Turning Engine Waste Heat into Electricity: Converting heat into power is the fundamental principle behind many energy generation systems, including steam turbines, internal combustion engines, and thermoelectric generators. The efficiency and effectiveness of this conversion depend on the thermodynamic cycle used, the working fluid, and the system design.

Key Methods for Converting Heat to Power:

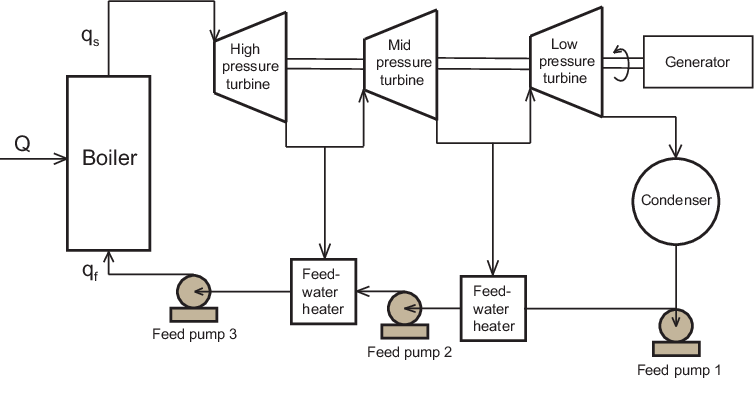

- Steam Turbines (Rankine Cycle)

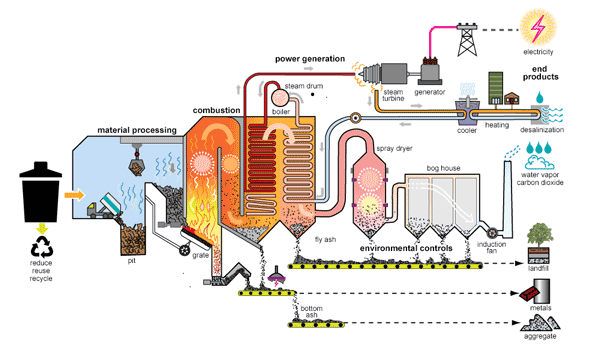

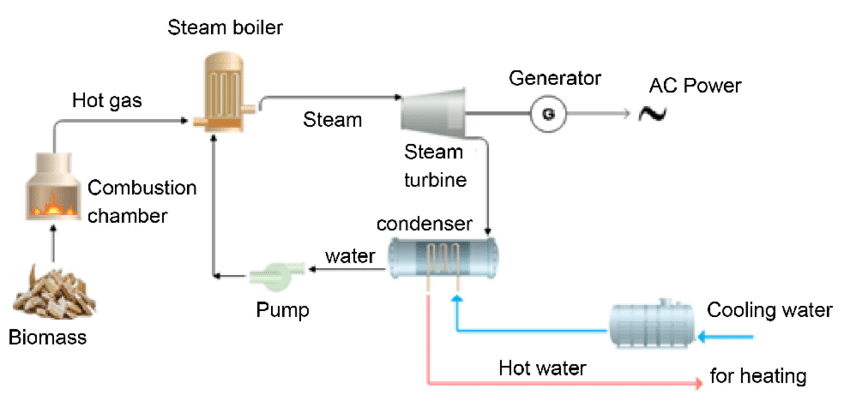

- Water is heated in a boiler to generate high-pressure steam.

- The steam expands through a turbine, converting thermal energy into mechanical work.

- The turbine drives a generator to produce electricity.

- The steam is then condensed back into water in a condenser and reused.

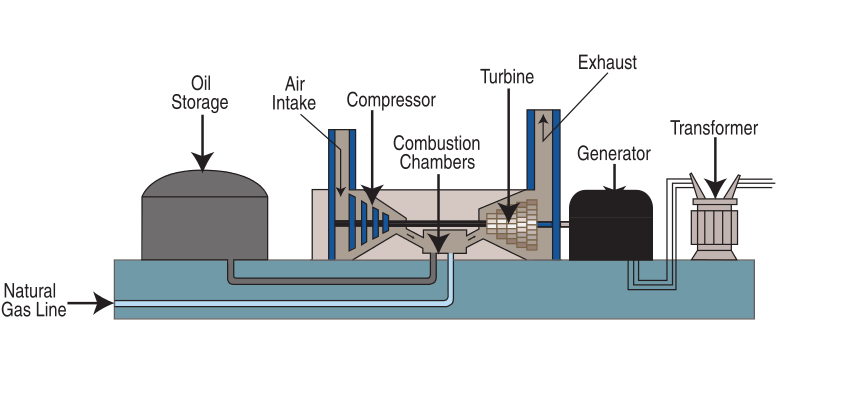

- Gas Turbines (Brayton Cycle)

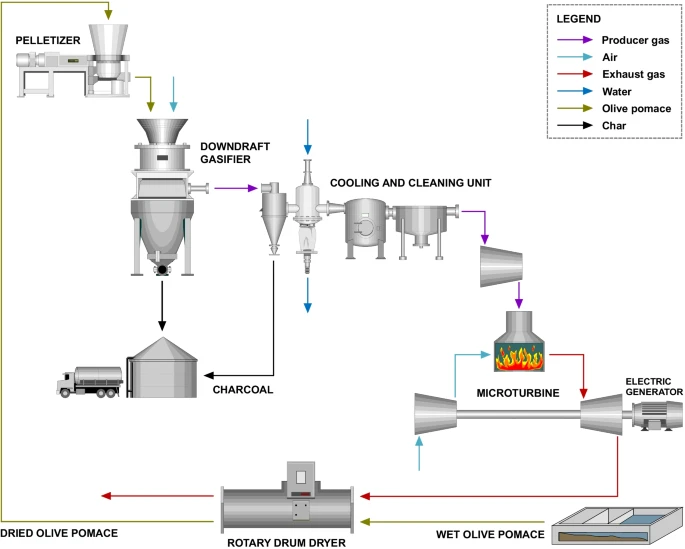

- Air is compressed and mixed with fuel in a combustion chamber.

- The mixture is ignited, producing high-temperature gases that expand through a turbine.

- The turbine spins a generator to produce electricity.

- Exhaust gases may be used for additional energy recovery.

- Internal Combustion Engines (Otto and Diesel Cycles)

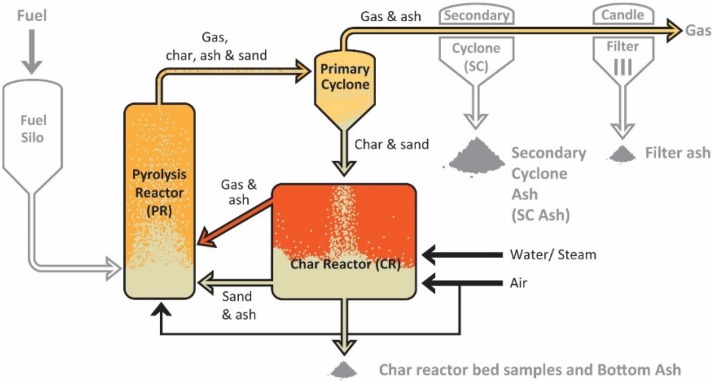

- Fuel is burned in a confined space (cylinder), generating high-temperature gases.

- The expanding gases push pistons, converting heat into mechanical work.

- The pistons drive a crankshaft, which can power machinery or generate electricity.

- Thermoelectric Generators (Seebeck Effect)

- Direct conversion of heat to electricity using thermoelectric materials.

- A temperature difference across a semiconductor generates an electric voltage.

- These are used in applications like space probes, remote sensors, and waste heat recovery.

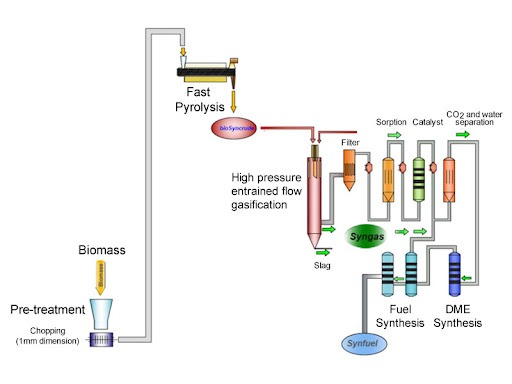

- Organic Rankine Cycle (ORC)

- Similar to the Rankine cycle but uses an organic fluid with a lower boiling point than water.

- Suitable for low-temperature heat sources such as geothermal, biomass, or industrial waste heat.

- Stirling Engines

- A closed-cycle heat engine that operates by cyclic compression and expansion of gas.

- External heat sources (solar, biomass, or waste heat) provide the energy.

- These engines are highly efficient and used in specialized applications.

- Supercritical CO₂ Cycle

- Uses supercritical carbon dioxide as a working fluid instead of steam.

- Operates at higher efficiency and compact size, ideal for power plants and waste heat recovery.

Efficiency Considerations

- The Carnot efficiency sets the theoretical limit for any heat engine: η=1−TcTh\eta = 1 – \frac{T_c}{T_h}η=1−ThTc where TcT_cTc is the cold reservoir temperature and ThT_hTh is the hot reservoir temperature (in Kelvin).

- Higher temperature differences lead to greater efficiency.

- Waste heat recovery and combined-cycle systems improve overall energy conversion.

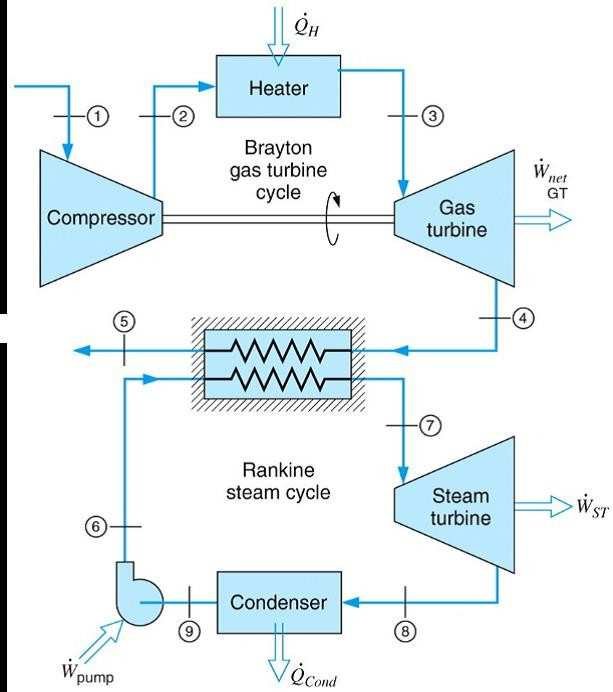

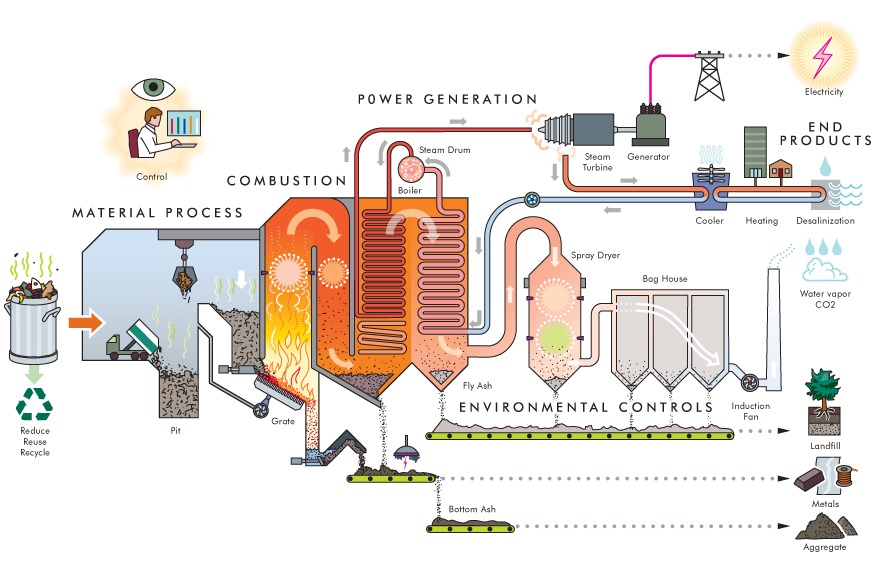

Converting heat into power relies on thermodynamic principles, where thermal energy is transformed into mechanical or electrical energy. The most common method is the Rankine cycle, used in steam turbines, where water is heated to produce steam that expands through a turbine, driving a generator. Gas turbines follow the Brayton cycle, compressing air, mixing it with fuel, and igniting it to produce high-temperature gases that spin a turbine. Internal combustion engines use confined fuel combustion to push pistons and generate mechanical work. Thermoelectric generators convert temperature differences into electricity using the Seebeck effect, while the Organic Rankine Cycle (ORC) allows for lower-temperature heat sources by using organic fluids. Stirling engines operate on cyclic gas expansion and compression, making them highly efficient in specialized applications. The supercritical CO₂ cycle, an emerging technology, offers higher efficiency with compact designs. The theoretical efficiency of any heat engine is governed by Carnot’s law, stating that efficiency increases with greater temperature differences. Practical improvements include combined-cycle systems and waste heat recovery to maximize energy output.

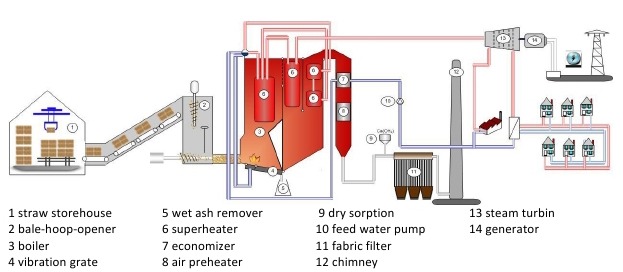

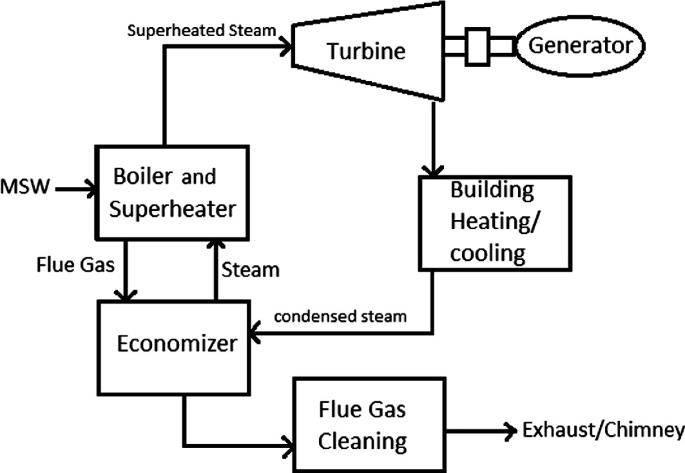

Converting heat into power is a fundamental process in energy generation, relying on thermodynamic cycles to transform thermal energy into mechanical or electrical energy. The most widely used method for large-scale power generation is the Rankine cycle, which forms the basis of steam turbines. In this process, water is heated in a boiler to produce high-pressure steam, which then expands through a turbine, converting its thermal energy into mechanical work. The turbine, in turn, drives a generator to produce electricity. After passing through the turbine, the steam is condensed back into liquid water in a condenser and recycled for continuous operation. The efficiency of this system depends on the temperature and pressure of the steam, with superheated and ultra-supercritical steam conditions offering improved performance.

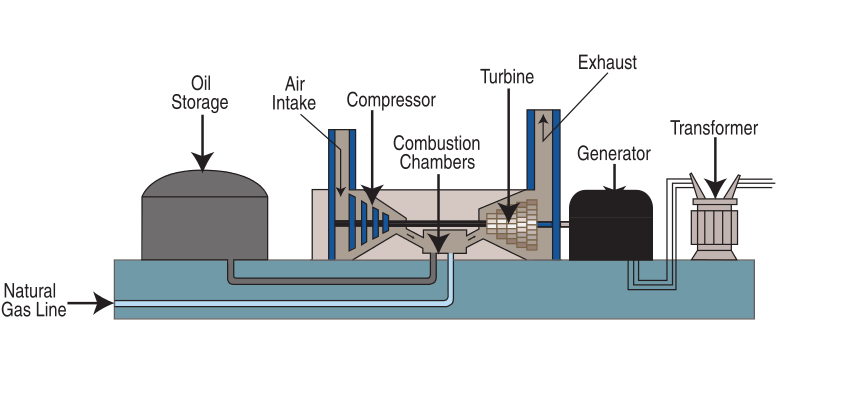

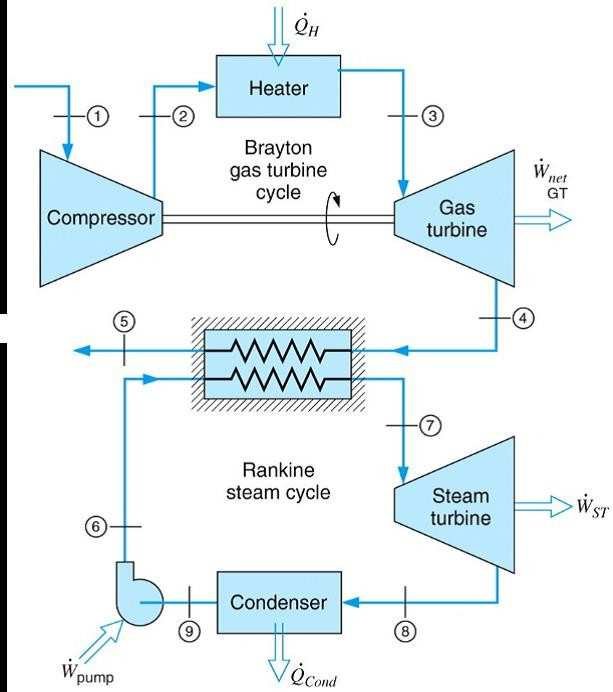

Gas turbines, which operate on the Brayton cycle, are another important method of converting heat into power. In this cycle, air is compressed and mixed with fuel in a combustion chamber, where it is ignited to produce high-temperature gases. These gases expand rapidly and pass through a turbine, spinning its blades and generating mechanical energy. This mechanical energy is then used to drive an electrical generator or provide propulsion in applications such as jet engines. Gas turbines are known for their ability to start quickly and their high power-to-weight ratio, making them ideal for applications in aviation, power plants, and emergency power generation. Combined-cycle power plants integrate gas and steam turbines to improve efficiency by using the hot exhaust gases from the gas turbine to produce steam, which then powers a steam turbine, maximizing energy extraction from the fuel.

Internal combustion engines, used in automobiles, backup generators, and small-scale power applications, convert heat into mechanical energy through the Otto or Diesel cycles. In gasoline (Otto cycle) and diesel (Diesel cycle) engines, fuel is burned inside a confined space, generating high-pressure gases that force a piston to move. The reciprocating motion of the piston is converted into rotational motion by a crankshaft, which can then be used to drive machinery or generate electricity. While these engines are highly versatile and widely used, their efficiency is limited by the incomplete combustion of fuel and heat losses. Advances such as turbocharging, hybridization, and fuel injection optimization have improved their efficiency over time.

For direct heat-to-electricity conversion, thermoelectric generators (TEGs) utilize the Seebeck effect, where a temperature difference across thermoelectric materials creates an electric potential, generating a current. While TEGs are less efficient compared to mechanical heat engines, they are valuable in niche applications such as deep-space probes, remote sensing equipment, and waste heat recovery systems in industrial plants. The Organic Rankine Cycle (ORC) is another method designed for low-temperature heat sources, such as geothermal energy, biomass, and industrial waste heat. Instead of water, ORC systems use organic fluids with lower boiling points, allowing them to generate power efficiently even at relatively low temperatures.

Another advanced heat-to-power conversion method is the Stirling engine, which operates on a closed-cycle regenerative process where gas is cyclically heated and cooled, causing it to expand and contract to drive a piston. Stirling engines are known for their high theoretical efficiency and ability to use various heat sources, including solar, biomass, and industrial waste heat. However, their practical application is somewhat limited by factors such as size, cost, and response time to load changes.

An emerging technology in heat-to-power conversion is the supercritical CO₂ cycle, which uses carbon dioxide in a supercritical state—where it behaves as both a liquid and a gas—to drive turbines with high efficiency. These systems operate at higher thermal efficiency than conventional steam turbines while offering a more compact design, making them suitable for next-generation power plants, waste heat recovery, and concentrated solar power applications.

The efficiency of any heat engine is fundamentally constrained by Carnot’s theorem, which states that the maximum possible efficiency is determined by the temperature difference between the heat source and the heat sink. The greater this difference, the higher the efficiency of the system. However, real-world inefficiencies arise due to friction, heat losses, and material limitations. To enhance overall efficiency, many power systems incorporate waste heat recovery methods, such as combined-cycle systems, cogeneration (where both electricity and useful heat are produced), and advanced cooling techniques.

The ongoing advancements in heat-to-power conversion focus on improving efficiency, reducing emissions, and optimizing system integration. The development of new materials, better heat exchangers, and improved thermodynamic cycles continues to push the boundaries of what is possible in energy conversion. As the world moves toward more sustainable energy solutions, technologies that can efficiently harness waste heat and alternative heat sources will play an increasingly critical role in the global energy landscape.

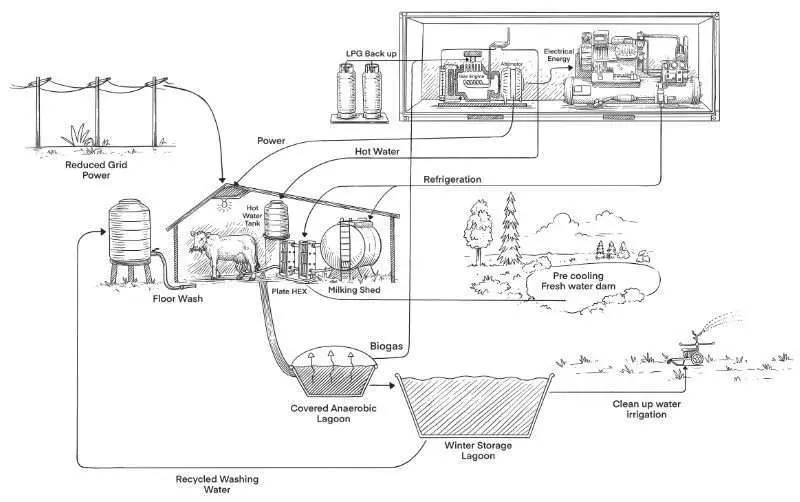

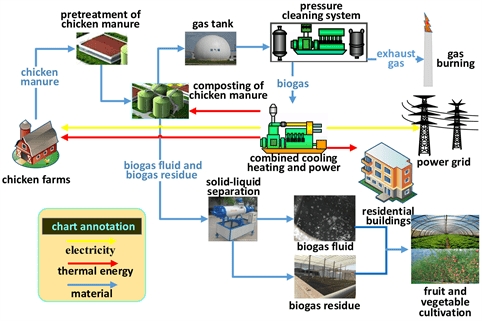

As energy demands continue to grow, optimizing heat-to-power conversion remains a central focus in both industrial and renewable energy sectors. The challenge lies in maximizing efficiency while minimizing environmental impact, fuel consumption, and waste heat losses. One approach to achieving this is through combined heat and power (CHP) systems, also known as cogeneration. These systems generate both electricity and useful thermal energy from a single fuel source, significantly improving overall efficiency. Unlike conventional power plants, where a large portion of heat is lost in the cooling process, CHP systems utilize this waste heat for heating, industrial processes, or even additional power generation. Industrial facilities, district heating networks, and commercial buildings benefit greatly from CHP, as it can reach efficiencies of 80–90% compared to the 30–50% efficiency of standalone power generation.

In large-scale power generation, ultra-supercritical steam cycles have emerged as a way to push the limits of steam turbine efficiency. Traditional Rankine cycle power plants operate at subcritical pressure levels, meaning steam remains at a temperature where it can condense under moderate conditions. Supercritical and ultra-supercritical plants, however, operate at extremely high pressures (above 3,200 psi) and temperatures exceeding 600°C (1,112°F), where steam behaves more like a dense fluid, allowing for greater efficiency. These advanced steam cycles reduce fuel consumption and emissions while delivering higher output, making them a preferred choice for modern coal and biomass power plants.

In the realm of renewable energy, geothermal power plants have successfully harnessed the Earth’s internal heat to generate electricity using both conventional steam turbines and Organic Rankine Cycle (ORC) systems. High-temperature geothermal reservoirs allow for direct steam generation, while lower-temperature sources require working fluids with lower boiling points. Binary cycle geothermal plants use heat exchangers to transfer geothermal heat to organic working fluids like isobutane or pentane, which then drive turbines. This technology is expanding the viability of geothermal power beyond traditional volcanic regions, making it a more scalable and sustainable source of baseload energy.

Similarly, concentrated solar power (CSP) systems use mirrors or lenses to focus sunlight onto a central receiver, generating intense heat that can be used to produce steam and drive turbines. Unlike photovoltaic solar panels, which convert sunlight directly into electricity, CSP systems enable thermal energy storage using molten salts, allowing for power generation even when the sun isn’t shining. This ability to store and dispatch energy on demand makes CSP an attractive solution for grid stability and large-scale renewable energy integration.

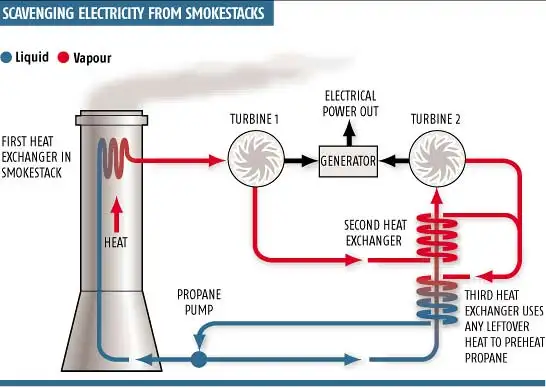

Waste heat recovery is another crucial avenue for improving heat-to-power efficiency. Many industrial processes—such as cement production, steel manufacturing, and glassmaking—release vast amounts of high-temperature exhaust gases. Instead of letting this energy dissipate, waste heat recovery units (WHRUs) and thermoelectric generators (TEGs) can capture and convert it into electricity. WHRUs use heat exchangers to transfer waste heat to a working fluid that drives a turbine, while TEGs directly convert temperature differences into electrical energy using semiconductor materials. Automotive manufacturers are also exploring waste heat recovery, with thermoelectric and turbo-compounding systems designed to reclaim lost engine heat and improve fuel efficiency.

Another emerging frontier is nanotechnology and advanced materials in thermal energy conversion. High-performance thermoelectric materials, such as bismuth telluride and lead telluride, have shown promise in improving the efficiency of thermoelectric generators. Additionally, phase-change materials (PCMs) are being researched for their ability to store and release heat efficiently, enabling better thermal energy management. Innovations in heat exchangers, such as microchannel and nanostructured surfaces, are also improving the efficiency of thermal transfer, leading to more compact and effective power generation systems.

On the larger scale of grid infrastructure, supercritical CO₂ (sCO₂) power cycles are being developed to replace traditional steam-based cycles in future power plants. Supercritical CO₂ turbines operate at much higher thermal efficiencies while being significantly smaller in size, making them ideal for modular power systems. These cycles are particularly well-suited for next-generation nuclear reactors, concentrated solar power, and advanced fossil-fuel plants where efficiency improvements are critical for reducing emissions.

The future of heat-to-power conversion is also being shaped by artificial intelligence (AI) and machine learning, which optimize energy systems by predicting load demands, managing thermal storage, and improving process efficiency. AI-driven predictive maintenance reduces downtime in power plants, while smart grid integration allows for better coordination between different energy sources.

As the world transitions toward cleaner energy solutions, improving heat-to-power conversion will be essential for reducing reliance on fossil fuels and enhancing the sustainability of industrial and power generation processes. Whether through high-efficiency turbines, waste heat recovery, or advanced thermoelectric materials, innovations in this field will continue to play a key role in shaping the future of energy production.

Reducing waste by converting heat to power

Reducing waste by converting heat to power is an essential strategy for improving energy efficiency, lowering fuel consumption, and reducing environmental impact. In many industrial and energy production processes, a significant amount of heat is lost as waste. Capturing and utilizing this heat through innovative technologies can dramatically improve overall system efficiency while reducing greenhouse gas emissions.

One of the most effective methods of recovering waste heat is through waste heat recovery units (WHRUs). These systems capture excess thermal energy from industrial processes, power plants, and even vehicle exhaust systems, converting it into useful power. In manufacturing sectors such as cement production, steelmaking, and glass manufacturing, furnaces and kilns operate at extremely high temperatures, releasing large amounts of waste heat. WHRUs integrate heat exchangers to transfer this heat to a working fluid, which then drives turbines or generates steam for additional power production. By implementing such systems, industries can recover up to 30% of lost energy, significantly reducing fuel consumption and operational costs.

Combined heat and power (CHP), or cogeneration, is another key approach to minimizing waste heat. Traditional power plants often discard more than half of the energy they produce as waste heat, primarily through cooling towers and exhaust systems. CHP systems, however, utilize this excess heat for useful purposes such as district heating, industrial processing, or additional electricity generation. This dual-use approach enables efficiencies of up to 80-90%, making CHP one of the most effective methods for energy conservation. These systems are widely used in hospitals, universities, data centers, and large commercial buildings where both electricity and thermal energy are required.

In the transportation sector, particularly in automotive and heavy-duty trucking applications, a substantial portion of fuel energy is lost as heat through exhaust gases and engine cooling systems. Technologies such as thermoelectric generators (TEGs) and turbo-compounding systems help capture and repurpose this waste heat. TEGs utilize the Seebeck effect, where a temperature gradient across thermoelectric materials generates electricity. These systems are being explored for integration into hybrid and electric vehicles to improve overall energy efficiency. Turbo-compounding, on the other hand, uses an additional turbine to extract energy from exhaust gases, improving fuel efficiency in diesel engines.

In power generation, supercritical CO₂ (sCO₂) cycles are emerging as an advanced method for enhancing waste heat recovery. Compared to traditional steam cycles, sCO₂ systems operate at higher efficiencies and can function with lower-grade heat sources. This makes them particularly useful for industrial waste heat applications, geothermal power plants, and next-generation nuclear reactors. Their compact design and ability to recover heat effectively at various temperatures position them as a promising solution for reducing waste in power systems.

Organic Rankine Cycle (ORC) technology has also gained traction for converting low-temperature waste heat into power. Unlike conventional steam turbines, ORC systems use organic fluids with lower boiling points, allowing them to operate efficiently with lower-temperature heat sources. This makes ORC ideal for recovering heat from industrial exhaust gases, biomass plants, and even flue gases from combustion processes. By integrating ORC technology, industries can harness previously untapped energy sources and convert them into usable electricity.

Another innovative waste heat recovery method is latent heat storage using phase-change materials (PCMs). These materials absorb excess thermal energy and release it when needed, helping to regulate temperature fluctuations and provide a more stable energy supply. This technology is particularly beneficial in solar thermal power plants, where stored heat can be used to generate electricity even when sunlight is unavailable. Additionally, in industrial applications, PCMs enable better thermal management, reducing energy waste and improving system reliability.

Heat-to-power solutions in data centers are also becoming a priority, as these facilities generate substantial amounts of waste heat. Instead of dissipating this heat into the environment, some data centers are now integrating waste heat recovery systems to provide heating for nearby buildings or generate additional power. This not only enhances energy efficiency but also supports sustainability initiatives by reducing the need for separate heating systems.

To maximize waste heat recovery, artificial intelligence (AI) and machine learning are being leveraged for real-time optimization. AI-driven energy management systems analyze operational data to identify inefficiencies, predict heat loads, and dynamically adjust heat recovery processes. This ensures that excess heat is utilized in the most effective manner, improving overall energy performance and reducing costs.

By prioritizing waste heat recovery and conversion into power, industries, transportation systems, and energy producers can significantly reduce their carbon footprint while improving economic efficiency. The integration of advanced waste heat recovery technologies, combined with ongoing research into new materials and energy conversion techniques, will continue to drive improvements in energy sustainability and resource utilization.

The potential for reducing waste by converting heat into power extends beyond traditional industrial and energy applications, reaching into emerging fields such as smart grids, sustainable urban planning, and space technology. As global energy demands increase and environmental regulations tighten, the importance of maximizing energy efficiency and minimizing heat waste has become more critical than ever.

Integration of Waste Heat Recovery into Smart Grids and Decentralized Energy Systems

Smart grids are designed to optimize the distribution and consumption of electricity, and incorporating waste heat recovery into these systems can significantly enhance their efficiency. In a decentralized energy system, power generation occurs closer to the point of consumption, reducing transmission losses and allowing for localized heat recovery solutions. For example, in urban environments, waste heat from industrial plants, data centers, and commercial buildings can be captured and redistributed through district heating networks, supplying residential and commercial properties with heating and hot water. In this way, excess thermal energy that would otherwise be lost can be repurposed, reducing reliance on fossil fuels and lowering carbon emissions.

A growing trend in smart grid development is the integration of thermal energy storage (TES), which allows excess heat to be stored and used when needed. This technology is particularly useful in renewable energy systems, where power generation fluctuates based on weather conditions. By capturing and storing waste heat during peak production periods, TES can ensure a stable energy supply, improving grid resilience and reducing the need for backup fossil-fuel power plants.

Utilizing Waste Heat in the Built Environment

Waste heat recovery is also transforming how cities and buildings manage energy consumption. Modern zero-energy buildings (ZEBs) are incorporating advanced heat recovery systems to maximize efficiency. For example, heat exchangers integrated into ventilation systems can capture warm air from inside a building and transfer it to incoming fresh air, reducing heating requirements. In high-rise buildings, waste heat from electrical equipment, lighting, and human activity can be captured and used for water heating or climate control.

Some innovative urban projects are even using underground infrastructure for heat recovery. Sewage heat recovery is an emerging technology where heat exchangers extract thermal energy from wastewater to supply heating and hot water to buildings. This system has already been successfully implemented in cities like Vancouver, where a sewage heat recovery plant provides district heating to thousands of residents.

Advanced Applications in Aerospace and Space Technology

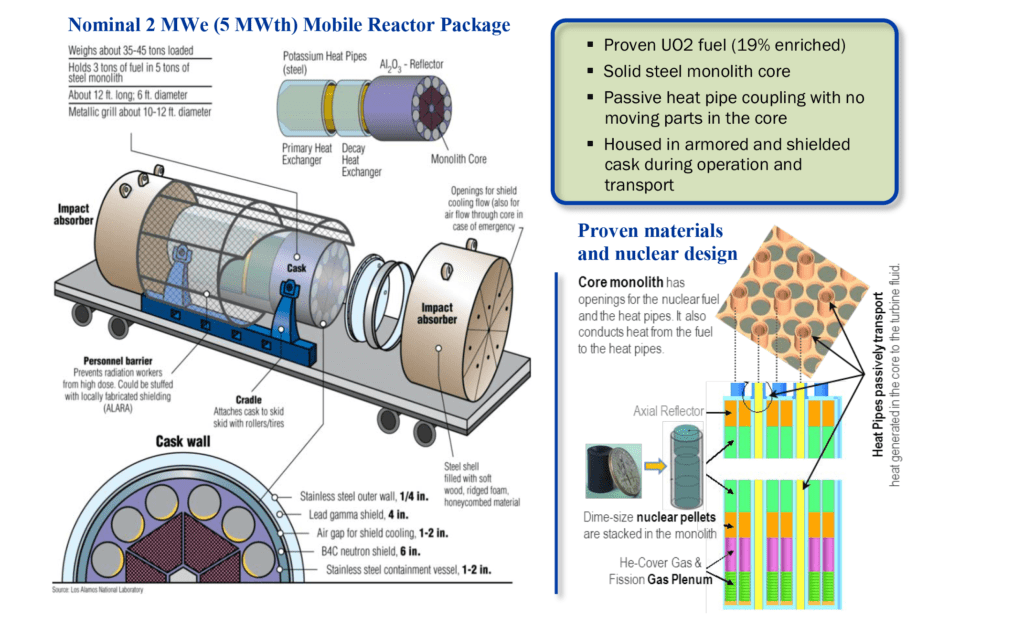

Waste heat recovery is not only beneficial on Earth but also plays a critical role in space exploration. Spacecraft, satellites, and space stations must manage extreme temperature fluctuations while maintaining power efficiency. Radioisotope Thermoelectric Generators (RTGs) have been used in deep-space missions, such as NASA’s Voyager and Mars rover programs, to convert heat from radioactive decay into electricity. These generators allow spacecraft to operate for decades without requiring solar power, making them ideal for missions to distant planets where sunlight is scarce.

On the International Space Station (ISS), heat recovery systems regulate onboard temperatures and reuse excess heat from electrical systems and human activity to maintain a livable environment. Future space missions, including those to Mars, will rely on advanced thermal management systems that integrate waste heat recovery with energy storage and life-support systems to maximize efficiency and sustainability.

Industrial Symbiosis: Turning Waste Heat into a Commodity

One of the most promising approaches to waste heat utilization is the concept of industrial symbiosis, where multiple industries collaborate to share and utilize excess heat as a resource. In industrial parks and manufacturing hubs, businesses can exchange heat energy rather than allowing it to dissipate into the environment. For instance, a steel plant producing high-temperature exhaust gases can supply waste heat to a nearby food processing facility that requires thermal energy for drying or pasteurization.

Countries like Denmark have successfully implemented large-scale industrial symbiosis projects, where excess heat from power plants and factories is captured and redirected to provide district heating to entire cities. This approach not only improves energy efficiency but also strengthens economic resilience by reducing the cost of energy inputs for multiple industries.

Future Technologies and Research in Heat-to-Power Conversion

The field of waste heat recovery is continuously evolving, with ongoing research focused on developing new materials and technologies to enhance efficiency. Some of the most promising innovations include:

- Solid-State Heat-to-Power Conversion – Advances in thermoelectric and thermophotovoltaic (TPV) materials are enabling more efficient direct conversion of heat into electricity without moving parts, reducing maintenance and improving system reliability.

- Nanostructured Heat Exchangers – The use of nanoscale materials in heat exchangers enhances thermal conductivity and improves heat transfer efficiency, making waste heat recovery systems more compact and effective.

- Artificial Intelligence for Heat Optimization – AI-driven systems can analyze real-time operational data, predicting and optimizing heat recovery strategies to ensure maximum energy utilization.

- Quantum Thermodynamics – Researchers are exploring quantum-based energy conversion methods that could one day revolutionize how waste heat is transformed into usable power.

Conclusion: The Path to a More Efficient Future

Reducing waste by converting heat to power is a key strategy for improving energy sustainability, enhancing industrial efficiency, and mitigating environmental impact. Whether through combined heat and power systems, thermoelectric generators, organic Rankine cycles, or emerging quantum technologies, harnessing waste heat offers immense potential to reshape the energy landscape. By integrating these solutions into power grids, industries, transportation systems, and even space exploration, we can significantly reduce energy waste while moving toward a cleaner, more efficient future.

As research and technology continue to advance, the ability to capture and convert every possible unit of wasted heat will become an increasingly valuable asset in the global transition toward sustainable energy systems.

Overcoming Challenges in Waste Heat Recovery and Power Conversion

While waste heat recovery and conversion technologies offer immense benefits, several challenges need to be addressed to enhance their widespread adoption and efficiency. These challenges range from economic and technical limitations to policy and infrastructure hurdles. Addressing these issues will require a combination of innovation, investment, and regulatory support.

1. Economic Barriers and Return on Investment (ROI)

One of the primary obstacles to large-scale waste heat recovery is the initial capital investment required for installing heat recovery systems. Industries and power plants often operate on tight budgets, making it difficult to justify the upfront cost of new technologies, even if they promise long-term savings. Many companies prioritize short-term profits over long-term efficiency improvements, which can slow the adoption of waste heat recovery solutions.

To overcome this barrier, financial incentives such as tax credits, subsidies, and low-interest loans can be provided to industries investing in energy efficiency. Governments and policymakers can play a crucial role in encouraging adoption by implementing regulatory frameworks that mandate heat recovery in high-energy-consuming industries. Additionally, energy-as-a-service (EaaS) models, where third-party companies install and maintain waste heat recovery systems in exchange for a share of the cost savings, are emerging as a viable solution to reduce financial risk for businesses.

2. Technical Challenges in Heat Capture and Conversion

Efficiently capturing and utilizing waste heat requires advanced technologies that can handle different temperatures and operating conditions. High-temperature waste heat from steel plants and power stations is relatively easy to recover, but low-temperature waste heat (below 200°C) from cooling systems, exhaust gases, and industrial processes is more challenging to convert into useful power.

- Materials and Heat Exchanger Efficiency: Many waste heat sources contain contaminants such as dust, corrosive gases, or moisture, which can degrade heat exchangers over time. Developing corrosion-resistant, high-conductivity materials, such as ceramic heat exchangers and nanostructured coatings, can help improve durability and efficiency.

- Thermoelectric and Thermophotovoltaic (TPV) Advances: Thermoelectric and TPV systems that convert heat directly into electricity have historically suffered from low conversion efficiencies (typically 5-10%). However, recent research into new topological insulators and nanostructured thermoelectric materials has shown promise in improving efficiency above 15-20%, making them more viable for industrial applications.

- Waste Heat at Different Temperatures: Many industrial processes produce waste heat at varying temperatures, requiring adaptable solutions. Hybrid systems, combining Organic Rankine Cycle (ORC) for low-grade heat and supercritical CO₂ cycles for high-grade heat, offer a promising way to extract more power from diverse heat sources.

3. Infrastructure and Grid Integration Challenges

In many regions, waste heat recovery potential is limited by a lack of infrastructure to transport and distribute excess thermal energy. District heating networks, for example, require extensive underground piping systems to transport heat from industrial sources to residential and commercial buildings. Retrofitting existing cities with these networks can be expensive and disruptive.

One potential solution is the modular heat battery approach, where excess heat is stored in phase-change materials (PCMs) or thermal batteries and transported to where it is needed. This allows industries to capture and store waste heat during off-peak hours and supply it to users when demand is high. Some experimental projects have demonstrated mobile heat storage solutions using molten salt and graphene-enhanced PCM materials for long-distance heat transport.

In power plants, integrating waste heat recovery with the electrical grid can be complex. Many heat-to-power systems generate electricity intermittently, depending on process conditions, which may not align with real-time electricity demand. Advanced AI-driven energy management systems can help optimize when and how waste heat is converted into power, ensuring seamless integration with the grid.

4. Industrial and Sector-Specific Adoption

Different industries have unique requirements when it comes to waste heat recovery. Some sectors, such as cement, steel, and glass manufacturing, have already adopted high-efficiency waste heat recovery technologies due to the high temperatures involved. However, sectors with predominantly low-temperature waste heat—such as food processing, chemical manufacturing, and commercial buildings—have been slower to implement recovery systems.

- Automotive and Transport Sector: In the automotive industry, waste heat recovery is gaining attention through turbo-compounding, Rankine cycle engines, and thermoelectric exhaust generators. Future electric vehicles (EVs) and hydrogen-powered vehicles may incorporate waste heat-driven auxiliary power systems to improve energy efficiency.

- Data Centers: With the rise of cloud computing and AI-driven workloads, data centers consume vast amounts of electricity and generate considerable waste heat. Liquid cooling systems with waste heat recovery are being tested to use this heat for district heating or power generation.

- Shipping and Maritime Industry: Large cargo ships and naval vessels rely on diesel engines that waste a significant portion of fuel energy as heat. The use of waste heat boilers, steam turbines, and ORC systems can increase fuel efficiency and reduce carbon emissions.

The Future of Heat-to-Power Conversion: Policy, Research, and Innovation

To unlock the full potential of waste heat conversion, governments, research institutions, and private industries must collaborate to develop new policies, invest in emerging technologies, and implement best practices.

1. Policy and Regulations

- Mandating Waste Heat Recovery: Governments can introduce energy efficiency regulations that require large industries to install waste heat recovery systems if their energy consumption exceeds a certain threshold.

- Carbon Pricing and Incentives: Implementing carbon pricing mechanisms can make waste heat recovery financially attractive by placing a cost on energy waste. Tax credits and subsidies can further accelerate adoption.

- International Standards and Certifications: Standardizing heat recovery technologies and efficiency metrics across industries can help streamline the development and deployment of new systems.

2. Cutting-Edge Research and Breakthrough Technologies

- Quantum Thermodynamics: Scientists are exploring quantum heat engines, which could push the efficiency of heat-to-power conversion beyond classical thermodynamic limits.

- Artificial Intelligence in Heat Optimization: AI-powered predictive maintenance and optimization algorithms are being developed to maximize heat recovery efficiency in real time.

- Nano-Enhanced Thermoelectrics: Research into graphene-based thermoelectric materials has shown promise in significantly improving waste heat-to-electricity conversion efficiency.

- Hybrid Power Cycles: The combination of ORC, sCO₂, and thermoelectric systems in a single power plant could drastically improve waste heat utilization across multiple temperature ranges.

Conclusion: A Roadmap to a Waste-Free Energy Future

Converting waste heat to power is one of the most impactful ways to improve energy efficiency, reduce emissions, and make better use of existing resources. While challenges exist in terms of economic feasibility, technology efficiency, and infrastructure development, ongoing advancements in materials science, AI-driven optimization, and hybrid energy systems are steadily overcoming these barriers.

As industries and policymakers recognize the potential of waste heat utilization, we can expect greater investment and innovation in this field. Whether through district heating networks, industrial symbiosis, or next-generation thermoelectric materials, reducing waste by converting heat to power will play a crucial role in shaping a sustainable and energy-efficient future. By fully integrating waste heat recovery into industrial, commercial, and urban energy systems, we can move closer to a world where no energy goes unused.

Scaling Waste Heat Recovery: The Next Steps Toward a Circular Energy Economy

As the global energy landscape evolves, waste heat recovery is emerging as a fundamental pillar of the circular energy economy, where energy is continuously repurposed rather than discarded. Transitioning from traditional energy systems to highly efficient, interconnected networks requires integrating waste heat recovery across all sectors—from heavy industry and transportation to urban infrastructure and renewable energy. To achieve this, the next phase of development will focus on large-scale implementation, innovative storage solutions, and cross-sector collaboration.

Large-Scale Deployment of Waste Heat Recovery Systems

While waste heat recovery technologies have been successfully implemented in some industries, large-scale deployment is still limited by technical, financial, and regulatory challenges. Widespread adoption requires a coordinated effort from businesses, governments, and research institutions to expand infrastructure, standardize best practices, and optimize heat-to-power conversion methods.

1. Scaling Up Industrial Waste Heat Recovery

Industrial facilities, including steel mills, cement plants, and refineries, are among the largest producers of waste heat. Many have already incorporated heat exchangers, waste heat boilers, and Organic Rankine Cycle (ORC) turbines, but further improvements can be made by:

- Integrating AI-Driven Optimization: Advanced algorithms can analyze plant operations in real-time, adjusting heat recovery processes to maximize efficiency. AI-driven predictive maintenance can also extend the lifespan of heat exchangers and reduce downtime.

- Developing Modular Heat Recovery Units: Prefabricated, plug-and-play heat recovery systems can lower installation costs and enable easier integration into existing industrial processes.

- Industrial Heat Clustering: Factories in industrial parks can share heat through symbiotic energy networks, where waste heat from one facility is used to power another. This concept has been successfully implemented in Denmark’s Kalundborg Symbiosis, where industries exchange excess heat, water, and by-products to improve efficiency.

2. Expanding District Heating and Cooling Networks

Urban areas represent a significant opportunity for waste heat utilization through district heating and cooling systems. In many cities, power plants, data centers, supermarkets, and wastewater treatment plants generate excess heat that could be redirected to residential and commercial buildings.

- Harnessing Data Center Heat: As cloud computing and artificial intelligence expand, data centers are expected to consume nearly 10% of global electricity by 2030. New initiatives are emerging to capture waste heat from server farms and distribute it through district heating systems. Cities like Stockholm and Helsinki already use data center heat to warm thousands of homes.

- Wastewater Heat Recovery: Sewage and wastewater treatment plants contain thermal energy that can be extracted using heat exchangers and heat pumps. Projects in Germany and Canada have demonstrated that wastewater heat can supply up to 50% of a city’s heating needs.

3. Powering Remote and Off-Grid Locations

Many rural and remote communities still rely on inefficient diesel generators for electricity, which results in substantial energy waste. Microgrid systems incorporating waste heat recovery can significantly improve fuel efficiency and reduce emissions.

- Cogeneration in Remote Areas: Small-scale combined heat and power (CHP) plants can provide both electricity and heating for isolated communities, industrial sites, or military bases.

- Waste Heat-Powered Desalination: In arid regions, recovered waste heat can be used to power multi-effect distillation (MED) or membrane distillation systems, providing clean drinking water from seawater.

Advanced Heat Storage and Distribution Technologies

One of the biggest challenges in waste heat recovery is temporal and spatial mismatches—heat is often available at times or locations where it is not immediately needed. Advanced storage and distribution solutions are critical for maximizing the utilization of waste heat.

1. Thermal Energy Storage (TES) Solutions

TES technologies allow waste heat to be stored for later use, balancing supply and demand across different timescales.

- Phase-Change Materials (PCMs): PCMs absorb and release heat as they change phases (e.g., from solid to liquid), providing efficient thermal storage. Researchers are developing graphene-enhanced PCMs that improve heat conductivity and storage capacity.

- Molten Salt Heat Storage: Used in concentrated solar power (CSP) plants, molten salt can store large amounts of heat for extended periods. This technology could be adapted for industrial waste heat storage, allowing excess heat to be used at night or during peak energy demand.

- Underground Heat Storage: Borehole thermal energy storage (BTES) systems store waste heat in deep underground wells, which can later be extracted for heating buildings or generating electricity.

2. Transporting Waste Heat Over Long Distances

In many cases, waste heat is produced far from where it can be effectively utilized. New heat transport solutions are being developed to bridge this gap:

- Mobile Heat Batteries: Companies are experimenting with portable heat storage units filled with PCM or molten salt, which can be transported by truck or rail to supply industrial heat users.

- Supercritical CO₂ Pipelines: Unlike traditional steam pipelines, sCO₂-based heat transport systems can move thermal energy over long distances with minimal losses, making them ideal for regional heat-sharing networks.

Cross-Sector Collaboration and the Future of Waste Heat Economy

For waste heat recovery to reach its full potential, collaboration between industries, governments, and academia is essential. A multi-sector approach can unlock new opportunities for repurposing waste heat across different industries.

1. Waste Heat in Hydrogen Production

The production of green hydrogen through electrolysis is energy-intensive, but waste heat from industrial processes or power plants can be used to improve efficiency. High-temperature solid oxide electrolyzers (SOECs) operate more efficiently when supplied with excess heat, reducing electricity consumption.

2. Waste Heat and Carbon Capture

Emerging carbon capture, utilization, and storage (CCUS) technologies require significant energy inputs. Instead of using additional fossil fuels, waste heat can power CO₂ capture systems, making the process more energy-efficient and cost-effective.

3. The Role of Artificial Intelligence and Digital Twins

AI-driven analytics and digital twin technology (virtual models of physical systems) can optimize waste heat recovery by simulating different scenarios and predicting the most efficient ways to capture and reuse excess energy.

Conclusion: Moving Toward a Waste-Free Energy Future

The next decade will be critical in scaling up waste heat recovery technologies and integrating them into a circular energy economy. As governments set ambitious climate goals and industries seek to improve energy efficiency, waste heat will transition from being a byproduct to a valuable resource that powers cities, industries, and transportation networks.

By leveraging advanced storage technologies, AI-driven optimization, and cross-industry collaboration, we can create a future where waste heat is fully harnessed, significantly reducing carbon emissions while increasing energy security and resilience. With continued innovation and investment, a waste-free energy system is within reach—one where every unit of heat is put to productive use, driving the transition to a more sustainable and efficient global energy landscape.

Furnace Heat Recovery for Power Generation

Industrial furnaces are among the largest energy consumers in manufacturing, with significant amounts of waste heat released through flue gases, cooling water, and exhaust streams. Recovering this waste heat and converting it into power can greatly improve energy efficiency, reduce fuel consumption, and lower greenhouse gas emissions. Various technologies, including heat exchangers, waste heat boilers, and thermoelectric generators, enable the conversion of furnace waste heat into usable electricity.

Sources of Waste Heat in Furnaces

Furnaces are used in industries such as steel, cement, glass, petrochemicals, and ceramics, where extreme temperatures (typically 800–1700°C) are required for material processing. The main sources of waste heat in these furnaces include:

- Flue Gases: High-temperature exhaust gases (often above 800°C) are expelled from the furnace chimney, carrying significant amounts of thermal energy.

- Cooling Systems: Water- or air-cooled furnace components (such as walls and burners) absorb heat, which is often dissipated without reuse.

- Radiant Heat Loss: Heat radiated from the furnace walls and openings can contribute to overall thermal inefficiency.

Recovering heat from these sources can significantly reduce the energy demand of industrial processes and generate additional power.

Technologies for Furnace Heat Recovery and Power Generation

Several technologies have been developed to capture and convert furnace waste heat into electricity, depending on temperature levels and industry requirements.

1. Waste Heat Boilers and Steam Turbines

One of the most effective ways to recover heat from high-temperature furnace exhaust gases is through a waste heat recovery boiler (WHRB). The heat from flue gases is used to generate steam, which drives a steam turbine to produce electricity.

- Ideal for: Steel, cement, and glass industries with furnace exhaust temperatures above 500°C.

- Efficiency: Can achieve conversion efficiencies of 20–30%.

- Challenges: Requires significant space and a steady flow of waste heat for optimal operation.

2. Organic Rankine Cycle (ORC) Systems

For lower-temperature waste heat (150–400°C), an Organic Rankine Cycle (ORC) system can be used instead of a traditional steam turbine. The ORC process uses an organic fluid with a lower boiling point than water, allowing it to vaporize at lower temperatures and drive a turbine to generate electricity.

- Ideal for: Medium-temperature waste heat sources, such as aluminum smelting and glass furnaces.

- Efficiency: 10–20% conversion efficiency.

- Advantages: Compact design, lower maintenance than steam turbines, and ability to operate at variable loads.

3. Thermoelectric Generators (TEGs)

Thermoelectric generators (TEGs) use the Seebeck effect to directly convert heat into electricity without moving parts. These solid-state devices are particularly useful for capturing radiant heat and low-grade exhaust heat from furnace surfaces.

- Ideal for: Small-scale power generation in metal and ceramic industries.

- Efficiency: Low (typically 5–10%) but improving with advances in nanotechnology.

- Advantages: Maintenance-free, silent operation, and modular scalability.

4. Supercritical CO₂ Power Cycles

The supercritical CO₂ (sCO₂) cycle is an emerging technology for high-efficiency waste heat conversion. Unlike steam, sCO₂ operates at high pressures and densities, improving thermal efficiency in compact turbine designs.

- Ideal for: Ultra-high-temperature furnace exhaust (above 700°C), such as in cement kilns.

- Efficiency: Up to 50% thermal efficiency in some applications.

- Advantages: Smaller equipment size, reduced water consumption, and higher efficiency than conventional Rankine cycles.

Industrial Applications of Furnace Heat Recovery

Different industries are implementing furnace heat recovery systems to improve energy efficiency and sustainability:

- Steel and Metal Processing: Many steel plants now use waste heat boilers to generate power from blast furnace and electric arc furnace exhaust. Some facilities also recover heat from molten slag using thermal storage systems.

- Cement Industry: Cement kilns release vast amounts of waste heat, much of which is now being recovered through WHRB and ORC systems, reducing electricity demand.

- Glass Manufacturing: Glass furnaces operate at extreme temperatures, making them ideal candidates for waste heat-to-power conversion using steam turbines or ORC systems.

- Petrochemical Refineries: Furnaces in refineries produce high-temperature exhaust gases that can be used to power heat recovery steam generators (HRSGs) or drive mechanical systems such as air compressors.

Challenges and Future Innovations

Despite the benefits, several challenges remain in scaling up furnace heat recovery for power generation:

- High Capital Costs: Many heat recovery systems require significant upfront investment, though long-term savings can offset initial costs.

- Intermittent Waste Heat Supply: Some furnace operations do not produce consistent waste heat, requiring thermal storage solutions to stabilize energy recovery.

- Material Durability: Heat exchangers and boilers must withstand high temperatures and corrosive flue gases, necessitating the use of advanced alloys and ceramic coatings.

- Space Constraints: Installing waste heat recovery units in existing facilities can be challenging, requiring compact and modular solutions.

Future Trends

- AI-Driven Optimization: Using artificial intelligence to analyze furnace operations and dynamically adjust heat recovery processes can improve overall efficiency.

- Hybrid Energy Systems: Combining waste heat recovery with solar PV, hydrogen production, or battery storage can enhance energy flexibility in industrial facilities.

- Nanomaterials in Thermoelectrics: Advances in graphene-based thermoelectric materials could significantly boost TEG efficiency, making them a more viable option for industrial power generation.

Conclusion

Furnace heat recovery for power generation is a critical strategy for improving industrial energy efficiency and reducing environmental impact. With advancements in waste heat boilers, ORC systems, TEGs, and supercritical CO₂ cycles, industries can convert excess heat into valuable electricity. By integrating these technologies with AI-driven optimization and hybrid renewable energy solutions, the future of furnace waste heat recovery is poised to become more efficient, cost-effective, and widespread.

Furnace heat recovery for power generation is an essential strategy for improving industrial energy efficiency, reducing operational costs, and minimizing environmental impact. Industrial furnaces, used in sectors such as steel, cement, glass, and petrochemicals, operate at extremely high temperatures, often exceeding 1000°C. A significant portion of this heat is lost through flue gases, cooling systems, and radiation. Instead of allowing this thermal energy to dissipate, industries are increasingly adopting technologies that capture and convert waste heat into electricity, creating a more sustainable and cost-effective energy cycle.

The most widely used method for furnace heat recovery is waste heat boilers coupled with steam turbines. High-temperature exhaust gases from furnaces are directed through heat exchangers or boilers, generating steam that drives a turbine to produce electricity. This approach is highly effective in energy-intensive industries like steel production, where blast furnaces and electric arc furnaces generate vast amounts of excess heat. However, traditional steam-based systems require significant space and infrastructure, making them less feasible for plants with spatial constraints or intermittent waste heat flows.

For lower-temperature waste heat, Organic Rankine Cycle (ORC) systems provide an alternative by using organic fluids with lower boiling points than water. These fluids can vaporize at lower temperatures, enabling efficient power generation from furnace exhaust streams in industries such as cement and aluminum manufacturing. ORC systems have the advantage of being compact, requiring minimal maintenance, and operating efficiently under varying heat loads. Another promising technology is thermoelectric generators (TEGs), which convert heat directly into electricity using the Seebeck effect. While current TEG efficiencies remain low, advancements in nanomaterials and semiconductor technology could make these devices more practical for large-scale industrial applications, particularly in capturing radiant heat from furnace surfaces.

Emerging supercritical CO₂ power cycles offer a high-efficiency alternative to traditional steam and ORC systems. Operating at high pressures and densities, supercritical CO₂ turbines achieve superior thermal efficiency and require smaller equipment footprints, making them particularly attractive for ultra-high-temperature waste heat recovery applications in cement kilns and metallurgical furnaces. Additionally, the integration of energy storage solutions such as phase-change materials and molten salt storage systems is helping to address the challenge of intermittent waste heat availability. These storage technologies allow surplus heat to be retained and released when needed, optimizing power generation even when furnace operations fluctuate.

Despite the clear advantages of furnace heat recovery for power generation, several challenges remain. High initial investment costs can deter industries from adopting these technologies, especially in sectors where profit margins are narrow. However, incentives such as government subsidies, carbon credit programs, and energy efficiency regulations are encouraging more industries to invest in heat recovery systems. Another challenge is the durability of heat exchangers and turbines exposed to corrosive and high-temperature environments. Advanced materials, including ceramic coatings and high-temperature alloys, are being developed to extend the lifespan of these components, improving reliability and reducing maintenance costs.

Digitalization is playing a crucial role in optimizing furnace heat recovery systems. Artificial intelligence and machine learning algorithms can analyze furnace operation data in real time, predicting the optimal conditions for heat capture and power generation. Digital twin technology, where virtual models of heat recovery systems simulate different operational scenarios, allows industries to fine-tune their processes for maximum efficiency. Furthermore, the integration of waste heat recovery with renewable energy sources, such as solar PV or hydrogen production, is opening new opportunities for hybrid energy systems that reduce reliance on fossil fuels.

As industries move toward decarbonization and energy efficiency, furnace heat recovery for power generation is becoming a key component of sustainable manufacturing. The future will likely see a greater adoption of modular, AI-driven, and hybrid systems that maximize the utilization of waste heat while minimizing costs and environmental impact. With ongoing advancements in heat recovery technology, the potential to transform waste heat into a valuable energy resource is growing, bringing industries closer to a circular and energy-efficient future.

The continued advancement of furnace heat recovery for power generation is shaping a new era of industrial energy efficiency, driven by innovations in materials, system integration, and energy market dynamics. As industries seek to minimize energy waste and optimize production costs, the implementation of waste heat recovery systems is transitioning from a niche practice to a mainstream solution. The integration of these technologies with broader industrial energy management strategies is enabling companies to achieve significant reductions in fuel consumption and carbon emissions while enhancing energy security.

One of the most promising developments in this field is the refinement of high-temperature materials and coatings that improve the efficiency and longevity of heat exchangers, waste heat boilers, and thermoelectric devices. Traditional heat recovery systems often suffer from material degradation due to prolonged exposure to extreme temperatures and corrosive flue gases. Advances in high-temperature alloys, ceramic coatings, and graphene-based heat transfer materials are enhancing system durability, reducing maintenance requirements, and improving thermal conductivity. These material innovations are particularly crucial in energy-intensive industries such as cement production and petrochemical refining, where waste heat recovery systems must withstand continuous operation in harsh conditions.

In parallel, digitalization is transforming how waste heat recovery systems are designed, operated, and maintained. The deployment of real-time monitoring and predictive analytics enables industries to optimize heat recovery processes dynamically, adjusting for variations in furnace operation and energy demand. Machine learning algorithms can analyze historical data to predict when maintenance is needed, reducing unplanned downtime and improving system reliability. Digital twin technology, which creates a virtual model of the heat recovery system, allows operators to simulate different scenarios, optimize performance, and implement improvements without disrupting actual operations. These smart technologies are making furnace heat recovery more adaptable and cost-effective, allowing companies to maximize their return on investment.

The integration of waste heat recovery with renewable energy sources is another emerging trend that is reshaping industrial energy strategies. Hybrid energy systems that combine waste heat utilization with solar photovoltaic (PV) panels, wind power, or hydrogen production are becoming increasingly viable. In steel plants, for example, excess heat can be used to drive high-temperature electrolysis for green hydrogen production, reducing reliance on fossil fuels. Similarly, in cement factories, waste heat recovery can complement solar thermal energy storage, ensuring a stable and continuous power supply. By leveraging multiple energy sources, industries can create more resilient and sustainable energy ecosystems.

Energy market dynamics and policy incentives are also playing a critical role in accelerating the adoption of furnace heat recovery technologies. Governments worldwide are introducing stricter energy efficiency regulations and offering financial incentives, such as tax credits and grants, to encourage industrial decarbonization. The rising cost of energy and the push for carbon neutrality are further motivating industries to invest in heat recovery as a means to reduce operating expenses and meet sustainability targets. Carbon pricing mechanisms and emissions trading schemes are making energy-efficient practices more financially attractive, providing additional economic incentives for companies to implement waste heat-to-power solutions.

Looking ahead, continued research and development will be essential to overcoming the remaining challenges and unlocking the full potential of furnace heat recovery. The ongoing miniaturization and efficiency improvements in thermoelectric generators could lead to more widespread use of direct heat-to-electricity conversion, especially for capturing low-grade heat losses. Advances in supercritical CO₂ power cycles may enable even greater efficiency gains, reducing the size and cost of power generation systems. Additionally, progress in phase-change materials and high-density thermal storage solutions could make waste heat recovery more flexible and scalable, allowing energy to be stored and utilized on demand.

As industries worldwide strive for energy efficiency, sustainability, and economic competitiveness, furnace heat recovery for power generation is set to become an increasingly critical component of modern industrial infrastructure. By embracing emerging technologies, digital optimization, and integrated energy solutions, companies can not only reduce waste and emissions but also turn excess heat into a valuable energy resource. In the coming years, the widespread adoption of these systems will contribute significantly to the global transition toward cleaner and more sustainable industrial processes, reinforcing the role of waste heat recovery as a key enabler of the energy transition.

The trajectory of furnace heat recovery for power generation is moving toward greater sophistication, efficiency, and integration with broader industrial energy systems. As industries recognize the economic and environmental benefits of utilizing waste heat, investment in heat recovery technologies continues to grow. Companies are not only deploying these systems for direct electricity generation but also integrating them into combined heat and power (CHP) plants, district heating networks, and advanced manufacturing processes to maximize overall energy utilization. This shift represents a fundamental change in industrial energy management, where every possible source of waste heat is seen as an opportunity to enhance efficiency and reduce reliance on primary energy sources.

One of the most transformative developments in this space is the growing role of artificial intelligence (AI) and automation in optimizing heat recovery systems. AI-driven control algorithms can continuously monitor furnace operations, adjusting heat exchanger and turbine settings in real time to match fluctuating demand and waste heat availability. These intelligent systems can also predict maintenance needs, minimizing downtime and extending equipment lifespan. As machine learning models become more sophisticated, they will be able to analyze vast datasets from multiple facilities, providing insights that improve overall industrial energy efficiency on a larger scale.

The expansion of industrial symbiosis is another promising trend that is further unlocking the value of waste heat recovery. In many industrial clusters, waste heat from one facility can be used by neighboring plants, creating an interconnected energy ecosystem that minimizes waste and maximizes efficiency. For example, steel mills with high-temperature furnace exhaust can supply excess heat to nearby chemical plants, which require large amounts of thermal energy for their processes. Similarly, cement kilns can contribute surplus heat to district heating networks, providing warmth to residential and commercial buildings. These collaborative approaches are gaining traction as industries and governments seek holistic solutions to reduce carbon footprints and improve energy resilience.

As global energy policies increasingly prioritize sustainability, regulatory frameworks are evolving to encourage widespread adoption of waste heat recovery. Many countries are introducing stricter energy efficiency mandates for industrial operations, incentivizing companies to invest in heat-to-power technologies. Carbon pricing mechanisms, such as emissions trading schemes and carbon taxes, are further driving the shift toward heat recovery by making energy waste more costly. In regions where renewable energy penetration is high, waste heat recovery is also being integrated into demand response programs, where industries can use stored heat as a flexible energy source to stabilize power grids.

The convergence of waste heat recovery with emerging energy storage technologies is another area of significant development. Thermal energy storage (TES) systems, using materials such as molten salts or phase-change substances, are allowing industries to capture waste heat when demand is low and release it when energy needs increase. This capability enhances the reliability and flexibility of heat recovery systems, making them more effective in industries where heat production fluctuates. Additionally, innovations in power-to-X technologies are opening new pathways for converting waste heat into other useful forms of energy, such as hydrogen or synthetic fuels, further expanding the potential applications of industrial heat recovery.

Looking forward, research and development efforts will continue to push the boundaries of what is possible with furnace heat recovery. Advances in nanotechnology may lead to breakthroughs in thermoelectric materials, significantly improving the efficiency of direct heat-to-electricity conversion. The refinement of supercritical CO₂ power cycles promises even higher efficiency and compact design, making them a viable alternative to traditional steam turbines. Furthermore, modular and prefabricated heat recovery systems are being developed to simplify installation and reduce capital costs, making these technologies more accessible to a wider range of industries.

As industries strive to meet ambitious decarbonization goals, furnace heat recovery for power generation will play an increasingly critical role in achieving a more sustainable and energy-efficient future. By leveraging digitalization, advanced materials, energy storage, and policy support, waste heat recovery is evolving from an optional efficiency measure to a fundamental pillar of industrial energy strategy. The coming decades will see continued innovation and expansion in this field, ensuring that waste heat is no longer an overlooked byproduct but a valuable resource that contributes to a cleaner, more resilient global energy system.

Turning lost energy into useful electricity

Turning lost energy into useful electricity is a critical strategy for improving energy efficiency and reducing environmental impact across industries. Every year, vast amounts of energy are wasted in the form of heat from industrial processes, power plants, transportation systems, and even residential buildings. Instead of allowing this energy to dissipate, various technologies are being developed and implemented to capture, convert, and repurpose it into electricity, maximizing the value of available resources and reducing dependence on primary energy sources.

One of the most significant sources of lost energy is waste heat from industrial furnaces, boilers, and engines. High-temperature exhaust gases from these systems carry immense thermal energy that can be recovered and converted into power using technologies like waste heat boilers, thermoelectric generators (TEGs), and Organic Rankine Cycle (ORC) systems. Waste heat boilers use heat exchangers to produce steam, which then drives a turbine to generate electricity, making them particularly effective in heavy industries such as steel, cement, and petrochemical refining. ORC systems, which operate on fluids with lower boiling points than water, enable heat recovery from medium- and low-temperature sources, expanding the range of viable waste heat applications. TEGs, which directly convert heat into electricity using the Seebeck effect, are emerging as a promising solution for capturing even small-scale heat losses in manufacturing, transportation, and electronics.

Beyond industrial settings, waste energy recovery is playing a growing role in power generation and transportation. Gas turbines, internal combustion engines, and other energy conversion systems typically waste a large fraction of their input energy as heat. By incorporating bottoming cycles—where excess heat is captured and used for additional power production—these systems can significantly boost efficiency. In modern power plants, combined-cycle gas turbines (CCGTs) use waste heat from a gas turbine to generate steam and drive a secondary steam turbine, improving overall efficiency from around 35% in single-cycle systems to over 60%. Similarly, in transportation, advanced exhaust heat recovery systems in vehicles can convert waste heat into additional mechanical or electrical power, reducing fuel consumption and emissions.

The integration of waste energy recovery with renewable energy technologies is further enhancing its impact. Solar thermal systems, for example, can store excess heat from concentrated solar power (CSP) plants and use it to generate electricity when sunlight is not available. In urban environments, waste heat from commercial buildings, data centers, and industrial facilities can be fed into district heating and cooling networks, optimizing energy distribution. Moreover, emerging power-to-X technologies are enabling the conversion of waste heat into hydrogen or synthetic fuels, expanding its role in the broader energy transition.

As global energy demand continues to rise, turning lost energy into useful electricity is becoming a priority for industries and policymakers. Advances in materials, energy storage, and digital optimization are making heat recovery systems more efficient, compact, and cost-effective. Governments are also encouraging adoption through stricter energy efficiency regulations, carbon pricing mechanisms, and financial incentives for waste heat utilization. These efforts are not only helping to reduce emissions but also improving economic competitiveness by lowering energy costs and increasing resource efficiency.

Looking ahead, further innovation in waste energy recovery will be key to building a more sustainable energy future. Improved thermoelectric materials, high-performance heat exchangers, and AI-driven energy management systems will enable more precise and efficient energy capture. The widespread deployment of heat-to-power solutions across industrial, commercial, and residential sectors will contribute to a more circular and resilient energy system, ensuring that every possible unit of energy is utilized to its full potential. By transforming lost energy into a valuable resource, society can move closer to a future where efficiency, sustainability, and economic growth go hand in hand.

The continued development of technologies for converting lost energy into useful electricity is shaping the future of industrial efficiency and sustainable power generation. As global energy consumption rises and the urgency to reduce greenhouse gas emissions increases, industries are exploring more advanced and integrated waste energy recovery solutions. These efforts are driven by technological advancements, economic incentives, and regulatory pressures that push for higher energy efficiency and lower environmental impact.

One of the key areas of innovation in this field is the enhancement of thermoelectric generators (TEGs). Traditionally limited by low efficiency, modern TEGs are benefiting from breakthroughs in nanomaterials, such as graphene-based and skutterudite materials, which significantly improve their power output and thermal conductivity. These improvements are making TEGs more viable for a wider range of applications, from industrial furnaces and power plants to automotive and aerospace waste heat recovery. With further advancements, TEGs could become a mainstream technology for capturing low-grade waste heat that is currently untapped due to technological and economic constraints.

The growing adoption of supercritical CO₂ power cycles is another game-changer in the field of waste heat-to-power conversion. These systems operate at high pressures and densities, allowing for more efficient and compact power generation compared to traditional steam cycles. Supercritical CO₂ turbines require smaller equipment footprints, making them particularly attractive for industries with space constraints, such as chemical processing plants and cement manufacturing. Additionally, these systems are capable of operating at higher temperatures, improving efficiency and enabling more effective heat utilization from a variety of industrial processes.

Another promising direction is the integration of waste heat recovery with energy storage technologies. One of the main challenges with waste energy utilization is the mismatch between heat availability and electricity demand. To address this, industries are investing in thermal energy storage (TES) systems that can capture and store heat for later use. These systems, which use materials like molten salts or phase-change substances, allow for more flexible and continuous power generation. In hybrid power plants, waste heat can be stored during low demand periods and used to generate electricity when grid demand is high, improving overall energy management and reducing reliance on fossil fuels.

Artificial intelligence (AI) and automation are playing a critical role in optimizing waste energy recovery. AI-driven control systems analyze real-time data from industrial processes, dynamically adjusting heat exchangers, turbines, and power conversion units to maximize energy capture. Predictive maintenance algorithms help extend equipment life by identifying potential failures before they occur, reducing downtime and improving reliability. Digital twin technology, which creates virtual models of industrial systems, is enabling engineers to test different heat recovery configurations before implementation, reducing costs and improving system design.

As industries and governments strive for greater energy efficiency, policy support is accelerating the adoption of waste heat-to-power technologies. Many countries are introducing stricter energy efficiency mandates and offering financial incentives, such as tax credits and grants, to encourage investment in heat recovery systems. Carbon pricing mechanisms are making energy waste more expensive, further incentivizing companies to implement energy recovery strategies. Additionally, industrial symbiosis initiatives, where businesses collaborate to share and utilize waste heat across multiple facilities, are gaining traction in regions with strong environmental policies.

Looking forward, the combination of advanced materials, digital optimization, and integrated energy systems will continue to drive improvements in waste energy recovery. The development of modular and scalable heat recovery systems will make it easier for businesses of all sizes to adopt these technologies, reducing barriers to entry. As energy markets evolve and sustainability goals become more ambitious, waste heat-to-power conversion will play an increasingly central role in shaping a cleaner, more efficient industrial landscape. By continuing to innovate and expand the adoption of these solutions, industries can significantly reduce their carbon footprints while creating new opportunities for economic growth and energy security.

The expansion of waste heat-to-power (WHP) technologies is not only transforming industrial energy efficiency but also reshaping the global energy landscape. As energy demand grows and sustainability targets become more stringent, capturing and converting lost energy into electricity is emerging as a critical strategy for reducing dependence on fossil fuels. Advances in materials, system integration, and policy frameworks are accelerating the adoption of these solutions across industries, urban infrastructure, and even consumer applications.

One of the most exciting frontiers in this field is the miniaturization and decentralization of waste heat recovery systems. Traditionally, heat-to-power conversion has been limited to large industrial facilities due to the scale and cost of existing technologies. However, new compact and modular systems are making it possible to implement heat recovery in smaller-scale applications, such as data centers, commercial buildings, and even residential homes. For instance, micro-Organic Rankine Cycle (ORC) systems and advanced thermoelectric generators (TEGs) are enabling businesses and homeowners to convert waste heat from HVAC systems, water heaters, and cooking appliances into usable electricity. These decentralized solutions could significantly reduce energy consumption in urban environments while providing backup power and improving grid resilience.

In transportation, waste heat recovery is becoming an essential tool for improving fuel efficiency and reducing emissions. Modern internal combustion engines waste more than half of their fuel energy as heat, primarily through exhaust gases and engine cooling systems. By integrating thermoelectric generators and Rankine cycle-based systems into vehicles, manufacturers can recapture this lost energy to power onboard electronics, reduce alternator loads, or even provide additional propulsion. In hybrid and electric vehicles, excess heat from braking systems and power electronics can be harnessed to extend battery life and improve overall efficiency. The aviation and shipping industries are also exploring waste heat recovery solutions to enhance engine performance and reduce fuel consumption, making transportation more sustainable.

Beyond direct electricity generation, innovative applications of waste heat are driving the transition to a more circular and interconnected energy system. In many cities, industrial and commercial waste heat is being repurposed for district heating networks, providing low-carbon heating solutions for residential and office buildings. Similarly, waste heat from manufacturing plants is being used to power desalination processes, reducing the energy required for clean water production in water-scarce regions. In the growing field of power-to-X technologies, excess heat is being used to drive chemical reactions that produce hydrogen, synthetic fuels, and other valuable energy carriers. These cross-sector integrations are transforming waste heat from a byproduct into a cornerstone of the clean energy transition.

As the economic and environmental case for waste heat recovery strengthens, governments and energy markets are increasingly supporting its adoption. Regulatory frameworks that mandate energy efficiency improvements in industrial processes are driving investments in heat recovery systems. Carbon pricing schemes are making energy waste more expensive, further encouraging industries to find ways to capture and repurpose lost energy. Additionally, emerging business models, such as energy-as-a-service, are enabling companies to deploy waste heat recovery systems without large upfront investments, making these technologies more accessible to a broader range of industries.