A charcoal gasifier is a device designed to convert solid biomass, such as charcoal, into a combustible gas known as syngas or producer gas. This gas can be used for various applications, including cooking, heating, and even powering internal combustion engines. Charcoal gasification is a form of biomass gasification, which is a process that utilizes thermochemical reactions to break down organic materials into a gaseous fuel.

The basic principle of a charcoal gasifier involves the partial combustion of charcoal in a controlled environment, where the oxygen supply is limited. This process, known as pyrolysis, occurs at elevated temperatures without the presence of sufficient oxygen to support complete combustion. As a result, the charcoal undergoes thermal decomposition, releasing volatile gases, tars, and charcoal residues.

Charcoal Gasifier

The primary components of a charcoal gasifier include a reaction chamber, air inlet, and a system for collecting and cleaning the produced gas. The reaction chamber is where the pyrolysis and gasification reactions take place. The air inlet controls the amount of oxygen introduced into the system, regulating the combustion process. The gas collection and cleaning system remove impurities and condensable compounds from the produced syngas, ensuring a cleaner and more efficient fuel.

One of the advantages of charcoal gasification is its ability to produce a clean and versatile fuel source. Syngas generated from charcoal gasifiers consists mainly of carbon monoxide, hydrogen, methane, and other trace gases. This composition makes it suitable for various applications, such as cooking and heating in households, as well as providing fuel for engines in small-scale power generation systems.

Charcoal gasifiers are often employed in areas with limited access to traditional energy sources, serving as a sustainable and environmentally friendly alternative. Additionally, the use of biomass-based fuels like charcoal helps reduce dependence on fossil fuels, contributing to lower greenhouse gas emissions and promoting a more sustainable energy future.

In conclusion, a charcoal gasifier is a valuable technology that harnesses the energy potential of charcoal through controlled pyrolysis and gasification processes. It provides a clean and versatile fuel source that can be utilized for various applications, making it an essential tool in promoting sustainable and environmentally friendly energy solutions.

Biomass Gasification:

Biomass gasification is a thermochemical process that involves converting biomass materials, such as wood, agricultural residues, or charcoal, into a gaseous fuel known as syngas. The process occurs in a controlled environment with restricted oxygen, promoting partial combustion through heat-induced chemical reactions. In the context of charcoal gasification, biomass, in the form of charcoal, undergoes pyrolysis, releasing volatile gases that are then further converted into syngas.

Biomass gasification offers a sustainable and renewable energy solution, utilizing organic materials to generate a versatile fuel source. This process has gained attention as a cleaner alternative to traditional combustion methods, reducing emissions and providing a pathway toward carbon-neutral energy production. The syngas produced through biomass gasification can be harnessed for various applications, including electricity generation, heating, and cooking, making it a valuable technology in the quest for environmentally friendly energy alternatives.

Charcoal Conversion:

Charcoal conversion refers to the process of transforming solid carbonaceous material, typically wood or agricultural residues, into charcoal through controlled pyrolysis. Pyrolysis involves heating the biomass in a low-oxygen environment, leading to the release of volatile organic compounds and leaving behind a carbon-rich residue known as charcoal.

Charcoal has been used for centuries as a reliable and efficient source of energy for cooking, heating, and industrial processes. The conversion of biomass into charcoal involves removing moisture and volatile components, resulting in a more concentrated and energy-dense fuel. This process not only enhances the calorific value of the material but also reduces its susceptibility to decay and increases its storability.

Charcoal conversion plays a crucial role in sustainable energy practices, offering a cleaner-burning alternative to traditional wood combustion. The resulting charcoal can be used in various applications, including traditional cooking methods, metallurgical processes, and as a feedstock for charcoal gasifiers to produce syngas for energy generation. As the world explores environmentally friendly energy options, charcoal conversion stands out as an essential process in the utilization of biomass resources for a wide range of applications.

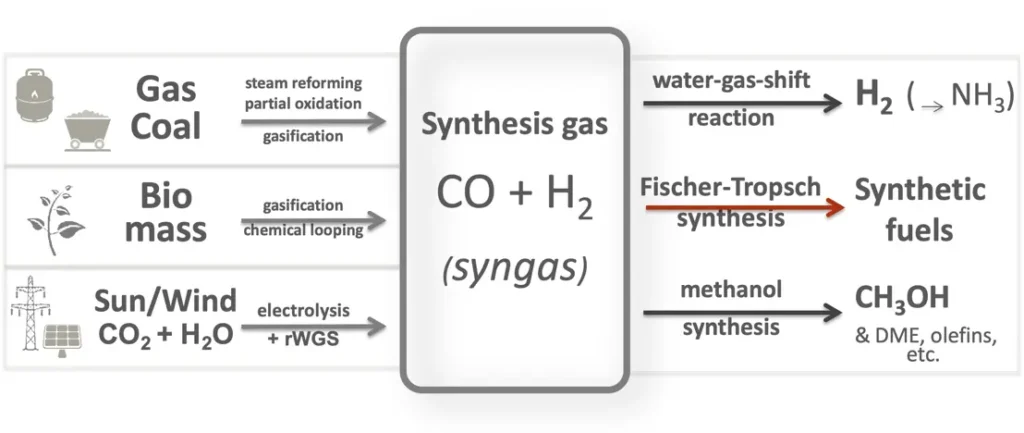

Syngas Production:

Syngas, short for synthetic gas, is a versatile fuel produced through the gasification of carbonaceous materials, such as biomass or fossil fuels, under controlled conditions. The process involves partial combustion, typically in a low-oxygen environment, leading to the generation of a gaseous mixture composed mainly of carbon monoxide, hydrogen, and methane, along with other trace gases.

Syngas production plays a pivotal role in various energy applications due to its flexibility and wide range of uses. In the context of charcoal gasification, syngas is generated by subjecting charcoal to high temperatures in a gasifier. The resulting syngas can be utilized for cooking, heating, or as a fuel for internal combustion engines and power generation.

The composition of syngas makes it an attractive energy source, and its adaptability for different purposes contributes to its growing popularity. Syngas can serve as a transitional energy carrier, facilitating the integration of renewable and sustainable energy sources into existing infrastructures. Its production from biomass, such as charcoal, aligns with environmentally conscious energy practices, offering a cleaner alternative to traditional fossil fuels while contributing to a diversified and resilient energy landscape.

Thermochemical Reactions:

Thermochemical reactions refer to chemical processes that involve the exchange or transformation of heat energy. In the context of charcoal gasification, thermochemical reactions play a crucial role in converting solid biomass, like charcoal, into a gaseous fuel. The primary thermochemical process involved is pyrolysis, which occurs at elevated temperatures in the absence of sufficient oxygen for complete combustion.

During pyrolysis, the biomass undergoes thermal decomposition, breaking down into volatile gases, tars, and charcoal residues. This process is integral to the gasification of charcoal, as it releases the energy stored in the biomass in the form of combustible gases. Thermochemical reactions in a controlled environment ensure efficient conversion, allowing for the harnessing of energy from biomass while minimizing the release of harmful byproducts.

Understanding and optimizing thermochemical reactions are essential for designing efficient and sustainable energy systems, such as charcoal gasifiers. By controlling the temperature, pressure, and oxygen levels in the gasification process, it is possible to tailor the thermochemical reactions to maximize the production of clean and usable syngas while minimizing environmental impact. Thermochemical processes, including pyrolysis, contribute significantly to the development of cleaner and more efficient energy technologies, paving the way for sustainable energy solutions.

Pyrolysis Process:

Pyrolysis is a fundamental thermochemical process crucial in the conversion of biomass, including charcoal, into valuable energy products. It involves the decomposition of organic materials at elevated temperatures in the absence of sufficient oxygen for complete combustion. In the context of charcoal gasification, pyrolysis is the initial stage where solid charcoal undergoes thermal degradation, leading to the release of volatile gases, liquids (tars), and a carbon-rich residue.

The pyrolysis process consists of three main stages: drying, devolatilization, and carbonization. In the drying phase, moisture is driven off from the biomass. Devolatilization is the subsequent stage where volatile organic compounds are released from the heated biomass. Finally, carbonization occurs, resulting in the formation of charcoal.

In a charcoal gasifier, the pyrolysis process is a crucial step in producing syngas. During pyrolysis, complex organic compounds in the biomass break down into simpler, gaseous compounds, which can then be further processed into a clean-burning fuel. Efficient control of pyrolysis conditions, such as temperature and residence time, is essential to optimize the production of syngas with desired composition and energy content.

Pyrolysis is not only a key component of charcoal gasification but also a widely studied process for converting various biomass feedstocks into valuable energy carriers. Its importance lies in its ability to contribute to sustainable energy solutions by harnessing the energy stored in biomass while minimizing environmental impact. Understanding and refining the pyrolysis process are integral to the development of cleaner and more efficient energy conversion technologies.

Gasification Technology:

Gasification technology involves the thermochemical conversion of carbonaceous materials, such as charcoal or biomass, into a combustible gas known as syngas. In the realm of energy production, gasification provides an alternative to traditional combustion methods by partially oxidizing the feedstock in a controlled environment with limited oxygen.

In the context of charcoal gasification, the technology utilizes solid biomass, namely charcoal, as the feedstock. The process typically occurs in a gasifier, a device designed to facilitate the controlled conversion of the biomass into syngas. Gasification involves three main reactions: drying, pyrolysis, and combustion of the char residue. Through these reactions, the complex organic compounds in charcoal break down into simpler, gaseous components, forming a versatile fuel source.

Gasification technology offers several advantages. It enables the utilization of a wide range of feedstocks, including agricultural residues and waste materials, contributing to the efficient and sustainable use of biomass resources. The produced syngas can be used for various applications, such as electricity generation, heating, and as a fuel for internal combustion engines. Gasification also facilitates the integration of renewable energy sources into existing energy infrastructures, promoting a more diverse and resilient energy landscape.

Continuous advancements in gasification technology aim to enhance efficiency, reduce environmental impacts, and broaden the range of applicable feedstocks. As a versatile and environmentally conscious energy conversion method, gasification technology plays a crucial role in the transition towards cleaner and more sustainable energy solutions.

Renewable Energy:

Renewable energy refers to energy derived from naturally replenishing sources that are not depleted when used. In the context of charcoal gasification, the biomass feedstock, such as wood or agricultural residues, is considered a renewable resource because it can be regrown or replenished through natural processes.

Charcoal gasification contributes to the broader concept of renewable energy by harnessing the energy stored in biomass and converting it into syngas, a versatile and clean-burning fuel. Unlike fossil fuels, which are finite and contribute to environmental degradation, renewable energy sources promote sustainability and environmental responsibility.

The use of charcoal as a renewable energy source is particularly significant in regions where biomass is abundant and can be harvested sustainably. By adopting charcoal gasification for energy production, communities can reduce their reliance on non-renewable resources, mitigate environmental impacts, and contribute to a more sustainable energy future.

Renewable energy technologies, including charcoal gasification, play a crucial role in addressing global challenges such as climate change and energy security. They offer a pathway to reducing greenhouse gas emissions, enhancing energy resilience, and promoting a transition towards a more sustainable and environmentally friendly energy paradigm. As the world continues to explore cleaner alternatives, renewable energy sources like charcoal gasification stand out as essential components in achieving a more sustainable and resilient global energy system.

Sustainable Fuel:

Sustainable fuel refers to a type of energy source that can be produced, utilized, and managed in a manner that minimizes environmental impact, promotes long-term viability, and does not deplete finite resources. In the context of charcoal gasification, the production and utilization of syngas derived from biomass, specifically charcoal, exemplify sustainable fuel practices.

Charcoal, as a biomass-derived material, is considered renewable since it originates from organic sources that can be regenerated through natural processes. Charcoal gasification enhances the sustainability of this resource by efficiently converting it into syngas, a clean-burning fuel. This process aligns with the principles of sustainability by reducing dependence on non-renewable fossil fuels, minimizing greenhouse gas emissions, and supporting the responsible use of biomass resources.

Sustainable fuel practices also encompass considerations of social, economic, and environmental aspects. Charcoal gasification, when implemented responsibly, can contribute to rural development by providing decentralized energy solutions, creating local employment opportunities, and fostering community resilience.

As the world grapples with the challenges of climate change and resource depletion, the adoption of sustainable fuels becomes imperative. Charcoal gasification, by utilizing biomass in an environmentally friendly and economically viable manner, exemplifies a sustainable approach to energy production. This not only addresses current energy needs but also contributes to building a more resilient and sustainable energy future for generations to come.

Clean Cooking:

Clean cooking refers to the use of cleaner and more efficient technologies for household cooking, aiming to reduce indoor air pollution, promote health, and minimize environmental impact. Charcoal gasification plays a significant role in advancing the concept of clean cooking by providing an alternative to traditional biomass combustion methods, such as open fires or rudimentary stoves.

In many developing regions, households rely on solid biomass, like wood or charcoal, for cooking purposes. However, traditional cooking methods often lead to incomplete combustion, releasing harmful pollutants such as particulate matter, carbon monoxide, and volatile organic compounds. These pollutants can have detrimental effects on respiratory health and contribute to indoor air pollution.

Charcoal gasification offers a cleaner and more efficient solution for cooking. By converting charcoal into syngas through controlled gasification, the process produces a cleaner-burning fuel. This not only improves combustion efficiency but also reduces the emission of harmful pollutants associated with traditional cooking methods. Implementing charcoal gasification for clean cooking contributes to better indoor air quality, lowers the risk of respiratory diseases, and enhances the overall well-being of communities.

As the global community focuses on achieving Sustainable Development Goals, including those related to health and environmental sustainability, the adoption of clean cooking technologies becomes crucial. Charcoal gasification stands out as a viable and sustainable option, addressing health concerns and contributing to a cleaner, healthier living environment for communities relying on solid biomass for their cooking needs.

Producer Gas:

Producer gas, also known as syngas, is a combustible gas mixture produced through the gasification of carbonaceous materials like biomass or coal. In the context of charcoal gasification, producer gas is generated by subjecting solid biomass, specifically charcoal, to controlled thermochemical reactions in a gasifier. The resulting gas typically consists of carbon monoxide (CO), hydrogen (H2), methane (CH4), and other trace gases.

Producer gas is a valuable energy carrier with diverse applications. In the realm of charcoal gasification, the producer gas derived from charcoal serves as a versatile fuel source. It can be used for cooking, heating, and as fuel for internal combustion engines or small-scale power generation systems.

The composition of producer gas makes it adaptable for various energy needs, and its production aligns with sustainable and renewable energy practices. When harnessed effectively, producer gas can replace conventional fossil fuels, contributing to reduced greenhouse gas emissions and mitigating environmental impacts.

The utilization of producer gas derived from charcoal in gasification processes exemplifies an innovative and sustainable approach to energy production. It not only enhances energy efficiency but also supports the transition towards cleaner and more environmentally friendly energy alternatives, contributing to a more sustainable and resilient energy landscape.

Energy Efficiency:

Energy efficiency refers to the ratio of useful energy output to the total energy input in a given system or process. In the context of charcoal gasification, improving energy efficiency is a key objective to maximize the utilization of the energy content in biomass, specifically charcoal, and enhance the overall performance of the gasification process.

Efficiency in charcoal gasification involves optimizing various parameters such as temperature, pressure, residence time, and the air-to-fuel ratio within the gasifier. These factors influence the extent of pyrolysis, the conversion of charcoal into syngas, and the subsequent combustion of char residues. Efficient gasification processes ensure that a higher proportion of the energy stored in the biomass is captured in the form of clean-burning syngas.

Enhancing energy efficiency in charcoal gasification is essential for promoting sustainable energy practices. It not only maximizes the yield of usable energy but also minimizes waste and environmental impact. Efficient gasification technologies contribute to the economic viability of biomass-based energy systems, making them more competitive with traditional fossil fuel alternatives.

As global energy demand continues to rise and the focus on sustainable practices intensifies, improving energy efficiency in processes like charcoal gasification becomes paramount. It aligns with the broader goal of achieving a more sustainable and resilient energy infrastructure, reducing environmental impact, and fostering responsible energy consumption practices.

Carbon-Neutral:

The term “carbon-neutral” refers to the state where the net release of carbon dioxide (CO2) emissions into the atmosphere is balanced by an equivalent amount of carbon sequestration or offsetting activities. In the context of charcoal gasification, the use of biomass-derived charcoal can be considered a carbon-neutral energy source under certain conditions.

When plants grow, they absorb carbon dioxide from the atmosphere through photosynthesis, converting it into biomass. If this biomass, such as wood or agricultural residues, is then used to produce charcoal through controlled gasification, the carbon stored in the biomass is released as carbon monoxide (CO) and other gases, but it is not contributing to a net increase in atmospheric CO2 levels.

To achieve carbon neutrality in charcoal gasification, it is crucial to ensure sustainable and responsible biomass management. This includes practices such as reforestation, afforestation, or the use of agricultural residues in a manner that maintains or increases carbon stocks. Additionally, the combustion of the produced syngas should be done efficiently, minimizing emissions and environmental impact.

The carbon-neutral aspect of charcoal gasification is a key advantage in the context of mitigating climate change. By utilizing biomass-derived charcoal in a sustainable manner, communities and industries can reduce their carbon footprint, contribute to carbon sequestration efforts, and play a role in fostering a more sustainable and environmentally friendly energy landscape.

Small-Scale Power Generation:

Small-scale power generation refers to the production of electricity on a localized or modest scale, typically serving specific communities, industries, or individual households. In the context of charcoal gasification, small-scale power generation involves the utilization of syngas derived from charcoal to produce electricity for local energy needs.

Charcoal gasification systems designed for small-scale power generation consist of a gasifier, where charcoal undergoes thermochemical reactions to produce syngas, and an engine or generator that converts the syngas into electricity. This decentralized approach to power generation is particularly valuable in areas with limited access to traditional electricity grids or in off-grid locations.

The advantages of small-scale power generation through charcoal gasification include reduced transmission losses, increased energy efficiency, and the ability to provide reliable electricity to remote or underserved communities. These systems can be tailored to meet specific energy demands, making them adaptable to diverse settings ranging from rural villages to industrial facilities.

The integration of small-scale power generation using charcoal gasification supports energy access initiatives, enhances local resilience, and contributes to sustainable development goals. It empowers communities to harness their local biomass resources, reducing dependence on external energy sources and promoting a more self-sufficient and sustainable energy infrastructure.

EMS Power Machines

We design, manufacture and assembly Power Machines such as – diesel generators, electric motors, vibration motors, pumps, steam engines and steam turbines

EMS Power Machines is a global power engineering company, one of the five world leaders in the industry in terms of installed equipment. The companies included in the company have been operating in the energy market for more than 60 years.

EMS Power Machines manufactures steam turbines, gas turbines, hydroelectric turbines, generators, and other power equipment for thermal, nuclear, and hydroelectric power plants, as well as for various industries, transport, and marine energy.

EMS Power Machines is a major player in the global power industry, and its equipment is used in power plants all over the world. The company has a strong track record of innovation, and it is constantly developing new and improved technologies.

Here are some examples of Power Machines’ products and services:

- Steam turbines for thermal and nuclear power plants

- Gas turbines for combined cycle power plants and industrial applications

- Hydroelectric turbines for hydroelectric power plants

- Generators for all types of power plants

- Boilers for thermal power plants

- Condensers for thermal power plants

- Reheaters for thermal power plants

- Air preheaters for thermal power plants

- Feedwater pumps for thermal power plants

- Control systems for power plants

- Maintenance and repair services for power plants

EMS Power Machines is committed to providing its customers with high-quality products and services. The company has a strong reputation for reliability and innovation. Power Machines is a leading provider of power equipment and services, and it plays a vital role in the global power industry.

EMS Power Machines, which began in 1961 as a small factory of electric motors, has become a leading global supplier of electronic products for different segments. The search for excellence has resulted in the diversification of the business, adding to the electric motors products which provide from power generation to more efficient means of use.