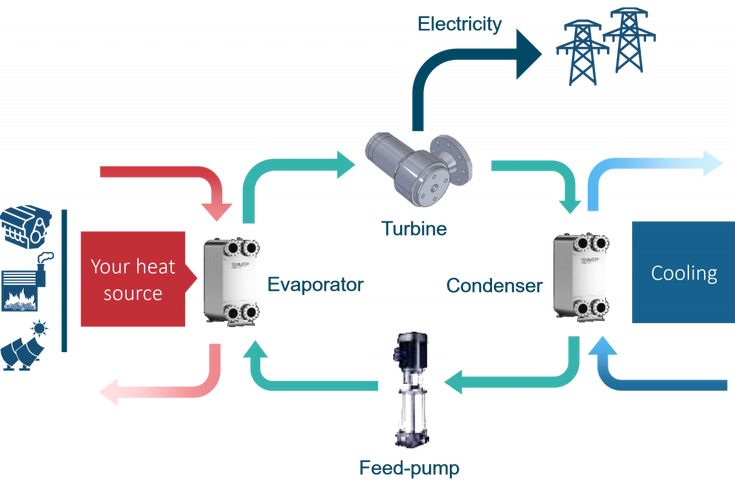

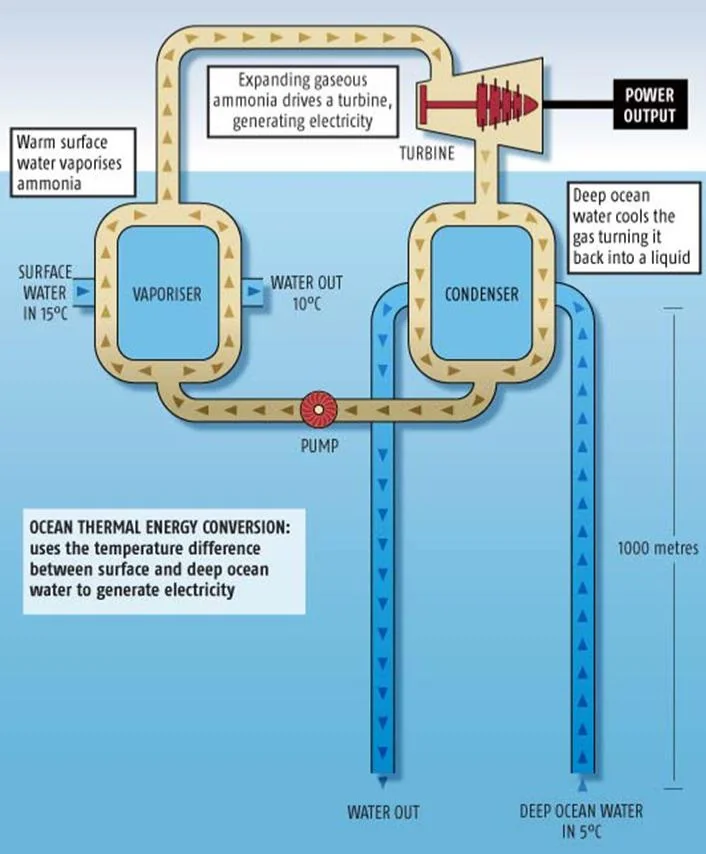

ORC System for Oven or Boiler Waste Heat: An Organic Rankine Cycle (ORC) system is a thermodynamic process used to convert low-grade or waste heat into useful power—typically electricity. It works similarly to a traditional steam Rankine cycle but uses an organic working fluid with a lower boiling point than water, making it suitable for heat sources in the 80°C to 350°C range.

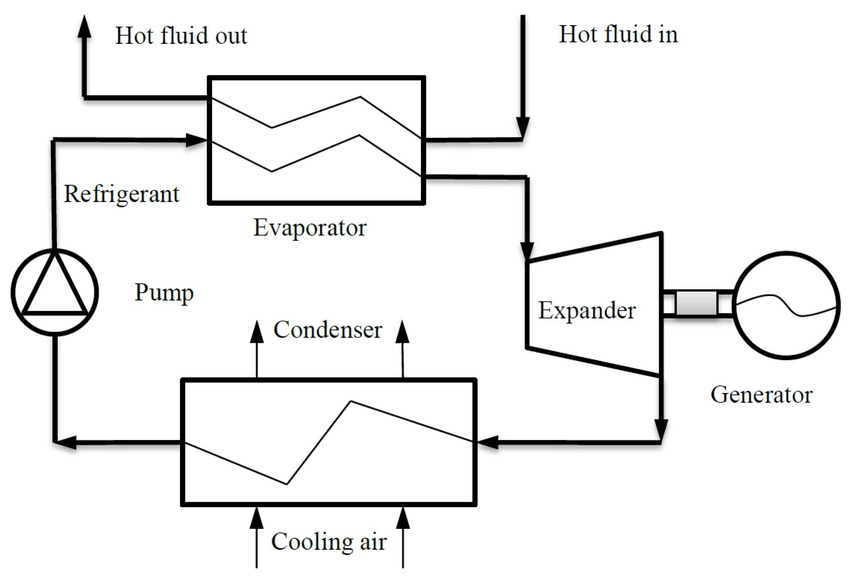

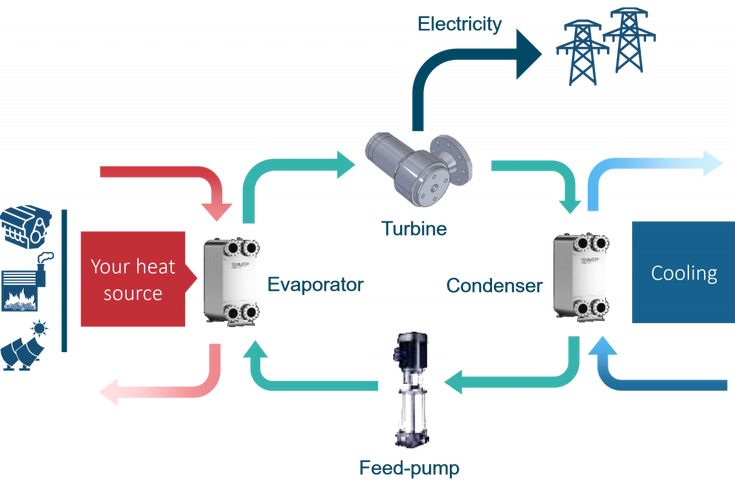

Basic Components of an ORC System:

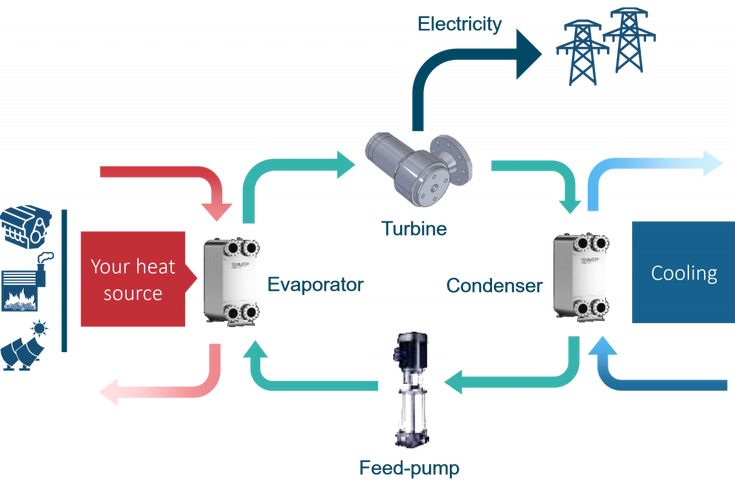

- Evaporator / Heat Exchanger: Transfers heat from the waste heat source to the working fluid, causing it to vaporize.

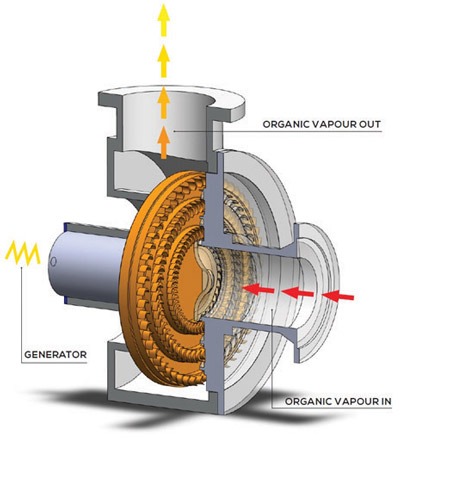

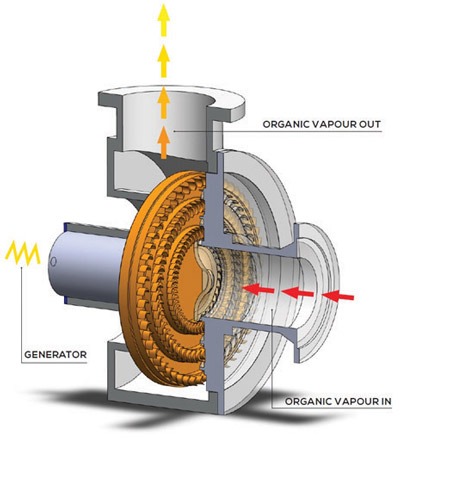

- Expander / Turbine: The high-pressure vapor drives a turbine or scroll expander to produce mechanical energy.

- Generator: Converts mechanical energy from the turbine into electricity.

- Condenser: Cools and condenses the working fluid back into a liquid.

- Pump: Pressurizes the liquid working fluid and sends it back to the evaporator.

Common Working Fluids:

- R245fa

- R1234yf

- Toluene

- Pentane

- Siloxanes

Working fluid choice depends on the temperature of the heat source and environmental/safety considerations.

Applications of ORC in Waste Heat Recovery:

- Industrial Processes (steel, cement, glass)

- Internal Combustion Engines (diesel gensets, marine engines)

- Geothermal Plants

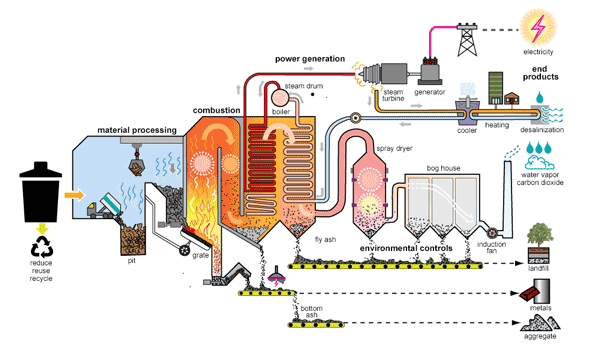

- Biomass Combustion

- Solar Thermal Systems

Advantages:

- Can utilize low-temperature heat that would otherwise be wasted.

- Works with air or water cooling, making it flexible.

- Modular and scalable for different industries.

- Quiet operation, low maintenance due to fewer moving parts.

- Can operate autonomously with minimal supervision.

Example Use Case:

Waste heat from a 200°C exhaust stream from a cement plant is fed into an ORC system. The ORC uses R245fa as a working fluid, vaporizes it, expands it through a turbine, and generates electricity—boosting overall plant efficiency by 5–10%.

An Organic Rankine Cycle (ORC) system is a thermodynamic process designed to convert low-temperature heat, especially waste heat, into useful energy, typically electricity. Unlike traditional steam-based Rankine cycles that use water as the working fluid, ORC systems use organic fluids with lower boiling points. This allows them to operate efficiently with heat sources ranging from about 80°C to 350°C, making them ideal for recovering waste heat from industrial processes, internal combustion engines, biomass burners, and even geothermal or solar thermal systems.

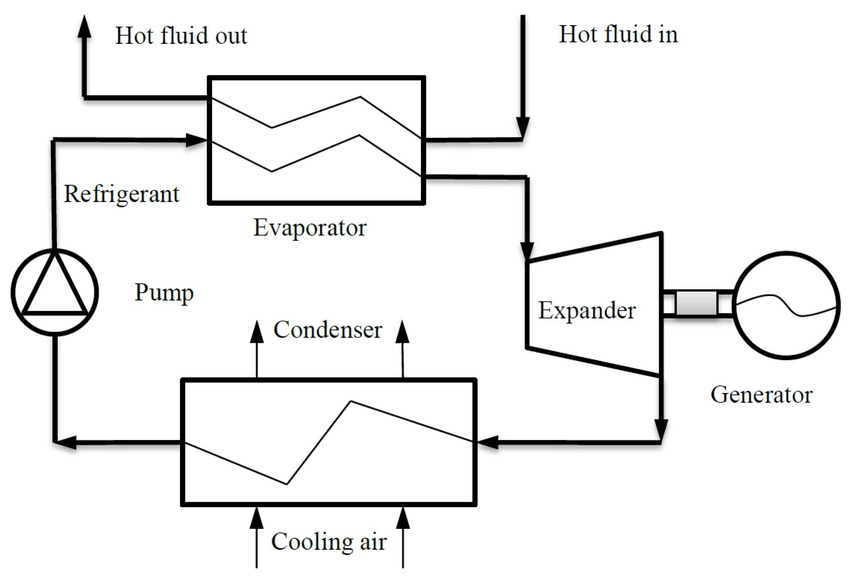

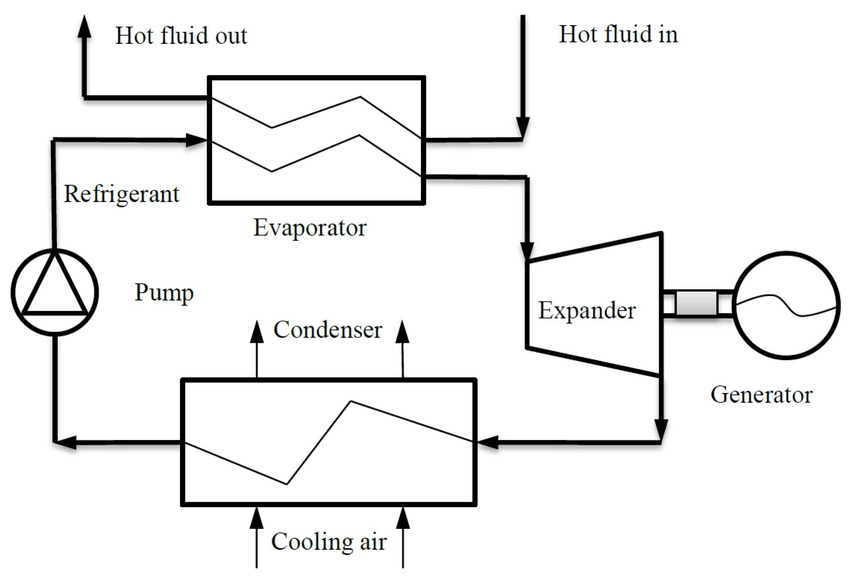

The process begins with the working fluid being pumped to a high pressure and then heated in a heat exchanger or evaporator, where it absorbs waste heat from an external source. This causes the fluid to vaporize. The high-pressure vapor then expands through a turbine or other type of expander, which drives a generator to produce electricity. After expansion, the vapor is cooled in a condenser and returns to a liquid state, completing the cycle as it gets pumped again to the evaporator.

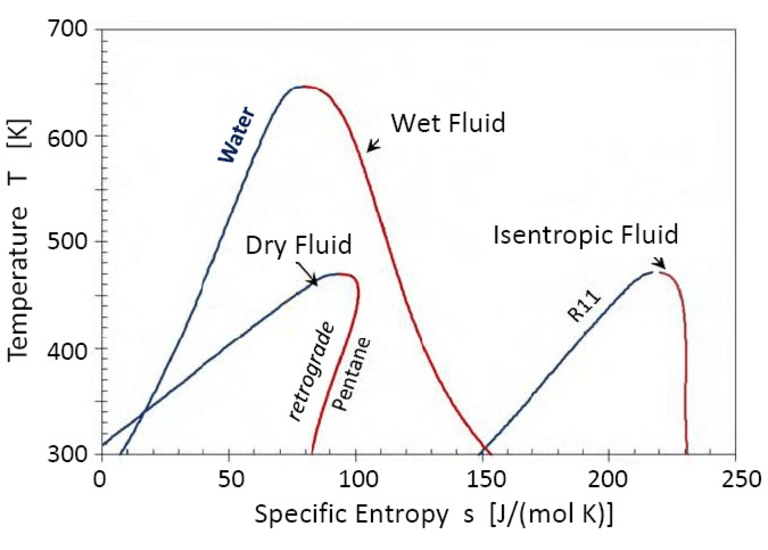

The choice of working fluid is critical and depends on the temperature of the heat source, the cooling method available, and environmental or safety concerns. Fluids such as R245fa, R1234yf, toluene, and siloxanes are commonly used, each offering different thermal and chemical properties. Some are more suited for high-temperature sources, while others are optimized for environmental friendliness or low global warming potential.

ORC systems are valued for their flexibility and efficiency, especially in situations where conventional power generation methods would be ineffective or uneconomical. They are generally modular, have low maintenance needs due to fewer moving parts, and can operate in off-grid or remote conditions with minimal supervision. In an industrial setting, an ORC unit added to a process that discharges hot exhaust gases can convert a portion of that waste heat into electricity, reducing the facility’s net energy consumption and improving overall efficiency by as much as 5 to 15 percent depending on the configuration.

As we continue, it’s essential to understand some of the core advantages and challenges that come with implementing an ORC system for waste heat recovery. The primary advantage is the ability to harness low-grade waste heat—something that would typically go unused or dissipate into the environment. By converting this thermal energy into electricity, ORC systems can significantly improve energy efficiency, often achieving gains of 10-15% in certain industries. This is especially useful for industries like cement, steel, glass, and chemical manufacturing, where heat is often generated in abundance but not always efficiently captured.

Another benefit of ORC systems is their scalability. They can be designed to fit small to large-scale operations, from single turbines in a small facility to more complex setups with multiple units integrated into a larger industrial process. The modularity of ORC technology allows it to be tailored to specific needs, with the system size and configuration adjusted based on the heat source’s temperature, available space, and the required electricity output.

Furthermore, ORC systems are often easier to integrate than traditional power generation methods. They require relatively little maintenance due to fewer moving parts, especially when compared to other power-generation systems like steam turbines, which involve more complex mechanical components. This results in lower operating costs over time, making ORC an attractive option for facilities looking to maximize their energy recovery while minimizing ongoing expenses.

However, ORC systems also face some challenges. One of the main obstacles is the capital investment. While the technology has matured over the years, the initial installation cost can still be relatively high compared to more conventional solutions. The need for a reliable heat source is another consideration, as the system requires a continuous supply of waste heat to operate effectively. Without a consistent and sufficiently high temperature, the system may not be able to produce enough electricity to justify its cost.

Moreover, the choice of working fluid plays a crucial role in the system’s performance. The working fluid must have properties that suit the heat source’s temperature range, and its environmental impact is also important, particularly for regulations related to greenhouse gas emissions and ozone depletion. Some fluids used in ORC systems have a low environmental impact, while others may present challenges in terms of leakage or disposal.

When it comes to specific industries, ORC systems are often used to recover heat from internal combustion engines in power generation or transportation sectors. For instance, in a diesel generator setup, the exhaust gases, which are usually hot and wasted, can be fed into an ORC system to generate electricity, providing a boost to the overall energy efficiency. Similarly, biomass combustion systems can utilize ORC technology to turn the heat from burning organic matter into power, making renewable energy systems even more efficient.

Another growing application is in geothermal energy. Geothermal plants often operate at temperatures that are too low for conventional steam turbines, making them an ideal match for ORC systems. This setup allows geothermal power plants to generate electricity from lower temperature sources, expanding the range of geothermal resources that can be used for power generation.

To conclude, the versatility and efficiency of ORC systems in harnessing waste heat for power generation make them an increasingly popular solution for industries looking to reduce their energy consumption and carbon footprint. While challenges like initial cost and fluid selection remain, the potential energy savings and environmental benefits continue to make ORC an attractive option for a variety of applications.

To dive deeper, let’s explore the thermodynamics of the Organic Rankine Cycle (ORC) in more detail, focusing on the principles behind its operation and how it differs from traditional steam Rankine cycles.

At the heart of the ORC process lies the Rankine cycle, which is a basic thermodynamic cycle used in heat engines to convert heat energy into mechanical work. In a typical Rankine cycle, water is heated to create steam, which expands through a turbine to generate electricity. However, in an ORC, instead of water, a low-boiling-point organic fluid is used. These fluids can vaporize at lower temperatures, enabling the ORC to be used with waste heat sources that are not hot enough to efficiently drive traditional steam turbines.

Thermodynamic Cycle:

- Heating: The organic fluid is pumped from the condenser (where it’s in a liquid state) to the evaporator, where it absorbs heat from the waste heat source (such as exhaust gases from industrial processes or engines). The heat causes the fluid to vaporize.

- Expansion: The high-pressure, high-temperature vapor then enters an expansion device—usually a turbine or scroll expander. As the vapor expands through this device, it loses pressure and temperature, which in turn drives the turbine to generate mechanical work.

- Cooling and Condensation: After expansion, the vapor is sent to a condenser, where it is cooled, usually by a heat sink like air or water. During this process, the vapor condenses back into a liquid state.

- Compression: The liquid is then pumped back to the evaporator at high pressure, where the cycle starts over. The pump in this step requires some energy but generally uses much less than the turbine produces, leading to a net energy gain.

Efficiency Considerations:

The efficiency of an ORC system depends on several factors, including:

- Temperature of the waste heat: The higher the temperature of the waste heat source, the more efficient the system becomes. Higher temperatures allow for a larger temperature differential between the heat source and the working fluid, which translates into more energy being extracted by the turbine.

- Thermal efficiency: ORC systems are less efficient than traditional Rankine cycles in terms of converting thermal energy into electricity, but they can still achieve overall system efficiency improvements when applied to waste heat.

- Heat source consistency: The more stable and continuous the heat source, the better the ORC system will perform. If the waste heat is intermittent, the ORC system may need supplementary systems or energy storage to remain effective.

One of the ways to increase efficiency is by optimizing the working fluid. Each fluid has specific thermodynamic properties that can make it more or less suited to a particular application. For instance, R245fa is a commonly used fluid because of its favorable thermodynamic properties, but its environmental impact is also an important factor, especially in regions with strict emissions regulations. R1234yf, a newer, more environmentally friendly fluid, is becoming popular for its low global warming potential, even though it may have different efficiency characteristics.

System Design and Optimization:

The design of an ORC system involves several key considerations:

- Heat exchanger design: The heat exchanger or evaporator is critical because it must efficiently transfer heat from the waste heat source to the working fluid. The efficiency of the heat exchanger can impact the overall performance of the ORC system, especially when dealing with fluctuating waste heat temperatures.

- Expander selection: Choosing the right type of expander is crucial. Turbines are commonly used but are not always the most cost-effective choice, especially for smaller systems. Scroll expanders and screw expanders are also used in certain cases, as they can offer greater efficiency at lower capacities.

- Condensation and cooling: The condenser needs to efficiently dissipate heat. In many cases, water-based cooling systems (such as cooling towers or closed-loop systems) are used, but air cooling can also be used when water is scarce or not available.

Economics and Return on Investment (ROI):

Despite the technical benefits, the capital cost of installing an ORC system can be significant. This includes the cost of the equipment, installation, and integration with existing systems. However, the long-term benefits can outweigh the upfront investment, especially when considering factors like:

- Fuel savings: By converting waste heat into electricity, ORC systems can reduce fuel consumption for facilities, offsetting energy costs.

- Government incentives: In many regions, ORC systems qualify for renewable energy incentives or tax credits, which can help reduce the upfront cost.

- Operational savings: With lower energy consumption and minimal maintenance requirements, ORC systems can lead to significant savings over their operational lifetime, often 15-25 years or more.

Payback Period:

The payback period for an ORC system varies based on factors such as the amount of waste heat available, the efficiency of the system, and local energy costs. On average, the payback period can range from 3 to 7 years, but this can be shorter if the facility has a particularly high waste heat output or if government incentives are available.

Future Outlook:

The market for ORC systems continues to grow as industries seek more efficient and sustainable ways to recover waste heat. Emerging applications include the use of ORC in electric vehicle (EV) charging stations, where waste heat from fast-charging systems could be recovered and used to generate power for the grid. Additionally, ORC is being integrated into district heating and combined heat and power (CHP) systems, improving the overall energy efficiency of these systems.

Moreover, advancements in materials science could lead to better-performing working fluids with lower environmental impacts, increasing the appeal of ORC systems in a wider range of applications. As global energy efficiency standards tighten, ORC systems will likely become an integral part of the waste heat recovery landscape, especially in energy-intensive industries.

ORC System for oven or boiler waste heat

An Organic Rankine Cycle (ORC) system for recovering waste heat from ovens or boilers is an effective way to harness energy that would otherwise be lost, improving the overall efficiency of the system. In industrial settings, both ovens and boilers generate significant amounts of heat, often in the form of hot exhaust gases, which can be used to power ORC systems for electricity generation or to provide additional heating.

Applying ORC to Oven or Boiler Waste Heat:

- Heat Source: Ovens and boilers typically operate at high temperatures, often between 200°C and 800°C depending on the type and purpose. The waste heat from these systems, usually in the form of exhaust gases, can be channeled into the ORC system for conversion into usable electricity or to supplement other thermal systems.

- Waste Heat Recovery:

- Ovens: In industries like baking, ceramics, or even metal heat treatment, ovens produce hot exhaust gases that often exit at temperatures around 200°C to 400°C. These gases can be captured and passed through an ORC heat exchanger (evaporator), where they heat the organic fluid (such as R245fa or other suitable fluids).

- Boilers: Boilers, particularly in industrial plants or power generation systems, can emit exhaust gases at 250°C to 600°C or higher. The higher the exhaust temperature, the more energy can be captured. The ORC system would take this exhaust and use it to vaporize the organic fluid, generating mechanical power.

- Heat Exchange and Fluid Vaporization: The captured exhaust gases enter a heat exchanger, where they transfer their thermal energy to the organic fluid in the ORC cycle. As the fluid is heated and vaporized, it creates high-pressure steam that is fed into an expansion turbine. This turbine then drives a generator to produce electricity.

- Electricity Generation: The mechanical energy generated by the turbine is converted into electrical energy via a generator. The amount of electricity produced depends on factors like the temperature and flow rate of the exhaust gases, the type of organic fluid used, and the efficiency of the entire system.

- Condensation and Recirculation: After the vapor expands and passes through the turbine, it is cooled in a condenser, typically using water or air as a coolant. Once condensed, the organic fluid is pumped back to the evaporator to begin the cycle again. This closed-loop process ensures continuous energy recovery from the waste heat.

Key Considerations for Implementing ORC with Oven or Boiler Waste Heat:

- Temperature Range: The working fluid selection is crucial for optimizing ORC performance. In applications like oven or boiler waste heat recovery, fluids with low boiling points such as R245fa or R134a are typically used. These fluids can vaporize at lower temperatures, making them suitable for heat sources that are not high enough to drive a traditional steam turbine but still provide a good amount of energy.

- Heat Recovery Efficiency: The efficiency of the heat exchanger is a key factor in maximizing the recovery of waste heat. A well-designed heat exchanger that minimizes heat loss and maximizes thermal transfer will improve the overall efficiency of the system. This is especially important in boiler applications, where exhaust gases are often at high flow rates and temperatures.

- System Size and Integration: The size of the ORC system must be designed to match the amount of waste heat available. For ovens, the system may be smaller and more compact, while larger boilers in industrial settings will require larger ORC units. The system also needs to be integrated with the existing boiler or oven setup, which may require retrofitting or additional modifications.

- Continuous Operation: ORC systems typically perform best with a stable and continuous heat source. Ovens and boilers, being relatively constant sources of heat, provide a good foundation for continuous ORC operation. However, fluctuations in temperature or exhaust gas flow could impact the performance, so these factors need to be considered during system design.

- Economic Viability: The initial investment for installing an ORC system can be high, but the savings in energy costs and the generation of electricity over time can result in a positive return on investment (ROI). The payback period for systems installed in ovens or boilers can vary, but it is typically around 3-7 years depending on the scale of the system and the amount of waste heat recovered.

Example Applications:

- Industrial Ovens: Consider a ceramic manufacturing plant with large ovens that operate at around 300°C. The waste heat from the oven could be used to drive an ORC system that produces electricity, which can be used to power other parts of the plant or be sold back to the grid. This would reduce reliance on external power sources and enhance the sustainability of the operation.

- Boilers in Power Plants: In power plants or industrial facilities with large steam boilers, the exhaust gases at temperatures between 350°C and 550°C could be used to generate power through an ORC system. This is particularly effective in cogeneration or combined heat and power (CHP) systems, where both electricity and useful thermal energy are generated from the same waste heat.

- Waste Heat from Biomass Boilers: Biomass boilers, often used for heating purposes in industrial or district heating systems, emit hot exhaust gases that can be routed to an ORC system for power generation. The electricity produced could either be used on-site to reduce energy costs or fed back into the local grid.

Challenges and Potential Solutions:

- Cost and Complexity: The installation of an ORC system can involve significant upfront costs and engineering work, particularly when retrofitting an existing oven or boiler setup. However, financial incentives or subsidies for waste heat recovery may help reduce costs. Additionally, using modular ORC systems can allow for more cost-effective scaling.

- Maintenance and Reliability: While ORC systems generally require less maintenance than traditional power generation methods, ensuring long-term reliability depends on proper system design, component selection, and the quality of installation. Preventative maintenance and periodic inspections of key components like pumps, expanders, and heat exchangers are crucial to minimizing downtime.

- Optimization for Low-Grade Heat: For lower-grade waste heat (i.e., temperatures below 200°C), ORC efficiency decreases. In these cases, hybrid systems that combine ORC with other heat recovery technologies (such as heat pumps) may be more effective.

Conclusion:

Integrating an ORC system into an oven or boiler setup for waste heat recovery offers an excellent opportunity to increase energy efficiency, reduce operational costs, and lower environmental impact. The technology is particularly beneficial in industries where heat is a byproduct of the production process, and by recovering this heat, businesses can turn waste into usable energy.

Using an Organic Rankine Cycle (ORC) system for recovering waste heat from ovens or boilers is a highly efficient method to capture and convert heat that would otherwise be wasted into useful electricity or additional heating. Ovens and boilers, common in many industrial processes, generate a significant amount of exhaust heat, which can be harnessed by ORC systems. The exhaust gases from these systems, often between 200°C and 600°C depending on the type and purpose of the oven or boiler, contain thermal energy that can be fed into the ORC cycle to drive a turbine and generate electricity.

The process starts by capturing the hot exhaust gases from the oven or boiler and directing them into a heat exchanger. This heat exchanger transfers thermal energy to an organic working fluid, typically one with a lower boiling point than water, such as R245fa. This fluid then vaporizes as it absorbs the heat. The high-pressure vapor produced from the heat exchange is directed to an expansion device, often a turbine, where it expands, losing pressure and temperature while driving the turbine to generate mechanical energy. The turbine’s mechanical energy is then converted into electricity through a generator.

After the vapor expands and passes through the turbine, it enters the condenser, where it is cooled, typically using a water or air-based cooling system. As the vapor cools, it condenses back into a liquid state and is pumped back to the evaporator to begin the cycle anew. This closed-loop process ensures the continuous operation of the ORC system, maximizing energy recovery from the waste heat produced by the oven or boiler.

In the case of ovens, which generally produce exhaust gases at lower temperatures than boilers, the ORC system can still generate useful electricity, though it might require more efficient heat exchangers and careful selection of the working fluid to ensure good performance at the given temperature. Boilers, on the other hand, often provide higher exhaust temperatures, making them an excellent candidate for ORC systems, especially when the exhaust gas temperature is between 350°C and 550°C.

The effectiveness of the ORC system depends on several factors, including the temperature and consistency of the heat source, the design of the heat exchanger, and the specific working fluid used. Choosing the right organic fluid is crucial because it needs to match the heat source’s temperature range while also considering factors like environmental impact and fluid efficiency.

The initial cost of installing an ORC system can be significant, but the long-term benefits often justify the investment. The system can reduce operational energy costs, as it converts waste heat into electricity that can either be used on-site or sold back to the grid. This can improve overall plant energy efficiency by capturing energy that would have been lost otherwise. Additionally, ORC systems can qualify for various energy incentives and subsidies in many regions, further improving their financial viability.

In industrial settings, integrating an ORC system into an oven or boiler operation can have long-term economic benefits, with a typical payback period ranging from 3 to 7 years. As industries continue to focus on sustainability and energy efficiency, ORC systems are becoming an increasingly popular choice for waste heat recovery, especially in sectors where high-temperature exhaust gases are regularly produced.

However, there are challenges, such as the upfront installation costs and the complexity of retrofitting existing systems. The performance of the ORC system may also be influenced by fluctuations in the heat source’s temperature or flow, so it’s essential to design the system to handle variable conditions. In some cases, hybrid systems that combine ORC with other heat recovery technologies, such as heat pumps or thermal storage, can be used to further optimize efficiency, especially when dealing with lower-grade waste heat.

Despite these challenges, the ability to generate electricity from waste heat makes ORC systems a valuable addition to oven and boiler setups, especially in industries like ceramics, metal heat treatment, power generation, and biomass combustion. These industries can significantly benefit from the increased energy efficiency and sustainability that ORC systems offer. As technology advances and the cost of installation continues to decrease, the application of ORC systems in waste heat recovery will likely expand across even more industrial sectors.

As we continue, it’s important to consider how the operational environment, maintenance practices, and long-term performance monitoring can further influence the success of ORC systems in waste heat recovery applications for ovens and boilers.

One of the most critical aspects of ORC systems is the continuous monitoring of key parameters, such as temperature, pressure, and flow rates. These parameters help ensure that the system is operating at peak efficiency. In a setting like an oven or boiler, where exhaust gas temperatures can fluctuate, it’s essential to maintain real-time data on the heat source conditions. This allows for quick adjustments in the ORC cycle, ensuring the working fluid stays within its optimal operating range. Monitoring systems also help identify any performance degradation over time, allowing for proactive maintenance before small issues become major problems.

Maintenance plays a significant role in the system’s long-term reliability. While ORC systems are generally low-maintenance compared to other types of power generation systems, components like the pump, expander, and heat exchangers still require regular inspections and periodic servicing. The pumps, for example, are responsible for moving the working fluid through the system, and their efficiency can decrease over time if not properly maintained. Similarly, the turbine or expander, which converts thermal energy into mechanical energy, needs to be checked for wear and tear. Regular cleaning of heat exchangers is also important to prevent fouling, which can decrease the efficiency of heat transfer.

Another factor to consider is system scalability. While small-scale ORC systems can be used for modest applications, large-scale industrial settings—such as a power plant or heavy manufacturing plant with large boilers—will likely require more robust, high-capacity ORC units. The flexibility of ORC technology allows it to be scaled up or down depending on the size of the facility, and in many cases, modular ORC systems can be added in increments to match the growing demand for electricity or heat recovery. This adaptability makes ORC an appealing option for industries with fluctuating energy needs or evolving production capacities.

One area where ORC systems are increasingly being integrated is within cogeneration or combined heat and power (CHP) systems. In these setups, the ORC system recovers waste heat not just to generate electricity, but also to provide additional heating for industrial processes or space heating within the plant. By recovering and utilizing more of the heat produced in a boiler or oven, these systems can achieve overall energy efficiency levels of up to 90%, significantly reducing the facility’s reliance on external energy sources.

Hybrid systems that combine ORC with other technologies, such as heat pumps, are also gaining traction. Heat pumps can extract heat from lower-grade waste sources and upgrade it to higher temperatures, making them more useful for driving the ORC cycle. This combination can improve the efficiency of heat recovery in applications where waste heat is not consistently high enough to drive a traditional ORC system by itself. Hybrid systems are particularly useful in industries that produce waste heat in varying temperatures or where the ORC system needs to be supplemented with additional sources of thermal energy.

The environmental benefits of ORC systems cannot be overstated. By capturing and utilizing waste heat, ORC technology reduces the amount of heat released into the atmosphere, lowering the carbon footprint of industrial operations. For industries focused on sustainability or facing emissions regulations, ORC systems offer an attractive option for improving energy efficiency and reducing overall environmental impact. This is especially important in industries like cement manufacturing, glass production, or chemical processing, where high energy consumption and associated emissions are often a concern.

Additionally, the growing trend towards renewable energy integration makes ORC systems even more relevant. By pairing ORC with renewable energy sources such as biomass, solar thermal, or geothermal energy, facilities can enhance their energy independence and sustainability. For example, a biomass plant that generates heat through combustion could use ORC to generate additional power from the waste heat, further increasing the plant’s renewable energy output. Similarly, geothermal systems, often at lower temperatures than traditional steam turbines can handle, can utilize ORC to extract energy from geothermal sources more efficiently.

For future applications, ORC systems are likely to evolve to handle a wider range of waste heat temperatures and improve their economic viability. Advances in working fluids and materials science could lead to more efficient and environmentally friendly options, which would open up new markets for ORC technology. Additionally, as industries move towards smart manufacturing and Industry 4.0, integrating ORC systems with digital monitoring and control systems could lead to more optimized and efficient operation, further improving the economic and environmental benefits.

In conclusion, ORC systems for oven and boiler waste heat recovery are not only technically feasible but increasingly cost-effective and sustainable. By converting wasted thermal energy into useful electricity or additional heating, ORC systems contribute to reduced energy consumption, lower emissions, and better overall efficiency in industrial operations. As the technology continues to improve and adapt to different industries and applications, the role of ORC systems in waste heat recovery will likely expand, providing even more opportunities for businesses to increase their energy independence and reduce their carbon footprint.

Looking ahead, there are several emerging trends and opportunities for ORC systems in the context of waste heat recovery from ovens and boilers. As industries increasingly seek to optimize energy use and meet stricter sustainability goals, ORC systems are poised to play an even more significant role in improving energy efficiency and reducing greenhouse gas emissions.

One promising area for ORC systems is the integration with energy storage solutions. As renewable energy sources like solar and wind power become more prevalent, the demand for energy storage technologies increases. ORC systems can be paired with energy storage systems, such as thermal energy storage (TES) or batteries, to store the electricity generated from waste heat. This combination allows industries to generate electricity from waste heat when it’s available, store it for later use, and optimize overall energy consumption. For example, in a biomass plant with an ORC system, the waste heat recovered during the day could be used to generate electricity, and this energy could be stored to meet demand at night when the renewable energy generation from biomass might be lower.

The role of artificial intelligence (AI) and machine learning (ML) in improving the performance of ORC systems is also on the horizon. By using AI and ML algorithms to analyze data from sensors and real-time system performance, ORC systems can be continuously optimized. These technologies can predict changes in waste heat temperature, flow rates, and other operating conditions, enabling more efficient operation and reducing the need for manual intervention. AI can also assist in predictive maintenance by identifying potential failures before they occur, thereby minimizing downtime and extending the lifespan of system components. For industries that rely on high-temperature processes like oven operations, these advancements can make ORC systems even more effective and economically viable.

Another aspect of future development lies in the integration of ORC systems with advanced manufacturing processes, such as 3D printing and additive manufacturing. As these industries evolve, they require precise and often high-temperature processes that generate waste heat. The ability to recover and utilize that waste heat through ORC systems will become increasingly valuable in ensuring energy efficiency and reducing operational costs in these cutting-edge sectors. For example, in industries using laser sintering or other high-heat processes, the exhaust heat could be efficiently recovered and converted into usable power or heat for other parts of the operation.

Additionally, there is growing interest in distributed energy systems, where small-scale ORC units are deployed across various industrial and commercial applications. Rather than relying on a large central power generation system, companies are looking for ways to generate energy on-site using waste heat. This decentralized approach is particularly attractive for industries with diverse facilities, as it reduces the need for costly grid infrastructure and provides energy security. For example, a chain of food processing plants that rely on multiple ovens can each install small ORC systems to recover waste heat and power their operations independently.

Furthermore, as the pressure on industries to reduce their carbon footprints increases, regulatory frameworks around energy efficiency and emissions will likely become stricter. Governments around the world are establishing more aggressive energy efficiency targets and renewable energy mandates, which could make the adoption of ORC systems more attractive. In some cases, industries may be required to adopt waste heat recovery technologies to comply with these regulations. As part of this shift, companies that integrate ORC systems into their operations may be able to take advantage of green certificates, tax credits, or other incentives for using renewable energy technologies, which can further improve the financial feasibility of these systems.

The cost of ORC systems is also expected to decrease as the technology matures and manufacturing scales up. As more suppliers enter the market and economies of scale are realized, the cost of installing and maintaining ORC systems could become more accessible, even for small to medium-sized enterprises. Advances in material science may also lead to cheaper, more durable components, further reducing operating costs and improving system longevity.

On the global stage, countries with significant industrial activity and high energy demands, such as those in Asia and Europe, are likely to be early adopters of ORC technology for waste heat recovery. For instance, regions with intensive manufacturing and energy production, such as China, India, and Germany, may see substantial investments in ORC systems as part of their efforts to meet carbon reduction goals. In these regions, waste heat recovery could play a key role in transitioning industries toward more sustainable, energy-efficient practices, driving economic growth while reducing reliance on fossil fuels.

As the ORC technology continues to evolve, it will increasingly become an integral part of the global energy landscape. The combination of recovering waste heat from ovens and boilers with the latest advancements in ORC technology can create a significant impact on energy efficiency, reduce emissions, and lower costs for industries. This will help companies not only stay competitive but also meet the growing demand for more sustainable and eco-friendly production processes.

To summarize, the future of ORC systems in waste heat recovery from ovens and boilers is bright. As industries continue to focus on sustainability, energy efficiency, and cost reduction, ORC technology will play an essential role in harnessing untapped energy potential, improving operational efficiencies, and helping businesses meet both economic and environmental goals. With continued innovation in working fluids, system design, integration with renewable energy sources, and advanced monitoring and control systems, ORC technology is set to become a cornerstone of industrial energy management in the years to come.

ORC System for dyeing process heat

The Organic Rankine Cycle (ORC) system can be effectively applied to recover waste heat from the dyeing process in textile industries. Dyeing processes typically involve the use of hot water or steam to ensure that dyes are properly absorbed by fabrics, and these processes generate significant amounts of waste heat in the form of hot water or exhaust steam. By integrating an ORC system, the waste heat from these processes can be converted into useful energy, reducing energy consumption, improving sustainability, and providing financial benefits to textile manufacturers.

Waste Heat in Dyeing Processes:

The dyeing process in the textile industry often requires substantial amounts of heat to maintain water or steam temperatures between 80°C to 130°C, depending on the type of dye and fabric. Waste heat can be found in several forms, such as:

- Exhaust Steam: Steam from the dyeing machine or exhaust steam from boilers used in the dyeing process is typically released into the atmosphere at high temperatures.

- Hot Water: Water used in rinsing or washing dyed fabrics often carries thermal energy, which can be recovered before it is discharged.

In many cases, this heat is either vented or lost to the environment, resulting in wasted energy that could be utilized through an ORC system.

How an ORC System Works for Dyeing Process Heat Recovery:

An ORC system can recover waste heat from these sources and convert it into usable electricity or thermal energy for other parts of the textile operation. Here’s how the process works:

- Heat Recovery: The ORC system captures the exhaust steam or hot water from the dyeing process. This waste heat is directed to a heat exchanger where the heat is transferred to an organic working fluid that has a lower boiling point than water. Common organic fluids used in ORC systems include R245fa or R134a, which have boiling points that make them ideal for lower-temperature heat sources like those found in dyeing processes.

- Vaporization and Expansion: The organic fluid, once heated in the heat exchanger, vaporizes and is directed to an expansion turbine. As the vapor expands in the turbine, it converts thermal energy into mechanical energy. This mechanical energy is then used to drive a generator, which produces electricity.

- Condensation and Recirculation: After passing through the turbine, the vapor enters a condenser where it cools and condenses back into a liquid form, usually with the help of water or air-based cooling systems. The cooled organic fluid is then pumped back to the heat exchanger to begin the cycle again, creating a closed-loop system that operates continuously.

Benefits of Using ORC for Dyeing Process Heat Recovery:

- Energy Savings: The main benefit of integrating an ORC system into a dyeing process is the potential for energy savings. The recovery of waste heat, typically lost through exhaust steam or hot water, can be transformed into electricity, reducing reliance on external power sources. This is particularly valuable in the textile industry, where energy costs often make up a significant portion of total operating expenses.

- Reduction of Carbon Footprint: By recovering waste heat, ORC systems reduce the amount of fuel needed to generate electricity or provide additional heating. This, in turn, reduces greenhouse gas emissions and helps companies meet sustainability targets. For textile industries aiming to improve their environmental performance, ORC systems offer a practical solution for reducing their carbon footprint.

- Improved Process Efficiency: The recovered energy can be used to power other parts of the production process, such as providing additional heat for pre-treatment or drying operations. This results in a more efficient use of energy throughout the plant and reduces overall operational costs.

- Financial Benefits: While the initial cost of installing an ORC system can be significant, the savings on energy bills over time typically result in a favorable return on investment (ROI). The payback period for an ORC system in a dyeing facility can vary, but it’s generally within the range of 3 to 7 years, depending on the scale of the system and the amount of waste heat recovered. Additionally, textile manufacturers may be eligible for incentives or subsidies related to energy efficiency or renewable energy.

- Modularity and Scalability: ORC systems are available in various sizes, making them suitable for a range of textile operations, from small-scale facilities to large manufacturing plants. Small-scale ORC units can be deployed in specific parts of the dyeing process, such as capturing heat from a particular dyeing machine or washing stage. Large-scale systems can be implemented to recover heat from the entire production line, maximizing energy recovery.

Key Considerations for Implementing ORC in Dyeing Processes:

- Temperature of Waste Heat: The temperature of the waste heat generated in dyeing processes is typically in the range of 80°C to 130°C. This is ideal for ORC systems, which are designed to recover energy from lower-grade heat. However, the efficiency of the ORC system will depend on the heat source’s temperature and the selected organic working fluid. For example, selecting the right working fluid that operates efficiently at these temperatures is crucial for maximizing energy recovery.

- Heat Source Consistency: The effectiveness of the ORC system depends on the consistency of the heat source. Dyeing operations can sometimes experience fluctuations in temperature or steam flow, which may impact the ORC system’s efficiency. It is important to integrate a control system that can adapt to these fluctuations to maintain optimal performance.

- Space and Integration: Implementing an ORC system requires space for installation and integration into the existing infrastructure. Retrofits for existing systems may require adjustments to accommodate the heat exchangers, turbines, and condensers. Proper integration into the plant’s energy management system is essential for smooth operation and maximizing energy recovery.

- Maintenance and Reliability: ORC systems require periodic maintenance to ensure the proper functioning of key components, including the pumps, turbines, and heat exchangers. Ensuring that the system is maintained according to the manufacturer’s guidelines will help avoid downtime and ensure that energy recovery remains efficient over time.

Example Applications:

- Small-Scale Textile Dyeing Facility: In a small textile dyeing operation, waste heat from exhaust steam and hot water can be captured and used to generate electricity. The electricity produced can either be used on-site to power lighting, machines, or other operational needs, reducing the reliance on external power sources. The ORC system could also be used to generate additional heating for other parts of the process, improving overall efficiency.

- Large Textile Manufacturing Plant: In larger textile factories with multiple dyeing machines and steam boilers, an ORC system could be designed to recover heat from all sources of waste heat in the facility. This recovered energy could be used to power a central generator or provide heating for other energy-intensive parts of the operation, such as drying, rinsing, or pre-treatment stages.

- Sustainability-Focused Textile Producer: For companies with a focus on sustainability and reducing their environmental impact, ORC systems present a way to enhance their green credentials. By capturing and utilizing waste heat from the dyeing process, the company can significantly reduce its energy consumption, decrease carbon emissions, and potentially meet energy efficiency requirements set by regulators or consumers.

Conclusion:

The use of ORC systems for recovering waste heat from the dyeing process in the textile industry represents a significant opportunity for improving energy efficiency, reducing environmental impact, and enhancing the financial sustainability of textile operations. By converting wasted thermal energy into usable electricity or thermal energy, ORC technology helps textile manufacturers reduce energy costs, comply with sustainability regulations, and increase the overall efficiency of their production processes. With the ongoing development of more efficient and cost-effective ORC systems, this technology is likely to become a more widespread solution for waste heat recovery in the textile industry.

The application of ORC systems in the textile dyeing industry holds tremendous potential for both operational and environmental improvements. With the growing focus on energy efficiency and sustainability, the textile industry is increasingly exploring ways to minimize energy consumption while reducing their carbon footprint. Since the dyeing process generates considerable amounts of waste heat, ORC systems present an effective method of converting this waste heat into usable energy, ultimately improving the overall efficiency of textile production.

In a typical dyeing operation, large amounts of hot water or steam are used to achieve the desired fabric coloring and finishing. This results in high energy consumption, and much of the heat used in these processes is typically lost to the environment. By integrating an ORC system, this wasted heat can be recovered, either from exhaust steam or hot water, and converted into electricity or thermal energy for other parts of the operation. This recovered energy can then be used to power equipment or provide heating for other stages of the textile manufacturing process, further improving the efficiency of the entire facility.

Moreover, ORC systems are scalable, making them adaptable to a variety of production sizes and facility types. Whether it’s a small-scale dyeing operation or a large industrial plant, the ORC system can be designed to suit the specific needs of the operation. The size of the ORC unit can be adjusted based on the amount of waste heat available, allowing businesses to capture energy in proportion to their needs. Small- to medium-sized textile plants can benefit from the ability to install smaller ORC units that recover heat from a few dyeing machines, while larger facilities can deploy large-scale ORC systems to recover heat from multiple sources across the plant.

Another compelling advantage of ORC systems is their potential to drive significant cost savings. Energy costs in textile production, particularly in the dyeing and finishing stages, can be substantial, making any opportunity for energy recovery highly valuable. ORC systems reduce the dependence on external energy sources by harnessing and utilizing waste heat, effectively lowering electricity bills and reducing the need to purchase additional energy from the grid. Over time, these savings can offset the initial investment in ORC technology, providing a clear return on investment for textile manufacturers.

The environmental benefits are equally significant. As global pressure mounts for industries to reduce their carbon emissions and operate more sustainably, ORC systems provide a practical solution for textile manufacturers to meet regulatory requirements and sustainability goals. By capturing and reusing waste heat, ORC technology reduces the need for additional fuel consumption and helps lower the plant’s overall greenhouse gas emissions. This aligns with the growing trend of eco-friendly manufacturing in the textile sector, where companies are looking for ways to make their operations more energy-efficient and sustainable.

In addition to direct energy recovery, ORC systems can also contribute to better resource management. For example, ORC systems may be coupled with other energy-saving technologies such as heat pumps or thermal storage systems, allowing facilities to manage energy supply and demand more effectively. This combination can optimize the use of recovered heat, ensuring that it is used when needed most, especially in facilities where energy demand fluctuates throughout the day.

While the technology offers substantial benefits, there are challenges to consider. One of the key challenges is the variability of waste heat in the dyeing process. Dyeing machines may not consistently produce the same temperature or flow rate of exhaust steam, which can affect the efficiency of the ORC system. To mitigate this, advanced control systems and sensors can be implemented to adjust the operation of the ORC system based on real-time data, ensuring that the system adapts to fluctuations in waste heat output and operates optimally at all times. This flexibility in the system design is crucial for maintaining consistent performance in the face of variable operational conditions.

The cost of installing an ORC system can also be a consideration, as the initial investment can be significant. However, many textile manufacturers find that the long-term energy savings and environmental benefits justify the cost. In some cases, governments and regulatory bodies offer subsidies or tax incentives to encourage the adoption of energy-efficient technologies like ORC, which can further reduce the financial barrier to entry.

ORC systems also require regular maintenance to ensure their long-term effectiveness. The turbines, pumps, and heat exchangers in the system need periodic inspection and servicing to avoid inefficiencies due to wear and tear. However, this level of maintenance is generally lower compared to other large-scale energy systems, making ORC a relatively low-maintenance solution for waste heat recovery.

Looking towards the future, we may see greater integration of digital technologies and AI-powered solutions within ORC systems. Machine learning algorithms and real-time data analytics could further optimize the performance of ORC systems by anticipating fluctuations in waste heat production and adjusting system settings automatically. This can maximize energy recovery while minimizing energy losses and downtime, contributing to even greater efficiency. Additionally, the integration of renewable energy sources such as solar thermal or biomass with ORC systems can further enhance energy recovery potential, providing a cleaner, more sustainable energy solution for the textile industry.

In conclusion, ORC systems offer a transformative opportunity for textile manufacturers to enhance energy efficiency, reduce costs, and promote sustainability in dyeing processes. With continued advancements in ORC technology and growing pressure on industries to adopt greener practices, the application of ORC systems in waste heat recovery is likely to increase. The technology provides a reliable, scalable, and cost-effective solution to capture otherwise wasted energy, making it a critical component of the industry’s shift towards more sustainable and efficient manufacturing processes.

As the demand for sustainable and energy-efficient technologies continues to grow, ORC systems are becoming increasingly integral to industries like textile manufacturing, where high temperatures and substantial waste heat are a consistent byproduct of operations. This trend towards adopting ORC systems will likely continue to accelerate, driven not only by the need for cost savings but also by the desire to meet stricter environmental regulations and enhance overall operational efficiency.

The potential for further innovations in ORC technology is another reason why this system will play an even larger role in the future of textile dyeing and similar industries. As new materials and working fluids with improved thermodynamic properties are developed, ORC systems may become more efficient at lower temperatures, allowing them to capture heat from even more marginal or lower-grade waste heat sources. This will make the technology viable for a wider range of applications beyond high-temperature processes like dyeing, extending its reach to other areas of the textile industry or even outside of it.

Moreover, advancements in heat exchanger technology could enhance the overall efficiency of ORC systems. Improved heat exchangers with higher thermal conductivity, better resistance to fouling, and smaller, more compact designs could increase the heat recovery rate and further reduce the system’s footprint. This would make it even easier to retrofit existing textile production facilities with ORC technology without requiring major modifications to the plant’s infrastructure. More efficient heat exchangers would also minimize heat losses during the heat transfer process, ensuring that the maximum possible amount of thermal energy is recovered and converted.

Additionally, hybrid systems that combine ORC technology with other renewable energy solutions could provide even greater energy recovery potential. For example, solar thermal collectors could be integrated with ORC systems to provide supplementary heat to the system, especially during sunny days. This could be particularly valuable in areas where the textile manufacturing facility is located in regions with abundant sunlight. Similarly, biomass heating systems could be used in conjunction with ORC systems to increase the temperature of the working fluid and improve the energy recovery from waste heat.

The global shift toward decarbonization in various industries also points to a growing role for ORC systems. As more countries introduce stricter carbon emission targets, the pressure on industries to reduce their carbon footprint will intensify. ORC systems provide a direct solution for reducing waste heat emissions by converting them into usable energy instead of allowing them to dissipate into the environment. This aligns well with international efforts to achieve net-zero emissions targets and will likely drive increased adoption of ORC technology in various industries, including textiles.

In addition to addressing climate change and energy efficiency, the continued use of ORC systems will also help improve the overall competitiveness of textile manufacturers. In a highly competitive market, companies that adopt energy-efficient technologies gain a significant advantage in terms of reducing operational costs, increasing sustainability, and demonstrating their commitment to corporate social responsibility (CSR). As consumers become more conscious of the environmental impact of the products they buy, textile companies can use their investment in ORC systems to market themselves as sustainable brands, which could translate to stronger customer loyalty and increased sales.

One emerging trend in the textile industry is the move toward circular economy principles, where waste and byproducts are reused or repurposed rather than discarded. ORC systems fit well within this framework, as they enable the reuse of waste heat—a byproduct of the dyeing process—turning it into valuable energy. This approach not only contributes to energy savings but also aligns with the principles of sustainability and resource efficiency, which are at the heart of the circular economy.

In terms of future regulatory developments, governments and international organizations are likely to impose even stricter regulations on waste heat recovery and energy efficiency. The introduction of standards and guidelines for industries to recover and utilize waste heat could create additional pressure for textile companies to adopt ORC systems or other energy recovery technologies. This regulatory landscape, combined with financial incentives such as tax credits, grants, or renewable energy credits, will help to lower the cost barrier and accelerate the adoption of ORC systems.

At the same time, advancements in digitalization are opening up new possibilities for enhancing ORC system performance. The integration of smart sensors and data analytics can allow operators to continuously monitor and optimize system performance. Machine learning models can predict fluctuations in waste heat, enabling the system to adapt in real time, ensuring maximum energy recovery and system longevity. These technologies will help reduce operational costs by providing insights into potential inefficiencies and allowing for predictive maintenance, thereby minimizing downtime and extending the lifespan of the ORC system.

Moreover, ORC systems can also play a role in integrating the textile industry into smart grids or microgrids. As part of a larger energy management system, ORC technology can contribute to balancing energy supply and demand by supplying excess energy generated from waste heat to the grid during periods of low consumption. This could help stabilize grid operations, especially in areas with a high penetration of intermittent renewable energy sources like solar and wind power.

Finally, in terms of market adoption, the increasing availability of modular ORC units will make it easier for small- to medium-sized textile manufacturers to adopt this technology. Smaller systems can be implemented incrementally, with businesses starting with a single ORC unit and scaling up as energy needs and waste heat generation grow. This modular approach provides flexibility for manufacturers that may not have the capital or infrastructure to implement large-scale ORC systems right away.

In summary, the future of ORC systems in textile dyeing and similar industries looks promising. As technology continues to evolve and energy efficiency becomes an even more critical focus, ORC systems will play an increasingly important role in converting waste heat into useful energy, improving the sustainability of textile production processes. With their ability to reduce energy costs, lower emissions, and contribute to environmental goals, ORC systems will continue to offer substantial benefits to textile manufacturers looking to optimize their operations and stay competitive in a rapidly changing marketplace.

As the global focus on sustainability and energy efficiency intensifies, the role of ORC systems in industrial applications like textile dyeing is poised to expand significantly. Beyond the immediate energy and financial savings, ORC systems present an opportunity for textile manufacturers to position themselves as leaders in sustainability, a factor increasingly important to both consumers and stakeholders alike. The growing pressure for industries to adopt green technologies and reduce their environmental impact will continue to drive interest in ORC systems and similar waste heat recovery solutions.

Looking forward, one significant development is the potential for policy-driven incentives that could further accelerate the adoption of ORC technology. Governments worldwide are rolling out programs designed to promote energy efficiency, renewable energy, and carbon neutrality. These programs often include financial incentives such as grants, rebates, tax credits, or subsidies for businesses that invest in energy-saving technologies like ORC systems. These incentives can help offset the initial installation costs, making it easier for textile manufacturers to justify the investment in these systems.

Additionally, many green building certifications, such as LEED (Leadership in Energy and Environmental Design), now consider the energy efficiency and sustainability of manufacturing operations as part of their evaluation criteria. Companies that adopt ORC systems can achieve higher ratings on these certifications, enhancing their corporate image and improving their marketability. Achieving such certifications may also provide access to certain business opportunities, particularly with eco-conscious brands or retailers who prioritize sustainability in their supply chain.

In regions where energy prices are high, the financial benefits of installing ORC systems can be particularly compelling. For example, textile manufacturers in parts of the world where energy costs are volatile or high, such as in Europe, North America, or Asia, can use ORC technology to stabilize their energy expenses. This stability offers a level of predictability that is crucial for long-term financial planning. Furthermore, by converting waste heat into electricity, companies can reduce their reliance on external power providers, allowing them to become more energy-independent and resilient to price fluctuations in the energy market.

As demand for energy-efficient solutions grows, we are also likely to see further innovation in the design and functionality of ORC turbines and associated components. Turbine efficiency and reliability are central to maximizing the performance of ORC systems, and improvements in turbine materials, designs, and control systems could make ORC systems even more effective at lower temperatures. As the global trend toward electrification and digitalization accelerates, AI-powered optimization tools could further enhance turbine operation by predicting performance and adjusting settings based on real-time energy consumption and waste heat data. This would increase system uptime and efficiency.

ORC systems could also play a crucial role in enabling the integration of renewable energy sources. Many textile manufacturing facilities already have some level of renewable energy capacity, such as solar panels or biomass boilers. ORC systems can complement these sources by providing a consistent supply of energy when renewable resources are not available or during periods of low production. For example, solar thermal energy, when combined with ORC technology, can effectively complement solar photovoltaic systems by generating electricity from waste heat during the day, storing energy in the form of thermal energy, or supplying power for non-peak times.

Another possibility lies in the integration of energy storage solutions with ORC systems. By pairing ORC technology with thermal energy storage (TES), businesses could store excess thermal energy recovered by the ORC system during periods of high waste heat production and use it when waste heat generation is lower. This integration would help smooth out energy generation fluctuations, further enhancing the flexibility and reliability of energy recovery systems.

In parallel, innovations in organic working fluids may help optimize ORC performance across various operating conditions. Research into new, low-global warming potential (GWP) fluids is ongoing. These fluids are not only environmentally friendly but also more effective at low temperatures, expanding the range of waste heat sources that can be efficiently utilized by ORC systems. These new fluids, designed to be more efficient, less toxic, and more readily available, could lower operating costs and improve the performance of ORC systems in the textile industry and other sectors.

Furthermore, emerging trends in digitalization are opening new opportunities for monitoring and optimizing the performance of ORC systems. IoT (Internet of Things) sensors and smart monitoring systems can track key parameters such as temperature, pressure, fluid flow, and energy output, providing real-time data that operators can use to adjust settings for optimal performance. Advanced data analytics can identify inefficiencies or areas where performance can be improved, allowing for continuous improvement and reduced operating costs. As more textile manufacturers adopt Industry 4.0 technologies, the ability to integrate ORC systems into these broader digital ecosystems will be a critical step toward maximizing their value.

Moreover, the potential for global collaborations between technology developers, textile manufacturers, and research institutions will lead to faster advancements in ORC system technologies. By pooling resources and expertise, these collaborations can address key challenges, such as reducing the initial capital investment required for installing ORC systems, improving their economic viability, and optimizing their design for specific industrial processes. Furthermore, partnerships with international organizations focused on sustainability could offer technical support and create new funding opportunities for textile manufacturers adopting ORC technology.

Looking beyond just the textile industry, the growth of waste heat recovery technology could lead to an even wider adoption of ORC systems across various sectors, such as chemical production, food processing, and cement manufacturing, where waste heat recovery is similarly needed. As these industries continue to invest in energy recovery technologies, the economies of scale could further reduce the costs of ORC systems, making them more accessible to smaller businesses across different sectors.

In conclusion, the integration of ORC systems in textile dyeing and other industrial processes represents a critical piece of the global energy efficiency puzzle. These systems offer a way to capture wasted heat and transform it into usable energy, offering benefits such as cost savings, reduced carbon emissions, and increased energy independence. With continued innovation in turbine technology, working fluids, energy storage solutions, and digitalization, ORC systems will continue to evolve, making them even more effective, efficient, and scalable for a broader range of industrial applications. For textile manufacturers, the decision to implement ORC technology offers not only financial and operational advantages but also the chance to meet the growing demand for sustainable practices in the face of a rapidly changing global market.

ORC System for dryer exhaust heat

The use of ORC (Organic Rankine Cycle) systems to recover waste heat from dryer exhausts is an emerging and effective solution for improving energy efficiency in various industries. Drying processes, particularly in industries such as textiles, paper manufacturing, food processing, and more, generate significant amounts of hot exhaust gases. These exhaust gases are typically vented to the atmosphere, resulting in a loss of valuable energy. By implementing an ORC system, this wasted heat can be captured and converted into usable energy, thereby improving the overall energy efficiency of the drying process.

How ORC Systems Work for Dryer Exhaust Heat Recovery

An ORC system typically operates by using an organic fluid (often a refrigerant or other working fluid) that is heated by waste heat, such as the hot exhaust gases from a dryer. The heat causes the fluid to evaporate, and the resulting vapor is used to drive a turbine that generates electricity. The vapor is then cooled, condensed back into a liquid, and recirculated to repeat the cycle. In dryer exhaust applications, the ORC system captures heat from the exhaust air or flue gases that are often released at high temperatures, making it ideal for recovery.

Key Advantages of Using ORC for Dryer Exhaust Heat

- Energy Recovery: One of the primary benefits of using ORC systems in drying processes is the ability to recover waste heat and convert it into electricity or usable thermal energy. This recovered energy can either be used to power equipment within the facility or returned to the drying process itself to reduce the consumption of external energy sources, such as electricity or fuel.

- Cost Savings: By capturing and utilizing otherwise wasted heat, companies can significantly reduce their energy bills. The amount of heat that can be recovered from dryer exhausts depends on the size of the drying operation and the temperature of the exhaust gases, but in many cases, it’s enough to generate a meaningful amount of energy savings. In the long term, the initial investment in an ORC system can be offset by the energy savings and reduced reliance on external energy sources.

- Reduced Carbon Emissions: ORC systems contribute to greenhouse gas emission reductions by decreasing the need for additional energy input from conventional sources. By recovering waste heat from dryer exhausts, these systems can help reduce a facility’s carbon footprint, aligning with growing environmental regulations and sustainability goals.

- Scalability: ORC systems are scalable, meaning they can be tailored to suit various drying operations, from small-scale businesses to large industrial operations. Whether the dryer exhaust consists of hot air from a small laboratory-scale dryer or large-scale industrial drying units, an ORC system can be designed to match the heat recovery needs of the facility.

- Reduced Energy Consumption: By using the recovered energy to power equipment within the plant or offset the need for additional heating or cooling, the ORC system reduces the overall energy consumption. This makes the system particularly useful in industrial plants where drying processes are a significant part of the energy load.

- Environmental Sustainability: The textile, food, and paper industries are particularly energy-intensive, and using ORC technology to recover heat from dryer exhausts helps reduce energy waste. This energy-efficient approach aligns with the global shift toward eco-friendly manufacturing and meeting regulatory compliance standards for energy use and emissions reductions.

- Modular and Flexible Design: ORC systems can be designed to work with existing infrastructure. For facilities that already have drying systems in place, an ORC system can be installed as a retrofit without requiring major changes to the existing drying equipment. This makes the technology an attractive option for industries looking to improve energy efficiency without completely overhauling their current operations.

Applications of ORC Systems for Dryer Exhaust Heat

- Textile Industry: In textile manufacturing, dryers are commonly used to remove moisture from fabrics after the dyeing or washing processes. These dryers often release large amounts of waste heat, which can be effectively captured by an ORC system. The recovered energy can then be used to power auxiliary equipment or provide heating to other parts of the production process, reducing the need for external electricity.

- Paper and Pulp Industry: Drying is a critical step in the paper production process, where large amounts of hot air or steam are used to dry paper sheets. ORC systems can recover waste heat from the dryer exhaust gases and convert it into usable energy, potentially powering dryers or other processes in the mill.

- Food Processing: In food processing, drying is an essential method for preserving ingredients and creating products like dried fruits, meat, and snacks. Dryers in these facilities can produce large volumes of exhaust heat, which can be captured and converted by ORC systems into electrical power, reducing energy costs in the facility.

- Wood and Biomass Drying: Similar to the paper industry, wood drying operations also produce significant amounts of exhaust heat. These operations, whether for lumber or biomass pellets, can take advantage of ORC technology to recover waste heat and improve energy efficiency, cutting down on fuel consumption and emissions.

Challenges and Considerations for Implementing ORC in Dryer Exhaust Systems

- Temperature Range: ORC systems typically work best with high-temperature exhaust gases (between 150°C and 450°C), which are common in drying operations. However, if the exhaust gases from the dryer are too cool, the efficiency of the ORC system may decrease. In such cases, preheating the exhaust gases using heat exchangers or combining the ORC system with other energy recovery technologies like heat pumps may improve performance.

- Initial Investment: While ORC systems can offer significant energy savings over time, the initial capital cost of purchasing and installing the system can be high. The return on investment (ROI) is generally seen over a period of several years, depending on the amount of waste heat available and the cost of energy in the region.

- Maintenance: ORC systems require regular maintenance to ensure optimal performance. Components like the turbine, heat exchangers, and pumps may require inspection and servicing to prevent operational inefficiencies or system failure. However, compared to other large-scale energy systems, ORC technology is typically considered low-maintenance once installed.

- System Integration: Integration of an ORC system with existing drying equipment and infrastructure may require some design work. Understanding the exhaust heat profile of the dryer and the required capacity of the ORC unit is critical to ensuring that the system operates efficiently. A thorough assessment of the dryer exhaust temperature, volume, and variability will help determine the ideal ORC system for a specific application.

Future Trends

- Hybrid Systems: The development of hybrid systems combining ORC technology with other waste heat recovery technologies could make dryer exhaust heat recovery more efficient. For example, heat pumps could be integrated into the system to raise the temperature of low-grade exhaust heat, improving the performance of the ORC system and allowing it to recover energy from a wider range of exhaust gases.

- Advancements in Working Fluids: Continued advancements in organic fluids will improve ORC systems’ ability to recover energy from lower temperature exhausts. New fluids that have better thermodynamic properties and lower environmental impacts will expand the application of ORC systems to even more industries, including those with lower-grade waste heat.

- IoT and Data Analytics: Smart sensors and data analytics will become increasingly integrated with ORC systems, allowing for real-time monitoring and optimization of system performance. By using predictive analytics, manufacturers can identify opportunities for improving energy recovery and system efficiency.

Conclusion

ORC systems for dryer exhaust heat recovery represent an innovative and effective solution to capture and utilize waste heat, making them an essential component in the drive toward greater energy efficiency and sustainability. With applications across multiple industries such as textiles, food processing, paper manufacturing, and biomass drying, ORC technology is well-positioned to reduce energy consumption, lower costs, and cut carbon emissions. By adopting ORC systems, manufacturers can not only improve their operational efficiency but also contribute to the global movement toward cleaner, more sustainable industrial practices.

ORC systems for dryer exhaust heat recovery represent a significant opportunity for industries to improve energy efficiency and reduce operational costs. These systems can transform waste heat from dryer exhaust gases, which are often released into the atmosphere, into useful electricity or thermal energy. The recovery of this waste heat can be used to power the facility’s operations, reducing reliance on external energy sources and lowering energy bills. Over time, this can result in substantial cost savings for manufacturers, offsetting the initial investment required for the system.

The adoption of ORC systems is particularly beneficial in industries with high drying demands, such as textiles, paper manufacturing, food processing, and biomass drying. These industries often generate large amounts of exhaust heat during the drying process, and ORC technology provides a means to recover this energy, making processes more sustainable. By utilizing energy that would otherwise be wasted, ORC systems help these industries meet sustainability goals, reduce their carbon footprint, and comply with increasingly stringent environmental regulations.

For companies operating in regions with high energy costs or unpredictable energy markets, the use of ORC systems can provide additional stability. By recovering waste heat from dryer exhausts, companies can reduce their dependence on external energy suppliers, mitigating the impact of rising energy prices and ensuring more predictable energy expenses. This is especially valuable in industries with large-scale drying operations that consume significant amounts of energy.

While the installation of an ORC system involves an initial capital investment, the long-term benefits typically outweigh the upfront costs. With careful planning and optimization, companies can see a rapid return on investment. The key to maximizing the financial benefits lies in accurately assessing the temperature and volume of waste heat available, ensuring the ORC system is appropriately sized for the specific needs of the facility. Some companies may even explore integrating other waste heat recovery technologies, such as heat pumps or heat exchangers, to enhance the overall system efficiency, especially if the dryer exhaust temperatures are lower than ideal for ORC performance.