Power Plants: A power plant, also known as a power station or generating station, is an industrial facility designed to produce electrical energy on a large scale. The primary function of a power plant is to convert different forms of energy, whether thermal, mechanical, chemical, nuclear, or renewable, into electricity that can be used for residential, commercial, and industrial purposes.

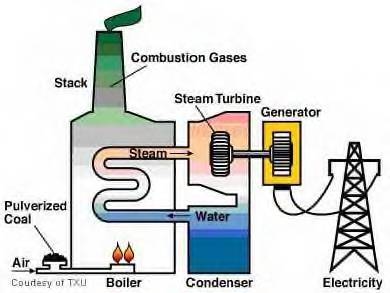

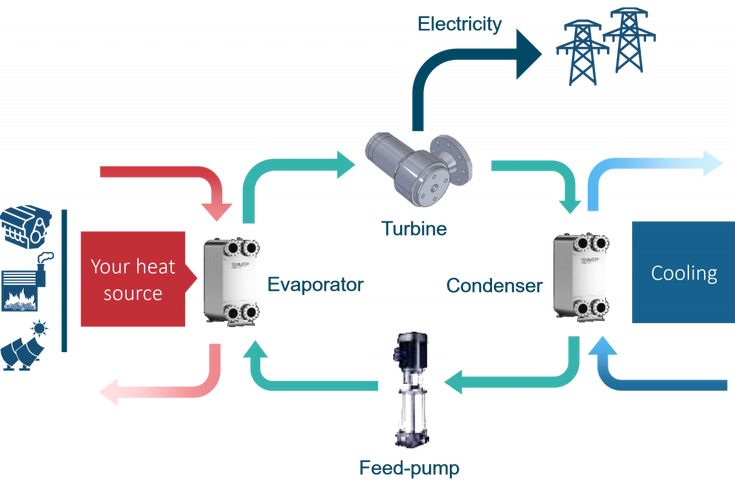

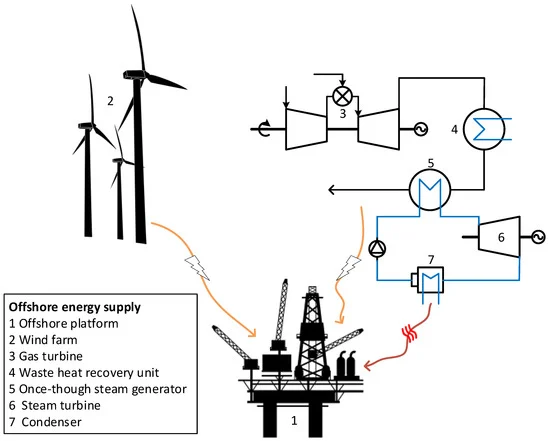

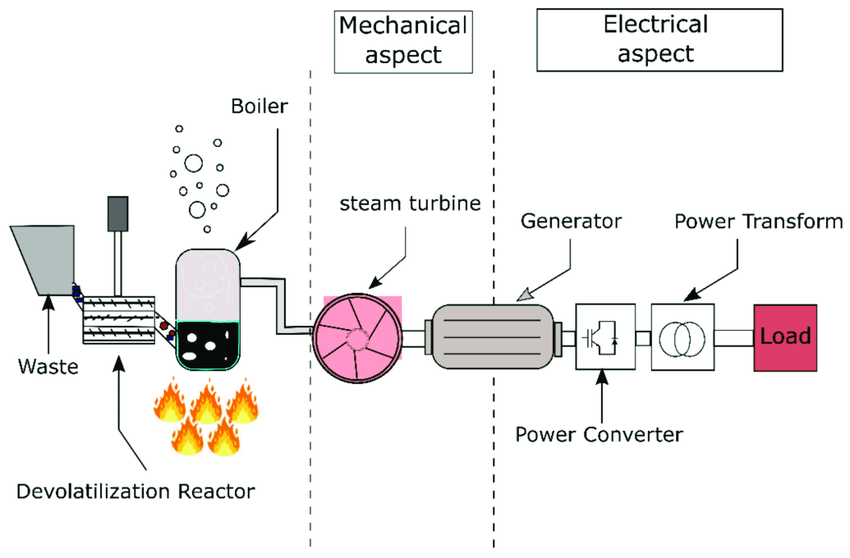

Electricity is a versatile form of energy that powers homes, industries, transportation systems, communication networks, and countless other applications, making the role of power plants central to modern life. The operation of a power plant generally involves several key steps. First, an energy source is used to produce mechanical energy, usually through the use of turbines. This energy source can vary widely depending on the type of power plant. In thermal power plants, fuels such as coal, natural gas, oil, or nuclear material are used to produce heat, which in turn generates steam from water.

The high-pressure steam then drives turbines, converting thermal energy into mechanical energy. In renewable energy plants, natural forces such as wind, flowing water, sunlight, or geothermal heat provide the mechanical or thermal energy needed to generate electricity. Once mechanical energy is obtained, it is converted into electrical energy using a generator. A generator works on the principle of electromagnetic induction, where the rotation of a coil within a magnetic field induces an electric current. After electricity is generated, it passes through transformers and transmission systems that increase voltage levels for efficient long-distance transmission to homes, factories, and businesses. Modern power plants also include advanced control systems to monitor and regulate the operation of turbines, generators, and other equipment, ensuring efficient, stable, and safe electricity production.

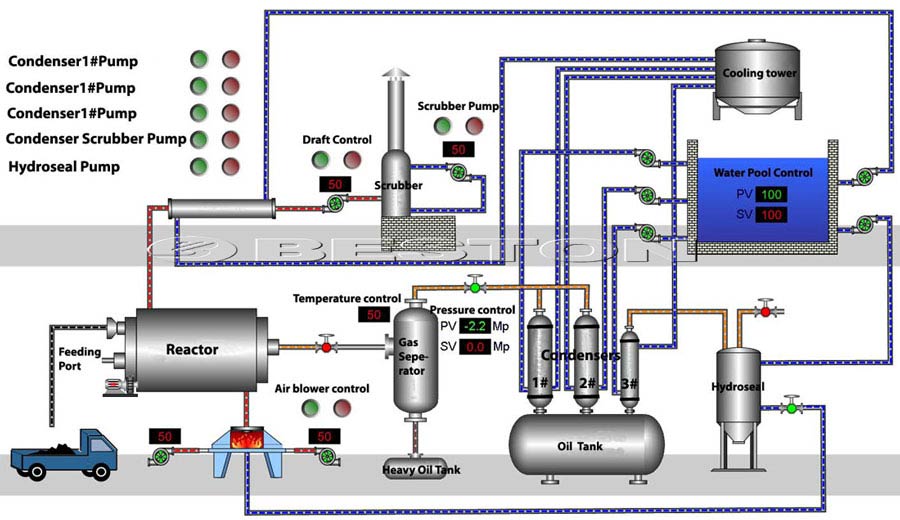

Cooling systems, such as condensers or cooling towers, are essential in most power plants to condense steam back into water after it has passed through the turbines, thereby maintaining the efficiency of the cycle and preventing overheating of equipment. Power plants vary widely in size and design, from small-scale facilities that supply power to a single community to massive plants capable of generating thousands of megawatts to meet the needs of entire regions or countries. They can be fueled by nonrenewable energy sources like fossil fuels and uranium, or by renewable sources such as wind, water, solar energy, biomass, and geothermal heat. Each type of power plant has its advantages and challenges. Fossil fuel-based plants are capable of producing large amounts of electricity continuously but contribute significantly to air pollution and greenhouse gas emissions.

Nuclear plants generate electricity with very low carbon emissions but require careful handling of radioactive materials and waste. Renewable power plants offer cleaner alternatives but can be intermittent, relying on weather conditions or natural cycles. Despite these differences, all power plants share the common goal of transforming energy from one form into electricity that is reliable, stable, and usable for society. They are critical infrastructure that supports modern life, economic development, and technological advancement.

Over time, innovations in power generation, such as combined heat and power systems, smart grids, and renewable integration, have further enhanced the efficiency, sustainability, and environmental compatibility of power plants. Ultimately, a power plant is not just a facility for generating electricity; it is a cornerstone of modern civilization, enabling virtually all aspects of contemporary life, from basic lighting and heating to industrial production and digital communication, while continuously evolving to meet the growing demand for cleaner, more sustainable, and more reliable energy.

A power plant is a facility built to generate electricity by converting different forms of energy into electrical energy, which is then transmitted and distributed to homes, businesses, industries, and infrastructure to meet the growing demands of modern life. Electricity is a fundamental necessity in contemporary society, and power plants play a critical role in providing a continuous, reliable, and stable supply of energy for countless applications. The fundamental principle of a power plant is the conversion of one form of energy into another, typically mechanical energy into electrical energy. This process begins with the use of an energy source, which can be derived from fossil fuels such as coal, natural gas, and oil, from nuclear reactions, from renewable resources such as sunlight, wind, water, biomass, and geothermal heat, or from other emerging sources like tidal or wave energy.

The energy source provides the primary force needed to drive turbines, engines, or other mechanical systems that produce rotational energy. In thermal power plants, the heat generated from burning fossil fuels or from nuclear fission is used to convert water into high-pressure steam. This steam is then directed onto the blades of a turbine, causing it to rotate and thereby transforming thermal energy into mechanical energy. The turbine is connected to an electrical generator, which operates on the principle of electromagnetic induction. As the turbine spins, a rotor within the generator turns inside a magnetic field, inducing an electric current that can then be harnessed for use in homes and industries. In renewable energy power plants, the conversion process varies depending on the source.

For example, in hydropower plants, the kinetic energy of flowing or falling water is used to rotate turbines, while wind power plants rely on the aerodynamic force of wind turning the blades of wind turbines. Solar power plants may use photovoltaic panels to convert sunlight directly into electricity or use concentrated solar power systems to heat fluids that drive turbines. Geothermal plants harness heat from beneath the Earth’s surface to produce steam, which then drives turbines in a similar manner to thermal plants. Once electricity is generated, it is typically stepped up to higher voltages using transformers to reduce losses during transmission over long distances. The electricity is then distributed through a complex network of transmission lines, substations, and distribution systems to reach end users efficiently and safely. Modern power plants incorporate advanced control systems that constantly monitor various parameters such as temperature, pressure, flow rates, and electrical output to optimize performance and prevent equipment failures.

Cooling systems are also an essential part of power plants, particularly in thermal and nuclear facilities, where steam must be condensed back into water after passing through turbines to maintain operational efficiency and to protect machinery from overheating. Power plants vary greatly in scale and complexity, ranging from small community-based plants that supply electricity to a limited area to massive industrial complexes capable of producing thousands of megawatts of power to serve entire cities or regions. The choice of power plant type depends on factors such as the availability of fuel or energy resources, environmental regulations, economic considerations, and the specific energy demands of the region. Fossil fuel-based power plants are capable of continuous, high-output electricity production but are associated with significant environmental impacts, including greenhouse gas emissions, air pollution, and resource depletion.

Nuclear power plants offer the advantage of large-scale electricity generation with minimal carbon emissions, but they require stringent safety measures, careful handling of radioactive materials, and long-term management of nuclear waste. Renewable energy power plants provide sustainable alternatives with lower environmental footprints, though they often face challenges such as intermittency, the need for energy storage solutions, and dependency on geographic and climatic conditions. Despite these differences, all power plants share the common objective of providing reliable and continuous electricity while striving for greater efficiency, lower costs, and reduced environmental impact. Over time, technological advancements have led to the development of more efficient systems, such as combined cycle power plants that utilize both gas and steam turbines to maximize energy extraction, and combined heat and power plants that capture waste heat for industrial or district heating applications. The integration of digital monitoring, predictive maintenance, and smart grid technology has further enhanced the ability of power plants to operate efficiently and respond dynamically to fluctuations in demand. Power plants are more than just electricity-generating facilities; they are vital infrastructure that sustains modern civilization by enabling industrial production, technological advancement, communication systems, transportation networks, and everyday domestic life. They are constantly evolving in response to growing energy demands, environmental concerns, and the global transition toward cleaner and more sustainable energy systems.

The importance of power plants extends beyond the immediate generation of electricity, as they influence economic development, environmental stewardship, energy security, and technological innovation. By converting various forms of energy into usable electrical power, they make possible the complex and interconnected systems upon which contemporary society depends, supporting everything from basic lighting and heating to industrial processes, healthcare, education, transportation, and digital communication. As the world moves toward a more sustainable and low-carbon future, power plants continue to play a crucial role in balancing energy demand with environmental responsibility, integrating renewable energy sources, improving efficiency, reducing emissions, and adopting new technologies that ensure a stable, reliable, and sustainable supply of electricity for generations to come.

A power plant is a complex industrial facility designed to generate electricity by converting various forms of energy into electrical energy that can be transmitted and distributed to meet the needs of residential, commercial, and industrial users. Electricity is one of the most important forms of energy in modern society, enabling the operation of everything from household appliances to industrial machinery, communication systems, transportation networks, and digital infrastructure. The role of power plants is therefore central to sustaining contemporary life and supporting economic growth, technological development, and social well-being. At its core, a power plant operates on the principle of energy conversion.

Energy exists in multiple forms, including thermal, mechanical, chemical, nuclear, solar, wind, and geothermal energy, and a power plant transforms these primary energy sources into mechanical energy, and ultimately into electricity. This conversion process generally involves a sequence of operations that begin with the capture or generation of primary energy and end with the delivery of electrical power to the grid. In thermal power plants, one of the most common types of power stations worldwide, heat energy is produced through the combustion of fossil fuels such as coal, oil, or natural gas, or through the nuclear fission of uranium or plutonium. The heat generated is used to convert water into high-pressure steam, which is then directed onto the blades of a steam turbine. The kinetic energy of the moving steam causes the turbine to rotate, producing mechanical energy in the form of rotational motion. This rotational motion is transmitted to an electrical generator, where it is converted into electrical energy through the principle of electromagnetic induction. In the generator, the rotation of a coil within a magnetic field induces an electric current, which can then be fed into transformers to adjust voltage levels for efficient long-distance transmission.

Cooling systems are an integral part of thermal power plants. After passing through the turbine, the steam must be condensed back into water to maintain the efficiency of the cycle and prevent overheating of equipment. This is achieved through condensers and cooling towers, which use air, water, or other cooling mediums to remove excess heat. Without such systems, turbines and generators would overheat, resulting in reduced efficiency and potential mechanical failure. Renewable energy power plants operate on similar principles of energy conversion but utilize natural forces rather than combustible fuels or nuclear reactions. In hydroelectric power plants, the kinetic energy of flowing or falling water is harnessed to rotate turbines connected to generators, producing electricity. These plants often use dams or reservoirs to store water and regulate flow, providing both energy generation and flood control. Wind power plants rely on the aerodynamic force of wind to turn turbine blades, which then drive generators.

Solar power plants can operate either as photovoltaic systems, which convert sunlight directly into electricity using semiconductor materials, or as concentrated solar power systems, which focus sunlight to heat fluids that drive turbines. Geothermal plants exploit heat from beneath the Earth’s surface, converting it into steam that powers turbines and generators, while biomass power plants burn organic materials such as wood, agricultural residues, or municipal waste to produce heat for steam generation. Power plants also vary significantly in size and capacity. Small-scale plants may serve a single community or industrial facility, while large-scale plants can generate thousands of megawatts of electricity to supply entire regions or countries. The design and operation of a power plant are influenced by factors such as the availability of fuel or energy resources, environmental regulations, economic considerations, and the specific energy demands of the region.

Fossil fuel-based power plants are capable of producing large amounts of electricity continuously and reliably but contribute significantly to greenhouse gas emissions, air pollution, and environmental degradation. Nuclear power plants offer high-capacity electricity generation with minimal carbon emissions, yet they require rigorous safety protocols, careful handling of radioactive materials, and long-term management of nuclear waste. Renewable energy power plants provide cleaner alternatives and contribute to sustainable energy goals, though they often face challenges such as intermittency, dependency on weather or geographic conditions, and the need for storage solutions to balance supply and demand. Modern power plants increasingly incorporate advanced technologies to enhance efficiency, reliability, and sustainability. Combined cycle plants, for example, utilize both gas and steam turbines to extract more energy from the same fuel, achieving efficiency rates significantly higher than conventional single-cycle plants. Combined heat and power systems capture waste heat from electricity generation for use in industrial processes or district heating, maximizing energy utilization and reducing overall emissions.

Digital monitoring, automated control systems, and predictive maintenance technologies enable operators to track performance, detect potential issues before they lead to failures, and optimize plant operations in real time. Smart grid integration further allows power plants to respond dynamically to fluctuations in electricity demand, coordinate with distributed energy resources, and support the integration of intermittent renewable energy sources. Throughout history, power plants have evolved from small, localized facilities to massive, technologically sophisticated installations capable of supplying electricity to millions of people. Early power plants were primarily steam-driven and coal-fired, supplying electricity to nearby communities and industries. As technology advanced, gas turbines, hydroelectric facilities, nuclear reactors, and renewable energy systems were introduced, each providing new capabilities, efficiencies, and environmental considerations.

The development of electricity transmission networks enabled power plants to supply energy over long distances, connecting regions and creating national and international grids. Power plants also play a critical role in economic development, providing the energy necessary for industrial production, technological innovation, transportation systems, and urban growth. Reliable electricity supply supports healthcare, education, communication, commerce, and other essential services, making power plants foundational to modern society. Environmental considerations have become increasingly important in the design and operation of power plants. Efforts to reduce emissions, improve efficiency, and transition to renewable energy sources are shaping the future of power generation. Carbon capture and storage technologies, emission controls, waste heat recovery, and water conservation measures are increasingly being implemented to minimize the environmental impact of conventional power plants. At the same time, renewable energy projects are expanding rapidly, with solar, wind, hydro, geothermal, and biomass plants contributing an ever-growing share of global electricity production. Power plants are not only facilities for generating electricity but also symbols of technological progress, economic development, and human ingenuity.

They embody the ability to harness natural and artificial energy sources to meet the demands of complex societies. By converting energy from one form to another, power plants enable the functioning of modern infrastructure, support industrialization, facilitate communication and transportation, and enhance quality of life. As global energy needs continue to rise, power plants are adapting to meet these challenges while balancing efficiency, reliability, cost, and environmental responsibility. The integration of renewable energy, advanced digital systems, energy storage, and sustainable operational practices is guiding the evolution of power plants toward cleaner, smarter, and more flexible electricity generation.

Ultimately, power plants are essential to modern civilization, providing the energy required to sustain human activity, foster technological innovation, and support the growth and development of societies worldwide. They remain a cornerstone of industrial and economic activity, continuously evolving to meet the changing demands of energy consumption, environmental stewardship, and technological advancement, ensuring that electricity remains available, reliable, and sustainable for generations to come.

Main Components of a Power Plant

A power plant, regardless of its type, relies on several essential components that work together to convert primary energy sources into electrical energy efficiently and reliably. At the heart of every power plant is the energy source, which provides the initial force required to generate electricity. This source can take many forms, including fossil fuels such as coal, natural gas, or oil; nuclear fuel such as uranium or plutonium; or renewable sources like sunlight, wind, flowing water, biomass, or geothermal heat. The energy from these sources is converted into mechanical energy, usually by rotating turbines, engines, or other machinery. In thermal and nuclear plants, the energy source produces heat, which converts water into high-pressure steam.

This steam drives the turbine, a crucial mechanical component that transforms thermal energy into rotational mechanical energy. Turbines are designed with precisely engineered blades that efficiently capture the energy of steam, gas, or moving water, ensuring smooth and continuous rotation. The rotational motion of the turbine is then transferred to the generator, the component responsible for producing electrical energy. Generators operate on the principle of electromagnetic induction, where the rotation of coils within a magnetic field induces an electric current. The generated electricity is often at a relatively low voltage, so it passes through transformers to increase the voltage for efficient long-distance transmission through the power grid. In addition to energy conversion components, power plants rely heavily on boilers, heat exchangers, or reactors depending on the plant type.

Boilers in thermal plants burn fuel to heat water and produce steam, while nuclear reactors generate heat through controlled fission reactions. Heat exchangers transfer thermal energy efficiently to water or other working fluids, ensuring maximum energy conversion while maintaining safe operating temperatures. To maintain operational stability and protect equipment, power plants use condensers and cooling systems, which return used steam or heated fluids to their original state. Cooling systems may use air, water, or other mediums to remove excess heat, preventing overheating of turbines and generators and improving the overall efficiency of the plant. Modern power plants also include control systems and instrumentation that monitor critical parameters such as temperature, pressure, flow rates, and electrical output. These systems allow operators to maintain optimal performance, quickly detect anomalies, and prevent potential equipment failures or safety hazards. Some plants also incorporate auxiliary systems, including fuel handling, water treatment, lubrication, and emission control systems, all of which support the smooth and continuous operation of the facility.

Switchyards and transmission lines are also integral to the plant, as they facilitate the connection between the generator and the power grid, allowing the electricity to be distributed over large distances with minimal losses. Together, these components—energy source, turbine, generator, boiler or reactor, condenser, cooling systems, control systems, transformers, and auxiliary equipment—form the backbone of a power plant. Each component plays a specific and vital role in ensuring that energy is efficiently converted into electricity, that equipment operates safely and reliably, and that the plant can meet the energy demands of the surrounding region or grid. By working in harmony, these elements allow power plants to serve as the foundation of modern civilization, supporting industrial activity, infrastructure development, and the daily lives of millions of people worldwide.

A power plant is composed of a series of interdependent components that work together to convert primary energy from various sources into electrical energy that can be used by homes, industries, and infrastructure. At the heart of every power plant is the energy source, which may vary widely depending on the type of plant and the resources available in the region. In thermal power plants, coal, natural gas, oil, or other combustible materials are used to generate heat through controlled combustion, while in nuclear power plants, nuclear fuel such as uranium or plutonium undergoes fission reactions to release enormous amounts of thermal energy. Renewable energy plants rely on natural forces such as sunlight, wind, flowing water, or geothermal heat as the primary energy source. The energy provided by these sources is first converted into mechanical energy, usually through turbines, engines, or other rotating machinery. Turbines are one of the most critical components of a power plant, acting as the primary interface between the energy source and the electrical generator. They are carefully engineered with multiple blades and rotor assemblies designed to extract the maximum amount of energy from steam, gas, water, or wind.

The high-pressure steam generated in thermal and nuclear plants or the kinetic energy from water or wind causes the turbine to rotate, producing mechanical energy in the form of rotational motion. This rotational energy is then transmitted to the generator, which is responsible for converting mechanical energy into electrical energy. Generators function on the principle of electromagnetic induction, where a rotating coil within a magnetic field induces an electric current that can then be directed to transformers and the electrical grid. The efficiency of energy conversion in generators depends on precise engineering, including the design of the rotor, stator, magnetic field strength, and cooling systems that prevent overheating during operation. To produce the mechanical energy needed by turbines, thermal and nuclear plants require boilers, reactors, or heat exchangers that convert the energy source into a usable form. Boilers in coal, oil, or gas plants burn fuel to produce high-pressure steam, while nuclear reactors release heat through controlled fission reactions, and concentrated solar plants use mirrors or lenses to focus sunlight to heat a working fluid.

Heat exchangers play a vital role in transferring thermal energy efficiently while maintaining the correct operating temperatures to optimize turbine performance. Once the energy has been converted into mechanical and electrical forms, power plants employ condensers and cooling systems to manage excess heat and maintain the continuous flow of operation. In thermal and nuclear plants, after steam has passed through the turbine, it must be condensed back into water to close the cycle and prevent energy loss. Cooling towers, water circulation systems, and air-cooled condensers serve this function, ensuring that equipment does not overheat and that the plant operates at maximum efficiency. In addition to the primary energy conversion components, power plants are equipped with sophisticated control systems and instrumentation that monitor and regulate operations. Sensors track critical parameters such as temperature, pressure, fluid flow, voltage, and current to detect any deviations from optimal performance.

Control rooms allow operators to manage plant operations, adjust outputs, and respond to emergency situations, maintaining stability and preventing equipment damage or unsafe conditions. Modern power plants often include auxiliary systems that support core operations, such as fuel handling systems, water treatment facilities, lubrication systems, and emission control equipment. These systems ensure that the plant runs smoothly, meets environmental standards, and maintains reliability over long operational periods. Another key component of power plants is the transformer and switchyard system, which enables the electrical energy produced by the generator to be adjusted to higher voltages for efficient long-distance transmission. Transformers increase the voltage to minimize losses during transmission, while switchyards and circuit breakers control the distribution of electricity to the grid, ensuring safe and reliable delivery to consumers.

The integration of these components requires careful engineering and design, as each element must function in harmony with the others to achieve optimal efficiency, reliability, and safety. Any failure in one component, whether it is the turbine, generator, boiler, cooling system, or control system, can disrupt the entire operation and reduce the plant’s capacity to deliver electricity. Consequently, power plants are designed with redundancy, safety measures, and maintenance protocols to ensure continuous operation even under challenging conditions. Together, the energy source, turbine, generator, boiler or reactor, heat exchangers, condensers, cooling systems, control and instrumentation systems, auxiliary equipment, transformers, and switchyard infrastructure form the backbone of a power plant. Each component serves a specific purpose, yet they are all interconnected, creating a complex system capable of transforming raw energy into the reliable electricity that powers modern civilization.

The effectiveness of a power plant depends not only on the individual efficiency of these components but also on the seamless integration and coordination among them. Engineers continuously work to improve the design, materials, and operation of these components to increase efficiency, reduce fuel consumption, minimize environmental impact, and extend the operational life of the plant. In addition to supporting electricity generation, power plants provide significant economic and social benefits, enabling industrial production, technological development, communication, transportation, and residential services. The reliability of these plants depends on the proper functioning of all their components, highlighting the importance of maintenance, monitoring, and upgrading to adapt to technological advancements and changing energy demands. As global energy needs grow and environmental considerations become increasingly important, the main components of power plants are evolving to incorporate renewable energy sources, digital monitoring systems, automated controls, and energy storage solutions.

These innovations not only improve efficiency and reduce emissions but also enhance the flexibility and resilience of power generation systems. Ultimately, the main components of a power plant work together as a highly integrated system, converting natural and artificial energy sources into electricity that sustains modern society. They represent a balance between engineering precision, energy management, environmental stewardship, and operational reliability, ensuring that power plants remain a cornerstone of infrastructure, economic growth, and technological progress around the world.

A power plant is an intricate facility designed to convert primary sources of energy into electrical energy, enabling the supply of electricity to residential, commercial, and industrial users across cities, regions, and entire countries. At the heart of every power plant lies the energy source, which can take many forms, each dictating the design and operation of the plant. Fossil fuels such as coal, natural gas, or oil provide thermal energy through combustion in traditional thermal power plants, while nuclear power plants derive immense energy from the controlled fission of uranium or plutonium nuclei. Renewable energy sources, including sunlight, wind, water, biomass, and geothermal heat, also serve as the primary energy inputs for modern sustainable power plants, utilizing natural forces to drive mechanical systems.

This energy, once harnessed, must be converted into mechanical energy to drive turbines, which form the central rotating machinery of nearly all power plants. Turbines are precision-engineered components with blades and rotors designed to extract the maximum possible energy from steam, gas, water, or wind. In thermal and nuclear power plants, high-pressure steam produced in boilers or nuclear reactors expands and flows over turbine blades, causing the turbine to rotate at high speeds, thereby transforming thermal energy into rotational mechanical energy. In hydropower facilities, flowing or falling water applies kinetic energy to turbine blades, and in wind power plants, the aerodynamic force of wind drives the rotation of wind turbine blades.

The rotational energy generated by turbines is transmitted to the electrical generator, the component responsible for converting mechanical energy into electrical energy. Generators operate on the principle of electromagnetic induction, whereby the rotation of a rotor within a magnetic field induces an electrical current in a surrounding coil. The generated electricity initially exists at a lower voltage suitable for internal plant use, but transformers within the plant step up the voltage to levels appropriate for long-distance transmission, ensuring efficient distribution to consumers while minimizing energy loss. Essential to the operation of thermal and nuclear power plants are boilers, reactors, and heat exchangers, which ensure that the energy source is efficiently converted into usable energy for turbines.

Boilers in fossil fuel plants burn fuel to generate high-pressure steam, while nuclear reactors release heat through controlled fission reactions to produce steam in a similar manner. Concentrated solar power plants, on the other hand, focus sunlight using mirrors or lenses to heat fluids that drive turbines, demonstrating the diverse ways in which energy can be harnessed. Heat exchangers facilitate the transfer of thermal energy from the energy source to the working fluid, maintaining optimal temperatures and pressures necessary for efficient turbine operation. After steam or working fluids have passed through the turbines, they must be cooled and condensed back to their original state to maintain a continuous cycle and prevent the overheating of critical machinery.

Condensers, cooling towers, and water circulation systems perform this function by removing excess heat from the system, ensuring that turbines, generators, and other components can operate safely and efficiently over long periods. Modern power plants also rely on sophisticated control systems and instrumentation to monitor and regulate their operations. Sensors measure parameters such as temperature, pressure, fluid flow, voltage, and current, providing real-time data to control rooms where operators can adjust performance, optimize output, and respond to potential faults. Automation and digital monitoring enhance the safety, reliability, and efficiency of power plants, allowing them to operate continuously under varying load conditions while minimizing the risk of equipment failure.

Auxiliary systems play an equally important role in supporting primary operations. Fuel handling systems manage the delivery, storage, and preparation of fuels, while water treatment plants ensure that water used in boilers and cooling systems is free from impurities that could damage equipment. Lubrication systems reduce friction in rotating machinery, and emission control systems minimize the release of pollutants into the environment. Together, these auxiliary systems complement the main components, enabling smooth, safe, and environmentally responsible operation. Another critical element in the architecture of a power plant is the transformer and switchyard system, which connects the generated electricity to the larger grid. Transformers step up voltage levels for efficient transmission across long distances, while switchyards and circuit breakers manage the distribution of electricity, isolate faults, and maintain the stability of the power system.

The seamless integration of all these components—the energy source, turbine, generator, boiler or reactor, heat exchangers, condensers, cooling systems, control and instrumentation systems, auxiliary equipment, transformers, and switchyard infrastructure—is vital to the successful operation of a power plant. Any failure or inefficiency in one component can disrupt the entire process, underscoring the need for precise engineering, regular maintenance, and monitoring. The efficiency of a power plant depends not only on the performance of individual components but also on how effectively they work together as a unified system. Engineers continually refine the design, materials, and operation of these components to maximize energy conversion, minimize losses, reduce emissions, and extend operational life. Beyond their technical functions, power plant components collectively support the social and economic infrastructure of modern society.

Reliable electricity enables industrial production, technological development, transportation systems, communication networks, and the daily activities of households. The main components of a power plant are therefore not merely mechanical or electrical devices; they are part of a complex system that sustains the growth, efficiency, and stability of human civilization. As global energy demands continue to rise, power plant components are evolving to accommodate new technologies, energy sources, and operational strategies. Renewable energy integration, smart grid compatibility, energy storage, digital monitoring, and automated controls are all being incorporated into modern power plants to improve flexibility, efficiency, and environmental sustainability. These innovations ensure that plants can meet dynamic electricity demands, incorporate intermittent energy sources, and continue to operate reliably under a wide range of conditions.

In essence, the main components of a power plant—including the turbines, generators, boilers, reactors, heat exchangers, condensers, cooling systems, control systems, auxiliary equipment, transformers, and switchyards—form a highly integrated network that transforms raw energy into electricity, supports industrial and economic activity, and powers the modern world. Their continuous development, adaptation, and optimization reflect the ongoing pursuit of efficiency, sustainability, and reliability in power generation, highlighting the indispensable role that these components play in providing the energy foundation for contemporary society and future generations.

A power plant is a complex and highly engineered facility that transforms raw energy from natural or artificial sources into electrical energy that can be transmitted and distributed to meet the electricity demands of households, businesses, industries, and infrastructure. At the heart of every power plant is the energy source, which can vary widely and largely determines the design, operation, and efficiency of the plant. Fossil fuels, such as coal, natural gas, and oil, are commonly used in thermal power plants, where combustion generates heat that converts water into high-pressure steam.

In nuclear power plants, heat is produced through the fission of uranium or plutonium atoms, releasing tremendous amounts of energy in a controlled manner to heat water and produce steam. Renewable energy power plants rely on natural phenomena, including the kinetic energy of flowing or falling water, the aerodynamic energy of wind, the radiant energy of the sun, geothermal heat from the Earth, and biomass, to generate mechanical or thermal energy for electricity production. Regardless of the source, the next critical step in electricity generation involves the conversion of this primary energy into mechanical energy, primarily through turbines or other rotating machinery. Turbines are central components in nearly all power plants, whether thermal, nuclear, hydroelectric, or wind, and are designed with precision-engineered blades and rotors to capture the maximum possible energy from steam, gas, water, or wind.

In thermal and nuclear plants, high-pressure steam is directed onto turbine blades, causing the rotor to spin and transforming the thermal energy of the steam into rotational mechanical energy. In hydroelectric plants, water passing over turbine blades applies kinetic energy to create rotation, while in wind power plants, the aerodynamic force of wind causes blades to turn, producing mechanical energy that drives generators. The rotational energy produced by turbines is transferred to electrical generators, which convert mechanical energy into electricity.

Generators operate based on the principle of electromagnetic induction, where the rotation of coils within a magnetic field induces an electrical current. This generated electricity, initially at relatively low voltages suitable for internal plant use, is passed through transformers that step up the voltage for efficient long-distance transmission. Transformers and switchyard systems also manage the distribution of electricity, ensuring it reaches the power grid safely and reliably. Thermal and nuclear plants rely heavily on boilers, reactors, or heat exchangers to efficiently convert the energy source into usable energy for turbines. Boilers in fossil fuel plants burn fuel to produce high-pressure steam, while nuclear reactors release heat through fission reactions that transfer energy to water, creating steam. Concentrated solar power plants employ mirrors or lenses to focus sunlight to heat fluids that drive turbines, and biomass plants burn organic material to produce heat for steam generation.

Heat exchangers facilitate efficient energy transfer from the primary source to the working fluid while maintaining temperatures and pressures that optimize turbine performance and minimize energy loss. Once energy has been extracted by turbines, cooling and condensation systems play a vital role in ensuring continuous plant operation and protecting machinery from overheating. Condensers, cooling towers, circulating water systems, and air-cooled heat exchangers remove excess heat from steam or other working fluids, returning them to their original state to close the energy conversion cycle. Without effective cooling systems, turbines, generators, and other critical equipment would be exposed to high temperatures, reducing efficiency, causing wear, and risking catastrophic failure. Modern power plants integrate advanced control systems and instrumentation to monitor and regulate operations in real time.

Sensors measure temperature, pressure, fluid flow, voltage, current, and other parameters, providing critical data to operators in control rooms who adjust operational settings to maintain optimal performance. Automation and digital monitoring systems enhance efficiency, reliability, and safety, allowing power plants to operate continuously under varying load conditions and quickly respond to emergencies or equipment anomalies. Auxiliary systems are equally important in supporting the main components of power plants. Fuel handling systems ensure proper delivery, storage, and preparation of fuels in fossil fuel and biomass plants, while water treatment systems remove impurities from water used in boilers, condensers, and cooling circuits to prevent scaling and corrosion. Lubrication systems reduce friction in turbines, generators, and pumps, extending equipment life, and emission control systems reduce environmental impacts by capturing or neutralizing pollutants before they enter the atmosphere.

The integration of transformers and switchyard infrastructure ensures that the generated electricity can be efficiently stepped up to high voltages for transmission and safely distributed through the grid. Switchyards include circuit breakers, busbars, and protective equipment that allow operators to manage power flows, isolate faults, and maintain grid stability. The seamless interaction of all these components—the energy source, turbines, generators, boilers, reactors, heat exchangers, condensers, cooling systems, control systems, auxiliary equipment, transformers, and switchyard infrastructure—is essential for the reliable operation of a power plant. Any inefficiency, malfunction, or failure in one component can affect the performance of the entire plant, highlighting the importance of precise engineering, regular maintenance, and continuous monitoring. Engineers continually refine component designs and plant operations to increase efficiency, minimize fuel consumption, reduce emissions, and ensure the long-term reliability of equipment.

The main components of a power plant do not merely convert energy; they also support the economic and social infrastructure of modern society. Electricity enables industrial activity, technological advancement, communication systems, transportation networks, healthcare, education, and everyday domestic life. Each component, from turbines and generators to cooling systems and control instruments, contributes to a highly coordinated system that sustains modern civilization. As global energy demand grows, power plant components are being adapted and upgraded to incorporate renewable energy, digital controls, energy storage, and smart grid technology, allowing plants to be more flexible, efficient, and environmentally sustainable. These innovations improve the ability of power plants to respond to fluctuating energy demand, integrate intermittent renewable sources, and maintain continuous, reliable electricity generation. In essence, the main components of a power plant form an integrated system that transforms primary energy into usable electricity while ensuring operational efficiency, safety, and environmental responsibility.

They are the physical and functional foundation that enables modern societies to function, supporting economic development, technological progress, and quality of life. From the energy source and turbines to generators, heat exchangers, condensers, cooling systems, control systems, auxiliary equipment, transformers, and switchyards, every component is indispensable in producing the reliable and continuous electricity that powers the world. Their continuous evolution and improvement reflect humanity’s ongoing efforts to meet growing energy demands, reduce environmental impacts, and optimize the complex process of converting natural and artificial energy into the electrical power that underpins modern civilization.

Energy Source

A power plant begins its operation with the energy source, which is the primary origin of the energy that will eventually be converted into electricity. The choice of energy source is fundamental, as it influences the design, operation, efficiency, environmental impact, and economic viability of the plant. Energy sources can be broadly divided into conventional sources, such as fossil fuels and nuclear materials, and renewable sources, such as wind, water, sunlight, biomass, and geothermal heat. Fossil fuels, including coal, natural gas, and oil, have been historically the most widely used energy sources for power generation.

Coal, abundant and relatively inexpensive, has powered thermal plants for centuries by burning it to produce heat that converts water into high-pressure steam, which then drives turbines. However, coal combustion releases large amounts of carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter, contributing to air pollution, acid rain, and global climate change. Natural gas has become a preferred alternative in many regions due to its higher efficiency, lower emissions, and ability to provide flexible and rapid start-up for electricity generation. It is used in gas turbines or combined cycle plants, where heat from combustion drives a gas turbine, and the exhaust heat generates steam for a secondary turbine, increasing overall efficiency.

Oil, though less commonly used today, is employed in areas where coal and gas are scarce or in plants that require fast ramp-up and compact design. Nuclear energy is another major conventional energy source, relying on controlled fission reactions in nuclear fuel such as uranium or plutonium to release massive amounts of heat. This heat is used to produce steam that drives turbines, similar to thermal plants, but with minimal greenhouse gas emissions during operation.

Nuclear power, while low in carbon emissions, requires stringent safety measures, specialized handling of radioactive materials, and long-term management of nuclear waste, making the choice and design of nuclear energy sources complex and highly regulated. Renewable energy sources provide alternatives that are more sustainable and environmentally friendly. Hydropower utilizes the kinetic energy of flowing or falling water to turn turbines directly, with the potential for large-scale and continuous electricity production in suitable geographic locations. Wind energy captures the aerodynamic force of moving air, turning turbine blades that drive generators. Solar energy can be harnessed either through photovoltaic cells that convert sunlight directly into electricity or through concentrated solar power systems that focus sunlight to heat a working fluid and drive turbines.

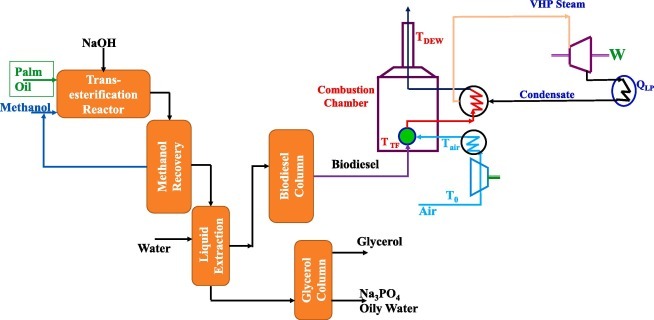

Biomass energy derives from organic materials, including wood, agricultural residues, and municipal waste, which can be burned or processed to produce heat or gas for electricity generation. Geothermal energy taps heat from beneath the Earth’s surface to produce steam or hot fluids that drive turbines, providing a stable and continuous power source in areas with geothermal activity. The selection of an energy source is influenced not only by availability but also by economic factors, environmental regulations, technological feasibility, and local infrastructure. Some plants may utilize hybrid approaches, combining multiple energy sources to maximize efficiency, reliability, or sustainability.

The energy source is the very foundation of a power plant’s operation because it provides the initial input that drives all subsequent processes. Its quality, consistency, and accessibility directly affect the plant’s performance, operational costs, environmental impact, and overall contribution to the electricity supply. Without an effective and reliable energy source, a power plant cannot generate electricity efficiently, which is why careful planning, evaluation, and management of the energy source are crucial for the long-term success and sustainability of any power generation facility.

A power plant begins its entire operation with the energy source, which is the fundamental origin of the energy that is ultimately converted into electricity, and the choice of this energy source determines almost every aspect of the plant’s design, operation, efficiency, and environmental footprint. Energy sources can be broadly categorized into conventional sources, such as fossil fuels and nuclear materials, and renewable sources, including wind, water, solar radiation, biomass, and geothermal heat, with each category presenting distinct characteristics, advantages, challenges, and implications for power generation. Fossil fuels have historically been the dominant energy source for electricity generation due to their high energy density, availability, and established infrastructure.

Coal, for example, has powered thermal plants for centuries by being combusted to release heat that transforms water into high-pressure steam, which then drives turbines connected to electrical generators. Coal-fired plants, while effective in producing continuous and large-scale electricity, are associated with significant environmental concerns. The combustion process emits large amounts of carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter, contributing to air pollution, acid rain, and the acceleration of global climate change. Despite these challenges, coal remains a major energy source in many parts of the world due to its abundance and relatively low cost.

Natural gas has emerged as a preferred alternative in recent decades because it burns cleaner than coal, with lower emissions of carbon dioxide and other pollutants, and because it offers the flexibility to ramp power output up or down quickly to match fluctuating electricity demand. Natural gas is often used in gas turbines or combined cycle plants, where the initial combustion produces hot gases that drive a gas turbine, while the exhaust heat is utilized to generate steam for a secondary steam turbine, significantly increasing overall efficiency. Oil, although less common in modern power generation due to high costs and environmental concerns, continues to be used in specific regions or in plants where rapid startup and operational flexibility are priorities, such as emergency power plants or remote installations.

Nuclear energy represents another major conventional energy source. In nuclear power plants, energy is released through controlled fission reactions, in which the nuclei of uranium or plutonium atoms split, releasing immense amounts of heat. This heat is transferred to water to produce high-pressure steam, which then drives turbines in much the same way as in thermal plants. Nuclear energy offers the advantage of producing large amounts of electricity with minimal carbon emissions during operation, but it also requires highly stringent safety measures, specialized handling of radioactive materials, and long-term management of nuclear waste. The choice of nuclear fuel, the design of the reactor, and the safety and containment systems are all dictated by the nature of the energy source and its inherent risks.

Renewable energy sources have grown in importance as societies seek cleaner and more sustainable ways to generate electricity. Hydropower harnesses the kinetic energy of flowing or falling water to drive turbines, and in many cases, dams and reservoirs are constructed to regulate water flow, store potential energy, and provide both electricity generation and flood control. Wind energy captures the aerodynamic energy of moving air, using turbine blades that convert wind into rotational mechanical energy, which is then transformed into electricity by generators. Solar energy can be converted directly into electricity through photovoltaic cells or indirectly through concentrated solar power systems, which focus sunlight to heat a working fluid that drives turbines. Biomass energy comes from organic materials such as wood, agricultural residues, or municipal waste, which are burned or processed to generate heat or gas for electricity production.

Geothermal energy taps heat from beneath the Earth’s surface, often in volcanic or tectonically active regions, to produce steam or hot fluids that drive turbines and generate a steady supply of electricity. The selection of an energy source is influenced by multiple factors, including local availability, cost, environmental regulations, technological feasibility, and infrastructure capacity. Some modern power plants utilize hybrid approaches, combining different energy sources to improve reliability, efficiency, and sustainability. For example, a plant may integrate solar or wind power with natural gas to provide consistent electricity while reducing emissions. The quality, consistency, and accessibility of the energy source directly affect the operational efficiency, capacity, and economic viability of the plant, and they also determine the type of equipment and technologies required for energy conversion, handling, and distribution. Beyond just supplying energy, the choice of energy source has long-term implications for environmental sustainability, economic cost, and energy security. Fossil fuels, while reliable and abundant in certain regions, contribute to global warming and air pollution, and their extraction and transportation have environmental and social impacts.

Nuclear energy provides low-carbon electricity but poses risks associated with radioactive waste, potential accidents, and long-term storage. Renewable sources, while cleaner and more sustainable, often face challenges such as intermittency, geographic dependency, and the need for energy storage and grid management to ensure consistent supply. The energy source is therefore the cornerstone of a power plant, setting the stage for every subsequent process, from the conversion of energy in turbines and generators to the management of heat and waste, the control of emissions, and the delivery of electricity to the grid. Its characteristics influence plant design, choice of machinery, operational protocols, safety measures, and maintenance schedules. Without a reliable and suitable energy source, a power plant cannot generate electricity efficiently or sustainably, and the stability of the broader electrical grid and the supply of electricity to consumers would be compromised.

Over time, innovations in energy technology, including the use of cleaner fossil fuels, advanced nuclear fuel cycles, and diverse renewable energy systems, have expanded the range of options for energy sources and improved the efficiency, safety, and environmental compatibility of power plants. Today, the energy source is not merely the starting point for electricity generation; it represents a strategic consideration for long-term sustainability, energy security, and technological development. It defines the plant’s operational parameters, dictates its environmental impact, and shapes the infrastructure required to harness, convert, and distribute energy effectively.

By carefully selecting and managing the energy source, power plants are able to provide the continuous, reliable, and high-quality electricity that underpins modern civilization, fuels industrial growth, enables technological advancement, supports transportation and communication networks, and enhances the quality of life for billions of people around the world. The energy source is ultimately the lifeblood of a power plant, determining its efficiency, cost, environmental footprint, and ability to meet the growing demands of modern societies, while driving ongoing innovation in energy conversion, plant design, and sustainable electricity generation.

The energy source is the most fundamental and critical element in any power plant, serving as the origin of the energy that will ultimately be transformed into electricity and distributed to homes, industries, and infrastructure. The selection and management of the energy source influence almost every aspect of a power plant, including its design, operation, efficiency, environmental impact, and long-term sustainability. Energy sources can be broadly classified into conventional sources, which include fossil fuels and nuclear materials, and renewable sources, such as water, wind, sunlight, biomass, and geothermal heat.

Fossil fuels have historically dominated electricity generation because of their high energy density, relative abundance in many regions, and established infrastructure for extraction, transportation, and combustion. Coal, in particular, has been used for centuries to generate heat in thermal power plants. When coal is burned in a boiler, it releases a substantial amount of thermal energy, which is used to convert water into high-pressure steam. This steam is then directed onto the blades of a turbine, causing it to rotate and produce mechanical energy that drives a generator to produce electricity.

Coal-fired power plants can provide large-scale, continuous electricity generation, but they also release significant amounts of carbon dioxide, sulfur dioxide, nitrogen oxides, and particulate matter, contributing to air pollution, acid rain, and global climate change. Natural gas has become increasingly popular due to its cleaner combustion, higher efficiency, and operational flexibility. In gas turbine and combined cycle plants, natural gas is burned to produce hot gases that rotate the turbine directly, while the exhaust heat is captured to generate steam for a secondary turbine, maximizing energy extraction. This dual-stage process increases efficiency and reduces emissions compared to traditional coal-fired plants, making natural gas an important bridge fuel in the transition toward cleaner energy sources.

Oil, although less widely used in modern power generation due to higher costs and environmental concerns, is still employed in specific situations where rapid start-up, compact plant design, or fuel availability is critical. Diesel and heavy fuel oil plants are often used in remote locations, emergency backup facilities, or industrial applications where other energy sources are less feasible. Nuclear energy represents a different type of conventional energy source, relying not on combustion but on controlled nuclear fission reactions. In nuclear reactors, the nuclei of heavy elements such as uranium-235 or plutonium-239 are split in a controlled manner, releasing enormous amounts of heat. This heat is used to produce steam, which drives turbines in a similar manner to thermal plants. Nuclear power offers the advantage of large-scale electricity production with minimal greenhouse gas emissions during operation, but it requires strict safety protocols, specialized handling of radioactive materials, and long-term waste management strategies, making it both highly effective and highly regulated. Renewable energy sources have become increasingly important as the global community seeks to reduce environmental impacts and ensure sustainable energy supply.

Hydropower, one of the oldest forms of renewable electricity generation, harnesses the kinetic and potential energy of moving or falling water to rotate turbines. Large dams and reservoirs allow water flow to be regulated, enabling reliable electricity generation and providing additional benefits such as flood control and irrigation. Wind energy captures the aerodynamic energy of moving air using large turbine blades. The rotation of these blades drives generators that convert mechanical energy into electrical energy. Wind power is abundant and clean, but it is intermittent and dependent on geographic and meteorological conditions, which necessitates energy storage solutions or complementary power sources to maintain a stable supply. Solar energy can be utilized in two primary ways. Photovoltaic systems convert sunlight directly into electricity using semiconductor materials, while concentrated solar power systems use mirrors or lenses to focus sunlight and heat a working fluid that drives turbines.

Solar energy is renewable and emits no greenhouse gases during operation, but its output is variable depending on time of day and weather, requiring energy storage or hybrid systems to provide continuous power. Biomass energy converts organic materials such as wood, agricultural residues, or municipal waste into heat or gas for electricity generation. Combustion, gasification, or fermentation processes release energy that can drive turbines or engines. Biomass provides a way to recycle waste materials while generating electricity, but it requires careful management to ensure sustainability and avoid environmental degradation. Geothermal energy taps the heat stored beneath the Earth’s surface, often in volcanic or tectonically active regions.

This heat is used to produce steam or hot fluids that drive turbines and generate a consistent, baseload power supply. Geothermal energy is highly reliable and low in emissions, but its availability is geographically limited. The selection of an energy source is not solely a technical decision; it is influenced by economic, environmental, geographic, and social factors. Availability, cost of extraction or harvesting, fuel transport infrastructure, environmental regulations, and long-term sustainability all play crucial roles in determining which energy source is most suitable for a particular power plant. Hybrid approaches are sometimes employed to optimize efficiency, reliability, and sustainability.

For example, a plant might combine solar or wind generation with natural gas turbines to balance intermittent renewable output with reliable fossil fuel generation, ensuring continuous electricity supply. The energy source not only provides the input for electricity generation but also defines the operational parameters of the plant, including the type of turbines, generators, boilers, reactors, heat exchangers, and auxiliary systems needed. It influences maintenance schedules, safety protocols, emission controls, and cooling requirements. Without a reliable and appropriate energy source, a power plant cannot operate efficiently or meet the electricity demands of its region. The characteristics of the energy source—such as its energy density, volatility, chemical composition, availability, and environmental impact—affect every stage of electricity production, from the initial capture or extraction of energy to its conversion into mechanical energy, generation of electricity, and delivery to the grid. Fossil fuels provide continuous, controllable energy but contribute significantly to environmental pollution and climate change.

Nuclear energy offers high-capacity, low-carbon electricity but entails complex safety and waste management challenges. Renewable sources offer cleaner, sustainable options but require careful integration, storage, and management due to variability and geographic limitations. The energy source is therefore not merely the starting point of a power plant; it is the lifeblood of the entire system, dictating design, performance, environmental impact, and long-term viability. It underpins every other component, from turbines and generators to condensers, cooling systems, and control instrumentation, ensuring that electricity can be produced efficiently, safely, and reliably. As global energy demands increase and environmental considerations become more pressing, the role of the energy source is evolving.

Advances in technology, such as more efficient combustion methods, advanced nuclear reactors, improved photovoltaic materials, larger and more efficient wind turbines, and enhanced geothermal systems, are expanding the range of viable energy sources. Smart grids, energy storage systems, and hybrid power plants are also enabling better integration of intermittent renewable sources, ensuring continuous electricity supply. Ultimately, the energy source determines the efficiency, cost, environmental footprint, and reliability of a power plant, serving as the foundation upon which all other components and processes depend. A careful selection and management of energy sources are therefore essential for the sustainable generation of electricity, economic stability, technological advancement, and the continued functioning of modern society.

By harnessing energy from fossil fuels, nuclear reactions, or renewable sources, power plants are able to provide the continuous, reliable, and high-quality electricity that supports industrial development, transportation systems, communication networks, residential life, and the technological infrastructure that modern civilization depends upon. The energy source is the starting point, the driver, and the defining element of a power plant, shaping its operations, influencing its design, and determining its ability to meet both current and future electricity demands while balancing environmental responsibility, economic feasibility, and technological innovation.

Boiler or Reactor (Thermal Plants)

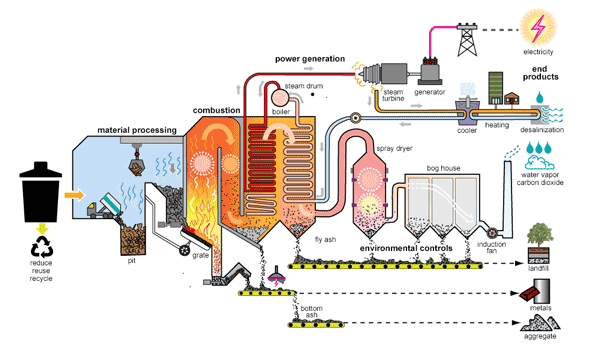

In thermal power plants, whether fueled by fossil fuels such as coal, oil, or natural gas, or powered by nuclear energy, the boiler or reactor is one of the most critical components because it is responsible for converting the primary energy source into thermal energy that can subsequently be used to generate steam, drive turbines, and ultimately produce electricity. In fossil fuel-fired thermal plants, the boiler serves as a large, enclosed vessel in which fuel is combusted under controlled conditions. The combustion process releases heat, which is absorbed by water circulating through pipes or tubes within the boiler.

As the water absorbs heat, it transforms into high-pressure, high-temperature steam. This steam carries immense thermal energy, which is then directed to the turbine system to produce mechanical energy. Boilers are designed to withstand extremely high temperatures and pressures, and they incorporate multiple subsystems such as burners, economizers, superheaters, reheaters, and air preheaters to maximize efficiency and ensure optimal energy transfer. Burners are responsible for mixing fuel with air and igniting it to produce a stable, high-temperature flame. Economizers preheat incoming feedwater using residual heat from flue gases, reducing the fuel required to reach boiling temperatures.

Superheaters further heat the steam beyond its saturation point to increase the energy content and efficiency of the turbine cycle, while reheaters allow partially expanded steam from intermediate turbine stages to be reheated and sent back to subsequent turbine stages, improving efficiency and reducing moisture content that could damage turbine blades. Air preheaters capture heat from flue gases to preheat the air entering the combustion chamber, improving combustion efficiency and reducing fuel consumption. Effective operation of a boiler requires precise control of fuel feed, air supply, combustion temperature, and water circulation to prevent issues such as incomplete combustion, overheating, scaling, or corrosion. Modern boilers are equipped with advanced sensors, automated control systems, and safety mechanisms to maintain stable operation and protect both the equipment and personnel.

In nuclear power plants, the reactor performs a function analogous to a boiler but operates on entirely different principles. Instead of burning fuel, a nuclear reactor generates heat through controlled nuclear fission reactions. In a reactor core, fuel rods containing fissile material such as uranium-235 or plutonium-239 undergo fission, releasing large amounts of thermal energy. This heat is transferred to a coolant, usually water, which circulates through the reactor and absorbs the thermal energy. The heated coolant then produces steam, either directly in the case of boiling water reactors (BWR) or indirectly in pressurized water reactors (PWR), where heat is transferred to a secondary loop to generate steam while maintaining the reactor coolant under high pressure.

Nuclear reactors are designed with extensive safety systems, including control rods to regulate the fission rate, multiple layers of containment to prevent the release of radioactive materials, emergency cooling systems, and continuous monitoring of temperature, pressure, neutron flux, and radiation levels. The precise management of these parameters ensures that the reactor operates safely while providing a consistent supply of thermal energy for electricity generation. Both boilers and reactors are equipped with feedwater systems that supply water at controlled temperatures and pressures, ensuring efficient steam generation and preventing thermal stresses that could damage tubes, piping, or pressure vessels. Additionally, flue gas cleaning systems in fossil fuel boilers remove pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, while nuclear reactors include systems to manage radioactive waste, control emissions, and safely handle spent fuel.

The design and operation of boilers and reactors are central to the overall efficiency of a thermal power plant. The temperature and pressure of the steam produced directly influence the performance of the turbines, and any inefficiency in heat transfer or control can significantly reduce the plant’s output. High-efficiency supercritical and ultra-supercritical boilers operate at extremely high temperatures and pressures, extracting more energy from the fuel and improving the thermal efficiency of the plant. Similarly, advanced nuclear reactors employ improved fuel designs, higher operating temperatures, and optimized coolant flow to maximize energy extraction while maintaining safety. In essence, the boiler or reactor in a thermal power plant acts as the primary energy converter, transforming chemical or nuclear energy into thermal energy in the form of high-pressure, high-temperature steam.

This steam serves as the driving force for turbines, generators, and ultimately the production of electricity. The complexity, precision, and safety considerations involved in designing, operating, and maintaining boilers and reactors make them among the most critical components of a thermal power plant. They are the heart of the energy conversion process, determining efficiency, reliability, safety, and environmental performance, and their proper operation is essential for sustaining continuous and efficient electricity generation.

In thermal power plants, the boiler or reactor represents the central component that converts the energy stored in fuel or nuclear material into thermal energy, which is subsequently transformed into mechanical energy through turbines and finally into electricity via generators. In fossil fuel-fired thermal plants, the boiler is a large, robust vessel designed to contain and manage extremely high-temperature combustion processes, where coal, oil, or natural gas is burned in a controlled environment to release heat. This heat is transferred to water circulating through a network of tubes or pipes inside the boiler, converting the water into high-pressure, high-temperature steam.

This steam contains immense thermal energy that is then directed toward the turbine system to drive mechanical rotation. The efficiency and performance of a boiler are directly linked to its ability to maximize heat transfer from combustion to water while minimizing energy losses and controlling emissions. To achieve this, boilers incorporate several subsystems that work together to improve thermal efficiency, reliability, and safety. Burners ensure proper mixing of fuel and air and maintain a stable, high-temperature flame. Economizers recover heat from flue gases to preheat incoming feedwater, reducing the energy required to reach boiling temperatures.

Superheaters increase the temperature of the saturated steam, raising its energy content and improving the thermodynamic efficiency of the steam cycle. Reheaters allow partially expanded steam exiting intermediate turbine stages to be reheated and sent back to subsequent stages, preventing moisture buildup that could damage turbine blades. Air preheaters capture residual heat from flue gases to preheat combustion air, enhancing combustion efficiency and reducing fuel consumption. The design of these systems must account for thermal expansion, material durability under extreme conditions, corrosion, scaling, and the chemical composition of fuel and water.

Modern boilers are equipped with automated control systems and sensors to monitor and adjust temperature, pressure, fuel feed, and water flow, ensuring stable operation and protecting both equipment and personnel from hazards. In nuclear power plants, the reactor performs the analogous function of a boiler but relies on a fundamentally different energy source: nuclear fission. In the reactor core, fuel rods containing fissile isotopes such as uranium-235 or plutonium-239 undergo controlled nuclear reactions, releasing large quantities of thermal energy. This heat is absorbed by a coolant, which can be water, liquid metal, or gas depending on the reactor design. In boiling water reactors (BWR), the coolant water is allowed to boil within the reactor core, producing steam directly for turbine operation.

In pressurized water reactors (PWR), the coolant is kept under high pressure to prevent boiling, and heat is transferred to a secondary water loop, where steam is generated separately, ensuring that radioactive material does not enter the turbine system. The reactor is surrounded by multiple layers of containment and shielding to prevent the escape of radiation, and control rods can be inserted or withdrawn to regulate the fission rate and thermal output. Nuclear reactors also include emergency cooling systems, redundant instrumentation, and automated shutdown mechanisms to maintain safe operation under normal and abnormal conditions. Feedwater systems in both fossil fuel boilers and nuclear reactors supply water at controlled temperatures and pressures to maintain steady steam production while minimizing thermal stress on components. Effective heat management is critical; in fossil fuel plants, flue gas cleaning systems reduce pollutants such as sulfur oxides, nitrogen oxides, and particulate matter, while in nuclear plants, systems are in place to manage radioactive waste, prevent contamination, and safely handle spent fuel. The efficiency of a thermal power plant is heavily influenced by the design and operation of the boiler or reactor.

The temperature and pressure of the generated steam determine the energy conversion potential in turbines, and even small improvements in heat transfer efficiency can result in significant increases in overall electricity output. Advanced boiler technologies, such as supercritical and ultra-supercritical designs, operate at extremely high pressures and temperatures, allowing more energy to be extracted from the same amount of fuel, reducing fuel consumption and emissions. Similarly, modern nuclear reactors incorporate improved fuel assemblies, enhanced coolant flow, and advanced safety features to optimize thermal output while maintaining strict regulatory compliance.

The boiler or reactor essentially acts as the heart of a thermal power plant, taking raw energy from fuel or fissile material and converting it into a usable thermal form that drives the entire energy conversion process. Its operation requires meticulous engineering to manage extreme conditions, ensure efficient energy transfer, maintain safety, and minimize environmental impact. Any inefficiency or failure in the boiler or reactor directly affects turbine performance, generator output, and the reliability of electricity supply, making its maintenance, monitoring, and design improvements critical priorities. The complexity of these systems also extends to operational protocols, requiring trained personnel to manage fuel handling, water chemistry, combustion or fission control, and emergency response procedures.

Advanced sensors and automated control systems continuously monitor parameters such as temperature, pressure, flow rates, radiation levels, and chemical composition to ensure the safe and efficient operation of the plant. Over the decades, innovations in boiler and reactor technology have significantly increased the efficiency, safety, and environmental performance of thermal power plants. In fossil fuel plants, circulating fluidized bed boilers, supercritical and ultra-supercritical designs, and integrated flue gas treatment systems have allowed for higher thermal efficiency and reduced emissions. In nuclear plants, reactor designs such as pressurized heavy water reactors, fast breeder reactors, and small modular reactors provide enhanced safety, efficiency, and scalability, while also addressing concerns related to fuel use and radioactive waste management.