Electric Turbine: Steam turbines are the heart of many industrial operations, especially in power generation, where their efficiency and reliability are paramount. Central to the smooth operation of these turbines is the bearing system, which supports the turbine’s rotating parts, allowing them to spin freely with minimal friction. Proper lubrication is essential for these bearings, ensuring longevity, efficiency, and safety in the steam turbine’s operation. A well-maintained lubrication system reduces friction, minimizes wear and tear, and helps dissipate heat from the moving components, safeguarding the system from potential failure.

The steam turbine operates under extreme conditions, where high temperatures and rotational speeds create a challenging environment for the bearings. Without an adequate lubrication system, friction between the moving parts would rapidly lead to overheating, increased wear, and ultimately, equipment failure. Therefore, understanding the intricacies of the lubrication system in steam turbines is critical for maintaining operational efficiency and reducing downtime.

Importance of Lubrication in Steam Turbines

Bearings are essential to a turbine’s function because they support the rotor, the rotating part of the turbine, and allow it to spin with minimal resistance. However, high speeds and heavy loads cause significant stress on these bearings. Lubrication plays a key role in mitigating the effects of this stress by creating a thin film between moving surfaces, which reduces friction and wear.

The main functions of the lubrication system in steam turbines include:

- Minimizing Friction: Lubricants form a thin film between bearing surfaces, reducing metal-to-metal contact, which lowers friction and prevents excessive wear.

- Cooling: As the turbine operates, the bearings generate heat due to friction. The lubrication system helps in absorbing and dissipating this heat, preventing overheating and potential damage.

- Protecting Against Corrosion: High temperatures and the presence of moisture in steam turbines can lead to corrosion. Lubricants form a protective barrier on metal surfaces, reducing the risk of rust and other forms of corrosion.

- Removing Contaminants: Over time, bearings and other parts of the turbine wear down, and contaminants such as metal particles or dust can accumulate. The lubrication system helps to carry these contaminants away from critical components and into filters or reservoirs for removal.

Inadequate lubrication leads to increased friction, overheating, and potential bearing failure, which can be catastrophic for turbine operations. Such failures may result in unplanned downtime, costly repairs, and safety hazards.

Types of Lubrication Systems

Several types of lubrication systems are used in steam turbines, each with its own strengths, weaknesses, and applications. These systems must meet the demands of high-temperature, high-speed environments, and as such, choosing the right type of lubrication is crucial for the long-term reliability of the turbine.

- Forced Lubrication Systems:

Forced lubrication is the most common lubrication system used in steam turbines. In this system, lubricating oil is pumped under pressure to the bearings, ensuring continuous and controlled oil flow. The oil is forced through the bearings and back into a reservoir, where it is cooled and filtered before being recirculated.Forced lubrication offers several advantages:- Continuous lubrication ensures that the bearings are always adequately lubricated, even under varying load conditions.

- It helps maintain optimal temperatures by circulating oil that absorbs and dissipates heat.

- Filters in the system help remove contaminants, extending the life of the bearings and oil.

- Dry Lubrication Systems:

While not as common in steam turbines, dry lubrication systems can be used in specific situations. These systems rely on solid lubricants, such as graphite or molybdenum disulfide, to reduce friction between bearing surfaces. Dry lubricants are particularly useful in environments where liquid lubricants may evaporate or degrade due to extreme temperatures.Advantages of dry lubrication systems include:- They can operate in environments with extremely high temperatures where liquid lubricants may break down.

- Dry lubricants are less likely to cause contamination in sensitive applications.

- Hybrid Lubrication Systems:

In some cases, a combination of liquid and dry lubricants may be used to provide enhanced protection. Hybrid systems can be designed to offer the advantages of both lubrication types, offering both cooling and high-temperature resilience.

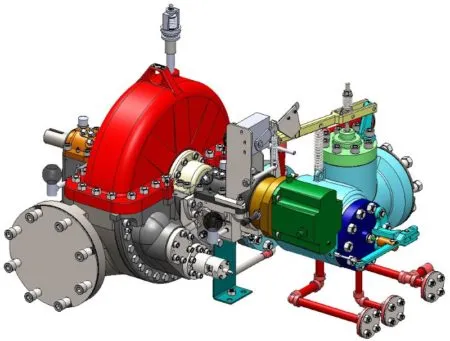

Components of a Lubrication System

A steam turbine’s lubrication system is composed of various critical components, all working together to ensure the proper functioning of the bearings and the overall turbine. Each component plays a distinct role in the lubrication process, ensuring the oil remains clean, cool, and adequately distributed.

- Lubrication Pump:

The pump is the heart of the lubrication system, responsible for circulating oil through the bearings. Depending on the turbine’s size and design, the system may use one or more pumps, such as main pumps, auxiliary pumps, and emergency pumps. These pumps ensure continuous oil flow, even during power outages or turbine shutdowns. - Oil Reservoir (Sump):

The oil reservoir stores the lubricating oil and is usually located below the turbine. As the oil circulates through the system, it returns to the reservoir, where it is cooled and filtered before being recirculated. Maintaining the correct oil level in the reservoir is critical for proper turbine operation. - Coolers and Heat Exchangers:

As the lubricating oil circulates through the turbine, it absorbs heat from the bearings. To prevent the oil from overheating, coolers and heat exchangers are used to dissipate the heat before the oil is recirculated. In most systems, water is used as a coolant to remove heat from the oil, maintaining optimal temperatures for both the oil and bearings. - Filters:

Filters play an essential role in keeping the lubricating oil clean. As the oil circulates through the system, it can pick up contaminants like dust, dirt, and metal particles from the bearings. Filters remove these contaminants, ensuring that the oil remains clean and does not damage the bearings or other turbine components. - Pressure Relief Valves:

To prevent damage from excessive pressure, lubrication systems are equipped with pressure relief valves. These valves open when the pressure exceeds a predetermined limit, protecting the system from overpressurization.

Common Issues and Troubleshooting

While steam turbine lubrication systems are designed to be highly reliable, they can still experience issues that compromise their performance. Understanding these common problems and how to troubleshoot them is essential for preventing costly breakdowns and ensuring the turbine operates at peak efficiency.

- Oil Degradation:

Over time, lubricating oil can degrade due to exposure to high temperatures, contamination, or oxidation. Degraded oil loses its ability to properly lubricate bearings, leading to increased friction and wear. Regular oil analysis and timely oil changes are critical for preventing oil degradation. - Oil Leakage:

Leaks in the lubrication system can result in a loss of oil pressure and inadequate lubrication of the bearings. Oil leaks can be caused by damaged seals, loose connections, or worn components. Regular inspections and maintenance can help identify and fix leaks before they lead to more serious problems. - Contamination:

Contaminants like dirt, water, and metal particles can enter the lubrication system and damage bearings. Regular oil filtration and monitoring can help reduce contamination, but it’s also important to ensure that seals and filters are functioning correctly to keep contaminants out. - Overheating:

If the lubrication system is not cooling the oil effectively, the bearings can overheat, leading to premature wear or failure. Overheating can be caused by issues with the cooling system, such as clogged heat exchangers or insufficient water flow. Regular maintenance of the cooling system is crucial for preventing overheating.

Maintenance of Turbine Lubrication Systems

Proper maintenance of the lubrication system is essential for ensuring the long-term reliability and performance of steam turbines. Regular maintenance tasks include:

- Oil Analysis: Periodically testing the oil for signs of degradation, contamination, or oxidation helps identify potential problems early.

- Filter Replacement: Replacing filters at regular intervals ensures the oil remains clean and free of contaminants.

- Pump Inspection: Checking the condition of the lubrication pumps and ensuring they are functioning properly is essential for maintaining oil flow.

- Cooler Maintenance: Cleaning and maintaining coolers and heat exchangers ensures that the oil is being effectively cooled and prevents overheating.

Case Studies in Lubrication Failure and Improvements

Several high-profile cases have demonstrated the importance of a well-maintained lubrication system in steam turbines. For instance, in power plants where lubrication systems have failed, it has resulted in catastrophic damage to bearings and turbine rotors, leading to extended downtimes and costly repairs. In contrast, facilities that implemented advanced monitoring systems and regular maintenance schedules have seen significant improvements in turbine reliability and lifespan.

One notable case involved a power plant that experienced repeated bearing failures due to contaminated lubricating oil. After implementing a rigorous oil analysis and filtration program, the plant significantly reduced bearing failures and improved overall turbine performance.

Future Developments in Lubrication Technology

As technology continues to evolve, so too do lubrication systems for steam turbines. Emerging trends and innovations include:

- Smart Lubrication Systems:

Advanced sensors and monitoring technology allow for real-time tracking of oil quality, temperature, and pressure. These smart systems can alert operators to potential issues before they cause significant damage, enabling more proactive maintenance. - Synthetic Lubricants:

The development of synthetic lubricants with improved thermal stability and resistance to oxidation has the potential to extend the life of lubricants and reduce maintenance requirements. Synthetic oils can also perform better under extreme conditions, making them ideal for use in high-temperature environments. - Nanotechnology in Lubrication:

Researchers are exploring the use of nanotechnology to improve the performance of lubricating oils. By incorporating nanoparticles into the oil, it is possible to enhance its lubricating properties and reduce wear on the bearings. Nanoparticles can also help improve heat transfer, leading to better cooling of the bearings.

Conclusion

The lubrication system is a critical component of any steam turbine, ensuring the smooth operation and longevity of the bearings. Proper lubrication reduces friction, dissipates heat, and protects the bearings from contamination and wear. While lubrication systems have come a long way, ongoing maintenance and attention to detail are essential to prevent issues such as oil degradation, contamination, and overheating.

As the demand for more efficient and reliable turbines grows, so too will innovations in lubrication technology. From synthetic lubricants to smart monitoring systems, the future of steam turbine lubrication promises to improve both efficiency and performance, ensuring that these vital machines continue to power industries for years to come.

A wood stove electricity generator is a unique and eco-friendly solution for off-grid power generation. In simple terms, it converts the heat from burning wood into electricity, enabling users to harness energy while heating their homes. This innovative technology appeals to those living in rural areas, survivalists, or individuals looking to reduce their carbon footprint and dependency on traditional grid-based power sources. Given the increasing demand for renewable energy, wood stove generators are gaining traction among environmentally-conscious users.

Wood stoves have been used for centuries for heating purposes, but recent technological advancements have allowed them to serve a dual purpose by generating electricity. The basic principle of these generators relies on converting thermal energy into electrical energy, a concept that dates back to the 19th century with the invention of thermoelectric devices and heat engines. While early prototypes were crude, today’s systems are far more efficient and sophisticated.

How They Work

Wood stove electricity generators use heat produced by burning wood to generate electricity through two main mechanisms: thermoelectric generation and Stirling engines.

- Thermoelectric Generators (TEGs):

A thermoelectric generator works based on the Seebeck effect, where a temperature difference between two different conductive materials generates an electric current. In a typical wood stove setup, the heat from the stove is directed to a thermoelectric module. On one side of the module, the stove provides heat, while the other side is cooled (usually by air or water). The temperature difference between the hot and cold sides creates a flow of electrons, producing electricity.TEGs are advantageous for their simplicity, with no moving parts, leading to lower maintenance. They are compact and can generate power quietly. However, their efficiency is typically lower compared to other energy conversion methods, with conversion rates often below 10%. - Stirling Engines:

The Stirling engine is an external combustion engine that works by cyclically compressing and expanding air or another gas (the working fluid) at different temperatures. The heat from the wood stove heats the gas, causing it to expand and drive a piston, which in turn generates mechanical energy. This mechanical energy can then be converted into electricity using a generator. Stirling engines are known for their high efficiency compared to thermoelectric generators and can operate on various heat sources, making them highly versatile.Stirling engines are more complex than TEGs, requiring regular maintenance due to their moving parts. However, they offer higher power output, making them suitable for larger-scale applications where more electricity is needed.

Benefits of Using Wood Stove Generators

Wood stove electricity generators offer numerous advantages for those looking to live off the grid or reduce their reliance on conventional power sources:

- Renewable Energy Source: Since wood is a renewable resource, wood stove generators provide a sustainable power solution. As long as trees are replanted, the cycle of using wood for fuel can be perpetuated indefinitely.

- Cost-Effective: In regions where wood is readily available, these generators can reduce energy bills significantly. By producing heat and electricity from a single source, they eliminate the need to purchase fuel for separate heating and power systems.

- Energy Independence: These systems are ideal for remote areas without access to the electrical grid. They enable households to become self-sufficient, particularly in emergency situations where grid power may not be available.

- Reduced Carbon Footprint: When sourced sustainably, wood is a carbon-neutral fuel. While burning wood releases carbon dioxide, the amount emitted is equal to what the tree absorbed during its lifetime, making it a much greener option than fossil fuels.

Types of Wood Stove Generators

Wood stove electricity generators come in various forms, each suited to different needs and applications:

- Portable Thermoelectric Generators: These are small, compact units that can be placed on top of a wood stove. They generate enough electricity to charge small devices, such as mobile phones or LED lights. Campers and outdoor enthusiasts often use these portable models.

- Integrated Wood Stove Generators: These are larger systems designed to be built into a home’s wood stove setup. They can generate enough electricity to power household appliances, lighting, and more. These systems are more complex and often require professional installation.

- Stirling Engine Wood Stoves: Some advanced models integrate Stirling engines directly into the stove. These are capable of generating higher amounts of electricity and can power entire homes, especially when paired with energy storage systems like batteries.

Practical Applications and Real-Life Examples

Wood stove electricity generators are particularly useful in several scenarios:

- Rural and Off-Grid Homes: For homeowners in remote areas, wood stove generators can provide a reliable power source. In areas prone to frequent power outages or where grid infrastructure is unreliable, these systems offer peace of mind.

- Emergency Preparedness: In case of natural disasters or emergencies that disrupt grid power, wood stove generators provide an independent power source for critical needs like lighting, heating, and communication devices.

- Campsites and Cabins: Outdoor enthusiasts often use portable wood stove generators to charge their devices while camping. In cabins or vacation homes, these systems can offer a simple and sustainable power solution without the need for large-scale infrastructure.

Key Considerations (Efficiency, Cost, Maintenance)

While wood stove electricity generators offer numerous benefits, there are several factors to consider:

- Efficiency: Both TEGs and Stirling engines have their pros and cons when it comes to efficiency. While TEGs are simpler and require less maintenance, they are less efficient, with lower power outputs. Stirling engines are more efficient but require more complex maintenance and installation.

- Cost: The cost of a wood stove generator can vary greatly depending on the system’s size and complexity. Portable TEG systems can be relatively inexpensive, while large integrated systems with Stirling engines can be significantly more costly, often requiring professional installation.

- Maintenance: TEGs are generally low-maintenance due to their lack of moving parts. Stirling engines, however, require regular servicing to ensure the mechanical parts function properly. Both systems need regular cleaning of the wood stove to ensure optimal performance.

- Availability of Wood: One of the key considerations when using a wood stove electricity generator is the availability of wood. Users must ensure they have a consistent and sustainable supply of wood, especially in remote or off-grid locations.

Environmental Impact and Sustainability

One of the most appealing aspects of wood stove electricity generators is their environmental sustainability. When sourced responsibly, wood is a renewable resource, making it a much greener option compared to fossil fuels like coal, oil, or natural gas. Furthermore, wood stoves produce fewer harmful emissions than traditional power plants, especially when the wood is burned efficiently.

However, the environmental impact can vary depending on the type of wood used and how it is sourced. To ensure sustainability, it’s important to use wood from renewable sources and to manage forests responsibly by planting new trees to replace those harvested for fuel. In addition, modern wood stove technology has significantly reduced emissions, making these systems more eco-friendly than ever before.

Innovations and Future Trends

As renewable energy technology advances, wood stove electricity generators are also evolving. Several innovations are currently in development:

- Improved Thermoelectric Materials: Researchers are working on developing new thermoelectric materials that are more efficient at converting heat into electricity. This could significantly boost the efficiency of TEG-based wood stove generators.

- Hybrid Systems: Some companies are exploring hybrid systems that combine wood stove generators with solar or wind power to create more reliable and diversified off-grid energy systems.

- Energy Storage Solutions: Advancements in battery technology have made it possible to store the electricity generated by wood stoves more effectively. This allows users to store excess power for use during times when the stove isn’t in use, improving overall energy efficiency.

- Automated Systems: Future wood stove generators may include automated controls that regulate heat output and power generation, making them easier to use and more efficient.

Conclusion

Wood stove electricity generators represent a promising and sustainable solution for off-grid living and eco-conscious homeowners. By leveraging the heat from burning wood, these systems provide a renewable energy source that can reduce reliance on the electrical grid and lower energy costs. While there are challenges in terms of efficiency, cost, and maintenance, ongoing innovations in thermoelectric and Stirling engine technology are likely to improve the performance and accessibility of these systems in the coming years.

Their dual functionality—providing both heat and electricity—makes them a particularly attractive option for rural homes, cabins, and even urban environments where sustainable living is a priority. As we continue to explore new ways to reduce our carbon footprint, wood stove electricity generators are poised to play a significant role in the future of renewable energy.

Steam Turbine Parts Manufacturing

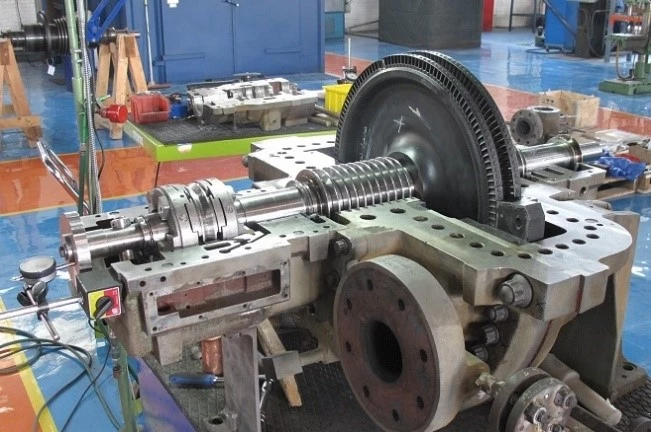

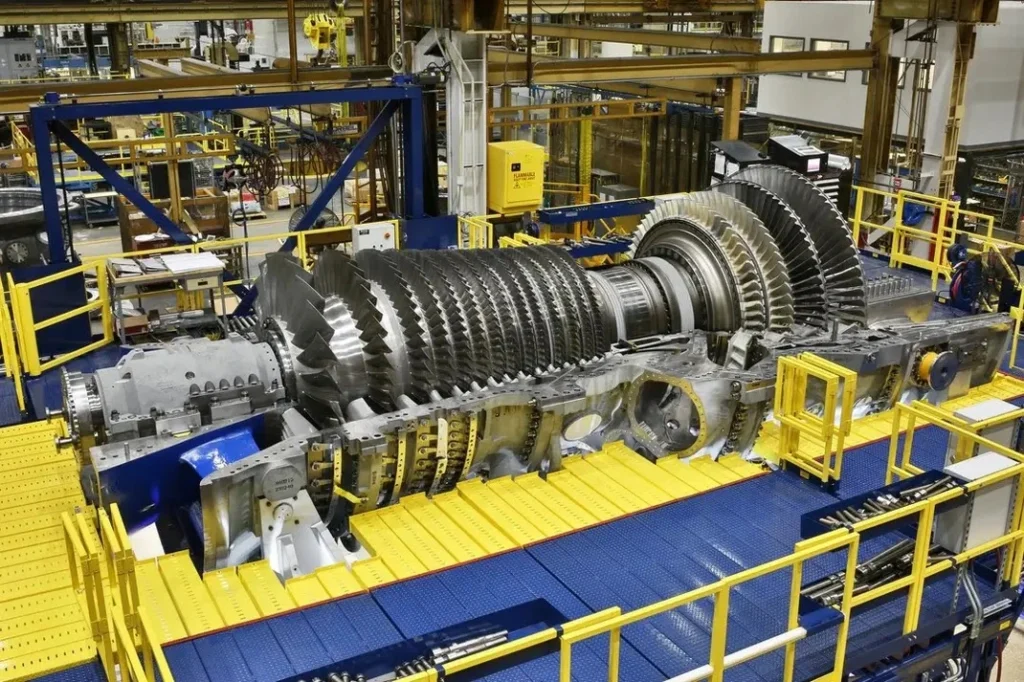

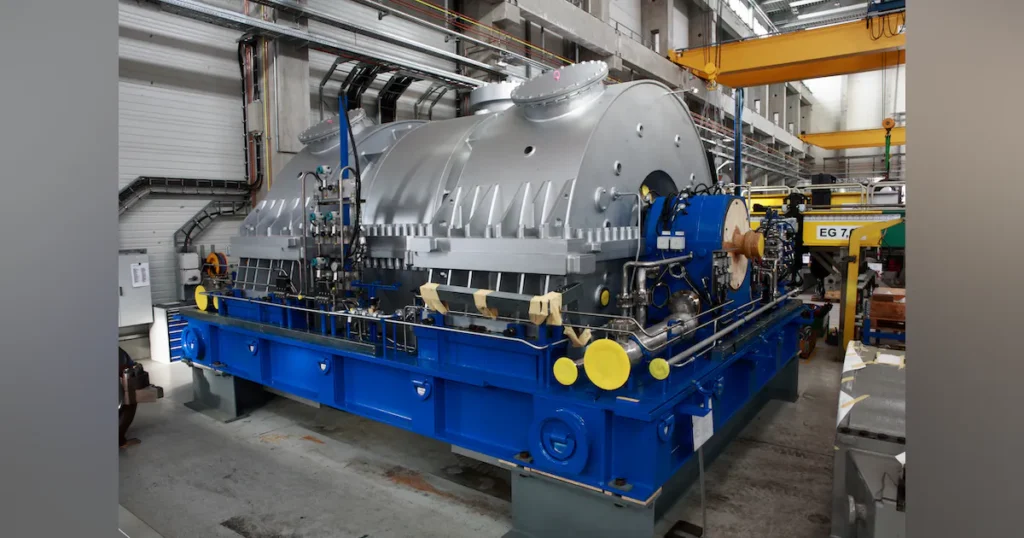

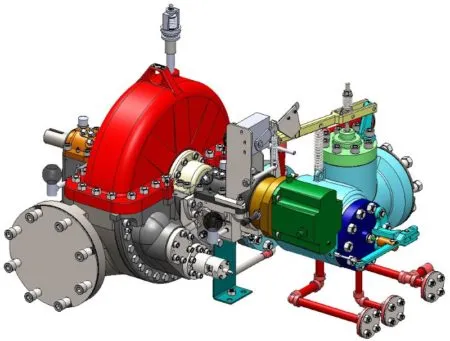

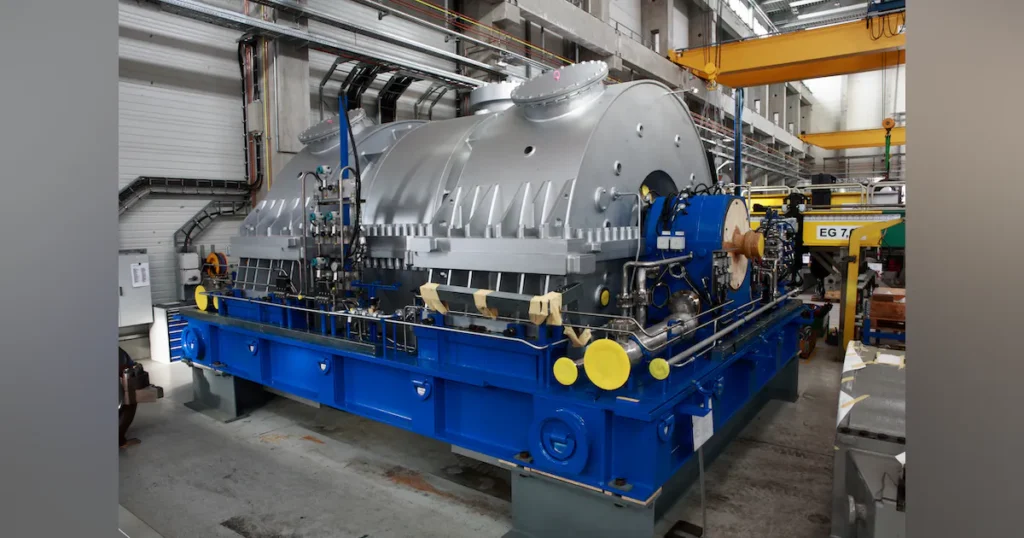

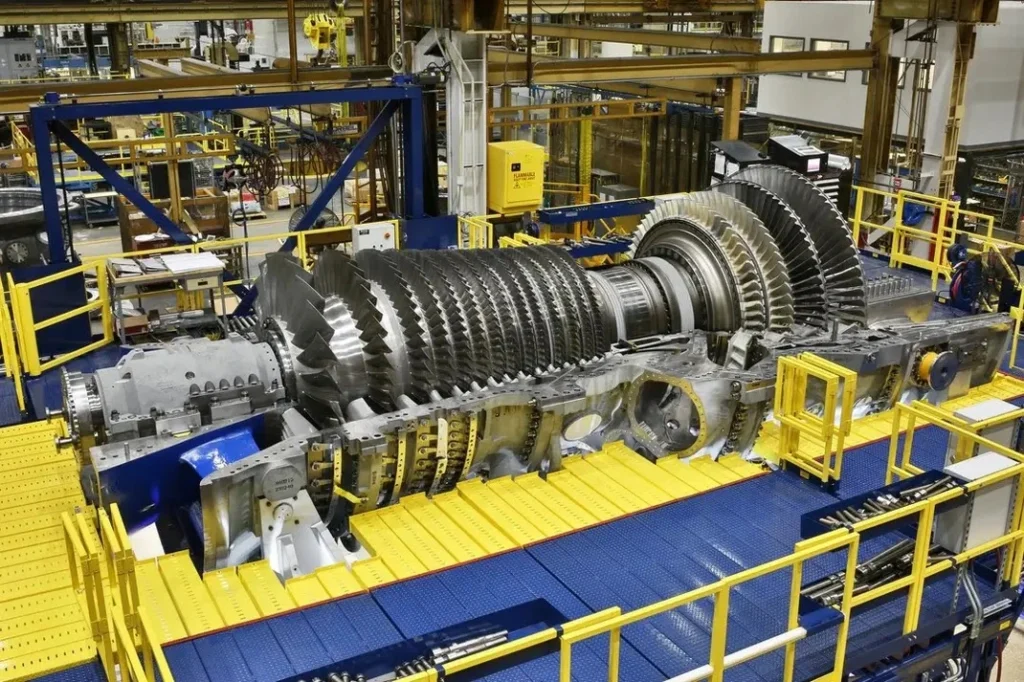

Steam turbines are complex machines consisting of various precision-engineered components, each designed to withstand extreme conditions of temperature and pressure while maintaining high efficiency. The manufacturing of steam turbine parts requires advanced techniques, specialized materials, and strict quality control to ensure reliability and durability over long operating periods.

Steam turbines are primarily used in power generation, industrial applications, and marine propulsion, and they play a critical role in converting thermal energy from steam into mechanical energy. The complexity and scale of steam turbines can vary significantly depending on their application, but the essential components include:

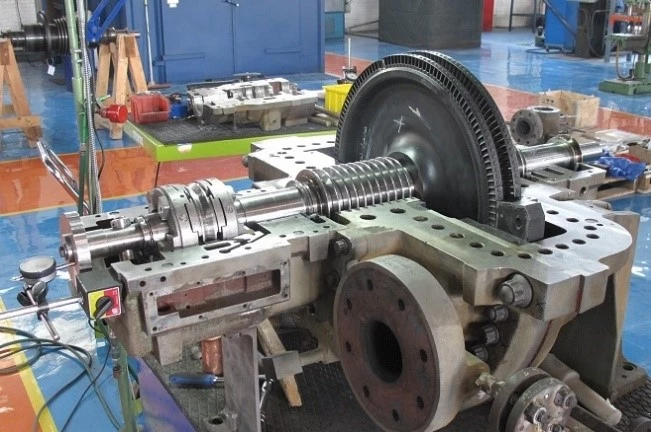

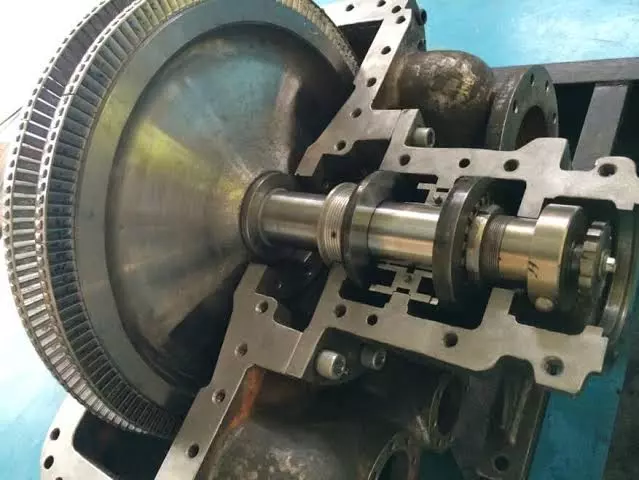

- Rotor:

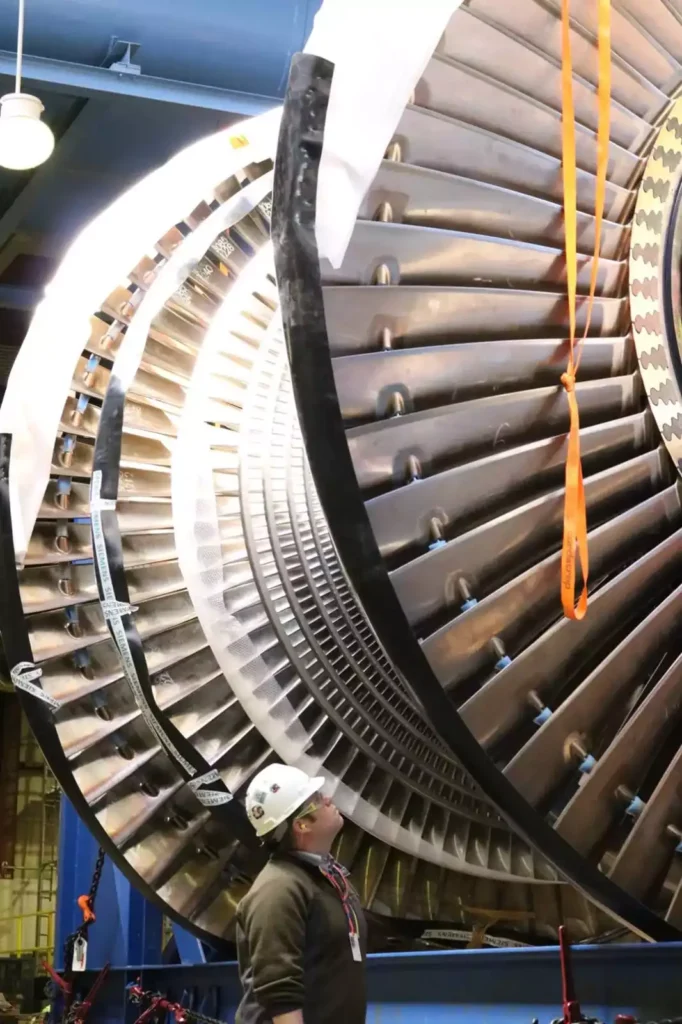

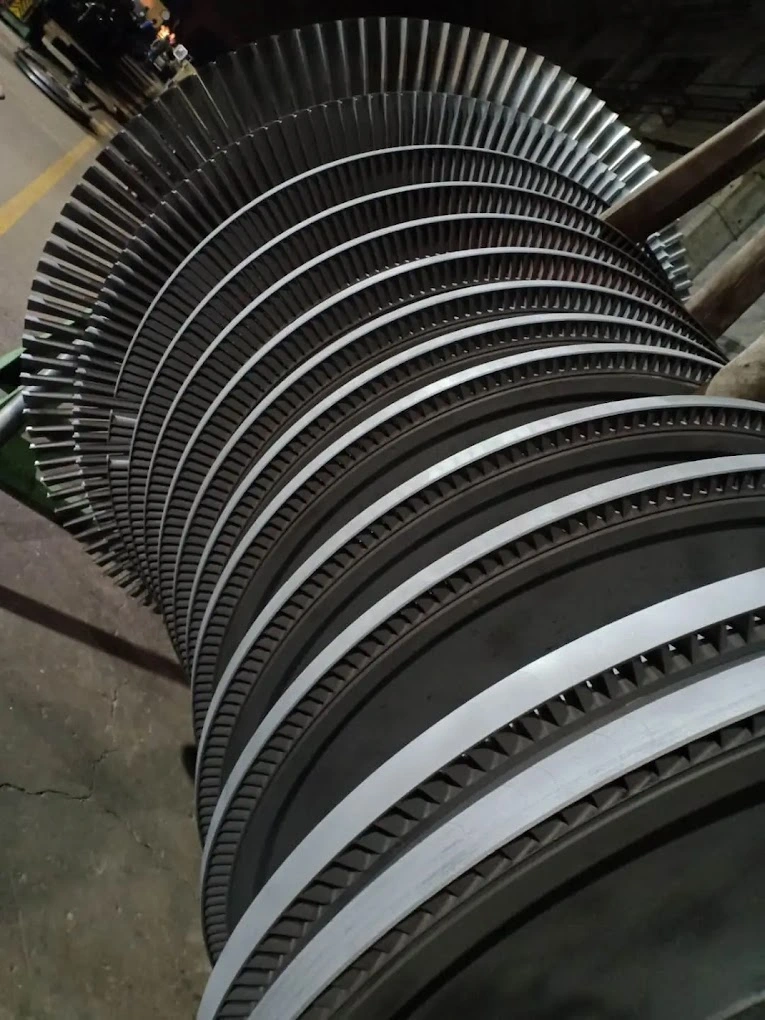

The rotor is the central rotating part of the turbine, connected to the shaft, and carries the turbine blades. It converts the thermal energy of steam into mechanical energy by spinning at high speeds. - Blades (Buckets):

Turbine blades are attached to the rotor and come in different shapes and sizes depending on the turbine stage. They are the critical components that directly interact with the steam, causing the rotor to rotate. The design and material of the blades are crucial for efficiency and durability, as they are exposed to high-temperature steam and must resist erosion, corrosion, and fatigue. - Casing (Shell):

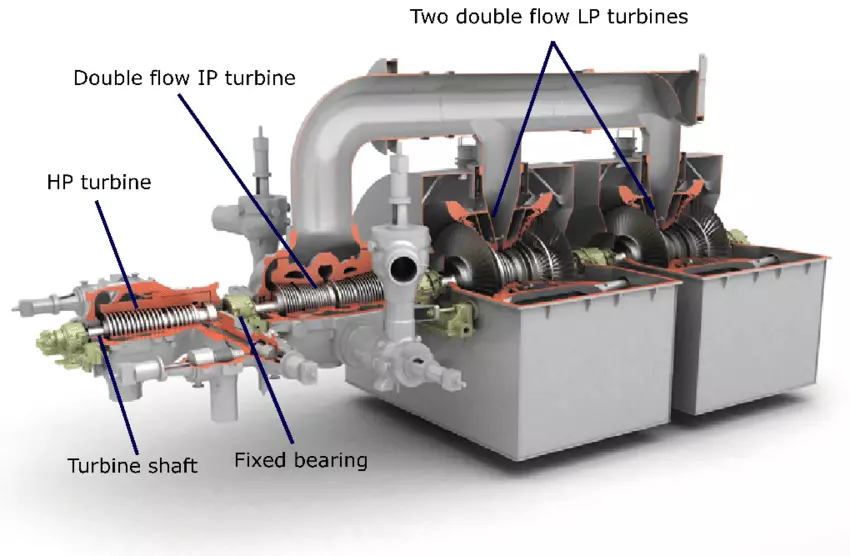

The casing encloses the turbine, ensuring steam flows efficiently through the stages. It also serves to maintain pressure within the turbine and protect the internal components. Turbine casings are typically made from high-strength materials like steel or special alloys capable of withstanding high pressures and temperatures. - Shaft:

The shaft connects the rotor to the generator or other mechanical systems. It transfers the mechanical energy generated by the spinning rotor to the generator, which converts it into electricity. Shafts are subjected to significant forces and must be made from durable materials that can handle stress and rotational speeds. - Bearings:

Bearings support the rotating shaft and ensure smooth operation with minimal friction. They are critical for maintaining the turbine’s alignment and preventing damage to the rotor and other components. Bearings must be lubricated continuously to prevent overheating and wear. - Nozzles and Diaphragms:

Nozzles direct the steam flow onto the blades, while diaphragms are stationary elements that separate the stages of the turbine. These components help control the velocity and pressure of the steam as it moves through the turbine. - Seals:

Seals are used to prevent steam from leaking out of the turbine casing and to maintain the correct pressure within the system. High-quality sealing materials are essential to avoid efficiency losses and maintain operational safety.

Materials Used in Steam Turbine Parts

Steam turbine components are subjected to extreme conditions, including high temperatures, high pressures, and corrosive environments. The choice of materials for each component is critical to ensuring the turbine’s performance and longevity. Materials must be strong, durable, and resistant to thermal stress, corrosion, and wear.

- High-Temperature Alloys:

Most of the components in a steam turbine, especially the rotor, blades, and casing, are made from high-temperature alloys such as stainless steel, Inconel, or titanium alloys. These materials are chosen for their ability to maintain structural integrity and resist deformation at high temperatures.- Stainless Steel: Commonly used for turbine casings and blades, stainless steel offers excellent corrosion resistance and strength at high temperatures. It is also relatively easy to manufacture and weld, making it a versatile choice for various turbine components.

- Inconel: A nickel-based superalloy, Inconel is often used in the hottest sections of the turbine, particularly for blades. It has excellent high-temperature strength, oxidation resistance, and resistance to thermal fatigue.

- Titanium Alloys: Titanium is favored in aerospace and some specialized industrial turbines due to its high strength-to-weight ratio and resistance to corrosion. Titanium alloys are commonly used in the blades of smaller, high-performance turbines.

- Ceramic Materials:

Advanced ceramics are sometimes used in steam turbine components for their ability to withstand extremely high temperatures without deforming. These materials are often used in nozzles and other parts that must endure high heat without compromising structural integrity. - Carbon Steels and Cast Irons:

Lower-cost steam turbines, particularly in less demanding applications, often use carbon steels or cast irons for certain parts, such as the casing or shaft. These materials offer good strength and machinability, although they may not provide the same level of high-temperature resistance as advanced alloys. - Specialized Coatings:

To enhance the durability of turbine blades and other critical components, specialized coatings such as thermal barrier coatings (TBCs) are applied. These coatings protect the base materials from corrosion, erosion, and high-temperature oxidation, extending the life of the components.

Manufacturing Techniques

The precision and reliability required in steam turbine manufacturing call for advanced manufacturing techniques. The process involves various steps such as casting, forging, machining, welding, and quality control to ensure that each component meets strict specifications.

- Casting:

Large turbine components, such as casings and some rotors, are typically cast from high-strength alloys. The casting process involves pouring molten metal into a mold, allowing it to solidify into the desired shape. Casting is ideal for producing complex geometries and large components, but it requires careful control to avoid defects such as porosity or inclusions, which can weaken the material. - Forging:

Forging is used for components that require high strength and durability, such as shafts and blades. In forging, a metal billet is heated and then shaped under pressure, which improves the material’s strength and resistance to fatigue. Forged components are generally stronger than cast components due to the refined grain structure resulting from the forging process. - Machining:

After casting or forging, components are machined to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machining allows for high precision and repeatability, which is essential for parts like turbine blades and shafts that must fit together with tight tolerances. - Welding:

Welding is used to join different components, such as attaching blades to the rotor. Turbine parts often require high-quality, specialized welding techniques such as TIG (Tungsten Inert Gas) or electron beam welding to ensure strong, defect-free joints that can withstand high temperatures and stresses. - Heat Treatment:

After machining or forging, many components undergo heat treatment processes such as annealing, quenching, or tempering. These processes alter the material’s microstructure to enhance its mechanical properties, such as toughness, hardness, and resistance to thermal fatigue. - Surface Treatment and Coating:

To improve durability, especially for blades and nozzles that experience high temperatures and erosive steam flows, surface treatments such as nitriding or shot peening are often used. These processes harden the surface and improve resistance to wear and erosion. Additionally, thermal barrier coatings may be applied to protect against high temperatures and oxidation. - 3D Printing and Additive Manufacturing:

An emerging trend in steam turbine manufacturing is the use of additive manufacturing (3D printing) for certain components. Additive manufacturing allows for the creation of highly complex geometries that would be difficult or impossible to achieve with traditional methods. It is particularly useful for rapid prototyping and for producing small, intricate parts like nozzles and seals.

Precision Engineering and Quality Control

Quality control is an essential aspect of steam turbine parts manufacturing, given the critical nature of the components and the extreme conditions they must endure. Every part must meet stringent specifications to ensure the turbine operates safely and efficiently.

- Non-Destructive Testing (NDT):

Before and after assembly, components undergo rigorous non-destructive testing to detect any defects that might compromise their performance. Techniques such as ultrasonic testing, radiographic testing (X-rays), and dye penetrant inspection are used to identify internal or surface defects like cracks, voids, or inclusions. - Dimensional Inspection:

Precision measuring tools, including coordinate measuring machines (CMMs) and laser scanners, are used to ensure that components meet the exact dimensions required for turbine assembly. Tight tolerances are critical, particularly for components like blades and shafts, which must fit together precisely to maintain turbine efficiency. - Material Testing:

In addition to dimensional checks, material properties are also tested to ensure components can withstand the operational stresses they will encounter. Tests such as hardness testing, tensile strength testing, and fatigue testing help verify that the materials used in manufacturing meet the necessary performance criteria. - Performance Testing:

In some cases, turbine components or assemblies may undergo performance testing in simulated operational conditions. This testing ensures that components will function as expected in the high-temperature, high-pressure environment of a steam turbine. Rotors, for example, may be spun at operational speeds to check for balance and integrity.

Challenges in Steam Turbine Part Production

Manufacturing steam turbine parts comes with several challenges due to the high precision required and the demanding operational environments in which the turbines operate.

- Material Availability and Cost:

The advanced materials used in turbine manufacturing, such as superalloys and ceramics, can be expensive and difficult to source in large quantities. These materials are often critical for performance, but their cost and availability can add significant challenges to the manufacturing process. - High Precision Requirements:

Steam turbines require extremely tight tolerances, especially in components like blades and rotors. Any slight deviation from design specifications can lead to inefficiencies, vibrations, or even catastrophic failure during operation. Achieving and maintaining this level of precision requires advanced machinery, skilled labor, and rigorous quality control. - Complexity in Design and Manufacturing:

Steam turbines are highly complex machines with numerous interdependent parts. Manufacturing these parts requires careful planning and coordination to ensure that all components fit together properly. Additionally, the design of steam turbine components often involves advanced computational modeling and simulation to optimize performance and efficiency. - Manufacturing Lead Time:

The production of steam turbine parts, especially custom-designed components, can be time-consuming. The casting and forging processes alone may take several weeks, and additional machining, heat treatment, and testing can add to the production timeline. This extended lead time must be accounted for in project planning and scheduling.

Leading Manufacturers and Innovations

Several companies are at the forefront of steam turbine parts manufacturing, developing innovative solutions to improve the performance, durability, and efficiency of steam turbines. Some of the leading players include:

- General Electric (GE):

GE is a global leader in the production of steam turbines and related components, known for its advanced materials and precision manufacturing processes. GE continues to invest in research and development to improve the efficiency and longevity of its turbines. - Siemens Energy:

Siemens is another key player in the steam turbine market, offering both manufacturing expertise and innovative technologies. Siemens has been a pioneer in using advanced materials and additive manufacturing techniques to enhance turbine performance. - Mitsubishi Heavy Industries (MHI):

MHI is known for producing highly efficient steam turbines for power generation. The company is also exploring new materials and manufacturing processes to improve the performance and sustainability of its turbines. - Doosan Heavy Industries:

Doosan is a major manufacturer of steam turbines, with a focus on large-scale turbines for power plants. The company has made significant advances in high-temperature alloys and coating technologies, helping to extend the life of turbine components.

Supply Chain and Logistics Considerations

The manufacturing of steam turbine components involves a complex supply chain, as the production of these parts often relies on raw materials and specialized machinery from multiple suppliers. Managing this supply chain effectively is critical to ensuring timely delivery and maintaining the quality of the final product.

- Raw Material Procurement:

Sourcing high-quality materials such as superalloys, ceramics, and stainless steel can be challenging due to their specialized nature. Manufacturers must work closely with material suppliers to ensure that they receive materials that meet their specifications and production timelines. - Logistics Management:

The large size and complexity of many steam turbine components can make transportation and logistics challenging. Specialized equipment and careful handling are required to move parts from the manufacturing facility to the assembly site. In some cases, components may need to be manufactured on-site to avoid transportation issues. - Lead Time Coordination:

Due to the long lead times required for manufacturing and testing steam turbine components, careful project management is essential to ensure that all parts are ready for assembly when needed. Any delays in the supply chain can have a ripple effect, potentially delaying the commissioning of the entire turbine system.

Trends in the Steam Turbine Manufacturing Industry

Several trends are shaping the future of steam turbine parts manufacturing, as companies strive to improve efficiency, reduce costs, and address environmental concerns.

- Additive Manufacturing (3D Printing):

The use of 3D printing is growing in the turbine industry, allowing manufacturers to produce complex components with less material waste and shorter lead times. This technology also enables rapid prototyping and the production of custom parts for specific turbine designs. - Advanced Materials Research:

Research into new materials, such as high-temperature superalloys and ceramic matrix composites (CMCs), is ongoing. These materials offer improved performance and durability, enabling turbines to operate at higher temperatures and pressures with greater efficiency. - Digitalization and Industry 4.0:

The integration of digital technologies, such as IoT sensors and AI-driven analytics, is transforming the way turbines are manufactured and maintained. These technologies allow for real-time monitoring of production processes and predictive maintenance, reducing downtime and improving overall efficiency. - Sustainability and Green Manufacturing:

As the world transitions toward more sustainable energy sources, steam turbine manufacturers are focusing on reducing the environmental impact of their production processes. This includes optimizing energy use in manufacturing, reducing material waste, and developing more efficient, lower-emission turbines for power generation.

Conclusion

Steam turbine parts manufacturing is a highly specialized field that requires precision engineering, advanced materials, and rigorous quality control to meet the demanding operational requirements of these critical machines. As the energy landscape evolves and new technologies emerge, manufacturers are constantly innovating to improve the efficiency, reliability, and sustainability of steam turbines. By adopting new materials, manufacturing techniques, and digital technologies, the steam turbine industry continues to push the boundaries of what is possible in power generation and industrial applications.

Steam Turbine Power Output

Steam turbines play a crucial role in power generation, being one of the most widely used machines for converting thermal energy from steam into mechanical energy, which is then transformed into electrical energy. The power output of a steam turbine refers to the amount of mechanical or electrical energy produced by the turbine, typically measured in megawatts (MW) or kilowatts (kW). The power output depends on various factors such as the turbine’s size, design, efficiency, and the thermodynamic properties of the steam used.

Steam turbines are integral to industries like power generation (coal, nuclear, solar thermal, and biomass plants), industrial processes, and even ship propulsion. The power output is often the primary performance metric used to assess a turbine’s efficiency and effectiveness in converting thermal energy into usable mechanical work.

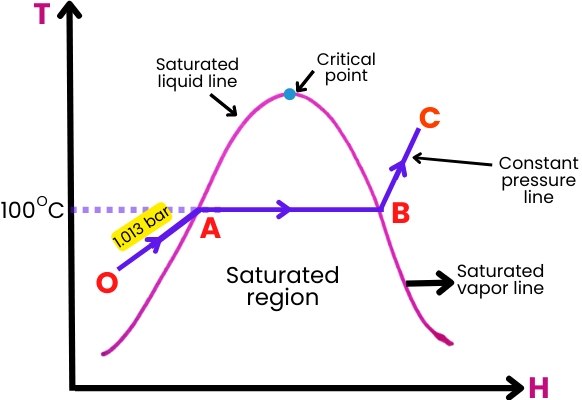

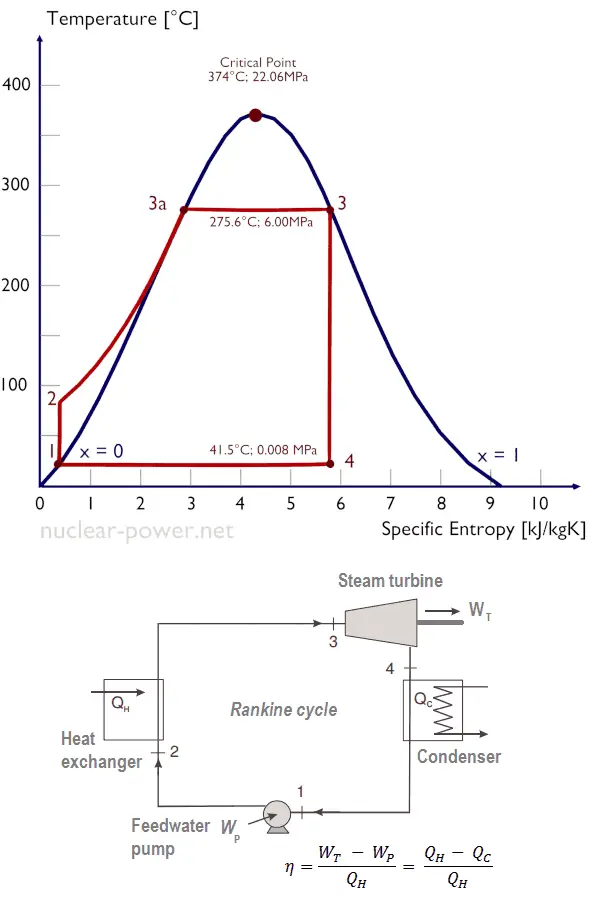

How Steam Turbines Generate Power

At the heart of a steam turbine’s ability to generate power is the Rankine cycle, a thermodynamic cycle used to convert heat energy from steam into mechanical energy. The steam turbine harnesses the energy stored in pressurized steam and converts it into rotational motion, which can then drive an electrical generator.

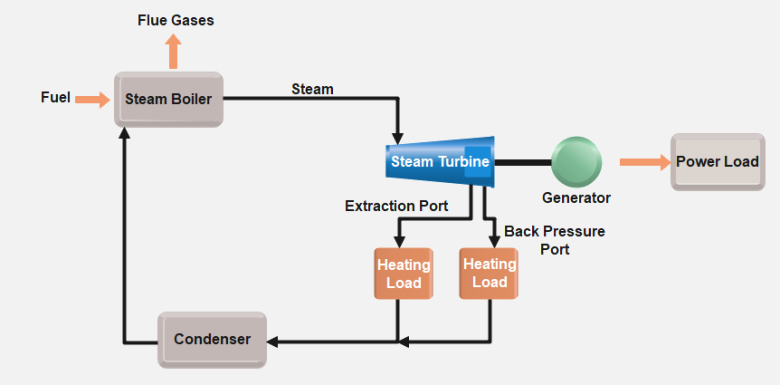

- Steam Generation (Boiler Stage):

The process begins in a boiler, where water is heated to generate high-pressure, high-temperature steam. The energy to produce this steam can come from various sources, such as burning fossil fuels, nuclear reactions, solar energy, or biomass. - Expansion in Turbine:

The high-pressure steam is introduced into the turbine at high velocity. As it expands through the turbine stages, it loses pressure and temperature, transferring its thermal energy to the turbine blades. These blades are connected to the rotor, which begins to spin due to the force exerted by the steam. - Conversion of Mechanical Energy:

The rotating motion of the rotor is transferred to a generator. Inside the generator, electromagnetic induction is used to convert the mechanical energy of the spinning rotor into electrical energy, which can be distributed through the power grid. - Condensation:

After the steam has passed through the turbine, it enters a condenser where it is cooled and condensed back into water. This water is then returned to the boiler to be reheated, continuing the cycle.

Factors Affecting Steam Turbine Power Output

The power output of a steam turbine is determined by several key factors, each of which influences how efficiently the turbine can convert steam’s thermal energy into mechanical work.

- Steam Pressure and Temperature:

The power output of a steam turbine increases with higher inlet steam pressures and temperatures. High-pressure steam has more energy and can do more work as it expands through the turbine. Superheated steam, which is steam at a temperature above its boiling point, is often used to maximize energy extraction. In contrast, lower pressure and saturated steam reduce the turbine’s overall efficiency.- High-pressure turbines typically operate with steam pressures as high as 2400 psi (pounds per square inch) and temperatures around 565°C (1050°F).

- Low-pressure turbines handle the lower-pressure steam at the later stages of expansion, often operating under vacuum conditions to maximize efficiency.

- Steam Flow Rate:

The amount of steam flowing through the turbine (measured in mass flow rate, typically kg/s or lbs/s) directly affects its power output. The more steam that flows through the turbine, the more energy can be extracted. However, there is a limit, as excessive steam flow can result in diminishing returns due to inefficiencies like increased friction and heat loss. - Turbine Efficiency:

Turbine efficiency, often expressed as isentropic efficiency, is a measure of how well the turbine converts the energy in the steam into mechanical work. In real-world turbines, inefficiencies arise due to friction, leakage, and losses in the system. A higher efficiency leads to higher power output.- Typical industrial steam turbines have isentropic efficiencies between 80-90%. Improving the turbine’s design and reducing mechanical losses can increase efficiency.

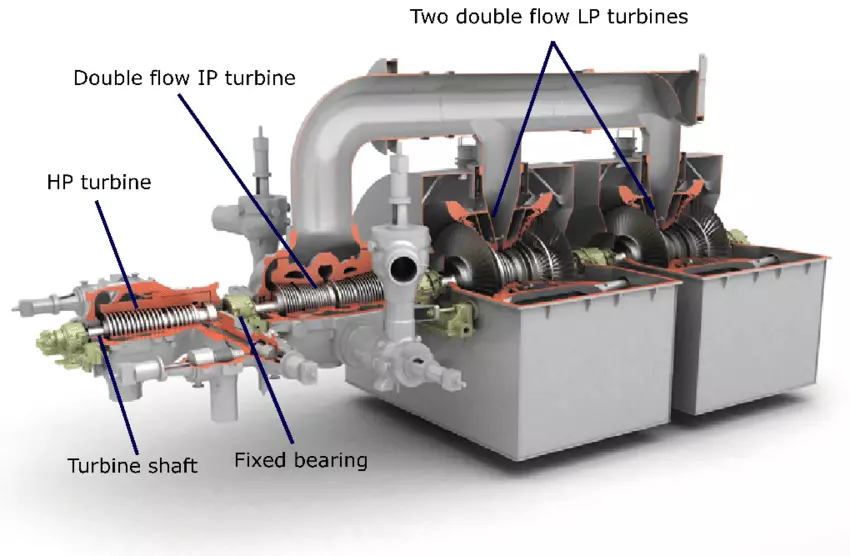

- Number of Turbine Stages:

Steam turbines are often divided into multiple stages, including high-pressure (HP), intermediate-pressure (IP), and low-pressure (LP) stages. The number of stages and the design of each stage can significantly affect power output.- Single-stage turbines are generally used for smaller applications with lower power requirements, while multi-stage turbines are used in larger power plants to handle higher loads and generate more power.

- Back Pressure:

The pressure at which steam exits the turbine, known as back pressure, also affects the power output. Ideally, the steam should exit the turbine at the lowest possible pressure to maximize energy extraction. In condensing turbines, steam exits at a near-vacuum pressure, maximizing efficiency. In contrast, back-pressure turbines release steam at higher pressures, which may be useful for industrial processes but reduces the overall power output. - Reheat Cycles:

In some steam turbines, the steam is reheated after partially expanding in the turbine, and then passed through another turbine stage. Reheating helps increase the average temperature of the steam over the expansion process, which improves efficiency and increases power output. Reheat turbines are common in large power plants where efficiency gains are essential.

Types of Steam Turbines Based on Power Output

Steam turbines are classified into several categories based on their power output and application:

- Micro Steam Turbines (Under 500 kW):

These small turbines are often used for localized power generation, especially in industrial applications or small-scale combined heat and power (CHP) systems. Micro turbines are designed for efficiency in low-demand environments, such as manufacturing plants or residential use. - Small Steam Turbines (500 kW to 10 MW):

Used in industries like chemical processing, sugar mills, and small power generation facilities, these turbines provide a middle ground between micro and utility-scale turbines. Small turbines are commonly used in cogeneration systems, where waste heat from industrial processes is used to generate electricity. - Medium-Sized Turbines (10 MW to 100 MW):

Medium-sized steam turbines are typically used in large industrial plants and medium-sized power plants. They are often part of combined-cycle power plants (CCPP), where a gas turbine and steam turbine work together to increase overall plant efficiency. - Large Steam Turbines (Over 100 MW):

Large steam turbines are used in utility-scale power plants, including coal, nuclear, and large renewable energy facilities. These turbines can generate hundreds of megawatts of power and often feature advanced technologies like reheat stages, high-efficiency blade designs, and high-temperature superheated steam.

Maximizing Steam Turbine Power Output

Achieving maximum power output from a steam turbine requires optimizing several factors, including steam conditions, turbine design, and operational practices. Below are strategies used to enhance turbine output:

- Superheating and Reheating Steam:

The addition of superheaters and reheaters in the boiler section can significantly increase the turbine’s power output. Superheated steam allows for higher energy transfer to the turbine blades, while reheating the steam between turbine stages prevents condensation, allowing for higher efficiency. - Improving Turbine Blade Design:

The efficiency of steam turbines can be improved through aerodynamic optimization of the blades. Modern turbines use 3D-shaped blades and computer-aided design (CAD) to reduce flow separation and turbulence, allowing for better energy transfer from the steam to the rotor. - Combined-Cycle Power Plants (CCPP):

Combined-cycle power plants use both gas and steam turbines to maximize power output. Waste heat from the gas turbine is used to generate steam, which drives the steam turbine. This increases the overall thermal efficiency of the power plant, with modern combined-cycle plants achieving efficiencies as high as 60%. - Variable Speed Turbines:

Traditional steam turbines operate at a fixed speed, but variable speed turbines can adjust to changes in load demand more effectively. This allows the turbine to operate closer to its optimal efficiency range, thereby improving power output under varying conditions. - Regular Maintenance and Condition Monitoring:

Regular maintenance and condition monitoring of the turbine, especially the lubrication system, seals, and bearings, are critical for maintaining high efficiency. Turbines that are kept in optimal condition will experience fewer losses due to mechanical wear and tear, leading to more consistent power output. - Use of High-Efficiency Condensers:

The condenser, which cools and condenses the exhaust steam back into water, plays a significant role in the turbine’s power output. High-efficiency condensers with improved heat transfer capabilities can lower the back pressure, allowing the turbine to extract more energy from the steam. - Optimizing Steam Flow Control:

Steam flow control devices, such as steam throttling valves and governors, are essential for regulating the flow of steam into the turbine based on load demands. Proper control can prevent excess steam loss and improve the turbine’s ability to maintain maximum power output.

Challenges in Increasing Power Output

Increasing the power output of steam turbines comes with its own set of challenges. Some of the primary challenges include:

- Thermal Limitations:

Increasing the temperature and pressure of steam is a common way to boost power output, but this approach is limited by the thermal capabilities of the turbine’s materials. High temperatures can cause creep, thermal fatigue, and stress corrosion in turbine components, limiting how much the steam can be superheated. - Efficiency Trade-offs:

While higher steam flow rates can increase power output, this can also lead to efficiency losses due to increased friction and mechanical stress on the turbine. Finding the balance between high output and efficiency is a constant challenge in turbine operation. - Condensation and Moisture Issues:

As steam expands and cools in the later stages of the turbine, it begins to condense into water droplets. This can cause erosion of the turbine blades, reducing efficiency and power output over time. Ensuring that steam remains superheated as long as possible before condensation occurs is crucial to maintaining high power output. - Mechanical Wear and Tear:

Steam turbines operate at high rotational speeds, subjecting the blades, bearings, and seals to significant wear and tear. Even small amounts of friction or misalignment can reduce the power output, necessitating regular maintenance to ensure that all components remain in optimal condition. - Environmental and Regulatory Challenges:

In many regions, steam turbines powered by fossil fuels face increasing scrutiny due to environmental regulations aimed at reducing greenhouse gas emissions. Improving turbine efficiency and transitioning to more sustainable energy sources are becoming essential to maintaining high power outputs while complying with environmental standards.

Future Trends in Steam Turbine Power Output

As the energy landscape continues to evolve, steam turbine technology is advancing to meet the growing demand for efficient, reliable, and sustainable power generation. Several trends are likely to shape the future of steam turbine power output:

- Advanced Materials:

Research into new materials such as ceramic matrix composites (CMCs) and superalloys will allow turbines to operate at higher temperatures and pressures, boosting efficiency and power output without compromising the durability of the turbine components. - Integration with Renewable Energy Sources:

As renewable energy sources like solar thermal and biomass become more prominent, steam turbines will increasingly be used in conjunction with these technologies. Innovations in solar power plants, for example, use steam turbines to convert solar energy into electricity through concentrated solar power (CSP) systems. - Energy Storage and Hybrid Systems:

The integration of energy storage systems with steam turbines allows for more flexible power generation. Hybrid systems that combine steam turbines with renewable energy storage technologies can maintain consistent power output even when renewable sources like wind or solar are intermittent. - Artificial Intelligence and Machine Learning:

AI and machine learning are being used to optimize turbine performance by analyzing vast amounts of operational data. Predictive maintenance, performance optimization algorithms, and real-time monitoring will enable operators to maximize power output while minimizing downtime and inefficiencies. - Supercritical and Ultra-Supercritical Steam Conditions:

Future steam turbines are expected to operate under supercritical and ultra-supercritical steam conditions, where the steam is heated and pressurized beyond traditional limits. These advanced turbines offer significantly higher thermal efficiency, leading to increased power output while using less fuel.

Conclusion

Steam turbines are among the most important machines in power generation, and their power output plays a key role in determining their effectiveness in converting thermal energy into mechanical and electrical energy. Numerous factors, including steam pressure, temperature, flow rate, and turbine efficiency, affect the power output of a steam turbine. With advancements in materials, turbine design, and operational technologies, steam turbines continue to evolve, becoming more efficient and capable of generating higher power outputs.

As the demand for cleaner and more efficient energy grows, innovations like supercritical steam, hybrid systems, and AI-driven performance optimization are shaping the future of steam turbine technology. Whether in traditional fossil fuel plants, nuclear reactors, or renewable energy systems, steam turbines will remain a cornerstone of the global energy infrastructure, continually improving to meet the challenges of the 21st century.

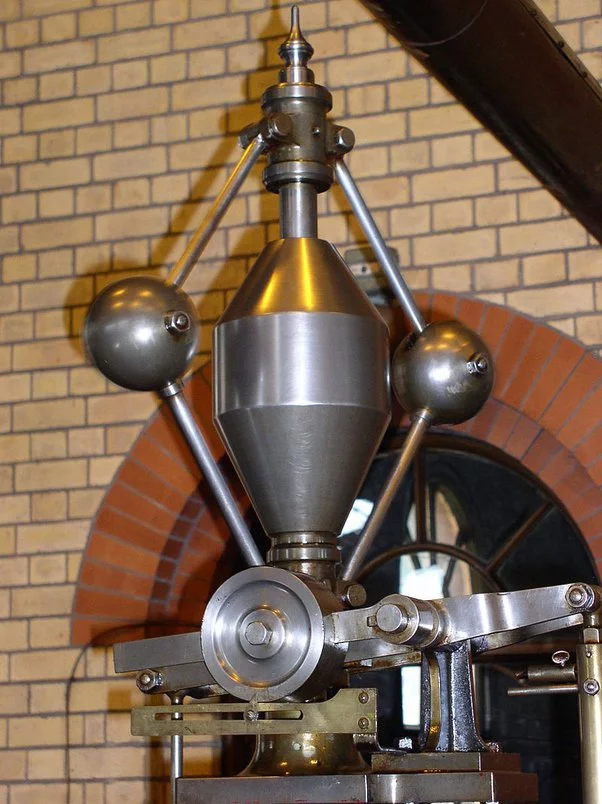

Steam Governor of Steam Engine

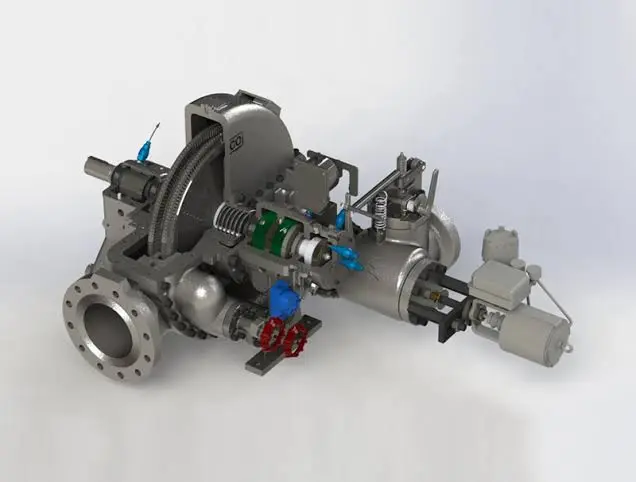

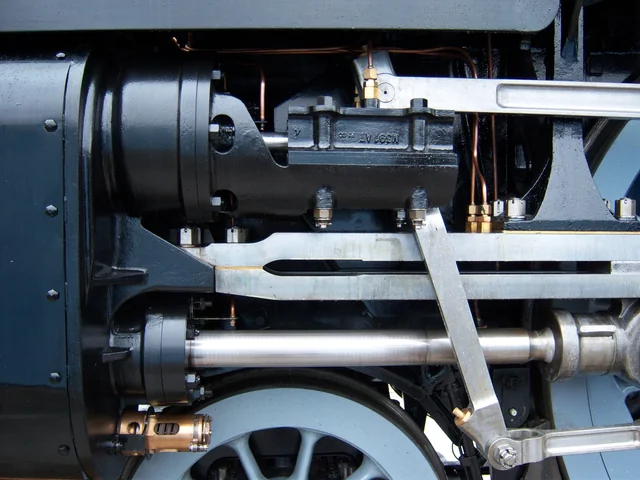

The steam governor is a critical component of a steam engine, responsible for controlling the speed of the engine by regulating the supply of steam to the turbine or piston chambers. In essence, it acts as an automatic throttle that adjusts the amount of steam entering the engine to maintain a constant speed, even under varying load conditions. Steam governors are especially vital in applications where speed stability is important, such as in power plants, locomotives, and industrial machinery.

The concept of a governor in steam engines dates back to the early 19th century, when it was first applied by James Watt to improve the efficiency of steam engines. By regulating the speed and power output automatically, the steam governor allows for more precise control over the engine’s performance, which is essential for both safety and efficiency.

Purpose and Function of a Steam Governor

Steam engines operate under varying loads, and without a speed-regulating mechanism, the engine’s speed would fluctuate as the load changes. For instance, if a steam engine driving a generator suddenly experiences a reduction in load (such as when electrical demand decreases), the engine would speed up unless the steam input is adjusted. Conversely, if the load increases, the engine might slow down without adequate steam supply. The steam governor ensures that these speed fluctuations are minimized by adjusting the flow of steam automatically.

The primary functions of a steam governor include:

- Maintaining Constant Speed:

The governor helps maintain a constant speed, which is especially critical in power generation where the turbine must rotate at a specific speed to generate electricity at a stable frequency. For example, in a 50 Hz power system, the turbine must rotate at 3000 RPM (Revolutions Per Minute) for synchronization. - Load Regulation:

As the load on the steam engine changes, the governor adjusts the steam supply to compensate. This allows the engine to operate efficiently under varying conditions without manual intervention. - Preventing Overspeed:

One of the critical safety functions of the governor is to prevent the engine from running at dangerously high speeds (overspeed), which can cause mechanical damage or failure. If the engine begins to speed up excessively, the governor reduces the steam flow to slow it down. - Fuel Efficiency:

By regulating the amount of steam entering the engine, the governor helps optimize fuel consumption. This is particularly important in power plants, where maximizing efficiency reduces fuel costs and emissions.

Types of Steam Governors

Several types of steam governors are used in steam engines, each with its own operating principles and applications. The choice of governor depends on factors such as the type of engine, the load characteristics, and the desired level of control.

- Centrifugal Governors:

The centrifugal governor is one of the earliest and most commonly used types in steam engines. It operates based on the principles of centrifugal force. A pair of rotating balls, connected to the engine shaft, move outward as the engine speeds up due to centrifugal force. These balls are connected to a mechanism that controls a throttle valve. As the balls move outward, they cause the valve to reduce the steam flow, thereby slowing the engine down. When the engine slows, the balls move inward, opening the valve to increase steam flow.- Working Mechanism:

The centrifugal governor works by detecting changes in the speed of the engine. As the engine accelerates, the balls move outward due to the increased centrifugal force, lifting a lever that closes the throttle valve, reducing steam flow and slowing the engine. When the engine slows, the opposite happens: the balls drop, opening the throttle and increasing the steam flow. - Advantages:

- Simple mechanical design

- Reliable and durable

- Requires little maintenance

- Disadvantages:

- Response time can be slow, particularly in large engines

- Can be less precise compared to modern electronic governors

- Working Mechanism:

- Throttle Governors:

Throttle governors are designed to regulate the flow of steam by controlling a throttle valve. This type of governor monitors the engine’s speed and adjusts the position of the valve to ensure that the right amount of steam is supplied to the engine. Throttle governors are typically used in smaller steam engines where precise control over steam pressure and speed is required.- Advantages:

- Simple and effective in low-pressure systems

- Suitable for smaller engines and locomotives

- Disadvantages:

- Not ideal for high-pressure, high-speed engines

- Limited range of speed control

- Advantages:

- Inlet Valve Governors (Cut-Off Governors):

Inlet valve governors, also known as cut-off governors, regulate the timing of steam admission to the engine by controlling the valve that determines when steam is allowed to enter the cylinders. By varying the cut-off point during the piston’s stroke, these governors can control the engine’s speed and power output. This is particularly useful in engines that need to maintain a constant speed under varying loads, such as steam turbines in power plants.- Working Mechanism:

In this system, the governor adjusts the timing of the inlet valve, closing it earlier in the piston stroke if less power is needed. This results in a more efficient use of steam, as the expansion of steam inside the cylinder provides the necessary force with less energy. - Advantages:

- Improves efficiency by optimizing steam usage

- Ideal for engines that experience variable loads

- Disadvantages:

- More complex than centrifugal and throttle governors

- Requires precise calibration for effective operation

- Working Mechanism:

- Hydraulic and Pneumatic Governors:

Modern steam turbines often use hydraulic or pneumatic governors, which offer more precise control compared to purely mechanical governors. These systems use hydraulic fluid or compressed air to control the steam supply valve. They can respond more quickly to changes in load and provide finer adjustments to the steam flow, making them suitable for large industrial steam turbines.- Advantages:

- Fast response time

- Precise control of steam flow

- Ideal for large turbines and modern applications

- Disadvantages:

- More complex and expensive than mechanical governors

- Requires regular maintenance and calibration

- Advantages:

- Electronic Governors:

The most advanced type of governor used in modern steam turbines is the electronic governor. These systems use sensors to monitor engine speed and other parameters in real-time, and a microcontroller adjusts the steam valve accordingly. Electronic governors offer extremely precise control, making them ideal for applications where speed stability is critical, such as in power generation and industrial processes.- Advantages:

- Extremely accurate and responsive

- Can be integrated with other control systems for automated operations

- Ideal for modern steam turbines and power plants

- Disadvantages:

- Expensive to install and maintain

- Complex system that requires specialized knowledge to operate and service

- Advantages:

Working Mechanism of a Steam Governor

The fundamental working principle of a steam governor is based on feedback control. The governor continuously monitors the engine’s speed and adjusts the steam supply to maintain a desired speed. This feedback loop ensures that any deviation from the set speed is corrected by increasing or decreasing the steam flow.

Here’s a step-by-step breakdown of how a typical centrifugal steam governor works:

- Engine Starts at Load:

When the engine is started, steam is admitted to the cylinders or turbine blades, causing the engine to accelerate. The governor is calibrated to maintain a specific speed based on the load demand. - Centrifugal Force Increases:

As the engine reaches its operational speed, the rotating governor balls experience centrifugal force. If the engine speed increases beyond the set point, the balls move outward. - Throttle Valve Adjusts:

The outward movement of the balls is connected to a lever mechanism that begins to close the steam throttle valve. As the throttle closes, less steam enters the engine, causing the engine to slow down. - Speed Stabilizes:

Once the engine’s speed stabilizes at the desired level, the governor balls return to a balanced position where the throttle valve remains partially open, allowing just enough steam to maintain the engine’s speed. - Speed Decreases (Load Increases):

If the engine’s load increases, causing it to slow down, the governor balls move inward due to reduced centrifugal force. This movement opens the throttle valve wider, allowing more steam to enter the engine and increasing its speed. - Continuous Feedback Loop:

The governor continually adjusts the throttle valve in real-time, ensuring that the engine’s speed remains constant despite changes in load or operating conditions.

Importance of Governors in Steam Engines

Governors are essential for maintaining the safety, efficiency, and reliability of steam engines. They perform several critical functions:

- Safety:

Without a governor, a steam engine could run too fast (overspeed) or too slow, leading to dangerous mechanical failures. Overspeed can result in catastrophic damage to the turbine or other components, and governors help prevent this by automatically reducing the steam supply. - Efficiency:

Governors help optimize the engine’s fuel and steam usage, ensuring that the engine operates efficiently under different load conditions. By supplying only the necessary amount of steam, governors reduce fuel consumption and emissions, particularly in large power plants. - Load Matching:

In many industrial applications, the load on the engine can change frequently. The governor allows the engine to adjust to these changes automatically, maintaining performance without the need for constant manual adjustments. This is particularly important in power generation, where fluctuations in demand must be managed in real-time. - Smooth Operation:

The steam governor ensures that the engine runs smoothly, minimizing vibrations and speed fluctuations. This reduces wear and tear on the engine components, extending their lifespan and reducing maintenance costs. - Automation and Control:

Modern electronic governors allow for greater automation of steam engines, integrating with digital control systems to provide precise control over engine speed and performance. In power plants, for example, electronic governors are part of larger control systems that optimize the entire plant’s operations.

Challenges and Maintenance of Steam Governors

Like all mechanical systems, steam governors can experience wear and tear over time, leading to performance issues. The primary challenges associated with steam governors include:

- Wear and Tear on Moving Parts:

Centrifugal governors rely on mechanical parts such as levers, gears, and bearings, all of which are subject to wear. Over time, this can reduce the governor’s sensitivity and effectiveness, leading to poor speed regulation. - Calibration Issues:

Steam governors must be precisely calibrated to maintain the correct speed and load regulation. Improper calibration can result in overspeeding or inefficient operation. Regular testing and adjustment are required to keep the governor functioning properly. - Response Time:

Mechanical governors, such as centrifugal types, have slower response times compared to electronic systems. In applications where rapid load changes occur, this slower response can result in temporary speed fluctuations, which may affect the engine’s performance. - Maintenance Requirements:

Hydraulic, pneumatic, and electronic governors require regular maintenance to ensure they function correctly. This includes checking for leaks, ensuring the integrity of hydraulic systems, and inspecting electronic components for wear or malfunction. - Environmental Factors:

Exposure to harsh conditions, such as high humidity, extreme temperatures, or contamination from dirt and oil, can affect the performance of a steam governor. Protective measures and regular cleaning are necessary to maintain optimal performance.

Future Developments in Steam Governor Technology

As steam engine technology continues to evolve, so too does the technology behind steam governors. Several innovations are on the horizon:

- Smart Governors with AI Integration:

Future steam governors may integrate artificial intelligence (AI) and machine learning to provide even more precise control over engine speed and performance. These smart governors could predict changes in load demand and adjust the steam supply preemptively, further improving efficiency and response time. - Digital Twins for Monitoring and Optimization:

Digital twin technology is already being explored in the power generation industry. By creating a virtual model of the steam engine and its governor, operators can monitor performance in real-time, run simulations, and make adjustments to improve efficiency and maintenance practices. - Improved Materials and Design:

Advances in materials science will likely lead to more durable and corrosion-resistant components for governors, reducing wear and extending their operational life. Lightweight and low-friction materials may also improve response times and performance. - Integrated Control Systems:

Modern power plants are moving toward fully integrated control systems where governors are just one part of a larger, highly automated network. These systems can optimize the entire plant’s performance, adjusting not only the steam governor but also the boiler, condenser, and electrical systems in real-time.

Conclusion

The steam governor plays a vital role in regulating the speed and efficiency of steam engines. Whether in early industrial applications or modern power plants, the governor ensures that the engine operates safely and efficiently, even under varying loads. From the simple yet effective centrifugal governor to advanced electronic systems, governors have evolved to meet the demands of increasingly complex and powerful steam turbines.

Looking to the future, innovations in AI, digital controls, and material science are set to further enhance the capabilities of steam governors. These advances will allow for even greater precision, efficiency, and reliability, helping steam turbines remain a cornerstone of global power generation for years to come.

Industrial steam turbines are integral to modern energy systems, converting heat energy into mechanical work to generate electricity or drive machinery. These turbines have evolved over a century of development, from early designs that powered factories and ships to highly advanced systems that drive today’s power plants and industrial processes.

Early steam turbines laid the groundwork for the rapid industrialization of the 20th century. Today, steam turbines are widely used in power generation, petrochemicals, pulp and paper, and even food processing industries. This document explores their operation, types, applications, and future developments, reflecting their continuing role in global industrial energy systems.

Basic Principles of Steam Turbines

At their core, steam turbines operate by harnessing the thermal energy in steam to perform mechanical work. The process begins by superheating water in a boiler, which transforms into steam. This high-pressure steam is directed through a series of turbine blades, causing the rotor to spin, converting thermal energy into mechanical energy.

Key topics:

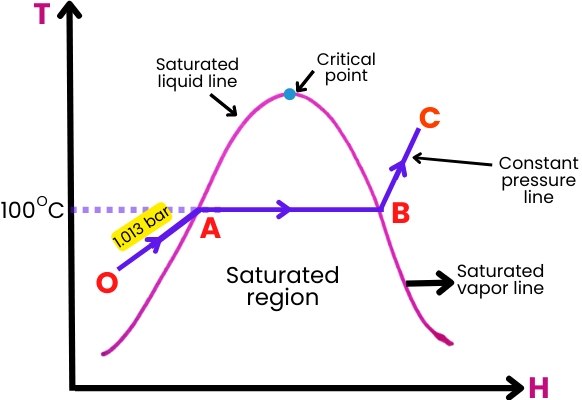

- Thermodynamics: Discuss the Rankine cycle, which is the basic thermodynamic cycle governing steam turbine operations.

- Mechanical to Electrical Energy: How generators convert mechanical rotation into electricity.

- Saturated vs. Superheated Steam: How different steam states affect efficiency and output.

Types of Industrial Steam Turbines

Industrial steam turbines come in various types based on application and design. This section will outline the main categories:

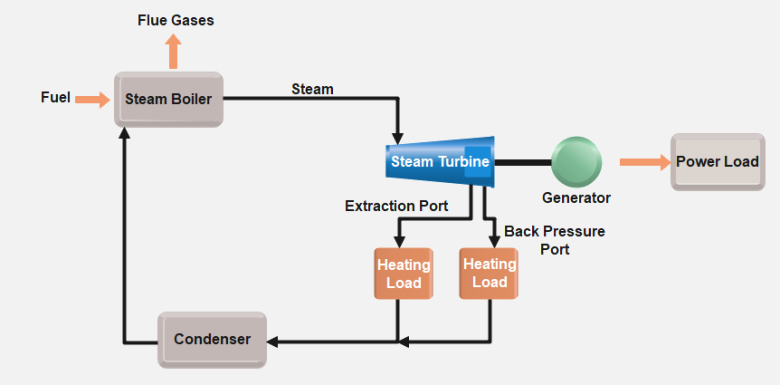

- Condensing Turbines: Commonly used in power generation, these turbines release exhaust steam at low pressures to maximize energy extraction.

- Back-pressure (Non-condensing) Turbines: Typically used in cogeneration applications, these turbines exhaust steam at higher pressures for additional industrial processes like heating.

- Impulse vs. Reaction Turbines: Impulse turbines use high-pressure steam jets to impact blades, while reaction turbines work by steam expansion along the blade surface.

Design and Construction of Steam Turbines

Steam turbines consist of several critical components designed for efficiency and durability:

- Rotor and Blades: Discuss the importance of blade design in maximizing energy transfer, the use of high-strength materials, and anti-corrosion coatings.

- Casing and Nozzles: The role of high-pressure steam in efficient turbine operation.

- Blade Materials: High-temperature alloys and innovations in metallurgy.

This section will also touch on challenges like managing vibration, noise, and blade fatigue, as well as technological advances in blade cooling techniques and aerodynamic designs.

Operation and Performance

Operating steam turbines efficiently requires careful monitoring and control of various parameters, including steam pressure, temperature, and flow rate. This section will describe typical start-up and shutdown procedures, as well as strategies for performance optimization through steam quality management and operational adjustments.

Key topics:

- Operational Efficiency: Analyzing key metrics like thermal efficiency, mechanical losses, and parasitic losses.

- Common Operational Issues: Addressing corrosion, erosion, and steam quality.

- Maintenance Best Practices: Routine inspections, preventive maintenance schedules, and component replacement strategies.

Applications in Power Generation

Steam turbines are the backbone of thermal power plants, whether fossil fuel-based, nuclear, or renewable. This section will cover the various types of power plants where steam turbines are used, focusing on their role in:

- Coal, Gas, and Oil-fired Power Plants: Discuss the Rankine cycle’s role in fossil-fuel power generation.

- Nuclear Power: How steam turbines function in nuclear plants, particularly in pressurized and boiling water reactors.

- Renewable Energy Integration: The role of steam turbines in biomass and geothermal power generation.

- Combined-cycle Power Plants: A comparison with gas turbines in modern power systems.

Industrial Applications Beyond Power Generation

While power generation is the most common application, steam turbines are also widely used in various industrial processes:

- Cogeneration and District Heating: How industrial plants use steam turbines to produce both power and heat.

- Petrochemical Industry: The role of turbines in refining processes.

- Pulp and Paper Manufacturing: Steam turbines for combined heat and power in paper mills.

- Desalination: The integration of steam turbines in large-scale desalination plants.

Efficiency and Performance Improvements

Advances in steam turbine design are continuously pushing the boundaries of efficiency. Some areas of improvement include:

- Blade Design and Aerodynamics: How modern blade profiles maximize efficiency.

- Digitalization: The role of sensors and AI in monitoring performance and predicting maintenance needs.

- Retrofitting Older Systems: Updating older turbines with modern technology for better performance.

Challenges and Limitations

Industrial steam turbines face challenges related to:

- Material Limitations: Corrosion, erosion, and fouling are major concerns.

- Regulatory Pressures: Compliance with emissions standards and efficiency benchmarks.

- Competitors: How steam turbines compare with other technologies like gas and wind turbines.

Future Trends and Innovations

The future of industrial steam turbines will be shaped by technological advancements and global energy trends:

- Hybrid Systems: Combining steam and gas turbines for enhanced efficiency.

- Hydrogen Integration: The potential of hydrogen-powered steam systems.

- AI and IoT: Predictive maintenance and real-time performance monitoring for better operational efficiency.

Conclusion

The conclusion will summarize the key points covered in the document, highlighting the continuing relevance of industrial steam turbines in both traditional and modern energy landscapes. It will also touch on the potential future developments and innovations that could reshape the role of steam turbines in global energy systems.

Industrial Steam Turbines

Industrial steam turbines are fundamental components of power generation and industrial processes worldwide, playing a critical role in converting heat energy into mechanical work and electricity. From small-scale applications in manufacturing plants to massive power generation facilities, steam turbines remain one of the most efficient and reliable technologies for energy conversion. These turbines function by utilizing high-pressure steam produced by heating water in boilers. The steam passes through a series of blades, causing the turbine to rotate and generate mechanical work. This process, dating back more than a century, remains crucial in the modern industrial landscape.

Historically, steam turbines were developed in the late 19th century as an evolution of earlier steam engines, which were significantly less efficient and more cumbersome. The invention of the steam turbine is often credited to Sir Charles Parsons, who introduced the first practical design in 1884. His design revolutionized marine propulsion, power generation, and many industrial processes, ushering in an era of rapid industrialization. As the industrial revolution progressed, steam turbines became more advanced and widely adopted in power plants, oil refineries, chemical processing plants, and other sectors.

Today, steam turbines are key components in a broad range of energy systems, from fossil fuel-based power plants to renewable energy setups. In power generation, they are primarily used in thermal plants, where coal, gas, or nuclear reactions heat water to create steam. In industrial applications, steam turbines drive machinery, compress gases, or generate electricity as part of cogeneration systems. These turbines can range in size from small units producing a few megawatts to giant turbines capable of generating several hundred megawatts, depending on the application.

Modern steam turbine technology has advanced to achieve high efficiencies through innovative materials, precision engineering, and digital monitoring systems. The versatility of steam turbines allows them to be integrated into diverse energy systems, including combined-cycle power plants, where they work in tandem with gas turbines, and geothermal or biomass plants, where they harness renewable steam sources.

With increasing global energy demands and the transition toward cleaner and more efficient energy sources, steam turbines continue to evolve. Efficiency improvements, integration with renewable energy technologies, and advancements in digitalization, such as predictive maintenance and AI-driven monitoring systems, are shaping the future of steam turbines. They also play a vital role in decarbonization efforts, particularly when coupled with carbon capture technologies or integrated into hybrid energy systems.

In conclusion, industrial steam turbines are integral to the global energy infrastructure, providing reliable, efficient, and scalable power generation solutions. From their historical origins to modern-day innovations, they remain a cornerstone of both traditional and emerging energy systems, ensuring their relevance well into the future.

Basic Principles of Steam Turbines

Industrial steam turbines operate based on well-established thermodynamic principles, converting thermal energy from steam into mechanical work. This section will discuss the key principles, energy conversion process, steam properties, and the basic components that make up a steam turbine.

Thermodynamics of Steam Power

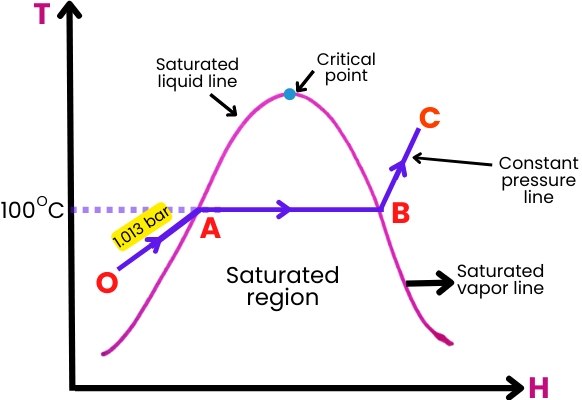

Steam turbines rely on the Rankine cycle, a thermodynamic process that describes how heat energy is converted into mechanical work in a closed-loop system. The cycle consists of four main stages:

- Heat Addition (Boiler): Water is heated in a boiler until it becomes steam, either saturated or superheated, depending on the application. This phase is crucial for generating the high-pressure steam needed to drive the turbine.

- Expansion (Turbine): The high-pressure steam is directed onto turbine blades, causing them to rotate. As the steam expands through the turbine stages, it loses pressure and temperature, transferring its energy to the rotor. This expansion is the core process where thermal energy is converted into mechanical energy.

- Condensation (Condenser): After passing through the turbine, the low-pressure steam enters a condenser, where it is cooled and returned to liquid form. This process helps maintain efficiency by creating a pressure difference that drives steam flow through the turbine.

- Pressurization (Pump): The condensed water is pumped back to the boiler under high pressure, completing the cycle.