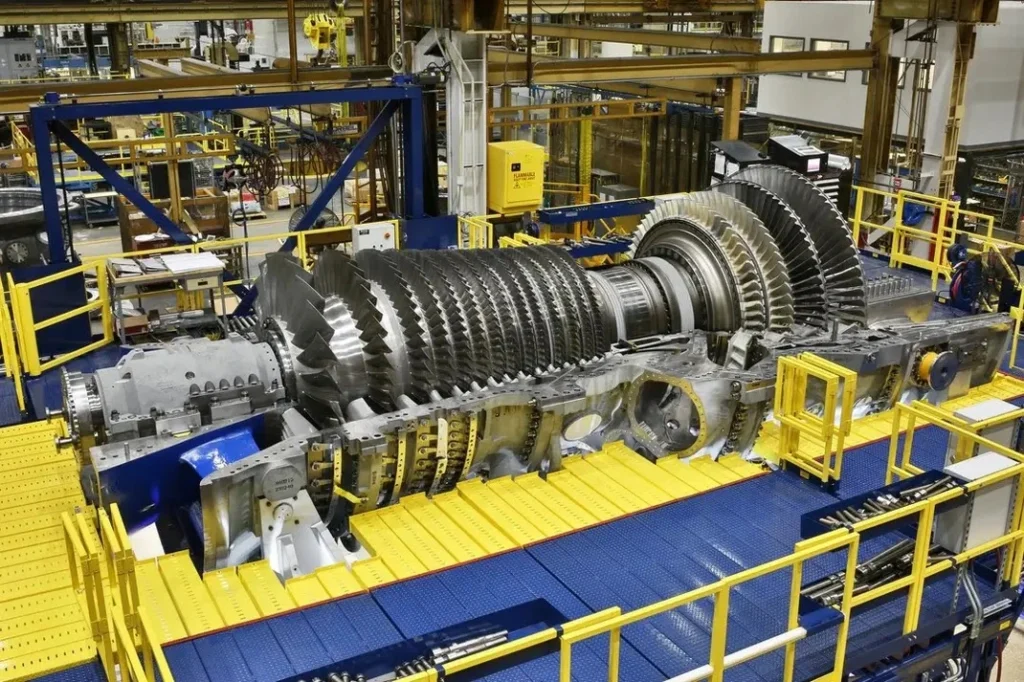

Extraction Back-pressure Turbines: Steam turbines are mechanical devices that convert the thermal energy of steam into mechanical work. They play a crucial role in power generation and industrial processes, operating based on the principles of thermodynamics and fluid dynamics. Steam turbines are widely used in power plants, ships, and industrial facilities due to their high efficiency, reliability, and ability to handle large power outputs. The working principle of a steam turbine involves steam generated in a boiler or heat source, which is then directed into the turbine. The high-pressure, high-temperature steam expands through a series of stationary and rotating blades arranged in stages. As the steam expands, it transfers its energy to the blades, causing the rotor to spin and generate mechanical power. This mechanical power can be used to drive a generator, producing electricity, or to power other machinery.

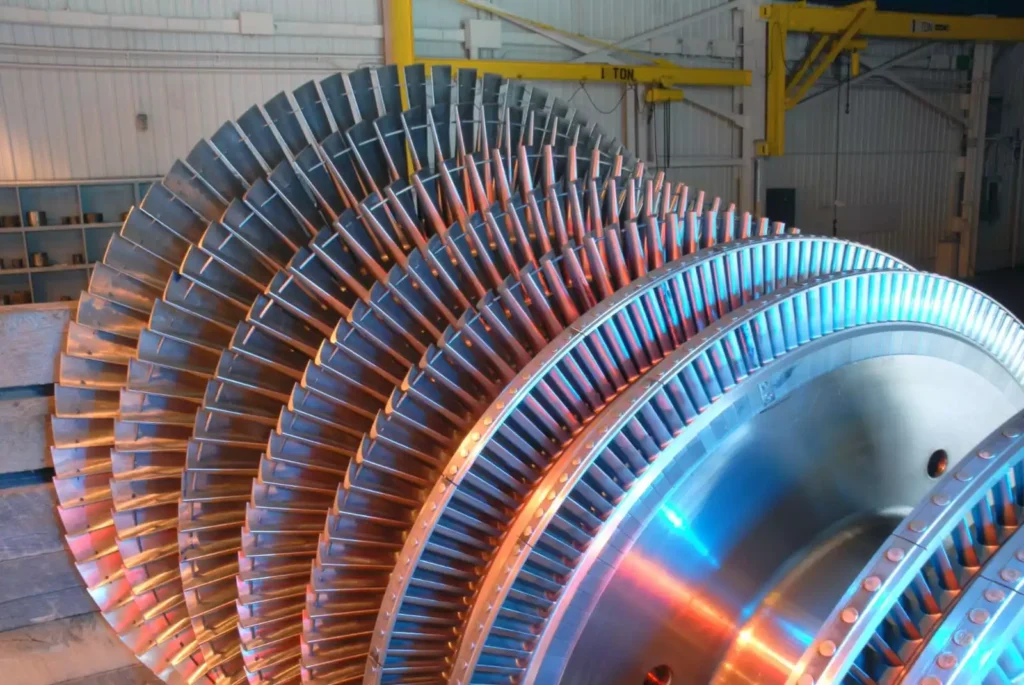

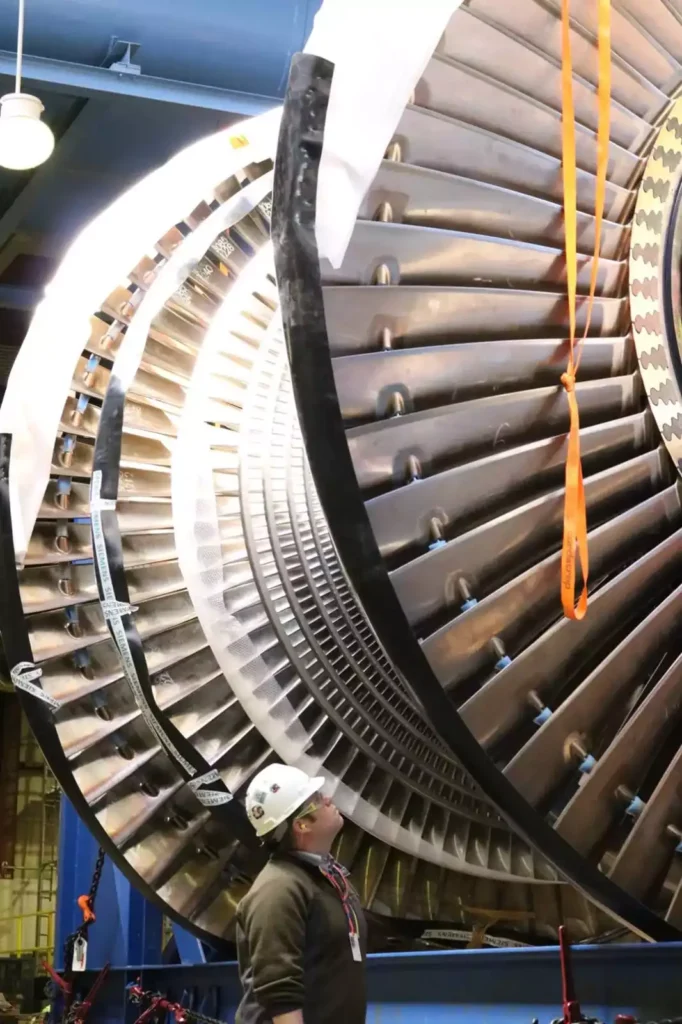

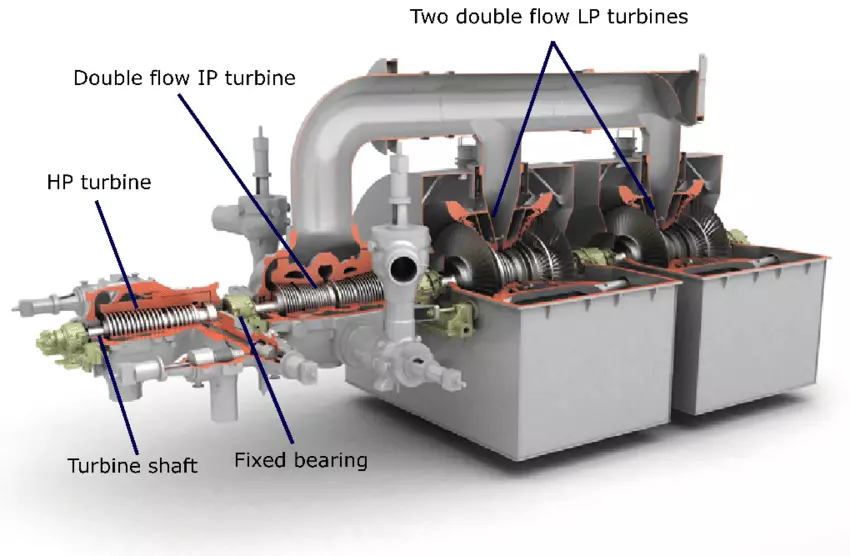

There are two main types of steam turbines: impulse and reaction turbines. Impulse turbines use high-velocity steam jets directed onto turbine blades to produce rotary motion. The kinetic energy of the steam is converted into mechanical energy primarily through the impulse force. In contrast, reaction turbines utilize both the pressure and velocity of the steam to generate motion. Here, the steam flows continuously through both stationary and moving blades, with energy conversion occurring due to the reaction force generated as the steam accelerates through the moving blades. Reaction turbines are generally used for applications requiring higher efficiency and larger power outputs, while impulse turbines are more suitable for smaller, simpler installations.

Steam turbines are classified further based on their operating conditions and applications. Condensing turbines are used in power generation to maximize efficiency by exhausting the steam into a condenser at sub-atmospheric pressure. This process allows for greater energy extraction from the steam. Back-pressure turbines, on the other hand, exhaust steam at a pressure suitable for downstream processes, such as heating or industrial applications. These turbines are often found in cogeneration systems where both power and process steam are required. Extraction turbines are a hybrid design that allows for controlled steam extraction at intermediate pressures for industrial processes while the remaining steam continues through the turbine for power generation. This flexibility makes them valuable in combined heat and power (CHP) systems.

Efficiency is a critical factor in steam turbine operation. Modern turbines are designed to operate at high efficiencies, often exceeding 40% in large power plants. Advanced materials, improved blade designs, and better thermal insulation contribute to these high efficiencies. However, steam turbines are still subject to losses due to heat transfer, friction, and leakage. Maintaining optimal operating conditions, such as proper steam temperature and pressure, is essential for achieving maximum efficiency. Additionally, regular maintenance and monitoring are necessary to ensure reliable and efficient operation over the turbine’s lifespan.

Steam turbines have significant advantages over other types of prime movers. They are capable of handling large power outputs and operate smoothly with minimal vibrations. They are also highly reliable and can achieve high thermal efficiencies, especially when combined with modern boiler technologies. Despite these advantages, steam turbines also have limitations. They require a significant initial investment and are best suited for applications with continuous and stable power demands. Furthermore, the operation of steam turbines relies on a consistent supply of high-quality steam, necessitating well-designed and maintained boilers or heat sources.

In recent years, advancements in materials science and manufacturing techniques have led to the development of more efficient and durable steam turbines. The use of advanced alloys and coatings has improved resistance to high temperatures and corrosion, while computational fluid dynamics (CFD) has enhanced blade design for better performance. Additionally, the integration of steam turbines with renewable energy sources, such as biomass and solar thermal systems, has expanded their role in sustainable energy solutions. These innovations continue to enhance the efficiency, reliability, and versatility of steam turbines, ensuring their continued relevance in modern energy systems.

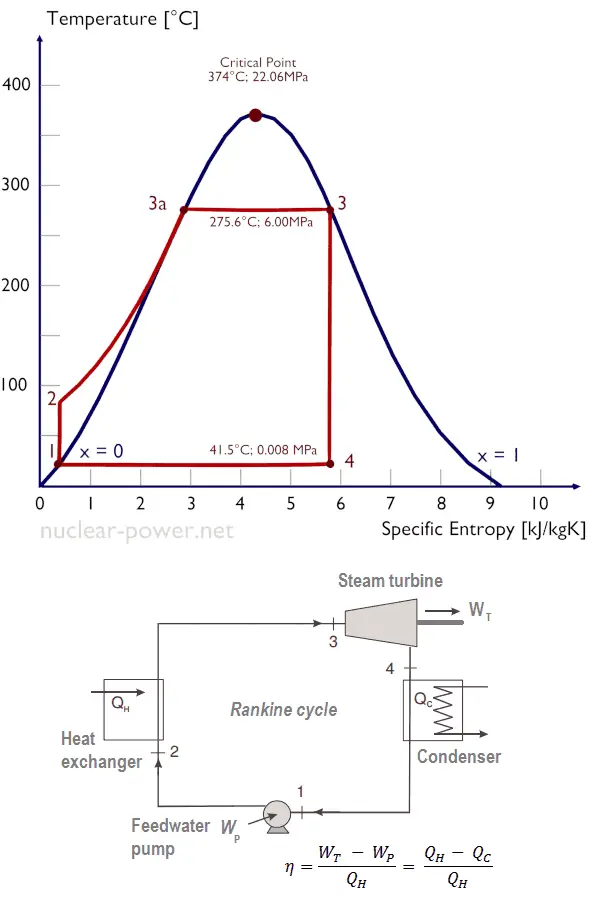

The role of steam turbines in power generation and industrial processes cannot be overstated. They form the backbone of large-scale electricity production, particularly in fossil fuel, nuclear, and some renewable energy plants. In a conventional thermal power plant, steam turbines are part of a broader Rankine cycle. Heat energy is generated by burning fuel or through nuclear reactions, and this heat is used to produce steam at high pressures and temperatures. The steam is then expanded through the turbine, converting its thermal energy into mechanical work. After expansion, the low-pressure steam is condensed back into water in a condenser, which is then recirculated to the boiler to complete the cycle. This closed-loop system ensures the efficient use of water and heat, while minimizing energy losses.

In addition to their application in electricity generation, steam turbines are extensively used in industrial settings for process steam and mechanical power. Industries such as petrochemical, pulp and paper, food processing, and textiles rely on steam turbines to meet their heating, cooling, and mechanical energy needs. In many of these applications, back-pressure turbines are employed, as they allow for the simultaneous generation of power and steam at suitable conditions for industrial processes. This combined heat and power (CHP) approach is highly efficient, as it utilizes the thermal energy of steam more effectively than generating electricity and process steam separately. For example, in a paper mill, steam turbines not only generate electricity but also provide steam for drying paper, ensuring efficient energy utilization.

The operation of a steam turbine is influenced by a variety of factors, including steam quality, load conditions, and environmental factors. High-quality steam, free of impurities and moisture, is essential to avoid damage to turbine blades and other components. Impurities in steam can cause erosion, scaling, and corrosion, which reduce efficiency and increase maintenance costs. Similarly, fluctuations in load demand can impact the turbine’s performance and efficiency. Steam turbines are typically designed to operate at specific conditions for maximum efficiency, and deviations from these conditions can lead to performance losses. As a result, sophisticated control systems are often used to optimize turbine operation, ensuring that steam flow, pressure, and temperature remain within the desired range.

Environmental considerations also play a significant role in steam turbine operation. The disposal of condenser cooling water, emissions from boilers, and overall plant efficiency are closely monitored to minimize environmental impact. Many modern power plants incorporate advanced technologies, such as air-cooled condensers and low-emission boilers, to address these concerns. Additionally, the integration of carbon capture and storage (CCS) technologies in some power plants aims to reduce greenhouse gas emissions, ensuring compliance with environmental regulations and sustainability goals.

Steam turbine technology has evolved significantly over the years, driven by the demand for greater efficiency, reliability, and sustainability. Advanced turbine designs now include features such as multi-stage configurations, reheat cycles, and supercritical and ultra-supercritical operating conditions. These innovations enable turbines to extract more energy from steam while operating at higher temperatures and pressures. Supercritical and ultra-supercritical turbines, for instance, operate above the critical point of water, where steam behaves as a single-phase fluid. This eliminates phase change losses and improves overall cycle efficiency. Such advancements are critical for reducing fuel consumption and emissions in power plants, making them more environmentally friendly.

Maintenance and monitoring are critical aspects of steam turbine operation. Regular inspections, lubrication, and component replacements are necessary to ensure reliable performance and prevent unexpected failures. Advanced monitoring systems, often employing sensors and data analytics, provide real-time insights into turbine performance, allowing operators to detect anomalies and take corrective actions before they escalate. Condition-based maintenance strategies, enabled by these technologies, help reduce downtime and maintenance costs, further improving the economic viability of steam turbines.

The future of steam turbines is likely to be shaped by emerging trends and innovations in energy and technology. As the world transitions toward cleaner energy sources, steam turbines are being adapted to work with renewable energy systems, such as geothermal, solar thermal, and biomass power plants. Hybrid systems that combine renewable and conventional energy sources also leverage steam turbines for efficient energy conversion. Furthermore, the development of small modular reactors (SMRs) in the nuclear sector presents new opportunities for steam turbines in compact, scalable power generation systems. These developments highlight the adaptability and enduring relevance of steam turbine technology in an ever-changing energy landscape.

Steam turbines are also gaining importance in the context of energy efficiency and sustainability. The shift towards decarbonization has led to a greater focus on optimizing existing energy systems and integrating steam turbines into combined cycle and cogeneration systems. In a combined cycle configuration, steam turbines operate alongside gas turbines, using the waste heat from gas turbine exhaust to generate additional power. This configuration significantly enhances the overall efficiency of the power plant, often exceeding 60%. By utilizing what would otherwise be wasted energy, combined cycle systems not only reduce fuel consumption but also lower greenhouse gas emissions, making them a key component in modern power generation.

The use of steam turbines in renewable energy systems, such as geothermal and solar thermal power plants, demonstrates their versatility and adaptability. Geothermal power plants exploit heat from the Earth’s interior to produce steam, which drives the turbine. These systems are particularly advantageous because they provide reliable, baseload power with minimal emissions. Similarly, solar thermal power plants use concentrated solar energy to heat a working fluid, producing steam for turbines. In both cases, the ability of steam turbines to handle a wide range of steam conditions and their scalability make them well-suited for these applications.

Beyond power generation, steam turbines play a vital role in industrial energy recovery. Many industrial processes generate large amounts of waste heat, which can be captured and used to produce steam for turbines. This practice, known as waste heat recovery, improves the overall efficiency of industrial operations and reduces energy costs. For example, in a steel plant, the hot exhaust gases from furnaces can be used to generate steam, which is then fed into a turbine to produce electricity or drive equipment. Such applications not only enhance energy efficiency but also contribute to sustainability by reducing the environmental footprint of industrial activities.

The design and materials used in steam turbines are critical to their performance, especially in demanding environments. High-temperature and high-pressure conditions necessitate the use of advanced materials that can withstand extreme thermal and mechanical stresses. Alloys with high creep resistance and corrosion resistance are commonly used for turbine blades and rotors. Additionally, coatings are often applied to enhance durability and minimize wear and tear. These materials and coatings have been developed through extensive research and testing, ensuring that modern steam turbines can operate reliably for decades under challenging conditions.

Another significant area of development in steam turbine technology is the use of advanced digital tools and analytics. Digital twins, which are virtual replicas of physical turbines, are becoming increasingly popular for monitoring and optimizing turbine performance. These models use real-time data from sensors to simulate the turbine’s behavior under various operating conditions. By analyzing this data, operators can identify inefficiencies, predict maintenance needs, and optimize performance, all of which contribute to reducing downtime and operational costs. Artificial intelligence and machine learning algorithms further enhance these capabilities by identifying patterns and providing actionable insights that would be difficult to detect manually.

The growing interest in hydrogen as a clean energy source presents another potential avenue for steam turbines. Hydrogen can be burned in gas turbines, and the waste heat can be used to generate steam for steam turbines in a combined cycle setup. Alternatively, hydrogen can be used to produce steam directly for turbine applications. These approaches are particularly promising as hydrogen production becomes more cost-effective and widespread, supporting the global shift towards low-carbon energy systems.

Despite their many advantages, steam turbines face challenges that must be addressed to maintain their relevance in the evolving energy landscape. The high capital cost of turbine installations can be a barrier for some applications, particularly in smaller-scale or remote locations. Additionally, the efficiency of steam turbines is inherently limited by the Carnot cycle, and further improvements require innovations in thermodynamics, materials, and system integration. The need for skilled operators and maintenance personnel is another challenge, as the complexity of steam turbine systems demands specialized knowledge and training.

In summary, steam turbines are a cornerstone of modern energy systems, offering high efficiency, reliability, and versatility across a range of applications. From large-scale power generation to industrial energy recovery, their ability to convert thermal energy into mechanical work has made them indispensable. Advances in materials, design, and digital technologies continue to push the boundaries of what steam turbines can achieve, ensuring their role in both traditional and renewable energy systems. As the energy sector evolves to meet the demands of a sustainable future, steam turbines will remain a critical technology, adapting to new challenges and opportunities.

The adaptability of steam turbines in diverse energy applications underscores their enduring relevance in a rapidly changing world. One of the key advantages of steam turbines is their scalability, enabling them to cater to both large-scale power plants and smaller industrial facilities. For instance, in small-scale or decentralized energy systems, steam turbines can be integrated into microgrids to provide reliable electricity and heat for local communities or industrial complexes. These installations are particularly valuable in remote areas where access to centralized power grids is limited. By utilizing locally available fuels, such as biomass or waste products, these systems enhance energy security while reducing transportation costs and emissions associated with fuel supply chains.

In the marine industry, steam turbines have historically played a critical role in powering large vessels, particularly during the era of steamships. Today, while diesel engines dominate the marine sector, steam turbines are still used in specialized applications, such as nuclear-powered ships and submarines. In these contexts, the turbines provide unmatched reliability, efficiency, and the ability to operate for extended periods without refueling. Additionally, advancements in turbine technology have made them a viable option for liquefied natural gas (LNG) carriers, where steam turbines can utilize boil-off gas as a fuel source, further improving efficiency and reducing waste.

Steam turbines are also finding innovative applications in emerging technologies. For example, they are being integrated into energy storage systems, such as molten salt energy storage, where excess renewable energy is used to heat molten salt. The stored thermal energy can later be used to produce steam and drive a turbine, providing electricity during periods of high demand or low renewable energy production. This approach not only enhances grid stability but also maximizes the utilization of renewable energy resources. Similarly, advanced thermodynamic cycles, such as the Kalina cycle, are being explored to improve the efficiency of low-temperature heat sources. These cycles leverage the flexibility of steam turbines to operate with alternative working fluids, expanding their applicability to geothermal, solar thermal, and waste heat recovery systems.

Environmental sustainability is an increasingly important consideration in steam turbine operation and development. The focus on reducing carbon footprints and complying with stringent environmental regulations has driven the adoption of cleaner and more efficient technologies. Supercritical and ultra-supercritical steam turbines, for instance, operate at much higher temperatures and pressures than traditional systems, enabling greater energy extraction from the same amount of fuel. This reduces fuel consumption and emissions, making them an attractive option for coal-fired and natural gas power plants. Furthermore, carbon capture and storage (CCS) technologies are being integrated with steam turbine systems to capture CO₂ emissions before they are released into the atmosphere. This combination of high-efficiency turbines and CCS can significantly mitigate the environmental impact of fossil fuel-based power generation.

One of the most promising avenues for the future of steam turbines lies in hybrid energy systems. These systems combine multiple energy sources to optimize efficiency and reliability. For example, a hybrid system might integrate solar thermal power with a steam turbine and a gas turbine, leveraging the strengths of each technology. During periods of high solar availability, the solar thermal system can generate steam to drive the turbine, while the gas turbine can provide backup power during cloudy or nighttime conditions. Such systems not only improve overall energy efficiency but also enhance the flexibility and resilience of the power grid, making them well-suited for the transition to a low-carbon energy future.

The economic benefits of steam turbines are also noteworthy. While the initial capital costs of turbine installations can be high, their long operational lifespans and low maintenance requirements make them cost-effective over time. Advances in predictive maintenance and real-time monitoring have further reduced operational costs, enabling operators to detect potential issues early and address them proactively. Moreover, the high efficiency of steam turbines translates into lower fuel consumption, resulting in significant cost savings, particularly in energy-intensive industries. These economic advantages, combined with their technical versatility, make steam turbines an attractive investment for both traditional and renewable energy projects.

In conclusion, steam turbines are not only a cornerstone of traditional power generation but also a vital component of the energy systems of the future. Their ability to adapt to diverse applications, from large-scale power plants to decentralized energy systems, highlights their versatility and importance. With ongoing advancements in materials, design, and integration with renewable energy technologies, steam turbines are poised to play a central role in the global transition to sustainable energy. As the energy landscape continues to evolve, steam turbines will remain a key technology, bridging the gap between legacy systems and innovative solutions, and ensuring a reliable, efficient, and sustainable energy supply for generations to come.

Double Extraction Steam Turbines

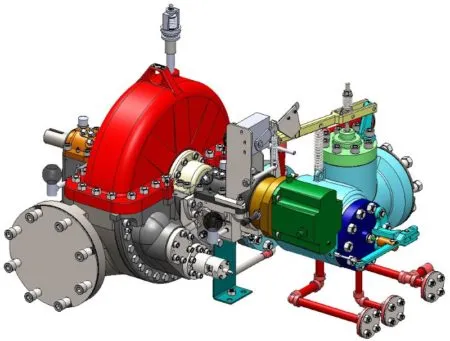

Double extraction steam turbines are specialized designs that allow for the controlled extraction of steam at two intermediate pressure levels during its expansion through the turbine. These turbines are particularly valuable in applications where both electricity generation and process steam are required, such as in combined heat and power (CHP) plants, industrial facilities, and chemical processing plants. By enabling steam to be extracted at multiple stages, double extraction turbines provide exceptional flexibility in meeting diverse energy and thermal demands.

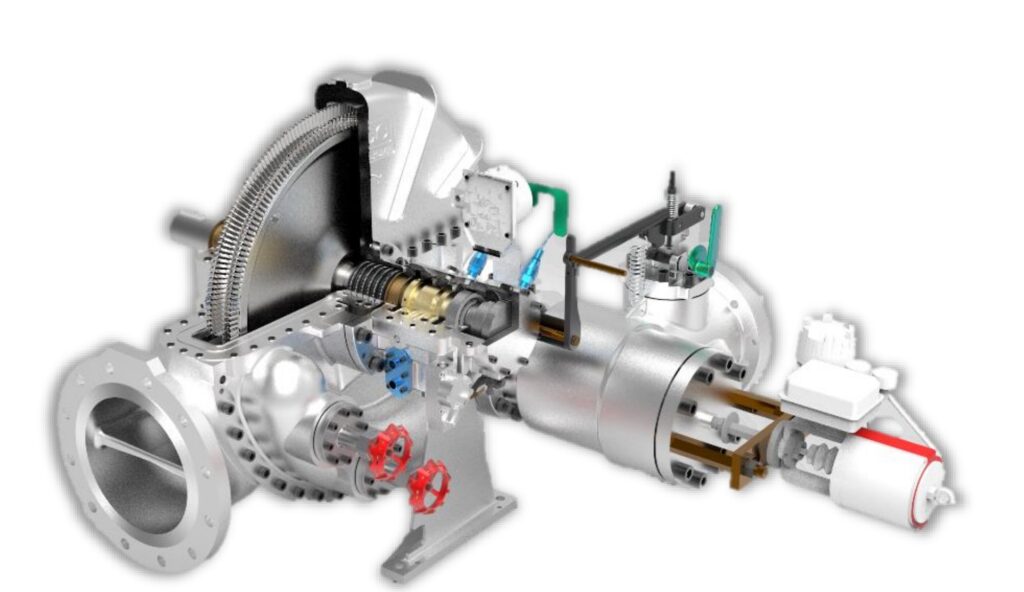

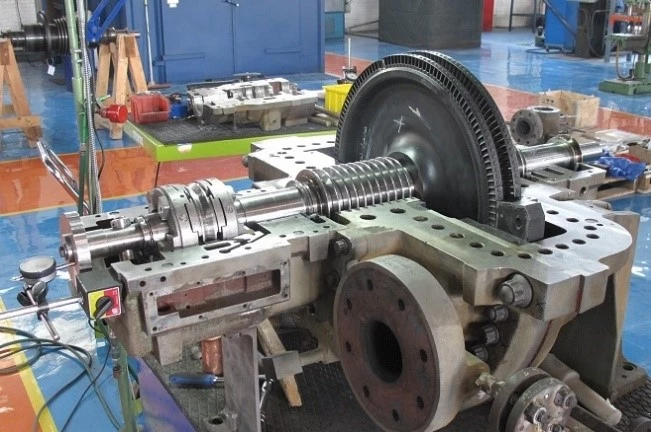

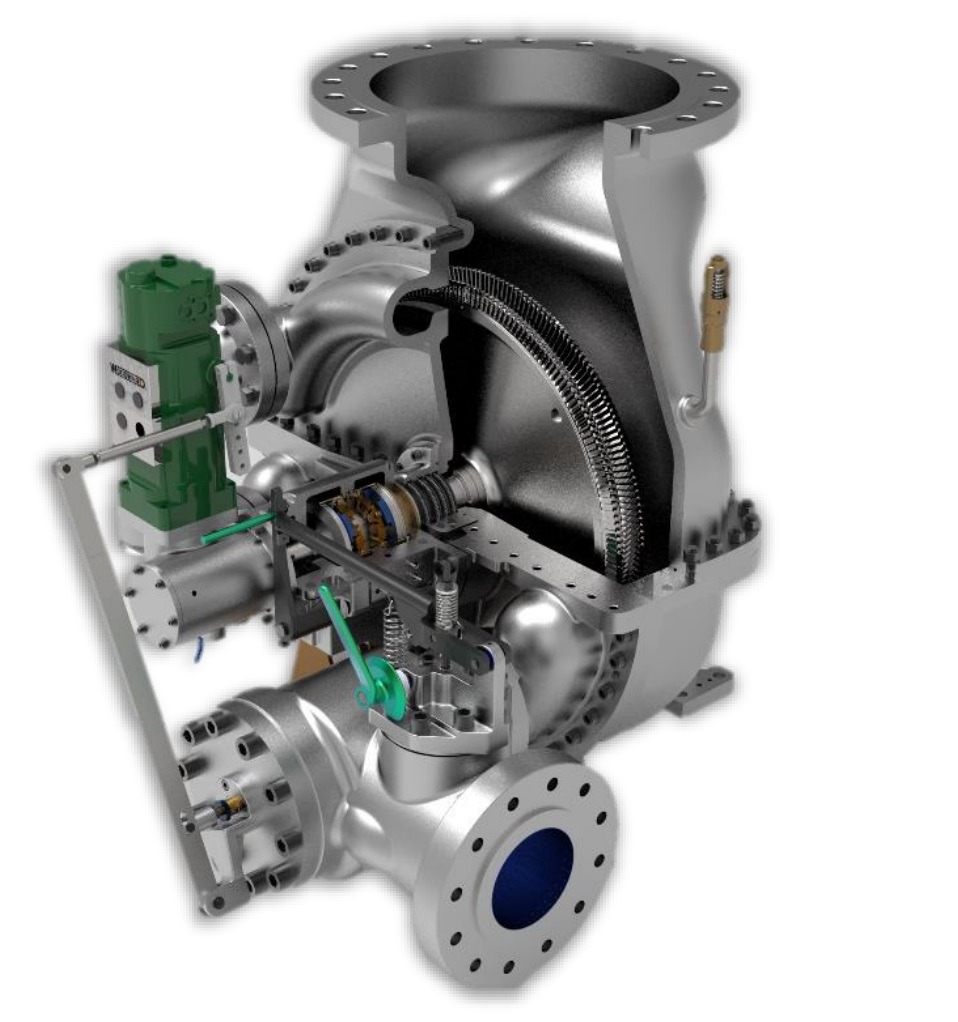

The design of a double extraction steam turbine is more complex than a standard condensing or single extraction turbine. Steam enters the turbine at high pressure and temperature, where it begins its expansion process. As the steam passes through the turbine, a portion is extracted at the first intermediate pressure level to supply process requirements, such as heating or drying. The remaining steam continues to expand, and another portion is extracted at a second intermediate pressure level. The final stage of the turbine exhausts the residual steam, typically into a condenser for energy recovery or into a back-pressure system for further industrial use.

One of the primary advantages of double extraction turbines is their ability to optimize energy utilization in cogeneration systems. For example, in a large industrial plant, steam at different pressure levels may be required for various processes. Low-pressure steam might be used for space heating, medium-pressure steam for industrial chemical reactions, and high-pressure steam for mechanical work or electricity generation. A double extraction turbine can efficiently meet all these requirements by supplying steam at precisely the needed pressures and temperatures without the need for separate boilers or steam reducing stations.

Another key benefit is the ability to improve overall plant efficiency. By extracting steam at intermediate pressures for process use, double extraction turbines reduce the amount of steam that must be fully expanded to the condenser. This leads to better utilization of the steam’s thermal energy, minimizing waste and increasing the efficiency of the system as a whole. In cases where the turbine is part of a power plant, this configuration can enhance the plant’s overall thermal efficiency, particularly when process steam is used locally, reducing distribution losses.

Double extraction turbines are highly customizable and can be tailored to specific plant requirements. The pressure levels of the two extraction points, as well as the flow rates of extracted steam, are typically designed based on the process and power generation needs of the facility. Advanced control systems are often employed to regulate the extraction flow rates and ensure a stable supply of steam to the various processes. These control systems also help maintain the turbine’s efficiency and balance under varying load conditions, as process steam demands and power generation needs can fluctuate over time.

The applications of double extraction turbines extend across a wide range of industries. In chemical plants, for instance, different processes might require steam at varying pressure levels for heating, distillation, or reaction control. Similarly, in pulp and paper mills, steam at medium pressure might be used for paper drying, while low-pressure steam is used for space heating or other auxiliary needs. In power plants, double extraction turbines can be integrated with district heating systems, where they supply both electricity to the grid and steam for heating residential or commercial buildings.

However, the implementation of double extraction turbines comes with certain challenges. Their design and operation are more complex than single extraction or condensing turbines, requiring precise engineering and control. The initial capital cost is typically higher due to the additional components, such as extraction ports, piping, and control systems. Moreover, operators must ensure that the turbine operates within its designed parameters to avoid efficiency losses or mechanical issues. This requires robust monitoring systems and skilled personnel to manage the turbine’s operation effectively.

Despite these challenges, the long-term benefits of double extraction steam turbines often outweigh the initial costs. Their ability to enhance energy efficiency, reduce fuel consumption, and provide flexibility in meeting thermal and electrical demands makes them a valuable asset in both industrial and power generation contexts. Advances in materials and digital control systems have further improved their reliability and performance, ensuring that double extraction turbines remain a key technology in modern energy systems.

As industries and power plants continue to prioritize sustainability and energy efficiency, double extraction steam turbines are expected to play an increasingly important role. Their ability to integrate seamlessly into CHP systems and adapt to variable process demands makes them particularly well-suited for applications where maximizing energy utilization is critical. By effectively combining power generation and process steam supply, double extraction turbines contribute to a more sustainable and efficient energy future.

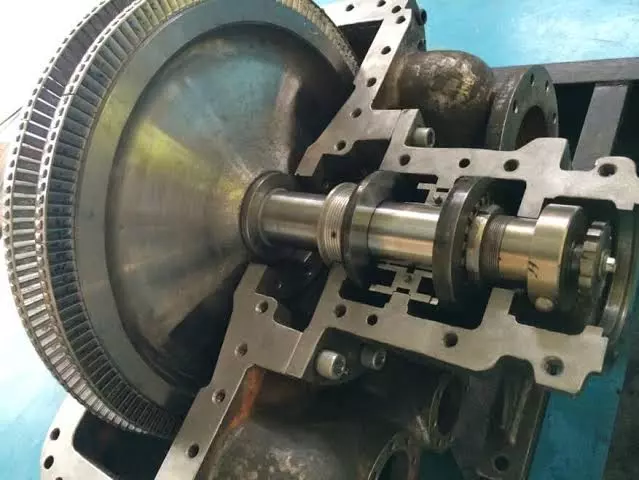

The design and operation of double extraction steam turbines involve several engineering considerations that ensure their performance, efficiency, and reliability. One critical aspect is the configuration of the turbine’s stages and extraction ports. The steam turbine must be designed to handle varying steam flow rates and pressures across its stages, which depend on the specific requirements of the extraction points. Each extraction port is strategically located at an intermediate stage of the turbine to achieve the desired steam pressure and temperature. The steam extracted from these ports is directed to industrial processes, heating systems, or other applications where it is needed. The remaining steam continues its expansion through the turbine, contributing to power generation or other uses.

Advanced control systems play a vital role in managing the operation of double extraction turbines. These systems regulate the flow of steam at the extraction points to ensure a stable and continuous supply of steam at the required pressure levels. This is particularly important in industrial plants, where steam demands can vary significantly depending on production schedules and operational conditions. Modern control systems utilize sensors, actuators, and real-time data analytics to monitor and adjust steam flows dynamically. This level of precision ensures that the turbine operates efficiently while meeting the varying thermal and electrical demands of the facility.

The integration of double extraction turbines into a larger energy system often requires detailed planning and coordination. For instance, in a cogeneration plant, the steam turbine is typically linked to a boiler or heat recovery steam generator (HRSG) that provides the high-pressure steam required for turbine operation. The extracted steam is then distributed to various process units or heating systems through a network of pipelines and heat exchangers. Ensuring that these components are properly sized, aligned, and optimized is essential for the efficient operation of the entire system. Additionally, provisions must be made to handle fluctuations in steam demand and supply, such as installing bypass systems or incorporating thermal storage solutions.

The thermodynamic efficiency of a double extraction steam turbine is influenced by the pressure and temperature conditions at the extraction points, as well as the quality of the steam entering the turbine. Higher inlet steam pressures and temperatures generally result in better overall efficiency, as they allow more energy to be extracted from the steam. However, the design must also account for the specific requirements of the extraction points, as extracting steam at too high or too low a pressure can lead to inefficiencies or process disruptions. Advanced modeling and simulation tools are often used during the design phase to optimize the turbine’s performance and ensure compatibility with the intended application.

Maintenance and reliability are also critical considerations for double extraction turbines. Regular inspections and preventive maintenance are necessary to ensure the long-term performance and durability of the turbine. Key components, such as the rotor, blades, and bearings, must be checked for signs of wear, erosion, or corrosion. Steam quality is another factor that directly impacts the turbine’s longevity; impurities, such as dissolved salts or particulates, can cause scaling or erosion of turbine components. Proper water treatment and steam conditioning are therefore essential to maintain the turbine’s reliability and efficiency.

One of the most significant advantages of double extraction turbines is their ability to adapt to a wide range of industrial and power generation scenarios. In a chemical plant, for example, the extracted steam may be used to drive chemical reactions in reactors, control temperatures in distillation columns, or provide heat for separation processes. In a sugar mill, the turbine can generate electricity while supplying steam for sugarcane juice evaporation and crystallization. In a district heating system, extracted steam can be distributed through an extensive network of insulated pipes to provide heating for residential and commercial buildings. These diverse applications demonstrate the versatility of double extraction turbines in addressing complex energy and thermal demands.

The economic and environmental benefits of double extraction turbines further enhance their appeal. By integrating power generation with process steam supply, these turbines maximize the utilization of fuel energy, reducing waste and lowering greenhouse gas emissions. This makes them an ideal choice for facilities seeking to improve energy efficiency and reduce their carbon footprint. In regions where energy costs are high or environmental regulations are stringent, the efficiency gains achieved with double extraction turbines can result in substantial cost savings and compliance benefits.

As industries continue to evolve, the role of double extraction steam turbines is expected to expand. Advances in materials science, turbine design, and digital technology are enabling the development of more efficient, durable, and adaptable turbines. For example, the use of advanced alloys and coatings can enhance the turbine’s resistance to high temperatures and corrosive environments, extending its operational life. Digital twins and predictive analytics are also being increasingly used to monitor turbine performance, identify potential issues, and optimize maintenance schedules. These innovations ensure that double extraction turbines remain at the forefront of energy-efficient and sustainable solutions in industrial and power generation applications.

Another critical factor in the adoption and continued innovation of double extraction steam turbines is their role in improving overall system reliability and energy security. By serving as a central component of cogeneration or combined heat and power (CHP) systems, these turbines allow facilities to operate independently of external electricity supplies in certain cases, enhancing resilience during grid outages or energy supply disruptions. This capability is particularly valuable for industries such as petrochemicals, pharmaceuticals, and food processing, where consistent power and steam supply are critical to maintaining production and product quality.

The flexibility of double extraction steam turbines also supports their use in facilities with highly variable energy and steam demands. For instance, in an industrial plant with seasonal production cycles or batch processing operations, steam demand may fluctuate widely over time. Double extraction turbines can handle these fluctuations efficiently by dynamically adjusting steam extraction rates and power output. This adaptability not only ensures that the facility’s energy and process steam needs are met but also prevents inefficiencies and potential losses associated with overproduction or underutilization of steam.

In terms of economic performance, the lifecycle cost benefits of double extraction turbines are particularly noteworthy. While these turbines may have higher initial capital costs due to their advanced design and additional extraction points, the long-term savings in fuel consumption and operating expenses often outweigh the upfront investment. This is because the turbines make better use of the thermal energy in the steam, reducing the amount of fuel required for both power generation and process heat. Additionally, integrating double extraction turbines into energy systems can lead to eligibility for government incentives, tax breaks, or carbon credits in jurisdictions that promote energy efficiency and low-carbon technologies.

The versatility of double extraction turbines also extends to their compatibility with a variety of fuels and energy sources. In traditional setups, high-pressure steam for the turbine is typically generated using fossil fuels such as natural gas, coal, or oil. However, double extraction turbines can also be integrated into systems using alternative and renewable fuels, such as biomass, municipal solid waste, or biogas. In a biomass power plant, for example, the combustion of wood chips, agricultural residues, or other organic materials generates steam for the turbine. The extracted steam can then be used for drying biomass feedstock or powering other industrial processes, creating a closed-loop system that minimizes waste and maximizes resource efficiency.

Moreover, double extraction turbines can play an important role in integrating renewable energy sources into industrial processes. In solar thermal power plants, for instance, steam generated from concentrated solar power (CSP) systems can be fed into a double extraction turbine. This setup enables simultaneous electricity generation and process steam supply, making it particularly valuable for industrial operations in regions with abundant sunlight. Similarly, in geothermal power plants, steam extracted from geothermal wells can be directed into a double extraction turbine to meet both power and heat requirements.

As global energy systems transition toward decarbonization, the potential for coupling double extraction turbines with emerging technologies, such as hydrogen and carbon capture, is becoming increasingly apparent. Hydrogen-fired boilers or gas turbines can produce high-pressure steam for double extraction turbines, enabling facilities to significantly reduce their carbon emissions. In carbon capture and storage (CCS) systems, steam extracted from intermediate stages of the turbine can be used to regenerate chemical solvents or drive compression equipment, further enhancing the system’s overall efficiency and environmental performance.

Advances in automation, digital monitoring, and data analytics are also transforming the operation of double extraction turbines. Modern turbines are equipped with extensive sensor networks that provide real-time data on parameters such as steam flow rates, temperatures, pressures, and vibration levels. This data is analyzed using predictive maintenance algorithms to identify early signs of wear, corrosion, or mechanical issues, allowing operators to address potential problems before they lead to costly downtime or damage. Digital twins—virtual models of the physical turbine—are increasingly being used to simulate turbine behavior under various scenarios, optimizing performance and maintenance strategies without interrupting operations.

From an engineering perspective, the materials and manufacturing techniques used in double extraction turbines continue to evolve to meet the demands of modern energy systems. Advanced materials, such as nickel-based superalloys and ceramic coatings, are being employed to improve the turbine’s resistance to high temperatures, corrosion, and mechanical stress. These innovations enable turbines to operate at higher temperatures and pressures, which directly translates to increased thermodynamic efficiency. Additive manufacturing techniques, such as 3D printing, are also being explored for producing complex turbine components, reducing lead times and enabling the customization of parts for specific applications.

In summary, double extraction steam turbines represent a highly efficient, flexible, and adaptable technology for meeting the diverse energy and steam demands of industrial and power generation facilities. Their ability to optimize energy use, support a wide range of fuels and applications, and integrate with emerging technologies positions them as a key component of sustainable energy systems. As innovations in materials, digital technologies, and renewable energy integration continue to advance, double extraction turbines are expected to play an even more significant role in shaping the future of energy efficiency and sustainability.

Looking toward the future, the role of double extraction steam turbines is set to expand as industries and power systems evolve to meet the demands of decarbonization, decentralization, and digitalization. One of the most significant drivers of this evolution is the global push to reduce greenhouse gas emissions and transition to a low-carbon energy economy. Double extraction turbines, with their ability to maximize energy efficiency and integrate seamlessly with renewable and low-carbon technologies, are uniquely positioned to support this transition.

For instance, as hydrogen emerges as a key component of clean energy systems, double extraction turbines could be utilized in hydrogen-based power and industrial systems. Hydrogen can be used as a fuel in boilers or combined cycle power plants to generate the high-pressure steam required for turbine operation. The extracted steam from these turbines could then be directed to hydrogen production processes, such as steam methane reforming (SMR) with carbon capture or advanced water electrolysis, creating a closed-loop system that minimizes energy losses and emissions. This synergy between hydrogen and steam turbines could be particularly valuable in hard-to-decarbonize sectors, such as steelmaking, chemicals, and heavy industry.

In addition to hydrogen, double extraction turbines are well-suited for integration into circular economy initiatives, where waste products are repurposed as valuable resources. For example, in waste-to-energy plants, municipal solid waste is incinerated to generate high-pressure steam for turbines. The extracted steam can then be used for district heating, industrial processes, or even desalination, while the remaining electricity can be supplied to the grid. Similarly, in biomass plants, agricultural residues, wood chips, or other organic materials are converted into steam, with the extraction points providing thermal energy for drying biomass or other pre-treatment steps.

The continued development of renewable energy technologies also presents opportunities for double extraction turbines to expand their applications. In hybrid renewable systems, these turbines can act as a bridge between intermittent energy sources like wind and solar and the stable energy requirements of industrial facilities. For example, during periods of high renewable energy production, excess electricity can be used to generate steam from renewable heat sources, such as solar thermal collectors or geothermal wells. The extracted steam can then supply thermal energy to industrial processes, reducing reliance on fossil fuels and enhancing overall energy efficiency.

The integration of advanced thermodynamic cycles offers another avenue for enhancing the performance of double extraction turbines. Concepts such as the Kalina cycle or Organic Rankine Cycle (ORC) are being explored to utilize low-grade heat sources, such as waste heat from industrial processes or geothermal fluids. These cycles often operate with working fluids that differ from water, but their principles can complement traditional double extraction turbines. For instance, a hybrid system could combine a double extraction steam turbine for high-temperature processes with an ORC system to recover low-temperature waste heat, maximizing the energy output from a given resource.

One of the most promising areas of innovation is the digital transformation of steam turbine technology. Advanced monitoring systems, powered by the Industrial Internet of Things (IIoT), allow operators to continuously monitor turbine performance and diagnose potential issues in real time. This data-driven approach enables predictive maintenance strategies, reducing unplanned downtime and extending the operational life of the turbine. Additionally, artificial intelligence and machine learning algorithms can be used to optimize turbine performance under varying load conditions, ensuring that the turbine operates at peak efficiency even as steam and power demands fluctuate.

Digital twins are increasingly being adopted in the design, operation, and maintenance of double extraction turbines. These virtual replicas of physical turbines allow engineers to simulate different operating scenarios, identify potential performance bottlenecks, and test design modifications before implementing them in the real world. In operation, digital twins can be used to optimize energy flows, predict wear and tear, and ensure that the turbine operates within its design limits, all of which contribute to improved reliability and efficiency.

From a policy and regulatory perspective, double extraction turbines are also benefiting from initiatives aimed at promoting energy efficiency and reducing carbon emissions. Many governments and organizations offer incentives, grants, or tax credits for facilities that implement high-efficiency cogeneration systems, including those utilizing double extraction turbines. These incentives help offset the higher initial capital costs of these turbines, making them a more attractive option for industrial and power generation applications. Additionally, the growing emphasis on carbon pricing and emissions trading systems further incentivizes the adoption of energy-efficient technologies like double extraction turbines.

In terms of infrastructure, the deployment of double extraction turbines often requires collaboration between multiple stakeholders, including equipment manufacturers, process engineers, and energy providers. This collaborative approach ensures that the turbine is integrated seamlessly into the broader energy and process systems of the facility. For instance, in a large industrial complex, the design and operation of the turbine must be coordinated with the steam distribution network, process equipment, and power generation systems to maximize efficiency and reliability.

The growing role of automation and robotics in manufacturing is also influencing the production and maintenance of double extraction turbines. Precision manufacturing techniques, such as additive manufacturing and advanced machining, are enabling the production of complex turbine components with greater accuracy and efficiency. These techniques reduce lead times and allow for the customization of turbine designs to meet specific application requirements. In maintenance, robotic systems are being developed to perform inspections, repairs, and component replacements in hard-to-access areas of the turbine, reducing downtime and improving worker safety.

In conclusion, double extraction steam turbines represent a versatile and forward-looking technology that is well-suited to meet the challenges and opportunities of the modern energy landscape. Their ability to optimize energy use, integrate with renewable and low-carbon systems, and adapt to a wide range of applications ensures their continued relevance in an era of rapid technological and environmental change. As innovations in materials, digital technology, and thermodynamic cycles continue to advance, double extraction turbines are poised to play an even greater role in driving energy efficiency, sustainability, and resilience in industrial and power generation systems around the world.

The future of double extraction steam turbines is increasingly tied to advancements in energy storage systems, hybrid energy systems, and decentralized energy generation. These trends reflect the growing need for energy systems that are both flexible and resilient in the face of shifting demands and the increasing penetration of renewable energy sources. By seamlessly integrating with these technologies, double extraction turbines are expected to expand their applications and redefine how energy is produced, distributed, and utilized.

One emerging area where double extraction turbines can play a pivotal role is in hybrid energy systems that combine traditional steam turbines with energy storage technologies, such as thermal energy storage (TES) or advanced battery systems. In such configurations, excess heat or power generated during periods of low demand can be stored for later use. For example, during off-peak hours, surplus steam could be stored in molten salt or phase-change materials within a thermal storage system. This stored energy can then be released during peak demand periods to provide additional process steam or boost power generation. By leveraging energy storage, double extraction turbines can enhance overall system efficiency, improve load balancing, and ensure a reliable supply of both electricity and thermal energy.

Additionally, the role of double extraction turbines in microgrid systems is gaining attention. Microgrids are localized energy systems that can operate independently or in conjunction with the main power grid. They are particularly useful in remote locations, industrial parks, and facilities where energy reliability is critical. Double extraction turbines can serve as a central component of a microgrid, providing both electricity and thermal energy to meet local demand. This is especially valuable in industrial microgrids, where the extracted steam can be used for manufacturing processes while the remaining energy is used to power local operations or exported to the grid. The integration of renewable energy sources, such as solar and wind, into these microgrids further enhances their sustainability and energy independence.

Decentralized energy systems are another growing trend where double extraction turbines can have significant applications. As energy production becomes increasingly distributed, facilities are seeking ways to generate power and heat locally rather than relying solely on centralized power plants. Double extraction turbines fit well into this model because of their ability to provide a reliable and efficient source of cogeneration. Industrial facilities, commercial buildings, and even large residential complexes can install these turbines to meet their specific energy and thermal needs while reducing transmission losses and enhancing energy security.

In addition to their compatibility with decentralized energy systems, double extraction turbines can support grid stabilization and demand response programs. As the share of variable renewable energy sources, such as wind and solar, increases in power grids, balancing supply and demand becomes more challenging. Double extraction turbines, especially when integrated with thermal energy storage or advanced control systems, can adjust their power and steam output dynamically to match grid requirements. For instance, during periods of high renewable energy generation, the turbine can focus on meeting process steam needs while reducing electricity output. Conversely, during low renewable energy generation, the turbine can ramp up electricity production to help stabilize the grid. This operational flexibility makes double extraction turbines a valuable asset in modern power systems that prioritize renewable integration.

The adoption of advanced materials and manufacturing techniques is expected to further enhance the performance and reliability of double extraction turbines. Research into high-temperature alloys, ceramics, and advanced coatings is enabling turbines to operate at higher temperatures and pressures, which translates directly into improved efficiency. These materials are particularly important for handling the harsh conditions associated with renewable fuels, such as biomass or waste-derived fuels, which can introduce additional corrosive or erosive challenges. Additive manufacturing, or 3D printing, is also being utilized to produce intricate turbine components with high precision and reduced lead times. This allows for greater customization and quicker responses to evolving energy demands.

Moreover, the focus on carbon neutrality and the circular economy has driven innovation in how steam is generated for double extraction turbines. Low-carbon and zero-carbon fuel options, such as renewable hydrogen, ammonia, or synthetic fuels, are increasingly being explored as alternatives to traditional fossil fuels. In these systems, double extraction turbines play a critical role in ensuring the efficient conversion of thermal energy into usable power and process steam. The use of such fuels, combined with the efficiency gains from double extraction, can significantly reduce the carbon footprint of industrial and power generation systems.

Another transformative development is the application of artificial intelligence (AI) and machine learning to optimize the operation and maintenance of double extraction turbines. AI algorithms can analyze real-time data from sensors embedded within the turbine to identify performance trends, predict maintenance needs, and optimize operation for maximum efficiency. For example, an AI-driven system might adjust extraction steam flow rates based on changing process demands or predict when turbine blades require inspection based on vibration analysis. This level of intelligence not only reduces downtime and maintenance costs but also ensures that the turbine operates at peak performance throughout its lifecycle.

Digital twins are particularly powerful in this context. By creating a virtual model of the turbine and its associated systems, operators can simulate various scenarios, such as changes in process steam demand, fluctuations in fuel supply, or grid outages. These simulations allow for proactive adjustments that enhance efficiency and reliability while minimizing risks. Digital twins also facilitate collaboration between engineers and operators, as they provide a shared platform for analyzing performance and planning improvements.

As global energy markets continue to prioritize sustainability, energy efficiency, and resilience, the versatility of double extraction turbines ensures they will remain an integral part of the energy landscape. Their ability to integrate with emerging technologies, adapt to decentralized and hybrid energy systems, and meet diverse industrial needs positions them as a cornerstone of modern energy solutions. Furthermore, ongoing research and development efforts are likely to unlock new capabilities and applications, ensuring that double extraction turbines continue to evolve in step with the changing demands of the energy industry.

In the coming decades, as industries embrace carbon-neutral practices and advanced energy systems, double extraction turbines are expected to play a central role in driving this transformation. Their unmatched flexibility, coupled with advancements in materials, digital technologies, and integration strategies, ensures their relevance and importance in achieving a more sustainable and efficient energy future.

Cogeneration

Cogeneration, also known as combined heat and power (CHP), is a highly efficient energy production process that simultaneously generates electricity and useful heat from a single energy source. Unlike conventional power generation methods, where energy is typically wasted in the form of excess heat, cogeneration captures and utilizes this heat for various industrial, residential, or commercial purposes. This process significantly improves the overall energy efficiency of a system, reduces fuel consumption, and lowers greenhouse gas emissions.

In a typical cogeneration system, a fuel source—such as natural gas, biomass, coal, or waste—is burned to produce heat, which drives a steam turbine or engine to generate electricity. The excess heat, which would otherwise be lost in traditional power plants, is captured and used for heating purposes, such as space heating, industrial processes, or water heating. This dual use of energy can result in overall efficiencies of 70% to 90%, compared to the 33% to 40% efficiency of conventional power plants. This makes cogeneration systems an attractive option for industries with both electricity and thermal energy demands, such as chemical manufacturing, food processing, paper mills, and refineries.

The key advantage of cogeneration is its ability to meet the combined demand for electricity and heat. This is particularly important for facilities that have a constant or variable need for both forms of energy. In industries such as food production, where precise temperature control is crucial, the ability to use waste heat for heating processes can lead to significant cost savings. In addition, cogeneration systems can be designed to scale with the needs of the facility, from small systems for individual buildings to large-scale industrial plants.

One of the most significant benefits of cogeneration is its contribution to energy efficiency and sustainability. By capturing and utilizing waste heat, cogeneration reduces the need for additional fuel consumption, leading to lower operating costs and a reduction in the environmental impact of energy production. This makes cogeneration a preferred option for industries aiming to improve energy efficiency, reduce their carbon footprint, and comply with increasingly stringent environmental regulations. The ability to use waste heat for applications such as district heating, steam supply, or absorption refrigeration also provides a significant advantage in terms of energy savings and emissions reductions.

In addition to its environmental and economic benefits, cogeneration offers energy security and reliability. In many cases, cogeneration systems can operate independently or in parallel with the main grid, providing backup power during grid outages or interruptions. This capability is particularly valuable for industries that require a consistent and reliable supply of energy for continuous operations. Cogeneration can also be integrated into microgrids or decentralized energy systems, where local energy generation and consumption are optimized to reduce dependence on external power sources.

The efficiency of cogeneration systems is further enhanced through the use of advanced technologies, such as combined cycle systems, which use both gas and steam turbines to generate electricity. In a combined cycle plant, exhaust gases from a gas turbine are directed to a steam boiler, where they generate additional steam to drive a steam turbine, thereby increasing the overall efficiency of the system. Additionally, advancements in digital control systems and monitoring technologies allow for the real-time optimization of energy production, further improving the performance and reliability of cogeneration plants.

Cogeneration is also gaining popularity as a key component of renewable energy integration. Biomass and waste-to-energy systems, which use organic materials to generate heat and power, are examples of renewable cogeneration systems that contribute to the decarbonization of the energy sector. These systems can be integrated with district heating networks to provide both electricity and heating to local communities, further reducing reliance on fossil fuels and enhancing sustainability.

Despite its many advantages, the implementation of cogeneration systems requires careful planning and investment. The initial capital cost of installing a cogeneration plant can be significant, particularly for larger-scale systems. However, this cost is often offset by long-term energy savings, reduced fuel consumption, and lower operating costs. Additionally, government incentives, tax credits, and environmental policies that support energy efficiency and emissions reductions can make cogeneration more financially attractive.

The success of a cogeneration system depends on various factors, including the type of fuel used, the scale of the operation, the efficiency of the turbines or engines, and the integration with existing infrastructure. Facilities considering cogeneration must conduct thorough feasibility studies to determine the best design and configuration for their specific energy needs. This may involve analyzing the demand for both electricity and heat, as well as evaluating the potential for utilizing waste heat in other applications. In some cases, cogeneration systems can be designed with multiple energy extraction points, such as in double extraction steam turbines, which allow for even more efficient use of available thermal energy.

Looking to the future, cogeneration is expected to continue playing a critical role in the global energy transition. As industries seek to reduce their carbon emissions and energy consumption, the demand for efficient and sustainable energy solutions like cogeneration will increase. The development of new technologies, such as hybrid systems that integrate renewable energy sources with cogeneration, will further expand the potential applications of cogeneration. For example, the combination of solar thermal energy and a cogeneration system can provide both electricity and heat with minimal environmental impact, making it an attractive solution for facilities seeking to meet sustainability goals.

The ability of cogeneration systems to integrate with various energy sources, including renewables, is one of the key reasons for their continued growth and importance in modern energy systems. As global energy markets shift toward decarbonization and greater sustainability, cogeneration will remain a cornerstone of efficient and reliable energy production, helping to meet both the current and future energy needs of industries, communities, and the world at large.

As cogeneration continues to evolve, the growing emphasis on smart energy management and digital technologies is further enhancing its efficiency and performance. The integration of advanced sensors, data analytics, and machine learning algorithms enables real-time monitoring of cogeneration systems, providing valuable insights into operational performance, energy consumption patterns, and equipment health. This information allows operators to optimize energy flows, adjust output based on demand, and predict maintenance needs, reducing downtime and extending the lifespan of the equipment.

The implementation of smart grids and automated energy management systems (EMS) is also improving the integration of cogeneration into larger energy networks. These systems can dynamically balance energy supply and demand across multiple sources, ensuring that electricity and heat are distributed efficiently to end-users. For example, in a microgrid setting, a cogeneration system can be controlled to meet local energy demand while interacting with renewable energy sources, such as solar and wind, to ensure grid stability and reliability. By integrating energy storage systems, such as batteries or thermal storage, cogeneration plants can further enhance their ability to store excess energy produced during periods of low demand and release it during peak times, minimizing energy waste and improving overall grid resilience.

The use of artificial intelligence (AI) and predictive analytics in cogeneration systems also enables the optimization of fuel use, combustion processes, and steam extraction. AI-powered algorithms can analyze historical data and make real-time adjustments to the system, ensuring that the cogeneration process operates at its peak efficiency. For instance, AI can optimize the combustion process to reduce emissions and improve fuel-to-energy conversion ratios, while simultaneously adjusting steam extraction points to meet varying demand for electricity and thermal energy. By continuously learning from the system’s performance, AI can predict future operational conditions and recommend adjustments that maximize energy savings and minimize operational costs.

As environmental concerns and sustainability goals continue to drive change in the energy sector, cogeneration is gaining increasing attention as a method to reduce emissions and improve resource efficiency. Many governments and organizations are recognizing the role of cogeneration in achieving energy transition targets and are providing financial incentives, grants, and tax breaks to encourage its adoption. Policies promoting energy efficiency and emissions reductions, such as carbon pricing, renewable energy mandates, and energy performance standards, are making cogeneration a more attractive option for industries looking to reduce their carbon footprint and energy costs.

Cogeneration’s potential for integrating with renewable energy sources is particularly significant in the context of the global push for decarbonization. As renewable energy technologies, such as solar, wind, and geothermal, become more widespread, cogeneration systems can be adapted to take advantage of these intermittent and decentralized energy sources. For example, in a hybrid cogeneration system, solar thermal collectors could provide the heat needed for a steam turbine while the turbine simultaneously generates electricity. This integration allows for the reliable supply of both power and thermal energy, reducing reliance on fossil fuels and enhancing the sustainability of industrial processes.

Furthermore, the ability of cogeneration systems to capture and utilize waste heat opens up opportunities for industries to reduce their environmental impact and improve the circularity of their operations. For example, in a food processing plant, the heat generated by a cogeneration system could be used for drying, pasteurization, or other thermal processes, further reducing the plant’s need for external energy sources. Similarly, in manufacturing industries, waste heat could be harnessed for preheating materials or driving mechanical processes, improving overall process efficiency and minimizing waste. This approach aligns with the growing trend of circular economy practices, where waste is minimized and resources are continuously reused.

As the technology behind cogeneration continues to advance, there is also the potential for more widespread adoption in smaller-scale applications, such as residential buildings, commercial complexes, and district heating networks. In these settings, smaller cogeneration units can be used to generate electricity and heat on-site, reducing energy costs for consumers and improving energy independence. These systems could also be paired with renewable energy sources, such as rooftop solar panels or small-scale wind turbines, to create highly efficient, decentralized energy networks that reduce reliance on traditional power grids and provide local energy resilience.

In the context of global energy transition efforts, cogeneration is expected to play an increasingly important role in industries such as heavy manufacturing, chemicals, cement, and metals, where process heat is a significant part of the energy demand. By improving energy efficiency and reducing fuel consumption, cogeneration can help these industries transition toward low-carbon energy systems, lowering both operational costs and emissions. The ability to integrate cogeneration with carbon capture and storage (CCS) technologies further enhances its potential for decarbonization, as it allows industries to capture and store CO2 emissions from the cogeneration process, further contributing to the reduction of their carbon footprint.

In conclusion, cogeneration represents a key strategy for improving energy efficiency, reducing emissions, and meeting the growing demand for both electricity and heat in a sustainable way. Its ability to integrate with renewable energy sources, adapt to changing energy demands, and contribute to circular economy principles positions it as an essential technology for the future of energy systems. As innovations in digital technologies, advanced materials, and hybrid systems continue to develop, cogeneration will become an increasingly integral part of the global energy landscape, helping to drive a more sustainable, resilient, and efficient energy future.

The expansion of cogeneration systems into new markets and applications is also a crucial development in the global energy landscape. As industries and municipalities look to become more energy efficient, there is a growing interest in deploying cogeneration for district heating and cooling systems. In urban areas, particularly those with dense populations or cold climates, cogeneration offers a way to meet the heating demands of multiple buildings while simultaneously generating electricity. By capturing waste heat from the cogeneration process, these systems can significantly reduce the need for separate heating plants, leading to energy savings and reduced emissions. District heating systems, often coupled with cogeneration plants, provide a reliable and efficient way to deliver thermal energy to residential, commercial, and industrial users, reducing reliance on fossil fuels and promoting the use of renewable energy sources.

The increasing focus on energy efficiency and sustainability also means that cogeneration is becoming more attractive in the context of global efforts to improve the environmental performance of cities and industries. In regions where energy security is a significant concern, particularly in developing countries, cogeneration can be used to provide reliable and cost-effective energy solutions. By decentralizing energy production and utilizing local resources, cogeneration reduces the dependence on centralized power grids, which may be vulnerable to disruptions caused by natural disasters or other crises. This decentralized energy model enhances resilience and can also lead to lower transmission and distribution losses, making the system more efficient overall.

In the industrial sector, where high-temperature processes are common, the role of cogeneration systems is becoming more prominent. Many heavy industries, such as petrochemicals, refineries, and cement manufacturing, require large amounts of both electricity and process heat to sustain their operations. Cogeneration offers these industries a way to simultaneously meet both of these needs in a highly efficient manner. The extracted steam from the cogeneration process can be used to drive industrial processes like drying, distillation, or chemical reactions, while the electricity generated can power the machinery or be fed into the grid. This dual energy provision not only reduces operational costs but also makes industries more competitive in an increasingly energy-conscious world.

In terms of future innovation, there is growing potential for cogeneration systems to integrate with carbon capture, utilization, and storage (CCUS) technologies. These technologies can capture CO2 emissions from the combustion of fossil fuels in cogeneration plants and either store the carbon underground or repurpose it for use in other applications, such as enhanced oil recovery or the production of chemicals and fuels. Integrating cogeneration with CCUS can significantly reduce the carbon footprint of industries that are traditionally difficult to decarbonize, such as cement, steel, and chemicals, making these sectors more sustainable in the long run. The combination of cogeneration and CCUS could become a key enabler of net-zero emissions targets, particularly in industries where eliminating CO2 emissions entirely through renewable energy is challenging.

Moreover, the development of new fuels and alternative energy sources provides even more opportunities for cogeneration. Biomass and biogas, derived from organic waste materials, are renewable fuels that can be used in cogeneration systems to produce both heat and power. Biomass cogeneration plants are particularly beneficial in regions with abundant agricultural or forestry waste, as they allow for the conversion of these materials into energy while reducing landfill waste and mitigating methane emissions. Similarly, biogas produced from organic waste materials such as food scraps, sewage, or agricultural byproducts can be used in cogeneration systems, providing a sustainable and environmentally friendly alternative to natural gas.

The rise of green hydrogen as a viable energy source is also poised to impact cogeneration systems. Hydrogen, when produced through electrolysis powered by renewable electricity, can serve as a clean fuel in cogeneration systems, emitting only water vapor when burned. As the cost of renewable hydrogen production continues to fall, hydrogen-based cogeneration systems could become a game-changer for industries looking to decarbonize their operations. For example, steel manufacturers could use hydrogen as a fuel to drive their cogeneration plants, helping them transition away from coal and reducing their overall carbon emissions.

The energy transition also brings an increased focus on the resilience of energy systems, particularly in the face of climate change and growing weather-related disruptions. As the frequency of extreme weather events rises, energy systems that rely on centralized, fossil-fuel-based power plants are becoming more vulnerable to outages and disruptions. Cogeneration systems, particularly those integrated with decentralized energy grids or microgrids, provide a more resilient solution, ensuring that communities and industries have access to reliable energy even during natural disasters or grid failures. By distributing energy generation and utilizing locally sourced fuels, cogeneration plants offer greater flexibility and reduce the impact of grid failures.

Furthermore, the ongoing digital transformation of energy systems will continue to enhance the performance and capabilities of cogeneration plants. The use of advanced digital technologies, such as sensors, data analytics, and AI, enables real-time monitoring and optimization of energy production. These tools can help operators track performance metrics, identify inefficiencies, and predict when maintenance or repairs are needed. By proactively addressing potential issues before they cause downtime, digital tools can extend the life of cogeneration systems and improve their overall efficiency.

As energy markets become increasingly complex, cogeneration systems are also being adapted to work in tandem with other distributed energy resources (DERs), such as rooftop solar, wind turbines, and energy storage systems. By integrating cogeneration with DERs, energy users can maximize their self-sufficiency, reduce reliance on the grid, and create more sustainable and resilient energy systems. For example, during periods of high renewable energy generation, a cogeneration system could be used to store excess energy in thermal storage or batteries for later use, ensuring that energy demand is met even when renewable energy sources are not producing at their peak.

In conclusion, the role of cogeneration in the future of energy systems is expected to grow significantly. With its ability to improve energy efficiency, reduce emissions, and integrate with renewable energy sources and advanced technologies, cogeneration offers a flexible and sustainable solution for meeting both electricity and thermal energy demands. The continued development of new fuels, digital technologies, and decentralized energy systems will further enhance the potential of cogeneration to contribute to a more sustainable, resilient, and efficient energy future. As industries, municipalities, and governments pursue their energy transition goals, cogeneration will remain a vital tool for achieving greater energy efficiency and environmental sustainability.

As the world continues to prioritize energy efficiency and sustainability, the role of cogeneration in both industrial and residential applications is becoming increasingly important. One of the major drivers of this trend is the growing need to reduce energy costs while simultaneously lowering carbon emissions. Cogeneration allows industries and facilities to optimize their energy consumption by producing both electricity and useful heat simultaneously, which reduces waste and increases the overall efficiency of energy production. This efficiency can be especially beneficial in energy-intensive industries such as chemicals, pulp and paper, cement, and metals, where both electricity and steam are vital for the production process.

One area where cogeneration is particularly effective is in the use of waste heat recovery. Many industries produce significant amounts of excess heat as a byproduct of their operations, which often goes unutilized or is vented into the environment. By capturing and repurposing this waste heat through a cogeneration system, industries can convert this otherwise lost energy into valuable electricity or process heat. This not only reduces their dependency on external energy sources but also helps in lowering their overall fuel consumption. For example, in a cement plant, waste heat from the kiln can be recovered and used to generate steam, which in turn drives a turbine to produce electricity. This energy recovery system significantly improves the plant’s energy efficiency, lowers operational costs, and reduces its environmental impact.

Cogeneration systems are also gaining attention in the context of sustainable building design. As urbanization increases and the demand for energy-efficient buildings rises, the integration of cogeneration into commercial and residential developments is becoming more common. In these settings, cogeneration plants can provide heating, cooling, and electricity, reducing a building’s reliance on the grid and promoting energy independence. For instance, in a large mixed-use development, a cogeneration unit can produce both hot water and electricity for the building’s residents while simultaneously reducing energy costs. Similarly, cogeneration is being used in district energy systems, where multiple buildings are connected to a central cogeneration plant that supplies both heat and electricity. This approach is particularly beneficial in urban areas, where space constraints and high energy demands make it difficult to rely solely on traditional energy sources.

One of the most significant advantages of cogeneration in urban areas is its potential to reduce grid congestion and improve energy resilience. By decentralizing energy production, cogeneration plants can help to alleviate stress on centralized power grids, particularly during periods of peak demand. In the event of grid failures or natural disasters, cogeneration plants can continue to operate independently or in conjunction with microgrids, providing a reliable source of electricity and heating. This capability is particularly valuable in regions that experience frequent power outages or where the energy infrastructure is vulnerable to disruptions. For example, during a power outage caused by a storm, a cogeneration plant serving a hospital or critical infrastructure facility can continue to supply electricity and heating, ensuring that vital operations remain unaffected.

As the renewable energy sector continues to grow, cogeneration is increasingly being integrated with renewable energy sources to create hybrid systems that maximize energy efficiency and minimize emissions. One example of this integration is the combination of cogeneration with solar thermal systems. In such a hybrid system, solar collectors capture solar energy and convert it into heat, which is then used in the cogeneration process to generate electricity. This combination reduces reliance on fossil fuels and helps to decarbonize the energy supply. Additionally, cogeneration systems can be paired with energy storage technologies, such as thermal storage or batteries, to store excess energy generated during periods of low demand and release it when needed. This ensures that the system can operate efficiently even when renewable energy sources, like solar or wind, are not producing electricity.

Furthermore, the rise of green hydrogen as a clean fuel source is opening up new possibilities for cogeneration systems. Green hydrogen, produced through electrolysis powered by renewable energy, can be used as a fuel in cogeneration plants to generate electricity and heat without emitting carbon dioxide. Hydrogen has the potential to replace natural gas in cogeneration systems, offering a low-carbon alternative to traditional fossil fuels. In regions with abundant renewable energy resources, such as wind and solar, hydrogen can be produced in large quantities and used to power cogeneration systems, further reducing the carbon footprint of industrial and residential energy consumption. The use of hydrogen in cogeneration systems is still in the early stages of development, but as the cost of hydrogen production continues to fall and infrastructure for its use improves, hydrogen-powered cogeneration systems are expected to play an increasingly important role in decarbonizing the energy sector.