Gasification Plants: Gasification plants are advanced industrial facilities designed to convert carbonaceous feedstocks—such as coal, biomass, municipal solid waste, industrial residues, or other organic materials—into a clean, combustible synthesis gas (syngas). This process takes place in a controlled environment where the feedstock reacts with a limited amount of oxygen, steam, or air at high temperatures, typically between 800°C and 1500°C. Unlike direct combustion, which fully oxidizes the material to release heat, gasification partially oxidizes the feedstock to produce syngas, a mixture primarily composed of carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), methane (CH₄), and trace amounts of other gases. This syngas can then be used as a versatile energy carrier for power generation, heating, production of synthetic fuels, and as a feedstock for the chemical industry.

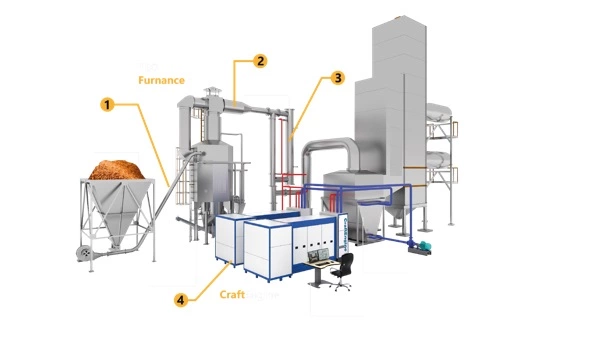

The structure of a gasification plant is based on a series of interconnected systems that ensure efficient and continuous operation. At its core lies the gasifier itself, where the thermochemical reactions occur. Surrounding this central unit are subsystems for feedstock preparation and feeding, oxygen or air supply, syngas cooling and cleaning, ash and slag handling, energy conversion, and control systems. Each of these parts plays a crucial role in maintaining the quality of syngas, the reliability of operations, and compliance with environmental regulations. Modern plants often include advanced gas cleaning systems capable of removing particulates, tars, heavy metals, and sulfur compounds, which makes syngas suitable for sensitive applications such as gas turbines or chemical synthesis.

One of the key advantages of gasification plants is their ability to handle a wide range of fuels. While traditional coal gasification plants dominated in the past, modern facilities increasingly focus on biomass, waste, and other renewable or recycled feedstocks. This flexibility allows gasification to support the transition to sustainable energy by reducing reliance on fossil fuels and enabling waste-to-energy solutions. Additionally, gasification provides higher efficiency and lower emissions compared to direct combustion, especially when integrated with combined cycle power plants (IGCC) or when combined with carbon capture and storage (CCS) technologies. In such cases, syngas can be cleaned and conditioned before combustion, leading to a significant reduction in greenhouse gas emissions.

Gasification plants also serve as a bridge between the energy and chemical industries. Syngas can be further processed to produce synthetic natural gas (SNG), liquid fuels via Fischer–Tropsch synthesis, hydrogen for fuel cells, or valuable chemicals like methanol and ammonia. This versatility positions gasification as a cornerstone of the circular economy, where waste and residues are transformed into valuable resources. Furthermore, the integration of digital monitoring and advanced process control in modern plants enhances operational safety, efficiency, and flexibility, allowing rapid adaptation to different feedstocks and market demands.

Gasification Plants

Gasification plants can be classified into several main types depending on the design of the gasifier, the method of feedstock introduction, the flow of gases and solids inside the reactor, and the application for which the syngas is intended. Each type has its own advantages, limitations, and preferred areas of use. The four principal categories of gasifiers used in large-scale plants are fixed-bed gasifiers, fluidized-bed gasifiers, entrained-flow gasifiers, and plasma gasifiers.

Fixed-Bed Gasifiers

These are the oldest and simplest types of gasifiers. The feedstock remains largely in solid form as gases pass through it. Depending on the direction of the gas flow relative to the feedstock, they are subdivided into:

- Updraft (counter-current): Air or oxygen enters from below while the syngas exits at the top. This design achieves high efficiency and can handle fuels with high moisture but often produces tars in the syngas.

- Downdraft (co-current): Both feedstock and gases flow downward together, resulting in cleaner syngas with low tar content, though it requires dry, uniform fuel.

Fixed-bed gasifiers are well-suited for small- to medium-scale applications, especially for biomass and waste feedstocks.

Fluidized-Bed Gasifiers

These gasifiers use a bed of inert material, such as sand, kept in motion by upward-flowing gas (air, oxygen, or steam). Feedstock is introduced into this turbulent environment, which ensures good mixing, uniform temperatures, and efficient conversion. Types include:

- Bubbling Fluidized Bed (BFB): The gas flow is moderate, creating bubbles within the bed. It offers good fuel flexibility and moderate tar levels.

- Circulating Fluidized Bed (CFB): Higher gas velocities carry bed material and unreacted feedstock out of the reactor, which are then recirculated. This design allows large-scale operation, uniform temperature distribution, and high efficiency.

Fluidized-bed gasifiers are widely used for biomass and waste, as well as for coal in large plants.

Entrained-Flow Gasifiers

In this type, finely ground feedstock is injected with oxygen or air and steam into a reactor at very high temperatures (over 1200°C). The feedstock reacts almost instantly, producing a tar-free syngas with very low methane content. Ash is typically removed as molten slag. Entrained-flow gasifiers are the preferred choice for large-scale coal and petroleum coke gasification, as well as for integrated gasification combined cycle (IGCC) power plants. However, they require finely pulverized fuel and careful feed preparation.

Plasma Gasifiers

Plasma gasification uses an electric arc or plasma torch to generate extremely high temperatures (2000–5000°C). This environment breaks down feedstock completely into syngas and vitrified slag. Plasma gasifiers are especially effective for hazardous waste, municipal solid waste, and complex materials that are difficult to process with conventional methods. While they produce very clean syngas, their energy requirements are high, making them more suitable for specialized applications.

Additional Variants and Emerging Types

- Dual-Fuel Gasifiers: Designed to handle mixed feedstocks (e.g., coal and biomass).

- Hydrothermal Gasification: Operates with wet biomass or sludge at supercritical water conditions, eliminating the need for drying.

- Chemical-Looping Gasifiers: Use solid oxygen carriers to separate nitrogen from the process, improving syngas purity.

Fixed-Bed Gasifiers

Fixed-bed gasifiers represent the earliest and most traditional form of gasification technology, and they remain relevant today due to their relatively simple design, robustness, and adaptability to smaller-scale applications. The fundamental principle of a fixed-bed gasifier is that the solid feedstock—whether coal, biomass, or waste-derived material—is introduced into a vertical reactor, forming a packed bed through which the oxidizing agent (air, oxygen, or steam) flows. The physical arrangement of the feedstock stays largely intact, with the gases moving through the interstices of the solid material, allowing for gradual conversion into a combustible syngas. Depending on the configuration of gas and solid flow, fixed-bed gasifiers are typically classified as updraft (counter-current) or downdraft (co-current), with some less common variations such as crossdraft designs used in niche applications.

The fixed-bed design is characterized by clearly defined thermal zones that appear along the height of the bed. At the top, feedstock enters and undergoes drying through contact with rising hot gases. Below this, in the pyrolysis zone, the material is decomposed by heat into char, tar vapors, and volatiles. Further down lies the oxidation zone, where oxygen or air reacts with the carbonaceous char, generating high temperatures. Finally, at the bottom, the reduction zone allows carbon dioxide and steam to react with hot char to form additional carbon monoxide and hydrogen, enriching the syngas. This stratified arrangement makes fixed-bed gasifiers relatively easy to understand, operate, and maintain, while also offering predictable gas compositions depending on the operating mode.

In updraft fixed-bed gasifiers, the oxidizing agent enters from below the bed and syngas exits at the top. The rising hot gases first dry the incoming fuel, then pyrolyze and partially oxidize it, producing high thermal efficiency and an ability to process fuels with high moisture or ash content. However, a major drawback of this configuration is the high tar content in the syngas, as the volatiles released in the upper part of the bed are not sufficiently cracked before exiting the reactor. This makes the gas less suitable for direct use in engines or turbines without additional cleaning or reforming stages. Updraft systems are therefore commonly used for heating applications, low- to medium-scale power generation with extensive gas cleaning, or in situations where fuel quality is inconsistent.

In contrast, downdraft fixed-bed gasifiers allow both feedstock and gasifying agent to flow downward together, with syngas leaving from the bottom. This design forces volatiles released during pyrolysis to pass through the hot oxidation and reduction zones, where many of the tars are thermally cracked into simpler gases. The result is a much cleaner syngas with significantly lower tar levels compared to updraft systems, making it more suitable for small power generation units, internal combustion engines, and distributed energy systems. The trade-off, however, is that downdraft gasifiers demand relatively dry and uniform feedstock, and they tend to have lower efficiency than updraft types due to less effective heat recovery from the rising gases.

A crossdraft fixed-bed gasifier represents a less common variation, where air enters from the side and the syngas exits on the opposite side. This design has a compact layout and can deliver gas rapidly, but it typically suffers from poor fuel conversion and uneven temperature distribution. Crossdraft systems are sometimes used in small-scale or mobile applications where space and rapid startup are priorities, but they are not as widely applied in modern industrial practice.

The advantages of fixed-bed gasifiers are strongly linked to their mechanical simplicity and robustness. They are comparatively inexpensive to build and operate, require minimal moving parts, and can handle a variety of fuels, especially in the updraft design. Their ability to operate with relatively high-moisture biomass makes them attractive in rural or agricultural settings where fuel drying infrastructure is limited. Furthermore, their stratified thermal zones provide stable operation and predictable performance, making them suitable for users who require dependable, low-maintenance systems.

On the other hand, limitations are also well recognized. Tar formation remains the most significant challenge, particularly in updraft systems, which restricts the direct usability of the gas for advanced energy conversion technologies without costly gas cleaning. Fuel flexibility, while a strength in some designs, is restricted in others; downdraft systems, for instance, require carefully sized and conditioned feedstock to prevent blockages, channeling, or unstable operation. Scaling fixed-bed gasifiers to very large capacities is also problematic, as uneven gas distribution and excessive pressure drops occur in large beds, confining their practicality mainly to small- and medium-scale plants.

Despite these challenges, fixed-bed gasifiers continue to be deployed across a range of applications, particularly where simplicity, ruggedness, and moderate syngas quality are acceptable trade-offs. In many developing regions, small biomass gasifiers based on the downdraft principle are used to generate electricity for off-grid communities, powering diesel engine generators with producer gas substitution. In industrial settings, updraft fixed-bed systems are used to gasify coal or biomass for process heat or to feed boilers. Additionally, research continues on hybrid approaches, combining fixed-bed principles with advanced tar cracking or gas cleaning technologies to improve syngas quality while retaining the operational benefits of the design.

In summary, fixed-bed gasifiers remain a cornerstone of gasification technology due to their longevity, adaptability, and straightforward operation. While they may not match the scale or syngas purity of entrained-flow or plasma gasifiers, they fill an important niche in distributed energy, rural electrification, small industrial power generation, and heating. By carefully matching the type of fixed-bed gasifier—updraft for high efficiency with tolerant fuel flexibility, downdraft for cleaner syngas at smaller scales, or crossdraft for specialized compact applications—to the intended use, operators can harness the benefits of gasification with relatively low capital and operational complexity.

The main parts of a fixed-bed gasifier are designed to create a stable flow of feedstock, maintain the thermochemical reaction zones, and extract syngas and by-products efficiently. Each component plays a specific role in ensuring proper gasification performance, syngas quality, and system durability. While the exact design can vary depending on whether the configuration is updraft, downdraft, or crossdraft, the fundamental elements remain similar. The main parts can be grouped as follows:

1. Feedstock Inlet and Hopper

The feed system begins with a hopper or storage bin where the raw fuel (biomass, coal, or waste-derived material) is stored before entering the reactor. From the hopper, the material is fed into the top of the gasifier by gravity. In some designs, feeding screws, conveyors, or lock-hoppers are added to maintain a continuous feed and prevent air leakage. The inlet must ensure uniform distribution of feedstock to avoid channeling and uneven bed formation.

2. Gasifier Reactor Vessel (Main Body)

This is the central chamber where the gasification reactions occur. It is typically a vertical cylindrical or rectangular vessel constructed from refractory-lined steel to withstand high temperatures. Inside the reactor, distinct thermal and reaction zones are established in a vertical sequence:

- Drying Zone (upper region): moisture in the feedstock is evaporated by contact with rising hot gases.

- Pyrolysis Zone (middle region): volatile compounds are released, leaving behind char.

- Oxidation/Combustion Zone (lower middle): oxygen reacts with part of the char, producing heat and creating CO₂ and H₂O.

- Reduction Zone (lowest part): CO₂ and H₂O react with the hot char to form CO and H₂, the main components of syngas.

The geometry and insulation of the reactor body are crucial for maintaining stable temperature profiles and ensuring efficient conversion.

3. Air / Oxygen / Steam Inlet (Tuyeres or Nozzles)

These are ports or nozzles through which the gasifying agent (air, oxygen, or steam) is introduced into the reactor. In updraft gasifiers, the inlets are located near the bottom, allowing gases to rise upward. In downdraft designs, the air is often introduced through side nozzles at the oxidation zone, forcing volatiles to pass through the hottest zone for tar cracking. The placement and design of tuyeres greatly influence syngas composition, tar levels, and overall efficiency.

4. Grate or Support Bed

At the bottom of the reactor lies a grate or support system that holds the solid bed of fuel while allowing ash, char, and slag to fall through. The grate also ensures that gases can pass upward (in updraft) or downward (in downdraft) through the fuel bed without obstruction. In modern systems, moving or rotating grates are sometimes used to avoid blockages and maintain continuous operation.

5. Ash and Char Removal System

Unreacted char, ash, and inert residues collect at the bottom of the reactor and must be removed continuously or periodically. Systems include mechanical ash screws, lock-hoppers, or manual removal depending on the scale of the plant. In updraft systems, this part must also handle higher amounts of unconverted char, while downdraft systems usually produce finer ash due to more complete fuel utilization.

6. Syngas Outlet

The exit for syngas is positioned differently depending on the type of fixed-bed gasifier:

- Updraft: the outlet is at the top, where gas leaves after passing through the drying zone.

- Downdraft: the outlet is located at the bottom or side, after gas has passed through the hot reduction zone for tar cracking.

- Crossdraft: the outlet is on the opposite side from the air inlet, allowing lateral gas flow.

The outlet is often connected to a cyclone or primary gas cleaning system to remove particulates before further use.

7. Refractory Lining and Insulation

The inner walls of the reactor are lined with refractory materials to withstand temperatures often exceeding 1000°C. This lining protects the steel shell from damage, minimizes heat loss, and ensures thermal stability of the reaction zones. Proper insulation is critical for efficiency and longevity of the gasifier.

8. Gas Cleaning and Cooling (External but Essential)

Although not part of the core reactor body, every fixed-bed gasifier is paired with gas cleaning equipment. This usually includes:

- Cyclones to remove particulates.

- Scrubbers or filters to capture tar, dust, and other contaminants.

- Coolers/heat exchangers to reduce syngas temperature before use in engines or turbines.

In updraft systems, this stage is especially important due to the high tar load in raw syngas.

9. Instrumentation and Control Systems

Modern fixed-bed gasifiers include temperature sensors, pressure gauges, flow meters, and automated control systems. These instruments help monitor bed conditions, prevent blockages, control feed rates, and maintain desired gas quality. Advanced control ensures safe and efficient operation, especially in continuous industrial setups.

Feedstock Inlet and Hopper

The feedstock inlet and hopper of a fixed-bed gasifier form the first critical interface between the raw material supply chain and the reactor itself. Their design, construction, and operation have a direct influence on the stability of the gasification process, the continuity of operation, and the quality of the syngas produced. Since fixed-bed gasifiers rely on a packed column of solid feedstock through which gases flow, the manner in which the material enters and settles in the bed is fundamental to ensuring uniform reaction conditions. Any irregularities in feeding—such as bridging, channeling, or surges—can disturb the bed structure, alter temperature distributions, and reduce efficiency. For this reason, engineers place considerable emphasis on the configuration of the feedstock inlet system and its integration with the reactor body.

At the most basic level, the hopper serves as a storage and buffer system that holds a sufficient quantity of feedstock above the gasifier to guarantee continuous operation. In small-scale downdraft gasifiers used for rural electrification with biomass, the hopper may be a simple vertical cylinder with a conical bottom feeding directly into the reactor throat by gravity. In larger or industrial systems, however, the hopper is designed as part of a lock-hopper arrangement to allow periodic refilling without disturbing the internal pressure or allowing air leakage into the reactor. These lock-hopper systems are especially important in pressurized gasifiers, where any uncontrolled air ingress would not only compromise syngas quality but also create serious safety hazards.

The inlet design must also account for the physical characteristics of the feedstock. Coal, for example, can be delivered in graded lumps of uniform size, which flow predictably through a chute or hopper. Biomass, on the other hand, presents greater challenges because it tends to be irregular in shape, lightweight, fibrous, and sometimes sticky when moist. Such characteristics can lead to bridging, where the feedstock forms an arch inside the hopper and stops flowing, or rat-holing, where the material flows only in a narrow channel, leaving stagnant zones. To prevent these problems, engineers often use mechanical agitators, screw feeders, or vibratory systems inside or beneath the hopper to ensure a consistent flow into the bed. The choice of feeder must be carefully matched to the type of biomass—wood chips, pellets, rice husks, or agricultural residues each behave differently under gravity feeding.

Another key function of the hopper and feed inlet is to minimize unwanted air entry into the reactor. Fixed-bed gasifiers rely on carefully controlled oxygen input through designated tuyeres or nozzles, and any additional air entering via the feed system can create uncontrolled combustion zones. To avoid this, hoppers are usually sealed, and when mechanical feeding systems are used, they incorporate airlocks or double-valve arrangements. In pressurized systems, where the reactor may operate at several bars above atmospheric pressure, lock-hopper feeding not only maintains sealing but also stages the pressure reduction between ambient and reactor levels to protect equipment and operators.

The thermal environment around the feed inlet also requires careful management. Since the top of the bed is the drying zone in most fixed-bed designs, hot gases rising from below transfer heat to the incoming feedstock. This process enhances drying efficiency but can also expose the hopper to elevated temperatures. If not properly insulated or cooled, the hopper walls may suffer damage or allow pre-ignition of feedstock inside the chute. Some designs incorporate water jackets or cooling systems around the upper section of the reactor and hopper to maintain safe operating temperatures and extend equipment life.

Dust, fines, and foreign objects represent additional concerns in the design of the feedstock inlet. Excessive fines can clog the bed, increase pressure drop, and reduce permeability for gases. Oversized particles, meanwhile, may create voids or cause uneven bed packing. For this reason, the feedstock supply system often includes screening and sizing equipment upstream of the hopper to ensure a uniform feed. Metal tramp removal systems, such as magnetic separators, are also common in waste-derived fuel applications, preventing damage to feeders or blockages in the gasifier throat.

In terms of operational strategy, the hopper acts as both a buffer and a regulator of feedstock delivery. Operators must monitor the fill level continuously to avoid starvation (leading to unstable gas quality) or overfilling (which can overload the bed and cause poor gas distribution). Modern gasifiers often integrate sensors, such as ultrasonic or radar level detectors, to provide continuous feedback on hopper contents. Automated controls then adjust feeding mechanisms—whether conveyors, screws, or rotary valves—to maintain a steady fuel column within the reactor. This automation not only improves consistency but also reduces labor requirements and minimizes human error in complex industrial environments.

From an environmental and safety perspective, the hopper and inlet system must also be designed to control emissions and operator exposure. In small open-top systems, smoke, dust, and gases can escape during refilling, posing hazards to workers. Advanced hoppers, particularly in waste and coal gasification plants, are fully enclosed and may include extraction systems to capture fugitive dust and vapors. In addition, safety interlocks prevent operators from opening feed inlets while the reactor is pressurized or in operation. Such measures are essential for compliance with occupational health standards and environmental regulations.

Looking forward, innovations in hopper and feed inlet design continue to evolve, particularly with the push toward greater fuel flexibility in biomass and waste gasification. Researchers are developing adaptive feeding systems that can handle heterogeneous mixtures without extensive preprocessing. For example, twin-screw feeders and fluidized lock-hopper systems are being tested to overcome bridging and flow issues. Moreover, integration with digital monitoring tools allows predictive maintenance of feeding equipment, ensuring that blockages or wear are detected before they lead to unplanned downtime.

In summary, the feedstock inlet and hopper of a fixed-bed gasifier, while seemingly simple components, are in fact highly engineered subsystems that play a pivotal role in process stability and efficiency. They must reliably deliver a uniform stream of feedstock, prevent air ingress, manage thermal exposure, and ensure operator safety. The success of the entire gasification process hinges on the performance of this first stage, because even the most advanced reactor and gas cleaning technologies cannot compensate for inconsistent or irregular feeding. For this reason, careful attention to hopper design, feeding mechanisms, sealing systems, and monitoring tools is a defining feature of modern fixed-bed gasifier engineering.

The feedstock inlet and hopper in a fixed-bed gasifier play a fundamental role in determining the efficiency and stability of the entire gasification process, as they establish the first point of contact between the raw material and the reactor system. The hopper is not only a storage unit but also a buffer zone that guarantees a consistent supply of feedstock into the gasifier, ensuring that the column of solid material inside the reactor remains stable and evenly distributed. Because fixed-bed gasifiers rely on a packed bed through which gases pass to initiate drying, pyrolysis, oxidation, and reduction reactions, the way the material enters the bed can directly influence the uniformity of temperature gradients and the permeability of gases. Any disruption at this stage, such as uneven feeding or bridging of biomass in the hopper, can disturb gas flow and create inefficiencies that compromise syngas quality. For this reason, feedstock inlets are carefully engineered to promote uninterrupted gravity flow or are supplemented with mechanical feeding systems when dealing with difficult fuels.

The design of the feedstock inlet and hopper is strongly tied to the type of material being processed, whether coal, biomass, or waste-derived fuels. Coal, with its predictable particle size and density, generally flows smoothly through hoppers, requiring only basic gravity-fed chutes. Biomass, however, introduces significant challenges due to its irregular shapes, low bulk density, and fibrous texture. Materials like wood chips or agricultural residues tend to form arches or bridges inside the hopper, preventing a continuous flow into the reactor. To overcome these challenges, engineers incorporate screw feeders, vibratory systems, or rotary valves beneath the hopper, which mechanically agitate the material and prevent flow interruptions. In pressurized fixed-bed gasifiers, the inlet system also includes lock-hopper mechanisms that not only regulate the feed but also maintain the pressure seal, preventing unwanted air ingress that could disrupt the controlled oxygen balance inside the reactor. These lock-hopper systems are essential in large-scale industrial applications, where maintaining reactor integrity and operator safety are non-negotiable.

Thermal management is another important consideration in the design of feedstock inlets and hoppers. Since the top of the gasifier bed typically functions as the drying zone, hot gases rise and transfer heat to the incoming feedstock. While this is beneficial for reducing the moisture content of the material, it also exposes the hopper walls to elevated temperatures. If left unprotected, this can cause structural damage or lead to pre-ignition of the feedstock before it enters the main reactor zones. To mitigate these risks, refractory linings, cooling jackets, or external insulation are commonly used to keep temperatures within safe limits. The hopper must also be designed to withstand mechanical stresses from large volumes of fuel while ensuring minimal leakage of gases or particulates into the environment. In modern systems, enclosed hoppers are equipped with dust extraction systems to maintain clean operation and protect workers from exposure to fine particles or volatile gases that might escape during refilling.

The functionality of the feedstock inlet extends beyond simply delivering material; it also plays a key role in maintaining the chemical environment within the gasifier. Fixed-bed gasification is highly sensitive to uncontrolled oxygen inflow, as even small leaks can create unwanted combustion zones that disrupt the carefully staged reactions in the reactor. Therefore, the sealing of the feed inlet is as critical as its feeding performance. In industrial plants, sophisticated double-valve arrangements or rotary airlocks ensure that no ambient air enters the system during fuel loading. For smaller-scale downdraft biomass gasifiers, simpler sealed hoppers may suffice, but even in these cases, poor sealing can result in erratic syngas quality and operational instability. These considerations highlight that the feedstock inlet, although often underestimated, is a decisive factor in maintaining both process efficiency and operational safety.

In practice, the feedstock inlet and hopper are also tightly integrated with fuel preparation systems. Since syngas quality and reactor performance depend on uniform fuel size and moisture, upstream processing often includes screening, drying, and densification of biomass into pellets or briquettes. This preprocessing ensures smooth flow through the hopper and consistent gasification reactions in the bed. Without such measures, irregular feedstock could cause blockages, uneven gas flow, or incomplete conversion, resulting in higher tar formation or reduced calorific value of the syngas. In waste-to-energy applications, the hopper is typically paired with magnetic separators or shredders to remove foreign materials before they can enter the reactor. This not only protects feeding equipment but also prevents operational disruptions caused by contaminants.

Automation and monitoring are increasingly important in modern feedstock inlet and hopper systems, especially as gasification plants move toward more continuous and industrialized operation. Advanced level sensors using radar or ultrasonic technology monitor the amount of material in the hopper in real time, feeding data into control systems that regulate feeding rates. This automation allows operators to maintain a consistent bed height inside the reactor, preventing starvation or overloading. In some designs, sensors are also used to detect bridging or irregular flow, triggering corrective measures such as mechanical agitation or feed adjustments. Combined with predictive maintenance technologies, these digital tools reduce downtime, improve efficiency, and make gasification plants more reliable.

The role of the feedstock inlet and hopper in a fixed-bed gasifier thus extends far beyond simple material delivery. It encompasses the regulation of fuel flow, the protection of reactor integrity, the control of air ingress, the management of thermal and mechanical stresses, and the integration with fuel preparation and automation systems. Their design is particularly influential in determining whether a gasifier operates with stable syngas output and minimal downtime or suffers from frequent disruptions and inconsistent gas quality. In smaller-scale applications, such as rural biomass gasification units, the simplicity and low cost of the feed system are advantageous, but even here, reliability remains essential to ensure local power supply. In large-scale industrial plants, the feedstock inlet and hopper become highly engineered subsystems, reflecting the complexity and demands of modern energy production. Ultimately, by ensuring continuous, safe, and uniform feeding, the feedstock inlet and hopper form the foundation on which the entire efficiency and performance of a fixed-bed gasifier is built.

The reactor vessel of a fixed-bed gasifier is the central structure in which the entire gasification process takes place, and its design largely determines the efficiency, stability, and longevity of the plant. This vessel is usually a vertical, refractory-lined steel chamber that accommodates the different thermal and chemical zones required for drying, pyrolysis, oxidation, and reduction of the feedstock. The feedstock inlet and hopper supply the material from above, and as it descends by gravity, it passes through these reaction zones in sequence, while the oxidizing agents such as air, oxygen, or steam are introduced through nozzles or tuyeres at carefully chosen points along the reactor wall. The geometry of the reactor vessel, the distribution of air inlets, and the type of grate or support system at the bottom are all critical factors that dictate gas flow, heat transfer, and the quality of syngas produced. In an updraft fixed-bed gasifier, the oxidizing agent enters at the bottom, allowing gases to rise counter-current to the descending fuel, which leads to high thermal efficiency but syngas rich in tar vapors. In downdraft designs, the oxidizing medium is introduced near the middle of the reactor, forcing volatiles to pass through the hot combustion zone before leaving at the bottom, which results in a much cleaner syngas more suitable for power generation engines. Crossdraft versions, though less common, introduce gases from the side and rely on a lateral flow across the bed, offering compactness at the expense of efficiency and uniformity.

The materials and construction of the reactor vessel must be robust enough to withstand continuous exposure to high temperatures often exceeding 1000°C as well as corrosive gases, abrasive feedstock particles, and thermal cycling. To achieve this, the vessel is lined with refractory materials that provide thermal insulation and protect the steel shell from chemical attack and heat damage. The choice of refractory lining depends on the type of feedstock and operating temperature; alumina, silica, and high-chromium bricks are commonly used in coal-based gasifiers, while biomass systems may use lighter linings optimized for lower ash content. The internal design also takes into account the accumulation of ash and slag, which must be directed toward the grate and ash removal system without obstructing the syngas flow. In pressurized gasifiers, the vessel must also handle significant internal pressures, requiring thicker steel shells, stronger welds, and precisely engineered seals. These design considerations make the reactor vessel one of the most complex and costly components of a fixed-bed gasifier.

Within the reactor vessel, the stability of the fuel bed is crucial for uniform reaction conditions. The packed bed must allow gases to flow evenly without channeling, which can lead to hot spots, incomplete conversion, or excessive tar formation. This is why the distribution of the feedstock from the inlet and the maintenance of a proper bed height are closely linked to the vessel’s performance. The tuyeres or nozzles that inject air or oxygen into the bed are strategically placed to maintain even combustion and to prevent localized overheating that could damage the refractory lining. The flow of the oxidizing medium must also be carefully balanced to ensure that only partial oxidation occurs, since excessive oxygen supply would result in direct combustion instead of gasification, thereby reducing syngas yield and efficiency. By maintaining these delicate balances within the reactor vessel, the fixed-bed gasifier can operate continuously with predictable performance and a steady output of syngas.

The design of the reactor vessel is also influenced by the type and quality of feedstock being used. Coal gasifiers, for example, are typically designed to handle larger particle sizes and higher ash content, requiring strong grates and effective slag tapping systems at the bottom. Biomass gasifiers, on the other hand, must accommodate lower bulk density, variable moisture content, and fibrous particles, which may demand taller vessels to ensure sufficient residence time for complete conversion. Waste-derived fuels add further challenges due to their heterogeneous composition, requiring vessels that can tolerate irregular feeding, variable ash melting points, and unpredictable contaminants. These differences highlight why fixed-bed gasifiers are not one-size-fits-all solutions but rather need tailored reactor designs to match the intended fuel source and application.

Modern reactor vessels are often equipped with advanced monitoring and control instruments to ensure optimal operation. Thermocouples placed at different heights within the vessel allow operators to track temperature profiles across the drying, pyrolysis, oxidation, and reduction zones, ensuring that each stage is performing as intended. Pressure sensors monitor gas flow resistance through the bed, providing early warnings of blockages or excessive ash buildup on the grate. In larger plants, sophisticated control systems automatically adjust the air supply, feed rate, and bed height to stabilize syngas quality even as fuel properties vary. This integration of digital monitoring into the reactor vessel design enhances reliability and safety, while also maximizing fuel utilization and reducing downtime caused by manual adjustments.

The reactor vessel of a fixed-bed gasifier is thus far more than a simple container; it is a carefully engineered core system where the transformation of solid feedstock into gaseous fuel is orchestrated through precise temperature control, gas distribution, and material handling. Its performance determines the composition of the syngas, the amount of tar and particulates produced, and the overall efficiency of the plant. Without a properly designed and well-maintained reactor vessel, even the best feeding system, gas cleaning units, or downstream equipment cannot deliver consistent results. For this reason, the vessel is often considered the heart of the gasifier, where engineering decisions on materials, geometry, and process integration directly shape the plant’s capability to produce clean and reliable syngas for power generation, industrial heat, or chemical synthesis.

The air, oxygen, or steam inlet system in a fixed-bed gasifier is one of the most critical subsystems because it determines how effectively the chemical reactions inside the reactor vessel proceed and how the quality of the syngas evolves during operation. These inlets, often designed as tuyeres or nozzles strategically located along the walls of the vessel, are responsible for introducing the oxidizing medium that enables partial combustion and generates the heat required to sustain the endothermic reactions of pyrolysis and reduction. Unlike full combustion systems, the gasifier depends on a carefully controlled supply of oxygen or air to avoid complete burning of the feedstock, which would only yield heat instead of syngas. The balance between oxygen, air, or sometimes steam injection is what makes gasification distinct, as the limited oxygen presence allows carbon-rich feedstock to break down into carbon monoxide, hydrogen, and other useful gases. Steam injection is particularly important in many designs because it reacts with hot carbon to produce additional hydrogen, thereby enhancing the calorific value and quality of the syngas. The precise ratio of oxidizing agents injected through the inlets is continuously monitored and adjusted to ensure stable operation and high conversion efficiency.

The geometry and durability of these inlet nozzles are essential for the long-term stability of the gasifier. Since they are exposed directly to extremely high temperatures and the corrosive environment of the reactor interior, they are typically manufactured from heat-resistant alloys or coated with refractory materials that resist chemical wear. In some gasifiers, the inlets are water-cooled or designed with protective linings to prevent them from burning out or clogging with ash and slag. The positioning of the inlets along the vertical reactor wall must also ensure even distribution of the oxidizing medium so that localized hot spots do not form, which could crack the refractory lining or cause inconsistent syngas production. In downdraft gasifiers, the placement of inlets around the oxidation zone forces volatiles to pass through intense heat, reducing tar levels and producing cleaner gas, while in updraft systems, the inlets at the bottom supply rising streams of air or oxygen that generate strong counter-current heat transfer and high efficiency but leave more tar in the gas stream. This demonstrates how the inlet system directly influences the chemical profile of the resulting gas.

The flexibility of the inlet system also makes it possible for operators to adapt to different types of feedstock. Biomass with high moisture content may require more oxygen injection to generate the additional heat needed to drive off excess water, whereas coal or char-based feedstocks may demand less air but more steam injection to optimize hydrogen yield. The valves and flow control units connected to these nozzles are therefore designed for precise modulation, often linked to sensors within the vessel that provide real-time feedback on temperature and pressure. Modern gasifiers often integrate automated control loops where sensors detect fluctuations in the reaction zones and adjust inlet flows almost instantly, maintaining stable syngas composition despite changes in fuel quality or load demand. This automation not only improves efficiency but also extends the lifespan of the inlet nozzles by preventing extreme operating conditions that accelerate wear and tear.

The inlet system is also closely tied to safety, as the wrong balance of oxygen or air could easily shift the process from controlled partial oxidation to uncontrolled combustion, leading to overheating, refractory damage, or even pressure build-up and explosions. To mitigate this risk, most gasifiers are equipped with purge systems that can flush the nozzles with inert gases such as nitrogen or carbon dioxide during startup, shutdown, or emergency situations. Additionally, nozzles are designed to minimize backflow of hot gases, which could otherwise reach the external piping and damage sensitive control equipment. This level of engineering highlights the dual role of the inlet system: not only to provide the correct amounts of oxidizing agents for efficient syngas generation but also to safeguard the entire gasification plant against dangerous operating conditions.

As fixed-bed gasifiers evolve, the inlet systems are increasingly optimized for higher flexibility and integration with advanced control systems. Computational fluid dynamics simulations are used during design to predict how injected gases will distribute inside the vessel and how they will interact with the descending bed of fuel. By fine-tuning nozzle positions and flow rates, engineers can minimize channeling effects, where gases bypass parts of the bed and cause uneven reactions. Innovations also include multi-stage injection systems that allow the operator to vary the type of gas introduced at different levels of the reactor, enabling more precise control of reaction zones. This level of sophistication allows modern fixed-bed gasifiers to handle a wider range of fuels, produce cleaner syngas, and operate with higher thermal efficiency compared to earlier designs.

The air, oxygen, and steam inlet system is therefore a key enabler of the gasification process, directly shaping the thermal environment of the reactor vessel, dictating the balance between combustion and reduction, and ultimately determining the quality and usability of the syngas produced. Without a carefully engineered and well-maintained inlet system, a fixed-bed gasifier cannot achieve the level of stability and efficiency required for industrial power generation, chemical synthesis, or combined heat and power applications. It is this subsystem that transforms the concept of gasification from a theoretical chemical process into a controlled, repeatable, and industrially viable operation.

Gasifier Reactor Vessel (Main Body)

The gasifier reactor vessel, often referred to as the main body, is the core and most defining component of a fixed-bed gasifier, acting as the physical and functional framework where the entire sequence of gasification reactions unfolds. It is a vertically oriented, cylindrical or rectangular structure made of heavy-gauge steel with a refractory lining inside to withstand the extreme thermal and chemical conditions of operation. The design of this main body dictates not only the durability of the plant but also the efficiency of the conversion process, as the reactor vessel must contain and guide the different thermochemical zones—drying, pyrolysis, oxidation, and reduction—that the feedstock passes through as it descends by gravity. The dimensions and internal configuration of the reactor vessel are carefully engineered to ensure that the descending fuel maintains adequate residence time in each zone, that the rising gases flow evenly without channeling, and that the oxidizing agents introduced via tuyeres or nozzles mix effectively with the fuel bed. It is in this vessel that the solid feedstock undergoes its transformation into a combustible mixture of gases, making the main body the true heart of the gasifier.

The refractory lining within the reactor vessel plays an indispensable role by providing thermal insulation, reflecting heat back into the reaction zones, and protecting the steel shell from chemical corrosion and mechanical abrasion. Depending on the operating conditions and the type of feedstock, the refractory may consist of high-alumina bricks, silica compounds, or specialized castables that resist slag attack and maintain integrity under thermal cycling. In biomass gasifiers, the refractory must be optimized for lower ash contents and different melting characteristics, while in coal gasifiers it must tolerate more aggressive slags with higher fusion temperatures. The thickness of the refractory lining and the type of insulating backup material are also adjusted based on whether the gasifier operates at atmospheric or pressurized conditions. In pressurized designs, the reactor vessel walls must be reinforced with thicker steel shells and stronger welds to prevent rupture, while still allowing the lining to expand and contract during heating and cooling cycles without cracking. These technical considerations illustrate how much of the vessel’s reliability and service life depend on the careful choice and maintenance of the refractory system.

The reactor vessel also integrates with several crucial subsystems that determine its overall performance. At the top, it connects seamlessly with the feedstock inlet and hopper, allowing the controlled introduction of solid fuel without excessive air leakage that would disturb the process balance. Along its midsection, the vessel is equipped with the air, oxygen, or steam inlets that supply oxidizing agents for partial combustion and reduction reactions, while the geometry of the wall ensures that these gases distribute evenly through the fuel bed. At the bottom, the main body interfaces with the grate and ash removal system, where the residual char, ash, and slag are discharged without allowing excessive syngas losses or backflow of air. Openings along the vessel are designed to extract syngas at the optimal point, depending on whether it is an updraft, downdraft, or crossdraft configuration. Each of these connections must be engineered with airtight seals, wear-resistant fittings, and proper cooling arrangements to maintain continuous operation and prevent process upsets.

Thermal and mechanical stresses place significant demands on the structural integrity of the reactor vessel, and as such, it is often the most expensive and carefully monitored part of a gasifier plant. The main body must endure sustained exposure to temperatures exceeding 1000°C in some zones, combined with the abrasive action of descending solids and the chemical attack of reducing and oxidizing gases. In addition to wear from normal operation, the vessel must withstand frequent startups and shutdowns, during which expansion and contraction cycles can cause refractory cracking or steel deformation. To manage these stresses, many modern reactor vessels incorporate expansion joints, segmented refractory layers, and water-cooled jackets at critical locations. Regular inspection and maintenance schedules are essential, as even small cracks in the refractory or leaks in the vessel shell can lead to serious operational inefficiencies, contamination of syngas, or safety hazards.

The geometry of the main body also defines the operational behavior of the gasifier. In tall and narrow vessels, fuel has a longer residence time, allowing for more complete conversion and a smoother temperature gradient, which is particularly beneficial for biomass with high moisture content. In shorter, wider vessels, the flow of gases may be less uniform, but they allow higher throughput and can handle fuels with larger particle sizes or more irregular shapes. The design of the vessel therefore must be tailored to the intended feedstock and the desired syngas output, balancing efficiency, throughput, and ease of maintenance. Computational fluid dynamics modeling and pilot-scale testing are often used in modern engineering practice to optimize vessel geometry before full-scale construction, reducing the risks of uneven flow, incomplete conversion, or tar accumulation.

From an operational perspective, the gasifier reactor vessel also serves as the central point for process monitoring and control. Embedded thermocouples, pressure sensors, and gas sampling ports provide continuous data on the internal environment, allowing operators to track the stability of the drying, pyrolysis, oxidation, and reduction zones. These measurements are critical for adjusting feed rates, air or oxygen supply, and steam injection in real time, ensuring that the process remains in balance and that syngas quality remains consistent. By integrating these monitoring systems into the vessel design, modern gasifiers can achieve higher automation, reduced operator intervention, and improved process reliability compared to earlier, manually controlled units.

Ultimately, the gasifier reactor vessel represents the convergence of structural engineering, materials science, thermodynamics, and chemical process design. Its role as the main body of the plant makes it the single most important element in determining whether the system produces a steady, high-quality syngas stream or suffers from inefficiencies, high tar levels, and frequent breakdowns. A well-designed and properly maintained reactor vessel enables a fixed-bed gasifier to operate continuously for thousands of hours, efficiently converting a wide range of feedstocks into valuable energy. Without this central component, the carefully orchestrated interaction of feedstock inlet, oxidizing agent injection, syngas outlet, and ash removal would be impossible, underscoring why the main body is regarded as the heart of the gasification process.

The syngas outlet system of a fixed-bed gasifier is the pathway through which the gas mixture generated in the reactor vessel exits and moves toward downstream cooling and cleaning units, and its design is decisive in maintaining both efficiency and gas quality. Since syngas composition is directly influenced by the location and configuration of the outlet, the outlet system is carefully integrated into the body of the gasifier at the level that best suits the specific type of fixed-bed design. In updraft gasifiers, the syngas outlet is located at the top of the reactor vessel, where the hot gases rise after passing through the drying and pyrolysis zones, carrying with them a significant load of tars and particulates. This configuration benefits from high thermal efficiency but creates additional demands on the outlet and subsequent cleaning systems. In downdraft gasifiers, by contrast, the syngas outlet is positioned at the bottom, after the gases have been forced downward through the intense oxidation zone, effectively cracking many of the tar vapors before they leave the reactor. This makes the outlet gas much cleaner and easier to use in engines or turbines. Crossdraft systems have lateral outlets, which allow compact designs but require precise flow control to ensure that the gas leaving through the outlet is representative of complete reaction rather than bypassing parts of the bed. In all these configurations, the outlet system must be airtight, thermally resistant, and designed to prevent leakage of combustible gases, as even small leaks could create serious safety hazards.

Because the syngas exiting the reactor vessel is typically at very high temperatures—sometimes in excess of 500°C—it must be directed through outlet ducts and piping capable of withstanding both heat and corrosive compounds. These outlet channels are often lined with refractory materials or equipped with water-cooled jackets to manage the thermal load and protect the steel casing from damage. Furthermore, the gas at this stage is heavily laden with dust, soot, ash particles, and condensable tars, which means the outlet system must not only provide a pathway for flow but also maintain a geometry that minimizes blockages and fouling. Smooth curves are preferred over sharp bends, as tar vapors condensing on cold spots can create deposits that clog the pipes. To mitigate this, the outlet ducts are sometimes insulated or actively heated to keep gas above tar condensation temperatures until it reaches the cleaning system. The design thus extends beyond a simple exit port, encompassing a managed flow environment that prepares the raw syngas for further conditioning.

The outlet system also plays a vital role in pressure control within the gasifier. Since the reactor operates slightly above atmospheric pressure in many designs, the syngas outlet must be fitted with valves and seals that maintain this pressure balance without allowing uncontrolled venting. In pressurized gasifiers, the outlet design becomes even more sophisticated, as it must prevent depressurization events and ensure a consistent flow into downstream pressurized cleaning and utilization units. Pressure sensors and control valves are often placed at the outlet to monitor flow rates, regulate backpressure, and stabilize the overall performance of the reactor vessel. In some cases, syngas recirculation loops are connected to the outlet, allowing a portion of the gas to be redirected back into the reactor for tar cracking or temperature stabilization. This level of integration demonstrates how the outlet system functions not in isolation, but as a dynamic part of the entire gasifier operation.

Another important consideration in outlet system design is safety. The syngas produced contains significant amounts of carbon monoxide, hydrogen, and other combustible gases, making it both flammable and toxic. To prevent leaks, all outlet joints and connections are fitted with high-integrity gaskets and flanges, often designed with double sealing arrangements. Flame arrestors or non-return valves may also be installed to prevent flashbacks from downstream combustion equipment into the gasifier. During startup and shutdown, when gas composition is unstable and may include excess tars or unreacted volatiles, the outlet system may be connected to flare stacks where the gas can be safely combusted instead of being fed into sensitive engines or turbines. This controlled management of gas during transient phases is crucial for both plant safety and reliability.

From a process perspective, the syngas outlet is the first stage of transition from chemical reaction to practical energy use. The quality of gas leaving the outlet directly affects the design requirements of the subsequent cleaning system, which may include cyclones, scrubbers, filters, or catalytic tar reformers. A poorly designed outlet that allows uneven flow or entrainment of excessive particulates will increase the load on these downstream units, leading to higher maintenance costs and shorter operational lifetimes. Conversely, a well-optimized outlet system that ensures uniform flow, maintains proper temperatures, and prevents localized condensation will ease the burden on cleaning systems and contribute to a more stable and economical gasification process. This is why in modern gasifier engineering, the outlet system is not treated as a secondary detail but as a primary factor influencing the plant’s performance.

The syngas outlet system is therefore not merely an exhaust pipe; it is an engineered component that serves multiple functions including flow management, thermal regulation, pressure stabilization, and safety assurance. It bridges the harsh and reactive environment of the reactor vessel with the more controlled stages of syngas cooling and cleaning, and any weakness in its design or maintenance can compromise the entire plant. By carefully managing the exit of the gas, preserving its energy content, and preventing hazards, the outlet system ensures that the gasifier delivers a steady, usable stream of syngas suitable for power generation, industrial processes, or synthesis of fuels and chemicals. In this sense, it is as critical to the gasification process as the main body of the reactor itself, completing the cycle from feedstock introduction to usable energy output.

The grate and ash removal system in a fixed-bed gasifier is a critical component that ensures the continuous operation of the plant by allowing the accumulation and controlled discharge of residual char, ash, and slag produced during gasification. This system is located at the bottom of the reactor vessel and serves both as a physical support for the descending fuel bed and as a mechanism for separating incombustible materials from the syngas. In fixed-bed designs, the grate must support a high column of solid feedstock while allowing gases to pass upward or downward depending on whether the system is updraft, downdraft, or crossdraft. The structural integrity, material composition, and geometry of the grate are therefore crucial for maintaining uniform gas flow, avoiding channeling, and preventing excessive pressure drop that could disrupt the controlled reaction zones above. In essence, the grate forms the interface between the high-temperature chemical environment within the reactor and the mechanical removal of residues, making it indispensable for both efficiency and safety.

The materials used for constructing grates are designed to withstand extreme temperatures, abrasive wear, and corrosive effects of ash and slag. High-grade alloys or water-cooled steel plates are commonly used in industrial fixed-bed gasifiers, and in some designs, refractory coatings are applied to further extend service life. The selection of materials is closely linked to the type of feedstock; coal gasifiers require more robust, slag-resistant grates capable of handling higher ash melting points, while biomass gasifiers often have grates optimized for lighter, fibrous feedstock that produces more fine ash and less molten slag. The spacing and size of openings in the grate are carefully calculated to permit the passage of ash while preventing large fuel particles from falling through prematurely, which could disrupt the uniformity of the bed and reduce conversion efficiency. In some advanced designs, moving or vibrating grates are employed to actively agitate the bed and prevent clogging or channel formation, ensuring even gas distribution and minimizing operational interruptions.

Ash and char removal is tightly integrated with the grate design. In updraft gasifiers, where the syngas exits from the top, the ash that collects on the grate must be continuously discharged to prevent accumulation that could block gas flow. Downdraft systems benefit from more complete combustion and reduction, which typically produces finer residual ash, but even here, effective removal mechanisms are essential to maintain a stable bed height and prevent backpressure. Mechanical systems such as screw conveyors, rotary valves, or ash rakes are often used to transport the ash from the bottom of the reactor to storage or disposal units. In pressurized gasifiers, these removal systems are often designed as lock-hoppers or double-valve arrangements to maintain pressure integrity while allowing continuous discharge. Proper design of the ash removal pathway is critical not only for maintaining operational stability but also for reducing maintenance downtime and ensuring safe handling of potentially hot, reactive residues.

The ash and grate system also influences the quality of the syngas. If ash accumulates excessively or is unevenly distributed across the grate, it can create localized hotspots or cold zones in the reactor, altering the temperature profile of the pyrolysis, oxidation, and reduction zones. These temperature variations can increase tar production, reduce overall carbon conversion, or result in fluctuating syngas composition, which complicates downstream gas cleaning and utilization. For this reason, careful attention is paid to the uniformity of ash flow and the mechanical reliability of the grate. Continuous monitoring through sensors can detect bed height, ash accumulation, or abnormal temperature variations near the grate, enabling operators to make timely adjustments or maintenance interventions.

Safety is another key function of the grate and ash removal system. Residual char can remain highly reactive and, if not properly cooled or discharged, may pose a fire hazard when exposed to air outside the reactor. To mitigate these risks, ash discharge systems often include water quenching, cooling conveyors, or sealed hoppers that prevent ignition while safely handling hot residues. In addition, the grate serves as a barrier preventing unwanted backflow of syngas and maintaining the integrity of the controlled atmosphere within the reactor vessel. Any failure in the grate or ash removal system can lead to sudden changes in pressure, potential damage to the refractory lining, or unsafe accumulation of combustible materials, highlighting its essential role in plant safety.

Modern fixed-bed gasifiers increasingly incorporate automation and monitoring into the grate and ash removal system. Sensors can measure the rate of ash discharge, detect blockages, and even assess the composition of residual char to provide feedback on the efficiency of the gasification reactions. In large-scale industrial applications, motorized or hydraulically actuated grates can be precisely controlled to maintain a constant bed height, optimize gas flow, and ensure continuous operation. The integration of these systems with the feedstock inlet, reactor vessel, and syngas outlet ensures that all components of the gasifier operate in harmony, maximizing fuel conversion efficiency, minimizing downtime, and producing a steady, reliable syngas output.

Overall, the grate and ash removal system is far more than a mechanical convenience; it is an integral part of the fixed-bed gasifier that maintains the structure of the fuel bed, ensures smooth gas flow, enables continuous discharge of residues, and safeguards both the quality of syngas and the safety of operations. Its performance directly affects the efficiency of the drying, pyrolysis, oxidation, and reduction zones within the reactor vessel, the cleanliness and usability of the syngas leaving the outlet, and the durability of the reactor itself. By combining robust materials, engineered geometry, controlled mechanical movement, and real-time monitoring, the grate and ash removal system ensures that the gasifier can operate efficiently and reliably, transforming feedstock into valuable syngas while handling the by-products safely and effectively.

The refractory lining and insulation of a fixed-bed gasifier are essential components that protect the structural integrity of the reactor vessel, ensure thermal efficiency, and maintain stable reaction conditions for syngas production. Since the gasification process involves temperatures that often exceed 1000°C in the combustion and reduction zones, the interior walls of the reactor are subjected to extreme thermal stress, chemical corrosion, and abrasive wear from descending fuel particles and ash. Without a properly engineered refractory lining, the steel shell of the reactor would quickly degrade, leading to structural failure, leaks of combustible syngas, or unsafe operating conditions. The lining serves not only as a physical barrier but also as a thermal buffer, reflecting heat back into the drying, pyrolysis, oxidation, and reduction zones, thereby maintaining the temperature gradients necessary for efficient conversion of feedstock into combustible gases. The choice of materials for the lining, their thickness, and method of installation are carefully tailored to the type of feedstock, operating temperature, and expected slag or ash characteristics.

High-alumina bricks, silica-based castables, magnesia-chrome composites, and other refractory materials are commonly used to construct the lining of industrial fixed-bed gasifiers. Coal gasifiers, which often deal with higher ash content and slagging tendencies, require robust refractory compositions capable of withstanding both chemical attack and the mechanical impact of larger fuel particles. Biomass gasifiers, while producing less slag, still demand refractory materials that can tolerate fibrous residues, variable moisture content, and uneven heating. In addition to the refractory bricks or castables themselves, insulating layers are often placed behind the lining to minimize heat loss through the reactor shell. This insulation not only improves the thermal efficiency of the gasifier, reducing fuel consumption and energy costs, but also protects the outer steel shell from thermal cycling that could otherwise lead to warping or cracking. Advanced designs may incorporate modular refractory panels, segmented castables, or even water-cooled sections in regions of extreme thermal stress, ensuring a long service life and ease of maintenance.

The lining also plays a critical role in controlling the gasification reactions within the reactor vessel. By maintaining consistent temperatures in each reaction zone, the refractory ensures that the feedstock passes through the drying, pyrolysis, oxidation, and reduction stages efficiently. In updraft gasifiers, the lining helps retain heat in the lower oxidation and reduction zones while allowing the rising syngas to carry heat upward, drying incoming feedstock and improving thermal efficiency. In downdraft designs, the refractory ensures that volatiles passing through the high-temperature oxidation zone are cracked effectively, reducing tar content in the syngas. Without proper refractory insulation, temperature fluctuations could lead to incomplete conversion, increased tar formation, uneven gas composition, and higher particulate loads, all of which complicate downstream gas cleaning and utilization.

Mechanical stresses and abrasion from feedstock particles are another consideration for the lining. Fixed-bed gasifiers handle descending solids that exert pressure on the walls, especially near the grate and ash collection zones, where char and slag accumulate. The refractory must resist erosion caused by these abrasive materials while maintaining structural cohesion over thousands of hours of operation. Some gasifiers incorporate protective coatings or sacrificial layers in high-wear areas to extend the lifespan of the lining. Additionally, proper installation with careful attention to expansion joints and thermal allowances is critical to prevent cracking or spalling of refractory panels, which could expose the steel shell and lead to catastrophic failure.

The refractory and insulation system also integrates with the overall control and monitoring strategy of the gasifier. Temperature sensors embedded within the lining or attached to its surface provide real-time feedback on the conditions in each reaction zone. This information allows operators to adjust feedstock flow, air or steam injection, and other process parameters to maintain stable operation. In advanced industrial plants, automated control systems use these readings to regulate the entire gasifier operation, ensuring consistent syngas composition and maximizing thermal efficiency. By combining robust materials, effective insulation, and continuous monitoring, the refractory lining becomes an active participant in process control rather than a passive protective barrier.

Finally, refractory lining and insulation directly influence the overall energy efficiency, safety, and maintenance of a fixed-bed gasifier. A well-engineered lining minimizes heat losses, reduces fuel requirements, stabilizes reaction zones, and protects the reactor vessel from chemical and mechanical damage. It allows the plant to handle a wide range of feedstocks, from coal to biomass and waste-derived fuels, while maintaining high-quality syngas production. Regular inspection and maintenance of the refractory, combined with careful design considerations, ensure long-term reliability and operational safety. In effect, the refractory lining and insulation form the backbone of the gasifier’s thermal and structural system, without which the complex interactions of feedstock, syngas, and reaction zones could not occur efficiently or safely.

Air / Oxygen / Steam Inlet (Tuyeres or Nozzles)

The air, oxygen, and steam inlet system, commonly realized through tuyeres or nozzles, is a critical subsystem in a fixed-bed gasifier that dictates the progression, efficiency, and stability of the gasification reactions occurring within the reactor vessel. These inlets are responsible for introducing the oxidizing agents required to initiate partial combustion, generate the necessary heat for endothermic reactions, and produce a syngas composition suitable for downstream utilization. Unlike conventional combustion, which aims for complete oxidation of the fuel, gasification relies on carefully controlled oxygen and air supply to convert carbonaceous feedstock into carbon monoxide, hydrogen, methane, and other combustible gases without excessive burning. Steam injection is often incorporated alongside air or oxygen to react with hot carbon and enhance hydrogen production through the water–gas shift reaction, improving both calorific value and flexibility of the syngas. The precise placement, flow rate, and composition of the oxidizing agents introduced through tuyeres or nozzles are therefore carefully engineered to maintain balanced reaction zones, prevent hotspots, and ensure uniform conversion of the feedstock.

Mechanically, tuyeres and nozzles must withstand extreme conditions within the reactor vessel, including temperatures exceeding 1000°C, abrasive particulate matter, corrosive gases, and chemical attack from molten ash or slag. As such, these components are typically manufactured from heat-resistant alloys or coated with refractory materials, and in larger industrial systems, water-cooled tuyeres are sometimes used to protect the structural integrity of the nozzle while maintaining precise control of gas injection. Their design also incorporates features to prevent clogging, backflow of hot gases, or erosion by the descending bed of fuel. Placement within the reactor is critical: in downdraft gasifiers, inlets are located near the midsection oxidation zone to force volatile gases through intense heat, effectively cracking tars and producing cleaner gas; in updraft designs, inlets at the bottom create counter-current flow with the rising syngas, optimizing thermal efficiency but producing syngas with higher tar content; and in crossdraft designs, lateral placement ensures compactness while demanding precise control of gas distribution. The geometry and angle of injection are therefore designed to achieve even mixing and maintain the desired temperature profiles across the bed.

Operational flexibility is another important aspect of the inlet system. Different feedstocks—coal, biomass, or waste-derived materials—have varying moisture contents, particle sizes, and chemical compositions, requiring adjustments to the amount of air, oxygen, or steam injected to sustain optimal reaction conditions. In biomass gasifiers, for example, higher moisture content may require increased oxygen or air to generate sufficient heat for drying, while steam injection can boost hydrogen yield. Flow control is usually achieved through precision valves, rotary feeders, or blowers that are integrated into automated control systems. These systems can adjust injection rates in real time based on temperature, pressure, and syngas composition readings, ensuring stable operation despite variations in fuel quality or load demand. Advanced designs also include multi-stage injection arrangements that allow different gas mixtures to be injected at multiple points along the reactor height, providing finer control over reaction zones and improving overall gasification efficiency.

Safety considerations are tightly coupled with the air, oxygen, and steam inlet design. Since syngas contains flammable and toxic components such as carbon monoxide and hydrogen, uncontrolled oxygen ingress or backflow can lead to flashbacks, local hotspots, or over-oxidation, potentially damaging the refractory lining or the reactor vessel itself. To mitigate these risks, inlets are often equipped with backflow prevention devices, purge systems using inert gases such as nitrogen, and flame arrestors. During startup, shutdown, or emergency situations, the inlet system can be isolated or purged to prevent hazardous conditions, protecting both equipment and personnel. Proper sealing and pressure balancing are especially critical in pressurized gasifiers, where even minor leaks could lead to catastrophic outcomes.

Thermodynamically, the inlets play a central role in defining the internal energy distribution of the gasifier. By regulating the supply of oxidizing agents and steam, the operator or automated system can control the temperature in each reaction zone—drying, pyrolysis, oxidation, and reduction—ensuring that the feedstock is fully converted while minimizing tar and particulate formation. Computational fluid dynamics and thermochemical modeling are frequently used in modern designs to optimize nozzle placement, injection angles, and flow rates, reducing the risks of channeling, uneven heating, and inefficient gas production. In effect, these tuyeres and nozzles transform the reactor vessel from a passive container into a highly controlled chemical reactor, where precise gas injection is as important as the feedstock quality or reactor geometry in determining syngas yield and composition.

Ultimately, the air, oxygen, and steam inlet system functions as the lifeline of a fixed-bed gasifier, controlling both the chemistry and the thermal environment of the reactor. Its proper design, material selection, placement, and integration with automated controls ensure that the gasifier produces a consistent, high-quality syngas while maintaining operational safety and protecting the reactor vessel from thermal and chemical stresses. Without this subsystem, even the best feedstock, reactor vessel, and ash handling systems would fail to deliver reliable energy conversion, highlighting the inlet system’s central role in the overall gasification process.

The feedstock inlet and hopper system in a fixed-bed gasifier serves as the essential gateway through which solid fuel enters the reactor vessel, and its design directly impacts the efficiency, stability, and continuity of the gasification process. The hopper functions both as a storage reservoir and as a controlled buffer, ensuring a steady, regulated flow of feedstock into the reactor to maintain a uniform bed height and consistent thermal and chemical conditions within the reaction zones. Since fixed-bed gasifiers rely on a packed bed through which oxidizing gases and steam interact with the descending fuel, any irregularities in feedstock delivery can lead to channeling, uneven heating, incomplete conversion, or excessive tar formation. As a result, the geometry of the hopper, the shape of the feed chute, and the method of material discharge are engineered to minimize bridging, rat-holing, or clumping, particularly when dealing with fibrous or irregularly shaped biomass. Gravity-fed systems are common in smaller plants, while industrial-scale gasifiers often employ mechanical feeding mechanisms such as screw feeders, rotary valves, or vibratory conveyors to ensure continuous, consistent fuel delivery.

The composition, moisture content, and particle size of the feedstock strongly influence the design of the inlet and hopper. Coal, with its dense and relatively uniform particle sizes, flows more predictably and generally requires simpler hopper designs. Biomass, however, introduces challenges due to its irregular shapes, low bulk density, and high fibrous content, which increases the risk of bridging or arching within the hopper. To address this, mechanical agitation or vibratory systems are frequently integrated, preventing flow disruptions that could compromise gasification efficiency. Additionally, feedstock preparation prior to entry—such as shredding, drying, or pelletizing—is often necessary to improve hopper flow characteristics, stabilize the bed in the reactor vessel, and ensure uniform conversion during pyrolysis and reduction. The design of the feed system thus extends beyond simple storage, encompassing the entire interface between raw material supply and controlled chemical reaction.