Waste Heat Recovery Systems: Waste Heat to Energy is a process that captures waste heat from industrial processes, power plants, and other heat-generating systems to produce useful energy, typically in the form of electricity or mechanical work. This approach improves overall efficiency, reduces fuel consumption, and lowers greenhouse gas emissions.

1. Sources of Waste Heat

Waste heat is generated in various industrial and commercial processes, including:

- Industrial Processes: Steel mills, cement plants, glass manufacturing, and refineries.

- Power Plants: Gas turbines, steam turbines, and diesel generators.

- Exhaust Gases: From internal combustion engines, furnaces, and incinerators.

- Cooling Systems: Heat rejection from air compressors, chillers, and refrigeration units.

2. Waste Heat Recovery Technologies

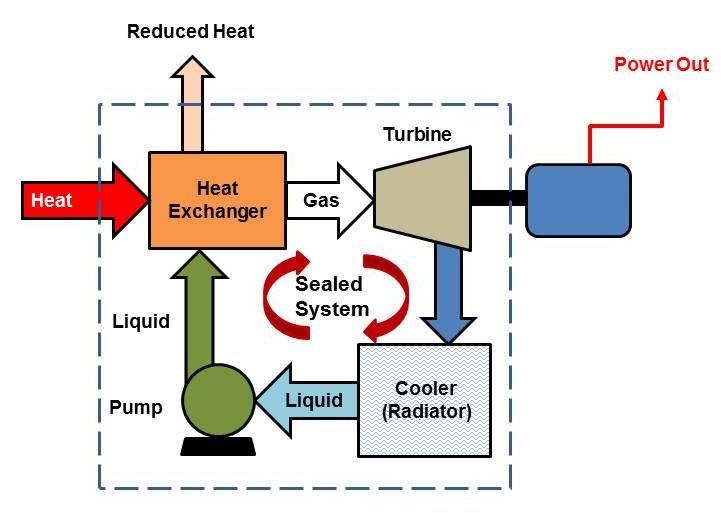

A. Heat-to-Power Conversion Technologies

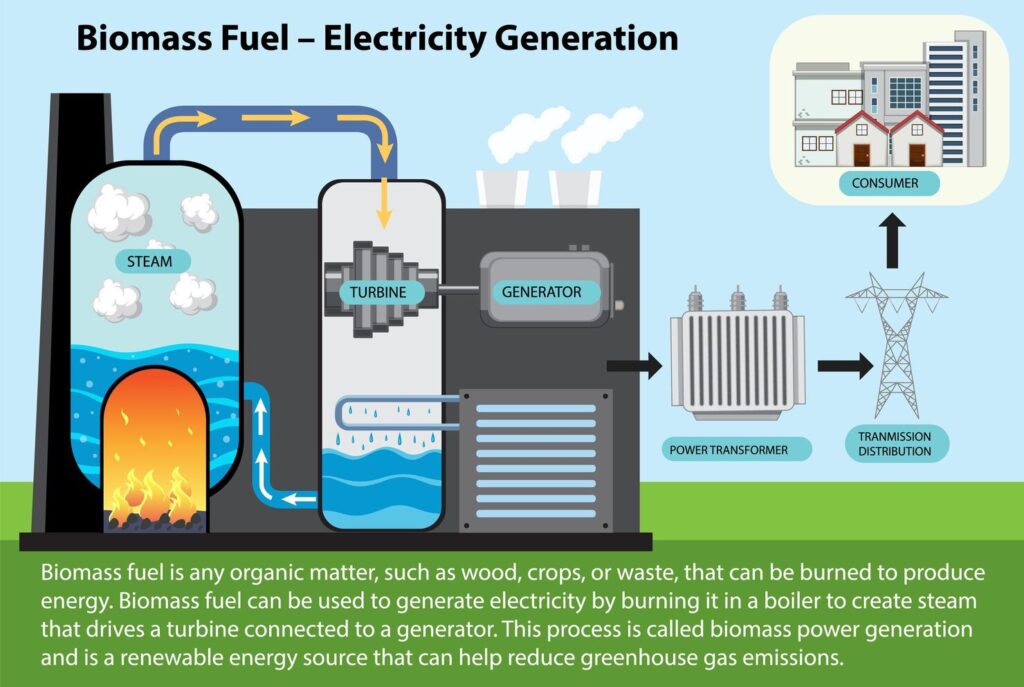

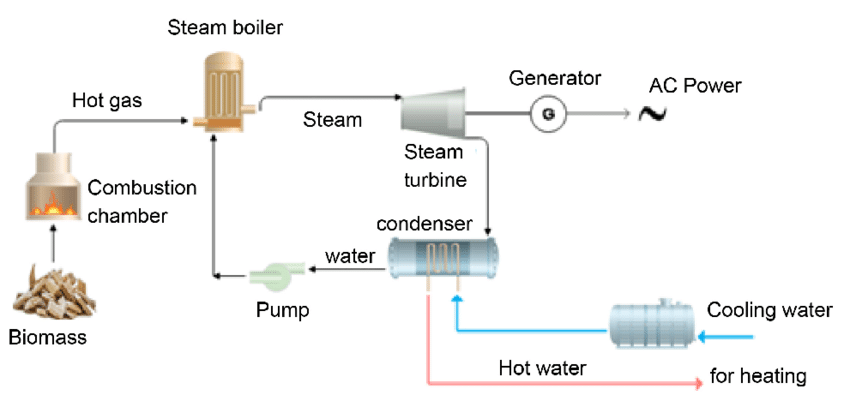

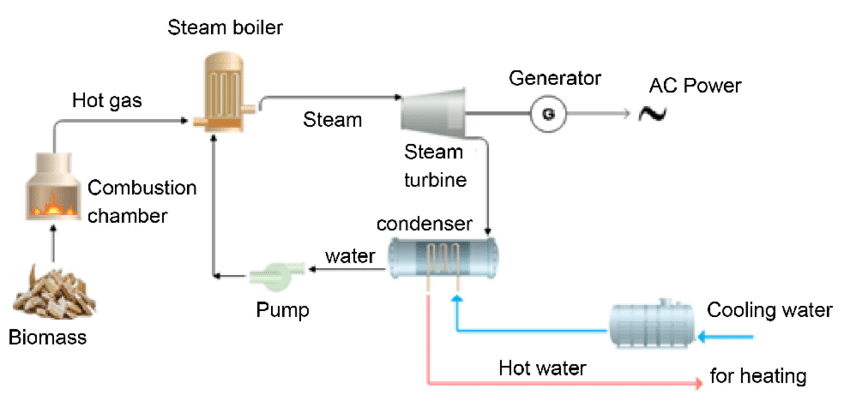

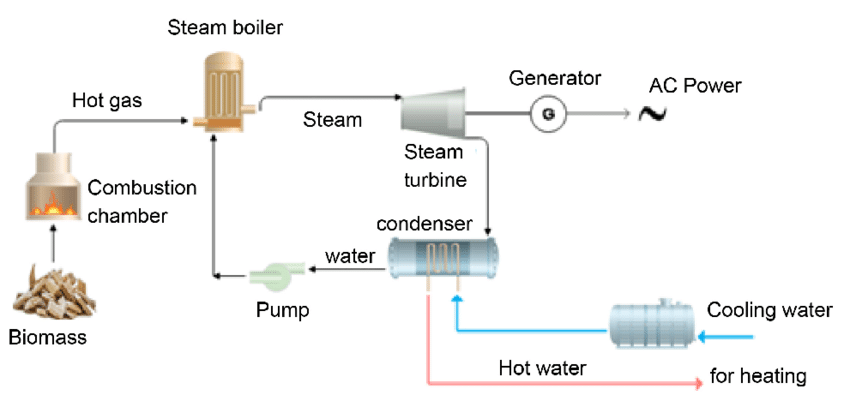

- Steam Rankine Cycle (SRC)

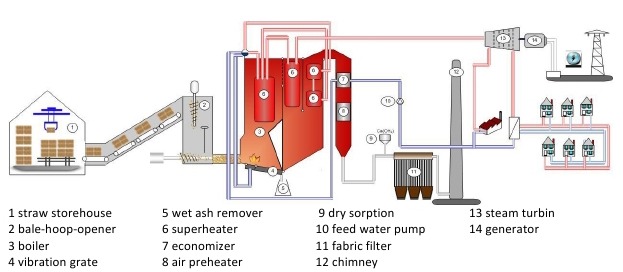

- Uses waste heat to generate steam, which drives a steam turbine to produce electricity.

- Best suited for high-temperature waste heat (>300°C).

- Organic Rankine Cycle (ORC)

- Uses an organic fluid with a lower boiling point than water, allowing waste heat recovery from medium- and low-temperature sources (80°C–300°C).

- Ideal for industrial processes and geothermal applications.

- Kalina Cycle

- Uses an ammonia-water mixture to enhance efficiency in recovering low- and medium-temperature waste heat.

- More efficient than ORC in certain conditions but has higher operational complexity.

- Thermoelectric Generators (TEGs)

- Convert heat directly into electricity using the Seebeck effect.

- Suitable for small-scale applications with low-grade waste heat (below 200°C).

B. Waste Heat Recovery Systems

- Heat Exchangers

- Transfer heat from exhaust gases or process fluids to another medium.

- Used in recuperators, regenerators, economizers, and heat recovery steam generators (HRSG).

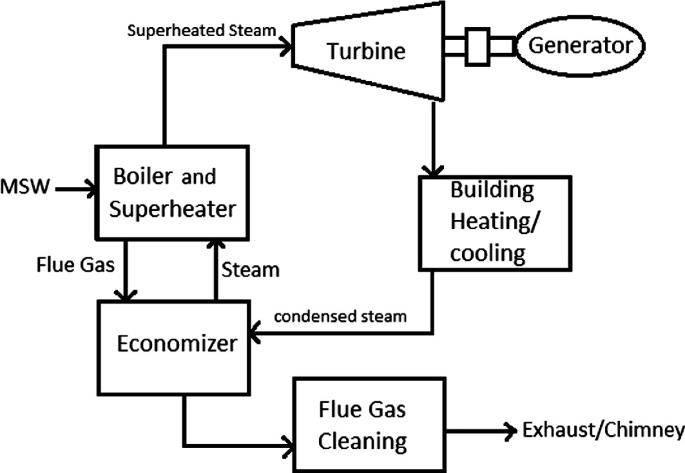

- Waste Heat Boilers

- Convert exhaust heat into steam, which can be used for power generation or industrial heating.

- Common in combined heat and power (CHP) systems.

- Absorption Chillers

- Use waste heat to drive cooling processes, reducing the need for electrical cooling.

- Suitable for district cooling and HVAC applications.

- Regenerative Thermal Oxidizers (RTOs)

- Capture heat from combustion processes and reuse it to preheat incoming gases.

3. Benefits of Waste Heat Recovery

✔ Improved Energy Efficiency – Reduces fuel consumption and operational costs.

✔ Lower Greenhouse Gas Emissions – Reduces reliance on fossil fuels, helping to meet environmental regulations.

✔ Cost Savings – Reduces energy bills and increases overall process efficiency.

✔ Enhanced Sustainability – Supports circular economy principles by utilizing existing energy streams.

4. Challenges and Considerations

- Capital Investment: Initial installation costs can be high.

- System Complexity: Requires careful integration into existing processes.

- Waste Heat Temperature & Quality: Not all waste heat is easily recoverable.

- Maintenance & Reliability: Some technologies require regular upkeep.

5. Applications and Industries

✔ Manufacturing & Heavy Industry – Steel, cement, glass, and chemical plants.

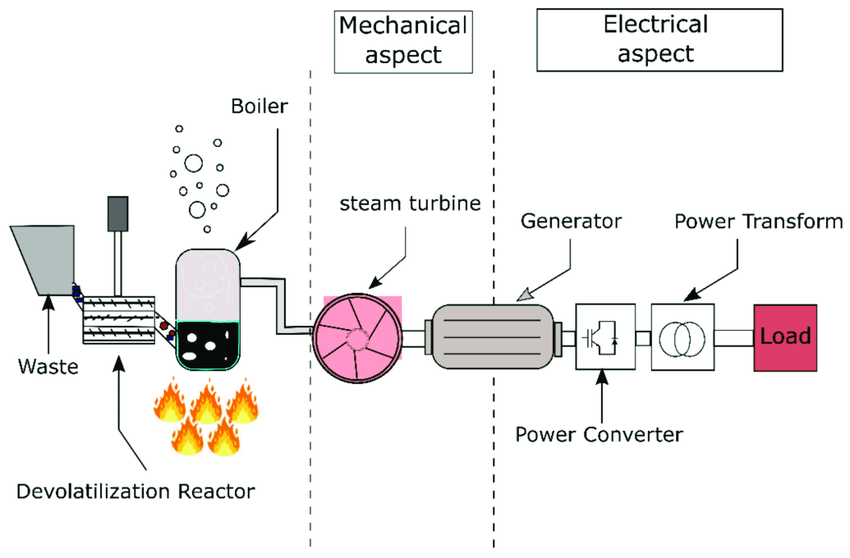

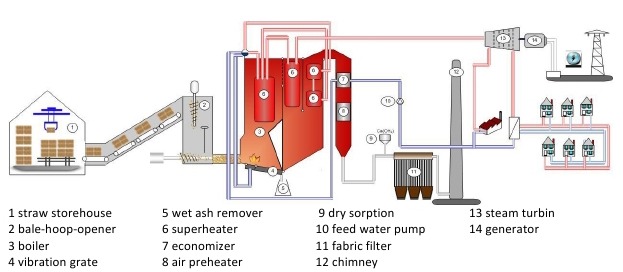

✔ Power Generation – Coal, gas, and biomass power plants.

✔ Oil & Gas – Refineries and natural gas processing.

✔ Transportation – Waste heat recovery in diesel engines and ships.

✔ Data Centers – Reuse of server-generated heat for district heating.

Sources of waste heat include industrial processes such as steel mills, cement plants, glass manufacturing, and refineries; power plants utilizing gas turbines, steam turbines, and diesel generators; exhaust gases from internal combustion engines, furnaces, and incinerators; and cooling systems that reject heat from air compressors, chillers, and refrigeration units.

Waste heat is generated from various industrial, commercial, and power generation processes where energy is not fully utilized and is instead lost to the environment. One of the primary sources of waste heat is industrial processes, including steel mills, cement plants, glass manufacturing, and refineries. These industries involve high-temperature operations where significant amounts of heat are expelled through exhaust gases, cooling water, and direct radiation from hot surfaces. The steel industry, for example, releases substantial heat through blast furnace slag, hot rolling mills, and coke ovens, while cement production emits waste heat from clinker cooling and rotary kilns. Similarly, in glass manufacturing, melting and forming processes generate large quantities of excess heat that can be captured and repurposed.

Another major source of waste heat is power plants, which utilize gas turbines, steam turbines, and diesel generators. In conventional thermal power plants, a significant portion of the fuel energy is lost in exhaust gases and cooling systems. Combined cycle power plants improve efficiency by using a gas turbine’s exhaust heat to generate steam and drive a secondary steam turbine, but even these systems still produce residual waste heat. Similarly, diesel generators, commonly used in remote locations and backup power applications, release high-temperature exhaust gases that can be recovered for useful energy generation.

Transportation and internal combustion engines are also significant contributors to waste heat. Automobiles, trucks, ships, and aircraft lose a substantial portion of their fuel energy as heat through engine exhaust and cooling systems. Modern advancements, such as turbochargers and thermoelectric generators, aim to capture and repurpose some of this waste heat for improved efficiency. Marine vessels, especially large cargo ships and naval fleets, produce waste heat from massive diesel engines, which can be recovered using heat exchangers and organic Rankine cycle systems.

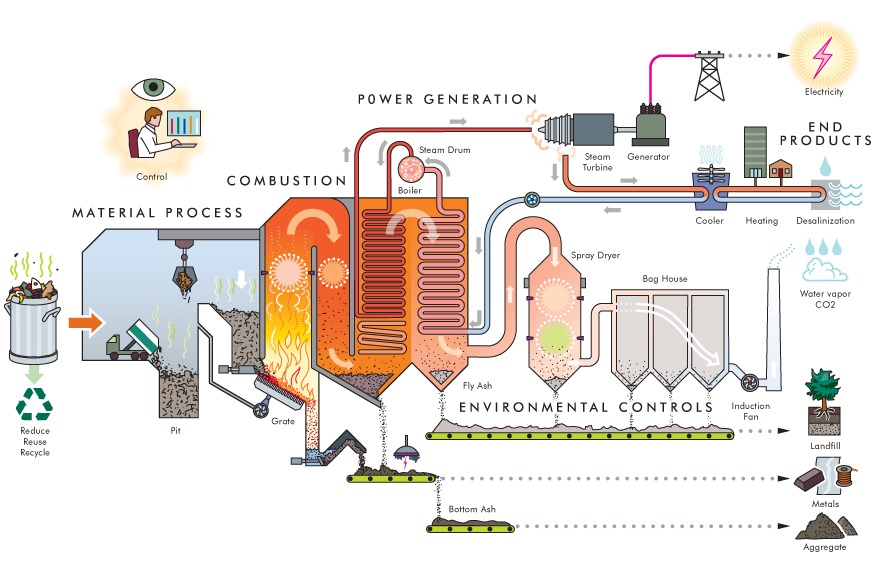

Industrial furnaces, boilers, and incinerators also expel high-temperature exhaust gases that carry significant energy potential. These systems are widely used in various sectors, including food processing, pulp and paper production, and waste management. In incineration plants, municipal solid waste and hazardous materials are burned to generate energy, but a considerable fraction of the heat is still lost if not properly recovered.

Cooling and refrigeration systems represent another important category of waste heat sources. Air compressors, chillers, and HVAC systems generate excess heat that is typically dissipated into the surrounding environment. Data centers, which require extensive cooling to maintain optimal operating conditions for servers, produce substantial waste heat that can be redirected for space heating or absorption cooling.

In addition to these sources, renewable energy systems such as geothermal and solar thermal plants also experience waste heat losses. Geothermal power plants extract hot fluids from beneath the Earth’s surface, but not all the heat is converted into electricity, leading to thermal discharge. Similarly, concentrated solar power (CSP) plants, which use mirrors to focus sunlight and generate steam, lose a portion of their collected heat through system inefficiencies.

Overall, waste heat is an unavoidable byproduct of energy-intensive processes, but with the right technologies and strategies, it can be captured and converted into useful energy, improving efficiency and sustainability across various industries.

Waste heat from industrial processes is one of the most significant untapped energy resources, with immense potential for recovery and utilization. Industrial facilities, including steel mills, cement plants, glass manufacturing, and oil refineries, operate at high temperatures and often release large amounts of heat into the environment through exhaust gases, cooling water, and hot surfaces. This waste heat, if properly harnessed, can be repurposed for electricity generation, process heating, or even district heating systems, significantly improving overall energy efficiency.

Steel Industry

The steel industry is one of the largest producers of waste heat due to the extreme temperatures required in smelting, refining, and shaping processes. Key sources of waste heat in steel plants include blast furnace gas, basic oxygen furnaces, electric arc furnaces, reheating furnaces, coke ovens, and hot rolling mills. Blast furnaces, which are used to reduce iron ore into molten iron, emit high-temperature off-gases that contain significant amounts of thermal energy. This heat can be recovered using heat exchangers or gas expansion turbines to produce electricity or preheat raw materials. Similarly, coke ovens release hot gases during the carbonization of coal, which can be utilized for steam generation or power production.

Hot rolling mills, used to shape steel into sheets, rods, and other forms, generate a significant amount of waste heat through the cooling of hot steel. The water or air used for cooling absorbs heat that is often dissipated without recovery. By implementing recuperative heat exchangers, this energy can be used for preheating incoming steel slabs, reducing fuel consumption.

Cement Industry

Cement manufacturing is another energy-intensive process that generates large quantities of waste heat, primarily from rotary kilns and clinker coolers. Rotary kilns operate at extremely high temperatures to convert raw materials into clinker, the key ingredient in cement. A substantial amount of heat is lost through the kiln exhaust gases and the hot clinker as it exits the kiln. Waste heat recovery (WHR) systems, such as waste heat boilers and organic Rankine cycle (ORC) systems, can capture this heat and convert it into electricity, reducing reliance on external power sources. In modern cement plants, WHR systems can recover up to 30% of the total heat input, significantly improving efficiency and lowering carbon emissions.

Glass Manufacturing

The glass industry also operates at high temperatures, primarily during the melting and forming processes. Glass furnaces require continuous heating to maintain the molten state of raw materials, and a significant portion of the heat is lost through exhaust gases and radiant heat. Recuperators and regenerators are commonly used in glass manufacturing to capture and reuse waste heat, preheating combustion air or raw materials to reduce energy consumption.

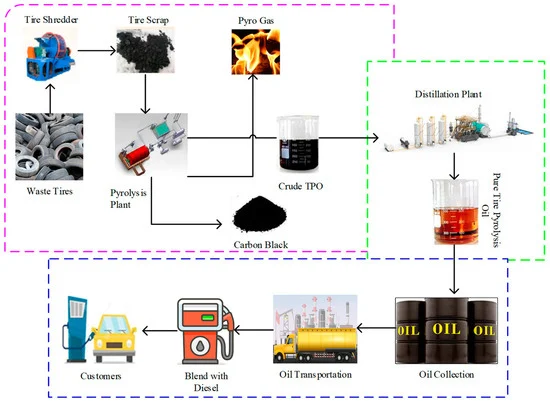

Oil Refineries

Oil refineries, which process crude oil into fuels and chemicals, generate considerable waste heat from distillation columns, cracking units, and heat exchangers. Process heaters, used for refining crude oil, produce high-temperature flue gases that often go unrecovered. Implementing heat recovery systems, such as waste heat boilers or cogeneration units, allows refineries to capture this energy and generate steam or electricity for internal use. Additionally, flare gas recovery systems can reduce heat losses by utilizing excess gas that would otherwise be burned off.

By integrating advanced heat recovery technologies in these industries, significant energy savings can be achieved, reducing operating costs and minimizing environmental impact. As industries continue to seek ways to improve energy efficiency, waste heat recovery will play a crucial role in sustainable manufacturing and energy management.

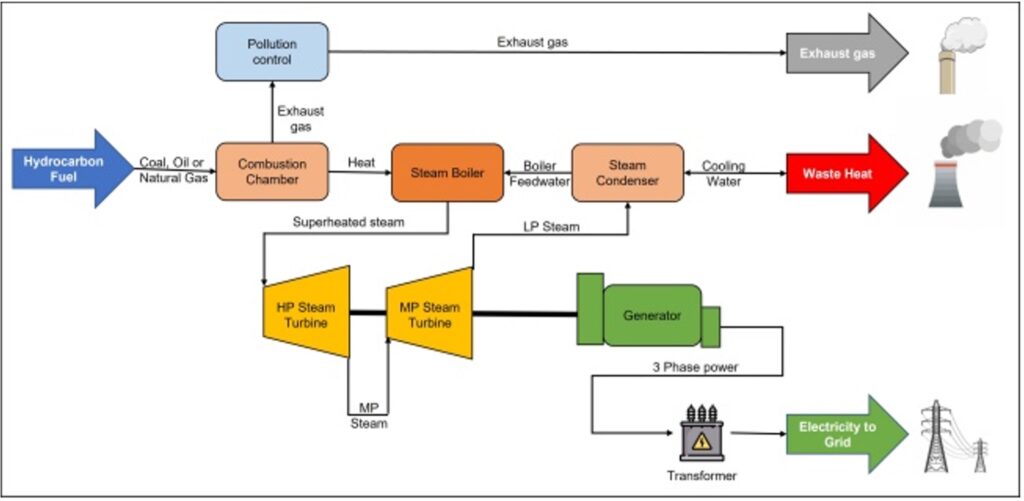

Power Plants as a Source of Waste Heat

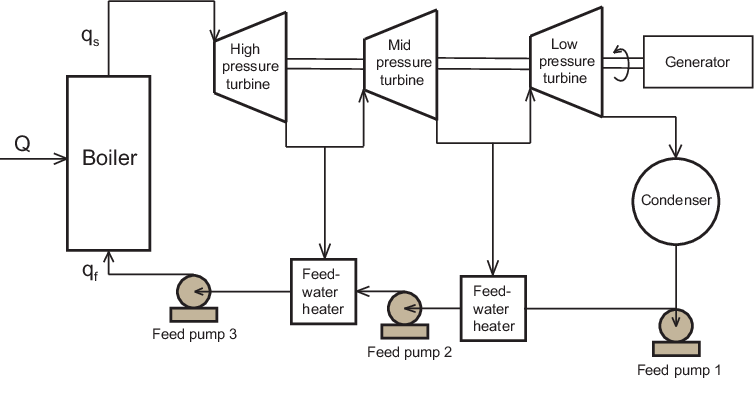

Power plants are among the largest producers of waste heat due to the inefficiencies inherent in electricity generation. Traditional thermal power plants, including coal-fired, natural gas, and nuclear plants, operate based on the Rankine cycle, where fuel is burned to heat water, producing steam that drives a turbine. However, a significant portion of the energy is lost as waste heat, either through exhaust gases, cooling towers, or discharged water. Even in more advanced combined-cycle power plants, which improve efficiency by using a secondary steam cycle, there is still residual waste heat that can be recovered for beneficial use.

Coal and Gas-Fired Power Plants

Conventional fossil fuel power plants typically operate at efficiency levels between 30% and 45%, meaning that more than half of the energy from fuel combustion is lost as heat. The primary sources of waste heat in these plants include:

- Flue Gas Exhaust – High-temperature combustion gases, often exceeding 500°C, are expelled from boilers and gas turbines. Heat recovery steam generators (HRSG) can capture this energy to generate additional steam for power production.

- Condenser Cooling Water – After steam passes through the turbine, it is condensed back into water using cooling towers or water bodies, leading to heat dissipation into the atmosphere or surrounding environment. District heating systems and industrial heat exchangers can recover some of this waste heat for heating applications.

- Turbine and Boiler Surface Radiation – Equipment surfaces radiate heat into the surrounding environment, contributing to thermal losses. Insulation and heat recapture technologies can minimize these losses.

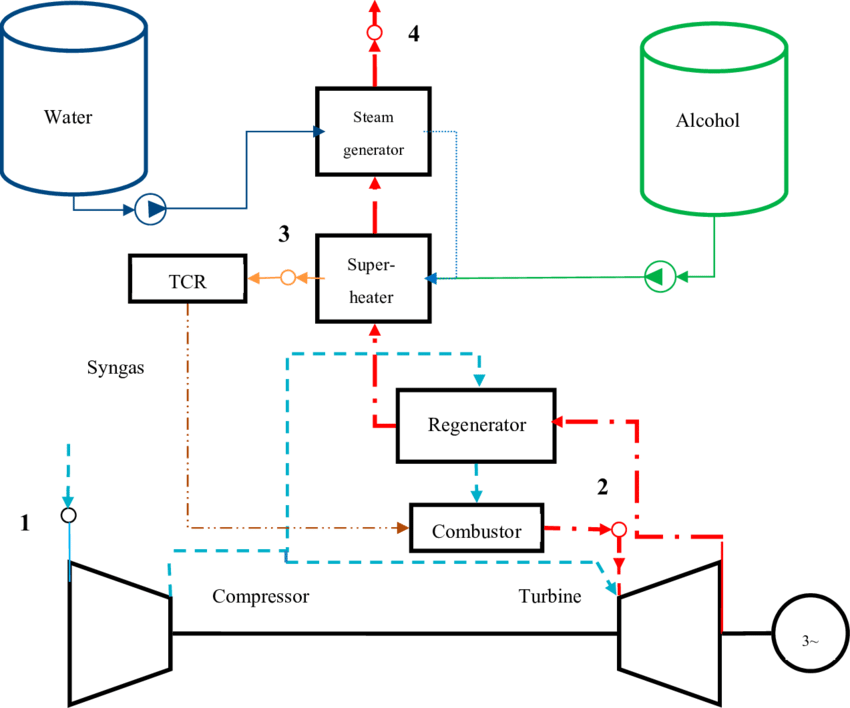

Combined-Cycle Power Plants (CCPPs)

Combined-cycle plants, which integrate a gas turbine with a steam turbine, achieve higher efficiencies (50%–60%) by using exhaust heat from the gas turbine to generate steam for an additional power cycle. However, even these plants still experience waste heat losses, particularly in the final stages of energy conversion. Waste heat from CCPPs can be further utilized in industrial cogeneration (combined heat and power, CHP) systems to provide steam for industrial processes, district heating, or desalination plants.

Nuclear Power Plants

Nuclear plants operate with similar thermodynamic limitations as fossil fuel power plants, with efficiency levels typically around 33%, meaning that nearly two-thirds of the thermal energy produced in nuclear reactions is lost as waste heat. Most of this heat is discharged through cooling towers or directly into nearby water bodies. Advanced heat recovery systems, such as high-temperature reactors and cogeneration applications, aim to harness nuclear waste heat for district heating, hydrogen production, or industrial applications.

Diesel and Gas Generators

Smaller-scale power generation units, such as diesel and natural gas generators used in remote locations, data centers, and backup power systems, also produce considerable waste heat. These engines typically convert only 30%–40% of the fuel’s energy into useful work, with the rest dissipated as exhaust gas and engine cooling losses. Waste heat recovery units (WHRUs) can be installed to capture heat from generator exhaust and engine cooling systems, converting it into electricity via an Organic Rankine Cycle (ORC) or using it for process heating.

Potential Applications for Power Plant Waste Heat

Waste heat from power plants can be effectively utilized in various ways:

- District Heating Systems – Capturing waste heat for residential and commercial heating can significantly reduce fuel consumption and emissions.

- Industrial Steam and Process Heating – Industries that require high-temperature steam, such as chemical plants, can benefit from power plant waste heat.

- Desalination – Thermal desalination processes, such as multi-stage flash (MSF) and multi-effect distillation (MED), can use waste heat to produce fresh water.

- Greenhouses and Agriculture – Waste heat can provide controlled heating for greenhouses, improving food production efficiency.

- Absorption Cooling – Waste heat can be used in absorption refrigeration systems to provide cooling, reducing electricity demand for air conditioning.

As global energy demands increase, improving the efficiency of power generation and utilizing waste heat will play a critical role in reducing carbon emissions and enhancing sustainability.

Waste Heat from Transportation and Internal Combustion Engines

Transportation is a major source of waste heat, particularly from internal combustion engines (ICEs) used in automobiles, trucks, ships, trains, and aircraft. In conventional gasoline and diesel engines, only about 25%–40% of the fuel’s energy is converted into useful mechanical work, while the rest is lost as heat through exhaust gases, engine cooling systems, and surface radiation. Capturing and utilizing this waste heat can significantly improve fuel efficiency, reduce emissions, and enhance overall performance.

Automobiles and Trucks

Road transportation relies heavily on internal combustion engines, where substantial waste heat is generated. The primary sources of heat loss in vehicles include:

- Exhaust Gases – A large portion of waste heat (up to 40% of fuel energy) escapes through the exhaust system. Technologies like turbochargers and thermoelectric generators (TEGs) can recover part of this heat for improved efficiency.

- Engine Cooling System – The cooling system removes heat from the engine block to prevent overheating, but this heat is typically dissipated into the atmosphere through radiators. Waste heat recovery (WHR) systems can redirect some of this thermal energy for auxiliary functions like cabin heating or electricity generation.

- Friction and Drivetrain Losses – Heat generated from moving engine parts and friction in the drivetrain is another source of wasted energy. Advanced lubricants and materials help reduce these losses, but some energy is still lost.

To address these inefficiencies, several waste heat recovery technologies are being developed:

- Turbochargers and Turbo-Compounding – Turbochargers use exhaust gas energy to compress incoming air, improving engine efficiency and power output. Turbo-compounding systems take this a step further by using an additional turbine to recover even more exhaust energy and convert it into mechanical or electrical power.

- Thermoelectric Generators (TEGs) – TEGs use the Seebeck effect to convert temperature differences between hot exhaust gases and cooler surfaces into electricity. These systems can power onboard electronics, reducing the load on the alternator and improving fuel economy.

- Rankine Cycle Waste Heat Recovery Systems – Similar to power plants, vehicles can use a small Rankine cycle system to convert waste heat into mechanical energy to assist in propulsion.

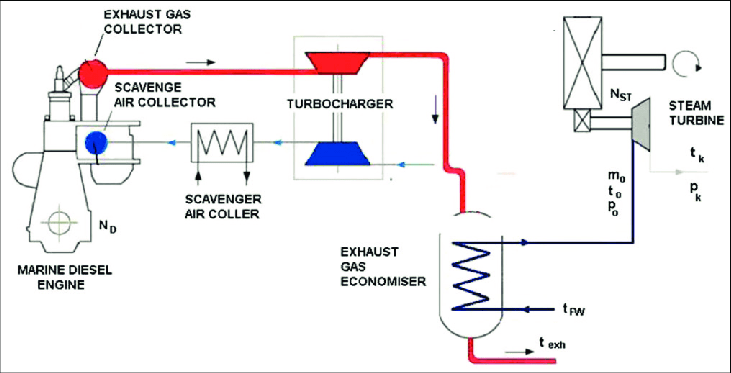

Marine and Shipping Industry

Ships and marine vessels, particularly large cargo ships and cruise liners, use massive diesel engines that operate for long periods, generating significant amounts of waste heat. Key waste heat sources in marine engines include:

- Exhaust Gases – Large marine engines produce high-temperature exhaust gases that can be captured using waste heat boilers to generate steam for auxiliary power.

- Cooling Water – Engine cooling systems absorb heat, which can be used for heating applications on board or converted into electricity via heat exchangers and ORC systems.

- Lubrication System Heat – Waste heat from lubricating oil can be recovered and reused for preheating fuel or other onboard applications.

Modern marine vessels are incorporating waste heat recovery systems (WHRS) to improve efficiency. Combined with shaft generators and electrical propulsion systems, WHR can reduce fuel consumption and lower emissions in compliance with environmental regulations.

Aircraft and Aviation

Aircraft engines, particularly jet engines, generate immense amounts of waste heat through exhaust gases and high-temperature components. While aviation has limited options for traditional waste heat recovery due to weight constraints, some innovative solutions include:

- Heat Exchangers for Cabin Heating – Waste heat from jet engines is already used for cabin pressurization and heating.

- More Efficient Engine Design – Advanced materials and cooling techniques reduce thermal losses and improve overall efficiency.

- Hybrid and Electric Aviation Concepts – Future aircraft designs may integrate waste heat recovery technologies to enhance battery performance or reduce fuel consumption.

Rail Transportation

Diesel-electric locomotives generate significant waste heat from their engines and electrical components. Similar to marine applications, Rankine cycle systems, thermoelectric generators, and improved cooling system designs can enhance locomotive efficiency by capturing and reusing waste heat.

Future of Waste Heat Recovery in Transportation

As fuel efficiency standards become stricter and sustainability becomes a priority, waste heat recovery will play a critical role in the future of transportation. Advancements in materials, thermoelectric technology, and hybrid powertrain integration will further enhance the ability to capture and utilize waste heat in various vehicle types. Reducing waste heat losses will not only improve fuel economy but also contribute to lower greenhouse gas emissions and reduced reliance on fossil fuels.

Waste Heat Recovery Systems (WHRS)

Waste Heat Recovery Systems (WHRS) are technologies designed to capture and utilize heat that would otherwise be lost from industrial processes, power generation, and transportation. These systems improve energy efficiency, reduce fuel consumption, lower greenhouse gas emissions, and enhance overall sustainability. The recovered heat can be used for electricity generation, process heating, space heating, or cooling applications.

Types of Waste Heat Recovery Systems

1. Regenerative Heat Exchangers

Regenerative heat exchangers store heat from hot gases and transfer it to incoming cold gases. They are commonly used in high-temperature industrial processes such as steel manufacturing and glass production.

- Examples: Regenerators in blast furnaces, thermal oxidizers, and regenerative thermal oxidizers (RTOs).

2. Recuperative Heat Exchangers

Recuperative heat exchangers directly transfer heat from hot gases to cold gases or liquids through a solid medium.

- Examples: Economizers in boilers, air preheaters, and plate heat exchangers.

3. Waste Heat Boilers (Heat Recovery Steam Generators – HRSG)

These systems use waste heat from industrial processes or power plants to produce steam, which can be used for electricity generation or industrial heating.

- Examples: Combined cycle power plants, cogeneration (CHP) systems, and steam-based district heating.

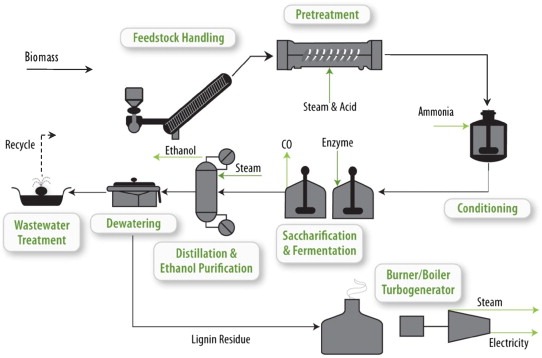

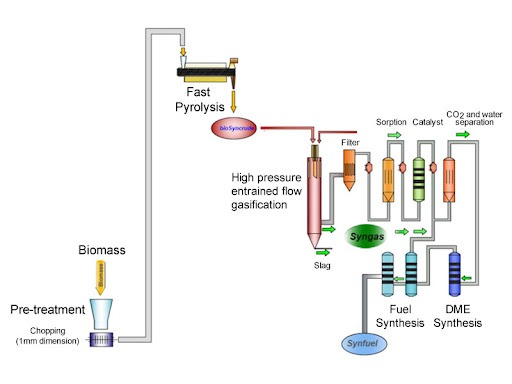

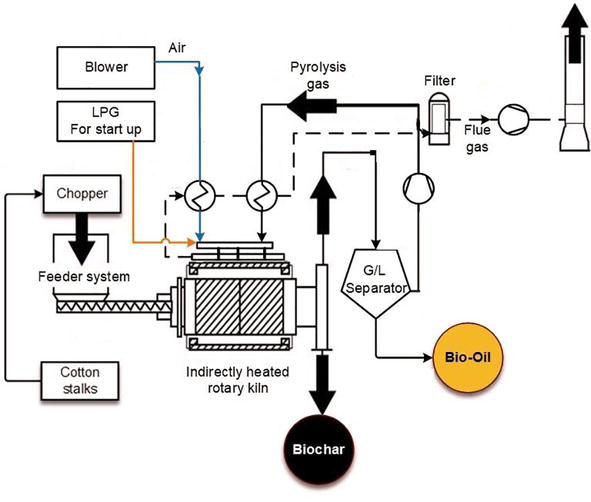

4. Organic Rankine Cycle (ORC) Systems

ORC systems convert low-temperature waste heat into electricity using organic fluids with lower boiling points than water.

- Applications: Biomass plants, geothermal energy, and low-grade waste heat recovery in industries.

5. Thermoelectric Generators (TEGs)

TEGs convert waste heat directly into electricity using the Seebeck effect.

- Applications: Automotive exhaust systems, industrial furnaces, and spacecraft power generation.

6. Kalina Cycle Systems

Kalina cycle technology uses a mixture of ammonia and water to recover heat more efficiently than traditional Rankine cycles.

- Applications: Geothermal power plants, industrial waste heat recovery, and solar thermal power.

7. Absorption Cooling Systems

These systems use waste heat to drive cooling cycles instead of electricity.

- Applications: Air conditioning in commercial buildings, industrial refrigeration, and data centers.

8. Flue Gas Heat Recovery

Captures heat from exhaust gases in power plants, industrial boilers, and incinerators.

- Applications: Preheating combustion air, district heating, and steam generation.

9. Mechanical Vapor Recompression (MVR)

MVR compresses and reuses steam to improve efficiency in evaporation and drying processes.

- Applications: Food processing, desalination, and paper manufacturing.

Benefits of Waste Heat Recovery Systems

- Energy savings – Reduces fuel consumption and operational costs.

- Lower emissions – Decreases CO₂ and other greenhouse gas emissions.

- Improved efficiency – Enhances process performance and sustainability.

- Economic benefits – Reduces energy costs and improves profitability.

Waste Heat Recovery Systems are essential for improving energy efficiency across multiple sectors, helping industries and power plants transition toward a more sustainable future.

Waste Heat Recovery Systems (WHRS) are designed to capture and repurpose heat that would otherwise be lost from industrial processes, power plants, and transportation systems. These systems enhance energy efficiency, lower fuel consumption, and reduce greenhouse gas emissions, contributing to both economic and environmental sustainability. Waste heat can be recovered using different technologies depending on temperature levels, heat sources, and the intended application. High-temperature waste heat from industrial furnaces, steel mills, and cement kilns can be used to generate steam, which can either drive turbines for electricity generation or be used directly in manufacturing processes. Medium- and low-temperature waste heat, such as that from exhaust gases, cooling systems, and hot surfaces, can be recovered using heat exchangers, economizers, or organic Rankine cycle (ORC) systems.

Thermoelectric generators (TEGs) convert heat directly into electricity using the Seebeck effect, making them useful in automotive applications and remote power generation. In the transportation sector, waste heat recovery is particularly valuable in internal combustion engines, where a significant portion of fuel energy is lost through exhaust and cooling systems. Turbochargers improve engine efficiency by using exhaust gases to compress incoming air, while turbo-compounding systems convert excess exhaust energy into mechanical or electrical power. In marine and locomotive engines, waste heat recovery boilers capture exhaust heat to produce steam for auxiliary power.

In power plants, heat recovery steam generators (HRSG) are widely used in combined-cycle plants, where gas turbines’ exhaust heat is used to generate additional steam for a secondary power cycle, improving overall efficiency. Industrial applications frequently use regenerative and recuperative heat exchangers to capture and reuse thermal energy, with applications in steel, glass, cement, and chemical industries. Absorption refrigeration systems utilize waste heat for cooling, making them ideal for data centers, commercial buildings, and process cooling in industrial facilities. Flue gas heat recovery systems extract residual heat from exhaust gases in boilers and furnaces, preheating combustion air to reduce fuel consumption.

Mechanical vapor recompression (MVR) technology captures and reuses steam in processes such as food processing, desalination, and paper manufacturing. Kalina cycle systems use a mixture of ammonia and water to recover waste heat more efficiently than conventional Rankine cycles, particularly in geothermal and industrial applications. These waste heat recovery technologies provide numerous benefits, including significant energy savings, lower operating costs, reduced reliance on fossil fuels, and decreased carbon emissions. By integrating waste heat recovery systems, industries and power plants can optimize their processes and contribute to a more sustainable energy landscape.

Waste heat recovery systems play a critical role in optimizing energy use across various industries, including power generation, manufacturing, and transportation. In power plants, where efficiency losses are significant, waste heat recovery technologies such as combined heat and power (CHP) and district heating systems help utilize excess thermal energy that would otherwise be lost through cooling towers or exhaust stacks. By capturing and repurposing this heat, power plants can provide electricity and thermal energy simultaneously, reducing fuel consumption and emissions.

In industrial settings, waste heat recovery is widely implemented in energy-intensive sectors such as steel, cement, glass, and petrochemical production, where furnaces, kilns, and boilers generate large amounts of high-temperature waste heat. This heat can be recovered using regenerative and recuperative heat exchangers, waste heat boilers, and organic Rankine cycle (ORC) systems to produce additional steam or electricity. In refineries and chemical plants, process heat from distillation, cracking, and reforming units can be reused to preheat raw materials, improving overall energy efficiency.

Waste heat recovery is also essential in the transportation sector, particularly in diesel engines used in trucks, ships, and trains, where exhaust gas heat can be converted into useful work through turbo-compounding, thermoelectric generators (TEGs), and Rankine cycle systems. Marine vessels benefit from waste heat boilers that generate steam from exhaust gases, reducing fuel consumption for auxiliary power. In aviation, research into thermoelectric and heat exchanger technologies aims to enhance engine efficiency and reduce fuel burn. On a broader scale, waste heat recovery contributes to sustainable energy solutions, including waste-to-energy plants that convert municipal and industrial waste heat into usable electricity and heat for district energy networks. Advanced absorption cooling systems further expand the utility of waste heat by converting excess thermal energy into cooling power for air conditioning and refrigeration, reducing electrical demand.

The integration of waste heat recovery with renewable energy sources, such as solar and geothermal power, enhances overall system efficiency and resilience. Digital monitoring and smart energy management systems further optimize waste heat utilization by analyzing thermal losses in real-time and adjusting recovery processes accordingly. As industries and governments prioritize decarbonization and energy efficiency, waste heat recovery systems will continue to evolve, incorporating advanced materials, improved heat exchangers, and emerging technologies like supercritical CO₂ cycles and phase-change materials. These innovations will play a crucial role in minimizing energy waste, lowering greenhouse gas emissions, and improving the sustainability of industrial and power generation processes worldwide.

The continuous advancement of waste heat recovery systems is driven by the increasing need for energy efficiency, cost reduction, and sustainability across industries. One of the most promising areas of development is the integration of artificial intelligence (AI) and machine learning in waste heat recovery optimization. AI-powered systems can analyze operational data in real time, predict heat loss patterns, and adjust recovery mechanisms dynamically to maximize efficiency. This is particularly beneficial in complex industrial settings where fluctuating process conditions require adaptive control strategies. Additionally, advancements in thermoelectric materials are making thermoelectric generators (TEGs) more efficient and viable for large-scale waste heat recovery. New materials, such as nanostructured thermoelectrics and high-performance semiconductors, are improving the conversion efficiency of heat into electricity, expanding their applications in automotive engines, power plants, and industrial furnaces.

Another innovative approach to waste heat utilization is the development of supercritical CO₂ (sCO₂) power cycles, which offer higher thermal efficiency than traditional steam-based systems. sCO₂ cycles operate at higher pressures and temperatures, allowing for more effective waste heat recovery in power generation and industrial processes. This technology is gaining traction in applications such as concentrated solar power (CSP), nuclear power plants, and waste heat recovery in heavy industries. Similarly, phase-change materials (PCMs) are being explored for thermal energy storage, allowing waste heat to be captured and stored for later use, addressing the intermittent nature of heat availability in many industrial operations. These materials absorb heat during phase transitions and release it when needed, providing a more flexible and efficient way to utilize waste heat.

Waste heat recovery is also playing an increasing role in urban energy systems, particularly in district heating and cooling networks. Many cities are integrating industrial waste heat, data center heat, and even low-grade heat from wastewater treatment plants into their heating networks, reducing reliance on fossil fuels for space heating. Combined heat and power (CHP) systems continue to be a key solution in urban energy infrastructure, simultaneously producing electricity and useful heat from a single fuel source, thereby improving overall system efficiency. Additionally, emerging technologies such as absorption heat pumps and adsorption chillers are enabling more effective use of low-temperature waste heat in commercial and residential applications, further reducing energy demand from conventional heating and cooling systems.

As industries and governments continue to focus on carbon reduction goals, waste heat recovery systems are becoming an essential component of energy policy and corporate sustainability strategies. Stricter environmental regulations and carbon pricing mechanisms are pushing industries to invest in more efficient waste heat utilization technologies. Incentives and funding for energy efficiency projects, including government grants and tax credits, are accelerating the adoption of waste heat recovery solutions across various sectors. Moreover, the transition to hydrogen-based economies is opening new possibilities for waste heat recovery, as excess heat from hydrogen production processes such as electrolysis and methane reforming can be captured and reused in industrial applications or district energy systems.

Looking ahead, the convergence of digitalization, advanced materials, and innovative thermodynamic cycles will continue to drive improvements in waste heat recovery efficiency and economic viability. Companies and researchers are exploring hybrid solutions that combine waste heat recovery with renewable energy systems to create more resilient and self-sustaining industrial and urban energy networks. The expansion of decentralized waste heat recovery, where smaller-scale industrial and commercial facilities contribute to local energy systems, is also gaining momentum, further decentralizing energy production and reducing dependence on centralized fossil fuel power generation. By embracing these advancements, industries can significantly reduce energy waste, lower operational costs, and contribute to a more sustainable and energy-efficient future.

Benefits of Waste Heat Recovery

The benefits of waste heat recovery are numerous, spanning economic, environmental, and operational improvements across various industries. By capturing and repurposing heat that would otherwise be lost, waste heat recovery systems can offer significant advantages in terms of energy efficiency, cost savings, and sustainability.

- Energy Efficiency: Waste heat recovery significantly enhances the overall energy efficiency of industrial processes, power plants, and transportation systems. By utilizing excess thermal energy, companies can reduce their reliance on primary energy sources (such as natural gas, coal, or electricity), making processes more efficient and reducing fuel consumption. This can lead to lower energy bills and a reduction in overall energy demand.

- Cost Savings: One of the most immediate benefits of waste heat recovery is cost savings. By capturing waste heat and repurposing it for useful applications, industries can reduce the need to purchase additional energy, thus cutting operating costs. For example, in manufacturing or power plants, recovered heat can be used to preheat incoming air or fluids, reducing the need for additional fuel to generate the required temperatures.

- Reduced Greenhouse Gas Emissions: Waste heat recovery systems help reduce greenhouse gas (GHG) emissions by lowering the overall fuel consumption of industrial processes and power plants. The less fuel that needs to be burned, the fewer emissions are generated. This is particularly important for companies working toward sustainability goals or those subject to emissions regulations. By using waste heat, industries can lower their carbon footprint and contribute to the global effort to combat climate change.

- Improved Process Efficiency: Waste heat recovery helps to optimize processes by providing a stable and reliable source of heat or energy. In many industries, the recovered heat can be used for processes such as preheating raw materials, producing steam, or powering auxiliary equipment. This integration leads to better system optimization, smoother operation, and reduced wear on equipment, enhancing overall process reliability and performance.

- Increased Energy Security: By recovering waste heat, industries can reduce their dependency on external energy supplies, contributing to greater energy security. Waste heat recovery allows companies to become more self-sufficient by generating their own power or reducing the need to purchase power from the grid. This can be particularly beneficial in regions with unstable energy prices or supply disruptions.

- Reduced Operational Costs: By reusing waste heat within a facility, industries can reduce the overall cost of running their operations. This includes savings from fuel, maintenance costs associated with equipment wear, and reduced demand on external utilities, leading to more predictable and manageable energy costs over time.

- Enhanced Sustainability: Waste heat recovery plays a key role in advancing sustainability initiatives. By reducing energy waste, emissions, and overall resource consumption, companies can contribute to sustainability goals, improve their public image, and meet corporate social responsibility (CSR) targets. Additionally, many waste heat recovery technologies, such as absorption chillers and organic Rankine cycles, can contribute to renewable energy generation, further boosting a facility’s sustainability efforts.

- Compliance with Environmental Regulations: Many countries have strict environmental regulations that require industries to reduce emissions and improve energy efficiency. Waste heat recovery systems help industries comply with these regulations by minimizing fuel consumption and GHG emissions. In some cases, the implementation of waste heat recovery systems may qualify companies for tax credits, grants, or other incentives aimed at supporting energy-efficient technologies.

- Opportunities for Combined Heat and Power (CHP) and District Heating: Waste heat recovery can be integrated into combined heat and power (CHP) systems, where both electricity and useful heat are generated from a single energy source. This increases overall system efficiency and allows for the utilization of otherwise wasted energy. Additionally, waste heat can be used in district heating systems, providing residential, commercial, and industrial buildings with affordable, low-carbon heat from local sources.

- Energy Flexibility and Reliability: Some waste heat recovery technologies, such as heat storage and thermal energy storage systems, allow for the storage of recovered heat for later use. This can provide a more flexible and reliable energy source, especially in operations that require heat on a fluctuating basis, such as in seasonal industries or those with variable production schedules.

- Innovation and Technological Advancements: Waste heat recovery encourages innovation in thermal management technologies, leading to the development of advanced systems like thermoelectric generators (TEGs), Kalina cycles, and supercritical CO₂ cycles. These technologies improve the ability to recover and use low- and medium-grade waste heat, further enhancing overall energy utilization.

- Market Competitiveness: Companies that adopt waste heat recovery technologies can gain a competitive edge by improving their bottom line through reduced energy costs and enhanced efficiency. Additionally, demonstrating a commitment to sustainability and energy efficiency can improve a company’s reputation and brand image, making it more attractive to customers, investors, and regulatory bodies.

In summary, waste heat recovery offers a wide range of benefits, from improved energy efficiency and cost savings to environmental sustainability and compliance with regulations. It is a critical tool in creating more sustainable, cost-effective, and energy-efficient industrial and energy systems worldwide.

Waste heat recovery systems offer significant advantages that contribute to operational, economic, and environmental improvements. By capturing and repurposing heat that would otherwise be wasted, industries can enhance their energy efficiency and reduce fuel consumption, which in turn lowers operating costs. The reduction in fuel consumption also directly results in fewer emissions, including greenhouse gases, contributing to environmental sustainability and helping industries meet regulatory compliance and sustainability goals. By recovering waste heat, companies can reduce their reliance on external energy sources, which not only boosts their energy security but also makes their energy needs more predictable and stable. This reduction in energy dependence can be particularly beneficial in areas with volatile energy prices or where energy security is a concern.

Waste heat recovery also improves process efficiency by providing a reliable source of thermal energy that can be used for applications like preheating raw materials, generating steam, or powering auxiliary equipment. This integration helps optimize overall system performance, enhancing reliability and productivity while reducing wear and tear on machinery. Furthermore, the reuse of waste heat can significantly cut down on fuel expenses, reducing the overall operational costs of a facility. The economic benefits of waste heat recovery systems extend beyond the immediate savings on energy costs, as the increased efficiency and reduced environmental impact can improve a company’s public image, helping to meet corporate social responsibility (CSR) targets and attract investment.

As industries move toward more sustainable practices, waste heat recovery plays a key role in advancing these efforts by reducing the amount of energy lost in industrial processes and enhancing overall resource conservation. The implementation of waste heat recovery systems aligns with sustainability initiatives, helping companies to reduce their carbon footprint while generating savings in the process. In regions where stringent environmental regulations are in place, waste heat recovery can be an effective strategy to comply with these laws, potentially qualifying businesses for incentives such as tax credits or grants for energy-efficient technologies.

Moreover, waste heat recovery contributes to the potential for combined heat and power (CHP) systems, where both electricity and useful heat are produced from a single fuel source. This not only boosts efficiency but also allows industries to create district heating systems that can provide low-carbon heating to nearby residential, commercial, and industrial buildings. Such integration further reduces reliance on traditional energy sources and promotes local, sustainable energy solutions. The flexibility of recovered heat, which can be stored for later use, also provides a level of reliability and energy security, particularly for industries with fluctuating energy demands.

Ultimately, the adoption of waste heat recovery technologies enables companies to remain competitive in a marketplace where energy efficiency and environmental responsibility are becoming increasingly important. These systems help businesses lower their energy costs, reduce emissions, and comply with regulations, all while boosting their reputation and market position. The ongoing innovation in waste heat recovery, through new technologies such as thermoelectric generators, supercritical CO₂ cycles, and advanced thermal storage solutions, continues to enhance the efficiency and viability of these systems, opening new opportunities for industries to harness and make use of energy that would otherwise be lost.

The widespread adoption of waste heat recovery systems is increasingly recognized as an essential strategy for optimizing energy usage and achieving sustainability goals across industries. As technologies continue to evolve, industries are finding new ways to leverage low- and medium-temperature waste heat that was previously considered difficult or uneconomical to recover. Innovations in materials, such as advanced heat exchangers and high-performance thermoelectrics, are improving the efficiency of heat recovery, even in lower temperature ranges. For example, organic Rankine cycles (ORC) and Kalina cycles have become more efficient at recovering heat from lower-grade waste streams, enabling industries to recover and utilize heat that would have otherwise been wasted.

Furthermore, waste heat recovery is playing an increasingly important role in the transition toward low-carbon and renewable energy solutions. By integrating recovered heat with renewable energy sources such as solar and biomass, industries can create hybrid systems that maximize overall energy efficiency and sustainability. For instance, waste heat recovery systems can be used in combination with solar thermal energy to create more reliable and efficient renewable power systems, or even in geothermal power plants where excess heat can be used to improve energy generation processes.

The growing emphasis on decarbonization, coupled with tightening regulations on carbon emissions and energy efficiency, is driving more industries to incorporate waste heat recovery technologies into their operations. As governments around the world implement stricter environmental policies, industries that adopt waste heat recovery systems will be better positioned to meet these regulatory requirements while also reducing their operational costs. In some regions, this can provide a competitive edge as companies that implement energy-efficient practices may benefit from financial incentives, subsidies, or preferential treatment in the market.

Beyond energy savings, waste heat recovery systems also contribute to improved resource utilization, as industries become more adept at making use of by-products that were previously overlooked. For example, in manufacturing processes, where high temperatures are often required, the ability to recover and reuse waste heat reduces the need for fresh inputs of fuel or electricity. This reduces both operating costs and the overall environmental impact of production processes, supporting circular economy principles by reducing waste and maximizing the reuse of available resources.

In the context of urban energy systems, waste heat recovery is also being integrated into district heating and cooling networks, where industrial or commercial heat is transferred to local buildings for space heating or hot water. This not only makes use of waste heat but also helps reduce the need for fossil fuels in urban energy systems, lowering emissions on a larger scale. Cities can greatly benefit from integrating waste heat recovery in their energy infrastructure, particularly as urban populations continue to grow and demand for energy rises. By creating more energy-efficient districts with shared heating and cooling resources, cities can become more resilient to energy price fluctuations and contribute to achieving national or global climate targets.

As energy markets evolve and new technological solutions emerge, waste heat recovery systems will continue to play an integral role in achieving a more sustainable energy future. The combination of digitalization, advanced analytics, and smart grids will further optimize the efficiency of these systems by enabling real-time monitoring and control, ensuring that waste heat recovery is maximized across a wide range of applications. In the long run, waste heat recovery not only offers a pathway to energy savings and cost reductions but also serves as a key pillar in the transition to a more sustainable, low-carbon economy.

As industries and governments continue to prioritize sustainability and energy efficiency, waste heat recovery technologies will become even more crucial in helping meet global energy demands while reducing environmental impact. The integration of waste heat recovery with emerging technologies like smart grids, advanced automation, and artificial intelligence will enable more dynamic and efficient energy systems. Real-time monitoring and predictive analytics will allow for better decision-making and optimization of energy use, ensuring that heat recovery systems operate at their peak efficiency, even in fluctuating conditions. With the increasing availability of data and digital tools, businesses can identify areas of heat loss and adjust recovery strategies to improve both economic performance and environmental outcomes.

Moreover, the development of new materials and technologies will continue to drive the expansion of waste heat recovery into previously untapped sectors. For instance, new heat-resistant alloys and ceramic materials are making high-temperature heat exchangers more durable and efficient, allowing for the recovery of heat from even more extreme industrial processes. Similarly, advances in heat storage technologies, such as advanced phase-change materials (PCMs) and thermochemical storage, are enabling industries to capture and store excess heat for later use, further increasing system flexibility and making it possible to use recovered heat during peak demand periods.

In addition, as global economies move toward hydrogen as a clean energy source, waste heat recovery will play an important role in optimizing hydrogen production processes. Technologies like electrolysis, which are used to produce green hydrogen from water, require significant amounts of electricity and produce waste heat. By integrating waste heat recovery into these processes, the efficiency of hydrogen production can be significantly improved, making it a more viable option for decarbonizing industries such as transportation, manufacturing, and power generation. Similarly, as the use of hydrogen in industrial heating systems grows, the integration of waste heat recovery can provide additional energy savings and further reduce emissions.

The expansion of decentralized energy systems and microgrids also presents new opportunities for waste heat recovery. In remote or off-grid locations, small-scale waste heat recovery systems can be used to generate electricity or provide heat for industrial and residential use. These systems could help power critical infrastructure, such as water treatment plants, hospitals, and schools, while reducing the reliance on expensive or unreliable external energy sources. By incorporating waste heat recovery into these systems, communities can create more resilient and self-sustaining energy solutions.

Waste heat recovery’s contribution to reducing the energy intensity of industrial operations, coupled with advances in renewable energy technologies, will help move industries closer to achieving their net-zero carbon goals. By addressing both operational efficiency and emissions reductions, waste heat recovery allows businesses to take a holistic approach to energy management, reducing costs while supporting their environmental and regulatory commitments.

As waste heat recovery technologies become more widespread, industries that adopt these systems will not only benefit from direct energy savings but also enhance their competitiveness in a market that increasingly values sustainability and resource efficiency. The ability to recover and reuse waste heat can also serve as a differentiating factor, as consumers, investors, and regulators place greater emphasis on environmentally responsible practices. For industries looking to future-proof their operations, investing in waste heat recovery technology is an important step toward building long-term resilience, enhancing sustainability, and maintaining market leadership.

Ultimately, the future of waste heat recovery holds great promise, with the potential to transform how industries utilize energy and reduce their environmental impact. As new technologies emerge and the global economy moves toward more sustainable and efficient energy solutions, waste heat recovery will continue to play an essential role in shaping a greener, more energy-efficient world. With ongoing innovation, strategic integration into energy systems, and a commitment to sustainability, waste heat recovery is poised to become an integral part of the global transition to a low-carbon economy.

While waste heat recovery offers substantial benefits, there are several challenges and considerations that industries must address to fully capitalize on these technologies.

- Initial Capital Investment: One of the primary challenges associated with waste heat recovery systems is the initial cost. The installation of recovery equipment, such as heat exchangers, thermoelectric generators, or ORC systems, can require a significant upfront investment. This cost may be a barrier for some industries, especially those with tight budgets or low-profit margins. However, the long-term savings from reduced energy consumption and improved efficiency often justify the initial expenditure.

- Technological Complexity: Implementing waste heat recovery systems often requires specialized knowledge and expertise. Different industries generate waste heat at various temperatures and scales, requiring tailored solutions to recover and repurpose this energy effectively. The complexity of integrating recovery systems with existing infrastructure can also pose a challenge, especially in older or less adaptable facilities. Proper planning, engineering, and technical support are critical to ensure a smooth implementation.

- Economic Viability for Low-Temperature Heat: Waste heat recovery is typically most effective when the heat source is high temperature, such as exhaust gases from industrial furnaces or power plants. Low-temperature waste heat (below 100°C or 212°F), which is common in many industrial processes, can be harder to recover efficiently. Technologies like organic Rankine cycles (ORC) and thermoelectric generators (TEGs) are increasingly being used to capture low-grade heat, but these systems may still have lower efficiency compared to high-temperature heat recovery systems. In some cases, the costs of recovering low-temperature heat may not be economically viable unless paired with other technologies or applications.

- System Integration and Compatibility: Integrating waste heat recovery systems into existing industrial processes and infrastructure can be challenging, particularly in industries with complex or outdated systems. The process of connecting recovery equipment to existing machinery, ensuring compatibility with control systems, and adjusting operations can be time-consuming and costly. Furthermore, the operational profile of industries often changes over time, which may impact the effectiveness of waste heat recovery solutions. Continuous monitoring and system optimization are essential for ensuring long-term performance.

- Operational and Maintenance Challenges: Like all energy systems, waste heat recovery systems require regular maintenance to ensure they continue to operate efficiently. This can involve cleaning heat exchangers, maintaining thermoelectric generators, and replacing worn-out components. Over time, system components can degrade due to factors like corrosion, scaling, or thermal fatigue. Maintenance and operational costs can accumulate, potentially offsetting some of the financial benefits of waste heat recovery. Furthermore, integrating waste heat recovery into existing operations may introduce new operational complexities that require specialized personnel.

- Space and Installation Constraints: Some industries, particularly in dense urban environments or in older facilities, may face space constraints that make the installation of waste heat recovery systems difficult. The additional equipment required for heat recovery, such as heat exchangers, storage tanks, or turbines, can require significant space, which may not be readily available in existing plants or industrial setups. In such cases, companies may need to invest in new infrastructure or undergo costly facility upgrades to accommodate waste heat recovery technologies.

- Regulatory and Environmental Considerations: While waste heat recovery can reduce greenhouse gas emissions, it must still comply with local environmental regulations. In some cases, recovering heat from industrial processes or exhaust gases may be subject to specific regulations regarding air quality, emissions, or thermal discharge. Regulatory constraints may limit the types of heat recovery technologies that can be used or the way in which heat is released back into the environment. Companies must carefully navigate these regulatory requirements to ensure their waste heat recovery systems operate within legal and environmental boundaries.

- Energy Quality and Consistency: The quality and consistency of the recovered heat are important considerations. Waste heat sources can vary in temperature, flow, and availability, which can impact the efficiency of recovery systems. For example, in processes where heat is not continuously available, energy storage or backup systems may be required to maintain a consistent supply of recovered heat. The varying nature of waste heat can also make it difficult to integrate these systems into broader energy networks, such as district heating or CHP systems, which rely on stable and predictable heat sources.

- Financial and Market Uncertainty: The financial return on investment (ROI) for waste heat recovery systems can be influenced by external factors, such as fluctuating energy prices, government incentives, or shifts in market conditions. For example, if energy prices decrease significantly, the cost savings from waste heat recovery may become less compelling. Similarly, changes in regulations, such as the removal of tax incentives for energy efficiency projects, could impact the financial viability of these systems.

- Technological Advancements and Future Proofing: As new technologies continue to emerge in the field of waste heat recovery, industries must carefully assess the long-term viability of the systems they install. New and more efficient technologies, such as advanced thermoelectric materials, supercritical CO₂ cycles, or hybrid renewable energy solutions, may provide better performance and longer-term savings, making older systems obsolete. This creates a challenge for industries seeking to future-proof their energy infrastructure while ensuring that their waste heat recovery investments remain competitive and relevant.

In conclusion, while waste heat recovery offers numerous benefits, industries must address several challenges in order to fully realize these advantages. Overcoming barriers such as high initial costs, technological complexity, system integration issues, and space constraints requires careful planning, expertise, and investment. However, with ongoing advancements in technology, more efficient solutions are emerging to address these challenges, making waste heat recovery an increasingly viable and integral part of sustainable energy strategies.

Addressing the challenges associated with waste heat recovery involves careful planning, investment, and ongoing optimization. One of the key areas that need focus is the economic viability of waste heat recovery systems, particularly in industries with low-temperature heat. Low-temperature waste heat is often less energy-dense, which can make recovery technologies less efficient and economically viable. In such cases, pairing waste heat recovery with complementary technologies, such as heat pumps, or integrating recovered heat into other parts of the industrial process, can improve the overall efficiency and cost-effectiveness of these systems. Additionally, industries must evaluate the long-term savings and the reduction in operational costs, weighing them against the initial investment required for system installation and integration.

Another consideration is the integration of waste heat recovery systems into existing industrial infrastructure. In many cases, industrial plants and processes are already operating with a set infrastructure, and introducing new technologies requires thoughtful integration with the current system. This could mean modifications to existing equipment, the installation of new heat exchangers, or the introduction of additional controls to ensure that recovered heat is effectively reused. This integration process can be resource-intensive, both in terms of time and financial outlay, as it may require downtime or system upgrades to ensure compatibility with the new technologies.

Space limitations also play a critical role in the successful implementation of waste heat recovery systems. Older facilities, in particular, may not have the physical space to accommodate new heat recovery equipment. Additionally, for industries located in highly urbanized areas, space constraints may limit the scale of waste heat recovery that can be practically installed. Solutions to these challenges could include the design and implementation of compact systems, modular recovery units, or leveraging off-site storage for recovered heat. However, this may still entail significant investment in infrastructure changes or spatial reconfigurations, which can be costly and logistically challenging.

In operational terms, the maintenance of waste heat recovery systems is an ongoing concern. While these systems can be highly beneficial in terms of efficiency and cost savings, they require regular attention to remain effective. For instance, heat exchangers need to be cleaned and maintained to prevent the buildup of scale, dirt, or corrosion, which could hinder heat transfer efficiency. Similarly, thermoelectric generators or other high-tech equipment in waste heat recovery systems may need periodic calibration and repairs to ensure consistent performance. Developing a reliable maintenance strategy and ensuring that personnel are trained to manage these advanced systems are crucial for the long-term success of waste heat recovery.

Moreover, external factors, such as changes in energy prices or environmental regulations, can also influence the economic feasibility of waste heat recovery projects. Fluctuating energy costs can directly impact the financial savings that waste heat recovery provides. If energy prices drop, the economic incentive to invest in waste heat recovery may diminish, as the payback period could become longer or the energy savings less significant. Conversely, if energy prices rise or stricter emissions regulations are implemented, the value proposition for waste heat recovery may improve. Businesses must continuously assess these external factors and adjust their strategies accordingly to ensure that their investments in waste heat recovery continue to yield positive returns.

Technological advancements will continue to evolve, providing new opportunities to overcome some of the limitations associated with waste heat recovery systems. Innovations in materials, such as advanced heat-resistant alloys or more efficient thermoelectric materials, are improving the ability to recover waste heat at lower temperatures, making these technologies more viable in a broader range of industrial applications. Moreover, improvements in energy storage technologies, such as thermal storage or advanced batteries, could help mitigate the intermittent nature of waste heat and allow industries to store and use recovered energy at times of peak demand.

In addition, policy support and government incentives will play an important role in driving the adoption of waste heat recovery technologies. Many countries are offering financial incentives, tax credits, or subsidies to encourage the adoption of energy-efficient technologies. Industries can take advantage of these programs to offset some of the initial costs associated with implementing waste heat recovery systems. However, the landscape of these incentives is often subject to change based on political and economic conditions, and businesses must stay informed about regulatory changes that could impact their ability to recover investments.

To fully address these challenges, industries must approach waste heat recovery with a long-term perspective, considering not only the immediate benefits but also the potential for future technological advancements, operational adjustments, and changes in the market and regulatory environments. By carefully navigating the complexities of waste heat recovery, businesses can improve their energy efficiency, reduce their environmental impact, and achieve significant cost savings over time.

As industries look to overcome these challenges, several strategies can be employed to ensure the successful implementation and long-term benefits of waste heat recovery systems.

- Strategic Planning and Feasibility Studies: Before investing in waste heat recovery technologies, industries should conduct detailed feasibility studies to assess the potential energy savings, payback periods, and the impact on overall system efficiency. These studies should consider factors such as the temperature and quantity of waste heat available, the specific energy demands of the facility, and the compatibility of potential recovery technologies with existing processes. A comprehensive analysis will help identify which heat recovery systems are most appropriate for the given conditions and whether the savings in energy consumption will justify the initial investment.

- Energy Audits and Monitoring Systems: Implementing a robust monitoring and energy auditing system is essential for identifying and quantifying the waste heat available within an industrial process. This helps companies pinpoint areas where heat loss is most significant and determine the most effective recovery methods. By using advanced monitoring tools, industries can track the performance of waste heat recovery systems in real-time, providing actionable data that can be used to optimize recovery rates and identify maintenance needs early. Regular audits and monitoring can also reveal new opportunities for additional energy savings over time.

- Government Support and Incentives: Many countries offer financial incentives to encourage industries to adopt energy-efficient technologies, including waste heat recovery systems. This could include grants, tax credits, or low-interest loans that help offset the capital cost of implementing recovery technologies. Additionally, some governments are offering funding or support for the development of new technologies to make waste heat recovery more efficient and accessible. Industries should actively seek out these programs and stay informed about the evolving regulatory landscape to take full advantage of available financial support.

- Technology Partnerships: Collaborating with technology providers, research institutions, and energy consultants can help industries overcome technical challenges and stay ahead of innovations in waste heat recovery. Partnerships with specialized suppliers can ensure that the most advanced and efficient systems are selected and correctly integrated into existing operations. Working with experts in the field can also help address integration challenges and identify ways to optimize the recovery process based on the unique needs of each industry. In some cases, technology providers may offer ongoing support and maintenance services to ensure the system continues to function optimally over its lifespan.

- Modular and Scalable Solutions: To mitigate space and cost constraints, industries may consider implementing modular and scalable waste heat recovery solutions. These systems are often easier to integrate into existing infrastructure and can be expanded or upgraded over time as energy demands grow or as technology improves. By adopting modular systems, industries can make incremental investments in waste heat recovery without having to commit to a large-scale installation upfront. This also allows for more flexibility in scaling up the system as energy efficiency needs evolve.

- Hybrid Solutions and Energy Storage: Hybrid systems, which combine multiple energy sources or recovery methods, can be effective in overcoming some of the limitations of individual waste heat recovery technologies. For example, waste heat recovery can be combined with renewable energy sources such as solar or biomass, or even with traditional power generation, to create a more resilient and efficient system. Additionally, incorporating energy storage technologies—such as thermal storage or battery systems—can allow industries to store recovered heat for later use, smoothing out fluctuations in energy demand and ensuring that recovered heat can be utilized during peak times.

- Upgrading Existing Infrastructure: In some cases, older facilities may require infrastructure upgrades to make them compatible with waste heat recovery systems. These upgrades could include improvements to heat distribution networks, the installation of heat exchangers, or the addition of advanced control systems. While this can involve significant upfront costs, it may be necessary to ensure that the waste heat recovery system functions efficiently and integrates seamlessly with the existing processes. Over time, the benefits from increased energy efficiency and cost savings can offset the initial investment in infrastructure upgrades.

- Employee Training and Skill Development: One of the critical factors in the successful operation of waste heat recovery systems is ensuring that employees are trained to understand and manage the new technologies. Staff members should be equipped with the necessary skills to monitor system performance, identify potential issues, and carry out routine maintenance. Training can also help employees understand the benefits of waste heat recovery, encouraging a culture of energy efficiency and sustainability within the organization. Additionally, having skilled personnel can help prevent operational disruptions and minimize the risk of costly breakdowns or inefficiencies.

- Sustainability Goals and Public Image: Companies that adopt waste heat recovery technologies can use these systems as part of their broader sustainability initiatives. In addition to the direct benefits of energy savings and emissions reductions, implementing waste heat recovery can enhance a company’s public image, positioning it as a leader in energy efficiency and environmental responsibility. Many consumers, investors, and stakeholders are increasingly prioritizing sustainability when making decisions, and businesses that integrate waste heat recovery systems can strengthen their market position by demonstrating their commitment to sustainability. This, in turn, can attract investors, improve customer loyalty, and contribute to a positive corporate reputation.

- Long-term Monitoring and Optimization: Continuous monitoring of waste heat recovery systems is essential to ensure that they operate at peak efficiency over time. Through data analytics, machine learning, and AI-based systems, industries can optimize the performance of waste heat recovery equipment and identify areas for further improvement. For instance, predictive maintenance tools can detect wear and tear before it leads to system failure, minimizing downtime and extending the lifespan of recovery equipment. Regular system optimization ensures that the technologies remain cost-effective and continue to deliver energy savings, even as industrial processes evolve.

By addressing these challenges proactively and considering these strategies, industries can successfully implement waste heat recovery systems that offer long-term benefits in terms of cost savings, energy efficiency, and environmental sustainability. The evolution of technology, regulatory frameworks, and business models will continue to support the widespread adoption of waste heat recovery, helping industries move closer to their sustainability and energy efficiency goals.

Looking ahead, the future of waste heat recovery holds significant promise, with evolving technologies and an increasing global focus on sustainability, energy efficiency, and decarbonization. Several emerging trends and innovations are poised to overcome existing challenges and unlock even greater potential for waste heat recovery systems. These advancements will help industries reduce operational costs, minimize environmental impact, and further contribute to the transition toward a low-carbon economy.

- Integration with Renewable Energy: As the global energy landscape shifts toward renewable sources, waste heat recovery will increasingly be integrated with renewable energy technologies, such as solar, wind, and biomass. This hybrid approach can help to balance the intermittency of renewable energy by providing a steady source of heat recovery, making energy systems more stable and reliable. For example, combining waste heat recovery with solar thermal systems can create more efficient district heating networks, reducing reliance on fossil fuels while improving overall energy security. Additionally, waste heat can be used in conjunction with renewable hydrogen production, which will be a key part of decarbonizing industries like steel, cement, and chemicals.

- Advanced Heat Recovery Technologies: As waste heat recovery technologies continue to evolve, more efficient and specialized systems will emerge. The development of high-performance materials, such as advanced alloys and ceramics, is improving the efficiency of heat exchangers, allowing industries to recover heat from even more extreme temperatures. Meanwhile, supercritical CO₂ cycles are an emerging technology that promises significant improvements in heat recovery efficiency, particularly for high-temperature waste heat. Supercritical CO₂ systems operate at higher pressures and temperatures than traditional steam cycles, making them ideal for capturing and converting waste heat from industrial processes into electricity or usable energy. Furthermore, advancements in thermoelectric materials are enabling more efficient conversion of heat into electricity, even at low temperatures. Thermoelectric generators (TEGs) can be used to recover waste heat from sources such as exhaust gases or industrial machinery, offering industries a more flexible and scalable solution to harnessing waste heat.

- Digitalization and Smart Monitoring: Digital technologies, including the Internet of Things (IoT), machine learning, and big data analytics, are revolutionizing the operation and optimization of waste heat recovery systems. Smart sensors and real-time data analytics can continuously monitor system performance, identifying inefficiencies and optimizing the recovery process in real-time. Machine learning algorithms can predict equipment failures before they occur, enabling predictive maintenance and minimizing downtime. The ability to collect and analyze data from waste heat recovery systems allows industries to fine-tune their operations for maximum efficiency, reducing costs and improving energy usage. Moreover, digital platforms and cloud-based software can integrate waste heat recovery data with broader energy management systems, providing a holistic view of energy consumption and performance across a facility or entire industrial complex. This enables businesses to optimize not just heat recovery but their overall energy strategy.

- Energy Storage Solutions: As industries increasingly adopt waste heat recovery, the need for effective storage solutions becomes more important. Heat storage technologies, such as phase-change materials (PCMs) and molten salt storage, are gaining traction as a way to store excess recovered heat for later use. These technologies can help buffer fluctuations in energy demand and ensure that recovered heat is available when needed, especially in industries where heat is intermittently produced or when systems need to be shut down temporarily for maintenance. Additionally, integrating thermal storage with battery storage solutions could provide more versatile energy systems. Batteries could store excess electricity generated from recovered heat and provide a backup power source for industrial facilities. This combination of heat and electrical energy storage could lead to greater energy independence and cost reductions for businesses.

- Decentralized and Microgrid Solutions: Waste heat recovery is also playing a key role in the development of decentralized energy systems and microgrids. These systems, which provide energy locally rather than relying on a central grid, can be particularly beneficial in remote or off-grid locations. For example, microgrids powered by waste heat recovery could supply energy to industrial facilities, residential areas, or critical infrastructure, reducing dependence on fossil fuels and external energy sources. By incorporating waste heat recovery, these microgrids can provide a more stable and resilient power supply while optimizing energy efficiency. In the future, waste heat recovery integrated with microgrids could support demand response systems, where recovered heat is used in real-time to balance supply and demand. These systems could also allow for excess recovered heat to be sold to neighboring communities or businesses, creating new revenue streams for industries while contributing to local energy solutions.

- Circular Economy and Industrial Symbiosis: Waste heat recovery is a natural fit for the principles of the circular economy, where resources are reused and waste is minimized. By recovering waste heat and reusing it in other industrial processes, companies can reduce their reliance on external energy sources, lower their carbon footprint, and contribute to the broader goals of resource efficiency and sustainability. Industrial symbiosis, where different industries exchange waste products (including heat), is gaining momentum as companies seek ways to minimize waste and optimize resource use. For instance, one industry’s waste heat could be used to power another industry’s heating needs, creating a mutually beneficial ecosystem where energy is shared rather than wasted.