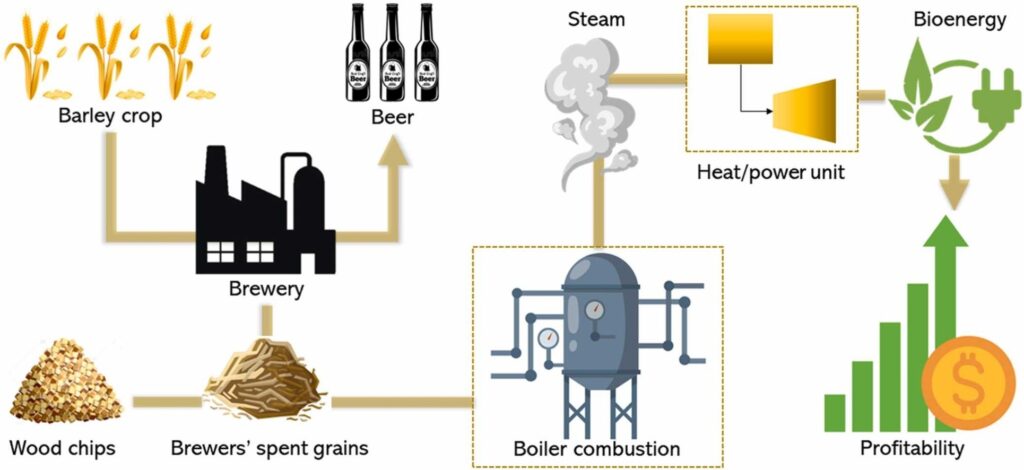

Steam Turbine for Electricity Generation with Cereal Grain Waste: Steam turbines are widely used for electricity generation in various industrial applications, including the utilization of biomass as a fuel source. One such biomass fuel is wood chips derived from furniture manufacturing waste. These chips, often consisting of wood scraps, sawdust, and other residual materials, serve as an energy source for steam generation, making them a viable option for sustainable and renewable power production. The process begins with the collection and preparation of the wood chips, which are typically stored in a controlled environment to ensure optimal moisture content for combustion efficiency. Excess moisture in the biomass can reduce combustion efficiency, leading to lower energy output and higher emissions, whereas overly dry fuel can burn too quickly, causing inefficiencies in heat transfer.

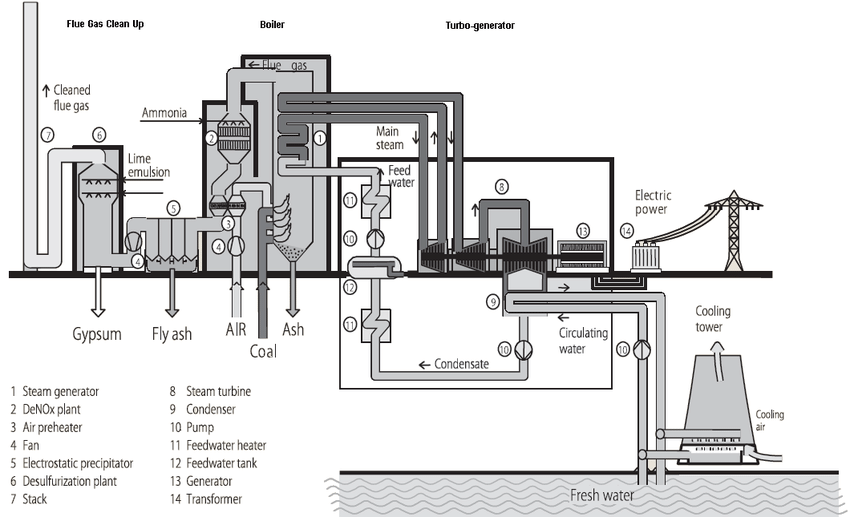

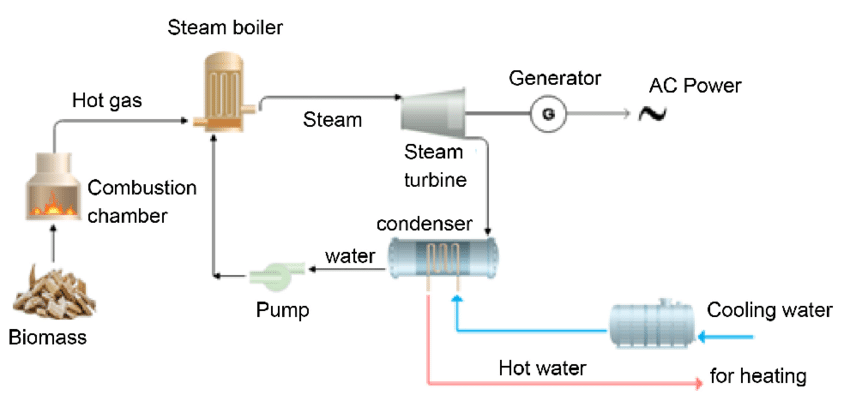

The wood chips are fed into a biomass boiler, where they undergo combustion to generate heat. The boiler is designed to efficiently convert the chemical energy stored in the biomass into thermal energy by burning the chips in a controlled environment. Advanced combustion systems, such as fluidized bed or moving grate boilers, are commonly used to ensure complete combustion, minimize emissions, and maximize energy extraction. The heat produced from combustion is transferred to water, generating high-pressure steam that is directed into the steam turbine.

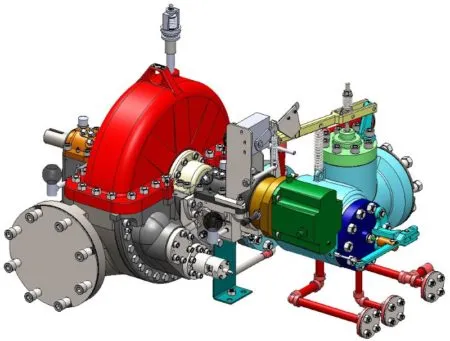

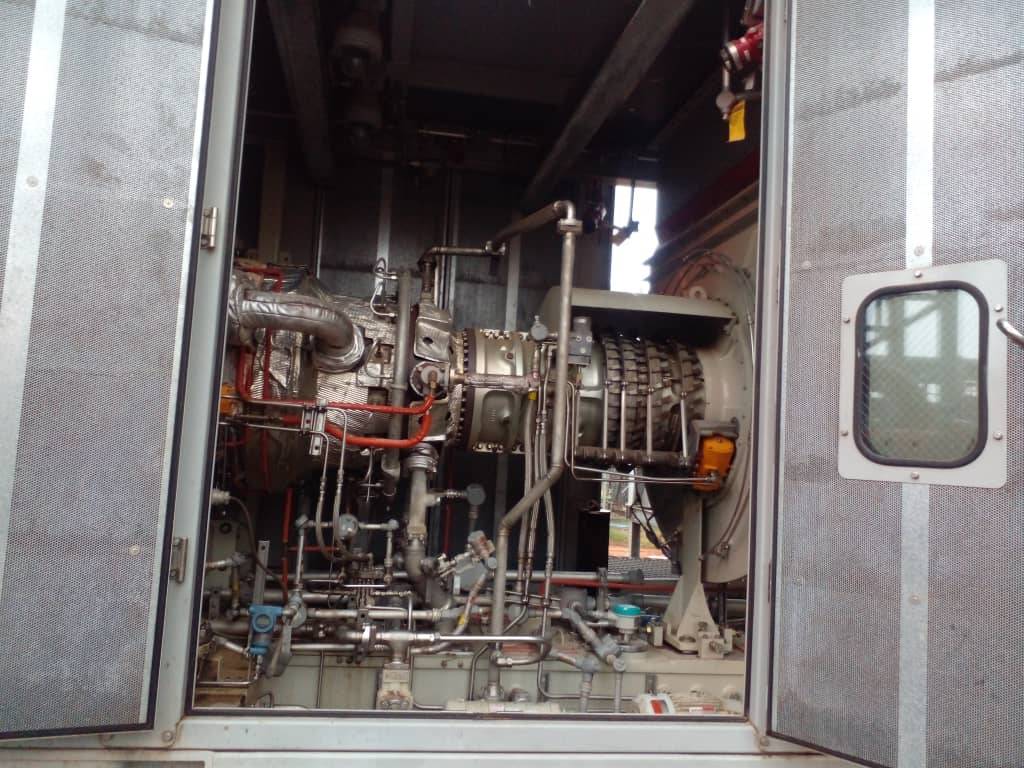

The steam turbine plays a crucial role in the energy conversion process, as it transforms the thermal energy of steam into mechanical work. The high-pressure steam enters the turbine and expands through a series of stationary and rotating blades. As the steam expands, it imparts kinetic energy to the rotating blades, causing the turbine shaft to spin. This rotational energy is then transferred to an electrical generator, which converts it into electricity. The efficiency of this process depends on various factors, including the steam temperature and pressure, turbine design, and the effectiveness of the condensation and heat recovery systems.

In many biomass power plants, a condensing steam turbine is used to maximize electricity generation. In this configuration, the steam is expanded to a low-pressure state, and after passing through the turbine, it enters a condenser where it is cooled and converted back into liquid water. The condensed water, or condensate, is then returned to the boiler through a feedwater system to be reheated and reused, forming a closed-loop cycle. This approach ensures high efficiency by recovering waste heat and minimizing water losses. An alternative setup is a back-pressure steam turbine, which is often used in cogeneration applications where both electricity and process heat are required. In this system, the steam exiting the turbine retains enough pressure to be used for industrial heating processes, increasing the overall efficiency of the facility.

The integration of a steam turbine system for electricity generation using furniture manufacturing waste offers multiple benefits. It provides a sustainable and cost-effective way to utilize wood waste that would otherwise be discarded or sent to landfills. Additionally, it reduces reliance on fossil fuels, lowering greenhouse gas emissions and promoting a circular economy. However, certain challenges must be addressed to optimize performance and ensure long-term viability. These include fuel variability, potential contamination of wood waste with non-combustible materials such as adhesives or coatings, and the need for efficient ash disposal systems. Proper fuel preparation, advanced emissions control technologies, and regular maintenance of the boiler and turbine system are essential to overcoming these challenges.

The overall feasibility of using steam turbines for electricity generation with wood chips from furniture manufacturing depends on factors such as fuel availability, economic considerations, regulatory compliance, and technological advancements. Government incentives for renewable energy and carbon reduction initiatives can further enhance the attractiveness of such projects. By implementing efficient biomass-to-energy conversion technologies, industries can not only reduce waste but also contribute to sustainable energy production and environmental conservation.

Steam Turbine

Another key factor influencing the efficiency and reliability of steam turbine systems using furniture manufacturing waste is the design and optimization of the combustion process. The performance of the biomass boiler plays a crucial role in determining the quality of the steam produced, which directly affects the turbine’s efficiency. The selection of an appropriate combustion technology depends on the characteristics of the wood chips, such as particle size, moisture content, and the presence of any impurities. Fluidized bed boilers, for instance, offer higher efficiency and better control of combustion conditions compared to traditional grate-fired boilers. They ensure complete combustion of the biomass by suspending fuel particles in a stream of air or gas, enhancing heat transfer and reducing emissions.

One of the challenges associated with burning wood chips from furniture manufacturing is the potential presence of contaminants such as glue, varnishes, and other chemical coatings. These substances can alter the combustion process, leading to the formation of harmful emissions such as volatile organic compounds (VOCs) and particulate matter. To mitigate these effects, advanced filtration and emission control technologies, such as electrostatic precipitators and fabric filters, are integrated into the system. Additionally, proper fuel sorting and preprocessing can help minimize the presence of non-combustible materials, ensuring a cleaner and more efficient combustion process.

Once the high-pressure steam is generated, it must be efficiently utilized within the turbine to maximize power output. The turbine’s performance depends on various parameters, including inlet steam pressure, temperature, and the level of expansion within the turbine stages. Multi-stage steam turbines, which consist of high-pressure, intermediate-pressure, and low-pressure sections, are often used to extract the maximum amount of energy from the steam before it exits the system. The degree of superheating also plays a crucial role in improving efficiency, as superheated steam reduces moisture content and prevents damage to turbine blades.

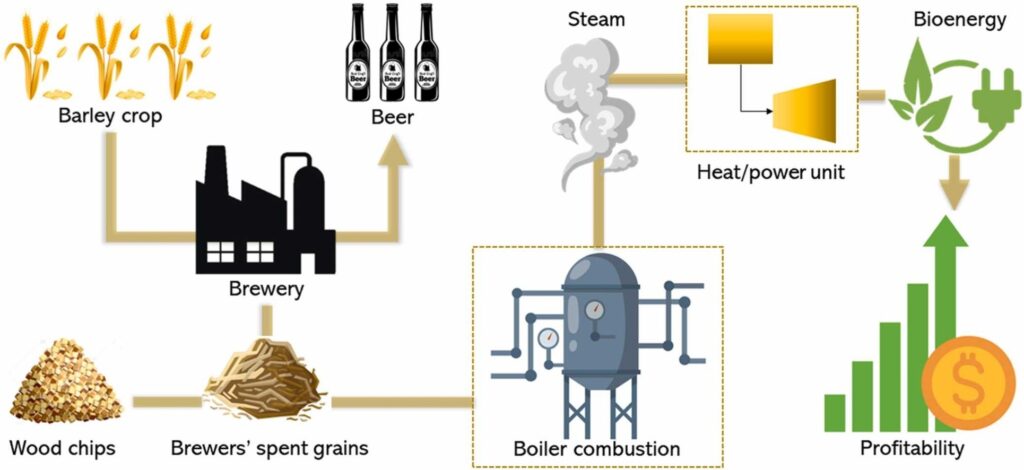

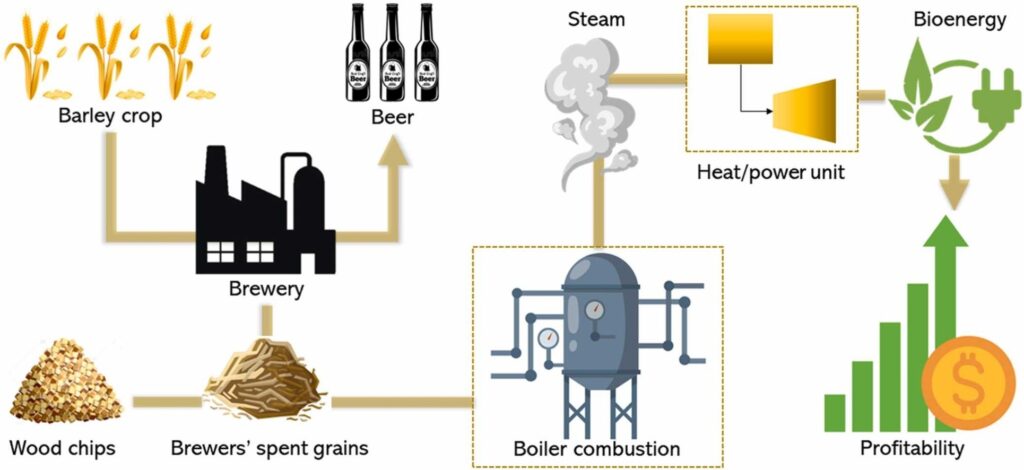

To further enhance the energy efficiency of the system, many facilities incorporate combined heat and power (CHP) configurations, also known as cogeneration. In this setup, the back-pressure steam from the turbine is used for industrial heating applications, such as drying processes in wood manufacturing or space heating within the facility. By utilizing the residual heat from the steam, CHP systems achieve overall efficiencies of up to 80%, compared to around 35-45% for standalone power generation systems. This makes cogeneration an attractive option for industries seeking to optimize their energy use while reducing fuel consumption and emissions.

Water and steam cycle management is another critical aspect of steam turbine operation. The quality of feedwater used in the boiler must be carefully monitored to prevent scaling, corrosion, and other issues that can reduce system efficiency and lifespan. Water treatment processes, including filtration, chemical conditioning, and demineralization, help maintain the purity of the steam cycle. Additionally, condensate recovery systems play a vital role in improving efficiency by recycling water from the condenser back into the boiler. This minimizes water wastage, reduces the need for fresh water intake, and lowers operational costs.

The economic feasibility of using steam turbines for electricity generation from wood chips depends on several factors, including initial capital investment, fuel costs, maintenance expenses, and potential revenue from electricity sales or government incentives. While biomass power generation requires a significant upfront investment in boilers, turbines, and emissions control systems, the long-term benefits of fuel cost savings and sustainability make it an attractive option for industries with a steady supply of biomass waste. Many countries offer financial incentives, tax credits, and feed-in tariffs to support renewable energy projects, further improving the economic viability of biomass-based power generation.

Another consideration is the environmental impact of biomass combustion. Although burning wood chips releases carbon dioxide, the overall carbon footprint is lower than that of fossil fuels because biomass is considered a renewable resource. The carbon released during combustion is offset by the carbon absorbed by trees during their growth, making the process close to carbon-neutral. However, sustainable sourcing of biomass is essential to ensure that the overall environmental benefits are realized. The use of certified sustainable wood waste and responsible forestry practices can help minimize deforestation and land degradation.

In summary, steam turbines offer an efficient and sustainable solution for electricity generation using wood chips from furniture manufacturing waste. By optimizing combustion technology, implementing advanced emissions controls, and integrating heat recovery systems, industries can maximize energy efficiency while minimizing environmental impact. While challenges such as fuel variability, contamination, and maintenance costs must be addressed, the overall benefits of biomass-based power generation make it a promising alternative to conventional fossil fuel power plants. With continued advancements in technology and supportive policies, the utilization of wood waste for energy production has the potential to contribute significantly to the global transition toward renewable energy and circular economy practices.

Another important aspect of steam turbine systems utilizing wood chips from furniture manufacturing waste is the optimization of operational parameters to achieve maximum energy conversion efficiency. The performance of a steam turbine is heavily influenced by the thermodynamic properties of steam, such as pressure, temperature, and enthalpy drop across turbine stages. Engineers and plant operators continuously monitor and adjust these parameters to ensure that the system operates within its optimal range. Advanced control systems, including automated sensors and predictive maintenance technologies, play a crucial role in maintaining the reliability and efficiency of the turbine. These systems use real-time data analysis to detect potential issues, such as steam leakage, turbine blade erosion, or fluctuations in steam quality, allowing for proactive maintenance and reduced downtime.

One of the key efficiency-improving techniques in biomass power plants is steam reheating. In larger installations, the steam exhausted from the high-pressure section of the turbine is sent back to the boiler for reheating before entering the intermediate-pressure section. This process increases the overall thermal efficiency of the system by reducing moisture content in the steam and preventing erosion damage to turbine blades. Additionally, the implementation of regenerative feedwater heating, where extracted steam is used to preheat the boiler feedwater, further improves energy utilization by reducing the fuel required to heat water to steam-producing temperatures.

The mechanical design of the steam turbine also has a significant impact on its performance and longevity. The turbine blades, made from high-strength alloys, must withstand high temperatures, pressures, and rotational stresses while maintaining aerodynamic efficiency. Blade cooling techniques and advanced coating materials help extend the operational lifespan of turbine components, reducing maintenance costs and increasing reliability. Additionally, the use of low-friction bearings and precision machining enhances the turbine’s ability to operate with minimal mechanical losses.

Apart from turbine optimization, the efficiency of the entire biomass-to-electricity conversion process can be enhanced through integrated waste heat recovery systems. Waste heat from the exhaust gases of the biomass boiler can be captured and utilized in various ways, such as preheating combustion air, drying incoming biomass fuel, or generating additional steam for use in the turbine. These measures improve overall plant efficiency and contribute to reducing fuel consumption, thereby lowering operational costs.

A critical consideration in biomass power plants using wood chips from furniture manufacturing waste is the handling and disposal of ash and other combustion byproducts. Biomass combustion produces both bottom ash and fly ash, which must be managed properly to comply with environmental regulations. Depending on the composition of the ash, it may be repurposed for applications such as soil conditioning, cement production, or road construction. However, if the ash contains contaminants from furniture coatings or adhesives, additional treatment may be necessary to prevent environmental harm. Many biomass power plants incorporate ash handling systems that collect and transport the ash for safe disposal or beneficial reuse.

Financial and economic factors also play a significant role in the viability of steam turbine-based biomass power generation. While the initial investment in boilers, turbines, and emissions control systems can be substantial, long-term fuel cost savings and potential revenue from electricity sales contribute to financial sustainability. Government policies, such as feed-in tariffs, renewable energy credits, and carbon offset incentives, can further enhance the economic attractiveness of biomass-based power generation. In some cases, surplus electricity generated by the biomass plant can be sold to the grid, providing an additional revenue stream for furniture manufacturers and industrial facilities.

Another advantage of using steam turbines for electricity generation with wood chips from furniture manufacturing is the potential for energy independence and resilience. Industrial facilities that produce large amounts of wood waste can generate their own electricity, reducing reliance on external power sources and mitigating the impact of fluctuating energy prices. This can be particularly beneficial for remote locations or regions with unstable electricity supply, where self-sustaining biomass power plants provide a reliable and cost-effective energy solution.

In conclusion, the utilization of steam turbines for electricity generation using wood chips from furniture manufacturing presents a highly efficient and sustainable solution for industrial energy needs. By optimizing turbine design, implementing advanced combustion and emissions control technologies, and integrating waste heat recovery systems, industries can achieve high energy conversion efficiencies while minimizing environmental impact. Although challenges such as fuel variability, ash disposal, and maintenance costs must be managed, the long-term benefits of renewable energy production, waste reduction, and economic savings make biomass-based power generation a compelling alternative to traditional fossil fuel energy sources. With ongoing technological advancements and supportive policy frameworks, biomass power plants have the potential to play a significant role in the global transition toward sustainable energy and circular economy practices.

Steam Turbine for Electricity Generation with Anthracite Coal

Steam turbines powered by anthracite coal for electricity generation represent a well-established method of producing large-scale power with high efficiency. Anthracite, known for its high carbon content, low moisture, and low volatile matter, is the highest-grade coal available. These properties make it an excellent fuel for steam power plants, as it produces high thermal energy per unit weight, burns cleaner than lower-grade coals, and generates less smoke and soot. However, the combustion of anthracite coal presents unique challenges in boiler operation, emissions control, and ash handling, which must be carefully managed to maximize efficiency and minimize environmental impact.

The process of generating electricity with anthracite coal begins with fuel preparation and handling. Since anthracite is a hard and dense coal, it requires specialized milling equipment to grind it into fine particles suitable for efficient combustion. Pulverized coal combustion (PCC) is the most common technique used in modern steam power plants. In this system, anthracite is ground into a fine powder and injected into the boiler furnace with a stream of preheated air. This ensures rapid and complete combustion, allowing for the efficient release of heat energy. Fluidized bed combustion (FBC) is another method that is particularly useful for burning anthracite coal, as it operates at lower temperatures, reducing nitrogen oxide (NOx) emissions and allowing for the direct injection of limestone to capture sulfur dioxide (SO₂).

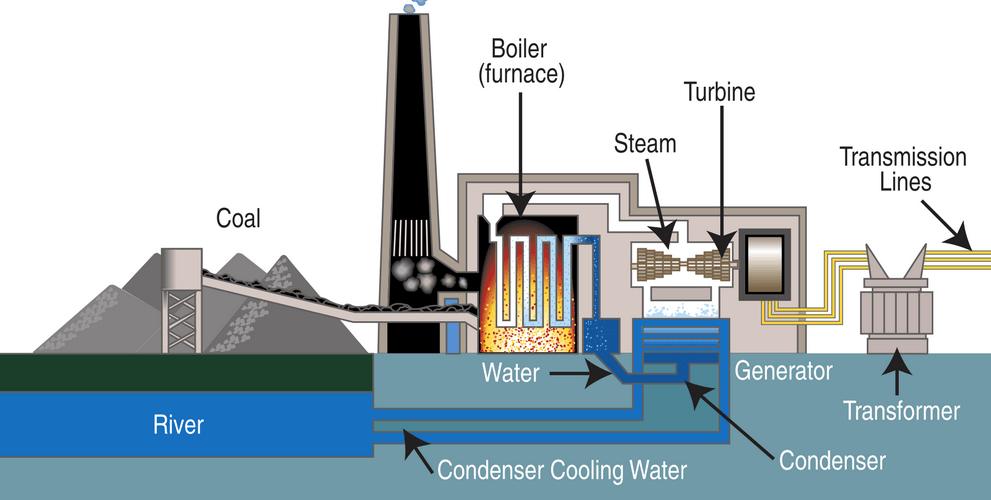

Once the anthracite coal is burned in the boiler, the heat generated is transferred to water, converting it into high-pressure steam. This steam is then directed into the steam turbine, where its thermal energy is converted into mechanical energy. As the high-pressure steam expands through the turbine blades, it imparts kinetic energy, causing the turbine shaft to rotate. This mechanical motion is then transmitted to an electrical generator, where it is converted into electricity. The efficiency of this energy conversion process depends on multiple factors, including steam temperature and pressure, turbine design, and the effectiveness of heat recovery systems.

In high-efficiency coal-fired power plants, supercritical and ultra-supercritical steam cycles are used to improve performance. These systems operate at extremely high pressures and temperatures, increasing the thermal efficiency of the power plant and reducing coal consumption per unit of electricity generated. Ultra-supercritical power plants achieve efficiencies above 45%, compared to subcritical plants, which typically operate at 35-38% efficiency. The higher efficiency results in lower carbon dioxide (CO₂) emissions per megawatt-hour (MWh) of electricity produced, making ultra-supercritical plants a preferred choice for modern coal-fired power generation.

To maximize the efficiency of anthracite-fueled steam turbines, many power plants incorporate reheat and regenerative cycles. In a reheat cycle, steam exiting the high-pressure section of the turbine is returned to the boiler for reheating before being expanded in the intermediate-pressure and low-pressure sections of the turbine. This process reduces moisture content in the steam, preventing erosion damage to turbine blades and increasing efficiency. In a regenerative cycle, steam is extracted at intermediate stages of the turbine to preheat the feedwater before it enters the boiler, reducing fuel consumption and enhancing overall plant performance.

The condensate recovery system plays a crucial role in maintaining the efficiency of a steam turbine power plant. After passing through the turbine, the steam enters a condenser, where it is cooled and converted back into liquid water. This process is facilitated by cooling towers or direct water sources such as rivers or lakes. The recovered condensate is then pumped back to the boiler to be reheated and converted into steam again, forming a closed-loop cycle. This reduces the need for fresh water intake and improves thermal efficiency.

Emissions control is a critical aspect of coal-fired power generation, particularly when using anthracite coal. While anthracite has lower volatile matter and sulfur content than other coal types, it still produces emissions such as carbon dioxide (CO₂), nitrogen oxides (NOx), sulfur dioxide (SO₂), and particulate matter. To mitigate these environmental impacts, modern power plants employ advanced emissions control technologies. Selective catalytic reduction (SCR) systems reduce NOx emissions by converting them into nitrogen and water vapor. Flue gas desulfurization (FGD) systems, commonly known as scrubbers, capture SO₂ emissions using limestone or other alkaline materials. Electrostatic precipitators (ESPs) and fabric filters remove fine particulate matter from the exhaust gases before they are released into the atmosphere.

Ash handling and disposal are also important considerations in anthracite coal-fired power plants. The combustion of coal generates both bottom ash and fly ash, which must be managed properly to comply with environmental regulations. Fly ash, a fine particulate byproduct, is often collected using electrostatic precipitators or bag filters and can be repurposed for applications such as cement manufacturing, road construction, and soil stabilization. Bottom ash, which consists of heavier, non-combustible residues, is typically removed from the boiler and either landfilled or processed for use in construction materials.

The economic feasibility of using anthracite coal for electricity generation depends on several factors, including fuel availability, market prices, regulatory policies, and carbon pricing mechanisms. While anthracite coal offers high energy content and efficiency, its extraction and transportation costs can be higher than those of lower-grade coals. Additionally, many countries are implementing stricter emissions regulations and carbon taxes, which impact the competitiveness of coal-fired power plants compared to renewable energy sources such as wind and solar.

Despite these challenges, anthracite coal remains an important fuel source for power generation in regions where it is abundant and where energy security is a priority. Advances in carbon capture and storage (CCS) technologies offer potential solutions for reducing the carbon footprint of coal-fired power plants. CCS systems capture CO₂ emissions before they are released into the atmosphere and store them underground or use them for industrial applications, such as enhanced oil recovery.

In conclusion, steam turbines powered by anthracite coal provide a reliable and efficient means of electricity generation, particularly in regions with access to high-grade coal resources. By optimizing combustion technologies, improving turbine efficiency, and implementing advanced emissions control systems, power plants can maximize energy output while minimizing environmental impact. While the global energy transition is shifting towards cleaner alternatives, coal-fired power generation continues to play a significant role in meeting energy demands, particularly in industrial economies. The future of anthracite-based power generation will depend on technological advancements, regulatory frameworks, and the economic competitiveness of coal relative to other energy sources.

Another critical aspect of steam turbine power generation using anthracite coal is fuel preparation and handling, which directly impacts combustion efficiency and plant performance. Unlike softer bituminous and sub-bituminous coals, anthracite is a dense, hard coal with low volatile content, making it more challenging to ignite and sustain efficient combustion. To address this, specialized pulverization systems are employed to grind the coal into fine particles, ensuring complete and rapid burning in the furnace. The pulverized fuel is then mixed with preheated air and injected into the boiler combustion chamber, where it ignites and generates the high temperatures needed to produce steam.

Boiler design plays a significant role in optimizing the combustion of anthracite coal. Due to its lower reactivity and higher ignition temperature, anthracite requires longer residence times in the combustion chamber to ensure complete burnout. Advanced boiler technologies such as fluidized bed combustion (FBC) and circulating fluidized bed combustion (CFBC) have been developed to enhance efficiency when burning difficult fuels like anthracite. These systems operate at lower temperatures than traditional pulverized coal boilers, reducing the formation of nitrogen oxides (NOx) while allowing for in-bed desulfurization, which captures sulfur emissions before they exit the flue gas stack.

Once the steam is generated at high pressure and temperature, it enters the steam turbine, where its thermal energy is converted into mechanical energy. In large-scale power plants, multi-stage steam turbines are used to maximize efficiency. These turbines typically consist of high-pressure, intermediate-pressure, and low-pressure sections, allowing the steam to expand progressively and extract the maximum amount of energy before being condensed back into water. Supercritical and ultra-supercritical steam conditions, which involve operating at pressures and temperatures above the critical point of water, further improve efficiency by reducing fuel consumption and lowering emissions per megawatt-hour of electricity produced.

To enhance the overall efficiency of the power plant, various heat recovery techniques are employed. One such method is the use of regenerative feedwater heaters, where steam extracted from intermediate turbine stages preheats the feedwater before it enters the boiler. This reduces the amount of fuel required to raise the water to steam-producing temperatures, improving thermal efficiency. Similarly, reheat cycles are commonly used in high-efficiency plants, where partially expanded steam is sent back to the boiler for reheating before returning to the turbine. This prevents excessive moisture formation in the later turbine stages, reducing wear on turbine blades and improving overall power generation efficiency.

Water management is another key factor in the operation of anthracite coal-fired steam turbines. After passing through the turbine, the steam is cooled in a condenser and converted back into liquid water. This process requires a steady supply of cooling water, which is typically sourced from nearby rivers, lakes, or cooling towers. Closed-loop cooling systems, such as air-cooled condensers, are sometimes used in regions with water scarcity to minimize fresh water consumption. Proper water treatment and purification are essential to prevent scaling and corrosion in boiler tubes and turbine components, ensuring long-term reliability and efficiency.

Emissions control technologies are crucial for mitigating the environmental impact of anthracite coal combustion. While anthracite contains less sulfur than lower-rank coals, it still produces sulfur dioxide (SO₂) emissions, which can contribute to acid rain and air pollution. Flue gas desulfurization (FGD) systems, also known as scrubbers, are used to capture SO₂ by reacting it with a sorbent such as limestone or lime, producing gypsum as a byproduct that can be repurposed for industrial applications. Additionally, selective catalytic reduction (SCR) and low-NOx burners are employed to reduce nitrogen oxide emissions, while electrostatic precipitators (ESPs) and fabric filters remove fine particulate matter from the exhaust gases.

The handling and disposal of coal combustion byproducts, such as fly ash and bottom ash, also require careful management. Fly ash, which consists of fine particles carried in the flue gas, is typically captured using ESPs or baghouse filters before being stored in silos for potential reuse. It can be utilized in cement manufacturing, concrete production, and road construction, reducing the need for landfill disposal. Bottom ash, which remains at the bottom of the boiler, is often processed for use in construction materials or disposed of in compliance with environmental regulations.

The economic feasibility of anthracite coal-fired power plants depends on multiple factors, including fuel availability, plant efficiency, emissions regulations, and market conditions. While anthracite provides high energy density and cleaner combustion compared to lower-grade coals, its higher cost and limited supply in some regions can affect the competitiveness of anthracite-based power generation. Additionally, evolving government policies and carbon pricing mechanisms are shaping the future of coal-fired electricity, with an increasing emphasis on emissions reductions and the transition to cleaner energy sources.

To address concerns about carbon emissions, research and development efforts are focusing on carbon capture and storage (CCS) technologies, which aim to capture CO₂ emissions from coal power plants and store them underground or utilize them in industrial processes. While CCS has the potential to significantly reduce the carbon footprint of coal-fired power generation, the technology remains expensive and is not yet widely implemented at a commercial scale. Ongoing advancements in high-efficiency, low-emissions (HELE) coal technologies, including integrated gasification combined cycle (IGCC) and oxy-fuel combustion, offer additional pathways for reducing environmental impact while maintaining the reliability of coal-based power generation.

In summary, steam turbines powered by anthracite coal provide a high-efficiency method for electricity generation, leveraging advanced combustion, emissions control, and heat recovery technologies to maximize performance and minimize environmental impact. While challenges such as fuel cost, regulatory constraints, and emissions concerns must be addressed, continued innovation in clean coal technologies and carbon capture solutions could play a role in the long-term sustainability of coal-based energy production. The future of anthracite coal-fired power plants will depend on their ability to adapt to changing energy policies, market conditions, and technological advancements in the global transition toward a cleaner and more sustainable energy landscape.

The long-term viability of anthracite coal-fired steam turbine power generation depends on the balance between energy demand, technological advancements, and regulatory constraints. As global energy policies increasingly emphasize decarbonization, coal-fired power plants must adopt cleaner and more efficient technologies to remain competitive. This shift is driving research into high-efficiency, low-emissions (HELE) technologies, including ultra-supercritical (USC) steam cycles, integrated gasification combined cycle (IGCC) systems, and carbon capture, utilization, and storage (CCUS) solutions. These innovations aim to reduce greenhouse gas emissions while maintaining the reliability and stability of coal-based electricity generation.

Ultra-supercritical steam plants represent the most advanced form of conventional coal power generation. By operating at temperatures above 600°C and pressures exceeding 30 MPa, USC plants achieve thermal efficiencies above 45%, significantly reducing coal consumption and emissions per unit of electricity generated. Compared to traditional subcritical and supercritical plants, USC technology minimizes carbon dioxide (CO₂) emissions while maximizing energy output. Further improvements in materials science, such as advanced nickel-based alloys, are enabling even higher operating temperatures, pushing the boundaries of steam cycle efficiency.

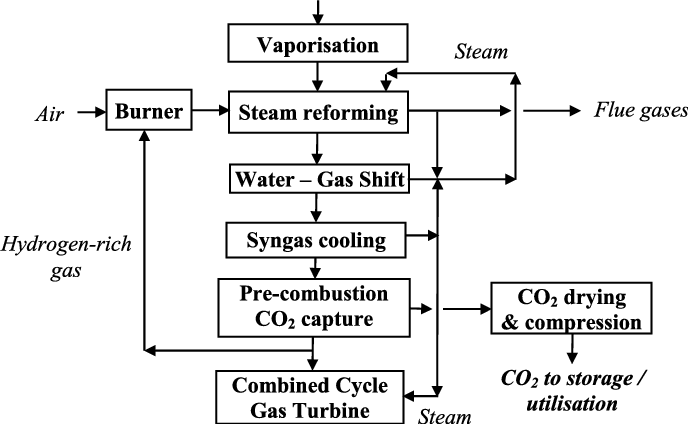

In parallel, IGCC technology is gaining attention as a cleaner way to utilize anthracite coal for power generation. Unlike traditional combustion-based methods, IGCC first converts coal into synthesis gas (syngas) through gasification. The syngas, primarily composed of hydrogen and carbon monoxide, is then cleaned of impurities before being combusted in a gas turbine to generate electricity. The waste heat from this process is used to produce steam for a secondary steam turbine cycle, enhancing overall efficiency. IGCC systems allow for easier integration with CCUS, as they produce a concentrated stream of CO₂ that can be captured and sequestered more efficiently than in conventional coal plants.

Carbon capture, utilization, and storage (CCUS) is another emerging strategy aimed at reducing the environmental impact of coal-fired power plants. Post-combustion capture technology involves scrubbing CO₂ from flue gases using chemical solvents, while pre-combustion capture in IGCC systems separates CO₂ before combustion occurs. Once captured, CO₂ can be stored underground in geological formations or repurposed for industrial applications such as enhanced oil recovery (EOR) or synthetic fuel production. Despite its potential, widespread adoption of CCUS faces economic and technical barriers, including high costs, energy penalties, and infrastructure requirements for CO₂ transportation and storage.

As environmental regulations tighten, coal-fired power plants must also address other pollutants beyond CO₂. Mercury, sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM) emissions are subject to stringent controls in many regions. Advanced emissions control technologies, including activated carbon injection for mercury removal, dry sorbent injection for SOx reduction, and low-NOx burners combined with selective catalytic reduction (SCR) systems, help mitigate these impacts. The integration of these systems ensures compliance with air quality standards while minimizing the ecological footprint of coal power generation.

Another challenge facing anthracite coal-fired power generation is competition from alternative energy sources. The declining cost of renewable energy technologies, such as wind and solar power, has shifted global investment away from new coal plants. Additionally, natural gas-fired combined cycle (NGCC) plants, which offer lower emissions and higher operational flexibility, have become a preferred choice in many markets. The increasing adoption of energy storage solutions, including grid-scale batteries, further enhances the viability of intermittent renewable energy, reducing reliance on baseload coal power.

Despite these challenges, anthracite coal remains an important energy resource in regions with abundant reserves and limited access to alternative fuels. Countries with significant coal infrastructure and industrial demand continue to rely on coal-fired power plants for energy security and economic stability. In such cases, modernization efforts focus on retrofitting existing plants with efficiency-enhancing technologies and emissions control upgrades rather than constructing new coal facilities. Co-firing anthracite with biomass or hydrogen is also being explored as a means of reducing net carbon emissions while maintaining coal’s role in the energy mix.

Economic considerations play a crucial role in determining the future of anthracite coal-fired power generation. While coal remains a relatively low-cost fuel in some regions, external factors such as carbon pricing, emissions trading schemes, and financing restrictions for new coal projects influence its competitiveness. Financial institutions and investors are increasingly prioritizing low-carbon projects, leading to reduced funding opportunities for new coal-fired power plants. Governments and industry stakeholders must weigh the costs of maintaining coal infrastructure against the long-term benefits of transitioning to cleaner energy sources.

In conclusion, the role of steam turbines in anthracite coal-fired power generation is evolving in response to technological advancements, environmental regulations, and shifting market dynamics. While coal-fired power remains a key component of the energy mix in certain regions, its long-term sustainability depends on the successful implementation of high-efficiency, low-emissions technologies and carbon mitigation strategies. The future of anthracite-based power generation will be shaped by innovation in cleaner combustion processes, the integration of CCUS, and the broader transition toward a more sustainable and diversified energy landscape.

Steam Turbine for Electricity Generation with Coke (from Coal)

Steam turbine electricity generation using coke derived from coal is a niche but technically feasible method that leverages the high carbon content and energy density of coke. Coke is a solid carbonaceous material produced through the destructive distillation of coal in the absence of oxygen, a process known as carbonization. It is primarily used in metallurgical applications, particularly in the iron and steel industry, but its potential as a fuel for steam power plants is worth exploring.

Characteristics of Coke as a Fuel

Coke has distinct properties that differentiate it from raw coal. It contains a high percentage of fixed carbon (typically 85-90%), very low volatile matter, and minimal impurities such as sulfur and moisture. These characteristics make it an efficient and clean-burning fuel compared to some types of coal. The low volatile content, however, makes ignition more challenging, necessitating specific combustion techniques to ensure efficient energy release.

The energy content of coke varies depending on the quality of the coal used for its production, but it typically ranges between 27-31 MJ/kg (megajoules per kilogram), which is slightly higher than many bituminous coals. Additionally, because coke undergoes extensive processing to remove volatile compounds, its combustion results in lower emissions of tar and other hydrocarbons, which can be beneficial for reducing air pollution in power generation applications.

Combustion of Coke in Boilers

Due to its high carbon content and low reactivity, coke combustion requires specialized boiler designs to achieve efficient and complete combustion. Conventional pulverized coal-fired boilers may not be ideal for coke, as its hardness makes pulverization energy-intensive. Instead, fluidized bed combustion (FBC) and stoker-fired boilers are more suitable.

- Fluidized Bed Combustion (FBC)

In an FBC system, coke is burned in a bed of sand or ash that is suspended and fluidized by a stream of air. This ensures complete combustion, even at lower temperatures, reducing nitrogen oxide (NOx) emissions. The process also allows for the addition of limestone to capture sulfur dioxide (SO₂), minimizing acid rain-related pollution. - Stoker-Fired Boilers

In stoker-fired systems, coke is burned on a moving grate, allowing for gradual combustion and improved heat transfer. These boilers are often used for solid fuels that do not require pulverization and can effectively handle the high-carbon content of coke.

Steam Generation and Power Conversion

Once the heat from coke combustion converts water into high-pressure steam, the steam is directed to a steam turbine, where it undergoes expansion to generate mechanical energy. This mechanical energy drives an electrical generator, producing electricity.

For high-efficiency power generation, supercritical and ultra-supercritical steam cycles are preferred, as they allow the steam to reach temperatures above 600°C and pressures beyond 30 MPa, improving overall thermal efficiency. Higher efficiencies reduce coke consumption and lower CO₂ emissions per unit of electricity generated.

The integration of reheat and regenerative cycles further enhances performance. In a reheat cycle, steam exhausted from the high-pressure turbine is sent back to the boiler for reheating before being expanded again in intermediate- and low-pressure turbines. This improves energy conversion efficiency while minimizing moisture-related turbine wear. Regenerative cycles use steam extraction at intermediate turbine stages to preheat the boiler feedwater, reducing fuel consumption and improving plant efficiency.

Environmental Considerations

Although coke burns cleaner than raw coal due to its lower volatile content, it still produces CO₂ emissions and some SO₂, depending on the sulfur content of the parent coal. Implementing emissions control technologies is necessary for compliance with environmental regulations.

- Flue Gas Desulfurization (FGD) – Limestone-based scrubbers can be used to capture SO₂, converting it into gypsum, which can be repurposed for construction materials.

- Electrostatic Precipitators (ESPs) and Fabric Filters – These systems capture particulate matter from flue gases, preventing fine particles from being released into the air.

- Selective Catalytic Reduction (SCR) – This technology helps reduce NOx emissions by converting them into harmless nitrogen and water vapor.

Carbon capture and storage (CCS) can also be integrated into coke-fired power plants to reduce their carbon footprint. CCS technologies can capture CO₂ before it is emitted into the atmosphere, storing it underground or utilizing it in industrial applications.

Comparison with Other Fuels

Coke offers several advantages and disadvantages when compared to traditional coal and alternative fuels:

| Fuel Type | Energy Content (MJ/kg) | Volatile Matter | Sulfur Content | Common Application |

|---|---|---|---|---|

| Anthracite Coal | 26-30 | Low (~10%) | Low | Power Generation |

| Bituminous Coal | 24-28 | Medium (20-35%) | Medium | Power & Industry |

| Sub-bituminous Coal | 18-24 | High (35-50%) | Medium-High | Power Generation |

| Coke (from coal) | 27-31 | Very Low (~1%) | Low-Medium | Metallurgy, Potential Power Generation |

| Natural Gas | 35-50 | N/A | Very Low | Power Generation |

While coke has a higher energy density than many coals, its higher production cost and limited availability make it a less common choice for large-scale electricity generation.

Economic and Practical Considerations

The feasibility of using coke for steam turbine electricity generation depends on several factors:

- Cost of Coke Production – The carbonization process required to produce coke adds to its cost compared to using raw coal directly. Unless coke is a byproduct of industrial processes (such as steelmaking), its use in power generation may not be economically viable.

- Supply Availability – Unlike coal, which is widely available, coke production is concentrated in regions with major steel industries. This can limit its accessibility for power generation.

- Regulatory Policies – Stricter carbon emission regulations may make coke-based power plants less attractive unless CCS technologies are implemented.

- Competition with Alternative Fuels – The decreasing cost of renewables and natural gas-fired power plants puts pressure on solid fuels like coke.

Potential Applications and Future Prospects

While coke is not commonly used as a primary fuel for power generation, it has potential applications in niche markets:

- Industrial Cogeneration (CHP – Combined Heat and Power): In industries that already produce coke as a byproduct, such as steel mills, coke-fired steam turbines can be used for on-site power generation and process heat.

- Co-firing with Biomass or Hydrogen: Mixing coke with biomass or hydrogen could help reduce net carbon emissions while utilizing its high energy content.

- Waste Heat Recovery from Coke Production: The heat generated during coke production (coke oven gas) can be utilized for electricity generation, improving overall energy efficiency in industrial settings.

Conclusion

Steam turbine electricity generation using coke from coal is technically feasible but has limited practical applications compared to direct coal combustion. While coke offers high carbon content and cleaner combustion, its production costs, limited availability, and competition from other fuels restrict its widespread adoption in power plants. However, in industrial settings where coke is already produced as a byproduct, its use in steam turbines for cogeneration and waste heat recovery could provide economic and environmental benefits. Future advancements in emissions control and carbon capture technologies may further influence the role of coke as an energy source in specialized power generation applications.

Looking ahead, the future of coke-based steam turbine electricity generation will be influenced by several factors, including technological advancements, evolving regulatory environments, and the broader shift towards decarbonization. While coke-fired power generation may not be a mainstream solution, its potential in specific applications and the increasing focus on clean energy technologies may provide avenues for further development and integration into the energy mix.

Technological Innovations and Efficiency Improvements

As with other fossil fuel-based power generation technologies, coke-fired plants will benefit from the continued improvement in efficiency-enhancing technologies. Key areas where innovation can increase the performance of coke-based steam turbines include:

- Advanced Steam Cycles: The integration of supercritical and ultra-supercritical steam cycles in coke-fired plants can increase thermal efficiency. These cycles allow the plant to operate at higher temperatures and pressures, maximizing energy extraction from the coke combustion process. Improved materials, such as advanced alloys and ceramics, can withstand the extreme conditions of ultra-supercritical cycles, pushing the limits of efficiency even further.

- Combined Heat and Power (CHP) Systems: Many industrial plants, such as steel mills, already produce coke as a byproduct. By integrating steam turbine-based CHP systems, these facilities can not only reduce their energy costs by generating electricity from their own coke but also capture and utilize waste heat. The ability to use both the electricity and heat within the plant boosts overall system efficiency and can reduce reliance on external energy supplies.

- Carbon Capture, Utilization, and Storage (CCUS): For coke-fired power generation to meet future emissions reduction targets, the integration of CCUS technologies will be crucial. These technologies capture CO₂ from the flue gas produced during combustion and store it underground or utilize it for industrial purposes. Continued advances in capture efficiency, as well as the development of economically viable storage solutions, could make coke-fired plants a more viable option in the post-carbon economy.

- Hybrid Systems: As the energy sector shifts towards decarbonization, hybrid systems that combine coke combustion with renewable energy sources, such as solar or wind, could play a role in providing baseload power. Such systems could leverage coke as a stable fuel while reducing reliance on it through intermittent renewable generation. Hybrid systems would enable flexible operation, with the ability to ramp up or down based on renewable energy availability.

- Cogeneration of Hydrogen: Hydrogen is gaining traction as a clean alternative to traditional fossil fuels. Some research is exploring the possibility of producing hydrogen through the gasification of coke, which could provide a low-carbon hydrogen source. By combining coke gasification with steam turbine-based power generation, it may be possible to produce both electricity and hydrogen, offering dual benefits for industrial processes and power generation.

Regulatory and Environmental Considerations

As the world moves toward stricter emissions regulations and greater environmental responsibility, coke-fired power plants will need to adapt to meet these challenges. Many regions are implementing carbon pricing mechanisms, emissions trading schemes, and stricter air quality standards. As a result, there will be increased pressure on coke-fired plants to reduce their carbon emissions and other pollutants, such as sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM).

While coke combustion produces fewer impurities than raw coal, it still emits CO₂, and stricter regulations could impose significant costs on coke-fired power generation. This could make coke-based power less competitive compared to cleaner energy sources unless further technological advancements are made.

To ensure coke-fired plants remain viable, they must integrate the following emissions control technologies:

- Low-NOx Combustion Systems: By incorporating low-NOx burners and improving combustion techniques, coke-fired plants can reduce nitrogen oxide emissions, which contribute to smog and acid rain.

- Desulfurization Technologies: Since coke can still contain sulfur, using advanced flue gas desulfurization (FGD) systems to capture and remove sulfur compounds from flue gases will be necessary to prevent SO₂ emissions.

- Particulate Matter Control: Electrostatic precipitators (ESPs) and fabric filter systems will help capture fine particulate matter produced during coke combustion, reducing the environmental impact of power generation.

Economic Considerations and Market Trends

The economic viability of coke-based power generation will be heavily influenced by the cost of coke production and the competitive landscape of energy markets. The global energy market is undergoing significant transformation, with renewable energy sources, such as wind, solar, and hydro, becoming more cost-competitive. The price of natural gas has also been fluctuating, but natural gas-fired combined cycle plants generally offer lower capital costs and better efficiency compared to coke-fired plants. The growing focus on decarbonization is further driving investment away from fossil fuels, leading to declining demand for new coal and coke power plants.

However, coke-fired power plants could still play a role in specific sectors where they provide critical energy security or are integrated with industrial processes that produce coke as a byproduct, such as steel production. For these sectors, investing in efficient technologies, emissions controls, and carbon capture solutions could make coke-based power generation more economically viable.

Additionally, in regions with abundant coke production and limited access to other fuels, the use of coke in power generation may remain a cost-effective option. Retrofitting existing coal plants with coke handling systems and advanced combustion technologies could provide a more affordable pathway to cleaner power generation compared to building entirely new infrastructure for renewable or natural gas-based plants.

Future Prospects for Coke-Based Power Generation

The prospects for coke-based steam turbine power generation will likely depend on a combination of factors, including the following:

- Local Availability and Cost of Coke: In regions with abundant steel manufacturing or coke production, leveraging coke for power generation could provide a cost-effective solution for utilizing local resources while reducing reliance on imported fuels.

- Technological Advancements: Improvements in boiler design, combustion techniques, and emissions control systems could make coke-fired plants more efficient and environmentally friendly.

- Regulatory Developments: The ability to meet increasingly stringent environmental standards through emissions control technologies, CCUS, and low-carbon alternatives will be critical for the future of coke-fired power generation.

- Hybrid and Integrated Systems: Coke could be integrated with other energy technologies, such as hydrogen or renewable sources, to offer a cleaner and more flexible power generation solution, contributing to the energy transition.

Ultimately, while coke-fired steam turbine power generation may not see widespread adoption as a standalone technology, it has the potential to serve as part of a broader strategy for energy production in regions with significant coke availability. The key to unlocking its potential lies in improving efficiency, reducing emissions, and integrating it with emerging clean energy technologies.

As the global energy landscape continues to evolve, the role of coke in steam turbine-based electricity generation may shift significantly, especially with an increasing emphasis on sustainability, environmental protection, and economic competitiveness. Below are further developments and strategies that can influence the future of coke-fired power generation.

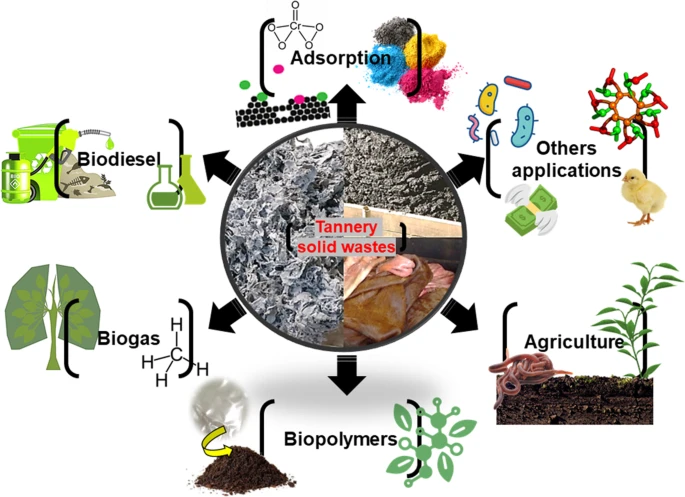

Diversification of Fuel Use and Co-Firing with Biomass

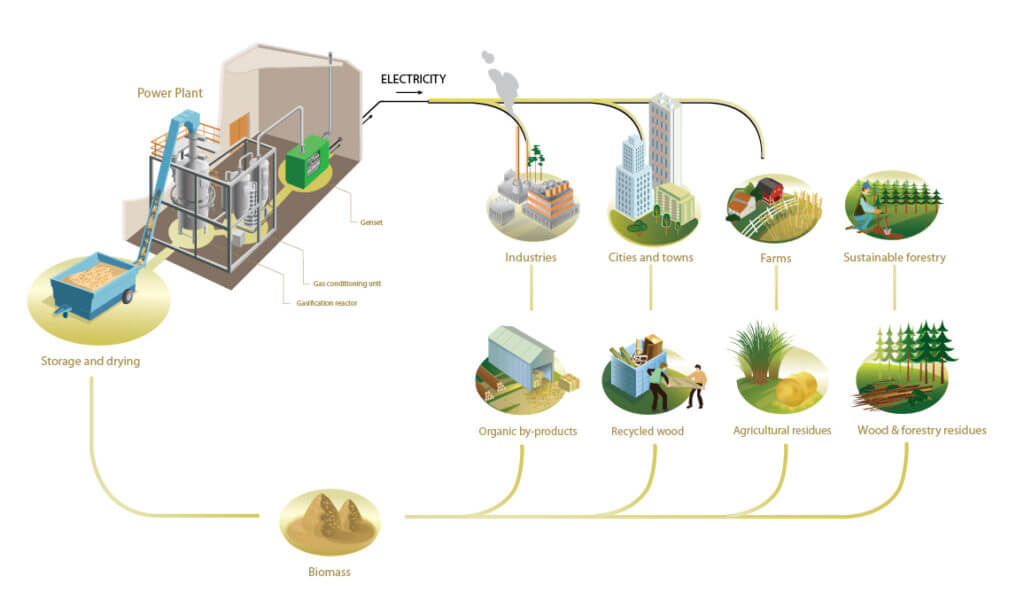

One of the ways to reduce the carbon intensity of coke-fired power generation is through co-firing. Co-firing involves the simultaneous combustion of coke and renewable fuels such as biomass. Biomass, such as wood chips, agricultural residues, or energy crops, is considered carbon-neutral, as the carbon dioxide released during combustion is offset by the carbon absorbed during the plants’ growth phase.

When coke is co-fired with biomass, several benefits can be realized:

- Reduced Net Carbon Emissions: Biomass offsets some of the CO₂ emissions from coke combustion, reducing the overall carbon footprint of the power plant.

- Improved Fuel Flexibility: Co-firing allows for greater fuel flexibility, as it provides the ability to adjust the mix of coke and biomass depending on fuel availability and cost.

- Support for Renewable Energy Goals: As renewable energy targets become more ambitious globally, co-firing could help conventional plants reduce their reliance on fossil fuels, while supporting the growth of the renewable energy sector.

However, challenges remain with co-firing, such as ensuring that the biomass is adequately sourced and processed to maintain a steady and reliable fuel supply. Additionally, the operational adjustments needed to handle the different combustion characteristics of coke and biomass, including modifications to combustion systems and emissions controls, could add to operational complexity and cost.

Advances in Gasification Technology

One of the most promising avenues for utilizing coke in electricity generation is the adoption of gasification technology. While traditional coke combustion in a boiler is a well-established method, gasification involves converting coke into a gas—typically a mixture of hydrogen, carbon monoxide, and methane—before it is used to generate power. Gasification offers a higher degree of flexibility, efficiency, and environmental control compared to direct combustion.

Key advantages of coke gasification include:

- Increased Efficiency: Gasification can produce syngas (a mixture of hydrogen and carbon monoxide), which is then burned in a gas turbine to generate electricity. This process is more efficient than traditional combustion because it can be combined with combined-cycle systems, where the exhaust heat from the gas turbine is used to produce steam for a steam turbine, boosting overall efficiency.

- Carbon Capture Compatibility: Gasification lends itself well to integration with carbon capture and storage (CCS) technologies. Since gasification produces a concentrated stream of CO₂, capturing and storing this CO₂ is more efficient compared to traditional combustion-based plants.

- Reduced Emissions: The gasification process can result in fewer emissions of particulate matter and sulfur compounds, which are typically produced in large quantities during direct coke combustion.

Despite its potential, gasification of coke faces some technical and economic challenges, including high capital costs and the need for specialized equipment to handle the gasification process. Additionally, coke’s low reactivity can sometimes make gasification more difficult, requiring precise control of process parameters and gasifier design.

Carbon Capture and Utilization (CCU) Opportunities

As part of efforts to reduce the environmental impact of coke-fired power generation, carbon capture and utilization (CCU) represents a promising opportunity. While carbon capture and storage (CCS) primarily focuses on sequestering CO₂ underground to mitigate its contribution to global warming, CCU aims to use captured CO₂ for other purposes, such as producing synthetic fuels, chemicals, or materials.

Key CCU applications for coke-fired power generation include:

- CO₂ Utilization in Enhanced Oil Recovery (EOR): CO₂ captured from coke combustion can be injected into oil fields to increase the extraction of oil, providing both an economic benefit and a means of using CO₂ rather than releasing it into the atmosphere.

- Conversion to Synthetic Fuels: Captured CO₂ can be combined with hydrogen to produce synthetic fuels, such as synthetic natural gas or liquid fuels. This technology could provide a bridge between coke-fired power generation and the hydrogen economy, where coke-derived CO₂ is repurposed for fuel production.

- Building Materials: CO₂ can be used in the production of construction materials, such as concrete, where it is chemically incorporated into the material. Some studies have explored the possibility of using captured CO₂ in concrete, potentially creating a closed-loop system that turns carbon emissions into a useful product.

The feasibility of CCU will depend on the economic viability of CO₂ utilization processes, the cost of capturing and compressing CO₂, and the development of market demand for CO₂-based products. While CCU technologies are still in the early stages of commercial deployment, they offer a promising route for reducing the net carbon impact of coke-based power generation.

Lifecycle and Sustainability Analysis

For coke-fired steam turbine electricity generation to remain a competitive option in a decarbonizing energy landscape, it is essential to evaluate the entire lifecycle of the fuel, from its production to its end use. A comprehensive lifecycle analysis (LCA) would consider the following factors:

- Mining and Production Impact: The extraction of coal and the carbonization process to produce coke involve significant energy and material inputs. Sustainable practices, such as reducing emissions from coal mining and adopting cleaner technologies for coke production, are critical to minimizing the environmental impact at the early stages of the fuel supply chain.

- Transport and Distribution: The transportation of coke to power plants can result in additional emissions, especially if long-distance transport is required. Using cleaner transport options, such as electric or hydrogen-powered vehicles, could mitigate some of these impacts.

- End-of-Life Waste Management: The combustion of coke in steam turbines produces ash and other residuals, which must be managed and disposed of responsibly. Ash from coke combustion often contains valuable metals, which could be recovered through recycling. If CCS is implemented, the long-term storage of captured CO₂ is another critical aspect to consider.

Lifecycle assessments would provide a more holistic view of the sustainability of coke-based electricity generation and help identify areas where improvements can be made to reduce environmental impact and enhance the overall sustainability of the process.

Global Energy Transition and Policy Influence

The role of coke in the global energy transition will ultimately be shaped by government policies and market incentives. International agreements, such as the Paris Agreement, are pushing for greater reductions in greenhouse gas emissions, and policies that tax carbon or offer incentives for clean energy technologies are likely to accelerate the shift toward renewable energy sources. However, in regions where coke production is a significant industry, it may be politically and economically challenging to phase out coke-based power generation entirely. In such cases, policies may focus on encouraging the transition to cleaner technologies, such as CCS, or incentivizing the use of coke in hybrid systems that integrate renewables.

Moreover, international trade policies could influence the competitiveness of coke as a fuel. For example, countries with significant coke production may look to export their excess supply to markets with high energy demands, further promoting its use for power generation in regions that are less focused on decarbonization.

Conclusion

Coke-fired steam turbine electricity generation remains a niche but technically viable option within the broader energy mix. While it faces economic, environmental, and technological challenges, the integration of advanced combustion technologies, carbon capture solutions, and hybrid systems could make it a more sustainable and efficient energy source in specific contexts. Innovations in gasification, co-firing, and carbon utilization provide potential pathways for reducing the carbon footprint of coke-based power generation. However, as the world transitions toward a low-carbon future, the future of coke in power generation will depend on a combination of policy, technological advancements, and the broader competitive landscape in the energy market.

Using methane from landfills as a fuel for steam turbine-based electricity generation presents an innovative and environmentally beneficial solution. Methane, a potent greenhouse gas that is often flared or allowed to escape from landfills, can be harnessed as a renewable energy source. Converting landfill methane into electricity using steam turbines offers several advantages, including reducing the environmental impact of landfills and contributing to renewable energy goals.

Methane from Landfills: A Renewable Energy Source

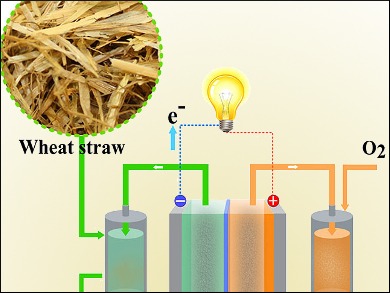

Landfill methane is primarily generated by the anaerobic decomposition of organic waste, such as food, paper, wood, and other biodegradable materials. As waste breaks down, microbes consume the organic matter in the absence of oxygen, producing methane gas in the process. Landfills can emit significant amounts of methane if this gas is not captured, which can contribute to climate change due to methane’s much higher global warming potential compared to carbon dioxide.

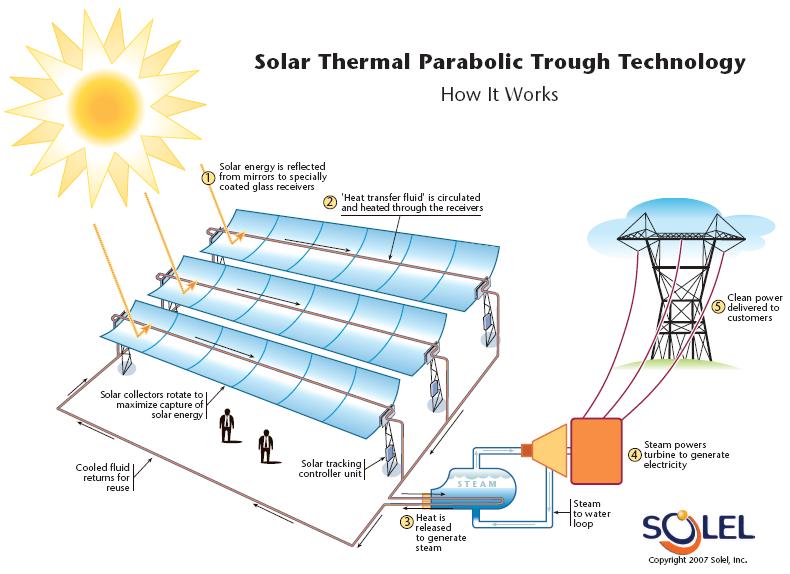

Capturing landfill methane and utilizing it as an energy source prevents it from being released into the atmosphere and reduces its environmental impact. The captured methane can be cleaned and processed to remove impurities such as moisture, carbon dioxide, and trace gases, making it suitable for combustion in gas turbines or steam boilers. Once processed, methane can be burned to produce heat, which generates steam to drive a steam turbine and generate electricity.

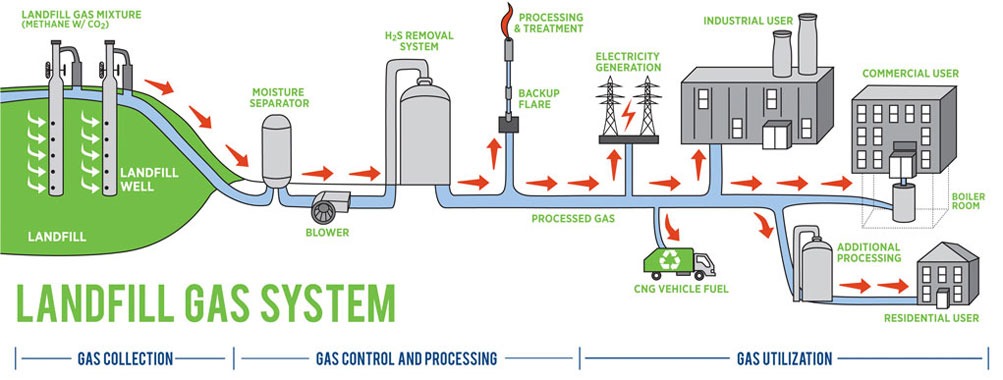

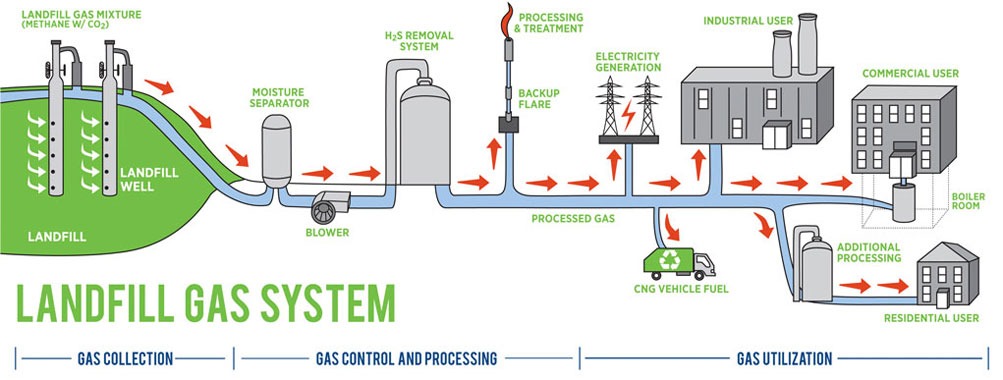

Capturing Methane from Landfills

Landfill gas collection systems are designed to capture methane and other gases produced by the decomposition of waste. These systems typically consist of a network of wells and pipes installed throughout the landfill to collect the gas. Once collected, the gas is directed to a processing facility where it is cleaned and conditioned for use in energy generation.

Key components of landfill gas collection and processing include:

- Gas Collection Wells: These wells are drilled into the landfill to extract methane. A vacuum system is used to draw the gas to the surface, where it is transported to the processing facility.

- Gas Conditioning: The captured gas may contain moisture, sulfur compounds, and other impurities that must be removed before it can be used for combustion. Gas conditioning typically involves filtration, compression, and drying processes to purify the methane.

- Flare Systems: In many cases, excess methane is flared off in a controlled burn when the gas cannot be used immediately. However, capturing methane for electricity generation offers a more environmentally friendly and economically viable solution than flaring.

Combustion of Landfill Methane for Steam Turbine Power Generation

Once the methane is captured and purified, it can be burned in a boiler to produce heat. This heat is used to generate steam, which is then expanded in a steam turbine to produce mechanical energy. This mechanical energy drives an electrical generator, producing electricity.

In terms of combustion technology, the process of burning methane in a boiler for steam turbine power generation is relatively similar to other natural gas or biogas combustion processes. Methane has a high calorific value, typically around 55-56 MJ/kg, which makes it an efficient fuel for generating heat and steam.

Key Considerations for Landfill Methane-Based Steam Turbine Power Generation

- Fuel Composition and Variability: Landfill gas is not a consistent fuel source. The methane content can vary depending on factors such as the type of waste, the age of the landfill, and the environmental conditions. Fresh landfills may produce higher concentrations of methane, while older landfills may have lower methane concentrations as the gas production slows down over time. This variability in fuel quality may require gas processing and blending to ensure a stable and reliable fuel supply for combustion.

- Gas Quality and Conditioning: Landfill methane typically contains a mixture of gases, including carbon dioxide, nitrogen, hydrogen sulfide, and trace compounds. These impurities must be removed to prevent corrosion in equipment and to ensure efficient combustion. Methane must be conditioned to meet specific quality standards before it can be used for power generation. If the gas is not adequately purified, it could lead to reduced combustion efficiency, equipment damage, and increased operational costs.

- Plant Design and Integration: Power plants that utilize landfill methane for steam turbine-based electricity generation need to be designed to accommodate the variable and sometimes inconsistent nature of landfill gas. A flexible design is essential to ensure that the plant can operate effectively even as the methane concentration fluctuates. Furthermore, since methane collection is often spread across large areas, it may be necessary to install a gas pipeline network to deliver the methane to the power generation facility.

- Efficiency of Steam Turbine Systems: The efficiency of steam turbines used in landfill methane power generation depends on factors such as the steam cycle and the design of the turbine. In most cases, Rankine cycle systems are employed, where the steam is expanded in a turbine to produce mechanical work, which is then converted into electricity. Modern turbines, especially those designed for combined-cycle or regenerative cycles, can improve efficiency and reduce the overall fuel consumption.

- Fluctuating Methane Availability: Unlike conventional fuels like coal or natural gas, landfill methane production is intermittent and can fluctuate based on the rate of waste decomposition. This means that landfill methane may not always be available in the quantities required for continuous power generation. As a result, power plants may need to rely on backup fuel sources or energy storage systems during periods of low methane production to ensure a reliable electricity supply.

- Environmental Benefits: One of the primary benefits of using landfill methane for power generation is its positive environmental impact. By capturing and utilizing methane, which would otherwise be vented into the atmosphere, the greenhouse gas emissions associated with landfills are significantly reduced. In fact, landfill methane is typically considered a form of renewable energy due to its biological origin, and utilizing it for power generation can help reduce the carbon footprint of a landfill site. This aligns with broader sustainability and climate change mitigation goals.

Economic and Policy Considerations

The economics of methane-based steam turbine power generation depend on several factors, including the capital cost of the power plant, operational and maintenance expenses, and the local market for electricity. Some key economic considerations include:

- Initial Investment: The construction of landfill gas collection systems and methane processing equipment requires a significant initial investment. However, this capital expenditure can be offset by long-term revenue from electricity generation and potential incentives or subsidies for renewable energy projects.

- Operational Costs: Operating a landfill methane power plant involves costs associated with maintaining the gas collection system, cleaning and conditioning the methane, operating the steam turbines, and managing any auxiliary systems, such as backup fuel supplies or energy storage.

- Revenue from Electricity Sales: Landfill methane can be sold as a renewable energy resource, and in many regions, power generation from biogas (including landfill methane) qualifies for renewable energy credits, carbon offsets, or other financial incentives. This can improve the financial viability of a landfill methane power project and make it competitive with other renewable energy sources.

Regulatory and Environmental Incentives

Governments worldwide are increasingly focused on reducing emissions from landfills and promoting renewable energy. As a result, there are numerous incentives and regulations that support landfill methane power generation:

- Renewable Energy Credits (RECs): In many countries, electricity generated from landfill methane qualifies for RECs or other renewable energy certificates, which can be sold or traded in renewable energy markets.

- Carbon Credits: By capturing and utilizing methane, landfill operators can earn carbon credits under carbon trading schemes, which provide additional revenue streams.

- Waste-to-Energy (WTE) Policies: Landfill methane-based power generation is often considered part of waste-to-energy programs. These programs encourage the diversion of waste from landfills and the use of waste materials to generate power, reducing landfill volumes and promoting sustainability.

- Tax Incentives and Subsidies: Some regions provide tax credits, grants, or subsidies for renewable energy projects, including landfill methane power generation, to support the transition to cleaner energy sources.

Challenges and Limitations

While there are significant advantages to using landfill methane for power generation, some challenges and limitations need to be addressed:

- Methane Collection Efficiency: Landfill methane collection systems may not always capture all the methane produced, particularly in older landfills. This inefficiency can limit the amount of gas available for power generation.

- Aging Landfills: Over time, the amount of methane produced by a landfill decreases as the organic matter decomposes. This can reduce the long-term viability of methane-based power generation from landfills, requiring supplemental energy sources or additional measures to ensure continued power output.

- Landfill Site Location: Landfill methane power plants are typically located near the landfill site to minimize transportation costs. However, not all landfills are in areas with high demand for electricity, which could limit the profitability of such projects unless the power can be transmitted to nearby urban centers.

Conclusion

Using methane from landfills for steam turbine-based electricity generation represents a promising renewable energy solution that can reduce greenhouse gas emissions, contribute to sustainability goals, and help meet renewable energy targets. By capturing and utilizing methane, landfill operators can turn a waste product into a valuable energy resource while reducing the environmental impact of landfills. Despite challenges such as fuel variability and the need for gas conditioning, advances in technology and policy support make landfill methane an increasingly viable option for electricity generation. With the right investment in infrastructure, regulations, and incentives, landfill methane-based steam turbine power generation could play a significant role in the transition to cleaner, more sustainable energy systems.

Continuing from the earlier explanation of steam turbine-based electricity generation using methane from landfills, let’s dive deeper into the various aspects and technologies that support this process, as well as its challenges and long-term prospects.

Landfill Gas Capture and Processing

The first step in utilizing landfill methane for electricity generation is capturing the gas efficiently. Landfills emit methane as a byproduct of the anaerobic decomposition of organic waste. Methane is a potent greenhouse gas, so its capture and use for energy purposes is essential for both climate mitigation and resource recovery.

Gas Collection Systems:

To capture methane, landfill operators install gas collection systems, which consist of a network of gas wells, pipes, and vacuum pumps to extract the gas from the landfill’s depths. The gas collection process typically involves:

- Vertical Wells: These are drilled into the landfill to tap into the methane layers and draw it out. The wells are often arranged in a grid pattern to ensure a uniform collection of gas throughout the site.

- Horizontal Collection Systems: In addition to vertical wells, horizontal collection systems may be installed in certain landfill configurations to enhance the collection efficiency, especially in large or complex sites.

- Vacuum Pumps: The collected gas is drawn through the pipes using a vacuum, ensuring that methane is extracted continuously as waste decomposes.

Gas Conditioning:

The captured methane is not pure and often contains impurities like carbon dioxide, moisture, hydrogen sulfide, and other trace gases. These impurities can reduce the efficiency of combustion and damage equipment. Therefore, the landfill gas must be conditioned before it can be used in power generation. The conditioning process typically involves:

- Dehydration: Removing moisture to prevent corrosion and ensure smooth combustion.

- Filtration: Removing solid particles, which could clog equipment or damage turbines.

- Desulfurization: Removing hydrogen sulfide, which can corrode metal surfaces and create sulfur emissions.

- CO₂ Removal: Some systems also remove carbon dioxide to ensure that the methane is pure enough for optimal combustion.

Combustion and Steam Turbine Technology

Once landfill methane is captured and conditioned, it can be burned as a fuel in a steam turbine power generation system. This process is similar to other forms of biogas power generation, with several key components involved:

Burning the Methane:

- Boiler System: The conditioned methane is fed into a boiler where it is burned to produce heat. This heat is used to convert water into steam. The efficiency of this combustion process is enhanced by the high calorific value of methane, which allows for significant energy production.

- Steam Generation: The heat from the methane combustion heats water to create high-pressure steam, which is the primary medium for transferring energy in steam turbine systems.

- Steam Turbine: The high-pressure steam is directed into a steam turbine, where it expands and spins the turbine blades, converting thermal energy into mechanical energy. This mechanical energy is then used to drive a generator that produces electricity.

Electricity Generation:

The mechanical energy produced by the steam turbine is converted into electrical energy by the generator connected to the turbine. The generator is typically a synchronous generator, which converts rotational energy into electrical current that can be fed into the grid.

Efficiency of the System:

The overall efficiency of the system depends on several factors:

- Turbine Efficiency: Steam turbines designed for biogas or methane combustion are typically optimized for stable and efficient operation under varying fuel conditions.

- Heat Recovery: Some plants use combined heat and power (CHP) systems, which recover the waste heat from the turbine exhaust to produce additional energy or provide heating for nearby buildings, improving overall system efficiency.

Challenges of Using Landfill Methane for Power Generation

Despite its potential as a renewable energy source, there are several challenges associated with using landfill methane for electricity generation:

Fluctuations in Methane Availability:

Landfill gas production is not constant, as it depends on factors such as:

- Landfill Age: Older landfills generally produce less methane because the organic waste has decomposed. In contrast, new landfills or active ones tend to produce more methane as fresh waste decomposes.

- Seasonal Variation: The rate of methane generation can fluctuate seasonally, depending on the temperature, moisture content, and microbial activity in the landfill.

- Inconsistent Gas Quality: The methane concentration can vary depending on the stage of decomposition, which can cause inconsistencies in the fuel quality fed to the power plant. This may require additional gas conditioning or blending to maintain combustion efficiency.

Landfill Methane Collection Efficiency:

Even with modern gas collection systems, not all methane produced by the landfill is captured. Older landfills or poorly maintained systems may have lower collection efficiencies. Additionally, some landfill sites may experience difficulties in maintaining a vacuum or ensuring the even distribution of collection wells, leading to methane leakage.

Capital and Operating Costs:

While utilizing landfill methane for power generation provides significant environmental benefits, it also comes with challenges related to capital investment and ongoing operational costs:

- Initial Investment: Setting up a landfill methane collection and processing system can require significant capital. The costs of drilling wells, installing piping systems, and building power plants can be substantial.

- Operational Costs: In addition to the ongoing maintenance of the collection and conditioning systems, there are costs associated with power plant operation, including fuel management, maintenance, and labor.

Regulatory and Environmental Considerations:

Regulations on methane emissions from landfills are becoming stricter, and the requirement to capture methane is increasingly being enforced. While these regulations help mitigate climate change, they also impose operational costs on landfill operators. In some regions, landfill operators are incentivized through carbon credits or renewable energy certificates (RECs) to develop landfill gas-to-power projects. However, navigating regulatory requirements and ensuring compliance with emissions standards can be complex.

Potential for Expansion and Technological Advancements

Despite the challenges, there are several avenues for expanding and improving landfill methane-based power generation:

Expansion of Gas Collection Systems:

Improved gas collection systems can significantly increase the amount of methane captured from landfills. Advances in horizontal gas collection systems and wellhead technologies could enhance the collection efficiency and help recover more methane from older landfills.

Hybrid Power Systems: