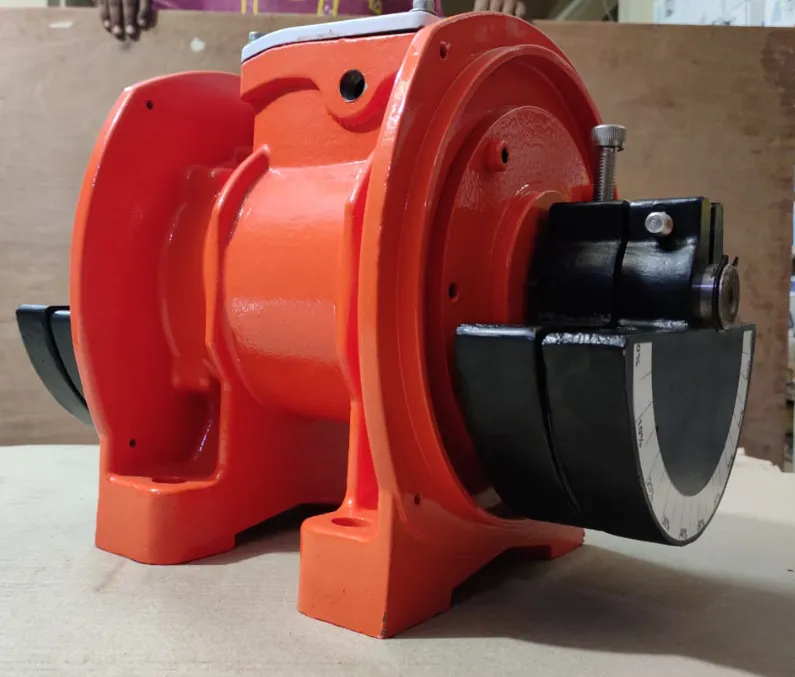

As an Electric Vibration Motor Manufacturer, we design and manufacture Electric Vibration Motors for the industry. Small and Big sizes are available

The EMS Power Machines can produce vibratory movements in patterns described as circular, elliptical, or linear. Single drive application with its gravity center coincident with the structure – gravity center creates circular movement, positioned outside the center of gravity, it produces an elliptical movement which varies at different points on the structure (Figure 1).

Double drive application with two identical EMS Power Machines vibration motors with their axes in the same plane rotating in opposite directions produces a linear vibratory movement (Figure 2). In consequence, the two asynchronous motors automatically become synchronized on account of the law of mass (Figure 3).

Electric Vibration Motor Definition

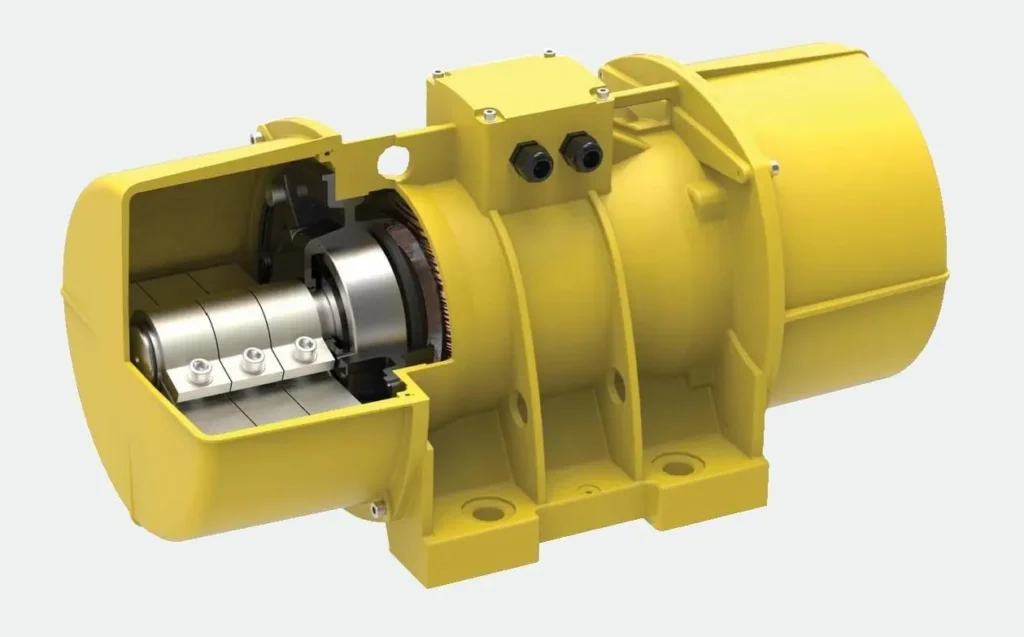

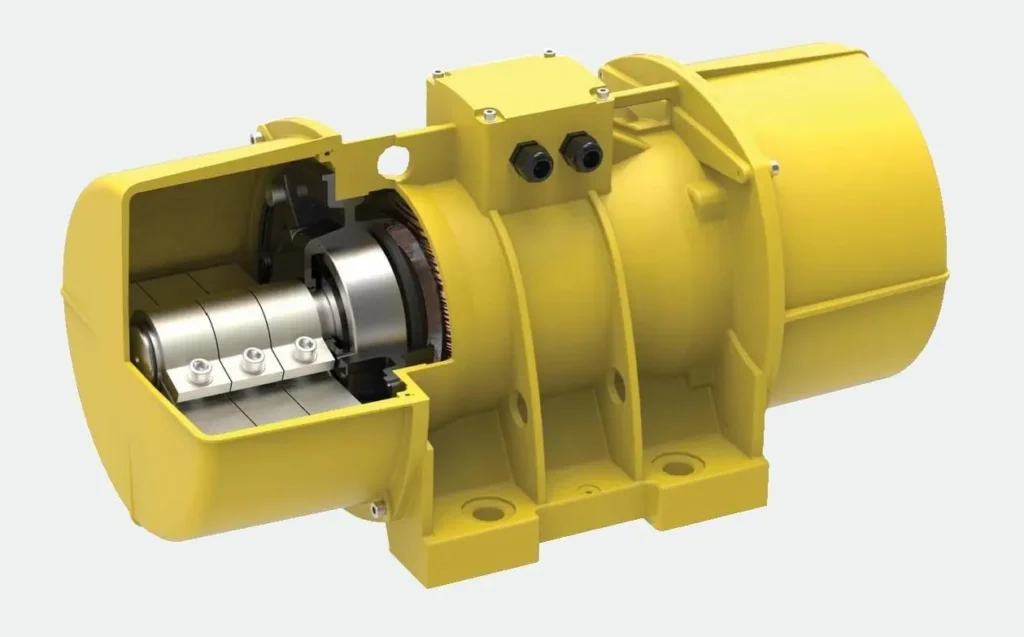

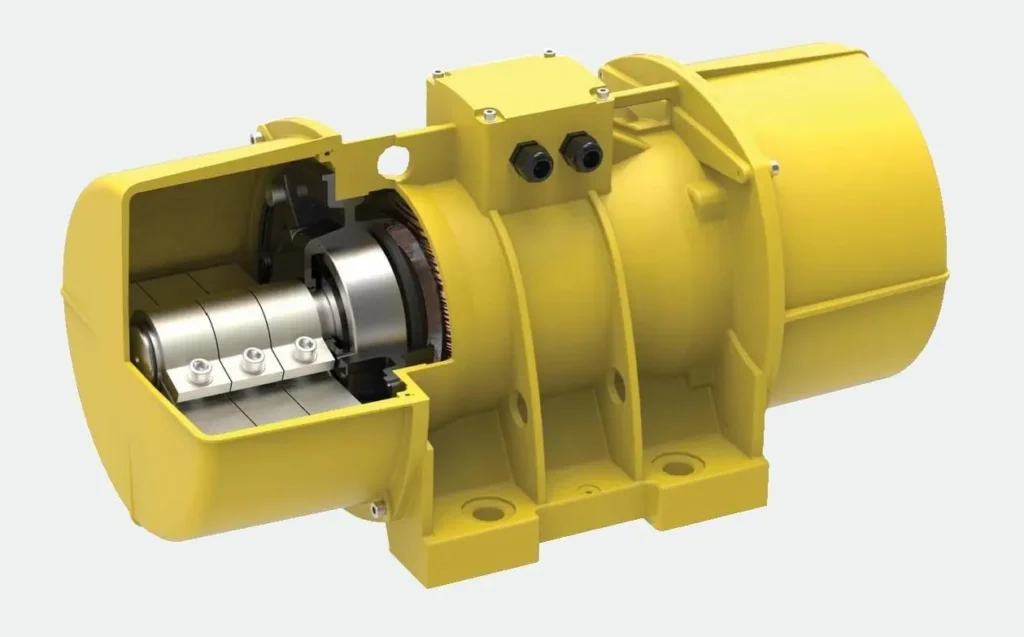

The EMS Power Machines vibration motors are asynchronous motors with short circuit armature. Table 1 and Table 2 list technical data for EMS Power Machines Vibrator Motors. All EMS Power Machines Vibrator Motors conform to IP 65 according to DIN 40050 specifications.

The stator with its coils is mounted vibration-proof inside a cast iron body. The shaft has the rotor shrunk on it and is supported by two heavy-duty bearings which are mounted on either side in bearing housings. The bearing housings are tightly fitted to the body.

The bearing outer races are tightly fitted to the bearing housings and the inner races are loosely fitted to the shaft allowing it to slide with eventually axial force. The EMS Power Machines Vibrator Motors are equipped with seal rings to prevent foreign matter from getting inside.

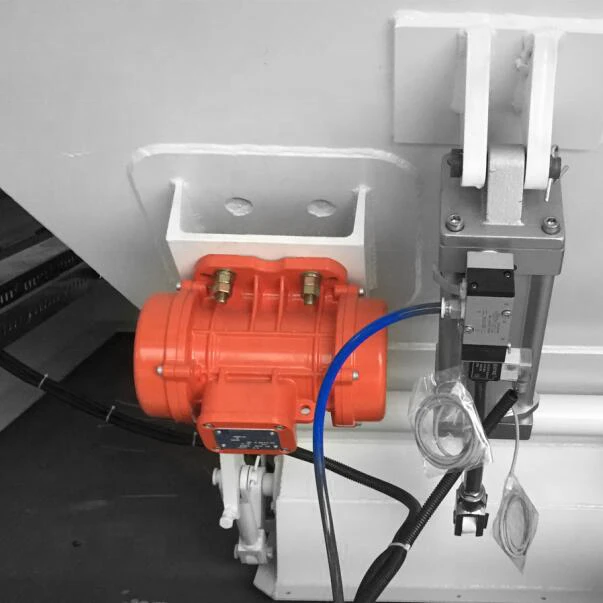

All EMS Vibrator Motors can be installed in any position. The fixation area should generally be rigid, in order to avoid the induced vibrations that might cause breakages due to stress; otherwise, plates and reinforcement ribs are required. The connection surface, furthermore, must be a flat plane, allowing for perfect contact of the fixing feet, otherwise, breakage of support legs or loosening of screws may occur.

Electric Vibrator Motors

Once these conditions have been insured, securely install the EMS Vibrator Motors using screws of min. quality 8.8 and self-locking nuts of quality 8. These must be tightened using a torque wrench to prevent screw loosening because even one loose can cause an accident. All fixing screws should be retightened after the EMS Vibrator Motors have gone into operation. Although no loose screws may be found when retightening, periodically check them for looseness. Retighten the screws for initial installation after the EMS Vibrator Motor has been reinstalled.

The EMS Vibrator Motors with 3000 RPM can be installed on almost all structures, while the motors with 1500, 1000, and 750 RPM which generate considerable amplitude, can be installed only on suspended masses. It is important to keep in mind that sometimes, due to certain ratios between the working frequency and natural frequency of the applied elastic system, the EMS Vibrator Motors do not reach nominal RPM, instead stabilizing in a lower RPM. In such case, in order to avoid damages to the EMS Vibrator Motors electrical parts it is necessary to modify the elastic system characteristic.

Electric Vibration Motor

An electric vibration motor is a type of motor that generates vibrations for various industrial applications. It works by converting electrical energy into mechanical energy, which creates vibration. The motor typically consists of a stator, rotor, bearings, and an eccentric weight.

The stator is the stationary part of the motor, consisting of a coil or multiple coils of wire wrapped around an iron core. The rotor is the rotating part of the motor that is connected to the eccentric weight. Bearings are used to support the rotor and maintain its alignment with the stator.

The eccentric weight is a weighted disc that is mounted to the rotor shaft off-center. When the motor is powered on, the weight rotates, generating centrifugal force that causes the motor and any attached equipment to vibrate. The amount of vibration can be adjusted by changing the speed or the position of the eccentric weight.

Electric vibration motors are commonly used in applications such as concrete compaction, conveyor systems, packaging equipment, and vibrating screens. They are typically available in a range of sizes and power ratings to suit different requirements.

An electric vibration motor, also known as an eccentric rotating mass (ERM) motor or a haptic motor, is a type of electric motor that is designed to create vibration. This vibration can be used for a variety of purposes, such as providing haptic feedback in smartphones and game controllers, or shaking materials in hoppers and bins.

How it works:

An electric vibration motor typically consists of an eccentric weight, a housing, and a coil. The eccentric weight is attached to the motor shaft, and when the motor is turned on, the weight is rotated. This rotation creates an unbalanced force that causes the motor to vibrate. The amount of vibration can be controlled by varying the speed of the motor or the size of the eccentric weight.

Types of electric vibration motors:

There are two main types of electric vibration motors:

- Rotary: Rotary vibration motors use an eccentric weight that is attached to the motor shaft. This weight is rotated by the motor, creating vibration. Rotary motors are the most common type of vibration motor.

- Linear: Linear vibration motors use a piezoelectric material to create vibration. When an electrical signal is applied to the material, it expands and contracts, creating vibration. Linear motors are smaller and more precise than rotary motors, but they are also less powerful.

Applications of electric vibration motors:

Electric vibration motors are used in a wide variety of applications, including:

- Haptic feedback: Electric vibration motors are used in smartphones and game controllers to provide haptic feedback, which is a physical sensation that can be used to enhance the user experience.

- Material handling: Electric vibration motors are used in hoppers and bins to shake materials, preventing them from bridging, clogging, or rat-holing.

- Medical devices: Electric vibration motors are used in medical devices, such as toothbrushes and massagers.

- Appliances: Electric vibration motors are used in appliances, such as washing machines and dryers.

Benefits of using electric vibration motors:

There are several benefits to using electric vibration motors, including:

- Compact size: Electric vibration motors are relatively small and lightweight, making them easy to integrate into a variety of devices.

- Low power consumption: Electric vibration motors are very efficient, consuming very little power.

- Long lifespan: Electric vibration motors are very durable and can last for many years.

Selection considerations:

When selecting an electric vibration motor, several factors should be considered, including:

- Size: The size of the motor should be appropriate for the application.

- Power: The power of the motor should be sufficient to create the desired vibration intensity.

- Speed: The speed of the motor should be controllable.

- Noise: The noise level of the motor should be low.

- Environment: The motor should be able to withstand the environmental conditions in which it will be used.

Conclusion:

Electric vibration motors are versatile and useful devices that have a wide range of applications. They are a valuable tool for providing haptic feedback, shaking materials, and powering a variety of devices.

Vibration motors are compact electric motors that generate vibrations or oscillations when energized. They are commonly used in a variety of applications where controlled vibration is required. Here’s an overview of vibration motors:

Components and Types:

- Rotor:

- The rotor is the rotating component of the motor that, when energized, causes the motor to vibrate.

- Stator:

- The stator is the stationary part of the motor that surrounds the rotor and provides the magnetic field necessary for the motor to operate.

- Eccentric Weight (Vibrator):

- Many vibration motors have an eccentric weight attached to the rotor. The eccentric weight’s off-center rotation creates an imbalance, leading to vibrations.

Rotor of the Vibration Motor

The rotor is a crucial component in various rotating machinery, such as electric motors, generators, turbines, and pumps. Its function and design can vary depending on the type of machinery it is part of. Here, I’ll provide a general overview of the rotor’s role in the context of electric motors, as this seems to be the most relevant to your previous inquiries.

Rotor in Electric Motors:

In the context of electric motors, the rotor is the rotating part of the motor that interacts with the stator, generating mechanical motion. There are two primary types of rotors in electric motors: squirrel-cage rotors and wound rotors.

- Squirrel-Cage Rotor:

- The squirrel-cage rotor is the most common type used in induction motors. It consists of laminated iron cores stacked together, and the conductors are typically aluminum or copper bars placed in slots on the iron cores. The ends of the conductors are shorted together by end rings, forming a closed loop.

- When electric current flows through the stator windings, it creates a rotating magnetic field. This magnetic field induces a current in the rotor conductors due to electromagnetic induction. The interaction between the stator’s magnetic field and the rotor’s induced current produces torque, causing the rotor to turn and drive the mechanical load.

- Wound Rotor:

- The wound rotor, also known as a slip ring rotor, has a set of insulated coils or windings connected to slip rings on the rotor shaft. The slip rings allow external electrical connections to the rotor windings.

- In operation, the wound rotor allows for external resistance to be connected to the rotor windings, enabling control of the motor’s speed and torque characteristics. This type of rotor is often used in applications where precise control over the motor’s performance is required.

Key Characteristics:

- Material:

- Rotor cores are typically made of laminated sheets of magnetic material (such as iron or steel) to reduce eddy current losses.

- Construction:

- The rotor construction can vary based on the motor type. In squirrel-cage rotors, conductive bars are embedded in the core, while wound rotors have coils or windings.

- Rotation:

- The rotor rotates within the stator’s magnetic field, creating mechanical motion. The rotational speed is influenced by the frequency and amplitude of the electric current in the stator.

- Torque Production:

- The primary function of the rotor is to generate torque by interacting with the stator’s magnetic field. This torque is responsible for driving the mechanical load connected to the motor.

- Control (Wound Rotor):

- In wound rotor motors, the external connections to the slip rings allow for additional control over the motor’s performance, including speed and torque regulation.

Applications:

Rotors are found in various types of electric motors used in a wide range of applications, including:

- Induction Motors: Squirrel-cage rotors are commonly used in induction motors for applications like pumps, fans, and compressors.

- Synchronous Motors: Rotors in synchronous motors maintain synchrony with the stator’s rotating magnetic field, making them suitable for applications where precise speed control is required.

- Wound Rotor Motors: These are used in applications requiring adjustable speed and torque characteristics, such as in large industrial drives.

Understanding the characteristics and types of rotors is essential in designing electric motors for specific applications, tailoring their performance to meet the requirements of different industries.

Stator of the Vibration Motor

The stator is a key component in electric motors, generators, and other rotating machinery. It serves as the stationary part of the machine, providing a magnetic field that interacts with the rotor to generate motion or electricity. Here, I’ll provide an overview of the stator in the context of electric motors:

Role of the Stator in Electric Motors:

- Magnetic Field Generation:

- The primary function of the stator is to generate a magnetic field when electric current flows through its windings. This magnetic field is essential for the operation of the motor.

- Interaction with the Rotor:

- The stator’s magnetic field interacts with the rotor (the rotating part of the motor), creating a force that produces mechanical motion. This motion is harnessed to drive various applications, such as turning a fan, pumping water, or propelling a vehicle.

- Stator Windings:

- The stator typically consists of a core made of laminated iron sheets to reduce eddy current losses. The stator windings, usually made of copper or aluminum, are wound around the core. The arrangement of these windings determines the motor’s characteristics.

Key Components and Characteristics:

- Laminated Core:

- The stator core is often made up of laminated sheets of magnetic material (such as iron or steel) to minimize energy losses due to eddy currents.

- Stator Windings:

- Copper or aluminum conductors are wound around the stator core to form coils. The configuration and connection of these windings influence the motor’s performance.

- Number of Poles:

- The number of poles in the stator refers to the number of magnetic poles created by the stator windings. The pole configuration affects the motor’s speed and torque characteristics.

- Three-Phase System:

- In many industrial applications, especially in larger motors, the stator windings are configured as a three-phase system. Three-phase motors are common due to their efficiency and smoother operation.

Types of Stators:

- Squirrel-Cage Stator:

- In squirrel-cage induction motors, the stator windings create a rotating magnetic field. The interaction between this field and the rotor’s conductive bars induces currents in the rotor, producing torque.

- Wound Stator:

- Some motors, especially those designed for specific control applications, have wound stators. These motors allow for external control over the stator windings, influencing the motor’s speed and torque characteristics.

Applications

Stators are integral to a wide range of electric motor applications, including:

- Induction Motors: In squirrel-cage induction motors, the stator’s rotating magnetic field induces currents in the rotor, generating torque for applications such as fans, pumps, and compressors.

- Synchronous Motors: Stators in synchronous motors maintain synchrony with the power supply frequency, making them suitable for applications requiring precise speed control.

- Wound Rotor Motors: Motors with wound stators provide additional control over speed and torque, making them suitable for industrial processes that require adjustable motor performance.

- Three-Phase Motors: Stators configured as three-phase systems are prevalent in industrial and commercial applications due to their efficiency and balanced power distribution.

The design and configuration of the stator are critical factors in determining the performance characteristics of an electric motor. Engineers carefully consider these factors to tailor motors for specific applications, ensuring optimal efficiency and functionality.

Eccentric Weight (Vibrator) of a Vibration Motor

The eccentric weight, also known as a vibrator or unbalance weight, is a crucial component in vibration motors. It plays a key role in generating vibrations by introducing an imbalance in the motor’s rotational movement. Here’s how the eccentric weight functions in a vibration motor:

Function and Operation

- Imbalance Creation:

- The eccentric weight is intentionally placed off-center on the motor’s rotating shaft. This off-center positioning creates an imbalance in the motor’s rotation.

- Centrifugal Force:

- As the motor rotates, the eccentric weight generates a centrifugal force due to its off-center position. This force creates an imbalance in the distribution of mass, leading to vibrations.

- Vibration Generation:

- The imbalance induced by the eccentric weight causes the motor to vibrate as it rotates. These vibrations are then transferred to the device or surface to which the motor is attached.

- Adjustment for Desired Vibrations:

- The size and position of the eccentric weight can be adjusted to control the amplitude and frequency of the vibrations produced by the motor. This allows for customization based on the specific requirements of the application.

Applications

Vibration motors with eccentric weights are commonly used in various applications where controlled vibrations are desired. Some common applications include:

- Haptic Feedback in Devices:

- Vibration motors with eccentric weights are frequently used in smartphones, tablets, and other electronic devices to provide haptic feedback during touch interactions or notifications.

- Gaming Controllers:

- Gaming controllers often incorporate vibration motors to enhance the gaming experience by providing tactile feedback during specific in-game events.

- Wearable Devices:

- Smartwatches and fitness trackers may use vibration motors with eccentric weights to deliver notifications and alerts to the wearer.

- Industrial Equipment:

- Vibration motors are used in industrial equipment for tasks such as compacting soil, conveying materials, and facilitating sieving processes.

- Medical Devices:

- Some medical devices use vibration motors for various applications, including alerting users or providing feedback.

- Automotive Applications:

- Vibration motors can be found in automobiles for haptic feedback in infotainment systems, alerting drivers, and enhancing the user experience.

- Consumer Electronics:

- Beyond smartphones, vibration motors with eccentric weights find applications in a range of consumer electronics, such as handheld gaming devices and remote controls.

Considerations

- Amplitude and Frequency:

- The amplitude (intensity) and frequency (speed) of vibrations produced by the motor depend on factors such as the size and positioning of the eccentric weight.

- Power Consumption:

- The power consumption of a vibration motor is an important consideration, especially in battery-powered devices.

- Durability and Lifespan:

- The durability and lifespan of the motor, including the eccentric weight, are crucial, especially in applications where the motor is subjected to frequent use.

- Control Options:

- Some vibration motors with eccentric weights come with control options to adjust vibration patterns or synchronize with specific events.

The eccentric weight is a design feature that allows vibration motors to efficiently generate controlled vibrations, making them versatile components in a variety of applications. The selection of a vibration motor with the appropriate eccentric weight characteristics depends on the specific requirements of the application.

Operating Principle

- Rotational Movement:

- When the motor is powered, the rotor (sometimes with an eccentric weight) starts to rotate.

- Centrifugal Force:

- The eccentricity in the rotor’s rotation creates a centrifugal force, leading to an imbalance in the system.

- Vibration Generation:

- The imbalance causes the motor to vibrate, producing oscillations that can be felt externally.

Types of Vibration Motors:

- Coin or Flat Motors:

- These motors are small, flat, and coin-shaped. They are commonly used in mobile phones, pagers, and other portable electronic devices.

- Cylinder Motors:

- These motors have a cylindrical shape and are often used in applications where a more extended vibration pattern is required.

- Pancake Motors:

- Pancake motors are thin and flat, similar to coin motors but with a larger diameter. They are suitable for applications requiring a larger vibrating surface.

- Brushed Motors:

- Traditional brushed DC motors can be used as vibration motors by attaching an eccentric weight. However, specialized vibration motors are more common for this purpose.

- Brushless Motors:

- Brushless vibration motors use electronic commutation and are known for their reliability and longer lifespan compared to brushed motors.

Applications:

- Haptic Feedback in Devices:

- Vibration motors are commonly used in smartphones, tablets, and other electronic devices to provide haptic feedback, such as during touchscreen interactions.

- Gaming Controllers:

- Vibration motors enhance the gaming experience by providing tactile feedback during specific in-game events.

- Wearable Devices:

- Smartwatches and fitness trackers often incorporate vibration motors to deliver notifications and alerts to the wearer.

- Industrial Equipment:

- Vibration motors are used in industrial equipment for tasks such as compacting soil, conveying materials, and facilitating sieving processes.

- Medical Devices:

- Some medical devices use vibration motors for various applications, including alerting users or providing feedback.

- Automotive Applications:

- Vibration motors are used in automobiles for haptic feedback in infotainment systems, alerting drivers, and enhancing the user experience.

- Consumer Electronics:

- Beyond smartphones, vibration motors find applications in a range of consumer electronics, such as handheld gaming devices and remote controls.

- Vibrating Conveyors:

- In industrial settings, vibration motors are employed in vibrating conveyors for material handling.

- Alert Systems:

- Vibration motors are used in alert systems, such as in alarms and pagers, where silent notifications are required.

Considerations:

- Amplitude and Frequency:

- The amplitude (intensity) and frequency (speed) of vibrations generated by the motor can be crucial, depending on the application.

- Power Consumption:

- The power consumption of a vibration motor is an important consideration, especially in battery-powered devices.

- Durability and Lifespan:

- The durability and lifespan of the motor are crucial, especially in applications where the motor is subjected to frequent use.

- Control Options:

- Some vibration motors come with control options to adjust vibration patterns or synchronize with specific events.

Vibration motors are versatile components used in a wide range of applications to provide tactile feedback, alert users, or facilitate various mechanical processes. The selection of a vibration motor depends on the specific requirements of the application.

Vibration motors are compact electric motors used to generate vibrations in a wide range of industrial and commercial applications. These motors consist of a rotor with an eccentric weight attached to it. When the motor rotates, the weight generates a centrifugal force, causing the motor to vibrate. Vibration motors are used to create various types of vibrations, such as linear vibrations, circular vibrations, and elliptical vibrations.

Vibration motors are commonly used in mobile phones, pagers, and other portable electronic devices to provide haptic feedback. They are also used in various industrial applications, such as conveyor systems, packaging equipment, and vibrating tables. In addition, they are used in automotive applications, such as airbag systems, seatbelt tensioners, and engine mounts.

Vibration motors come in different sizes and configurations, depending on the application requirements. They can be classified based on their operating principle, such as electromagnetic, eccentric rotating mass (ERM), and linear resonant actuator (LRA) motors.

Electromagnetic Vibration Motors

Electromagnetic vibration motors are the most common type of vibration motors. They consist of a coil of wire and a permanent magnet. When an electric current is passed through the coil, it generates a magnetic field that interacts with the magnetic field of the permanent magnet, causing the motor to vibrate.

ERM vibration motors consist of an eccentric rotating mass attached to the motor shaft. When the motor rotates, the eccentric mass generates a centrifugal force that causes the motor to vibrate.

LRA vibration motors use a similar principle to ERM motors but are more precise and consume less power. They consist of a moving mass attached to a spring. When an electric current is passed through the motor, the mass moves back and forth, generating vibrations.

Overall, vibration motors are versatile devices that play an essential role in many industrial and commercial applications. They provide a simple and effective way to create controlled vibrations that can be used for a wide range of purposes.

Types of Vibration Motors

What is a vibration motor? A vibration motor is a compact size coreless DC or AC motor used to inform the users of receiving the signal by vibrating, with no sound. Vibration motors are widely used in a variety of applications including cell phones, handsets, pagers, and so on.

The main feature of vibration motors is the magnet coreless AC or DC motors are permanent, which means they will always have their magnetic properties (unlike an electromagnet, which only behaves like a magnet when an electric current runs through it); another main feature is the size of the motor itself is small, and thus lightweight.

Moreover, the noise and the power consumption that the motor produces while used are low. Based on those features, the performance of the motor is highly reliable. The vibration motors are configured in two basic varieties: coin (or flat) and cylinder (or bar). There are some components in both of their internal constructions.

EMS Power Machines vibration motors are intended and suited to drive vibrating devices, like e.g.: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knock-out grates, vibrating trestles, resonance conveyors, vibrating mills and fluid-bed dryers, bin vibrating machines, etc.

Any other use or application beyond the specified shall be deemed an application for purposes other than the intended.

No claims will be accepted by EMS Power Machines for any damage resulting therefrom. Application for the purpose intended shall also include compliance with the operating manual and, in particular, the inspection and maintenance regulations. For technical information on our motors, such as type, speed, working torque and centrifugal force, and electrical values please refer to the leaflet of vibration motors or the motor datasheet.

Construction of Vibration Motors

Rotor: The rotor is the non-stationary part of a rotary electric motor. The wires and magnetic field of the motor are arranged so that a torque is developed about the rotor’s axis. In some designs, the rotor can act to serve as the motor’s armature, across which the input voltage is supplied.

The stator is the stationary part of a rotary electric motor. It could be worked as the magnet field and interact with the armature to create motion. Another function of the stator is it could act as the armature, which receives its influence from moving field coils on the rotor.

A commutator is a rotary electrical switch in certain types of electric motors or electrical generators that periodically reverses the current direction between the rotor and the external circuit. In a motor, it applies power to the best location on the rotor, and in a generator, picks off power similarly. As a switch, it has an exceptionally long life, considering the number of circuit makes and breaks that occur in normal operation.

The armature in this motor is a set of thin metal plates stacked together, with thin copper wire coiled around each of the three poles of the armature. (How the electric motor works) The main function of the armature is to convert magnetic energy into kinetic energy.

The Windings

Windings consist of some turns of coils. These coils are assembled to generate a magnetic field once the electricity goes through them.

In order to make a vibrating alert, a weight mass needs to be attached to the shaft. Through the high-speed displacement of weight, vibration can be achieved. Moreover, the magnitude of the force can be controlled and adjusted, and the factors that could affect it will be discussed below.

In the motor’s shaft, the brushes conduct the current between the stator and coils. The life of the motor depends on when the brushes will be worn out. Based on this factor, a brushless dc motor, which is also called BLDC, is used to extend the life of motors.

The cylinder shape is also called a bar-type vibration motor. This vibrating motor is essentially a motor that is improperly balanced. In other words, there is an off-centered weight attached to the motor’s rotational shaft that produces a centrifugal force while rotating. This unbalanced force displaces the motor. Its high-speed displacement makes the motor wobble, which is known as “vibrating”.

The wobble can be changed by the weight mass you attach, the weight’s distance to the shaft, and the speed at which the motor spins. What’s more, the centrifugal force, which is generated by rotating an unbalanced weight, causes the motor vibrates in 2 axes (Z axis and X axis).

Besides, the centrifugal force can be calculated through the equations in figure 3. According to the relationship of each component in this equation, it is easy to tell that a larger weight mass with a bigger offset from the shaft will produce more force and hence more vibration amplitude. Moreover, increasing the voltage supplied to the motor will increase its speed, and therefore the vibration frequency, as well as the vibration amplitude.

Technical Characteristics

Power Supply: The power supply of vibration motors is 230 ∆/400 Y Volt and 50-60 Hz as a standard. Please contact us for the special voltage and frequency rate.

Electric Motor: The electric motor vibration motors have higher starting torques than a three-phase asynchronous electric motor. The overheating problem of the vibration motor due to no ventilation system is taken into consideration at designing.

Polarity: As standard vibration, motors are manufactured in 2, 4, 6, and 8 poles. Motor Shaft: The motor shaft of vibration motors is produced from C45 structural steel. Rotor: Rotor is produced by injecting high alloyed aluminum into the channel of the packed siliceous sheet metal.

Bearings: The series with lower centrifugal force (from VA to VC series) are equipped with deep groove ball bearing (2Z) with C3 internal clearance. The series with higher centrifugal force (from VD to VL series) are equipped with cylindrical roller bearings ( NJ Series) with C4 internal clearance. All of the bearings, that we are using, are suitable to operate at heavy-duty conditions.

Eccentric Weights: The weights can adjust easily by rotating or subtracting according to the type of vibration motors. Casing: The casing of the vibration motor is high alloyed aluminum from the VA series to the VE series. The casing of vibration motors that have higher centrifugal force (from VE series to VL series) is nodular cast iron (GGG 50).

Eccentric Weights Cover: The eccentric weights cover is sheet metal up to the VK series. VK and VL series have aluminum weight covers. The purpose of the eccentric weight covers is to protect the eccentric weights from external factors and provide safety. Insulation Class: The insulation class of our standard range vibration motor is F class (155 °C).

Degree of Protection: The degree of protection is IP 66. Lubrication: Except for the vibration motors that used self-lubricated bearings (deep groove ball bearings – 2Z), the bearings of the vibration motors (NJ series) are lubricated in our factory. Apart from this, bearings have to be

lubricated with the aid of a grease nipple that is on the vibration motor case during maintenance. The required grease amount is written in the “ Vibration Motor User’s Manual”.

Painting: Vibration motors are painted with RAL 1003 paint by using the electrostatic painting method.

As a Vibration Equipment Manufacturer, we design and manufacture AC and DC vibration motors for the industry. Small and Big sizes are available

Vibration equipment is a special electric motor, on which both ends of unbalanced weights are fixed. These unbalanced weights cause vibration during rotation.

Vibration equipment refers to machines and devices designed to generate controlled vibrations for various purposes across different industries. These devices are used in applications such as materials testing, quality control, manufacturing, construction, and research. Here are some common types of vibration equipment:

- Vibration Tables:

- Purpose: Vibration tables are used to settle, compact, and evenly distribute materials. They find applications in packaging, foundry operations, concrete compaction, and more.

- Usage: Vibration tables are often used in product testing, quality control, and manufacturing processes to ensure uniformity and reduce voids in materials.

- Vibration Shakers (Electrodynamic Shakers):

- Purpose: Vibration shakers are used for dynamic testing of structures, components, and materials. They are commonly used in aerospace, automotive, and electronic industries for durability and fatigue testing.

- Usage: Vibration shakers are employed to simulate real-world vibrations and assess how materials and structures respond to dynamic loading.

- Vibration Testing Systems:

- Purpose: Comprehensive systems that include vibration tables, shakers, and associated instrumentation for various testing applications, including product reliability testing, structural analysis, and modal analysis.

- Usage: Vibration testing systems are used in laboratories and testing facilities to evaluate the performance and durability of products and materials.

- Vibration Compactors:

- Purpose: Vibration compactors are used to compact soil, asphalt, or other materials in construction and civil engineering projects.

- Usage: In road construction and infrastructure projects, vibration compactors help achieve proper compaction of materials to ensure stability and longevity.

- Vibration Analyzers:

- Purpose: Vibration analyzers are used to measure and analyze vibrations in structures and machinery.

- Usage: These devices help diagnose and monitor the condition of rotating machinery, identify potential issues, and assess the health of industrial equipment.

- Vibration Isolation Systems:

- Purpose: Vibration isolation systems are designed to reduce or eliminate the transmission of vibrations between a vibrating source and its surroundings.

- Usage: These systems are crucial in applications where vibrations can negatively impact precision instruments, such as in laboratories or manufacturing processes.

- Vibration Sensors and Accelerometers:

- Purpose: Vibration sensors and accelerometers are devices that measure vibrations and acceleration.

- Usage: They are commonly used in structural health monitoring, machine condition monitoring, and industrial automation to detect and analyze vibrations.

- Vibration Platforms:

- Purpose: Vibration platforms are used for applications such as fitness training, physical therapy, and rehabilitation.

- Usage: In the health and fitness industry, these platforms deliver controlled vibrations to users, promoting muscle activation and enhancing exercise routines.

- Vibration Feeders:

- Purpose: Vibration feeders are used to transport bulk materials or parts in a controlled manner.

- Usage: Commonly used in manufacturing and assembly lines, vibration feeders ensure a steady and controlled flow of materials for further processing.

- Vibration Damping Pads and Materials:

- Purpose: Vibration damping materials are used to reduce or absorb vibrations in machinery and structures.

- Usage: These materials are applied to mitigate the impact of vibrations on sensitive equipment or to control vibrations in construction and industrial settings.

Vibration equipment plays a critical role in various industries, contributing to product quality, testing, and research across different applications. The specific type of vibration equipment chosen depends on the intended purpose and industry requirements.

Vibration Tables

Vibration tables are specialized devices designed to generate controlled vibrations for various applications in industries such as manufacturing, quality control, research, and materials testing. These tables are used to settle, compact, or evenly distribute materials, and they find diverse applications across different fields. Here are some key aspects of vibration tables:

- Purpose and Applications:

- Settling and Compaction: Vibration tables are commonly used to settle or compact materials in containers, molds, or packaging. This helps reduce voids and ensures uniformity.

- Quality Control: In manufacturing, vibration tables are employed for quality control purposes to eliminate air bubbles, improve product consistency, and assess material properties.

- Foundry Operations: Vibration tables are used in foundries for shake-out processes, where they aid in separating solidified castings from molding material.

- Types of Vibration Tables:

- Electrodynamic Vibration Tables: These tables use electromagnets to generate vibrations and are often used in dynamic testing applications.

- Pneumatic Vibration Tables: These tables use compressed air to generate controlled vibrations and are suitable for applications requiring a clean and dry environment.

- Hydraulic Vibration Tables: These tables use hydraulic systems to produce vibrations and are known for their high force capabilities, making them suitable for heavy loads.

- Adjustable Settings:

- Vibration tables typically come with adjustable settings for parameters such as frequency and amplitude. These settings can be customized based on the specific requirements of the application.

- Vibration Isolation:

- Some vibration tables are equipped with features for vibration isolation to prevent unwanted transmission of vibrations to the surrounding environment. This is crucial in applications where external vibrations may interfere with the testing or manufacturing process.

- Construction and Materials:

- Vibration tables are constructed using materials that provide durability and stability. Common materials include steel or aluminum for the table structure.

- The table surface may have a textured or coated finish to enhance grip and prevent slippage of materials during vibration.

- Control Systems:

- Vibration tables are often integrated with control systems that allow users to precisely adjust and monitor the vibration parameters. These control systems contribute to the repeatability and accuracy of the process.

- Safety Features:

- Safety considerations are essential, and vibration tables may include features such as emergency stop buttons, protective enclosures, and safety interlocks to ensure safe operation.

- Customization:

- Vibration tables can be customized based on the specific needs of the application. Custom sizes, shapes, and additional features can be incorporated to meet unique requirements.

- Testing and Quality Assurance:

- Vibration tables are subject to testing and quality assurance measures to ensure their performance and reliability. Compliance with industry standards is often a critical factor.

- Diverse Industries:

- Vibration tables find applications in industries such as electronics, aerospace, automotive, packaging, pharmaceuticals, and construction, reflecting their versatility and utility.

Vibration tables play a crucial role in improving product quality, optimizing manufacturing processes, and conducting various tests and experiments. Their ability to induce controlled vibrations makes them valuable tools in a range of industries where material compaction, settling, and quality control are paramount.

Vibration Shakers

Vibration shakers, also known as electrodynamic shakers or vibration testing systems, are specialized devices designed for dynamic testing of structures, components, and materials. These systems are commonly used in industries such as aerospace, automotive, electronics, and materials testing to simulate real-world vibrations and assess how materials and structures respond to dynamic loading. Here are key features and applications of vibration shakers:

- Purpose and Applications:

- Dynamic Testing: Vibration shakers are designed to subject test specimens to controlled vibrations to simulate real-world conditions and evaluate their performance.

- Durability and Fatigue Testing: These systems are used to assess the durability, fatigue life, and structural integrity of materials and components.

- Modal and Structural Analysis: Vibration shakers are employed for modal testing to identify a structure’s natural frequencies, damping ratios, and mode shapes.

- Electrodynamic Shaker Principle:

- Vibration shakers operate on the principle of electromagnetic induction. An electromagnetic coil is attached to the shaker armature, and when an alternating current passes through the coil, it interacts with a magnetic field, causing the armature to move and generate vibrations.

- Adjustable Parameters:

- Vibration shakers offer adjustable parameters, including frequency, amplitude, and waveform shape. These settings can be customized based on testing requirements and standards.

- Frequency Range:

- Vibration shakers can cover a broad frequency range, from very low frequencies for seismic testing to higher frequencies for testing components subject to rapid oscillations.

- Amplitude Control:

- The amplitude of vibrations is a crucial parameter, and vibration shakers provide precise control over this parameter to simulate specific loading conditions.

- Mounting and Fixturing:

- Test specimens are mounted or fixtured to the shaker’s table or head to ensure secure and repeatable testing conditions.

- Acceleration Levels:

- Vibration shakers can generate a wide range of acceleration levels, allowing for testing under varying degrees of stress.

- Modal Excitation:

- In modal testing, vibration shakers can selectively excite specific modes of vibration to identify a structure’s natural frequencies and characteristics.

- Controller Systems:

- Vibration shakers are typically equipped with sophisticated control systems that allow users to program and monitor tests. These controllers contribute to the precision and repeatability of tests.

- Integrated Sensors:

- Some systems come with integrated sensors or accelerometers to measure the response of the test specimen during testing. This data is crucial for analysis and evaluation.

- Applications in Industry:

- Vibration shakers are widely used in industries such as aerospace for testing aircraft components, automotive for testing vehicle components, and electronics for assessing the durability of electronic devices.

- Testing Standards:

- Vibration shakers adhere to industry-specific testing standards, ensuring that tests are conducted in a consistent and standardized manner.

Vibration shakers are essential tools in the field of structural dynamics and materials testing. They allow engineers and researchers to evaluate the performance and reliability of materials, components, and structures under dynamic loading conditions, contributing to the development of safer and more durable products.

Vibration Testing Systems

Vibration testing systems are comprehensive setups that include various components designed to subject structures, components, or materials to controlled vibrations. These systems are commonly used in industries such as aerospace, automotive, electronics, and materials testing for assessing the durability, fatigue life, and structural integrity of materials and products. Here are key features and components of vibration testing systems:

- Vibration Shaker:

- A central component of the system is the vibration shaker or electrodynamic shaker, which generates controlled vibrations. It operates on the principle of electromagnetic induction, using an electromagnetic coil and an armature to produce vibrations.

- Control System:

- Sophisticated control systems are integral to vibration testing setups. These systems allow users to program, monitor, and control various parameters such as frequency, amplitude, and waveform shape.

- Power Amplifier:

- The power amplifier is responsible for amplifying the electrical signal sent to the shaker, enabling it to generate the required mechanical vibrations.

- Accelerometers and Sensors:

- Accelerometers and other sensors are used to measure the response of the test specimen to the applied vibrations. This data is crucial for analyzing and evaluating the specimen’s behavior.

- Fixturing and Mounting Systems:

- Test specimens need to be securely mounted or fixtured to the shaker’s table or head to ensure accurate and repeatable testing conditions.

- Modal Excitation Systems:

- Some vibration testing systems are equipped with modal excitation capabilities, allowing selective excitation of specific modes of vibration for modal testing and structural analysis.

- Vibration Controllers:

- Vibration controllers are software or hardware components that facilitate the programming, control, and monitoring of vibration tests. They play a crucial role in ensuring precision and repeatability.

- Dynamic Signal Analyzers:

- These analyzers process and analyze the signals from accelerometers and other sensors to provide insights into the dynamic behavior of the test specimen.

- Amplifier Cooling Systems:

- As power amplifiers generate heat during operation, cooling systems are often incorporated to maintain optimal operating temperatures and ensure the system’s reliability.

- Hydraulic or Pneumatic Actuators (Optional):

- Some testing systems use hydraulic or pneumatic actuators instead of electrodynamic shakers. These actuators apply forces directly to the structure, simulating real-world conditions.

- Test Chambers (Optional):

- In some applications, especially in the electronics industry, enclosed test chambers with environmental control features may be integrated to simulate temperature and humidity conditions.

- Vibration Isolation Systems:

- To prevent external vibrations from interfering with tests, vibration isolation systems are often employed. These systems isolate the testing apparatus from external disturbances.

- Customizable Configurations:

- Vibration testing systems are highly customizable to meet specific testing requirements. Configurations can be tailored based on factors such as specimen size, weight, and the type of testing required.

- Safety Features:

- Safety features such as emergency stop buttons, protective enclosures, and safety interlocks are incorporated to ensure safe operation during testing.

Vibration testing systems are crucial in various industries for evaluating the performance and durability of materials, components, and structures. They play a key role in research, development, and quality assurance processes, helping engineers and researchers understand how materials respond to dynamic loading conditions.

Installation of the Vibration Equipment

The mounting bolts used must be of grade 8 material. When installing the

motor, it is necessary to use locking nuts (do not use split lock washers) and tighten the bolts evenly to the recommended torque ratings. Never reinstall used fasteners as they may fail under load. Check the bolts for security after a few hours of operation. It is imperative that the eccentric weights at both ends of the shaft are adjusted identically: “mirror images of each other.”

When adjusting the eccentric weights, use the least amount of amplitude and force to move your material. This will provide longer motor life. See the “Eccentric Weight Adjustment” section. The motors are supplied with a terminal block to provide safe and secure lead attachment. Wiring of these motors must be done in accordance with the National Electric Code. See Figures 2 through 6 for wiring diagrams.

Each motor is supplied with a wiring diagram inside the terminal box. Always use closed-loop wire connectors only with crimped or soldered terminal ends on cable leads. See Figure 1 for the correct technique for assembling the wire connectors. Reinstall the foam rubber blocks supplied in the junction box on top of the cable leads. When wiring the motor, always use the ground connection.

Eccentric Weight Adjustment

All Metalfab, Inc.Vibratory Motors feature eccentric weights to change the

amplitude and centrifugal force. The following procedure should be adhered to whenever the eccentric weights are adjusted.

- Remove weight covers on both ends of the motor.

- Note the present eccentric weight setting.

- Loosen bolts on the outer adjustable eccentric weights only.

- Rotate outer eccentric weights on the shaft and line up the outer eccentric with the desired percentage setting on the inside eccentric.

- Retighten eccentric bolts and reinstall weight covers.

The motion generated by the explosion-proof vibrator motors is transmitted to the screen frame to separate and convey solids over the screen panels. The motors are rated for continuous duty with Totally Enclosed Non-Ventilated (TENV) construction and oil-bath lubricated bearings.

To maximize the G-forces produced by the vibrator motors, they are attached directly to the screen frame and are positioned over the screening bed. Eccentric weights installed on the rotor shaft produce the motor’s vibratory action. The weight, which is measured in in-lbs, varies depending on the application and equipment on which the vibrator motor is installed. The weight is stamped on the motor nameplate.

When two vibrator motors are installed on a single screen frame, the motors are connected to cause the motors to rotate in opposite directions for maximum G-forces. The vibrator motors must be operated at their rated three-phase supply voltage. The model designation shown on the nameplate is defined as follows:

Vibration Equipment Characteristics

STORAGE: If a spare motor is to be placed in storage, the instructions in the following paragraphs must be observed to protect the stored motor and maintain all warranties.

New Motors: New spare vibrator motors should be stored in a clean, dry (50 percent relative humidity or less), warm location. The storage location should not undergo severe daily temperature changes.

Used Motors: Before storing vibrators that have been in service, run the unit for approximately one hour to allow the unit to heat up and dissipate any internal moisture. At the end of the run, shut down the motor and

allow it to cool. Follow all applicable lock-out and tag-out rules when removing the motor. While the motor is in storage, periodically check the integrity of the winding insulation using a megohmmeter. Maintain a continuous record of megohmmeter readings, and immediately investigate any significant decrease in insulation resistance.

OPERATING ENVIRONMENT: EMS Power Machines vibrator motors are designed to operate in ambient temperatures slightly higher than 131°F (55°C). If higher temperatures are anticipated, please contact the EMS Power Machines Technical

Service: Department for assistance. DO NOT install hoods or enclosures that may cause inadequate ventilation, which could reduce vibrator life.

REPLACEMENT PARTS: The cross-sectional views and parts lists on the following pages include all replaceable parts for the EMS Power Machines vibrator motor. This information should be used to identify and order a replacement or spare parts for the motor.

Vibration Motor Maintenance

The vibration motors are supplied from the works with a 100 % centrifugal force setting as standard. If requested by the customer, the motors are supplied from the works with another set of centrifugal forces. The centrifugal forces can be set as follows to modify the output:

- Remove the protective hoods (1) from both sides.

- Loosen the clamping screws (14) of the inner centrifugal weights (3) and turn the discs in the same direction of 100 % (refer to warning note) to the required centrifugal force setting. Each of the external flyweights (2) is held in place by a key. Keep turning the inner flyweights with the desired setting (on the sketch 95 %) until they are lined up with the scale line on the edge of the external flyweight. Each scale line corresponds to a certain percentage of the maximum centrifugal force and operating torque.

- Re-tighten the clamping screws (14) of the internal centrifugal weights. The torques for tightening the centrifugal weights – refer to Chapter 17, Table 17.2.

- Attach both the protective hoods (1) and tighten them crosswise. Make sure that the two cord gaskets (9) for the protective hoods to contact properly, do not jam, and have not been damaged when demounting.

Vibration

Vibration is the periodic back-and-forth motion of an object or medium about its equilibrium point. It is a mechanical phenomenon that occurs when an object is displaced from its equilibrium position and then allowed to return to its equilibrium position.

The frequency of a vibration is the number of times the object or medium completes a full cycle of oscillation per unit of time. The amplitude of a vibration is the maximum displacement of the object or medium from its equilibrium position.

Vibration can be caused by a variety of factors, including:

- Mechanical forces: Mechanical forces can cause vibration by striking an object or by applying a force to an object that is already in motion.

- Electrical forces: Electrical forces can cause vibration by creating a fluctuating magnetic field that interacts with the object or medium.

- Thermal forces: Thermal forces can cause vibration by causing the atoms in an object or medium to vibrate at different frequencies.

Vibration can have a variety of effects on objects and media, including:

- Movement: Vibration can cause objects and media to move. For example, the vibration of a tuning fork causes the air around it to vibrate, which in turn causes our eardrums to vibrate, which we perceive as sound.

- Damage: Vibration can damage objects and media. For example, the vibration of a machine can cause the machine to wear out prematurely.

- Noise: Vibration can create noise. For example, the vibration of a car engine can create noise.

Vibration can also be used for a variety of purposes, including:

- Communication: Vibration can be used to transmit information. For example, Morse code is a system of communication that uses vibration to transmit information.

- Measurement: Vibration can be used to measure physical properties. For example, the vibration of a guitar string can be used to measure the frequency of the note being played.

- Entertainment: Vibration can be used for entertainment. For example, the vibration of a speaker can be used to create sound.

Vibration is a fundamental phenomenon that has a wide range of applications in science, engineering, and everyday life.

Here are the main features related with vibration

- Oscillation: A regular back-and-forth motion, such as that of a pendulum or a swing. This process of oscillation occurs when an object or system returns to a central position after being displaced from it.

- Frequency: The number of cycles of oscillation completed per unit of time. The frequency of a vibration is measured in hertz (Hz), which is one cycle per second.

- Amplitude: The maximum displacement of an oscillating object from its equilibrium position. The amplitude of a vibration is measured in meters.

- Wavelength: The distance between two consecutive points on a waveform that are the same phase. The wavelength of a vibration is measured in meters.

- Resonance: The tendency of a system to vibrate more strongly when excited by a frequency close to its natural frequency. Resonance can cause a system to vibrate uncontrollably, which can lead to damage.

- Damping: The process of dissipating energy from a vibrating system. Damping can be used to reduce the amplitude of a vibration.

- Forced vibration: A vibration that is caused by an external force. Forced vibration occurs when an object is subjected to a periodic force, such as the vibration of a machine.

- Free vibration: A vibration that occurs after an object has been displaced from its equilibrium position and then released. Free vibration occurs when no external force is acting on the object.

- Transmissibility: The ratio of the output vibration amplitude to the input vibration amplitude. Transmissibility is a measure of how well a system transmits vibration.

- Vibration isolation: The process of preventing vibration from transmitting from one system to another. Vibration isolation can be used to protect sensitive equipment from damage caused by vibration.

- Vibration control: The process of controlling the amplitude, frequency, and phase of a vibration. Vibration control can be used to reduce noise, prevent damage, and improve the performance of systems.

These keywords are just a few of the many that are related to vibration. Vibration is a complex phenomenon that can be studied from a variety of perspectives.

Oscillation

Oscillation is a repetitive or periodic variation, typically in time, of some measure about a central value (often a point of equilibrium) or between two or more different states. Familiar examples of oscillation include a swinging pendulum and alternating current.

Oscillation can be classified into two main types:

- Simple harmonic oscillation: This type of oscillation occurs when the restoring force is directly proportional to the displacement from equilibrium. The motion of a pendulum is a good example of simple harmonic oscillation.

- Damped oscillation: This type of oscillation occurs when there is a force that resists the motion of the object. The motion of a car suspension is a good example of damped oscillation.

Oscillation can also be classified according to the number of degrees of freedom:

- Single-degree-of-freedom oscillation: This type of oscillation occurs when the object has only one direction in which it can move. The motion of a pendulum is a good example of a single-degree-of-freedom oscillation.

- Multi-degree-of-freedom oscillation: This type of oscillation occurs when the object has more than one direction in which it can move. The motion of a molecule in a gas is a good example of a multi-degree-of-freedom oscillation.

Oscillation is a fundamental phenomenon that has a wide range of applications in science, engineering, and everyday life. Some examples of applications of oscillation include:

- Mechanical systems: Oscillation is used in a variety of mechanical systems, such as pendulums, clocks, and springs.

- Electrical systems: Oscillation is used in a variety of electrical systems, such as oscillators, filters, and amplifiers.

- Optical systems: Oscillation is used in a variety of optical systems, such as lasers and interferometers.

- Acoustics: Oscillation is used in a variety of acoustic systems, such as musical instruments and loudspeakers.

- Biology: Oscillation is used in a variety of biological systems, such as the heart and the brain.

Oscillation is a complex phenomenon that can be studied from a variety of perspectives. Some of the fields that study oscillation include physics, engineering, mathematics, and biology.

Here are some additional interesting facts about oscillation:

- The frequency of an oscillation is the number of times the object or medium completes a full cycle of oscillation per unit of time. The frequency of a vibration is measured in hertz (Hz), which is one cycle per second.

- The amplitude of an oscillation is the maximum displacement of the object or medium from its equilibrium position. The amplitude of a vibration is measured in meters.

- The wavelength of an oscillation is the distance between two consecutive points on a waveform that are the same phase. The wavelength of a vibration is measured in meters.

Frequency

The frequency of vibration refers to the number of oscillations or cycles that occur in a unit of time. In the context of vibration, it specifically indicates how many times a vibrating object completes a full cycle of motion within a given time period.

Key points related to the frequency of vibration:

- Unit of Measurement: The standard unit of frequency is the hertz (Hz), where one hertz is equal to one cycle per second.

- Relation to Period: The frequency (f) and period (T) of vibration are inversely related. The period is the time it takes for one complete cycle of vibration, and it is the reciprocal of the frequency (T = 1/f).

- Harmonic Motion: Vibration is often described as harmonic motion, especially in the context of simple harmonic oscillators. In harmonic motion, the displacement of the vibrating object is a sinusoidal function (e.g., sine or cosine wave), and the frequency determines how quickly the oscillations occur.

- Human Perception: In the field of acoustics, frequency is closely related to the perceived pitch of a sound. Higher frequencies are generally associated with higher pitches, while lower frequencies are associated with lower pitches.

- Engineering and Design: Controlling and understanding the frequency of vibration is crucial in various engineering applications. For example, in structural engineering, it is important to consider the natural frequencies of structures to avoid resonance, which can lead to excessive vibrations and potential structural failure.

- Measuring Devices: Devices such as accelerometers or seismometers are commonly used to measure and analyze vibrations, providing information about both the amplitude and frequency of the vibrations.

In summary, the frequency of vibration is a fundamental parameter that characterizes the rate at which a vibrating object completes cycles of motion. It is a crucial factor in various scientific, engineering, and industrial applications.

Amplitude

In the context of vibration, amplitude refers to the maximum displacement or distance moved by a vibrating object from its equilibrium position. When an object or a system undergoes vibrational motion, it oscillates back and forth around a central point. The amplitude of the vibration is the measure of how far the object moves from its rest position to one extreme.

Here are some key points related to amplitude in vibration:

- Definition: Amplitude is the maximum distance from the equilibrium position to the furthest point reached by a vibrating object during its oscillation.

- Representation: In graphical representations of vibrations, the amplitude is often depicted as the distance from the midpoint (resting position) to the peak of a wave or the trough.

- Units: The units of amplitude depend on the system of measurement being used. For example, it could be measured in meters, millimeters, inches, etc., depending on the scale of the vibration.

- Relation to Energy: The amplitude of vibration is directly related to the energy of the vibrating system. Higher amplitudes generally correspond to greater energy levels in the oscillating object.

- Importance in Engineering: Understanding and controlling the amplitude of vibrations is crucial in engineering, especially in areas such as structural engineering and mechanical design. Excessive vibrations with large amplitudes can lead to structural failures or mechanical problems.

In summary, amplitude in the context of vibration describes the extent to which a vibrating object moves away from its resting or equilibrium position during its oscillation.

Wavelength

Wavelength is a concept that is closely related to frequency and is commonly used in the context of waves, including electromagnetic waves, sound waves, and other types of waves. It is defined as the distance between two consecutive points in a wave that are in phase, meaning they are at the same point in their oscillation or cycle.

Here are key points about wavelength:

- Definition: Wavelength is the distance between two successive points in a wave that are characterized by the same phase of oscillation. In the case of a sine wave, for example, it is the distance between two consecutive points with the same amplitude and direction.

- Symbol: The symbol for wavelength is typically represented by the Greek letter lambda (λ).

- Relation to Frequency: Wavelength and frequency are inversely proportional. The product of wavelength and frequency is equal to the speed of the wave.

- Units: Wavelength is usually measured in meters (m) or other appropriate units depending on the type of wave. For example, in electromagnetic waves, it could be measured in nanometers (nm) or meters.

- Electromagnetic Waves: In the context of electromagnetic waves (such as light), different colors correspond to different wavelengths. Shorter wavelengths are associated with higher frequencies and higher energy, while longer wavelengths are associated with lower frequencies and lower energy.

- Sound Waves: In the case of sound waves, the wavelength is related to the pitch of the sound. Shorter wavelengths correspond to higher-pitched sounds, while longer wavelengths correspond to lower-pitched sounds.

Understanding the concept of wavelength is crucial in various fields, including physics, engineering, and telecommunications, as it helps describe and analyze the behavior of different types of waves.

Resonance

Resonance is a phenomenon that occurs when a vibrating system or external force drives another system to oscillate with greater amplitude at a specific frequency. In simpler terms, it’s the reinforcement or amplification of an oscillation due to the synchronization of frequencies.

Here are key points about resonance:

- Natural Frequency: Every physical system has a natural frequency at which it tends to oscillate when disturbed. Resonance occurs when an external force is applied at the natural frequency of the system.

- Amplification of Oscillations: When resonance occurs, the amplitude of the vibrations or oscillations in the system increases significantly. This can lead to large displacements and potentially cause damage if not controlled.

- Conditions for Resonance: For resonance to occur, three conditions must be met:

- The driving frequency of the external force must match the natural frequency of the system.

- The system must have a damping factor low enough to sustain the oscillations.

- Energy must be continuously supplied to the system to overcome any damping effects.

- Examples of Resonance:

- Musical Instruments: Resonance is fundamental in the production of sound in musical instruments. For example, when a guitarist plucks a string at its natural frequency, the resonance enhances the sound.

- Structural Resonance: Buildings and bridges can experience resonance under certain conditions, especially if exposed to vibrations that match their natural frequencies. This can lead to structural damage.

- Avoidance and Control: Resonance is not always desirable, especially in engineering and structural design. Engineers often take measures to avoid resonance or dampen its effects to prevent structural failures.

- Electrical Resonance: In electrical circuits, resonance can occur in situations where the inductive and capacitive reactances balance each other out at a specific frequency, leading to a peak in impedance.

Understanding resonance is crucial in various fields, including physics, engineering, acoustics, and structural design, as it can have both beneficial and potentially harmful effects depending on the context and application.

Damping

Damping is a process used to reduce or control oscillations, vibrations, or the amplitude of a system. It involves dissipating energy from the system to counteract the effects of any external force or disturbance. Damping is crucial in various fields, including engineering, physics, and mechanics, to prevent unwanted and potentially harmful oscillations.

Here are key points about damping:

- Purpose of Damping: The primary purpose of damping is to reduce or eliminate the amplitude of oscillations or vibrations in a system. This is important to ensure stability, prevent resonance, and avoid excessive wear or damage to components.

- Types of Damping:

- Viscous Damping: In viscous damping, the damping force is proportional to the velocity of the system. This is often represented by a damping coefficient in mathematical models.

- Structural Damping: This type of damping is associated with the internal friction within a material or structure. It is particularly relevant in the context of mechanical and structural systems.

- Air Damping: In some systems, such as moving vehicles, air resistance can act as a form of damping.

- Damping Ratio: The damping ratio is a dimensionless parameter that describes the level of damping in a system. It is often denoted by the Greek letter “zeta” (ζ). A system with low damping (ζ < 1) is underdamped and may exhibit oscillatory behavior, while a system with high damping (ζ > 1) is overdamped and tends to return to equilibrium without oscillating.

- Critical Damping: Critical damping is the minimum amount of damping required to prevent oscillations or overshooting when a system is disturbed. It provides the fastest approach to equilibrium without oscillation.

- Applications:

- Vibration Control: Damping is extensively used in controlling vibrations in mechanical systems, such as vehicles, buildings, and machinery.

- Shock Absorbers: In automotive applications, shock absorbers use damping to control the motion of the suspension system and provide a smooth ride.

- Structural Engineering: Damping is considered in the design of structures to prevent excessive vibrations during earthquakes or other dynamic events.

- Mathematical Modeling: Damping is often represented mathematically in equations of motion for dynamic systems. The damping term in these equations accounts for the dissipation of energy.

In summary, damping is a crucial aspect in controlling oscillations and vibrations, and it plays a significant role in ensuring the stability and safety of various mechanical and structural systems.

Forced vibration

Forced vibration occurs when a system is subjected to an external force or excitation at a frequency that is different from its natural frequency. Unlike natural or free vibrations, where a system oscillates spontaneously at its natural frequency, forced vibration is a response to an external driving force.

Key points about forced vibration:

- External Excitation: Forced vibration occurs when a periodic or non-periodic external force is applied to a system. This force can be a harmonic force, such as a sinusoidal oscillation, or a non-harmonic force.

- Resonance: If the frequency of the external force matches the natural frequency of the system, resonance can occur, leading to a significant increase in the amplitude of the vibrations. Resonance is a condition where the system responds with maximum amplitude due to the frequency match.

- Mathematical Representation: The response of a system to forced vibration is often described using mathematical models, such as the equation of motion. The solution to these equations provides insights into how the system responds to external forces.

- Amplitude and Phase Shift: The amplitude and phase shift of the forced vibration depend on the frequency of the external force, the damping in the system, and the system’s natural frequency.

- Applications:

- Musical Instruments: The sound produced by musical instruments often involves forced vibrations. For example, a guitar string is forced to vibrate by plucking or strumming.

- Mechanical Systems: Forced vibration is a common occurrence in mechanical systems subjected to periodic forces, such as engines, pumps, and rotating machinery.

- Mitigation: Engineers often design systems to avoid or control forced vibrations. This can involve adjusting the natural frequency of the system, adding damping, or employing isolators to reduce the effects of external forces.

Understanding forced vibration is essential in various fields, including mechanical engineering, structural engineering, and acoustics, as it helps engineers and researchers analyze and design systems to withstand or exploit external forces.

Free vibration

Free vibration occurs when a system undergoes oscillation or vibration without any external force acting on it after an initial disturbance. In other words, the system is allowed to move freely once it has been displaced from its equilibrium position.

Key points about free vibration:

- Natural Frequency: Free vibrations are characterized by the natural frequency of the system. The natural frequency is an inherent property of the system and is determined by its mass, stiffness, and damping characteristics.

- Initial Displacement or Velocity: To initiate free vibration, the system must be given an initial displacement or velocity from its equilibrium position. Once set in motion, the system will continue to oscillate back and forth without any external interference.

- Decay or Sustainment: In the absence of damping, free vibrations would theoretically continue indefinitely. However, most real-world systems have some form of damping, leading to a gradual decay in amplitude over time.

- Simple Harmonic Motion: If the system experiences no damping, the free vibration follows simple harmonic motion, which is characterized by a sinusoidal oscillation.

- Mathematical Representation: The motion of a system undergoing free vibration can be mathematically described using equations of motion. These equations typically involve terms related to the natural frequency and initial conditions.

- Applications:

- Structural Engineering: Free vibration is crucial in the analysis and design of structures. Buildings, bridges, and other structures can experience free vibrations after being subjected to external disturbances such as earthquakes or wind.

- Mechanical Systems: In mechanical engineering, free vibrations are relevant to the study of oscillations in machinery, rotating components, and other mechanical systems.

- Physics Experiments: Free vibrations are often observed in physics experiments, such as in the case of a simple pendulum or a mass-spring system.

Understanding free vibration is essential for engineers and scientists, as it allows them to predict and analyze the dynamic behavior of systems without the influence of external forces. It also plays a role in the design and optimization of structures and mechanical systems.

A vibration motor is a type of electric motor that is commonly used in electronic devices to produce vibrations. These motors are often small and are designed to generate vibrations with a varying intensity and frequency. Here are some key points about vibration motors:

- Construction: Vibration motors typically consist of an off-center load (often a small mass or eccentric weight) attached to the shaft of a motor. As the motor rotates, the off-center load creates an imbalance, resulting in vibrations.

- Applications: Vibration motors find applications in various devices where tactile feedback or vibration alerts are needed. Common examples include mobile phones (for notifications and haptic feedback), game controllers, fitness trackers, and other handheld electronic devices.

- Haptic Feedback: In smartphones and other devices with touchscreens, vibration motors are often used to provide haptic feedback, making the touchscreen interaction more tactile. For example, when you type on a virtual keyboard, the phone may vibrate slightly with each keypress.

- Types: There are different types of vibration motors, including eccentric rotating mass (ERM) motors and linear resonant actuators (LRA). ERM motors are more common and work by spinning an eccentric mass, while LRAs use a linear motion principle to generate vibrations.

- Control: The intensity and frequency of vibrations produced by a vibration motor can be controlled by adjusting the voltage, frequency, or duty cycle of the electrical input.

- Power Source: Vibration motors are typically powered by direct current (DC) and are often designed to operate at low voltages to suit the power requirements of portable electronic devices.

- Usage in Wearables: Vibration motors are commonly integrated into wearable devices, such as smartwatches and fitness trackers, to provide users with alerts and notifications without the need for audible signals.

These motors play a crucial role in enhancing the user experience in electronic devices by providing haptic feedback and alerts in a compact and efficient manner.

Construction

The construction of a typical vibration motor involves several key components. The exact design can vary depending on the type of vibration motor, but here are the basic elements commonly found in many vibration motors: