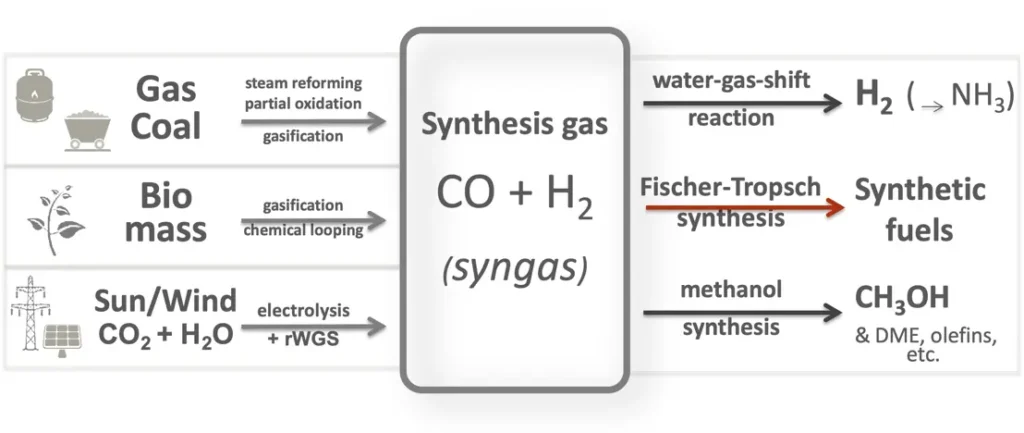

Gasification is a thermochemical conversion process that converts carbonaceous materials, such as biomass, coal, or municipal solid waste, into synthesis gas (syngas) by reacting them with a controlled amount of oxygen, steam, or a combination of both at elevated temperatures. The process typically occurs in a gasifier, which is a reactor vessel designed to withstand high temperatures and pressures.

Gasification involves several chemical reactions, including pyrolysis, oxidation, and reduction, which occur in distinct zones within the gasifier. In the pyrolysis zone, the feedstock is heated in the absence of oxygen, leading to the release of volatile compounds such as hydrocarbons, tars, and methane. These volatile compounds are then partially oxidized in the oxidation zone, where they react with oxygen or steam to produce carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), and water vapor. Finally, in the reduction zone, carbon dioxide and water vapor react with carbonaceous char to produce additional syngas and carbon monoxide.

Syngas produced through gasification is a versatile fuel that can be used for a variety of applications, including electricity generation, heat production, and the synthesis of fuels and chemicals. It consists primarily of hydrogen and carbon monoxide, with trace amounts of methane, nitrogen, and other impurities. Syngas can be combusted directly in a gas turbine or reciprocating engine to generate electricity, or it can be further processed to remove impurities and separate hydrogen for use in fuel cells or chemical synthesis.

Gasification offers several advantages over other biomass conversion technologies. It can accommodate a wide range of feedstocks, including woody biomass, agricultural residues, and municipal solid waste, making it a flexible and versatile option for renewable energy production. Gasification also enables the efficient utilization of biomass resources by converting them into a high-energy-density syngas that can be easily transported and stored.

Furthermore, gasification is considered a more environmentally friendly option compared to traditional combustion processes, as it produces syngas with lower emissions of sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. The syngas can also be cleaned and conditioned to remove impurities such as tars, ammonia, and sulfur compounds, further reducing environmental impacts.

Despite its numerous advantages, gasification also presents technical and economic challenges. The process requires high temperatures and pressures, which can increase capital costs and energy consumption. Gasification reactors must also be carefully designed and operated to ensure efficient conversion and minimize the formation of tars and other byproducts. Additionally, the economics of gasification projects can be sensitive to factors such as feedstock availability, energy prices, and policy incentives.

In summary, gasification is a promising technology for converting biomass and other carbonaceous materials into clean and versatile syngas for renewable energy production. With ongoing research and development efforts focused on improving process efficiency, reducing costs, and addressing technical challenges, gasification has the potential to play a significant role in the transition to a more sustainable and low-carbon energy future.

Syngas:

Syngas, short for synthesis gas, is a mixture of gases primarily composed of hydrogen (H2) and carbon monoxide (CO), along with varying amounts of carbon dioxide (CO2), methane (CH4), water vapor (H2O), and other trace gases. It is produced through thermochemical conversion processes such as gasification, pyrolysis, or steam reforming of carbonaceous feedstocks, including biomass, coal, natural gas, and municipal solid waste.

The composition of syngas depends on several factors, including the type of feedstock used, the operating conditions of the conversion process, and the presence of catalysts or additives. Syngas produced from biomass typically has a higher hydrogen-to-carbon monoxide ratio compared to syngas from coal or natural gas, making it suitable for a wider range of applications, including electricity generation, heat production, and the production of fuels and chemicals.

Syngas is a versatile and valuable intermediate product that can be used as a fuel or feedstock for various industrial processes. Some of the key applications of syngas include:

- Power Generation: Syngas can be combusted in gas turbines, reciprocating engines, or fuel cells to generate electricity. Gasification-based power plants utilize syngas as a fuel to produce electricity with high efficiency and low emissions, making them an attractive option for decentralized and distributed power generation.

- Heat and Steam Production: Syngas can be used as a fuel for boilers, furnaces, and industrial heating applications to produce heat and steam for industrial processes, district heating systems, and cogeneration plants. Syngas-based heating systems offer an alternative to fossil fuels, reducing greenhouse gas emissions and reliance on imported energy sources.

- Fuels and Chemicals Production: Syngas serves as a feedstock for the production of fuels and chemicals through catalytic processes such as Fischer-Tropsch synthesis, methanol synthesis, and ammonia synthesis. Syngas can be converted into liquid fuels such as synthetic diesel, gasoline, and jet fuel, as well as chemicals such as methanol, hydrogen, ammonia, and synthetic natural gas (SNG).

- Hydrogen Production: Syngas can be further processed through water-gas shift reactions or membrane separation to produce high-purity hydrogen for fuel cells, chemical synthesis, and industrial applications. Hydrogen derived from syngas is a clean and versatile energy carrier with potential applications in transportation, energy storage, and renewable energy integration.

Syngas production and utilization offer several advantages, including resource diversification, energy security, and environmental sustainability. By utilizing syngas as a renewable energy source, we can reduce our dependence on fossil fuels, mitigate climate change, and promote a more sustainable and low-carbon energy future. However, it’s essential to address technical, economic, and environmental challenges associated with syngas production and utilization, such as gasification efficiency, carbon capture and storage, and life cycle emissions, to maximize the potential benefits of this versatile energy resource.

Feedstock:

Feedstock refers to the raw material or biomass source used as input in various industrial processes, particularly in the context of renewable energy production, biofuel manufacturing, and chemical synthesis. It encompasses a wide range of organic materials derived from plants, animals, and organic wastes, which can be converted into energy, fuels, chemicals, and other valuable products through different conversion technologies and processes.

In the context of renewable energy and bioenergy production, feedstock plays a crucial role in determining the availability, cost, and sustainability of the resulting energy products. Different types of feedstocks have varying compositions, energy contents, and conversion potentials, influencing the choice of conversion technology, process efficiency, and environmental impacts of the energy production process.

Common types of feedstocks used in renewable energy and bioenergy production include:

- Biomass Feedstocks: Biomass feedstocks consist of organic materials derived from plants, trees, crops, agricultural residues, forestry residues, and dedicated energy crops. Biomass feedstocks can be used in various conversion processes, such as combustion, gasification, pyrolysis, and anaerobic digestion, to produce heat, electricity, biofuels, and bioproducts.

- Woody Biomass: Woody biomass includes wood chips, sawdust, logging residues, and tree trimmings obtained from forestry operations, timber processing, and urban wood waste. Woody biomass feedstocks are widely used in biomass-fired power plants, district heating systems, and biomass boilers for heat and electricity generation.

- Agricultural Residues: Agricultural residues are byproducts of agricultural crops and farming activities, such as crop residues, straw, husks, stalks, and bagasse. Agricultural residues can be used as feedstocks for bioenergy production through processes like biomass combustion, gasification, and bioethanol fermentation.

- Energy Crops: Energy crops are dedicated biomass crops grown specifically for bioenergy production, such as switchgrass, miscanthus, willow, and poplar. Energy crops offer high yields of biomass per hectare and can be cultivated on marginal lands unsuitable for food crops, providing a sustainable and renewable source of feedstock for bioenergy production.

- Animal Manure and Wastes: Animal manure, livestock waste, and organic residues from agricultural and livestock operations can be used as feedstocks for anaerobic digestion to produce biogas and renewable natural gas (RNG). Anaerobic digestion of organic waste materials not only generates renewable energy but also helps reduce methane emissions from waste decomposition and provides nutrient-rich digestate for soil amendment.

- Municipal Solid Waste (MSW): Municipal solid waste, including household waste, commercial waste, and industrial waste, can be used as a feedstock for waste-to-energy (WtE) facilities, such as waste incineration plants and landfill gas recovery systems. MSW feedstocks can be converted into electricity, heat, and biofuels through combustion, gasification, or landfill gas capture.

The choice of feedstock for renewable energy production depends on factors such as feedstock availability, cost, quality, sustainability, and local regulations. Sustainable feedstock sourcing practices, including responsible land management, crop rotation, and waste diversion, are essential to ensure the long-term viability and environmental sustainability of bioenergy feedstock supply chains. Additionally, advancements in feedstock pretreatment, conversion technologies, and process optimization can improve the efficiency, economics, and environmental performance of renewable energy production from diverse feedstock sources.

Thermochemical:

Thermochemical processes involve the transformation of chemical substances through the application of heat. In the context of renewable energy and bioenergy production, thermochemical processes play a crucial role in converting biomass and other organic materials into useful energy carriers such as syngas, biofuels, and heat. These processes utilize heat to drive chemical reactions that break down complex organic molecules into simpler compounds, releasing energy in the form of heat, gases, and liquids.

Key thermochemical processes used in renewable energy and bioenergy production include:

- Combustion: Combustion is a thermochemical process that involves the rapid oxidation of biomass or fossil fuels in the presence of oxygen to release heat energy. In biomass combustion, organic materials such as wood, agricultural residues, and bioenergy crops are burned in a controlled environment, typically in boilers, furnaces, or stoves, to produce heat for space heating, water heating, and electricity generation.

- Gasification: Gasification is a thermochemical conversion process that converts carbonaceous feedstocks, such as biomass, coal, or waste materials, into a mixture of gases known as syngas. The process occurs in a gasifier reactor, where the feedstock is subjected to high temperatures and a controlled amount of oxygen or steam, leading to the partial oxidation of organic matter and the production of syngas.

- Pyrolysis: Pyrolysis is a thermochemical decomposition process that breaks down organic materials into biochar, bio-oil, and syngas in the absence of oxygen or with limited oxygen supply. During pyrolysis, biomass feedstocks are heated to high temperatures in an oxygen-starved environment, causing them to undergo thermal degradation and chemical decomposition, resulting in the formation of biochar, a solid carbon-rich residue, bio-oil, a liquid mixture of organic compounds, and syngas.

- Steam Reforming: Steam reforming, also known as steam methane reforming (SMR), is a thermochemical process used to produce hydrogen gas (H2) from natural gas, biogas, or other hydrocarbon feedstocks. The process involves reacting methane (CH4) with steam (H2O) at high temperatures and pressures in the presence of a catalyst to produce hydrogen gas and carbon monoxide.

- Biomass Liquefaction: Biomass liquefaction is a thermochemical process that converts biomass into liquid fuels such as bio-oil, biodiesel, and synthetic fuels through the application of heat and pressure. The process involves heating biomass feedstocks in the presence of a solvent or catalyst to break down complex organic molecules into liquid hydrocarbons, which can be upgraded and refined into transportation fuels.

Thermochemical processes offer several advantages for renewable energy and bioenergy production, including high energy efficiency, versatility in feedstock utilization, and the ability to produce a range of energy carriers and products. These processes can also help reduce greenhouse gas emissions, promote resource efficiency, and enhance energy security by utilizing renewable and sustainable feedstocks.

However, thermochemical processes also present challenges such as high capital costs, complex process integration, and environmental concerns related to emissions, waste management, and byproduct utilization. Addressing these challenges requires ongoing research and development efforts focused on improving process efficiency, reducing costs, and optimizing environmental performance to realize the full potential of thermochemical technologies for renewable energy and bioenergy production.

Biomass-to-energy:

Biomass-to-energy refers to the process of converting biomass resources into usable energy forms such as heat, electricity, or biofuels. It involves a variety of conversion technologies and processes that harness the energy stored in organic materials derived from plants, animals, and organic wastes. Biomass-to-energy technologies play a crucial role in the transition to a more sustainable and renewable energy system by utilizing locally available biomass resources to produce clean and renewable energy while reducing greenhouse gas emissions and dependence on fossil fuels.

There are several biomass-to-energy conversion technologies, each suited to different types of biomass feedstocks and energy applications:

- Combustion: Biomass combustion is one of the oldest and most widely used biomass-to-energy technologies. It involves burning biomass feedstocks such as wood, agricultural residues, and energy crops in a controlled environment to produce heat. The heat generated can be used directly for space heating, water heating, or industrial processes, or it can be converted into electricity using steam turbines or other power generation technologies.

- Gasification: Biomass gasification is a thermochemical conversion process that converts biomass feedstocks into a combustible gas mixture known as syngas. The process involves heating biomass in a gasifier reactor with a controlled amount of oxygen or steam, resulting in the partial oxidation of organic matter and the production of syngas. Syngas can be used as a fuel for power generation, combined heat and power (CHP) systems, or as a feedstock for the production of biofuels and chemicals.

- Pyrolysis: Biomass pyrolysis is a thermochemical decomposition process that converts biomass feedstocks into biochar, bio-oil, and syngas in the absence of oxygen or with limited oxygen supply. During pyrolysis, biomass is heated to high temperatures in a low-oxygen environment, causing it to undergo thermal degradation and chemical decomposition. The resulting products, including biochar for soil amendment, bio-oil for biofuel production, and syngas for energy generation, have various applications in energy, agriculture, and industry.

- Anaerobic Digestion: Biomass anaerobic digestion is a biological conversion process that breaks down organic materials in the absence of oxygen to produce biogas, a mixture of methane and carbon dioxide. The process occurs in anaerobic digesters, where microorganisms decompose organic matter, such as animal manure, agricultural residues, and food waste, to produce biogas. Biogas can be used as a renewable fuel for electricity generation, heating, or vehicle fuel, or it can be upgraded to biomethane for injection into natural gas pipelines or use as a transportation fuel.

- Biochemical Conversion: Biomass biochemical conversion involves using enzymes or microorganisms to convert biomass feedstocks into biofuels such as ethanol, biodiesel, and biobutanol through fermentation, enzymatic hydrolysis, or other biochemical processes. These biofuels can be used as renewable alternatives to gasoline, diesel, and other fossil fuels in transportation, industry, and agriculture.

Biomass-to-energy technologies offer several advantages, including carbon neutrality, renewable energy generation, waste reduction, and rural development opportunities. By utilizing locally available biomass resources, biomass-to-energy projects can enhance energy security, promote economic growth, and support sustainable development goals. However, challenges such as feedstock availability, technology costs, and environmental impacts must be addressed to realize the full potential of biomass-to-energy as a clean and sustainable energy solution. Ongoing research, innovation, and policy support are essential to overcome these challenges and advance the deployment of biomass-to-energy technologies worldwide.

Renewable Fuel:

Renewable fuel refers to any fuel derived from renewable or sustainable sources, such as biomass, solar energy, wind energy, or hydropower. Unlike fossil fuels, which are finite and contribute to environmental degradation and climate change, renewable fuels are produced from resources that can be replenished naturally and do not deplete finite resources or contribute to greenhouse gas emissions when used.

Key types of renewable fuels include biofuels, hydrogen, and renewable electricity:

- Biofuels: Biofuels are liquid or gaseous fuels derived from biomass feedstocks such as crops, agricultural residues, forestry residues, algae, and organic wastes. Common biofuels include ethanol, biodiesel, biogas, and renewable diesel. Ethanol is produced through fermentation of sugars or starches found in crops such as corn, sugarcane, and wheat, while biodiesel is produced from vegetable oils or animal fats through a process called transesterification. Biogas is generated through anaerobic digestion of organic wastes such as animal manure, food scraps, and wastewater sludge.

- Hydrogen: Hydrogen is a versatile renewable fuel that can be produced from water through electrolysis, biomass gasification, or thermochemical processes. It can be used as a fuel for fuel cells to generate electricity or as a feedstock for chemical processes to produce synthetic fuels such as hydrogenated vegetable oil (HVO) or ammonia. Hydrogen fuel cells offer high efficiency, zero emissions, and quiet operation, making them suitable for various applications, including transportation, stationary power generation, and energy storage.

- Renewable Electricity: Renewable electricity is generated from renewable energy sources such as solar, wind, hydro, geothermal, and biomass. It is produced through technologies such as photovoltaic (PV) solar panels, wind turbines, hydroelectric dams, and biomass power plants. Renewable electricity can be used directly to power electric vehicles, heat pumps, and appliances, or it can be stored in batteries or converted into other forms of energy such as hydrogen through electrolysis. Renewable electricity is a clean and sustainable alternative to fossil fuel-based electricity generation, offering environmental benefits such as reduced greenhouse gas emissions, air pollution, and water usage.

Renewable fuels offer several advantages over conventional fossil fuels, including:

- Environmental Benefits: Renewable fuels are derived from sustainable sources and produce lower emissions of greenhouse gases, air pollutants, and toxic substances compared to fossil fuels. Using renewable fuels can help mitigate climate change, improve air quality, and reduce environmental impacts associated with fossil fuel extraction, processing, and combustion.

- Energy Security: Renewable fuels reduce dependence on imported fossil fuels and enhance energy security by utilizing locally available resources and diversifying energy sources. Renewable fuels can be produced domestically, reducing reliance on foreign oil and enhancing energy independence and resilience.

- Economic Opportunities: Renewable fuel production and deployment create economic opportunities for farmers, rural communities, and clean energy industries. Renewable fuel projects support job creation, economic growth, and investment in renewable energy infrastructure, contributing to local economies and sustainable development.

- Technological Innovation: Renewable fuels drive technological innovation and advancements in renewable energy technologies, including bioenergy, hydrogen, and renewable electricity generation. Research and development efforts focused on improving renewable fuel production processes, efficiency, and cost-effectiveness help drive down costs and accelerate the transition to a clean energy future.

Overall, renewable fuels play a crucial role in transitioning to a more sustainable, low-carbon energy system by offering clean, renewable alternatives to conventional fossil fuels. By promoting the development and deployment of renewable fuels, policymakers, businesses, and consumers can contribute to reducing greenhouse gas emissions, promoting energy security, and fostering economic growth while ensuring a sustainable future for generations to come.

Tar:

Tar, in the context of biomass gasification and pyrolysis processes, refers to a complex mixture of organic compounds that are produced as byproducts during the thermal conversion of biomass feedstocks. It is a viscous, sticky substance with high molecular weight and can vary widely in composition depending on the feedstock, operating conditions, and process parameters.

During biomass gasification or pyrolysis, organic materials undergo thermal decomposition in the absence of oxygen or with limited oxygen supply, leading to the release of volatile compounds such as gases (e.g., carbon monoxide, hydrogen, methane) and condensable vapors. These condensable vapors, also known as tar, consist of a wide range of organic compounds, including polycyclic aromatic hydrocarbons (PAHs), phenols, aldehydes, ketones, and organic acids.

Tar formation occurs through a series of complex chemical reactions involving the pyrolysis and decomposition of biomass constituents such as cellulose, hemicellulose, lignin, and other organic compounds present in the feedstock. Factors influencing tar formation include temperature, residence time, heating rate, biomass composition, moisture content, reactor design, and gasification/pyrolysis conditions.

Tar poses several challenges in biomass gasification and pyrolysis processes, including:

- Equipment Fouling: Tar can condense on reactor walls, heat exchangers, and downstream equipment, leading to fouling and corrosion. Accumulation of tar deposits reduces heat transfer efficiency, decreases process performance, and increases maintenance requirements, resulting in downtime and higher operating costs.

- Catalyst Deactivation: Tar can deactivate catalysts used in downstream processing units or gas cleaning systems, reducing their effectiveness and catalytic activity. Tar deposition on catalyst surfaces inhibits active sites and pore blockage, leading to decreased catalyst performance and shorter catalyst lifetimes.

- Gas Quality and Composition: Tar contaminants in syngas can adversely affect downstream gas utilization equipment such as engines, turbines, and fuel cells. High tar levels in syngas can cause engine fouling, corrosion, and tar condensation in combustion chambers, leading to engine damage, reduced efficiency, and increased emissions.

- Environmental and Health Concerns: Tar contains toxic and carcinogenic compounds such as PAHs, benzene, toluene, and xylene, posing environmental and health risks to workers, communities, and ecosystems. Tar emissions from biomass gasification and pyrolysis processes contribute to air pollution, smog formation, and respiratory illnesses, necessitating emission control measures and environmental regulations.

To mitigate the adverse effects of tar, various tar removal and mitigation strategies are employed, including:

- Tar Cracking: Tar cracking involves catalytic or non-catalytic decomposition of tar molecules into lighter gases such as methane, hydrogen, and carbon monoxide at high temperatures. Tar cracking reactors or reformers are integrated into gasification or pyrolysis systems to reduce tar levels and improve syngas quality.

- Tar Removal and Conditioning: Tar removal techniques such as filtration, scrubbing, condensation, and catalytic tar reforming are used to remove tar from syngas streams and convert it into useful products or inert solids. These tar removal systems are integrated into gasification or pyrolysis plants to improve gas quality and protect downstream equipment.

- Biomass Pretreatment: Biomass pretreatment techniques such as drying, torrefaction, and pelletization can reduce tar formation by removing moisture, volatiles, and reactive components from the feedstock. Pretreated biomass exhibits improved handling properties, thermal stability, and gasification/pyrolysis performance, resulting in lower tar yields and enhanced process efficiency.

Addressing tar formation and management is essential to the successful operation of biomass gasification and pyrolysis processes for renewable energy production. Research and development efforts focused on tar characterization, detection, mitigation, and utilization continue to advance tar management strategies and improve the efficiency, reliability, and environmental performance of biomass conversion technologies.

Syngas Cleanup:

Syngas cleanup refers to the process of removing impurities and contaminants from synthesis gas (syngas) produced during biomass gasification, pyrolysis, or other thermochemical conversion processes. Syngas cleanup is essential to ensure the quality, purity, and stability of syngas before it can be utilized as a fuel or feedstock for downstream applications such as power generation, heat production, or chemical synthesis.

Syngas produced from biomass gasification or pyrolysis typically contains various impurities and contaminants, including tar, particulates, sulfur compounds, ammonia, alkali metals, trace metals, and moisture. These impurities can adversely affect the performance, efficiency, and reliability of syngas utilization equipment such as engines, turbines, fuel cells, and catalysts, leading to equipment fouling, corrosion, catalyst deactivation, and increased maintenance requirements.

Syngas cleanup processes typically involve a combination of physical, chemical, and thermal treatment steps to remove or reduce impurities to acceptable levels. Key syngas cleanup technologies and techniques include:

- Particulate Removal: Particulate matter such as ash, dust, and char particles are removed from syngas using filtration, cyclone separators, or electrostatic precipitators. Particulate removal helps protect downstream equipment from fouling and erosion and improves syngas quality and cleanliness.

- Tar Removal: Tar compounds present in syngas are removed through tar cracking, tar reforming, or tar removal systems such as filters, scrubbers, or condensers. Tar removal prevents fouling and corrosion of downstream equipment and enhances syngas stability and combustion performance.

- Sulfur Removal: Sulfur compounds such as hydrogen sulfide (H2S) and carbonyl sulfide (COS) are removed from syngas using desulfurization techniques such as absorption, adsorption, or catalytic conversion. Sulfur removal prevents corrosion, catalyst poisoning, and environmental emissions and enables syngas utilization in sensitive applications such as fuel cells and chemical synthesis.

- Ammonia Removal: Ammonia (NH3) present in syngas is removed through selective catalytic reduction (SCR) or scrubbing with acidic solutions. Ammonia removal prevents catalyst poisoning, corrosion, and environmental emissions and improves syngas quality for downstream applications.

- Moisture Removal: Moisture content in syngas is reduced using condensation, cooling, or dehydration techniques such as membrane separation or molecular sieves. Moisture removal prevents corrosion, ice formation, and gasifier fouling and improves syngas storage and handling properties.

- Gas Composition Adjustment: Syngas composition is adjusted by controlling the ratio of hydrogen (H2) to carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and other gases through syngas conditioning, reforming, or catalytic conversion. Gas composition adjustment ensures syngas meets specific process requirements and enables efficient utilization in end-use applications.

Syngas cleanup is an essential and often complex step in biomass-to-energy conversion processes, requiring careful selection and integration of cleanup technologies to achieve desired syngas quality, purity, and stability. Advances in syngas cleanup technologies, process optimization, and control systems continue to improve the efficiency, reliability, and environmental performance of biomass gasification and pyrolysis plants, enabling the widespread adoption of renewable syngas as a clean and sustainable energy source.

Syngas Utilization:

Syngas utilization refers to the conversion and utilization of synthesis gas (syngas) produced from biomass gasification, pyrolysis, or other thermochemical processes as a valuable energy carrier or feedstock for various industrial applications. Syngas is a versatile intermediate product containing hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and other trace gases, making it suitable for a wide range of energy and chemical production processes.

Key syngas utilization pathways include:

- Power Generation: Syngas can be utilized as a fuel for power generation through combustion in gas turbines, reciprocating engines, or fuel cells. Gasification-based power plants use syngas to generate electricity efficiently with low emissions, offering a renewable and flexible energy solution for decentralized and distributed power generation applications.

- Combined Heat and Power (CHP): Syngas can be used for combined heat and power (CHP) applications, where it is simultaneously used for electricity generation and heat production. CHP systems utilize the waste heat generated during electricity generation for space heating, water heating, or industrial processes, improving overall energy efficiency and reducing energy costs.

- Biofuels Production: Syngas serves as a feedstock for the production of biofuels such as ethanol, methanol, biodiesel, and synthetic diesel through catalytic processes such as Fischer-Tropsch synthesis, methanol synthesis, and alcohol synthesis. Biofuels produced from syngas offer renewable alternatives to fossil fuels for transportation, industry, and agriculture, reducing greenhouse gas emissions and dependence on imported oil.

- Chemical Synthesis: Syngas is a key feedstock for the production of various chemicals and industrial products through catalytic processes such as ammonia synthesis, methanol synthesis, and hydrocarbon synthesis. Chemicals derived from syngas include ammonia for fertilizer production, methanol for chemical synthesis and fuel blending, and synthetic hydrocarbons for plastics, polymers, and specialty chemicals.

- Hydrogen Production: Syngas can be further processed through water-gas shift reactions or membrane separation to produce high-purity hydrogen gas (H2) for fuel cells, chemical synthesis, and industrial applications. Hydrogen derived from syngas serves as a clean and versatile energy carrier with applications in transportation, energy storage, and renewable energy integration.

- Synthetic Natural Gas (SNG): Syngas can be upgraded and converted into synthetic natural gas (SNG) through methanation processes, where carbon monoxide (CO) and hydrogen (H2) are reacted to produce methane (CH4). SNG can be injected into natural gas pipelines or used as a renewable substitute for natural gas in heating, cooking, and industrial processes.

Syngas utilization offers several advantages, including resource diversification, energy security, and environmental sustainability. By utilizing syngas as a renewable energy source and feedstock for chemical synthesis, we can reduce our dependence on fossil fuels, mitigate climate change, and promote a more sustainable and low-carbon energy future. However, challenges such as syngas quality, process efficiency, and market integration must be addressed to maximize the economic and environmental benefits of syngas utilization across various sectors. Ongoing research, innovation, and policy support are essential to accelerate the adoption and deployment of syngas utilization technologies worldwide.

Biomass Gasification:

Biomass gasification is a thermochemical conversion process that transforms biomass feedstocks into a gaseous mixture known as syngas (synthesis gas), which consists primarily of hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and trace amounts of other gases. This process occurs in the absence of oxygen or with limited oxygen supply, distinguishing it from traditional combustion processes.

The biomass gasification process typically involves several key steps:

- Feedstock Preparation: Biomass feedstocks, which can include wood chips, agricultural residues, energy crops, and municipal solid waste, are prepared for gasification by reducing particle size and moisture content. This preparation step enhances the efficiency of biomass conversion and facilitates uniform feeding into the gasifier.

- Gasification Reactor: The prepared biomass feedstock is introduced into a gasifier reactor, where it undergoes thermal decomposition and chemical reactions at high temperatures (typically between 700°C and 1,200°C) in the presence of a controlled amount of steam, oxygen, or a combination of both. The primary reactions that occur during biomass gasification include pyrolysis, partial oxidation, and reduction:

- Pyrolysis: Biomass feedstocks are heated in the absence of oxygen, leading to the release of volatile organic compounds and the formation of char.

- Partial Oxidation: Volatile compounds released during pyrolysis react with oxygen or steam to produce carbon monoxide (CO) and hydrogen (H2) through endothermic reactions.

- Reduction: Carbon monoxide (CO) reacts with steam (H2O) or carbon dioxide (CO2) to produce additional hydrogen (H2) and carbon dioxide (CO2), along with smaller amounts of methane (CH4) and other trace gases.

- Syngas Cleanup: The raw syngas produced in the gasifier contains impurities such as tar, particulates, sulfur compounds, and ammonia, which must be removed or reduced to acceptable levels to prevent equipment fouling, corrosion, and environmental emissions. Syngas cleanup technologies include tar cracking, particulate removal, desulfurization, ammonia scrubbing, and moisture removal.

- Syngas Conditioning: The cleaned syngas may undergo further conditioning and treatment to adjust its composition, temperature, and pressure to meet specific process requirements and optimize its utilization in downstream applications. Syngas conditioning may involve cooling, compression, moisture removal, and gas composition adjustment through catalytic conversion or chemical reactions.

- Syngas Utilization: The conditioned syngas is utilized as a renewable energy source or feedstock for various industrial applications, including power generation, combined heat and power (CHP) systems, biofuels production, chemical synthesis, hydrogen production, and synthetic natural gas (SNG) production. Syngas utilization pathways depend on factors such as syngas composition, quality, and end-use requirements.

Biomass gasification offers several advantages over traditional combustion and other biomass conversion processes, including higher energy efficiency, lower emissions, greater fuel flexibility, and the ability to produce a versatile energy carrier (syngas) for multiple applications. Gasification technology has the potential to play a significant role in the transition to a more sustainable and low-carbon energy system by utilizing abundant biomass resources to produce clean and renewable energy while reducing greenhouse gas emissions and dependence on fossil fuels. Ongoing research, development, and deployment efforts are essential to advance biomass gasification technology, improve process efficiency, reduce costs, and expand its commercial viability for widespread adoption in various sectors.

Gasification Plant

A gasification plant is an industrial facility designed to convert various carbonaceous feedstocks, such as biomass, coal, petroleum coke, or waste materials, into synthesis gas (syngas) through the process of gasification. Gasification plants play a crucial role in the production of clean and renewable energy, as well as in the synthesis of chemicals, fuels, and other valuable products.

Key components and processes involved in a gasification plant include:

- Feedstock Handling and Preparation: The gasification process begins with the handling and preparation of the feedstock. Depending on the type of feedstock used (e.g., wood chips, coal, municipal solid waste), feedstock preparation may involve size reduction (shredding or grinding), drying to reduce moisture content, and removal of contaminants or impurities.

- Gasifier Reactor: The prepared feedstock is fed into a gasifier reactor, where it undergoes thermal decomposition and chemical reactions in a controlled environment. Gasifier designs vary, but most operate at high temperatures (typically between 700°C and 1,200°C) and pressures, and use a controlled amount of oxygen, steam, or a combination of both to convert the feedstock into syngas.

- Syngas Cleanup: The raw syngas produced in the gasifier contains impurities such as tar, particulates, sulfur compounds, ammonia, and moisture, which must be removed or reduced to acceptable levels. Syngas cleanup processes include tar cracking, particulate removal (e.g., cyclones, filters), desulfurization, ammonia scrubbing, and moisture removal (e.g., condensation, absorption).

- Syngas Conditioning: After cleanup, the syngas may undergo further conditioning and treatment to adjust its temperature, pressure, and composition to meet specific process requirements and optimize its utilization in downstream applications. Syngas conditioning processes may include cooling, compression, moisture removal, and gas composition adjustment through catalytic conversion or chemical reactions.

- Syngas Utilization: The conditioned syngas is utilized as a renewable energy source or feedstock for various industrial applications. Common syngas utilization pathways include:

- Power Generation: Syngas is combusted in gas turbines, reciprocating engines, or fuel cells to generate electricity.

- Combined Heat and Power (CHP): Syngas is used for combined heat and power applications, where waste heat from electricity generation is utilized for heating or industrial processes.

- Biofuels Production: Syngas serves as a feedstock for the production of biofuels such as ethanol, methanol, biodiesel, and synthetic diesel through catalytic processes.

- Chemical Synthesis: Syngas is used as a feedstock for the production of chemicals and industrial products through catalytic processes such as ammonia synthesis, methanol synthesis, and Fischer-Tropsch synthesis.

Gasification plants offer several advantages over conventional combustion-based power plants, including higher energy efficiency, lower emissions, greater fuel flexibility, and the ability to utilize a wide range of feedstocks, including biomass and waste materials. Gasification technology has the potential to play a significant role in the transition to a more sustainable and low-carbon energy system by enabling the production of clean and renewable energy from abundant and diverse carbonaceous resources. Ongoing research, development, and deployment efforts are essential to advance gasification technology, improve process efficiency, reduce costs, and enhance its commercial viability for widespread adoption in various sectors.

Biomass Feedstock:

Biomass feedstock refers to organic materials derived from plants, animals, or organic wastes that are used as raw materials for biomass conversion processes, such as gasification, pyrolysis, fermentation, or combustion, to produce energy, fuels, chemicals, or other valuable products. Biomass feedstocks are renewable resources that can be sustainably harvested, cultivated, or obtained from agricultural, forestry, industrial, and municipal sources.

There are various types of biomass feedstocks, each with unique characteristics, availability, and suitability for different conversion processes:

- Woody Biomass: Woody biomass includes trees, shrubs, branches, bark, and wood residues obtained from forestry operations, sawmills, lumber yards, and urban tree trimmings. Woody biomass feedstocks, such as wood chips, sawdust, wood pellets, and logging residues, are commonly used in biomass gasification, combustion, and pelletization processes to produce heat, electricity, or biofuels.

- Agricultural Residues: Agricultural residues are byproducts of agricultural production processes, such as crop residues, straw, husks, stalks, bagasse, and hulls. These residues are obtained from crops such as corn, wheat, rice, sugarcane, and soybeans and can be used as feedstocks for biomass gasification, pyrolysis, or combustion to generate heat, power, or biofuels.

- Energy Crops: Energy crops are dedicated biomass crops grown specifically for energy production purposes. Examples of energy crops include switchgrass, miscanthus, willow, poplar, and hybrid poplar. Energy crops can be cultivated on marginal lands or fallow agricultural fields and harvested for use in biomass conversion processes to produce biofuels or bioproducts.

- Municipal Solid Waste (MSW): Municipal solid waste, also known as garbage or trash, consists of household, commercial, and industrial wastes collected from urban and municipal areas. MSW feedstocks include organic materials such as food waste, yard waste, paper, cardboard, and other biodegradable materials. MSW can be processed through anaerobic digestion, composting, or waste-to-energy technologies to produce biogas, compost, or electricity.

- Industrial Wastes: Industrial wastes are byproducts generated from industrial processes, such as manufacturing, food processing, pulp and paper production, and wastewater treatment. Industrial waste feedstocks include organic residues, sludges, byproducts, and waste streams rich in organic matter. These wastes can be utilized as feedstocks for biomass conversion processes to recover energy or produce value-added products.

- Animal Manure: Animal manure is organic waste produced by livestock, poultry, and dairy operations. Manure contains organic matter, nutrients, and pathogens and can be processed through anaerobic digestion or composting to produce biogas, biofertilizers, or soil amendments. Anaerobic digestion of animal manure generates biogas, a renewable fuel consisting primarily of methane and carbon dioxide.

Biomass feedstocks offer several advantages as renewable and sustainable resources for energy production and waste management, including carbon neutrality, resource diversification, rural development, and waste reduction. However, challenges such as feedstock availability, logistics, handling, and sustainability must be addressed to ensure the efficient and environmentally responsible utilization of biomass feedstocks in biomass conversion processes. Ongoing research, technology development, and policy support are essential to promote the sustainable use of biomass feedstocks and advance the deployment of biomass-based energy systems worldwide.

Fluidized Bed Gasifier:

A fluidized bed gasifier is a type of gasification reactor that utilizes a fluidized bed technology to convert solid biomass feedstocks into synthesis gas (syngas) by subjecting them to high temperatures and controlled air or oxygen flow in a fluidized state. This technology is widely used in biomass-to-energy conversion systems for the production of heat, power, biofuels, and chemicals.

Key features and components of a fluidized bed gasifier include:

- Fluidized Bed Reactor: The heart of the fluidized bed gasifier is the reactor vessel, which contains a bed of inert particles (e.g., sand, alumina, dolomite) that are fluidized by a stream of gas (usually air or oxygen) entering from the bottom of the reactor. The fluidization process suspends the solid biomass feedstock particles within the bed, creating a fluidized bed of solids with properties similar to a boiling liquid.

- Biomass Feeding System: Solid biomass feedstocks, such as wood chips, agricultural residues, or energy crops, are introduced into the fluidized bed reactor through a feeding system, which may include screw conveyors, rotary valves, or pneumatic conveyors. The biomass feedstock is continuously fed into the reactor to maintain a steady gasification process.

- Gasification Zone: The biomass feedstock undergoes thermal decomposition, pyrolysis, and chemical reactions as it moves through the fluidized bed reactor. Heat is supplied to the reactor through direct combustion of a portion of the biomass or by injecting hot gases into the bed. The high temperature (typically between 700°C and 1,200°C) promotes the gasification reactions, resulting in the production of syngas.

- Gasification Reactions: In the fluidized bed gasifier, biomass feedstock particles are converted into syngas through a series of thermochemical reactions, including:

- Pyrolysis: Biomass feedstock is heated in the absence of oxygen, leading to the release of volatile compounds (tar, gases, and char).

- Partial Oxidation: Volatile compounds react with oxygen or steam to produce carbon monoxide (CO), hydrogen (H2), methane (CH4), and other gases.

- Char Gasification: Char residues undergo gasification reactions with carbon dioxide (CO2) or steam (H2O) to produce additional CO and H2.

- Syngas Collection and Cleanup: The raw syngas produced in the fluidized bed gasifier contains impurities such as tar, particulates, sulfur compounds, and ammonia, which must be removed or reduced to acceptable levels. Syngas cleanup technologies such as cyclones, filters, scrubbers, and catalytic converters are used to remove impurities and condition the syngas for downstream utilization.

- Heat Recovery System: Heat generated during the gasification process is recovered and utilized for various purposes, such as preheating biomass feedstocks, generating steam for power generation, or supplying process heat for industrial applications. Heat recovery systems improve overall energy efficiency and reduce the environmental footprint of fluidized bed gasification plants.

Fluidized bed gasification offers several advantages over other gasification technologies, including:

- Uniform Temperature Distribution: Fluidized bed reactors provide excellent heat transfer and temperature control, resulting in uniform temperature distribution throughout the reactor and enhanced gasification performance.

- High Reactor Efficiency: The fluidized bed design allows for continuous mixing and agitation of biomass feedstock particles, maximizing contact with the gasification agent and promoting efficient conversion of biomass into syngas.

- Fuel Flexibility: Fluidized bed gasifiers can accommodate a wide range of biomass feedstocks with varying sizes, moisture contents, and compositions, making them suitable for diverse biomass-to-energy applications.

- Reduced Tar Formation: The turbulent and well-mixed environment in fluidized bed reactors minimizes tar formation and enhances tar cracking and reforming reactions, resulting in cleaner syngas production and reduced downstream cleanup requirements.

Fluidized bed gasification technology has demonstrated its effectiveness and reliability in converting biomass feedstocks into syngas for renewable energy production and waste valorization. Ongoing research and development efforts focused on reactor design optimization, process control, and syngas utilization are essential to further improve the performance and commercial viability of fluidized bed gasification systems for sustainable energy production.

Syngas Composition:

Syngas, short for synthesis gas, is a versatile mixture of gases primarily composed of hydrogen (H2) and carbon monoxide (CO), along with varying amounts of carbon dioxide (CO2), methane (CH4), water vapor (H2O), and other trace gases. The composition of syngas depends on several factors, including the type of biomass feedstock used, the gasification process employed, and the operating conditions of the gasifier. Understanding the composition of syngas is crucial for optimizing gasification processes, designing downstream utilization systems, and assessing the overall performance and environmental impact of biomass-to-energy conversion technologies.

The typical composition of syngas produced from biomass gasification can be summarized as follows:

- Hydrogen (H2): Hydrogen is a key component of syngas and is typically produced through the gasification reactions involving steam (H2O) and carbon (C) in the biomass feedstock. Hydrogen content in syngas can range from 10% to 50% by volume, depending on gasification conditions and feedstock characteristics. High hydrogen content enhances the energy density and combustion properties of syngas, making it suitable for various energy and chemical applications.

- Carbon Monoxide (CO): Carbon monoxide is another major component of syngas and is formed through the partial oxidation of carbonaceous materials in the biomass feedstock. CO content in syngas can range from 15% to 40% by volume and serves as a valuable intermediate for chemical synthesis, fuel production, and combustion processes. High CO content in syngas indicates efficient gasification and carbon conversion.

- Carbon Dioxide (CO2): Carbon dioxide is a byproduct of gasification reactions involving carbon oxidation and gas-phase combustion. CO2 content in syngas typically ranges from 10% to 30% by volume and depends on factors such as the amount of oxygen or air supplied to the gasifier and the degree of carbon conversion. CO2 can be captured and sequestered to reduce greenhouse gas emissions or utilized in various industrial processes.

- Methane (CH4): Methane is a minor component of syngas and is formed through secondary reactions such as methanation and tar reforming. CH4 content in syngas is usually less than 5% by volume but can be higher in gasification systems with low-temperature operation or high methane-forming potential. Methane can be utilized as a fuel or converted into higher-value products through catalytic processes.

- Water Vapor (H2O): Water vapor is present in syngas as a result of steam injection or moisture content in the biomass feedstock. H2O content in syngas varies depending on gasification conditions and can range from 5% to 30% by volume. Water vapor serves as a reactant in gasification reactions and affects the equilibrium composition of syngas.

- Trace Gases: Syngas may contain trace amounts of other gases such as nitrogen (N2), oxygen (O2), hydrogen sulfide (H2S), ammonia (NH3), and volatile organic compounds (VOCs) depending on feedstock composition and gasification conditions. Trace gases can impact syngas quality, combustion performance, and downstream utilization processes and may require removal or treatment for specific applications.

Understanding the composition of syngas is essential for optimizing gasification processes, designing syngas cleanup and conditioning systems, and selecting appropriate utilization pathways for energy production, biofuels synthesis, chemical manufacturing, and other industrial applications. Syngas composition analysis provides valuable insights into gasification performance, carbon conversion efficiency, energy content, and environmental impact, enabling informed decision-making and technology development in the field of biomass-to-energy conversion.

Syngas Cleanup:

Syngas cleanup is a crucial stage in the biomass gasification process that involves the removal or reduction of impurities and contaminants from the raw syngas produced in the gasifier. The cleanup process is essential to ensure the quality, purity, and stability of syngas for downstream utilization in power generation, biofuels production, chemical synthesis, and other industrial applications. Syngas cleanup technologies are designed to remove various impurities, including tar, particulates, sulfur compounds, ammonia, moisture, and trace contaminants, while maintaining the desired composition and properties of the syngas.

Several syngas cleanup technologies and methods are employed to achieve the desired syngas quality:

- Tar Removal: Tar, also known as volatile organic compounds (VOCs), is a complex mixture of hydrocarbons and aromatic compounds formed during biomass gasification. Tar can cause fouling, corrosion, and operational issues in downstream equipment and catalytic converters. Tar removal technologies include:

- Tar Cracking: Thermal or catalytic decomposition of tar molecules at elevated temperatures to break them down into simpler, less harmful compounds.

- Tar Filtration: Passage of syngas through ceramic or metallic filters to physically capture tar particles and condensable compounds.

- Catalytic Tar Reforming: Use of catalysts (e.g., nickel, cobalt, or alkali metals) to catalyze tar cracking reactions and promote the conversion of tar into syngas components.

- Particulate Removal: Particulates, such as ash, char, and fine dust particles, can be present in the raw syngas and can cause erosion, abrasion, and fouling in downstream equipment. Particulate removal technologies include:

- Cyclone Separators: Centrifugal separators that utilize centrifugal force to separate solid particles from the syngas stream based on their mass and size.

- Filter Beds: Porous filter media (e.g., ceramic, metallic, or fibrous materials) that trap and collect solid particles as syngas passes through them.

- Electrostatic Precipitators (ESP): Electrostatically charged plates or wires that attract and capture particulates through electrostatic forces.

- Desulfurization: Sulfur compounds, such as hydrogen sulfide (H2S) and sulfur dioxide (SO2), can be present in the raw syngas and can lead to corrosion, catalyst poisoning, and environmental emissions. Desulfurization technologies include:

- Hydrodesulfurization (HDS): Chemical reaction of sulfur compounds with hydrogen over a catalyst (e.g., cobalt-molybdenum) to convert them into hydrogen sulfide (H2S), which can be removed through scrubbing or adsorption.

- Adsorption: Use of adsorbent materials (e.g., activated carbon, metal oxides) to selectively adsorb sulfur compounds from the syngas stream.

- Ammonia Scrubbing: Ammonia (NH3) can be present in the syngas as a result of nitrogen-containing compounds in the biomass feedstock or as a byproduct of gasification reactions. Ammonia can cause corrosion, catalyst deactivation, and environmental emissions. Ammonia scrubbing technologies involve:

- Wet Scrubbing: Contacting the syngas stream with an aqueous solution (e.g., water or amine solution) to absorb ammonia and form ammonium salts, which can be separated from the liquid phase.

- Moisture Removal: Water vapor (H2O) present in the syngas stream can condense and cause corrosion, reduce heating value, and affect downstream processes. Moisture removal technologies include:

- Cooling and Condensation: Cooling the syngas stream to below its dew point to condense water vapor, followed by separation and removal of the liquid water.

- Absorption: Contacting the syngas stream with a desiccant material (e.g., glycol, silica gel) to selectively absorb water vapor and remove it from the gas stream.

Syngas cleanup is essential for ensuring the efficient and reliable operation of biomass gasification systems and maximizing the performance and environmental benefits of syngas utilization. The selection of syngas cleanup technologies depends on factors such as feedstock composition, gasifier design, syngas quality requirements, and specific application needs. Ongoing research and development efforts are focused on improving the efficiency, reliability, and cost-effectiveness of syngas cleanup technologies to enable the widespread adoption of biomass-to-energy conversion technologies and accelerate the transition to a more sustainable and low-carbon energy system.

Syngas Conditioning:

Syngas conditioning is a critical stage in the biomass gasification process that involves the adjustment and optimization of the composition, temperature, pressure, and cleanliness of the raw syngas produced in the gasifier to meet specific process requirements and maximize its utilization in downstream applications. Syngas conditioning aims to improve syngas quality, stability, and compatibility with various end-use technologies, such as power generation, biofuels production, chemical synthesis, and industrial applications.

Key aspects of syngas conditioning include:

- Gas Composition Adjustment: The composition of raw syngas produced in the gasifier may need to be adjusted to meet the requirements of downstream processes or applications. This may involve modifying the ratios of hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and other gases in the syngas through catalytic conversion, gas separation, or chemical reactions.

- Tar and Particulate Removal: Raw syngas may contain impurities such as tar, particulates, ash, and contaminants that can interfere with downstream equipment and processes. Syngas conditioning includes tar cracking, particulate removal, and scrubbing to reduce impurity levels and ensure the cleanliness of the syngas stream.

- Temperature Adjustment: The temperature of raw syngas from the gasifier may be too high or too low for certain downstream applications. Syngas conditioning involves cooling or heating the syngas to the desired temperature range using heat exchangers, cooling towers, or direct combustion of syngas.

- Pressure Adjustment: Syngas pressure may need to be adjusted to match the pressure requirements of downstream equipment or processes. Pressure adjustment can be achieved through compression or expansion of the syngas using compressors, expanders, or pressure-reducing valves.

- Moisture Removal: Water vapor (H2O) present in raw syngas can condense and cause corrosion, reduce heating value, and affect downstream processes. Syngas conditioning includes moisture removal through cooling and condensation or absorption using desiccants to ensure the dryness of the syngas stream.

- Gas Purification: Syngas conditioning may involve additional purification steps to remove trace contaminants, sulfur compounds, ammonia, and other impurities that can affect downstream processes or product quality. Gas purification technologies include adsorption, absorption, chemical scrubbing, and catalytic conversion.

Syngas conditioning technologies and methods vary depending on the specific requirements of the gasification process and the intended applications of the syngas. Advanced syngas conditioning systems may incorporate multiple stages of purification, temperature and pressure control, and gas composition adjustment to achieve the desired syngas quality and performance. Optimization of syngas conditioning processes is essential to ensure the efficient and reliable operation of biomass gasification systems and maximize the economic and environmental benefits of syngas utilization. Ongoing research and development efforts are focused on improving syngas conditioning technologies, reducing costs, and enhancing the overall efficiency and sustainability of biomass-to-energy conversion processes.

Syngas Utilization:

Syngas, short for synthesis gas, is a versatile mixture of gases primarily composed of hydrogen (H2) and carbon monoxide (CO), along with varying amounts of carbon dioxide (CO2), methane (CH4), and other trace gases. Syngas produced from biomass gasification processes can be utilized in a wide range of applications across various industries, including power generation, biofuels production, chemical synthesis, and industrial processes. Syngas utilization offers several advantages, including energy diversification, resource efficiency, greenhouse gas reduction, and waste valorization.

Key pathways for syngas utilization include:

- Power Generation:Syngas can be combusted in gas turbines, reciprocating engines, or fuel cells to generate electricity. Gasification-based power generation offers high efficiency and flexibility, allowing for the use of diverse feedstocks and the integration of combined heat and power (CHP) systems to maximize energy recovery and utilization.

- Combined Heat and Power (CHP):Syngas can be used for combined heat and power applications, where waste heat from electricity generation is captured and utilized for heating, cooling, or industrial processes. CHP systems maximize energy efficiency and resource utilization, reducing overall energy consumption and emissions.

- Biofuels Production:Syngas serves as a feedstock for the production of biofuels such as ethanol, methanol, biodiesel, and synthetic diesel through catalytic processes such as Fischer-Tropsch synthesis or methanol synthesis. Biofuels produced from syngas offer renewable alternatives to fossil fuels, with lower greenhouse gas emissions and reduced dependence on imported oil.

- Chemical Synthesis:Syngas is a key precursor for the synthesis of various chemicals and industrial products, including ammonia, methanol, hydrogen, synthetic natural gas (SNG), and higher alcohols. Chemical synthesis pathways such as ammonia synthesis, methanol synthesis, and hydrocarbon synthesis utilize syngas as a building block for manufacturing a wide range of value-added products.

- Hydrogen Production:Syngas can be converted into hydrogen (H2) through water-gas shift (WGS) reactions or steam reforming processes. Hydrogen produced from syngas serves as a clean and versatile energy carrier for fuel cell vehicles, industrial processes, and chemical manufacturing.

- Synthetic Natural Gas (SNG) Production:Syngas can be upgraded into synthetic natural gas (SNG) through methanation reactions, where CO and H2 are catalytically converted into methane (CH4) and water vapor (H2O). SNG can be injected into natural gas pipelines or used as a transportation fuel.

- Industrial Applications:Syngas can be utilized in various industrial processes such as heat treatment, metal smelting, glass manufacturing, and chemical production. Syngas-based industrial processes offer energy-efficient and environmentally sustainable alternatives to conventional fossil fuel-based technologies.

Syngas utilization plays a crucial role in the transition to a more sustainable and low-carbon energy system by enabling the efficient and environmentally responsible conversion of biomass feedstocks into clean and renewable energy, fuels, and chemicals. Continued research, development, and deployment efforts are essential to advance syngas utilization technologies, improve process efficiency, reduce costs, and enhance the commercial viability of biomass-to-energy conversion systems. Collaboration between industry, academia, and government stakeholders is key to accelerating the adoption of syngas utilization technologies and achieving global energy and climate goals.

Gasification Reactor Design:

Gasification reactor design plays a crucial role in the performance, efficiency, and reliability of biomass gasification processes for the production of syngas. The design of the gasification reactor influences factors such as gasification efficiency, residence time, temperature distribution, heat transfer, feedstock compatibility, tar reduction, and syngas quality. Various types of gasification reactors are employed in biomass gasification systems, each with its own advantages, limitations, and suitability for different feedstocks and applications.

- Fixed-Bed Gasifier:

- In a fixed-bed gasifier, biomass feedstock is fed into a stationary reactor bed, typically filled with a bed of inert material (e.g., sand, char, or ceramic beads).

- Gasification reactions occur as the biomass moves downward through the reactor bed, undergoing pyrolysis, oxidation, and gasification.

- Fixed-bed gasifiers offer simplicity, reliability, and scalability, making them suitable for small-scale and decentralized biomass gasification applications.

- However, fixed-bed gasifiers may suffer from limited heat transfer, uneven temperature distribution, and bed agglomeration issues, particularly with high-moisture or high-ash feedstocks.

- Fluidized Bed Gasifier:

- In a fluidized bed gasifier, biomass feedstock is suspended and fluidized by a stream of gas (e.g., air, oxygen, steam) flowing upward through the reactor bed.

- The fluidized bed of biomass particles promotes excellent mixing, heat transfer, and gas-solid contact, leading to efficient gasification reactions.

- Fluidized bed gasifiers offer high gasification efficiency, uniform temperature distribution, and tolerance to variations in feedstock size, moisture content, and composition.

- However, fluidized bed gasifiers may require complex gas-solid separation systems, have higher operating costs, and may be prone to erosion and abrasion of reactor components.

- Entrained-Flow Gasifier:

- In an entrained-flow gasifier, finely ground biomass feedstock is entrained by a high-velocity stream of gas (e.g., oxygen, steam) and injected into a reaction chamber.

- Gasification reactions occur in a turbulent, high-temperature environment, resulting in rapid conversion of biomass into syngas.

- Entrained-flow gasifiers offer high gasification rates, high thermal efficiency, and flexibility in feedstock selection.

- However, entrained-flow gasifiers require robust refractory materials, precise control of gas flow and temperature, and may produce tar and particulate emissions that require downstream cleanup.

- Hybrid Gasifier:

- Hybrid gasifiers combine features of different gasification reactor types to leverage their respective advantages and overcome limitations.

- For example, hybrid gasifiers may combine a fixed-bed or fluidized bed for biomass pyrolysis and partial oxidation with an entrained-flow reactor for complete gasification of char and tar.

- Hybrid gasifiers aim to achieve high gasification efficiency, improved tar reduction, and enhanced process flexibility for a wide range of feedstocks and applications.

Gasification reactor design considerations include reactor geometry, size, shape, configuration, material selection, insulation, heating methods, gas distribution, mixing, residence time, and process control strategies. Advanced computational modeling, simulation, and experimental testing techniques are employed to optimize gasification reactor designs and improve performance, reliability, and cost-effectiveness. Ongoing research and development efforts are focused on advancing gasification reactor technologies, enhancing process efficiency, reducing emissions, and enabling the widespread adoption of biomass-to-energy conversion systems for sustainable energy production.

Syngas Tar Removal:

Syngas tar removal is a critical process in biomass gasification systems aimed at reducing the concentration of tar compounds in the raw syngas stream. Tar, also known as volatile organic compounds (VOCs), is a complex mixture of hydrocarbons and aromatic compounds produced during the pyrolysis and thermal decomposition of biomass feedstocks. Tar compounds can cause fouling, corrosion, and operational issues in downstream equipment and catalysts, leading to reduced efficiency and reliability of syngas utilization processes.

Several methods and technologies are employed for syngas tar removal:

- Tar Cracking:

- Tar cracking involves the thermal or catalytic decomposition of tar molecules at elevated temperatures to break them down into simpler, less harmful compounds.

- Thermal tar cracking occurs naturally at high temperatures (> 800°C) in the gasification reactor and downstream equipment, promoting the conversion of tar into syngas components (e.g., CO, H2, CH4).

- Catalytic tar cracking utilizes catalyst materials (e.g., nickel, cobalt, alkali metals) to accelerate tar decomposition reactions and enhance tar conversion efficiency at lower temperatures.

- Tar Filtration:

- Tar filtration involves passing the raw syngas stream through porous filter media (e.g., ceramic or metallic filters) to physically capture and remove tar particles and condensable compounds.

- Filter beds can be designed with different pore sizes and configurations to efficiently trap tar particles while allowing syngas to pass through.

- Tar filtration is effective for removing coarse tar particles but may require periodic cleaning or replacement of filter elements to maintain optimal performance.

- Catalytic Tar Reforming:

- Catalytic tar reforming utilizes catalysts to promote the cracking and reforming of tar molecules into simpler hydrocarbons and syngas components.

- Reforming reactions occur at lower temperatures and with higher selectivity compared to thermal cracking, reducing energy consumption and minimizing the formation of undesirable byproducts.

- Catalyst materials and reactor configurations are optimized to maximize tar conversion efficiency and minimize catalyst deactivation due to fouling or poisoning.

- Tar Scrubbing:

- Tar scrubbing involves contacting the raw syngas stream with a liquid scrubbing solution to absorb tar compounds and condensable vapors.

- Scrubbing solutions may include water, oil, solvents, or chemical additives that selectively dissolve tar components and separate them from the syngas stream.

- Tar scrubbing can effectively remove tar contaminants but may require additional downstream processing steps to recover and recycle the scrubbing solution.

- Tar Decomposition Catalysts:

- Tar decomposition catalysts are specifically designed catalyst materials that promote the cracking and reforming of tar compounds into lighter hydrocarbons and syngas components.

- Catalysts can be deployed in various configurations, including fixed-bed reactors, fluidized bed reactors, or integrated into gasification reactor systems.

- Tar decomposition catalysts enhance tar conversion efficiency, reduce tar emissions, and improve the overall performance of biomass gasification processes.

Syngas tar removal technologies are essential for ensuring the reliability, efficiency, and environmental sustainability of biomass gasification systems. Effective tar removal minimizes the risk of equipment fouling, improves syngas quality, and enhances the economic viability of syngas utilization pathways for power generation, biofuels production, chemical synthesis, and industrial applications. Ongoing research and development efforts are focused on advancing tar removal technologies, optimizing process integration, and reducing costs to enable the widespread adoption of biomass-to-energy conversion systems for sustainable energy production.

Gasification

Gasification is a thermochemical conversion process that transforms carbon-containing feedstocks, such as biomass, coal, or waste materials, into a gaseous mixture known as syngas or synthesis gas. This process occurs under controlled conditions of temperature, pressure, and oxygen supply, typically in the absence of complete combustion. Gasification represents a versatile and efficient approach to convert diverse feedstocks into a valuable energy carrier with numerous applications.

The gasification process involves several key steps:

- Feedstock Preparation: The feedstock, which can range from wood chips and agricultural residues to coal and municipal solid waste, undergoes pretreatment to achieve the desired size, moisture content, and composition. This may involve drying, shredding, or pelletizing the feedstock to enhance its suitability for gasification.

- Gasification Reaction: The prepared feedstock is introduced into the gasification reactor, where it undergoes chemical reactions in the presence of a controlled amount of oxygen, steam, or a combination of both. These reactions typically include pyrolysis (thermal decomposition), combustion (partial oxidation), and gasification (conversion of carbon to syngas constituents).

- Syngas Production: The primary product of the gasification process is syngas, a mixture of hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), and other trace gases. The composition of syngas depends on factors such as the feedstock type, gasification temperature, residence time, and gasification agent.

- Tar and Particulate Removal: During gasification, tar compounds and particulate matter may be formed as byproducts of incomplete combustion and thermal decomposition. These impurities can foul equipment, reduce gas quality, and pose environmental and health risks. Therefore, syngas undergoes purification steps, such as tar cracking, filtration, or scrubbing, to remove these contaminants and improve syngas quality.

- Syngas Utilization: The produced syngas can be utilized in various applications, including power generation, biofuels production, chemical synthesis, and industrial processes. Depending on the specific requirements and desired end products, syngas may undergo further processing, such as catalytic conversion, reforming, or upgrading, to tailor its composition and properties for different applications.

Gasification offers several advantages compared to conventional combustion-based technologies:

- Fuel Flexibility: Gasification can utilize a wide range of feedstocks, including biomass, coal, municipal solid waste, and industrial residues, providing flexibility and resilience in energy supply.

- Energy Efficiency: Gasification processes can achieve high energy conversion efficiencies, especially when integrated with combined heat and power (CHP) systems, where waste heat is utilized for heating or industrial processes.

- Emissions Reduction: Gasification can produce syngas with lower emissions of greenhouse gases, particulates, and sulfur compounds compared to conventional combustion processes, contributing to environmental sustainability and air quality improvement.

- Resource Recovery: Gasification facilitates the recovery of energy and valuable byproducts from waste materials, promoting resource conservation and waste valorization.

Gasification technology continues to evolve with ongoing research and development efforts aimed at improving efficiency, reducing costs, and expanding the range of feedstocks and applications. The versatility, efficiency, and environmental benefits of gasification make it a promising technology for sustainable energy production and resource management in the transition towards a low-carbon economy.

Biomass