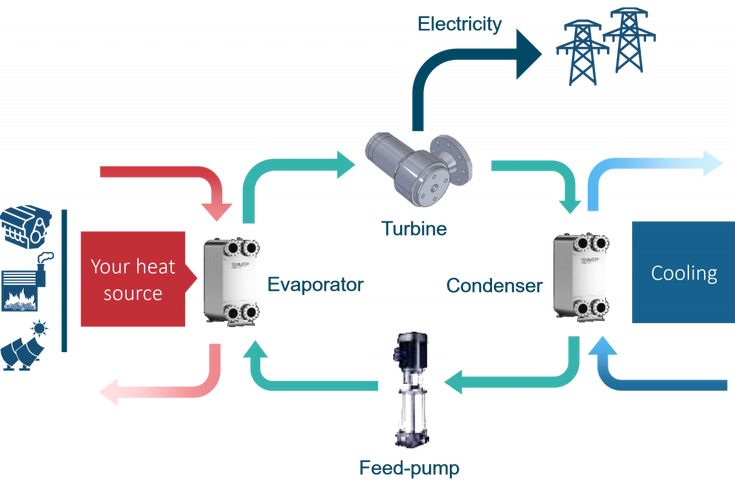

Using n-Hexane for ORC Systems: The Future of ORC: ORC Technology (Organic Rankine Cycle) is a thermodynamic system that converts waste heat into electricity at low temperatures. This technology is particularly used to improve energy efficiency in industrial facilities, geothermal power plants, and solar energy applications.

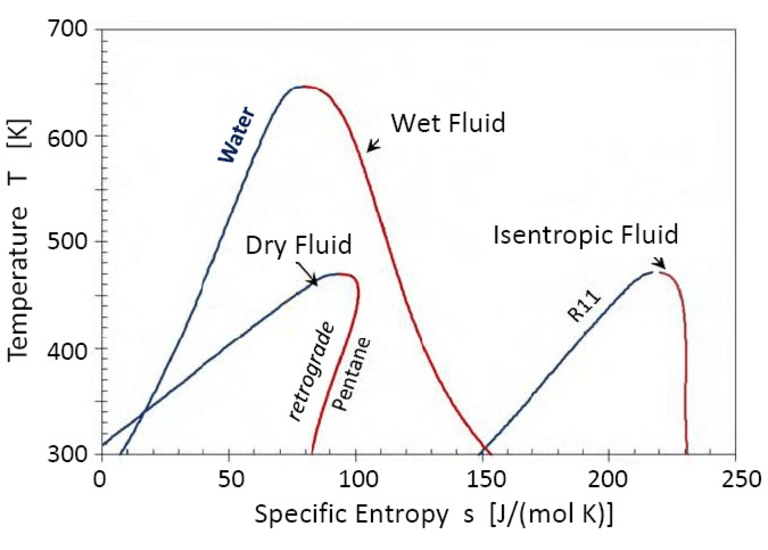

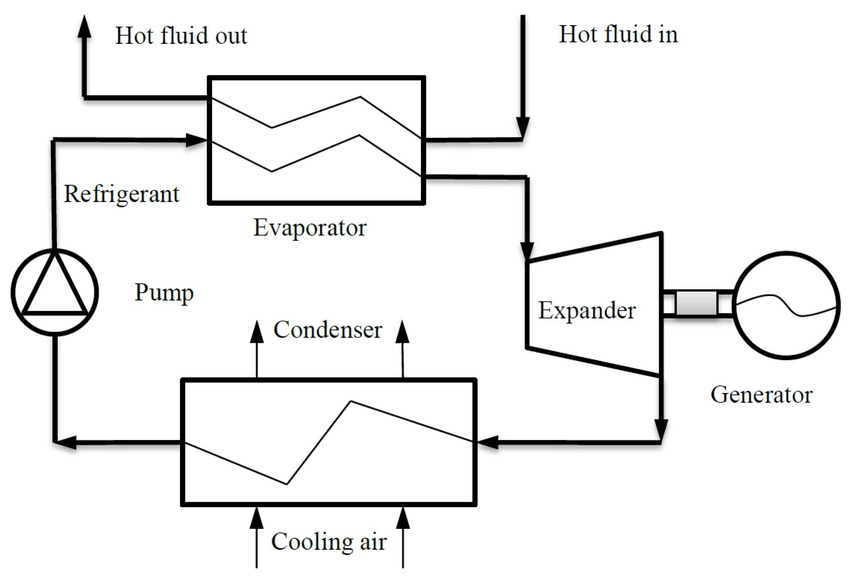

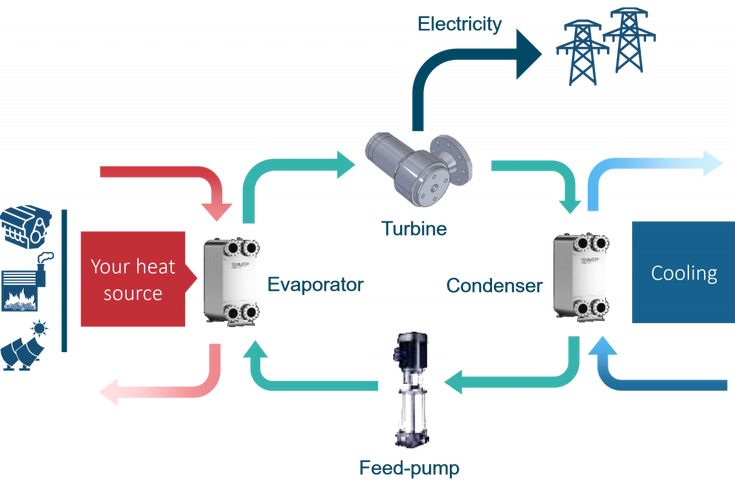

Basic Principle of ORC Technology

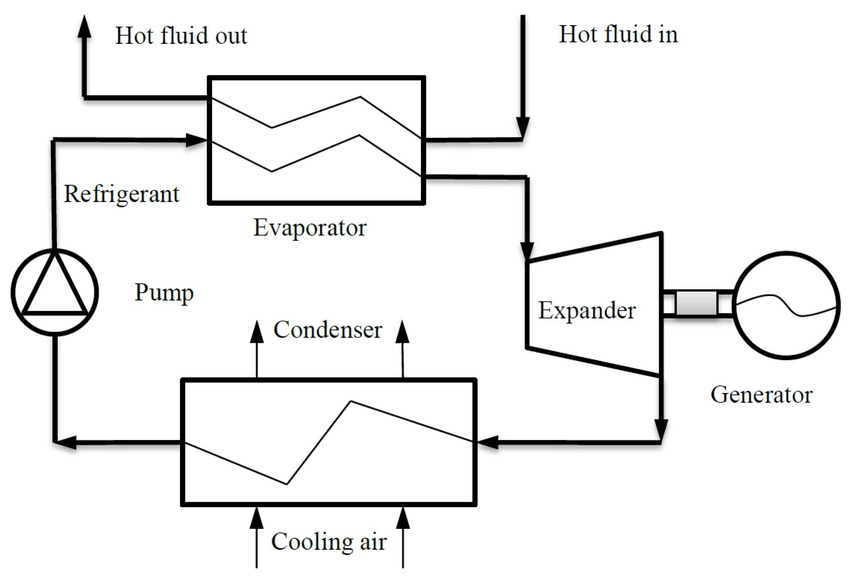

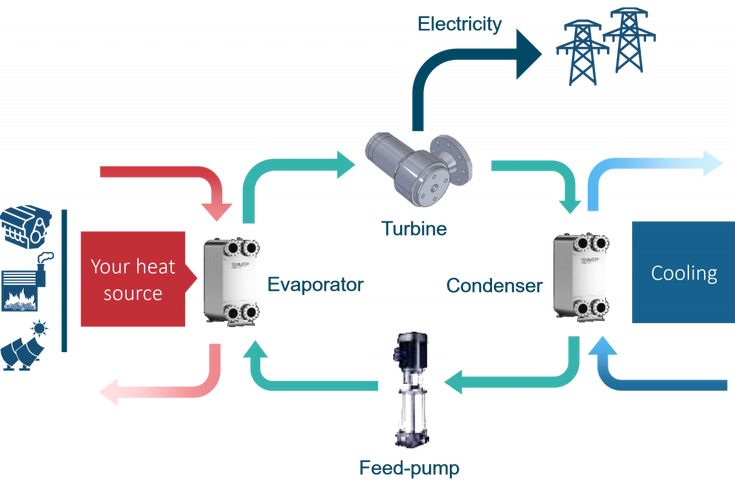

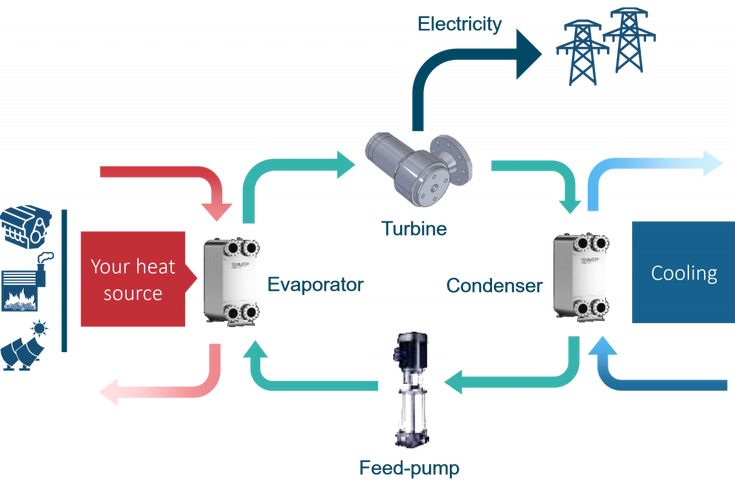

The ORC system uses an organic fluid (such as R-245fa) instead of water, which allows for the evaporation of the working fluid at low temperatures. This makes it possible to generate electricity from heat sources as low as 80–100°C.

Application Areas

- Industrial Waste Heat: Used in energy-intensive sectors such as steel, glass, cement, and wood processing to convert waste heat from production processes into electricity.

- Geothermal Energy: Ideal for generating electricity from low-temperature geothermal sources.

- Solar Energy: ORC systems are used in solar power plants to convert heat from the sun into electricity.

- Marine Engines and Shipping: In the maritime sector, ORC systems are used to convert waste heat from ship engines into electricity.

Advantages

- Low Temperature Operation: ORC systems can operate efficiently at temperatures as low as 80°C.

- Low Emissions: By recovering waste heat, they help reduce carbon emissions.

- Energy Efficiency: They improve overall energy efficiency by converting waste heat from industrial processes into electricity.

- Modular Design: ORC systems can be customized to fit different capacity and application needs.

Notable Applications

- Climeon HeatPower 300: An ORC system designed to generate electricity from waste heat at temperatures between 80–100°C. This system optimizes energy recovery in industrial processes.

- Turboden ORC Systems: These systems offer a wide range of applications for generating electricity from industrial waste heat in sectors such as steel, glass, cement, and wood processing.

Performance and Efficiency

The efficiency of ORC systems depends on the properties of the organic fluid used and the system design. Typically, the energy efficiency from low-temperature sources is limited by the Carnot efficiency. However, system design and optimization techniques can improve this efficiency.

ORC technology offers a solution to increase energy efficiency and reduce environmental impact by converting low-temperature waste heat into electricity. Integrating this technology into industrial processes can be a significant step toward sustainable energy production.

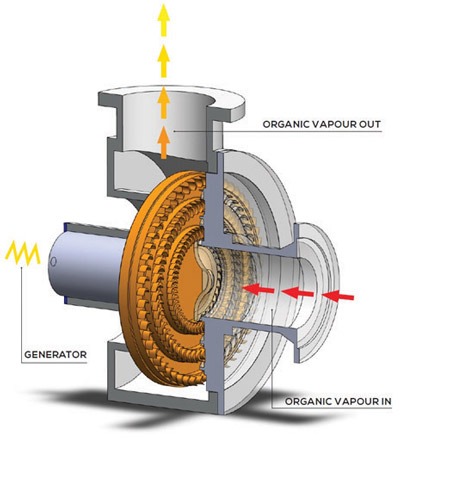

ORC (Organic Rankine Cycle) technology is a method used to convert low-temperature waste heat into electricity. It operates by using an organic working fluid, such as R-245fa, which has a lower boiling point than water, allowing it to vaporize and drive a turbine at temperatures as low as 80–100°C. This makes it ideal for utilizing waste heat from industrial processes, geothermal sources, or even solar thermal energy. The organic fluid is vaporized by the heat source, and the vapor then drives a turbine connected to an electricity generator. Afterward, the vapor is condensed back into liquid form, and the cycle repeats.

One of the key advantages of ORC technology is its ability to operate effectively at low temperatures, making it useful in situations where traditional steam turbines would not be efficient. This capability opens up the possibility for energy recovery from sources like industrial waste heat, geothermal fields, and even ship engines, which typically emit excess heat that could otherwise go unused. Moreover, it provides a way to lower carbon emissions by turning waste heat into useful energy, contributing to both energy efficiency and sustainability goals.

In practice, ORC systems have been applied in various industries, including cement, steel, glass manufacturing, and even in marine applications. For example, in a typical ORC setup, industries with high energy consumption may capture the excess heat from their operations and use it to generate additional electricity, improving overall energy efficiency. Additionally, in renewable energy sectors, ORC systems can be used to harness low-temperature geothermal energy, providing a continuous and reliable source of power.

The technology is also becoming popular in remote or off-grid locations, where access to traditional energy sources may be limited. The systems are modular and scalable, meaning they can be tailored to specific needs and capacities, whether it’s for a large industrial plant or a smaller, more localized application.

Overall, ORC technology presents an innovative solution for enhancing energy recovery from waste heat, improving energy efficiency, and reducing the environmental impact of industries. With the increasing demand for sustainable energy solutions, ORC systems are expected to play an important role in both industrial applications and the broader renewable energy landscape.

As ORC technology continues to evolve, its applications are becoming more widespread. One of the emerging trends is the integration of ORC systems with other renewable energy technologies, such as solar thermal and biomass power generation. By pairing ORC with solar thermal systems, for example, it is possible to convert excess heat from solar collectors into electricity, even when the sun is not shining. This increases the overall efficiency of solar power systems, making them more reliable and capable of generating power during off-peak times, such as nighttime or cloudy days.

Additionally, ORC systems are being adapted to work in tandem with waste-to-energy (WTE) plants, where municipal solid waste is converted into electricity. In these plants, ORC technology can be used to recover the heat generated during the combustion of waste, turning it into additional electricity. This not only improves the efficiency of WTE plants but also reduces their environmental impact by making better use of the energy produced during waste incineration.

The development of new, more efficient organic fluids is also enhancing the performance of ORC systems. Fluids with improved thermal properties, such as higher heat capacity and better thermal stability, enable ORC systems to operate more efficiently over a broader range of temperatures. Advances in materials science are contributing to longer lifespans for ORC components, reducing maintenance needs and improving the overall cost-effectiveness of the technology.

One of the key factors driving the growth of ORC technology is its ability to work in distributed energy systems. As more industries and communities look for ways to reduce their reliance on centralized power grids, ORC technology offers a decentralized solution to energy generation. It enables industries and facilities to become more self-sufficient by producing their own electricity from waste heat, reducing both energy costs and dependency on external power sources. This is particularly appealing for off-grid operations, such as remote mining sites, oil rigs, or even small communities in developing regions, where reliable access to electricity is a challenge.

The increasing availability of ORC systems with modular and flexible designs is making them more accessible to a wider range of industries and applications. Manufacturers are now able to offer custom solutions that fit specific energy needs, whether it’s a small-scale installation or a large-scale industrial application. This adaptability is helping ORC technology expand its footprint in sectors that were previously overlooked, such as agriculture, where it can be used to recover heat from biogas production processes.

Overall, ORC technology has the potential to revolutionize how industries and communities generate power. By tapping into waste heat sources that would otherwise be lost, it can significantly reduce energy consumption, improve efficiency, and contribute to sustainability goals. As the technology matures, it is expected to play a critical role in helping to meet global energy demands while minimizing environmental impacts.

As the demand for clean and sustainable energy solutions continues to rise, ORC technology stands to play an increasingly pivotal role in supporting global energy transition goals. One of the key factors driving its adoption is the growing emphasis on circular economies, where waste is minimized, and resources are used more efficiently. ORC systems contribute directly to this concept by turning waste heat—often considered a byproduct of industrial processes—into valuable electricity. This process not only conserves energy but also helps industries reduce their carbon footprints and meet stricter environmental regulations.

Another aspect of ORC technology’s growing influence is its ability to enhance grid stability in certain regions. In areas with unreliable or intermittent power supplies, ORC systems can provide a stable and continuous source of power derived from waste heat. By operating in parallel with renewable energy sources like solar and wind, ORC can fill gaps in power generation during periods of low renewable output, making the energy mix more reliable. This is particularly beneficial in regions transitioning to renewables but still dependent on fossil fuels for base-load power.

Additionally, as the global economy moves toward decarbonization, there’s a growing need for industries to adapt their existing infrastructure to minimize greenhouse gas emissions. ORC technology provides a viable pathway for industries to reduce their reliance on traditional, carbon-intensive energy sources by capturing and converting waste heat into usable electricity. This not only helps industries lower their carbon emissions but also reduces their operating costs by utilizing energy that would otherwise be lost.

In the context of power generation, ORC systems are being integrated into combined heat and power (CHP) plants, allowing for more efficient use of fuel and heat. In a CHP system, both electricity and heat are generated simultaneously, reducing the overall energy demand. When combined with ORC, these systems can operate with greater efficiency, ensuring that more energy is recovered and utilized.

The future of ORC technology also looks promising in the field of transportation. In the automotive and aerospace industries, for example, waste heat recovery using ORC could play a role in improving fuel efficiency and reducing emissions. The technology could be applied in electric vehicles (EVs) or hybrid systems to recover heat from the engine or battery, converting it into additional power to extend the vehicle’s range or enhance overall system performance.

Additionally, research into hybrid ORC systems that combine organic Rankine cycles with other thermal cycles, such as Kalina or even supercritical CO2 cycles, is gaining traction. These hybrid systems could further optimize efficiency by expanding the operating temperature range and increasing energy recovery from low-grade heat sources. This could open up new applications and further push the boundaries of what is possible with waste heat recovery.

Looking ahead, governments and international organizations are expected to continue providing incentives and funding to support the development and deployment of waste heat recovery technologies like ORC. Policymakers recognize the potential of these systems to improve energy efficiency, reduce emissions, and promote sustainable development. As a result, more favorable regulations and financial support are likely to drive further investments in ORC technology, making it even more accessible and widespread.

In summary, ORC technology represents a powerful tool in the transition to a more sustainable, energy-efficient future. By capitalizing on low-temperature waste heat, it provides industries and power plants with a means to recover and convert energy that would otherwise be lost. With continued advancements in system design, fluid technology, and integration with renewable and waste-to-energy sources, ORC has the potential to play a transformative role in global efforts to combat climate change and meet future energy demands.

Green Technology: The Future of ORC

Green technology is rapidly evolving, and the future of ORC (Organic Rankine Cycle) technology is closely tied to the global drive for more sustainable energy solutions. As industries, governments, and researchers focus on reducing carbon emissions and improving energy efficiency, ORC systems are poised to play a significant role in addressing these challenges, particularly in harnessing low-temperature waste heat for power generation.

One of the major advantages of ORC technology in the context of green technology is its ability to recover waste heat from industrial processes, geothermal sources, and even renewable energy systems. This aligns well with the increasing push for circular economy principles, where waste is minimized, and resources are used more efficiently. In a world where sustainability is a top priority, ORC helps industries move toward carbon-neutral operations by turning wasted energy into usable electricity, thus decreasing the reliance on fossil fuels.

The future of ORC technology is particularly exciting in terms of its potential for scaling up and integrating with renewable energy sources. As the world transitions to a low-carbon future, ORC can complement solar, wind, and biomass energy by providing a consistent and efficient way to convert waste heat into power, especially during times when renewable generation is intermittent. For example, ORC systems can be integrated with solar thermal plants, where they capture excess heat and generate electricity even when the sun isn’t shining, effectively reducing energy variability and enhancing grid stability.

In addition, ORC technology holds promise for use in combination with emerging green technologies like hydrogen production and storage. In the process of producing hydrogen through electrolysis, for example, excess heat is often generated, which could be captured and used by an ORC system to generate additional electricity. This integration could make green hydrogen production more energy-efficient and cost-effective, accelerating its role as a clean energy source for industries and transportation.

Another major area where ORC technology is advancing is in the development of new, environmentally friendly organic fluids. Research is focused on finding fluids that are not only more efficient but also have minimal environmental impact. The use of non-toxic, non-flammable, and biodegradable fluids is crucial for ensuring that ORC systems are safe and sustainable. As these fluids improve in performance, ORC systems will be able to operate at even higher efficiencies, further reducing their environmental footprint and enhancing their contribution to green energy initiatives.

The future of ORC is also being shaped by the increasing interest in decentralized energy systems. As more industries and communities seek energy independence, ORC systems offer a way to produce on-site electricity from waste heat, reducing reliance on central power grids and lowering energy costs. This is particularly beneficial for remote locations or off-grid areas, where traditional energy infrastructure may be limited or expensive to develop. By enabling localized power generation, ORC technology can help reduce transmission losses and enhance energy security, contributing to a more resilient and sustainable energy future.

Governments and regulatory bodies are expected to continue promoting green technologies through subsidies, incentives, and research funding, which will further accelerate the adoption of ORC systems. As policymakers look for solutions to meet global climate goals, technologies like ORC that reduce emissions, improve energy efficiency, and harness renewable resources will be key players in the energy landscape. Supportive policies could include tax credits for waste heat recovery, financial incentives for ORC installations in industrial facilities, or renewable energy standards that encourage the integration of ORC with other green energy systems.

The future of ORC technology is also intertwined with the growing demand for energy storage solutions. As the need for energy storage increases, especially with the rise of intermittent renewable energy sources, ORC could play a role in thermal energy storage systems. Waste heat recovered by ORC could be stored in thermal storage units for later use, helping to smooth out fluctuations in energy supply and demand. This integration with energy storage could further enhance the efficiency and sustainability of power generation systems, making them more reliable and adaptable.

In conclusion, the future of ORC technology is bright, with increasing potential to contribute to a greener, more sustainable energy future. By recovering waste heat and converting it into electricity, ORC systems offer a valuable solution for improving energy efficiency, reducing emissions, and supporting the integration of renewable energy sources. As ORC technology continues to evolve and integrate with other green technologies, it will undoubtedly become a cornerstone of the transition toward a cleaner, more sustainable energy landscape.

The future of ORC technology in green energy is increasingly promising as the world accelerates its push for cleaner, more sustainable solutions. As industries, governments, and researchers continue to focus on reducing carbon emissions and improving energy efficiency, ORC technology stands out as a versatile and effective method for harnessing low-temperature waste heat. The potential of ORC to contribute to the circular economy is especially significant, as it allows waste heat—often considered an inevitable byproduct of industrial processes—to be transformed into usable energy, reducing reliance on traditional, polluting energy sources.

With the growing adoption of renewable energy systems, ORC technology is finding new ways to complement and enhance energy generation. In solar thermal plants, for example, ORC systems can convert excess heat into electricity even when sunlight is not available, addressing one of the key limitations of solar energy: intermittency. Similarly, ORC systems can work in tandem with wind and biomass energy, providing consistent power generation by capturing and converting waste heat into electricity during times when renewable sources may be producing less power. This flexibility makes ORC a valuable asset in ensuring that the energy grid remains stable and reliable as renewable sources grow.

ORC’s integration into green hydrogen production is another exciting development. The process of producing hydrogen via electrolysis generates heat that could be captured by ORC systems to produce additional electricity, thereby improving the energy efficiency of hydrogen production. Green hydrogen, which is produced using renewable energy sources, is widely seen as a crucial element in decarbonizing industries like steel, chemicals, and transportation. The coupling of ORC systems with hydrogen production processes could lower costs and make the transition to green hydrogen more feasible on a global scale.

Additionally, there is significant progress being made in improving the efficiency of ORC systems by developing better organic fluids. Research into environmentally friendly fluids that are non-toxic, non-flammable, and biodegradable is crucial for ensuring that ORC technology remains safe and sustainable. These advancements in fluid technology could further increase the efficiency of ORC systems, enabling them to recover more waste heat and convert it into electricity, thus maximizing their environmental and economic benefits.

The future of ORC technology is also closely tied to the rise of decentralized energy systems. In a world where energy independence is becoming more desirable, ORC provides an ideal solution for on-site power generation. Industries and remote communities that may not have access to centralized grids can use ORC systems to convert waste heat into electricity, improving energy security and reducing reliance on external power sources. This also reduces the transmission losses typically associated with long-distance electricity transport, helping to increase the overall efficiency of the energy system. ORC systems’ modular and scalable nature makes them adaptable to a wide range of applications, from large-scale industrial plants to small, off-grid operations.

Governments and regulatory bodies are increasingly supporting green technologies through financial incentives, subsidies, and research funding. This support is likely to fuel the further development and deployment of ORC systems, especially in industries where energy consumption is high, such as manufacturing, mining, and petrochemical production. Policies aimed at reducing greenhouse gas emissions, improving energy efficiency, and encouraging the use of renewable energy are expected to create favorable conditions for ORC adoption. With these incentives, businesses are more likely to invest in ORC technology as a cost-effective way to reduce energy costs, minimize waste, and meet sustainability targets.

Furthermore, as energy storage becomes more critical in the context of renewable energy integration, ORC systems could play a role in thermal energy storage. The waste heat captured and converted by ORC could be stored in thermal storage units, which would allow for electricity to be generated when needed, even if the heat source is not available. This form of energy storage would help smooth out fluctuations in energy supply and demand, making the energy grid more reliable and capable of accommodating an increasing share of renewable sources.

In conclusion, ORC technology has a bright future in the green energy landscape. It offers a sustainable solution for recovering waste heat and converting it into electricity, contributing to greater energy efficiency and a reduction in carbon emissions. As the world moves toward a more sustainable energy future, ORC systems will become increasingly important, particularly as they integrate with renewable energy sources, green hydrogen production, and energy storage systems. With continued advancements in technology and supportive policies, ORC will undoubtedly play a key role in the transition to a cleaner, more efficient energy system.

As ORC technology continues to evolve, its role in the global energy transition will only become more critical. The ability to efficiently recover waste heat is an often overlooked yet immensely valuable tool in improving the energy efficiency of both industrial and energy production processes. In a world where reducing environmental impact and increasing energy efficiency are imperative, ORC systems help optimize energy use by converting waste heat—an otherwise lost resource—into useful power.

The technological advancements in ORC systems go beyond simply improving efficiency. The systems are becoming more versatile, able to handle a wider range of heat sources. For example, ORC can be paired with combined heat and power (CHP) systems, where both electricity and useful heat are produced from the same source. This combination boosts the efficiency of power generation and is particularly useful in industrial facilities where both electricity and heat are required. By reducing the need for additional fuel to generate heat or power, ORC in CHP applications becomes a more sustainable option for businesses aiming to reduce their energy costs and environmental footprints.

Looking further ahead, the global push for decarbonization, and more specifically net-zero emissions targets, will likely accelerate the development and deployment of ORC technology. Governments worldwide are introducing stricter emissions regulations and providing incentives for companies that embrace low-carbon solutions. ORC is poised to be a key player in meeting these goals by providing industries with a means to tap into otherwise unused energy, significantly reducing their carbon emissions. By utilizing waste heat, ORC systems directly contribute to lowering the consumption of fossil fuels and mitigating the environmental impacts associated with traditional energy generation.

One of the most promising applications of ORC technology is in the transportation sector, particularly in ships and trucks, where fuel consumption and emissions are key concerns. Marine engines, for instance, produce a significant amount of waste heat, which can be captured by ORC systems to provide additional electricity. This can reduce the reliance on fuel-powered generators on ships, leading to lower fuel consumption and reduced greenhouse gas emissions. In the automotive industry, ORC could be integrated into hybrid vehicles or electric cars to capture heat from the engine or battery and convert it into power, thus improving overall fuel efficiency and reducing emissions.

In the coming years, as more industries and companies adopt ORC technology, the cost of implementing these systems is expected to decrease. Technological advances and economies of scale will make ORC solutions more accessible to a broader range of industries, especially small- and medium-sized enterprises (SMEs) that might have been hesitant to adopt the technology due to high initial investment costs. As the technology matures, its potential to be deployed in diverse applications—from remote power generation to industrial waste heat recovery—will continue to grow.

Additionally, the synergy between ORC technology and smart grid systems will help further optimize energy use. In a smart grid environment, energy is dynamically distributed based on supply and demand, and ORC systems can contribute by providing an efficient and flexible energy source that complements intermittent renewable sources. As more renewable energy comes online, the need for grid flexibility increases. ORC systems, which can be deployed in distributed generation models, will help meet demand when solar or wind output is low, ensuring that the grid remains stable and reliable. The combination of ORC and smart grids could unlock even greater levels of efficiency and sustainability in the energy system.

Ultimately, the future of ORC technology is intertwined with the broader movement toward sustainable energy solutions. As it continues to develop, ORC will increasingly become a cornerstone of efforts to improve energy efficiency, reduce emissions, and transition to renewable energy sources. It offers a reliable, cost-effective, and environmentally friendly solution to help industries meet global climate goals. As research into new fluids, system designs, and integration methods continues to advance, ORC systems will only grow in importance, helping drive the shift toward a greener, more sustainable energy future.

As the energy landscape continues to shift toward sustainability, ORC technology is likely to see deeper integration with emerging innovations in the renewable energy sector. One area of particular interest is the convergence of ORC with waste-to-energy (WTE) technologies. WTE plants often generate excess heat during the incineration of waste materials, and ORC systems can be implemented to convert this waste heat into electricity, enhancing the overall energy recovery process. By pairing ORC with WTE plants, cities and industries can address both waste management challenges and energy production simultaneously, further promoting a circular economy.

The role of ORC technology is also expanding into new and untapped markets. For instance, in the agricultural sector, ORC systems can be integrated into biogas plants, where organic waste is converted into methane for energy production. The anaerobic digestion process used in these plants generates substantial amounts of heat, much of which is currently wasted. By implementing ORC systems, that heat can be converted into electricity, providing additional power for the plant and reducing the reliance on external energy sources. As more rural or off-grid areas look for ways to become self-sufficient, ORC could offer a practical, scalable solution for local energy generation.

Beyond the immediate applications, ORC systems can also play a role in future technologies like carbon capture, utilization, and storage (CCUS). As industries strive to capture carbon dioxide emissions and either store or reuse them, ORC systems could be integrated into the carbon capture process by helping recover the heat generated during CO2 compression and purification. This would allow for more efficient operations within CCUS facilities, further advancing efforts to reduce global greenhouse gas emissions.

The continued development of ORC technology is also likely to contribute to the decarbonization of heavy industries. Industries such as cement, steel, and chemical production are significant emitters of carbon dioxide due to their high energy consumption and reliance on fossil fuels. By incorporating ORC systems to recover waste heat from these energy-intensive processes, these industries can significantly reduce their carbon footprints. ORC could also enable these sectors to become more energy-independent by generating electricity on-site from waste heat, which could power various processes within the plant.

Furthermore, ORC technology’s adoption is expected to be boosted by ongoing improvements in its efficiency and scalability. As new, higher-performance organic fluids are developed, and as heat exchangers and turbines become more efficient, the overall energy recovery of ORC systems will improve. These advancements will enable ORC systems to operate in a broader range of industries and applications, further solidifying their role as a key player in the future of green energy. Smaller, more modular ORC systems will also become more accessible to smaller businesses and emerging markets, offering energy-efficient solutions that were once only available to large-scale industrial operations.

Collaboration between private industry, research institutions, and governments will be essential in accelerating ORC technology’s development and ensuring its widespread adoption. Governments can continue to provide incentives for businesses that adopt ORC technology, as well as fund research into more efficient systems and fluids. Public-private partnerships will be instrumental in driving technological innovation and scaling ORC systems, particularly in regions where access to reliable and affordable energy is still a significant challenge.

The future of ORC technology is also closely tied to the increasing global focus on energy equity. As developing nations seek to improve their infrastructure and reduce reliance on imported fossil fuels, ORC systems could provide a cost-effective and sustainable means of generating electricity from local, often untapped, resources. These regions, which may not have access to conventional energy grids, could harness waste heat from local industries, agricultural processes, or even geothermal sources to generate clean power. This would contribute to a more equitable energy transition, providing affordable energy to communities that are often left behind in the global energy conversation.

Looking further ahead, ORC technology may evolve into even more integrated and adaptable energy solutions. With advancements in artificial intelligence (AI) and data analytics, ORC systems could become smarter and more efficient by continuously optimizing their performance based on real-time data. AI could help monitor waste heat sources, predict energy production levels, and adjust operations to ensure maximum efficiency, while data analytics could help businesses track their energy use and identify further opportunities for waste heat recovery. Such innovations would further position ORC technology as a cornerstone of the green energy revolution.

In conclusion, ORC technology’s future is full of promise as it continues to evolve and contribute to a sustainable energy future. Its ability to efficiently recover waste heat, reduce emissions, and integrate with renewable and emerging technologies places it at the forefront of efforts to decarbonize industries and improve global energy efficiency. As the world pushes for cleaner energy systems and more sustainable practices, ORC will remain a critical part of the transition, offering a scalable, cost-effective solution to harness waste heat and convert it into valuable electricity. With ongoing innovation, supportive policies, and expanding applications, ORC technology has the potential to make a significant impact in shaping the future of global energy systems.

Using R113 for ORC Systems

R113 (1,2,2-Trichloro-1,1,2-trifluoroethane) is a fluorocarbon compound that has been used historically in refrigeration and cooling applications. It has also been considered as a working fluid for Organic Rankine Cycle (ORC) systems. However, while R113 can be used in ORC systems, it comes with certain advantages and drawbacks that need to be carefully considered before deciding whether it is the right choice for a particular application.

Advantages of Using R113 in ORC Systems

- Thermodynamic Properties: R113 has favorable thermodynamic properties, such as a relatively high critical temperature and pressure, making it suitable for systems that need to operate at relatively high temperatures. Its boiling point at atmospheric pressure (around 47°C) is also low enough to allow efficient heat transfer in systems that recover low-grade waste heat.

- Low Toxicity and Non-flammability: R113 is generally considered to be less toxic and non-flammable, making it safer to handle and use in industrial applications compared to other organic fluids or refrigerants. This makes it a more attractive option for applications where safety is a concern.

- Good Performance at Medium Temperatures: R113 is a particularly good choice for ORC systems that need to operate within the medium temperature range (roughly 150-300°C). This range corresponds well with many industrial heat recovery applications, such as those found in chemical processing, cement production, and geothermal energy recovery.

- Availability and Cost: R113 has been widely used in refrigeration and HVAC systems, meaning that it is relatively easy to source and may be more cost-effective than some other more specialized organic fluids.

Disadvantages of Using R113 in ORC Systems

- Environmental Concerns: One of the major drawbacks of using R113 in ORC systems is its environmental impact. R113 is a chlorofluorocarbon (CFC), and while it has been phased out in many applications due to its ozone-depleting potential, it still poses environmental concerns if released into the atmosphere. Despite this, R113 has a relatively low global warming potential (GWP) compared to other halocarbon-based fluids, but its ozone depletion potential (ODP) is a significant drawback in the context of increasing environmental regulation.

- Regulatory Restrictions: Due to its ozone-depleting properties, the use of R113 is increasingly restricted in many countries. It has been phased out of use in new refrigeration and air conditioning equipment under the Montreal Protocol. As environmental regulations continue to tighten, the use of R113 in ORC systems could become more challenging or even legally restricted, making it a less attractive long-term solution.

- System Corrosion: Like other halocarbon-based fluids, R113 can cause corrosion in certain metal components over time, particularly when exposed to high temperatures or reactive materials. This could result in maintenance challenges and increased system wear, reducing the overall lifespan of the ORC system.

- Higher Viscosity and Lower Heat Transfer Efficiency: Compared to other organic fluids such as R245fa or more environmentally friendly refrigerants like R134a, R113 may have higher viscosity, which could lead to higher friction losses in the system and reduced overall heat transfer efficiency. This could potentially decrease the performance of the ORC system in the long run.

- Limited Applications: Given its environmental impact, R113 is increasingly being replaced by more sustainable working fluids in ORC systems. For example, natural fluids like ammonia or organic fluids with low environmental impacts (such as R245fa or R134a) are now more commonly used for ORC applications.

Alternatives to R113

Due to the environmental concerns associated with R113, several alternative fluids are now more commonly used in ORC systems. These alternatives include:

- R245fa (1,1,1,3,3-Pentafluoropropane): This fluid is widely used in ORC systems due to its relatively low environmental impact, good thermodynamic properties, and non-ozone-depleting characteristics. It also performs well in medium-temperature ORC applications and is considered a safer and more sustainable alternative to R113.

- R134a (1,1,1,2-Tetrafluoroethane): R134a is another popular working fluid for ORC systems, offering good efficiency and environmental performance. While it has a higher global warming potential than R245fa, it is still less harmful to the ozone layer compared to R113.

- Natural Fluids (e.g., Water, Ammonia, CO2): Natural working fluids such as water, ammonia, or supercritical CO2 are being increasingly explored for use in ORC systems due to their low environmental impact and abundant availability. These fluids often have thermodynamic properties that are well-suited for specific ORC applications, particularly in geothermal, biomass, and waste heat recovery systems.

- Hydrofluoroolefins (HFOs): Fluids like HFO-1234yf and HFO-1234ze are newer options with very low global warming potential and no ozone-depleting potential. These fluids are emerging as viable alternatives in refrigeration and air conditioning systems and may be suitable for ORC systems as well.

Conclusion

While R113 can be used in ORC systems, its environmental impact, particularly concerning ozone depletion, makes it less attractive in today’s context of strict environmental regulations and growing concerns about climate change. There are now more sustainable and efficient alternatives available, such as R245fa, R134a, and natural fluids, which provide better environmental performance and system efficiency. If you are considering using R113 in an ORC system, it is important to weigh these factors carefully and consider the long-term sustainability of the chosen fluid, especially as global regulations continue to evolve.

While R113 can be used in Organic Rankine Cycle (ORC) systems, its environmental drawbacks and the increasing regulatory pressures around ozone-depleting substances make it less favorable for long-term applications. R113 has a relatively low global warming potential compared to other refrigerants, but its ozone-depleting properties are a significant concern in the face of international environmental agreements like the Montreal Protocol. As environmental awareness continues to rise and regulations tighten, industries are moving toward more eco-friendly alternatives for working fluids in ORC systems. These alternatives, such as R245fa, R134a, and natural fluids like ammonia or CO2, offer better thermodynamic efficiency, lower environmental impact, and, in some cases, even improved system reliability.

The main challenge with R113 in ORC systems lies in its ozone depletion potential, which makes it a less attractive choice in industries where sustainability and compliance with environmental regulations are top priorities. As a result, the need for more sustainable fluids is pushing the ORC technology field toward innovations and the adoption of fluids with no ozone depletion potential and lower global warming potential. For example, R245fa is widely favored due to its excellent performance in medium-temperature ranges and its minimal environmental impact. The shift toward using fluids like R245fa and R134a is helping future-proof ORC systems, ensuring that they meet both efficiency goals and environmental standards.

Moreover, as ORC systems continue to be integrated into more renewable energy applications and energy recovery solutions, such as waste heat recovery from industrial processes or geothermal energy generation, the demand for cleaner, greener technologies is likely to accelerate. R113’s limited lifespan as a viable solution in ORC applications makes it important for industries to consider alternatives that not only provide high thermodynamic efficiency but also align with global environmental objectives. This shift in working fluids is part of a broader trend toward more sustainable energy systems that can play a key role in the decarbonization of industries, the reduction of carbon footprints, and the overall transition to cleaner energy sources.

As these greener options continue to mature and become more widely adopted, ORC technology will continue to evolve. The use of R113 in ORC systems will likely diminish as more environmentally friendly fluids gain market share and offer better efficiency with less environmental risk. Therefore, while R113 may still serve as a viable option in some applications, especially where specific operational conditions require it, the future of ORC systems will undoubtedly depend on the continued development of more sustainable, cost-effective, and high-performance fluids that meet the needs of modern energy systems and comply with increasingly stringent environmental regulations.

As the demand for cleaner and more sustainable technologies grows, the development of alternative working fluids for ORC systems is becoming a crucial area of research and innovation. These alternatives are not only addressing environmental concerns but also improving the overall performance and efficiency of ORC systems. Fluids like R245fa and R134a, for example, offer better energy efficiency, lower toxicity, and minimal environmental impact, making them more suitable for modern ORC applications.

Moreover, the adoption of natural refrigerants, such as water, ammonia, and CO2, is gaining momentum due to their zero ozone depletion potential and much lower global warming potential. Natural fluids like CO2 are particularly promising in specific applications, such as waste heat recovery and geothermal energy, where their thermodynamic properties are well-matched to the temperature and pressure conditions of ORC systems. While these natural fluids may require more advanced system designs and operational expertise, they offer significant long-term benefits in terms of environmental sustainability and operational costs.

Another exciting development in ORC technology is the exploration of supercritical CO2 (sCO2) as a working fluid. Supercritical CO2 has several advantages, such as a higher thermal efficiency and a relatively low operating pressure compared to traditional organic fluids. This allows for smaller, more compact ORC systems, which can be particularly useful in applications where space or weight constraints are important, such as in transportation or remote power generation.

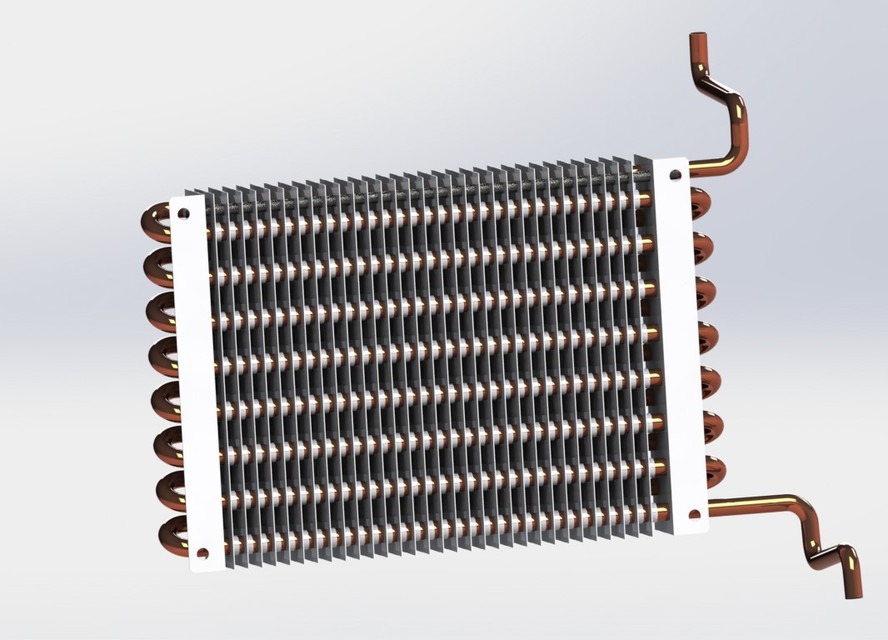

Furthermore, advances in the design of ORC systems are focusing on optimizing the heat exchange process and improving the overall efficiency of these systems. Modern ORC systems are being designed with better materials, such as advanced heat exchangers and high-performance turbines, which are more durable and efficient. These innovations not only make the systems more reliable but also reduce the cost of energy production, making ORC technology more attractive for both industrial and commercial applications.

The role of ORC systems in the global energy transition is also closely tied to the increasing focus on decentralization and energy resilience. As more industries, businesses, and even communities look for ways to generate their own power and reduce their dependence on centralized grids, ORC systems provide an excellent solution for on-site power generation. By capturing waste heat from industrial processes, biomass, or even geothermal sources, ORC systems can help reduce energy costs and carbon footprints, making them a key component in the future of sustainable energy production.

In addition to industrial applications, ORC systems are also being increasingly utilized in the renewable energy sector, particularly in geothermal and biomass power plants. These industries produce heat as a byproduct that can be effectively captured and converted into electricity using ORC technology. The scalability and flexibility of ORC systems also make them ideal for integrating with intermittent renewable energy sources like wind and solar. In hybrid energy systems, ORC can help smooth out the supply of electricity by converting excess heat into usable energy, providing stability to the grid and ensuring that renewable energy can be harnessed more effectively.

Governments and international organizations are playing a key role in supporting the development and implementation of ORC technology. Through incentives, funding programs, and regulatory support, they are encouraging the adoption of energy-efficient technologies and promoting the use of renewable energy sources. This is especially true in sectors such as waste heat recovery, geothermal energy, and bioenergy, where ORC systems are gaining significant traction. As the demand for clean energy solutions grows, ORC technology will likely receive further support from both public and private sectors, accelerating its deployment worldwide.

As ORC technology continues to evolve, there is also a growing focus on improving its integration with other emerging technologies, such as energy storage and hydrogen production. In the context of green hydrogen, for example, ORC systems can be used to capture the waste heat generated during electrolysis and convert it into additional electricity, improving the overall energy efficiency of hydrogen production. Similarly, ORC systems could be integrated into thermal energy storage solutions, where waste heat can be stored and later used to generate power when demand peaks or when renewable sources are unavailable. This type of synergy between ORC systems and other technologies is helping to create more resilient, efficient, and sustainable energy systems.

In conclusion, while R113 may have been an option for ORC systems in the past, the increasing shift toward more sustainable and environmentally friendly alternatives is reshaping the landscape of ORC technology. As new working fluids and system designs emerge, ORC will continue to play an important role in the global transition to renewable and low-carbon energy systems. The ongoing advancements in fluid technology, system optimization, and integration with other green technologies will ensure that ORC remains a key player in the future of energy generation, offering both environmental and economic benefits.

As the future of ORC technology unfolds, it’s clear that the next wave of innovation will be focused on enhancing both the efficiency and flexibility of ORC systems. One of the promising areas for improvement is the development of advanced materials and coatings for the system components. For instance, the heat exchangers, which play a crucial role in heat recovery and transfer, can benefit from innovations in materials that are more resistant to corrosion and high temperatures. Improved materials will not only enhance the system’s durability but also optimize the heat transfer process, contributing to higher overall efficiency.

Additionally, research into hybrid systems that combine ORC technology with other renewable energy sources is gaining traction. These hybrid systems, which integrate solar thermal, geothermal, or biomass energy with ORC, offer a powerful solution for maximizing energy recovery and improving overall system performance. For example, in a combined solar-ORC system, solar thermal collectors can provide heat that drives the ORC, producing electricity even when the sun is not at peak intensity. This hybrid approach increases the capacity factor of renewable energy generation, ensuring a more stable and continuous power supply.

Another exciting avenue for the future of ORC systems lies in their role within microgrids. Microgrids are localized networks that can operate independently or in conjunction with the main power grid. As cities and industries become more focused on energy resilience and self-sufficiency, ORC systems can serve as an efficient means of providing decentralized power. By utilizing waste heat or renewable energy sources, ORC systems can generate electricity in a more sustainable way and contribute to the overall reliability of a microgrid. This is especially important in areas prone to grid instability, where ORC can serve as a backup power source during outages or peak demand times.

The integration of ORC systems into decentralized energy production is also closely tied to the trend toward electrification of various sectors. As industries, transportation, and heating systems increasingly shift toward electric power, the need for flexible, on-site power generation systems like ORC will grow. ORC can help reduce the reliance on centralized fossil-fuel-based power plants, leading to a more distributed and resilient energy system. In particular, industries with high energy consumption, such as cement, steel, and chemical production, can use ORC technology to offset their energy needs by converting waste heat into electricity, thus reducing their carbon footprints.

The growing focus on sustainability and environmental impact is also encouraging industries to adopt ORC technology as part of their broader environmental strategies. The potential for ORC systems to significantly reduce energy consumption and greenhouse gas emissions by recovering waste heat makes them an essential part of corporate sustainability initiatives. In addition to meeting regulatory requirements, companies that invest in ORC systems are also positioning themselves as leaders in the green economy, which can improve their reputation, reduce operational costs, and gain a competitive edge in the marketplace.

The development of more efficient and cost-effective ORC systems is expected to lower the entry barriers for smaller businesses and emerging markets. As the technology matures and production volumes increase, the costs associated with ORC systems are expected to decrease, making them more accessible to a broader range of applications. This could unlock new opportunities for waste heat recovery and renewable energy generation in smaller, less industrialized regions that were previously unable to invest in such systems.

The combination of technical advancements, policy support, and growing demand for sustainable energy solutions will drive the widespread adoption of ORC technology across various sectors. Whether it’s industrial waste heat recovery, the integration with renewable energy sources, or decentralized power generation in microgrids, ORC technology has a critical role to play in the global transition to a low-carbon economy.

Moreover, as digitalization and the Internet of Things (IoT) continue to make inroads into energy management, ORC systems will likely benefit from increased automation and smart monitoring capabilities. The integration of sensors, real-time data analytics, and predictive maintenance tools will help optimize ORC system performance, ensuring that they operate at peak efficiency and minimize downtime. AI and machine learning could also play a role in optimizing the operational parameters of ORC systems, adjusting the process dynamically based on changes in heat source availability, temperature, or demand.

The regulatory landscape is another important factor shaping the future of ORC systems. Governments worldwide are setting increasingly ambitious decarbonization goals, with many nations committing to achieve net-zero emissions by 2050 or earlier. In response to these goals, there is growing financial and policy support for energy-efficient technologies like ORC. Policies such as tax incentives, subsidies, and grants will continue to encourage industries to invest in ORC technology, further accelerating its adoption. Additionally, ORC systems may be integrated into carbon capture, utilization, and storage (CCUS) projects, helping industries that are difficult to decarbonize—like cement and steel—reduce their emissions and transition to cleaner energy.

Ultimately, the continued evolution of ORC technology reflects a broader trend of innovation and transformation in the energy sector. As ORC systems become more efficient, affordable, and adaptable, their potential to contribute to a sustainable energy future becomes ever more significant. With growing global emphasis on reducing carbon footprints, improving energy efficiency, and maximizing the use of renewable resources, ORC technology stands poised to play a central role in the transition toward a greener, more resilient global energy system.

The future of ORC is not just about improving the technology itself but about how it can integrate with other systems, contribute to the circular economy, and drive a shift toward more sustainable, localized energy generation. The impact of ORC systems will continue to grow, helping industries reduce waste, improve efficiency, and lower their environmental impact while contributing to a more sustainable energy future for all.

Using R11 for ORC Systems

R11 (trichlorofluoromethane) is a chlorofluorocarbon (CFC) refrigerant that was once commonly used in refrigeration, air conditioning, and as a working fluid in Organic Rankine Cycle (ORC) systems. However, like R113, R11 is now facing significant restrictions due to its ozone-depleting properties. The use of R11 in ORC systems is largely obsolete, and its use is actively discouraged due to environmental concerns. Let’s explore the pros and cons of using R11 in ORC systems in greater detail.

Advantages of Using R11 in ORC Systems (Historical Perspective)

- Good Thermodynamic Properties: R11 was once favored for its thermodynamic properties, including its relatively high boiling point (around 23.8°C at atmospheric pressure) and its stability at moderate operating temperatures. These characteristics made it suitable for ORC systems that needed to operate at medium to high temperatures.

- Efficiency in Certain Applications: R11’s thermodynamic efficiency was quite favorable for certain ORC applications, particularly in systems recovering waste heat at moderate temperature levels. This made it useful in industrial processes where waste heat was available at temperatures around 100-200°C.

- Non-Flammability: R11 is non-flammable, which made it safer than some alternative organic fluids or refrigerants, particularly in industrial environments where fire hazards were a concern.

- Established History of Use: R11 had been used in various heat pump, refrigeration, and industrial applications for many years, meaning its behavior in real-world systems was well-understood. This made it a reliable choice for engineers working on ORC systems in the past.

Disadvantages of Using R11 in ORC Systems

- Ozone Depletion Potential (ODP): The most significant issue with R11 is its high ozone depletion potential (ODP). As a CFC, R11 contributes to the depletion of the ozone layer, which protects the Earth from harmful ultraviolet radiation. Because of this, R11 is being phased out globally under the Montreal Protocol, which aims to eliminate the use of substances that harm the ozone layer.

- Global Warming Potential (GWP): In addition to its ozone-depleting properties, R11 also has a relatively high global warming potential compared to more modern refrigerants and working fluids. Although its GWP is lower than some other refrigerants, the environmental impact of releasing R11 into the atmosphere is significant. The trend toward reducing carbon footprints and limiting greenhouse gas emissions has made R11 an increasingly undesirable choice for any energy system, including ORC.

- Regulatory Restrictions: Due to its environmental impact, R11 is heavily regulated and restricted in many countries. The use of R11 in new equipment is prohibited under international agreements like the Montreal Protocol. This means that using R11 in new ORC systems is not only environmentally unsustainable but may also be illegal in many regions. In some countries, R11 is allowed only for servicing existing equipment, but even that is becoming increasingly difficult as supplies dwindle.

- Safety Concerns: While R11 is non-flammable, it can still pose health risks if exposure occurs in high concentrations. Inhalation of R11 can lead to symptoms such as dizziness, nausea, and even more serious health effects with prolonged exposure. Additionally, if R11 is exposed to high temperatures or is involved in fire, it can decompose and produce toxic gases, including hydrogen chloride and phosgene, which are highly hazardous.

- Limited Modern Applications: In recent years, R11 has been largely replaced by more environmentally friendly and efficient alternatives such as R245fa, R134a, and natural refrigerants like ammonia, CO2, and water. These alternatives have better thermodynamic properties, no ozone depletion potential, and lower global warming potential, making them more attractive for use in ORC systems and other refrigeration or heat pump applications.

Alternatives to R11 in ORC Systems

Given the significant environmental and regulatory issues associated with R11, several alternative working fluids are now commonly used in ORC systems. These alternatives are more sustainable, efficient, and in compliance with modern environmental standards.

- R245fa (1,1,1,3,3-Pentafluoropropane): R245fa is one of the most commonly used fluids for ORC applications. It has a low ozone depletion potential (ODP) and a relatively low global warming potential (GWP). R245fa offers excellent thermodynamic performance, particularly in medium-temperature ORC systems, making it a suitable replacement for R11.

- R134a (1,1,1,2-Tetrafluoroethane): R134a is another popular alternative for ORC systems. While it has a higher GWP than R245fa, it still has no ozone depletion potential and offers good thermodynamic performance. R134a is widely available and relatively inexpensive, making it an attractive option for many applications.

- CO2 (Carbon Dioxide): CO2 is a natural refrigerant that has no ozone depletion potential and a very low global warming potential. It performs well in supercritical ORC systems and is gaining popularity, particularly in applications where high pressure and high efficiency are required, such as in geothermal and waste heat recovery systems.

- Ammonia (NH3): Ammonia is another natural refrigerant that has a low environmental impact. It has excellent thermodynamic properties and is often used in industrial refrigeration. However, ammonia is toxic and requires careful handling, which can limit its use in certain applications.

- Hydrofluoroolefins (HFOs): HFOs, such as HFO-1234yf and HFO-1234ze, are newer refrigerants with extremely low global warming potential and no ozone depletion potential. These fluids are being explored as alternatives to both CFCs and HFCs for ORC systems, as they offer better environmental performance without compromising efficiency.

- Water: Water is a natural working fluid with no ozone depletion potential and very low environmental impact. It is used in some ORC systems, particularly in geothermal energy generation, where the temperature and pressure conditions are suitable.

Conclusion

While R11 was once a viable option for ORC systems due to its thermodynamic properties, its environmental impact and regulatory restrictions have made it an unsuitable choice for modern applications. The phase-out of R11 under the Montreal Protocol and the growing demand for sustainable, energy-efficient technologies have led to the development and widespread adoption of alternatives such as R245fa, R134a, CO2, ammonia, and HFOs. These alternatives offer better performance, lower environmental impact, and compliance with international regulations, making them the preferred choice for ORC systems today.

In light of these advancements, the future of ORC systems will be defined by the use of environmentally friendly fluids that not only improve efficiency but also contribute to the global effort to reduce greenhouse gas emissions and protect the ozone layer. The transition away from R11 and other ozone-depleting substances is essential for ensuring that ORC technology remains part of the solution to global energy and environmental challenges.

The transition away from R11 in ORC systems is a critical step towards more sustainable and environmentally friendly energy production technologies. As the focus on reducing the impact of greenhouse gases and protecting the ozone layer intensifies, the industry is moving toward refrigerants and working fluids with lower global warming potential (GWP) and zero ozone depletion potential (ODP). This transition is not only driven by regulatory pressures but also by the growing demand for cleaner, more efficient energy solutions.

The development and adoption of newer refrigerants, such as R245fa, R134a, CO2, ammonia, and HFOs, have been a direct response to the limitations of R11. These fluids offer better thermodynamic efficiency in ORC applications, making them ideal replacements in both industrial and renewable energy applications. The increased efficiency of these fluids, combined with their lower environmental impact, is a driving force in the widespread adoption of ORC systems.

Beyond the refrigerants themselves, improvements in ORC system design and component materials are also contributing to greater energy efficiency and sustainability. New heat exchangers, for instance, are designed to optimize heat recovery and reduce thermal losses. Advanced turbines, designed for higher efficiency and reliability, are also helping to maximize the power output from lower temperature waste heat. These innovations ensure that ORC systems continue to improve, making them even more attractive for industries looking to lower energy consumption and reduce carbon emissions.

The expanding use of ORC systems in the renewable energy sector is another important factor driving this transition. By utilizing waste heat from industrial processes, geothermal energy, or biomass, ORC systems are playing a key role in capturing otherwise wasted thermal energy and converting it into electricity. This aligns with global efforts to reduce reliance on fossil fuels and increase the use of renewable and sustainable energy sources.

As industries and governments look for ways to meet ambitious climate goals, the role of ORC technology in waste heat recovery and decentralized power generation will become even more critical. In particular, ORC systems are well-suited for use in microgrids and off-grid locations, where they can help improve energy resilience and reliability. The ability to generate power from locally available waste heat or renewable energy sources reduces the dependency on centralized power grids, ensuring that energy production is more distributed, efficient, and sustainable.

The integration of digital technologies like IoT (Internet of Things) and AI (Artificial Intelligence) into ORC systems is also shaping the future of these technologies. Smart sensors, real-time monitoring, and predictive analytics are being integrated into ORC systems to optimize performance, prevent failures, and reduce maintenance costs. By leveraging these technologies, operators can improve the efficiency of ORC systems, predict and prevent issues before they arise, and extend the lifespan of system components.

The continued development of ORC systems will also involve collaboration between industries, research institutions, and government organizations. Policy support, such as tax incentives for renewable energy projects or subsidies for energy efficiency improvements, will play a crucial role in accelerating the adoption of ORC systems. Furthermore, as global energy markets continue to evolve, ORC technology will need to adapt to new challenges, including increased pressure to decarbonize and optimize energy usage.

In conclusion, while R11 was once a common working fluid in ORC systems, its environmental impact and regulatory restrictions have led to a shift toward more sustainable alternatives. The future of ORC technology is focused on the use of environmentally friendly fluids, increased efficiency, and the integration of smart technologies that help optimize system performance. These advancements ensure that ORC systems will continue to play an important role in the global transition to renewable energy and more sustainable energy production. The continued evolution of ORC systems, combined with the adoption of greener refrigerants, will contribute to a cleaner, more resilient energy future.

As the global energy landscape continues to shift toward more sustainable and low-carbon solutions, ORC technology remains an integral part of this transition. The adoption of alternative working fluids, along with advancements in system design, plays a crucial role in expanding the reach of ORC systems across various industries and energy applications. The demand for ORC systems is poised to grow, driven by their ability to efficiently harness waste heat, a valuable resource that is often underutilized.

One significant aspect of the future development of ORC technology lies in its integration with emerging energy sectors, particularly in the growing field of waste-to-energy systems. Waste-to-energy technologies, which convert municipal solid waste or biomass into usable energy, can significantly benefit from ORC systems. These systems can be used to recover heat from the combustion process and convert it into electricity, helping to reduce reliance on conventional fossil fuels while minimizing waste. In this context, ORC systems are ideal for not only producing power from waste but also improving the overall efficiency of waste-to-energy plants.

In addition to waste-to-energy, ORC technology is becoming increasingly valuable in geothermal energy generation. Geothermal power plants use the natural heat from the Earth’s core to generate electricity. ORC systems are well-suited for low- and medium-temperature geothermal resources, where traditional steam turbines may not be as effective. By using an organic fluid with a lower boiling point, ORC systems can efficiently convert geothermal heat into electricity, expanding the potential for geothermal energy development. As more regions tap into geothermal resources, ORC technology will be a key enabler in maximizing the potential of this renewable energy source.

The role of ORC technology in industrial applications is also evolving, with more industries seeking ways to recover waste heat and improve energy efficiency. Industries such as cement, steel, and chemical manufacturing generate significant amounts of heat during production processes, much of which is often wasted. By integrating ORC systems into their operations, these industries can capture this waste heat and convert it into electricity, reducing their overall energy consumption and carbon emissions. This aligns with both environmental goals and economic incentives, as recovering waste heat not only reduces costs but also helps businesses meet increasingly stringent environmental regulations.

Moreover, as the demand for decentralized energy solutions grows, ORC technology is well-positioned to play a vital role in off-grid applications. Microgrids, which can operate independently from the main power grid, are increasingly being used in remote areas, disaster-prone regions, and areas with unreliable grid infrastructure. ORC systems can be an essential part of these microgrids, enabling on-site power generation from waste heat or renewable energy sources. This ability to provide reliable, local energy helps improve energy security and resilience, especially in areas where access to the central grid is limited or non-existent.

The ongoing development of ORC technology also includes efforts to reduce the cost of installation and operation. While ORC systems are already highly efficient, their initial capital costs can be a barrier to adoption, particularly in smaller-scale applications. However, as the technology matures and economies of scale come into play, the cost of ORC systems is expected to decrease, making them more accessible to a broader range of industries and applications. Additionally, as competition grows and more manufacturers enter the market, it’s likely that the cost of components such as turbines, heat exchangers, and working fluids will continue to fall, further driving the economic feasibility of ORC systems.

Another area of potential for ORC technology is in its integration with energy storage systems. Energy storage plays a key role in stabilizing power grids and ensuring a consistent energy supply, especially as the share of intermittent renewable energy sources like wind and solar increases. ORC systems can be integrated into thermal energy storage solutions, where excess heat is stored and later used to generate power during periods of high demand or when renewable energy sources are unavailable. This combination of energy recovery and storage enhances the flexibility and reliability of renewable energy systems, contributing to a more stable and sustainable energy grid.

The development of hybrid energy systems, which combine multiple renewable energy sources and technologies, will also benefit from ORC systems. For example, ORC can be integrated into combined heat and power (CHP) systems, which simultaneously generate electricity and useful heat. These hybrid systems can use a variety of renewable sources, such as solar, wind, and biomass, to provide continuous power and heat, with ORC technology playing a crucial role in maximizing the efficiency of the overall system. By optimizing both electricity generation and thermal energy recovery, hybrid systems offer a highly efficient, sustainable solution for a wide range of energy needs.

The growing emphasis on circular economy principles will further support the integration of ORC technology into industrial processes. In a circular economy, waste materials are treated as valuable resources that can be reused, recycled, or converted into energy. ORC systems fit perfectly within this framework, as they allow industries to recover waste heat and convert it into electricity, reducing the need for additional energy inputs. This not only helps reduce the environmental impact of industrial processes but also creates a more sustainable and efficient system overall.

Looking ahead, the potential for ORC technology to contribute to global decarbonization efforts is immense. By enabling the recovery of waste heat and the generation of renewable energy, ORC systems can help reduce greenhouse gas emissions, lower energy costs, and improve the overall efficiency of industrial, commercial, and residential energy systems. With continued innovation in system design, fluid selection, and integration with other technologies, ORC will remain a key player in the transition to a cleaner, more sustainable energy future.

In conclusion, the future of ORC technology is bright, with a wealth of opportunities for expansion and improvement. From enhancing industrial energy efficiency to supporting renewable energy integration, ORC systems are poised to play a critical role in the global push for sustainability. As new working fluids and innovative system designs emerge, ORC technology will continue to evolve, helping industries and communities harness the full potential of waste heat and renewable energy sources. The continued development of ORC systems will be essential in creating a more sustainable, resilient, and energy-efficient world.

The trajectory of ORC (Organic Rankine Cycle) technology continues to evolve as it plays an increasingly pivotal role in addressing the world’s energy challenges. The integration of ORC systems into emerging energy sectors, particularly those focused on renewable energy and waste heat recovery, is expanding. This growth is being fueled not just by technological advancements but also by a broader commitment to sustainability, economic efficiency, and environmental responsibility across industries.

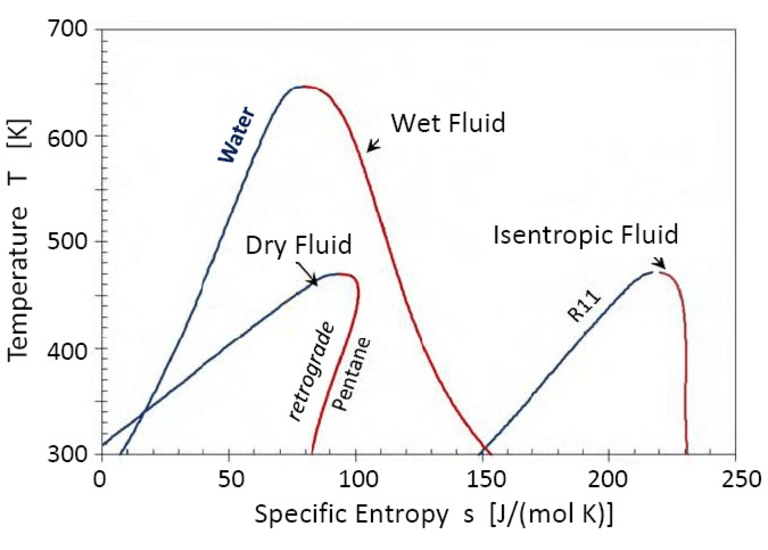

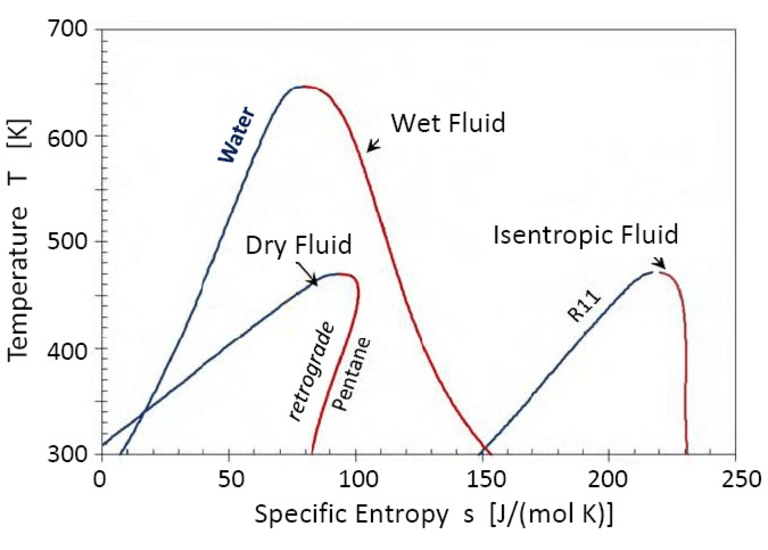

As industries push for even more advanced energy solutions, there is a growing recognition of the importance of optimizing ORC systems for various temperature ranges and application scenarios. The versatility of ORC technology allows it to be tailored to different waste heat sources, from high-temperature sources like industrial furnaces to lower-temperature sources like geothermal energy and biomass. Research is also being conducted into new, hybrid working fluids designed to improve the overall performance of ORC systems, especially in low-temperature applications, where traditional working fluids might struggle to maintain high efficiency.

In particular, ORC systems designed for lower-temperature heat sources—such as industrial processes that operate below 100°C—are gaining attention. These systems are increasingly being used for capturing waste heat that would otherwise be discarded and transforming it into electricity. The utilization of waste heat from various sectors, including food processing, paper production, and chemical manufacturing, represents a significant opportunity to reduce energy consumption and emissions across a wide range of industries.

One of the driving forces behind the expanding use of ORC technology is the urgent need to decarbonize the global economy. By converting waste heat into useful electricity or thermal energy, ORC systems offer a straightforward path toward improving overall energy efficiency and lowering emissions in hard-to-decarbonize sectors. For example, in industries with high energy demand and substantial heat waste, ORC technology provides a way to generate electricity on-site, offsetting the need for energy drawn from fossil-fuel-based power grids.

At the same time, ORC systems’ growing role in renewable energy applications, such as geothermal, solar thermal, and biomass, is another significant trend. Geothermal energy, in particular, has a vast untapped potential that can be unlocked using ORC systems. In areas with moderate geothermal temperatures, where traditional steam turbines might not be effective, ORC offers a highly efficient solution for generating electricity from this renewable energy source. In the case of solar thermal systems, ORC technology can be employed to convert stored thermal energy into electricity, ensuring a stable and continuous power supply even when solar radiation is not available. Biomass-based ORC systems are also being explored, offering a low-carbon alternative to fossil-fuel-based energy generation by converting organic matter into thermal energy and electricity.

The transition to electric-based energy systems is another significant trend influencing the adoption of ORC technology. As various sectors—from transportation to industrial heating—shift towards electrification, the demand for localized, efficient power generation systems that can support this transition grows. ORC systems, especially when paired with energy storage solutions, can be deployed in industrial applications to generate electricity from waste heat, while also providing backup power during peak demand or grid outages. This localized energy generation reduces dependence on centralized power plants and strengthens the resilience of energy systems.

Additionally, ORC systems are gaining attention in off-grid and remote applications, where access to the central grid is unreliable or non-existent. Microgrids, which can operate autonomously or be integrated with the main grid, are an ideal environment for ORC technology. These systems can harness locally available waste heat, solar, or biomass energy to provide power and heat in remote communities, industrial sites, or disaster-prone regions. The ability of ORC systems to operate independently and use renewable resources makes them a key enabler of energy access in underserved areas.

As ORC systems are deployed in more diverse applications, their role in energy storage is also expanding. Thermal energy storage (TES) is becoming an important component of renewable energy systems, allowing excess energy to be stored and used when demand is high or when renewable generation is low. ORC systems can be integrated with TES systems to capture surplus thermal energy and convert it into electricity. This combination enhances the flexibility and reliability of renewable energy systems, ensuring that power is available when needed, even if renewable generation fluctuates. As energy storage technologies mature and become more affordable, the synergy between ORC systems and storage solutions will likely be a key factor in the widespread adoption of renewable energy.

The development of low-cost, high-efficiency ORC systems is also a priority for the industry. Advances in turbine design, heat exchanger efficiency, and fluid management are driving improvements in the performance and cost-effectiveness of ORC technology. New manufacturing techniques and materials, such as advanced alloys and coatings, are helping reduce wear and tear on ORC system components, improving reliability and extending operational lifetimes. These innovations are contributing to the continued reduction in both capital and operational costs, making ORC technology more accessible to smaller businesses and emerging markets.

Another important aspect of the future of ORC systems is their integration with digital technologies. The use of sensors, smart controls, and real-time data analytics is improving the monitoring and optimization of ORC systems. These technologies enable operators to make data-driven decisions, allowing them to optimize system performance and reduce energy consumption. Predictive maintenance, powered by AI and machine learning, will also help prevent unexpected failures and reduce downtime, increasing the overall reliability and longevity of ORC systems. By utilizing these digital technologies, ORC systems can be more effectively integrated into broader smart grid and industrial automation systems.