Biomass: A biomass waste-to-energy plant is a facility designed to convert organic waste materials, including agricultural residues, forestry by-products, municipal green waste, and certain industrial biomass, into usable energy in the form of electricity, heat, or combined heat and power. The plant begins with feedstock reception, where biomass materials are collected, sorted, and temporarily stored to ensure a consistent and homogeneous supply. Proper feedstock preparation is crucial for efficient conversion, as it reduces variability in moisture content, particle size, and composition, which directly impacts combustion or gasification efficiency. Preprocessing systems typically include shredding, drying, and screening to achieve optimal physical characteristics of the biomass.

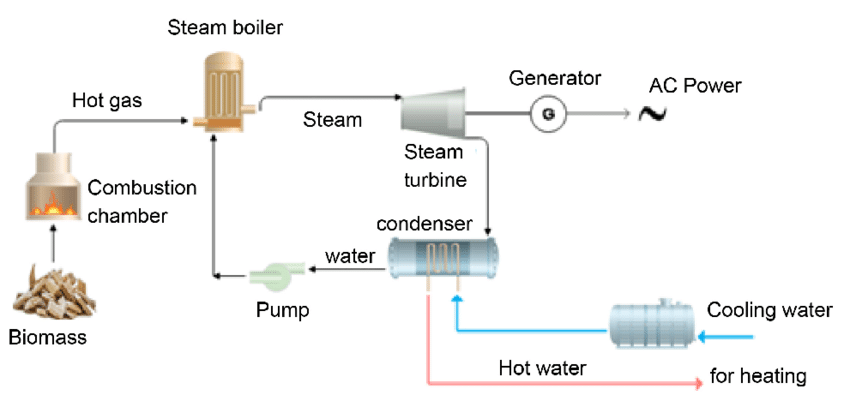

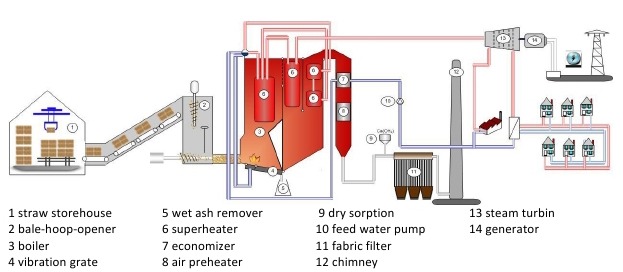

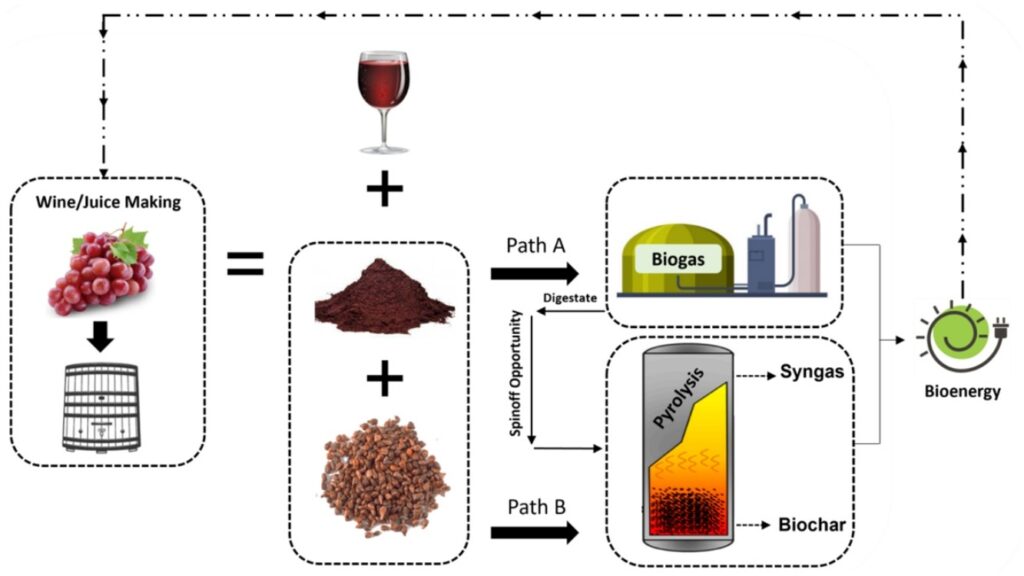

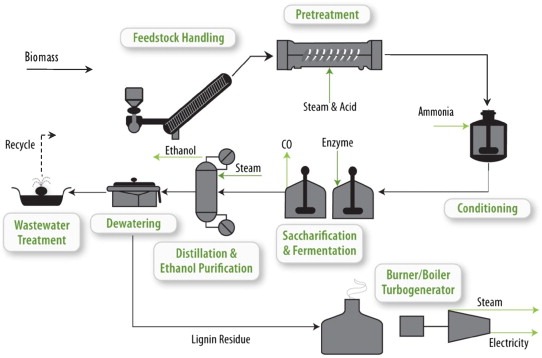

Once prepared, the biomass is conveyed into the energy conversion unit, which may employ direct combustion, gasification, pyrolysis, or anaerobic digestion technologies depending on the plant design and desired energy output. In direct combustion systems, biomass is burned in a boiler or furnace to generate steam, which then drives a turbine connected to a generator for electricity production. Gasification systems, on the other hand, convert biomass into a combustible gas mixture, known as syngas, through partial oxidation at high temperatures, which can then fuel internal combustion engines, gas turbines, or combined cycle systems. Pyrolysis processes thermally decompose biomass in the absence of oxygen to produce bio-oil, syngas, and char, offering flexibility for downstream energy utilization. Anaerobic digestion relies on microbial decomposition of wet biomass under controlled conditions to generate biogas, primarily composed of methane, which can be used in boilers, engines, or upgraded to biomethane for grid injection.

Critical to the plant’s operation is the management of heat and energy efficiency. Modern biomass plants often integrate combined heat and power (CHP) systems to maximize energy utilization, capturing both electricity and thermal energy for district heating or industrial processes. Flue gas cleaning and emission control systems are also essential, as combustion or gasification of biomass can release particulate matter, nitrogen oxides, and other pollutants. Technologies such as electrostatic precipitators, fabric filters, scrubbers, and selective catalytic reduction systems ensure compliance with stringent environmental regulations. Continuous monitoring and control systems optimize feedstock flow, combustion conditions, boiler pressure, temperature, and emissions, maintaining both efficiency and safety.

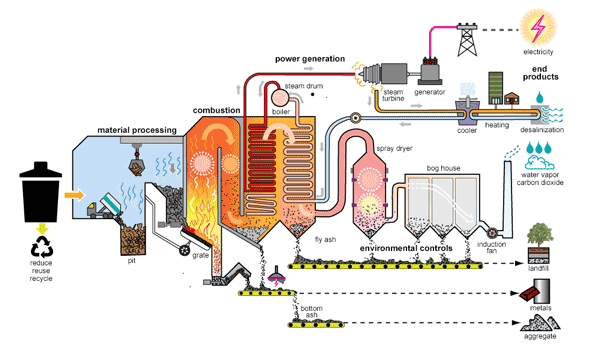

The plant also includes ash handling and residue management systems to deal with by-products such as bottom ash, fly ash, and digestate. Bottom ash is typically collected from the furnace and can be further processed for use in construction materials, while fly ash captured from flue gas cleaning is handled with care due to potential heavy metal content. In the case of anaerobic digestion, digestate is separated into solid and liquid fractions, with solids often used as soil conditioners and liquids recycled or treated for nutrient recovery. Storage and logistics infrastructure support the steady supply of biomass, including silos, hoppers, conveyor systems, and trucks, while robust safety measures address fire risks, dust explosions, and gas leaks.

Advanced biomass waste-to-energy plants increasingly employ digital monitoring, predictive maintenance, and energy management systems to optimize operations, reduce downtime, and enhance sustainability. Integration with renewable energy grids, flexible operation modes, and combined heat and power applications further increase the plant’s value proposition. Overall, such plants contribute significantly to circular economy objectives, reducing landfill dependency, mitigating greenhouse gas emissions, and providing renewable energy, all while managing a wide range of biomass feedstocks efficiently and safely.

Biomass Waste-to-Energy Plant

A biomass waste-to-energy plant operates as a complex, highly integrated system designed to extract energy from organic waste materials while minimizing environmental impact. The process begins with the careful reception and handling of biomass feedstock, which can include agricultural residues such as straw, husks, and stalks, forestry by-products like wood chips, sawdust, and bark, as well as green municipal waste, industrial organic residues, and certain forms of energy crops. Consistency in feedstock quality is vital, as variations in moisture content, particle size, and composition directly affect combustion efficiency, gasification quality, and the performance of downstream energy conversion systems. To achieve this, preprocessing facilities are employed to reduce particle size, remove contaminants, and, where necessary, dry the biomass to an optimal moisture level. Shredders, grinders, trommels, and dryers work together to produce a uniform, manageable material that can be fed continuously into the energy conversion units without interruptions or performance fluctuations, ensuring the plant maintains steady thermal output and efficiency.

Once processed, the biomass enters the energy conversion stage, which may employ direct combustion, advanced gasification, pyrolysis, or anaerobic digestion technologies, depending on the plant’s design and energy output requirements. In direct combustion systems, carefully controlled burning of biomass in high-efficiency boilers generates superheated steam that drives turbines connected to electrical generators, often integrated with combined heat and power applications to utilize both electricity and thermal energy for industrial processes or district heating. Gasification plants transform solid biomass into syngas through partial oxidation at high temperatures, producing a versatile fuel that can be combusted in internal combustion engines, gas turbines, or converted into chemicals and liquid biofuels. Pyrolysis, by contrast, decomposes biomass in the absence of oxygen to produce bio-oil, syngas, and char, providing flexible downstream options for energy or material use. Anaerobic digestion takes a different approach, using microbial processes in sealed, controlled digesters to break down wet biomass and organic residues, producing methane-rich biogas suitable for combustion in engines or boilers, or for purification and injection into natural gas grids, while the resulting digestate serves as a nutrient-rich soil amendment.

The efficiency and sustainability of a biomass waste-to-energy plant depend heavily on its thermal management, emissions control, and process optimization. Advanced plants integrate combined heat and power systems to maximize energy recovery, ensuring that heat generated during combustion or gasification is captured and reused for process heating, drying operations, or local heating networks. Emissions control systems are critical to compliance with environmental regulations and to protect air quality; they include electrostatic precipitators, fabric filters, cyclones, scrubbers, and selective catalytic reduction units that remove particulate matter, nitrogen oxides, sulfur compounds, and other pollutants from flue gases. Continuous monitoring and automation allow operators to adjust feed rates, combustion temperatures, oxygen levels, and pressure conditions in real time, maintaining optimal efficiency while minimizing harmful emissions. Sensors, programmable logic controllers, and energy management software work together to ensure that the plant operates within strict safety and environmental parameters, reducing the risk of operational disruptions or accidents associated with dust, flammable gases, or high-temperature equipment.

Residue handling and material recovery are equally important to the plant’s sustainability and economic viability. Bottom ash collected from combustion processes can be repurposed as aggregate material in construction, while fly ash captured through filtration systems must be carefully managed due to potential heavy metal content. In anaerobic digestion, the digestate is separated into solid and liquid fractions, with solids used as fertilizer or soil conditioner and liquids either treated for nutrient recovery or recycled into the process to maintain moisture balance. Logistics and storage infrastructure support consistent feedstock supply and residue handling, including silos, hoppers, conveyors, trucks, and automated material handling systems, which ensure smooth operations while minimizing labor and exposure risks.

Modern biomass waste-to-energy plants increasingly employ digital monitoring, predictive maintenance, and real-time energy optimization strategies to enhance operational efficiency, reduce downtime, and extend equipment life. Integration with renewable energy grids, flexible operation modes, and advanced control strategies allow plants to adapt to variations in feedstock supply, energy demand, and market conditions, making them highly resilient components of sustainable energy systems. By efficiently converting a wide range of biomass feedstocks into electricity, heat, and biogas, these plants contribute to reducing landfill dependency, lowering greenhouse gas emissions, and supporting circular economy objectives, all while providing reliable, renewable energy solutions. The combination of robust preprocessing, efficient energy conversion, stringent emissions control, sophisticated monitoring, and careful residue management makes a biomass waste-to-energy plant a highly effective and sustainable technology for addressing the dual challenges of waste management and renewable energy generation.

A biomass waste-to-energy plant represents a sophisticated integration of technologies aimed at converting organic waste streams into valuable energy while maintaining environmental compliance and operational efficiency. At its core, the plant begins with the reception and storage of a diverse range of biomass feedstocks, which can include agricultural residues such as straw, corn stover, and husks, forestry by-products including wood chips, sawdust, and bark, municipal green waste, organic fractions of industrial waste, and specially cultivated energy crops. Proper handling and preprocessing of these materials are crucial, as variations in moisture content, particle size, and chemical composition directly influence combustion characteristics, gasification performance, and the overall efficiency of energy conversion. Shredding, grinding, screening, and drying processes are employed to produce uniform biomass that can be reliably fed into energy conversion units without causing blockages or performance fluctuations. Conveyor systems, hoppers, and automated feed mechanisms ensure that the flow of biomass remains continuous, allowing for steady energy production and operational stability.

Once the feedstock is prepared, it enters the energy conversion phase, which may utilize direct combustion, gasification, pyrolysis, or anaerobic digestion depending on plant design and desired outputs. In direct combustion facilities, biomass is burned in highly controlled furnaces or boilers to generate superheated steam, which drives turbines connected to generators, producing electricity. Many modern plants combine this with heat recovery systems, enabling the simultaneous production of heat for district heating networks or industrial processes, effectively implementing combined heat and power (CHP) strategies that maximize overall energy efficiency. Gasification systems convert biomass into syngas, a mixture of carbon monoxide, hydrogen, and other combustible gases, through partial oxidation at high temperatures. This syngas can be combusted in internal combustion engines, gas turbines, or even processed into biofuels, providing flexibility in energy output. Pyrolysis thermally decomposes biomass in an oxygen-free environment, generating bio-oil, syngas, and char, each with multiple energy or material applications. Anaerobic digestion utilizes microbial activity under controlled conditions to produce biogas from wet organic waste streams, with methane-rich gas captured for use in engines, boilers, or purification for grid injection, while digestate is managed as a nutrient-rich soil amendment.

Thermal management, emissions control, and operational optimization are critical to the success of a biomass plant. Advanced plants integrate sophisticated heat recovery systems to utilize exhaust heat for drying feedstock, preheating boiler water, or supplying district heating, enhancing efficiency and reducing energy losses. Flue gas cleaning systems are essential for minimizing environmental impact, employing electrostatic precipitators, fabric filters, scrubbers, and catalytic reduction units to remove particulates, nitrogen oxides, sulfur compounds, and other potential pollutants. Automation and control systems continuously monitor combustion parameters, boiler pressure, temperature, feedstock flow rates, and emissions, allowing for real-time adjustments that maintain optimal efficiency and ensure compliance with environmental regulations. Safety systems are implemented to manage the risks associated with dust explosions, fire hazards, high-pressure steam, and flammable gases, while predictive maintenance strategies minimize downtime and prolong equipment life.

Residue and by-product management form an integral part of plant operations. Combustion generates bottom ash and fly ash, which require proper handling: bottom ash can be repurposed as construction material, while fly ash must be carefully contained due to potential heavy metal content. In anaerobic digestion systems, digestate is separated into solids and liquids; solids can serve as fertilizer or soil conditioners, and liquids may be treated for nutrient recovery or recycled into the process to maintain moisture balance. Storage and logistics systems, including silos, conveyors, and automated handling equipment, are essential to maintaining a consistent feedstock supply and ensuring safe, efficient residue management.

Modern biomass waste-to-energy plants increasingly incorporate digital monitoring, predictive analytics, and advanced energy management systems to enhance performance, reduce operational risks, and increase sustainability. Flexibility in operations allows plants to adapt to fluctuations in feedstock availability, energy demand, and grid requirements, ensuring continuous and efficient energy production. By efficiently converting biomass feedstocks into electricity, heat, and biogas, these plants not only provide renewable energy solutions but also contribute to reducing landfill dependency, lowering greenhouse gas emissions, and supporting circular economy objectives. The combination of feedstock preprocessing, efficient energy conversion, rigorous emissions control, real-time monitoring, and residue management positions biomass waste-to-energy technology as a vital solution for modern sustainable energy systems, addressing both waste management challenges and the growing need for renewable energy resources.

When discussing biomass waste-to-energy plants, the main types of technologies for converting biomass into energy can be grouped based on the method of energy conversion, and each type has its own operational characteristics, advantages, and applications. These types are generally described without breaking into sections but as a continuous explanation:

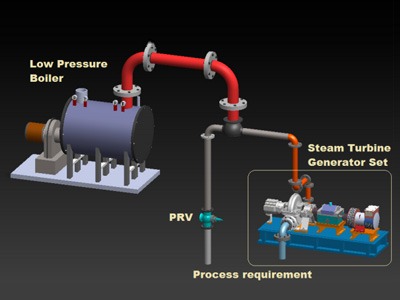

Biomass combustion or direct firing is the most established and widely used method. In this type, solid biomass feedstocks such as wood chips, agricultural residues, or municipal green waste are burned in a furnace or boiler to produce heat. This heat is then used to generate steam, which drives a turbine connected to an electricity generator, often in combination with heat recovery for district heating or industrial use, forming a combined heat and power (CHP) system. Combustion systems can handle a wide variety of feedstocks but require careful control of moisture content and particle size to maintain stable operation and reduce emissions.

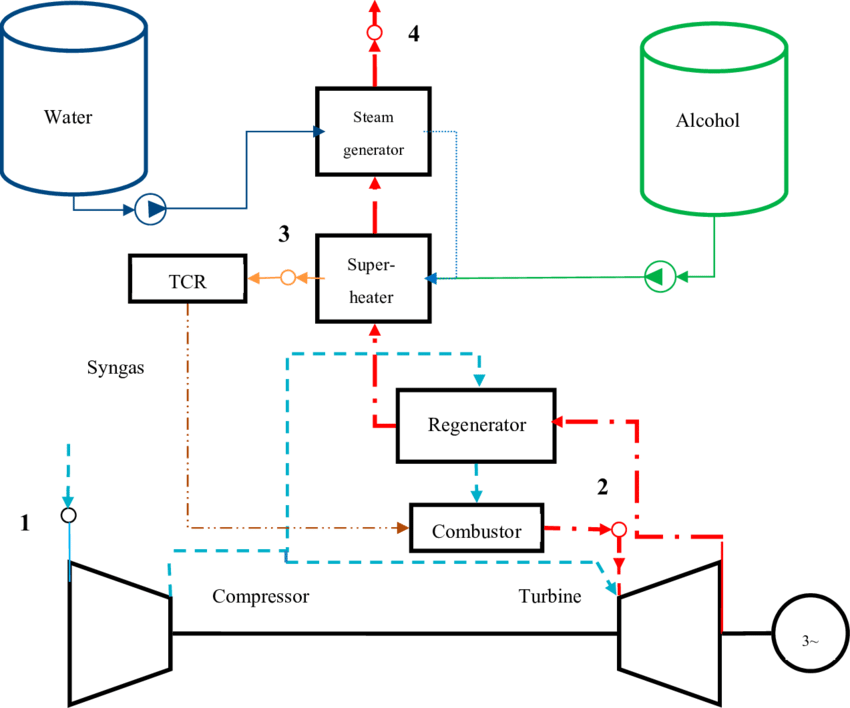

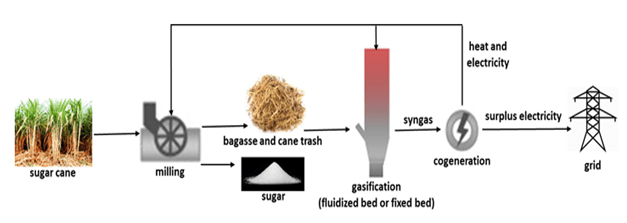

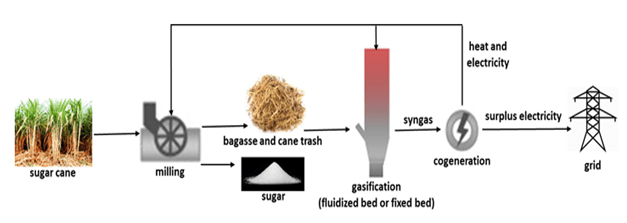

Gasification is another major type, where biomass is converted into a combustible gas mixture known as syngas through partial oxidation at high temperatures in a controlled oxygen environment. This syngas, primarily composed of carbon monoxide, hydrogen, and small amounts of methane, can then be used to fuel gas engines, turbines, or further processed into liquid biofuels or chemicals. Gasification offers higher efficiency than simple combustion and enables more flexible energy use, though it requires more sophisticated control systems and feedstock preparation.

Pyrolysis is a thermochemical process that decomposes biomass in the absence of oxygen, producing bio-oil, syngas, and char. Bio-oil can be used as a renewable liquid fuel for boilers or engines, syngas can be burned for electricity, and char can serve as a soil amendment or solid fuel. Pyrolysis is particularly useful for managing high-moisture or heterogeneous biomass streams and allows for diversified energy and material outputs.

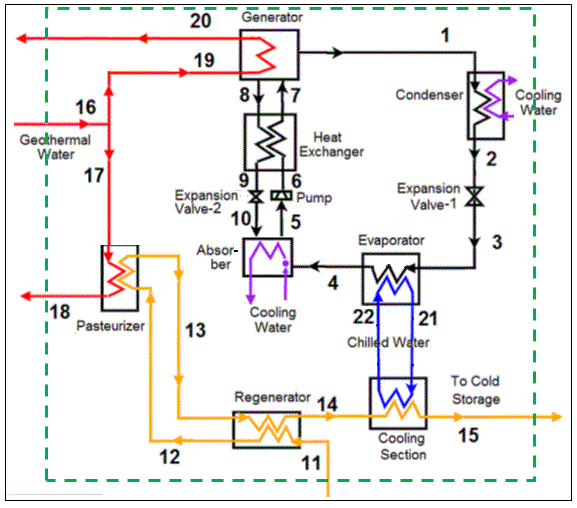

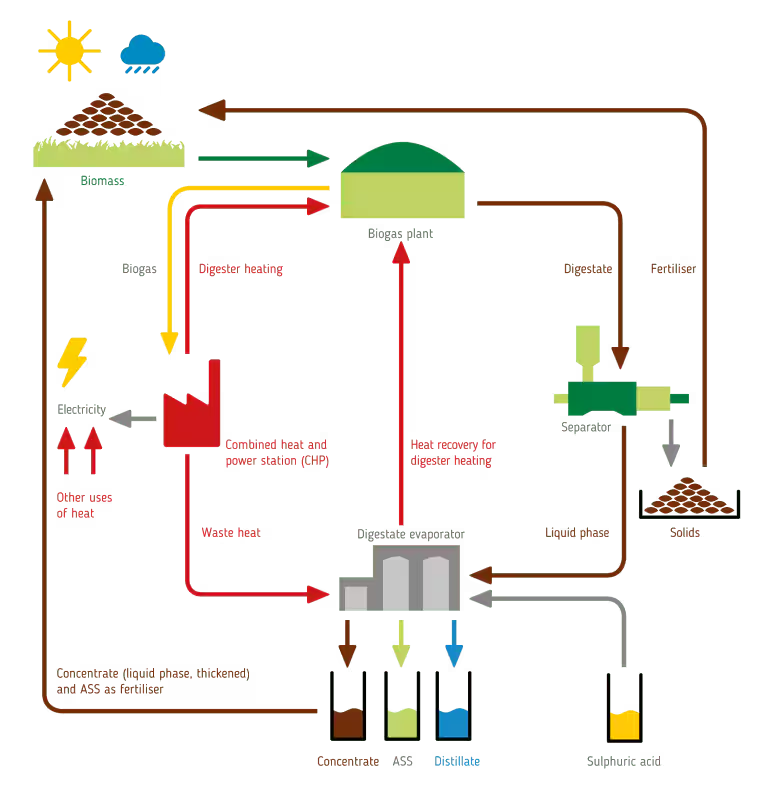

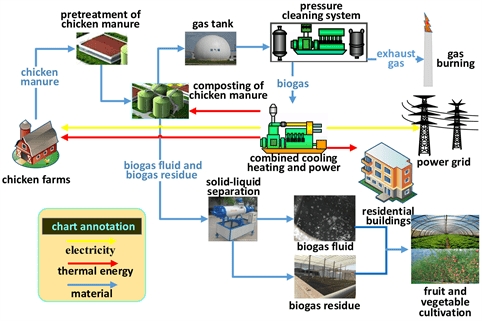

Anaerobic digestion represents a biological conversion type, in which wet biomass such as food waste, agricultural slurry, or sewage sludge is decomposed by microorganisms in sealed, oxygen-free digesters. This process produces methane-rich biogas, which can be used for electricity generation, heating, or injection into natural gas grids after purification. The residual digestate is a nutrient-rich material suitable for fertilizer use. Anaerobic digestion is highly suitable for wet organic waste and contributes to both renewable energy generation and nutrient recycling.

Advanced combined or hybrid systems integrate these technologies to optimize energy recovery from biomass. For instance, gasification or pyrolysis can be paired with combustion of the residual char to maximize energy efficiency, while anaerobic digestion can be combined with CHP systems to utilize biogas for electricity and heat. These hybrid approaches increase flexibility, efficiency, and the ability to handle diverse biomass streams while supporting environmental and sustainability goals.

Overall, the main types of biomass waste-to-energy plants—direct combustion, gasification, pyrolysis, anaerobic digestion, and hybrid systems—offer a spectrum of technical solutions for converting organic waste into electricity, heat, and biogas. The choice of type depends on feedstock characteristics, desired energy outputs, environmental requirements, and economic considerations, allowing biomass energy technology to be adapted to different industrial, municipal, or agricultural applications.

Biomass Energy Recovery Plant

A biomass energy recovery plant is a highly specialized facility designed to convert organic waste materials, including agricultural residues, forestry by-products, municipal green waste, food processing residues, and certain industrial organic wastes, into usable forms of energy such as electricity, heat, or biogas, while minimizing environmental impact and supporting sustainable resource management. The process begins with feedstock reception, where raw biomass is collected, sorted, and temporarily stored to ensure a continuous and uniform supply. Preprocessing is a critical step, as variations in moisture content, particle size, and material composition can significantly affect the efficiency of energy conversion processes. Preprocessing equipment such as shredders, grinders, trommels, and dryers is used to produce biomass of a consistent size and dryness, which facilitates smooth feeding into energy conversion systems and prevents operational disruptions or inefficiencies. Advanced plants often incorporate automated feeding systems, hoppers, and conveyor mechanisms to maintain continuous and controlled material flow.

Once prepared, the biomass enters the energy conversion phase, which may involve direct combustion, gasification, pyrolysis, or anaerobic digestion depending on the plant design and desired energy outputs. In direct combustion systems, biomass is burned in high-efficiency boilers to generate superheated steam, which drives turbines connected to generators for electricity production. Many modern facilities integrate combined heat and power (CHP) systems to utilize the thermal energy produced during combustion for district heating, industrial processes, or other thermal applications, thereby maximizing energy recovery. Gasification technology converts biomass into a combustible syngas composed mainly of carbon monoxide, hydrogen, and methane through partial oxidation at high temperatures. This syngas can fuel internal combustion engines, gas turbines, or be further processed into liquid biofuels and chemicals, providing a versatile and efficient energy conversion route. Pyrolysis thermally decomposes biomass in an oxygen-free environment to generate bio-oil, syngas, and char, which can all be used for energy or material applications. Anaerobic digestion employs microbial processes to decompose wet organic waste under oxygen-free conditions, producing methane-rich biogas suitable for electricity generation, heating, or upgrading to biomethane for grid injection, with the resulting digestate serving as a nutrient-rich soil conditioner.

Efficient thermal management, emissions control, and operational optimization are key to the successful operation of a biomass energy recovery plant. Modern plants employ heat recovery systems that capture waste heat from combustion or gasification for use in preheating biomass, drying feedstock, or supplying local heating networks, increasing overall energy efficiency. Advanced flue gas cleaning systems, including electrostatic precipitators, fabric filters, scrubbers, and selective catalytic reduction units, remove particulates, nitrogen oxides, sulfur compounds, and other pollutants, ensuring compliance with environmental regulations. Continuous monitoring and automation of feed rates, combustion temperature, oxygen concentration, and boiler pressure allow real-time optimization of energy conversion and emissions, while safety systems mitigate risks associated with dust explosions, flammable gases, and high-pressure steam. Predictive maintenance programs, digital monitoring, and remote diagnostics further enhance operational reliability and reduce unplanned downtime.

Residue management is an integral component of biomass energy recovery plants. Combustion produces bottom ash and fly ash, which must be handled carefully: bottom ash can be repurposed as construction material, while fly ash is treated to minimize environmental risks. In anaerobic digestion, the digestate is separated into solid and liquid fractions, with solids often used as fertilizer or soil conditioner and liquids treated for nutrient recovery or recycled within the process. Storage and logistics systems, including silos, hoppers, conveyor systems, and trucks, support consistent feedstock supply and efficient residue handling, reducing labor requirements and operational bottlenecks.

Modern biomass energy recovery plants increasingly incorporate digital energy management systems, predictive analytics, and advanced process control to enhance efficiency, reduce operational risks, and extend equipment life. Hybrid configurations combining combustion, gasification, pyrolysis, or anaerobic digestion are also becoming more common, maximizing energy output and providing flexibility in handling diverse biomass streams. By converting waste biomass into electricity, heat, and biogas, these plants contribute to circular economy objectives, reduce landfill dependence, mitigate greenhouse gas emissions, and provide renewable energy solutions for industrial, municipal, and agricultural applications. The integration of preprocessing, efficient energy conversion, emissions control, digital monitoring, and residue management ensures that biomass energy recovery plants operate sustainably, safely, and efficiently, making them a critical technology for modern renewable energy and waste management strategies.

A biomass energy recovery plant functions as an integrated system designed to transform organic waste materials into usable energy in the form of electricity, heat, or biogas while ensuring environmental compliance and operational efficiency. The plant begins with the reception and handling of biomass feedstock, which can encompass agricultural residues such as straw, husks, and stalks, forestry by-products including wood chips, sawdust, and bark, municipal green waste, food processing residues, and select industrial organic waste streams. Proper feedstock management is critical because variations in moisture content, particle size, and chemical composition can significantly impact combustion efficiency, gasification quality, or digestion performance. Preprocessing facilities such as shredders, grinders, trommels, and dryers ensure that biomass is uniform, manageable, and suitable for continuous feeding into the conversion units. Advanced conveyor systems, automated hoppers, and metered feeding mechanisms maintain a steady flow of material, preventing blockages or interruptions that could compromise energy output or damage equipment.

Once the biomass is prepared, it enters the energy conversion phase, which may involve direct combustion, gasification, pyrolysis, anaerobic digestion, or hybrid approaches depending on the plant design and energy requirements. In direct combustion systems, biomass is burned in high-efficiency furnaces or boilers to generate superheated steam, which powers turbines connected to generators for electricity production. Many modern facilities utilize combined heat and power (CHP) systems, allowing the simultaneous capture and use of thermal energy for district heating or industrial applications, enhancing overall energy efficiency. Gasification technology converts solid biomass into a combustible syngas through partial oxidation at high temperatures; this syngas can then be combusted in engines or turbines, or processed into liquid biofuels or chemical intermediates, providing versatile and efficient energy utilization. Pyrolysis thermochemically decomposes biomass in an oxygen-free environment, producing bio-oil, syngas, and char, each of which can serve energy or material applications, offering flexibility for waste streams with high moisture or mixed compositions. Anaerobic digestion leverages microbial processes to break down wet organic biomass in oxygen-free digesters, producing methane-rich biogas suitable for electricity generation, heating, or purification for grid injection, with digestate acting as a nutrient-rich soil conditioner.

Thermal management and emissions control are central to the plant’s sustainable operation. Heat recovery systems capture waste heat from combustion or gasification processes for preheating biomass, drying feedstock, or supplying district heating networks, increasing overall energy efficiency and reducing losses. Advanced flue gas cleaning systems, including electrostatic precipitators, fabric filters, cyclones, scrubbers, and selective catalytic reduction units, remove particulate matter, nitrogen oxides, sulfur compounds, and other pollutants, ensuring compliance with strict environmental regulations. Automation and monitoring systems continuously track combustion parameters, boiler pressure, temperature, oxygen levels, and feedstock flow rates, allowing real-time adjustments to optimize energy output and emissions. Safety systems are implemented to mitigate risks associated with high-pressure steam, flammable gases, and combustible dust, while predictive maintenance programs and remote diagnostics enhance operational reliability and minimize downtime.

Residue management is another crucial component of biomass energy recovery plants. Combustion produces bottom ash and fly ash, which are handled and processed to reduce environmental risks: bottom ash can be reused in construction materials, while fly ash is carefully treated to mitigate potential heavy metal content. In anaerobic digestion, digestate is separated into solid and liquid fractions, with solids often used as fertilizer or soil amendments and liquids treated for nutrient recovery or recycled to maintain process moisture balance. Storage and logistics systems, including silos, hoppers, conveyors, and trucks, facilitate continuous feedstock supply and efficient handling of by-products, reducing labor requirements and operational bottlenecks.

Modern biomass energy recovery plants increasingly integrate digital monitoring, predictive analytics, and energy management systems to optimize efficiency, reduce operational risks, and extend equipment life. Hybrid configurations, which combine combustion, gasification, pyrolysis, or anaerobic digestion, are increasingly used to maximize energy recovery and handle diverse biomass streams with varying moisture, composition, and particle size. By converting biomass into electricity, heat, and biogas, these plants contribute to circular economy objectives, reduce landfill dependency, mitigate greenhouse gas emissions, and provide renewable energy solutions across industrial, municipal, and agricultural sectors. The integration of preprocessing, efficient energy conversion, emissions control, digital monitoring, and residue management ensures that biomass energy recovery plants operate sustainably, safely, and efficiently, establishing them as a vital technology in modern renewable energy and waste management strategies.

A biomass energy recovery plant is a complex and highly integrated facility designed to efficiently convert a wide range of organic waste materials into useful forms of energy, including electricity, heat, and biogas, while adhering to strict environmental and safety standards. The process begins with the reception and handling of biomass feedstocks, which may include agricultural residues such as straw, corn stalks, husks, and cobs, forestry by-products including wood chips, sawdust, and bark, municipal green waste, food processing residues, and certain industrial organic wastes. The quality, moisture content, particle size, and composition of these feedstocks are critical factors affecting the efficiency of energy conversion processes. Preprocessing equipment such as shredders, grinders, trommels, and dryers is employed to create a uniform material suitable for continuous feeding into combustion, gasification, pyrolysis, or anaerobic digestion systems. Automated conveyors, hoppers, and feeding mechanisms ensure a steady flow of biomass, preventing blockages, interruptions, or fluctuations in energy output that could compromise the stability of the plant.

The core of a biomass energy recovery plant lies in its energy conversion units, which may operate on one or multiple principles depending on the plant design. In direct combustion systems, biomass is burned in high-efficiency furnaces or boilers to generate superheated steam, which drives turbines connected to electricity generators. Many modern facilities incorporate combined heat and power (CHP) systems, allowing thermal energy from combustion to be captured and used for district heating networks, industrial processes, or on-site energy needs, maximizing overall energy utilization. Gasification processes convert solid biomass into a combustible gas mixture, known as syngas, through partial oxidation at high temperatures. This syngas can be used in internal combustion engines, gas turbines, or further processed into liquid biofuels or chemicals, offering high efficiency and flexibility. Pyrolysis thermochemically decomposes biomass in the absence of oxygen to produce bio-oil, syngas, and char, each with multiple energy or material applications. Anaerobic digestion uses microbial processes to decompose wet organic biomass in oxygen-free digesters, generating methane-rich biogas for electricity, heat, or purification for grid injection, while the digestate is recovered as a nutrient-rich soil amendment.

Efficient thermal management and emissions control are fundamental to the sustainable operation of biomass energy recovery plants. Advanced heat recovery systems capture waste heat from combustion or gasification processes for preheating biomass, drying feedstock, or supplying district heating networks, significantly improving overall efficiency. Flue gas cleaning systems, including electrostatic precipitators, fabric filters, scrubbers, and selective catalytic reduction units, remove particulates, nitrogen oxides, sulfur compounds, and other pollutants, ensuring compliance with environmental regulations and minimizing impact on air quality. Automation, monitoring, and control systems track combustion parameters, feedstock flow rates, oxygen levels, boiler pressure, and temperatures in real time, allowing operators to optimize performance, maintain stable operations, and minimize emissions. Safety systems address the risks associated with high-pressure steam, flammable gases, combustible dust, and mechanical failures, while predictive maintenance and digital monitoring reduce downtime and prolong equipment life.

Residue and by-product management is a crucial aspect of biomass energy recovery plants. Combustion generates bottom ash and fly ash, which must be collected, treated, and either safely disposed of or repurposed. Bottom ash can often be used in construction materials, while fly ash is treated to minimize environmental risks due to potential heavy metal content. Anaerobic digestion produces digestate, which is separated into solid and liquid fractions. Solid digestate can be used as fertilizer or soil conditioner, while liquid fractions are often treated for nutrient recovery or recycled to maintain moisture balance within the digester. Storage, logistics, and material handling systems, including silos, hoppers, conveyors, and trucks, are critical for maintaining a consistent feedstock supply and efficient residue handling, reducing labor requirements and operational bottlenecks.

Modern biomass energy recovery plants increasingly rely on digital monitoring, predictive analytics, and advanced energy management systems to optimize performance, improve energy recovery, and enhance operational safety. Hybrid configurations that integrate combustion, gasification, pyrolysis, or anaerobic digestion allow plants to handle a wide range of biomass feedstocks with varying moisture content, composition, and particle size, maximizing flexibility and efficiency. These plants contribute significantly to circular economy objectives by reducing landfill dependency, lowering greenhouse gas emissions, and producing renewable energy that can be used locally or fed into national grids. The combination of preprocessing, efficient energy conversion, emissions control, real-time monitoring, safety systems, and residue management ensures that biomass energy recovery plants operate sustainably, reliably, and efficiently, establishing them as a key technology for modern waste management and renewable energy generation strategies.

By carefully coordinating feedstock handling, energy conversion processes, heat recovery, emission controls, and by-product management, biomass energy recovery plants transform organic waste streams into valuable energy while supporting environmental sustainability, resource efficiency, and energy security. These plants provide an essential bridge between waste management and renewable energy generation, converting what would otherwise be discarded as low-value biomass into high-value electricity, heat, and biogas. Their adaptability to different types of biomass and integration with industrial, municipal, or agricultural energy systems make them highly versatile solutions in the global transition toward clean energy. With ongoing advancements in process automation, hybrid conversion technologies, and emission mitigation, biomass energy recovery plants continue to increase in efficiency, environmental performance, and economic viability, reinforcing their role as a cornerstone of sustainable energy infrastructure.

Biomass CHP System

A biomass combined heat and power (CHP) system is an advanced technology designed to simultaneously generate electricity and useful heat from organic biomass materials, providing highly efficient energy utilization while supporting sustainable waste management and renewable energy goals. In a biomass CHP system, organic waste streams such as agricultural residues, forestry by-products, wood chips, sawdust, municipal green waste, food processing residues, and certain industrial organic wastes are collected, sorted, and prepared for energy conversion. Proper preprocessing of biomass is essential to ensure uniformity in moisture content, particle size, and composition, which directly impacts system efficiency and operational stability. Shredders, grinders, trommels, and dryers are used to process biomass into a consistent feedstock, while automated conveyors, hoppers, and feeding mechanisms maintain continuous and controlled material flow to the energy conversion unit. This consistent feedstock supply is crucial for preventing blockages, maintaining steady steam production, and ensuring reliable operation of turbines and engines.

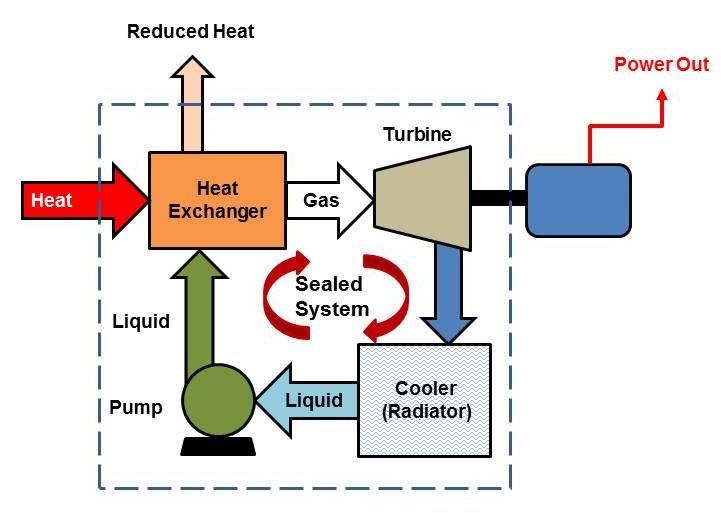

The core of a biomass CHP system is its energy conversion process, which may utilize direct combustion, gasification, or anaerobic digestion technologies. In combustion-based systems, biomass is burned in high-efficiency boilers to generate superheated steam, which drives a steam turbine or reciprocating engine connected to an electrical generator. The waste heat from this process is captured in heat exchangers and distributed as thermal energy for district heating networks, industrial processes, or on-site heating, enabling combined heat and power generation and significantly improving overall energy efficiency compared to electricity-only generation. Gasification-based CHP systems convert biomass into syngas through partial oxidation at high temperatures, producing a clean and versatile fuel that can be used in gas engines, gas turbines, or further processed into biofuels and chemicals. The heat generated in these systems can also be recovered for heating applications, further enhancing the energy yield of the biomass feedstock. Anaerobic digestion-based CHP systems process wet biomass and organic residues in oxygen-free digesters, generating methane-rich biogas that can be combusted in engines or boilers to simultaneously produce electricity and heat, while the remaining digestate serves as a nutrient-rich soil amendment.

Efficient operation of a biomass CHP system depends heavily on thermal management, emissions control, and automated process optimization. Heat recovery systems capture exhaust heat from turbines, engines, and flue gases to maximize energy utilization, preheat biomass, or supply thermal networks, reducing overall fuel consumption and increasing plant efficiency. Flue gas cleaning and emissions control systems, such as electrostatic precipitators, fabric filters, scrubbers, and selective catalytic reduction units, remove particulates, nitrogen oxides, sulfur compounds, and other pollutants, ensuring compliance with environmental standards. Advanced monitoring and automation technologies continuously track parameters such as feedstock flow, combustion temperature, oxygen concentration, boiler pressure, and turbine speed, allowing real-time optimization of energy production and emission reduction. Safety systems manage the risks associated with high-pressure steam, flammable gases, combustible dust, and other hazards, while predictive maintenance programs, digital diagnostics, and remote monitoring reduce unplanned downtime and enhance operational reliability.

Residue and by-product management is an integral component of biomass CHP systems. Combustion generates bottom ash and fly ash, which are collected, treated, and either safely disposed of or repurposed, for example as construction material, while fly ash is carefully managed to mitigate environmental risks. Anaerobic digestion produces digestate, which is separated into solid and liquid fractions; solids can be used as fertilizer or soil conditioner, and liquids can be treated for nutrient recovery or recycled within the digester to maintain moisture balance. Storage, handling, and logistics systems, including silos, conveyors, hoppers, and trucks, ensure a consistent supply of feedstock and facilitate efficient handling of residues, reducing labor requirements and operational bottlenecks.

Modern biomass CHP systems increasingly integrate digital energy management, predictive analytics, and hybrid configurations to optimize efficiency, adapt to varying feedstock characteristics, and maximize energy recovery. Hybrid systems may combine combustion, gasification, or anaerobic digestion processes to handle different types of biomass and improve overall plant flexibility. These systems contribute to circular economy objectives by reducing waste sent to landfills, lowering greenhouse gas emissions, and generating renewable energy for industrial, municipal, and agricultural applications. The integration of feedstock preprocessing, efficient energy conversion, heat recovery, emissions control, automated monitoring, and residue management ensures that biomass CHP plants operate sustainably, safely, and reliably, establishing them as a cornerstone of modern renewable energy infrastructure and waste-to-energy solutions.

By converting organic waste into both electricity and thermal energy, biomass CHP systems maximize the energy potential of biomass feedstocks and provide a versatile, environmentally responsible solution to the dual challenges of renewable energy generation and organic waste management. Their adaptability to different feedstock types, advanced process control, and integration with district heating, industrial applications, or local energy networks make biomass CHP plants a highly efficient, sustainable, and economically viable technology for modern energy systems. These plants exemplify the synergy between waste management and renewable energy production, turning biomass into a continuous, reliable source of combined heat and power while supporting broader environmental and energy sustainability goals.

A biomass CHP system is a highly integrated energy solution designed to extract maximum value from organic waste streams by simultaneously producing electricity and useful heat, creating a highly efficient and sustainable energy cycle. The process begins with the careful reception, sorting, and storage of biomass feedstocks, which can include agricultural residues such as straw, husks, stalks, and corn cobs, forestry by-products like wood chips, sawdust, and bark, municipal green waste, food processing residues, and selected industrial organic wastes. The quality, moisture content, particle size, and consistency of these feedstocks are crucial, as variations directly influence the performance and efficiency of the energy conversion process. Preprocessing equipment such as shredders, grinders, trommels, and dryers is used to create a uniform biomass material suitable for continuous feeding into combustion, gasification, or anaerobic digestion units. Automated conveyors, hoppers, and metered feeding systems maintain a controlled and uninterrupted supply of biomass, preventing blockages, maintaining stable steam or gas production, and ensuring reliable electricity generation and thermal output.

The core energy conversion of a biomass CHP system can utilize a variety of technologies depending on the plant design, feedstock type, and energy output requirements. Combustion-based systems burn biomass in high-efficiency boilers to produce superheated steam that drives turbines connected to generators, simultaneously generating electricity and heat. Heat recovery systems capture thermal energy from flue gases, turbines, and exhaust streams for use in district heating networks, industrial processes, or on-site heating applications, significantly enhancing the overall energy efficiency of the system. Gasification-based CHP plants convert biomass into syngas through partial oxidation at high temperatures. This syngas can then be combusted in internal combustion engines, gas turbines, or further processed into biofuels or chemicals. The heat generated during this process is recovered through heat exchangers and utilized for thermal energy applications, providing a dual energy output. Anaerobic digestion-based CHP systems process wet organic waste in oxygen-free digesters, generating methane-rich biogas that fuels engines or boilers to produce both electricity and heat, while the remaining digestate can be used as a nutrient-rich soil conditioner or fertilizer, closing the nutrient cycle and contributing to sustainable agricultural practices.

The efficiency and sustainability of a biomass CHP system rely heavily on advanced thermal management, emissions control, and automated process optimization. Heat recovery from exhaust gases, turbines, and engine cooling systems is used to preheat incoming biomass, supply district heating, or provide industrial process heat, minimizing energy losses and maximizing the usable energy extracted from the feedstock. Flue gas cleaning and emissions control systems, including fabric filters, electrostatic precipitators, cyclones, scrubbers, and selective catalytic reduction units, are essential for removing particulate matter, nitrogen oxides, sulfur compounds, and other pollutants, ensuring the plant operates within strict environmental regulations. Modern CHP systems employ sophisticated digital monitoring and control systems that continuously track feedstock flow, combustion temperature, boiler or engine pressure, oxygen levels, and turbine or engine performance, allowing real-time adjustments to optimize energy output and minimize emissions. Safety systems manage risks associated with high-pressure steam, combustible dust, flammable gases, and mechanical failures, while predictive maintenance, remote diagnostics, and automated fault detection enhance reliability and reduce unplanned downtime.

Residue and by-product management is a crucial aspect of biomass CHP plant operation. Combustion produces bottom ash and fly ash, which must be collected, treated, and either safely disposed of or repurposed in applications such as construction materials. Fly ash is handled carefully to mitigate potential environmental impacts due to heavy metal content. In anaerobic digestion systems, digestate is separated into solid and liquid fractions; solids are often used as fertilizer or soil conditioner, while liquid fractions are treated for nutrient recovery or recycled to maintain digester moisture levels. Storage, handling, and logistics systems, including silos, hoppers, conveyors, and trucks, ensure a steady feedstock supply and efficient handling of by-products, reducing labor requirements and operational bottlenecks.

Modern biomass CHP systems increasingly adopt hybrid configurations that combine combustion, gasification, and anaerobic digestion processes to improve feedstock flexibility, maximize energy recovery, and handle a wide range of biomass characteristics. These hybrid systems allow plants to efficiently manage variations in moisture content, particle size, and chemical composition of feedstocks while providing both electricity and heat to industrial, municipal, or agricultural applications. Digital energy management systems, predictive analytics, and automated controls optimize performance, enhance fuel efficiency, and extend equipment life, ensuring that the plant operates reliably, safely, and sustainably. By converting diverse organic waste streams into electricity, thermal energy, and biogas, biomass CHP systems contribute to circular economy objectives, reduce reliance on landfills, lower greenhouse gas emissions, and provide renewable energy solutions that are both economically and environmentally viable.

Through careful integration of feedstock handling, preprocessing, energy conversion, heat recovery, emissions control, automated monitoring, and residue management, biomass CHP systems transform biomass into a reliable and efficient source of combined heat and power. These systems demonstrate the synergy between sustainable waste management and renewable energy generation, turning materials that would otherwise be discarded into high-value energy while supporting environmental protection, resource efficiency, and energy security. With continued advances in hybrid technology, digital monitoring, process optimization, and emission reduction, biomass CHP systems represent a cornerstone of modern sustainable energy infrastructure, capable of delivering continuous, reliable, and efficient energy while promoting a circular and low-carbon economy.

A biomass CHP system is an advanced and highly integrated energy solution that captures the full potential of organic waste streams by simultaneously generating electricity and useful heat, making it one of the most efficient methods of converting biomass into energy. The process starts with the collection, sorting, and storage of a wide variety of biomass feedstocks, including agricultural residues such as straw, husks, corn stalks, and cobs, forestry by-products like wood chips, sawdust, and bark, municipal green waste, food processing residues, and select industrial organic wastes. Proper feedstock management is crucial to system efficiency, as variations in moisture content, particle size, density, and chemical composition can significantly impact combustion, gasification, or digestion performance. Preprocessing equipment such as shredders, grinders, trommels, and dryers ensures that the biomass is uniform and suitable for continuous feeding, while automated hoppers, conveyors, and metered feeding systems maintain a steady and controlled supply to the energy conversion unit. This continuous flow of feedstock prevents operational interruptions, ensures stable steam or gas production, and maintains consistent electricity generation and heat output throughout the plant’s operation.

The energy conversion process in a biomass CHP system can involve combustion, gasification, or anaerobic digestion, depending on the specific design and the characteristics of the biomass feedstock. In combustion-based CHP systems, biomass is burned in high-efficiency boilers to produce superheated steam that drives turbines or reciprocating engines connected to electricity generators. The heat produced during combustion is captured through heat exchangers and used for district heating, industrial processes, or on-site thermal applications, dramatically improving the overall energy efficiency of the system. Gasification-based CHP plants convert solid biomass into syngas, a mixture of carbon monoxide, hydrogen, and methane, through partial oxidation at elevated temperatures. This syngas can then be combusted in internal combustion engines or gas turbines to generate electricity, while residual heat is recovered for thermal applications. Anaerobic digestion-based CHP systems process wet biomass and organic residues in sealed, oxygen-free digesters, producing methane-rich biogas that fuels engines or boilers to produce both electricity and heat, while the digestate serves as a nutrient-rich fertilizer or soil conditioner, closing the nutrient loop and supporting sustainable agriculture.

Efficiency and sustainability in biomass CHP systems rely heavily on advanced thermal management, emissions control, and process optimization. Heat recovery systems capture energy from flue gases, exhaust streams, turbines, and engine cooling circuits, using it to preheat incoming biomass, supply district heating, or provide thermal energy to industrial processes, reducing fuel consumption and maximizing the energy extracted from the biomass. Flue gas cleaning technologies, including fabric filters, electrostatic precipitators, cyclones, scrubbers, and selective catalytic reduction units, remove particulates, nitrogen oxides, sulfur compounds, and other pollutants to ensure compliance with stringent environmental regulations and to minimize impact on air quality. Sophisticated monitoring and automation systems continuously track critical parameters such as feedstock flow, combustion temperature, boiler or engine pressure, oxygen levels, and turbine or engine performance, enabling real-time adjustments that optimize energy output and minimize emissions. Safety systems address hazards associated with high-pressure steam, flammable gases, combustible dust, and mechanical equipment, while predictive maintenance, digital diagnostics, and automated fault detection enhance reliability and reduce unplanned downtime.

Residue and by-product management is a fundamental component of biomass CHP operation. Combustion produces bottom ash and fly ash, which are collected, treated, and either safely disposed of or repurposed; bottom ash can often be used as construction material, while fly ash is carefully managed to mitigate environmental risks from heavy metals or other contaminants. Anaerobic digestion produces digestate, which is separated into solid and liquid fractions. Solids can serve as fertilizer or soil conditioner, while liquid fractions are either treated for nutrient recovery or recycled to maintain moisture levels in the digester. Robust storage, handling, and logistics systems, including silos, hoppers, conveyors, and trucks, ensure a continuous feedstock supply and efficient management of residues, minimizing labor requirements and preventing operational bottlenecks.

Modern biomass CHP systems increasingly incorporate hybrid configurations that combine combustion, gasification, and anaerobic digestion to enhance feedstock flexibility, maximize energy recovery, and efficiently handle a wide range of biomass materials with varying moisture content, particle size, and chemical composition. These hybrid systems allow for highly adaptable energy production, supplying electricity and heat to industrial, municipal, and agricultural applications with high efficiency. Digital energy management, predictive analytics, and automated process controls are used to optimize performance, improve fuel utilization, extend equipment life, and enhance environmental performance. By converting diverse organic waste streams into electricity, thermal energy, and biogas, biomass CHP systems contribute to circular economy objectives, reduce landfill dependence, mitigate greenhouse gas emissions, and provide renewable energy solutions that are economically viable and environmentally sustainable.

Through the careful integration of feedstock handling, preprocessing, energy conversion, heat recovery, emissions control, digital monitoring, safety management, and residue handling, biomass CHP systems transform organic waste into reliable and efficient sources of combined heat and power. These plants exemplify the synergy between renewable energy generation and sustainable waste management, converting materials that would otherwise be discarded into continuous, high-value electricity and thermal energy. With ongoing advancements in hybrid conversion technologies, process optimization, digital monitoring, and emissions mitigation, biomass CHP systems continue to improve in efficiency, reliability, and sustainability, reinforcing their role as a cornerstone of modern renewable energy infrastructure and circular economy strategies. They provide flexible, resilient, and high-efficiency energy solutions while simultaneously addressing environmental and waste management challenges, making them a key technology for industrial, municipal, and agricultural energy applications around the world.

A biomass CHP system is a highly advanced, integrated facility designed to extract the maximum energy potential from organic waste streams by simultaneously generating electricity and useful heat, delivering exceptional efficiency compared to traditional single-output energy systems. The operation begins with the collection, reception, sorting, and storage of a wide variety of biomass feedstocks, which may include agricultural residues such as straw, corn stalks, husks, and cobs, forestry by-products like wood chips, sawdust, bark, and logging residues, municipal green waste, food processing residues, and selected industrial organic by-products. The quality, moisture content, particle size, and chemical composition of these feedstocks are critical parameters that directly influence combustion, gasification, or anaerobic digestion efficiency. To ensure operational stability and consistent energy output, preprocessing equipment such as shredders, grinders, trommels, and dryers is used to produce a uniform biomass feedstock. Automated hoppers, conveyors, and metered feeding mechanisms maintain a controlled, uninterrupted flow of material into the energy conversion units, preventing blockages, fluctuations, and inefficiencies that could compromise the generation of electricity and heat.

In a biomass CHP system, energy conversion can be achieved through multiple technologies depending on the plant design, feedstock characteristics, and desired energy outputs. Combustion-based systems burn biomass in high-efficiency boilers to generate superheated steam, which drives turbines or reciprocating engines coupled with electrical generators. The waste heat from these systems is captured via heat exchangers and distributed to district heating networks, industrial processes, or on-site thermal applications, significantly enhancing the overall energy utilization of the biomass feedstock. Gasification-based CHP systems convert biomass into syngas, a mixture of carbon monoxide, hydrogen, and methane, through partial oxidation at high temperatures. This syngas can then be combusted in internal combustion engines or gas turbines, producing electricity, while the thermal energy is recovered for heat applications. Anaerobic digestion-based CHP systems leverage microbial activity in oxygen-free digesters to process wet biomass, food waste, or slurry, generating methane-rich biogas that fuels engines or boilers for combined electricity and heat production, while the digestate serves as a nutrient-rich fertilizer or soil conditioner, closing the nutrient cycle and supporting sustainable agricultural practices.

The efficiency and sustainability of biomass CHP plants depend on advanced thermal management, emissions control, and automated process optimization. Heat recovery systems capture thermal energy from flue gases, turbines, engines, and cooling circuits, using it to preheat biomass, supply district heating, or provide process heat to industrial operations, minimizing energy losses and improving overall plant efficiency. Sophisticated flue gas cleaning technologies, including fabric filters, electrostatic precipitators, cyclones, scrubbers, and selective catalytic reduction units, remove particulate matter, nitrogen oxides, sulfur compounds, and other pollutants to ensure compliance with strict environmental regulations. Digital monitoring and automation systems continuously track key parameters such as feedstock flow, combustion temperature, boiler or engine pressure, oxygen levels, and turbine or engine performance, allowing real-time adjustments that optimize energy output, maintain system stability, and minimize emissions. Safety systems are implemented to mitigate risks associated with high-pressure steam, combustible dust, flammable gases, and mechanical failures, while predictive maintenance, remote diagnostics, and automated fault detection enhance plant reliability and minimize unplanned downtime.

Residue and by-product management is a critical aspect of biomass CHP operations. Combustion generates bottom ash and fly ash, which must be collected, treated, and either safely disposed of or repurposed; bottom ash can often be reused in construction applications, while fly ash is carefully managed to reduce potential environmental risks associated with heavy metals. Anaerobic digestion produces digestate, which is separated into solid and liquid fractions. Solid digestate can be applied as fertilizer or soil conditioner, while liquid fractions are treated for nutrient recovery or recycled to maintain digester moisture balance. Robust storage, handling, and logistics infrastructure, including silos, conveyors, hoppers, and trucks, ensures a steady and reliable feedstock supply, while facilitating efficient handling of residues and by-products, reducing labor requirements and operational bottlenecks.

Modern biomass CHP systems increasingly utilize hybrid configurations that combine combustion, gasification, and anaerobic digestion technologies to enhance operational flexibility, maximize energy recovery, and handle a diverse range of biomass feedstocks with varying moisture content, particle size, and chemical composition. These hybrid systems allow for high adaptability, enabling continuous and efficient production of both electricity and heat for industrial, municipal, or agricultural applications. Integration with digital energy management systems, predictive analytics, and automated controls optimizes performance, increases fuel utilization efficiency, extends equipment life, and improves environmental compliance. By converting diverse organic waste streams into electricity, thermal energy, and biogas, biomass CHP systems support circular economy principles, reduce landfill dependency, lower greenhouse gas emissions, and provide renewable energy solutions that are both economically and environmentally sustainable.

The successful operation of biomass CHP systems relies on careful coordination of feedstock handling, preprocessing, energy conversion, heat recovery, emissions control, residue management, and digital process monitoring. These systems transform organic waste into continuous, high-value energy while simultaneously addressing waste management challenges and promoting resource efficiency. The integration of hybrid technologies, real-time process control, and predictive maintenance ensures that the plant operates efficiently, safely, and sustainably under varying feedstock conditions and energy demands. By maximizing the energy potential of biomass feedstocks and providing reliable electricity and heat, biomass CHP plants play a vital role in renewable energy infrastructure, supporting industrial, municipal, and agricultural energy needs while contributing to environmental protection, sustainable resource management, and the advancement of a low-carbon circular economy.

Biomass Boiler System

A biomass boiler system is a critical component in renewable energy production, designed to convert organic biomass materials into thermal energy for heating, steam generation, or combined heat and power (CHP) applications, providing a highly efficient and environmentally sustainable solution for industrial, municipal, and agricultural energy needs. The operation of a biomass boiler system begins with the careful reception, sorting, and storage of a wide range of biomass feedstocks, including agricultural residues such as straw, husks, stalks, corn cobs, and other crop by-products, forestry residues like wood chips, sawdust, bark, and small branches, municipal green waste, food processing residues, and certain organic industrial by-products. The physical characteristics of the feedstock—moisture content, particle size, density, and chemical composition—are crucial factors that influence combustion efficiency, heat output, and emissions performance. Preprocessing equipment, such as shredders, grinders, trommels, and dryers, is employed to create a uniform and manageable biomass feed suitable for continuous feeding into the boiler. Automated hoppers, conveyors, and metered feeding systems ensure a consistent and controlled supply of fuel to the combustion chamber, preventing operational interruptions, improving thermal efficiency, and maintaining steady heat output.

In a biomass boiler system, the core energy conversion process relies on the controlled combustion of biomass to produce thermal energy, which is transferred to water or steam via heat exchangers. High-efficiency boilers are designed to optimize fuel combustion, minimize heat losses, and ensure stable steam or hot water production. Advanced systems may include moving grate, fluidized bed, or pulverized fuel designs, each capable of handling different types of biomass and moisture content, and allowing for more flexible feedstock utilization. The heat generated can be used for a variety of applications, including process steam for industrial operations, space heating for municipal or commercial facilities, and as part of a combined heat and power configuration where the thermal energy drives turbines or engines to produce electricity in addition to heat. Fluidized bed boilers, for instance, allow more uniform combustion of heterogeneous feedstocks and improve heat transfer efficiency, while moving grate systems are robust and reliable for larger-scale operations using wood chips or mixed agricultural residues.

Efficient operation of a biomass boiler system depends on precise control of combustion parameters, thermal management, and emissions mitigation. Modern systems incorporate automated monitoring and control of feedstock flow, combustion temperature, oxygen levels, boiler pressure, and flue gas composition to optimize energy output and reduce pollutant formation. Heat recovery systems capture residual thermal energy from flue gases or boiler surfaces for preheating feedwater, drying biomass feedstock, or supplying district heating or industrial processes, thereby maximizing the usable energy derived from the biomass. Advanced flue gas cleaning technologies, including cyclones, fabric filters, electrostatic precipitators, scrubbers, and selective catalytic reduction units, remove particulates, nitrogen oxides, sulfur compounds, and other emissions, ensuring compliance with environmental regulations and maintaining air quality standards. Safety systems are critical, managing risks associated with high-pressure steam, combustible dust, flammable gases, and potential boiler tube failures, while predictive maintenance programs, remote monitoring, and automated diagnostics enhance operational reliability and minimize unplanned downtime.

Residue and by-product management is an essential aspect of biomass boiler operation. Combustion produces bottom ash and fly ash, which are collected and handled appropriately. Bottom ash can often be repurposed as construction material, while fly ash is treated to minimize environmental risks due to potential heavy metal content. Storage, handling, and logistics systems, including silos, hoppers, conveyors, and trucks, ensure a steady feedstock supply and efficient collection, treatment, and disposal of combustion residues. Some advanced biomass boiler systems may also integrate hybrid configurations, combining with gasification or pyrolysis technologies to improve fuel flexibility, maximize energy recovery, and efficiently utilize diverse feedstocks with varying moisture content, particle size, or chemical composition.

Modern biomass boiler systems are increasingly equipped with digital monitoring, process optimization tools, and energy management systems that enhance operational efficiency, minimize fuel consumption, and improve environmental performance. Integration with district heating networks, industrial processes, or CHP systems allows the biomass boiler to contribute to local or regional energy supply while reducing reliance on fossil fuels. These systems support circular economy principles by converting organic waste streams into high-value thermal energy, reducing landfill dependency, lowering greenhouse gas emissions, and providing renewable heat for industrial, commercial, or municipal applications.

Through careful integration of feedstock handling, preprocessing, combustion, thermal energy management, flue gas cleaning, residue handling, and digital process monitoring, biomass boiler systems transform biomass into a reliable, high-efficiency source of heat and steam. These systems exemplify the synergy between renewable energy generation and sustainable waste management, turning low-value organic residues into continuous, high-value thermal energy. With ongoing advancements in combustion technology, hybrid fuel integration, emissions reduction, and digital monitoring, biomass boiler systems continue to improve in efficiency, reliability, and sustainability, establishing themselves as a cornerstone of modern renewable energy infrastructure and industrial heating solutions. By maximizing the energy potential of biomass feedstocks and providing safe, efficient, and sustainable thermal energy, biomass boiler systems offer an environmentally responsible alternative to fossil fuel-based heating, contributing to the transition toward low-carbon energy systems and circular resource management strategies.

A biomass boiler system is a sophisticated energy technology designed to convert organic biomass materials into thermal energy for industrial processes, space heating, or combined heat and power applications, creating a sustainable, renewable, and environmentally responsible alternative to fossil fuel-based heating. The operation begins with the reception, sorting, and storage of biomass feedstocks, which can include agricultural residues such as straw, corn stalks, husks, and cobs, forestry by-products including wood chips, sawdust, bark, and branches, municipal green waste, food processing residues, and selected industrial organic by-products. The physical and chemical characteristics of the biomass—moisture content, particle size, density, and calorific value—are critical to combustion efficiency, heat output, and emissions performance. To ensure consistent and efficient operation, feedstock preprocessing is essential. Equipment such as shredders, grinders, trommels, and dryers is used to create a uniform feedstock suitable for continuous feeding into the boiler, while automated hoppers, metered conveyors, and material handling systems maintain a steady and controlled supply, preventing interruptions, fluctuations in combustion, and variations in thermal output.

In the combustion process of a biomass boiler system, the preprocessed biomass is fed into a furnace or combustion chamber where it is burned under carefully controlled conditions to generate heat. High-efficiency boilers are engineered to optimize the combustion of biomass, reduce heat losses, and maintain stable production of steam or hot water. Depending on the design, biomass boilers may use moving grate, fluidized bed, or pulverized fuel configurations, each providing unique advantages in handling feedstocks of varying sizes, moisture contents, and compositions. Moving grate boilers are robust and suitable for larger-scale applications with coarse feedstocks such as wood chips or mixed agricultural residues, while fluidized bed boilers allow more uniform combustion of heterogeneous feedstocks and achieve higher thermal efficiency. Pulverized fuel boilers can handle finely ground biomass for rapid combustion and precise heat control. The heat produced in these systems is transferred through heat exchangers to water or steam, which can be used for industrial process heating, building heating, or as part of a CHP system where electricity generation is combined with heat utilization, maximizing overall energy efficiency.

Efficient thermal management, emissions control, and automated process monitoring are fundamental to the reliable operation of biomass boiler systems. Heat recovery systems capture residual thermal energy from flue gases, boiler surfaces, and exhaust streams, directing it toward preheating feedwater, drying biomass feedstock, or supplying district heating or industrial thermal processes. Advanced flue gas cleaning technologies, including fabric filters, cyclones, electrostatic precipitators, scrubbers, and selective catalytic reduction units, remove particulate matter, nitrogen oxides, sulfur compounds, and other pollutants, ensuring that the system meets environmental standards and minimizes its impact on air quality. Modern biomass boilers are equipped with digital control and monitoring systems that continuously track feedstock flow, combustion temperature, oxygen levels, boiler pressure, and flue gas composition, enabling real-time adjustments that optimize efficiency, stabilize thermal output, and reduce emissions. Safety systems are critical for mitigating risks associated with high-pressure steam, flammable gases, and combustible dust, while predictive maintenance, remote monitoring, and automated diagnostics enhance operational reliability and minimize unplanned downtime.

Residue management is an essential aspect of biomass boiler operation. Combustion produces bottom ash and fly ash, which must be collected, processed, and either disposed of safely or repurposed. Bottom ash can be used in construction or road building, while fly ash is treated to mitigate potential environmental risks due to heavy metal content or other contaminants. Efficient storage, handling, and logistics systems, including silos, conveyors, hoppers, and trucks, ensure a consistent supply of biomass feedstock and enable proper collection, transport, and processing of combustion residues. Some modern biomass boiler systems incorporate hybrid designs that combine conventional combustion with gasification or pyrolysis technologies, improving fuel flexibility, enhancing energy recovery, and enabling efficient handling of diverse biomass types with varying moisture content, particle size, or chemical composition.

Integration with digital energy management, predictive analytics, and automated process control further enhances the efficiency and sustainability of biomass boiler systems. These systems allow operators to monitor performance metrics, adjust combustion parameters in real time, optimize heat recovery, and minimize fuel consumption and emissions. By supplying thermal energy to industrial, municipal, or district heating networks, biomass boilers contribute to reducing reliance on fossil fuels, lowering greenhouse gas emissions, and supporting circular economy principles. They provide a renewable, reliable, and efficient source of heat while transforming organic waste streams into valuable energy, supporting sustainable energy and waste management strategies.

Through the coordinated integration of feedstock handling, preprocessing, controlled combustion, thermal energy management, emissions control, residue management, and digital monitoring, biomass boiler systems transform low-value organic materials into high-value thermal energy. These systems exemplify the synergy between renewable energy generation and sustainable waste management, providing continuous and reliable heat for industrial, commercial, and municipal applications while minimizing environmental impact. With ongoing technological advancements in combustion efficiency, heat recovery, emissions mitigation, hybrid fuel integration, and digital process optimization, biomass boiler systems continue to improve in performance, reliability, and environmental sustainability, reinforcing their role as a cornerstone of modern renewable energy infrastructure. By converting diverse biomass feedstocks into efficient thermal energy, these systems support the transition to low-carbon energy solutions, promote circular resource management, and provide versatile, sustainable, and economically viable energy for a wide range of applications.

A biomass boiler system is a highly engineered and integrated energy solution designed to convert a wide range of organic biomass materials into thermal energy, providing renewable heat for industrial processes, district heating, or as part of combined heat and power (CHP) systems. These systems are central to sustainable energy strategies, turning agricultural residues, forestry by-products, municipal green waste, food processing by-products, and select industrial organic wastes into efficient, reliable, and environmentally responsible energy. The operation begins with the careful collection, sorting, and storage of biomass feedstocks, as the moisture content, particle size, density, and chemical composition of these materials have a direct impact on combustion efficiency, heat output, emissions, and overall system performance. Preprocessing of feedstock is essential for creating a uniform, manageable material suitable for continuous feeding into the combustion chamber. Shredders, grinders, trommels, and dryers are used to prepare the biomass, while automated hoppers, conveyors, and metered feeding mechanisms maintain a steady and controlled flow, preventing interruptions, uneven combustion, or thermal fluctuations that could reduce efficiency or compromise operational stability.

In the core combustion process, the prepared biomass is fed into high-efficiency boilers, where it is burned under carefully controlled conditions to generate heat. Modern biomass boilers employ a variety of designs, including moving grate, fluidized bed, and pulverized fuel systems, each optimized for different types of biomass and operational scales. Moving grate boilers are robust and suitable for larger feedstocks such as wood chips or mixed agricultural residues, providing reliable and stable combustion. Fluidized bed boilers enable uniform combustion of heterogeneous feedstocks, improved heat transfer, and the capacity to handle higher moisture contents while reducing emissions of nitrogen oxides and carbon monoxide. Pulverized fuel boilers allow for rapid and controlled combustion of finely ground biomass, offering precise heat output and high efficiency for specialized applications. The heat generated during combustion is transferred through heat exchangers to water or steam, which can be used in industrial process heating, building heating, or as part of a CHP configuration where electricity generation is integrated, maximizing the total energy extracted from the biomass.