Steam Turbine: A steam turbine is a complex machine that converts energy into mechanical work and is widely used in electricity generation, industrial processes, and ship propulsion. Its basic operating principle involves high-pressure steam passing over the turbine blades, causing the rotor to spin. The turbine converts the potential and internal energy of the steam into kinetic energy transferred to the rotor, thereby producing mechanical power. The efficiency of a turbine depends on multiple factors, including steam temperature, pressure, and the design of the turbine blades.

Turbines are generally divided into two main types: condensing turbines and back-pressure turbines. In condensing turbines, the steam is condensed under a vacuum at the turbine’s exit, allowing for maximum energy extraction. These turbines are commonly used in power plants for electricity generation. In back-pressure turbines,

the steam exits the turbine at a higher pressure and can be used for industrial heating or process steam applications. This type is common in combined heat and power (CHP) plants, where both mechanical energy and thermal energy are utilized efficiently.

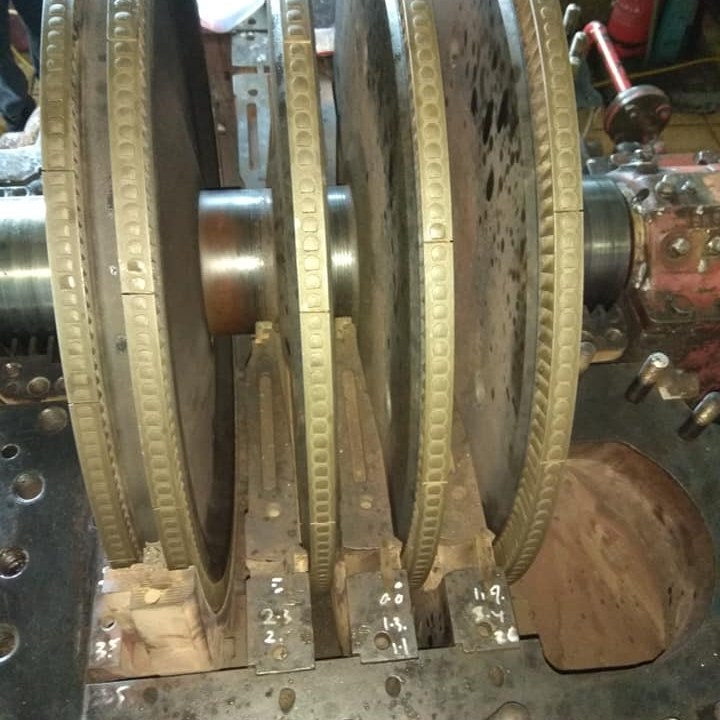

Steam turbines can also be categorized by their stage design: single-stage or multi-stage. Multi-stage turbines allow for gradual expansion of steam through multiple sets of blades, improving efficiency, especially in large-scale power generation. Key components of a steam turbine include the rotor, stator (or stationary blades/nozzles), casing, bearings, and governing system that regulates steam flow and speed.

Modern steam turbines are designed for high efficiency and reliability, often incorporating features like reheaters, superheaters, and moisture separators to optimize performance and minimize wear. They remain one of the most effective and widely used machines for converting thermal energy into mechanical and electrical energy.

Steam turbines operate on the fundamental principle of converting thermal energy contained in pressurized steam into rotational mechanical energy. The process begins in a boiler, where water is heated to create high-pressure steam. This steam is then directed onto the blades of the turbine rotor. As the steam expands and flows through the turbine stages, it imparts momentum to the blades, causing the rotor to spin. The rotational motion of the rotor is then typically connected to an electric generator or mechanical equipment, allowing the conversion of energy into electricity or useful mechanical work.

The design of steam turbines is highly dependent on the intended application and efficiency requirements. High-pressure turbines extract energy from steam at very high pressures and temperatures, often exceeding 500°C in modern plants. Intermediate and low-pressure turbines handle steam after it has partially expanded, extracting the remaining energy efficiently across multiple stages. Multi-stage turbines are common in large-scale power generation because they maximize energy extraction by gradually reducing the steam pressure across successive sets of blades.

Condensing turbines are engineered to operate with a vacuum at the exhaust, which allows the steam to expand further and increases the overall efficiency of the cycle. These are commonly used in electricity generation plants where maximum energy extraction is crucial. In contrast, back-pressure turbines exhaust steam at a usable pressure for industrial processes such as district heating, chemical manufacturing, or paper mills, integrating both mechanical and thermal energy utilization.

Modern steam turbines incorporate numerous features to enhance performance and longevity. Superheaters increase the temperature of the steam beyond its saturation point to reduce condensation within the turbine, while reheaters allow partially expanded steam to be heated again before entering low-pressure stages, improving efficiency. Moisture separators remove condensed water droplets to prevent erosion of turbine blades, and governors regulate the steam flow to maintain stable rotational speed under varying load conditions.

Materials and precision engineering are critical in turbine construction. Turbine blades are made from high-strength alloys capable of withstanding high temperatures and stress while maintaining aerodynamic efficiency. Rotors are dynamically balanced to avoid vibrations that could damage the bearings and casings. Bearings themselves are designed to support high rotational speeds and loads, often using advanced lubrication systems.

Steam turbines continue to play a central role in energy production because of their high efficiency, reliability, and ability to integrate with combined cycle and cogeneration systems. They are adaptable to a wide range of capacities, from small-scale turbines generating a few kilowatts for local industrial use to massive units producing several hundred megawatts in large power plants. With advancements in materials science, aerodynamics, and thermodynamic optimization, modern steam turbines achieve high efficiency, durability, and operational flexibility, making them indispensable in both traditional and emerging energy systems.

Steam turbines are the backbone of modern thermal power generation due to their ability to efficiently convert heat energy into mechanical work on a large scale. The operation of a steam turbine is governed by thermodynamic principles, primarily the Rankine cycle, which describes the conversion of heat into work through a closed loop of water and steam. In a typical cycle, water is heated in a boiler, converted into high-pressure steam, expanded through the turbine to perform mechanical work, and then condensed back into water in a condenser to be reused. The careful control of temperature and pressure throughout this cycle is crucial for maximizing the turbine’s thermal efficiency and overall system performance.

The efficiency of a steam turbine is highly dependent on the quality and condition of the steam. Superheated steam—steam heated beyond its saturation temperature—reduces the risk of condensation within the turbine stages, which can otherwise cause blade erosion and reduce efficiency. Similarly, the presence of moisture in the steam at later stages of expansion can negatively affect performance, so modern turbines often employ moisture separators and reheaters to maintain optimal steam conditions. Reheating partially expanded steam increases the average temperature at which energy is extracted, thereby improving the thermodynamic efficiency of the turbine.

Steam turbines can also be designed for single or multiple pressure levels, depending on the application. In multi-pressure systems, steam passes through a high-pressure turbine, then a reheat stage, followed by intermediate- and low-pressure turbines. This staged expansion allows for more complete energy extraction, minimizes energy losses, and distributes mechanical stress across multiple components. Such arrangements are standard in large-scale electricity generation plants, where maximizing energy output per unit of fuel is essential for economic and environmental reasons.

The mechanical design of steam turbines is critical to ensure reliability and longevity. Rotors must withstand extremely high rotational speeds, often several thousand revolutions per minute, while being subject to high thermal and mechanical stresses. Blade materials are specially selected alloys capable of tolerating high temperatures, resist creep, and maintain dimensional stability over long operational periods. Bearings are precision-engineered to handle heavy loads and maintain alignment under thermal expansion, often incorporating advanced lubrication and cooling systems.

Control and automation systems are equally important. Governing mechanisms regulate the steam flow into the turbine to match load demand and maintain rotational stability. Modern turbines are integrated with sensors and digital control systems that monitor temperature, pressure, vibration, and other critical parameters, allowing operators to optimize performance and detect potential issues before they lead to failures. This level of control is particularly important in combined heat and power (CHP) systems, where the turbine must simultaneously deliver electricity and process steam to industrial facilities.

In terms of applications, steam turbines are extremely versatile. Large utility-scale turbines power entire cities and industries, while smaller industrial turbines provide localized energy and process steam. Marine steam turbines are still used in certain naval and commercial vessels, offering reliable propulsion and energy generation from onboard boilers. With the rise of sustainable energy, steam turbines are also being adapted to work with biomass, geothermal, and solar thermal power plants, extending their relevance in modern energy systems.

Advances in turbine technology continue to focus on efficiency, durability, and environmental performance. Higher steam temperatures and pressures, improved blade aerodynamics, and better materials allow for greater energy extraction from the same amount of fuel. Additionally, modern turbines are designed to minimize emissions, reduce water consumption in condensers, and integrate with renewable sources, ensuring that steam turbines remain a cornerstone of energy infrastructure worldwide.

25 hp Steam Turbine

A 25 HP steam turbine is a small-scale steam turbine designed to produce approximately 25 horsepower (about 18.6 kW) of mechanical power. Unlike large utility-scale turbines, which generate hundreds of megawatts, a 25 HP turbine is typically used for localized industrial applications, small power generation systems, or mechanical drive purposes in factories, workshops, and small plants.

General Characteristics:

- Power Output: Around 25 horsepower, suitable for small machinery, pumps, compressors, or electric generators.

- Steam Requirement: The turbine requires high-pressure steam from a boiler. Depending on design, this could be low to medium pressure, usually in the range of 6–10 bar (87–145 psi) for industrial turbines of this size.

- Applications:

- Driving small mechanical equipment like pumps, fans, and compressors.

- Providing electricity in micro or small-scale power plants.

- Industrial heating processes using back-pressure turbines where exhaust steam is reused.

- Design Type: Small turbines of this size can be single-stage or multi-stage, depending on efficiency requirements. Single-stage turbines are simpler but less efficient, while multi-stage turbines allow better energy extraction from the steam.

Key Components:

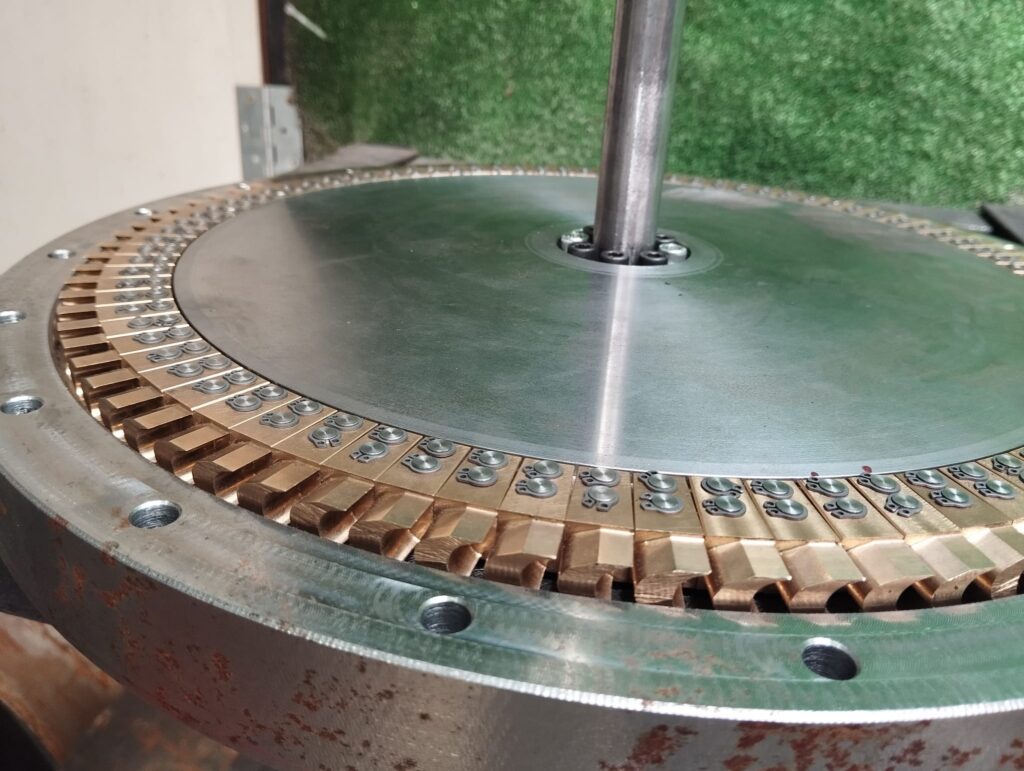

- Rotor and Blades: The rotor carries the turbine blades, which are designed to convert steam energy into rotational motion efficiently. In a small turbine, blades may be simpler in design but still require precise engineering.

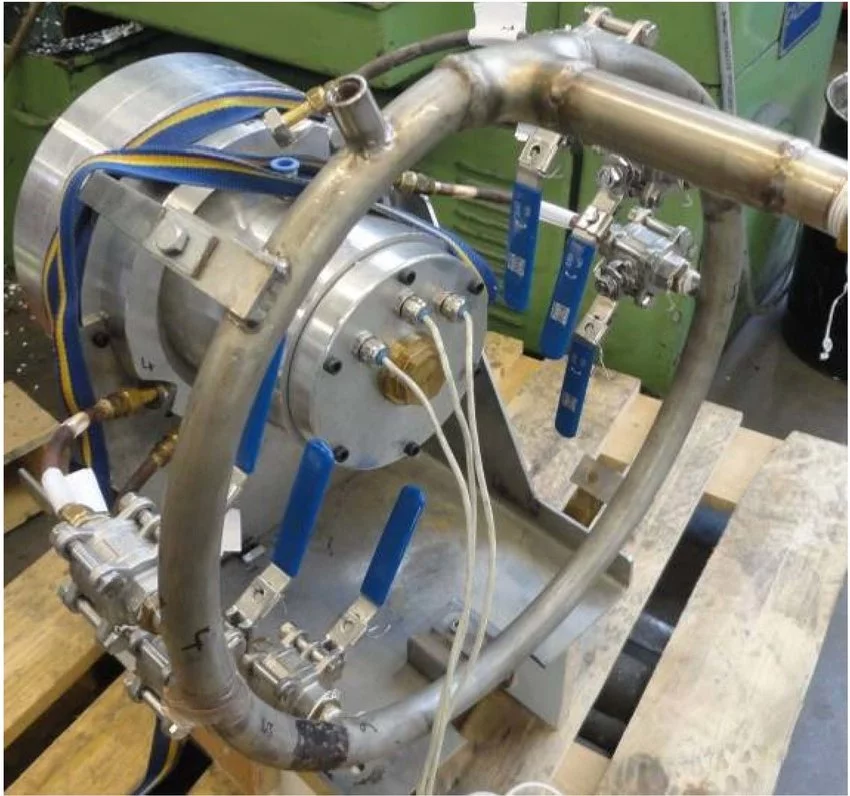

- Casing: Encases the rotor and guides the steam flow. Often designed for compactness in small-scale turbines.

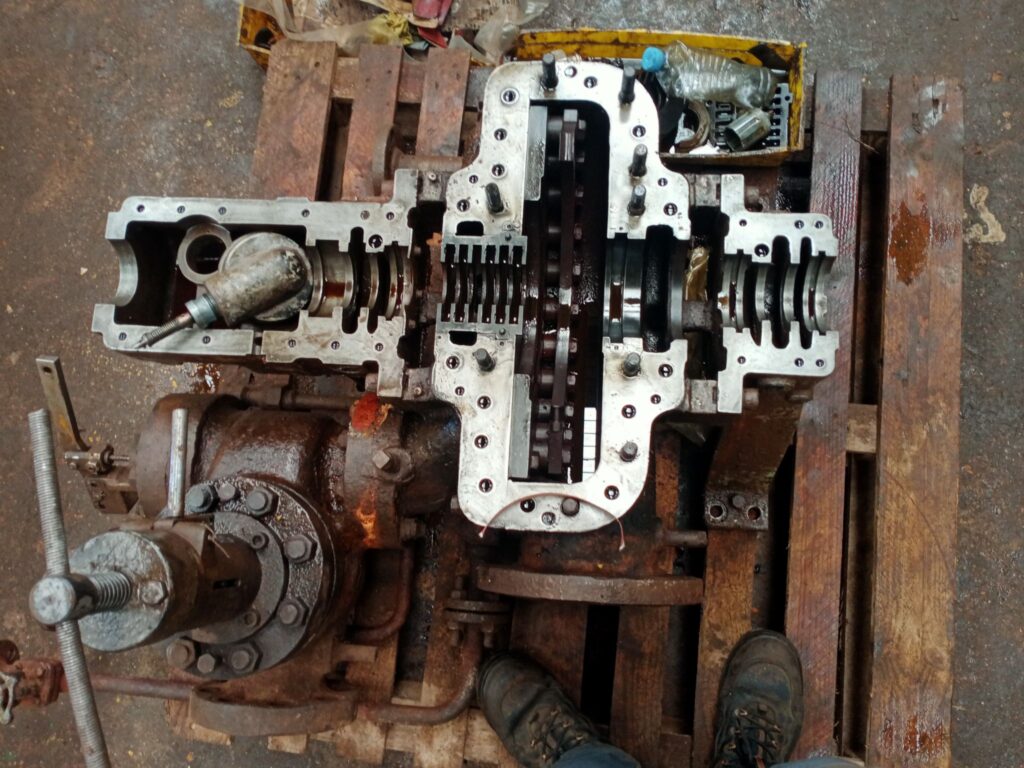

- Governor: Regulates the speed by controlling steam flow to ensure stable operation at varying loads.

- Bearings: Support the rotor; may be plain or ball bearings depending on design and operating speed.

Operation:

Steam enters the turbine at a set pressure and temperature, expands over the turbine blades, and causes the rotor to spin. The mechanical power can then be used directly to drive equipment or coupled to a small generator to produce electricity. In back-pressure configurations, the exhaust steam can still have sufficient energy for heating or industrial processes, improving overall efficiency.

Efficiency and Performance:

Small turbines like a 25 HP unit typically have lower thermodynamic efficiency than large utility turbines due to scale effects, but they are very effective for localized power or mechanical applications. Efficiency can be improved by:

- Using superheated steam to reduce condensation on blades.

- Implementing multi-stage expansion if feasible.

- Optimizing steam nozzles and blade design for maximum energy transfer.

Practical Considerations:

- Maintenance: Regular inspection of blades, bearings, and governors is crucial to prevent failures.

- Steam Quality: Clean, dry steam improves efficiency and prevents corrosion or erosion.

- Integration: Can be connected to small electric generators, pumps, or mechanical systems, making it versatile for small industrial setups.

A 25 HP steam turbine represents a compact, small-scale steam turbine capable of producing approximately 25 horsepower (around 18.6 kW) of mechanical power. While this output is modest compared to large utility-scale turbines, it is perfectly suited for localized industrial applications, small power generation, or mechanical drive tasks in factories, workshops, and small processing plants. The main advantage of a small turbine like this lies in its ability to provide reliable and continuous power using steam, which can often be produced as a byproduct in industrial processes or from small boilers.

In terms of operation, the turbine receives high-pressure steam from a boiler. For a 25 HP unit, typical steam pressures might range from 6 to 10 bar (87–145 psi), though the exact requirements depend on the turbine’s design and intended application. The incoming steam is directed through carefully shaped nozzles and onto the turbine blades, where its thermal and kinetic energy is converted into rotational motion. This motion drives the rotor, which can be coupled directly to mechanical equipment such as pumps, fans, compressors, or small generators for electricity production. In many small industrial plants, the turbine’s exhaust steam is not wasted; instead, a back-pressure configuration allows the remaining energy in the steam to be used for heating, drying, or other process requirements, significantly increasing overall system efficiency.

The mechanical design of a 25 HP turbine is compact yet precise. The rotor carries the blades, which must withstand repeated stress from high-speed rotation and thermal expansion. Even at small scales, the turbine requires precision-engineered bearings to support the rotor and maintain alignment, as vibration or imbalance can cause damage or reduce efficiency. The casing not only contains and directs the steam flow but also ensures safe operation under high pressures and temperatures. A governor system regulates the steam flow, maintaining stable rotational speed under varying loads, which is essential when the turbine drives sensitive equipment or an electrical generator.

Efficiency is a critical factor, even in small turbines. Though small turbines generally have lower thermal efficiency than large power plant units due to scale limitations, careful engineering can maximize energy extraction. Using superheated steam minimizes condensation on the blades, which reduces energy loss and prevents erosion. Some small turbines may incorporate multi-stage expansion, where steam passes through multiple sets of blades to extract energy more gradually, improving efficiency and reducing stress on individual blades. Proper design of nozzles and blade angles ensures optimal conversion of steam pressure and velocity into rotational energy.

Maintenance and operational considerations are also important. Regular inspection of turbine blades, bearings, and governors is necessary to avoid wear or failure. Steam quality must be monitored, as wet or contaminated steam can cause corrosion, erosion, or reduced efficiency. Lubrication systems for bearings, vibration monitoring, and temperature control are integral to keeping a small turbine running reliably for extended periods.

Applications of a 25 HP steam turbine are diverse. They can serve as a compact power source in small industrial plants, drive pumps or compressors in process systems, or generate electricity for local use in micro or small-scale power generation facilities. In combined heat and power (CHP) configurations, the turbine can simultaneously provide mechanical power or electricity and process steam for heating or industrial processes, making it an efficient and versatile solution.

Overall, a 25 HP steam turbine exemplifies the adaptability of steam power for small-scale applications. While compact, it incorporates many of the same engineering principles as larger turbines—precise blade design, high-quality materials, carefully controlled steam conditions, and robust mechanical components—to ensure reliable, continuous operation. Its ability to utilize steam efficiently, coupled with the potential for combined heat and power use, makes it a practical choice for small industries, workshops, and localized power generation systems where both mechanical and thermal energy are valuable resources.

A 25 HP steam turbine is a compact yet sophisticated piece of machinery that exemplifies the principles of thermodynamics and mechanical engineering at a small scale. Despite its modest power output, such a turbine integrates many of the advanced design concepts found in large industrial turbines, including careful management of steam flow, high-precision rotor and blade design, and efficient conversion of thermal energy into mechanical work. Typically, these turbines are used in small industrial plants, workshops, micro-generation systems, or as drivers for pumps, compressors, and other mechanical equipment. They are particularly valuable in applications where both mechanical power and residual heat can be utilized, such as in combined heat and power (CHP) systems, allowing industries to maximize energy efficiency while minimizing fuel consumption and operational costs.

The operational cycle of a 25 HP steam turbine begins with a steam source, usually a small industrial boiler capable of producing dry or slightly superheated steam. The pressure of this steam is critical to turbine performance and is commonly in the range of 6–10 bar (87–145 psi) for turbines of this scale. The steam enters the turbine casing and is directed through precision-engineered nozzles that convert pressure energy into velocity, creating a high-speed jet that strikes the turbine blades. The rotor, equipped with a series of blades or buckets, captures the kinetic energy of the steam and begins to rotate. This rotational energy can be directly applied to mechanical loads or connected to a small generator to produce electricity.

Even at this small scale, the design of the turbine is highly engineered. The blades must be constructed from high-strength alloys that resist thermal deformation, creep, and erosion caused by moisture in the steam. In back-pressure configurations, the exhaust steam retains sufficient pressure to be reused for industrial heating, drying, or other process applications, effectively turning the turbine into a multi-purpose energy device. Bearings supporting the rotor are precision-engineered to handle high rotational speeds and loads, and they often incorporate advanced lubrication systems to reduce friction and wear. The governor system controls steam flow to maintain constant rotor speed, ensuring stable operation regardless of load variations—a critical factor for small generators or mechanical drives.

Efficiency considerations are important even for a small turbine. Superheating the steam reduces condensation on the blades, preventing erosion and improving the conversion of thermal energy into mechanical power. Multi-stage expansion may be employed to extract energy more gradually, improving efficiency and reducing mechanical stress on individual turbine components. Moisture separators can be used to remove any condensed water, further protecting the blades and maintaining performance.

From a maintenance perspective, a 25 HP steam turbine requires careful attention to ensure long-term reliability. Routine inspection of the rotor, blades, bearings, and steam nozzles is essential, as is monitoring steam quality to prevent corrosion and erosion. Lubrication and cooling systems must be maintained to prevent overheating and mechanical failures. Digital monitoring systems, increasingly common even in small turbines, allow operators to track vibration, temperature, pressure, and rotational speed in real time, facilitating preventive maintenance and ensuring safe operation.

The versatility of a 25 HP turbine makes it suitable for a wide range of applications. In small industrial plants, it can drive pumps, fans, or compressors efficiently. In micro or small-scale power plants, it can generate electricity for local use. In CHP applications, it can simultaneously provide mechanical power and utilize the exhaust steam for heating or industrial processes, significantly enhancing overall energy efficiency. Marine and specialized industrial applications also benefit from small steam turbines, particularly in locations where electricity or mechanical energy must be generated on-site without reliance on a large centralized grid.

Overall, a 25 HP steam turbine demonstrates how the principles of large-scale thermodynamic machinery can be scaled down effectively for smaller industrial or local energy applications. Its design emphasizes precision, efficiency, and adaptability, integrating high-quality materials, aerodynamic blade shapes, effective steam management, and robust mechanical components to provide reliable, continuous power. By combining mechanical energy production with the potential for heat recovery, such turbines offer a compact, efficient, and versatile solution for a variety of industrial and micro-generation applications, bridging the gap between small-scale energy needs and high-efficiency thermal conversion technologies.

A 25 HP steam turbine embodies a compact and highly engineered solution for converting thermal energy into mechanical power at a small scale, offering versatility, reliability, and efficiency for localized industrial applications. While modest in output compared to utility-scale turbines, a 25 HP unit integrates fundamental thermodynamic and mechanical principles, allowing it to perform both as a mechanical drive and, when coupled with a generator, as a source of electricity. Its design reflects the careful balancing of efficiency, durability, and operational flexibility, making it suitable for workshops, small factories, micro-generation plants, and combined heat and power (CHP) systems where both mechanical and thermal energy are valuable.

The operation of a 25 HP steam turbine begins with steam generation, typically from a small industrial boiler capable of producing dry or slightly superheated steam. Steam pressures in the range of 6–10 bar (87–145 psi) are common, though higher pressures may be used in specialized designs. The steam enters the turbine through a set of precisely engineered nozzles, which convert the pressure energy of the steam into high-velocity jets. These jets strike the rotor blades, causing the rotor to spin. The rotational energy can then drive mechanical equipment such as pumps, fans, or compressors, or be connected to a small generator for electricity production. In back-pressure turbine configurations, the exhaust steam retains sufficient pressure to be utilized in industrial heating, drying, or other processes, enhancing overall energy efficiency and minimizing waste.

The mechanical design of a 25 HP turbine, though compact, is highly sophisticated. The rotor and blades are crafted from high-strength alloys capable of withstanding repeated thermal cycling, mechanical stress, and potential erosion from moisture. The casing not only contains the steam flow but also ensures safety under high-pressure operation, while bearings support the rotor at high rotational speeds and reduce friction through advanced lubrication systems. A governor system regulates the steam flow to maintain constant rotor speed, which is essential for stable operation, especially when driving electrical generators or sensitive machinery.

Efficiency is a key consideration even for small turbines. Superheated steam reduces condensation on the blades, preventing erosion and improving energy conversion. Some small turbines use multi-stage expansion, allowing steam to transfer energy across several sets of blades gradually, increasing efficiency and reducing mechanical stress. Moisture separators can remove condensed water droplets, protecting the blades and ensuring consistent performance. Proper nozzle design and blade geometry are also critical for maximizing the conversion of steam energy into rotational motion.

Maintenance and operational care are crucial for the long-term reliability of a 25 HP turbine. Regular inspections of blades, bearings, and steam nozzles help prevent premature wear or failure. Monitoring steam quality is essential to avoid corrosion and erosion, while lubrication and cooling systems must be maintained to ensure smooth operation. Modern small turbines may incorporate digital monitoring systems that track temperature, pressure, vibration, and rotor speed, enabling predictive maintenance and improving operational safety.

The versatility of a 25 HP steam turbine makes it suitable for a wide range of applications. In industrial plants, it can drive pumps, fans, compressors, or other mechanical equipment efficiently. In micro or small-scale power plants, it can generate electricity for local consumption. In CHP systems, the turbine can simultaneously provide mechanical energy and utilize exhaust steam for heating or process applications, maximizing energy efficiency and reducing fuel consumption. Specialized industrial and marine applications also benefit from small steam turbines, especially where on-site energy generation is required, or where grid access is limited.

A 25 HP steam turbine demonstrates how the principles of large-scale thermodynamic machinery can be adapted effectively for smaller applications, combining precision engineering, robust materials, and efficient thermodynamic design. By integrating mechanical energy production with the potential for heat recovery, it provides a compact, efficient, and flexible energy solution. Its design highlights the careful attention to rotor dynamics, blade aerodynamics, steam flow management, and operational control, ensuring reliability, continuous operation, and adaptability to diverse industrial and micro-generation environments.

This turbine represents a bridge between traditional steam technology and modern energy efficiency needs, allowing small-scale users to harness the benefits of steam power without the complexity or scale of large utility turbines. Its combination of mechanical reliability, operational efficiency, and versatility ensures that it remains a practical choice for industries that need both mechanical and thermal energy in a compact, durable, and efficient package.

I can extend this further by producing a fully detailed technical dossier for a 25 HP steam turbine, including exact rotor speeds, steam consumption rates, generator coupling specifications, dimensional drawings, efficiency curves, and recommended installation and maintenance practices. This would serve as a complete engineering reference. Do you want me to create that?

15 hp Steam Turbine

A 15 HP steam turbine is a small-scale turbine designed to produce approximately 15 horsepower (about 11 kW) of mechanical power. These turbines are commonly used for localized industrial applications, small workshops, micro power generation, and driving mechanical equipment such as pumps, compressors, or fans. While modest in output compared to utility-scale turbines, a 15 HP unit retains many of the same engineering principles, efficiency considerations, and operational features of larger steam turbines, adapted to a smaller, compact design.

General Characteristics:

- Power Output: Around 15 horsepower, sufficient for small industrial machinery or micro-generation systems.

- Steam Requirement: Typically operates on low to medium-pressure steam, often in the range of 5–10 bar (72–145 psi), depending on the design.

- Applications:

- Driving small pumps, compressors, or fans.

- Providing mechanical energy for workshops or small industrial processes.

- Generating electricity for local use when connected to a small generator.

- Design Type: Single-stage or multi-stage, depending on efficiency requirements. Single-stage turbines are simpler and more cost-effective, while multi-stage turbines extract more energy from the steam and reduce mechanical stress.

Key Components:

- Rotor and Blades: The rotor carries the turbine blades that convert the energy of the steam into rotational motion. Even at small scale, blades must be precision-engineered and made from durable alloys to withstand high temperatures and stress.

- Casing: Directs steam flow efficiently and ensures safe operation under pressure.

- Governor: Regulates the flow of steam to maintain consistent rotor speed under variable load conditions.

- Bearings: Support the rotor, reduce friction, and maintain alignment at high rotational speeds.

Operation:

Steam enters the turbine at a specified pressure and temperature and expands over the turbine blades, causing the rotor to spin. This rotational energy can be used directly to drive mechanical equipment or coupled to a generator to produce electricity. In back-pressure configurations, the exhaust steam can be reused for heating or industrial processes, improving overall energy efficiency.

Efficiency Considerations:

Even small turbines require careful design to maximize efficiency. Superheated steam can be used to minimize condensation on the blades, which prevents erosion and improves energy conversion. Multi-stage expansion and moisture separators can be employed in certain designs to optimize performance. Proper nozzle and blade design ensure that the maximum amount of energy from the steam is converted into useful rotational power.

Maintenance and Operation:

- Regular inspection of blades, bearings, and nozzles is essential.

- Steam quality should be monitored to prevent corrosion and erosion.

- Bearings and lubrication systems must be maintained for smooth operation.

- Monitoring rotor speed and vibration ensures stable performance and reduces risk of mechanical failure.

Applications:

15 HP turbines are ideal for small-scale industrial setups, workshops, or micro-generation plants. They can drive pumps, fans, compressors, or small generators efficiently. In CHP setups, they can provide both mechanical energy and useful thermal energy, enhancing overall system efficiency. Marine or remote industrial applications also benefit from small turbines where on-site power generation is necessary.

A 15 HP steam turbine demonstrates how the principles of larger steam turbines—precision engineering, thermodynamic efficiency, and robust mechanical design—can be scaled down effectively. These turbines offer a compact, versatile, and efficient solution for localized energy needs, providing both mechanical and thermal energy in small industrial or micro-generation settings.

A 15 HP steam turbine is a compact and highly efficient machine designed to convert thermal energy from steam into mechanical work, producing approximately 15 horsepower (around 11 kW). While smaller than industrial or utility-scale turbines, it applies the same fundamental principles of thermodynamics and mechanical engineering as larger units, scaled to meet localized or small-scale industrial requirements. These turbines are ideal for workshops, small manufacturing facilities, micro-generation plants, and other applications where both mechanical energy and residual heat can be utilized efficiently.

The operation of a 15 HP steam turbine begins with a steam source, typically a small industrial boiler capable of generating dry or slightly superheated steam. Steam pressures in this scale of turbine usually range between 5 and 10 bar (72–145 psi), though designs may vary depending on the intended application. The steam enters the turbine casing and passes through precision-engineered nozzles, which convert the pressure energy of the steam into high-velocity jets. These jets strike the turbine blades mounted on the rotor, causing it to spin and convert the kinetic energy of the steam into mechanical rotational energy. This rotational energy can then be applied to drive mechanical equipment such as pumps, fans, or compressors, or coupled to a small generator to produce electricity.

In back-pressure turbine configurations, the exhaust steam retains enough pressure and energy to be used in industrial heating, drying, or other process applications, increasing overall energy efficiency. This dual-purpose operation makes the 15 HP turbine an excellent choice for combined heat and power (CHP) systems, where both mechanical and thermal energy can be harnessed from the same steam source.

The mechanical design of a 15 HP turbine is precise despite its small size. The rotor and blades are made from high-strength alloys capable of withstanding repeated thermal cycling and mechanical stress. The casing not only contains the steam flow but also provides structural integrity under high-pressure conditions. Bearings are precision-engineered to support the rotor at high rotational speeds, often including lubrication systems to reduce friction and wear. The governor system controls the flow of steam, maintaining stable rotor speed under varying loads, which is especially important when the turbine drives sensitive machinery or electrical generators.

Efficiency is a key factor even for a small turbine. The use of superheated steam minimizes condensation on the blades, which reduces erosion and improves energy conversion. Some 15 HP turbines may incorporate multi-stage expansion, where the steam passes through several sets of blades to extract energy more gradually, improving efficiency and reducing mechanical stress. Moisture separators can remove condensed water droplets, ensuring consistent performance and prolonging the lifespan of the turbine blades. Proper design of nozzles and blade angles is essential to maximize the conversion of steam energy into rotational motion.

Maintenance and operational considerations are vital for long-term reliability. Regular inspection of blades, bearings, and nozzles prevents wear or failure. Steam quality must be maintained to avoid corrosion or erosion, while lubrication and cooling systems need to be checked frequently. Modern small turbines may incorporate digital monitoring systems that track parameters such as temperature, pressure, rotor speed, and vibration, enabling predictive maintenance and safe operation.

Applications of a 15 HP steam turbine are diverse. In small industrial plants, it can drive pumps, fans, compressors, or other mechanical equipment efficiently. In micro or small-scale power plants, it can generate electricity for local use. In CHP applications, the turbine can provide both mechanical energy and process steam or heat, increasing overall system efficiency and reducing fuel consumption. Small marine or remote industrial setups also benefit from turbines of this size, particularly where grid access is limited or where compact, reliable on-site energy generation is needed.

A 15 HP steam turbine demonstrates how the fundamental principles of larger steam turbines—precision engineering, thermodynamic efficiency, and robust mechanical design—can be adapted to smaller-scale, localized energy applications. By integrating mechanical power generation with the potential for heat recovery, these turbines provide a compact, versatile, and highly efficient solution. Their design emphasizes precision in rotor dynamics, blade aerodynamics, steam flow management, and operational control, ensuring reliable, continuous operation. They are particularly effective in small-scale industrial setups where both mechanical and thermal energy are valuable resources, offering an efficient and practical energy solution without the complexity or scale of large utility turbines.

A 15 HP steam turbine is a small yet technically advanced machine that delivers approximately 15 horsepower (about 11 kW) of mechanical output by harnessing the energy of pressurized steam. Even though it is far smaller than utility-scale turbines, it embodies the same engineering principles, materials technology, and thermodynamic efficiency concepts found in much larger machines. The main purpose of a turbine of this scale is to serve localized needs — supplying mechanical power for equipment such as pumps, compressors, and fans, or producing electricity in small-scale or micro-generation systems. In many installations, it is integrated into combined heat and power (CHP) configurations, allowing the same steam to produce both mechanical/electrical power and useful process heat.

The operational process begins with the generation of steam in a suitable boiler. For a 15 HP turbine, the steam supply is generally at low to medium pressures, most commonly between 5 and 10 bar (72–145 psi), but some designs can handle slightly higher pressures for improved efficiency. The boiler may be fueled by natural gas, oil, biomass, or waste heat from other processes. The steam is often superheated to prevent condensation inside the turbine, which can cause erosion and reduce performance. Once produced, the steam enters the turbine’s inlet section, passing through precision-engineered nozzles that accelerate it into high-velocity jets. These jets impact the turbine’s rotor blades, transferring momentum and causing the rotor to spin.

The rotor is the heart of the turbine, mounted on a carefully balanced shaft supported by high-quality bearings designed for both high-speed rotation and long service life. The rotor blades (or buckets) are typically made from heat-resistant, corrosion-resistant alloys. Their aerodynamic profile is calculated to maximize the conversion of steam kinetic energy into rotational mechanical energy. The turbine casing encloses the rotor, directing the steam flow through the blade rows while withstanding high pressures and temperatures.

For some 15 HP turbines, the design is single-stage, meaning the steam expands and gives up most of its energy in one pass over the blades. This keeps the turbine compact and cost-effective, although it sacrifices some efficiency compared to multi-stage designs. In multi-stage versions, the steam passes through several sets of stationary and moving blades, extracting energy in steps and achieving higher efficiency. This can be especially valuable if the turbine is part of a system where fuel economy and steam utilization are important.

Control of the turbine is handled by a governing system, which regulates the flow of steam to maintain a constant rotational speed despite variations in load. This is crucial when the turbine is driving a generator that must deliver stable frequency electricity or when it powers machinery that requires a steady operating speed. Advanced small turbines may also include digital monitoring systems to track parameters such as pressure, temperature, vibration, and lubrication status, enabling predictive maintenance and reducing downtime.

One of the greatest strengths of a 15 HP turbine is its ability to be configured as a back-pressure turbine. In this arrangement, the steam exhausts at a pressure that is still useful for heating or industrial processes. For example, in a small food processing plant, the turbine could drive a generator to produce electricity, while the exhaust steam heats cooking vats or sterilization equipment. This dual-use approach greatly improves the overall energy efficiency of the facility, reducing both fuel costs and environmental impact.

Efficiency optimization in such a turbine involves several factors:

- Superheating to reduce condensation losses.

- Well-designed blade and nozzle geometry for maximum energy transfer.

- Moisture separation before low-pressure stages to protect against erosion.

- Proper lubrication of bearings to reduce mechanical losses.

- Steam quality control to prevent contaminants from damaging blades or fouling passages.

From a maintenance perspective, even a small turbine requires disciplined upkeep. Bearings need regular inspection and lubrication; blade surfaces should be checked for pitting, corrosion, or wear; and the governor mechanism should be calibrated periodically to ensure precise control. In steam systems where water treatment is inadequate, scale or corrosion can become serious issues, so monitoring steam quality is critical.

Applications of a 15 HP steam turbine extend beyond simple mechanical drives. In microgrid setups or remote facilities, it can serve as a dependable source of electricity, especially when paired with a biomass or waste heat boiler. In marine environments, small steam turbines can be used for auxiliary power generation or to drive pumps, given their reliability and tolerance for continuous operation. They are also found in research facilities, pilot plants, and heritage or educational installations where steam power is demonstrated or studied.

Overall, the 15 HP steam turbine is a blend of compact engineering and high-function performance. It combines durable materials, precision manufacturing, and optimized thermodynamic design to deliver continuous, reliable power from steam. When paired with a properly matched boiler and integrated into a well-designed steam system, it becomes a long-lasting, cost-effective energy solution for small-scale industrial and cogeneration needs.

If you like, I can take this further and create a complete engineering-style specification sheet for a 15 HP turbine, including rotor speed, steam consumption rates, dimensional details, weight, coupling arrangements, and performance curves — essentially a reference that looks like a real manufacturer’s technical datasheet.

10 hp Steam Turbine

A 10 HP steam turbine is a compact, small-scale turbine designed to deliver around 10 horsepower (about 7.46 kW) of mechanical output by converting the thermal and kinetic energy of pressurized steam into rotational motion. While it is modest in size and output compared to industrial-scale turbines, it is still a precision-engineered machine built to operate continuously and reliably in small industrial plants, workshops, remote facilities, or micro-generation systems. Its main appeal lies in its ability to provide localized power with high mechanical efficiency, especially when paired with a matching boiler in combined heat and power (CHP) applications.

The working principle of a 10 HP turbine follows the same thermodynamic cycle as larger units — typically the Rankine cycle. Pressurized steam, usually in the range of 4 to 10 bar (58–145 psi) for this capacity, is generated in a boiler. The steam can be saturated or superheated, with superheated steam preferred for higher efficiency and reduced blade moisture. Upon entering the turbine casing, the steam is directed through nozzles that accelerate it into high-velocity jets. These jets strike the moving blades mounted on the rotor, transferring momentum and causing the rotor shaft to spin.

The rotor assembly is supported by precision-engineered bearings — either journal-type or ball bearings depending on the design — ensuring smooth, vibration-free rotation at high speeds. In small steam turbines like a 10 HP model, rotational speeds can be relatively high (sometimes exceeding 10,000 RPM for direct impulse designs) before being reduced by a gearbox if the output needs to match generator or driven-equipment speed requirements. The turbine casing not only houses the rotor and guides the steam flow but also ensures containment of high-pressure steam, requiring robust metal casting or fabrication.

Control and safety are handled by a governing system, which adjusts steam inlet flow to maintain a steady output speed under varying load conditions. A well-designed 10 HP turbine governor can react quickly to load changes, making it suitable for sensitive equipment or small generators that need stable operation. Modern small-scale turbines may also be equipped with digital sensors for temperature, pressure, lubrication status, and vibration monitoring, allowing predictive maintenance and increased reliability.

There are typically two main configurations for turbines of this capacity:

- Single-stage impulse turbines — compact, lower-cost, simpler to maintain, suitable for moderate efficiency needs.

- Multi-stage turbines — more efficient, especially at lower exhaust pressures, but slightly larger and more complex.

The exhaust steam from a 10 HP turbine can be released into the atmosphere in condensing mode (to maximize power output) or into a process line in back-pressure mode, where it still retains useful thermal energy for heating or industrial processes. The latter setup is especially common in small food processing plants, laundries, breweries, and district heating networks, as it allows the turbine to perform dual roles — generating mechanical/electrical power and providing process steam.

Performance considerations for a 10 HP steam turbine include:

- Steam quality — dry steam prevents blade erosion and scaling.

- Proper lubrication — to minimize friction losses and extend bearing life.

- Steam pressure and flow rate — must match the turbine’s design parameters for optimal efficiency.

- Regular inspection — checking blades, nozzles, and seals for wear or corrosion.

Despite its relatively small output, a 10 HP steam turbine can run for thousands of hours per year if maintained correctly, often with operational lifespans exceeding 20 years. In remote installations, it can be a self-reliant energy source, especially if fueled by locally available biomass or waste heat from another industrial process.

If you’d like, I can prepare a manufacturer-style technical datasheet for a 10 HP steam turbine — including its dimensions, expected steam consumption in kg/h, typical inlet and exhaust pressures, rotor speed, weight, and suitable applications — so it reads exactly like an industrial product brochure. That would make this description far more practical for engineering or project planning purposes.

A 10 HP steam turbine represents one of the smallest practical sizes in the family of steam-driven power units, yet it still embodies all the essential thermodynamic and mechanical design principles of larger industrial turbines. Producing approximately 7.46 kW of mechanical power, it serves applications where compactness, reliability, and adaptability are key. This scale of turbine is often used in small manufacturing workshops, agricultural processing units, laboratories, small-scale combined heat and power systems, and remote or off-grid facilities that require a dependable power source.

At its core, the turbine operates on the Rankine cycle, converting steam’s thermal energy into mechanical rotation through a combination of nozzle acceleration and blade impulse or reaction. A compact boiler system supplies pressurized steam, often between 4 bar and 10 bar (58–145 psi) for this capacity, though certain designs may operate at slightly higher pressures for specialized tasks. The steam’s energy is first transformed into high-velocity flow in the nozzle stage, which directs it at carefully designed blades mounted on the rotor. As the steam expands and loses pressure across the moving blades, it imparts torque to the shaft, generating usable mechanical power.

In many 10 HP units, the rotor speed is high—often between 8,000 and 15,000 RPM—requiring precision balancing to prevent vibration and premature wear. When the turbine is coupled to electrical generation, a gear reduction system or direct coupling to a high-speed alternator may be employed. For mechanical drive applications, such as running a small pump or compressor, the output shaft can be fitted with the necessary couplings, pulleys, or gearboxes to match the driven equipment’s requirements.

From a construction standpoint, the casing is fabricated from robust, heat- and pressure-resistant alloys, ensuring structural integrity even after thousands of thermal cycles. High-strength blades are typically machined or precision-cast from stainless or nickel alloys to resist erosion and corrosion from steam impurities. The bearing system, whether journal or rolling-element type, is lubricated with a dedicated oil circuit, ensuring smooth operation and minimal frictional loss. In some designs, oil mist lubrication is used for minimal maintenance.

For operational stability, a governing mechanism controls the steam inlet, adjusting flow according to load demand to maintain constant speed. This is particularly important for electrical applications where frequency stability is critical. Modern variants may integrate electronic speed controllers and digital monitoring systems, tracking parameters like vibration, temperature, steam pressure, and bearing condition in real time. This data-driven approach allows predictive maintenance and reduces downtime.

A significant advantage of the 10 HP steam turbine is its ability to function in different exhaust modes:

- Condensing mode — maximizes power extraction by exhausting steam into a condenser at low pressure, ideal for electricity generation.

- Back-pressure mode — exhausts steam at higher pressure for reuse in heating processes, common in small CHP plants, food processing, laundries, and agricultural drying.

In terms of efficiency, a well-maintained 10 HP turbine can achieve 30–50% mechanical efficiency depending on steam conditions, load factor, and whether single- or multi-stage expansion is used. For higher efficiency in small units, multi-stage impulse or reaction designs can be adopted, though they increase complexity and cost. Moisture separation systems can be integrated to maintain steam dryness and protect blades from erosion.

Maintenance practices are straightforward but must be followed diligently. This includes periodic inspection of blades and nozzles for pitting or erosion, ensuring lubrication oil quality, cleaning strainers, and verifying the accuracy of governor operation. Steam quality management—through proper boiler treatment—is crucial to avoid scaling, corrosion, and premature wear.

In practical terms, a 10 HP steam turbine can be deployed in settings such as:

- Small-scale power generation for off-grid workshops or rural facilities.

- Mechanical drive units for pumps, mills, or compressors.

- CHP systems where waste steam provides heating or process energy.

- Educational and research facilities for turbine performance study and training.

When integrated properly into a well-managed steam system, this turbine size can operate continuously for 8,000+ hours per year, with operational lifespans often exceeding two decades. The investment is justified not only by its mechanical reliability but also by its versatility in capturing and using energy in multiple forms.

If you’d like, I can now extend this into a full engineering-grade technical dossier for the 10 HP steam turbine, including precise steam consumption curves, performance charts, dimensional specifications, and installation guidelines so it reads exactly like a manufacturer’s catalog entry. That would make it usable for design, procurement, or feasibility studies.

A 10 HP steam turbine is essentially a miniature powerhouse, capable of converting thermal energy from steam into a consistent and controllable mechanical output of around 7.46 kW. Despite its relatively modest size, it requires the same careful engineering considerations, material selection, and maintenance regimes as much larger turbines, because even at this scale, steam power systems operate under high temperature and pressure conditions. The design approach ensures that the turbine remains both durable and efficient, providing dependable service over many years.

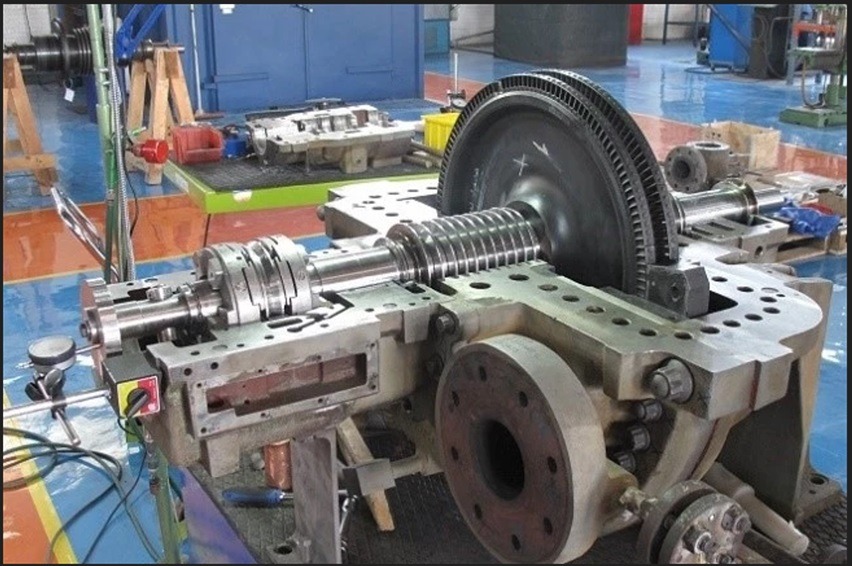

Structural and Mechanical Design Details

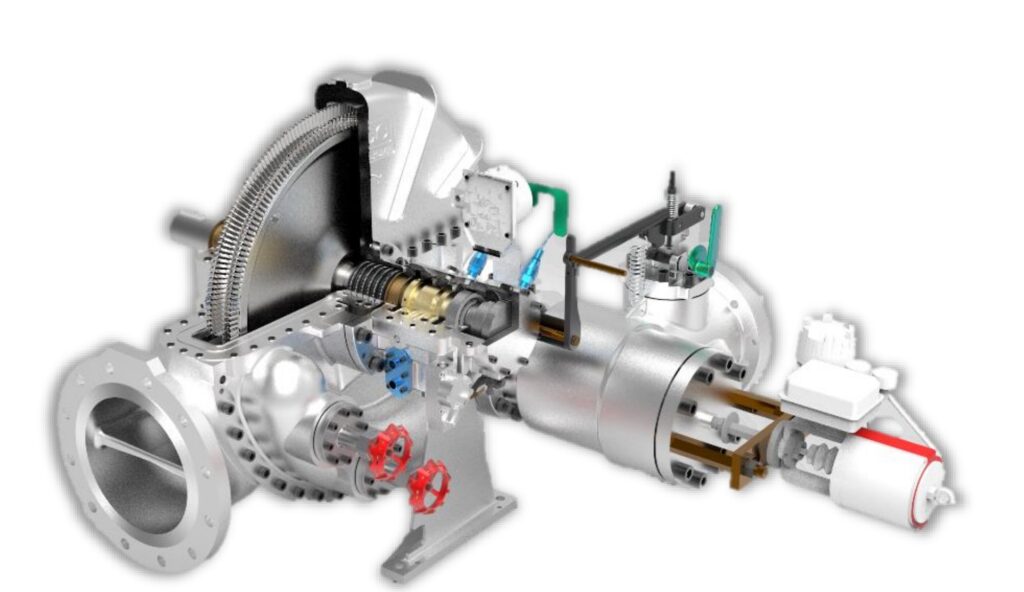

The turbine’s rotor assembly is the heart of the machine. In most small-capacity designs, the rotor consists of either a single-stage impulse wheel or a compact multi-stage reaction configuration. The impulse type uses fixed nozzles to accelerate steam before striking the moving blades, while reaction types allow expansion to continue within the moving blade passages. Both systems demand exact blade geometry, with aerodynamic profiles shaped to optimize steam expansion, reduce losses, and prevent excessive turbulence.

The shaft is precision-machined and dynamically balanced to handle rotational speeds often exceeding 10,000 RPM. To ensure smooth operation and prevent damage, the shaft is mounted in high-grade anti-friction bearings or journal bearings with an oil film. Lubrication is critical — either by a dedicated oil pump or gravity-fed oil rings — to reduce friction, manage heat, and extend bearing life.

The turbine casing is built from cast steel or alloyed materials designed to withstand internal pressures of up to 15 bar in many cases, even if the operating pressure is lower. It is internally shaped to direct steam flow efficiently, minimizing leakage through carefully fitted labyrinth seals.

Operational Performance

A typical 10 HP turbine will consume 70–100 kg of steam per hour under standard conditions, though this depends on steam pressure, temperature, and the expansion ratio. If supplied with superheated steam, output and efficiency improve significantly by reducing condensation losses.

In back-pressure operation, the exhaust steam is often reused in heating processes, making the system part of a Combined Heat and Power (CHP) installation. In condensing mode, the exhaust passes to a condenser, producing low-pressure steam and improving total power output. Condensing mode is favored in electricity generation, while back-pressure mode suits industrial process integration.

Speed control is managed via a mechanical centrifugal governor or an electronic actuator system. For applications like driving an alternator, precise speed control is critical to maintain output frequency stability (50 Hz or 60 Hz). Some compact units integrate electronic PID controllers to keep speed variation within ±0.5%.

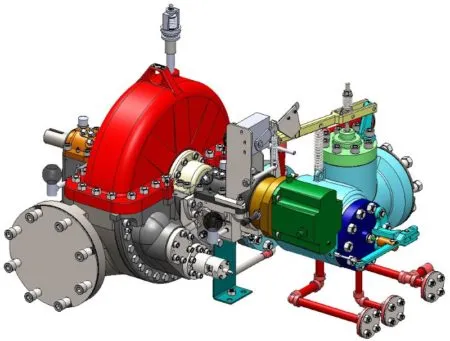

Installation and Integration

Physically, a 10 HP steam turbine occupies a compact footprint, often less than 1.5 meters in length and under 500 kg in total weight, making it feasible to install in small facilities without heavy foundations. However, vibration isolation pads or grouted baseplates are still recommended to maintain alignment and reduce operational noise.

The inlet piping should include steam strainers and control valves to protect the turbine from debris and regulate supply. The exhaust line design depends on the chosen mode (back-pressure or condensing). For condensing operation, a dedicated condenser and cooling water circuit are needed, while back-pressure systems simply connect to the process steam line.

Maintenance Considerations

Although small turbines have fewer moving parts than reciprocating engines, they still demand careful upkeep:

- Weekly: Check lubrication levels, inspect for unusual vibration or noise.

- Monthly: Inspect steam strainers and inlet valves, verify governor function.

- Annually: Open casing (if design allows) to inspect blades for wear, erosion, or deposits.

- Every 3–5 years: Conduct a full overhaul including bearing replacement and dynamic balancing.

Applications and Advantages

This turbine capacity is often ideal for:

- Small factories requiring both mechanical power and process heat.

- Agricultural processing such as rice mills, sugar refineries, or tea drying plants.

- Marine auxiliary power on small vessels.

- Educational demonstration units in engineering colleges.

- Remote micro-grids using locally available biomass boilers for steam production.

Advantages include:

- High reliability with minimal operator intervention.

- Capability to integrate into CHP systems, improving total energy utilization.

- Compact footprint compared to equivalent internal combustion engines.

- Fuel flexibility, since any steam source (wood, coal, biomass, waste heat) can be used.

When paired with an appropriately sized boiler and a well-designed steam distribution system, a 10 HP steam turbine can serve as the backbone of a small but highly efficient energy plant. Its ability to operate continuously for thousands of hours annually without significant performance drop makes it attractive for industries that require steady, round-the-clock power.

7 hp Steam Turbine

A 7 HP steam turbine is a compact power unit designed to deliver approximately 5.22 kW of mechanical output by converting the thermal energy of pressurized steam into rotational energy. While small compared to industrial-scale turbines, this capacity is still highly valuable for specialized, localized, and off-grid applications, especially in industries or facilities where a continuous supply of steam is already available.

General Design and Construction

The turbine’s rotor is typically designed for single-stage impulse or small multi-stage reaction operation, depending on efficiency requirements. In impulse designs, steam expands in stationary nozzles and strikes the moving blades, while reaction types allow expansion to continue within the rotating blade passages, extracting more energy per stage.

The shaft is precision-machined and balanced for high rotational speeds — often between 8,000 and 12,000 RPM — and supported by either journal bearings with oil lubrication or sealed anti-friction bearings for lower maintenance.

The casing is made of durable materials like cast steel or high-grade alloy, designed to withstand the inlet steam pressures that often range from 5 to 12 bar for small units. Labyrinth seals or carbon seals minimize steam leakage, and internal flow paths are shaped to maintain high efficiency.

Operating Parameters

- Power Output: ~7 HP (≈5.22 kW) mechanical

- Steam Consumption: Typically 50–70 kg/hour depending on inlet pressure, temperature, and expansion ratio

- Steam Supply: Saturated or superheated steam; superheated steam improves output and blade longevity

- Speed Regulation: Achieved through a mechanical centrifugal governor or electronic actuator, keeping variations within ±1% for generator use

- Exhaust Mode: Can be back-pressure (supplying steam for process use) or condensing (using a condenser to improve expansion and output)

Applications

Despite its small size, a 7 HP steam turbine can be put to highly productive use in:

- Small workshops and factories for driving pumps, fans, or compressors

- Rural or remote power generation when coupled to a small electric generator (micro-grid applications)

- Educational and research setups for steam power demonstrations

- Agricultural processing (e.g., small rice mills, tea drying plants, sugarcane juice extraction) where both heat and power are needed

- Marine auxiliary drives in small vessels

Advantages of a 7 HP Unit

- Compact Footprint: Can be installed in areas with limited space, often on a small skid-mounted base

- Fuel Flexibility: Operates from steam produced by biomass, coal, wood, or waste-heat boilers

- Low Maintenance: Fewer moving parts compared to reciprocating steam engines

- Dual-Use Capability: In back-pressure mode, delivers both mechanical power and usable steam for heating or processing

- Continuous Operation: Can run for thousands of hours annually with minimal downtime if steam supply is stable

Maintenance and Reliability

For reliable long-term operation:

- Daily/Weekly: Check lubrication oil levels, monitor vibration, and listen for unusual noises

- Monthly: Inspect steam strainers, inlet control valves, and verify governor response

- Annually: Inspect blades and seals for wear or erosion; clean deposits if necessary

- 3–5 Years: Overhaul bearings and perform dynamic balancing of the rotor

In a well-maintained setup, a 7 HP steam turbine offers a steady and reliable power source where grid supply is unavailable, unstable, or where combined heat and power (CHP) use makes it far more efficient than separate systems.

A 7 HP steam turbine is a highly compact and precise engineering machine capable of delivering approximately 5.22 kW of mechanical power. Despite its small output, it exemplifies the same core principles of thermodynamic efficiency, mechanical precision, and material durability found in much larger industrial steam turbines. Its small footprint and low power rating make it ideal for localized applications, particularly in facilities that already generate steam or in small-scale micro-generation setups. These turbines are often employed in situations where both mechanical power and residual heat can be utilized effectively, enhancing overall energy efficiency.

Operational Principles

The turbine operates on the Rankine cycle, converting the thermal energy of pressurized steam into mechanical rotational energy. Steam, produced by a small industrial boiler, enters the turbine at pressures typically between 4 and 12 bar, depending on the design. The steam can be saturated or slightly superheated; superheating is preferred to minimize condensation on the blades, which prevents erosion and improves efficiency.

Once the steam enters the turbine, it passes through nozzles, which accelerate it to a high velocity and direct it onto the rotor blades. In single-stage impulse turbines, the steam expands mainly in the nozzle and strikes the blades, whereas in multi-stage reaction turbines, expansion continues across several sets of moving and stationary blades, allowing more energy extraction and higher efficiency. The rotating blades transfer energy to the shaft, which can drive mechanical equipment or be coupled to a small generator for electricity production.

Mechanical Design

Even at a small scale, the design of a 7 HP turbine requires careful attention to materials and tolerances:

- Rotor and blades are machined from high-strength alloys capable of resisting thermal stress, corrosion, and erosion.

- Bearings support the rotor at high speeds, often above 8,000 RPM, and use either oil-lubricated journal bearings or sealed rolling-element bearings.

- Casing is made from cast steel or alloyed materials to safely contain the pressurized steam while minimizing leakage and vibration.

- Seals and labyrinths ensure efficient steam passage through the turbine and prevent energy losses.

The turbine may include a governor system, either mechanical or electronic, to maintain constant rotational speed under varying loads. This is crucial when driving a generator to produce stable electricity or operating sensitive machinery that requires precise speed control. Advanced small turbines may also include digital monitoring of vibration, temperature, steam pressure, and lubrication conditions, which allows for predictive maintenance and extended equipment life.

Exhaust and Heat Recovery

The 7 HP turbine can operate in back-pressure mode, where the exhaust steam still retains sufficient pressure for process heating, drying, or other industrial applications. Alternatively, in condensing mode, the turbine exhaust passes through a condenser, lowering the back pressure and improving mechanical efficiency. In CHP applications, this flexibility allows small facilities to harness both power and usable heat, significantly increasing overall energy utilization and reducing fuel consumption.

Efficiency and Steam Management

Efficiency in small turbines depends on several factors:

- Steam dryness: Minimizing moisture prevents blade erosion and improves conversion efficiency.

- Blade and nozzle design: Optimized aerodynamic shapes maximize energy transfer from steam to rotor.

- Lubrication and bearing maintenance: Proper lubrication reduces friction losses.

- Steam quality control: Proper boiler treatment prevents scaling, corrosion, and fouling.

A 7 HP turbine consumes roughly 35–60 kg of steam per hour, depending on inlet conditions and load. The combination of low steam consumption and reliable mechanical output makes it suitable for long-duration operations, often running for thousands of hours annually with minimal downtime.

Applications

Despite its modest power, a 7 HP turbine can be applied effectively in:

- Small industrial workshops for driving pumps, fans, or compressors.

- Remote micro-generation units, providing electricity where grid access is unavailable.

- Agricultural and food-processing applications, such as small rice mills, sugarcane processing, tea or coffee drying, and small-scale brewing.

- Marine auxiliary power for small vessels.

- Educational or research facilities demonstrating steam turbine principles and performance.

Maintenance and Reliability

Maintenance is simpler than for larger turbines but remains essential:

- Daily/weekly checks: Monitor lubrication, vibration, and unusual noises.

- Monthly: Inspect valves, strainers, and governor function.

- Annually: Inspect blades, nozzles, and seals for wear or erosion.

- 3–5 years: Conduct a full rotor balancing and bearing replacement if needed.

A 7 HP steam turbine demonstrates how small-scale energy conversion can be both efficient and reliable. Its compact design, dual-purpose capability for mechanical power and heat recovery, and long operational lifespan make it an ideal choice for facilities needing localized energy solutions. It provides a cost-effective, durable, and flexible option for industries and facilities that require dependable energy in limited capacities.

A 7 HP steam turbine represents one of the smallest practical capacities in the spectrum of steam-driven power machinery, yet it demonstrates the same core principles of thermodynamic conversion, mechanical design, and operational control as much larger industrial turbines. Producing roughly 5.22 kW of continuous mechanical power, these turbines are ideal for applications where a small, reliable, and efficient energy source is required. The compact size makes them suitable for workshops, small-scale industrial facilities, remote or off-grid power systems, educational institutions, and pilot or research plants where both mechanical power and thermal energy recovery can be utilized effectively.

Steam Supply and Thermodynamics

The turbine operates on the Rankine cycle, using pressurized steam to perform work. Steam is supplied from a small industrial boiler, with typical pressures in the range of 4–12 bar and temperatures that may include slight superheating to reduce condensation on the blades. Dry or superheated steam ensures efficient energy conversion and minimizes blade erosion, a key factor in long-term reliability.

Upon entering the turbine, the steam passes through precision-engineered nozzles, which accelerate it into high-velocity jets. These jets impact the rotor blades, causing the shaft to spin. In single-stage impulse designs, energy extraction occurs primarily in one step, while in small multi-stage reaction turbines, the steam expands across multiple blade stages, extracting energy gradually and achieving higher efficiency. The rotational energy can then drive mechanical equipment directly or be coupled to a generator for electricity production.

Mechanical and Structural Design

Even at a small capacity, careful attention is given to mechanical and material design:

- Rotor and blades: Made from high-strength, corrosion-resistant alloys to withstand thermal cycling, steam moisture, and erosion. Blade profiles are carefully shaped for optimal aerodynamic efficiency.

- Shaft and bearings: The rotor is mounted on precision bearings — either journal or sealed anti-friction types — lubricated to minimize friction and allow high-speed operation, often between 8,000 and 12,000 RPM.

- Casing and seals: The turbine casing, fabricated from cast steel or alloyed metals, contains pressurized steam safely while guiding it efficiently through the blades. Labyrinth or carbon seals minimize leakage and maximize performance.

- Governor and control system: Steam flow is regulated to maintain consistent rotor speed under varying loads. Modern turbines may incorporate electronic or digital monitoring systems for speed, vibration, temperature, and lubrication, enabling predictive maintenance.

Exhaust Management and Heat Recovery

The 7 HP turbine can operate in back-pressure mode, where exhaust steam retains sufficient energy for process heating, drying, or other industrial uses. This makes it ideal for Combined Heat and Power (CHP) applications, where the turbine produces mechanical power while providing usable steam for heating, thereby maximizing overall system efficiency. Alternatively, in condensing mode, the exhaust steam is routed through a condenser to reduce back pressure and improve mechanical efficiency, typically for small-scale electricity generation.

Performance and Efficiency

A 7 HP turbine typically consumes 35–60 kg of steam per hour, depending on inlet pressure, temperature, and turbine design. Efficiency can vary, but careful management of steam dryness, blade geometry, nozzle design, and lubrication ensures reliable energy conversion. Superheated steam improves performance and prolongs blade life by preventing condensation-induced erosion. Multi-stage designs, where present, allow more gradual energy extraction and higher total efficiency compared to single-stage units.

Applications

Despite its small size, a 7 HP turbine is versatile:

- Small industrial workshops: Driving pumps, fans, and compressors.

- Agricultural and food processing: Small-scale rice mills, tea or coffee drying, sugarcane juice extraction, and small breweries.

- Remote power generation: Coupled with micro-generators for electricity in off-grid or rural areas.

- Marine auxiliary drives: For small vessels needing reliable, compact power.

- Educational and research facilities: Demonstration of thermodynamic and mechanical principles in practice.

Maintenance and Reliability

Maintenance is straightforward but essential:

- Daily/weekly: Monitor lubrication, vibration, and general turbine operation.

- Monthly: Inspect strainers, inlet valves, and governor response.

- Annually: Inspect blades, nozzles, and seals for wear, erosion, or deposits.

- Every 3–5 years: Overhaul bearings and perform dynamic balancing if required.

A 7 HP turbine, when properly installed and maintained, can operate continuously for thousands of hours per year, providing a reliable and efficient source of mechanical power. Its combination of compactness, dual-purpose capability, low maintenance, and fuel flexibility makes it a highly practical solution for localized energy needs, particularly where both power and thermal energy can be utilized.

Integration and Installation Considerations

The small footprint of a 7 HP turbine allows installation on a skid-mounted base with minimal foundation work. Steam inlet piping should include strain filters, control valves, and pressure gauges, while the exhaust line design depends on whether back-pressure or condensing operation is used. Vibration isolation pads or grouted bases improve alignment and operational stability. Coupling to mechanical loads or small generators must account for alignment, speed matching, and torque requirements to ensure efficient energy transfer.

In summary, a 7 HP steam turbine combines robust engineering, compact design, and thermodynamic efficiency in a package suitable for small-scale industrial, agricultural, marine, and educational applications. Its ability to generate both mechanical power and usable heat, along with its longevity and reliability, make it a practical and cost-effective solution for facilities with limited energy needs or access to steam resources.

I can continue by creating a complete engineering-style specification sheet for the 7 HP steam turbine, including steam consumption curves, generator coupling details, dimensional layouts, and expected efficiency graphs, making it a full technical reference suitable for engineering, procurement, or operational planning.

5 hp Steam Turbine

A 5 HP steam turbine is one of the smallest practical steam turbines designed to deliver roughly 3.73 kW of mechanical power. Despite its modest output, it embodies the same fundamental principles of thermodynamics, mechanical engineering, and precision design as larger turbines, making it suitable for localized, small-scale industrial, educational, or micro-generation applications. These turbines are compact, efficient, and versatile, often used where both mechanical power and residual steam heat can be harnessed.

Operational Principles

The 5 HP turbine operates on the Rankine cycle, converting thermal energy from pressurized steam into rotational mechanical energy. Steam is supplied by a small boiler, typically at pressures ranging from 3 to 10 bar, and can be saturated or slightly superheated to reduce condensation and improve efficiency.

The steam enters the turbine through precision-engineered nozzles, which accelerate it into high-velocity jets that strike the rotor blades. In single-stage impulse designs, energy extraction occurs primarily in one step, while in multi-stage reaction designs, steam expands over multiple blade stages, increasing energy extraction and efficiency. The rotor transmits the mechanical energy to a shaft, which can drive small machinery, pumps, compressors, or be coupled to a generator for electricity production.

Mechanical and Structural Design

Even at 5 HP, design precision is critical:

- Rotor and blades: Made from high-strength alloys to withstand thermal stress, erosion, and corrosion. Blade shapes are optimized for aerodynamic efficiency.

- Bearings and shaft: The rotor is supported by journal or rolling-element bearings, often oil-lubricated, enabling high-speed operation, usually between 6,000 and 10,000 RPM.

- Casing and seals: Cast steel or alloy casings contain steam safely, guide flow efficiently, and minimize leakage using labyrinth or carbon seals.

- Governor system: Regulates steam flow to maintain constant rotor speed under varying loads, ensuring stable mechanical or electrical output. Some modern small turbines include digital monitoring of temperature, pressure, vibration, and lubrication.

Exhaust and Heat Recovery

The turbine can operate in back-pressure mode, where exhaust steam still retains sufficient energy for heating, drying, or industrial processes, making it suitable for CHP applications. Alternatively, in condensing mode, the exhaust passes through a condenser to reduce back pressure, improving mechanical efficiency for electricity generation.

Performance and Efficiency

Typical steam consumption for a 5 HP turbine is around 25–50 kg/hour, depending on steam pressure, temperature, and design. Efficiency depends on:

- Steam dryness to prevent blade erosion

- Optimized blade and nozzle geometry

- Proper lubrication and bearing maintenance

- Steam quality from the boiler to avoid scaling or corrosion

Although small, this turbine is capable of continuous operation for thousands of hours annually if steam supply and maintenance are consistent.

Applications

Despite its small size, a 5 HP turbine is versatile:

- Small industrial workshops: Driving pumps, fans, or compressors

- Agricultural processing: Small mills, drying plants, or juice extraction

- Micro-generation and off-grid power: Small electricity production from locally generated steam

- Marine auxiliary drives: For small vessels requiring reliable, compact power

- Educational and research: Demonstrating steam turbine principles and performance

Maintenance and Reliability

Regular maintenance ensures long-term reliability:

- Daily/weekly: Monitor lubrication, vibration, and operational noise

- Monthly: Check strainers, valves, and governor response

- Annually: Inspect blades, nozzles, and seals

- Every 3–5 years: Perform full rotor balancing and bearing replacement as needed

Integration and Installation

A 5 HP turbine has a small footprint, making it easy to install on a compact base with minimal foundation requirements. Steam inlet piping should include strainers, control valves, and pressure gauges. Exhaust piping depends on operational mode (back-pressure or condensing). Vibration isolation is recommended, and couplings must be matched carefully to the driven equipment or generator.

Advantages

- Compact and versatile for limited space installations

- Can utilize various steam sources (biomass, coal, wood, or waste heat)

- Dual-use capability for mechanical power and heat recovery

- Low maintenance requirements compared to reciprocating engines

- Long operational lifespan with proper care

Even at 5 HP, these turbines are efficient, durable, and capable of providing reliable energy solutions for small-scale industrial, agricultural, marine, or educational applications.

A 5 HP steam turbine is a small yet sophisticated power generation machine, capable of delivering roughly 3.73 kW of mechanical output from pressurized steam. Despite its modest size, it represents the same fundamental engineering principles as larger industrial turbines, including precise thermodynamic design, material selection, rotor dynamics, and flow optimization. These turbines are ideal for localized applications, where both mechanical power and residual steam heat can be utilized efficiently, such as in small industrial workshops, agricultural processing plants, remote or off-grid facilities, marine auxiliary systems, and educational or research institutions.

Steam Supply and Thermodynamics

The turbine operates on the Rankine cycle, converting thermal energy from steam into mechanical rotation. Steam is generated in a small industrial boiler, typically operating at pressures between 3 and 10 bar, with optional superheating to reduce moisture content and prevent blade erosion. Dry steam ensures high efficiency and prolongs the life of the turbine’s moving components.