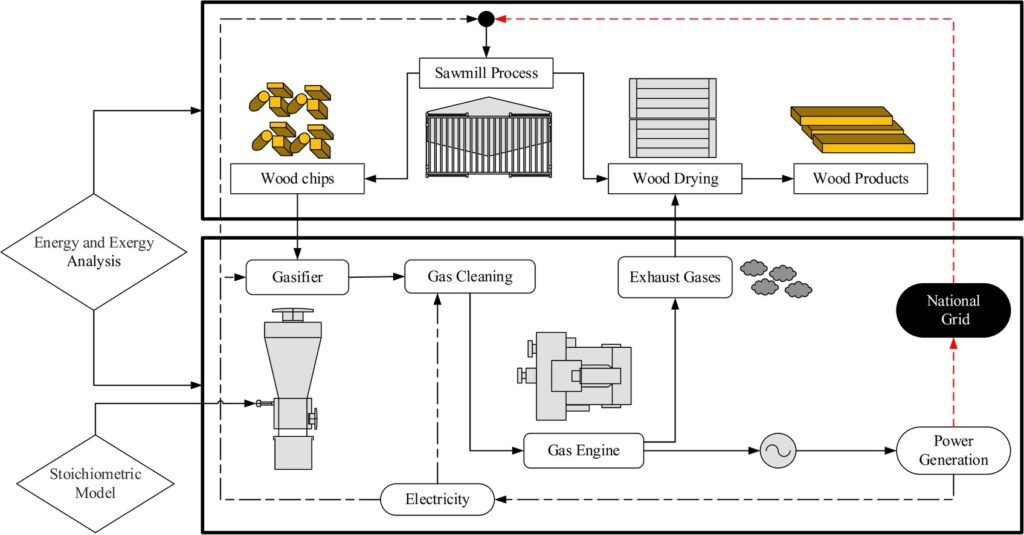

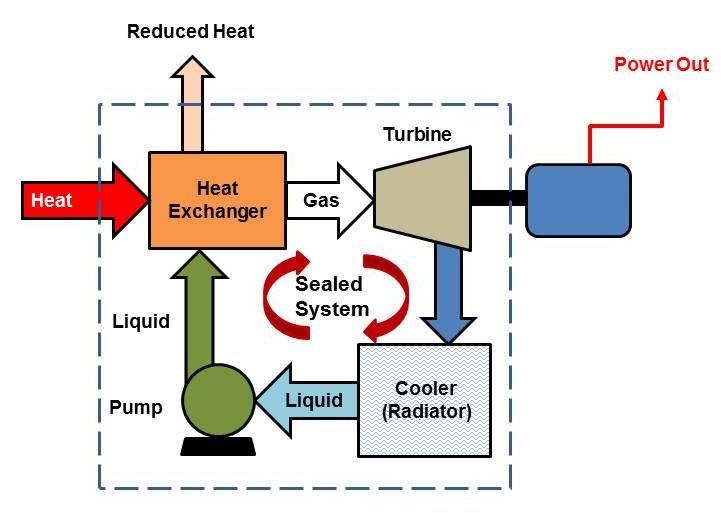

Cogeneration (Combined Heat and Power – CHP) Plants: Cogeneration, also known as Combined Heat and Power (CHP), refers to power plants or energy systems that simultaneously produce electricity and useful thermal energy from a single source of fuel. Unlike conventional power generation, where a large portion of fuel energy is lost as waste heat during electricity production, cogeneration captures this heat and puts it to productive use, significantly increasing overall energy efficiency.

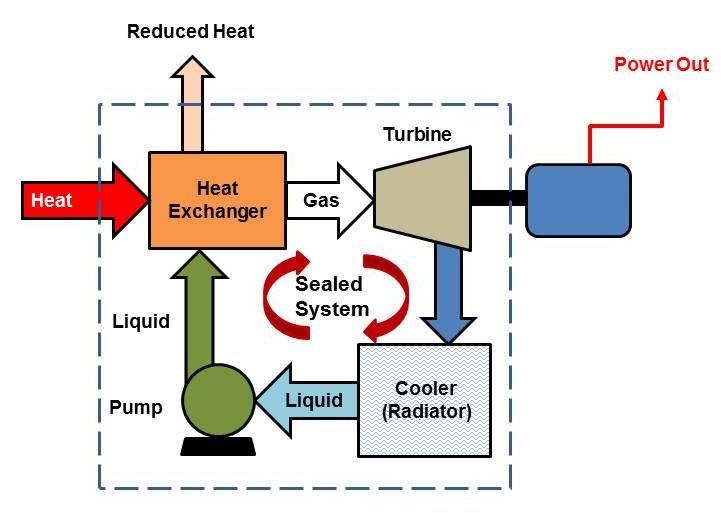

In a CHP plant, the primary fuel can be natural gas, biomass, coal, biogas, or even industrial waste gases. The system is designed so that when the fuel is burned in a prime mover—such as a gas turbine, steam turbine, or reciprocating engine—it generates electricity, and the byproduct heat, instead of being released into the atmosphere, is recovered through heat exchangers. This thermal energy can then be used for industrial processes, district heating, hot water supply, or even cooling through absorption chillers.

The main advantage of cogeneration plants lies in their high efficiency, often reaching 70–90% compared to the 30–40% typical of conventional power-only plants. This efficiency translates into reduced fuel consumption, lower operating costs, and significantly lower greenhouse gas emissions. In industrial settings, CHP systems are particularly valuable because they can provide both the electricity and the process heat required for manufacturing, making them a cornerstone of energy-intensive sectors such as chemicals, pulp and paper, food processing, and refineries. In urban applications, CHP units are often used for district energy systems, supplying electricity to the grid while providing centralized heating or cooling to entire neighborhoods.

Cogeneration can be implemented at various scales, from large utility-grade CHP plants that serve cities and industrial clusters, down to small modular units installed in hospitals, hotels, office complexes, or residential buildings. These distributed systems increase local energy resilience, reduce dependency on centralized grids, and provide stable energy at competitive costs.

From an environmental perspective, CHP supports decarbonization strategies, as it enables the integration of renewable fuels like biogas, biomass, or green hydrogen. Policymakers and energy planners are increasingly promoting cogeneration as part of sustainable energy infrastructure because it directly addresses the twin challenges of energy efficiency and emission reduction.

Cogeneration Plant Types

1. Gas Turbine CHP Plants

- A gas turbine burns natural gas or liquid fuels to produce electricity.

- The hot exhaust gases, instead of being released into the atmosphere, are recovered in a Heat Recovery Steam Generator (HRSG).

- The steam can be used for industrial processes, district heating, or to drive a steam turbine in a combined cycle.

- Common in medium to large-scale industrial facilities and district heating networks.

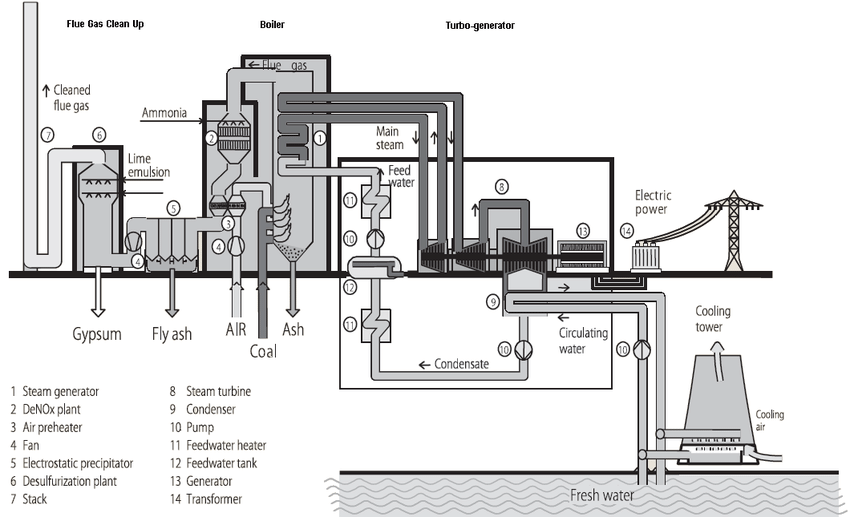

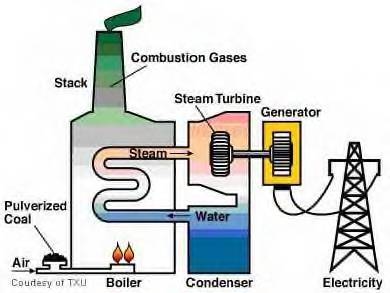

2. Steam Turbine CHP Plants

- Operates on the principle of a steam Rankine cycle.

- High-pressure steam is generated in a boiler and used to drive a steam turbine that produces electricity.

- After expansion, the lower-pressure steam is extracted and used for heating or industrial processes instead of being condensed.

- Widely applied in industries with high process heat demand such as pulp & paper, chemicals, and refineries.

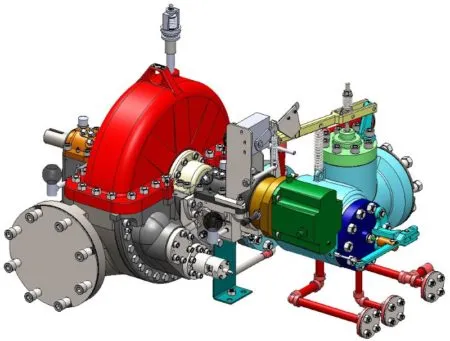

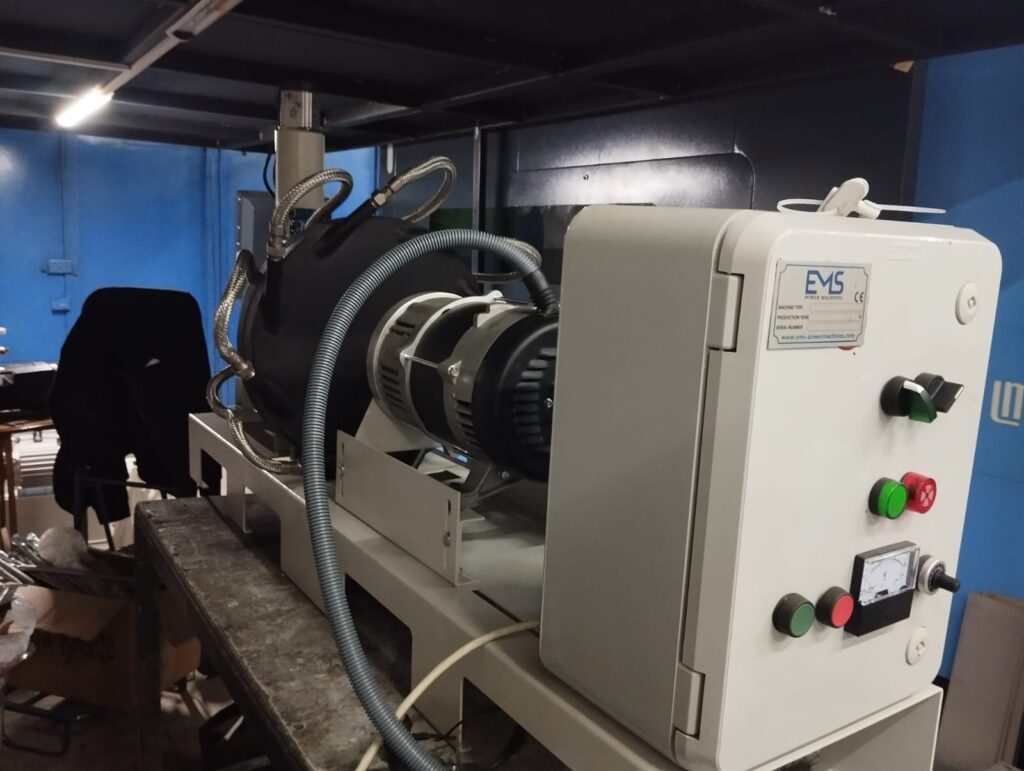

3. Reciprocating Engine CHP Plants

- Uses large internal combustion engines (diesel engines, gas engines) as the prime mover.

- Produces electricity while the engine’s jacket water and exhaust gases are recovered as useful heat.

- Highly efficient in small to medium-scale applications.

- Popular in hospitals, hotels, commercial buildings, and smaller industrial sites due to quick start-up and load flexibility.

4. Combined Cycle CHP Plants

- Integrates gas turbines and steam turbines in a single plant.

- Gas turbine produces electricity and hot exhaust gases, which generate steam in an HRSG.

- Steam turbine produces additional electricity while also supplying heat.

- Very high efficiency (up to 80–90%) and commonly used in large-scale cogeneration facilities and utility power plants.

5. Microturbine CHP Plants

- Small-scale gas turbines (30–500 kW range) that generate electricity and recover exhaust heat.

- Suited for distributed generation in commercial buildings, residential complexes, and small industries.

- Compact, low-maintenance, and able to use a variety of fuels including natural gas, biogas, and liquid fuels.

6. Fuel Cell CHP Plants

- Fuel cells convert chemical energy (from hydrogen, natural gas, or biogas) directly into electricity through electrochemical reactions.

- The process also generates heat, which can be used for local heating or cooling.

- Very efficient, low emissions, and suitable for distributed energy in urban areas, though still relatively costly.

7. Biomass and Waste-Fired CHP Plants

- Uses solid biomass (wood chips, agricultural residues) or waste (municipal solid waste, industrial byproducts) as fuel.

- Generates steam for electricity production in a steam turbine and provides process heat or district heating.

- Strong sustainability benefits, as they replace fossil fuels and utilize renewable or waste resources.

Gas Turbine CHP Plants

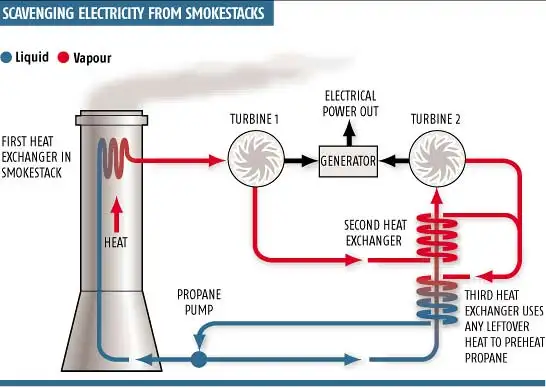

Gas turbine cogeneration plants, often referred to as gas turbine CHP plants, represent one of the most efficient and widely used forms of combined heat and power production. These systems operate on the principle of utilizing a gas turbine as the prime mover to generate electricity while simultaneously capturing the high-temperature exhaust gases for productive use. In a conventional gas turbine power plant, the exhaust gases are discharged directly into the atmosphere, wasting a substantial portion of the fuel’s energy potential. However, in a CHP configuration, this waste heat is harnessed, typically through a heat recovery steam generator (HRSG), which significantly increases overall efficiency and provides valuable thermal energy for a wide range of applications.

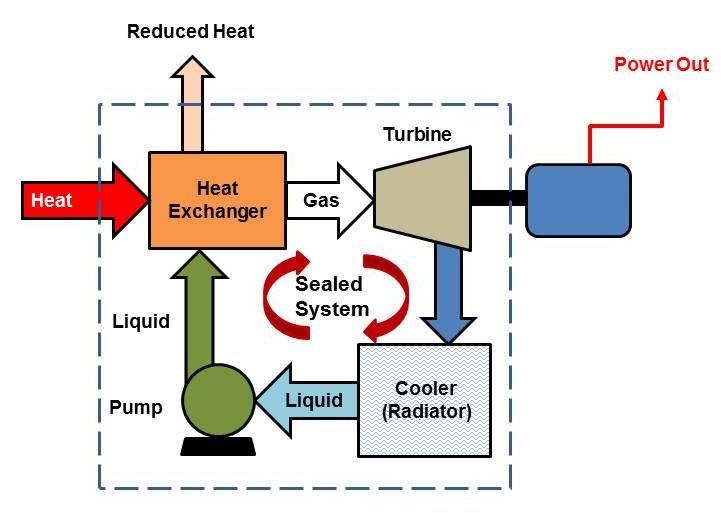

The basic operating cycle of a gas turbine CHP plant follows the Brayton cycle. Fuel, usually natural gas but sometimes alternative fuels such as biogas, syngas, or liquid hydrocarbons, is mixed with compressed air and combusted in the combustion chamber. The resulting hot gases expand through the turbine blades, driving the turbine and producing mechanical energy, which is converted into electricity by the generator. The exhaust gases leaving the turbine can reach temperatures of 400–600 °C, a level of thermal energy that is more than sufficient to generate steam or hot water. By integrating a heat recovery steam generator, this energy is captured instead of wasted, producing high-pressure steam for industrial processes, district heating networks, or additional power generation when coupled with a steam turbine in a combined cycle configuration.

One of the primary advantages of gas turbine CHP plants is their high overall efficiency, which can reach 70–80% when both electricity and useful heat are accounted for. This is a remarkable improvement compared to conventional simple-cycle gas turbine power plants, which typically achieve only 30–40% efficiency. By reducing fuel consumption per unit of useful energy, cogeneration not only lowers operational costs but also significantly reduces greenhouse gas emissions and environmental impact. The high efficiency of gas turbine CHP systems makes them particularly attractive in regions where energy prices are high and sustainability targets are stringent.

Gas turbine CHP plants are highly flexible in terms of scale and application. They can be designed as large utility-scale installations providing both power to the grid and steam to industrial parks, or as medium-sized plants integrated into refineries, chemical complexes, and paper mills where large volumes of process steam are required. In urban settings, gas turbine CHP systems are often integrated into district heating and cooling networks, supplying entire residential and commercial areas with electricity, hot water, and even chilled water through absorption chillers. This distributed energy approach enhances energy resilience, reduces dependency on centralized grids, and provides a reliable supply of both power and heat close to the point of consumption.

Another important feature of gas turbine CHP plants is their fuel flexibility and operational reliability. Although natural gas remains the preferred fuel due to its high efficiency, low emissions, and availability, these systems can also operate on alternative fuels such as biogas, syngas from waste gasification, or liquid fuels in cases where natural gas supply is limited. This versatility allows operators to adapt to changing fuel markets and environmental regulations. Furthermore, gas turbines have relatively low maintenance requirements and long operational lifespans, making them a dependable choice for continuous power and heat generation.

In many cases, gas turbine CHP plants are designed as combined cycle cogeneration systems. In such a configuration, the gas turbine generates electricity and produces hot exhaust gases, which are directed into a heat recovery steam generator. The HRSG produces steam not only for industrial or district heating applications but also for a steam turbine that generates additional electricity. This combined cycle CHP approach can push overall plant efficiency even higher, often above 80%, while maximizing both the power output and the heat supply.

From an environmental and regulatory perspective, gas turbine CHP systems contribute significantly to carbon reduction goals. By optimizing the use of fuel and avoiding waste heat losses, they help industries and municipalities lower their carbon footprint while ensuring compliance with strict emission standards. Moreover, when integrated with renewable fuels such as biogas or hydrogen, gas turbine CHP plants can transition toward nearly carbon-neutral operation, aligning with global sustainability objectives. This makes them a key component in the energy transition strategies of many countries and corporations.

Economically, gas turbine CHP plants provide strong returns on investment by reducing energy costs and increasing efficiency. Industries that have both high electricity and thermal energy demands often achieve rapid payback periods, since CHP enables them to produce both utilities on-site instead of purchasing electricity from the grid and generating steam separately with boilers. In addition, many regions offer incentives, tax benefits, or preferential tariffs for cogeneration projects, further improving their financial attractiveness.

In conclusion, gas turbine CHP plants stand out as a proven, efficient, and versatile technology in the field of combined heat and power generation. They offer a unique balance of high electrical efficiency, reliable thermal energy production, operational flexibility, and environmental benefits. Whether applied at a large industrial complex, a utility-scale energy project, or an urban district heating system, gas turbine CHP provides a sustainable and economically viable pathway to optimize fuel use, reduce emissions, and enhance energy security.

Gas turbine CHP plants represent one of the most advanced and efficient solutions in the field of cogeneration, combining the proven performance of gas turbine technology with the ability to recover and utilize high-quality waste heat. At the core of this system is the gas turbine itself, which operates on the well-established Brayton cycle. Air is compressed, mixed with a fuel—most commonly natural gas—and combusted at high pressure, producing hot gases that expand through turbine blades and drive the generator to produce electricity. In a conventional power plant, the hot exhaust gases would be released into the atmosphere, carrying away a large amount of energy as waste. In a cogeneration setup, however, this thermal energy is recovered in a heat recovery steam generator, which transforms the exhaust gases into useful steam or hot water for a wide variety of industrial and commercial applications. This simple but highly effective modification changes the energy balance dramatically, raising the overall efficiency of the plant from the 30 to 40 percent typical of a simple-cycle turbine to levels that can exceed 70 or even 80 percent.

The impact of such efficiency improvements is significant from both an economic and environmental perspective. For industries and municipalities that operate energy-intensive processes or provide heating and cooling to large populations, the ability to use one fuel input to supply both electricity and heat results in substantial reductions in fuel consumption. This translates into lower energy costs and an increase in competitiveness, while also contributing to a considerable reduction in greenhouse gas emissions and pollutants. For operators in sectors such as petrochemicals, paper production, food processing, and district energy, gas turbine CHP plants have become an essential part of their energy infrastructure. The dual production of electricity and process heat allows them to meet internal energy demands while, in many cases, also exporting surplus power to the grid, generating additional revenue streams.

Another strength of gas turbine CHP plants lies in their flexibility of application. They can be built as large central stations supplying electricity to national grids while simultaneously delivering steam to industrial parks or city-wide heating networks. At the same time, they can also be designed in medium-scale configurations that fit seamlessly into the energy systems of refineries, chemical plants, or paper mills. In urban environments, gas turbine CHP plants are often integrated into district heating and cooling networks, where the captured heat is distributed to residential and commercial buildings, while absorption chillers can transform part of that heat into cooling energy for summer demand. This versatility has made them a cornerstone of modern energy strategies that prioritize efficiency, sustainability, and resilience.

Fuel flexibility adds another layer of attractiveness to gas turbine CHP systems. While natural gas remains the preferred fuel due to its clean combustion, high efficiency, and availability, gas turbines can also operate on a wide range of alternatives. These include liquid fuels, biogas from landfills or anaerobic digesters, syngas from biomass or waste gasification, and, increasingly, hydrogen or hydrogen-enriched fuels. This adaptability ensures that gas turbine CHP plants can evolve alongside energy markets and environmental regulations, allowing operators to reduce their dependency on a single fuel source and to prepare for a future in which low-carbon and renewable fuels will play a much larger role.

One of the most advanced configurations of gas turbine cogeneration is the combined cycle CHP plant, where the gas turbine not only generates electricity but also provides hot exhaust gases for a heat recovery steam generator. The steam from the HRSG can then be used to drive a steam turbine that produces additional electricity while also supplying steam for heating or industrial processes. This dual-turbine arrangement achieves the highest possible efficiency levels, making combined cycle CHP one of the most powerful and sustainable technologies available for large-scale energy production. Plants of this type are often deployed in utility-scale projects where both the electricity grid and local industries benefit from a highly efficient and reliable energy supply.

Reliability and operational stability are further advantages that make gas turbine CHP plants an attractive investment. Modern gas turbines are engineered for long service lifetimes, with robust designs that allow continuous operation for thousands of hours with relatively low maintenance compared to other prime movers. Their ability to ramp up and down relatively quickly also makes them valuable in power systems that need to balance fluctuating loads or integrate variable renewable energy sources such as wind and solar. By combining steady baseload production with flexible operation, gas turbine CHP plants contribute not only to energy efficiency but also to grid stability and security of supply.

From the perspective of environmental policy and climate goals, gas turbine CHP plants provide a practical and immediate pathway to reduce carbon emissions. By using fuel more efficiently and avoiding the waste of thermal energy, they achieve significant reductions in greenhouse gas output compared to separate heat and power generation. Furthermore, as they transition to renewable fuels such as biogas or hydrogen, they can move closer to carbon-neutral operation. This adaptability ensures that gas turbine CHP technology will continue to play an important role in the global energy transition, serving as a bridge between the current reliance on natural gas and the future vision of a low-carbon or carbon-free energy system.

Economically, gas turbine CHP plants often prove to be highly cost-effective investments, particularly in industries with steady and simultaneous demands for electricity and heat. By generating both on-site, operators reduce their dependency on grid electricity and separate boilers, lowering operational costs and improving overall energy management. In many cases, governments also provide incentives, tax benefits, or favorable regulatory frameworks to promote cogeneration, further enhancing the financial case. For industrial operators, the payback time for such systems is often relatively short, and the long-term savings in energy costs are substantial.

Ultimately, gas turbine CHP plants embody the key principles of modern energy systems: efficiency, sustainability, flexibility, and resilience. They transform what would otherwise be wasted heat into a valuable resource, delivering reliable electricity and useful thermal energy from the same fuel input. Their ability to adapt to different scales, fuels, and applications makes them an indispensable part of the energy landscape, whether in industrial zones, cities, or large-scale utilities. As energy systems around the world move toward cleaner, smarter, and more integrated solutions, gas turbine cogeneration plants will remain a critical technology that combines immediate benefits with long-term potential for a sustainable future.

Gas turbine cogeneration plants, also known as gas turbine CHP plants, are among the most efficient and versatile technologies available for producing electricity and useful heat simultaneously from a single fuel source. Their development has been driven by the need for energy systems that can deliver high efficiency, lower emissions, and reliable operation in a wide range of industrial, commercial, and municipal settings. At the core of this concept lies the gas turbine, a prime mover that operates on the well-established Brayton cycle. In this cycle, air is compressed, mixed with fuel, and combusted at high pressure, producing a high-temperature gas stream that expands through turbine blades to generate mechanical power, which is then converted into electricity by a generator. In a conventional simple-cycle power plant, the hot exhaust gases, which leave the turbine at temperatures often exceeding 400 to 600 °C, are released into the atmosphere, wasting a substantial fraction of the fuel’s energy potential. In contrast, gas turbine CHP systems are specifically designed to capture and utilize this otherwise wasted heat, typically through a heat recovery steam generator that produces steam or hot water. The steam can then be used directly in industrial processes, distributed through district heating networks, or even used to drive an additional steam turbine for further electricity generation.

The efficiency advantage of gas turbine CHP plants over conventional power generation is one of their defining characteristics. A simple-cycle gas turbine plant typically achieves an efficiency in the range of 30 to 40 percent, meaning that more than half of the fuel energy is lost as waste heat. When configured as a cogeneration system, the same plant can reach overall efficiencies of 70 to 80 percent, and in some cases even higher, because the thermal energy is put to productive use instead of being discarded. This improvement has major implications both for operating costs and for environmental performance. By extracting more useful energy from the same fuel input, operators reduce fuel consumption, which directly translates into financial savings. At the same time, carbon dioxide and other pollutant emissions per unit of useful energy are reduced, making gas turbine CHP a powerful tool for meeting climate and air quality objectives. This dual benefit of cost reduction and environmental performance explains why the technology has been adopted across many industries and cities worldwide.

The applications of gas turbine CHP plants are diverse and can be tailored to the specific needs of different users. In large industrial complexes such as refineries, petrochemical plants, paper mills, and food processing facilities, there is typically a constant demand for both electricity and process steam. A gas turbine CHP plant in such an environment can supply the facility with reliable power while providing the steam required for manufacturing operations, eliminating the need for separate boilers and purchased grid electricity. This integration not only reduces costs but also provides a high degree of energy independence and reliability, which is critical for industries where downtime is extremely costly. In urban environments, gas turbine CHP systems are frequently deployed as part of district heating and cooling networks. Here, the electricity is either used locally or fed into the grid, while the captured heat is distributed through pipelines to supply hot water or space heating to residential, commercial, and institutional buildings. During summer months, the same heat can be used to drive absorption chillers, producing chilled water for air conditioning and refrigeration, which further extends the versatility of the system. This capacity to serve multiple energy needs with a single plant makes cogeneration particularly valuable in densely populated areas where energy efficiency and sustainability are priorities.

Another important feature of gas turbine CHP plants is their scalability. They can be designed as large central stations with outputs of hundreds of megawatts, serving entire cities and industrial regions, or as medium-sized facilities dedicated to a single industrial plant. Advances in gas turbine technology have also made smaller modular units feasible, making cogeneration accessible even to smaller commercial complexes, hospitals, universities, or hotels. Regardless of scale, the underlying principle remains the same: maximize the value of fuel by simultaneously generating electricity and capturing usable heat. This adaptability ensures that gas turbine CHP can meet the requirements of many different users, from large-scale utilities to small distributed energy systems.

Fuel flexibility is another dimension that enhances the attractiveness of gas turbine CHP systems. While natural gas is by far the most commonly used fuel due to its clean combustion characteristics, widespread availability, and high energy content, gas turbines can be configured to run on alternative fuels. These include liquid fuels such as diesel or kerosene in areas where natural gas is not available, as well as renewable and low-carbon options such as biogas from landfills or anaerobic digestion, syngas produced from biomass or municipal waste gasification, and increasingly hydrogen or hydrogen-enriched natural gas blends. The ability to integrate renewable or waste-derived fuels makes gas turbine CHP plants a valuable component of sustainable energy strategies, as they not only reduce reliance on fossil fuels but also enable the utilization of resources that might otherwise be wasted. Looking toward the future, the potential to operate on green hydrogen positions gas turbine CHP as a key transitional technology on the path to carbon-neutral energy systems.

One of the most advanced configurations of gas turbine cogeneration is the combined cycle CHP plant. In this arrangement, the hot exhaust gases from the gas turbine are not only used to generate steam for industrial use or district heating but are also directed to a steam turbine to produce additional electricity. This dual-turbine approach achieves some of the highest efficiencies of any fossil-fuel-based energy technology, with overall efficiencies often surpassing 80 percent. Combined cycle CHP plants are commonly deployed in utility-scale projects where large amounts of electricity are required alongside significant thermal demand, such as in industrial hubs or metropolitan areas with extensive district heating networks. These plants represent the pinnacle of gas turbine cogeneration technology, combining the advantages of large-scale electricity generation with the fuel-saving benefits of cogeneration.

From the perspective of energy policy and environmental regulation, gas turbine CHP plants play an important role in helping industries and municipalities meet increasingly strict efficiency and emissions standards. By extracting the maximum possible value from each unit of fuel, they allow operators to significantly reduce carbon dioxide emissions per megawatt-hour of energy delivered. This is particularly important as governments around the world push for decarbonization of energy systems while still maintaining reliable supply. Moreover, the ability to integrate renewable fuels into gas turbine CHP systems provides a pathway toward even lower emissions in the future. For example, plants that today operate primarily on natural gas can be progressively adapted to run on biogas or hydrogen, thus extending their usefulness in a decarbonizing energy market. This adaptability ensures that investments in gas turbine CHP remain relevant for decades, even as energy systems evolve.

Reliability and operational stability are additional advantages of gas turbine CHP plants. Modern turbines are designed for long service lifetimes, capable of running continuously for thousands of operating hours with relatively modest maintenance requirements compared to other prime movers. Their ability to start quickly and adjust output makes them particularly useful in systems where load demands fluctuate or where variable renewable energy sources such as wind and solar need to be balanced. In such contexts, gas turbine CHP plants not only provide efficient heat and power but also contribute to overall grid stability and energy security. This combination of efficiency, flexibility, and reliability makes them indispensable in many modern energy systems.

Economically, gas turbine CHP plants often deliver strong returns on investment. For industries with constant demand for heat and power, the savings generated by reducing grid electricity purchases and boiler fuel consumption can result in relatively short payback periods. In many regions, additional financial benefits are available in the form of tax incentives, grants, or preferential tariffs for cogeneration projects, all designed to encourage adoption of more efficient and sustainable energy systems. Beyond direct financial returns, the investment in CHP also strengthens competitiveness by improving energy security, reducing exposure to volatile energy markets, and demonstrating environmental responsibility, which is increasingly important for corporate image and compliance with sustainability standards.

In the broader context of the global energy transition, gas turbine CHP plants serve as a crucial bridging technology. They combine the reliability and scalability of conventional fossil-fuel-based systems with the efficiency and adaptability required in a low-carbon future. By using existing fuels more efficiently, they deliver immediate environmental and economic benefits. By being able to integrate renewable fuels such as biogas or hydrogen, they ensure compatibility with long-term decarbonization goals. This unique combination makes gas turbine CHP plants a central component of sustainable energy strategies in many parts of the world, from industrial zones in Asia and Europe to urban energy systems in North America and emerging markets.

Ultimately, gas turbine cogeneration plants embody the essential principles of modern energy engineering: efficiency, sustainability, resilience, and adaptability. They transform what would otherwise be wasted heat into a valuable resource, creating a balanced supply of electricity and thermal energy from the same fuel input. Their ability to scale from medium-sized industrial plants to large utility projects, to operate on a variety of fuels, and to integrate with district energy systems ensures their continued relevance in a rapidly changing energy landscape. As the world moves toward cleaner, smarter, and more integrated energy solutions, gas turbine CHP technology stands out as a proven, dependable, and forward-looking option that meets the pressing demands of today while preparing for the challenges of tomorrow.

Gas turbine cogeneration plants, or gas turbine CHP plants, are today considered one of the most effective and reliable solutions for meeting the dual needs of electricity and heat in a wide range of applications. Their strength lies in the combination of proven turbine technology with the principle of combined heat and power production, which allows a single fuel input to be converted into multiple useful forms of energy. By recovering the high-temperature exhaust gases produced during turbine operation and putting them to productive use, these plants maximize fuel utilization and minimize waste, achieving efficiency levels that are significantly higher than conventional power generation systems. For industries and municipalities alike, this translates into lower energy costs, reduced greenhouse gas emissions, and enhanced energy security.

The working principle of a gas turbine CHP plant begins with the Brayton cycle. In this cycle, ambient air is drawn into a compressor, where it is pressurized and directed into a combustion chamber. Fuel, most commonly natural gas but potentially other alternatives such as biogas, syngas, or liquid fuels, is injected and combusted with the compressed air, producing high-temperature, high-pressure gases. These gases expand through the turbine section, driving the blades connected to a generator that produces electricity. In a simple-cycle turbine, the hot exhaust gases would be released into the atmosphere, carrying away a large share of the energy content. In cogeneration mode, however, the exhaust gases are directed to a heat recovery steam generator (HRSG), where their energy is used to produce steam or hot water. This steam can serve industrial processes, district heating, or additional power generation if a steam turbine is incorporated into the cycle. In this way, gas turbine CHP plants achieve a synergy that fundamentally alters the efficiency profile of power generation.

The efficiency gains from cogeneration are striking. While a typical simple-cycle gas turbine has an electrical efficiency of around 35 percent, the integration of heat recovery increases the total useful efficiency to 70, 80, or even 85 percent in optimized systems. This dramatic increase means that for every unit of fuel consumed, nearly twice as much useful energy is obtained compared to conventional configurations. For industrial operators, this reduction in fuel consumption per unit of output translates directly into lower operating expenses. For policymakers and society, it means fewer greenhouse gas emissions and pollutants for the same amount of energy service, supporting both climate goals and public health objectives. In many countries, regulatory frameworks recognize these benefits by offering incentives, tax credits, or favorable tariffs to promote CHP deployment, further enhancing its attractiveness.

Industrial applications are among the most important use cases for gas turbine CHP plants. Industries such as petrochemicals, refining, pulp and paper, textiles, and food processing have simultaneous and continuous demands for both electricity and process steam. In these sectors, a gas turbine CHP plant can provide the electricity needed to power motors, drives, and lighting, while also supplying the high-pressure steam required for manufacturing processes, drying, or chemical reactions. The elimination of separate boilers and external grid purchases not only reduces costs but also enhances reliability, as the facility becomes largely self-sufficient in energy. In refineries, for example, cogeneration units often supply both internal energy needs and surplus electricity to the grid, improving the facility’s overall economics while supporting local energy supply.

Municipal and district energy systems represent another area where gas turbine CHP plants have demonstrated great value. In cities across Europe, Asia, and North America, cogeneration plants are integrated into district heating networks, supplying hot water and steam through pipelines to residential, commercial, and institutional buildings. In such systems, the electricity generated is either used locally or sold to the grid, while the recovered heat provides a low-cost and sustainable alternative to individual heating solutions. In warmer climates or during summer months, the recovered heat can be used in absorption chillers to produce chilled water for air conditioning, creating a district cooling network. This multi-functional energy service model demonstrates the versatility of gas turbine CHP and its ability to adapt to seasonal variations in demand. By serving as centralized hubs for efficient energy production, these plants contribute to reducing overall urban emissions, improving air quality, and lowering energy costs for end users.

The scale of gas turbine CHP plants can vary widely, which makes them suitable for different operational contexts. Large-scale plants with outputs in the hundreds of megawatts are used by utilities to serve cities or industrial regions, often operating as combined cycle plants that integrate both gas and steam turbines for maximum efficiency. Medium-sized plants are commonly found in large factories, industrial parks, and refineries, where they can provide tens of megawatts of power and substantial amounts of process steam. Smaller modular gas turbine CHP units are increasingly being used in commercial complexes, universities, hospitals, and hotels, where they provide reliable electricity alongside heating and cooling. This scalability ensures that gas turbine CHP can be tailored to match specific energy demand profiles, avoiding overcapacity and ensuring optimal efficiency.

One of the most advanced configurations of gas turbine CHP is the combined cycle cogeneration system. In this setup, the gas turbine produces electricity while the exhaust gases are directed into a heat recovery steam generator. The HRSG then produces steam that can either be used for industrial processes or sent to a steam turbine for additional electricity generation. The integration of both turbines results in higher electrical output while still providing thermal energy to users. Combined cycle CHP plants often achieve efficiencies exceeding 80 percent, making them among the most efficient fossil-fuel-based energy systems currently available. Such plants are frequently deployed in areas with high and continuous demand for both power and heat, as their efficiency and reliability make them ideal for long-term, large-scale operation.

Fuel flexibility is an increasingly important consideration in the deployment of gas turbine CHP plants. Natural gas remains the dominant fuel due to its high energy content, relatively low emissions, and established infrastructure. However, the ability of gas turbines to operate on alternative fuels is expanding their role in sustainable energy strategies. Biogas from landfills or anaerobic digestion provides a renewable substitute, while syngas from biomass or municipal waste gasification offers another pathway to reduce fossil fuel dependence. In addition, hydrogen is emerging as a key fuel of the future, and turbine manufacturers are investing heavily in developing models that can operate on hydrogen blends or eventually pure hydrogen. This capability positions gas turbine CHP plants as a transitional technology that not only delivers immediate efficiency and emissions benefits but also has the potential to operate with zero-carbon fuels in the future.

Reliability and operational flexibility are other reasons why gas turbine CHP plants are widely adopted. Gas turbines are robust machines designed for continuous operation, with long service intervals and proven durability. Their ability to ramp output up or down makes them valuable in modern power systems where renewable energy sources like solar and wind introduce variability. In such systems, gas turbine CHP plants can provide a steady supply of both electricity and heat while also helping balance the grid, ensuring stability and preventing disruptions. In facilities where energy reliability is critical, such as hospitals or data centers, the ability to maintain uninterrupted power and thermal supply is a decisive advantage.

From an economic perspective, gas turbine CHP plants often offer favorable investment returns, especially in applications with continuous heat and power demand. By displacing the need to purchase electricity from the grid and reducing or eliminating boiler fuel consumption, they lower operating costs significantly. Many projects also benefit from the ability to export surplus electricity, creating an additional revenue stream. The payback period for gas turbine CHP investments is often relatively short, particularly when government incentives or preferential tariffs are available. Beyond the financial returns, CHP systems enhance competitiveness by reducing exposure to energy price volatility and demonstrating environmental responsibility, which can improve corporate reputation and compliance with sustainability standards.

In the broader context of global energy transitions, gas turbine CHP plants are positioned as a critical bridging technology. They combine the advantages of conventional fuel reliability with the efficiencies needed in modern sustainable energy strategies. By using fuel more efficiently, they immediately reduce emissions and energy costs. By being capable of integrating renewable and low-carbon fuels such as biogas, syngas, or hydrogen, they offer long-term compatibility with decarbonization goals. This dual capacity makes them highly relevant to both current and future energy systems. Policymakers increasingly view CHP as a cornerstone technology for sustainable energy infrastructure, recognizing its potential to reduce carbon footprints while ensuring reliable and affordable energy supply.

Ultimately, gas turbine cogeneration plants embody the essential characteristics demanded of modern energy solutions: efficiency, adaptability, resilience, and environmental performance. They transform waste into value, producing electricity and thermal energy in a balanced and optimized manner. Their ability to operate at different scales, on different fuels, and in different contexts ensures their continued relevance, whether serving a single industrial plant, a large metropolitan district energy system, or an entire industrialized region. As industries and cities pursue greater efficiency and lower emissions, gas turbine CHP will remain a cornerstone technology, providing a proven, dependable, and future-ready approach to meeting the world’s growing energy needs.

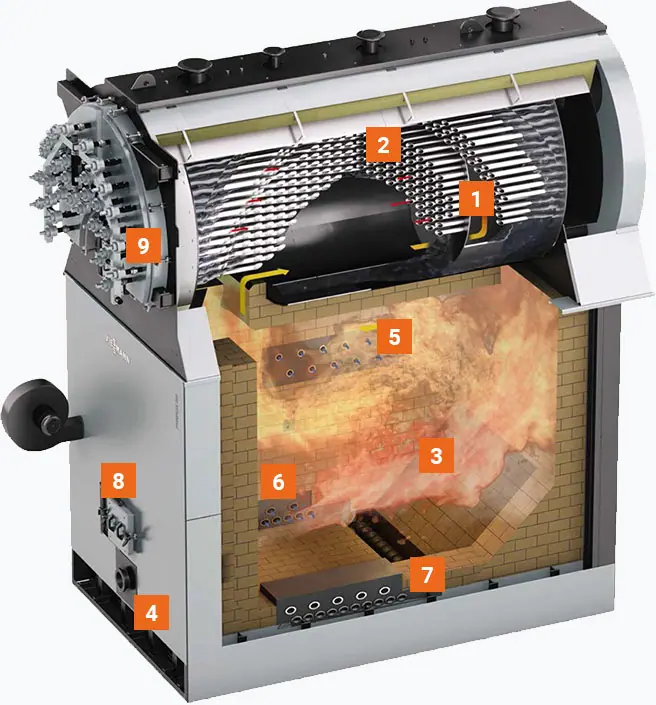

The main parts of a Gas Turbine CHP Plant can be described in terms of the major components that allow it to generate both electricity and useful heat efficiently:

1. Air Intake and Compression System

- Ambient air is drawn into the system through an air intake filter to remove dust and particles.

- A compressor then pressurizes the air, increasing its pressure and temperature before it enters the combustion chamber.

- The compressor is usually an axial or centrifugal type and is mechanically linked to the turbine shaft.

2. Combustion Chamber (Combustor)

- Fuel, most commonly natural gas but sometimes biogas, syngas, hydrogen, or liquid fuels, is injected into the compressed air stream.

- The mixture is ignited in the combustion chamber, producing high-temperature, high-pressure gases.

- Advanced combustors are designed to minimize NOx and CO₂ emissions while ensuring stable combustion.

3. Gas Turbine

- The hot gases expand through the turbine section, driving turbine blades connected to a rotating shaft.

- This shaft powers both the compressor (at the front of the machine) and the generator (for electricity production).

- The efficiency and output of the turbine depend on the design and the inlet temperature of the gases.

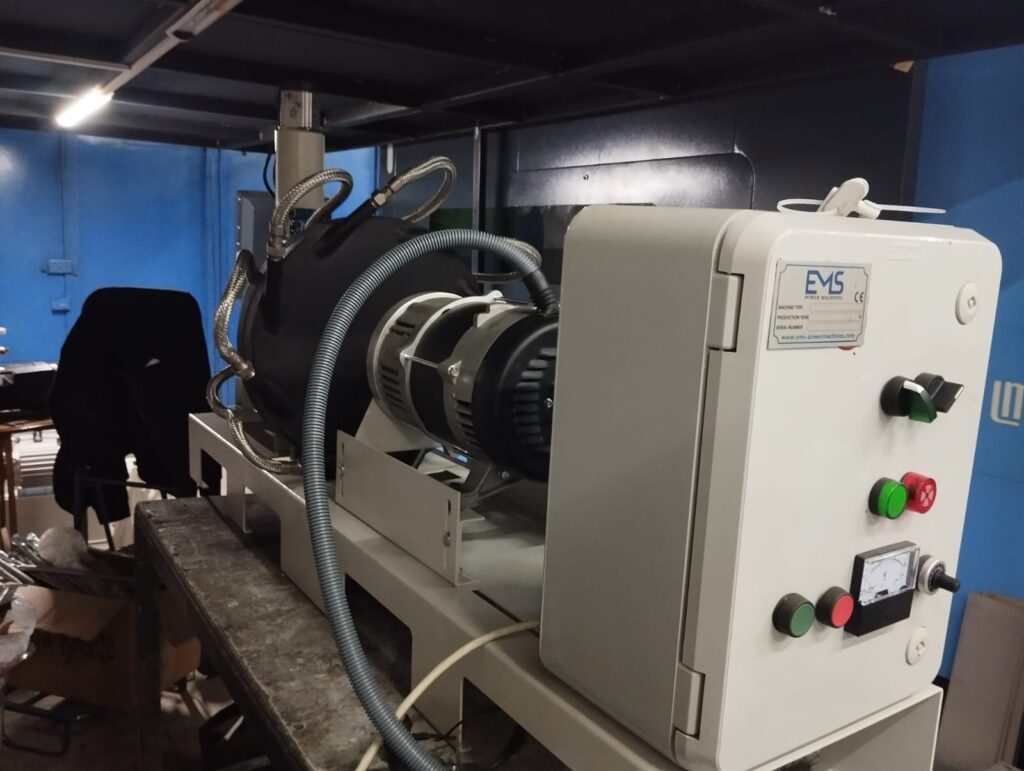

4. Electric Generator

- The turbine shaft is mechanically coupled to an alternator that converts mechanical energy into electricity.

- Electricity can be used locally or exported to the grid, depending on the plant configuration.

- A control system ensures stable voltage and frequency output.

5. Exhaust Gas System

- After passing through the turbine, the exhaust gases still carry a large amount of heat energy (400–600 °C).

- Instead of being released to the atmosphere, these gases are directed to a heat recovery system.

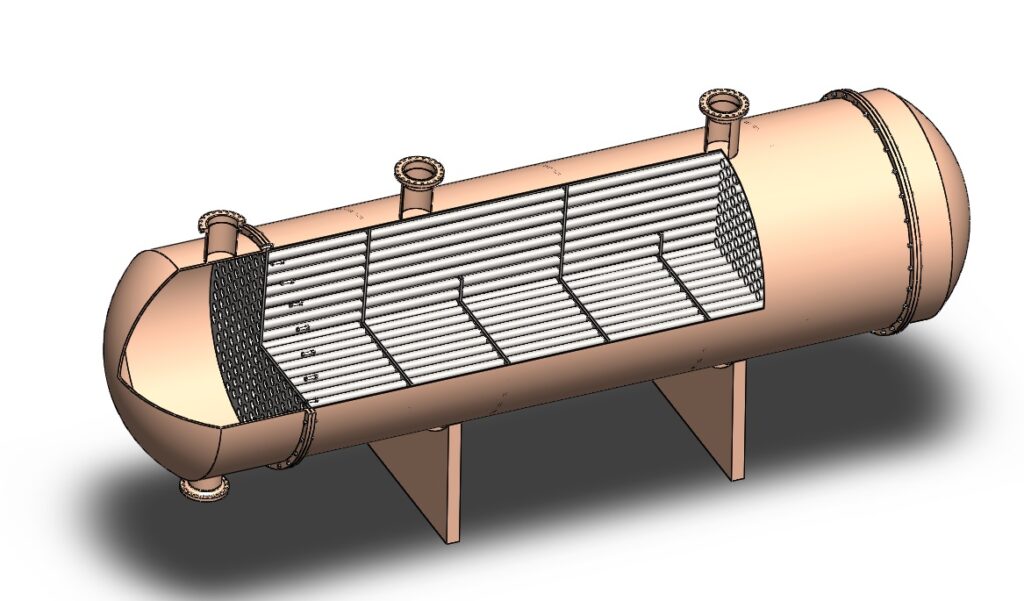

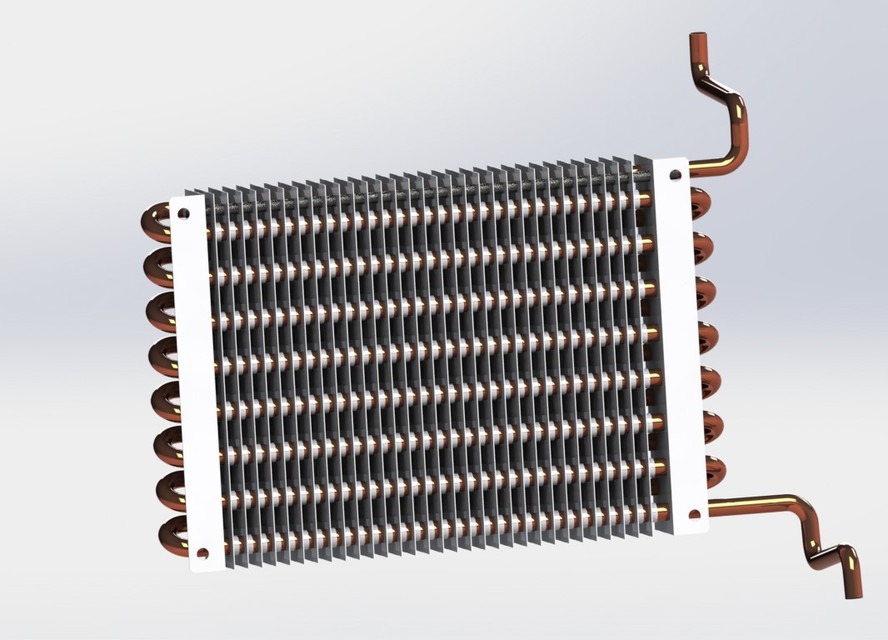

6. Heat Recovery Steam Generator (HRSG)

- The HRSG is the key cogeneration component.

- It captures heat from the turbine exhaust gases and converts it into steam or hot water.

- The steam can be used directly in industrial processes, supplied to district heating networks, or used to power a steam turbine in a combined cycle CHP system.

7. Steam Turbine (in Combined Cycle CHP)

- In larger CHP plants, the steam from the HRSG is directed into a steam turbine.

- This turbine produces additional electricity while still allowing extraction of steam for heating or industrial use.

- This combined arrangement pushes overall efficiency to very high levels.

8. Cooling and Condensate Systems

- If steam is not fully utilized for heating, part of it may be condensed in a condenser and recirculated as feedwater.

- Cooling systems (air-cooled or water-cooled) ensure stable operation and maintain thermal balance.

9. Heat Distribution System

- The recovered heat is delivered to industrial processes (high-pressure steam, hot air, hot water).

- In urban setups, it is distributed via district heating pipelines to residential and commercial buildings.

- In some cases, heat drives absorption chillers for district cooling.

10. Control and Monitoring Systems

- Advanced automation and control systems manage fuel flow, turbine operation, generator synchronization, and HRSG performance.

- They optimize efficiency, ensure safety, and maintain emissions within regulatory limits.

- Remote monitoring is often used for diagnostics and predictive maintenance.

Air Intake and Compression System

The air intake and compression system of a gas turbine CHP plant plays a fundamental role in the overall performance and efficiency of the installation, since it is the first step of the thermodynamic process that later makes electricity and heat generation possible. Ambient air, which naturally contains varying amounts of dust, dirt, humidity, and even small particles depending on the location, must be carefully managed before it enters the turbine. For this reason, the air intake system is equipped with large filter units designed to remove contaminants and ensure that the turbine receives a continuous supply of clean air. Any impurity that enters the compressor section can cause erosion, fouling, or corrosion of the blades, which not only reduces efficiency but can also shorten the life of the turbine. Therefore, the intake filters are engineered to deliver high air purity while maintaining low pressure drop, since excessive resistance at this stage would reduce the overall efficiency of the plant.

Once the air has been drawn in and filtered, it enters the compressor, which is one of the most energy-intensive components of the gas turbine system. The compressor’s task is to raise the pressure and temperature of the incoming air so that it can mix efficiently with the fuel and combust under controlled high-pressure conditions in the combustion chamber. Most gas turbines use axial-flow compressors, which consist of multiple stages of rotating and stationary blades that progressively compress the air as it flows through the machine. Some smaller turbines may employ centrifugal compressors, which are simpler in design but less common in large-scale CHP applications. In an axial compressor, each stage adds a modest increase in pressure, but by the time the air passes through a series of 10 to 20 stages, the overall pressure ratio becomes significant, often reaching 10:1, 15:1, or even higher in advanced turbines. The quality of this compression process is critical, since the efficiency of combustion and the power output of the turbine depend heavily on the pressure and temperature of the air entering the combustor.

The compressor is mechanically coupled to the turbine shaft, meaning that part of the energy generated in the turbine section is used to drive the compressor. This internal energy demand is substantial, sometimes consuming more than half of the turbine’s gross power output, which highlights how essential an efficient compressor design is for the viability of the entire CHP system. Despite this, the compressor’s contribution to overall plant performance is immense, because the higher the pressure ratio achieved at this stage, the more efficient the combustion process becomes, and the greater the potential for high turbine output and higher exhaust temperatures that feed the downstream heat recovery steam generator.

Another important aspect of the air intake and compression system in CHP plants is its adaptability to ambient conditions. Since turbines often operate in outdoor environments, variations in temperature, humidity, and air density can significantly affect performance. For example, during hot summer days, the density of air decreases, leading to lower mass flow rates through the compressor and, consequently, reduced power output. To counter this, many plants incorporate inlet cooling technologies such as evaporative coolers, fogging systems, or even mechanical chillers that lower the temperature of the incoming air, thereby increasing its density and improving the overall efficiency of the system. Similarly, in cold climates, heating systems may be used to prevent icing at the air intake, which could otherwise damage filters and compressor blades.

Noise reduction is another consideration in the design of the air intake system. As large volumes of air are drawn into the turbine at high velocity, significant noise is generated. To address this, intake silencers and acoustic enclosures are often employed, particularly in urban cogeneration plants where noise levels must remain within regulatory limits. These acoustic treatments ensure that the plant can operate reliably without disturbing nearby communities, which is an important factor in district heating or distributed generation projects.

Maintenance and monitoring of the air intake and compression system are also essential for ensuring long-term reliability. The filters in the intake system must be inspected and replaced regularly to prevent clogging, which would otherwise increase pressure drop and reduce efficiency. The compressor itself must be kept free from deposits, as fouling can degrade aerodynamic performance and increase fuel consumption. In many CHP plants, online or offline washing of the compressor is conducted to remove accumulated dirt and restore performance. Advanced monitoring systems track vibration, temperature, and pressure at different stages of the compressor, providing operators with valuable data to detect early signs of wear or imbalance. Predictive maintenance based on these diagnostics minimizes downtime and extends the operational life of the machine.

In the broader context of CHP, the air intake and compression system indirectly influences not only the turbine’s electrical output but also the quality of the exhaust gases supplied to the heat recovery steam generator. The temperature and mass flow rate of the exhaust gases are directly related to how efficiently the compressor operates and how much fuel can be combusted in the chamber. This, in turn, determines how much useful heat can be captured for district heating, industrial processes, or additional steam turbine generation. A poorly performing compressor would lead to lower exhaust temperatures and reduced thermal recovery, undermining the very concept of cogeneration.

Thus, the air intake and compression system is far more than just the front-end of a gas turbine; it is a cornerstone of the plant’s overall efficiency, reliability, and environmental performance. By ensuring that the turbine always receives clean, properly conditioned, and efficiently compressed air, this system maximizes the effectiveness of the combustion process, optimizes fuel utilization, and supports the generation of both electricity and valuable heat. Whether in a large industrial CHP installation supplying steam to a refinery or in an urban district heating project providing power and hot water to thousands of homes, the air intake and compression system sets the stage for the successful operation of the entire cogeneration process.

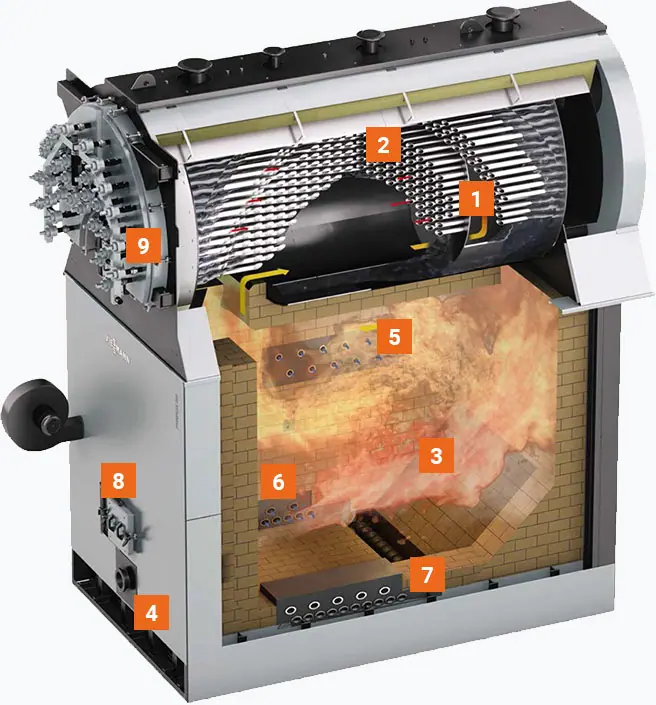

The combustion chamber of a gas turbine CHP plant is the heart of the entire energy conversion process, where the compressed air from the compressor meets the fuel and undergoes rapid chemical reactions to release large amounts of energy. This component must perform an extremely delicate balance: it has to mix fuel and high-pressure air in the correct proportions, ensure stable and complete combustion, maintain high flame temperatures, and at the same time keep emissions within strict environmental limits. In cogeneration plants, the performance of the combustion chamber directly determines both the electrical efficiency of the turbine and the temperature of the exhaust gases that later provide useful heat in the heat recovery steam generator. For this reason, its design is one of the most technologically advanced areas of gas turbine engineering.

When compressed air enters the combustion chamber, it is already at elevated pressure and temperature due to the work of the compressor. Fuel is injected into this stream through specially designed nozzles that promote fine atomization and mixing. The most common fuel in CHP applications is natural gas, valued for its high calorific value, clean combustion, and widespread availability. However, combustion chambers can also be adapted to burn alternative fuels such as biogas, syngas from waste gasification, hydrogen blends, or liquid fuels like diesel and kerosene. This versatility allows CHP plants to adapt to local fuel markets, regulations, and sustainability goals. Ignition of the mixture is initiated by spark plugs or pilot flames, after which the flame becomes self-sustaining as long as the fuel and air flow are maintained.

The high-pressure combustion releases enormous amounts of thermal energy, raising the temperature of the gases to over 1,000 °C or more, depending on turbine design. These hot gases then expand toward the turbine section, where their energy is converted into mechanical power. But the combustion chamber is more than just a space for burning fuel—it must also protect the surrounding structure and materials from these extreme conditions. To achieve this, advanced cooling techniques are used, such as film cooling, where a thin layer of cooler air is bled from the compressor and directed along the inner walls of the chamber to form a protective barrier. This prevents the metal surfaces from overheating and ensures the chamber’s longevity even under continuous operation.

Emissions control is another critical function of the combustion chamber in a CHP plant. High flame temperatures tend to favor the formation of nitrogen oxides (NOx), which are harmful pollutants subject to stringent environmental regulations. To mitigate this, modern combustion systems employ dry low-NOx (DLN) technology, where the fuel and air are premixed before ignition to produce a lean mixture that burns at lower peak temperatures. This reduces NOx formation while maintaining stable combustion. In some cases, water or steam injection is used to further reduce flame temperature and control emissions, though this method is less common in modern designs due to efficiency considerations. The ability to deliver clean combustion is especially important in urban cogeneration plants, where CHP installations often operate close to residential or commercial areas.

The stability of the combustion process also plays a decisive role in the reliability of a CHP plant. Any instability, such as flame oscillations or incomplete combustion, can cause vibrations, damage to turbine components, or efficiency losses. Therefore, combustion chambers are designed to promote a uniform flame, avoid hot spots, and ensure consistent mixing across the full range of operating conditions. Since CHP plants often need to respond flexibly to variations in heat and power demand, the combustion system must remain stable and efficient even during load changes or when running on different fuel blends. Advanced monitoring systems track pressure, temperature, and emissions in real time, allowing operators to fine-tune the combustion process and maintain optimal performance.

From the perspective of cogeneration, the combustion chamber not only initiates the conversion of fuel energy into mechanical work but also sets the stage for the quality of thermal energy that can be recovered. The temperature of the exhaust gases leaving the turbine depends heavily on how combustion is managed, and this exhaust heat is the very resource that CHP plants are designed to capture and use productively. A combustion chamber that achieves high efficiency and clean burning ensures that the exhaust gases retain both high energy content and low pollutant levels, making them ideal for downstream recovery in the heat recovery steam generator. In contrast, poorly managed combustion would not only waste fuel and increase emissions but also reduce the amount of useful heat available for industrial processes or district heating systems.

Economically, the combustion chamber contributes to the fuel efficiency that underpins the financial viability of CHP projects. By enabling complete and optimized combustion, it maximizes the energy extracted from every unit of fuel, reducing operating costs and improving payback periods. Since fuel is the largest cost factor in any CHP plant, this efficiency directly translates into savings and makes cogeneration more competitive compared to separate production of electricity and heat. Additionally, the capability to operate on renewable or low-carbon fuels provides a pathway toward sustainable operation and compliance with future environmental standards, enhancing the long-term value of the investment.

In practical terms, the combustion chamber embodies the transformation from chemical energy to thermal energy, which is the foundation of the gas turbine CHP process. It combines advanced engineering, materials science, fluid dynamics, and environmental technology in a compact unit that must perform reliably over thousands of operating hours. The heat it generates not only drives the turbine to produce electricity but also enriches the exhaust flow with valuable energy that CHP plants harness to supply steam, hot water, or even chilled water through absorption cooling. In this way, the combustion chamber is central to the dual mission of cogeneration: to produce electricity efficiently and to make full use of the heat that conventional power plants would otherwise waste.

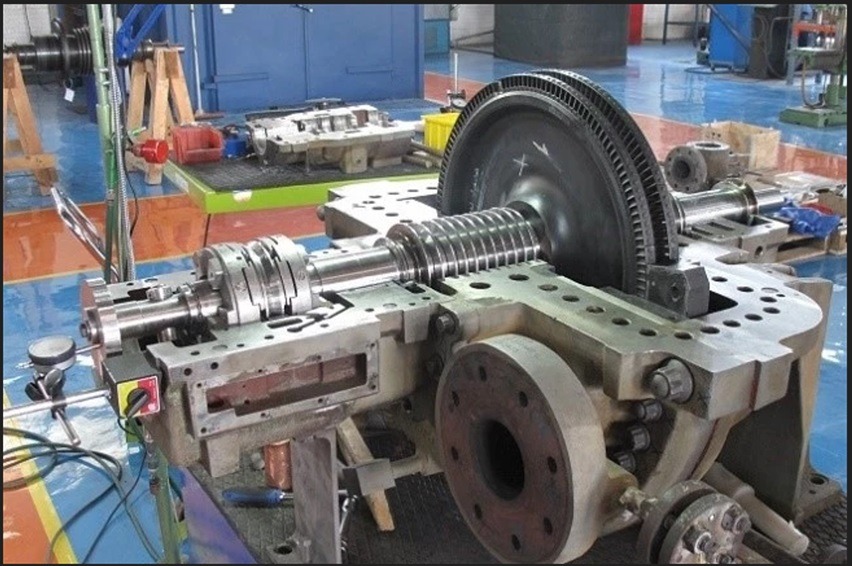

The gas turbine itself is the central rotating machine of the cogeneration plant and the component where the thermal energy generated in the combustion chamber is transformed into mechanical power. When the high-pressure, high-temperature gases leave the combustor, they expand rapidly through a series of turbine stages equipped with precisely engineered blades. These blades are arranged in alternating rows of stationary and rotating elements, with the stationary vanes directing the flow of gases at the optimal angle onto the rotating blades. As the gases expand and lose pressure, they transfer their kinetic and thermal energy to the turbine shaft, setting it into motion. This rotating shaft is directly coupled to both the compressor at the front of the turbine and the generator that produces electricity, which means the turbine is at the core of the entire cycle. Its efficiency and reliability determine the plant’s performance, making it one of the most critical and technically advanced components in a CHP system.

The materials used in turbine blades and rotors must withstand extreme operating conditions, as temperatures in the turbine can exceed 1,200 °C, with pressures dropping sharply as the gases expand. To cope with these stresses, turbine blades are manufactured from high-performance alloys, often nickel-based, and are equipped with complex internal cooling passages that allow a flow of cooler air, bled from the compressor, to circulate inside them. In some designs, the blade surfaces are coated with thermal barrier materials that protect them against heat and oxidation. These technologies make it possible for the turbine to operate reliably for thousands of hours without failure, even under demanding cogeneration conditions where the plant may run continuously to supply both electricity and thermal energy to users.

The mechanical energy produced by the turbine shaft is partially consumed by the compressor, which can require more than half of the shaft power to operate. The remaining portion is used to drive the electric generator, which converts the rotational energy into electrical output. The balance between compressor demand and turbine output is critical, since only the net power delivered to the generator is available for external use. In a CHP configuration, however, the importance of the turbine goes beyond just the electricity it generates. The exhaust gases that leave the turbine still carry a large amount of usable thermal energy at temperatures typically between 400 and 600 °C. This hot stream is what makes cogeneration possible, since instead of releasing it to the atmosphere, the system directs it to a heat recovery steam generator to produce steam or hot water for heating or industrial use.

Operational flexibility is another defining feature of gas turbines in CHP plants. They can be designed to start up relatively quickly compared to steam turbines, allowing them to respond to variations in electricity and heat demand. This is particularly valuable in urban district heating applications, where daily and seasonal fluctuations in demand can be significant. The turbine can be operated at part load when demand is low, though efficiency decreases somewhat under these conditions. Modern control systems help mitigate this by optimizing fuel flow, combustion stability, and turbine blade cooling, ensuring reliable performance across a wide range of operating modes.

The reliability of the gas turbine is vital for the overall success of cogeneration projects. Since many CHP plants supply not only electricity but also essential thermal energy to industrial processes or entire heating networks, interruptions in turbine operation can have serious consequences. To prevent unexpected downtime, turbines are equipped with sophisticated monitoring systems that track temperature distributions, vibration levels, rotor speeds, and pressure variations. Any anomaly detected can trigger alerts or automatic protective actions, ensuring safe and continuous operation. Maintenance strategies are usually based on a combination of scheduled inspections and predictive diagnostics, with critical components such as blades, bearings, and seals being checked and replaced at defined intervals to extend the plant’s lifespan.

From an efficiency standpoint, the gas turbine contributes significantly to the overall performance of a CHP plant. Simple-cycle gas turbines operating alone usually reach electrical efficiencies of around 30–40%, but when the exhaust heat is recovered and used in cogeneration, the total system efficiency can reach 70–80% or even higher. This means that the turbine, while not perfect on its own, becomes a highly effective tool for maximizing fuel utilization when integrated into a CHP arrangement. The high temperature of the exhaust gases is a direct result of the turbine’s expansion process, and this feature is precisely what distinguishes cogeneration from conventional electricity-only generation.

Environmentally, the turbine section benefits from the clean combustion achieved in the combustor, ensuring that the exhaust gases are suitable for heat recovery without producing excessive levels of pollutants. With the increasing interest in sustainable fuels, turbines are also being adapted to operate with blends of hydrogen and natural gas, or even pure hydrogen in the future. This would make gas turbine CHP plants a bridge technology between today’s natural gas-based systems and tomorrow’s low-carbon or carbon-neutral energy solutions.

Economically, the gas turbine is the engine that makes cogeneration financially attractive. Its ability to generate both electricity for local use or sale to the grid and exhaust heat for steam or hot water reduces the total cost of energy production. This dual output improves return on investment and shortens payback periods, especially for industries with high and continuous demand for both power and process heat. In addition, the long operational life and proven reliability of modern gas turbines make them a secure investment for companies and municipalities seeking stable energy supply.

In summary, the gas turbine is the centerpiece of a CHP plant, converting the chemical energy of fuel into mechanical power and providing high-temperature exhaust gases that enable efficient heat recovery. It embodies decades of engineering innovation in materials, aerodynamics, cooling technologies, and emissions control, all aimed at delivering maximum efficiency, flexibility, and reliability. In the context of cogeneration, its role extends beyond simple electricity generation to becoming a foundation for integrated energy systems that simultaneously meet the electrical, thermal, and environmental needs of modern society.

Combustion Chamber (Combustor)

The combustion chamber, or combustor, in a gas turbine CHP plant is the critical component where the chemical energy of the fuel is transformed into the high-temperature, high-pressure gases that drive the turbine and ultimately enable both electricity and heat production. This chamber must perform a complex and delicate task: it has to mix compressed air with fuel in precise proportions, ignite it safely and efficiently, sustain stable combustion under variable load conditions, and simultaneously control the formation of pollutants such as nitrogen oxides (NOx) and carbon monoxide. The design of the combustion chamber is therefore central not only to the operational efficiency of the turbine but also to the quality and temperature of the exhaust gases that feed the heat recovery steam generator, which is the heart of the cogeneration aspect of the plant.

When the compressed air from the turbine compressor enters the combustion chamber, it is at elevated pressure and temperature, ready to support efficient fuel combustion. Fuel, typically natural gas for its high energy content, low pollutant emissions, and availability, is injected through precision-engineered nozzles that ensure fine atomization and thorough mixing with the air. In addition to natural gas, many modern CHP plants are designed to operate on alternative fuels such as biogas, syngas produced from biomass or waste gasification, hydrogen-enriched fuels, or even liquid fuels such as diesel or kerosene. This fuel flexibility is crucial for adapting plants to local energy markets, renewable energy integration, and long-term decarbonization strategies. Ignition is initiated through spark plugs or pilot flames, after which the combustion becomes self-sustaining as long as fuel and air are continuously supplied.

The combustion process produces gases with extremely high temperatures, often exceeding 1,000 °C, and high pressure. These gases are then directed toward the turbine section to produce mechanical power. The chamber itself, however, must withstand these extreme conditions without damage. To achieve this, advanced cooling techniques are employed, including film cooling, where a small portion of air from the compressor flows along the inner walls to protect them from overheating, and the use of thermal barrier coatings on metallic components to resist high temperatures and oxidation. These design features ensure durability and reliability even under continuous operation, which is essential for plants that operate day and night to provide electricity and process heat.

Emissions control is a key aspect of combustor design. High flame temperatures naturally lead to the formation of nitrogen oxides, which are regulated pollutants. Modern combustion systems employ dry low-NOx (DLN) technology, where the fuel and air are premixed to create a lean combustion mixture that burns at lower temperatures while still providing complete fuel conversion. In some systems, water or steam injection is used to reduce flame temperature and further control emissions, though this is less common in newer designs due to efficiency losses. The result is a combustion process that maintains high thermal output while minimizing harmful emissions, an important requirement for urban CHP installations or industrial sites operating under strict environmental regulations.

The stability of combustion is also critical for turbine and plant reliability. Any fluctuations or instabilities in the flame can lead to vibrations, uneven heating, or incomplete combustion, which could reduce efficiency or even damage turbine components. Combustion chambers are therefore carefully designed to ensure uniform flame distribution, avoid hot spots, and maintain performance over a wide range of operating conditions, including partial loads or varying fuel compositions. Advanced monitoring systems track parameters such as pressure, temperature, and emissions, allowing real-time adjustments to optimize combustion and protect turbine integrity.

The performance of the combustion chamber directly impacts the cogeneration efficiency of the plant. The temperature and flow rate of the exhaust gases leaving the turbine are a function of how well combustion is carried out. High-temperature, consistent exhaust gases ensure maximum energy recovery in the heat recovery steam generator, which in turn produces steam or hot water for industrial processes, district heating, or even additional electricity generation in a combined cycle setup. Poor combustion, in contrast, would not only waste fuel but also limit the amount of usable heat, undermining the economic and environmental benefits of cogeneration.

Economically, an efficient combustion chamber maximizes fuel utilization, reducing operating costs and improving payback periods for the CHP investment. By ensuring complete and optimized combustion, every unit of fuel contributes to electricity production and usable heat, enhancing the financial viability of the plant. Moreover, the capability to burn renewable or low-carbon fuels adds long-term value, allowing operators to comply with evolving environmental regulations and to participate in sustainable energy initiatives.

In practical terms, the combustion chamber embodies the transformation of chemical energy into thermal energy, which is essential for both the mechanical power generation and the thermal output that define cogeneration. It integrates advanced engineering, fluid dynamics, material science, and emissions control into a compact, high-performance unit capable of thousands of continuous operational hours. The heat it generates not only drives the turbine for electricity production but also provides the high-quality exhaust stream that CHP plants recover for steam, hot water, or even absorption cooling. In this way, the combustion chamber is central to achieving the twin objectives of cogeneration: efficient electricity generation and effective utilization of heat that would otherwise be wasted.

The electric generator in a gas turbine CHP plant is the component that converts the mechanical energy produced by the rotating turbine shaft into electrical energy that can be used on-site or supplied to the grid. The turbine shaft, driven by the high-temperature, high-pressure gases from the combustor, rotates at high speed, and the generator is directly coupled to this shaft in most designs. As the rotor of the generator spins within a magnetic field, it induces an alternating current in the stator windings, producing electricity. The efficiency and stability of this conversion process are critical because any losses in the generator reduce the overall energy output of the CHP plant, while fluctuations in voltage or frequency can compromise the quality of power supplied to industrial processes, district heating networks, or the electrical grid.

Modern gas turbine generators are typically synchronous machines, capable of maintaining precise frequency and voltage output even under variable load conditions. This capability is essential in cogeneration applications, where the plant may need to respond to changes in both electricity and heat demand. The generator is designed to handle the full output of the turbine while minimizing electrical losses, and its construction includes high-quality copper windings, robust insulation, and efficient

The electric generator in a gas turbine CHP plant is the device that transforms the mechanical rotation of the turbine shaft into usable electrical energy. As the turbine spins under the force of the high-pressure, high-temperature gases produced in the combustion chamber, the rotor of the generator rotates within a precisely designed magnetic field. This rotation induces an alternating current in the stator windings, producing electricity that can either be consumed on-site to supply industrial processes or district energy networks, or exported to the external electrical grid. The performance of the generator is critical because it determines the amount of electricity available relative to the mechanical energy produced by the turbine, and any inefficiency in this conversion directly reduces the overall energy output of the plant. Modern generators are built to operate under high-speed, high-torque conditions with minimal electrical losses, ensuring that the maximum fraction of the turbine’s mechanical energy is converted into electrical energy.

Generators used in cogeneration plants are typically synchronous machines, capable of producing electricity at a stable voltage and frequency even under varying load conditions. This is especially important for CHP applications, where electricity demand may fluctuate while thermal demand is simultaneously changing. The generator’s ability to maintain grid synchronization ensures that industrial users and district heating systems receive reliable and consistent power, which is critical for processes sensitive to voltage variations or interruptions. Advanced control systems constantly monitor the generator’s output, adjusting excitation and load conditions to optimize efficiency and prevent electrical faults, while protective systems guard against overheating, overcurrent, and other abnormal operating conditions.

In addition to electrical conversion, the generator also plays an indirect role in cogeneration efficiency by influencing turbine operation. The load applied to the generator affects the rotational speed of the turbine shaft and the energy extracted from the combustion gases. When the generator operates efficiently and can accept variable load without disruption, the turbine can maintain optimal performance across a range of operating conditions, which in turn ensures that the exhaust gases retain sufficient thermal energy for capture in the heat recovery steam generator. A generator that is poorly matched to the turbine or suffers from losses would not only reduce electrical output but also potentially compromise the temperature and flow of the exhaust gases, diminishing the plant’s overall cogeneration efficiency.

Cooling and insulation of the generator are essential for its reliable operation in a CHP environment, where the plant often runs continuously to meet constant thermal and electrical demands. Generators are equipped with air or hydrogen cooling systems, depending on size and design, to dissipate the heat generated in the windings and core. Proper cooling prevents degradation of insulation, reduces maintenance requirements, and prolongs operational life. Hydrogen-cooled generators, commonly used in larger CHP installations, offer superior thermal conductivity and lower friction losses, allowing higher efficiency and stable operation at large outputs. Routine monitoring and maintenance, including vibration analysis, thermal imaging, and electrical testing, are performed to ensure the generator maintains its performance over thousands of operational hours.

The generator also enables the integration of cogeneration systems with the broader energy infrastructure. In industrial plants, the electricity produced may power motors, pumps, lighting, and process equipment, reducing the need for external electricity purchases and lowering operational costs. In district heating applications, surplus electricity can be sold to the grid, providing an additional revenue stream. The generator’s design and control system must accommodate these variable operating modes without compromising reliability or efficiency, which requires careful engineering and integration with turbine, combustor, and heat recovery systems.

From an environmental perspective, a high-efficiency generator contributes indirectly to reduced emissions. By maximizing the conversion of mechanical energy into electricity, less fuel is required to produce the same electrical and thermal output. This reduces the overall consumption of natural gas or alternative fuels, which in turn lowers carbon dioxide, nitrogen oxide, and other pollutant emissions per unit of useful energy delivered. In CHP plants that operate on renewable fuels such as biogas or hydrogen, generator efficiency is equally critical to ensure that the renewable energy resource is utilized optimally, further enhancing sustainability.

Economically, the generator represents a key factor in the return on investment of a CHP plant. Its performance directly impacts both the quantity and quality of electricity available for use or sale, influencing operational savings and revenue potential. A well-maintained, high-efficiency generator minimizes downtime, reduces maintenance costs, and ensures that the cogeneration system delivers predictable and reliable energy over decades of operation. Its integration with turbine and heat recovery systems is carefully calibrated to maximize both electricity production and the thermal energy that supports industrial processes or district heating.

In essence, the electric generator in a gas turbine CHP plant is more than a component for producing electricity; it is a central enabler of the cogeneration concept. By efficiently converting mechanical energy into electrical energy while allowing the turbine to operate optimally and maintain high-quality exhaust gases, it ensures that the plant achieves the dual goals of reliable power generation and productive heat recovery. Its reliability, efficiency, and integration with advanced control systems make it indispensable for the operation of modern gas turbine CHP installations, whether serving a single industrial facility, a cluster of commercial users, or an entire urban district heating network.

The combustion chamber, or combustor, in a gas turbine CHP plant continues to be central to the overall efficiency and performance of the system, as it not only generates the high-temperature gases needed to drive the turbine but also determines the quality of the exhaust heat that will be recovered for cogeneration purposes. The chamber is designed to achieve complete and stable combustion across a wide range of operating conditions, which is critical in CHP applications where the plant must respond simultaneously to fluctuating electrical and thermal demands. Any inefficiency in the combustion process can result in lower turbine output, reduced exhaust temperature, and ultimately diminished energy recovery, affecting both the economic and environmental performance of the plant.

Inside the combustor, advanced fuel injection and air mixing techniques ensure that the fuel-air mixture burns evenly and at optimal temperatures. Lean premix combustion is commonly used to reduce nitrogen oxide emissions while maintaining high efficiency, and modern designs often incorporate multiple fuel nozzles to allow flexible operation with varying fuel types. In addition to natural gas, which remains the primary fuel, many CHP plants are increasingly capable of burning biogas, syngas, or hydrogen blends, allowing operators to take advantage of renewable or low-carbon fuels. This flexibility is particularly valuable in industrial settings where fuel availability or cost may vary, or in regions with regulatory incentives for using alternative fuels.