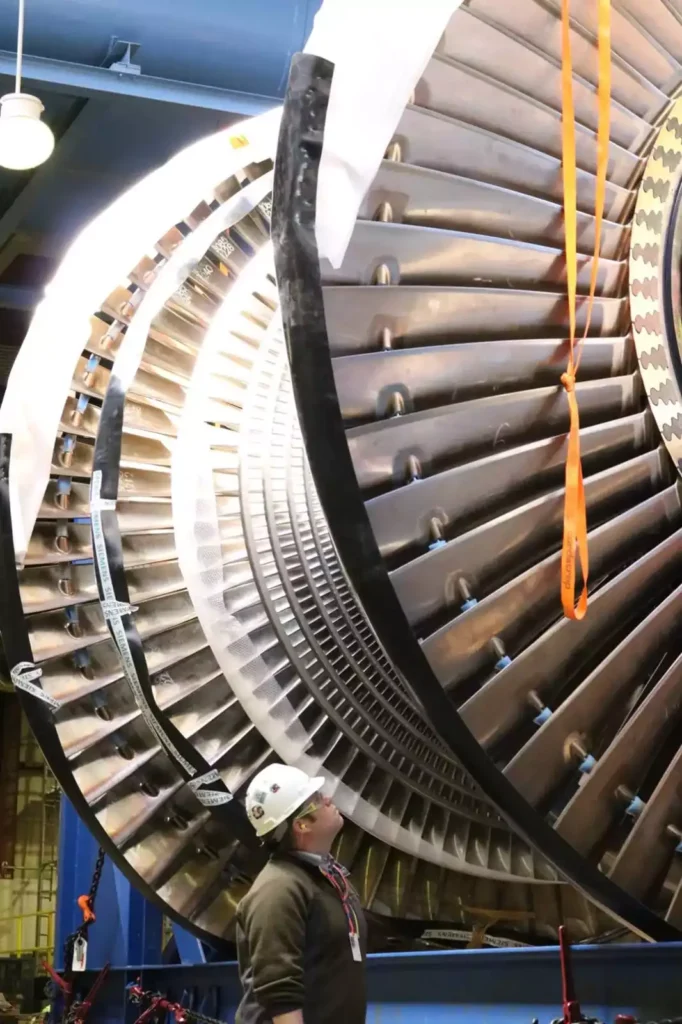

Steam Turbine Blade Manufacturers: Steam turbines are devices that convert thermal energy from steam into mechanical energy, driving generators to produce electricity. Blades are a critical component of steam turbines as they interact with the steam to extract energy efficiently. Proper blade design significantly impacts the turbine’s performance, reliability, and efficiency.

Types of Steam Turbine Blades

Impulse Blades

Impulse blades operate by redirecting steam flow. Steam is directed at the blades at high speed, and the energy is transferred primarily by a change in the steam’s direction. The pressure of the steam remains constant across the blade, making these blades suitable for high-pressure stages.

Applications: Often used in the high-pressure section of turbines where the steam velocity is very high.

Reaction Blades

In reaction blades, energy is extracted from both the pressure and the velocity of the steam. The blades are designed to create a pressure drop as steam passes over them, causing the blades to experience a reactive force. These blades are typically found in low-pressure sections of the turbine.

Applications: Commonly used in low to medium pressure stages.

Difference Between Impulse and Reaction Blades

- Impulse Blades: Operate mainly through changes in steam velocity. Suitable for high-pressure sections.

- Reaction Blades: Use both velocity and pressure drop. Suitable for lower pressure sections.

- Key Design Difference: Impulse blades have simpler designs compared to reaction blades, which are more aerodynamically complex.

Blade Materials

The choice of material for turbine blades is critical because they must withstand extreme conditions, including high temperatures, pressures, and potential corrosion from steam impurities.

Common Materials:

- Nickel-based Superalloys: Excellent heat resistance and strength.

- Titanium Alloys: Lightweight and strong, used where corrosion resistance is needed.

- Stainless Steel: Affordable and widely used in many parts of the turbine.

Material Selection Criteria:

- Heat Resistance

- Corrosion Resistance

- Strength and Durability

- Cost-effectiveness

Manufacturing Technologies for Steam Turbine Blades

Forging

Process: Heating metal to a high temperature and shaping it using a press or hammer. Advantages: Strong, high-quality components with good grain structure. Challenges: Costly for complex designs.

Casting

Process: Molten metal is poured into a mold that shapes the blade. Types:

- Sand Casting: Good for larger, less intricate blades.

- Investment Casting: Allows for precise and complex designs. Advantages: Economical for mass production. Applications: Suitable for both impulse and reaction blades.

Machining

Process: CNC machines precisely cut and finish the blade from a solid piece of metal. Benefits: High precision, smooth surface finishes. Drawbacks: Material wastage can be a concern.

Additive Manufacturing (3D Printing)

Process: Building blades layer by layer using powdered metals. Benefits: Design flexibility, reduced material waste, and quick prototyping. Future Potential: Suitable for rapid production and custom designs.

Coating and Surface Treatment

Coatings enhance blade performance by adding protective layers to resist corrosion, erosion, and heat.

Common Techniques:

- Plasma Spraying: Forms a protective layer.

- Thermal Spray Coating: Adds thermal resistance.

- Importance: Extends blade life and maintains efficiency.

Quality Control and Testing

Ensuring the integrity of turbine blades is vital due to the harsh operating conditions. Quality control involves various Non-Destructive Testing (NDT) methods:

- Ultrasonic Testing: Detects internal flaws.

- X-ray Inspection: Checks for defects inside the material.

- Surface Crack Testing: Ensures the blade’s surface is free from cracks.

Future Trends in Turbine Blade Manufacturing

- Advanced Materials: Research into lighter, stronger composite materials and new superalloys.

- Smart Manufacturing: Automation, AI, and real-time monitoring.

- Computational Design: Use of simulation to optimize blade shape, efficiency, and cooling.

Conclusion

Steam turbine blades are the cornerstone of efficient energy generation. With continued advancements in materials, design, and manufacturing technologies, turbine blades will become more efficient, durable, and cost-effective, ensuring a steady supply of energy for future generations.

Introduction to Steam Turbine Blades

Steam turbines are one of the most critical components in power generation systems, playing a vital role in converting thermal energy from steam into mechanical energy. This mechanical energy can then be used to drive electrical generators, pumps, and other machinery. A key component within a steam turbine is its blades, which are responsible for extracting energy from the high-pressure, high-temperature steam that flows through the turbine. Without well-designed and precisely manufactured blades, steam turbines cannot operate efficiently or reliably.

Understanding the Role of Steam Turbine Blades

Steam turbine blades are carefully engineered structures designed to interact with high-velocity steam to extract kinetic energy. As steam flows through the turbine, it strikes the blades, causing them to rotate and, in turn, drive a connected shaft. The energy transformation in a steam turbine involves two major steps:

- Steam Expansion: The pressurized steam is allowed to expand, converting its pressure energy into kinetic energy.

- Energy Extraction: The blades extract this kinetic energy, causing the rotor to spin.

The efficiency and performance of a steam turbine are directly influenced by the design and arrangement of its blades. The blades must be capable of withstanding extreme conditions, including high temperatures, pressures, and sometimes corrosive environments. Therefore, the design, material selection, and manufacturing process for turbine blades are crucial aspects that determine the overall success and longevity of the turbine system.

The Importance of Blade Design in Turbine Efficiency

Blades are the core functional elements that determine the efficiency of energy conversion in a steam turbine. The design of these blades has a significant impact on how effectively the turbine can convert steam energy into mechanical energy. Key factors influencing blade design include:

- Aerodynamics: Efficient aerodynamic design ensures that steam flows smoothly over the blades, reducing turbulence and energy losses. Streamlined blade profiles help in maximizing the energy extracted from the steam.

- Mechanical Strength: Blades need to endure high levels of mechanical stress due to the centrifugal forces at high rotational speeds. Therefore, they must be designed to be strong and durable.

- Thermal Efficiency: Since turbines operate at high temperatures, blade materials must maintain their integrity without deforming or melting. Proper cooling mechanisms are sometimes integrated into the blade design to prevent overheating.

- Corrosion and Erosion Resistance: Steam can contain impurities that may cause corrosion or erosion of blades over time. The material and coatings used for blades play a key role in minimizing these effects.

A well-designed blade ensures that the turbine operates with high efficiency, minimizing energy losses and maximizing power output. Conversely, poor blade design can lead to inefficiencies, higher operational costs, and potential mechanical failures.

Types of Steam Turbine Blades

Steam turbine blades can be classified into two main types: impulse blades and reaction blades. Each type is suited to different stages within the turbine, based on the specific energy conversion requirements.

3.1 Impulse Blades

Impulse blades operate on the principle of impulse, where steam jets are directed onto the blades at high velocity. The blades extract energy by changing the direction of the steam flow, resulting in a reactionary force that rotates the turbine rotor. Impulse blades are typically used in the high-pressure stages of the turbine because they can handle the high velocities and forces involved.

Key Characteristics:

- Steam pressure remains constant as it passes over the blade.

- Energy is extracted by changing the steam’s direction.

- Simple blade design, which is easier to manufacture.

- Typically found at the front (high-pressure) stages of the turbine.

3.2 Reaction Blades

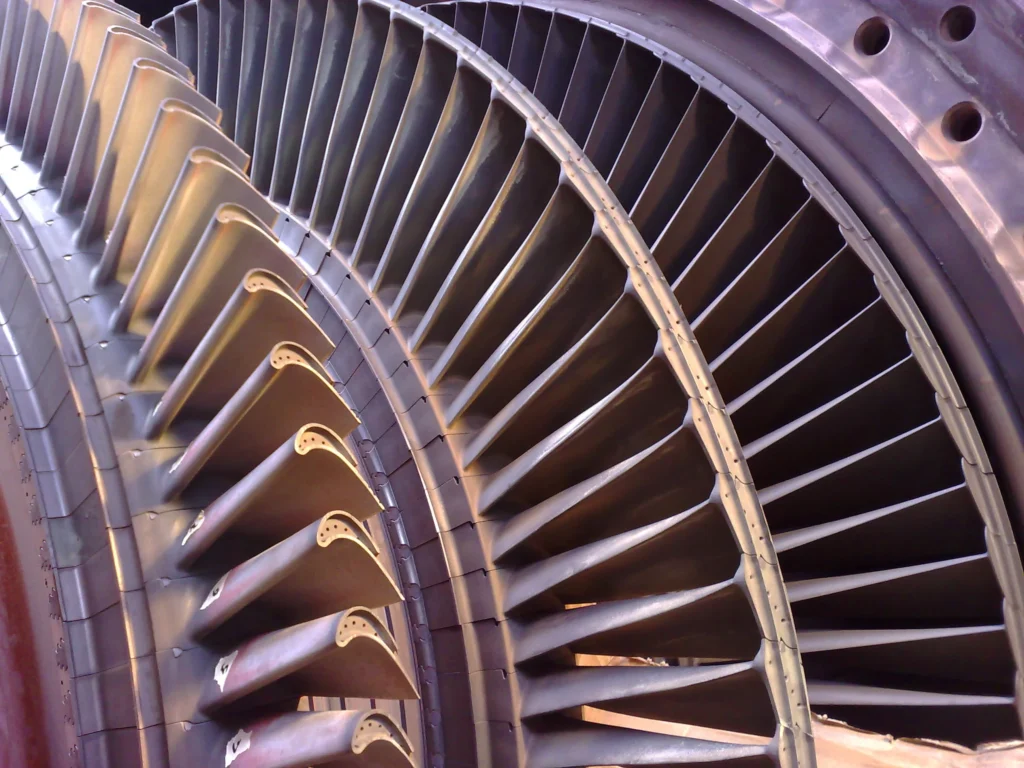

Reaction blades work on the principle of both pressure drop and velocity change. Unlike impulse blades, reaction blades extract energy from steam through a gradual expansion process, where both the pressure and velocity of the steam change as it passes over the blade. These blades are used in the low-pressure stages of the turbine, where steam pressure has already been reduced.

Key Characteristics:

- Pressure drops as steam passes over the blade, causing a reactive force.

- More complex aerodynamic design compared to impulse blades.

- Found in the low to medium-pressure stages of the turbine.

- Require precise manufacturing to ensure smooth operation.

Design Considerations for Steam Turbine Blades

The design of turbine blades involves several considerations to optimize performance, durability, and cost-efficiency. Some of the key aspects are:

4.1 Aerodynamic Efficiency

Blades must be designed to ensure maximum energy extraction from the steam flow. This requires a deep understanding of fluid dynamics to minimize losses caused by turbulence, drag, and steam leakage. Modern blade designs often incorporate features such as twisted profiles to optimize the angle of attack and reduce energy losses.

4.2 Structural Integrity and Mechanical Stress

The high rotational speeds of steam turbines subject blades to significant mechanical stresses, particularly centrifugal forces. If not properly designed, these forces can lead to deformation, cracking, or even catastrophic failure. Blades must, therefore, be designed with sufficient mechanical strength, often using sophisticated finite element analysis (FEA) to predict stress distribution and identify potential failure points.

4.3 Thermal Resistance

Operating temperatures in steam turbines can exceed 600°C (1112°F), which can cause metal blades to soften or warp. The materials used for turbine blades must maintain their mechanical properties under these high temperatures. In some designs, cooling passages are integrated within the blades to dissipate heat, preventing overheating and thermal fatigue.

4.4 Corrosion and Erosion Protection

Steam can carry moisture and impurities, leading to corrosion and erosion of the blades over time. These effects can degrade blade performance and reduce the lifespan of the turbine. To counteract this, blades are often made from corrosion-resistant alloys or coated with protective materials that guard against wear and chemical attack.

Materials Used for Steam Turbine Blades

The choice of material for turbine blades is essential to ensure durability and reliability. The materials must possess a unique combination of properties, including high strength, corrosion resistance, and thermal stability. Common materials include:

5.1 Nickel-Based Superalloys

Nickel-based superalloys are among the most commonly used materials for turbine blades, especially in high-temperature sections. These alloys maintain their strength at high temperatures and are resistant to oxidation and corrosion. Examples include Inconel and Waspaloy.

5.2 Titanium Alloys

Titanium alloys are valued for their excellent strength-to-weight ratio and corrosion resistance, making them ideal for low-pressure, high-velocity sections of the turbine where reduced blade weight can improve efficiency.

5.3 Stainless Steels

Stainless steels are a more cost-effective option, often used in lower temperature and lower-stress sections of the turbine. They offer a good balance of strength, corrosion resistance, and cost, making them suitable for less demanding applications.

5.4 Ceramic-Matrix Composites (CMCs)

Recent advancements have introduced ceramic-matrix composites, which can operate at higher temperatures than metal alloys. Although still in experimental and limited commercial use, CMCs hold the potential to significantly improve turbine efficiency by allowing for higher operational temperatures without the risk of material degradation.

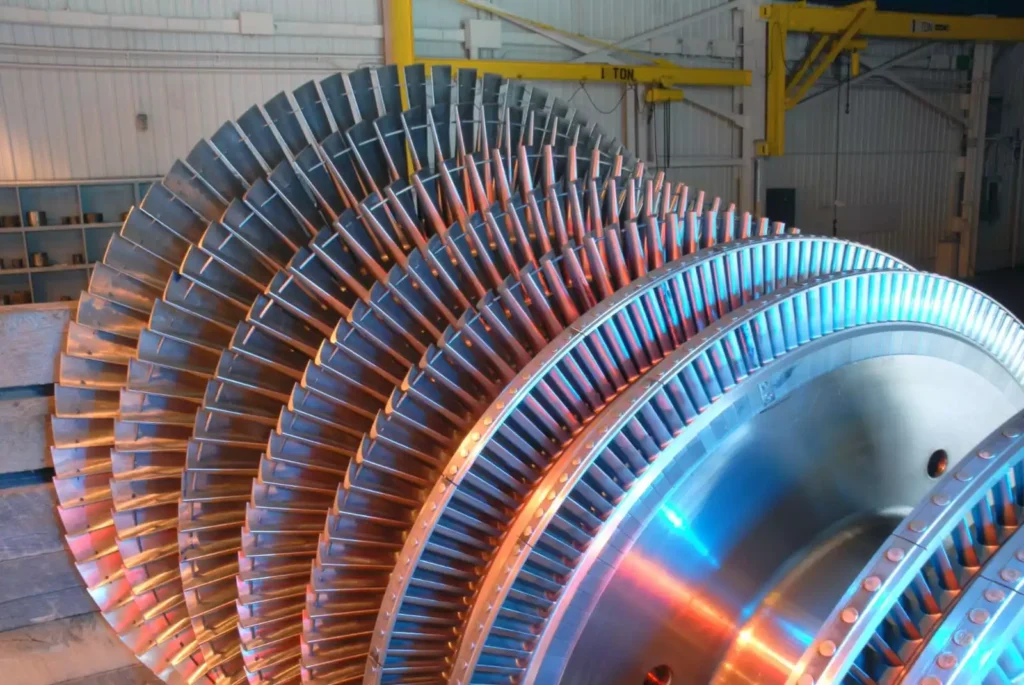

6. Manufacturing Processes for Steam Turbine Blades

Manufacturing turbine blades involves precision processes to ensure exact specifications and high-quality finishes. Typical manufacturing methods include:

6.1 Forging

Forging involves shaping metal under high pressure, producing strong and durable blades. It is particularly useful for creating high-strength components that can withstand significant mechanical stresses.

6.2 Casting

Casting allows for the production of complex blade geometries by pouring molten metal into molds. Investment casting, in particular, is a preferred method for reaction blades, where precise shapes and smooth surface finishes are essential for performance.

6.3 Machining

Machining processes, including CNC (Computer Numerical Control) milling, are used to achieve precise blade dimensions and fine surface finishes. This process is crucial for final shaping and trimming to ensure aerodynamic efficiency.

6.4 Additive Manufacturing

Additive manufacturing, or 3D printing, has emerged as a cutting-edge technology for producing turbine blades. It allows for the creation of intricate designs that are difficult to achieve through traditional manufacturing. While still not widespread, additive manufacturing holds promise for rapid prototyping and production of customized blade designs.

7. The Future of Steam Turbine Blade Technology

The design and manufacturing of steam turbine blades continue to evolve, with ongoing research aimed at improving efficiency, reducing costs, and extending operational life. Future trends include:

- Advanced Materials: Development of new alloys and composite materials that can withstand even higher temperatures and pressures.

- Coating Innovations: Improved coatings that offer better protection against corrosion, erosion, and thermal degradation.

- Digital Twins and Simulation: The use of digital twins to simulate blade performance under various conditions, enabling engineers to optimize designs before manufacturing.

- Smart Manufacturing: Integration of AI and machine learning in the manufacturing process for real-time quality control and defect detection.

Conclusion

Steam turbine blades are fundamental to the operation of modern power generation systems, responsible for converting thermal energy into mechanical energy with high efficiency. The intricate design and precise manufacturing of these blades require a careful balance of aerodynamics, material science, and mechanical engineering. With advancements in material technology and manufacturing processes, the future of steam turbine blades looks promising, with improvements aimed at enhancing performance, reducing maintenance needs, and enabling cleaner, more sustainable energy production.

Understanding the complexities behind blade design and manufacturing highlights the importance of continuous innovation, ensuring that steam turbines remain a reliable source of power for years to come.

Types of Steam Turbine Blades

Steam turbine blades are the critical components responsible for converting thermal energy from steam into mechanical energy. The design and configuration of these blades are pivotal in determining the efficiency, performance, and operational characteristics of a steam turbine. Broadly, steam turbine blades are classified into two major types: impulse blades and reaction blades. This classification is based on the principles of operation and the way they extract energy from the steam.

This detailed exploration will cover the different types of blades, their operational principles, design considerations, and applications within the turbine system. By understanding the distinctions between these blade types, it becomes easier to appreciate their specific uses, advantages, and how they contribute to the overall performance of a steam turbine.

1. The Role of Steam Turbine Blades in Energy Conversion

Before diving into the types of blades, it’s essential to understand their role in the turbine’s energy conversion process. Steam turbines operate on the principle of expanding high-pressure, high-temperature steam to extract energy. This expansion process occurs through a series of stages, where the blades play a key role:

- Energy Extraction: Blades interact with the steam to convert its kinetic energy into mechanical rotation. This rotational motion drives a generator, producing electricity.

- Efficient Energy Use: The design and arrangement of blades are crucial to maximize energy extraction while minimizing losses, turbulence, and inefficiency.

- Pressure and Velocity Management: Through careful design, blades manage the steam’s pressure and velocity, ensuring optimal performance across different stages of the turbine.

Steam turbines are often divided into high-pressure, intermediate-pressure, and low-pressure sections, with different types of blades used in each section to handle varying energy levels and steam characteristics.

2. Impulse Blades

2.1 Operating Principle

Impulse blades operate based on the impulse principle, where the kinetic energy of high-velocity steam is used to rotate the turbine rotor. In an impulse turbine, steam is directed at the blades through nozzles, converting the steam’s pressure energy into kinetic energy. As the high-speed jet of steam strikes the impulse blades, it changes direction, causing a force that turns the rotor. Importantly, the pressure of the steam remains constant as it passes over the blades; only the velocity changes.

2.2 Design Characteristics

- Shape and Structure: Impulse blades are bucket-shaped, designed to capture and redirect the steam flow. They are often symmetrical, with a concave surface to catch the steam effectively.

- Fixed Blade and Moving Blade Arrangement: In an impulse turbine, steam first passes through fixed nozzles, which guide the steam onto the moving blades. The fixed nozzles are not part of the rotor, while the moving blades are mounted on the rotor shaft.

- Energy Distribution: The energy extracted by impulse blades comes solely from the kinetic energy of the steam, with no change in pressure. This requires high precision in blade design to minimize losses due to turbulence and steam leakage.

2.3 Advantages of Impulse Blades

- Simple Design: The straightforward shape of impulse blades makes them easier to manufacture compared to more complex designs.

- High Efficiency at High Pressure: Impulse blades are efficient at handling high-pressure steam, making them ideal for the high-pressure sections of a turbine.

- Ease of Maintenance: Due to their simplicity, impulse blades are easier to inspect, maintain, and replace, reducing operational costs.

2.4 Applications

Impulse blades are primarily used in the high-pressure stages of a turbine. This is because they are well-suited to handle the high-velocity steam generated at the beginning of the energy conversion process. Their design allows them to extract energy efficiently even when the steam pressure is very high, which is common in the initial stages of steam expansion.

3. Reaction Blades

3.1 Operating Principle

Reaction blades operate on the principle of both impulse and reaction forces. Unlike impulse blades, reaction blades utilize a continuous pressure drop across the blades to extract energy. As steam passes through the blades, it expands and accelerates, creating a reactive force that pushes the blades and rotates the rotor. This process involves both a change in pressure and velocity, unlike the impulse system where only velocity changes.

3.2 Design Characteristics

- Aerodynamic Shape: Reaction blades are more aerodynamically complex than impulse blades. They are designed with a profile that allows steam to expand and accelerate as it flows over the surface, creating lift-like forces.

- Fixed and Moving Blade Rows: Similar to impulse turbines, reaction turbines also have fixed and moving blade rows. However, in this case, both sets contribute to energy extraction. The fixed blades act as guides, causing the steam to change direction and accelerate onto the moving blades.

- Pressure Distribution: In reaction blades, the pressure decreases as steam moves over the blades, which differentiates them from impulse blades. This pressure drop across the blades contributes to the generation of mechanical force.

3.3 Advantages of Reaction Blades

- Higher Energy Extraction: Since reaction blades utilize both pressure and velocity changes, they can extract more energy from steam than impulse blades in certain situations.

- Smooth and Continuous Operation: The design of reaction blades allows for smoother operation, as the energy conversion is more gradual. This can lead to improved efficiency in the low-pressure stages.

- Efficiency Across Pressure Ranges: Reaction blades can be adapted to operate efficiently across different pressure ranges, making them versatile within the turbine system.

3.4 Applications

Reaction blades are typically found in the intermediate and low-pressure sections of a turbine. As the steam pressure drops throughout the turbine, reaction blades continue to extract energy efficiently. Their design is particularly beneficial where the steam pressure and velocity are lower, and a smooth, continuous conversion of energy is desired.

4. Comparative Analysis: Impulse vs. Reaction Blades

To better understand the distinctions between impulse and reaction blades, it is useful to compare their operational characteristics, design features, and typical uses within a turbine system.

| Feature | Impulse Blades | Reaction Blades |

|---|---|---|

| Operating Principle | Utilizes kinetic energy from high-velocity steam. | Uses both pressure and velocity changes. |

| Pressure Change | No change in pressure across the blades. | Pressure drops as steam moves over the blades. |

| Design Complexity | Relatively simple and bucket-shaped. | More complex, aerodynamically designed. |

| Energy Extraction | Extracts energy primarily from velocity. | Extracts energy from both velocity and pressure. |

| Preferred Pressure Stage | High-pressure stages of turbines. | Low and intermediate-pressure stages. |

| Maintenance | Easier to maintain and replace. | Requires more precise manufacturing and maintenance. |

5. Special Blade Configurations and Hybrid Designs

In modern steam turbines, there are also configurations that combine the principles of both impulse and reaction designs to optimize performance across varying steam conditions. These are often called “hybrid” or “compound” turbines and are designed to handle different stages of steam expansion more efficiently.

5.1 Compound Staging

- Combination Approach: In a compound turbine, high-pressure sections may utilize impulse blades to handle the intense kinetic energy of the initial steam flow. As the steam pressure drops, reaction blades take over to continue the energy extraction process more smoothly.

- Enhanced Efficiency: This approach allows the turbine to maintain high efficiency across a wide range of operational conditions, accommodating both high and low-pressure steam effectively.

5.2 Curtis Stage (Multi-Stage Impulse)

- Design Description: The Curtis stage is a multi-stage impulse design, often used as a part of the high-pressure stage of a turbine. Instead of a single set of impulse blades, multiple sets are arranged in series, allowing for a gradual reduction in steam velocity.

- Applications: This design is used to improve efficiency when dealing with very high-velocity steam, making it suitable for large, high-capacity power plants.

6. Key Design Considerations for Turbine Blades

6.1 Aerodynamic Efficiency

Both impulse and reaction blades must be designed to ensure smooth steam flow, minimizing drag and turbulence. This is especially critical for reaction blades, where the aerodynamic profile is more complex.

6.2 Material Strength and Durability

Given the high-speed rotation and the extreme conditions under which turbine blades operate, material selection is crucial. Both types of blades are subject to stress, but impulse blades face more intense impact forces, while reaction blades endure a combination of pressure and shear forces.

6.3 Precision Manufacturing

Impulse blades are simpler in shape, making them easier to manufacture. However, reaction blades require higher precision in both design and manufacturing due to their aerodynamic complexity and need to handle gradual pressure drops without losing efficiency.

7. Advances in Blade Design and Future Trends

The field of turbine blade design continues to evolve, driven by the demand for higher efficiency, lower emissions, and greater operational flexibility. Future advancements are likely to include:

- 3D Printed Blades: Offering more intricate designs that improve aerodynamics and efficiency.

- Advanced Materials: Development of new alloys and composites that can withstand even higher temperatures and pressures.

- Adaptive Blade Designs: Innovations in blade shapes that can adjust to varying steam conditions, further optimizing performance across different operational modes.

Conclusion

Steam turbine blades, whether impulse or reaction, are fundamental components that enable efficient energy conversion in power plants. The choice between impulse and reaction blades, or a combination of both, depends on the specific application and the operating conditions of the turbine. Understanding the principles, advantages, and design characteristics of each blade type is essential for designing turbines that operate efficiently, reliably, and with minimal maintenance. As technology continues to advance, the future of turbine blade design looks to become even more innovative, leading to cleaner, more sustainable, and more efficient power generation systems.

Impulse Blades in Steam Turbines: An In-Depth Exploration

Impulse blades are one of the two primary types of blades used in steam turbines, and they play a crucial role in the conversion of steam’s kinetic energy into mechanical energy. These blades are designed to harness high-velocity steam to drive the turbine rotor, generating power. In this comprehensive exploration, we will delve into the design, operating principles, material considerations, applications, and manufacturing techniques of impulse blades, along with their advantages and challenges.

1. Understanding Impulse Turbines and Their Blades

Impulse turbines are characterized by their unique method of energy conversion. Unlike reaction turbines, where energy extraction involves a gradual pressure drop across the blades, impulse turbines convert the steam’s pressure energy into kinetic energy before it reaches the blades. This high-velocity steam then strikes the impulse blades, causing them to rotate.

1.1 Operating Principle of Impulse Blades

The operating principle of impulse blades is based on the impulse force, which is the result of steam jets striking the blades at high speeds. Here’s how it works:

- Steam Expansion in Nozzles: The pressurized steam is expanded in nozzles before it reaches the impulse blades. The nozzles convert the pressure energy of the steam into high-velocity jets. By the time the steam exits the nozzles, most of its pressure energy has been converted into kinetic energy.

- Kinetic Energy Transfer: As the steam jet strikes the impulse blades, it changes direction, creating a force (impulse) that pushes the blades. The steam’s pressure remains constant throughout this process; only its velocity changes. The resulting impulse force rotates the rotor, converting kinetic energy into mechanical energy.

- Mechanical Rotation: The blades are mounted on a rotor, and as they turn, they drive the connected shaft. This shaft is connected to a generator, which ultimately converts the mechanical energy into electrical energy.

This method of energy extraction allows impulse turbines to operate efficiently at high steam pressures, making them ideal for the initial stages of steam turbines where the pressure is at its peak.

2. Design Characteristics of Impulse Blades

The design of impulse blades is crucial to their function. These blades must be shaped and arranged in a way that maximizes energy extraction from the steam while minimizing energy losses. Key design characteristics include:

2.1 Blade Shape and Geometry

- Bucket Shape: Impulse blades are often designed with a “bucket” or “cup” shape. This design allows the blades to catch the steam effectively and redirect it, generating the maximum impulse force.

- Symmetrical Design: The blades are typically symmetrical, allowing for a uniform distribution of force and ensuring balanced rotation of the rotor. The symmetrical design also helps to minimize wear and tear, leading to improved longevity.

- Curvature and Angle: The curvature of the blades is carefully designed to change the direction of the steam flow without causing excessive turbulence or drag. The angle at which the blades are positioned ensures that the steam strikes them at the optimal point, maximizing energy transfer.

2.2 Fixed and Moving Blade Arrangement

Impulse turbines typically utilize a combination of fixed nozzles and moving blades:

- Fixed Nozzles: These are stationary components that direct the steam onto the moving blades. They play a crucial role in converting the steam’s pressure energy into high-velocity jets.

- Moving Blades: Mounted on the rotor, the moving blades receive the steam from the nozzles and extract kinetic energy from it. The rotor rotates due to the impulse force generated by the change in the steam’s direction.

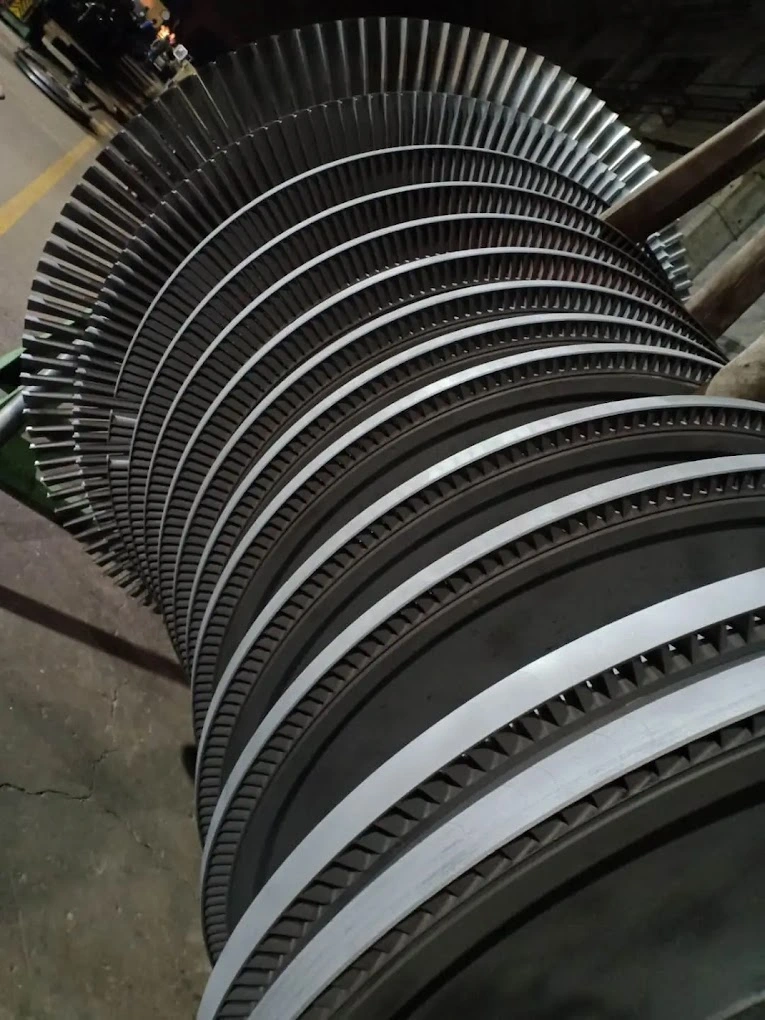

2.3 Stage Configuration

Impulse turbines can be designed with multiple stages to enhance energy extraction. In a single-stage impulse turbine, all the energy is extracted in one go, which may not be efficient. Multi-stage impulse turbines, like the Curtis stage, utilize multiple rows of nozzles and blades, allowing for gradual energy extraction. This staged approach reduces the velocity of the steam in increments, improving overall efficiency and minimizing mechanical stress on the blades.

3. Advantages of Impulse Blades

Impulse blades offer several benefits that make them a preferred choice for certain stages of steam turbines. Some of these advantages include:

3.1 High Efficiency at High Pressure

Impulse blades are well-suited for high-pressure steam because they convert the steam’s pressure energy into kinetic energy before the steam reaches the blades. This makes them efficient in the initial stages of the turbine where steam pressure is highest.

3.2 Simplicity of Design

The design of impulse blades is relatively simple compared to reaction blades. This simplicity translates to easier manufacturing and maintenance. The straightforward design reduces manufacturing costs and simplifies the process of inspection and repair, making impulse blades a cost-effective option for turbine operators.

3.3 Adaptability to Varying Conditions

Impulse blades can operate effectively under varying steam conditions without significant loss of efficiency. This adaptability makes them useful in applications where steam conditions may fluctuate, such as in industrial power generation.

3.4 Ease of Maintenance and Replacement

Since impulse blades are designed to handle high-impact forces and do not experience pressure drops, they are typically less susceptible to damage from wear and tear. Additionally, their simpler design means that they can be easily inspected, maintained, and replaced if necessary, minimizing downtime during maintenance activities.

4. Applications of Impulse Blades in Steam Turbines

Impulse blades are primarily used in the high-pressure stages of steam turbines. In these sections, the steam pressure is at its peak, and the goal is to convert this pressure into kinetic energy as efficiently as possible. Impulse blades are also used in certain industrial turbines where conditions may vary, but high efficiency is still required.

4.1 Power Plants

In large-scale power plants, impulse blades are typically found in the high-pressure stages of the turbine, where they are responsible for extracting energy from steam that is fresh out of the boiler. The blades can handle the high pressure and temperature conditions effectively, ensuring efficient energy conversion right from the start.

4.2 Industrial Applications

Many industries use steam turbines for driving equipment like compressors, pumps, and blowers. Impulse blades are commonly used in these applications because they can handle varying loads and pressures, providing reliable performance across a range of operating conditions.

4.3 Marine Propulsion

Impulse turbines have also been used in the marine industry to drive ship propellers. The turbines convert the high-pressure steam produced in the boiler into mechanical energy, which then drives the ship’s propeller shaft, propelling the vessel forward.

5. Materials Used in Impulse Blade Manufacturing

The materials used for impulse blades must withstand harsh conditions, including high temperatures, high pressures, and exposure to steam and other elements. Key material properties include thermal resistance, strength, corrosion resistance, and durability. Some of the common materials used include:

5.1 Stainless Steel

Stainless steel is widely used due to its strength, durability, and resistance to corrosion. It is capable of withstanding the high temperatures and pressures encountered in the high-pressure stages of turbines. Additionally, stainless steel is relatively cost-effective, making it a popular choice for many turbine manufacturers.

5.2 Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel and Waspaloy, are often used in high-performance applications where extreme temperatures are a concern. These alloys retain their mechanical properties at high temperatures and are resistant to oxidation and corrosion. However, they are more expensive than stainless steel.

5.3 Titanium Alloys

Titanium alloys are valued for their high strength-to-weight ratio, which makes them ideal for applications where reduced weight is an advantage. These alloys also offer excellent resistance to corrosion, which is beneficial in environments where the steam may contain impurities.

6. Manufacturing Technologies for Impulse Blades

The production of impulse blades requires precision engineering to ensure they meet exact specifications. Manufacturing technologies include:

6.1 Forging

Forging involves shaping metal under high pressure to produce strong, durable blades. This process is often used for the production of high-strength components that need to endure significant mechanical stress. Forging helps achieve a robust grain structure, enhancing the blade’s strength and durability.

6.2 Machining

After the initial forging, the blades are typically machined to achieve the precise shapes and dimensions required for optimal performance. CNC (Computer Numerical Control) machining is commonly used for this purpose, as it allows for high precision and control over the blade’s final form.

6.3 Investment Casting

For more complex blade geometries, investment casting is often used. This process involves creating a wax model of the blade, which is then coated in a ceramic shell. Once the wax is melted out, molten metal is poured into the ceramic mold to form the blade. Investment casting allows for the production of intricate designs with smooth finishes, which are critical for minimizing energy losses.

7. Challenges and Future Trends in Impulse Blade Design

7.1 Challenges in Impulse Blade Operation

- Erosion and Corrosion: Impulse blades can suffer from erosion and corrosion due to the high-speed impact of steam, especially if the steam contains impurities. This can lead to gradual wear and a decrease in efficiency over time.

- Thermal Stress: The blades operate under high-temperature conditions, leading to thermal stress that can cause material fatigue and cracking if not properly managed.

- Noise and Vibration: High-speed operation can lead to noise and vibration, which may require damping mechanisms to minimize wear and improve performance.

7.2 Future Trends in Impulse Blade Technology

- Advanced Materials: Ongoing research is focused on developing new materials that can withstand higher temperatures and pressures, improving turbine efficiency. Superalloys and ceramic-matrix composites (CMCs) are among the materials being explored for future applications.

- Additive Manufacturing: Also known as 3D printing, additive manufacturing offers the potential to create complex blade geometries that are difficult to achieve with traditional methods. This could lead to more efficient designs and faster production times.

- Improved Coating Technologies: Enhanced coating technologies can improve the blades’ resistance to erosion and corrosion, extending their lifespan and reducing maintenance costs. Thermal barrier coatings (TBCs) are particularly promising for high-temperature applications.

Conclusion

Impulse blades are fundamental to the operation of steam turbines, especially in the high-pressure stages. Their design and function are based on the principle of impulse, where kinetic energy from high-velocity steam is converted into mechanical energy. The simplicity of their design, combined with their ability to handle high-pressure conditions, makes them an essential component in power generation, industrial, and marine applications.

Advancements in material science, manufacturing technologies, and design engineering are continuously improving the performance and durability of impulse blades. As the demand for more efficient and reliable power generation continues to grow, the role of impulse blades in steam turbines will remain crucial, driving innovation and development in this field.

Reaction Blades in Steam Turbines: An In-Depth Exploration

Reaction blades are a fundamental component of steam turbines, especially in the low to medium-pressure stages. Unlike impulse blades, which rely solely on changes in the velocity of steam to generate mechanical force, reaction blades harness both pressure and velocity changes. This makes them essential for the efficient extraction of energy from steam as it expands and loses pressure within the turbine. In this comprehensive exploration, we will delve into the design, principles of operation, materials, applications, manufacturing techniques, and future trends of reaction blades.

1. Understanding Reaction Turbines and Their Blades

Reaction turbines operate on a combined principle of impulse and reaction. As steam passes over the blades, it experiences a drop in both pressure and velocity, causing the blades to move. This dual-action method of energy extraction allows for a smoother and more gradual transfer of energy, making reaction turbines highly efficient across varying steam pressures.

1.1 Operating Principle of Reaction Blades

The operating principle of reaction blades is based on Newton’s Third Law of Motion, which states that for every action, there is an equal and opposite reaction. Here’s how it works:

- Energy Conversion: Unlike impulse turbines, where energy is mainly converted in the nozzles before reaching the blades, reaction turbines use blades that act as both nozzles and energy extractors. Steam accelerates as it passes over the blades, expanding and losing pressure. This creates a reactive force that drives the rotor.

- Pressure Drop Across the Blades: As steam flows over the reaction blades, it expands, resulting in a pressure drop. This pressure drop occurs gradually, allowing for a smoother and continuous extraction of energy.

- Reactive Force and Rotor Motion: The steam’s acceleration creates a reactive force that propels the blades forward, turning the rotor. The rotor’s motion then drives the connected shaft, converting the extracted energy into mechanical work, which can then be used to generate electricity.

Because the energy extraction involves changes in both pressure and velocity, reaction blades are typically used in stages where the steam pressure is lower and has already undergone some expansion.

2. Design Characteristics of Reaction Blades

The design of reaction blades is more complex compared to impulse blades because they need to accommodate both pressure and velocity changes. This complexity ensures that the turbine operates efficiently and extracts maximum energy from the steam.

2.1 Blade Shape and Geometry

- Aerofoil Design: Reaction blades have a more aerodynamic, aerofoil-like shape. This design is crucial for guiding the steam smoothly over the blade surface, allowing it to expand and accelerate without creating excessive turbulence or energy losses.

- Twisted Profile: The blades often feature a twisted or contoured profile. This design helps optimize the steam’s angle of attack as it flows through different sections of the blade, improving efficiency. The twisting also allows the blades to handle variations in steam velocity and pressure more effectively.

- Fixed and Moving Blade Rows: Reaction turbines consist of alternating rows of fixed blades (stator blades) and moving blades (rotor blades). The fixed blades direct the steam onto the moving blades, causing it to accelerate and expand. The moving blades then convert this energy into mechanical motion.

2.2 Gradual Pressure Drop Across Stages

- Energy Extraction Across Multiple Stages: Unlike impulse turbines, where the energy is extracted in discrete bursts, reaction turbines operate over multiple stages, with a gradual decrease in pressure across each stage. This staged approach allows for a smoother, more controlled energy transfer, reducing mechanical stress on the blades.

- Staggered Blade Arrangement: The blades are arranged in a staggered pattern to ensure efficient steam flow. This arrangement helps maintain continuous energy extraction across each stage, minimizing disruptions in the steam flow and improving overall turbine efficiency.

3. Advantages of Reaction Blades

Reaction blades offer several benefits that make them suitable for specific applications in steam turbines. Some of the key advantages include:

3.1 High Efficiency in Low to Medium-Pressure Stages

Reaction blades are particularly effective in the low and medium-pressure sections of a steam turbine, where the steam has already undergone significant expansion. The gradual energy extraction ensures that even when the steam pressure is lower, the turbine can still operate efficiently, making the most of the remaining energy in the steam.

3.2 Smooth and Continuous Energy Conversion

The design of reaction blades allows for a continuous and smooth energy conversion process. By gradually extracting energy across multiple stages, reaction turbines minimize mechanical shocks and vibrations, which can lead to more stable and reliable operation. This smooth operation also contributes to less wear and tear, enhancing the lifespan of the turbine components.

3.3 Adaptability Across Pressure Ranges

Reaction blades can handle a wide range of steam pressures, making them versatile and adaptable. This flexibility is especially beneficial in power plants that operate under varying load conditions, as the turbine can maintain efficiency across different operational settings.

3.4 Enhanced Aerodynamic Performance

The aerodynamic design of reaction blades reduces drag and turbulence, which helps improve the overall efficiency of the turbine. By minimizing aerodynamic losses, the blades can extract more energy from the steam, leading to higher performance levels.

4. Applications of Reaction Blades in Steam Turbines

Reaction blades are primarily used in the medium to low-pressure stages of steam turbines. Their ability to handle gradual energy extraction makes them ideal for these sections, where the steam has expanded and the pressure is lower. Some of the typical applications include:

4.1 Power Generation Plants

In power plants, reaction blades are found in the latter stages of the turbine, where the steam has already passed through high-pressure sections. The blades continue to extract energy efficiently from the steam as it expands further, ensuring that no energy is wasted.

4.2 Industrial and Mechanical Drives

In industrial applications, such as in factories and manufacturing plants, reaction turbines are used to drive mechanical equipment. The smooth operation and efficiency of reaction blades make them suitable for industrial processes that require consistent, reliable power.

4.3 Marine Propulsion Systems

Reaction turbines are sometimes used in marine propulsion systems, where efficiency and smooth operation are critical. The gradual energy extraction process of reaction blades helps maintain steady propulsion, even when the steam pressure varies.

5. Materials Used in Reaction Blade Manufacturing

The choice of materials for reaction blades is essential due to the challenging operating conditions, including exposure to high temperatures, moisture, and corrosive elements. Key properties include thermal resistance, strength, corrosion resistance, and durability. Some of the common materials used for reaction blades include:

5.1 Stainless Steel

Stainless steel is widely used due to its balance of strength, durability, and resistance to corrosion. It can withstand high temperatures and provides reliable performance in the low-pressure stages of the turbine. Additionally, stainless steel is relatively affordable, making it a practical choice for many turbine designs.

5.2 Nickel-Based Superalloys

Nickel-based superalloys, such as Hastelloy and Inconel, are used in high-performance turbines where higher operating temperatures and more demanding conditions are expected. These materials retain their mechanical properties at high temperatures and are resistant to oxidation and corrosion, making them ideal for long-term use in reaction blades.

5.3 Titanium Alloys

Titanium alloys offer a high strength-to-weight ratio and excellent corrosion resistance, making them suitable for applications where reduced weight is advantageous. They are particularly effective in low-pressure stages where the steam has cooled, and lightweight components can improve overall efficiency.

6. Manufacturing Technologies for Reaction Blades

The manufacturing of reaction blades requires precision and expertise to ensure that the blades meet exact specifications and can operate efficiently. Some of the common manufacturing techniques include:

6.1 Precision Casting

Casting, particularly investment casting, is a popular method for manufacturing reaction blades. This process involves creating a detailed wax model of the blade, which is then coated in a ceramic shell. Once the wax is melted out, molten metal is poured into the mold to form the blade. Investment casting allows for the production of intricate shapes and smooth surfaces, which are critical for aerodynamic efficiency.

6.2 CNC Machining

Computer Numerical Control (CNC) machining is used to refine the blades after casting. This process ensures that the blades have precise dimensions and smooth surfaces, which are necessary for optimal aerodynamic performance. CNC machining also allows for customization, enabling engineers to fine-tune blade designs for specific applications.

6.3 Additive Manufacturing (3D Printing)

Additive manufacturing is an emerging technology that offers the potential to produce complex blade geometries that are difficult to achieve with traditional methods. This technique allows for rapid prototyping and the creation of customized blade designs, improving flexibility and reducing production times. Though still not widespread in commercial turbine manufacturing, 3D printing holds promise for future developments.

7. Challenges and Future Trends in Reaction Blade Design

7.1 Challenges in Reaction Blade Operation

- Corrosion and Erosion: Reaction blades are exposed to steam that may contain impurities, leading to corrosion and erosion over time. This can degrade blade performance and reduce the efficiency of the turbine.

- Thermal Fatigue: Operating at high temperatures for extended periods can cause thermal fatigue, leading to material degradation. Engineers must carefully select materials that can withstand these conditions without losing mechanical integrity.

- Precision Manufacturing Requirements: The aerodynamic complexity of reaction blades makes them challenging to manufacture. Any imperfections can lead to reduced efficiency, making precision manufacturing essential.

7.2 Future Trends in Reaction Blade Technology

- Advanced Materials and Coatings: Research is ongoing into new materials and coatings that can withstand higher temperatures, improve corrosion resistance, and reduce wear. Advanced ceramics and superalloys are being explored as potential materials for future reaction blades.

- Smart Blades: With the rise of digital technologies, there is potential for the development of “smart” blades that can monitor their own performance in real time. Sensors embedded within the blades could provide data on temperature, stress, and wear, enabling predictive maintenance and enhancing reliability.

- Improved Aerodynamic Designs: Computational fluid dynamics (CFD) and simulation tools are being used to refine the aerodynamic designs of reaction blades. These tools allow engineers to optimize the blade shapes and profiles for better performance, even under varying operating conditions.

Conclusion

Reaction blades are integral to the operation of steam turbines, especially in the medium to low-pressure stages where the steam has already expanded. Their design, which leverages both pressure and velocity changes, allows for efficient, smooth, and continuous energy extraction. The complex aerodynamic shape of these blades, combined with the need for durable, high-performance materials, makes them one of the most challenging yet essential components of turbine engineering.

Advancements in materials science, precision manufacturing, and aerodynamic design continue to improve the efficiency and reliability of reaction blades. As the demand for more efficient power generation grows, the role of reaction blades will become even more significant, driving innovation and ensuring the sustainable production of energy. With future trends pointing toward smart, adaptable, and high-performance designs, reaction blades will likely remain at the forefront of steam turbine technology for years to come.

Differences Between Impulse and Reaction Blades in Steam Turbines: A Comprehensive Exploration

Steam turbines are a crucial part of power generation systems, transforming thermal energy from steam into mechanical energy that drives electrical generators. The efficiency of this energy conversion depends largely on the design of the turbine blades. There are two primary types of blades used in steam turbines: impulse blades and reaction blades. Each type operates on distinct principles and is suited to different stages of the turbine. This comprehensive exploration will delve into the key differences between impulse and reaction blades, including their operating principles, design characteristics, material considerations, applications, and advantages. Understanding these distinctions is essential for optimizing turbine performance and improving overall energy efficiency.

1. Operating Principles

The fundamental difference between impulse and reaction blades lies in how they convert steam energy into mechanical motion. The distinction arises from the way each type of blade handles the pressure and velocity of steam.

1.1 Impulse Blades:

- Impulse Principle: Impulse blades operate on the principle of converting the kinetic energy of high-velocity steam into mechanical motion. Steam is first expanded and accelerated in stationary nozzles, where its pressure energy is converted into kinetic energy. The high-speed steam then strikes the impulse blades, causing them to rotate. The blades themselves do not cause a change in steam pressure; instead, they redirect the steam, changing its velocity and generating an impulse force that drives the rotor.

- Constant Pressure Across the Blades: As steam flows over impulse blades, its pressure remains constant, but its velocity changes. This results in an impulse force that rotates the turbine.

1.2 Reaction Blades:

- Reaction Principle: Reaction blades, on the other hand, utilize both pressure and velocity changes to generate mechanical motion. Steam expands and accelerates directly as it passes over the blades, experiencing a gradual drop in pressure. This process generates a reactive force, much like the thrust produced by a rocket engine. The combination of pressure drop and change in steam velocity creates a continuous driving force on the blades.

- Pressure Drop Across the Blades: Unlike impulse blades, reaction blades cause the steam to experience a pressure drop as it flows over them. The energy conversion process is continuous, and the reactive force generated by the pressure change drives the turbine.

2. Design Characteristics

The design of impulse and reaction blades reflects their distinct operating principles. These design differences are crucial for maximizing efficiency and ensuring smooth operation in different stages of the turbine.

2.1 Impulse Blade Design:

- Bucket-Shaped Blades: Impulse blades are typically bucket-shaped or cup-shaped, designed to catch and redirect the steam flow. The shape allows for efficient conversion of the kinetic energy of the steam into mechanical energy.

- Symmetrical Design: The blades are often symmetrical, with a concave profile that ensures uniform force distribution, minimizing wear and tear. The design also helps in reducing turbulence and energy losses.

- Fixed and Moving Blade Arrangement: Impulse turbines use a combination of fixed nozzles (or stators) and moving blades. The nozzles are stationary components that direct steam onto the moving blades, which are mounted on the rotor shaft. Energy is extracted as the steam changes direction upon striking the moving blades.

2.2 Reaction Blade Design:

- Aerofoil-Shaped Blades: Reaction blades are more aerodynamic and resemble an aerofoil shape. This shape is essential for allowing the steam to expand and accelerate smoothly over the surface, facilitating both pressure drop and velocity change.

- Twisted Profile: Reaction blades often feature a twisted or contoured profile to optimize the steam’s angle of attack and ensure smooth flow. This design minimizes drag and turbulence, increasing efficiency.

- Alternating Fixed and Moving Blade Rows: Reaction turbines consist of alternating rows of fixed and moving blades. The fixed blades, or stators, direct the steam onto the moving blades, causing it to expand and accelerate. Both sets of blades play a role in energy conversion, unlike in impulse turbines where only the moving blades are responsible for extracting energy.

3. Energy Conversion Process

The way impulse and reaction blades convert energy highlights another key difference between the two. The efficiency and application of each blade type are directly influenced by their respective energy conversion mechanisms.

3.1 Impulse Energy Conversion:

- Discrete Energy Transfer: In impulse turbines, energy is transferred in a discrete manner. Steam’s pressure energy is converted entirely into kinetic energy in the nozzles before it reaches the blades. The blades extract energy by redirecting the steam, causing a change in momentum and producing mechanical rotation.

- High-Pressure Operation: Impulse turbines are ideal for high-pressure stages, where the steam has not yet expanded significantly. The high velocity of the steam jets allows for efficient energy extraction even when the steam pressure is high.

3.2 Reaction Energy Conversion:

- Continuous Energy Transfer: In reaction turbines, energy transfer is continuous. As steam passes over the blades, it undergoes a pressure drop and accelerates, providing a continuous reactive force. This gradual energy extraction ensures smooth and efficient operation, especially at lower steam pressures.

- Low to Medium-Pressure Operation: Reaction turbines are most effective in low to medium-pressure stages, where the steam has already expanded and its pressure has decreased. The ability to extract energy continuously from the expanding steam makes reaction blades suitable for these conditions.

4. Applications Within the Steam Turbine

The differences in operating principles and design characteristics mean that impulse and reaction blades are used in different sections of a steam turbine. Each blade type is suited to specific conditions, enhancing overall turbine performance.

4.1 Impulse Blade Applications:

- High-Pressure Stages: Impulse blades are primarily used in the high-pressure stages of the turbine. Here, steam pressure is at its peak, and the goal is to convert this pressure into kinetic energy as efficiently as possible. The impulse design allows for effective energy extraction from high-speed steam jets.

- Industrial and Mechanical Turbines: Due to their ability to handle high-pressure, high-velocity steam, impulse turbines are also common in mechanical drives and industrial applications, such as driving compressors, pumps, and blowers.

4.2 Reaction Blade Applications:

- Medium to Low-Pressure Stages: Reaction blades are typically found in the medium and low-pressure sections of a turbine. These blades continue to extract energy from the steam as it expands and its pressure drops. The gradual energy extraction process makes reaction turbines suitable for handling the remaining energy in the steam efficiently.

- Power Generation and Marine Propulsion: Reaction turbines are commonly used in power plants and marine propulsion systems, where continuous and smooth energy conversion is necessary for stable operation.

5. Advantages and Disadvantages

The unique characteristics of impulse and reaction blades come with their own sets of advantages and challenges. Understanding these can help determine the most appropriate application for each blade type.

5.1 Advantages of Impulse Blades:

- Simple Design: The straightforward, bucket-shaped design of impulse blades makes them easier to manufacture and maintain. This simplicity translates to lower production costs and simpler maintenance procedures.

- Effective High-Pressure Performance: Impulse blades are efficient at converting the kinetic energy of high-velocity steam jets, making them ideal for high-pressure stages where steam pressure is still high.

- Ease of Maintenance: The simple design allows for easy inspection, maintenance, and replacement, reducing downtime during repairs.

5.2 Disadvantages of Impulse Blades:

- Less Efficient at Lower Pressures: Impulse blades are less effective in extracting energy from steam at lower pressures, limiting their application to high-pressure stages.

- Mechanical Stress: The high-speed impact of steam on impulse blades can cause mechanical stress, which can lead to wear over time.

5.3 Advantages of Reaction Blades:

- High Efficiency Across Pressure Ranges: Reaction blades can operate efficiently across a range of pressures, making them versatile and adaptable. They can continue to extract energy from steam even when the pressure is lower.

- Smooth and Continuous Energy Conversion: The gradual energy extraction process ensures a smoother operation with less mechanical vibration, improving the longevity of the turbine components.

- Aerodynamic Design: The aerodynamic shape reduces drag and turbulence, leading to better efficiency and performance.

5.4 Disadvantages of Reaction Blades:

- Complex Design and Manufacturing: The aerodynamic and twisted design of reaction blades requires precise engineering, making them more difficult and expensive to manufacture compared to impulse blades.

- Maintenance Challenges: Due to their complex design, reaction blades can be harder to inspect, maintain, and replace, leading to potential maintenance challenges.

6. Material Considerations for Impulse and Reaction Blades

Both impulse and reaction blades must be made from materials that can withstand extreme conditions, including high temperatures, pressures, and exposure to moisture and corrosion. However, their specific operating environments can influence material choices.

6.1 Impulse Blades:

- Materials for High-Impact Forces: Impulse blades are subject to high-impact forces from steam jets, so they require materials with high tensile strength and resistance to impact. Stainless steel and nickel-based superalloys are commonly used due to their ability to maintain structural integrity at high temperatures.

- Corrosion Resistance: As these blades operate in high-pressure environments, materials must also resist corrosion and oxidation to prevent degradation.

6.2 Reaction Blades:

- Materials for Aerodynamic Performance: Reaction blades require materials that maintain their shape under thermal stress to ensure aerodynamic efficiency. Nickel-based superalloys and titanium alloys are often used because of their high-temperature resistance, strength, and corrosion resistance.

- Lightweight Options: In lower-pressure stages, where reducing the weight of the blades can improve efficiency, materials like titanium alloys are preferred due to their strength-to-weight ratio.

7. Future Trends and Technological Advancements

As technology advances, the design and efficiency of both impulse and reaction blades continue to improve. Future trends include:

7.1 Advanced Materials:

- Ceramic-Matrix Composites (CMCs): New materials, such as CMCs, offer high-temperature resistance and reduced weight, which could improve the performance of both impulse and reaction blades. These materials allow turbines to operate at higher temperatures, increasing overall efficiency.

7.2 Smart Manufacturing Techniques:

- Additive Manufacturing: 3D printing and additive manufacturing enable the production of complex blade geometries that are difficult to achieve with traditional methods. This allows for more aerodynamic designs and quicker production times.

- Precision Machining: Advances in CNC machining and computer-aided design (CAD) enable the production of more precise and efficient blade shapes, optimizing steam flow and energy conversion.

7.3 Integrated Sensors and Monitoring:

- Smart Blades: Future blades may integrate sensors that monitor temperature, pressure, and stress in real time. This data can help detect potential issues early, allowing for predictive maintenance and reducing the risk of unexpected failures.

Conclusion

Impulse and reaction blades are integral to the efficient operation of steam turbines, each serving specific roles within the turbine’s energy conversion process. Impulse blades excel in high-pressure environments by converting kinetic energy into mechanical motion, while reaction blades offer continuous energy extraction across medium and low-pressure stages. The differences in their design, operating principles, and material requirements reflect their distinct functions and highlight the need for tailored solutions in turbine engineering.

Understanding these differences is essential for optimizing turbine performance, ensuring reliable operation, and advancing the technology behind power generation systems. As research continues to push the boundaries of material science and manufacturing techniques, the future of turbine blade design promises even greater efficiency, durability, and adaptability, driving the next generation of energy solutions.

Design Considerations for Steam Turbine Blades: A Comprehensive Exploration

Steam turbine blades are the heart of a steam turbine system, playing a pivotal role in converting thermal energy from steam into mechanical energy. The design of these blades has a direct impact on the efficiency, performance, and reliability of the turbine. Proper blade design is essential for minimizing energy losses, reducing maintenance costs, and ensuring long-term operational stability. This comprehensive guide will explore the key design considerations for steam turbine blades, covering aspects such as aerodynamics, mechanical strength, thermal efficiency, material selection, and manufacturing processes. By understanding these factors, engineers can optimize blade performance and enhance overall turbine efficiency.

1. Aerodynamic Efficiency

Aerodynamic design is one of the most critical considerations for steam turbine blades. Efficient aerodynamic profiles minimize energy losses, improve steam flow, and enhance overall turbine performance.

1.1 Streamlined Blade Profiles

- Minimizing Drag and Turbulence: The shape of the blades must be optimized to allow smooth steam flow, minimizing drag and turbulence. Poorly designed blades can cause steam flow separation, leading to energy losses. Streamlined, aerofoil-shaped blades help in maintaining laminar flow, which reduces friction and improves efficiency.

- Blade Curvature and Twist: Turbine blades often feature a curved, twisted design to ensure that steam strikes the blades at an optimal angle, known as the angle of attack. This curvature helps in maintaining consistent steam velocity across the blade surface, leading to better energy extraction. Twisting also compensates for the varying radius of the blade from the hub to the tip, ensuring efficient steam flow along the entire blade length.

- Importance of Leading and Trailing Edges: The design of the blade’s leading and trailing edges is crucial. A sharp leading edge reduces resistance when steam first strikes the blade, while a smooth trailing edge minimizes wake and turbulence, ensuring efficient steam exit.

1.2 Blade Angle and Pitch

- Optimizing Steam Flow: The pitch and angle of the blades must be carefully designed to optimize the direction and velocity of steam flow. If the angle is too steep, it may cause steam to bounce off, reducing energy extraction. Conversely, a shallow angle may lead to steam passing over without sufficient interaction, resulting in energy loss.

- Variable Blade Angle Designs: Modern turbines sometimes employ variable blade angles, allowing the blades to adjust based on steam conditions. This adaptability can improve efficiency under varying load conditions.

2. Mechanical Strength and Durability

Mechanical integrity is another critical factor in blade design. Steam turbine blades must withstand high rotational speeds, mechanical stresses, and forces generated by steam flow, all while maintaining structural integrity.

2.1 Centrifugal Forces

- High Rotational Speeds: Steam turbine blades rotate at extremely high speeds, subjecting them to significant centrifugal forces. These forces increase towards the blade tips, potentially causing deformation or failure if not properly managed. Blades must be designed with sufficient mechanical strength to withstand these forces without bending or cracking.

- Stress Distribution: Engineers use finite element analysis (FEA) to assess stress distribution across the blade. The goal is to design a blade that can evenly distribute stress, reducing the likelihood of weak points that could lead to failure. Proper material selection and blade geometry play a crucial role in achieving this balance.

2.2 Blade Vibration and Resonance

- Avoiding Harmful Vibrations: The high-speed operation of turbines can lead to vibrations, which, if not controlled, can cause fatigue and blade damage over time. Blade designs must account for natural frequencies to avoid resonance conditions, where the blade’s natural frequency matches the operational frequency, leading to amplified vibrations.

- Damping Mechanisms: Incorporating damping mechanisms in blade design can help mitigate vibrations. This can include internal damping features or external damping systems, reducing the stress on the blades and enhancing their longevity.

2.3 Blade Length and Aspect Ratio

- Balancing Performance and Strength: The length and aspect ratio of turbine blades affect both their aerodynamic performance and mechanical strength. Longer blades can capture more energy, but they are also more susceptible to bending and mechanical stress. Designers must balance these factors, considering the specific operating conditions of the turbine.

3. Thermal Efficiency and Cooling Mechanisms

Steam turbines operate at high temperatures, especially in the high-pressure sections. Blade materials must retain their mechanical properties at elevated temperatures without deforming or melting.

3.1 Thermal Resistance and Heat Tolerance

- High-Temperature Operation: Steam turbine blades in high-pressure stages can face temperatures exceeding 600°C (1112°F). The design must ensure that the blades can withstand these conditions without compromising their mechanical strength. The choice of materials and coatings is crucial in achieving this.

- Thermal Expansion Management: Different parts of a blade can expand at different rates when exposed to heat. If not properly managed, thermal expansion can lead to deformation or even cracking. Blade design must account for thermal expansion, incorporating features that allow for controlled and uniform expansion.

3.2 Cooling Systems for Blades

- Internal Cooling Passages: For blades operating at very high temperatures, especially in gas turbines, internal cooling passages can be integrated into the design. These passages allow cool air to flow through the blade, reducing the temperature and preventing overheating. While more common in gas turbines, similar cooling technologies can be adapted for steam turbines.

- Thermal Barrier Coatings (TBCs): Applying thermal barrier coatings to the blade surfaces can improve their thermal resistance. These coatings act as an insulating layer, reducing the amount of heat that penetrates the blade material. This helps to maintain the blade’s structural integrity and extends its operational life.

4. Material Selection

The choice of material is fundamental to blade performance, impacting durability, heat tolerance, corrosion resistance, and cost-effectiveness. Material selection depends on the specific requirements of the turbine stage and operating conditions.

4.1 Common Blade Materials

- Nickel-Based Superalloys: These alloys are commonly used in high-temperature sections due to their excellent heat resistance and mechanical strength. Superalloys such as Inconel and Waspaloy maintain their properties at high temperatures, making them ideal for high-pressure, high-temperature environments.

- Stainless Steel: Stainless steel is often used for blades in lower-temperature sections of the turbine. It offers a good balance of strength, corrosion resistance, and affordability, making it suitable for a variety of applications.

- Titanium Alloys: Titanium alloys are valued for their high strength-to-weight ratio and corrosion resistance. They are particularly useful in situations where reducing blade weight is advantageous, such as in low-pressure stages where longer blades can improve efficiency.

4.2 Corrosion and Erosion Resistance

- Corrosive Environments: Steam can contain impurities that cause corrosion over time, weakening the blades. Material selection must consider the likelihood of corrosion, especially in wet steam regions or in environments where the steam quality may vary.

- Erosion Protection: The high-velocity impact of steam can lead to erosion, gradually wearing away the blade surfaces. To combat this, materials are selected for their erosion resistance, and coatings may be applied to enhance protection. Tungsten carbide coatings, for instance, are sometimes used to shield blades from erosive wear.

5. Manufacturing Processes and Quality Control

The manufacturing process of turbine blades must ensure precise dimensions, smooth surfaces, and structural integrity. Advanced manufacturing techniques help achieve these goals, while quality control is essential for ensuring that each blade meets the required specifications.

5.1 Precision Casting and Forging

- Investment Casting: Investment casting is a popular method for producing turbine blades, allowing for complex geometries and smooth surface finishes. This process involves creating a wax model of the blade, which is then coated with a ceramic shell. Once the wax is melted out, molten metal is poured into the shell, forming the blade.

- Forging: Forging involves shaping metal under high pressure, resulting in blades with excellent mechanical properties. Forging can produce strong, durable blades with a robust grain structure that enhances their resistance to stress and deformation.

5.2 CNC Machining

- Precision and Surface Finish: After casting or forging, blades may undergo CNC (Computer Numerical Control) machining to achieve precise dimensions and fine surface finishes. This process ensures that the blades are aerodynamic and fit perfectly within the turbine assembly.

- Customization and Prototyping: CNC machining also allows for customization and rapid prototyping, enabling engineers to test different blade designs and optimize performance before mass production.

5.3 Quality Control and Non-Destructive Testing (NDT)

- Ensuring Blade Integrity: Quality control is essential throughout the manufacturing process to ensure that each blade meets stringent specifications. Non-destructive testing methods, such as ultrasonic testing, X-ray inspection, and dye penetrant testing, are used to detect internal and surface defects without damaging the blades.

- Dimensional Accuracy and Tolerance: Maintaining dimensional accuracy is critical for blade performance. Even minor deviations from the design can lead to inefficiencies, turbulence, or mechanical failure. Quality control processes verify that the blades are manufactured to exact tolerances.

6. Advanced Design Techniques and Computational Tools

Modern steam turbine blade design has been greatly enhanced by the use of advanced computational tools, allowing engineers to simulate and optimize blade performance before physical prototypes are produced.

6.1 Computational Fluid Dynamics (CFD)

- Simulating Steam Flow: CFD tools allow engineers to simulate how steam flows over the blades, enabling them to analyze and optimize aerodynamic performance. By visualizing steam flow patterns, engineers can identify areas of turbulence or drag and make design adjustments to improve efficiency.

- Thermal Analysis: CFD tools can also be used for thermal analysis, simulating how heat interacts with the blades and assessing the effectiveness of cooling mechanisms or thermal barrier coatings.

Materials Used for Steam Turbine Blades: A Comprehensive Exploration

Steam turbine blades are exposed to harsh operating conditions, including high temperatures, high pressures, and potential corrosive environments. Therefore, the selection of materials for these blades is critical to ensure performance, reliability, and longevity. The materials must possess a combination of properties, such as high strength, thermal stability, corrosion resistance, and durability. This section will delve into the various materials used for steam turbine blades, exploring their properties, advantages, and applications in different sections of the turbine.

1. Key Properties Required for Steam Turbine Blade Materials

Steam turbine blades must meet a range of stringent requirements to operate efficiently under harsh conditions. Some of the essential properties include:

1.1 High-Temperature Strength

Blades in the high-pressure stages of a turbine operate at extremely high temperatures, often exceeding 600°C (1112°F). The material must retain its strength and structural integrity at these elevated temperatures without softening, deforming, or failing.

1.2 Corrosion and Oxidation Resistance

Steam can contain impurities that cause corrosion over time, weakening the blades and reducing their efficiency. Therefore, materials must resist oxidation and corrosion, especially in sections where steam quality may vary or where blades are exposed to moisture (in low-pressure sections).

1.3 Creep Resistance

Prolonged exposure to high temperatures can lead to creep, which is the gradual deformation of the material under stress. Turbine blades need to withstand creep to maintain their shape and performance over long periods.

1.4 Fatigue Resistance

The high-speed rotation of turbine blades subjects them to cyclic mechanical stresses, which can cause fatigue over time. Materials must have good fatigue resistance to endure these repeated stress cycles without cracking or failure.

2. Common Materials for Steam Turbine Blades

2.1 Nickel-Based Superalloys

Nickel-based superalloys are widely regarded as one of the best materials for steam turbine blades, particularly in the high-pressure and high-temperature sections. These alloys, such as Inconel, Waspaloy, and Rene alloys, are known for their exceptional heat resistance and strength at elevated temperatures.

Key Properties: