A micro steam turbine is a type of steam turbine that is designed to produce a small amount of power, typically in the range of 1 kilowatt to 100 kilowatts. Micro steam turbines are often used in applications where a small amount of power is needed, such as in remote locations where there is no access to the grid, or in applications where waste heat can be used to generate power.

A mini steam turbine is a smaller version of a traditional steam turbine, typically used in applications where a lower power output is required. They are often used in industrial processes, power generation, and various other applications.

Micro steam turbines are compact and efficient machines designed to generate electricity or mechanical power from steam, typically for small-scale applications. These turbines are often used in industries where waste steam is available or where a small, decentralized power generation source is needed. The primary principle behind micro steam turbines is similar to that of larger turbines, as they convert the thermal energy of steam into mechanical energy through rotational motion. However, their design is optimized for lower capacities, making them suitable for localized operations, such as powering small facilities, cogeneration systems, or renewable energy setups.

One of the key advantages of micro steam turbines is their ability to utilize low-pressure or waste steam, which might otherwise be vented or condensed without performing useful work. This characteristic makes them an excellent choice for enhancing the efficiency of industrial processes, where steam is often a byproduct. For example, they are frequently employed in chemical plants, sugar mills, and food processing facilities to harness waste steam and generate electricity or drive equipment. This not only reduces energy costs but also minimizes environmental impact by making better use of available resources.

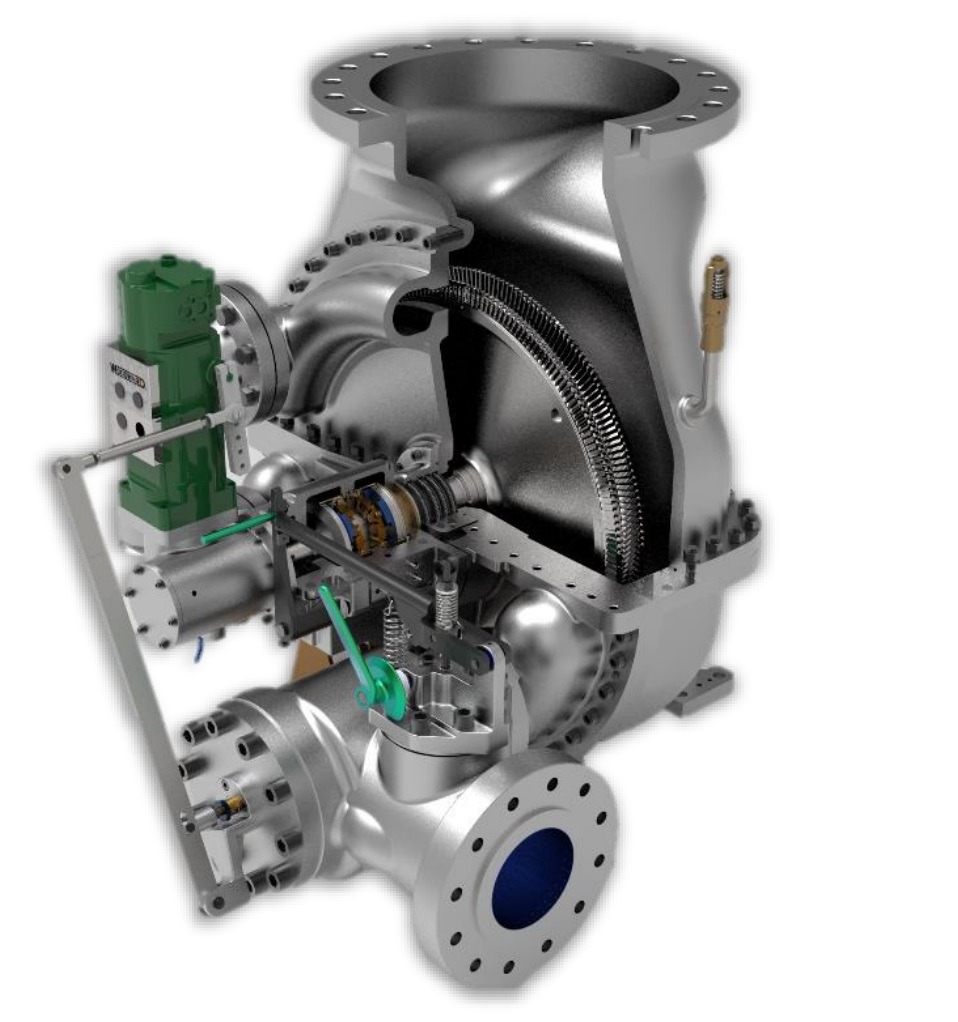

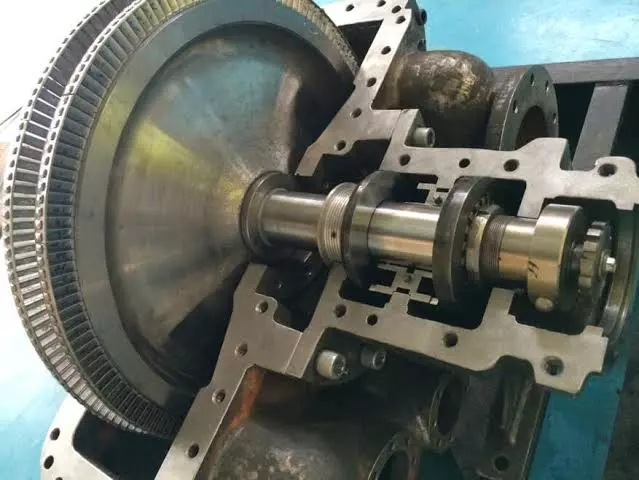

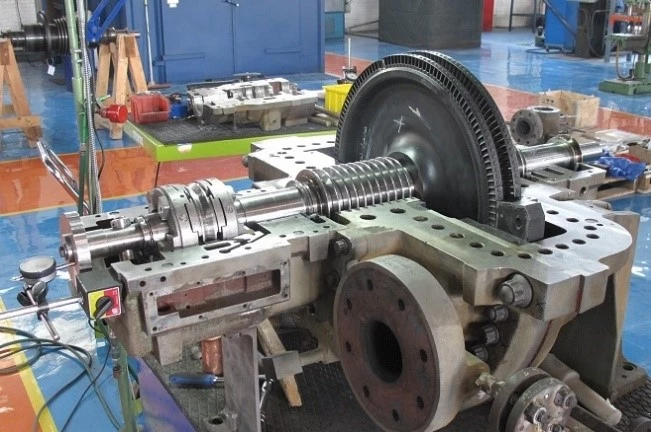

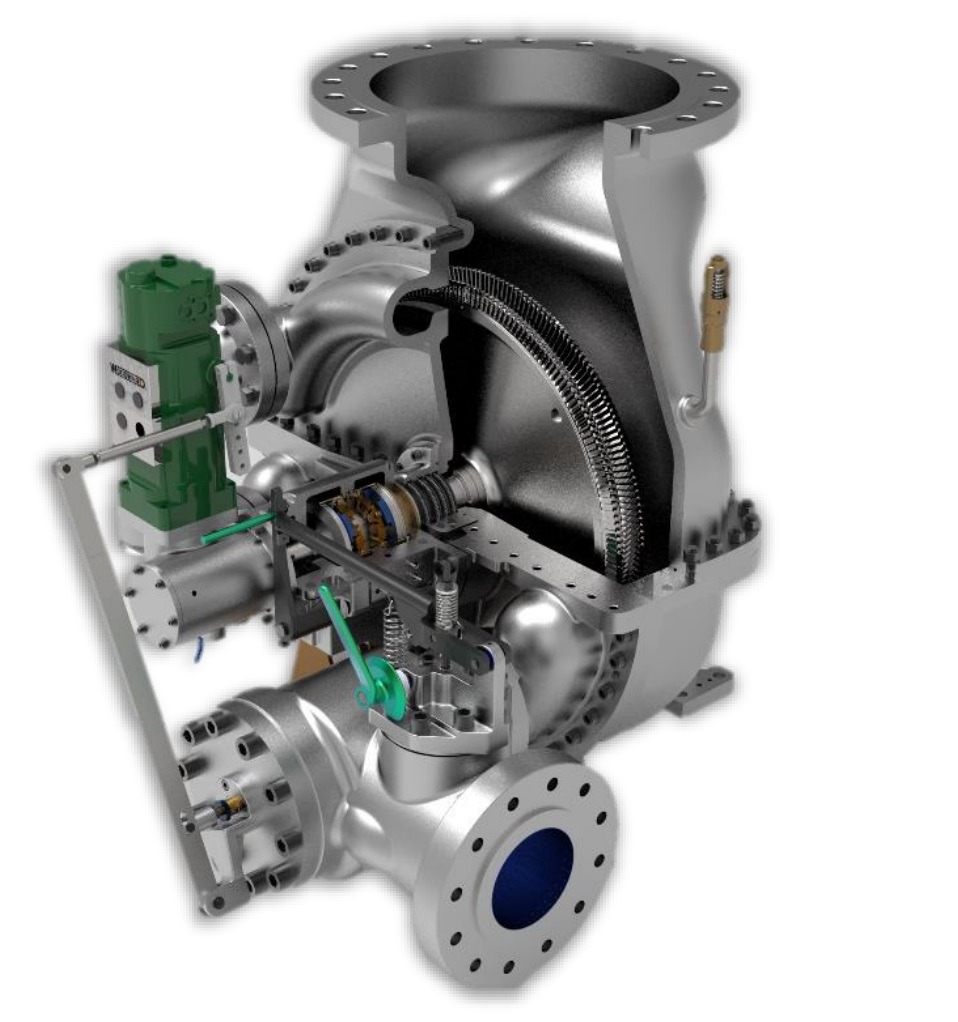

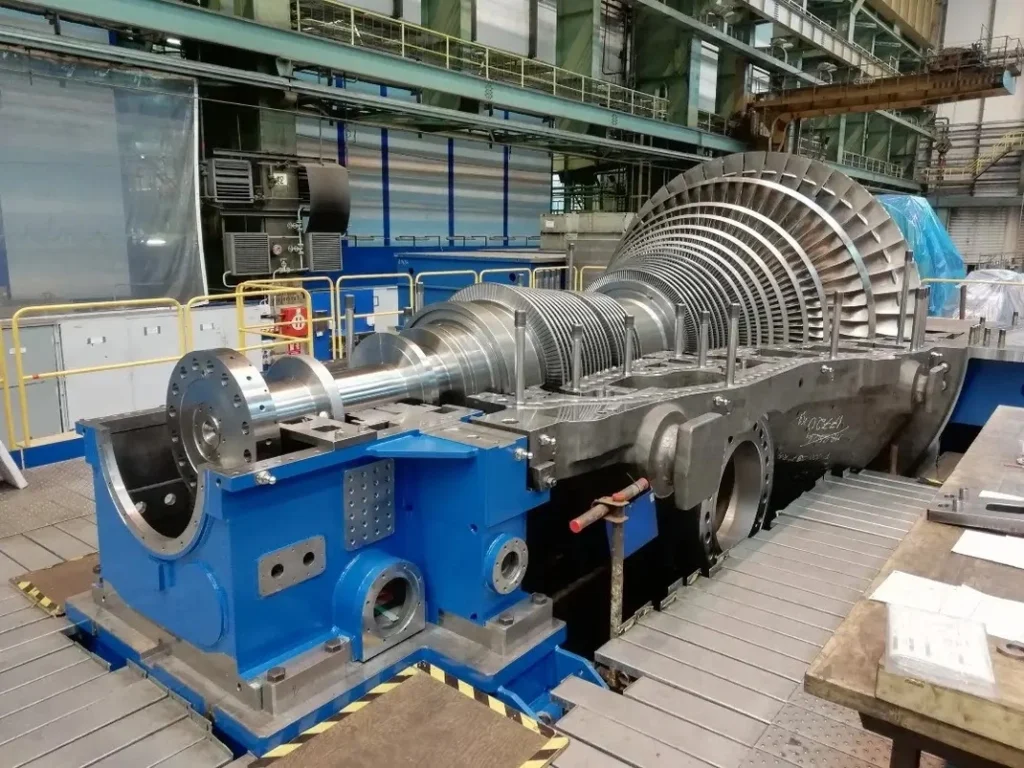

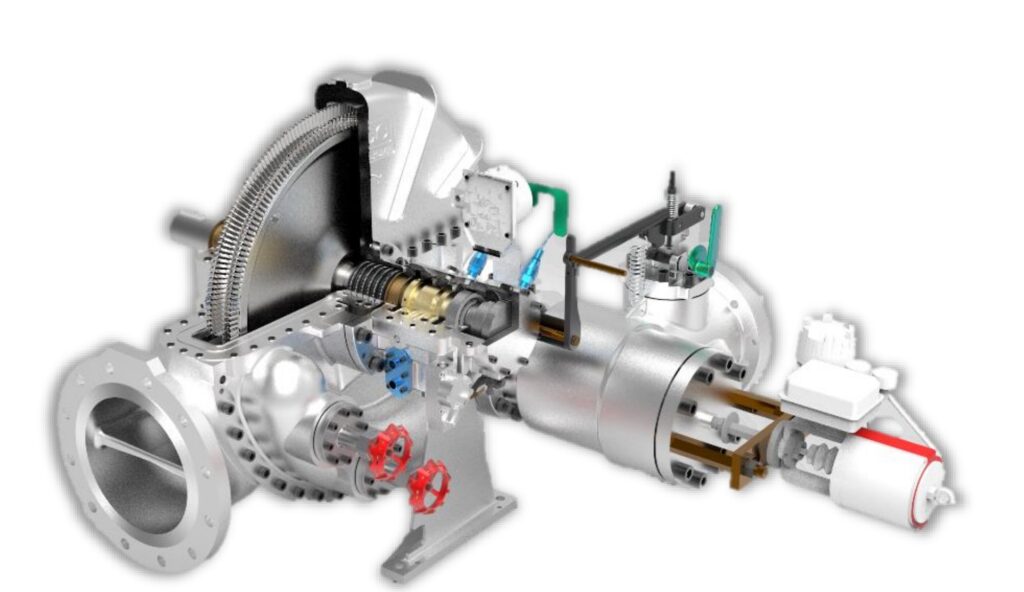

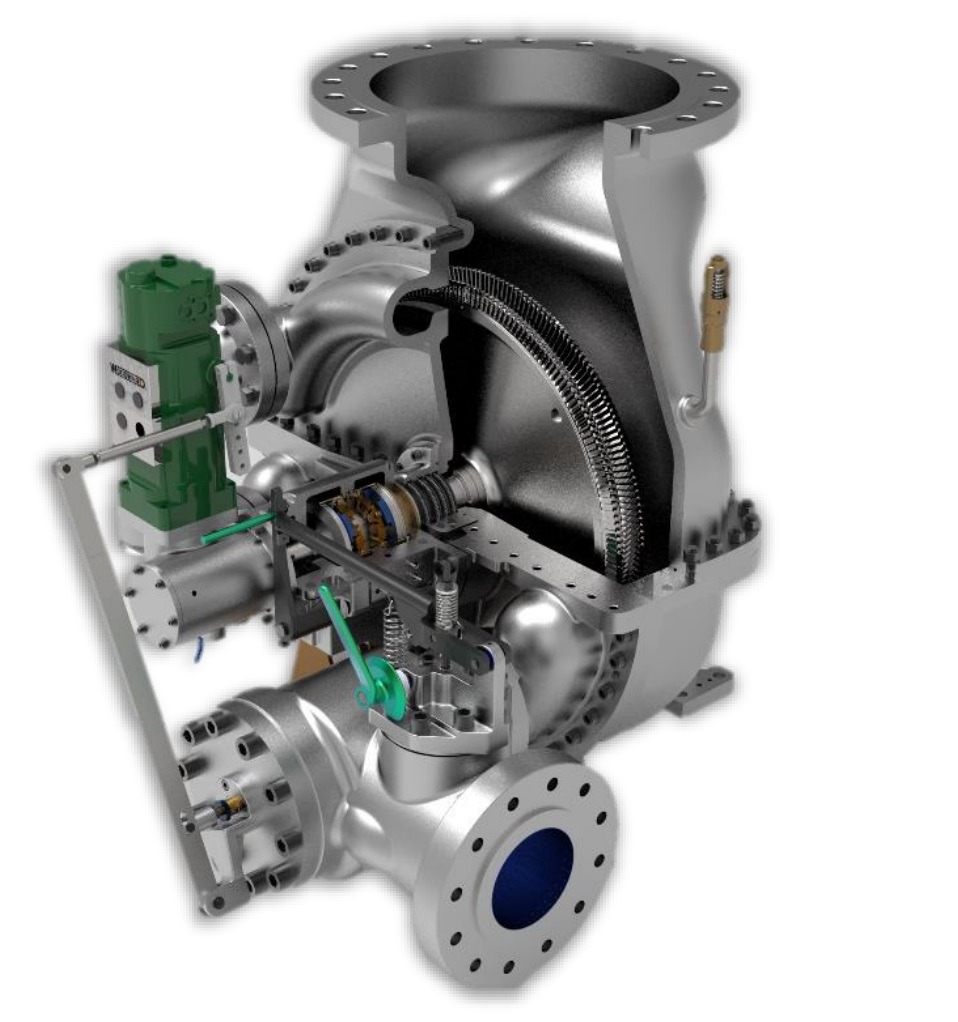

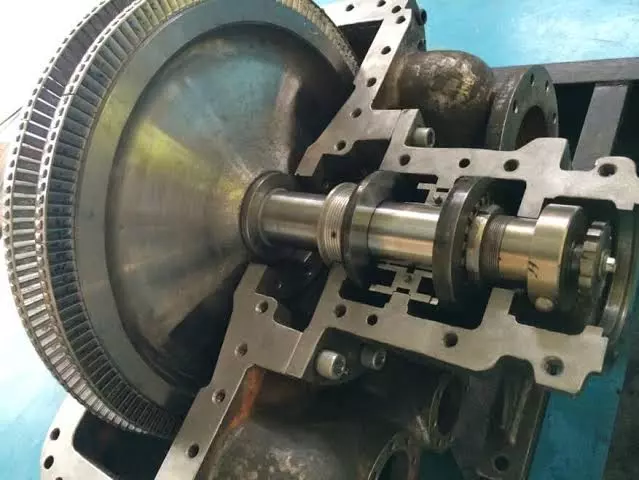

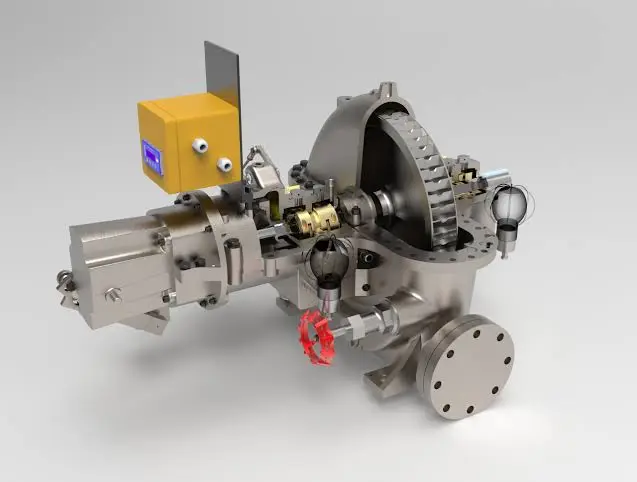

The design of a micro steam turbine typically includes a high-speed rotor, nozzle, and casing. The steam is directed onto the turbine blades through nozzles, creating high-velocity jets that impart energy to the blades, causing the rotor to spin. This rotational motion is then converted into electricity using a generator or utilized directly for mechanical applications. Due to their small size, micro turbines often operate at higher rotational speeds compared to larger turbines, necessitating precise engineering to ensure durability and efficiency. The materials used in their construction are chosen to withstand high temperatures and pressures while maintaining reliability over extended periods of operation.

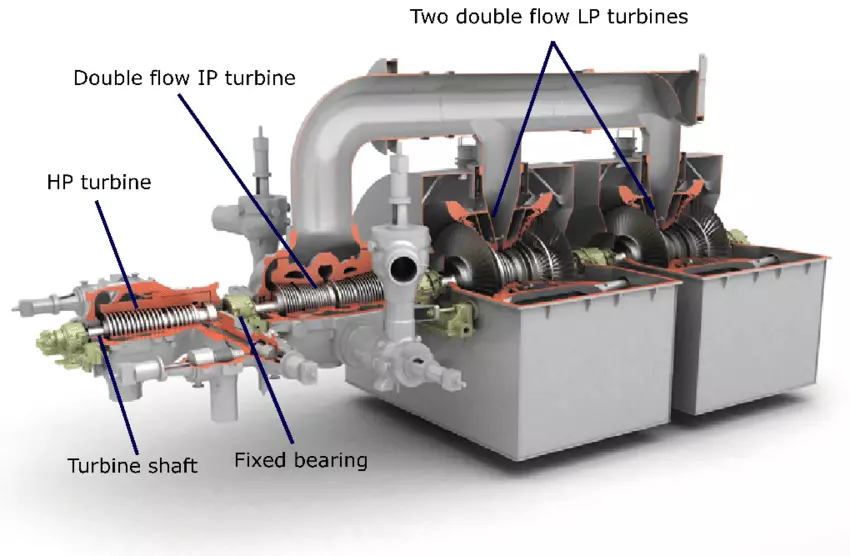

Micro steam turbines can be classified based on their operational principles and configurations. Back-pressure micro turbines discharge steam at a pressure suitable for downstream processes, making them ideal for cogeneration systems where both electricity and heat are required. Condensing micro turbines, on the other hand, exhaust steam at low pressure or vacuum conditions, maximizing energy extraction from the steam but requiring a condenser system to handle the exhaust. The choice between these types depends on the specific needs of the application and the characteristics of the available steam.

Advances in materials science and precision engineering have significantly improved the performance and reliability of micro steam turbines. Modern designs often incorporate advanced coatings and alloys to resist corrosion and wear, extending the operational lifespan of the equipment. Additionally, innovations in computational fluid dynamics (CFD) and finite element analysis (FEA) have enabled engineers to optimize turbine blade designs for maximum efficiency and minimal energy losses.

The efficiency of a micro steam turbine depends on various factors, including the steam conditions (pressure and temperature), the turbine design, and the quality of maintenance. Regular inspection and upkeep are essential to ensure optimal performance, as even minor issues such as blade erosion or nozzle clogging can significantly impact efficiency. The integration of condition monitoring systems, such as vibration analysis and thermal imaging, has further enhanced the ability to maintain these systems proactively.

Micro steam turbines are increasingly being integrated with renewable energy systems to enhance sustainability. For instance, they can be paired with biomass boilers to create a carbon-neutral energy source or used in geothermal power plants where steam is derived from underground reservoirs. Their compact size and modular design make them particularly well-suited for decentralized energy generation, enabling communities and small industries to reduce reliance on centralized power grids and lower their carbon footprint.

Despite their advantages, micro steam turbines also have limitations. Their efficiency is typically lower than that of larger turbines, and the initial capital investment can be a barrier for some users. However, these challenges are often outweighed by the long-term savings and environmental benefits they provide. In many cases, government incentives and subsidies for renewable energy projects can further improve the economic feasibility of adopting micro steam turbine technology.

In conclusion, micro steam turbines represent a versatile and sustainable solution for small-scale power generation. By leveraging waste steam or renewable energy sources, they offer a way to enhance energy efficiency and reduce environmental impact. Their adaptability to various applications, combined with ongoing advancements in technology, ensures their continued relevance in the global energy landscape. As industries and communities seek to transition toward more sustainable practices, the role of micro steam turbines is likely to grow, providing a valuable tool for decentralized and efficient energy production.

Micro steam turbines are particularly advantageous in environments where the availability of waste heat or low-grade steam can be capitalized on for productive purposes. For example, in industrial processes that require significant heat inputs, such as in the paper and pulp industry, distilleries, or petrochemical plants, the integration of micro steam turbines can substantially improve overall system efficiency. The ability to extract additional energy from waste steam makes these turbines an essential component of energy recovery systems, where they contribute to reduced energy costs and improved sustainability metrics.

Another critical aspect of micro steam turbines is their scalability. Due to their compact design and modular nature, they can be customized to meet specific operational requirements. This flexibility is particularly beneficial for small businesses or facilities with unique energy demands. By tailoring the turbine’s capacity and configuration to match the available steam and desired output, operators can maximize the return on investment. Moreover, the relatively small footprint of micro steam turbines means they can be installed in locations where space is limited, further broadening their applicability.

In addition to industrial applications, micro steam turbines have significant potential in the residential and commercial sectors. When paired with micro combined heat and power (CHP) systems, they can supply electricity while simultaneously providing heating or hot water. This dual functionality makes them an attractive option for eco-friendly buildings and off-grid installations. The decentralized nature of these systems can enhance energy security and reduce dependency on conventional power grids, particularly in remote or underserved areas.

The integration of digital technologies and smart controls has further enhanced the functionality of micro steam turbines. Modern systems often feature automated control mechanisms that optimize performance based on real-time data, such as steam flow rates, pressure, and temperature. These controls can adjust turbine operation dynamically, ensuring maximum efficiency and reliability under varying conditions. Additionally, the incorporation of Internet of Things (IoT) technologies allows for remote monitoring and diagnostics, enabling operators to address issues promptly and reduce downtime.

From an economic perspective, micro steam turbines offer a compelling value proposition, especially when used in energy-intensive industries. The ability to generate electricity on-site reduces the need for purchased power, while the use of waste steam minimizes fuel consumption. Over time, these factors can lead to substantial cost savings, offsetting the initial investment and operational expenses. Furthermore, many countries offer incentives for energy-efficient technologies, such as tax credits or grants, which can make adopting micro steam turbines even more financially attractive.

The environmental benefits of micro steam turbines are another key factor driving their adoption. By utilizing waste heat and reducing reliance on fossil fuels, they help lower greenhouse gas emissions and contribute to the global effort to combat climate change. When combined with renewable energy sources, such as biomass or geothermal energy, they can play a crucial role in transitioning to a low-carbon energy system. These turbines align with the principles of circular economy and sustainable development, emphasizing resource efficiency and waste minimization.

Despite these advantages, the successful implementation of micro steam turbines requires careful planning and consideration of specific site conditions. Factors such as the quality and availability of steam, the compatibility of the turbine with existing infrastructure, and the potential for integration with other energy systems must be thoroughly evaluated. Additionally, operators must ensure that the turbine’s maintenance requirements can be met, as regular servicing is essential to maintain efficiency and prevent operational issues.

Research and development in the field of micro steam turbines continue to drive improvements in performance, durability, and cost-effectiveness. Advances in turbine blade design, such as the use of three-dimensional aerodynamics, have enhanced energy extraction and reduced losses. Similarly, innovations in material science, such as the development of high-performance alloys and coatings, have improved resistance to corrosion and wear, extending the operational life of these turbines. As technology evolves, it is expected that micro steam turbines will become even more efficient, reliable, and accessible to a broader range of users.

In summary, micro steam turbines are a versatile and efficient solution for small-scale power generation, offering a range of economic and environmental benefits. Their ability to utilize waste steam, adaptability to various applications, and potential for integration with renewable energy systems make them an essential tool in the transition toward sustainable energy practices. As industries and communities continue to seek innovative ways to reduce energy consumption and carbon emissions, the role of micro steam turbines is poised to expand, contributing to a more resilient and sustainable energy future.

The role of micro steam turbines in energy systems is particularly significant as industries and communities strive to adopt sustainable energy solutions. One of the most promising trends is the integration of these turbines into microgrid systems. Microgrids are localized energy networks that can operate independently or in conjunction with the main power grid. By incorporating micro steam turbines into microgrids, operators can enhance energy resilience, reduce transmission losses, and optimize the utilization of local energy resources. This integration is particularly beneficial in regions prone to grid instability or in remote locations where access to the main grid is limited or nonexistent.

Micro steam turbines also play a vital role in waste-to-energy applications. These systems convert waste materials, such as municipal solid waste or agricultural residues, into heat through combustion or other processes. The generated heat produces steam, which powers the turbines to generate electricity. This approach not only reduces the volume of waste destined for landfills but also creates a renewable source of energy. By leveraging micro steam turbines, waste-to-energy plants can operate more efficiently at smaller scales, making the technology accessible to municipalities and industrial facilities.

In addition to their practical applications, micro steam turbines contribute to the broader goals of energy efficiency and environmental sustainability. Their ability to recover and utilize waste heat aligns with global energy efficiency targets set by organizations such as the International Energy Agency (IEA). Furthermore, as governments worldwide establish stricter regulations on emissions and energy efficiency, the adoption of micro steam turbines is expected to grow. These turbines provide industries with a viable solution for meeting regulatory requirements while simultaneously improving their operational efficiency.

The versatility of micro steam turbines extends to their use in experimental and emerging technologies. For instance, researchers are exploring the potential of combining micro turbines with advanced energy storage systems, such as thermal batteries or compressed air storage. These hybrid systems aim to balance the intermittency of renewable energy sources and provide reliable power output. Similarly, the integration of micro steam turbines into hydrogen production processes is gaining attention. Steam can be used to generate hydrogen through thermochemical reactions, and micro turbines can utilize the waste steam generated in these processes to improve overall system efficiency.

From a technical perspective, advancements in turbine control systems and monitoring technologies have transformed the operational landscape of micro steam turbines. The incorporation of predictive maintenance tools, powered by machine learning and artificial intelligence, has significantly improved reliability and reduced unexpected downtime. By analyzing data from sensors embedded in the turbine, these systems can predict potential failures and recommend maintenance activities before issues escalate. This proactive approach minimizes operational disruptions and extends the lifespan of the turbine.

Economic considerations also highlight the potential of micro steam turbines in fostering energy independence. For industries operating in regions with high electricity costs or unreliable grid connections, these turbines offer a means of generating their own power at a relatively low operational cost. In agricultural sectors, for example, micro steam turbines can convert biomass residues, such as husks or straw, into steam for electricity generation. This approach not only provides a sustainable energy source but also creates opportunities for rural development by promoting energy self-sufficiency.

Despite their numerous advantages, challenges remain in the widespread adoption of micro steam turbines. The initial capital investment can be a barrier, particularly for small businesses or communities with limited financial resources. Additionally, the efficiency of these turbines can be influenced by fluctuations in steam supply or quality, requiring careful design and operation to ensure consistent performance. Addressing these challenges will require continued innovation, supportive policy frameworks, and targeted financial incentives to make the technology more accessible.

The future of micro steam turbines is closely linked to the ongoing evolution of the global energy landscape. As renewable energy sources like solar and wind power continue to expand, the need for complementary technologies that enhance system reliability and efficiency becomes increasingly important. Micro steam turbines, with their ability to provide stable power output and recover waste heat, are uniquely positioned to fill this role. Their integration with cutting-edge technologies, such as smart grids and advanced energy storage, will further solidify their relevance in modern energy systems.

In conclusion, micro steam turbines represent a critical component of the transition toward sustainable and decentralized energy systems. Their capacity to harness waste steam, improve energy efficiency, and adapt to diverse applications underscores their value in addressing contemporary energy challenges. As technological advancements continue to enhance their performance and affordability, micro steam turbines will play an increasingly prominent role in shaping the future of energy generation, contributing to a cleaner, more efficient, and more resilient energy infrastructure worldwide.

Introduction to Micro Steam Turbines

Micro steam turbines are small-scale turbines designed to generate power or mechanical energy from steam. Unlike their larger counterparts, micro turbines are compact, efficient, and suited for decentralized energy generation in industrial, commercial, and residential settings. Their ability to harness low-grade or waste steam makes them ideal for industries seeking to optimize energy use and reduce waste.

Operating Principles

Micro steam turbines operate on the same fundamental principles as larger steam turbines. Steam, at high pressure and temperature, is directed through nozzles to create high-velocity jets that strike the turbine blades. The energy transfer causes the rotor to spin, which is converted into mechanical energy to drive a generator or other machinery. These turbines often operate at higher speeds due to their compact size, necessitating precise engineering and robust materials to withstand thermal and mechanical stresses.

Types of Micro Steam Turbines

Back-Pressure Turbines

These turbines discharge steam at a pressure suitable for downstream applications, such as heating or industrial processes. They are commonly used in cogeneration systems to produce both electricity and thermal energy.

Condensing Turbines

Condensing micro turbines exhaust steam at low pressures or vacuum conditions, maximizing energy extraction. They require a condenser to manage the exhaust, making them more efficient but slightly more complex to operate.

Applications

Industrial Settings

Micro steam turbines are widely used in industries like food processing, chemical manufacturing, and textiles, where steam is a byproduct of operations. They enhance energy efficiency by converting waste steam into electricity or mechanical power.

Combined Heat and Power (CHP) Systems

When integrated into CHP systems, micro turbines generate both electricity and useful heat, making them ideal for residential and commercial buildings.

Waste-to-Energy Systems

These turbines are integral to waste-to-energy plants, converting steam produced from incinerating waste into electricity, reducing landfill dependency, and producing renewable energy.

Renewable Energy Systems

Micro steam turbines are often paired with renewable sources like biomass or geothermal energy, enabling sustainable and decentralized power generation.

Design Features

The design of micro steam turbines includes high-speed rotors, precision-engineered blades, and durable casings. Materials such as advanced alloys and specialized coatings are used to resist high temperatures, pressures, and corrosion. Computational tools like CFD and FEA optimize blade design to improve efficiency and reduce energy losses.

Advantages

- Energy Efficiency: Micro turbines maximize energy recovery from waste steam, reducing overall energy costs.

- Sustainability: They promote the use of renewable energy sources and reduce greenhouse gas emissions.

- Decentralization: Their compact size and modularity make them ideal for localized energy generation.

- Versatility: They can be tailored to suit specific industrial or residential requirements.

Challenges

Despite their advantages, micro steam turbines face challenges such as high initial costs, dependency on consistent steam quality, and maintenance demands. Addressing these issues requires technological advancements and supportive policies.

Emerging Technologies

Smart Controls and IoT

Modern micro turbines incorporate smart systems for real-time monitoring and performance optimization. IoT-enabled sensors provide data for predictive maintenance, minimizing downtime and enhancing reliability.

Hybrid Systems

Innovations include combining micro turbines with energy storage or hydrogen production systems, offering solutions for grid stability and energy sustainability.

Advanced Materials

The use of high-performance materials and coatings extends the lifespan of components, ensuring durability under demanding conditions.

Economic and Environmental Impact

Micro steam turbines offer significant economic benefits by reducing energy costs and enhancing operational efficiency. Their ability to generate power from waste steam contributes to a circular economy, while their integration with renewable energy systems helps achieve carbon reduction targets.

Future Prospects

As the energy sector transitions toward sustainability, the role of micro steam turbines is expected to grow. They align with global trends toward decentralized energy systems, waste minimization, and renewable energy adoption. Continued innovation in turbine design, control systems, and integration with advanced technologies will further enhance their relevance.

Conclusion

Micro steam turbines are a vital technology for small-scale, sustainable energy generation. Their efficiency, adaptability, and environmental benefits position them as a cornerstone of modern energy strategies. By recovering waste heat and utilizing renewable sources, they play a crucial role in creating a more resilient and sustainable energy infrastructure. With ongoing advancements, these turbines are set to remain a key player in the global energy landscape.

Operating Principles

Micro steam turbines operate by converting the thermal energy of steam into mechanical energy through a process rooted in thermodynamics and fluid mechanics. When high-pressure, high-temperature steam is directed into the turbine, it passes through a series of nozzles that accelerate the steam and convert its thermal energy into kinetic energy. The resulting high-velocity steam jets strike the turbine blades, which are mounted on a rotor. As the steam transfers its energy to the blades, the rotor begins to spin, transforming the steam’s energy into rotational mechanical energy.

The design of the turbine blades plays a crucial role in the efficiency and performance of the system. These blades are often shaped and angled in a way that maximizes the amount of energy extracted from the steam while minimizing losses due to turbulence or inefficiencies. Advanced engineering tools like computational fluid dynamics (CFD) are used to simulate steam flow and optimize blade geometry, ensuring that the turbine operates at peak efficiency.

The high rotational speeds typical of micro steam turbines require precise balancing and robust materials to withstand the mechanical stresses involved. The rotor, connected to a generator in most applications, converts the mechanical energy into electrical energy. In mechanical drive systems, the rotational motion may directly power equipment such as pumps or compressors.

Micro turbines are designed to handle a range of steam pressures and temperatures, which is essential for their versatility in various applications. In some cases, the turbines are integrated with control systems that regulate steam flow based on real-time conditions, optimizing performance and protecting the turbine from damage caused by fluctuations in steam supply.

The exhaust steam from the turbine can either be directed to other processes or condensed and reused. In back-pressure turbines, the steam exits the turbine at a pressure sufficient for use in heating or industrial processes. In condensing turbines, the steam is discharged at low pressure or a vacuum state, maximizing energy extraction but requiring additional equipment like condensers to handle the low-pressure exhaust. This adaptability allows micro steam turbines to be configured for specific operational requirements, making them an efficient and flexible solution for energy generation.

Types of Micro Steam Turbines

Micro steam turbines offer substantial advantages in a variety of settings due to their compact design and ability to operate with low or waste steam pressures. In industrial applications, where steam is often a byproduct of processes, micro steam turbines can capture and convert this energy into usable power, reducing the need for external energy sources and improving the overall efficiency of operations. This is particularly important in industries such as chemical manufacturing, food processing, and textiles, where steam is generated continuously as part of the production cycle.

Beyond industrial settings, micro steam turbines are increasingly being adopted for Combined Heat and Power (CHP) systems. These systems provide both electricity and thermal energy, offering a more efficient and sustainable alternative to separate electricity and heating systems. By utilizing steam for both power generation and heating needs, businesses and residences can significantly reduce their energy costs and minimize waste. For example, in residential or commercial buildings, micro turbines can be integrated with district heating systems to provide heat while simultaneously generating electricity, enhancing energy efficiency.

Another growing application for micro steam turbines is in renewable energy systems. When paired with biomass boilers, micro turbines can generate electricity from renewable sources, contributing to the reduction of fossil fuel dependence. In these systems, biomass materials, such as wood chips or agricultural waste, are burned to create steam, which is then used to power the turbine. This setup not only provides clean, renewable energy but also reduces greenhouse gas emissions compared to conventional energy production methods.

In addition to biomass, micro steam turbines can be integrated with geothermal energy systems. In these applications, the turbine is powered by steam produced from the earth’s natural heat sources, which are accessed through geothermal wells. This method of energy generation is renewable and produces minimal environmental impact, making it an attractive option for sustainable power production. The compact nature of micro turbines allows them to be installed in smaller geothermal plants, making geothermal energy more accessible for smaller-scale operations or remote communities.

One of the key advantages of micro steam turbines is their scalability. These turbines can be tailored to meet the specific energy needs of a particular application. Whether it’s a small factory or a residential building, micro turbines can be designed and configured to match the steam supply and desired power output. This adaptability makes them ideal for decentralized energy generation, where localized power production can reduce reliance on centralized grids and enhance energy security. In areas where access to reliable electricity is limited, such as in rural or off-grid locations, micro turbines offer an affordable and effective solution for power generation.

Furthermore, micro steam turbines are an integral component of waste-to-energy (WTE) systems, where they help convert various types of waste into useful energy. In WTE facilities, waste materials such as municipal solid waste, agricultural residues, or even waste heat from industrial processes are used to generate steam. This steam can then drive a turbine to produce electricity. By converting waste into energy, micro turbines contribute to waste reduction, provide a renewable energy source, and help mitigate environmental impacts by diverting waste from landfills.

The environmental benefits of micro steam turbines are not limited to their ability to reduce waste or utilize renewable energy. Their efficient energy conversion processes reduce fuel consumption and carbon emissions, particularly when integrated with clean energy sources like biomass or geothermal systems. As the world moves toward cleaner energy solutions, micro turbines offer a significant opportunity to enhance sustainability by improving energy efficiency and reducing the carbon footprint of both industrial and residential energy consumption.

One of the more promising developments in the use of micro steam turbines is their integration into microgrid systems. Microgrids are localized networks that can operate independently from the main power grid, providing power to a specific area, such as a factory, campus, or community. These systems offer enhanced reliability and resilience, as they are less vulnerable to disruptions in the main grid. By incorporating micro steam turbines into microgrids, operators can optimize energy production and consumption, reducing reliance on external power sources and minimizing energy losses that occur during long-distance transmission.

As the global energy landscape evolves, innovations in turbine design and materials continue to enhance the performance, reliability, and affordability of micro steam turbines. Advances in high-strength alloys, corrosion-resistant coatings, and energy-efficient designs contribute to longer operational lifespans and higher performance under demanding conditions. Furthermore, the integration of digital control systems, such as automated monitoring and predictive maintenance tools, has made these turbines easier to operate and maintain, ensuring that they run optimally over time.

Despite the growing interest in micro steam turbines, their widespread adoption faces several challenges. Initial capital costs can be a significant barrier, especially for smaller businesses or communities with limited budgets. However, government incentives and subsidies for renewable energy technologies, such as grants or tax breaks, can help offset these costs and make micro turbines more accessible. Additionally, micro turbines are sensitive to the quality and consistency of the steam supply, which can affect their efficiency. Therefore, careful planning and design are essential to ensure that the turbine is suited to the specific operating conditions.

The future of micro steam turbines looks promising as industries and communities continue to seek innovative solutions to reduce energy costs, increase efficiency, and minimize environmental impact. With continued advancements in technology, micro steam turbines are expected to play an even more significant role in decentralized energy production, renewable energy systems, and sustainable industrial practices. By leveraging waste heat and renewable resources, micro turbines are poised to contribute to the transition toward a more resilient, sustainable, and low-carbon global energy infrastructure.

Back-Pressure Turbines

Micro steam turbines designed for back-pressure operation are particularly valuable in industrial and cogeneration settings, where they serve as a bridge between power generation and process heating. These turbines extract energy from steam while leaving it at a pressure suitable for downstream applications, making them highly efficient for facilities with continuous steam demand. As the steam passes through the turbine, it loses some of its pressure and temperature, transferring energy to the rotor to produce mechanical or electrical power. The remaining steam, still at a usable pressure, exits the turbine and is routed to other processes such as drying, sterilization, or space heating.

The advantage of this approach lies in its dual-purpose utility, enabling industries to optimize their energy use without significant waste. For example, in food processing facilities, the exhaust steam from a micro steam turbine can be used for cooking or pasteurization, while simultaneously generating electricity to power machinery. Similarly, in chemical plants, this setup allows the turbine to produce electricity while the discharged steam supports chemical reactions or heating requirements. This integration of power and thermal energy generation is a hallmark of back-pressure turbine applications and underscores their role in improving energy efficiency.

Back-pressure turbines also play a critical role in reducing energy costs by utilizing existing steam resources more effectively. In facilities where boilers already produce steam for processes, the addition of a micro steam turbine can enhance energy recovery without requiring significant changes to the existing infrastructure. This retrofitting capability makes them a cost-effective solution for industries seeking to lower energy expenses and reduce reliance on external power supplies. Additionally, the use of back-pressure turbines can contribute to the reduction of greenhouse gas emissions by optimizing fuel use and minimizing the need for additional energy production.

One of the significant benefits of back-pressure turbines is their adaptability to various steam conditions and requirements. These turbines are designed to handle a wide range of inlet pressures and temperatures, allowing them to be tailored to the specific needs of a facility. Whether operating with high-pressure steam from a large industrial boiler or lower-pressure steam from a biomass system, back-pressure micro turbines can be configured to maximize efficiency and performance.

The ability to recover energy from waste steam further enhances the environmental and economic benefits of back-pressure turbines. In many industrial processes, surplus steam is vented to the atmosphere or condensed without being utilized. By directing this steam through a micro turbine, operators can capture valuable energy that would otherwise be lost, transforming waste into a productive resource. This capability aligns with sustainability goals and supports the transition to a circular economy, where resources are used as efficiently as possible.

Although back-pressure turbines are highly efficient in their operation, their successful implementation requires careful consideration of system design and integration. Factors such as the availability of steam, the compatibility of turbine output with downstream processes, and the efficiency of the overall system must be evaluated to ensure optimal performance. Proper maintenance is also critical, as the high-speed operation and exposure to varying steam conditions can cause wear on turbine components over time.

Advances in materials and turbine design have significantly improved the durability and efficiency of back-pressure micro turbines. Modern turbines are constructed with high-performance alloys and coatings that resist corrosion and thermal stress, extending their operational lifespan. Blade designs have also been optimized using advanced engineering techniques, allowing for more efficient energy transfer and reduced losses. These improvements not only enhance the performance of the turbines but also reduce their operational costs, making them more accessible to a wider range of users.

In addition to their industrial applications, back-pressure turbines are finding new uses in decentralized energy systems. For instance, in district heating networks, these turbines can generate electricity while supplying heat to residential or commercial buildings, providing an efficient and sustainable energy solution. Their ability to operate at smaller scales makes them suitable for localized energy generation, supporting the development of microgrids and other decentralized energy systems. This flexibility is particularly important in regions with limited access to centralized power grids, where back-pressure turbines can help ensure reliable and cost-effective energy supply.

As global energy systems evolve, the role of back-pressure turbines in supporting sustainability and energy efficiency is expected to grow. Their integration with renewable energy sources, such as biomass or geothermal systems, enhances their environmental benefits and aligns with the shift toward low-carbon energy solutions. By enabling more efficient use of steam resources and reducing energy waste, back-pressure turbines contribute to the broader goals of energy conservation and emissions reduction, making them an essential component of modern energy infrastructure.

Condensing Turbines

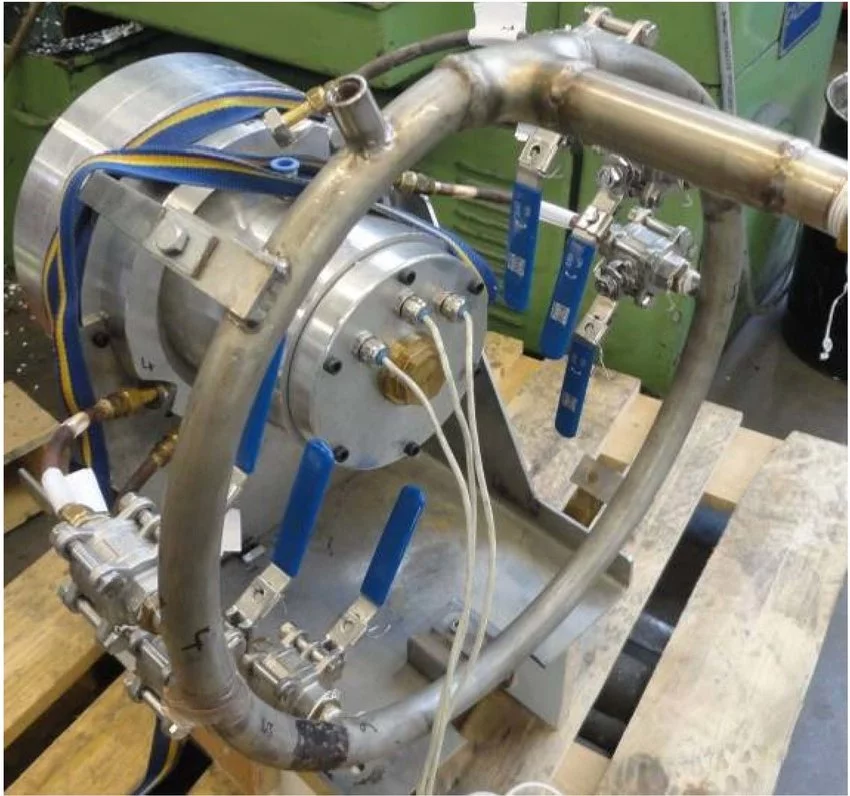

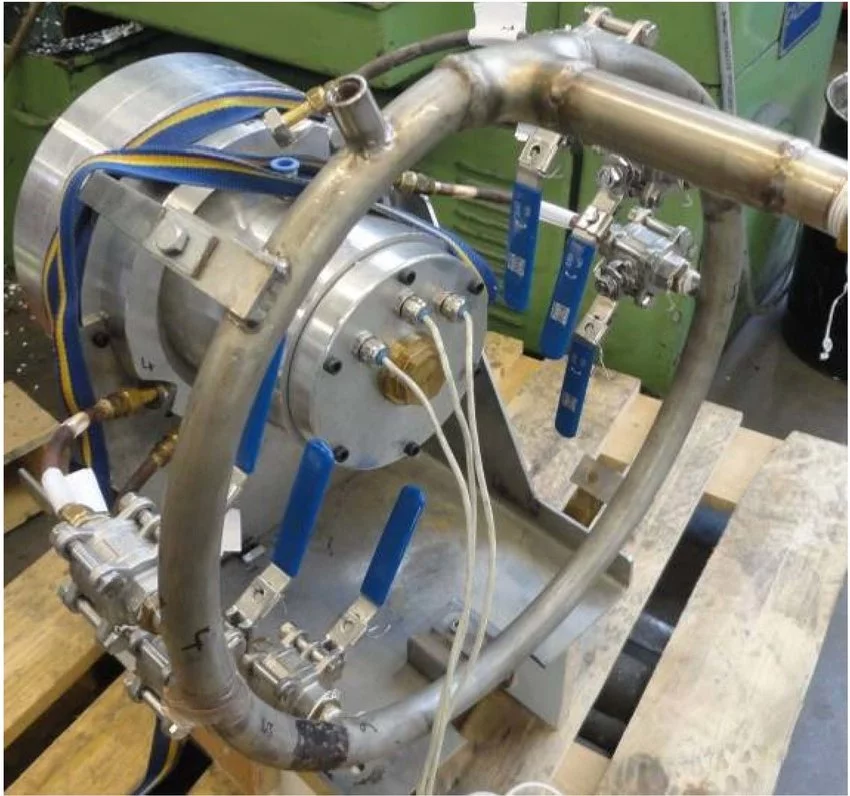

Micro steam turbines operating in a condensing configuration are designed to maximize energy extraction from steam by exhausting it at the lowest possible pressure, often at or near vacuum conditions. This approach allows the turbine to capture nearly all the available thermal energy in the steam, resulting in higher efficiency and increased power output compared to other turbine types. The steam, after passing through the turbine, enters a condenser where it is cooled and converted back into water, completing the cycle for reuse in the boiler or other steam generation systems.

The effectiveness of condensing turbines lies in their ability to operate with high pressure and temperature gradients, making them particularly suitable for applications where maximizing energy production is a priority. By utilizing the enthalpy difference between the inlet and exhaust steam, these turbines achieve significant energy conversion, which is especially valuable in settings focused on power generation rather than combined heat and power (CHP).

Condensing micro turbines are widely used in scenarios where there is no downstream demand for low-pressure steam, allowing all the energy from the steam to be converted into electricity. This makes them an excellent choice for standalone power plants, renewable energy systems like biomass or geothermal facilities, and waste-to-energy plants. In biomass applications, for instance, organic materials such as agricultural residues or wood chips are burned to produce steam that drives the turbine. The condensing design ensures that the maximum amount of energy is extracted from the steam, enhancing the overall efficiency of the system.

The condenser itself is a critical component of the system and plays a key role in the performance of condensing turbines. By rapidly cooling the exhaust steam, the condenser creates the vacuum conditions necessary for efficient turbine operation. Various types of condensers, such as air-cooled or water-cooled systems, can be used depending on the availability of resources and environmental considerations. Water-cooled condensers are highly effective but require a consistent water supply, while air-cooled systems are more suitable for regions where water is scarce.

One of the challenges in operating condensing turbines is managing the large volume of exhaust steam and maintaining the vacuum conditions in the condenser. Effective design and operation of the condenser are essential to prevent performance losses and ensure that the turbine operates efficiently. This includes selecting appropriate cooling technologies, maintaining clean heat transfer surfaces, and optimizing the flow of cooling fluids.

The high energy efficiency of condensing micro turbines makes them a valuable asset in renewable energy systems. For example, in geothermal power plants, where steam is derived from underground reservoirs, condensing turbines are used to extract maximum energy from the steam before it is re-injected into the geothermal wells. This approach minimizes resource wastage and supports the sustainable use of geothermal energy.

Despite their efficiency, condensing turbines are more complex and require additional infrastructure, such as the condenser and its associated cooling systems. This increases the initial cost and maintenance requirements compared to simpler turbine configurations. However, the high efficiency and energy output often justify the investment, particularly in applications where electricity generation is the primary objective.

Advancements in materials and turbine design have further enhanced the performance of condensing micro turbines. Modern turbines are constructed with materials capable of withstanding high thermal and mechanical stresses, while advanced blade designs optimize steam flow and energy transfer. Additionally, the integration of automation and monitoring systems allows for precise control of turbine operation, ensuring consistent performance and reducing the risk of downtime.

The use of condensing turbines also aligns with global efforts to reduce greenhouse gas emissions and transition to sustainable energy systems. By maximizing energy recovery from renewable and waste resources, these turbines contribute to reducing the carbon footprint of power generation. Their ability to operate efficiently with various steam sources, including low-grade steam from waste heat recovery systems, further underscores their versatility and environmental benefits.

In summary, condensing micro steam turbines are a powerful tool for maximizing energy extraction from steam, particularly in applications focused on electricity generation. Their high efficiency, adaptability to different steam sources, and contribution to sustainable energy goals make them an integral part of modern power generation systems. Despite the complexities associated with their operation, the benefits they offer in terms of energy recovery and environmental impact make them a valuable investment for industries and energy producers seeking to optimize performance and sustainability.

Combined Heat and Power (CHP) Systems

Micro steam turbines are central to systems that efficiently utilize both thermal and electrical energy. Their ability to extract power from steam while leaving residual energy for secondary applications enhances energy efficiency and sustainability across various settings. These turbines operate by capturing the mechanical energy of steam, converting it into electricity, and then routing the remaining steam for other uses, such as process heating, drying, or cooling. This dual-purpose capability ensures minimal energy waste and maximizes resource utilization.

The integration of micro turbines into energy systems is particularly advantageous where heat is required alongside power. For example, in industrial settings, the residual steam from a turbine can be directed to heat exchangers or other process equipment, providing a consistent and controlled source of thermal energy. This arrangement not only reduces the need for separate heating systems but also optimizes the use of fuel, as a single steam generation process fulfills both power and heating requirements.

In residential and commercial buildings, micro steam turbines contribute to efficient energy systems by providing power and heat for space heating, hot water, or air conditioning. These systems are especially valuable in colder climates, where demand for heating is high. By capturing and reusing the thermal energy in exhaust steam, these turbines help reduce reliance on external energy sources, lower operational costs, and decrease greenhouse gas emissions.

The adaptability of micro turbines to varying steam conditions makes them suitable for a range of configurations, from small-scale setups in individual buildings to larger installations in industrial facilities or district energy systems. This scalability is a key advantage, as it allows operators to design systems that meet specific energy demands without overbuilding or underutilizing capacity.

Energy savings and environmental benefits are significant motivators for the adoption of systems that incorporate micro steam turbines. By using the same steam for both power generation and heating, overall fuel consumption is reduced, leading to lower emissions. This is particularly important in industries that rely on fossil fuels for steam production, as improved efficiency can significantly mitigate their environmental impact.

In addition to their efficiency benefits, micro steam turbines offer operational flexibility. Their ability to adjust to fluctuations in steam supply or demand makes them a reliable choice for facilities with variable energy needs. Modern turbines equipped with advanced control systems can dynamically optimize their performance, ensuring that both power and thermal energy outputs match the requirements of the application. These systems can also monitor turbine operation, diagnose potential issues, and facilitate maintenance, reducing downtime and operational costs.

The role of micro turbines extends beyond traditional industrial and building applications. They are increasingly being integrated into renewable energy systems where sustainability and efficiency are paramount. For instance, in biomass power plants, micro turbines can generate electricity while using the remaining steam for drying biomass feedstock or other processing tasks. This integrated approach enhances the overall sustainability of the system by making the most of the available energy resources.

Micro steam turbines also support energy resilience by enabling decentralized energy generation. In regions with unreliable power grids or remote locations, these turbines can operate independently or as part of a microgrid, ensuring a consistent supply of electricity and heat. This independence from centralized systems reduces vulnerability to outages and supports the development of self-sufficient energy systems.

While the benefits of using micro turbines in combined systems are clear, their implementation requires careful planning and consideration. Designing an efficient system involves balancing the power and thermal energy outputs, selecting suitable turbine configurations, and integrating the system with existing infrastructure. The initial investment in micro turbines and associated equipment may be a barrier for some operators, but the long-term cost savings and environmental advantages often outweigh these upfront costs.

Technological advancements are further driving the adoption of micro steam turbines by making them more efficient, reliable, and user-friendly. Innovations in turbine materials, blade design, and automation have improved performance while reducing maintenance requirements. These developments, combined with increasing awareness of the importance of energy efficiency, are contributing to the growing popularity of systems that integrate micro turbines.

Ultimately, micro steam turbines represent a critical technology for enhancing energy efficiency, reducing waste, and supporting sustainability. Their ability to simultaneously provide power and heat aligns with global energy goals and offers significant benefits for both industrial and residential applications. As energy systems continue to evolve, the role of micro turbines in creating efficient, integrated energy solutions is expected to expand, driving further innovation and adoption.

Waste-to-Energy Systems

Micro steam turbines are integral components of waste-to-energy (WTE) systems, where their role is to convert steam generated from the combustion of waste materials into usable electrical or mechanical power. By leveraging the energy content of municipal solid waste, agricultural residues, or industrial by-products, WTE systems provide an efficient means of addressing two critical challenges: energy generation and waste management. The use of micro steam turbines in these systems enhances energy recovery and contributes to the overall efficiency and sustainability of the process.

In a typical WTE system, waste is combusted in a controlled environment to produce high-temperature flue gases, which then heat water in a boiler to generate steam. This steam, under high pressure and temperature, is directed into a micro steam turbine, where it undergoes expansion and releases energy to drive the turbine’s rotor. The mechanical energy from the rotor is either used directly to power equipment or converted into electricity through a generator. The exhaust steam from the turbine may then be condensed and recirculated, or it can be used for secondary purposes like heating or industrial processes.

The ability of micro steam turbines to operate with varying steam conditions makes them particularly well-suited for WTE applications. Waste-derived steam often exhibits fluctuations in pressure and temperature due to the heterogeneous nature of the fuel. Advanced turbine designs and control systems allow micro turbines to adapt to these variations, ensuring consistent performance and reliable energy output even in challenging conditions.

One of the key advantages of integrating micro steam turbines into WTE systems is their contribution to energy efficiency. By capturing the energy from waste materials that would otherwise be discarded or incinerated without energy recovery, these turbines reduce the need for conventional fossil fuel-based power generation. This not only lowers greenhouse gas emissions but also helps conserve finite natural resources. Additionally, the use of waste as a feedstock for energy production aligns with principles of the circular economy by transforming discarded materials into valuable resources.

The environmental benefits of micro steam turbines in WTE systems extend beyond energy generation. By reducing the volume of waste destined for landfills, these systems help mitigate issues such as land use, groundwater contamination, and methane emissions associated with decomposing organic waste. Furthermore, modern WTE facilities are equipped with advanced pollution control technologies, such as scrubbers and filters, to minimize emissions of particulate matter and harmful gases during the combustion process.

Micro steam turbines also enhance the economic viability of WTE systems by enabling revenue generation through electricity sales. In many regions, electricity produced from waste is eligible for renewable energy credits or subsidies, further incentivizing the adoption of WTE technologies. The compact size and modular design of micro turbines make them an attractive option for small-scale WTE facilities, where larger turbines may be impractical or uneconomical.

Despite these advantages, there are challenges associated with using micro steam turbines in WTE applications. The composition of waste can vary widely, leading to inconsistencies in the quality and quantity of steam produced. These variations necessitate robust system design and the use of advanced control mechanisms to maintain stable turbine operation. Additionally, the corrosive nature of flue gases and residues generated during waste combustion can pose risks to turbine components, requiring the use of specialized materials and coatings to ensure durability.

Ongoing advancements in turbine technology and waste processing techniques are addressing many of these challenges. For example, improvements in boiler design and combustion control systems help produce more consistent steam, while innovations in turbine materials and blade designs enhance resistance to wear and corrosion. Additionally, the integration of data-driven monitoring systems allows operators to optimize performance and predict maintenance needs, reducing downtime and operational costs.

The role of micro steam turbines in WTE systems is not limited to industrial-scale operations. These turbines are increasingly being used in smaller, decentralized WTE facilities, which are ideal for communities or regions with limited access to large-scale waste management infrastructure. By converting locally generated waste into energy, these systems support energy independence and provide a sustainable solution to waste disposal challenges.

As global energy and environmental priorities continue to evolve, the importance of micro steam turbines in WTE systems is likely to grow. Their ability to efficiently harness the energy potential of waste materials makes them a valuable tool in the transition to sustainable energy systems. By combining energy generation with waste reduction, micro turbines contribute to the dual goals of reducing environmental impact and meeting rising energy demands, highlighting their essential role in the future of energy and waste management.

Renewable Energy Systems

Micro steam turbines play a crucial role in renewable energy systems, particularly in applications where steam is generated from sources such as biomass, geothermal, and solar thermal energy. These turbines are well-suited for environments where renewable resources are abundant and can be harnessed to provide reliable power generation while minimizing environmental impacts. By efficiently converting thermal energy from renewable sources into electricity or mechanical energy, micro steam turbines contribute to reducing reliance on fossil fuels and promoting sustainable energy solutions.

In biomass energy systems, micro steam turbines are commonly used to generate power from organic materials such as wood chips, agricultural residues, and other plant-based feedstocks. These materials are combusted or processed through thermochemical conversion technologies like gasification or pyrolysis to produce steam. The steam is then directed into a micro steam turbine, where it drives a generator to produce electricity. The ability of micro turbines to operate efficiently with lower steam pressures and temperatures makes them an ideal solution for biomass applications, where steam conditions may not always match those of conventional power plants.

One of the key advantages of using micro steam turbines in biomass power generation is their scalability. Small-scale biomass plants can benefit from micro turbines, providing a decentralized power solution that reduces transmission losses and enhances energy security for rural or remote areas. These plants can operate on locally sourced biomass, reducing transportation costs and contributing to the local economy. In addition to electricity generation, the heat from the steam can be used for district heating or industrial processes, enhancing the overall efficiency of the system and ensuring that waste heat is put to productive use.

Geothermal energy systems also benefit from the integration of micro steam turbines. In these systems, steam is extracted from geothermal reservoirs deep within the Earth, where it is heated naturally by the planet’s internal heat. This steam is brought to the surface, where it drives a turbine to produce electricity. Micro turbines are particularly well-suited for geothermal power generation due to their ability to operate with varying steam pressures and temperatures, which are common in geothermal systems. By efficiently capturing energy from the steam, micro turbines contribute to the generation of clean, renewable power with minimal environmental impact.

One of the major benefits of geothermal energy is its reliability as a baseload power source. Unlike intermittent renewable resources like solar and wind, geothermal energy is available 24/7, making it an attractive option for steady power generation. Micro steam turbines enhance this reliability by ensuring that the energy extracted from the geothermal steam is used efficiently, maximizing the potential of the resource. Additionally, geothermal systems with micro turbines can be designed to provide both electricity and heating, further improving the overall energy efficiency and reducing operational costs.

Solar thermal power generation is another area where micro steam turbines are increasingly being integrated. In solar thermal systems, sunlight is concentrated using mirrors or lenses to heat a fluid, which then generates steam to power a turbine. While large-scale solar thermal plants typically use steam turbines, micro turbines are being deployed in smaller, distributed solar thermal systems, providing a scalable solution for residential or commercial applications. These systems are particularly valuable in regions with high solar insolation, where the use of concentrated solar power can generate clean electricity without relying on fossil fuels.

The use of micro steam turbines in renewable energy systems offers several advantages, including their ability to operate with a variety of thermal sources, their compact size, and their efficiency in low- and medium-pressure steam environments. These characteristics make micro turbines an ideal choice for decentralized, small-scale renewable energy projects, which can be integrated into communities or businesses seeking to reduce their carbon footprint and improve energy independence. Additionally, as renewable energy adoption continues to grow, the flexibility and scalability of micro steam turbines will be increasingly important in meeting the diverse energy needs of different sectors.

One of the challenges associated with the use of micro turbines in renewable energy systems is the variability in steam conditions. For example, in biomass and solar thermal systems, the quality and quantity of steam can fluctuate depending on fuel availability, weather conditions, and other factors. Micro turbines, however, are designed to adapt to these variations, ensuring that energy is still efficiently extracted from the steam. This adaptability makes them a valuable tool in renewable energy systems, where resource availability is often less predictable than in conventional power plants.

Furthermore, as technology advances, the performance of micro steam turbines continues to improve. Innovations in materials, turbine design, and digital control systems are enhancing efficiency, reliability, and ease of maintenance. For example, advanced coatings and materials are increasing the durability of turbines in harsh environments, such as those found in geothermal and biomass applications. Digital control systems also enable real-time monitoring and optimization of turbine performance, reducing the need for manual intervention and improving overall system reliability.

The growing interest in renewable energy systems, coupled with increasing concerns about climate change and energy security, is driving demand for technologies like micro steam turbines that can provide clean, reliable, and cost-effective power generation. By tapping into renewable resources like biomass, geothermal, and solar thermal energy, micro turbines offer a sustainable solution to meeting global energy needs while reducing environmental impact.

As renewable energy adoption continues to increase, micro steam turbines will play an increasingly important role in facilitating the transition to a low-carbon energy future. Their efficiency, scalability, and ability to work with a variety of renewable sources make them a key component of the evolving energy landscape. With continued technological advancements and growing support for sustainable energy solutions, micro steam turbines are poised to become a vital part of the renewable energy infrastructure.

Key Features of Mini Steam Turbines:

- Compact Size: Mini steam turbines are significantly smaller than conventional steam turbines, making them suitable for installation in confined spaces and smaller applications.

- Modular Design: Mini steam turbines are often designed as modular units, allowing for scalability and customization based on specific application requirements.

- High Efficiency: Mini steam turbines can achieve high efficiency levels, converting a substantial portion of the thermal energy of steam into mechanical energy.

- Versatility: Mini steam turbines can operate on a variety of steam sources, including boilers, waste heat recovery systems, and other heat sources.

- Low Maintenance: Mini steam turbines are generally low-maintenance devices, requiring minimal upkeep compared to larger steam turbines.

Applications of Mini Steam Turbines:

- Industrial Processes: Mini steam turbines are used in various industrial processes, such as material handling, drying, and power generation for specific machinery.

- CHP (Combined Heat and Power) Systems: Mini steam turbines are incorporated into CHP systems to provide both electricity and heat for industrial or commercial buildings.

- Microgrids: Mini steam turbines can be integrated into microgrids, providing decentralized power generation and improving grid stability.

- Renewable Energy Integration: Mini steam turbines can be paired with renewable energy sources, such as solar or geothermal power, to optimize energy production and efficiency.

- Waste Heat Recovery: Mini steam turbines can recover waste heat from industrial processes, converting it into usable energy and reducing energy consumption.

Benefits of Using Mini Steam Turbines:

- Reduced Energy Costs: Mini steam turbines can help lower energy costs by optimizing energy production and reducing reliance on external power sources.

- Space Savings: Mini steam turbines are compact, allowing for installation in smaller spaces and reducing the need for dedicated power generation facilities.

- Reduced Environmental Impact: Mini steam turbines can contribute to improved environmental performance by reducing reliance on fossil fuels and utilizing waste heat.

- Adaptability to Various Applications: Mini steam turbines can be tailored to specific application requirements, making them versatile for a wide range of industrial and power generation needs.

- Modular Scalability: Mini steam turbines can be scaled up or down based on increasing or decreasing power demands, providing flexibility for project expansion or modifications.

Future Trends in Mini Steam Turbine Technology:

- Advanced Steam Cycles: Research is focusing on developing more efficient steam cycles for mini steam turbines to further improve energy conversion and reduce emissions.

- High-Temperature and Pressure Operation: Advances in materials and design are enabling mini steam turbines to operate at higher temperatures and pressures, enhancing power output and efficiency.

- Integrated Control Systems: Intelligent control systems are being developed to optimize mini steam turbine operation, ensuring efficient power generation and minimizing maintenance requirements.

- Hybrid Power Systems: Mini steam turbines are being integrated into hybrid power systems with renewable energy sources, such as solar and wind power, to create more sustainable and efficient energy solutions.

- Adaptation to Microgrids: Mini steam turbines are being designed to operate seamlessly within microgrids, providing flexible and reliable power distribution.

Micro Steam Turbine

A micro steam turbine is a small-scale steam turbine designed for decentralized power generation in applications where a compact and efficient power source is needed. Micro steam turbines are typically used in capacities ranging from a few kilowatts to a few hundred kilowatts. These turbines are well-suited for applications such as residential or small-scale commercial power generation, combined heat and power (CHP) systems, and distributed energy generation. Here are key features and considerations related to micro steam turbines:

- Size and Compact Design:

- Micro steam turbines are characterized by their small size and compact design, making them suitable for installation in limited spaces.

- Decentralized Power Generation:

- The primary application of micro steam turbines is for decentralized power generation, providing electricity on-site for specific applications or localities.

- Combined Heat and Power (CHP) Systems:

- Micro steam turbines can be integrated into Combined Heat and Power (CHP) systems, where they simultaneously generate electricity and useful thermal energy for heating or other industrial processes.

- Low to Medium Power Outputs:

- Micro steam turbines typically operate in the low to medium power output range, making them suitable for applications where a few kilowatts to a few hundred kilowatts of electrical power are needed.

- Applications in Residential and Commercial Settings:

- Micro steam turbines can be used in residential and small commercial settings to provide on-site power generation and potentially contribute to grid stability.

- Fuel Sources:

- Micro steam turbines can operate on various fuel sources, including natural gas, biomass, or waste heat from industrial processes. The choice of fuel depends on the specific application and available resources.

- Efficiency Considerations:

- The efficiency of micro steam turbines is an important consideration, especially in combined heat and power applications. Maximizing the overall energy efficiency is crucial for optimizing the system’s performance.

- Modularity:

- Some micro steam turbine systems are designed with modularity in mind, allowing for the installation of multiple units to meet varying power demand or to provide redundancy.

- Electrical Generation with Alternators:

- Micro steam turbines typically include an alternator or generator to convert the mechanical energy produced by the turbine into electrical power.

- Maintenance and Reliability:

- Due to their smaller size and simplified design, micro steam turbines often require less maintenance compared to larger industrial turbines. Regular inspections and preventive maintenance help ensure reliable operation.

- Environmental Considerations:

- Micro steam turbines can contribute to environmental sustainability, especially when they utilize renewable or waste heat sources. They can help reduce greenhouse gas emissions by providing cleaner and more efficient power generation.

- Customization for Specific Applications:

- Micro steam turbines may be customized for specific applications, taking into account factors such as the type of fuel available, the power demand, and the desired thermal output.

Micro steam turbines play a role in decentralized energy systems, providing a compact and efficient solution for on-site power generation. Their versatility makes them suitable for a range of applications where localized and efficient power production is required.

Size and Compact Design

The size and compact design of a steam turbine play a crucial role in determining its suitability for various applications. When discussing the size and compactness of a steam turbine, several factors come into play:

- Physical Dimensions:

- The physical dimensions of a steam turbine refer to its overall size, including the length, width, and height. Compact design aims to minimize the space occupied by the turbine, making it suitable for installations with limited space availability.

- Weight:

- The weight of a steam turbine is an important consideration, especially in applications where weight restrictions or structural limitations exist. A compact and lightweight design allows for easier installation and integration into existing systems.

- Footprint:

- The footprint of a steam turbine refers to the area it occupies on the ground or within a facility. Compact turbines have a smaller footprint, which is advantageous in situations where space is a premium.

- Modularity:

- Some steam turbines, including micro steam turbines, are designed with modularity in mind. Modularity allows for the installation of multiple units in parallel, providing scalability and flexibility in meeting varying power demands.

- Ease of Installation:

- Compact steam turbines are often designed for ease of installation. This includes considerations for transportation, handling, and assembly, making the installation process more straightforward and cost-effective.

- Integration into Existing Systems:

- In many applications, steam turbines need to be integrated into existing systems or facilities. A compact design facilitates the integration process, allowing for easier retrofitting or addition to an existing power generation or industrial setup.

- Reduced Infrastructure Requirements:

- Compact steam turbines may require less supporting infrastructure, such as foundations and structural reinforcements. This can contribute to cost savings and faster deployment.

- Portability:

- In certain applications, portability may be a key consideration. Portable steam turbines can be moved and deployed as needed, which is beneficial in temporary or remote power generation setups.

- Materials and Construction:

- The materials used in the construction of a steam turbine can influence its size and weight. Advancements in materials technology allow for the design of lightweight yet durable components, contributing to a more compact overall turbine.

- Efficiency of Design:

- A compact design does not necessarily mean a sacrifice in efficiency. Modern design practices and advanced engineering techniques enable the development of turbines that are both compact and highly efficient in converting thermal energy into mechanical or electrical energy.

- Environmental Considerations:

- A compact and efficient steam turbine can contribute to environmental sustainability by reducing the environmental footprint associated with the installation, operation, and maintenance of the turbine.

The size and compact design of a steam turbine are critical considerations in determining its applicability to specific settings and applications. These features become particularly important in decentralized power generation, microgeneration, and industrial applications where space constraints and ease of integration are key factors.

Decentralized Power Generation

Decentralized power generation, also known as distributed generation, refers to the generation of electricity from a variety of small-scale or modular energy sources that are located close to the point of use. Instead of relying solely on large centralized power plants, decentralized power generation involves multiple smaller generators distributed across a network. Here are key characteristics and advantages of decentralized power generation:

- Localized Generation:

- Decentralized power generation involves producing electricity near the end-users or at the site where it is needed. This contrasts with centralized power generation, where electricity is generated at a distant power plant and transmitted over long distances.

- Diverse Energy Sources:

- Various energy sources can be employed for decentralized power generation, including solar photovoltaic (PV) systems, wind turbines, small-scale hydroelectric systems, biomass generators, and micro gas turbines. This diversity allows for the use of locally available resources.

- Reduced Transmission Losses:

- Since electricity is generated closer to the point of use, there are fewer transmission and distribution losses associated with transporting electricity over long distances. This can contribute to overall energy efficiency.

- Increased Resilience:

- Decentralized systems enhance the resilience of the electricity grid. If one generator or section of the grid experiences a failure, other distributed generators can continue to provide power, reducing the impact of outages.

- Quick Deployment:

- Small-scale generators can often be deployed more quickly than large centralized power plants. This is especially important in emergency situations or in regions where rapid access to electricity is crucial.

- Scalability:

- Decentralized power generation systems are often scalable, allowing for the addition of more generators to match increasing energy demand. This flexibility is beneficial in growing or dynamic communities.

- Local Economic Development:

- By utilizing local energy resources and supporting small-scale projects, decentralized power generation can contribute to local economic development. This includes job creation and investment in local energy infrastructure.

- Integration of Renewable Energy:

- Decentralized systems are well-suited for integrating renewable energy sources, such as solar and wind power. They enable the distributed integration of intermittent renewable sources into the grid.

- Community and Industrial Applications:

- Decentralized power generation is applicable in a variety of settings, including residential, commercial, industrial, and community-level applications. It can be utilized for both grid-connected and off-grid scenarios.

- Combined Heat and Power (CHP):

- Decentralized generation systems can incorporate Combined Heat and Power (CHP) technologies, where the waste heat generated during electricity production is used for heating or other industrial processes. This enhances overall energy efficiency.

- Technological Innovation:

- The decentralized model encourages the adoption of innovative technologies, including smart grids, energy storage, and advanced control systems. These technologies enhance the reliability and efficiency of distributed energy systems.

- Environmental Benefits:

- Depending on the energy sources used, decentralized power generation can contribute to environmental sustainability by reducing emissions, promoting renewable energy use, and minimizing the environmental impact associated with large centralized power plants.

Decentralized power generation represents a shift towards a more resilient, flexible, and sustainable energy infrastructure. As technology continues to advance, the integration of decentralized systems into the overall energy landscape is expected to grow, providing a more diverse and efficient approach to meeting energy needs.

Combined Heat and Power (CHP) Systems

Combined Heat and Power (CHP) systems, also known as cogeneration systems, simultaneously generate electricity and useful thermal energy (heat) from a single primary energy source. This integrated approach to power generation offers increased overall efficiency compared to separate heat and power generation. Here are key components and features of Combined Heat and Power systems:

- Electricity Generation:

- CHP systems produce electricity using a prime mover, which can be a steam turbine, gas turbine, or internal combustion engine. The prime mover converts the energy from the primary fuel into mechanical energy, which is then used to drive an electric generator.

- Useful Thermal Energy:

- In addition to electricity, CHP systems capture and utilize the waste heat generated during the electricity generation process. This waste heat is recovered and used for heating applications, such as space heating, industrial processes, or hot water production.

- High Overall Efficiency:

- CHP systems achieve higher overall efficiency compared to traditional separate heat and power systems. By utilizing the waste heat, CHP systems can achieve total energy efficiencies that exceed those of conventional power plants.

- Applications:

- CHP systems find applications in various industries, including manufacturing, commercial buildings, hospitals, universities, and district heating. They are especially beneficial in situations where there is a simultaneous need for electricity and thermal energy.

- Types of Prime Movers:

- CHP systems can be configured with different types of prime movers based on the specific requirements and available resources. Common prime movers include steam turbines, gas turbines, internal combustion engines, and microturbines.

- Fuel Flexibility:

- CHP systems can operate on a variety of fuels, including natural gas, biomass, coal, and waste heat from industrial processes. The choice of fuel depends on factors such as availability, cost, and environmental considerations.

- District Heating:

- CHP systems can be integrated into district heating networks, where the surplus heat generated during electricity production is utilized for space heating in residential and commercial areas.

- Micro-CHP:

- In addition to larger-scale CHP systems, there are also micro-CHP systems designed for smaller applications, such as residential or small commercial buildings. These systems can provide both electricity and heat at a smaller scale.

- Combined Cooling, Heating, and Power (CCHP):

- Some CHP systems are configured as Combined Cooling, Heating, and Power systems. These systems incorporate technologies such as absorption chillers to provide cooling in addition to electricity and heat.

- Environmental Benefits:

- CHP systems contribute to reduced greenhouse gas emissions compared to separate heat and power systems. The efficient use of fuel and the utilization of waste heat help minimize the environmental impact of energy production.

- Regulatory Support:

- In some regions, there are regulatory incentives and support for the installation and operation of CHP systems. These incentives aim to promote energy efficiency and sustainability.

- Load Following:

- CHP systems, especially those with flexible prime movers, can adjust their output to match variations in electricity demand. This load-following capability enhances grid stability.

Combined Heat and Power systems play a crucial role in enhancing energy efficiency and reducing environmental impact by maximizing the use of primary energy sources. The ability to simultaneously generate electricity and useful thermal energy makes CHP systems a valuable option in various industries and applications.

Low to Medium Power Outputs

When referring to low to medium power outputs in the context of power generation systems, it generally implies that the system is designed to produce electrical power within a certain range, typically from a few kilowatts (kW) to a few megawatts (MW). This power output range is often suitable for various applications where decentralized or distributed power generation is needed. Here are some key considerations associated with low to medium power outputs:

- Decentralized Power Generation:

- Low to medium power outputs are well-suited for decentralized power generation, where energy is produced near the point of use. This can be beneficial for residential, commercial, and industrial applications.

- Residential and Small Commercial Applications:

- Systems with low to medium power outputs are commonly used in residential settings for individual homes or small commercial buildings. Examples include solar photovoltaic systems, small wind turbines, and micro-CHP (Combined Heat and Power) units.

- Micro-Grids: