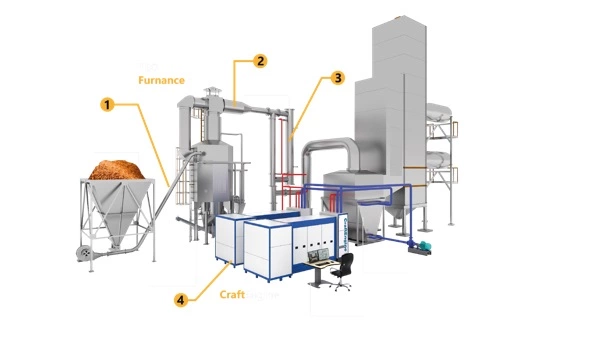

A wood gasifier is a device that converts wood or other biomass materials into a combustible gas called wood gas or syngas. The gas can be used as a fuel for various applications, including heating, cooking, and generating electricity. Here’s a general overview of how a wood gasifier works:

- Fuel Preparation: The wood or biomass material is first processed into small pieces or chips. This allows for better gasification and efficient combustion.

- Pyrolysis: The wood gasifier operates in a low-oxygen environment. The fuel is heated to a high temperature, typically around 700-1,200 degrees Celsius (1,300-2,200 degrees Fahrenheit), causing it to undergo a process called pyrolysis. During pyrolysis, the fuel breaks down into volatile gases, including carbon monoxide (CO), hydrogen (H2), and methane (CH4).

- Combustion Chamber: The pyrolysis gases move into the combustion chamber of the gasifier. The chamber contains a limited supply of oxygen, allowing for partial combustion of the gases. This produces additional heat and carbon dioxide (CO2).

- Gasification: The partially combusted gases, along with the remaining solid char, pass into the gasification zone of the gasifier. In this zone, the remaining carbon monoxide and water vapor react with the char at high temperatures to produce more carbon monoxide and hydrogen. This is the primary stage where the wood gas is formed.

- Gas Cleaning: The gas produced in the gasification zone contains impurities such as tar, ash, and particulate matter. To ensure a clean and usable gas, it undergoes a cleaning process. This may involve passing the gas through filters, scrubbers, or other cleaning mechanisms to remove impurities and cool down the gas.

- Gas Utilization: The cleaned and cooled wood gas can be utilized for various applications. It can be directed to an internal combustion engine, such as a generator or vehicle engine, where it replaces conventional fuels like gasoline or diesel. It can also be used for heating by burning the gas in a furnace or boiler, or for cooking by using specialized wood gas stoves.

How Does a Wood Gasifier Work

Wood gasifiers offer the advantage of utilizing renewable biomass resources, such as wood chips, sawdust, or agricultural waste, for energy production. They provide an alternative energy solution that can be more sustainable and environmentally friendly compared to fossil fuels. However, it’s important to note that operating a wood gasifier requires proper knowledge, maintenance, and safety precautions due to the combustible nature of the produced gas.

Fuel Preparation

Fuel preparation for a wood gasifier involves transforming solid biomass, such as wood chips, into a suitable form for efficient gasification. Proper fuel preparation is important to ensure optimal gasification performance and maximize the energy output. The fuel preparation process typically includes the following steps:

- Size Reduction: The biomass fuel, such as logs, branches, or wood chips, needs to be reduced in size to increase its surface area and facilitate the gasification process. This can be achieved through mechanical methods such as chipping, shredding, or grinding. The size of the fuel particles may vary depending on the specific design and requirements of the gasifier.

- Moisture Content Control: Biomass typically contains moisture, which can negatively affect the gasification process. Excess moisture can reduce the gasifier’s efficiency and decrease the energy output. Therefore, it is important to control and reduce the moisture content of the fuel. This can be done by properly drying the biomass before using it in the gasifier. Drying methods may include air drying, using a kiln, or utilizing solar or thermal energy to remove moisture.

- Size Sorting: Depending on the gasifier design, it may be necessary to sort the fuel particles based on their size. Some gasifiers require a specific particle size range to ensure optimal gasification and prevent issues such as clogging or uneven combustion. Sorting the fuel particles can be done using sieves or screens to separate them into different size fractions.

- Quality Control: Ensuring the quality of the fuel is essential for efficient gasification. It is important to remove any contaminants or non-combustible materials, such as rocks, metals, or excessive bark, from the biomass. These contaminants can interfere with the gasification process and cause damage to the gasifier. Additionally, the fuel should be free from chemical treatments or coatings that could release harmful emissions during gasification.

Proper fuel preparation is crucial for the smooth operation and efficiency of a wood gasifier. It allows for consistent and controlled gasification, leading to reliable energy production. It is recommended to follow the manufacturer’s guidelines and recommendations regarding the fuel specifications and preparation methods for a specific gasifier model.

Pyrolysis

Pyrolysis is a thermal decomposition process that occurs when organic materials are heated in the absence or with limited oxygen. It is a key step in the wood gasification process and plays a crucial role in converting solid biomass into gas and liquid products. During pyrolysis, the organic material undergoes chemical and physical transformations, breaking down into different components.

The pyrolysis process involves several stages:

- Drying: Initially, as the biomass is heated, any moisture present in the material is driven off. The temperature increases, and the biomass starts to release water vapor.

- Degradation: As the temperature continues to rise, the biomass undergoes thermal degradation. The organic material breaks down into solid char, liquid tar, and gases. The exact composition and distribution of these products depend on factors such as temperature, heating rate, and the composition of the biomass.

- Char Formation: The solid char, or carbonaceous residue, is a byproduct of pyrolysis. It consists of carbon-rich material that remains after the volatile components have been released. The char can be further utilized as a source of heat or energy.

- Tar Formation: The liquid tar is a complex mixture of organic compounds that condenses during the pyrolysis process. It contains a range of hydrocarbons and other organic substances. Tar can be sticky and viscous, and it requires further processing or treatment to remove impurities before it can be used.

- Gas Production: The primary gases produced during pyrolysis are carbon monoxide (CO), hydrogen (H2), methane (CH4), and other hydrocarbons. These gases are collectively known as syngas or wood gas. The composition of the syngas depends on various factors, including the type of biomass, temperature, and residence time in the pyrolysis zone.

The pyrolysis process is typically controlled by adjusting the temperature and residence time to achieve the desired gas and liquid products. The generated gases and liquids are valuable energy sources and can be used for various applications, including heating, electricity generation, and as feedstock for the production of chemicals and fuels.

It is important to note that pyrolysis is just one stage of the overall wood gasification process. After pyrolysis, the resulting gases and liquids undergo further reactions and cleaning before they are used as fuel in a gasifier or other combustion devices.

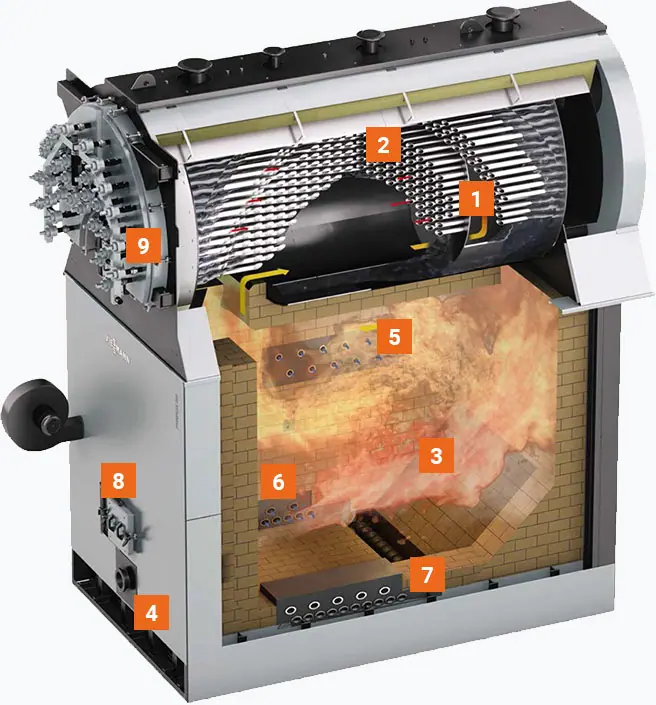

Combustion Chamber

The combustion chamber is a crucial component of various combustion systems, including wood gasifiers, boilers, and furnaces. It is the space where the combustion of fuel takes place, converting the chemical energy of the fuel into heat energy. In the context of a wood gasifier, the combustion chamber is where the wood gas produced during the gasification process is burned.

The main functions of the combustion chamber are as follows:

- Fuel Combustion: The primary purpose of the combustion chamber is to facilitate the controlled combustion of the fuel. In the case of a wood gasifier, the wood gas produced from the gasification process is introduced into the combustion chamber, along with an adequate supply of air or oxygen. The mixture of fuel and oxygen is ignited, and the combustion reaction occurs, releasing heat energy.

- Heat Transfer: The combustion chamber is designed to maximize heat transfer from the combustion process to the surrounding medium, such as water or air. The heat generated by the burning fuel is transferred through the walls of the combustion chamber to the heat transfer medium, which can then be utilized for various purposes, such as space heating, water heating, or electricity generation.

- Combustion Control: The design of the combustion chamber plays a crucial role in achieving efficient and controlled combustion. It involves considerations such as optimizing the air-fuel ratio, maintaining proper turbulence and mixing of fuel and air, and ensuring sufficient residence time for complete combustion. The combustion chamber may have features like baffles, secondary air injection, or other mechanisms to enhance combustion efficiency and minimize emissions.

- Emission Control: The combustion chamber also serves to minimize emissions of harmful pollutants generated during the combustion process. By ensuring complete combustion and providing appropriate conditions for combustion, the combustion chamber helps to reduce the formation of pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. This is important for environmental and health considerations.

The design and construction of the combustion chamber depend on the specific application, fuel type, desired heat output, and emission requirements. It is important to consider factors such as chamber geometry, insulation, refractory materials, and the provision of air supply and exhaust systems to optimize combustion efficiency and ensure safe and reliable operation. Regular maintenance and cleaning of the combustion chamber are also essential to maintain its performance and prevent the accumulation of ash or soot.

Gasification

Gasification is a thermochemical process that converts solid or liquid carbon-based fuels into a combustible gas known as syngas (synthesis gas). It is a versatile and efficient method of harnessing energy from biomass, coal, or other organic materials. Gasification involves the partial oxidation of the fuel at high temperatures, typically in the range of 700 to 1,200 degrees Celsius (1,300 to 2,200 degrees Fahrenheit), in the presence of a controlled amount of oxygen or air.

The gasification process can be summarized in the following steps:

- Drying: In the initial stage, the feedstock is dried to remove moisture. This is important to ensure efficient gasification and prevent excessive energy loss due to evaporation.

- Pyrolysis: The dried feedstock is then subjected to pyrolysis, which is the thermal decomposition of organic materials in the absence of oxygen. This leads to the release of volatile compounds, including gases, tars, and char.

- Combustion: The next step involves introducing a limited amount of oxygen or air into the gasification reactor. The volatiles released during pyrolysis undergo partial oxidation or combustion, resulting in the production of carbon dioxide (CO2), water vapor (H2O), and heat.

- Gasification: The remaining char and any carbonaceous material present in the feedstock undergo gasification in the presence of the high-temperature environment. This process converts the carbon in the fuel into a mixture of gases, primarily carbon monoxide (CO) and hydrogen (H2), along with traces of methane (CH4) and other hydrocarbons. This gas mixture is known as syngas.

The produced syngas is a valuable fuel that can be used in various applications, including heat and power generation, as well as the production of chemicals and fuels. It can be combusted directly in a gas engine or boiler, or further processed to remove impurities and separate individual components for specific uses.

Gasification offers several advantages over conventional combustion methods:

- Higher Efficiency: Gasification can achieve higher energy conversion efficiencies compared to direct combustion, as it allows for the extraction of more energy from the fuel by converting a larger portion of the carbon content into combustible gases.

- Fuel Flexibility: Gasification can utilize a wide range of feedstock materials, including biomass, coal, municipal solid waste, and even certain types of industrial waste. This makes it a versatile technology that can utilize diverse sources of fuel.

- Reduced Emissions: Gasification can be designed to minimize emissions of pollutants, such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. By optimizing the gasification process, it is possible to achieve cleaner combustion and lower environmental impact.

- Syngas Utilization: The syngas produced from gasification can be used in various applications, including electricity generation through gas engines or turbines, combined heat and power (CHP) systems, and as a feedstock for the production of chemicals, fertilizers, and transportation fuels.

Overall, gasification is a versatile and efficient technology for converting carbon-based fuels into a useful gas product. It offers opportunities for sustainable energy production, waste management, and the utilization of diverse fuel sources.

Gas Cleaning

Gas cleaning is an important step in the gasification process to remove impurities and contaminants from the syngas produced. The syngas generated during gasification contains various by-products, such as tars, particulate matter, sulfur compounds, ammonia, and other trace elements, which need to be removed to meet specific quality requirements for different applications.

Gas cleaning typically involves a combination of physical, chemical, and thermal processes to achieve the desired level of purification. The specific gas cleaning methods employed can vary depending on the composition of the syngas and the end-use requirements. Here are some common gas cleaning techniques:

- Particulate Removal: Syngas often contains solid particulate matter, such as ash, char, or dust. Particulate removal techniques, such as cyclone separators, electrostatic precipitators, or bag filters, are used to capture and remove these solid particles from the gas stream.

- Tar Removal: Tar is a complex mixture of organic compounds that can be present in the syngas. Tar can condense and cause fouling or damage to downstream equipment. Tar removal methods include processes like condensation, cooling, and filtration, which help to separate and capture the tar molecules from the gas stream.

- Acid Gas Removal: Syngas may contain sulfur compounds, such as hydrogen sulfide (H2S), which need to be removed to prevent corrosion and reduce environmental emissions. Techniques like amine scrubbing, adsorption, or catalytic conversion are used to selectively capture and remove acid gases from the syngas.

- Particulate Filtration: Fine particulate matter or aerosols present in the syngas can be removed through filtration techniques, such as ceramic filters or porous membranes. These filters effectively trap and separate fine particles, ensuring a cleaner gas stream.

- Water-Gas Shift Reaction: In certain gas cleaning processes, the syngas is subjected to the water-gas shift reaction, where carbon monoxide (CO) is reacted with steam to produce hydrogen (H2) and carbon dioxide (CO2). This reaction helps to adjust the hydrogen-to-carbon monoxide ratio in the syngas and remove excess carbon monoxide.

- Gas Cooling and Condensation: Cooling the syngas helps to remove moisture and condensable components, such as water vapor and light hydrocarbons. By reducing the temperature, these components can be condensed and separated from the gas stream.

The selection and combination of gas cleaning methods depend on factors such as the composition of the syngas, desired gas quality, process requirements, and environmental regulations. The goal of gas cleaning is to produce a purified syngas with the desired composition and properties suitable for its intended use, whether it is for power generation, heat production, or conversion into other valuable products.

Gas Utilization

Gas utilization refers to the various ways in which the syngas produced from gasification is used or converted into valuable products. Syngas is a versatile fuel that can be utilized in several applications, including:

- Power Generation: Syngas can be used as a fuel in gas engines, gas turbines, or combined heat and power (CHP) systems to generate electricity and heat. This is a common application for large-scale gasification plants where the syngas is combusted in an internal combustion engine or turbine to produce mechanical power, which is then converted into electricity.

- Heat Production: Syngas can be used for direct heat applications, such as heating buildings, industrial processes, or district heating systems. The syngas can be burned in a boiler or furnace to generate high-temperature heat for space heating or industrial processes.

- Biochemical Processes: Syngas can be converted into various biochemical products through fermentation or catalytic processes. For example, syngas can be converted into biofuels such as ethanol or methanol, which can be used as transportation fuels or as feedstocks for the chemical industry.

- Chemical Synthesis: Syngas can be used as a feedstock for the production of a wide range of chemicals. Through processes like Fischer-Tropsch synthesis or methanol synthesis, syngas can be converted into valuable chemicals, including hydrocarbons, alcohols, olefins, and other compounds used in the manufacturing of plastics, solvents, and other industrial products.

- Gasification for Biomass-to-Liquid (BTL) Technologies: Syngas can be further processed into liquid fuels through gas-to-liquids (GTL) or biomass-to-liquids (BTL) technologies. These processes involve converting the syngas into synthetic hydrocarbons, such as diesel, jet fuel, or gasoline, through catalytic reactions.

- Gas Grid Injection: In some cases, the syngas can be cleaned and upgraded to meet the quality standards for natural gas and injected into the existing natural gas grid. This allows for the syngas to be distributed and utilized in a wide range of applications that rely on natural gas, including residential, commercial, and industrial sectors.

The specific utilization of syngas depends on factors such as the composition of the syngas, local energy demands, infrastructure availability, and economic considerations. Different gasification technologies and gas cleaning processes can be employed to tailor the syngas composition for the desired utilization pathway.

A wood gasifier is a device that converts wood or other biomass materials into a combustible gas, known as wood gas or syngas. The gas can be used as a fuel for various applications, including heating, cooking, and generating electricity. Here’s how a wood gasifier typically works:

- Fuel Preparation: The wood or biomass material is processed into small pieces or chips to ensure efficient gasification. The size and moisture content of the fuel can affect the gasifier’s performance.

- Gasification Process: The wood gasifier consists of a combustion chamber where the fuel is heated in a low-oxygen environment, a process known as pyrolysis. This leads to the release of volatile gases from the wood, such as carbon monoxide, hydrogen, and methane.

- Gas Cleaning: The gas produced in the combustion chamber contains impurities like tar and particulate matter. It is then passed through a series of filters and cooling systems to remove these impurities and cool down the gas.

- Gas Utilization: The cleaned and cooled wood gas can be directed to various applications. It can be used to power internal combustion engines, such as generators or vehicles, by feeding it into the engine’s intake system. It can also be used for heating purposes by burning the gas in a combustion chamber or stove.

Wood gasifiers offer several advantages, including the ability to use renewable and locally available biomass resources for energy production. They can provide a sustainable and cost-effective energy solution, especially in areas with limited access to conventional fuels. However, it’s important to note that operating a wood gasifier requires proper knowledge and safety precautions due to the combustible nature of the gas produced.

When considering a wood gasifier, it’s essential to choose a model that suits your specific needs, taking into account factors such as power output, fuel consumption, and the availability of maintenance and support services. It’s also important to ensure compliance with local regulations and obtain any necessary permits or certifications before installing and operating a wood gasifier system.

Wood Gasifier for Sale USA

Wood gasifiers are a renewable energy technology that converts wood or biomass into a combustible gas known as wood gas or syngas. This gas can be used for various applications, including heat generation, electricity production, and powering internal combustion engines. If you are considering a wood gasifier for the USA market, here are some important factors to consider:

- Compliance with Regulations: Ensure that the wood gasifier meets all applicable regulations and standards in the USA. This includes safety standards, emission limits, and any specific requirements for wood-burning appliances. It is important to select a wood gasifier that is certified or compliant with relevant regulatory bodies or standards, such as the Environmental Protection Agency (EPA) guidelines.

- Sizing and Capacity: Determine the appropriate size and capacity of the wood gasifier based on your specific energy needs. Consider factors such as the heat or power output required, the availability of wood or biomass feedstock, and the intended application. The size of the wood gasifier will impact its efficiency, fuel consumption, and overall performance.

- Efficiency and Emissions: Look for wood gasifiers that offer high efficiency and low emissions. Efficiency is important to maximize the energy output from the available wood or biomass fuel. Low emissions help minimize the environmental impact and comply with air quality regulations. Consider features such as optimized combustion processes, advanced gas cleaning systems, and integrated emission control technologies.

- Fuel Flexibility: Check if the wood gasifier is designed to handle a variety of wood types and biomass feedstocks. Some gasifiers can accommodate different wood sizes, moisture content, and densities. The ability to use a range of feedstocks provides flexibility in sourcing fuel and ensures reliable operation throughout the year.

- Reliability and Maintenance: Assess the reliability and maintenance requirements of the wood gasifier. Look for systems with a track record of reliable performance and durability. Consider factors such as ease of maintenance, availability of spare parts, and access to technical support or service providers in the USA.

- System Integration and Controls: Consider how the wood gasifier integrates into your overall energy system. Look for features such as control systems, automation, and compatibility with other components, such as heat exchangers or electricity generators. Integration with existing infrastructure and energy management systems can enhance the overall efficiency and functionality of the wood gasifier.

- Training and Support: Ensure that adequate training and support are available for the installation, operation, and maintenance of the wood gasifier. This may include training programs, technical documentation, and access to knowledgeable support personnel. Having reliable support resources can help optimize the performance and longevity of the wood gasifier.

It is advisable to consult with reputable manufacturers, distributors, or industry experts who specialize in wood gasification technology to understand the specific options available in the USA market. They can provide guidance on selecting the most suitable wood gasifier based on your requirements, local regulations, and market availability.

Fuel Preparation

Fuel preparation for a wood gasifier involves properly processing and preparing the wood or biomass fuel before it is fed into the gasifier. The goal is to optimize the fuel’s characteristics to ensure efficient gasification and reliable operation of the system. Here are some important aspects of fuel preparation for a wood gasifier:

- Wood Selection: Choose the right type of wood for gasification. Hardwoods, such as oak, beech, or maple, are generally preferred due to their higher energy content and lower moisture content compared to softwoods. Select wood that is dry, seasoned, and free from contaminants, such as paints, coatings, or treated wood, as these can produce harmful emissions during gasification.

- Wood Size and Density: Prepare the wood fuel by cutting it into appropriate sizes for the gasifier. The wood should be in the form of small chips, pellets, or blocks with dimensions that are suitable for the gasifier’s feed system. The size and density of the wood can impact the gasification process and the gasifier’s performance, so it is important to follow the manufacturer’s guidelines or recommendations.

- Moisture Content: Ensure that the wood fuel has an optimal moisture content. High moisture content in the wood can result in incomplete combustion, reduced gas quality, and decreased overall efficiency. The ideal moisture content may vary depending on the specific gasifier design, but generally, a moisture content of around 10-20% is desirable. Properly drying and storing the wood fuel in a dry environment can help achieve the desired moisture content.

- Fuel Storage: Proper storage of the wood fuel is important to maintain its quality and prevent moisture absorption. Store the wood in a covered and well-ventilated area, protected from rain or excessive humidity. It is also advisable to store the wood in a way that allows for proper air circulation to prevent mold or decay.

- Fuel Processing: Depending on the gasifier design and fuel requirements, additional fuel processing may be necessary. This can include tasks such as debarking, chipping, or grinding the wood to the desired size and form. Some gasifiers may have specific fuel processing equipment or recommendations provided by the manufacturer.

It is essential to follow the gasifier manufacturer’s guidelines and recommendations for fuel preparation to ensure safe and efficient operation. Each gasifier system may have specific requirements based on its design, fuel feed mechanism, and gasification process. Consulting the manufacturer or an experienced professional in wood gasification technology will provide valuable guidance on the appropriate fuel preparation methods for your specific system.

Gasification Process

Gasification is a thermochemical process that converts organic materials, such as wood, biomass, or coal, into a gas known as syngas (synthetic gas). The gasification process involves the partial oxidation of the feedstock at high temperatures in a controlled environment, resulting in the production of a combustible gas mixture. Here is a general overview of the gasification process:

- Feedstock Preparation: The feedstock, such as wood chips, biomass pellets, or coal, is prepared by reducing its size, removing impurities, and ensuring a consistent feedstock quality. Proper feedstock preparation helps optimize the gasification process and improve the efficiency of gas production.

- Heating and Drying: The prepared feedstock is fed into the gasifier, which is a high-temperature reactor. Initially, the feedstock is heated and dried to remove any moisture content. The drying process is important to ensure efficient combustion and prevent excessive energy loss due to evaporating moisture.

- Pyrolysis: In the gasification process, the dried feedstock undergoes pyrolysis, which is the thermal decomposition of organic material in the absence of oxygen. The high temperature in the gasifier breaks down the complex organic compounds into simpler molecules, producing volatile gases, tars, and char.

- Gasification: The pyrolyzed products, including the volatile gases and tars, are then subjected to the gasification phase. In the presence of a controlled amount of oxygen or air, the volatile gases react with the oxygen to produce a mixture of carbon monoxide (CO), hydrogen (H2), methane (CH4), and other combustible gases. This mixture is known as syngas or producer gas.

- Tar and Particulate Removal: The syngas produced in the gasification process contains impurities such as tars and particulate matter. These impurities need to be removed to prevent fouling and damage to downstream equipment. Various cleaning methods, such as cyclones, filters, or scrubbers, are employed to separate and remove the tars and particulates from the syngas.

- Gas Cooling and Conditioning: After the cleaning process, the syngas is typically cooled to reduce its temperature and remove excess heat. It may also undergo further conditioning to adjust its composition, such as removing sulfur compounds or adjusting the gas ratios. This ensures that the syngas meets the desired specifications for specific applications.

- Syngas Utilization: The cleaned and conditioned syngas can be utilized for various applications, depending on the specific requirements. It can be used for heat and power generation in boilers, engines, or turbines. It can also be converted into liquid fuels, such as methanol or synthetic diesel, through additional processes like gas-to-liquids (GTL) technology.

Gasification offers several advantages, including high energy efficiency, fuel flexibility, and reduced emissions compared to conventional combustion processes. The specific details of the gasification process may vary depending on the feedstock, gasifier design, and intended application. Different gasifier technologies, such as fixed-bed gasifiers, fluidized bed gasifiers, or entrained flow gasifiers, may have variations in their operating parameters and process steps.

Gas Cleaning

Gas cleaning is an important step in the gasification process to remove impurities and ensure that the produced syngas meets the required specifications for further utilization. During the gasification process, various contaminants can be present in the syngas, including tars, particulates, sulfur compounds, and other trace elements. Gas cleaning involves the use of different technologies and methods to purify the syngas by removing these impurities. Here are some common gas cleaning techniques:

- Cyclones: Cyclone separators are used to remove particulate matter, such as ash, char, and dust, from the syngas. The gas is passed through a cyclone chamber, where centrifugal force causes the particles to separate and settle down.

- Filters: Filters, such as fabric filters or ceramic filters, are used to capture and remove fine particulate matter from the syngas. These filters operate based on various mechanisms, including mechanical filtration, electrostatic precipitation, or ceramic candle filtration.

- Wet Scrubbers: Wet scrubbers are used to remove tars and other organic compounds from the syngas. The gas is passed through a scrubbing liquid, typically water or a solvent, which captures the contaminants through absorption or chemical reaction.

- Gas Washing: Gas washing involves using a liquid, such as water or a solvent, to wash the syngas and remove impurities. This method is effective in removing water-soluble contaminants and can also help to reduce the gas temperature.

- Catalytic Conversion: Catalytic conversion processes utilize catalysts to convert or break down specific contaminants in the syngas. For example, sulfur compounds can be converted into hydrogen sulfide (H2S) and then removed using scrubbing techniques.

- Adsorption: Adsorption involves passing the syngas through adsorbent materials, such as activated carbon or zeolites, which have a high affinity for specific contaminants. The adsorbents capture the impurities, allowing the purified syngas to pass through.

- Tar Cracking: Tar cracking is a process where tars present in the syngas are thermally decomposed or cracked into simpler molecules. This can be achieved by subjecting the syngas to high temperatures in a secondary reactor or through the use of catalytic cracking.

The selection of gas cleaning methods depends on factors such as the composition of the impurities, desired syngas specifications, process conditions, and the intended end-use of the syngas. Gas cleaning technologies can be combined and tailored to meet specific requirements and ensure the syngas quality is suitable for subsequent utilization, such as power generation, heat production, or conversion into synthetic fuels.

Gas Utilization

Gas utilization refers to the process of utilizing the syngas (synthetic gas) produced from gasification for various applications. Syngas is a mixture of carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), and other trace gases, depending on the specific gasification process and feedstock used. Here are some common applications of syngas utilization:

- Power Generation: Syngas can be used as a fuel in gas turbines or internal combustion engines to generate electricity. The syngas is burned in the combustion chamber, and the heat energy is converted into mechanical energy, which is then used to drive a generator.

- Heat Production: Syngas can be combusted in boilers or furnaces to produce heat for various industrial processes, district heating systems, or space heating applications. The heat energy released during the combustion of syngas can be used directly or transferred to a heat transfer fluid for further distribution.

- Biofuel Production: Syngas can be further processed to produce liquid biofuels, such as synthetic diesel or synthetic gasoline. This typically involves additional steps, such as Fischer-Tropsch synthesis, where the syngas is converted into hydrocarbon fuels through catalytic reactions.

- Chemical Synthesis: Syngas can serve as a feedstock for the production of various chemicals and materials. For example, it can be used as a precursor for the synthesis of methanol, ammonia, methanol-to-olefins (MTO) processes, and other chemical reactions that utilize carbon monoxide and hydrogen.

- Hydrogen Production: Syngas can be reformed or processed further to produce high-purity hydrogen gas, which has applications in fuel cells, chemical processes, and transportation.

- Combined Heat and Power (CHP) Systems: Syngas can be used in combined heat and power systems, where the heat produced during power generation or other processes is captured and utilized for heating purposes, maximizing overall energy efficiency.

- Syngas Injection: Syngas can be injected into natural gas pipelines and used as a blend with natural gas for heating or power generation. This can help reduce greenhouse gas emissions and utilize renewable or carbon-neutral feedstocks.

The choice of syngas utilization depends on factors such as the composition of the syngas, local energy needs, infrastructure availability, and economic considerations. The syngas may require further purification or conditioning depending on the specific application and requirements.

Wood Gasifier

A wood gasifier is a device that converts wood or biomass into a combustible gas called syngas, also known as wood gas or producer gas. This gas can be used to power engines, generators, or for heating purposes. Wood gasifiers are a relatively simple and efficient way to utilize biomass as a fuel source.

Working Principle of a Wood Gasifier:

- Charring: In the primary chamber, wood is heated to a high temperature without oxygen, causing it to decompose into charcoal and pyrolysis gas.

- Gasification: The charcoal and pyrolysis gas enter the gasification chamber, where they are further heated in the presence of oxygen. This generates syngas, a mixture of carbon monoxide, hydrogen, and methane.

- Cleaning and Conditioning: The syngas passes through a cleaning and conditioning stage to remove impurities like tars and particulate matter.

- Burning or Utilization: The clean syngas can then be used to power engines, generators, or for heating purposes.

Advantages of Wood Gasification:

- Self-Sufficiency: Wood gasifiers can be used to utilize biomass resources locally, providing a source of renewable energy for rural communities or individuals.

- Fuel Flexibility: Wood gasifiers can operate on a variety of wood types, including both hardwood and softwood. They can also be used with other biomass feedstocks, such as agricultural residues and yard waste.

- Combustion Efficiency: Wood gasifiers can achieve high combustion efficiencies, converting up to 70% of the biomass feedstock into syngas.

- Reduced Emissions: Compared to direct combustion of wood, wood gasification can significantly reduce emissions of particulate matter, carbon monoxide, and other pollutants.

Disadvantages of Wood Gasification:

- Complexity and Maintenance: Wood gasifiers are more complex than traditional wood-burning stoves or fireplaces and require regular maintenance to ensure optimal performance.

- Tar Formation: The gasification process can produce tars, which can accumulate in the gasifier and hinder its operation. Regular cleaning is necessary to prevent tar buildup.

- Storage and Handling: Syngas is a flammable gas and requires careful storage and handling to prevent leaks and potential safety hazards.

- Energy Conversion Efficiency: While wood gasifiers can achieve high combustion efficiencies, the overall energy conversion efficiency from wood to syngas and then to useful work is still lower than some other energy conversion technologies.

Applications of Wood Gasifiers:

- Power Generation: Wood gasifiers can be used to power engines and generators to produce electricity.

- Heating Applications: Wood gasifiers can be used to provide heat for homes, businesses, and industrial applications.

- Cooking and Heating: Wood gasifiers can be used to provide cooking fuel and heating for household or small-scale applications.

Safety Considerations for Wood Gasifiers:

- Secure Installation: Wood gasifiers must be installed in a well-ventilated and secure location to prevent gas leaks and potential explosions.

- Regular Maintenance: Wood gasifiers require regular maintenance to ensure optimal operation and prevent safety issues.

- Proper Storage and Handling: Syngas is a flammable gas and must be stored and handled safely to prevent leaks and ignition hazards.

- Operator Training: Individuals operating wood gasifiers should receive proper training on safety procedures and maintenance requirements.

- Local Regulations: Check local regulations and building codes regarding the installation and operation of wood gasifiers in your area.

We manufacture Off-grid Biomass Generator for Electricity Production. Electricity generation from steam by burning woodchip and wood pellet. Free Consultation

An off-grid biomass generator is a type of generator that produces electricity using biomass fuel and is not connected to the electric grid. These generators can be used in remote locations or in areas where access to the grid is limited or non-existent.

Off-grid biomass generators operate in much the same way as other types of biomass generators, by converting organic waste or biomass material into electricity. This involves fuel handling and preparation, gasification, combustion, and ash removal, as described in my previous response.

The key difference with off-grid biomass generators is that they are designed to operate independently of the electric grid, using batteries or other energy storage systems to store excess electricity for later use. This allows users to generate their own electricity and reduce reliance on the grid, while providing a reliable source of power in areas where the grid is unreliable or non-existent.

Off-grid biomass generators can be used for a variety of applications, including remote power generation for homes, farms, or businesses, as well as for emergency backup power in the event of grid outages or natural disasters.

While off-grid biomass generators offer many benefits, they also come with some challenges. For example, proper fuel selection and handling are critical to ensure efficient and reliable operation, and maintenance requirements can be significant. Additionally, energy storage systems can be expensive and may require regular maintenance to ensure proper operation. Overall, the use of off-grid biomass generators requires careful planning and consideration to ensure effective and reliable operation.

Advantages and Disadvantages

Advantages of off-grid biomass generators:

- Energy independence: Off-grid biomass generators provide energy independence to users, allowing them to generate their own electricity and reduce reliance on the grid.

- Renewable energy source: Biomass is a renewable energy source, meaning it can be replenished over time. This makes it a more sustainable energy source compared to fossil fuels, which are finite resources.

- Reduced greenhouse gas emissions: Biomass generators produce less greenhouse gas emissions compared to fossil fuel generators. This is because biomass is a carbon-neutral fuel, meaning the carbon dioxide released during combustion is offset by the carbon dioxide absorbed during the biomass material’s growth.

- Local availability: Biomass material is widely available and can often be sourced locally, reducing transportation costs and increasing energy security.

Disadvantages of off-grid biomass generators:

- High capital costs: Off-grid biomass generators can be expensive to purchase and install, especially for larger systems.

- Maintenance requirements: Biomass generators require regular maintenance to ensure efficient and reliable operation. This can include cleaning and maintenance of the gasifier and engine components, as well as ash removal and fuel handling.

- Fuel variability: The composition and quality of biomass fuel can vary significantly depending on the source and preparation. This can affect the efficiency and reliability of the generator, and require careful fuel selection and handling.

- Land use and biodiversity impacts: The production of biomass fuel can have impacts on land use and biodiversity, especially if biomass crops are grown on land that was previously used for other purposes.

Overall, off-grid biomass generators offer many benefits as a renewable energy source, but also come with some challenges that need to be carefully managed. Proper fuel selection, handling, and maintenance are important to ensure efficient and reliable operation, while minimizing environmental impacts. Additionally, the high capital costs of these systems may limit their use in certain applications, and careful consideration of the potential impacts on land use and biodiversity is important.

Application Areas

Off-grid biomass generators can be used in a wide range of applications, including:

- Remote power generation: Off-grid biomass generators can provide reliable and sustainable electricity to remote locations where grid connections are not available or are unreliable. This includes powering remote communities, off-grid cabins, and other remote facilities such as communication towers and weather stations.

- Agriculture and forestry: Off-grid biomass generators can be used in agriculture and forestry settings to power equipment such as irrigation pumps, sawmills, and grain dryers.

- Emergency backup power: Off-grid biomass generators can be used as backup power in the event of grid outages or natural disasters. This is particularly important for critical facilities such as hospitals, emergency response centers, and water treatment facilities.

- Industrial applications: Off-grid biomass generators can be used to power industrial processes such as manufacturing, food processing, and mining.

- Microgrids: Off-grid biomass generators can be used as part of a microgrid, where they can work in conjunction with other renewable energy sources such as solar and wind power to provide reliable and sustainable electricity to a community or facility.

- Residential and commercial power: Off-grid biomass generators can be used to provide electricity to individual homes and businesses in areas where grid connections are not available or are unreliable.

Overall, off-grid biomass generators are versatile and can be used in a wide range of applications, providing reliable and sustainable electricity in areas where grid connections are limited or non-existent.

Small-scale biomass generators are systems that convert biomass, such as wood, agricultural waste, or municipal solid waste, into usable energy at a smaller capacity compared to large-scale power plants. They typically range in power output from a few kilowatts to a few megawatts and are often used in rural or remote areas where grid access is limited or unreliable.

Types of Small-Scale Biomass Generators:

- Direct Combustion Generators: These generators directly burn biomass in a boiler to produce hot water or steam, which can then be used for various applications, such as space heating, hot water production, or power generation.

- Gasification Generators: These generators convert biomass into syngas through a thermochemical process and then use the syngas to drive an internal combustion engine or a gas turbine to generate electricity.

- Biogas Generators: These generators utilize organic waste to produce biogas, a mixture of methane and carbon dioxide, through anaerobic digestion. The biogas can be burned to generate heat or electricity.

Applications of Small-Scale Biomass Generators:

- Residential and Commercial Heating: Small-scale biomass generators can provide heating for homes, businesses, and community centers.

- Off-Grid Power Generation: These generators can provide electricity to remote areas without access to the grid.

- Industrial Process Heat: Biomass generators can provide heat for industrial processes, such as drying, sterilization, and food processing.

- Combined Heat and Power (CHP) Systems: Small-scale CHP systems can simultaneously produce electricity and heat from biomass, maximizing energy efficiency.

- Waste Utilization: Biomass generators can utilize agricultural waste, municipal solid waste, and forestry residues, reducing the need for landfills.

Advantages of Small-Scale Biomass Generators:

- Renewable Energy Source: Biomass is a renewable energy source that can be replenished naturally.

- Reduced Reliance on Fossil Fuels: Small-scale biomass generators can reduce dependence on fossil fuels and contribute to a cleaner energy future.

- Local Energy Production: These generators can provide energy locally, reducing reliance on long-distance transmission infrastructure.

- Waste Management: Biomass generators can utilize waste materials, reducing their environmental impact and providing economic benefits.

- Economic Development: Small-scale biomass projects can create jobs and boost local economies in rural areas.

Challenges of Small-Scale Biomass Generators:

- Fuel Supply and Logistics: Ensuring a consistent supply of biomass fuel can be challenging, especially in remote areas.

- Emissions Control: Biomass combustion can produce air pollutants, requiring proper emission control systems.

- Maintenance and Reliability: Small-scale biomass generators require regular maintenance to ensure efficient operation and prevent malfunctions.

- Cost-Effectiveness: The initial investment cost for small-scale biomass generators can be higher than traditional energy sources.

- Sustainable Practices: Sustainable biomass harvesting and utilization practices are crucial to avoid negative environmental impacts.

Future Directions:

Research and development efforts are focused on improving the efficiency, environmental performance, and cost-effectiveness of small-scale biomass generators. This includes developing advanced combustion and gasification technologies, optimizing fuel preparation methods, and exploring innovative applications for syngas and biogas. Small-scale biomass generators are expected to play an increasingly important role in providing sustainable energy solutions for rural communities and off-grid applications.

Direct Combustion Generators

Direct combustion generators are a type of biomass generator that converts biomass directly into heat or steam through combustion. They are a simple and mature technology that is widely used in various applications, including residential and commercial heating, industrial process heat, and power generation.

Working Principle of Direct Combustion Generators:

- Fuel Preparation: Biomass fuel, such as wood pellets, wood chips, or agricultural waste, is prepared by drying and sizing to ensure efficient combustion.

- Fuel Feeding: The prepared biomass is fed into a combustion chamber, where it is ignited and burned.

- Heat Release: The combustion process releases heat, which is transferred to a heat exchanger or boiler.

- Heat Utilization: The heat from the heat exchanger or boiler can be used directly for applications like space heating or hot water production, or it can be used to generate steam for power generation or industrial processes.

Types of Direct Combustion Generators:

- Stoker-fired Boilers: Stoker-fed boilers utilize mechanical devices to move the biomass fuel into the combustion chamber and maintain a consistent burn rate.

- Fluidized Bed Boilers: Fluidized bed boilers suspend biomass particles in a stream of air, creating a highly turbulent environment for efficient combustion.

- Pellet Boilers: Pellet boilers are designed specifically for burning wood pellets, offering high efficiency and compact design.

Advantages of Direct Combustion Generators:

- Simplicity and Maturity: Direct combustion generators are a well-established technology with relatively simple operation and maintenance requirements.

- Fuel Versatility: These generators can utilize a variety of biomass fuels, including wood, agricultural waste, and municipal solid waste.

- High Efficiency: Direct combustion generators can achieve high thermal efficiencies, converting a significant portion of the biomass fuel’s energy into usable heat or steam.

- Cost-Effectiveness: The initial investment and operating costs of direct combustion generators are generally lower compared to other biomass conversion technologies.

Challenges of Direct Combustion Generators:

- Emissions Control: Combustion of biomass can produce air pollutants, such as particulate matter, nitrogen oxides, and sulfur dioxide, requiring emission control systems to meet environmental regulations.

- Fuel Quality: The quality of the biomass fuel can impact the efficiency and emissions of the generator. High moisture content and impurities in the fuel can lead to incomplete combustion and increased emissions.

- Ash Handling: Combustion of biomass produces ash, which needs to be collected and disposed of properly to avoid environmental impacts.

- Fuel Storage: Biomass fuel requires proper storage facilities to prevent moisture absorption and deterioration, which can affect its combustion properties.

- Space Requirements: Direct combustion generators can be larger and require more space compared to some other biomass conversion technologies.

Future Prospects:

Direct combustion generators are expected to continue playing a significant role in the utilization of biomass for energy production. Technological advancements focus on improving combustion efficiency, emission control systems, and fuel preparation methods to enhance the environmental performance and cost-effectiveness of these generators. Direct combustion generators are particularly well-suited for applications where simplicity, fuel versatility, and high thermal efficiency are priorities.

Gasification Generators

Gasification generators are a type of biomass generator that converts biomass into a combustible gas called syngas through a thermochemical process. Syngas is a mixture of primarily carbon monoxide, hydrogen, and methane, which can be used to generate electricity, heat, or liquid fuels. Gasification generators offer several advantages over direct combustion generators, including higher efficiency, lower emissions, and greater versatility.

Working Principle of Gasification Generators:

- Feedstock Preparation: Biomass feedstock, such as wood, agricultural waste, or municipal solid waste, undergoes preparation processes like drying, sizing, and pre-treatment to ensure efficient gasification.

- Gasification Reactor: The prepared biomass feedstock is fed into a gasification reactor, where it is heated in a controlled environment with limited oxygen.

- Thermochemical Reactions: The thermochemical reactions in the gasifier break down the biomass into a mixture of gases primarily composed of carbon monoxide, hydrogen, and methane, forming syngas.

- Syngas Purification: The syngas is passed through a purification system to remove impurities and contaminants, such as tar, water vapor, and sulfur compounds.

- Syngas Utilization: The purified syngas can be used for various applications, including:

- Electricity Generation: Syngas can be used to drive internal combustion engines or gas turbines to generate electricity.

- Heat Production: Syngas can be burned directly to produce heat for industrial processes, space heating, or hot water production.

- Liquid Fuel Production: Syngas can be processed further to produce liquid fuels, such as methanol or Fischer-Tropsch fuels.

Types of Gasification Technologies:

- Fixed Bed Gasification: Biomass feedstock is fed into a stationary bed, where it is gasified by a stream of hot gas or air.

- Fluidized Bed Gasification: Biomass particles are suspended in a stream of hot gas, creating a highly turbulent environment for efficient gasification.

- Entrained Flow Gasification: Biomass particles are fed into a high-velocity stream of hot gas, allowing for rapid gasification and high energy density.

Advantages of Gasification Generators:

- Higher Efficiency: Gasification generators can achieve higher energy conversion efficiencies compared to direct combustion, converting a larger portion of the biomass fuel’s energy into usable syngas.

- Lower Emissions: Gasification can produce lower emissions of air pollutants, such as particulate matter and nitrogen oxides, compared to direct combustion.

- Fuel Versatility: Gasification can utilize a wider range of biomass feedstocks, including low-quality or unconventional biomass sources.

- Syngas Versatility: Syngas can be used for a variety of applications, including electricity generation, heat production, and liquid fuel production.

- Environmental Benefits: Gasification can contribute to reduced reliance on fossil fuels and minimize the environmental impact of biomass utilization.

Challenges of Gasification Generators:

- Technological Complexity: Gasification technology is more complex than direct combustion, requiring specialized equipment and expertise for operation and maintenance.

- Feedstock Preparation: Proper preparation of the biomass feedstock is crucial for efficient gasification and syngas quality.

- Emission Control Systems: While gasification generally produces lower emissions, additional emission control systems may be required to meet environmental standards.

- Syngas Conditioning: Syngas may require conditioning processes, such as cooling and purification, to ensure compatibility with downstream applications.

- Cost Considerations: Gasification generators typically have higher initial investment costs compared to direct combustion generators.

Future Prospects:

Gasification technology is expected to play an increasingly important role in the utilization of biomass for sustainable energy production. Research and development efforts focus on improving gasification efficiency, reducing emission levels, and developing cost-effective syngas conditioning processes. Gasification generators are particularly well-suited for applications where high efficiency, low emissions, and fuel versatility are paramount.

Biogas Generators

Biogas generators are a type of biomass generator that converts organic waste into biogas, a mixture of primarily methane and carbon dioxide, through anaerobic digestion. Biogas can be burned to generate electricity, heat, or transport fuel.

Working Principle of Biogas Generators:

- Digester: Organic waste, such as agricultural waste, food scraps, or municipal solid waste, is placed in an enclosed digester.

- Anaerobic Digestion: Anaerobic bacteria break down the organic waste in the absence of oxygen, producing biogas and digestate.

- Biogas Separation: The biogas is separated from the digestate and purified to remove impurities, such as hydrogen sulfide and ammonia.

- Biogas Utilization: The purified biogas can be used for various applications, including:

- Electricity Generation: Biogas can be burned to drive turbines or engines to generate electricity.

- Heat Production: Biogas can be burned directly to produce heat for industrial processes, space heating, or hot water production.

- Transport Fuel Production: Biogas can be compressed into biomethane, which can be used as a vehicle fuel.

Types of Biogas Digesters:

- Fixed-dome Digesters: These digesters have a semi-circular shape and are commonly used for small-scale applications.

- Floating-cover Digesters: These digesters have a floating cover that rises and falls with the biogas volume, allowing for efficient gas collection.

- Plug-flow Digesters: These digesters have a long, narrow shape, allowing for efficient mixing and digestion of the organic waste.

Advantages of Biogas Generators:

- Renewable Energy Source: Biogas is a renewable energy source that can be produced from various organic waste streams.

- Lower Emissions: Biogas combustion produces lower emissions of carbon dioxide compared to fossil fuels.

- Waste Utilization: Biogas generators can utilize organic waste, reducing the need for landfills.

- Local Energy Production: Biogas generators can be located near waste sources, minimizing transportation costs.

- Environmental Benefits: Biogas production can contribute to reduced reliance on fossil fuels and a more sustainable waste management system.

Challenges of Biogas Generators:

- Waste Availability: Availability of organic waste can be limited or seasonal, affecting biogas production consistency.

- Digestion Process: The anaerobic digestion process can be sensitive to temperature, moisture content, and the type of waste.

- Infrastructure Costs: Developing and maintaining biogas infrastructure, such as digesters and gas collection systems, can be costly.

- Emission Control: While biogas combustion produces lower emissions, additional emission control systems may be required to meet environmental standards.

- Economic Viability: The economic viability of biogas production depends on factors such as waste availability, gas sales, and government incentives.

Future Prospects:

Biogas technology is expected to play an increasingly important role in the utilization of organic waste for renewable energy production and sustainable waste management. Research and development efforts focus on improving biogas production efficiency, reducing costs, and developing innovative applications for biogas, such as grid-scale electricity generation and synthetic fuel production. Biogas generators are particularly well-suited for applications where waste utilization, carbon reduction, and local energy production are priorities.

Wood as Biomass and Wood Fired Steam Power Generators

Wood-fired steam generators can be used to generate electricity in a variety of settings, particularly in off-grid or remote locations where access to the grid is limited or non-existent. These systems typically operate by burning wood or other biomass materials to generate steam, which then drives a turbine connected to an electric generator. The heat produced by the combustion of wood is used to create steam, which is then used to generate electricity.

Wood-fired steam generators can be used in a wide range of applications, including:

- Remote power generation: Wood-fired steam generators can provide reliable and sustainable electricity to remote locations where grid connections are not available or are unreliable. This includes powering remote communities, off-grid cabins, and other remote facilities such as communication towers and weather stations.

- Agriculture and forestry: Wood-fired steam generators can be used in agriculture and forestry settings to power equipment such as irrigation pumps, sawmills, and grain dryers.

- Emergency backup power: Wood-fired steam generators can be used as backup power in the event of grid outages or natural disasters. This is particularly important for critical facilities such as hospitals, emergency response centers, and water treatment facilities.

- Industrial applications: Wood-fired steam generators can be used to power industrial processes such as manufacturing, food processing, and mining.

- Microgrids: Wood-fired steam generators can be used as part of a microgrid, where they can work in conjunction with other renewable energy sources such as solar and wind power to provide reliable and sustainable electricity to a community or facility.

Overall, wood-fired steam generators offer a renewable and sustainable way to generate electricity in a variety of settings, particularly in off-grid or remote locations. However, it is important to carefully manage the sourcing and handling of wood or other biomass materials to ensure sustainable and environmentally responsible operations.

Advantages and Disadvantages

Advantages of wood-fired steam generators for electricity include:

- Renewable and sustainable: Wood is a renewable resource that can be sustainably sourced, making it an environmentally friendly option for electricity generation.

- Versatile: Wood-fired steam generators can be used in a wide range of applications, including remote locations, industrial settings, and emergency backup power.

- Reliable: Once operational, wood-fired steam generators can provide reliable and continuous power, reducing dependence on fossil fuels and grid connections.

- Local economic benefits: Sourcing and processing wood for fuel can provide economic benefits to local communities and businesses.

- Carbon-neutral: When sustainably sourced and managed, wood-fired steam generators can be carbon-neutral or even carbon-negative, meaning they have a net positive impact on the environment.

Disadvantages of wood-fired steam generators for electricity include:

- Fuel sourcing and handling: Sourcing and handling of wood for fuel can be labor-intensive and may require significant infrastructure and transportation costs.

- Emissions: While wood is a renewable resource, combustion of wood does produce emissions, including particulate matter and greenhouse gases, which can contribute to air pollution and climate change.

- Equipment maintenance: Wood-fired steam generators require regular maintenance and cleaning to ensure efficient and safe operations.

- Capital costs: The capital costs associated with purchasing and installing a wood-fired steam generator can be higher than other types of renewable energy systems.

- Fuel availability: Availability of fuel sources may be limited in some areas, particularly in urban or densely populated areas.

Overall, wood-fired steam generators offer a renewable and sustainable option for electricity generation in a variety of settings, but careful consideration should be given to fuel sourcing, emissions, and equipment maintenance to ensure safe and environmentally responsible operations.

Application Areas

Wood-fired steam generators for electricity can be used in a variety of application areas, including:

- Remote locations: Wood-fired steam generators can be used to provide off-grid power in remote locations, such as rural communities or mining operations.

- Industrial settings: Wood-fired steam generators can be used to provide process heat and power in industrial settings, such as sawmills or pulp and paper mills.

- Emergency backup power: Wood-fired steam generators can provide emergency backup power in the event of a power outage, particularly in areas prone to natural disasters or other disruptions to the grid.

- Heating and cooling: Wood-fired steam generators can be used in conjunction with absorption chillers to provide both heat and cooling in buildings, particularly in larger commercial or industrial buildings.

- Microgrids: Wood-fired steam generators can be integrated into microgrid systems, which combine multiple sources of renewable energy to provide reliable and sustainable power to small communities or groups of buildings.

Overall, wood-fired steam generators for electricity offer a versatile and sustainable option for power generation in a variety of settings, particularly in areas where access to the grid is limited or unreliable.

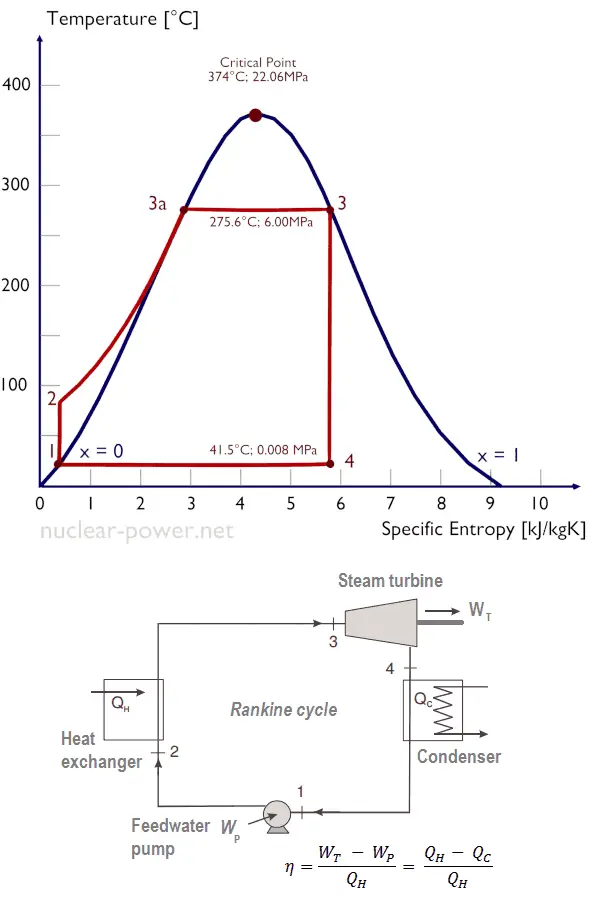

Wood fired steam generators for electricity

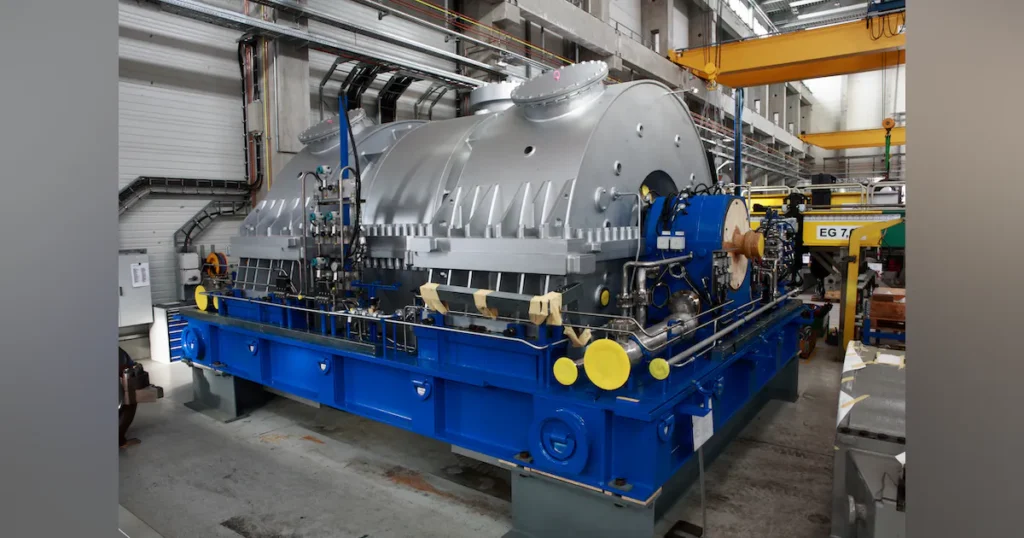

Wood-fired steam generators for electricity generation are systems that use wood or biomass as a fuel source to produce high-pressure steam. This steam is then used to drive a steam turbine connected to an electrical generator, producing electricity. This process is a form of biomass power generation and can be an environmentally friendly and sustainable way to generate electricity. Here’s how wood-fired steam generators for electricity work:

- Fuel Supply: The primary fuel for these generators is wood or biomass. Biomass can include wood chips, sawdust, wood pellets, agricultural residues, or other organic materials. The biomass fuel is stored in a designated area and fed into a combustion chamber.

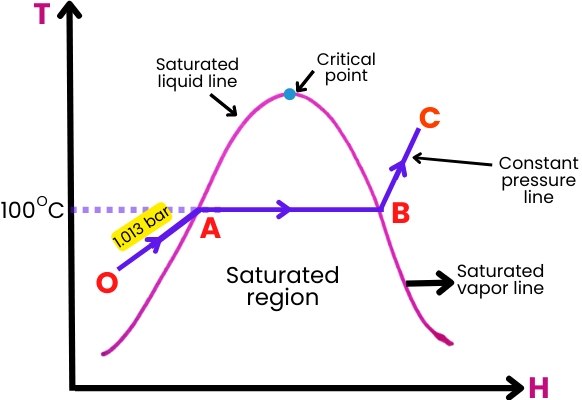

- Combustion: In the combustion chamber, the biomass fuel is burned to produce high-temperature gases. This combustion process releases energy in the form of heat. The heat generated from burning wood is used to heat water, turning it into steam.

- Boiler: The steam generator includes a boiler where water is heated to produce steam. The hot gases from the combustion chamber pass through tubes or other heat exchange surfaces within the boiler, transferring their heat to the water. The water is typically stored in a high-pressure vessel.

- Steam Production: As the water absorbs heat from the combustion gases, it turns into high-pressure steam. The pressure of the steam can vary depending on the system design but is usually in the range of 100 to 500 psi (pounds per square inch).

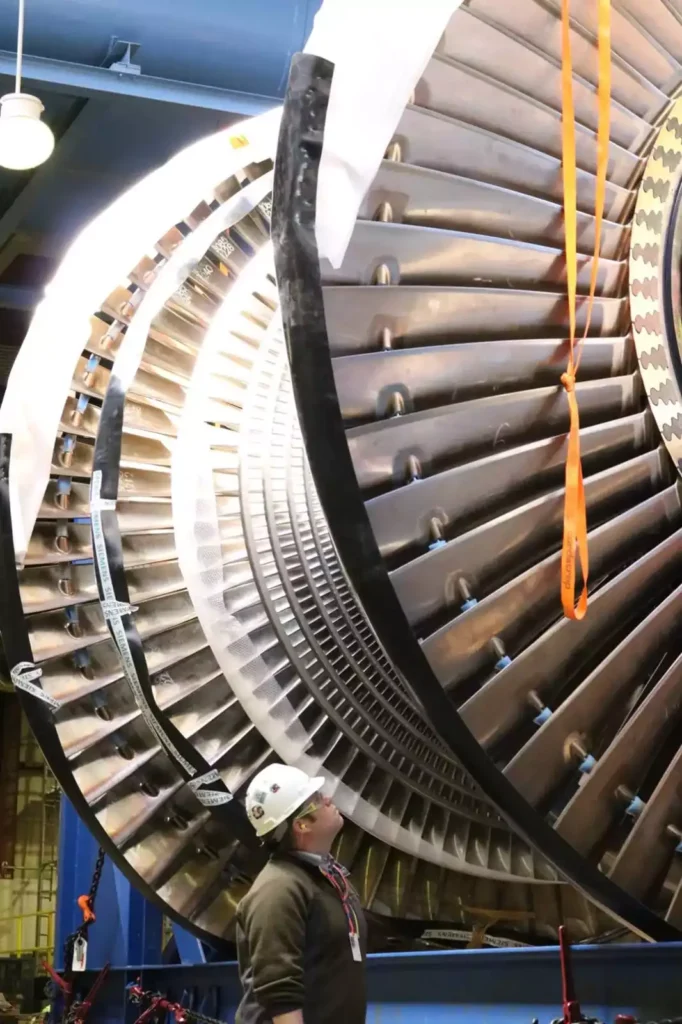

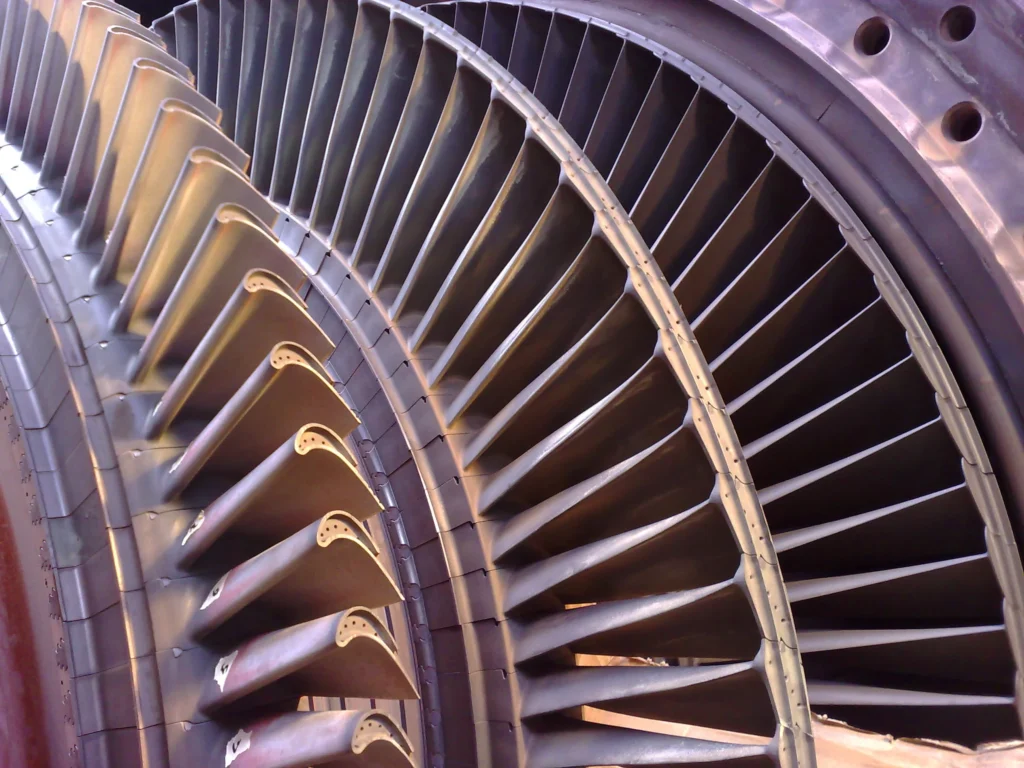

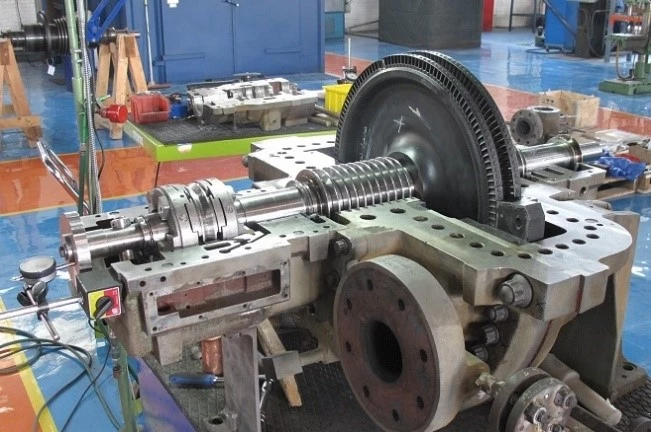

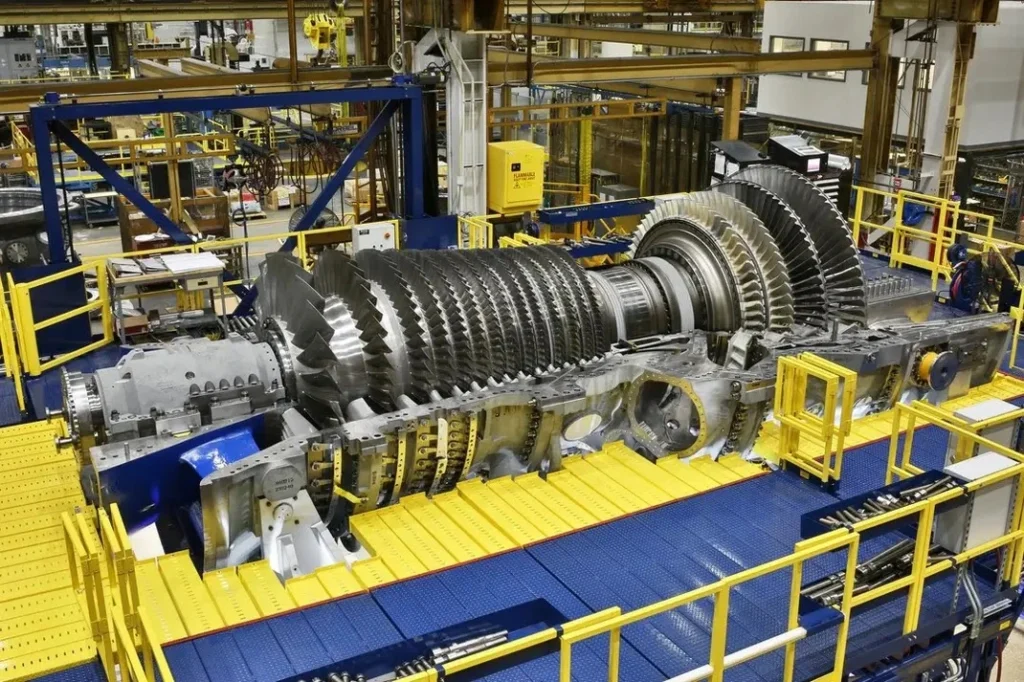

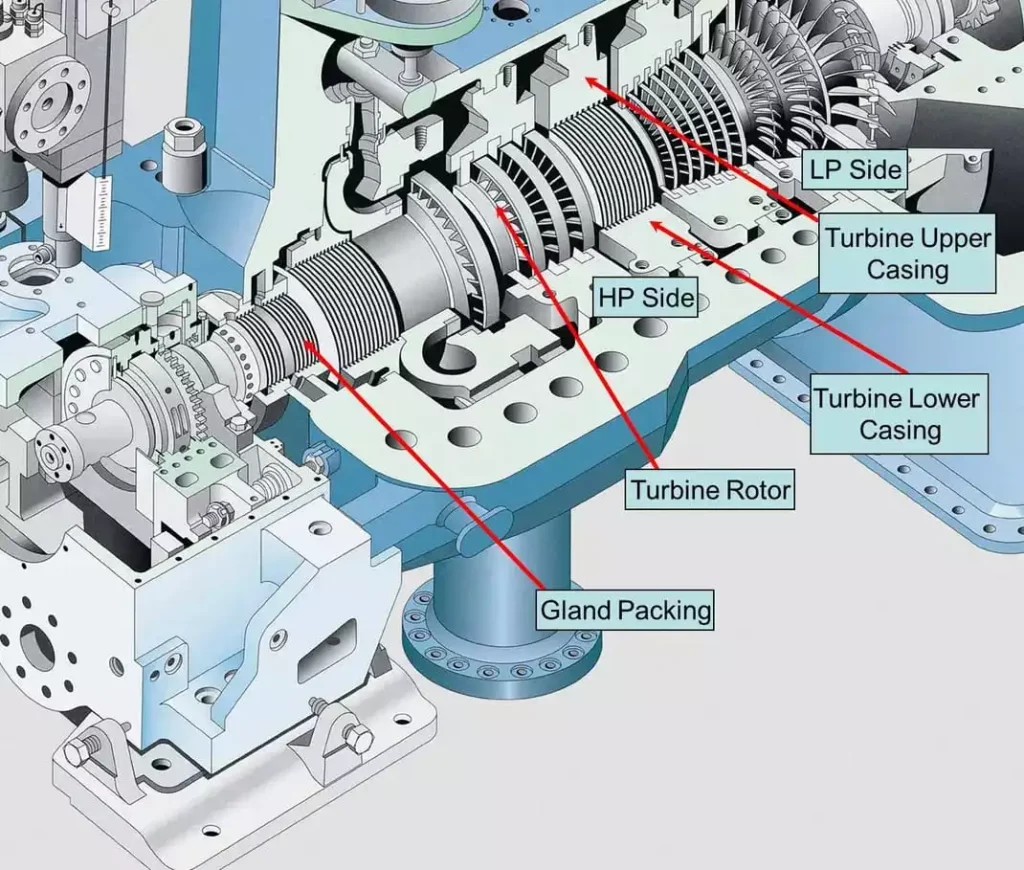

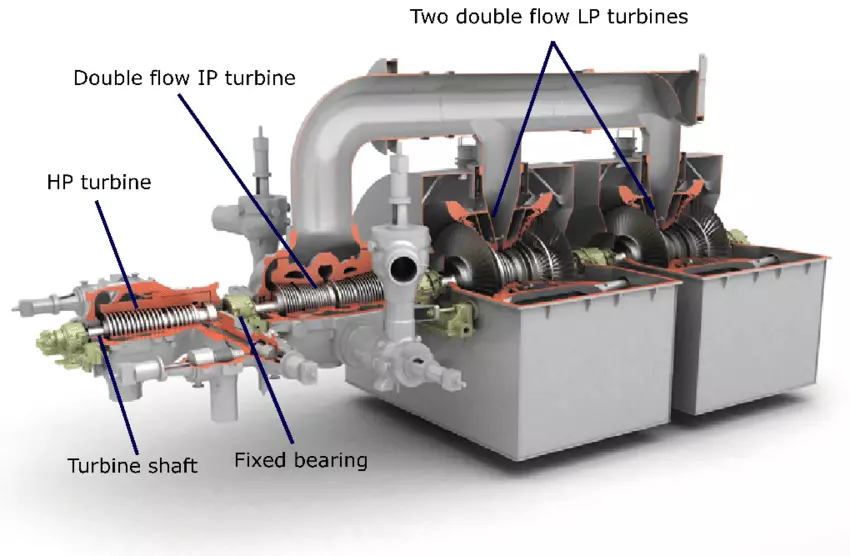

- Steam Turbine: The high-pressure steam is directed to a steam turbine. Steam turbines are rotary machines with blades attached to a rotor. The expanding steam flows over the turbine blades, causing them to spin. The spinning turbine rotor is connected to an electrical generator.

- Electricity Generation: The rotation of the turbine rotor drives the electrical generator, which converts mechanical energy into electrical energy. The generator produces alternating current (AC) electricity.

- Power Distribution: The generated electricity can be distributed for use in homes, businesses, or industries through a power distribution grid.

Key considerations for wood-fired steam generators for electricity:

- Fuel Sustainability: Using wood or biomass as a fuel source can be sustainable if the biomass is sourced responsibly and replanted to maintain a renewable supply.

- Efficiency: The efficiency of the system depends on the combustion efficiency, boiler design, and turbine efficiency. Well-designed systems can achieve high overall efficiency.

- Environmental Impact: Biomass power generation is considered a renewable energy source and can have lower greenhouse gas emissions compared to fossil fuels when managed sustainably.

- Emissions Control: Emissions from wood combustion should be monitored and controlled to minimize air pollution.

- Scale: These systems can range in size from small decentralized units providing power for a single facility to larger installations for utility-scale electricity generation.

- Maintenance: Regular maintenance and cleaning of the system are necessary to ensure efficient operation and prevent issues related to ash buildup and corrosion.

Wood-fired steam generators for electricity can be a viable option for regions with access to abundant biomass resources and can contribute to reducing dependence on fossil fuels for power generation. However, careful planning, fuel sustainability, and emissions control are essential considerations when implementing such systems.

Wood Fired Steam Generators for Electricity

Wood-fired steam generators, also known as biomass-fired steam boilers, are systems that utilize wood as a fuel to generate steam for various applications, including electricity production. They offer a renewable and environmentally friendly alternative to fossil fuel-based steam generators.

Working Principle:

- Wood Combustion: Wood is fed into a combustion chamber where it is burned to release heat. This heat is transferred to water circulating through tubes or coils within the boiler.

- Water Evaporation: The heat from the burning wood causes the water to evaporate, forming steam. The steam pressure within the boiler increases as more water evaporates.

- Steam Generation: The pressurized steam is then directed to a steam turbine, where its kinetic energy is converted into mechanical energy. The mechanical energy from the turbine drives an electrical generator, producing electricity.

Advantages of Wood-Fired Steam Generators:

- Renewable Energy Source: Wood is a renewable energy source, unlike fossil fuels that are finite and contribute to greenhouse gas emissions.

- Environmentally Friendly: Wood burning produces fewer pollutants compared to fossil fuels, reducing the environmental impact of electricity generation.

- Locally Sourced Fuel: Wood is often available locally, minimizing transportation costs and supporting local economies.

- Waste Utilization: Wood-fired steam generators can utilize wood waste from forestry operations, reducing the need for landfills.

- Carbon-Neutral Operation: When wood is sourced from sustainably managed forests, the carbon emissions from combustion are offset by carbon sequestration through new tree growth.

Applications of Wood-Fired Steam Generators:

- Electricity Generation: Wood-fired steam generators are used in power plants to generate electricity for commercial, industrial, and residential use.

- Industrial Process Heat: Wood-fired steam generators can provide process heat for various industries, such as papermaking, food processing, and textile manufacturing.

- District Heating Systems: Wood-fired steam generators can supply heat for district heating systems, providing warm water or steam to buildings in a centralized manner.

- Combined Heat and Power (CHP) Plants: Wood-fired steam generators can be integrated into CHP plants, producing both electricity and heat from a single fuel source.

- Off-Grid Power Generation: Wood-fired steam generators can be employed in remote or off-grid locations, providing a reliable source of electricity without relying on the grid.

Challenges and Considerations:

- Fuel Moisture Content: High moisture content in wood can reduce boiler efficiency and increase emissions.

- Fuel Preparation: Wood requires proper preparation, such as drying and sizing, to ensure consistent combustion and efficient steam generation.

- Ash Handling: Wood combustion generates ash, which needs to be collected and disposed of properly.

- Emission Control Systems: Wood-fired steam generators may require emission control systems to comply with environmental regulations.

- Fuel Availability and Cost: The availability and cost of wood fuel can vary depending on location and market conditions.

Future Prospects:

Wood-fired steam generators are expected to play an increasingly important role in the transition towards a more sustainable energy future. Technological advancements in combustion efficiency, emission control systems, and fuel preparation are further enhancing the attractiveness of wood-fired steam generators for electricity generation and industrial applications. As the demand for renewable energy sources grows, wood-fired steam generators are poised to make a significant contribution to a cleaner and more sustainable energy mix.

Wood Combustion

Wood combustion is a complex process that involves a series of chemical reactions that convert wood into heat, gases, and ashes. The specific reactions and products depend on various factors, including the type of wood, the combustion conditions, and the presence of catalysts or inhibitors.

Stages of Wood Combustion:

- Drying: The first stage of wood combustion is drying, where the moisture in the wood is evaporated. This endothermic process requires heat from the surrounding environment.

- Devolatilization: As the temperature increases, the wood undergoes devolatilization, where volatile gases are released from the wood. These gases primarily consist of carbon monoxide, methane, and hydrogen.

- Char Formation: The remaining solid material after devolatilization is called char. Char is primarily composed of carbon and some inorganic compounds.

- Char Combustion: The char reacts with oxygen in the air to release heat and produce carbon dioxide. This exothermic reaction is the primary source of heat energy from wood combustion.

- Ash Formation: A small amount of ash is produced during wood combustion, consisting of inorganic compounds that were present in the wood. The composition of ash varies depending on the wood species.

Factors Affecting Wood Combustion:

- Wood Type: Different wood types have varying moisture content, volatile matter content, and char content, which influence the combustion process and properties.

- Combustion Temperature: The combustion temperature significantly impacts the rate of combustion and the formation of combustion products. Higher temperatures generally lead to faster combustion and more complete combustion.

- Oxygen Availability: Oxygen availability is crucial for sustained combustion. Insufficient oxygen can lead to incomplete combustion, producing carbon monoxide and other undesirable products.

- Catalytic Effects: The presence of certain substances, such as minerals in the wood or additives in the combustion environment, can act as catalysts, accelerating the combustion reactions.

- Inhibiting Effects: Certain substances, such as flame retardants or combustion inhibitors, can slow down or prevent combustion by interfering with the chemical reactions.

Applications of Wood Combustion:

- Heating: Wood combustion is a traditional and widely used method for heating homes, businesses, and industrial facilities.

- Power Generation: Wood-fired boilers are used to generate steam for electricity production.

- Cooking: Wood combustion is still used for cooking in many parts of the world, providing a readily available and affordable fuel source.

- Industrial Processes: Wood combustion is employed in various industrial processes, such as wood drying, pulp and paper production, and food processing.

- Biomass Energy: Wood is a significant source of biomass energy, offering a renewable alternative to fossil fuels.

Environmental Considerations:

While wood combustion is considered a more environmentally friendly alternative to fossil fuels, it still produces emissions, including carbon dioxide, particulate matter, and nitrogen oxides. Proper combustion practices, emission control systems, and sustainable forestry practices can help minimize the environmental impact of wood combustion.

Future Directions:

Research and development efforts focus on improving the efficiency and environmental performance of wood combustion technologies. This includes developing advanced combustion systems, optimizing fuel preparation methods, and exploring the use of wood-based biofuels. Wood combustion is expected to continue playing a role in the transition towards a more sustainable energy future, particularly in regions with abundant wood resources.

Water Evaporation

Water evaporation is a phase transition process where liquid water changes into gaseous water vapor. It occurs when water molecules gain enough energy to overcome the intermolecular forces that hold them together in the liquid phase and escape into the atmosphere. Evaporation is a critical component of the Earth’s water cycle, responsible for transporting water from the surface to the atmosphere and back again.

Mechanism of Water Evaporation:

- Energy Input: Water evaporation requires an input of energy to break the intermolecular bonds between water molecules. This energy can come from various sources, such as solar radiation, heat from the surrounding environment, or even mechanical agitation.

- Molecular Movement: As water molecules absorb energy, their kinetic energy increases, causing them to move more rapidly. This increased movement leads to more frequent collisions between water molecules.

- Energy Transfer: During collisions, energy is transferred from more energetic molecules to less energetic molecules. This energy transfer results in a distribution of molecular energies, with some molecules having enough energy to overcome the intermolecular forces and escape into the atmosphere.