Vessels with Steam Turbine Propulsion: Steam turbine propulsion has been a cornerstone of marine engineering for much of the 20th century, playing a pivotal role in the evolution of naval and commercial shipping. This propulsion method leverages the thermodynamic principles of steam to convert thermal energy into mechanical work, which drives the vessel’s propellers. The steam turbine system typically begins with a boiler, where water is heated to produce high-pressure steam. This steam is then channeled into turbines, which consist of a series of blades attached to a rotor. As the steam passes through the turbine blades, it expands and cools, transferring its energy to the blades and causing the rotor to spin.

This spinning rotor is connected to the ship’s propeller shaft, and the rotational energy generated by the turbine is transmitted to the propeller, propelling the ship forward. One of the key advantages of steam turbine propulsion is its ability to generate substantial power output, making it suitable for large vessels such as ocean liners, warships, and large cargo ships. The propulsion system is also relatively smooth and efficient, with fewer moving parts compared to reciprocating engines, leading to lower maintenance requirements and higher reliability.

However, steam turbine propulsion is not without its drawbacks. The system requires significant space and weight for the boilers, turbines, condensers, and associated piping. Moreover, the process of generating steam and maintaining the required pressure and temperature levels demands a considerable amount of fuel, leading to high operational costs. Despite these challenges, the robustness and power output of steam turbines made them the propulsion method of choice for many naval vessels and commercial ships, particularly in the first half of the 20th century.

Over time, advancements in technology and the advent of more efficient propulsion systems, such as diesel engines and gas turbines, have led to a decline in the use of steam turbines in modern shipping. These newer systems offer higher fuel efficiency, lower emissions, and more compact designs, making them more suitable for contemporary maritime needs. Nevertheless, steam turbines still hold a significant place in maritime history and continue to be used in certain applications, such as nuclear-powered ships, where the heat generated by nuclear reactors is used to produce steam.

The legacy of steam turbine propulsion is evident in its impact on ship design, engineering practices, and the evolution of marine technology. The principles of thermodynamics, fluid dynamics, and materials science that underpin steam turbine technology continue to influence modern engineering disciplines, highlighting the enduring importance of this propulsion system in the history of maritime transportation.

Vessels with Steam Turbine Propulsion

Despite the decline in their prevalence, steam turbines remain relevant in specific contexts, notably in naval vessels and certain large commercial ships where their unique advantages are still valuable. In the military domain, steam turbines are often used in aircraft carriers and submarines, particularly those with nuclear propulsion. The reason for this is the inherent compatibility between nuclear reactors and steam turbines. Nuclear reactors generate heat through nuclear fission, and this heat is used to produce steam, which then drives the turbines. This combination allows for extended periods of operation without refueling, a critical requirement for naval operations.

In commercial shipping, steam turbines are sometimes employed in liquefied natural gas (LNG) carriers. These ships often utilize boil-off gas from the LNG cargo as a fuel source to generate steam, which then drives the turbines. This approach provides a practical solution for managing boil-off gas while also powering the ship, demonstrating the versatility of steam turbine systems in specialized applications.

One of the key engineering challenges in steam turbine propulsion systems is the management of condensate. After steam has passed through the turbine and transferred its energy, it condenses back into water in the condenser. Efficiently recovering and recycling this condensate is crucial for maintaining system efficiency and preventing water loss. Advanced condensate management systems have been developed to maximize the recovery of water and ensure that it is returned to the boiler for reuse, thereby improving the overall efficiency of the propulsion system.

Another aspect of steam turbine propulsion is the design and material selection for turbine blades. These blades operate under extreme conditions of high temperature and pressure, and they must withstand significant mechanical stress. Materials used in turbine blade manufacturing are often specially engineered alloys designed to resist thermal creep and corrosion. The design of the blades is also critical, with aerodynamic profiles optimized to maximize the efficiency of steam expansion and energy transfer.

In the context of environmental impact, steam turbine propulsion systems have traditionally been less efficient than modern alternatives, leading to higher fuel consumption and greater emissions. However, advancements in boiler technology, combined with the development of more efficient turbines and better insulation materials, have mitigated some of these concerns. Additionally, regulatory pressures have driven the adoption of cleaner fuels and more stringent emissions controls in maritime operations, further influencing the evolution of steam turbine technology.

The historical significance of steam turbines in marine propulsion cannot be overstated. They represented a significant technological leap from the earlier era of sail and reciprocating steam engines, enabling faster, larger, and more powerful ships. This technological advancement facilitated global trade, naval supremacy, and the expansion of maritime transportation networks, shaping the modern world in profound ways.

In summary, while steam turbine propulsion may no longer be the dominant force in maritime propulsion, its legacy endures. The systems that once powered the largest and most formidable vessels on the seas continue to inform and inspire contemporary engineering practices. The story of steam turbine propulsion is one of innovation, adaptation, and enduring impact, reflecting the broader narrative of human ingenuity in harnessing the power of steam to conquer the oceans.

Steam Turbine Propulsion

The influence of steam turbine propulsion extends beyond its direct application in ships to its role in advancing broader engineering and industrial practices. The development and refinement of steam turbines for marine use have contributed significantly to the fields of thermodynamics, fluid mechanics, and materials science. These advancements have had a ripple effect, influencing the design and operation of land-based power plants, industrial machinery, and even aerospace technology.

In the maritime sector, the evolution of steam turbine propulsion has been closely tied to the changing demands and priorities of the industry. During the early to mid-20th century, the need for larger, faster, and more powerful ships drove the adoption of steam turbines. The technology was seen as a solution to the limitations of reciprocating engines, which were bulky, complex, and less efficient at converting steam energy into mechanical work. Steam turbines offered a more compact and efficient means of propulsion, enabling the construction of vessels that could carry more cargo or passengers over greater distances at higher speeds.

One of the key milestones in the history of steam turbine propulsion was the launch of the RMS Mauretania in 1906, which, along with her sister ship RMS Lusitania, was among the first major ocean liners to be powered by steam turbines. These ships set new standards for speed and efficiency, capturing the Blue Riband for the fastest transatlantic crossing and demonstrating the potential of steam turbine technology in commercial shipping. The success of these vessels spurred further investment and innovation in steam turbine propulsion, leading to its widespread adoption in both the commercial and military sectors.

As steam turbines became more prevalent, engineers and designers faced the challenge of optimizing their performance and reliability. This led to significant advancements in turbine blade design, thermal insulation, and lubrication systems. The development of multi-stage turbines, where steam is expanded and energy extracted in multiple stages, further improved the efficiency of steam turbine systems. These technological advancements not only enhanced the performance of ships but also reduced operating costs and extended the lifespan of the propulsion systems.

In the naval domain, steam turbines played a crucial role in the modernization of fleets. During World War II, many of the world’s most powerful warships, including aircraft carriers and battleships, were equipped with steam turbine propulsion. The high power output and reliability of steam turbines were critical in enabling these vessels to perform a wide range of combat and support operations. The strategic importance of steam turbine-powered ships underscored the need for continuous improvement in turbine technology, driving research and development in areas such as fuel efficiency, thermal management, and noise reduction.

The post-war period saw a gradual shift in maritime propulsion technology, with diesel engines and gas turbines gaining prominence due to their superior fuel efficiency and lower emissions. However, steam turbines remained in use in specific applications where their unique advantages were still relevant. The advent of nuclear propulsion in the 1950s and 1960s provided a new lease of life for steam turbines, as the heat generated by nuclear reactors could be efficiently converted into steam to drive turbines. This development was particularly significant in the context of submarines and aircraft carriers, where the ability to operate for extended periods without refueling was a major strategic advantage.

In the modern era, the use of steam turbines in marine propulsion is limited but still important in certain niches. For example, some LNG carriers continue to use steam turbines, taking advantage of the availability of boil-off gas as a fuel source. Additionally, the lessons learned from decades of operating and maintaining steam turbine systems have informed the design and development of more advanced propulsion technologies, ensuring that the legacy of steam turbines continues to influence the future of maritime engineering.

Overall, the story of steam turbine propulsion is one of technological evolution, adaptation, and enduring impact. From its heyday in the early 20th century to its specialized applications today, steam turbine technology has left an indelible mark on the maritime industry and beyond. Its contributions to the fields of engineering, transportation, and energy have helped shape the modern world, highlighting the transformative power of human innovation in harnessing the energy of steam to propel ships across the seas.

- Historical Development and Adoption

Steam turbine propulsion emerged in the late 19th and early 20th centuries as a revolutionary technology in maritime engineering. The shift from reciprocating steam engines to steam turbines marked a significant advancement in ship propulsion. Early adopters, such as the RMS Mauretania and RMS Lusitania, demonstrated the advantages of turbines, including higher speeds and greater efficiency, prompting widespread adoption in both commercial and naval vessels. These ships set new benchmarks for performance, influencing the design of future maritime vessels and establishing steam turbines as the preferred propulsion method for large ships. - Engineering Principles and System Components

The core of steam turbine propulsion lies in the conversion of thermal energy from steam into mechanical work. The system comprises a boiler to generate high-pressure steam, turbines with precision-engineered blades to extract energy, and a condenser to recycle water. The turbines operate on thermodynamic cycles, typically the Rankine cycle, and involve multiple stages to maximize energy extraction. Materials science plays a crucial role, with advanced alloys used for turbine blades to withstand high temperatures and pressures. This engineering complexity ensures efficient and reliable propulsion for large ships. - Applications and Advantages in Maritime Operations

Steam turbine propulsion proved invaluable for a range of maritime applications, from luxury liners to military vessels. Its ability to generate substantial power made it ideal for large ships requiring high speeds and extended operational ranges. The smooth and continuous power delivery of turbines also contributed to their preference in naval vessels, where reliability was paramount. In commercial shipping, turbines enabled the transportation of goods and passengers at unprecedented speeds, fostering global trade and connectivity. - Challenges and Evolution

Despite its advantages, steam turbine propulsion faced challenges, including high fuel consumption and significant space requirements. The complexity of the system demanded rigorous maintenance and operational expertise. The mid-20th century saw a shift towards more fuel-efficient propulsion methods, such as diesel engines and gas turbines. However, the advent of nuclear propulsion in naval vessels offered a new application for steam turbines, utilizing reactor-generated heat to produce steam. This development highlighted the adaptability of steam turbines and their continued relevance in specific contexts. - Legacy and Modern Relevance

While steam turbines have largely been replaced by more modern propulsion systems, their legacy endures in maritime history. They represent a critical phase in the evolution of marine engineering, influencing contemporary propulsion technologies. Steam turbines remain in use in specialized applications, such as LNG carriers and nuclear-powered ships, where their unique benefits are still advantageous. The engineering principles and innovations derived from steam turbine development continue to impact modern technologies, underscoring their lasting significance in the field of maritime propulsion.

Historical Development and Adoption

The historical development and adoption of steam turbine propulsion represent a significant chapter in the evolution of maritime engineering. This transition from traditional reciprocating steam engines to the more advanced steam turbines marked a pivotal moment in the history of naval and commercial shipping. The initial foray into steam turbine technology can be traced back to the late 19th century when engineers began to explore ways to improve the efficiency and performance of ship propulsion systems. The limitations of reciprocating steam engines, which were bulky, complex, and less efficient, spurred the search for alternative propulsion methods that could offer higher speeds and greater power.

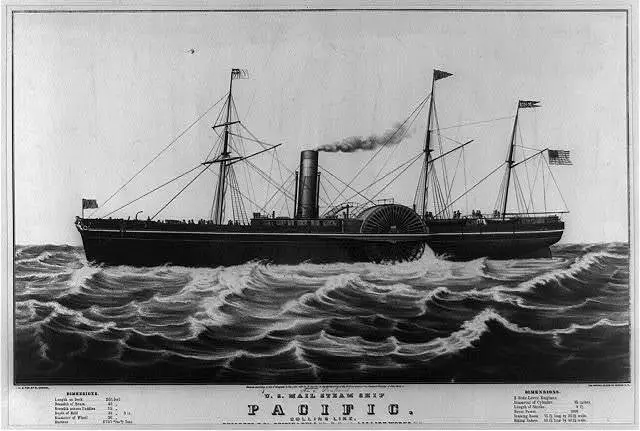

The breakthrough came with the invention of the steam turbine by Sir Charles Parsons in 1884. Parsons’ design featured a continuous rotary motion that was more efficient than the back-and-forth motion of reciprocating engines. His demonstration of a small steam turbine-powered vessel, Turbinia, at the Royal Navy Fleet Review in 1897, showcased the potential of this new technology. Turbinia achieved unprecedented speeds, far surpassing those of contemporary ships, and this performance caught the attention of the maritime industry.

The success of Turbinia led to the adoption of steam turbines in larger vessels, with the RMS Mauretania and RMS Lusitania being among the first major ocean liners to be equipped with this technology. Launched in the early 20th century, these ships set new records for transatlantic crossings, capturing the Blue Riband and demonstrating the superior performance of steam turbines. Their ability to maintain higher speeds and carry more passengers and cargo than their reciprocating engine-powered counterparts made them icons of a new era in maritime travel.

The adoption of steam turbines was not limited to commercial shipping. Naval fleets quickly recognized the strategic advantages of turbine propulsion, particularly in terms of speed and maneuverability. The Royal Navy and other major naval powers began to incorporate steam turbines into their warships, leading to the development of faster and more powerful vessels. During World War I and World War II, steam turbine-powered ships played crucial roles in naval operations, with aircraft carriers, battleships, and cruisers leveraging the technology for enhanced combat capabilities.

The widespread adoption of steam turbines in both commercial and military vessels was driven by several factors. The higher efficiency and smoother operation of turbines compared to reciprocating engines reduced fuel consumption and maintenance costs, making them economically advantageous. Additionally, the compact design of turbines allowed for more efficient use of space within the ship, providing room for additional cargo or armament.

As the 20th century progressed, the technological advancements in steam turbine design continued to evolve. The development of multi-stage turbines, which allowed for greater energy extraction from steam, further improved their efficiency and performance. These advancements, combined with improvements in boiler technology and materials science, enhanced the reliability and durability of steam turbine systems, solidifying their place in maritime propulsion.

However, the dominance of steam turbines began to wane in the mid-20th century with the rise of diesel engines and gas turbines. These newer propulsion systems offered better fuel efficiency and lower emissions, aligning with the changing priorities of the maritime industry. Despite this shift, steam turbines found a new application in the emerging field of nuclear propulsion. The heat generated by nuclear reactors was effectively used to produce steam, which then powered turbines, making them a critical component of nuclear-powered submarines and aircraft carriers.

In conclusion, the historical development and adoption of steam turbine propulsion marked a transformative period in maritime history. The transition from reciprocating engines to steam turbines enabled the creation of faster, more efficient, and more powerful ships, revolutionizing both commercial and military maritime operations. While newer technologies have since taken precedence, the legacy of steam turbines continues to influence modern engineering and propulsion systems, underscoring their enduring impact on the maritime industry.

The adoption of steam turbine propulsion had a profound impact on shipbuilding and maritime operations, shaping the future of global transportation and naval strategy. The transition to steam turbines brought about significant changes in ship design, as the compact and efficient nature of turbines allowed for more streamlined hulls and improved overall vessel performance. This period saw the emergence of iconic ships that exemplified the advantages of steam turbine propulsion, not only in terms of speed but also in reliability and operational efficiency.

One of the most notable effects of this technological shift was the enhancement of global trade and commerce. Steam turbine-powered vessels could traverse long distances more quickly and with greater reliability than their predecessors, which was particularly advantageous for transoceanic routes. The reduced travel times and increased cargo capacity enabled shipping companies to expand their networks, facilitating the growth of international trade and contributing to the globalization of markets. Passenger liners also benefited from these advancements, offering faster and more comfortable journeys, which helped to popularize transatlantic travel among the general public.

In the naval sphere, the strategic advantages of steam turbine propulsion were quickly realized. The increased speed and maneuverability of turbine-powered warships provided naval forces with a critical edge in both offensive and defensive operations. The ability to outpace enemy ships and reposition rapidly was a game-changer in naval warfare, influencing tactics and fleet compositions. The Royal Navy, for instance, leveraged steam turbine technology to maintain its dominance on the high seas, particularly during the early 20th century when naval power was a cornerstone of global influence.

The introduction of steam turbines also spurred a wave of innovation and competition within the maritime industry. Shipyards and engine manufacturers invested heavily in research and development to optimize turbine designs and improve their efficiency. This period of intense innovation led to numerous advancements, such as better turbine blade aerodynamics, enhanced thermal efficiency, and more robust materials capable of withstanding the harsh marine environment. These improvements not only extended the operational lifespan of turbines but also made them more cost-effective and reliable.

Despite the eventual decline in the use of steam turbines for conventional ships, their legacy persisted through their continued use in specialized applications and the lessons they provided for future technologies. The experience gained in designing and operating steam turbines laid the groundwork for advancements in other areas of engineering, including power generation and aerospace. The principles of thermodynamics and fluid dynamics honed through turbine development have been applied to a wide range of industries, illustrating the far-reaching impact of this maritime innovation.

In the modern era, the influence of steam turbine propulsion can still be seen in the context of nuclear-powered vessels. The synergy between nuclear reactors and steam turbines remains a key aspect of naval engineering, with many of today’s most advanced submarines and aircraft carriers utilizing this combination to achieve unparalleled endurance and operational capability. Furthermore, the expertise in managing high-pressure steam systems and optimizing thermal cycles continues to inform contemporary engineering practices, ensuring that the knowledge gained from the era of steam turbine dominance is not lost.

In retrospect, the historical development and adoption of steam turbine propulsion represent a landmark in maritime history, one that not only transformed the shipping industry but also set the stage for future technological advancements. The legacy of steam turbines is evident in the way they reshaped global trade, military strategy, and engineering practices, leaving an indelible mark on the world and highlighting the enduring significance of this remarkable technology.

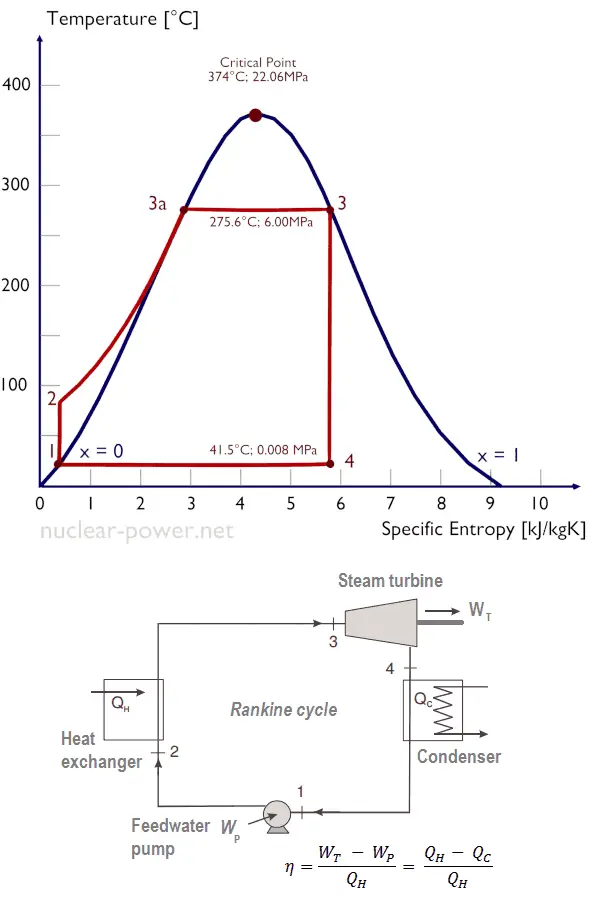

Engineering Principles and System Components

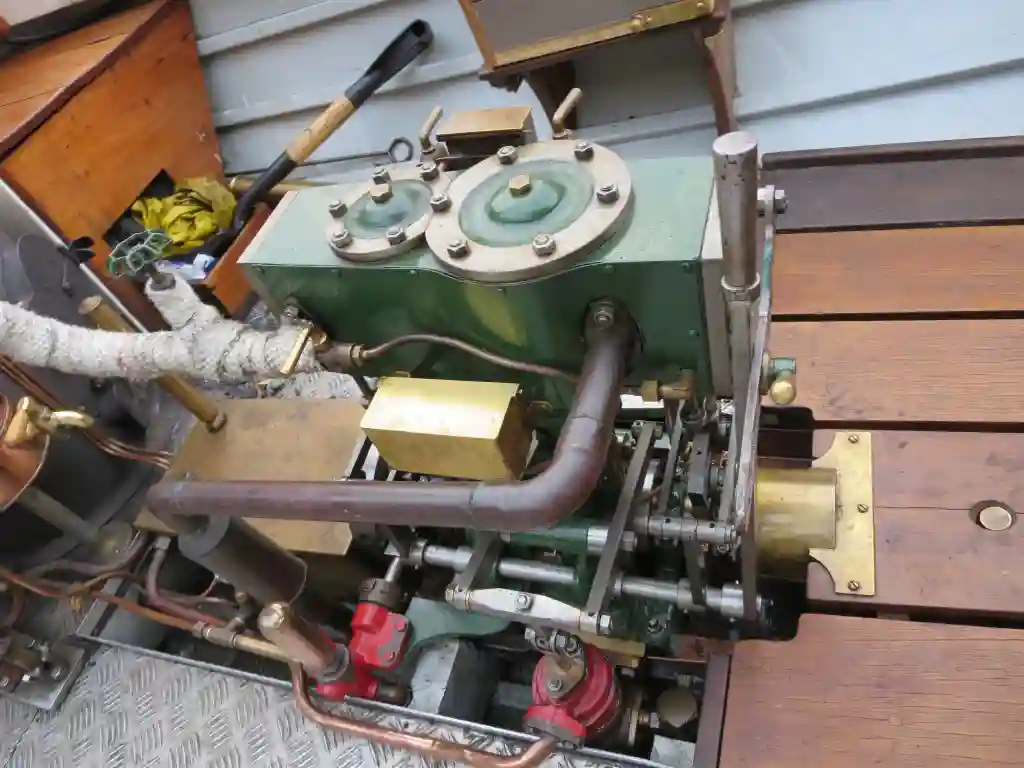

The engineering principles and system components of steam turbine propulsion form a complex yet elegant system designed to efficiently convert thermal energy from steam into mechanical work for propelling ships. Central to this technology is the thermodynamic cycle, typically the Rankine cycle, which describes the processes through which water is converted into steam and then condensed back into water for reuse. This cycle involves several key components: the boiler, the steam turbine, the condenser, and the feedwater pump, each playing a crucial role in the overall operation and efficiency of the propulsion system.

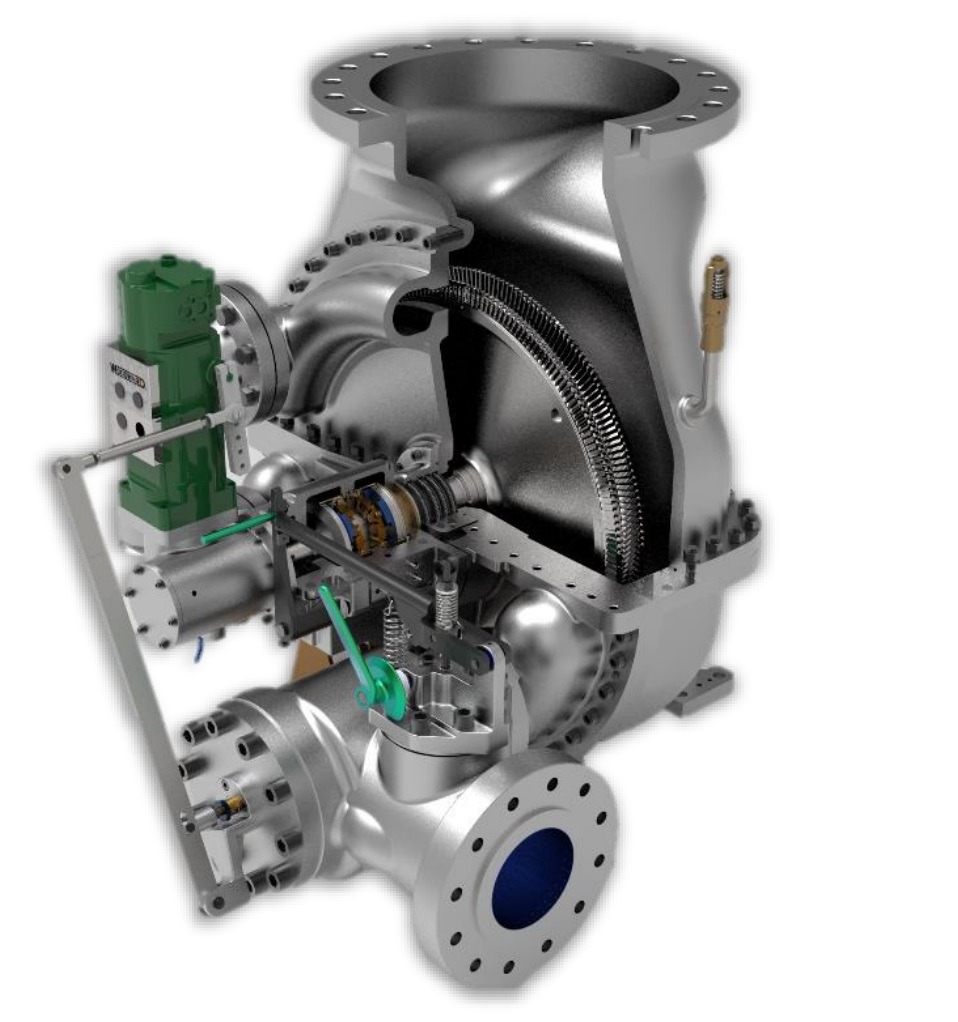

At the heart of the system is the boiler, where water is heated to produce high-pressure steam. The boiler must maintain precise temperature and pressure conditions to ensure the efficient generation of steam. This steam, at a high temperature and pressure, is then directed to the steam turbine. The steam turbine itself is a marvel of engineering, consisting of a series of blades arranged in multiple stages on a rotor. These blades are designed to extract energy from the steam as it expands and cools through the turbine. The arrangement of blades is crucial, with the first set of blades (nozzles) accelerating the steam and directing it onto the rotor blades, where the actual energy transfer occurs. This setup allows for the efficient conversion of the steam’s thermal and kinetic energy into mechanical work.

The turbine operates on the principle of converting the energy of steam into rotational energy. As steam enters the turbine, it strikes the blades at high velocity, causing the rotor to spin. This spinning rotor is connected to the ship’s propeller shaft, and the mechanical energy generated by the turbine is transmitted to the propeller, propelling the ship through the water. The design of the turbine blades is critical; they must be aerodynamically optimized to maximize energy extraction while withstanding the high temperatures and pressures of the steam. Materials used in these blades are typically advanced alloys that offer high strength and resistance to thermal creep and corrosion.

Once the steam has passed through the turbine, it enters the condenser, where it is cooled and converted back into water. The condenser plays a vital role in the system by ensuring that the steam is efficiently condensed into water for reuse in the boiler. This closed-loop system minimizes water loss and enhances the overall efficiency of the propulsion system. The cooling process in the condenser is typically achieved using seawater, which absorbs the heat from the steam. Efficient condensate management is essential to maintain the system’s efficiency and to prevent the buildup of air or non-condensable gases, which can reduce the effectiveness of the condensation process.

After condensation, the water is pumped back into the boiler using feedwater pumps. These pumps must be capable of handling high pressures to ensure the continuous and efficient flow of water back into the boiler. The entire process is carefully monitored and controlled to maintain optimal operating conditions, ensuring the efficient conversion of heat energy into mechanical work.

One of the key challenges in steam turbine propulsion is the management of heat losses and the optimization of the energy conversion process. Engineers have developed various strategies to improve the efficiency of steam turbines, including the use of superheated steam, which increases the temperature of the steam above its saturation point, thereby increasing the efficiency of the energy transfer process. Additionally, the development of multi-stage turbines, where steam is expanded and energy is extracted in multiple stages, has significantly improved the efficiency of steam turbine systems.

Another important aspect of steam turbine propulsion is the lubrication and cooling of the turbine components. The high rotational speeds and temperatures involved require effective lubrication to reduce friction and wear on the turbine’s moving parts. Lubrication systems must be meticulously maintained to ensure the smooth operation of the turbine and to prevent mechanical failures.

Overall, the engineering principles and system components of steam turbine propulsion reflect a sophisticated integration of thermodynamics, fluid dynamics, and materials science. The precise control of steam generation, energy extraction, and heat dissipation is essential for the efficient operation of the propulsion system. The innovations in turbine design and materials have not only enhanced the performance and reliability of steam turbines but also paved the way for advancements in other fields of engineering. This complex interplay of components and principles underscores the ingenuity behind steam turbine propulsion and its lasting impact on maritime engineering.

Building on the foundations of steam turbine propulsion, further advancements in engineering principles and system components have continued to shape the efficiency and adaptability of these systems. As steam turbines were implemented in a variety of vessels, engineers worked on refining the technology to optimize power output while minimizing fuel consumption and maintenance needs. One of the most significant advancements in this regard was the development of multi-stage turbines. These turbines utilize multiple stages of blades and nozzles, with steam passing through each stage sequentially. Each stage extracts a portion of the energy from the steam, which is then converted into mechanical energy, allowing for more efficient use of the steam’s potential. This multistage process ensures that the energy is not wasted and that the steam’s pressure and temperature are gradually reduced in a controlled manner, increasing the turbine’s overall efficiency.

A key consideration in steam turbine design is the thermodynamic efficiency of the system. The efficiency of converting heat into mechanical work is directly linked to the temperature difference between the steam and the surroundings. To maximize this efficiency, superheating the steam became a critical innovation. Superheating involves raising the temperature of the steam beyond its saturation point before it enters the turbine. This process prevents the steam from condensing within the turbine, ensuring that all of its thermal energy is available for work. Superheated steam also helps reduce moisture formation in the turbine, which can cause erosion and damage over time. These innovations have led to significantly improved performance, allowing turbines to operate at higher pressures and temperatures without compromising durability.

In conjunction with superheating, reheat systems were introduced to further boost the efficiency of steam turbines. In this setup, steam is passed through the turbine in stages, with the steam being partially expanded and then reheated before entering the next stage. This allows the steam to maintain its energy level and increase the turbine’s efficiency by avoiding significant temperature loss between stages. Reheating has been especially important for large marine vessels, where high efficiency and power output are essential for performance and fuel economy.

Another area of improvement has been the materials used in turbine construction. As turbines operate under extreme conditions of heat and pressure, the materials used to construct the turbine blades, rotors, and other components must be able to withstand significant mechanical stresses. Early turbines used simple metals, but as turbine efficiency increased and operating conditions became more demanding, advanced alloys and composite materials were developed. Nickel-based alloys, for example, have become common in turbine blades because of their ability to resist high temperatures and corrosion. These materials are also designed to maintain their strength and flexibility under the constant rotational forces that turbines generate. The choice of materials not only extends the operational life of the turbine but also helps reduce the frequency of maintenance and downtime.

Lubrication systems have also evolved to ensure the smooth operation of steam turbines, especially given the high rotational speeds involved. Proper lubrication is critical to minimizing friction and wear, which can significantly affect turbine efficiency and reliability. Advanced oils and synthetic lubricants have been developed to cope with the high temperatures and pressures within the turbine. These oils are specifically formulated to prevent oxidation and degradation, ensuring that the turbines remain well-lubricated throughout their lifespan.

One of the most innovative developments in steam turbine technology has been the advent of nuclear-powered steam turbines, which use the heat generated by nuclear reactors to produce steam. This marriage of nuclear energy and steam turbine propulsion has had a transformative effect on naval vessels, particularly submarines and aircraft carriers, where extended operational endurance without the need for refueling is crucial. The nuclear reactor heats the water to produce steam, which then drives the turbine in the same manner as conventional steam systems. This technology allows nuclear-powered vessels to remain at sea for months without needing to return to port for fuel, a game-changer for military applications, especially in strategic defense and long-range missions.

The integration of condensers in the steam cycle has further enhanced the efficiency of steam turbines. By recovering and condensing steam into water in a closed-loop system, condensers help minimize water wastage, reducing the need for large quantities of freshwater. In marine environments, this is particularly valuable as it conserves water resources and improves the overall sustainability of the propulsion system. The condenser works by transferring the heat from the steam to the surrounding environment—often using seawater as a cooling medium. The effectiveness of the condenser directly impacts the overall performance of the turbine, as the ability to rapidly cool and condense the steam allows the system to continuously operate at peak efficiency.

Feedwater heaters have also been introduced into the steam cycle to improve the overall thermal efficiency. These systems preheat the water before it enters the boiler, using waste heat from the exhaust steam. This minimizes the amount of energy required to bring the water to the necessary boiling point, reducing the fuel needed and improving the overall efficiency of the cycle. These components are typically installed as part of an integrated energy recovery system, which also helps to reduce the environmental impact of steam turbine propulsion.

As steam turbine technology advanced, its application spread beyond ships to other areas, such as land-based power generation. The same principles of energy conversion used in marine turbines were adapted to produce electricity in thermal power plants. The massive turbines in power plants often operate on the same basic principles as those used in marine vessels, except on a larger scale. These land-based applications also spurred further innovations in materials, heat transfer technologies, and turbine design, influencing the development of highly efficient power systems.

In summary, the engineering principles and system components of steam turbine propulsion are a study in continuous innovation and adaptation. From the basic components such as the boiler, turbine, condenser, and feedwater system to advancements like multi-stage turbines, superheating, and nuclear integration, the evolution of steam turbine technology has been shaped by a drive to maximize power output, efficiency, and reliability. The integration of advanced materials, lubricants, and energy recovery systems has made steam turbine propulsion a sophisticated and resilient technology, capable of meeting the demands of modern marine vessels and power plants alike. This legacy of innovation continues to influence modern engineering practices, ensuring that the principles of steam turbine propulsion remain a key part of the broader landscape of energy conversion technologies.

Challenges and Evolution

The challenges and evolution of steam turbine propulsion reflect the ongoing quest to improve efficiency, reduce operational costs, and address emerging needs in the maritime and energy sectors. While steam turbines offered significant advantages over reciprocating engines, particularly in terms of speed, reliability, and power output, they also presented a set of technical and operational challenges that engineers had to overcome. As the technology evolved, many of these challenges were addressed through innovations in design, materials, and operating practices. However, other new hurdles emerged, prompting further advancements in turbine technology and shifting the focus of propulsion systems in some areas of maritime and industrial engineering.

One of the primary challenges faced by steam turbine systems in the early stages of their development was the complexity and size of the machinery. Steam turbines required large, intricate components, and the associated systems, such as boilers and condensers, were similarly large and required significant amounts of space within a vessel. This space requirement limited the design flexibility of ships, particularly those with more compact hulls or specific operational needs. Moreover, the high operating pressures and temperatures of steam turbines demanded advanced engineering and materials capable of withstanding these extreme conditions. Early turbine systems were prone to failures caused by material fatigue, corrosion, and thermal stresses, which made maintenance and repairs more frequent and costly.

As a result, steam turbine technology had to undergo significant refinement in terms of both design and materials to ensure greater reliability. The development of high-strength alloys that could withstand higher temperatures and pressures led to more durable turbine blades and rotors. Additionally, the introduction of more advanced sealing systems and lubrication techniques helped reduce the incidence of mechanical failures. The evolution of multi-stage turbines was another response to the challenge of improving efficiency and reducing energy loss. In multi-stage systems, the steam is expanded and utilized in several stages, extracting energy progressively and improving the overall efficiency of the turbine. These improvements made steam turbines more reliable and operationally viable for larger vessels and power plants.

However, the inherent complexity and the need for frequent maintenance and repairs kept steam turbines from being a universally ideal solution. In the mid-20th century, the advent of diesel engines and gas turbines began to challenge the supremacy of steam turbines. Diesel engines, which operate using combustion rather than steam, offered several key advantages: they were more fuel-efficient, simpler to operate, and required less maintenance than steam turbines. Additionally, diesel engines could be more easily adapted to smaller vessels and commercial shipping, where the space and cost constraints of steam turbines were more pronounced. This shift to diesel-powered propulsion systems was further accelerated by advancements in fuel processing, engine design, and the growing need for more environmentally friendly options in terms of emissions and fuel consumption.

The rise of gas turbines, initially developed for military aircraft, also posed a challenge to steam turbines in naval and commercial ships. Gas turbines offered high power-to-weight ratios, quick startup times, and a simpler operational mechanism. Their efficiency at higher speeds and ability to produce thrust in a more compact form made them especially attractive for naval vessels, where maneuverability and speed were critical. Despite these advantages, gas turbines still faced limitations in terms of fuel efficiency and operational costs, which made steam turbines more appealing for certain applications, such as large merchant vessels and power generation plants.

One of the more unique evolutions of steam turbine technology came with the introduction of nuclear-powered ships. The coupling of nuclear reactors with steam turbines allowed for a new class of vessels, including nuclear submarines and aircraft carriers, to operate for extended periods without the need for refueling. Nuclear reactors provided a virtually unlimited source of heat to generate steam, which could then drive turbines, making these ships capable of remaining at sea for months or even years without refueling. The evolution of nuclear-powered steam turbines marked a significant milestone in the development of propulsion systems, as it demonstrated the adaptability of steam turbines to new sources of energy beyond traditional fossil fuels. Despite their complexity and high operational costs, nuclear-powered ships demonstrated the power and endurance that steam turbines could offer in specific military and strategic contexts.

However, as steam turbines were increasingly replaced by more efficient and simpler alternatives in the commercial and naval sectors, they found a new lease on life in power generation. Steam turbines became the backbone of many thermal power plants, where they were used to convert heat from burning fossil fuels or nuclear reactions into electrical power. This marked the beginning of a new chapter in the evolution of steam turbine technology, one that focused on large-scale energy production rather than transportation. The principles and components used in maritime steam turbines were adapted for land-based power stations, and innovations in turbine design, such as reheat cycles, condensate recovery, and feedwater heating, helped further improve the efficiency and environmental impact of steam turbine systems. Over time, these improvements allowed steam turbines to maintain a significant role in the energy sector, despite the growing dominance of other energy production methods like gas and wind power.

Throughout the latter half of the 20th century, steam turbine technology evolved in response to the global push for energy efficiency and environmental sustainability. Efforts were made to reduce the environmental impact of steam turbines, including the adoption of cleaner fuels and more advanced combustion techniques in fossil-fuel-powered turbines. Additionally, the development of combined-cycle systems, where gas turbines are paired with steam turbines to capture and reuse waste heat, significantly improved the overall efficiency of power plants, contributing to a more sustainable energy production process.

Despite facing competition from newer technologies, steam turbines have not disappeared from modern applications. They continue to be used in specialized fields where their benefits—such as high power output and long operational lifespans—are still valued. Their application in nuclear power plants, hydropower plants, and large industrial processes highlights the continued relevance of steam turbines in the global energy landscape. Furthermore, ongoing research into materials, cooling systems, and turbine blade designs continues to improve their performance, keeping steam turbines viable even in the face of alternative technologies.

In conclusion, the challenges and evolution of steam turbine propulsion have been marked by both technological advancements and shifts in operational requirements. Initially hindered by complexity and maintenance needs, steam turbines overcame many obstacles through innovations in materials, design, and efficiency. While they were largely displaced by diesel engines and gas turbines in certain maritime applications, steam turbines adapted to new roles in nuclear-powered ships and power generation. Their enduring legacy in the energy sector underscores their adaptability and efficiency, ensuring that steam turbine technology remains an important part of modern engineering, even as the search for more sustainable and efficient propulsion systems continues.

As the steam turbine continued to evolve, its role in modern engineering remained significant, especially in industries where reliability, large-scale power generation, and long operational cycles were paramount. One of the most notable evolutions in recent years has been the focus on enhancing operational efficiency while reducing the environmental footprint of steam turbines. In the wake of growing concerns about climate change and the demand for cleaner energy sources, many steam turbine systems have been adapted to work in tandem with renewable energy sources, such as biomass and geothermal energy, creating more sustainable power generation systems. These adaptations enable steam turbines to continue contributing to the global energy landscape while meeting the increasing emphasis on sustainability.

The integration of combined heat and power (CHP) systems has become another key development in the evolution of steam turbine technology. CHP systems, also known as cogeneration systems, utilize the waste heat from electricity generation to provide heating, either for industrial processes or residential use. By harnessing this otherwise wasted heat, CHP systems achieve much higher overall efficiency than traditional steam turbine-only power plants, reducing fuel consumption and greenhouse gas emissions. This technology is especially valuable in applications like district heating, where the heat produced can be distributed to large areas, providing both electricity and thermal energy from a single source.

Another emerging trend in the evolution of steam turbine technology is the push for hybrid propulsion systems in ships and industrial applications. These systems combine the benefits of steam turbines with other technologies, such as diesel engines or gas turbines, to optimize performance and fuel consumption under varying operational conditions. In marine vessels, for instance, hybrid systems may allow ships to operate at lower speeds using diesel engines for greater fuel efficiency, while employing steam turbines when higher speeds or greater power are needed. This flexibility can significantly reduce operating costs and emissions, providing a more adaptable solution to meet the diverse energy demands of modern fleets.

The continued development of advanced materials is also contributing to the ongoing evolution of steam turbines. Research into more heat-resistant and corrosion-resistant materials has led to the creation of advanced alloys and ceramic materials that can withstand higher operational temperatures and more aggressive chemical environments. These materials not only enhance the durability and efficiency of steam turbines but also help reduce the frequency and cost of maintenance. In particular, materials that can maintain structural integrity at high temperatures are critical for turbines in nuclear power plants, where consistent and reliable performance is essential. Furthermore, additive manufacturing (3D printing) technologies have begun to play a role in the design and production of steam turbine components, offering new opportunities for precision manufacturing and rapid prototyping.

In addition to materials innovation, digital technologies have increasingly been incorporated into steam turbine systems. Sensors, data analytics, and predictive maintenance tools are now integrated into modern steam turbines, enabling operators to monitor performance in real-time and identify potential issues before they lead to failures. These digital advancements provide significant cost savings by reducing unplanned downtime, extending the life of turbine components, and optimizing the operating conditions of the turbine to maximize efficiency. The trend toward Industry 4.0 and smart manufacturing is likely to further enhance the performance and lifespan of steam turbines, contributing to their continued viability as a key component in power generation and industrial applications.

Despite these advancements, the overall trend in the propulsion and power generation sectors has seen a shift toward alternative energy sources. The push for reducing reliance on fossil fuels has led to the development of renewable energy technologies like wind turbines, solar power, and hydroelectric plants, which, in some cases, offer more sustainable and cost-effective solutions than steam turbines. For instance, offshore wind farms and solar farms are rapidly growing in popularity due to their ability to harness clean energy without the environmental costs associated with fossil fuel combustion. This shift, while impacting the traditional roles of steam turbines, is also driving the evolution of hybrid energy systems where steam turbines may still play a role, but in conjunction with renewable energy sources.

The ongoing research into green hydrogen also presents a potential avenue for steam turbine technology. As a zero-emission fuel source, hydrogen could be used to generate steam without the harmful emissions typically associated with fossil fuel combustion. The development of hydrogen-powered steam turbine systems, coupled with the growing infrastructure for hydrogen production and distribution, could present a new and sustainable direction for steam turbines in the energy landscape. This transition would allow steam turbines to maintain relevance in the global effort to decarbonize energy systems while continuing to leverage their established strengths in large-scale, reliable power generation.

In conclusion, the evolution of steam turbine technology has been a dynamic journey, driven by continuous advancements in engineering, materials science, and energy efficiency. While steam turbines once faced significant challenges in terms of complexity, fuel consumption, and maintenance, their ongoing adaptation to modern energy demands has allowed them to remain a key player in power generation and maritime propulsion. As new technologies emerge, such as hybrid systems, renewable energy integration, and digital innovations, steam turbines continue to evolve, ensuring their role in a more sustainable and technologically advanced future. Even as other technologies vie for dominance, steam turbines’ capacity for large-scale power generation and their continued relevance in specialized applications underscore the enduring significance of this foundational technology in the modern world.

Legacy and Modern Relevance

The legacy and modern relevance of steam turbine technology are deeply intertwined with the evolution of industrial engineering, energy production, and transportation. Steam turbines, which first revolutionized power generation and propulsion in the late 19th and early 20th centuries, continue to influence a wide range of industries, even as newer technologies emerge. Their legacy can be seen in the lasting impact they’ve had on the design of power plants, the development of naval vessels, and the way energy systems are structured today. While they may no longer be the dominant technology in many fields, steam turbines have evolved and adapted to remain a critical part of modern infrastructure, especially in large-scale power generation, nuclear energy, and specialized applications in both maritime and industrial sectors.

At the heart of the steam turbine’s legacy is its profound influence on power generation. As the principal technology for converting thermal energy into mechanical work for much of the 20th century, steam turbines helped pave the way for large-scale electricity generation in power plants. The development of steam turbines allowed for a higher degree of efficiency in converting heat into electricity compared to earlier methods, such as reciprocating engines. This shift enabled power plants to become larger and more reliable, supporting the growth of modern cities and industries, and directly contributing to the rise of mass electrification. Today, steam turbines remain a key component in many of the world’s largest thermal power plants, including those that operate on fossil fuels (coal, natural gas) and nuclear power.

The advent of nuclear-powered steam turbines marked a pivotal moment in both the legacy of the technology and its continued relevance. Nuclear reactors, which generate heat through nuclear fission, pair with steam turbines to produce electricity, just as thermal power plants use fossil fuels. The ability to harness the immense energy of nuclear reactions and convert it into mechanical power for electricity generation represented a major breakthrough. Nuclear-powered steam turbines became the backbone of some of the most powerful and enduring energy systems, providing a low-carbon alternative to traditional fossil fuel-based plants. The role of steam turbines in nuclear power plants not only highlights their adaptability but also underscores their ongoing importance in meeting the world’s energy needs in the face of growing concerns about climate change and the need for cleaner energy sources.

In maritime propulsion, the legacy of steam turbines is just as enduring. The transition from slower, less reliable reciprocating engines to high-speed, efficient steam turbines revolutionized naval warfare and commercial shipping in the early 20th century. Steam turbines powered the great ocean liners, battleships, and aircraft carriers of the 20th century, enabling faster travel and more effective military capabilities. Despite the rise of diesel engines and gas turbines in the second half of the century, steam turbines are still used in specific maritime applications. Nuclear-powered submarines and aircraft carriers, for example, rely on steam turbines driven by nuclear reactors to provide sustained, high-performance propulsion without the need for frequent refueling. Even though other propulsion technologies may offer advantages in certain areas, steam turbines continue to offer unparalleled reliability and efficiency in specialized, long-range naval applications.

Steam turbines have also had a significant impact on the industrial sector, especially in large-scale manufacturing and processing industries. Many industries that rely on thermal energy, such as chemical plants, oil refineries, and paper mills, use steam turbines to generate the power needed to run various processes. In these industries, steam turbines often work in tandem with other systems to optimize energy efficiency, improve reliability, and reduce operational costs. The integration of steam turbines into these industries helped set the stage for the modern energy management practices we see today, where maximizing efficiency and reducing waste are primary considerations.

Despite their continuing importance, the legacy of steam turbines has not been without challenges. As diesel engines and gas turbines gained popularity due to their better fuel efficiency and flexibility, the role of steam turbines in commercial maritime propulsion decreased. Diesel engines, with their compact size, lower operational costs, and fuel flexibility, became the go-to propulsion system for most commercial shipping. Gas turbines, with their rapid acceleration capabilities and high power-to-weight ratios, found favor in military applications. However, steam turbines have not disappeared entirely. They remain in use where large, continuous power output is needed or where specific energy requirements exist, such as in power plants or certain naval vessels.

In modern applications, combined-cycle systems, which pair gas turbines with steam turbines, have enhanced the efficiency of power plants by allowing the waste heat from the gas turbine to be used to generate steam for the steam turbine. This combined approach significantly boosts the overall efficiency of power generation systems, and steam turbines continue to play a vital role in this process. The trend towards hybrid energy systems also keeps steam turbines relevant in modern times. For example, hybrid propulsion systems that combine steam turbines with other technologies—such as diesel engines or batteries—are increasingly used in maritime vessels and large industrial applications. These systems offer the best of both worlds by optimizing fuel consumption and reducing emissions, ensuring that steam turbines can still contribute to meeting modern energy demands.

Looking to the future, the renewable energy landscape presents both challenges and opportunities for steam turbine technology. As the world shifts away from fossil fuels and toward cleaner energy sources, there is a growing interest in integrating steam turbines with biomass and geothermal energy, which generate heat that can be used to produce steam. This shift allows steam turbines to continue to play a role in renewable energy systems, where they can help maximize energy efficiency and reduce waste. Additionally, green hydrogen—produced using renewable energy sources to split water into hydrogen and oxygen—has the potential to provide a clean fuel for generating steam. The combination of green hydrogen and steam turbines could offer a carbon-neutral solution for power generation, ensuring that steam turbines remain relevant as the world moves toward a more sustainable future.

Digital technologies are also helping to extend the life and improve the performance of steam turbines. The integration of sensors, smart monitoring systems, and predictive maintenance tools allows operators to optimize turbine performance and detect potential issues before they lead to significant failures. These advancements in data analytics and artificial intelligence can improve the efficiency of steam turbines by ensuring that they operate at optimal conditions and by minimizing unplanned downtime. In industries like power generation and naval propulsion, these technological enhancements are helping steam turbines remain a viable option in increasingly demanding operational environments.

In conclusion, the legacy of steam turbine technology is marked by its pivotal role in the development of modern power generation, naval propulsion, and industrial manufacturing. Though other technologies have emerged to meet the growing demands for energy efficiency, speed, and flexibility, steam turbines continue to evolve and maintain their relevance in specialized sectors. Their capacity to adapt to new energy sources, integrate with hybrid systems, and benefit from digital innovations ensures that steam turbines will remain a key component of the global energy and transportation infrastructure for years to come. As we move toward a future that emphasizes sustainability, reliability, and efficiency, the legacy of steam turbines and their continued evolution will remain integral to shaping the world’s energy landscape.

As we continue to explore the future relevance of steam turbines, it’s clear that their adaptability will play a crucial role in modern energy systems. Although newer technologies such as solar, wind, and hydrogen energy are gaining traction, steam turbines are poised to continue contributing significantly to both the energy and industrial sectors. As nations and industries strive to meet more stringent environmental targets, steam turbines remain a vital technology due to their proven ability to handle large-scale energy production efficiently.

One of the major factors driving the continued relevance of steam turbines is their scalability. Steam turbines are capable of handling massive power generation needs, which makes them ideal for utility-scale power plants. While renewable sources like wind and solar are growing rapidly, they have limitations in terms of constant power generation, especially in regions where weather patterns are inconsistent. Steam turbines, particularly in combined-cycle plants, complement these renewable sources by providing consistent and stable baseload power. This integration ensures that power generation can remain reliable, even when renewable resources are not available, helping to balance the grid and ensure energy security.

Moreover, as the global demand for electrification and electrical storage solutions grows, steam turbines are finding renewed roles in thermal storage systems. In such systems, excess energy from renewable sources is used to generate heat, which is stored for later use. The stored heat is then used to generate steam, which drives the turbine to produce electricity when demand peaks. This integration of steam turbines with thermal storage technologies is helping to enhance the viability of renewable energy systems by addressing the challenges of intermittency and grid stability.

In industrial processes, steam turbines continue to play an essential role in cogeneration systems, where they provide both electricity and useful thermal energy. Industrial processes in sectors such as chemical manufacturing, oil refining, and pulp and paper production require substantial amounts of both electricity and steam. By using steam turbines in cogeneration, these industries can optimize their energy use, reduce overall fuel consumption, and lower emissions. These systems are particularly advantageous in industries that operate continuously and need reliable, 24/7 power, making steam turbines an invaluable component in industrial energy solutions.

Nuclear energy also continues to be a significant application for steam turbines, especially in nuclear power plants. As many countries transition toward low-carbon energy sources, nuclear power is being seen as a cleaner alternative to fossil fuels. Steam turbines, powered by nuclear reactors, remain central to electricity generation in nuclear plants due to their ability to handle high thermal energy efficiently. While the nuclear industry has faced challenges related to safety concerns and waste disposal, advances in reactor design, such as small modular reactors (SMRs), are reigniting interest in nuclear power. These smaller, more flexible reactors are expected to work in tandem with steam turbines, further ensuring the relevance of steam turbine technology in future energy systems.

The global energy transition is placing a stronger emphasis on decarbonization, and steam turbines are poised to adapt to these goals. As the push for renewable energy sources intensifies, technologies like green hydrogen and biomass offer new pathways to generate steam without the environmental impacts of fossil fuels. Steam turbines are being integrated into systems that produce energy from renewable sources, allowing them to maintain their role in power generation while helping to reduce the carbon footprint of industrial activities. The combination of clean fuels like hydrogen and advanced turbine technologies could play a major role in decarbonizing not only power plants but also hard-to-abate sectors such as heavy industry and shipping.

As the global shipping industry seeks to reduce its carbon emissions, there is also potential for steam turbines to play a part in the evolution of sustainable maritime propulsion. With international shipping being a significant contributor to global greenhouse gas emissions, the search for alternative propulsion technologies is critical. In the realm of hybrid propulsion systems for large ships, steam turbines could work alongside other green technologies, such as batteries and wind propulsion, to reduce reliance on traditional marine fuels. Moreover, nuclear-powered ships—such as aircraft carriers and submarines—will continue to rely on steam turbines for propulsion, as they provide a reliable and efficient solution for long-duration voyages without the need for frequent refueling.

The advancements in materials science are also contributing to the modernization of steam turbine technology. The development of superalloys and ceramic materials has allowed for higher operational temperatures and pressures, enhancing the efficiency and lifespan of turbines. Furthermore, additive manufacturing (3D printing) is playing an increasing role in the production of turbine components. This technology allows for the creation of more complex and lightweight turbine parts that would be difficult or impossible to manufacture using traditional methods. As these innovations continue to improve the performance and durability of steam turbines, they will remain a competitive technology in both energy generation and industrial applications.

In addition to these technical advancements, digital technologies are revolutionizing the way steam turbines are monitored and maintained. The incorporation of advanced sensors, Internet of Things (IoT) technology, and machine learning algorithms into steam turbine systems allows operators to monitor turbine performance in real-time. This enables predictive maintenance, where potential issues are identified before they lead to catastrophic failures, reducing downtime and maintenance costs. The ability to optimize turbine performance based on real-time data ensures that turbines can operate at peak efficiency, extending their operational lifespan and minimizing environmental impacts.

Despite the challenges posed by newer technologies and the transition to renewable energy sources, the legacy and modern relevance of steam turbines are undeniable. Their ability to generate reliable, large-scale power remains essential in many sectors, including power generation, industrial manufacturing, and maritime propulsion. Innovations in turbine design, materials, hybrid systems, and integration with renewable energy sources will ensure that steam turbines continue to evolve and remain a critical part of the global energy landscape. As the world seeks to meet its energy demands while addressing climate change, the steam turbine will continue to play a vital role in shaping the future of energy and industrial systems.

Turbo Generator on Ship

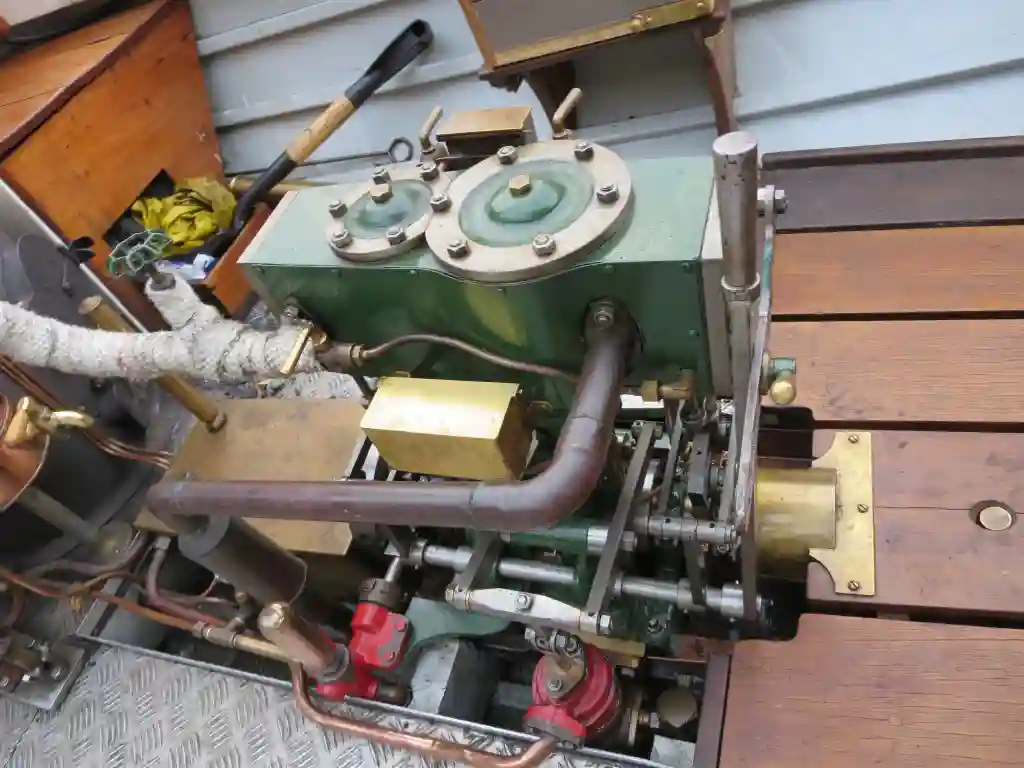

A turbo generator on a ship is an essential component of the vessel’s power generation system, playing a crucial role in ensuring the availability of electrical power for various onboard systems and operations. This complex piece of machinery combines a turbine with an electrical generator to convert mechanical energy into electrical energy, which is then distributed to power everything from navigation systems and communication equipment to lighting, HVAC systems, and propulsion in some cases.

At the core of a ship’s turbo generator is the steam turbine, which harnesses the energy of high-pressure steam generated by the ship’s boilers. This steam is directed through the turbine’s blades, causing them to spin and transfer mechanical energy to the generator. The steam turbine is designed to operate at high efficiency, converting as much thermal energy as possible into mechanical work. The output from the turbine is then used to drive the electrical generator, which converts the mechanical energy into electricity through electromagnetic induction. This electricity is distributed throughout the ship via an electrical distribution network, supplying power to various systems and equipment.

The use of turbo generators on ships, especially in larger vessels such as naval ships, cruise liners, and tankers, is primarily due to their ability to provide a reliable and steady supply of electrical power. Unlike smaller generators that might be used for auxiliary purposes, turbo generators are capable of producing large amounts of power to meet the demands of modern ships, which often require substantial electrical loads. The combination of steam turbines with electrical generators allows for efficient energy conversion and utilization, making turbo generators a preferred choice for ships that operate over long distances and require continuous power.

One of the key advantages of turbo generators is their efficiency in energy conversion. By using steam turbines, which operate at high temperatures and pressures, turbo generators can achieve a higher thermal efficiency compared to other types of generators. This is particularly important on ships, where fuel efficiency is a critical concern due to the high costs associated with marine fuel. Efficient turbo generators reduce fuel consumption, which not only lowers operating costs but also minimizes the environmental impact of the ship by reducing greenhouse gas emissions.

The integration of turbo generators into a ship’s power system also allows for flexibility in power management. On ships with combined propulsion systems, turbo generators can supplement or replace traditional propulsion methods, such as diesel engines, under certain conditions. For example, during cruising at steady speeds, the ship might rely on the turbo generator to provide the necessary electrical power for propulsion, thereby optimizing fuel usage and reducing engine wear. This hybrid approach can extend the life of the main engines and provide redundancy in case of engine failure, enhancing the overall reliability of the ship.

Turbo generators are also crucial in nuclear-powered ships, such as nuclear submarines and aircraft carriers, where the heat generated by the nuclear reactor is used to produce steam that drives the turbine. In these vessels, the turbo generator is part of a sophisticated power generation system that must operate under extreme conditions, including high pressures and temperatures. The reliability of the turbo generator in these settings is paramount, as it not only powers the ship’s systems but also ensures the safe operation of the nuclear reactor by supporting essential cooling and safety systems.

In modern shipbuilding, there is a growing emphasis on incorporating digital monitoring and control systems into turbo generators. These systems enhance the operational efficiency and maintenance of the turbo generator by providing real-time data on performance metrics such as temperature, pressure, vibration, and electrical output. With this data, operators can make informed decisions about load management, preventive maintenance, and troubleshooting. Advanced control systems can also optimize the operation of the turbo generator, adjusting parameters to ensure the most efficient use of steam and fuel, thereby further improving the overall efficiency of the ship’s power system.

The design and maintenance of turbo generators on ships require specialized knowledge and expertise. The engineering of the turbine blades, the generator’s electromagnetic components, and the control systems must all be carefully calibrated to ensure optimal performance. Regular maintenance is essential to prevent wear and tear, especially in the harsh marine environment where saltwater, humidity, and constant motion can accelerate the degradation of mechanical components. Maintenance routines typically include inspections, cleaning, lubrication, and the replacement of worn parts to ensure the turbo generator continues to operate reliably and efficiently.

Despite their advantages, turbo generators are not without challenges. The initial cost of installation can be high, and the complexity of the system requires skilled personnel for operation and maintenance. Additionally, the need for a continuous supply of high-quality steam places demands on the ship’s boiler system, which must be capable of producing the necessary steam at the required pressure and temperature. Any issues with the boiler can directly impact the performance of the turbo generator, making the maintenance of both systems critical to the ship’s overall operational readiness.

As the maritime industry continues to evolve, there is a growing focus on reducing emissions and improving energy efficiency, which has led to increased interest in alternative energy sources and hybrid power systems. While turbo generators are well-suited to integrate with these new technologies, such as LNG (liquefied natural gas) systems or battery storage, their fundamental role in providing reliable electrical power remains unchanged. The ability to integrate with these systems allows turbo generators to remain relevant in an industry that is increasingly looking towards sustainable solutions for power generation.

In conclusion, turbo generators are a vital component of a ship’s power generation system, providing reliable and efficient electrical power for a wide range of applications. Their ability to convert steam energy into electrical energy with high efficiency makes them a preferred choice for large vessels and those with specific power requirements, such as nuclear-powered ships. As the industry moves towards more sustainable practices, the flexibility and efficiency of turbo generators will continue to play a crucial role in meeting the evolving power needs of modern ships.

As the maritime industry advances, turbo generators are evolving to meet the increasing demands for efficiency, reliability, and environmental sustainability. The integration of turbo generators with renewable energy sources and energy storage solutions is becoming more prevalent, helping ships reduce their dependence on traditional fossil fuels and minimize their environmental impact. These advancements position turbo generators as a critical component in the transition towards greener shipping technologies.

One area of significant development is the use of waste heat recovery systems on ships. In such systems, waste heat from the ship’s engines or exhaust gases is captured and used to produce steam, which then drives the turbo generator. This process enhances the overall energy efficiency of the ship by utilizing energy that would otherwise be lost. By recovering and converting waste heat into useful electrical power, ships can reduce fuel consumption and emissions, contributing to both cost savings and environmental benefits.

Additionally, the integration of hybrid power systems that combine turbo generators with other forms of energy production, such as battery storage, is gaining traction. These hybrid systems allow for more flexible and efficient energy management. For example, during periods of low energy demand, the turbo generator can charge onboard batteries, which can then be used to power the ship during peak demand periods or when the generator is offline. This not only reduces fuel consumption but also enhances the redundancy and reliability of the ship’s power system.

The development of smart grid technologies on ships is another advancement that is enhancing the efficiency and management of turbo generators. Smart grids enable better distribution and use of electrical power generated by the turbo generator, optimizing energy flow based on real-time demand. This intelligent energy management system can automatically adjust the operation of the turbo generator to ensure that energy production matches consumption, reducing waste and improving overall efficiency.

In the context of future fuels, turbo generators are well-suited to work with alternative fuel sources such as hydrogen, ammonia, and biofuels. These fuels can be used to produce steam in the ship’s boilers, which then drives the turbo generator. The adaptability of turbo generators to different fuel types makes them a flexible solution for ships looking to transition to cleaner energy sources. As the maritime industry explores these alternative fuels to meet stringent emissions regulations, turbo generators will likely play a crucial role in enabling this transition.

Autonomous and remotely operated vessels are also expected to benefit from the robust and reliable nature of turbo generators. In such vessels, the need for dependable power systems that can operate with minimal human intervention is paramount. Turbo generators, with their established track record of reliability and efficiency, are an ideal choice for these advanced vessels. Furthermore, the integration of remote monitoring and diagnostics allows for continuous assessment of the turbo generator’s performance, enabling timely maintenance and ensuring optimal operation even in remote locations.

In summary, the role of turbo generators on ships is expanding and adapting to meet the challenges of modern maritime operations. With ongoing advancements in energy recovery, hybrid systems, smart grid technology, and alternative fuels, turbo generators are poised to remain a cornerstone of shipboard power generation. Their ability to provide reliable, efficient, and adaptable power solutions makes them indispensable as the maritime industry navigates towards a more sustainable and technologically advanced future.

The future trajectory of turbo generators on ships is marked by their capacity to adapt to rapidly changing technological and environmental demands. As shipping moves toward greater sustainability, turbo generators are likely to be central to various innovative propulsion and power generation strategies.

One of the promising developments is the adoption of supercritical and ultra-supercritical steam conditions in turbo generators. By operating at much higher pressures and temperatures than traditional systems, these advanced steam cycles significantly increase the thermal efficiency of power generation. This means more electricity can be produced from the same amount of fuel, thereby reducing fuel consumption and emissions. Ships equipped with these cutting-edge turbo generators can operate more efficiently, which is critical as environmental regulations tighten globally.

In conjunction with advanced steam cycles, carbon capture and storage (CCS) technologies are being explored to reduce the carbon footprint of ships using turbo generators. By capturing the CO2 emissions from the ship’s exhaust and storing or repurposing them, the overall environmental impact can be reduced, allowing ships to comply with stricter emission standards. The integration of CCS with turbo generator systems represents a forward-looking approach to balancing energy needs with environmental stewardship.

Another area of development is the use of digital twin technology for turbo generators. A digital twin is a virtual replica of the turbo generator that allows operators to simulate and analyze its performance under various conditions without affecting the physical equipment. This technology enables predictive maintenance, optimization of operations, and testing of new configurations or upgrades before they are implemented in the real world. By leveraging digital twins, ship operators can enhance the efficiency and reliability of turbo generators, reduce downtime, and extend the lifespan of the equipment.

The trend toward modular and scalable designs in turbo generators is also gaining momentum. Modular designs allow for easier installation, maintenance, and upgrading of turbo generator systems. This approach is particularly beneficial for retrofitting older ships with new technology, enabling them to meet modern efficiency and emission standards without the need for a complete overhaul. Scalable systems also offer flexibility in power generation, allowing ship operators to adjust the capacity of the turbo generator to match the specific needs of different voyages or operational scenarios.

In terms of operational efficiency, artificial intelligence (AI) and machine learning (ML) are becoming integral to the management of turbo generators on ships. These technologies can analyze vast amounts of data collected from the generator and other ship systems to optimize performance, predict failures, and suggest operational adjustments in real time. AI and ML can help in fine-tuning the operation of the turbo generator to achieve the best balance between fuel efficiency, power output, and emissions, making them invaluable tools for modern ship operations.