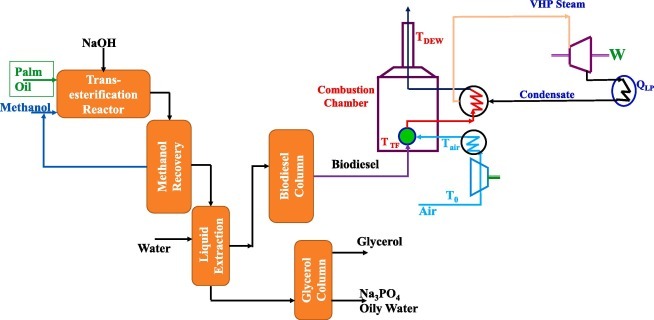

Municipal Solid Waste Plant: A Municipal Solid Waste (MSW) Plant is a large-scale facility designed to handle, process, and treat household and commercial waste generated in cities and towns. Its main purpose is to reduce the environmental and health impacts of waste by diverting it from open dumping or uncontrolled landfilling and instead converting it into useful products such as energy, recyclable materials, or compost.

Municipal Solid Waste Plant

At the core of an MSW plant is the waste reception and segregation system. When municipal trucks bring in mixed waste, the first step involves weighing and unloading at a controlled reception area. From there, waste is sorted into different streams—organic matter, recyclables like plastics, glass, and metals, and residuals that cannot be reused. Advanced plants use a combination of manual sorting and automated technologies such as conveyor belts, trommel screens, magnetic separators, air classifiers, and optical sorters to achieve efficient material recovery.

The organic fraction of MSW is often sent to composting units or anaerobic digesters. Composting produces a nutrient-rich soil conditioner, while anaerobic digestion generates biogas that can be used for electricity and heat. Recyclables are baled and sold to industries for reprocessing, reducing the need for virgin raw materials. Residual waste that cannot be recycled or composted is usually directed to waste-to-energy (WtE) incineration systems, where it is combusted under controlled conditions to produce steam and electricity. Modern incinerators are equipped with advanced flue gas cleaning systems to minimize emissions and meet strict environmental regulations.

For waste that is not recyclable or suitable for energy recovery, engineered sanitary landfills are used. These landfills incorporate leachate collection systems, gas recovery networks, and impermeable liners to prevent contamination of soil and groundwater. In many integrated MSW plants, landfill gas is captured and utilized as an additional energy source.

Municipal Solid Waste plants play a critical role in achieving a circular economy by maximizing resource recovery and minimizing environmental impact. They also provide a structured and hygienic approach to urban waste management, helping municipalities reduce greenhouse gas emissions, control public health risks, and meet sustainability targets.

The main types of Municipal Solid Waste (MSW) plants can be categorized based on how they handle, process, and recover resources from waste. Each type uses different technologies and strategies depending on the composition of the waste stream, local regulations, and sustainability goals. The main ones include:

- Material Recovery Facilities (MRFs)

These plants focus on separating and recovering recyclable materials such as paper, cardboard, plastics, glass, and metals. They can be “clean” MRFs (handling pre-sorted recyclables) or “dirty” MRFs (processing mixed MSW). Automated sorting equipment is often used, including conveyors, trommel screens, air classifiers, magnetic separators, and optical sorters. - Composting Plants

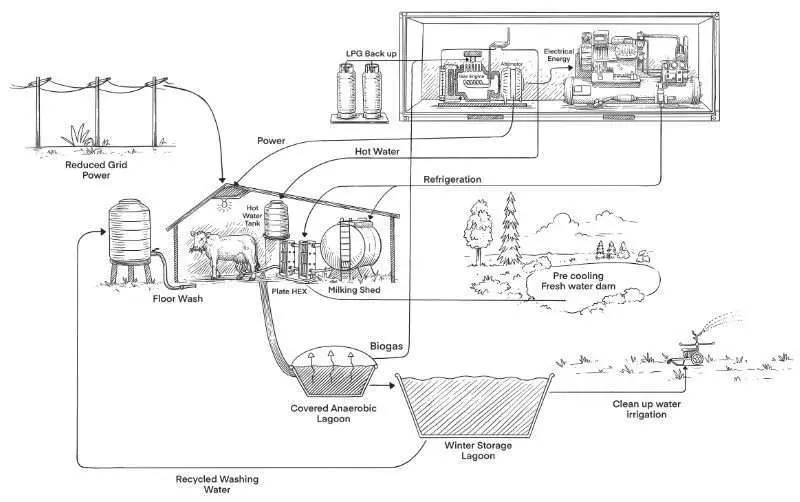

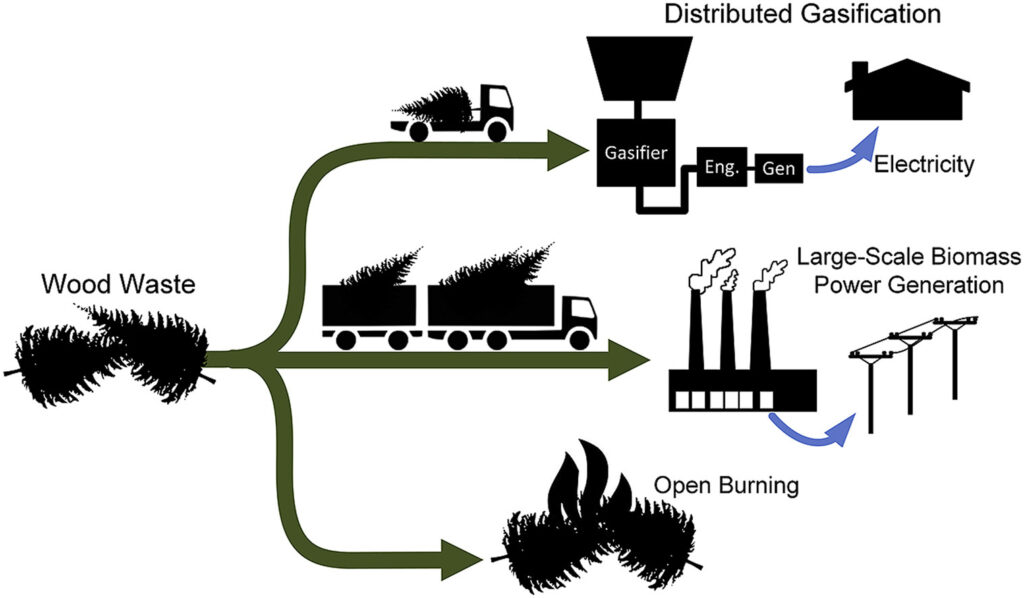

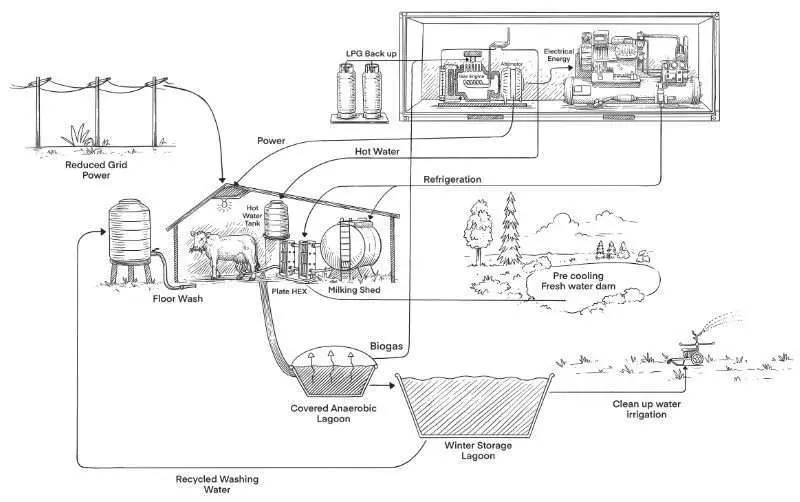

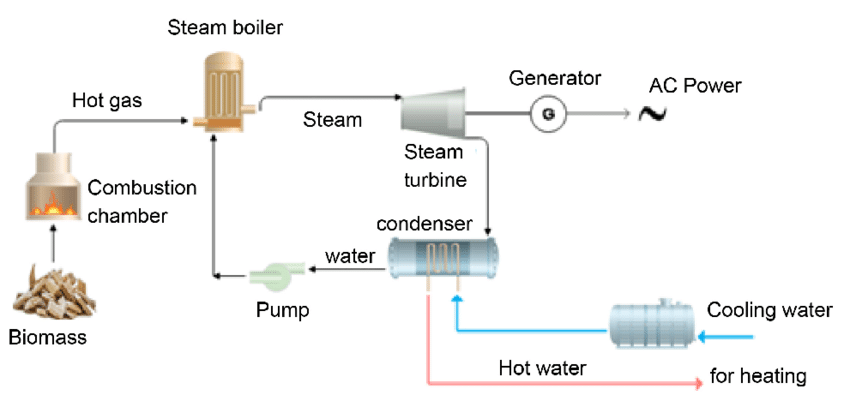

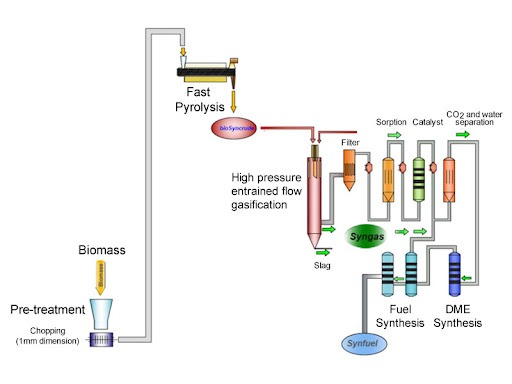

Designed to process the organic fraction of MSW—mainly food waste, yard trimmings, and biodegradable materials. Through aerobic decomposition, the waste is transformed into compost, which is a soil conditioner used in agriculture, landscaping, or land restoration. - Anaerobic Digestion (Biogas Plants)

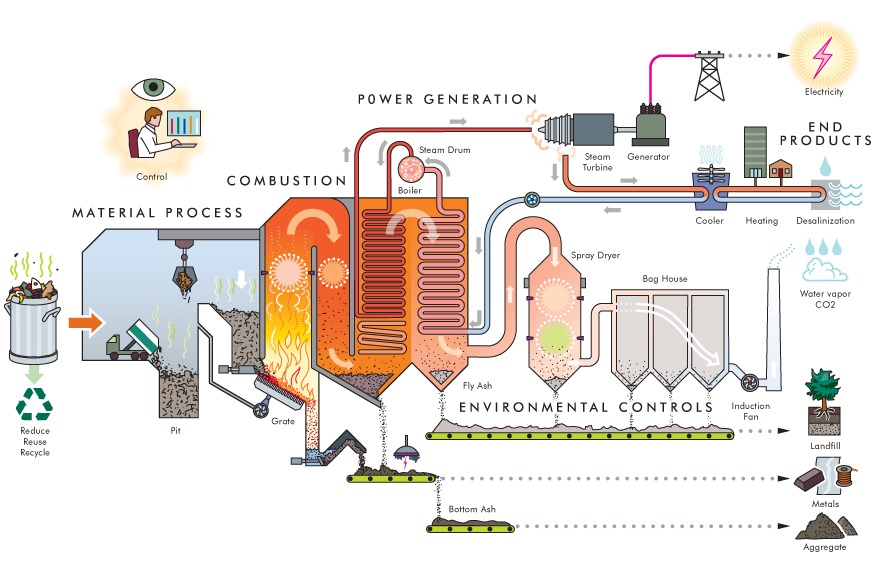

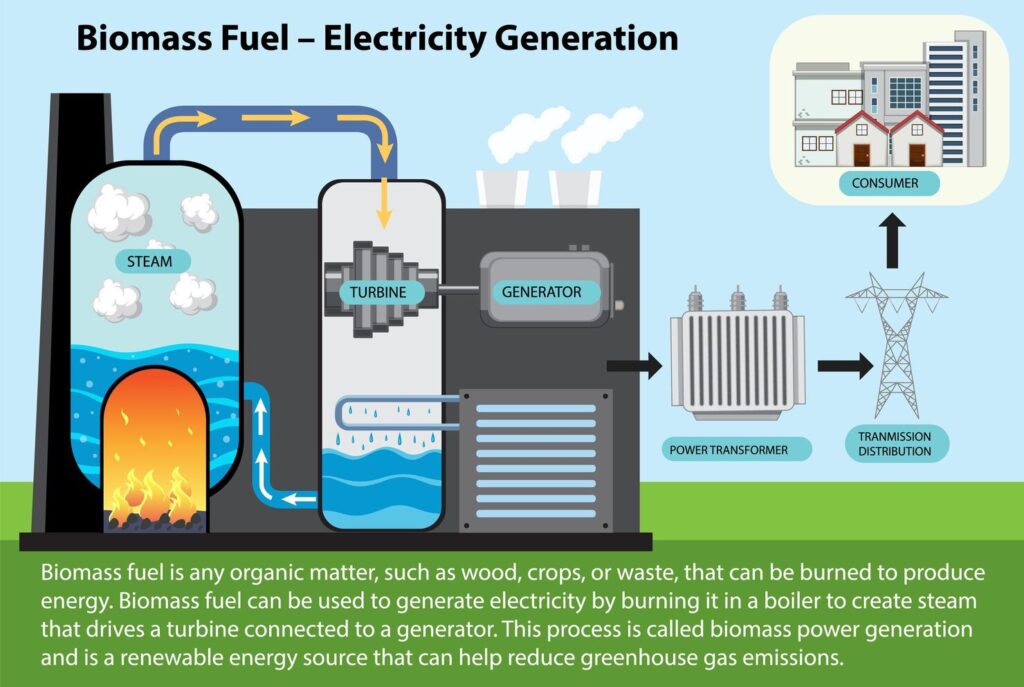

These plants treat organic waste under oxygen-free conditions to produce biogas (a mixture of methane and CO₂). The biogas can be used to generate electricity, heat, or upgraded to biomethane for injection into natural gas grids. The remaining digestate can be used as fertilizer. - Waste-to-Energy (WtE) Incineration Plants

Incinerators burn the combustible fraction of MSW at high temperatures to produce steam, which drives turbines to generate electricity and heat. Modern plants include advanced flue gas cleaning systems to control emissions. They significantly reduce waste volume (up to 90%) and provide energy recovery. - Refuse-Derived Fuel (RDF) and Solid Recovered Fuel (SRF) Plants

These plants process MSW to extract a fuel-rich fraction (plastics, paper, textiles, wood) which is shredded and prepared into a standardized fuel. RDF or SRF can be used in cement kilns, industrial boilers, or specialized power plants. - Sanitary Landfills with Energy Recovery

While landfilling is the least preferred option, engineered sanitary landfills are still common. They are equipped with liners, leachate collection systems, and landfill gas capture technology. Collected methane can be used for electricity generation or as an industrial fuel. - Integrated MSW Plants

Many modern facilities combine several of the above systems into a single integrated plant. For example, they may include a material recovery facility for recyclables, anaerobic digesters for organics, incinerators for residuals, and landfills for final rejects. This holistic approach maximizes resource recovery and minimizes environmental impact.

Material Recovery Facilities (MRFs)

A Material Recovery Facility (MRF) is one of the most important components of a modern municipal solid waste management system, as it is specifically designed to sort, separate, and prepare recyclable materials for further processing. Unlike disposal-oriented waste facilities, the purpose of an MRF is to maximize the recovery of valuable resources from the mixed waste stream, ensuring that materials such as paper, cardboard, plastics, metals, and glass are diverted from landfills and reintroduced into manufacturing cycles. By doing so, MRFs not only reduce the environmental burden associated with waste disposal but also support the concept of a circular economy by keeping resources in use for as long as possible.

The operation of an MRF begins with the reception of waste. Depending on the type of MRF, this can be either a “clean” stream of recyclables collected separately from households and businesses, or a “dirty” stream of mixed municipal solid waste that requires more extensive sorting. In both cases, trucks unload the waste onto a tipping floor where it is first visually inspected for contaminants or oversized items that could damage the equipment. From here, the material is fed onto conveyor belts that begin the journey through various stages of separation and sorting.

Mechanical equipment plays a central role in the efficiency of MRF operations. Trommel screens are used to separate materials by size, allowing finer organic particles and small debris to be filtered out while larger recyclables continue on. Air classifiers and ballistic separators help distinguish between light materials such as paper or plastic films and heavier items like glass or metal. Magnetic separators extract ferrous metals like steel, while eddy current separators target non-ferrous metals such as aluminum. Optical sorting systems, which use advanced sensors and near-infrared technology, are increasingly common for identifying and separating plastics by resin type or color. Manual sorting stations are also included, where workers remove items that automated systems might miss or misclassify, ensuring higher quality output.

Once the materials have been properly separated, they are cleaned, compacted, and baled into standardized units for transportation. These bales are then sold to recycling industries where they are reprocessed into raw materials for new products. For example, paper and cardboard are pulped and remade into packaging, aluminum cans are melted and reformed, and plastics are shredded, washed, and pelletized for reuse in manufacturing. The value of these secondary raw materials can vary depending on global commodity markets, and so the economics of an MRF are closely linked to recycling demand and pricing trends.

Environmental benefits are a strong justification for the existence of MRFs. By diverting recyclables from landfills, MRFs help reduce methane emissions associated with decomposing waste. They also lower the demand for virgin raw materials, thereby conserving energy and natural resources. For instance, recycling aluminum uses up to 95% less energy than producing it from bauxite ore. Similarly, recycling paper saves water, reduces deforestation, and cuts down on pollution from the pulp and paper industry.

However, MRFs also face challenges. Contamination of the waste stream, such as food-soiled paper, plastic bags, or hazardous materials, can reduce the quality of recyclables and increase processing costs. Public education on proper waste separation is therefore essential to support efficient MRF operations. Additionally, the volatility of global recycling markets means that some materials may be less profitable to process, creating financial pressures on facility operators.

Despite these challenges, MRFs remain indispensable in modern waste management systems. They are evolving to incorporate more automation, artificial intelligence, and robotics to improve sorting precision and reduce labor dependency. Many new-generation facilities are designed as part of integrated waste management plants, combining recycling, composting, energy recovery, and landfill management into a single coordinated system. In this way, Material Recovery Facilities play a key role not only in handling waste more responsibly but also in shaping a more sustainable future where resources are continuously recovered and reused.

A Material Recovery Facility (MRF) is an essential part of any modern municipal solid waste management system, since it provides the infrastructure, technology, and operational framework necessary to transform a mixed and often contaminated waste stream into valuable resources that can re-enter the industrial cycle. Unlike traditional disposal approaches that primarily focus on landfilling or incineration, MRFs are designed with a resource-centric perspective, aiming to maximize the recovery of materials such as paper, cardboard, plastics, metals, and glass. The main goal is to minimize the amount of waste that is finally disposed of, while increasing the proportion of waste that can be recycled or reused. This shift in focus not only reduces the environmental footprint associated with waste management but also fosters a circular economy model where waste is no longer seen as an unwanted burden but rather as a source of secondary raw materials.

The way a material recovery facility operates depends largely on the type of system in place, which can be broadly categorized into clean MRFs and dirty MRFs. A clean MRF processes recyclables that have already been separated at the source by households, businesses, or institutions. This type of system is generally more efficient, since the incoming material has lower contamination levels and can be processed into higher-quality outputs with greater market value. A dirty MRF, on the other hand, receives mixed municipal solid waste, which requires extensive sorting to extract recyclables from organic material, residuals, and contaminants. While this approach is more complex and less efficient, it has the advantage of capturing recyclables even when source separation practices are weak or poorly enforced, thereby ensuring that valuable resources are not lost to landfills or incinerators.

The internal workflow of an MRF is highly mechanized, though manual intervention still plays an important role. Waste is first unloaded onto the tipping floor and then placed on conveyor systems that transport it through various separation stages. Trommel screens rotate and sift the waste, separating finer particles like dirt and small organics from larger items. Air classifiers and ballistic separators further separate materials based on density and shape, distinguishing lightweight materials such as plastic films from heavier components like glass bottles or aluminum cans. Magnetic separators are used to extract ferrous metals such as steel, while eddy current systems target non-ferrous metals like aluminum. Advanced optical sorters have become increasingly important, using near-infrared technology, color recognition, and even artificial intelligence to distinguish between different types of plastics, ensuring that polyethylene terephthalate, polyethylene, polypropylene, and other resins are directed to the correct processing stream. Manual sorting stations are integrated into the line to capture items that automated systems miss, remove contaminants, and ensure that quality standards are met for each category of material.

Once separated, materials are compacted and baled to meet industry standards for transportation and sale. These bales are then shipped to specialized recycling industries where they are reprocessed into new raw materials. For example, paper and cardboard are pulped and remade into packaging products, aluminum cans are melted and reformed into new cans or industrial components, and plastics are washed, shredded, and pelletized for reuse in manufacturing consumer goods. The revenue generated from selling these secondary raw materials is a key economic driver for MRFs, but it is also subject to fluctuations in global recycling markets, which can make the operation of such facilities financially challenging. Nonetheless, by providing a steady supply of recycled materials, MRFs reduce dependence on virgin raw material extraction, lower greenhouse gas emissions, and contribute to resource conservation at a global scale.

Environmental benefits are among the strongest arguments in favor of expanding and improving MRF systems. Recycling aluminum saves up to 95 percent of the energy required to produce it from bauxite ore, while recycling paper helps preserve forests, reduces water usage, and lowers air pollution associated with pulp and paper mills. The diversion of plastics from landfills and incinerators not only reduces waste volume but also prevents plastic pollution in ecosystems and oceans. Moreover, by diverting organic-contaminated materials from disposal, MRFs indirectly reduce methane emissions, since less biodegradable waste ends up decomposing anaerobically in landfills. In this way, material recovery facilities play an important role in climate change mitigation strategies adopted by many municipalities and governments worldwide.

Despite their benefits, MRFs face significant operational and strategic challenges. One of the main issues is contamination of the recycling stream, which reduces the value of sorted materials and increases processing costs. Items such as food-soiled packaging, plastic bags, or hazardous household waste can damage equipment, pose health risks to workers, and lower the quality of recyclables. Public education and outreach programs are therefore essential to improve source separation and reduce contamination. Another challenge lies in the volatility of global recycling markets. For example, changes in international trade policies, such as restrictions on the import of recyclables by certain countries, can disrupt the economics of MRFs, leaving operators with large stockpiles of unsellable material. Addressing these issues often requires public subsidies, long-term contracts with recycling industries, and diversification of end markets for recycled products.

Technological innovation is helping MRFs adapt to these challenges. Robotics and artificial intelligence are increasingly being deployed in sorting lines, where robotic arms equipped with cameras and sensors can identify and pick specific materials with high speed and accuracy. These systems not only improve sorting precision but also reduce dependence on manual labor in environments that can be physically demanding and sometimes hazardous. Data analytics and real-time monitoring systems are also being integrated into MRF operations, allowing managers to track material flows, contamination levels, and equipment performance more effectively. As these technologies mature, the efficiency, profitability, and sustainability of MRFs are expected to improve significantly.

The role of material recovery facilities goes beyond waste processing—they are central to the vision of a sustainable and circular economy. By providing a reliable supply of recycled materials, they enable industries to reduce their reliance on virgin resources, cut down on energy consumption, and lower production costs in the long run. Municipalities that invest in MRF infrastructure are not only improving their waste management systems but also creating green jobs, stimulating local recycling industries, and meeting sustainability goals related to emissions reduction and resource conservation. The future of waste management will likely see MRFs integrated with other advanced facilities such as anaerobic digestion plants, composting units, and waste-to-energy systems, creating fully closed-loop waste management hubs that maximize recovery, minimize disposal, and contribute to cleaner, more resilient urban environments.

The main parts of a Material Recovery Facility (MRF) can be described as the key systems and equipment that enable the sorting, separation, and preparation of recyclables from mixed municipal solid waste or source-separated recycling streams. Each part has a specific role, and together they form a coordinated process that moves waste from reception to high-quality recovered materials.

At the entrance of the facility, the tipping floor and reception area are the first main part. This is where waste trucks unload their contents for initial inspection and handling. Here, oversized or hazardous items are often removed manually to prevent damage to equipment or safety hazards during processing. The design of the tipping floor is crucial to allow for continuous feeding of waste into the system and to handle peak loads efficiently.

Next comes the conveyor system, which forms the backbone of the facility. Conveyors transport materials through each stage of separation and ensure a steady, controlled flow. The layout of conveyors determines the efficiency of the plant, since every machine in the line depends on the correct spacing, speed, and orientation of waste on the belts.

A critical group of components are the screening and separation systems, which sort materials by size, weight, and shape. Trommel screens, which are rotating cylindrical sieves, separate fine particles like dirt, glass shards, and small organics from larger recyclables. Disc screens or star screens are also used to separate flat items such as paper and cardboard from containers like bottles and cans. Air classifiers or ballistic separators further divide materials by density and shape, directing light materials such as paper and plastic films to one stream and heavier items like metals and glass to another.

The metal recovery systems are another key part. Magnetic separators are installed along the conveyor lines to capture ferrous metals like steel cans, while eddy current separators use induced currents to eject non-ferrous metals such as aluminum. These systems recover high-value materials and play a major role in the financial viability of MRFs.

For plastics and other mixed recyclables, optical sorting systems are increasingly vital. Using near-infrared sensors, cameras, and air jets, these machines can identify different types of plastics, cartons, or paper grades and direct them into the correct stream with high precision. This level of separation is necessary to meet the stringent quality requirements of recycling industries and global markets.

Even with advanced technology, manual sorting stations remain a key part of most facilities. Human operators work along conveyor lines to remove contaminants, capture items missed by machines, and ensure that each output stream maintains high purity. Manual sorting is also used to target materials that are difficult for machines to identify, such as flexible packaging, odd-shaped containers, or mixed-material items.

Once separated, materials pass to the compaction and baling systems, which compress recyclables into dense, uniform bales that can be easily stored, transported, and sold. Balers are designed to handle different types of materials, and the resulting bales must meet industry standards for size, weight, and contamination levels.

Finally, every modern MRF includes residue handling systems for materials that cannot be recycled. These non-recoverable wastes are collected and sent to landfills, incineration, or other disposal methods. Efficient residue management is important to maintain cleanliness, reduce fire risks, and keep overall operations running smoothly.

Supporting all of these parts are control and monitoring systems, which oversee the entire process. Modern facilities use computerized systems, sensors, and sometimes AI-based analytics to optimize throughput, track material recovery rates, and detect issues in real time. This ensures maximum efficiency and allows operators to adapt quickly to changing waste compositions.

1. Tipping Floor and Reception Area

This is the first stage of the facility where incoming waste is unloaded from collection trucks. The tipping floor acts as a buffer zone, allowing operators to visually inspect the load for oversized, hazardous, or inappropriate materials that could damage downstream equipment. A well-designed reception area ensures a continuous feed into the processing line and accommodates fluctuations in daily waste volumes.

2. Conveyor System

Conveyors form the backbone of an MRF, linking all the machinery and enabling a steady, controlled flow of materials. They move waste from one stage of separation to another and are often designed with variable speeds to optimize sorting efficiency. The arrangement of conveyors is carefully engineered to minimize blockages and ensure consistent throughput across the facility.

3. Screening and Separation Equipment

MRFs rely heavily on screening systems to sort materials based on size, weight, and shape. Trommel screens separate fine particles such as dirt and broken glass from larger recyclables, while disc or star screens divide flat items like paper and cardboard from three-dimensional containers such as bottles and cans. Ballistic separators and air classifiers further refine this process by separating light materials from heavier ones.

4. Metal Recovery Systems

Metals are among the most valuable materials recovered in an MRF. Magnetic separators are used to extract ferrous metals like steel cans, while eddy current separators recover non-ferrous metals such as aluminum. These systems ensure that metals are diverted from the waste stream and baled for recycling into new industrial products.

5. Optical Sorting Systems

Modern MRFs often include advanced optical sorters, which use near-infrared sensors and cameras to identify different materials by their physical and chemical properties. Once identified, targeted items are separated using high-pressure air jets. Optical sorting is particularly effective for plastics, where it can distinguish between PET, HDPE, and other resins, ensuring high-quality recycling outputs.

6. Manual Sorting Stations

Despite automation, manual sorting remains an important part of most MRFs. Human operators stationed along conveyors remove contaminants, recover misplaced recyclables, and ensure the purity of output streams. Manual sorting is also useful for handling materials that machines cannot easily identify, such as mixed-material packaging or irregularly shaped items.

7. Compaction and Baling Systems

After separation, recovered materials must be prepared for transport and sale. Balers compress recyclables into dense, uniform bales that meet industry standards for weight and size. Baling improves storage efficiency and reduces transportation costs, making it easier to move large volumes of recyclables to reprocessing plants.

8. Residue Handling Systems

Not all materials entering an MRF can be recycled. Residual waste, which may include contaminated or non-recyclable items, is collected and directed to landfills, incinerators, or waste-to-energy plants. Effective residue handling ensures operational safety, reduces the risk of fire, and maintains overall facility cleanliness.

9. Control and Monitoring Systems

Modern facilities rely on digital control rooms, sensors, and real-time monitoring systems to oversee operations. These systems track material flows, contamination levels, equipment performance, and recovery rates. Advanced facilities are increasingly integrating artificial intelligence and robotics, enabling better decision-making and higher efficiency in material recovery.

Tipping Floor and Reception Area

The tipping floor and reception area of a Material Recovery Facility (MRF) represent the first and one of the most critical stages in the entire waste processing operation. This is the entry point where municipal collection trucks arrive, unload their contents, and where the raw waste stream begins its transformation into sorted and recoverable materials. The design and operation of this part of the facility have a significant impact on the efficiency, safety, and cleanliness of the overall process, as everything that happens downstream depends on how well waste is received, inspected, and prepared for feeding into the system.

When a truck enters the facility, it is usually weighed on a scale to register the incoming tonnage of municipal solid waste or recyclables. Accurate weighing is essential for tracking performance, billing municipalities, and recording recovery rates later in the process. After this step, the vehicle is directed to the tipping floor, which is typically a large, reinforced concrete area designed to withstand the constant heavy loads of trucks and loaders. The floor itself must be durable, resistant to wear, and easy to clean, since it will constantly be exposed to large amounts of mixed waste that often contain liquids, fine debris, and contaminants.

Once the truck empties its load onto the floor, operators and facility staff have the opportunity to perform an initial inspection. This inspection is crucial to identify oversized or hazardous materials such as gas cylinders, car batteries, construction debris, or even electronic waste that could damage the processing equipment or create safety risks. Removing such items early helps protect both the machinery and the workers involved in later stages. At this point, bulky waste may also be set aside for specialized processing, while more manageable waste is gathered and directed toward the main feed conveyors.

The design of the tipping floor includes considerations for workflow and safety. Clear traffic management systems must be in place to ensure that collection trucks, loaders, and staff can operate without accidents. Ventilation and dust suppression systems are also important, as waste unloading can generate dust, odors, and emissions that need to be controlled to maintain acceptable working conditions. In enclosed facilities, negative air pressure and air filtration systems may be used to reduce odor leakage and improve air quality. Proper drainage is another critical factor, as liquids present in the waste can accumulate and create hygiene issues if not properly managed.

From the tipping floor, waste is typically pushed by front-end loaders or mechanical grabs onto conveyor belts that transport the material into the next stage of sorting. The efficiency of this feeding process determines whether the facility can maintain a steady flow of material, which is essential for continuous operation of downstream equipment. If the flow is too irregular, the entire system can suffer from bottlenecks or downtime. In some facilities, metering bins or hoppers are used to regulate the feed rate, ensuring that sorting machinery receives a consistent input.

The tipping floor and reception area also serve as the primary point for contamination control. Contamination, such as food waste mixed with recyclables, non-recyclable plastics, or hazardous materials, poses one of the biggest challenges for MRFs. Identifying and removing contaminants at this stage reduces the burden on sorting equipment and improves the quality of the recovered materials. Facilities that handle source-separated recyclables typically face lower contamination levels, while dirty MRFs dealing with mixed municipal waste require more thorough inspection and handling.

Finally, this part of the facility is also where overall efficiency and cost-effectiveness are influenced. A well-managed tipping floor allows for faster turnaround of collection trucks, which reduces waiting times and helps municipalities complete their waste collection routes more efficiently. Moreover, by ensuring proper inspection, contamination removal, and steady feeding of waste, the tipping floor establishes the foundation for successful material recovery in all subsequent stages of the plant. In essence, it is not just a simple unloading area but a highly functional and strategically important component that determines the success of the entire recycling process.

The tipping floor and reception area in a Material Recovery Facility is far more than just a dumping ground for waste; it is the first stage of transformation where the journey of mixed municipal solid waste or pre-sorted recyclables begins. Every truck that arrives at the facility carries the combined efforts of a city’s waste collection system, and the moment it enters the reception area marks the start of an intricate process designed to turn discarded materials into valuable resources. Trucks are weighed before unloading to register the exact tonnage received, a step that is critical not only for operational records but also for performance tracking, billing accuracy, and efficiency monitoring. The floor itself is a massive concrete surface engineered to handle the constant weight and stress of heavy vehicles, loaders, and compactors. It must resist abrasion from sharp debris, corrosion from liquids and chemicals present in the waste stream, and withstand daily cleaning operations. The layout is carefully planned so that vehicles can maneuver efficiently, unload without delay, and exit the area quickly, minimizing congestion and maximizing throughput.

Once waste is deposited on the tipping floor, the inspection process begins. This is the moment where operators and trained staff visually scan the load to identify problematic or hazardous items that could pose risks further along the processing line. Large, bulky, or dangerous objects such as gas cylinders, batteries, concrete blocks, electronic appliances, or tangled wires are immediately removed. Doing this at the reception stage is crucial because it protects delicate sorting equipment downstream from damage, reduces downtime due to breakdowns, and ensures worker safety. In addition, this first round of screening already sets the tone for contamination control, since items that do not belong in the recycling stream, such as food-soiled packaging or medical waste, can compromise the quality of the recovered materials if allowed to pass through the system. The tipping floor is therefore not just an unloading zone but a critical checkpoint where the waste stream is stabilized, pre-sorted, and prepared for controlled feeding into the conveyors.

To maintain efficiency, loaders or grabs move the piles of waste from the reception floor onto conveyor belts that lead into the mechanical separation systems. This transition must be smooth and steady, since the entire facility depends on maintaining a continuous flow of material. Any irregularities in this feed, whether from truck scheduling delays, poor floor management, or uneven loading practices, can create bottlenecks that ripple through the entire operation. To address this, some facilities use hoppers or metering bins that regulate the rate at which waste enters the sorting line, ensuring a balanced and consistent supply for the downstream equipment. This level of control is vital in a system that processes hundreds of tons per day, as it minimizes stress on machines, optimizes throughput, and reduces the risk of stoppages.

Another important consideration in the design and management of the tipping floor and reception area is hygiene and environmental control. Waste arriving at this stage is often a mixture of dry recyclables, organic residues, and liquids, all of which can generate odors, dust, and leachate. Without proper ventilation, drainage, and dust suppression systems, the reception area can quickly become a source of environmental nuisance and health hazards for workers. Enclosed facilities often use negative air pressure systems combined with air filtration to prevent odors from escaping into surrounding neighborhoods, while drainage channels and collection systems manage liquids to prevent contamination of floors and reduce the spread of pathogens. These measures are essential not only to maintain compliance with environmental regulations but also to ensure a safe and acceptable working environment.

The efficiency of the tipping floor also impacts the larger municipal waste management system. Faster unloading and processing of trucks means that waste collection routes can be completed more quickly, reducing costs for municipalities and freeing up vehicles for additional runs. A poorly managed floor, on the other hand, can result in long queues of waiting trucks, wasted fuel, and delays that affect entire neighborhoods. Therefore, the design and operation of this area must balance capacity, safety, and speed. Furthermore, by allowing for proper inspection and early removal of contaminants, the tipping floor enhances the quality of recyclables recovered later, supporting the economic sustainability of the facility by producing higher-grade material for resale to recycling industries.

In a broader sense, the tipping floor and reception area embody the philosophy of efficiency and control that defines a Material Recovery Facility. They represent the interface between the chaotic, unsorted waste generated by society and the highly organized, mechanical, and market-driven processes of material recovery. A well-designed reception system transforms disorder into order, setting the pace for the rest of the facility and determining how effectively resources can be extracted from what was once considered garbage. As waste management practices evolve and facilities adopt more automation, robotics, and artificial intelligence, the tipping floor remains the human-controlled gateway where oversight, adaptability, and experience continue to play a vital role in ensuring that the rest of the process functions smoothly.

The conveyor system in a Material Recovery Facility is often described as the backbone of the entire operation because it serves as the continuous link that carries waste through every stage of processing, from the reception area to the final baling stations. Without an efficient conveyor system, the complex sequence of sorting, screening, separating, and recovering materials would not be possible, as all the machinery in the facility depends on a steady and controlled flow of waste. Conveyors are designed to withstand the harsh conditions of handling mixed municipal solid waste, which can include everything from lightweight plastic films and cardboard to heavy glass bottles, metals, and even unexpected contaminants. Their structure must be robust, resistant to abrasion, and adaptable to variations in load and material type. Most MRFs use a combination of belt conveyors, chain conveyors, and vibrating conveyors, each chosen according to the type of material being transported and the process requirement. The belts themselves are reinforced with layers of rubber, steel, or synthetic fabrics to ensure durability, while the frames and rollers are engineered to minimize downtime and resist the wear that comes from constant use.

The movement of materials through the conveyor system is not random; it is carefully engineered to maintain balance and consistency in flow. If the waste enters the sorting line in irregular bursts or uneven piles, the downstream machines cannot function at their optimal capacity. To solve this problem, facilities often use feeders and metering bins at the start of the conveyor system. These devices regulate the rate at which waste is released from the tipping floor, breaking down large piles into a more even stream that can be handled effectively by trommel screens, separators, and optical sorters. The ability to control the flow of material in this way not only prevents bottlenecks but also protects sensitive sorting equipment from sudden overloads, reducing the risk of mechanical failures. Smooth feeding is particularly important in facilities that process mixed municipal solid waste, where density and composition can vary significantly from one load to another.

As the waste travels along the conveyors, it passes through different separation stages, and the system itself must be adaptable to these transitions. Inclined conveyors lift materials to elevated sorting platforms, while horizontal conveyors provide access for workers at manual sorting stations. Some conveyors are fitted with variable speed drives, allowing operators to slow down or speed up the line depending on the type of material being processed or the level of contamination detected. In advanced MRFs, the conveyor system is integrated with real-time monitoring and control systems, enabling managers to track flow rates, detect blockages, and adjust settings remotely to maximize efficiency. This level of automation ensures that the facility can handle large volumes of waste without frequent interruptions, maintaining the balance between throughput and quality of recovered materials.

The conveyor system also plays a crucial role in worker safety and ergonomics. Manual sorting stations are positioned along specific sections of the conveyors, where operators have access to the waste stream to remove contaminants or recover valuable materials. For this to be effective, the conveyors must be designed at appropriate heights and widths, with guardrails, emergency stop systems, and adequate lighting to create a safe working environment. Noise and dust control are also important considerations, since conveyors generate constant mechanical movement that can contribute to difficult working conditions if not managed properly. By integrating protective features and ensuring ergonomic layouts, the conveyor system becomes not only an efficient material transport network but also a workspace that supports human involvement in the recovery process.

At the later stages of the MRF, conveyors are responsible for delivering separated streams of materials to their designated destinations. Paper and cardboard are sent to balers, metals are directed to storage bins after magnetic or eddy current separation, and plastics are transported to further processing areas where optical sorters refine them by resin type. Even residual waste that cannot be recycled is carried away by conveyors to compactors or transport containers for disposal in landfills or waste-to-energy plants. The flexibility of the conveyor system allows it to handle these multiple material streams simultaneously, coordinating the entire operation and ensuring that each type of material is directed toward the right output channel.

In essence, the conveyor system is not just a passive transport mechanism but an active component of the MRF’s efficiency, productivity, and adaptability. It provides the rhythm that the entire facility follows, ensuring that waste moves at a controlled pace through the different sorting and recovery stages. When designed and managed effectively, it minimizes downtime, enhances worker safety, and enables precise coordination of mechanical and manual sorting efforts. As technology evolves, conveyors are being increasingly equipped with sensors, smart controls, and predictive maintenance systems that allow operators to identify potential issues before they cause disruptions. This continuous improvement makes the conveyor system a vital foundation for the smooth and reliable functioning of modern Material Recovery Facilities, allowing them to meet the growing demands of urban waste management while maximizing resource recovery.

Screening and separation equipment in a Material Recovery Facility is one of the most critical stages in the journey from mixed municipal solid waste to sorted, marketable recyclables, because this is where the waste stream is divided according to size, density, weight, and material properties. The first machines that the material usually encounters are trommel screens or disc screens, which are designed to separate smaller particles such as glass shards, food waste, and dirt from larger items like cardboard, plastics, and metals. A trommel screen consists of a rotating cylindrical drum with perforations that allow smaller materials to fall through while the larger pieces continue to move along. This simple mechanical process provides an essential first cut that prepares the waste stream for further, more specialized separation. Disc screens, on the other hand, use rotating shafts fitted with discs that agitate and spread materials, separating flat items such as cardboard and paper from three-dimensional containers. Both systems reduce the complexity of the waste stream, enabling downstream machines to work more efficiently.

After the size-based separation, air classifiers often come into play, particularly in facilities that deal with high volumes of lightweight plastics and films. These machines use streams of air to blow lighter materials into one path while allowing heavier materials to fall onto another conveyor. This process is invaluable in dealing with plastic bags, foils, and other films that can otherwise tangle and clog sorting lines. By separating these problematic items early, air classifiers ensure smoother operation throughout the system. Similarly, density separators and ballistic separators help distinguish between materials not only by weight but also by shape and rigidity. A ballistic separator, for example, can split the stream into flat fractions such as paper, rolling fractions like bottles and cans, and fine materials that fall through screens. Each of these technologies contributes to breaking down the waste flow into more manageable categories, reducing contamination and improving the purity of the recovered recyclables.

Magnetic separation is another cornerstone of MRF operations. Powerful magnets are strategically positioned along conveyors to remove ferrous metals such as iron and steel from the stream. These metals are easily attracted and separated without requiring manual intervention, making the process both fast and reliable. For non-ferrous metals like aluminum, eddy current separators are employed. These machines use rapidly rotating magnetic fields to induce electric currents in the non-ferrous metals, repelling them from the rest of the waste and directing them into separate collection bins. This combination of magnetic and eddy current separation ensures that all valuable metals are recovered, preventing them from being lost to landfills and allowing them to reenter the manufacturing cycle.

Optical sorters represent one of the most advanced forms of separation technology in modern MRFs. Using cameras, sensors, and high-speed air jets, these machines can identify and eject specific types of plastics, glass, or paper based on color, chemical composition, or reflective properties. For example, an optical sorter can differentiate between PET and HDPE plastics, sending each into separate chutes with remarkable precision. This is particularly important for plastics recycling, as mixing different resin types reduces the quality and usability of the final recycled product. Optical sorters are highly versatile and can be programmed to adapt to changing waste streams, making them indispensable in facilities aiming for high recovery rates and low contamination levels.

Glass processing often requires specialized equipment because broken glass behaves differently from other materials in the waste stream. After being separated by size, glass is further cleaned to remove contaminants such as paper labels, plastic caps, and metals. Vibrating screens and air suction systems are commonly used to refine the glass fraction. The cleaned glass, known as cullet, can then be sent directly to glass manufacturers for reuse in new bottles and containers, closing the recycling loop.

Altogether, screening and separation equipment forms the technological heart of a Material Recovery Facility. Each stage progressively refines the waste stream, reducing contamination and increasing the purity of recyclable outputs. Without this machinery, MRFs would be unable to meet the quality standards required by recycling markets, where buyers demand consistent, clean material. The seamless integration of trommels, air classifiers, ballistic separators, magnetic systems, eddy current machines, and optical sorters ensures that every material type finds its correct pathway, maximizing recovery and minimizing landfill disposal. The efficiency of this equipment directly determines the financial viability and environmental impact of the facility, making it one of the most heavily invested and continuously evolving aspects of modern waste management infrastructure.

Conveyor System

The conveyor system in a Material Recovery Facility functions as the vital circulatory network of the entire operation, transporting materials from one stage of processing to the next and ensuring that the flow of waste remains continuous, controlled, and optimized for sorting efficiency. From the moment materials leave the tipping floor, conveyors carry them through a complex series of screens, separators, and sorting stations, making it possible for every type of recyclable to be extracted from the mixed municipal solid waste stream. These systems are engineered to handle a wide variety of materials, ranging from lightweight plastics and paper to heavier metals and glass, all while withstanding the abrasive, irregular, and sometimes hazardous nature of the waste itself. Conveyor belts are typically reinforced with rubber, steel, or composite materials to ensure durability and longevity, and the supporting frames, rollers, and motors are designed to resist wear, corrosion, and continuous heavy use. Some facilities also incorporate vibrating or slat conveyors to handle specific types of materials that might otherwise stick, jam, or slide off standard belts.

The movement of materials along the conveyor system is carefully controlled to maintain a balanced flow and prevent bottlenecks. Feeders, hoppers, and metering bins are strategically placed at the entrance to regulate the quantity and speed of waste entering the line. This ensures that trommel screens, air classifiers, magnetic separators, and optical sorters all receive a steady stream of material that they can process efficiently. Without this regulated flow, sorting machinery would be subject to uneven loading, potential jams, and decreased throughput, ultimately reducing recovery rates and increasing wear on equipment. Advanced conveyor systems often feature variable speed drives and automated controls, which allow operators to adjust belt speed in real time according to material type, contamination levels, or the capacity of downstream machines, ensuring optimal performance under changing conditions.

Beyond simply transporting waste, conveyors are integral to the ergonomics and safety of the facility. Manual sorting stations are positioned along key points of the conveyor system, where human operators can remove contaminants and recover items that machines might miss. For these stations to be effective, conveyors must be designed at suitable heights and widths, with adequate spacing for workers, emergency stop systems, and protective barriers. Dust suppression systems and noise reduction measures are also important, as conveyors contribute to airborne particles and mechanical noise throughout the facility. Proper design not only protects workers but also ensures consistent productivity, which is critical in high-volume facilities that process hundreds of tons of waste per day.

At later stages, conveyors are responsible for directing sorted materials to their respective endpoints. Paper and cardboard are carried to balers, metals are moved to storage bins after magnetic or eddy current separation, and plastics are delivered to optical sorting or shredding stations. Even residual waste that cannot be recycled is transported via conveyors to compactors or containers for landfilling or waste-to-energy treatment. The flexibility and adaptability of conveyors allow multiple material streams to run simultaneously, coordinated in a way that maximizes recovery and minimizes contamination. Each conveyor must be carefully aligned, monitored, and maintained to ensure that materials reach the correct processing stage without spillage, overlap, or loss.

In modern MRFs, the conveyor system is increasingly integrated with digital control and monitoring technologies. Sensors along the belts track material flow, detect blockages, and measure weight and volume, feeding data into control systems that optimize throughput and maintenance schedules. Predictive maintenance technologies help anticipate wear or mechanical failure before it disrupts operations, reducing downtime and operational costs. Some advanced facilities even incorporate robotic interventions along conveyor lines, allowing machines to automatically remove contaminants or redirect materials with high precision, further enhancing recovery rates and operational efficiency.

Overall, the conveyor system is far more than a simple mechanical transport network; it is the circulatory and operational backbone of the MRF, ensuring that materials flow smoothly, sorting machinery operates efficiently, and recovered recyclables are delivered to the proper endpoints. Its design, capacity, and control directly affect the facility’s throughput, safety, and ability to produce high-quality recycled materials. By combining robust mechanical construction with automation, monitoring, and ergonomics, the conveyor system transforms a chaotic stream of incoming waste into a structured, controllable flow, laying the foundation for the successful separation and recovery of valuable resources.

Metal recovery systems in a Material Recovery Facility are among the most crucial components, as they are responsible for extracting high-value metals from the mixed waste stream, ensuring that both ferrous and non-ferrous metals are recovered efficiently and returned to the manufacturing cycle. Ferrous metals, which include steel and iron, are typically the first to be removed using powerful magnetic separators. These systems generate a magnetic field that attracts and lifts ferrous materials from the conveyor, diverting them into dedicated collection bins. This not only protects downstream equipment from damage—since metal fragments can jam or wear mechanical components—but also guarantees that valuable resources are not lost to landfill. Magnetic separation is highly effective, able to handle large volumes of metal objects such as steel cans, appliances, and metal fragments embedded in other waste, and is usually installed at multiple points along the conveyor line to maximize recovery rates.

Non-ferrous metals, such as aluminum and copper, are recovered using eddy current separators, which operate on a completely different principle. These machines induce a rapidly changing magnetic field, generating electric currents in conductive non-ferrous metals. The interaction of these currents with the magnetic field creates a repulsive force, effectively ejecting metals like aluminum cans, foil, and other non-ferrous components from the waste stream. Eddy current systems are carefully calibrated to separate metals from plastics, glass, and other materials without causing cross-contamination or loss of recyclable items. In combination with magnetic separation, eddy current systems enable a facility to capture nearly all metals from a waste stream, transforming what would otherwise be low-value residuals into marketable raw materials with strong industrial demand.

In addition to the basic separation of metals, metal recovery systems often include pre-processing elements such as shredders, crushers, or balers that reduce the size of large metal objects, making them easier to handle and transport. Shredding also exposes embedded metals in mixed materials, allowing magnetic or eddy current systems to extract metals more effectively. For example, aluminum from composite packaging or metal straps from cardboard can be liberated and captured after pre-shredding. This process enhances recovery efficiency and ensures that materials meet the quality standards required by recycling industries.

Another important aspect of metal recovery systems is their integration with the overall workflow of the MRF. Magnets and eddy current separators are typically positioned after preliminary screening and separation equipment, such as trommel screens, ballistic separators, and air classifiers, so that the waste reaching the metal recovery stage has already been partially sorted by size and density. This sequencing ensures that metals are separated from the correct fractions, reduces contamination, and allows the equipment to operate at maximum capacity. Some advanced facilities even use multiple passes of magnetic and eddy current separation, combined with sensors and automated diverters, to capture metals that might have escaped initial extraction.

Maintenance and operational control are also vital for metal recovery systems. Magnetic separators must be cleaned regularly to remove debris that can reduce their magnetic strength, while eddy current systems require precise calibration and monitoring to maintain consistent separation performance. Operators use real-time data from sensors to adjust belt speeds, magnetic field intensity, and airflow parameters, ensuring that metals are recovered efficiently without loss or contamination. Proper maintenance not only extends the lifespan of these systems but also preserves the economic and environmental benefits associated with metal recycling.

The economic impact of metal recovery in a Material Recovery Facility is significant. Recovered metals are among the most valuable components of the waste stream, with high demand from foundries, smelters, and manufacturing industries. Steel and aluminum, in particular, can be melted and reprocessed into new products with a fraction of the energy required for producing metals from virgin ores. By maximizing metal recovery, MRFs reduce reliance on raw material extraction, lower greenhouse gas emissions, and contribute to the circular economy. At the same time, capturing metals from municipal waste streams prevents them from being lost in landfills, reducing environmental impact and conserving natural resources for future generations.

In essence, metal recovery systems are indispensable in modern waste management. They combine mechanical engineering, magnetic technology, and electronic control to extract valuable materials from a highly complex waste stream. By ensuring efficient, safe, and high-quality separation of ferrous and non-ferrous metals, these systems enhance the overall performance of the Material Recovery Facility, contribute to economic sustainability, and support environmental goals by diverting metals from disposal and returning them to productive use in industrial supply chains.

Optical sorting systems have become a cornerstone of modern Material Recovery Facilities, providing a level of precision and automation that greatly enhances the quality and efficiency of recyclable material recovery. These systems are particularly important for plastics, paper, cartons, and other materials where manual or mechanical separation alone cannot achieve the high purity standards required by recycling industries. Using a combination of high-resolution cameras, near-infrared (NIR) sensors, and sometimes laser or X-ray technology, optical sorters can identify materials based on color, shape, chemical composition, and reflective properties. Once a material is detected, high-speed air jets or mechanical diverters redirect it to the appropriate collection stream. This capability allows facilities to separate different types of plastics, such as PET, HDPE, and polypropylene, with remarkable accuracy, ensuring that each output stream meets stringent market specifications and can be efficiently reprocessed into new products.

The integration of optical sorters into the MRF workflow occurs after initial size and density-based separation stages, such as trommel screening and ballistic or air classification. By this point, materials are partially categorized, which allows optical sorters to focus on refining streams that still contain mixed materials. For example, a conveyor carrying plastics may still include contaminants like labels, caps, or different resin types. Optical sorting systems detect these differences and eject unwanted materials while ensuring that the target resin flows into the correct chute for further processing. This significantly reduces contamination, improves the economic value of the recovered material, and minimizes the downstream processing required in recycling plants.

In addition to plastics, optical sorters are highly effective for separating paper and cardboard from mixed streams. Different grades of paper, including office paper, newspaper, and packaging materials, can be identified by color and texture, and separated accordingly. Some systems are also capable of detecting composite materials, such as Tetra Pak cartons, which contain layers of paper, plastic, and aluminum. By distinguishing these complex materials, optical sorters allow facilities to divert them to specialized processing streams, ensuring maximum resource recovery and reducing the amount of material sent to landfill or incineration.

The effectiveness of optical sorting systems is enhanced through continuous calibration and real-time monitoring. Sensors and cameras generate vast amounts of data on material flow, contamination levels, and sorting performance, which is fed into control systems that adjust air pressure, conveyor speed, or detection algorithms in real time. Some advanced facilities incorporate artificial intelligence and machine learning to improve recognition accuracy over time, adapting to changes in material composition or contamination patterns. This adaptability makes optical sorting a dynamic tool in maintaining high recovery rates, even as municipal waste streams evolve with changing consumption patterns and packaging materials.

Maintenance and operational oversight are essential for sustaining the performance of optical sorters. Cameras and sensors must be cleaned regularly to remove dust, debris, and residue that could interfere with accurate detection. Air jets require precise calibration to ensure materials are ejected accurately without causing cross-contamination, and the conveyor belts feeding the systems must be kept free of jams or blockages that could disrupt flow. Skilled operators monitor performance data, troubleshoot issues, and perform routine maintenance to ensure the system maintains optimal efficiency. Proper upkeep not only preserves the reliability of the equipment but also maximizes the economic and environmental benefits of material recovery.

From an environmental and economic perspective, optical sorting systems are invaluable. They increase the purity of recovered recyclables, allowing materials to be sold at higher market value, and reduce the quantity of contaminated or low-quality output that must be disposed of. By separating plastics by resin type, paper by grade, and composites into specialized streams, these systems facilitate recycling processes that require less energy and produce higher-quality recycled products. For municipalities and MRF operators, this means better revenue streams, reduced landfill dependency, and a smaller carbon footprint, contributing to broader goals of sustainability and resource efficiency.

In essence, optical sorting systems represent a convergence of advanced technology, precision engineering, and operational intelligence within the MRF. They bridge the gap between mechanical sorting and high-quality output, ensuring that materials extracted from the waste stream are clean, correctly categorized, and ready for reprocessing. By integrating optical sorting into the facility’s workflow, operators can achieve higher recovery rates, greater economic efficiency, and superior environmental outcomes, making these systems indispensable in the design and operation of modern Material Recovery Facilities.

Manual sorting stations remain an indispensable part of Material Recovery Facilities, complementing the mechanical and optical sorting systems by providing the human judgment necessary to remove contaminants, recover valuable materials, and ensure that output streams meet strict quality standards. Even with the most advanced automated equipment, there are materials that machines struggle to identify or properly separate, such as flexible packaging, composite materials, irregularly shaped plastics, or items partially covered in labels and adhesives. Human operators positioned along the conveyors at these stations can visually inspect the waste stream and make decisions in real time, picking out contaminants and directing recyclables into the correct chutes or bins. This combination of human oversight and mechanical precision ensures that the quality of recovered materials is maximized and contamination rates are minimized, which is critical for meeting the requirements of downstream recycling industries and global commodity markets.

The design of manual sorting stations focuses on ergonomics, safety, and efficiency. Operators work alongside moving conveyor belts, so the height and width of the belts are carefully calibrated to allow comfortable access to the material without excessive bending or reaching, reducing fatigue over long shifts. Guardrails, emergency stop mechanisms, and protective equipment are standard, ensuring that workers are shielded from accidents, sharp objects, or potential hazards within the waste stream. Adequate lighting and dust control measures are also essential, as visual accuracy is a core requirement for effective manual sorting, and the handling of mixed waste can generate airborne particles that must be mitigated to maintain a safe working environment. Facilities often include rotating teams and structured breaks to maintain focus and reduce the risk of errors or injuries in this physically and visually demanding environment.

In terms of workflow, manual sorting stations are strategically positioned at points in the MRF where human intervention provides the greatest benefit. For example, after optical sorting or ballistic separation, operators can remove contaminants that were misclassified or materials that the machines were unable to properly divert. They may also perform quality checks on specific output streams, such as plastics or paper, removing non-recyclable items or foreign objects that could lower the purity of the bale. In facilities that process “dirty” mixed waste streams, manual sorting is even more critical, as automated systems alone cannot fully separate materials from the high levels of organics, soil, and miscellaneous debris present.

Training and experience are vital for manual sorters, as the ability to quickly identify materials and contaminants requires knowledge of different types of plastics, metals, paper grades, and composite products. Workers learn to recognize which items can be recovered and which should be discarded or sent to residue handling. This knowledge directly affects recovery rates and the economic viability of the facility, as higher purity levels in recovered materials command better market prices and reduce processing costs in downstream recycling operations. Supervisors often monitor performance metrics, adjust staffing levels according to material flow, and ensure that operators adhere to safety protocols, creating a well-managed and efficient sorting environment.

The effectiveness of manual sorting stations also has a direct environmental impact. By removing contaminants and ensuring that each material stream is as clean as possible, human operators help prevent recyclable materials from being downgraded or sent to landfills unnecessarily. This contributes to higher overall recovery rates, reduced waste disposal volumes, and greater conservation of natural resources. Even as automation and optical sorting technologies become more advanced, the human role in final quality assurance remains critical, especially for materials that are difficult to separate or require judgment calls based on subtle visual or tactile cues.

In summary, manual sorting stations integrate human skill, experience, and decision-making into the highly mechanized process of a Material Recovery Facility. They provide a level of adaptability and quality control that machines alone cannot achieve, ensuring that recovered materials meet industry standards and that contamination is minimized. By combining manual oversight with mechanical and optical technologies, MRFs can maximize the recovery of valuable resources, improve economic performance, and contribute meaningfully to sustainable waste management practices, making these stations a cornerstone of the facility’s overall operation and efficiency.

Screening and Separation Equipment

Screening and separation equipment in a Material Recovery Facility plays a pivotal role in transforming a mixed municipal solid waste stream into sorted, recoverable materials by systematically dividing waste based on size, density, shape, and composition. This equipment essentially serves as the first line of mechanical refinement after waste leaves the tipping floor, ensuring that each material type can be effectively processed in subsequent stages. Trommel screens are often the starting point, consisting of rotating cylindrical drums with perforations that allow small particles, such as dirt, broken glass, and food waste, to pass through while larger items continue along the drum to other sorting mechanisms. This initial separation reduces the complexity of the waste stream and prepares it for more advanced mechanical or optical sorting. Disc or star screens are also used to handle flat materials like paper and cardboard, separating them from three-dimensional items such as bottles and cans, thereby reducing the likelihood of jams or blockages downstream and improving the efficiency of recovery systems.

Air classifiers and ballistic separators complement these screens by providing density and shape-based separation. Air classifiers use controlled airflow to divert lightweight materials, such as plastic films and foils, from heavier fractions like metals, glass, and dense plastics. Ballistic separators, meanwhile, categorize materials into flat fractions, rolling fractions, and fines, allowing for more precise downstream handling. This stratification of materials is crucial, especially in facilities that process “dirty” mixed waste streams, as it not only enhances the purity of recovered materials but also reduces wear and tear on more sensitive machinery, such as optical sorters or magnetic separators, by removing contaminants that could interfere with their operation.

Metal recovery, while sometimes considered separately, is often integrated into the screening and separation stage through magnetic and eddy current systems. Magnetic separators remove ferrous metals by attracting steel and iron objects from the waste stream, while eddy current separators employ rapidly changing magnetic fields to repel non-ferrous metals such as aluminum. These processes are highly efficient when materials have been pre-screened by size and density, which ensures that metals are not mixed with organic matter, glass, or plastics that could reduce separation efficiency. Pre-processing steps, such as shredding or crushing, are sometimes employed to expose metals embedded in composite or layered products, maximizing recovery rates and maintaining the economic viability of the facility.

Optical sorting systems represent the most advanced form of separation within the MRF and are often deployed after preliminary screening and density separation. Using near-infrared sensors, cameras, and high-speed air jets, optical sorters can distinguish between different types of plastics, paper grades, or composite materials with remarkable accuracy. For example, PET, HDPE, and polypropylene plastics can be separated into distinct streams, allowing each to be sent to the appropriate recycling process. Similarly, paper streams can be sorted by color, texture, or brightness, while cartons and composite packaging can be directed to specialized processing. These systems are vital for maintaining high purity standards, which directly affect the market value of recovered materials and reduce contamination in downstream recycling operations.

Glass separation and refinement also fall under the screening and separation stage. After initial size-based separation through screens, glass is further processed to remove contaminants like paper labels, plastic caps, and metal fragments. Vibrating screens, air suction systems, and manual interventions are used to ensure that the cullet—cleaned, sorted glass—is suitable for reprocessing into new glass products. This careful separation prevents contamination, improves recycling efficiency, and minimizes the volume of glass sent to landfill.

Maintenance, calibration, and integration of screening and separation equipment are essential to the continuous operation of an MRF. Sensors and monitoring systems track material flow, detect blockages, and measure the effectiveness of separation processes, allowing operators to adjust settings and prevent downtime. Regular cleaning, inspection, and replacement of worn components ensure that efficiency and recovery rates remain high. By combining mechanical screening, density separation, magnetic and eddy current metal recovery, optical sorting, and specialized glass processing, the screening and separation stage forms the technological backbone of the facility. It ensures that materials are systematically categorized, contamination is minimized, and each stream is prepared for the final stages of compaction, baling, and resale to recycling industries, making it one of the most critical stages in modern waste recovery operations.

Compaction and baling systems are a critical stage in a Material Recovery Facility, representing the point where recovered materials are transformed from loose, irregularly shaped streams into dense, uniform, and transportable forms suitable for storage, shipping, and resale to recycling industries. After materials have been separated through mechanical, magnetic, and optical sorting, they are still bulky, uneven, and difficult to handle efficiently. Compaction and baling machines address this issue by compressing these materials into tightly packed bales, which reduces volume, optimizes storage space, and minimizes transportation costs. Balers are typically designed to handle specific material types, such as paper, cardboard, plastics, or metals, with adjustments in pressure, chamber size, and binding mechanisms to ensure that the resulting bales meet industry specifications for density, weight, and size. Properly baled materials are easier to manage, store, and sell, ensuring that the high recovery rates achieved earlier in the process are maintained through to the final market.

The process begins with the feeding of sorted materials into hoppers connected to the baling unit. Conveyors deliver the material evenly, and the machine applies uniform pressure to compress the material into a compact form. For paper and cardboard, this may involve multiple compression cycles to achieve the necessary density, while plastics, which are often more resistant to compaction, may require pre-shredding or multiple passes through the baler to reach optimal size and density. Metals, depending on type and thickness, may be crushed or compacted to reduce volume while retaining structural integrity. Advanced baling systems are often equipped with automatic tying or strapping mechanisms that secure the bales with steel or plastic bands, ensuring they remain intact during storage and transportation.

The efficiency of compaction and baling systems has a direct impact on the operational performance and economic viability of the facility. Dense, uniform bales reduce the number of trips required to transport materials to recycling centers, cutting fuel consumption, labor costs, and carbon emissions. Baling also allows for better space utilization in storage areas, enabling facilities to maintain larger volumes of sorted materials without excessive footprint. Consistent bale quality is essential to meet the specifications of buyers, who often require precise weight, dimension, and contamination standards. By producing reliable, standardized bales, MRFs can command higher market prices for recovered materials, increasing revenue and supporting the financial sustainability of recycling operations.

Compaction and baling systems are also crucial for maintaining facility cleanliness and safety. Loose, scattered materials are prone to spilling, creating slip hazards for workers and potential blockages in conveyor systems. By consolidating materials into bales, the plant reduces the risk of accidents, improves workflow, and facilitates cleaner, more organized storage and handling areas. Some facilities integrate automated stacking systems with balers, enabling bales to be moved directly onto pallets or storage racks, further minimizing manual handling and reducing the risk of injury.

Maintenance and operational oversight are key to sustaining high performance in baling systems. Regular inspection of hydraulic systems, pressure settings, binding mechanisms, and feed hoppers ensures consistent bale density and prevents unplanned downtime. Sensors and automated controls in modern balers allow operators to monitor bale formation in real time, adjust settings for different material types, and detect malfunctions before they cause operational disruptions. This level of control not only protects the machinery but also maintains the quality and marketability of the recovered materials.

From an environmental perspective, compaction and baling systems contribute significantly to sustainable waste management. By enabling the efficient transport of high-quality recovered materials, these systems reduce the environmental footprint of recycling logistics, minimize landfill disposal, and support the circular economy by ensuring that resources such as paper, plastics, and metals are returned to manufacturing cycles. In this way, compaction and baling are not merely operational steps; they are strategic components that bridge the gap between material recovery and market utilization, reinforcing the economic and ecological value of the facility.

In essence, compaction and baling systems consolidate the results of all preceding sorting and separation processes, converting diverse streams of recyclables into organized, transportable units that retain their quality and maximize their economic and environmental value. Their role is vital for operational efficiency, safety, and profitability, ensuring that the full potential of recovered materials is realized from the point of separation through to delivery to recycling industries. These systems exemplify the integration of engineering precision, automation, and strategic facility management within modern Material Recovery Facilities.

Residue handling systems in a Material Recovery Facility represent the final stage of processing, addressing the fraction of waste that cannot be economically or technically recovered through mechanical, optical, or manual sorting. Even the most advanced MRFs are unable to reclaim every component of the incoming municipal solid waste stream, and residual materials—often a mixture of contaminated recyclables, organics, textiles, or non-recyclable plastics—must be safely collected, contained, and directed to appropriate disposal or energy recovery pathways. Proper management of residues is critical not only for operational efficiency but also for environmental compliance, worker safety, and the overall sustainability of the facility. These systems ensure that residual waste does not interfere with sorted material streams, clog processing equipment, or pose hazards to personnel.

Residue handling begins immediately after the final sorting and separation stages, where conveyors and diverters funnel non-recoverable material into designated collection areas. Depending on the facility design, this may involve hoppers, chutes, or automated transfer conveyors that lead to compactors, storage bunkers, or containers prepared for transport. Compactors reduce the volume of residual waste, making storage and handling more efficient and minimizing the space required within the plant. Some facilities also use shredders or grinders to homogenize the residue, facilitating safer handling and, in some cases, preparing the material for waste-to-energy conversion or further mechanical treatment. The goal is to maintain a continuous flow of recovered materials while keeping residues segregated, reducing contamination risk, and ensuring that the MRF can operate without interruption.

Residue handling systems are also designed to address environmental and health considerations. Residual waste streams often contain moisture, organic matter, or hazardous substances, which can create odors, attract pests, or pose a risk of fire. Effective residue management incorporates ventilation, dust suppression, and leachate collection systems to control these risks. In enclosed facilities, negative air pressure and filtration may be used to prevent odors and airborne particles from escaping into the surrounding environment, ensuring regulatory compliance and maintaining safe working conditions. Regular monitoring and cleaning are essential to prevent accumulation, reduce hazards, and maintain continuous operational efficiency.