Individual Power and Energy Plants: A power plant (also called a power station, generating station, or powerhouse) is an industrial facility designed to generate electricity on a large scale. These plants convert primary energy sources such as coal, natural gas, oil, nuclear fuel, biomass, hydropower, wind, or solar energy into electrical energy that can be distributed through transmission and distribution networks to consumers.

There are several main types of power plants:

- Thermal Power Plants – Use fossil fuels (coal, natural gas, oil) or biomass to produce steam that drives turbines connected to generators.

- Coal-fired plants: Traditional but highly polluting.

- Natural gas plants: More efficient and cleaner, often using combined cycle systems.

- Oil-fired plants: Less common due to high fuel cost.

- Nuclear Power Plants – Use controlled nuclear fission reactions (usually uranium or plutonium fuel) to generate heat, which produces steam for turbine-driven generators.

- Hydroelectric Power Plants – Convert the kinetic energy of flowing water (dams or rivers) into electricity using turbines.

- Renewable Energy Plants

- Solar power plants: Use photovoltaic (PV) panels or concentrated solar power (CSP) systems.

- Wind farms: Use wind turbines to generate electricity.

- Geothermal plants: Harness heat from the Earth’s crust.

- Biomass plants: Burn organic material or use anaerobic digestion to generate biogas.

- Hybrid and Emerging Power Plants

- Combined heat and power (CHP): Produce both electricity and usable heat.

- Hydrogen fuel-based plants: Under development for a cleaner energy transition.

Power plants vary in scale, from small decentralized facilities (like rooftop solar or small gas turbines) to massive centralized stations capable of powering entire regions. Their design, efficiency, and environmental impact are crucial factors in today’s global energy transition.

A power plant is a complex industrial facility designed to convert various forms of primary energy into electrical energy for widespread distribution and consumption. In traditional thermal power plants, fossil fuels such as coal, natural gas, and oil serve as the primary energy source, where the chemical energy stored in these fuels is converted into heat energy through combustion. This heat is used to produce high-pressure steam in boilers, which then drives turbines connected to electrical generators. Coal-fired power plants, long considered the backbone of electricity generation in many regions, are known for their high energy output but also for significant environmental impacts due to greenhouse gas emissions and particulate matter. Natural gas plants offer higher efficiency and cleaner combustion, particularly when operating in combined cycle configurations, where both gas and steam turbines work together to maximize energy extraction. Oil-fired plants, though less common today due to fuel costs, still serve as backup or peaking power sources in many countries. Biomass combustion in thermal plants has gained attention as a renewable alternative, using organic materials like wood chips, agricultural residues, or dedicated energy crops to produce steam and electricity while potentially reducing net carbon emissions when managed sustainably.

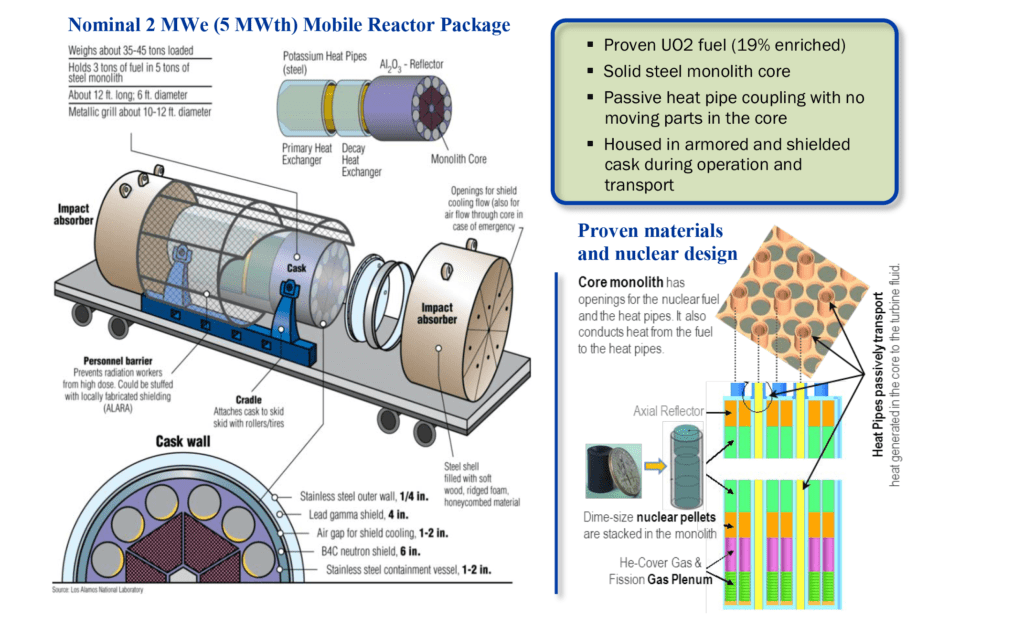

Nuclear power plants operate on entirely different principles, relying on nuclear fission reactions to release enormous amounts of heat from relatively small quantities of fuel such as uranium or plutonium. This heat is used to generate steam in a controlled environment, which then drives turbines to produce electricity. Nuclear plants are characterized by their high reliability, low operational greenhouse gas emissions, and complex safety requirements. Modern nuclear facilities integrate multiple safety systems, redundant cooling circuits, and containment structures to minimize the risks associated with radiation release. The energy density of nuclear fuel far exceeds that of fossil fuels, meaning that a relatively small volume of uranium can produce massive amounts of electricity compared to coal or gas, though issues such as radioactive waste disposal and plant decommissioning present ongoing challenges.

Hydroelectric power plants harness the kinetic and potential energy of flowing water to generate electricity, often through large dams or river diversion systems. Water stored in reservoirs is released through turbines, converting mechanical energy into electrical energy. Hydropower is highly efficient, provides a steady base load in many regions, and has minimal greenhouse gas emissions during operation, though its environmental and social impacts, such as habitat disruption, fish migration interference, and community displacement, must be carefully managed. Run-of-river hydro plants and small-scale hydro installations are increasingly used to minimize environmental disruption while still contributing to local electricity generation.

Renewable energy sources such as solar, wind, and geothermal have transformed the landscape of power generation in the 21st century. Solar power plants use photovoltaic cells to directly convert sunlight into electricity or concentrated solar power systems to focus solar radiation onto thermal receivers, producing steam for turbines. Wind farms convert the kinetic energy of moving air into electricity using large-scale turbines, whose efficiency and output depend on wind speed, turbine design, and site selection. Geothermal plants extract heat from the Earth’s interior, typically through the use of steam or hot water reservoirs, providing a constant and reliable energy source that is largely unaffected by weather conditions. Biomass-based power plants, in addition to traditional combustion, can utilize advanced gasification techniques to produce synthesis gas, which is then burned or used in fuel cells, offering additional flexibility and renewable energy potential.

Hybrid and emerging power plant technologies are increasingly important in the context of decarbonization and energy transition strategies. Combined heat and power (CHP) plants simultaneously produce electricity and usable thermal energy, improving overall efficiency and reducing fuel consumption. Hydrogen-based power generation, either through fuel cells or combustion turbines, represents a promising avenue for zero-emission electricity, provided that the hydrogen is produced sustainably, for instance via electrolysis powered by renewable energy. Advanced nuclear designs, small modular reactors, and carbon capture and storage (CCS) retrofits for fossil fuel plants aim to reduce emissions while maintaining high levels of energy output. The integration of smart grids, energy storage systems, and demand response strategies further enhances the operational flexibility of power plants, enabling more efficient balancing of intermittent renewable sources and ensuring reliable electricity supply.

Overall, power plants remain central to modern civilization, underpinning industrial activity, commercial operations, and household energy use. Their technological diversity—from coal-fired thermal stations to nuclear reactors, hydroelectric dams, wind farms, and solar parks—reflects the wide range of available energy resources and the evolving priorities of efficiency, sustainability, and environmental stewardship. As global energy demand grows and decarbonization pressures increase, power plants must adapt by incorporating cleaner fuels, renewable sources, hybrid systems, and innovative operational strategies to meet both economic and ecological objectives while ensuring the continuous availability of electricity to societies worldwide.

Power Plants

Power plants are the backbone of modern energy systems, serving as the primary means by which society converts natural resources into usable electricity to power homes, industries, and infrastructure. These facilities operate by transforming various energy sources—fossil fuels, nuclear reactions, water flow, sunlight, wind, geothermal heat, and biomass—into electrical energy through mechanical, thermal, or chemical processes. Fossil fuel power plants, which include coal, oil, and natural gas plants, remain a major contributor to global electricity generation, although their environmental impacts are significant due to greenhouse gas emissions and air pollutants. Coal-fired plants operate by burning pulverized coal to heat water in boilers, producing high-pressure steam that drives turbines connected to generators, with efficiency often improved through supercritical and ultra-supercritical boiler technologies. Natural gas plants, particularly combined cycle systems, offer higher efficiency and lower carbon emissions by using a gas turbine to generate electricity from combustion, while the hot exhaust gases produce steam to drive a secondary steam turbine. Oil-fired plants, while less common today due to high fuel costs, still serve as peaking plants to meet sudden spikes in demand or as backup generation. Biomass-fired plants convert organic materials such as wood chips, agricultural residues, or dedicated energy crops into heat energy, which is then used to produce steam and electricity, providing a renewable alternative that, when managed sustainably, can contribute to reducing net carbon emissions.

Nuclear power plants function on the principle of controlled nuclear fission, releasing massive amounts of heat from small quantities of uranium or plutonium fuel. This heat produces steam that drives turbines, generating electricity at scales comparable to large thermal plants but with minimal operational greenhouse gas emissions. Nuclear plants are characterized by high energy density, meaning they can produce tremendous amounts of electricity from a small amount of fuel, but they require intricate safety systems, redundant cooling circuits, and secure containment structures to prevent accidents and manage radioactive waste. Modern reactor designs, including pressurized water reactors, boiling water reactors, and emerging small modular reactors, prioritize safety, efficiency, and flexibility, and aim to reduce long-term waste and decommissioning challenges. While nuclear power contributes significantly to base load electricity supply, societal concerns regarding radioactive waste disposal, potential accidents, and long-term environmental impacts continue to influence public policy and investment in nuclear energy.

Hydroelectric power plants harness the kinetic and potential energy of water to generate electricity, typically using dams to create reservoirs that release water through turbines. This conversion of mechanical energy to electrical energy is highly efficient and produces minimal direct emissions. Hydropower provides reliable base load energy in many regions and can also contribute to grid stability by allowing rapid adjustments to electricity output based on demand. However, the construction of large dams and reservoirs can have profound environmental and social consequences, including habitat disruption, changes in river ecosystems, and displacement of local populations. To mitigate these effects, run-of-river hydro projects and small-scale hydro installations are increasingly utilized, emphasizing minimal ecological disruption while still providing sustainable energy generation. Pumped-storage hydroelectric systems further enhance energy storage and grid management capabilities by allowing water to be cycled between reservoirs to balance supply and demand fluctuations, particularly in regions with significant intermittent renewable energy sources.

Renewable energy power plants, including solar, wind, geothermal, and biomass systems, have increasingly transformed global energy portfolios. Solar power plants use photovoltaic cells to directly convert sunlight into electricity or employ concentrated solar power systems to generate heat for steam turbines. These systems offer clean energy generation with minimal emissions, though efficiency can be affected by weather and geographic location. Wind farms convert kinetic energy from wind into electricity using large turbines, with output dependent on wind speed, turbine design, and site selection. Geothermal power plants exploit heat from the Earth’s interior to produce steam or hot water, offering a reliable and constant energy source that is largely independent of surface weather conditions. Biomass and biogas plants utilize organic materials through direct combustion, gasification, or anaerobic digestion to produce electricity, contributing to renewable energy targets while providing flexible fuel options. Emerging technologies in biomass utilization, such as advanced gasification and combined heat and power systems, enhance overall energy efficiency and reduce environmental impacts compared to traditional combustion processes.

Hybrid and emerging power generation technologies are becoming increasingly important in the context of energy transition and decarbonization goals. Combined heat and power plants simultaneously generate electricity and thermal energy for industrial processes or district heating, significantly improving overall efficiency compared to separate electricity and heat production. Hydrogen-based power generation, whether through fuel cells or combustion turbines, is a promising pathway for zero-emission electricity, provided the hydrogen is produced sustainably, for instance via electrolysis powered by renewable energy. Carbon capture and storage retrofits on fossil fuel plants aim to reduce CO₂ emissions, while advanced nuclear reactors, including small modular reactors, seek to provide safer, more flexible, and lower-waste nuclear options. The integration of smart grids, battery storage, and demand-response systems enhances the operational flexibility of power plants, allowing them to better manage intermittent renewable energy generation and maintain grid stability in increasingly complex electricity networks.

In modern energy systems, power plants are not only technological installations but also critical components in economic, environmental, and societal frameworks. Their diversity—from fossil fuel plants to nuclear reactors, hydroelectric facilities, wind farms, and solar parks—reflects the wide array of energy resources available and the evolving priorities of efficiency, sustainability, and resilience. The development and optimization of power plants involve a careful balance between maximizing energy output, minimizing environmental impact, and ensuring economic feasibility. Advances in materials science, turbine technology, energy storage, and digital monitoring have improved the efficiency, reliability, and safety of power plants, while ongoing innovation in renewable and hybrid systems points to a future in which electricity generation becomes cleaner, more flexible, and more integrated with broader energy networks. As global energy demand grows and the imperative for decarbonization intensifies, power plants will continue to evolve, combining traditional and emerging technologies to meet the needs of modern society while striving for environmental sustainability and energy security.

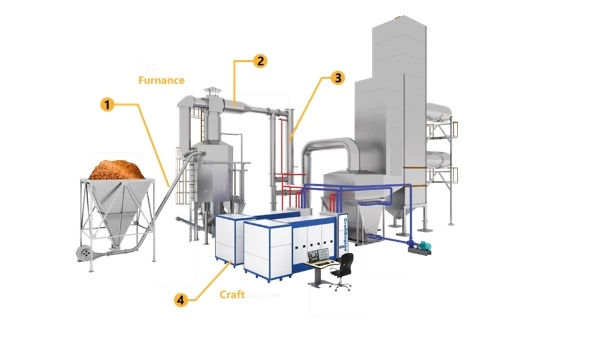

Biomass Gasification Power Plant

A biomass gasification power plant is a facility that converts organic materials such as agricultural residues, wood chips, forestry waste, and other biodegradable biomass into electricity through a thermochemical process known as gasification. Unlike direct combustion, gasification involves heating biomass in a controlled environment with limited oxygen to produce a combustible gas mixture called syngas, which primarily consists of carbon monoxide, hydrogen, methane, and small amounts of other gases. This syngas can then be used to fuel internal combustion engines, gas turbines, or boilers to generate electricity, often in combination with heat recovery systems to improve overall plant efficiency. The gasification process is highly flexible in terms of feedstock and can utilize a wide variety of biomass types, making it an attractive option for regions with abundant agricultural or forestry residues. In addition to electricity generation, gasification allows for the production of valuable by-products such as biochar, which can be used as a soil amendment, and tar or condensates that can serve as chemical feedstocks.

The operation of a biomass gasification power plant begins with feedstock preparation, which may include drying, shredding, and screening to ensure uniform particle size and moisture content. High moisture content can reduce gasification efficiency and increase tar formation, so pre-treatment of biomass is a critical step. Once prepared, the biomass enters the gasifier, which can be designed as an updraft, downdraft, fluidized bed, or entrained flow reactor, each configuration affecting the composition and quality of the syngas produced. In a downdraft gasifier, for instance, the biomass moves downward through zones of drying, pyrolysis, combustion, and reduction, producing relatively clean syngas with lower tar content, suitable for engine or turbine applications. Fluidized bed gasifiers, on the other hand, provide excellent temperature uniformity and fuel flexibility but may require additional gas cleaning to remove particulates and condensable tars before the syngas can be used in sensitive equipment.

After gasification, the raw syngas undergoes a cleaning and conditioning stage, which is crucial to protect downstream equipment and ensure efficient combustion. This stage typically includes particle filtration, tar removal, and moisture adjustment. Advanced cleaning technologies such as cyclones, bag filters, wet scrubbers, or catalytic tar reformers are often employed depending on the syngas application. Cleaned syngas is then directed to a gas engine, gas turbine, or combined cycle system, converting chemical energy into mechanical energy and subsequently into electricity through a generator. Biomass gasification plants are often integrated with heat recovery systems, allowing excess heat from engine cooling, exhaust gases, or gasification itself to be used for district heating, industrial processes, or pre-drying of feedstock, significantly improving overall plant efficiency and making them a form of combined heat and power (CHP) generation.

Environmental performance is a significant advantage of biomass gasification power plants compared to conventional fossil fuel plants. By utilizing renewable feedstocks, they contribute to the reduction of net carbon dioxide emissions, as the CO₂ released during syngas combustion is roughly equivalent to the CO₂ absorbed during biomass growth. Gasification also allows for more controlled and cleaner combustion compared to direct biomass burning, producing lower levels of particulate matter, nitrogen oxides, and sulfur compounds. Furthermore, the generation of biochar as a by-product can sequester carbon in soils, providing additional climate mitigation benefits while improving soil fertility. However, successful operation requires careful attention to feedstock supply chains, gasifier maintenance, and syngas cleaning systems to avoid issues such as tar fouling, slagging, and equipment corrosion.

Biomass gasification power plants vary in scale, from small decentralized units capable of supplying electricity and heat to a local community or industrial facility, to large commercial plants integrated into regional grids. Their modularity and scalability make them suitable for rural electrification projects in agricultural areas, where they can simultaneously provide renewable electricity, waste management, and local economic development. Emerging technologies are improving efficiency, reliability, and feedstock flexibility, including high-pressure gasification, dual fluidized bed designs, and hybrid systems that co-gasify biomass with waste plastics or other materials to optimize energy output. Integration with energy storage systems and smart grid technologies further enhances the role of biomass gasification plants in a modern, resilient, and low-carbon energy system, allowing them to complement intermittent renewable sources like solar and wind while providing baseload or dispatchable power.

Overall, biomass gasification power plants represent a sustainable and versatile approach to electricity generation, bridging the gap between renewable energy adoption and industrial-scale power production. By converting abundant biomass resources into clean syngas and efficiently generating electricity and heat, these plants offer both environmental and economic benefits, particularly in regions with significant agricultural or forestry residues. Their capacity to reduce greenhouse gas emissions, produce valuable co-products such as biochar, and integrate into distributed energy systems makes them a critical technology for achieving decarbonization targets and advancing sustainable energy strategies worldwide. As technological innovations continue to enhance gasifier performance, feedstock flexibility, and syngas utilization, biomass gasification power plants are poised to play an increasingly prominent role in the transition toward renewable and circular energy systems.

A biomass gasification power plant represents a sophisticated approach to renewable energy generation, converting organic materials such as wood chips, agricultural residues, forestry by-products, and various biodegradable wastes into electricity and heat through the thermochemical process of gasification. Unlike traditional combustion-based biomass power generation, gasification occurs under controlled conditions with limited oxygen, transforming solid biomass into a combustible gas mixture known as syngas, which consists primarily of carbon monoxide, hydrogen, methane, and smaller quantities of other hydrocarbons. This syngas can be directed into internal combustion engines, gas turbines, or boilers to produce electricity efficiently, often in combination with heat recovery systems that capture excess thermal energy for industrial processes, district heating, or pre-drying biomass feedstock. The flexibility of gasification allows it to handle a wide range of biomass types and moisture levels, making it particularly suitable for regions with abundant agricultural or forestry residues. Moreover, biomass gasification not only produces energy but also generates by-products such as biochar, which can be used as a soil amendment to enhance fertility and sequester carbon, and tars or condensates that have potential applications as chemical feedstocks, further increasing the sustainability and economic viability of the plant.

The operation of a biomass gasification power plant begins with meticulous feedstock preparation, which typically involves drying, shredding, and screening to achieve uniform particle size and moisture content. Feedstock quality is crucial because high moisture levels or irregular particle sizes can decrease gasification efficiency, increase tar formation, and cause operational difficulties within the gasifier. Once prepared, biomass is fed into the gasifier, which can be designed in several configurations, such as downdraft, updraft, fluidized bed, or entrained flow reactors, each influencing the composition and cleanliness of the syngas produced. Downdraft gasifiers, for instance, pass biomass downward through successive zones of drying, pyrolysis, combustion, and reduction, producing syngas with relatively low tar content suitable for engine or turbine applications. Fluidized bed gasifiers, on the other hand, maintain uniform temperatures and excellent mixing, allowing for higher throughput and fuel flexibility but requiring additional gas cleaning measures to protect sensitive downstream equipment. Regardless of design, the gasification stage is optimized to maximize syngas yield and calorific value while minimizing unwanted by-products and operational challenges.

After the gasification process, the raw syngas undergoes comprehensive cleaning and conditioning, a step that is essential to prevent damage to downstream combustion engines, turbines, or boilers. Gas cleaning typically involves the removal of particulate matter, condensable tars, ash, and other impurities that could cause corrosion, fouling, or operational inefficiencies. Technologies employed for this purpose include cyclones, bag filters, wet scrubbers, electrostatic precipitators, and catalytic tar reformers. In addition to mechanical cleaning, moisture adjustment and sometimes chemical conditioning are applied to stabilize the syngas composition and calorific value. Once cleaned and conditioned, the syngas is used in combustion systems to drive generators, converting chemical energy into mechanical energy and ultimately into electricity. Many biomass gasification plants incorporate combined heat and power (CHP) systems, capturing residual heat from syngas combustion or engine exhaust for industrial processes or district heating, thereby significantly increasing overall energy efficiency and reducing fuel consumption.

Environmental and economic advantages make biomass gasification power plants an attractive alternative to conventional fossil fuel-based generation. By utilizing renewable feedstocks, they help reduce net greenhouse gas emissions because the carbon dioxide released during combustion roughly equals the carbon dioxide absorbed by the biomass during its growth, creating a near-neutral carbon cycle. Gasification also allows more controlled and cleaner combustion compared to direct biomass burning, resulting in lower emissions of particulate matter, nitrogen oxides, and sulfur compounds. Additionally, the production of biochar as a by-product provides a form of carbon sequestration while enhancing soil fertility and agricultural productivity. However, the successful operation of a biomass gasification plant depends on a consistent supply of feedstock, proper maintenance of the gasifier, and effective syngas cleaning systems to prevent operational issues such as tar fouling, slagging, and equipment corrosion, which could reduce efficiency and increase maintenance costs.

The scale of biomass gasification plants can range from small decentralized systems serving individual communities or industrial facilities to large commercial plants integrated into regional electricity grids. Smaller modular units are particularly advantageous for rural electrification projects in agricultural regions, as they provide renewable electricity, manage agricultural residues, and stimulate local economic development simultaneously. Larger plants can leverage economies of scale to optimize energy output, improve heat recovery integration, and potentially co-gasify biomass with other waste materials such as plastics or municipal solid waste to increase efficiency and syngas quality. Emerging technological innovations, including high-pressure gasification, dual fluidized bed systems, and hybrid gasification-combustion approaches, are improving the performance, reliability, and feedstock flexibility of these plants, making them more adaptable to diverse energy systems and challenging operational environments. Integration with smart grid technologies and energy storage further enhances the ability of biomass gasification plants to provide dispatchable power and complement intermittent renewable energy sources like wind and solar, thereby increasing overall grid stability and resilience.

Overall, biomass gasification power plants play a pivotal role in the transition toward renewable and sustainable energy systems, providing a versatile solution that converts abundant organic residues into clean electricity and heat. Their ability to reduce greenhouse gas emissions, generate valuable co-products like biochar, integrate with CHP systems, and adapt to a wide range of biomass feedstocks makes them a strategic technology for both industrial and rural energy applications. By combining advanced gasification techniques, effective syngas cleaning, and efficient energy conversion systems, these plants offer not only a renewable electricity source but also an environmentally sustainable method of managing biomass residues and supporting circular economy principles. As technology continues to evolve and integration with energy storage, smart grids, and hybrid renewable systems improves, biomass gasification power plants are poised to become an increasingly important component of global efforts to achieve energy security, carbon reduction, and sustainable development goals.

A biomass gasification power plant is a sophisticated and versatile facility designed to convert renewable organic materials such as agricultural residues, forestry waste, wood chips, energy crops, and other biodegradable biomass into electricity and heat through a controlled thermochemical process called gasification. Unlike traditional biomass combustion, which directly burns feedstock to produce heat, gasification involves heating the biomass in an environment with limited oxygen, producing a combustible gas mixture known as syngas. This syngas primarily consists of carbon monoxide, hydrogen, methane, and minor amounts of other hydrocarbons, which can then be directed into gas engines, gas turbines, or boilers to generate electricity. The gasification process allows for more efficient energy conversion and greater control over emissions compared to direct burning, and it can be coupled with heat recovery systems to capture waste heat from engine exhaust, syngas cooling, or other processes, creating combined heat and power (CHP) systems with significantly higher overall efficiency. The versatility of biomass gasification enables it to utilize a wide range of feedstocks with different moisture contents, particle sizes, and chemical compositions, making it particularly suitable for rural areas or regions with abundant agricultural and forestry residues. In addition to energy production, gasification generates valuable by-products such as biochar, which can be applied as a soil amendment for carbon sequestration and improved fertility, and condensable tars or other organics that can be further refined into chemicals or fuels, enhancing the overall economic value of the plant.

The operation of a biomass gasification power plant begins with careful feedstock preparation to ensure optimal performance and stable operation of the gasifier. This preparation often includes drying, shredding, and screening the biomass to achieve a uniform size and moisture content, as variations can lead to reduced gasification efficiency, increased tar formation, and operational issues such as slagging or clogging. Once prepared, the biomass enters the gasifier, which may be designed as a downdraft, updraft, fluidized bed, or entrained flow reactor, each configuration offering distinct advantages and influencing the composition, quality, and cleanliness of the resulting syngas. In downdraft gasifiers, biomass passes downward through zones of drying, pyrolysis, combustion, and reduction, producing syngas with relatively low tar content that is ideal for combustion in engines or turbines. Fluidized bed gasifiers, in contrast, maintain uniform temperatures and excellent mixing, allowing for higher throughput and fuel flexibility but necessitating more rigorous gas cleaning to remove particulates and tars before utilization. Entrained flow gasifiers can achieve higher reaction rates and produce syngas with lower methane content, which may be suitable for industrial synthesis or large-scale power generation, but they generally require finely ground feedstock and higher operating temperatures.

After gasification, the raw syngas undergoes an extensive cleaning and conditioning stage to remove particulates, condensable tars, ash, and other impurities that could damage downstream equipment or reduce energy conversion efficiency. Gas cleaning technologies include cyclones, bag filters, wet scrubbers, electrostatic precipitators, and catalytic tar reformers, depending on the syngas composition and the type of generator being used. Moisture and temperature are adjusted to optimize the gas quality and calorific value, ensuring stable and efficient combustion. Once cleaned, the syngas is directed to gas engines, turbines, or boilers to produce mechanical energy, which is then converted into electricity by generators. Many biomass gasification plants also capture residual heat from exhaust gases, engine cooling systems, or other thermal sources, channeling it to industrial processes or district heating networks, which significantly improves overall plant efficiency and aligns with energy optimization principles. By combining power generation with heat utilization, biomass gasification plants can achieve energy efficiencies of 60% or higher, far surpassing conventional biomass or fossil fuel power plants.

Environmental sustainability is a central advantage of biomass gasification power plants. By using renewable biomass, these plants help reduce net greenhouse gas emissions, as the carbon dioxide released during syngas combustion is roughly balanced by the carbon dioxide absorbed during the growth of the biomass feedstock, creating a near-carbon-neutral energy cycle. Gasification also provides cleaner combustion than direct biomass burning, resulting in lower emissions of particulate matter, sulfur oxides, and nitrogen oxides, while minimizing smoke and odor issues. The production of biochar as a by-product further enhances environmental benefits by sequestering carbon in soils and improving soil structure and fertility. Nevertheless, successful operation requires careful management of feedstock supply chains, gasifier maintenance, and syngas cleaning processes to prevent operational challenges such as tar fouling, slagging, corrosion, and equipment wear, which could reduce efficiency, increase maintenance costs, or lead to unplanned downtime. Optimizing plant design, feedstock logistics, and operational protocols is therefore critical to achieving reliable, efficient, and environmentally sustainable performance.

Biomass gasification power plants can be deployed at a range of scales, from small decentralized units serving a single community or industrial facility to large commercial plants supplying regional electricity grids. Smaller modular systems are particularly beneficial for rural electrification, offering renewable electricity, heat for local industrial or agricultural applications, and effective management of biomass residues, thereby supporting local economic development. Large-scale plants can take advantage of economies of scale, allowing more efficient gasification, better heat recovery integration, and even co-gasification of biomass with other waste streams such as municipal solid waste or plastics to enhance syngas yield and calorific value. Technological innovations, including high-pressure gasification, dual fluidized bed systems, and hybrid gasification-combustion approaches, continue to improve efficiency, feedstock flexibility, and reliability, enabling these plants to operate under diverse conditions and with a variety of feedstock compositions. The integration of energy storage solutions, smart grid technologies, and digital monitoring allows biomass gasification plants to provide dispatchable power, complement intermittent renewable sources such as solar and wind, and contribute to grid stability and resilience in modern energy networks.

Overall, biomass gasification power plants represent a critical technology for the sustainable energy transition, offering a versatile and efficient way to convert organic waste into electricity and heat. By utilizing widely available biomass resources, generating valuable by-products such as biochar, and integrating with CHP and energy storage systems, these plants deliver both environmental and economic benefits. Their scalability, adaptability to diverse feedstocks, and ability to provide both baseload and flexible power make them particularly valuable in regions seeking to reduce dependence on fossil fuels, manage agricultural or forestry residues, and meet renewable energy targets. Advances in gasification technology, syngas cleaning, and hybrid system integration are continually enhancing the performance and cost-effectiveness of biomass gasification power plants, positioning them as a sustainable and reliable solution for electricity generation in both rural and urban settings. As the global push for decarbonization and circular energy systems intensifies, biomass gasification plants are likely to play an increasingly important role in achieving energy security, reducing greenhouse gas emissions, and supporting the development of resilient and sustainable energy infrastructure worldwide.

A biomass gasification power plant is a highly advanced renewable energy facility that transforms organic materials such as wood chips, agricultural residues, forestry by-products, energy crops, and other biodegradable wastes into electricity and thermal energy through a controlled thermochemical process called gasification. This process differs from conventional biomass combustion because it converts solid biomass into a combustible gas mixture, known as syngas, under conditions of limited oxygen rather than directly burning it. The syngas typically consists of carbon monoxide, hydrogen, methane, and small amounts of other hydrocarbons, and it can be utilized in gas engines, gas turbines, or boilers to generate electricity with high efficiency. In addition to power production, biomass gasification allows for heat recovery, which can be used for industrial processes, district heating, or pre-drying of biomass feedstock, thus creating combined heat and power (CHP) systems that maximize overall energy utilization. The technology is highly flexible in terms of feedstock types, handling variations in moisture content, size, and chemical composition, making it suitable for rural regions with abundant agricultural or forestry residues. Moreover, the process generates valuable by-products such as biochar, which serves as a soil amendment and carbon sequestration tool, and condensable tars or other organics that can be refined into chemicals or fuels, enhancing the overall economic viability and sustainability of the plant.

The initial stage in a biomass gasification power plant involves thorough feedstock preparation, which includes drying, shredding, and screening to achieve consistent particle size and moisture content. Proper preparation is critical because inconsistencies in biomass characteristics can decrease gasification efficiency, increase tar formation, and cause operational problems such as slagging, fouling, or clogging within the gasifier. After preparation, biomass is introduced into the gasifier, which can be configured as a downdraft, updraft, fluidized bed, or entrained flow reactor, each type influencing the composition, energy content, and cleanliness of the resulting syngas. Downdraft gasifiers, for example, allow biomass to pass downward through zones of drying, pyrolysis, combustion, and reduction, producing syngas with relatively low tar content suitable for direct use in engines and turbines. Fluidized bed gasifiers offer excellent temperature uniformity and mixing, supporting higher throughput and a wide variety of feedstocks, although additional syngas cleaning may be required. Entrained flow gasifiers can operate at higher temperatures, producing syngas with lower methane content, which can be advantageous for certain industrial processes but require finely ground biomass and precise operational control. Regardless of the gasifier design, the goal is to maximize the yield and calorific value of syngas while minimizing the formation of unwanted by-products such as tars, ash, or particulate matter.

After gasification, the raw syngas undergoes extensive cleaning and conditioning to remove impurities that could damage downstream equipment or reduce energy conversion efficiency. This includes the removal of particulates, condensable tars, ash, and other contaminants through devices such as cyclones, bag filters, wet scrubbers, electrostatic precipitators, or catalytic tar reformers. Syngas temperature and moisture are also adjusted to optimize combustion and maintain stable operation. Once cleaned, the syngas is directed to internal combustion engines, gas turbines, or boilers to generate mechanical energy, which is converted into electricity via generators. Many biomass gasification plants integrate heat recovery systems to capture waste heat from exhaust gases, engine cooling systems, or the gasification process itself, supplying heat for industrial processes or district heating networks. This combined heat and power approach can significantly increase the overall efficiency of the plant, with energy utilization rates often exceeding 60%, compared to the lower efficiency of conventional biomass or fossil fuel power plants.

Environmentally, biomass gasification power plants provide substantial benefits over conventional fossil fuel and direct biomass combustion systems. By using renewable feedstocks, these plants contribute to a reduction in net greenhouse gas emissions because the carbon dioxide released during combustion is approximately offset by the carbon dioxide absorbed during the growth of the biomass. Gasification also allows for cleaner and more controlled combustion, producing lower emissions of particulate matter, nitrogen oxides, sulfur oxides, and other pollutants. Additionally, biochar produced as a by-product can sequester carbon when applied to soils while improving soil structure and fertility. Despite these advantages, effective operation requires careful management of feedstock supply, gasifier maintenance, and syngas cleaning to prevent operational issues such as tar fouling, slagging, corrosion, and equipment wear, which could compromise efficiency, increase maintenance costs, or cause unplanned downtime. Achieving reliable, high-performance operation demands careful optimization of plant design, operational procedures, and feedstock logistics to balance energy production, economic viability, and environmental performance.

Biomass gasification power plants are scalable and can be deployed in various sizes, from small modular units providing electricity and heat to individual communities or industrial facilities, to large commercial plants integrated into regional or national electricity grids. Small modular systems are particularly effective in rural electrification, as they utilize locally available biomass residues to produce renewable electricity, supply heat for local industrial or agricultural applications, and reduce waste disposal challenges, thereby supporting economic development in rural areas. Large-scale plants benefit from economies of scale, improved gasification efficiency, enhanced heat recovery integration, and the potential to co-gasify biomass with other waste streams, such as municipal solid waste or plastic residues, to increase energy output and syngas quality. Technological innovations such as high-pressure gasification, dual fluidized bed systems, and hybrid gasification-combustion approaches have improved the reliability, feedstock flexibility, and efficiency of these plants, enabling them to operate effectively under diverse conditions and with variable feedstock types. Integration with smart grids, energy storage systems, and digital monitoring platforms further enhances the flexibility of biomass gasification plants, allowing them to provide dispatchable power and support grid stability alongside intermittent renewable sources like wind and solar power.

The strategic significance of biomass gasification power plants lies in their capacity to deliver both environmental and economic benefits while supporting the transition to sustainable energy systems. By converting widely available biomass residues into electricity and heat, generating biochar and other by-products, and integrating with CHP and energy storage technologies, these plants provide a multifaceted solution to energy, environmental, and waste management challenges. Their adaptability to diverse feedstocks, scalability from small rural installations to large industrial plants, and ability to provide both base-load and flexible power make them particularly valuable for regions aiming to reduce fossil fuel dependence, manage agricultural or forestry residues, and achieve renewable energy targets. Continuous technological improvements in gasification efficiency, syngas cleaning, and hybrid system integration enhance the performance, cost-effectiveness, and sustainability of these plants. As global energy systems evolve toward decarbonization, circular economy models, and resilient distributed energy networks, biomass gasification power plants are poised to play a pivotal role in delivering reliable, renewable, and environmentally sustainable electricity and heat across both rural and urban contexts, contributing to energy security, carbon reduction, and sustainable development on a global scale.

Future Individual Power Plants

Future individual power plants are likely to transform the landscape of energy generation by combining advanced technologies, decentralized operation, renewable resources, and intelligent control systems to meet the growing demand for sustainable, resilient, and self-sufficient electricity solutions. Unlike traditional centralized power stations, which rely on large-scale fossil fuel or nuclear infrastructure, future individual power plants will emphasize modularity, flexibility, and integration with local energy systems, allowing homes, commercial buildings, and industrial facilities to generate their own electricity, store it efficiently, and even share excess power with the grid or neighboring users. These plants will incorporate renewable energy sources such as solar photovoltaics, small wind turbines, biomass gasifiers, geothermal units, and micro-hydropower, often in hybrid configurations that optimize output under varying environmental conditions. By combining multiple energy sources with advanced storage solutions, such as lithium-ion batteries, flow batteries, or hydrogen storage, future individual power plants will be able to maintain continuous electricity supply, balance peak demand, and provide backup power in the event of grid outages, effectively making each facility a self-contained, intelligent energy hub.

A key feature of future individual power plants will be their reliance on smart technologies and digital management systems. Artificial intelligence, predictive analytics, and real-time monitoring will allow these plants to optimize energy production and consumption according to weather patterns, electricity pricing, and user demand. For instance, a rooftop solar PV system integrated with a home energy management system could automatically adjust battery charging, household appliance usage, and electric vehicle charging to maximize self-consumption and minimize grid dependency. Similarly, small-scale biomass gasification units or micro-CHP systems could operate in coordination with heat demand, storing excess energy as thermal reserves or syngas for later conversion to electricity. The convergence of smart grid infrastructure, blockchain-enabled energy trading, and IoT devices will enable individual power plants not only to serve their own energy needs but also to participate in local energy markets, sell surplus electricity, or provide ancillary services such as frequency regulation and voltage support to the broader grid. This decentralized and interactive model of electricity generation will enhance overall grid resilience and reduce transmission losses while empowering consumers to actively participate in energy management and decarbonization efforts.

Environmental sustainability and carbon reduction will also be central to the design and deployment of future individual power plants. By prioritizing renewable energy sources, highly efficient conversion technologies, and advanced storage, these systems can drastically reduce greenhouse gas emissions compared to traditional fossil fuel-based power generation. Small-scale biomass gasification units, for example, will convert locally available organic residues into electricity and heat with minimal emissions, often in CHP configurations that capture and utilize thermal energy. Combined with rooftop solar, small wind, or geothermal units, these systems will enable households, communities, and businesses to significantly lower their carbon footprint while contributing to circular energy models where waste is transformed into energy. Advanced energy storage solutions, including hydrogen production and fuel cells, will further allow for renewable energy to be stored over long periods, addressing intermittency challenges and ensuring continuous electricity supply. Moreover, future individual power plants will likely incorporate carbon capture or biochar generation in biomass-based systems, further enhancing their environmental benefits and enabling localized contributions to climate mitigation strategies.

The economic and operational flexibility of future individual power plants will make them attractive not only for environmentally conscious consumers but also for commercial and industrial applications. Microgrids or individual power plants can reduce electricity costs by allowing users to generate power on-site, avoid peak pricing, and participate in energy trading programs. Hybrid systems combining solar, wind, biomass, and storage provide redundancy and adaptability, enabling facilities to operate independently of centralized grids or to switch seamlessly between grid-connected and islanded modes. Maintenance and operation of these plants will be increasingly automated, with remote monitoring, predictive maintenance algorithms, and modular components simplifying the lifecycle management and reducing downtime. Additionally, the modular and scalable nature of individual power plants means they can grow incrementally, adapting to increased energy demand or integrating new technologies as they become available, creating a dynamic, future-proof energy solution for residential, commercial, and industrial applications.

Social and community impacts of future individual power plants will also be significant. Widespread adoption of decentralized power generation can empower communities to achieve energy independence, improve local resilience against natural disasters or grid failures, and foster innovation in energy management practices. Local energy hubs could facilitate shared energy resources, such as community solar arrays, micro-hydropower facilities, or biomass gasification units, enabling cooperative energy production and distribution models. These systems will also promote awareness and engagement with energy efficiency, storage strategies, and demand-side management, as users actively participate in monitoring and optimizing their energy use. By decentralizing energy production and integrating smart systems, future individual power plants can contribute to a more democratized and resilient energy system, where electricity is not only a commodity but also a locally managed resource that supports sustainability, reliability, and economic empowerment.

Technologically, future individual power plants will benefit from advances in materials science, energy conversion devices, and digital control systems. High-efficiency photovoltaic panels, low-wind-speed turbines, compact biomass gasifiers, micro-CHP units, and small-scale fuel cells will increase energy output while minimizing footprint and environmental impact. Power electronics and inverters will enable seamless integration of multiple energy sources and storage units, while AI-driven optimization algorithms will ensure that energy is generated, stored, and consumed in the most efficient manner possible. Integration with electric vehicles will further enhance the utility of individual power plants, allowing vehicles to act as both storage devices and flexible loads, participating in vehicle-to-grid schemes that stabilize the local or regional electricity network. As these technologies mature, individual power plants will increasingly function as intelligent, self-sufficient energy nodes capable of meeting diverse electricity and thermal needs while reducing dependency on centralized power generation and fossil fuels.

In conclusion, future individual power plants represent a paradigm shift in electricity generation, combining renewable energy, decentralized operation, energy storage, and intelligent digital management to create highly efficient, sustainable, and resilient energy systems. These plants will leverage hybrid technologies such as solar, wind, biomass gasification, micro-CHP, and fuel cells, paired with advanced storage and predictive control systems, to provide continuous electricity and heat tailored to local needs. By decentralizing energy production, enabling smart grid participation, and supporting carbon reduction initiatives, future individual power plants will empower consumers, communities, and industries to manage their energy independently while contributing to broader sustainability goals. Their modularity, scalability, and integration with emerging technologies make them a flexible and future-proof solution, capable of adapting to evolving energy demands, environmental standards, and economic conditions. As adoption increases, future individual power plants are poised to play a central role in shaping a more sustainable, resilient, and democratically managed global energy landscape, transforming the way electricity is generated, distributed, and consumed across homes, businesses, and communities worldwide.

Future individual power plants are expected to redefine how electricity is generated, distributed, and consumed, moving away from the centralized, large-scale model of traditional power stations toward modular, decentralized, and highly intelligent systems that can serve homes, commercial buildings, industrial facilities, and even small communities. These plants will harness a combination of renewable energy sources, such as rooftop solar photovoltaics, small-scale wind turbines, micro-hydropower, biomass gasification units, geothermal systems, and hybrid configurations that optimize energy production depending on local conditions and resource availability. Unlike conventional centralized plants that rely on the transmission of electricity over long distances, future individual power plants will operate close to the point of consumption, reducing transmission losses, enhancing energy efficiency, and increasing resilience against grid disturbances or outages. By integrating advanced energy storage technologies such as lithium-ion or solid-state batteries, flow batteries, hydrogen storage, or thermal storage systems, these plants will be capable of providing continuous power regardless of intermittency in renewable energy production, balancing fluctuating demands while offering backup capabilities during emergencies or peak usage periods. This decentralized and intelligent energy paradigm will allow each household, facility, or community to function as an autonomous energy hub, with the flexibility to generate, store, and distribute electricity efficiently while participating in wider smart grid ecosystems.

A core characteristic of future individual power plants will be the integration of digital and smart technologies that optimize operation, maintenance, and energy management. Artificial intelligence, predictive analytics, and real-time monitoring will allow these systems to dynamically adjust energy generation, storage, and consumption based on weather forecasts, electricity pricing, demand patterns, and resource availability. For instance, a hybrid solar PV and small biomass gasification unit could automatically regulate battery charging, syngas production, and engine operation to maximize energy self-consumption while minimizing waste and costs. Internet of Things (IoT) devices will facilitate granular monitoring of energy flows, appliance usage, and equipment health, while blockchain-enabled peer-to-peer energy trading platforms will allow excess electricity to be sold or shared with neighbors, communities, or local microgrids. Such technologies will not only enhance energy efficiency and reliability but also empower consumers to participate actively in energy markets, turning previously passive electricity users into active energy managers who can influence grid stability, pricing, and environmental outcomes. By enabling real-time responsiveness, predictive maintenance, and decentralized energy trading, future individual power plants will form the foundation of intelligent energy networks capable of optimizing supply and demand across multiple scales.

Environmental sustainability and carbon reduction will be central to the design and deployment of future individual power plants. By prioritizing renewable energy sources, highly efficient conversion technologies, and integrated storage solutions, these systems can significantly reduce greenhouse gas emissions compared to traditional fossil fuel-based power generation. Small-scale biomass gasification plants, for example, will transform locally sourced organic residues into electricity and heat while producing biochar as a by-product, contributing to carbon sequestration and soil enrichment. Hybrid configurations that combine solar, wind, biomass, and geothermal systems will ensure continuous electricity supply while minimizing reliance on carbon-intensive fuels. Energy storage will allow intermittent renewable generation to be utilized effectively, ensuring reliable power even during periods of low sunlight, weak wind, or seasonal variations. Additionally, future individual power plants may incorporate emerging technologies such as fuel cells, hydrogen production, and carbon capture in biomass-based systems, further enhancing environmental benefits and enabling localized contributions to climate mitigation objectives. By generating energy close to the point of use and integrating renewable sources, these plants will reduce the ecological footprint associated with long-distance electricity transmission and distribution, helping communities achieve both sustainability and energy security goals.

Economically, future individual power plants will provide substantial value to both residential and industrial users by lowering electricity costs, enabling participation in energy markets, and enhancing energy independence. On-site generation allows users to avoid peak electricity prices, optimize self-consumption, and, in some cases, sell surplus energy to the grid or neighbors, creating new revenue streams. Hybrid systems combining solar, wind, biomass, and storage provide redundancy and adaptability, allowing facilities to operate independently from centralized grids or switch seamlessly between grid-connected and islanded modes during outages. Automation, predictive maintenance, and modular design will simplify plant operation, reduce downtime, and extend equipment life, while scalability ensures that plants can grow incrementally as energy demand increases or as new technologies become available. In industrial or commercial contexts, individual power plants can also support process heating, cooling, and other energy-intensive operations, providing both electricity and thermal energy through CHP or waste-heat recovery systems, which further enhances economic efficiency and overall return on investment.

Socially and communally, the widespread adoption of future individual power plants will empower communities, foster energy independence, and enhance resilience against natural disasters, grid failures, and fluctuating energy costs. Localized power generation encourages shared ownership models, such as community solar arrays, neighborhood microgrids, or cooperative biomass facilities, allowing multiple users to benefit from decentralized energy production. By involving communities directly in energy management, these systems promote greater awareness of energy consumption, efficiency practices, and sustainability goals. They also enable flexible demand-side management strategies, in which households or businesses can adjust energy use based on grid conditions or local generation, supporting the stability and reliability of the wider energy system. Decentralized energy generation will also play a key role in disaster preparedness, ensuring that essential services, healthcare facilities, and critical infrastructure remain operational during outages, while empowering local authorities and communities to manage energy autonomously.

Technologically, future individual power plants will leverage advances in energy conversion, storage, and digital control systems to achieve higher efficiency, reliability, and sustainability. High-efficiency photovoltaic panels, low-wind-speed turbines, compact biomass gasifiers, micro-CHP units, small-scale fuel cells, and hybrid systems will deliver robust energy output while minimizing land use, noise, and emissions. Power electronics and inverters will integrate multiple energy sources, regulate voltage and frequency, and manage bi-directional energy flows to storage systems and grids. AI-driven optimization algorithms will coordinate generation, storage, and consumption, while vehicle-to-grid integration will allow electric vehicles to function as distributed storage resources and flexible loads, enhancing both the utility of individual power plants and grid stability. These technological advancements will allow individual power plants to function as intelligent, self-sufficient energy nodes that meet diverse electricity and thermal needs while supporting broader energy transition objectives, including decarbonization, grid resilience, and circular economy principles.

In summary, future individual power plants are poised to revolutionize energy generation by combining renewable energy, decentralized operation, hybrid technologies, energy storage, and intelligent control systems to provide efficient, reliable, and environmentally sustainable power. By operating close to the point of consumption, integrating multiple energy sources, and leveraging digital management platforms, these systems will reduce dependence on centralized fossil fuel generation, optimize energy utilization, and empower consumers, businesses, and communities to actively manage electricity and heat production. They will enable participation in local energy markets, enhance resilience, and provide scalable, modular solutions adaptable to evolving energy needs, technological developments, and environmental regulations. Through these innovations, future individual power plants will play a central role in shaping a resilient, sustainable, and democratically managed energy landscape, transforming how energy is produced, distributed, and consumed across homes, industries, and communities worldwide.

Future individual power plants are poised to fundamentally transform the way energy is generated, stored, and consumed, creating a paradigm shift from centralized, large-scale electricity generation toward highly localized, modular, and intelligent energy systems that serve homes, commercial enterprises, industrial facilities, and small communities. These plants are expected to combine a variety of renewable and low-carbon energy sources, including rooftop solar photovoltaic arrays, small-scale wind turbines, micro-hydropower installations, compact biomass gasification units, geothermal systems, and hybrid configurations that optimize energy production according to local climate conditions, seasonal variations, and the availability of resources. Unlike traditional centralized power stations, which require the transmission of electricity over long distances with inherent losses and vulnerability to disruptions, future individual power plants will operate close to points of consumption, reducing energy losses, increasing reliability, and providing resilience in the face of natural disasters, grid failures, or peak demand fluctuations. By integrating advanced energy storage technologies such as lithium-ion batteries, flow batteries, hydrogen storage, thermal energy storage, or even vehicle-to-grid systems, these plants will maintain a continuous supply of electricity, store excess energy during periods of high generation, and dynamically manage energy output to meet fluctuating consumption demands, thereby functioning as autonomous, intelligent energy hubs capable of both self-sufficiency and contribution to broader smart grid networks.

Central to the operation of future individual power plants will be the use of sophisticated digital management, predictive analytics, and artificial intelligence systems that allow for real-time optimization of energy generation, storage, and consumption. Smart control systems will be able to predict electricity demand based on historical usage, forecast weather and solar or wind availability, and adjust generation schedules accordingly to maximize efficiency and minimize operational costs. For example, a hybrid system combining solar photovoltaics and a small biomass gasification unit could automatically manage battery charging, syngas production, and engine operation to ensure that energy is available when needed while storing surplus for future use. Internet of Things (IoT) sensors will monitor equipment health, energy flows, and environmental conditions, while blockchain-enabled energy trading platforms may allow individual plants to participate in decentralized peer-to-peer electricity markets, selling surplus energy to neighbors, microgrids, or the main grid. These capabilities will transform electricity consumers into active energy managers, enabling households, businesses, and communities to directly influence grid stability, energy pricing, and carbon emissions while optimizing the use of locally generated energy.

Environmental sustainability and climate impact reduction will be major drivers in the design and deployment of future individual power plants. By prioritizing renewable and low-carbon energy sources, these systems can drastically reduce greenhouse gas emissions and other pollutants compared to conventional fossil fuel-based electricity generation. Biomass gasification units, for instance, can convert locally sourced agricultural or forestry residues into electricity and thermal energy while producing biochar as a by-product that can be used for carbon sequestration and soil enhancement. Hybrid configurations that integrate solar, wind, geothermal, and biomass generation will ensure continuous energy availability while reducing reliance on carbon-intensive fuels. Advanced energy storage technologies will address the intermittency of solar and wind resources, ensuring reliable electricity even during periods of low generation. Moreover, future individual power plants may incorporate additional innovations such as fuel cells, hydrogen production and storage, or carbon capture technologies in biomass systems, providing further pathways for sustainable energy production, carbon footprint reduction, and local climate mitigation efforts. By producing energy close to the point of use, these plants will minimize the environmental and economic costs associated with long-distance transmission and distribution, while also reducing the overall ecological footprint of energy consumption.

Economically, future individual power plants will offer significant advantages by reducing electricity costs, providing energy independence, and creating opportunities for participation in energy markets. On-site generation allows households, businesses, and industries to avoid peak electricity pricing, maximize self-consumption, and potentially generate revenue by selling surplus energy to the grid or through peer-to-peer energy trading. Hybrid systems combining solar, wind, biomass, and storage offer redundancy and operational flexibility, enabling users to remain self-sufficient during grid outages while adjusting generation to meet varying demands. Automation, predictive maintenance, and modular plant design will reduce operational complexity, minimize downtime, and extend equipment lifespan, making future individual power plants cost-effective and reliable solutions for diverse applications. In industrial contexts, these systems will support electricity-intensive processes, provide heat for manufacturing, or integrate with cooling and thermal systems through combined heat and power (CHP) configurations, further increasing energy efficiency, reducing operational costs, and enhancing return on investment.

Socially and communally, the proliferation of individual power plants will empower communities to achieve energy independence, increase resilience, and promote participatory energy management models. Decentralized energy generation will allow neighborhoods and municipalities to establish local microgrids, community solar arrays, shared biomass gasification units, or cooperative hybrid energy hubs that distribute electricity efficiently among multiple users. These models will encourage awareness of energy consumption patterns, efficiency improvements, and sustainable practices, fostering engagement and responsibility among users. Decentralized energy networks also improve preparedness for emergencies, ensuring critical services, healthcare facilities, and infrastructure remain operational during grid failures or natural disasters. By democratizing access to energy production and management, future individual power plants will strengthen local control over energy resources, supporting both social equity and resilience while contributing to broader sustainability and climate goals.

Technologically, future individual power plants will capitalize on advances in energy conversion, storage, and digital control systems to achieve unprecedented levels of efficiency, flexibility, and sustainability. High-efficiency photovoltaic panels, low-wind-speed turbines, compact biomass gasification units, micro-CHP systems, small fuel cells, and advanced hybrid configurations will enable robust electricity and thermal energy generation in limited spaces while minimizing environmental impact. Power electronics, inverters, and smart control interfaces will seamlessly integrate multiple generation and storage technologies, manage bi-directional energy flows, and maintain voltage and frequency stability for local grids. Artificial intelligence-driven optimization algorithms will coordinate energy production, consumption, and storage dynamically, while integration with electric vehicles will enable vehicle-to-grid functionality, where EV batteries act as distributed storage resources and flexible loads to stabilize energy supply. Collectively, these technological developments will transform future individual power plants into intelligent, self-sufficient energy nodes capable of supplying reliable electricity and thermal energy while supporting broader energy transition objectives such as decarbonization, resilience, and circular economy integration.

In conclusion, future individual power plants will redefine energy generation and consumption by combining renewable energy, decentralized operation, hybrid technology configurations, advanced storage, and intelligent digital control systems to deliver sustainable, efficient, and reliable electricity and heat. By operating close to the point of consumption, integrating multiple energy sources, and leveraging predictive analytics and smart grid technologies, these plants will reduce dependence on centralized fossil fuel generation, enhance energy efficiency, and empower consumers, businesses, and communities to actively manage energy resources. They will facilitate participation in local energy markets, increase resilience, support decarbonization, and provide scalable, modular solutions adaptable to evolving energy needs and technological advancements. As adoption spreads, future individual power plants will play a central role in shaping a resilient, sustainable, and democratically managed global energy landscape, transforming electricity generation from a centralized commodity into a flexible, locally managed, and environmentally responsible resource for homes, industries, and communities worldwide.

Future individual power plants are increasingly being envisioned as the cornerstone of a decentralized, resilient, and sustainable energy future, where electricity generation, storage, and management are integrated directly into homes, commercial buildings, industrial facilities, and local communities. These plants will leverage a combination of renewable and low-carbon energy sources, such as rooftop solar photovoltaic systems, small-scale wind turbines, micro-hydropower installations, compact biomass gasification units, geothermal systems, and hybrid arrangements that optimize energy production based on resource availability, seasonal variations, and local energy demands. By operating close to the point of consumption, future individual power plants will significantly reduce transmission losses, improve energy efficiency, and enhance local resilience against grid disruptions, extreme weather events, and fluctuating demand. The incorporation of advanced energy storage solutions, including lithium-ion, solid-state, and flow batteries, as well as hydrogen and thermal storage, will allow these plants to provide continuous electricity supply, store excess energy during periods of high generation, and manage load fluctuations, transforming each installation into a self-sufficient and intelligent energy hub capable of interacting dynamically with the wider electricity network.

The operation of future individual power plants will be defined by smart, automated control systems and advanced digital management technologies. Artificial intelligence, machine learning, predictive analytics, and real-time monitoring will enable precise control over energy generation, storage, and consumption. For example, hybrid configurations combining solar photovoltaics and biomass gasification units can automatically regulate battery charging, syngas production, and engine operation to optimize self-consumption, minimize waste, and ensure energy availability during peak demand periods. Internet of Things (IoT) devices will provide granular monitoring of equipment performance, energy flows, and environmental conditions, while blockchain-enabled platforms will allow peer-to-peer energy trading, enabling households, businesses, and communities to sell surplus energy to neighbors, microgrids, or the main grid. These technologies will empower energy consumers to actively manage electricity, contribute to grid stability, reduce energy costs, and participate in carbon reduction efforts, fundamentally transforming the traditional consumer-producer relationship into one of dynamic, interactive energy management.

Environmental sustainability will be central to the design and deployment of future individual power plants. By prioritizing renewable energy sources and highly efficient conversion systems, these plants will reduce greenhouse gas emissions and other pollutants compared to conventional fossil fuel-based power generation. Small-scale biomass gasification units, for instance, can transform locally sourced agricultural residues or forestry by-products into electricity and heat while producing biochar that can be used for carbon sequestration and soil enhancement. Hybrid systems integrating solar, wind, geothermal, and biomass sources will ensure energy continuity while minimizing dependency on carbon-intensive fuels. Advanced storage solutions will manage the intermittency of renewables, enabling reliable electricity supply even when sunlight or wind is unavailable. Future plants may also incorporate cutting-edge technologies such as fuel cells, hydrogen generation, and carbon capture in biomass systems, offering additional pathways for sustainability, carbon footprint reduction, and climate mitigation. By generating energy close to the point of use, these systems reduce transmission losses, infrastructure strain, and the environmental impacts associated with centralized energy distribution.

Economically, future individual power plants will deliver multiple advantages. On-site generation reduces electricity costs by allowing users to avoid peak tariffs, maximize self-consumption, and potentially monetize surplus energy through local trading or grid integration. Hybrid configurations combining solar, wind, biomass, and storage increase operational flexibility and reliability, enabling facilities to operate independently during grid outages or participate in demand response programs. Automation, predictive maintenance, and modular plant designs will minimize operational complexity, reduce downtime, extend equipment life, and improve return on investment. Industrial applications of these plants can also benefit from combined heat and power (CHP) configurations, using thermal energy for process heating, cooling, or drying operations, further enhancing economic efficiency and overall energy utilization. Incremental scalability allows plants to adapt to growing energy needs, incorporate new technologies as they emerge, and remain flexible in response to evolving market conditions, energy policies, or local infrastructure developments.

Socially and communally, widespread adoption of future individual power plants will empower users and communities to achieve energy autonomy, resilience, and sustainability. Decentralized energy generation can support local microgrids, community solar or wind projects, and cooperative biomass or hybrid systems that distribute electricity and thermal energy efficiently among multiple stakeholders. Such arrangements encourage community engagement, awareness of energy consumption, and active participation in demand-side management. Localized power production improves resilience to natural disasters, grid failures, or energy price volatility, ensuring that critical infrastructure, healthcare facilities, and essential services remain operational. By democratizing energy production, future individual power plants will strengthen local control over resources, promote sustainable practices, and foster innovative energy management strategies that enhance both social equity and environmental responsibility.