We manufacture pumps for different purposes and in different sizes. Check our link above for more information

Pumps are mechanical devices designed to move fluids, such as liquids or gases, from one place to another. They play a crucial role in various industries, providing a means to transfer, circulate, or pressurize fluids for different applications. Pumps are classified based on their operating principles, construction, and applications. Here are some common types of pumps:

- Centrifugal Pumps:

- Operating Principle: Centrifugal force is used to impart kinetic energy to the fluid, which is then converted into potential energy as the fluid exits the impeller. This results in a continuous flow.

- Applications: Centrifugal pumps are widely used in water supply systems, irrigation, industrial processes, and HVAC (Heating, Ventilation, and Air Conditioning) systems.

- Reciprocating Pumps:

- Operating Principle: Reciprocating pumps use a piston or diaphragm to create a reciprocating motion, drawing in and discharging the fluid in a pulsating manner.

- Applications: Reciprocating pumps are used in applications requiring high-pressure pumping, such as hydraulic systems, certain chemical processes, and some types of metering applications.

- Rotary Pumps:

- Operating Principle: Rotary pumps use rotating elements, such as gears, lobes, or screws, to create a continuous flow of fluid. Positive displacement rotary pumps trap and transport a fixed amount of fluid with each rotation.

- Applications: Rotary pumps are utilized in various industries, including oil and gas, chemical processing, and food and beverage production.

- Diaphragm Pumps:

- Operating Principle: Diaphragm pumps use a flexible diaphragm to displace the fluid. The diaphragm is typically moved by a mechanical linkage or an elastomeric diaphragm that flexes in and out.

- Applications: Diaphragm pumps are suitable for handling corrosive or abrasive fluids and find applications in chemical processing, pharmaceuticals, and wastewater treatment.

- Peristaltic Pumps:

- Operating Principle: Peristaltic pumps use rollers or shoes to compress and relax a flexible tube, creating a wave-like motion that moves the fluid.

- Applications: Peristaltic pumps are used in applications where contamination or product integrity is a concern, such as in the pharmaceutical and food industries.

- Jet Pumps:

- Operating Principle: Jet pumps use a high-velocity jet of fluid to entrain and transport another fluid. They rely on the Venturi effect to create a pressure differential.

- Applications: Jet pumps are often used for lifting or pumping liquids, such as in wells for water supply.

- Submersible Pumps:

- Operating Principle: Submersible pumps are designed to be submerged in the fluid they are pumping. They use an electric motor to drive an impeller, pushing fluid to the surface.

- Applications: Submersible pumps are commonly used for pumping water from wells, sumps, and other submerged sources.

- Axial Flow Pumps:

- Operating Principle: Axial flow pumps move fluid parallel to the pump shaft. They are designed to create a flow with a low head and high flow rate.

- Applications: Axial flow pumps are used in applications where a large volume of fluid needs to be pumped, such as in irrigation and drainage systems.

Pumps are essential in numerous industrial, commercial, and residential applications, providing a means to transport and control fluids in various processes. The selection of a pump depends on factors such as the type of fluid, flow rate, pressure requirements, and the intended application.

Electric pumps are devices that use electrical energy to transport liquids or gases from one location to another. They are used in various applications, including water supply, irrigation, drainage, sewage, and chemical processing.

There are different types of electric pumps, each with its unique characteristics and applications. Some of the most common types include centrifugal pumps, positive displacement pumps, and axial-flow pumps.

Centrifugal pumps use centrifugal force to move fluids. They are widely used in industrial and commercial applications due to their high flow rate and low maintenance requirements. They work by spinning an impeller that pulls fluid into the center of the pump and then pushes it out through the discharge port.

Positive displacement pumps work by trapping a fixed amount of fluid and then forcing it through the pump. They are used for applications that require high-pressure pumping or precise flow rates, such as in chemical processing or metering applications.

Axial-flow pumps move fluid parallel to the axis of the pump. They are commonly used in applications that require a high flow rate and low head, such as cooling towers, water supply systems, and irrigation systems.

Electric pumps can be powered by various sources of electricity, including mains power, batteries, and solar panels. They are designed to be efficient and reliable, with minimal maintenance requirements.

When selecting an electric pump, several factors must be considered, such as the type of fluid to be pumped, the required flow rate and pressure, the size and design of the pump, and the available power source. Proper installation, operation, and maintenance of the pump are also essential to ensure its efficient and long-lasting operation.

In summary, electric pumps are essential devices used in various applications for transporting fluids or gases. Understanding the different types of pumps and their applications is crucial in selecting the most appropriate pump for a particular application. Proper installation and maintenance of the pump are also essential to ensure its efficient and reliable operation.

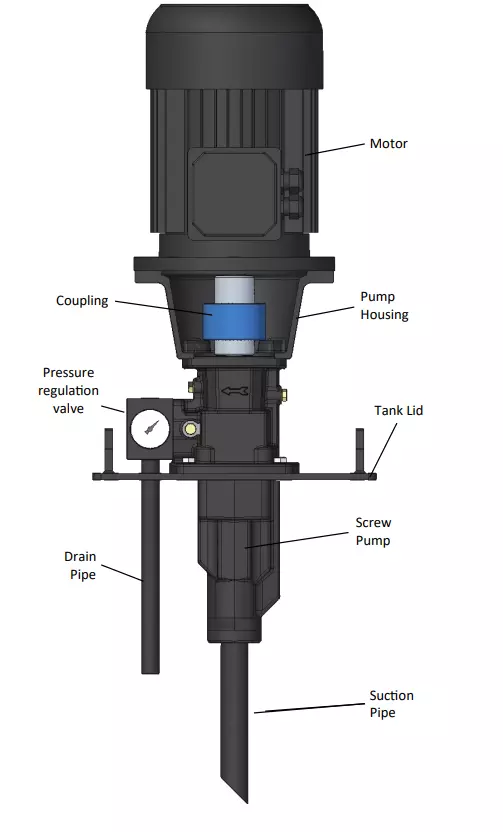

Screw series pumps provide high pressure (up to 100 bar) at low

volumetric delivery (up to 50lt/min). VP Screw pumps are mostly used on deep hole drilling applications on CNC machine tools. In deep hole drilling applications, while the workpiece is drilled by the cutting tool, coolant liquid is sprayed onto the workpiece through the cutting tool.

So workpiece and the cutting tool can be cooled and metal chips can be thrown out enhancing the quality of machining. It also accelerates the process and prolongs the lifetime of the cutting tool. Only high-pressure pumps can overcome the high flow resistance of the system and provide the required flow rate.

Pumps

Characteristics of the EMS Pumps

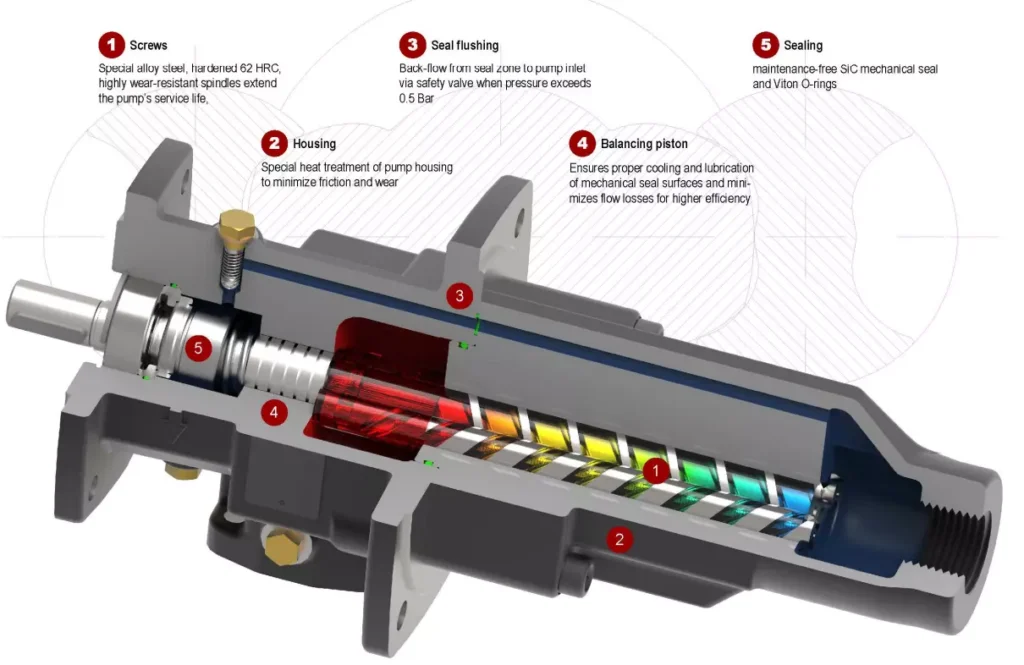

The medium is compressed by a set of spindles in VP series self-priming pumps. Rotation of the driving (main) screw provides the pumped medium to move continuously from the suction to the discharge port. The special profile formation of the spindles leads to a minimum leakage between the spindles and provides a high level of efficiency. VP series screw pumps have a pressure control and a regulation valve that is required for the safety of the system. VP series features:

- High efficiency,

- High reliability,

- Low noise level,

- Self-priming capacity,

- Near-zero pulsation.

Primary application areas of VP series screw pumps:

- Machine tools and machining centers,

- Pumping of the coolant and lubricant fluid (minimum 5% oil)

- Deep hole drilling applications for cooling machine tools and work-piece and to remove the chips out of the hole.

- Hydraulic systems,

- Pumping for coolants and fluids with high viscosity (between 1-400 cSt)

- Central units for heat exchange and energy recovery,

- Circulation of the system fluid

- Due to its wear-resistant design

- Processes that are difficult to mill materials such as titanium and stainless steel,

- High-precision applications such as the aerospace industry,

- Grinding applications.

- Properties of the medium Fluids with lubricating properties such as

- Oil in water emulsions with minimum 5% oil.

- Cooling and cutting oils are suggested. Also, the pumped fluid should not include abrasives or long fiber components. Installation of a strainer on the suction port of the pump has to be avoided. The usage of a strainer creates additional forces on the suction port of the pump and as a result power consumption of the motor increases.

- Generally acceptable contamination:

- Maximum solids contents: 120mg/l

- Maximum grain size: 0.05mm (50µm) for machining (turning, milling, drilling) Special values can be applied on request. Recommended filtration quality and maximum solid content of pumped fluid are given on page 4.

- Kinematic viscosity: 1-400 mm2 /s (CST)

- Operation temperature: 0 °C to 80 °C VP type screw pumps are self-priming pumps with 4m geodesic suction heads. Running dry and operating with a closed valve is not permissible.

- VP series screw pumps are delivered with tank lid, valve block, and manometer shown in Figure 1.

Types of the Pumps

There are various types of pumps designed to meet specific requirements and applications. Here’s an overview of some common types of pumps:

1. Centrifugal Pumps:

- Operating Principle: Centrifugal force is used to impart kinetic energy to the fluid, converting it into potential energy as the fluid exits the impeller.

- Applications: Commonly used in water supply, irrigation, industrial processes, and HVAC systems.

2. Reciprocating Pumps:

- Operating Principle: Use a piston or diaphragm to create a reciprocating motion, drawing in and discharging fluid in a pulsating manner.

- Applications: High-pressure applications, hydraulic systems, chemical processes, and metering applications.

3. Rotary Pumps:

- Operating Principle: Use rotating elements, such as gears, lobes, or screws, to create a continuous flow of fluid.

- Applications: Oil and gas, chemical processing, food and beverage production.

4. Diaphragm Pumps:

- Operating Principle: Use a flexible diaphragm to displace fluid, often through a mechanical linkage or elastomeric diaphragm.

- Applications: Corrosive or abrasive fluid handling, chemical processing, pharmaceuticals, and wastewater treatment.

5. Peristaltic Pumps:

- Operating Principle: Use rollers or shoes to compress and relax a flexible tube, creating a wave-like motion that moves the fluid.

- Applications: Pharmaceutical, food and beverage, and applications where contamination is a concern.

6. Jet Pumps:

- Operating Principle: Use a high-velocity jet of fluid to entrain and transport another fluid, relying on the Venturi effect.

- Applications: Lifting or pumping liquids, common in wells for water supply.

7. Submersible Pumps:

- Operating Principle: Designed to be submerged in the fluid they are pumping, using an electric motor to drive an impeller.

- Applications: Pumping water from wells, sumps, and other submerged sources.

8. Axial Flow Pumps:

- Operating Principle: Move fluid parallel to the pump shaft, designed for low head and high flow rate.

- Applications: Irrigation, drainage systems, and situations where a large volume of fluid needs to be pumped.

9. Gear Pumps:

- Operating Principle: Use intermeshing gears to pump fluid.

- Applications: Hydraulic systems, fuel transfer, and applications where a constant flow is required.

10. Vane Pumps:

- Operating Principle: Use sliding vanes to pump fluid.

- Applications: Automotive power steering, refrigeration, and hydraulic systems.

11. Screw Pumps:

- Operating Principle: Use rotating screws to move fluid along the screw axis.

- Applications: Oil transfer, hydraulic systems, and pumping viscous fluids.

12. Piston Pumps:

- Operating Principle: Use one or more pistons to displace fluid.

- Applications: High-pressure applications, hydraulic systems, and industrial processes.

13. Air Diaphragm Pumps:

- Operating Principle: Use compressed air to flex a diaphragm, creating suction and discharge cycles.

- Applications: Chemical transfer, wastewater treatment, and applications requiring portability.

The selection of a pump depends on factors such as the type of fluid being pumped, flow rate requirements, pressure considerations, and the intended application. Each type of pump has its advantages and limitations, making it suitable for specific use cases.

Centrifugal Pumps

Centrifugal pumps are dynamic machines that use an impeller to transfer fluid from one location to another. They are widely used in various industries for moving liquids, such as water, chemicals, and oils. Here’s an overview of centrifugal pumps:

Components and Operating Principle:

- Impeller:

- The impeller is a rotating component with blades or vanes that accelerates the fluid. It is mounted on a shaft and is the key component responsible for imparting energy to the fluid.

- Casing (Volute or Diffuser):

- The casing surrounds the impeller and guides the fluid to the outlet. The shape of the casing, whether volute or diffuser, influences the pump’s performance.

- Inlet:

- Fluid enters the pump through the inlet, typically located at the center of the impeller.

- Outlet:

- Accelerated fluid is expelled through the outlet, and the direction and speed of the fluid are influenced by the design of the impeller and casing.

Operating Principle:

- Centrifugal Force:

- The impeller rotates at high speed, creating centrifugal force that pushes the fluid away from the impeller’s center.

- Low Pressure at the Impeller Eye:

- The rapid rotation of the impeller creates a low-pressure area at the impeller eye, drawing fluid into the pump.

- Acceleration of Fluid:

- As the fluid moves radially outward from the impeller eye, it gains kinetic energy, creating a flow with increased velocity.

- Conversion of Kinetic Energy to Pressure:

- The kinetic energy is then converted into pressure energy as the fluid passes through the casing. The shape of the casing (volute or diffuser) plays a role in this energy conversion.

- Discharge:

- The fluid exits the pump through the outlet at a higher pressure than at the inlet, ready for distribution or further processing.

Key Features:

- High Flow Rates:

- Centrifugal pumps are capable of handling large volumes of fluid, making them suitable for applications with high flow rate requirements.

- Simple Design:

- The design of centrifugal pumps is relatively simple, consisting of fewer moving parts compared to some other pump types.

- Versatility:

- Centrifugal pumps can handle a wide range of fluids, including liquids with varying viscosities and low to moderate solids content.

- Self-Priming Capability:

- Some centrifugal pumps are designed with a self-priming feature, allowing them to draw in fluid and create suction without external priming.

- Easy Maintenance:

- Centrifugal pumps are often easier to maintain compared to some positive displacement pumps, as they have fewer parts subject to wear.

- Efficiency:

- Centrifugal pumps can operate with high efficiency, especially in applications with lower pressure differentials.

Applications:

- Water Supply and Distribution:

- Centrifugal pumps are commonly used in municipal water supply systems, irrigation, and residential water distribution.

- Industrial Processes:

- Widely applied in various industrial processes, including chemical processing, food and beverage production, and manufacturing.

- HVAC Systems:

- Used in heating, ventilation, and air conditioning (HVAC) systems to circulate water for temperature control.

- Oil and Gas Industry:

- Employed for transferring fluids in oil refineries, petrochemical plants, and other oil and gas applications.

- Wastewater Treatment:

- Centrifugal pumps play a role in pumping wastewater in treatment plants.

- Marine Applications:

- Used for ballasting, bilge pumping, and fire protection on ships.

- Mining and Construction:

- Applied in mining operations for dewatering and transporting fluids, as well as in construction sites for water handling.

Centrifugal pumps are one of the most common types of pumps due to their simplicity, efficiency, and versatility. The choice of a centrifugal pump depends on factors such as the type of fluid, flow rate requirements, and the pressure conditions of the application.

Screw Pumps

Screw pumps are a type of positive displacement pump that uses rotating screws to move fluid along the screw axis. These pumps are known for their ability to handle viscous fluids, making them suitable for a range of applications. Here’s an overview of screw pumps:

Types of Screw Pumps:

- Single-Screw (Progressive Cavity) Pumps:

- Operating Principle: Consists of a single helical rotor turning inside a double helical stator. As the rotor turns, it moves the fluid along the axis.

- Applications: Viscous fluids, sludge, sewage, and applications requiring a steady flow.

- Twin-Screw Pumps:

- Operating Principle: Two intermeshing screws rotate to move fluid along the screws’ axis. The screws can have various profiles, such as twin-spindle, single-spindle, or external bearing.

- Applications: High-viscosity fluids, lubrication, fuel transfer, and hygienic applications in the food industry.

- Three-Screw Pumps:

- Operating Principle: Three screws (one driving screw and two idler screws) rotate to create fluid movement. Fluid is trapped between the screws and transported axially.

- Applications: Lubrication systems, hydraulic systems, fuel injection systems, and applications requiring high pressure.

Single-Screw (Progressive Cavity) Pumps

Single-screw pumps, also known as progressive cavity pumps, are positive displacement pumps that use a single helical rotor rotating within a double helical stator to move fluid along the screw axis. These pumps are well-suited for handling viscous fluids, slurries, and liquids with solids content. Here’s an overview of single-screw (progressive cavity) pumps:

Components and Operating Principle:

- Rotor:

- The rotor is a single helical screw that rotates within the stator. It typically has a progressing pitch, meaning the pitch increases along the length of the rotor.

- Stator:

- The stator is a double helix with a shape that complements the rotor. It surrounds the rotor and forms a cavity between the rotor and stator.

- Cavity:

- As the rotor rotates, it creates a cavity between the rotor and stator. This cavity progresses along the length of the pump, hence the name “progressive cavity pump.”

- Fluid Movement:

- As the rotor turns, fluid is trapped in the cavity and displaced axially along the screw axis. The progressing pitch of the rotor contributes to the movement of the fluid.

- Seal Between Rotor and Stator:

- The close fit between the rotor and stator forms a seal that prevents the backward flow of fluid, ensuring a positive displacement action.

Key Features:

- Viscosity Handling:

- Excellent for handling fluids with high viscosity, including those containing solids or abrasive materials.

- Continuous and Non-Pulsating Flow:

- Progressive cavity pumps provide a smooth, continuous flow, making them suitable for applications where a pulsation-free flow is critical.

- Self-Priming:

- Progressive cavity pumps are generally self-priming, allowing them to handle suction lift applications.

- Efficiency:

- These pumps can operate with high efficiency, especially in applications with varying pressures and viscosities.

- Versatility:

- Suitable for a wide range of fluids, including shear-sensitive liquids, slurries, and fluids with varying viscosities.

- Solids Handling:

- Progressive cavity pumps can handle fluids with suspended solids, making them suitable for applications in wastewater treatment and other industries.

Applications:

- Wastewater Treatment:

- Used for pumping sludge, sewage, and wastewater in treatment plants.

- Oil and Gas Industry:

- Applied in the transfer of crude oil, drilling mud, and other fluids in the oil and gas sector.

- Food and Beverage Industry:

- Used for pumping viscous food products, such as sauces, syrups, and chocolate.

- Chemical Processing:

- Suitable for handling a variety of chemicals and corrosive fluids.

- Mining and Minerals:

- Used for transferring slurries and abrasive materials in mining operations.

- Pulp and Paper Industry:

- Applied for pumping paper pulp and other viscous materials in paper mills.

- Environmental and Industrial Cleaning:

- Used in applications such as cleaning industrial equipment and removing waste.

- Marine Industry:

- Applied for bilge pumping, fuel transfer, and other marine applications.

Progressive cavity pumps offer reliable and efficient performance in applications where positive displacement and the handling of challenging fluids are essential. The choice of pump size, materials, and design depends on the specific requirements of the application.

Twin-Screw Pump

Twin-screw pumps, also known as double-screw pumps, are positive displacement pumps that use two intermeshing screws to move fluid along the screws’ axis. These pumps are designed to handle a variety of fluids, including those with high viscosity or containing solids. Here’s an overview of twin-screw pumps:

Components and Operating Principle:

- Screws:

- Twin-screw pumps have two parallel, intermeshing screws that rotate in opposite directions. The screws are usually helical and can have various profiles, such as twin-spindle, single-spindle, or external bearing.

- Cavities:

- The rotation of the screws creates cavities between the screw threads and the pump casing. These cavities progress along the length of the screws.

- Fluid Movement:

- As the screws rotate, fluid is trapped in the cavities and moved axially along the screws’ axis. The continuous intermeshing of the screws provides a smooth and pulsation-free flow.

- Sealing:

- The tight clearance between the screw threads and the pump casing forms a seal that prevents backflow, ensuring positive displacement.

Key Features:

- Viscosity Handling:

- Well-suited for handling high-viscosity fluids, making them effective for applications involving heavy oils, lubricants, and other viscous materials.

- Pulsation-Free Flow:

- Twin-screw pumps provide a smooth and pulsation-free flow, making them suitable for applications where a constant flow rate is crucial.

- Versatility:

- Suitable for a wide range of fluids, including those with varying viscosities, low lubricity, and entrained gases.

- Solids Handling:

- Twin-screw pumps can handle fluids with a certain amount of solids, making them applicable in industries such as wastewater treatment and mining.

- Self-Priming:

- These pumps are often capable of self-priming, allowing them to lift fluids from lower elevations without external priming.

- Efficiency:

- Twin-screw pumps can operate at high efficiency levels, providing reliable performance in various applications.

- Low NPSH Requirements:

- Generally have low Net Positive Suction Head (NPSH) requirements, making them suitable for applications with limited suction pressure.

Applications:

- Oil and Gas Industry:

- Used for the transfer of crude oil, refined products, and other hydrocarbons.

- Chemical Processing:

- Applied in the pumping of various chemicals, including corrosive fluids.

- Marine Industry:

- Utilized for cargo handling, fuel transfer, and lubrication on ships.

- Power Generation:

- Used for lubrication and fuel transfer in power plants.

- Food and Beverage Industry:

- Applied in the transfer of viscous food products, such as syrups and molasses.

- Wastewater Treatment:

- Used for pumping sludge and other viscous fluids in treatment plants.

- Mining and Minerals:

- Applied for transferring slurries and other abrasive materials in mining operations.

- Hydraulic Systems:

- Utilized in hydraulic systems for various industrial machinery.

Twin-screw pumps offer reliable and efficient fluid handling in diverse industrial applications, particularly where positive displacement and the handling of viscous fluids are required. The specific type of twin-screw pump chosen depends on the characteristics of the fluid, flow requirements, and the conditions of the application.

Three-Screw Pumps

Three-screw pumps are positive displacement pumps that use three intermeshing screws to move fluid along the screws’ axis. These pumps are designed to handle a variety of fluids and are often used in applications requiring high pressure. Here’s an overview of three-screw pumps:

Components and Operating Principle:

- Screws:

- Three-screw pumps have three parallel, intermeshing screws that rotate in synchronization. The screws can have different profiles, but they typically have a helical shape.

- Cavities:

- The rotation of the screws creates cavities between the screw threads and the pump casing. These cavities progress along the length of the screws.

- Fluid Movement:

- As the screws rotate, fluid is trapped in the cavities and moved axially along the screws’ axis. The continuous intermeshing of the screws provides a smooth and pulsation-free flow.

- Sealing:

- The close clearance between the screw threads and the pump casing forms a seal, preventing backflow and ensuring positive displacement.

Key Features:

- High-Pressure Capability:

- Three-screw pumps are capable of generating high discharge pressures, making them suitable for applications requiring high-pressure pumping.

- Smooth and Pulsation-Free Flow:

- These pumps provide a smooth, continuous flow with minimal pulsation, making them suitable for applications with strict flow rate requirements.

- Viscosity Handling:

- Well-suited for handling high-viscosity fluids, making them effective in applications involving heavy oils and lubricants.

- Versatility:

- Suitable for a wide range of fluids, including those with varying viscosities and lubricity.

- Solids Handling:

- Three-screw pumps can handle fluids with a certain amount of solids, making them applicable in industries such as wastewater treatment and chemical processing.

- Efficiency:

- Three-screw pumps can operate at high efficiency levels, providing reliable performance in various applications.

- Low NPSH Requirements:

- Generally have low Net Positive Suction Head (NPSH) requirements, making them suitable for applications with limited suction pressure.

Applications:

- Hydraulic Systems:

- Used for hydraulic fluid transfer in various industrial machinery and hydraulic systems.

- Oil and Gas Industry:

- Applied in the transfer of crude oil, refined products, and other hydrocarbons.

- Power Generation:

- Used for lubrication and fuel transfer in power plants.

- Marine Industry:

- Utilized for cargo handling, fuel transfer, and lubrication on ships.

- Chemical Processing:

- Applied in the pumping of various chemicals, including corrosive fluids.

- Wastewater Treatment:

- Used for pumping sludge and other viscous fluids in treatment plants.

- High-Pressure Applications:

- Suitable for applications requiring high-pressure pumping, such as boiler feedwater systems.

Three-screw pumps offer reliable and efficient fluid handling, particularly in applications requiring high pressure and the handling of viscous fluids. The specific type of three-screw pump chosen depends on the characteristics of the fluid, flow requirements, and the conditions of the application.

Key Features of Screw Pumps:

- Positive Displacement:

- Screw pumps are positive displacement pumps, meaning they displace a fixed volume of fluid with each revolution.

- Viscosity Handling:

- Well-suited for handling viscous fluids, including those with a high viscosity or containing solids.

- Smooth and Pulsation-Free Flow:

- Screw pumps provide a relatively smooth and pulsation-free flow, making them suitable for applications requiring a constant and consistent fluid output.

- Self-Priming:

- Screw pumps are often capable of self-priming, allowing them to draw in fluid and create suction without the need for external priming.

- High Efficiency:

- Screw pumps can operate at high efficiency levels, especially in applications with varying pressures and viscosities.

- Low NPSH Requirements:

- Screw pumps generally have low Net Positive Suction Head (NPSH) requirements, making them suitable for applications with limited suction pressure.

- Versatility:

- Screw pumps are versatile and find applications in various industries, including oil and gas, petrochemical, marine, wastewater treatment, and food processing.

Applications of Screw Pumps:

- Oil and Gas Industry:

- Used for transferring crude oil, refined products, and various hydrocarbons.

- Chemical Industry:

- Suitable for handling a wide range of chemicals and viscous fluids.

- Marine Industry:

- Used for cargo handling, fuel transfer, and lubrication in ships.

- Wastewater Treatment:

- Employed for handling sludge and sewage in wastewater treatment plants.

- Food and Beverage Industry:

- Used for hygienic applications, such as transferring food products with delicate handling requirements.

- Power Generation:

- Utilized in lubrication and fuel transfer systems in power plants.

- Hydraulic Systems:

- Applied in hydraulic systems for various industrial machinery.

Screw pumps offer reliable and efficient fluid handling in diverse industrial applications, particularly where the pumping of viscous fluids is a requirement. The specific type of screw pump chosen depends on the characteristics of the fluid, flow requirements, and the conditions of the application.

EMS Power Machines

We design, manufacture and assembly Power Machines such as – diesel generators, electric motors, vibration motors, pumps, steam engines and steam turbines

EMS Power Machines is a global power engineering company, one of the five world leaders in the industry in terms of installed equipment. The companies included in the company have been operating in the energy market for more than 60 years.

EMS Power Machines manufactures steam turbines, gas turbines, hydroelectric turbines, generators, and other power equipment for thermal, nuclear, and hydroelectric power plants, as well as for various industries, transport, and marine energy.

EMS Power Machines is a major player in the global power industry, and its equipment is used in power plants all over the world. The company has a strong track record of innovation, and it is constantly developing new and improved technologies.

Here are some examples of Power Machines’ products and services:

- Steam turbines for thermal and nuclear power plants

- Gas turbines for combined cycle power plants and industrial applications

- Hydroelectric turbines for hydroelectric power plants

- Generators for all types of power plants

- Boilers for thermal power plants

- Condensers for thermal power plants

- Reheaters for thermal power plants

- Air preheaters for thermal power plants

- Feedwater pumps for thermal power plants

- Control systems for power plants

- Maintenance and repair services for power plants

EMS Power Machines is committed to providing its customers with high-quality products and services. The company has a strong reputation for reliability and innovation. Power Machines is a leading provider of power equipment and services, and it plays a vital role in the global power industry.

EMS Power Machines, which began in 1961 as a small factory of electric motors, has become a leading global supplier of electronic products for different segments. The search for excellence has resulted in the diversification of the business, adding to the electric motors products which provide from power generation to more efficient means of use.