Steam Engines in Marine Transport and Shipping: A steam engine is a heat engine that performs mechanical work using steam as its working fluid. It was one of the key technologies driving the Industrial Revolution and laid the groundwork for modern mechanical engineering and thermodynamics.

Basic Working Principle

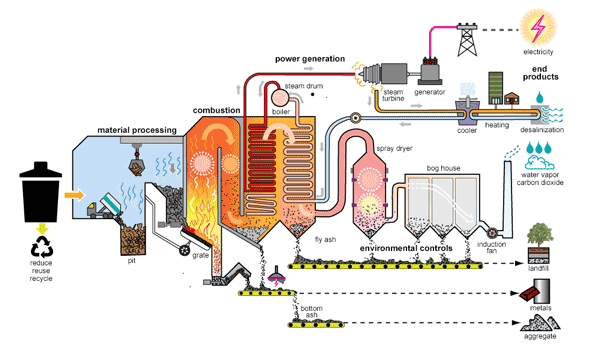

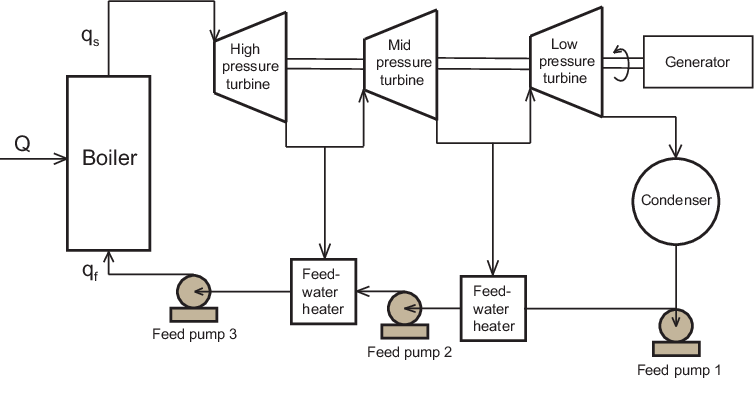

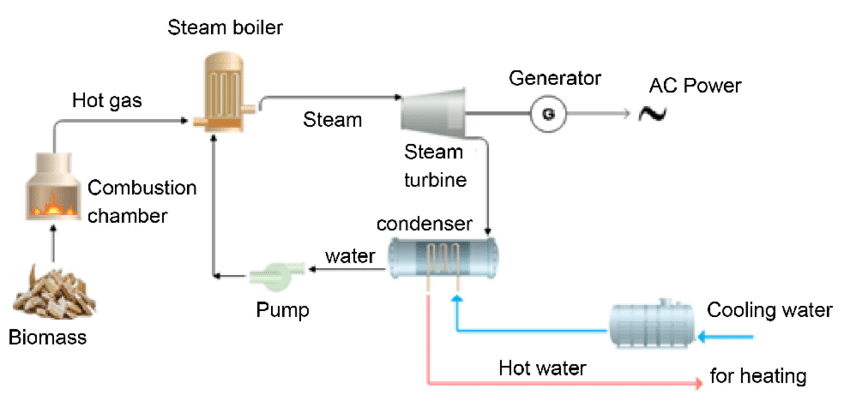

Steam engines operate on the Rankine cycle, where water is heated to create steam, which expands to perform mechanical work, and is then condensed back into water.

Key Steps:

- Boiling Water: Heat is applied to water in a boiler, producing high-pressure steam.

- Steam Expansion: Steam enters the engine’s cylinder or turbine, pushing a piston or turning a shaft.

- Exhaust and Condensation: The steam is then exhausted and typically condensed for reuse.

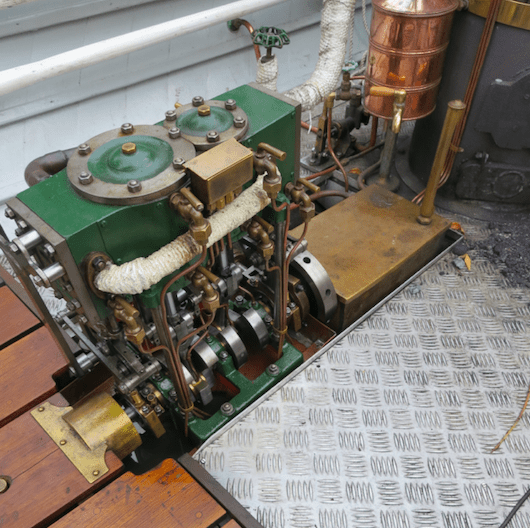

Main Components

- Boiler: Heats water to produce steam.

- Cylinder & Piston (or Turbine Blades): Where the steam does mechanical work.

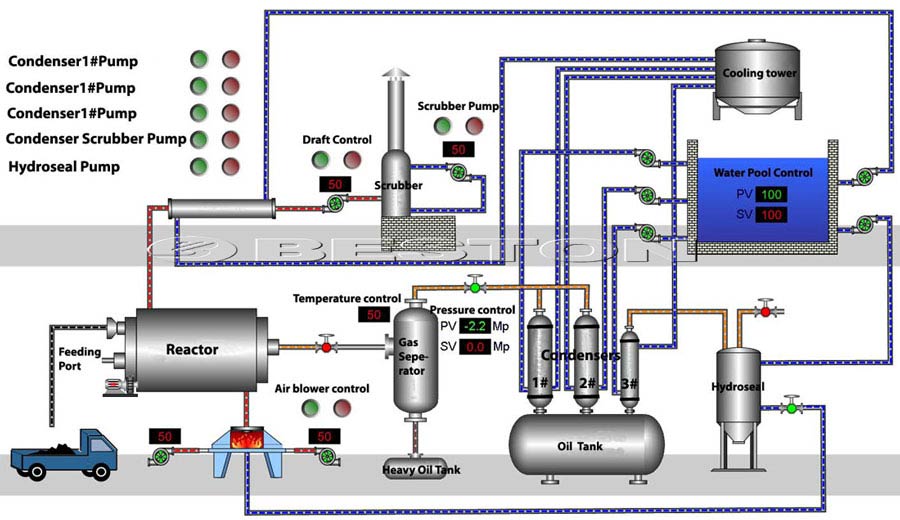

- Condenser: Cools exhaust steam to water for reuse.

- Flywheel: Regulates engine speed and smooths power output.

- Valve Gear: Controls steam admission and exhaust.

Types of Steam Engines

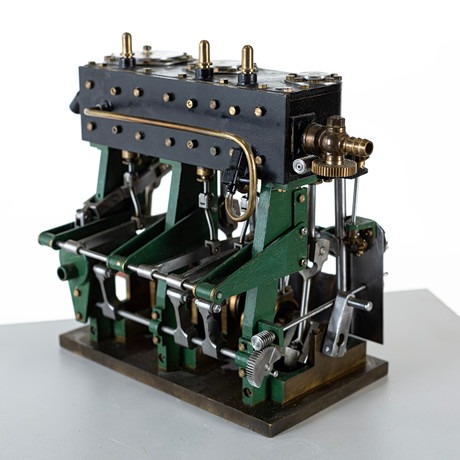

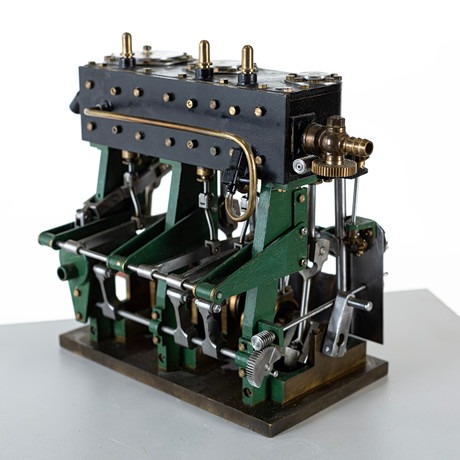

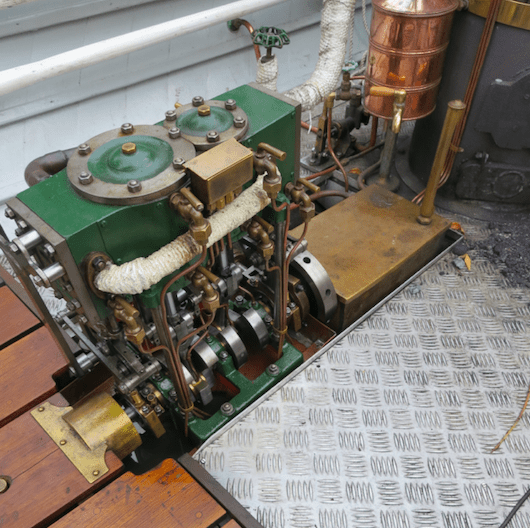

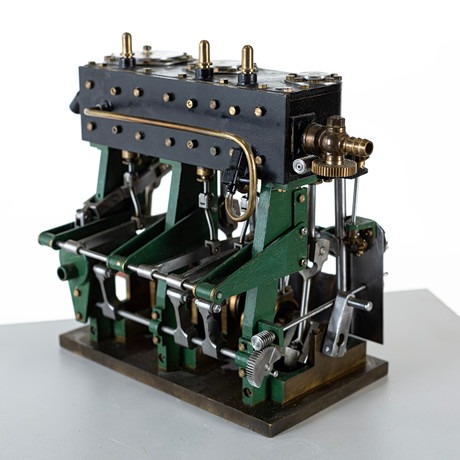

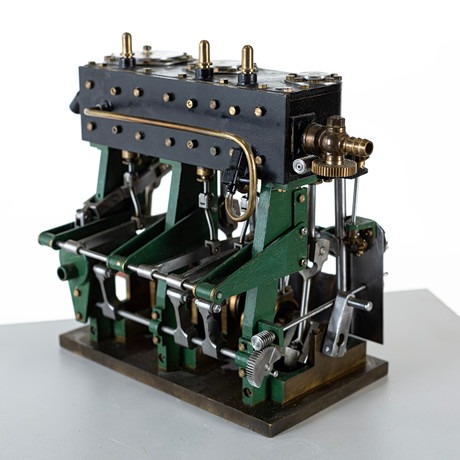

a. Reciprocating Steam Engines

- Use pistons moving in cylinders.

- Common in early locomotives and stationary engines.

b. Steam Turbines

- Steam turns a rotor with blades.

- More efficient; used in power plants and ships.

c. Condensing vs. Non-Condensing

- Condensing Engines: Use condensers to improve efficiency.

- Non-Condensing (Back-Pressure) Engines: Exhaust steam is used for heating or industrial processes.

Historical Context

- 1712: Thomas Newcomen builds the first practical steam engine.

- 1769: James Watt improves efficiency with a separate condenser and rotary motion.

- 1800s: Steam powers factories, trains, ships, and early cars.

Advantages

- High torque at low speeds.

- Can use various heat sources (coal, biomass, nuclear, etc.).

- Suitable for large-scale power generation.

Limitations

- Lower efficiency compared to internal combustion engines or electric motors.

- High maintenance requirements.

- Bulky and heavy, especially reciprocating types.

Modern Applications

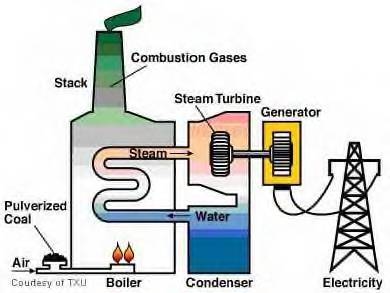

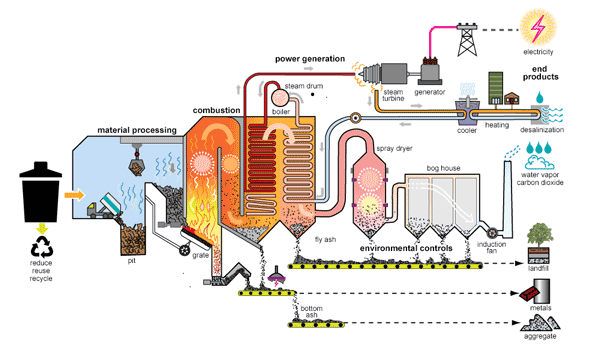

- Power Plants: Steam turbines generate most of the world’s electricity.

- Cogeneration Systems: Use back-pressure turbines for both electricity and process heat.

- Historic and Niche Uses: Steam locomotives (tourism), hobby engines, and educational purposes.

Recent Innovations

- Supercritical Steam Technology: Operates at higher pressures and temperatures for greater efficiency.

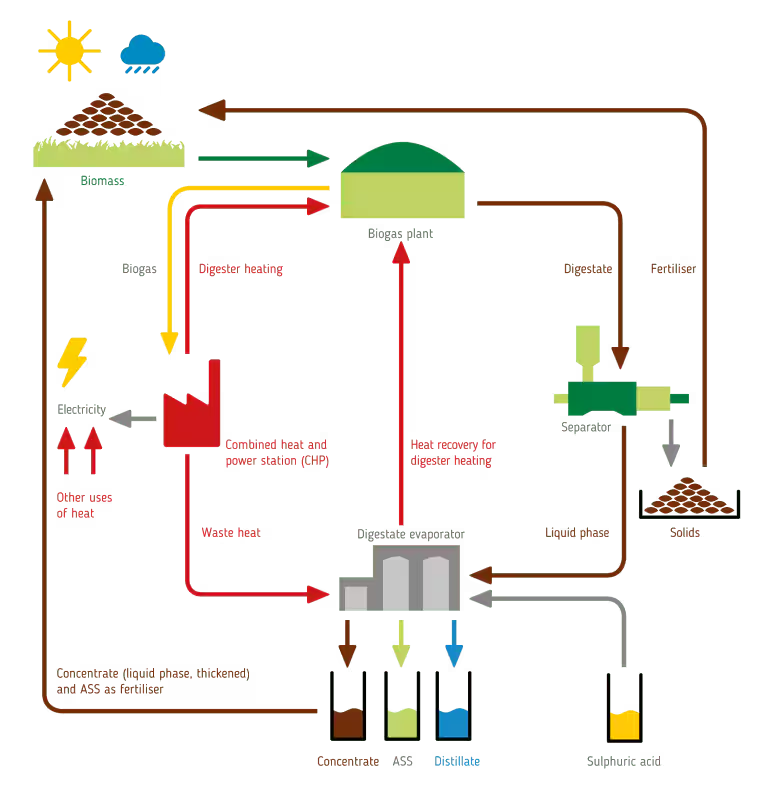

- Combined Heat and Power (CHP): Systems recover and use waste heat.

- Solar Thermal Plants: Use mirrors to heat water into steam.

Steam engines are heat engines that convert thermal energy from steam into mechanical work. They played a pivotal role during the Industrial Revolution, transforming industries, transportation, and manufacturing by providing a reliable and powerful source of energy. The fundamental principle behind a steam engine is the Rankine cycle. In this cycle, water is heated in a boiler to produce high-pressure steam. This steam then expands and pushes against mechanical components—typically pistons in early engines or turbine blades in modern ones—causing motion. After the steam has done its work, it is exhausted and, in many systems, condensed back into water to be reused.

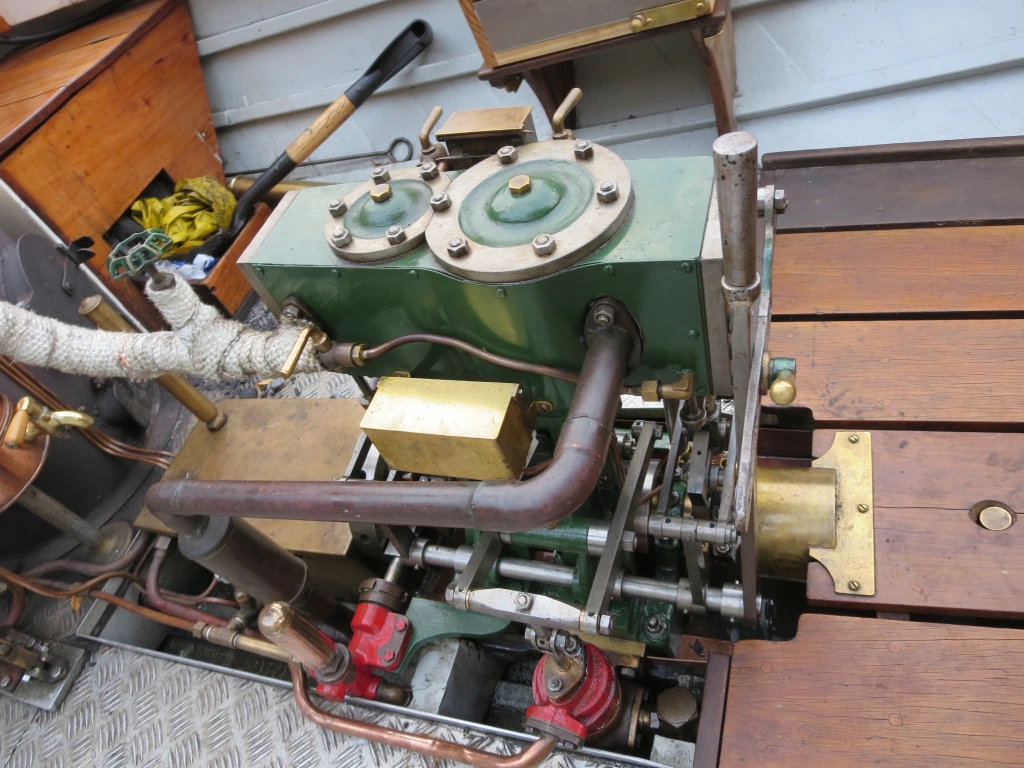

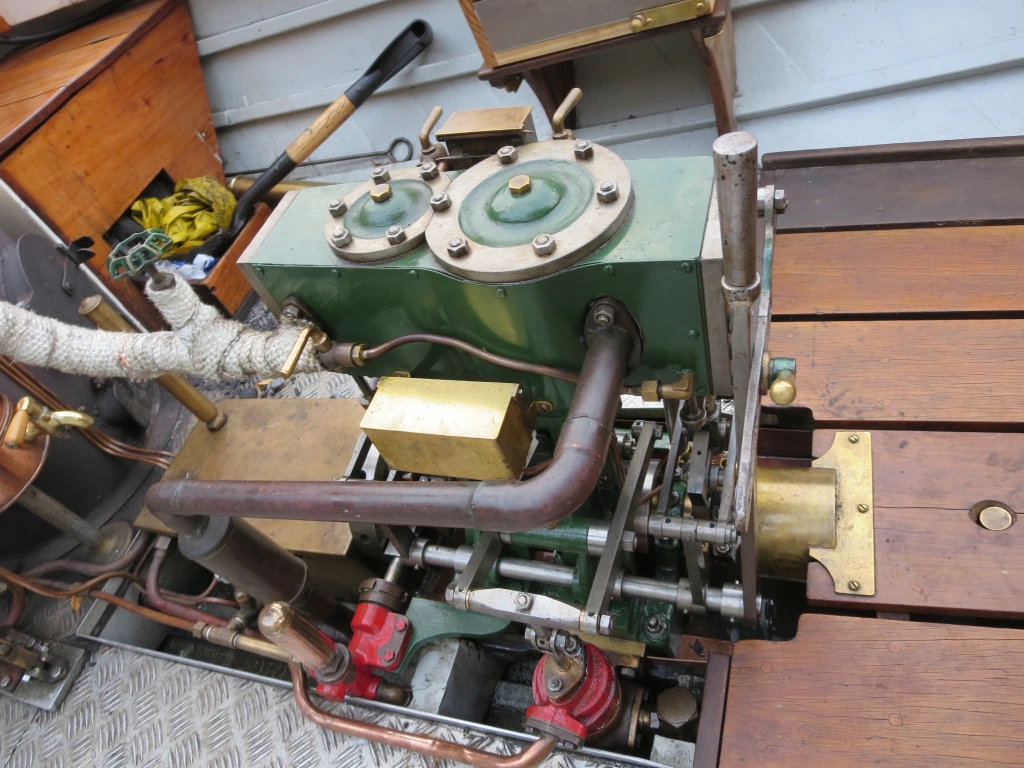

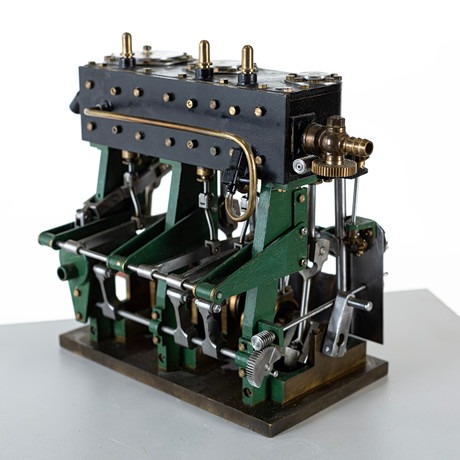

The earliest steam engines were reciprocating engines, where steam pushed a piston back and forth within a cylinder. These pistons were connected to a crankshaft, converting linear motion into rotary motion suitable for driving machinery or wheels. James Watt made significant improvements to this design in the 18th century, including the addition of a separate condenser and the development of rotary motion capability, which greatly increased efficiency and utility.

As technology progressed, steam turbines became more prominent, especially in power generation. Unlike reciprocating engines, steam turbines use high-pressure steam to spin a rotor with attached blades. This method is smoother, more efficient, and better suited for continuous power production. Today, steam turbines remain central to electricity generation, particularly in thermal power plants that use fossil fuels, nuclear energy, or solar thermal energy.

Steam engines consist of several critical components: the boiler, which heats water; the cylinder or turbine, where steam does mechanical work; the condenser, which recaptures steam as water; and the valve gear, which controls the flow of steam. Flywheels and governors are used to regulate speed and maintain consistent operation.

There are two main categories of steam engines—condensing and non-condensing. Condensing engines use a condenser to create a vacuum that improves efficiency by lowering the exhaust pressure. Non-condensing engines, also known as back-pressure engines, exhaust steam at a pressure above atmospheric and are often used where the exhaust steam’s heat can be recovered for other purposes like heating or drying in industrial processes.

Despite their historical importance, steam engines have been largely replaced in transportation and small-scale applications by internal combustion engines and electric motors. However, they remain vital in large-scale power generation. Innovations such as supercritical and ultra-supercritical steam cycles have significantly improved efficiency by operating at higher temperatures and pressures. Additionally, combined heat and power systems and solar thermal technologies continue to use steam as a versatile and effective energy carrier.

Steam engine technology, though centuries old, remains a cornerstone of modern energy systems, evolving with new materials and engineering techniques to meet today’s energy challenges.

Steam engine technology is based on converting heat energy from steam into mechanical work. At its core, the system operates by heating water in a boiler to create steam, which then expands and exerts pressure. This pressurized steam is directed into a cylinder or turbine, where it pushes a piston or spins a rotor, creating motion that can be used to power machinery, vehicles, or generators. Once the steam has done its work, it is released—either into the atmosphere in simple systems or into a condenser where it’s cooled and turned back into water for reuse in more efficient setups.

The earliest practical steam engines were developed in the early 18th century, with Thomas Newcomen’s atmospheric engine being among the first. James Watt later introduced key improvements like the separate condenser and rotary motion, making steam engines more efficient and adaptable to industrial needs. These innovations allowed steam power to become the driving force behind the Industrial Revolution, revolutionizing manufacturing, mining, and transportation.

There are two main types of steam engines: reciprocating and turbine-based. Reciprocating engines use pistons that move back and forth, while turbines use high-speed rotating blades. Turbines are generally more efficient and are the standard in modern power plants. Depending on how steam is handled after expansion, steam engines can also be categorized as condensing or non-condensing. Condensing engines reuse steam by converting it back to water, improving efficiency. Non-condensing engines (also called back-pressure engines) release steam for heating or other industrial uses.

Steam engine systems include several key components: the boiler to generate steam, the engine or turbine to convert pressure into motion, a condenser (in closed-loop systems) to turn steam back into water, and various control mechanisms like valves, governors, and regulators to manage flow, pressure, and speed. Over time, these systems have been refined to handle higher pressures and temperatures, leading to better performance and lower fuel consumption.

Even though steam engines are no longer common in vehicles or small-scale use, they remain essential in power generation. Modern thermal power plants, whether fueled by coal, natural gas, nuclear reactions, or solar heat, often use steam turbines to generate electricity. Advances such as supercritical and ultra-supercritical steam cycles allow these plants to operate at higher efficiencies by using higher temperatures and pressures.

Steam technology also plays a role in cogeneration (combined heat and power systems), where steam produced for electricity generation is also used for industrial processes or space heating. In renewable energy, solar thermal power plants use concentrated sunlight to produce steam, offering a clean, sustainable alternative to fossil fuels.

In essence, steam engine technology is a foundational element of industrial engineering, and while its role has shifted, it continues to evolve and support critical infrastructure around the world.

Innovative Steam Engine Designs for Modern Applications

Innovative steam engine designs for modern applications focus on enhancing efficiency, sustainability, and versatility. While traditional steam engines laid the foundation for industrialization, contemporary designs adapt the core principles to meet current energy demands and environmental standards.

Modern steam engines are being reimagined with advanced materials, precision engineering, and integration into hybrid and renewable systems. One area of innovation is supercritical and ultra-supercritical steam cycles, which operate at temperatures and pressures beyond the critical point of water. These systems dramatically increase thermal efficiency in power plants, often exceeding 45%, and are commonly used in coal and nuclear power generation. Their advanced metallurgy and heat-resistant components allow for sustained operation under extreme conditions.

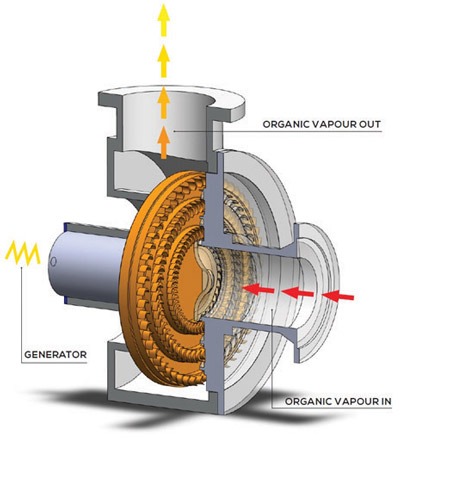

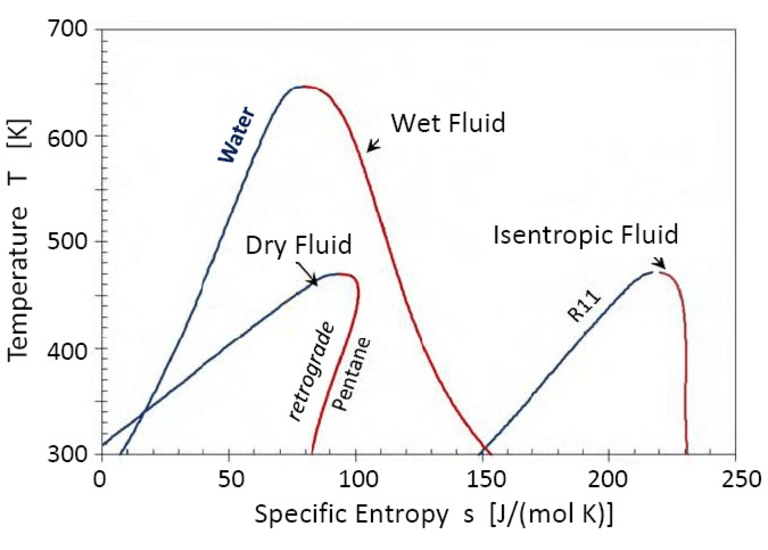

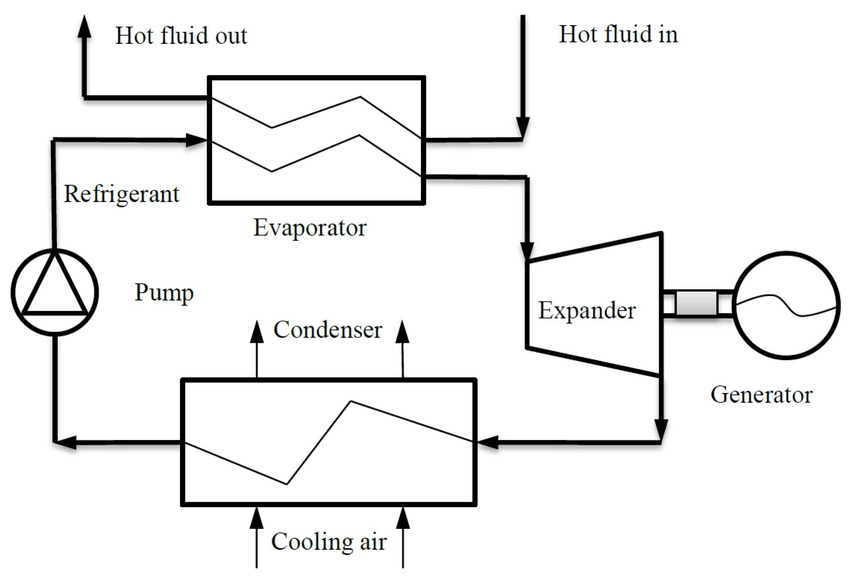

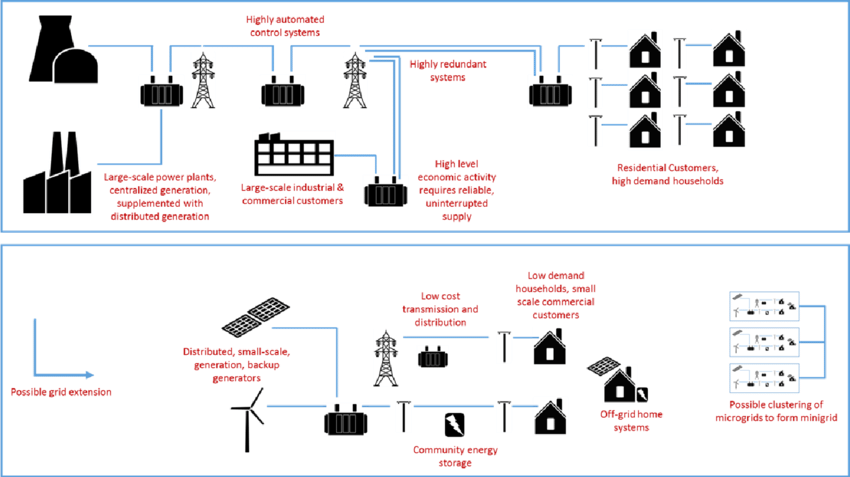

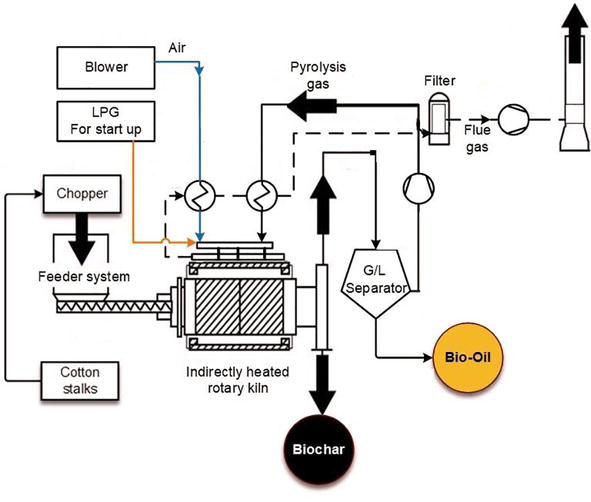

Compact steam engines are another area of exploration, especially in off-grid and portable energy systems. Small-scale steam engines designed for biomass or solar thermal inputs are being tested for rural electrification and micro-grid setups. These engines use organic Rankine cycles (ORC), where organic fluids with lower boiling points than water allow energy recovery from low-grade heat sources, such as industrial waste heat or geothermal energy. ORC-based engines can generate electricity where conventional systems would be inefficient or unfeasible.

Waste heat recovery steam engines are increasingly popular in industrial environments. These systems capture residual heat from manufacturing, internal combustion engines, or other thermal processes to generate steam and produce additional electricity. By converting otherwise lost energy into usable power, these systems reduce fuel consumption and emissions, contributing to sustainability goals.

In transportation, while steam power is largely obsolete in mainstream vehicles, niche applications are seeing a resurgence. Engineers and enthusiasts have developed modern steam-powered cars and motorcycles with closed-loop systems, rapid-start boilers, and computer-controlled valve timing. These prototypes often run on cleaner fuels and promise quiet operation, high torque, and reduced emissions, although they remain largely experimental.

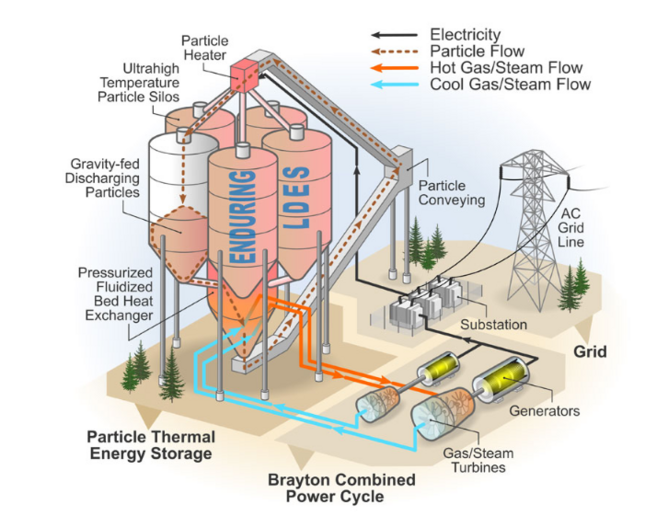

Innovative designs also explore solar steam engines, which use concentrated solar power (CSP) systems to heat water and generate steam. These engines are used in regions with high solar irradiance for decentralized power generation and desalination. Some systems store thermal energy in molten salts, allowing for electricity production even after sunset—a key advantage over photovoltaic solar.

Another forward-thinking approach involves combined heat and power (CHP) systems using back-pressure steam turbines. These setups generate electricity while simultaneously providing steam or hot water for industrial processes, district heating, or building climate control. By utilizing the full energy content of the fuel, CHP systems can achieve efficiencies up to 80%.

Material science is also contributing to innovation. The development of ceramic coatings, corrosion-resistant alloys, and nano-structured surfaces helps steam engines operate at higher pressures and temperatures with reduced wear. Precision control systems and digital monitoring further enhance reliability, safety, and performance.

Although internal combustion engines and electric motors dominate most sectors, innovative steam engine designs still offer unique advantages in specific applications—especially where heat is abundant or where integrated thermal-electric solutions are needed. As the world shifts toward cleaner energy, steam technology, reinvented through modern engineering, continues to play a relevant and adaptive role.

Innovative steam engine designs today are reshaping how we think about this centuries-old technology by integrating modern materials, precision control, and alternative energy sources. Unlike the bulky and maintenance-heavy engines of the past, current designs are compact, efficient, and often tailored for specific roles in energy systems that prioritize sustainability and resource optimization. One of the most significant advances comes from the use of supercritical and ultra-supercritical steam cycles in power plants. These systems push water past its critical point, allowing for significantly higher efficiencies compared to traditional steam cycles. They operate at extreme temperatures and pressures, made possible through advances in metallurgy and thermal management, making them central to modern coal, gas, and nuclear plants striving to minimize fuel consumption and carbon emissions.

At smaller scales, engineers are developing steam engines for decentralized energy production, particularly in rural or off-grid areas. These compact engines often run on biomass or solar heat and are designed to generate electricity and useful thermal energy simultaneously. By using the organic Rankine cycle, which employs fluids with lower boiling points than water, these systems can extract energy from relatively low-temperature heat sources—such as industrial waste heat, geothermal sources, or solar collectors—turning otherwise wasted heat into productive power. The flexibility of these systems makes them ideal for remote communities, agricultural applications, or industrial facilities looking to improve energy efficiency and reduce reliance on fossil fuels.

In industrial settings, the concept of waste heat recovery has become a major driver of innovation in steam technology. Instead of allowing heat from engines, furnaces, or other processes to dissipate, new steam engine systems capture and convert it into usable energy. These setups not only enhance overall efficiency but also contribute to lower greenhouse gas emissions by making the most out of every unit of fuel. Some systems are even designed to retro-fit existing plants, offering a cost-effective path to greater energy sustainability.

While steam has largely disappeared from modern vehicles, enthusiasts and engineers continue to explore advanced steam-powered transportation. Some experimental cars and motorcycles now incorporate flash boilers, closed-loop systems, and digital controls, allowing for rapid startup times and precise steam flow management. These vehicles produce high torque with smooth, quiet operation and have potential niche uses in areas where emissions and noise are critical concerns. Though not likely to replace internal combustion or electric engines broadly, they highlight how steam can still compete when designed with today’s tools and expectations.

Another area of growth lies in solar thermal applications. Solar steam engines harness the power of concentrated sunlight to produce steam for electricity generation, water purification, or heating. Some systems use parabolic mirrors or heliostats to focus sunlight onto a central receiver, where water is heated to generate steam. With thermal storage mediums like molten salt, these plants can operate even when the sun isn’t shining, addressing the intermittency that plagues other renewable sources. This makes them especially useful in sunny regions where grid infrastructure is limited or where reliable clean energy is needed.

The integration of modern materials such as advanced ceramics, corrosion-resistant alloys, and nanostructured surfaces has greatly improved the durability and thermal performance of steam engine components. These materials can withstand the high temperatures and pressures necessary for modern applications while reducing maintenance needs and extending service life. Alongside this, computerized control systems have become standard in new designs, allowing real-time monitoring of pressure, temperature, flow rates, and efficiency metrics. Automation ensures optimal operation, safety, and adaptability to changing conditions, whether in a power plant or a micro-generator.

Altogether, steam engine innovation today reflects a blend of old principles and new possibilities. While it may not dominate headlines, this quiet reinvention continues to influence sectors ranging from renewable energy to industrial sustainability. As global demand for cleaner and more efficient energy grows, modern steam technology—refined, repurposed, and reinvented—remains an essential part of the solution.

As the world pivots toward sustainable and efficient energy solutions, steam technology continues to evolve in ways that complement modern environmental goals. A major trend is the development of hybrid systems, where steam engines are integrated with renewable energy sources like wind, solar, and geothermal. For example, some solar thermal power plants use steam engines not just for electricity generation but also for thermal storage, enabling 24/7 operation. The stored heat from the day is converted into steam and used to generate power during the night or on cloudy days, solving the intermittency issue that affects other renewable sources like solar and wind.

In industrial applications, steam engines are increasingly part of combined heat and power (CHP) systems, where the same steam is used for both generating electricity and providing heat to nearby facilities or homes. This dual-use approach enhances overall efficiency, often achieving efficiencies upwards of 80%, compared to the 30-40% typical of separate electricity and heating systems. It’s especially relevant in sectors like manufacturing, where excess heat is a byproduct of production processes that would otherwise go to waste. By capturing this heat and converting it into useful power, these systems help reduce both fuel consumption and environmental impact.

Waste heat recovery is also becoming more sophisticated with steam engines that can capture heat from a broader range of industrial sources. Advanced steam cycles, using materials designed for higher temperatures, can harness low-grade heat that was once considered unusable. These systems are particularly valuable in heavy industries such as steel, cement, and glass manufacturing, where large amounts of heat are generated. By converting this waste heat into power, these industries can significantly reduce energy costs while minimizing their carbon footprint.

Furthermore, small-scale steam engines using biomass or organic waste as fuel are gaining traction in rural areas and developing economies. Biomass-fueled steam engines can power isolated communities, small farms, or remote industries by providing both electricity and heat from locally available resources like wood, agricultural residue, or even waste from food production. These localized, renewable solutions help reduce dependence on imported fuels and offer a more sustainable path to rural electrification and economic development.

In the transportation sector, while the widespread use of steam engines in vehicles has long since passed, there are still niches where steam-powered designs are seeing renewed interest. Modern steam-powered boats, trains, and vehicles are being developed by enthusiasts and researchers looking to harness steam’s high torque and relatively simple mechanical design. These systems are increasingly powered by alternative fuels like biodiesel or ethanol, reducing the environmental impact associated with fossil fuels. While these applications remain experimental, they demonstrate the continuing potential of steam technology in settings that demand low emissions, quiet operation, or retrofitting older systems.

Another promising innovation lies in micro-scale steam engines, which can be used in residential and small-scale commercial applications. These engines often pair with small-scale biomass boilers or geothermal systems to provide off-grid power and heating. Micro steam turbines can generate power from small heat sources like wood stoves or waste heat from industrial processes, offering an efficient solution for decentralized energy production. As advancements in materials and digital control systems make these engines smaller, more efficient, and more cost-effective, they could be a viable option for areas where grid access is limited or unreliable.

The future of steam engine technology looks increasingly connected and intelligent. Smart systems that monitor and optimize performance in real-time, predicting maintenance needs and adjusting to changes in load or fuel type, are already becoming a standard in many modern applications. The integration of Internet of Things (IoT) sensors and artificial intelligence (AI) allows for better energy management, ensuring that steam engines are operating at peak efficiency while minimizing waste. These smart systems can adapt to changes in energy demand or supply conditions, improving the reliability and cost-effectiveness of steam-driven power systems.

Additionally, nanotechnology and advanced coatings are enabling steam engines to work in more demanding environments. Nanomaterials can significantly enhance the heat resistance, corrosion resistance, and thermal efficiency of steam engine components, ensuring that these systems can operate at higher temperatures and pressures for longer periods without degradation. This opens up possibilities for high-performance steam engines in power plants, industrial applications, and renewable energy systems that require a more durable and efficient approach.

With all of these advancements, it’s clear that while steam engines may have been an invention of the 18th century, their modern evolution shows that the technology still has a vital role to play in the future of energy generation. By combining time-tested principles with innovative materials, digital control systems, and alternative fuels, steam technology is not only adapting to the needs of modern industry but is also being reborn as a cornerstone of a more sustainable, efficient, and energy-conscious world.

Steam Engine Manufacturing Process

The manufacturing process of steam engines involves several stages, from the initial design and material selection to the final assembly and testing. Modern steam engines, whether used in power plants, industrial settings, or experimental designs, require precise engineering and high-quality materials. Below is a breakdown of the general process for manufacturing a steam engine:

1. Design and Engineering

The first step in manufacturing a steam engine is the design phase, where engineers and designers develop detailed plans and blueprints. This involves:

- Selecting the type of steam engine: Deciding whether it will be a reciprocating engine, a steam turbine, or another variation. The application of the engine (power generation, industrial use, transportation) will largely dictate the design.

- Engine parameters: Defining critical specifications, including the cylinder size, pressure, temperature, efficiency, and fuel type.

- Material selection: Choosing suitable materials for various components like the boiler (which must withstand high pressure), turbine blades, pistons, valves, and exhaust systems. High-strength alloys, corrosion-resistant materials, and heat-resistant coatings are commonly used.

- Computational fluid dynamics (CFD): Using simulations to optimize steam flow, heat transfer, and the mechanical motion of moving parts.

2. Material Procurement

Once the design is finalized, the required materials are sourced. The materials needed for steam engine construction include:

- Metals: Steel, cast iron, and special alloys for durability and strength under high-pressure conditions.

- Boiler materials: Copper, stainless steel, and alloys with high resistance to corrosion and heat.

- Heat-resistant coatings: These are used on turbine blades and other high-heat areas.

- Seals and gaskets: Made of rubber, synthetic materials, or metal, designed to prevent leaks in high-pressure steam systems.

3. Component Fabrication

The manufacturing process for the various steam engine components involves specialized fabrication techniques:

- Boiler Construction: Boilers are typically made from thick steel plates. The plates are cut, shaped, and welded together. Special attention is given to the integrity of the welds and the thickness of the walls to ensure they can withstand high pressures and temperatures. Pressure tests are conducted to verify the strength of the boiler.

- Cylinder and Piston Manufacturing: Cylinders are typically made from steel and are precision-machined to ensure a perfect fit with the pistons. Pistons are often cast and then machined to exact specifications. The cylinders are honed to a smooth finish to reduce friction and prevent leaks. The piston and cylinder are the heart of reciprocating steam engines, and their accurate alignment is crucial.

- Turbine Manufacturing: In the case of steam turbines, the manufacturing process is more complex. Turbine blades are made from high-strength alloys, often with a turbine casing made of a heat-resistant material. The blades are carefully shaped, and the turbine rotor is balanced to ensure smooth operation at high speeds.

- Valve Gear and Control Systems: The valves that regulate steam flow are precisely engineered and often made from high-strength materials like stainless steel. The valve gear is assembled with gears, shafts, and actuators that allow for the controlled admission and exhaust of steam at the correct times.

4. Precision Machining and Assembly

After all the components are fabricated, they undergo precision machining to ensure the correct fit and alignment. This is especially important for components like pistons, cylinders, valves, and turbine blades. CNC (Computer Numerical Control) machines are used to mill, grind, and drill components with extreme accuracy. The machining process includes:

- Cylindrical machining for the pistons and cylinders.

- Surface grinding for creating smooth, tight-fitting components.

- Heat treatment for hardening certain parts, such as valves and turbine blades, to increase their resistance to wear.

Once the individual components are manufactured, the engine begins the assembly process:

- Boiler and Pressure System Assembly: The boiler is connected to the pressure system, including pipes, valves, and safety mechanisms.

- Turbine or Cylinder Assembly: In steam turbines, the turbine blades are mounted on the rotor, and the casing is assembled. For reciprocating engines, the cylinder, piston, connecting rods, and crankshaft are assembled.

- Valve and Governor Systems: The valve gear, which regulates the admission of steam into the cylinder or turbine, is installed. A governor is also set up to regulate engine speed and maintain stable operation.

5. Welding and Joining

Various components of the steam engine are welded or bolted together to create a strong and leak-free structure:

- Welding: Especially important in boiler construction, where high-pressure components must be joined securely.

- Bolting and fasteners: Used for assembling parts that may require periodic disassembly, such as the turbine casing, pistons, and valve systems.

- Sealing: Gaskets and seals are used between mating surfaces to prevent steam leaks and maintain pressure integrity.

6. Testing and Calibration

Once the steam engine is fully assembled, it undergoes a series of rigorous tests:

- Pressure testing: The boiler and pressure system are subjected to high-pressure steam to ensure they can withstand the operational conditions without leaking or failing.

- Steam flow testing: For turbines and reciprocating engines, the flow of steam through the system is measured to ensure efficiency and correct operation. This may involve testing the power output, torque, and RPM.

- Efficiency testing: Efficiency is tested by monitoring fuel consumption, steam output, and overall performance under varying load conditions. Any inefficiencies are noted and adjustments are made.

- Safety checks: Steam engines are tested for safety, including the function of pressure relief valves, temperature sensors, and automatic shutdown systems.

7. Final Adjustments

After testing, any necessary adjustments are made to improve performance or resolve issues identified during testing. This may involve:

- Adjusting valve timing or steam flow for optimal performance.

- Fine-tuning governor settings to maintain constant speed.

- Replacing seals or gaskets if leaks are detected.

8. Painting and Coating

Once the engine is fully assembled and tested, it may undergo a final painting or coating process to protect against corrosion and give it an aesthetic finish. This is particularly important for external parts exposed to high temperatures or the elements, such as the boiler and turbine housing.

9. Installation and Commissioning

The steam engine is then transported to its installation site (such as a power plant, factory, or ship). Commissioning involves setting up the engine in its final location, connecting it to the power grid, and running a final round of operational tests. Engineers ensure that all connections are secure, safety systems are operational, and the engine is ready for long-term operation.

This entire manufacturing process requires a high level of precision, quality control, and specialized knowledge to ensure the engine performs safely and efficiently over a long lifespan. Modern steam engines are a result of years of engineering advancements and careful material selection, aimed at improving efficiency and minimizing the environmental impact of steam power.

The manufacturing process of steam engines is a complex and highly detailed procedure that blends traditional craftsmanship with modern technology. After the design phase is completed, the process begins with the procurement of materials suited to the specific needs of each component. Steel, cast iron, and high-strength alloys are essential for parts exposed to high pressure and heat, while specialized metals like copper and stainless steel are often used for areas like the boiler or components in direct contact with steam.

Once materials are sourced, the individual components are fabricated using various techniques. For example, boilers, which are central to steam engine operation, are constructed by carefully shaping and welding thick steel plates together. These plates are then subjected to rigorous pressure testing to ensure they can withstand the intense stress they will endure during operation. Precision machining is essential for the production of pistons, cylinders, and turbine blades. Each part is carefully shaped, drilled, and polished to exact specifications, often using computer numerical control (CNC) machinery to achieve the necessary level of accuracy. Components like cylinders are honed to achieve a smooth surface that minimizes friction, while pistons are often ground to ensure they fit precisely within their corresponding cylinders.

For turbine-based engines, the manufacturing process is even more intricate. Turbine blades, which are exposed to extreme temperatures, are often made from high-strength alloys that can endure the stress of high-speed rotation. These blades are shaped and tested for optimal aerodynamics and resistance to thermal expansion. The turbine rotor, which spins under the pressure of steam, is carefully balanced to prevent vibrations that could reduce performance or cause damage.

Once all parts are fabricated, the engine is assembled, starting with the installation of the boiler and pressure system. The boiler is connected to a complex network of pipes, valves, and pressure relief systems designed to maintain the integrity of the steam engine under high-pressure conditions. After the boiler is installed, components like the cylinder, piston, and turbine are put together, with each part carefully aligned to ensure smooth motion and efficiency. The valve gear, responsible for controlling the flow of steam into the engine, is also carefully installed and calibrated. A governor is added to regulate the engine’s speed, ensuring that it operates within the desired range.

Next, various components are welded or bolted together, with special attention given to sealing systems that prevent steam leaks. Gaskets and seals are used between joints to ensure a tight fit, which is crucial for maintaining pressure within the engine. These seals are often made from high-quality synthetic materials or rubber that can withstand the heat and pressure generated by the steam.

Once the engine is fully assembled, a series of testing procedures are conducted to ensure it meets safety and performance standards. Pressure tests are performed on the boiler and pressure system to check for leaks or weaknesses. The engine is then tested for efficiency, with steam flow and power output carefully monitored. Any inefficiencies or problems that arise during testing are addressed, whether it’s adjusting valve timing, optimizing steam flow, or fine-tuning the engine’s control systems.

After all tests are completed and any necessary adjustments are made, the engine undergoes a final round of checks, including safety inspections and fine-tuning of the governor system. The engine is then painted or coated to protect it from corrosion, particularly on components that are exposed to the elements, such as the boiler casing or the turbine housing. This coating helps ensure that the engine can operate effectively for many years, even in harsh environmental conditions.

Finally, the steam engine is transported to its installation site, where it undergoes commissioning. During commissioning, the engine is connected to its final infrastructure, whether it’s a power grid, industrial plant, or transportation system. A final set of operational tests is run to ensure that the engine functions as expected and is ready for long-term operation. Throughout this entire process, precision, attention to detail, and adherence to safety standards are paramount to producing a steam engine that performs efficiently and reliably under the demanding conditions it was designed for.

Once the steam engine is installed and commissioned, it enters its operational phase, where ongoing monitoring and maintenance become crucial for ensuring long-term performance. During its operation, the engine’s performance is continuously assessed through various parameters, such as temperature, pressure, steam flow, and power output. Modern steam engines often incorporate advanced sensors and control systems that allow operators to track these metrics in real time, providing a level of precision and reliability that earlier steam engines lacked.

In power plants or industrial applications, steam engines may operate continuously, so regular maintenance schedules are implemented to prevent wear and ensure the engine stays in peak condition. The steam boiler, which operates under high pressure and heat, is particularly prone to scaling, corrosion, and wear, which is why regular inspections are necessary. Boiler tubes are inspected for signs of erosion or fatigue, and water chemistry is carefully managed to prevent the formation of scale or sludge that could impair the heat exchange process.

Other components, such as pistons, cylinders, and valves, also undergo regular checks to ensure they are working properly. Pistons and cylinders are subject to wear over time due to the constant friction and pressure from the steam. To extend the life of these components, regular lubrication and careful inspection for signs of damage or misalignment are required. Valve seals are replaced as necessary to prevent leaks, and the valve gear system, which controls steam admission, may need periodic calibration to maintain precise timing and performance.

Turbine blades, in particular, require careful monitoring, as they are subjected to extreme heat and mechanical stress. Over time, turbines may experience thermal degradation, cracking, or erosion. To mitigate these issues, many modern steam turbines are equipped with sensors that monitor vibrations, temperature, and stress levels in real time. These sensors can detect potential problems early, allowing for preventive maintenance before any catastrophic failure occurs. Turbine blades may also need periodic polishing or resurfacing to maintain their aerodynamic properties and reduce friction.

The efficiency of steam engines is also affected by external factors, such as fuel quality or the thermal environment. In renewable or hybrid applications, where steam engines work alongside solar, geothermal, or biomass energy systems, there may be additional considerations regarding fuel consistency or the need to switch between different energy sources based on availability. In such cases, steam engines must be flexible enough to handle a variety of input conditions, and operators may adjust settings to optimize performance depending on the source of the heat.

As with any complex mechanical system, steam engines require routine monitoring of auxiliary systems, such as the condensate recovery system, pumps, and safety valves. A well-maintained condensate recovery system, for instance, ensures that water used in the steam cycle is recycled effectively, reducing the need for fresh water input and improving overall efficiency. Pumps, which maintain the flow of steam and water, need to be checked for wear and tear, and safety valves must be tested periodically to ensure they are functioning properly to release excess pressure if the system becomes dangerously pressurized.

The long-term performance of steam engines also depends on advances in materials and technology. New alloys and composites designed for high-temperature, high-pressure applications are continuously being developed, and these may be incorporated into older steam engines during maintenance or upgrade procedures. Materials such as ceramic coatings or nanostructured surfaces are increasingly being used to reduce friction, enhance durability, and improve thermal efficiency. These technological advances help steam engines maintain or even improve their performance over time, even as the operating conditions become more demanding.

Lastly, with the growing emphasis on sustainability and energy efficiency, steam engines are increasingly being integrated into broader energy management systems. In modern power plants or industrial operations, steam engines often operate in conjunction with other energy systems, such as combined heat and power (CHP) units, energy storage solutions, and renewable energy sources. The integration of steam engines with these systems requires advanced control strategies and software that can manage the interaction between multiple energy sources, ensuring that steam generation is optimized for the current energy demand while minimizing waste and emissions.

In summary, while the manufacturing process for steam engines is intricate and requires specialized knowledge and skill, the operation and maintenance phase is equally critical to ensure long-term efficiency and reliability. By combining rigorous maintenance schedules, real-time monitoring, technological advancements, and integration with renewable energy systems, modern steam engines can continue to be a valuable asset in a variety of industrial, commercial, and power generation applications, playing an essential role in today’s energy landscape.

Custom Steam Engine Solutions for Industry

Custom steam engine solutions are increasingly being tailored to meet the specific needs of various industries, providing highly efficient and optimized systems that are suited for unique operational requirements. These solutions go beyond standard off-the-shelf steam engines, incorporating design modifications, specialized materials, and advanced technologies to meet the challenges and goals of particular industrial applications. Below are some examples of how custom steam engine solutions are being implemented across different sectors:

1. Industrial Power Generation

In large-scale industrial operations, custom steam engine solutions are used for power generation that complements the overall energy strategy. For industries like paper mills, chemical plants, or refineries, where substantial heat is produced during manufacturing processes, steam engines can be integrated into combined heat and power (CHP) systems. These systems not only generate electricity but also capture and reuse the thermal energy, significantly improving overall efficiency.

Custom steam engines in these environments are designed to handle specific heat loads, operate efficiently at varying pressure levels, and accommodate fluctuations in fuel availability. For instance, a custom steam turbine might be designed to operate in a wide range of thermal conditions, adapting to both conventional fossil fuels and renewable energy sources like biomass. Additionally, the turbines may be designed to handle corrosive or dirty feedwater, common in some industrial settings, ensuring the longevity and durability of components under harsh conditions.

2. Waste Heat Recovery

Many industries generate significant amounts of waste heat—from exhaust gases, industrial furnaces, or cooling processes—that can be harnessed for energy production. Custom steam engines are frequently used in waste heat recovery systems, where the engine is specifically designed to handle low-temperature or low-grade heat that would otherwise be wasted.

For example, industries like steel production, cement manufacturing, and glass making all produce vast quantities of waste heat during their processes. Custom steam turbines or organic Rankine cycle (ORC) systems are often engineered to extract energy from this waste heat, producing electricity or useful thermal energy. These engines are optimized to run efficiently at lower steam temperatures and pressures compared to traditional systems, allowing for energy recovery in conditions that would be inefficient for conventional steam engines. The flexibility in design helps to ensure that even small or intermittent sources of heat can be converted into useful power.

3. Renewable Energy Systems

As industries shift towards more sustainable energy solutions, custom steam engines are being integrated into renewable energy systems like geothermal, solar thermal, and biomass plants. In these applications, steam engines must be adapted to handle the variable nature of renewable energy sources.

For example, solar thermal plants utilize mirrors or lenses to focus sunlight and generate high temperatures, which can be used to produce steam. Custom steam engines are often designed with high-temperature materials and innovative cooling systems to ensure optimal performance, even under fluctuating solar conditions. In geothermal power plants, where steam or hot water is drawn from deep underground reservoirs, steam engines must be designed to handle not only the high pressure and temperature of the geothermal fluids but also the potential for minerals or gases in the steam that could cause corrosion or scaling. These custom solutions are tailored to meet specific geothermal resource characteristics, ensuring reliable operation and maximum efficiency.

4. District Heating Systems

Custom steam engine solutions are also valuable for district heating systems, where steam is used to provide heat to multiple buildings or facilities from a central plant. In this case, steam engines are designed to operate in large-scale, community-based energy systems that deliver heat to residential, commercial, and industrial customers. These engines are optimized for continuous operation, often with the ability to adjust heat and power output based on seasonal demand.

In some cases, steam engines are used to convert excess heat from industrial processes into steam for district heating, reducing the need for additional fuel consumption. Custom steam turbines or heat exchangers can be designed to efficiently manage varying temperatures and load demands, ensuring that customers receive reliable heating while minimizing energy waste.

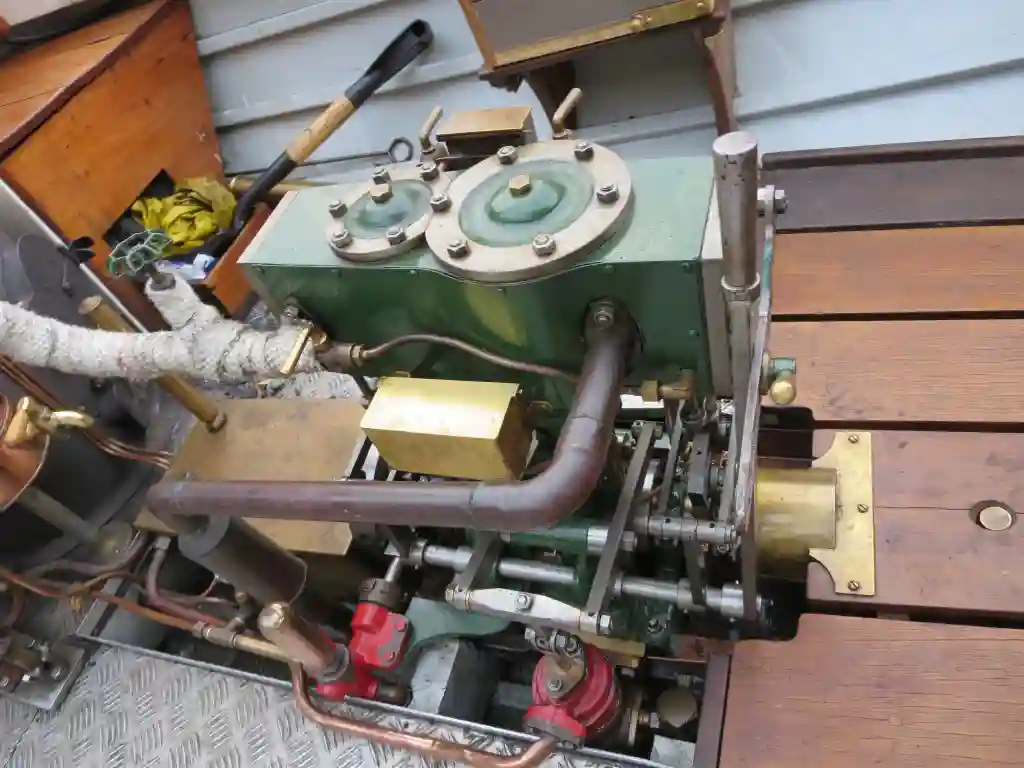

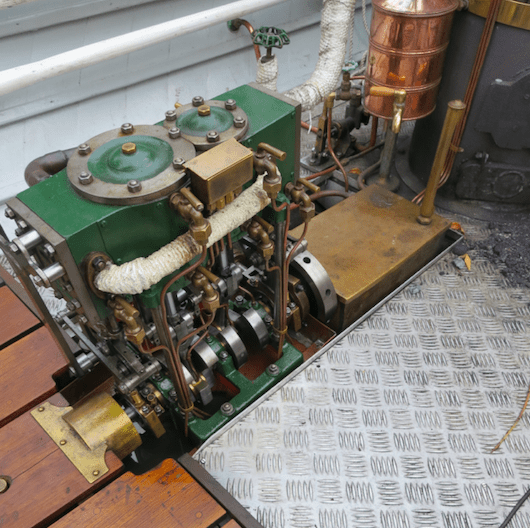

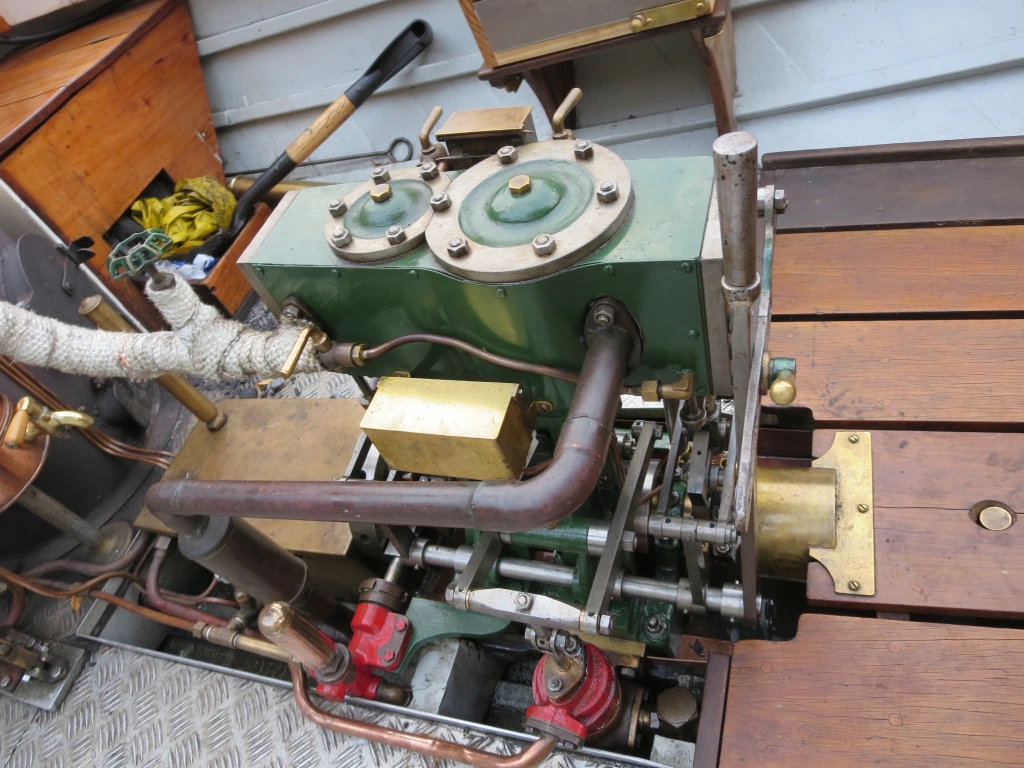

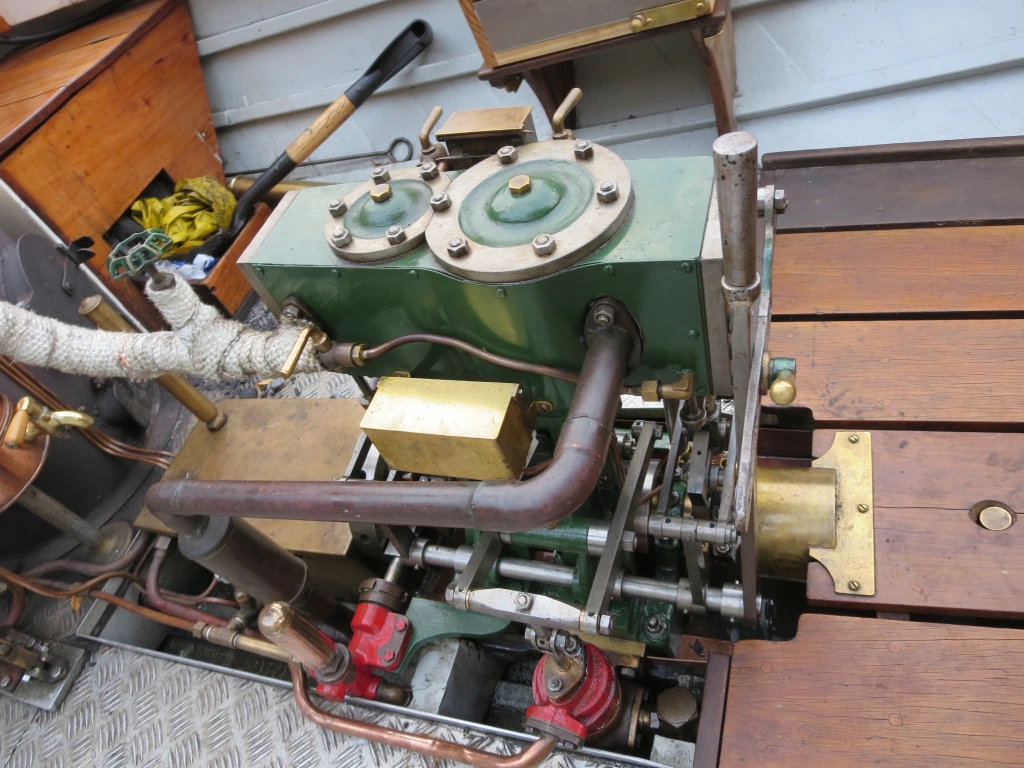

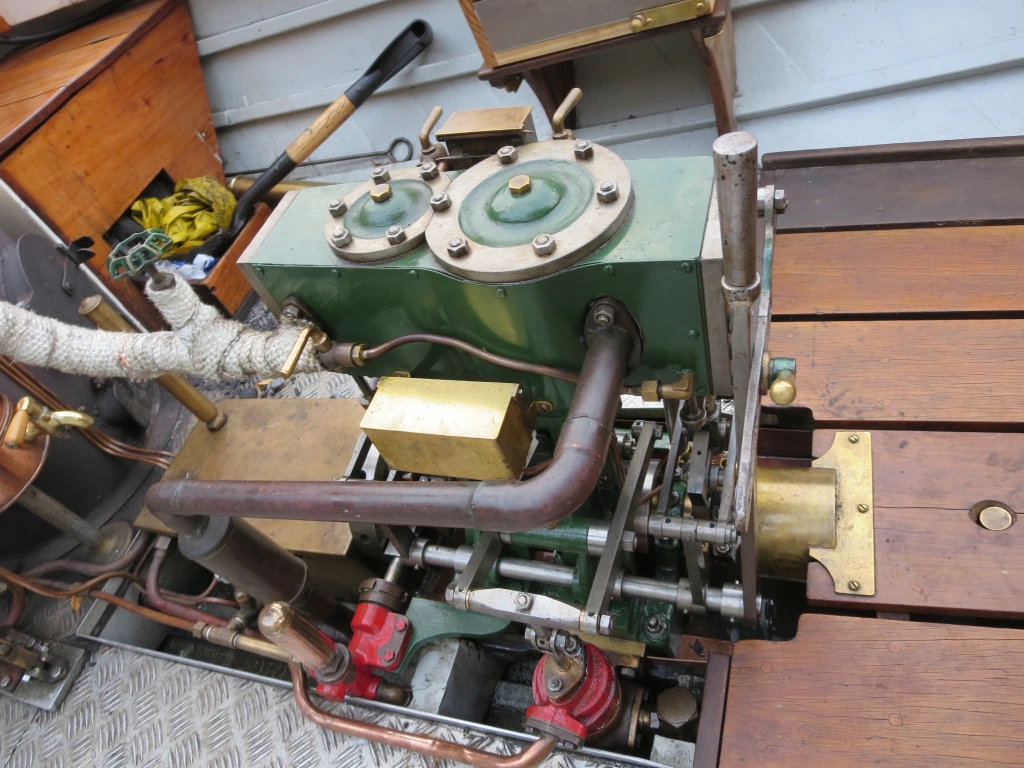

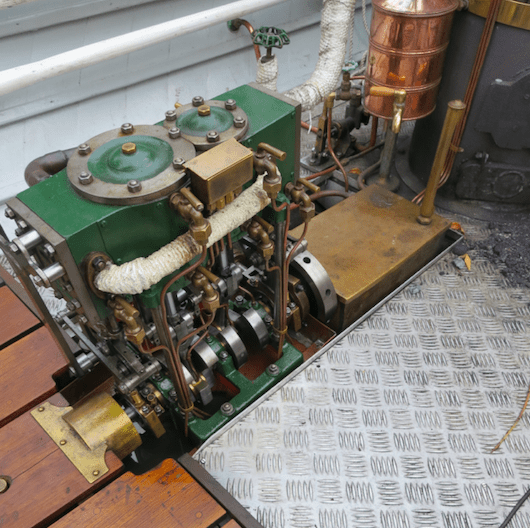

5. Marine and Transportation Applications

Custom steam engine solutions have found niche applications in marine and transportation sectors, particularly in historical restoration projects or experimental designs. Steam engines can be integrated into ships, trains, and even electric vehicles that require a low-emission, high-torque power source.

In marine applications, for example, custom-designed steam turbines or engines can provide power to large vessels, where efficiency and durability are critical. These engines are tailored to work with specific fuel types such as biomass, biodiesel, or propane, making them a sustainable alternative for certain types of vessels. For train operators or operators of historic locomotives, custom steam engines can be modified to meet modern regulatory standards while maintaining the traditional steam power that offers high torque and low-speed operation.

6. Custom Solutions for Harsh Environments

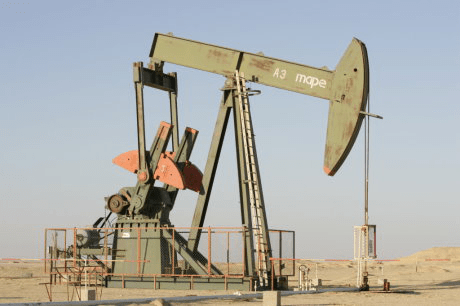

Certain industries, such as mining, oil and gas, and marine operations, demand custom steam engines that can withstand harsh and extreme environments. Custom steam engines in these sectors are often designed with specialized materials that resist corrosion, abrasion, and extreme temperatures. In the oil and gas industry, for example, steam engines are frequently used in Enhanced Oil Recovery (EOR) methods, where steam is injected into reservoirs to reduce oil viscosity and improve extraction.

To withstand such conditions, custom steam turbines or reciprocating engines are engineered with heat-resistant alloys, enhanced lubrication systems, and protective coatings to prevent damage from corrosive materials such as hydrogen sulfide or saline water. These engines are also designed to operate reliably in remote or off-grid locations, with self-sufficient power and water treatment systems to handle the needs of the site.

7. Custom Steam Solutions for Small and Remote Applications

Custom steam engine solutions are also being employed in small-scale or off-grid applications, where a flexible, compact energy system is needed. For example, in rural or isolated communities where access to the electrical grid is limited, custom-designed steam engines can run on biomass, wood, or organic waste to provide both electricity and heat. These systems are optimized to operate with locally available fuels and can be scaled to meet the specific energy needs of the community.

Similarly, in the agricultural sector, steam engines are used in greenhouses, drying facilities, and irrigation systems, where they can provide both thermal energy for heating and power for mechanical operations like pumps or fans. Custom steam engines in these applications are designed for efficiency, easy operation, and low maintenance, providing farmers and rural communities with sustainable energy solutions.

8. Custom Solutions for Specialty Industries

In some niche applications, steam engines are customized to meet the needs of specialty industries that require unique energy solutions. Industries such as pharmaceutical production, food processing, and textile manufacturing often have specific temperature, humidity, and pressure requirements that can be met with custom steam engines. For instance, in pharmaceutical manufacturing, where precise temperature control is critical for sterilization processes, custom steam systems are designed to deliver exact steam conditions without overheating or underheating the materials being processed.

For textile mills, steam engines provide the power needed for various stages of production, including dyeing, finishing, and drying fabrics. In these settings, custom steam systems are engineered to accommodate the specific requirements of the production process, with a focus on energy efficiency and consistent steam delivery

In conclusion, custom steam engine solutions allow industries to take full advantage of the energy efficiency and operational flexibility of steam power while addressing the unique challenges they face. These tailored systems are designed to improve performance, reduce fuel consumption, and lower environmental impacts, while providing the reliability and durability needed for demanding industrial environments. Whether for power generation, waste heat recovery, renewable energy, or specialized applications, custom steam engines remain an essential tool for modern industrial solutions.

Custom steam engine solutions continue to evolve as industries demand higher efficiency, flexibility, and sustainability. These solutions allow companies to tailor their steam systems to meet very specific needs, optimizing their operations while reducing costs and environmental impact. One of the key advantages of custom solutions is the ability to design engines that can operate with a variety of fuels, including renewable and waste-based resources. This flexibility allows industries to lower their reliance on fossil fuels and reduce carbon emissions while still meeting their power and heating requirements.

In many applications, the adaptability of custom steam engines allows them to operate in conjunction with other energy systems, creating hybrid solutions that improve overall energy efficiency. For example, integrating steam engines with solar thermal or biomass systems can enable a facility to operate with a reduced carbon footprint while maintaining consistent power generation. These systems can be designed to switch between different heat sources or combine multiple sources of energy to ensure reliable operation, even in fluctuating conditions. This makes custom steam engine solutions not only more energy-efficient but also more resilient in the face of changing energy availability or environmental factors.

Moreover, the use of advanced materials and manufacturing techniques is helping to push the boundaries of what steam engines can do. With innovations in high-temperature alloys, coatings, and composites, steam engines can now handle more extreme conditions, extending their lifespan and improving their performance under high-pressure or high-temperature scenarios. These improvements also help reduce the need for frequent maintenance, which can lower operating costs and reduce downtime. Furthermore, custom steam engines are increasingly equipped with smart sensors and monitoring systems, allowing operators to track performance in real time. This enables predictive maintenance, where issues are identified and addressed before they lead to failure, further enhancing reliability and efficiency.

The integration of custom steam engine solutions into industrial processes also opens up new opportunities for energy recovery and waste heat utilization. Many industries generate large amounts of waste heat that can be captured and converted back into usable energy. Custom steam engines designed for waste heat recovery systems can extract energy from exhaust gases, cooling systems, or other sources of waste heat, improving overall plant efficiency. This is particularly useful in industries like steel production, cement manufacturing, or chemical processing, where high-temperature processes produce excess heat that would otherwise go to waste.

In addition to improving energy efficiency, custom steam engines can be optimized for specific operational characteristics, such as high torque at low speeds or the ability to start up quickly and ramp up to full power in a short amount of time. This is important for applications where load demands fluctuate rapidly or where power needs to be generated quickly in response to changes in production schedules or energy demand.

One of the key aspects of custom steam engine solutions is their ability to be highly tailored to the operational constraints and specific goals of a given industry. For example, some industries may require very precise steam quality and pressure for critical processes, while others might prioritize long-term operational stability under heavy load conditions. Custom steam engine designs can incorporate the necessary adjustments to meet these requirements, such as optimizing the steam cycle, enhancing heat transfer, and fine-tuning the control systems to manage pressure and temperature with greater precision.

As sustainability becomes an increasingly important focus across all sectors, custom steam engines are also being integrated into broader sustainability initiatives. In many cases, steam systems are designed to minimize energy consumption and maximize resource efficiency, often aligning with green building certifications or carbon-neutral goals. In the case of agricultural applications, custom steam systems can be designed to use organic waste materials or renewable resources like biomass, which further reduces environmental impacts. The ability to integrate these systems with energy storage solutions or power management systems can help industries ensure that they can meet both their operational and environmental goals.

Custom steam engine solutions are also playing a role in sectors where reliable backup power is critical. In facilities like hospitals, data centers, or emergency response centers, where power failure is not an option, steam engines can serve as reliable backup power sources. These engines can be designed to quickly respond to power outages, providing uninterrupted energy to critical systems until the main grid is restored. In some cases, these backup steam engines may be designed to operate in tandem with other backup systems, such as diesel generators or battery storage, to ensure seamless and reliable power delivery during outages.

Finally, as industries around the world continue to modernize and adopt new technologies, custom steam engine solutions will become increasingly sophisticated. With the advancement of artificial intelligence (AI), machine learning, and predictive analytics, steam engines will be able to self-optimize based on real-time operational data, improving performance over time without the need for manual adjustments. These developments will further enhance the versatility of steam engines, enabling them to integrate into smart grid systems, contribute to decentralized energy solutions, and support the transition toward more sustainable industrial practices.

In conclusion, custom steam engine solutions are helping industries to meet their unique energy and operational needs in increasingly efficient, sustainable, and cost-effective ways. By tailoring these systems to specific applications, industries can optimize their energy use, improve performance, and reduce environmental impact, all while ensuring reliability and operational efficiency. With continued advances in materials, technology, and design, the future of custom steam engine solutions is bright, offering even more opportunities for industries to embrace cleaner, more efficient, and more adaptable energy solutions.

As industries continue to seek more sustainable and cost-effective energy solutions, custom steam engine technologies are poised to evolve further, integrating even more advanced systems and features that can address the challenges of tomorrow’s industrial landscape. Several trends and innovations are expected to shape the future of custom steam engines and their applications.

One key area of growth is the integration of digital technologies into steam engine systems. The use of Internet of Things (IoT) devices, smart sensors, and real-time data analytics is allowing operators to closely monitor and optimize the performance of steam engines. By collecting data from multiple points in the system—such as pressure, temperature, steam flow, and component wear—these systems can continuously adjust to improve performance and efficiency. Additionally, advanced machine learning algorithms can analyze the vast amounts of data generated by these sensors to predict potential failures or performance declines before they occur, allowing for predictive maintenance. This approach reduces downtime, extends the lifespan of components, and minimizes the cost of repairs by addressing issues before they become major problems.

Another exciting development is the hybridization of steam engine systems with renewable and low-carbon technologies. Steam engines have traditionally relied on fossil fuels, but increasingly, they are being adapted to work in conjunction with solar thermal, geothermal, biomass, and other renewable energy sources. In these systems, steam engines can play a complementary role, either by providing backup power when renewable sources are unavailable or by converting waste heat from renewable processes into usable steam. This synergy not only maximizes the efficiency of renewable systems but also reduces reliance on non-renewable energy sources, helping industries meet ambitious carbon reduction goals.

The demand for decentralized and off-grid power generation is also driving the development of custom steam engine solutions. Remote or rural areas, where access to centralized electrical grids is limited or non-existent, are increasingly turning to independent energy systems. Custom steam engines are ideal for these settings, especially when paired with biomass, wood, or other locally available fuels. These systems can be designed to operate autonomously, generating electricity and heat for local communities, reducing energy costs, and providing a reliable power source even in regions with poor grid infrastructure. This trend is not limited to developing regions but is also gaining traction in industrial facilities or operations located in remote or harsh environments, such as oil rigs, mining operations, or military bases, where reliable power is critical.

Modular steam systems are another innovative development in custom steam engine solutions. These systems are designed with scalability and flexibility in mind, allowing companies to start with a smaller, more cost-effective solution and scale up as their energy needs grow. In these modular setups, multiple smaller steam engines can be linked together to create a larger power generation system, enabling better load management and improved efficiency across the facility. Modular systems also allow for easy maintenance and replacement of individual components without disrupting overall operations, which is particularly useful in industrial facilities where downtime can be costly.

As energy storage technologies continue to advance, custom steam engines are being integrated into hybrid systems that incorporate both battery storage and steam generation. In these configurations, steam engines can provide base-load power while batteries handle peak demand, ensuring that energy is consistently available even when renewable sources like solar or wind are intermittent. The combination of steam and battery storage not only enhances the overall efficiency of the system but also supports the grid by stabilizing fluctuations in energy supply and demand.

The growing emphasis on circular economy principles is also influencing the design of custom steam engines. Industries are increasingly focusing on resource efficiency and minimizing waste. Steam engines that can run on waste biomass or organic waste materials, for instance, contribute to a circular economy by converting discarded materials into valuable energy. Additionally, advancements in waste-to-energy technologies enable steam engines to recover energy from various waste products, such as municipal solid waste or industrial by-products. By incorporating waste streams into energy production, industries can minimize landfill waste while generating clean, renewable energy.

Another aspect of future custom steam engine design is thermal energy storage. This technology allows excess heat generated during off-peak hours to be stored and used when demand is high. Steam engines can be integrated with thermal energy storage systems to improve overall energy efficiency and balance supply and demand. This approach is particularly beneficial in industries that require high amounts of heat for processes, such as in the food processing, chemical, or textile industries. By capturing and storing thermal energy, these industries can avoid spikes in energy costs and reduce their environmental impact by using renewable heat sources when possible.

Environmental sustainability will continue to be a key driving factor for custom steam engine design. As governments and industries worldwide push for cleaner energy solutions, steam engines are being designed with advanced emissions control technologies to reduce pollutants such as nitrous oxides (NOx), sulfur oxides (SOx), and carbon dioxide (CO2). New materials, improved combustion techniques, and better integration with emission control systems allow for cleaner and more efficient operation. Additionally, the development of steam engines capable of using biogas or syngas—a gas derived from renewable sources such as organic waste—further reduces the carbon footprint of steam-based power generation.

As the cost of renewable energy technologies continues to decline and their efficiency improves, the adoption of custom steam engine solutions that rely on these technologies will expand. Custom systems that integrate solar concentrators, geothermal loops, and biomass conversion are expected to become more prevalent, providing industries with versatile, low-emission alternatives to traditional energy systems. These systems, which can include both thermal and electrical output, provide a continuous, renewable energy source while reducing reliance on fossil fuels and minimizing greenhouse gas emissions.

Finally, customization itself will continue to be an area of growth, with manufacturers offering highly tailored solutions to meet the unique needs of industries, from power generation to specialized manufacturing processes. Steam engines will become more efficient in terms of fuel consumption, heat recovery, and power output, while the integration of digital and smart technologies will allow for greater adaptability in real-time energy management. As industries demand more specialized applications—whether it’s for backup power, waste heat recovery, or specialized process requirements—custom steam engines will evolve to meet these demands, offering bespoke solutions that push the boundaries of performance, energy efficiency, and sustainability.

In conclusion, the future of custom steam engine solutions lies in the ability to adapt to emerging technologies, evolving energy demands, and the growing push for environmental sustainability. These engines will continue to serve as a cornerstone for industries seeking reliable, efficient, and clean energy sources. By leveraging innovations in digital technology, renewable energy, materials science, and energy storage, custom steam engines will not only remain relevant in the modern energy landscape but will also become integral to the transition toward cleaner, more sustainable industrial operations worldwide.

Types of Steam Engines: A Comprehensive Guide

Steam engines, though rooted in the past, continue to be pivotal in various modern applications, and understanding the different types can help identify which is best suited for specific uses. These engines have evolved over time, incorporating new materials, technologies, and refinements. Below is a comprehensive guide to the various types of steam engines, highlighting their unique features and applications.

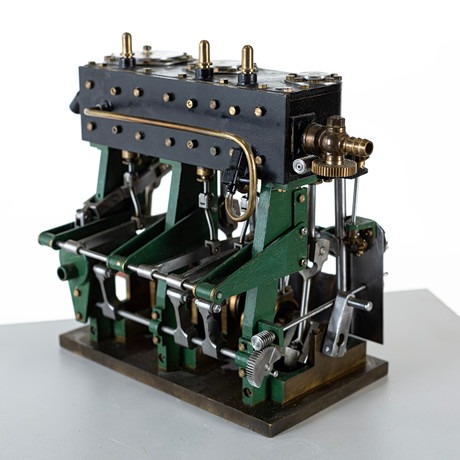

1. Reciprocating Steam Engines

Reciprocating steam engines are the most traditional type, where steam pressure is used to push a piston back and forth inside a cylinder. These engines convert the thermal energy of steam into mechanical work through linear motion, which is then converted to rotary motion using a crankshaft.

- Applications: Historically used in locomotives, steamships, and factory machinery. They remain in use in certain small-scale applications, such as in old-fashioned pumps, agricultural engines, and educational demonstrations.

- Advantages: Simple design, reliable, and easy to maintain.

- Disadvantages: Less efficient at high speeds, larger and heavier compared to other types.

2. Steam Turbines

Steam turbines are a more modern and efficient evolution of the steam engine. In this design, steam is directed at blades attached to a shaft, causing the shaft to spin. The spinning shaft is then used to generate mechanical energy.

- Applications: Predominantly used in power plants for electricity generation, marine propulsion (such as in large ships and naval vessels), and in some industrial applications like petrochemical processing.

- Advantages: Higher efficiency than reciprocating engines, especially at larger scales. Can generate large amounts of power with relatively compact designs.

- Disadvantages: Expensive to build and maintain, requires precise engineering.

3. Compound Steam Engines

Compound steam engines are a type of reciprocating engine that uses multiple cylinders to maximize efficiency. In these engines, steam is expanded in stages through multiple cylinders of varying sizes. The steam first passes through a high-pressure cylinder, then moves to progressively larger cylinders at lower pressures, extracting more energy at each stage.

- Applications: Often found in marine vessels, large industrial machinery, and early power plants.

- Advantages: More efficient than simple steam engines due to the multi-stage expansion of steam.

- Disadvantages: More complex design, requiring precise synchronization between cylinders.

4. Double-Acting Steam Engines

In a double-acting steam engine, steam is applied to both sides of the piston, allowing for a more continuous and efficient motion compared to a single-acting engine, which only uses steam on one side of the piston. This type of engine can provide power during both the forward and backward strokes of the piston.

- Applications: Used in various industries for pumping, lifting, and other heavy-duty tasks.

- Advantages: Greater power output for the same size, more continuous operation.

- Disadvantages: Slightly more complex due to the need for two valve systems.

5. Non-Condensing Steam Engines

Non-condensing steam engines, also known as atmospheric engines, exhaust steam into the atmosphere rather than condensing it into water. These engines operate at lower pressures and are less efficient than their condensing counterparts but are simpler in design and cheaper to construct.

- Applications: Early industrial applications, including pumping stations and in some vintage steam locomotives.

- Advantages: Simple design and lower maintenance costs.

- Disadvantages: Lower efficiency, greater fuel consumption.

6. Condensing Steam Engines

Condensing steam engines work by cooling the exhaust steam to create a vacuum or lower pressure, which allows the engine to extract more energy from the steam, increasing overall efficiency. This type of engine typically uses a separate condenser to cool the steam back into water, which can then be reused in the boiler.

- Applications: Commonly used in power plants, especially for electricity generation, as well as in large-scale industrial applications.

- Advantages: Higher efficiency, reduced fuel consumption, and lower operating costs.

- Disadvantages: Requires more complex equipment and maintenance, including the condenser.

7. Flash Steam Engines

Flash steam engines are a type of steam engine that uses flash steam, which is created by rapidly releasing steam from pressurized water. The water quickly vaporizes into steam when the pressure is released, and this steam can then be used to drive an engine. Flash steam engines are typically used in applications where a heat source is already available, such as in geothermal or biomass energy systems.

- Applications: Used in geothermal power plants, and also in some waste heat recovery systems.

- Advantages: Can efficiently use lower-grade heat sources, relatively compact design.

- Disadvantages: Limited to certain applications, especially where flash steam can be efficiently generated.

8. Locomotive Steam Engines

Locomotive steam engines are a type of reciprocating engine specifically designed for use in steam trains. These engines use a series of pistons and a driving wheel system to propel the train forward. A coal-fired boiler generates steam, which is then used to drive the pistons, translating into mechanical energy.

- Applications: Historical rail transportation, and still used in some tourist or heritage railways.

- Advantages: High torque at low speeds, ideal for pulling heavy loads over long distances.

- Disadvantages: Inefficient by modern standards, large fuel consumption, and high maintenance.

9. Steam-Driven Pumps

These are specialized steam engines designed specifically for pumping water or other liquids. They can be either reciprocating or rotary types, but the key feature is that they use steam power to move fluids.

- Applications: Often used in mining, irrigation, waterworks, and sewage treatment plants.

- Advantages: Can operate independently of electricity, suitable for remote areas.

- Disadvantages: Typically lower efficiency compared to modern electric pumps.

10. Rotary Steam Engines

Rotary steam engines use steam pressure to turn a rotor instead of a piston. These engines operate on a principle that differs from the traditional reciprocating engine, utilizing rotary motion to drive mechanical processes.

- Applications: Less common, but can be found in specialized industrial applications, such as in compressors, pumps, and small power plants.

- Advantages: Continuous, smooth operation, compact design.

- Disadvantages: Less efficient than other types at large scales, can be difficult to scale up.

11. Stirling Engines

Though not technically a steam engine in the traditional sense, Stirling engines work by expanding and contracting gas using heat. They are an example of external combustion engines that use heat to drive mechanical work. While they can run on steam, they are more commonly powered by air, biomass, or other heat sources.

- Applications: Used in small-scale, solar thermal power generation and experimental power applications.

- Advantages: High efficiency at small scales, environmentally friendly, and relatively low emissions.

- Disadvantages: Limited to smaller power applications, slower response times.

12. Rocket Engines (Steam Rockets)

Though largely obsolete and specialized, steam rocket engines were once used in rocketry experiments. They work by producing high-pressure steam, which is expelled through a nozzle to create thrust.

- Applications: Used historically for experimental propulsion, now of interest in niche aerospace applications.

- Advantages: Simple design, potential for high thrust at low altitudes.

- Disadvantages: Inefficient, impractical for modern space exploration.

Conclusion

Steam engines, despite the rise of more efficient and modern energy systems, continue to hold importance in niche applications, where they provide advantages in energy efficiency, fuel flexibility, and power generation. The type of steam engine used in any given application depends on several factors, including efficiency, operational requirements, space, and fuel availability. Whether for industrial power generation, transportation, or waste heat recovery, each type offers unique benefits tailored to specific needs. As industries continue to explore more sustainable energy solutions, some of these steam engine technologies may see a resurgence, particularly in renewable energy contexts, where steam cycles are combined with clean sources like geothermal or biomass.

As steam engine technology continues to evolve, more specialized and innovative applications are emerging. One of the key drivers for the continued development of steam engines is the push for cleaner and more sustainable energy sources. With the growing demand for renewable energy, steam engines are finding new life in geothermal and biomass power plants, where they can efficiently convert heat into mechanical energy, contributing to cleaner electricity generation. In geothermal power plants, steam extracted from the Earth’s natural heat sources is used to power steam turbines, driving electrical generators while minimizing environmental impact. Similarly, biomass plants use organic waste materials to generate steam, further reducing reliance on fossil fuels.

Another area where steam engines are making a comeback is in small-scale, off-grid power generation. As energy security becomes a priority in remote or underserved areas, steam engines offer a reliable, low-tech solution for communities that may not have access to electricity through conventional means. In these settings, flash steam engines, which can harness heat from locally available resources like wood or waste biomass, are particularly effective for providing energy in off-grid applications. These systems can operate independently, producing both heat and electricity, and they can often be scaled according to the specific needs of the community or facility.

The integration of combined heat and power (CHP) systems also presents new opportunities for steam engine technology. In a CHP system, steam engines or turbines generate both electricity and useful thermal energy, such as hot water or steam for industrial processes, space heating, or district heating networks. These systems are especially popular in industrial applications where there is a consistent demand for both heat and electricity, and they help maximize the overall efficiency of energy use. By capturing waste heat and using it in other processes, these systems can achieve efficiencies of 70% to 80%, significantly reducing fuel consumption and emissions.

With advances in digital control systems and sensor technologies, steam engines are also becoming smarter and more efficient. Modern steam engines can be equipped with sophisticated monitoring systems that track performance in real time, allowing operators to adjust settings for optimal efficiency. For instance, steam pressure, temperature, and flow can be continuously monitored, and adjustments can be made automatically to ensure the engine operates within ideal parameters. This allows for improved fuel efficiency, reduced emissions, and increased system reliability. Predictive maintenance technologies, powered by artificial intelligence and machine learning, further enhance the lifespan and reliability of steam engines by predicting when components need maintenance or replacement, reducing unplanned downtime and repair costs.

Another exciting development is the potential for integrating steam engines with solar power. In solar thermal power plants, mirrors or lenses focus sunlight onto a fluid (typically oil or water), which is then used to produce steam. This steam can then power turbines or engines, providing renewable electricity. Hybrid systems that combine solar thermal energy with steam engines offer an efficient way to store and utilize solar energy even when the sun isn’t shining, as the stored heat can be used to generate steam when needed, providing a continuous and reliable energy source.

While many of the traditional uses of steam engines, such as in steamships and trains, have been largely replaced by more efficient technologies, there is still a niche market for these applications, particularly in heritage railways and historical attractions, where steam engines offer a glimpse into the past. In these settings, they not only serve as a source of education and entertainment but also continue to capture the imagination of those fascinated by the history of industrialization.

At the same time, new types of steam engines are emerging, incorporating innovations such as microturbines or miniaturized systems that can be used for personal power generation or in remote monitoring applications. These smaller, more portable steam engines may use a variety of heat sources, including waste heat, and are ideal for applications where space is limited, and conventional power sources are unavailable or impractical.

The future of steam engine technology also points toward increasing integration with digital infrastructure. As industries move towards more automated and connected operations, steam engines are becoming part of larger smart grids and integrated energy systems. These systems can automatically adjust energy generation based on demand, enabling better overall management of power generation and consumption. The integration of steam engines into such smart networks allows for better synchronization between power sources, reducing waste and ensuring energy is used efficiently across multiple applications.

Ultimately, the ongoing advancements in steam engine technology promise to keep them relevant in the coming decades. While the core principles of steam engines remain grounded in centuries-old technology, innovations in materials, digital controls, renewable energy integration, and energy efficiency are expanding their applications. Whether for industrial processes, renewable energy systems, or small-scale off-grid power generation, the continued evolution of steam engine technology represents an exciting opportunity to improve sustainability, efficiency, and energy security across various sectors. As industries seek to reduce their environmental footprints and embrace more sustainable energy solutions, steam engines will remain a key player in the broader energy landscape, demonstrating their adaptability in the modern world.