Biomass-fueled Steam Turbines: Steam turbines are widely used in power generation and industrial applications due to their efficiency and reliability. They operate by converting thermal energy from pressurized steam into mechanical energy, which is then used to generate electricity or drive mechanical equipment. The fundamental principle of steam turbines relies on the expansion of high-pressure steam through a series of rotating blades, which causes the rotor to spin and produce useful work. The efficiency of a steam turbine depends on several factors, including steam pressure, temperature, and the design of the turbine stages.

There are several types of steam turbines, each suited to different applications. The most common types include condensing and back-pressure turbines. Condensing turbines are primarily used in power generation, where steam expands through multiple stages until it reaches a condenser, where it is cooled and converted back into water. This process maximizes efficiency by extracting as much energy as possible from the steam. In contrast, back-pressure turbines exhaust steam at higher pressures and are often used in industrial processes where the remaining steam is required for heating or other applications.

The design of steam turbines varies based on their intended use. A key consideration is the number of stages, which can be either single-stage or multi-stage. Single-stage turbines are simpler and are typically used for smaller applications, while multi-stage turbines are more efficient and are used in large-scale power plants. The efficiency of a multi-stage turbine is enhanced through the use of reheat and regenerative cycles, which help to improve thermal efficiency by reducing energy losses.

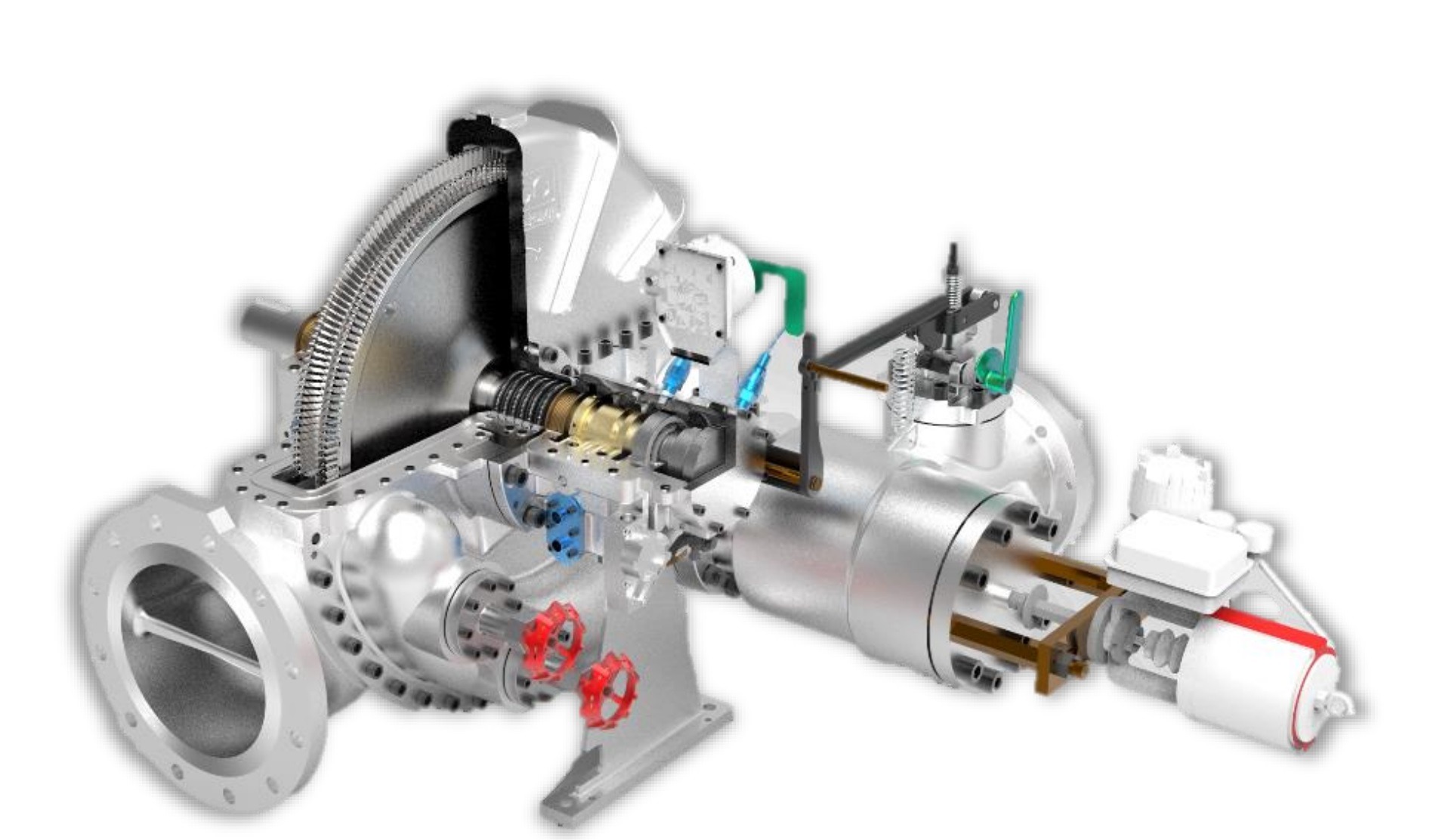

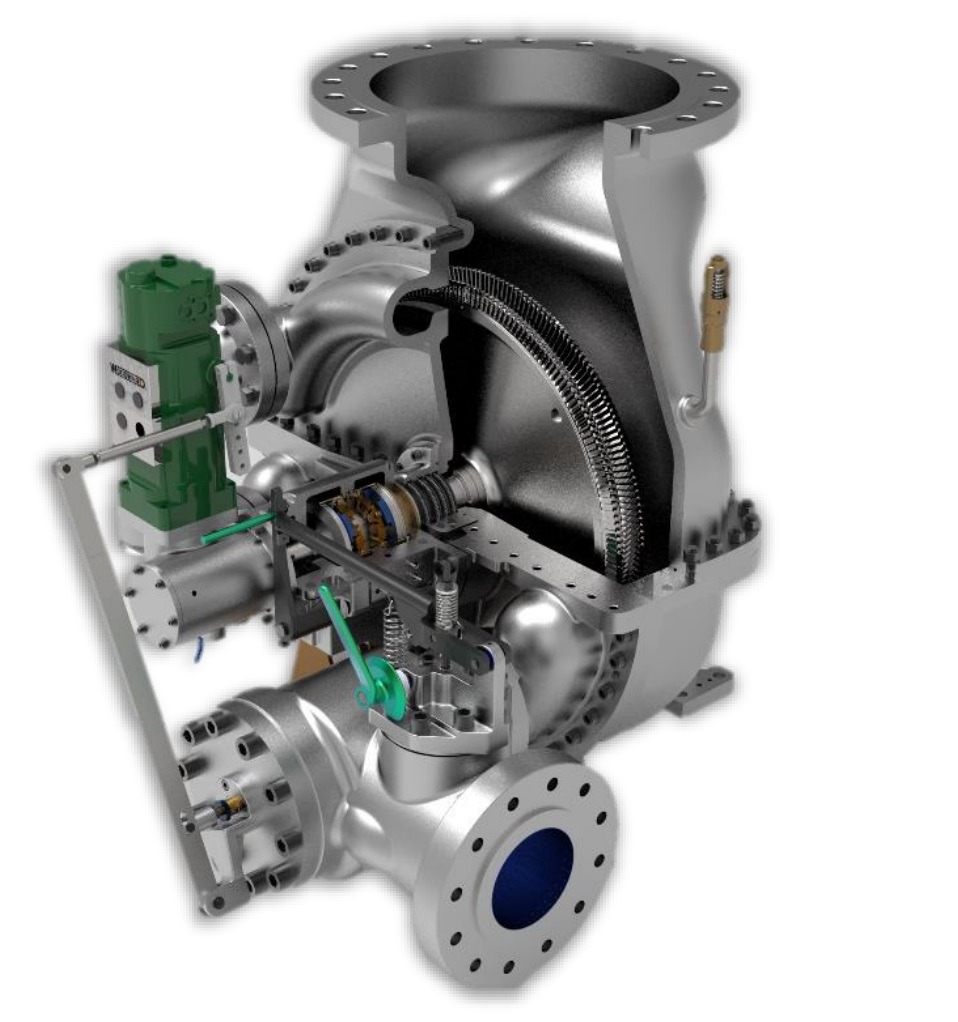

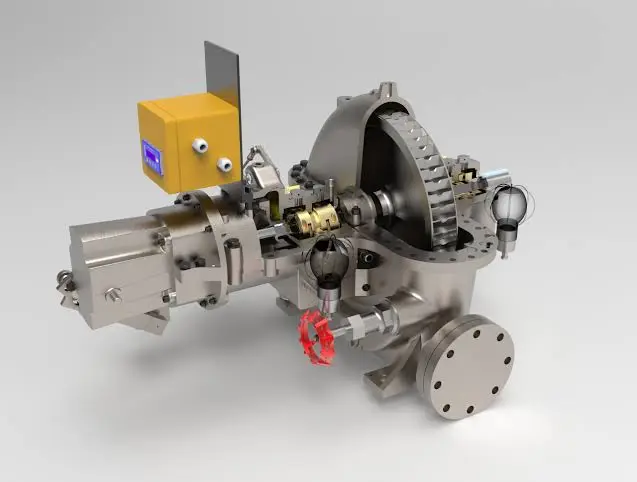

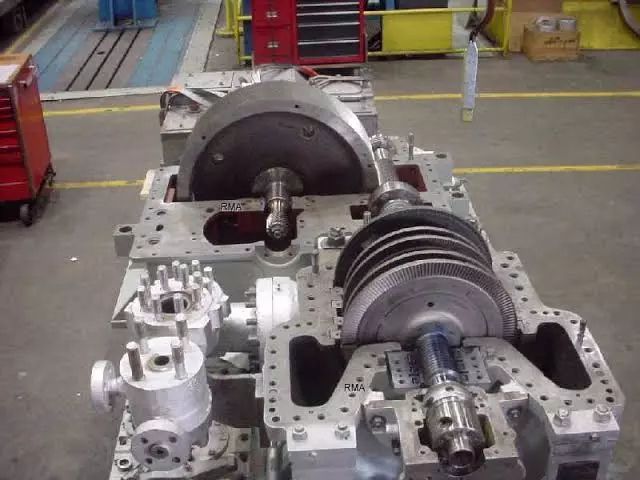

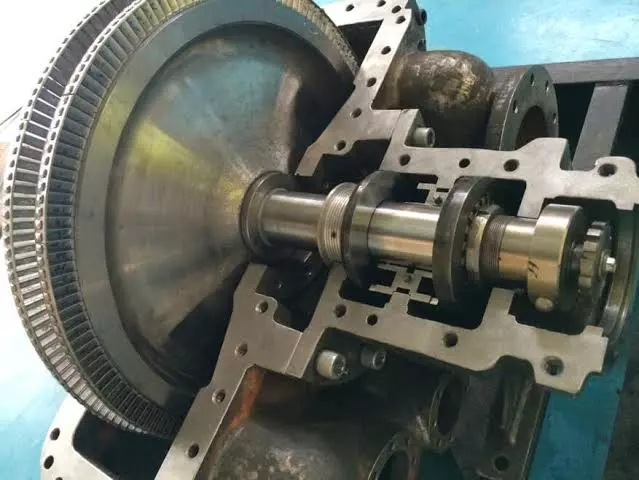

The components of a steam turbine include the rotor, stator, blades, casing, and bearings. The rotor is the rotating component that carries the blades and is supported by bearings to ensure smooth operation. The stator consists of stationary blades or nozzles that direct the steam flow onto the moving blades. The blades are a critical part of the turbine, as their shape and arrangement determine the efficiency and power output. Advanced materials and coatings are used to withstand high temperatures and pressures, ensuring durability and performance.

Steam turbines operate under various thermodynamic cycles, with the Rankine cycle being the most common. In the Rankine cycle, water is heated to produce steam, which expands through the turbine to generate power. The steam is then condensed back into water and recycled through the system. Variations of this cycle, such as the regenerative and reheat cycles, improve efficiency by optimizing the temperature and pressure conditions at different stages of the process.

Maintenance and reliability are crucial aspects of steam turbine operation. Regular inspections and monitoring help detect issues such as blade wear, bearing failures, and steam leakage. Proper lubrication and cooling systems are essential to prevent overheating and reduce friction losses. Modern steam turbines are equipped with advanced control systems that optimize performance and detect potential problems before they lead to failures.

Steam turbines are widely used in fossil fuel, nuclear, and renewable energy power plants. In fossil fuel power plants, steam is generated by burning coal, natural gas, or oil in a boiler. In nuclear power plants, steam is produced by the heat generated from nuclear fission reactions. Renewable energy sources, such as biomass and concentrated solar power, also use steam turbines to generate electricity.

The future of steam turbines is influenced by advancements in materials, design, and operational efficiency. Innovations such as supercritical and ultra-supercritical steam conditions allow turbines to operate at higher temperatures and pressures, improving overall efficiency and reducing emissions. Additionally, combined-cycle power plants, which integrate steam turbines with gas turbines, enhance energy utilization and reduce environmental impact.

Overall, steam turbines continue to be a vital component of the global energy infrastructure. Their ability to provide reliable and efficient power generation makes them indispensable in various industries. With ongoing technological advancements, steam turbines are expected to remain a key part of the energy landscape, contributing to sustainable and efficient power generation for years to come.

Steam Turbines for Mechanical Drive

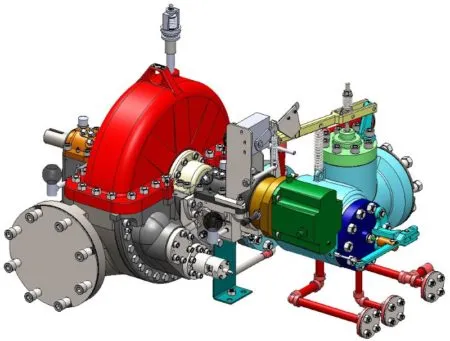

Steam turbines for mechanical drive applications are widely used in industrial settings where reliable and efficient power is needed to drive machinery directly. Unlike steam turbines used for power generation, which primarily convert steam energy into electricity, mechanical drive steam turbines are designed to provide rotational energy for various types of equipment, such as compressors, pumps, fans, and other rotating machinery. These turbines are essential in industries such as oil and gas, petrochemicals, refineries, and manufacturing, where they offer a robust and efficient means of converting steam energy into mechanical motion.

The operation of mechanical drive steam turbines is based on the same fundamental principles as those used in power generation. High-pressure steam is directed through a series of nozzles and blades, causing the rotor to spin and produce mechanical work. The turbine’s speed and power output are carefully controlled to match the operational requirements of the driven equipment. Mechanical drive turbines are often selected over electric motors when high reliability, variable speed control, and the ability to operate in harsh conditions are required.

Mechanical drive steam turbines are categorized based on their design and function. The two primary types are condensing and back-pressure turbines. Condensing turbines exhaust steam at a pressure lower than atmospheric pressure, maximizing energy extraction and efficiency. They are used when excess steam is not required elsewhere in the process. Back-pressure turbines, on the other hand, release steam at an intermediate pressure for use in other industrial applications, such as heating or additional mechanical processes. The selection of a condensing or back-pressure turbine depends on the specific energy balance and process requirements of the facility.

Another important classification is between single-stage and multi-stage turbines. Single-stage turbines are typically used for low-power applications with minimal pressure drops, while multi-stage turbines are employed in high-power applications requiring greater energy extraction. Multi-stage turbines feature multiple rows of rotating and stationary blades, which progressively reduce steam pressure and increase efficiency. Additionally, reaction and impulse designs determine how steam interacts with the blades. Impulse turbines use nozzles to direct high-velocity steam jets onto the rotor blades, while reaction turbines rely on the expansion of steam through both stationary and moving blades to generate rotation.

Mechanical drive steam turbines are valued for their ability to provide continuous and stable operation. Unlike electric motors, they can operate independently of the electrical grid, making them suitable for remote or hazardous environments where electrical equipment may not be practical. Their reliability is further enhanced by their ability to handle variable loads and speeds without complex electronic controls. This makes them particularly useful in applications such as large compressors in gas processing plants, where flow rates and pressure conditions fluctuate significantly.

Efficiency and reliability are key considerations in the design and operation of mechanical drive steam turbines. Advanced materials and coatings are used to withstand high temperatures and pressures, reducing wear and extending service life. Bearings and lubrication systems ensure smooth operation and minimize friction losses. Regular maintenance, including inspection of blades, seals, and bearings, is necessary to prevent issues such as erosion, corrosion, and misalignment. Condition monitoring technologies, such as vibration analysis and temperature sensors, help detect potential failures before they cause significant downtime.

Steam turbines for mechanical drive applications are often integrated into larger process systems, where they play a critical role in maintaining overall efficiency and productivity. In refineries and petrochemical plants, they drive large pumps and compressors that transport and process fluids. In the oil and gas industry, they are used to power gas compressors for pipeline transmission and liquefaction processes. In chemical plants, they provide mechanical energy for mixers, agitators, and other processing equipment. Their ability to operate using steam generated as a byproduct of industrial processes makes them an energy-efficient choice in many facilities.

Advancements in steam turbine technology continue to improve their performance and efficiency. The use of high-efficiency blade designs, optimized steam path configurations, and digital control systems enhances operational precision and reduces energy losses. Superheated and reheat steam cycles further increase efficiency by reducing moisture content and improving thermodynamic performance. Additionally, combined heat and power (CHP) systems integrate steam turbines with industrial processes to maximize energy utilization, reducing fuel consumption and emissions.

The selection of a steam turbine for mechanical drive applications depends on factors such as power output, operating conditions, steam availability, and process requirements. Custom-engineered solutions are often developed to ensure optimal performance and seamless integration with existing systems. Manufacturers offer a range of standard and customized turbines, allowing industries to choose the most suitable configuration for their needs.

Overall, steam turbines for mechanical drive applications provide a highly reliable and efficient means of converting steam energy into mechanical work. Their ability to operate in demanding industrial environments, handle variable loads, and integrate with complex process systems makes them a preferred choice for many industries. As technology advances, mechanical drive steam turbines will continue to play a crucial role in industrial operations, supporting energy efficiency and sustainability in a wide range of applications.

One of the key advantages of steam turbines for mechanical drive applications is their ability to operate across a wide range of speeds and power outputs. Unlike electric motors, which often require variable frequency drives to achieve speed control, steam turbines can be designed with governing systems that allow precise regulation of rotational speed. This makes them highly suitable for driving equipment such as compressors and pumps, where process conditions may require frequent adjustments in speed and torque. The ability to handle variable loads without significant loss in efficiency is a major reason why steam turbines are preferred in critical industrial operations.

The integration of steam turbines into industrial processes is often dictated by the availability and characteristics of steam. Many facilities, such as refineries, chemical plants, and pulp and paper mills, generate steam as a byproduct of their operations. By utilizing this steam to drive mechanical equipment, these facilities achieve higher overall efficiency through combined heat and power (CHP) systems. In CHP setups, steam turbines extract useful mechanical work from steam before it is used for heating or other process requirements. This approach significantly improves fuel utilization and reduces waste energy.

In heavy industries such as oil and gas, steam turbines are extensively used to drive large compressors that transport natural gas through pipelines or compress gas for liquefaction. The high reliability and long service life of steam turbines make them particularly attractive for offshore platforms and remote installations, where maintenance access is limited, and uninterrupted operation is critical. Steam turbines can operate in hazardous environments without the risks associated with electrical equipment, such as sparking or electromagnetic interference, making them ideal for explosive atmospheres.

One of the challenges associated with steam turbine operation is managing steam quality to prevent issues such as erosion and deposition on turbine blades. The presence of moisture in the steam can lead to blade wear and reduced efficiency over time. To mitigate these effects, steam turbines are often designed with superheated or reheated steam cycles, which help maintain dry steam conditions throughout the expansion process. Additionally, advanced blade coatings and erosion-resistant materials are used to enhance durability and prolong service life.

Another critical aspect of steam turbine performance is the efficiency of energy conversion. High-performance steam turbines incorporate advanced aerodynamic blade designs that optimize steam flow and minimize losses. The use of computational fluid dynamics (CFD) and finite element analysis (FEA) allows engineers to develop turbine components that maximize efficiency and withstand high mechanical stresses. Improved sealing technologies, such as labyrinth and brush seals, help reduce steam leakage, further enhancing overall performance.

Steam turbine control systems have also seen significant advancements in recent years. Modern turbines are equipped with digital control and monitoring systems that provide real-time data on operating parameters such as speed, temperature, pressure, and vibration. These systems enable precise control of turbine operation, improving efficiency and reliability while reducing the risk of unplanned shutdowns. Predictive maintenance techniques, leveraging artificial intelligence and machine learning, allow operators to anticipate potential failures and schedule maintenance proactively.

Environmental considerations have also influenced the development and deployment of steam turbines for mechanical drive applications. The push for lower emissions and improved energy efficiency has led to innovations in steam turbine technology that reduce fuel consumption and enhance sustainability. Many industries are transitioning to cleaner steam sources, such as biomass or waste heat recovery systems, to power their turbines. This shift helps reduce greenhouse gas emissions while maintaining the benefits of reliable mechanical drive systems.

The longevity of steam turbines is another reason they remain a preferred choice for industrial applications. With proper maintenance and periodic overhauls, steam turbines can operate for decades, often outlasting other forms of mechanical drive equipment. Their robust construction and ability to handle demanding conditions make them well-suited for continuous operation in industries where downtime is costly and must be minimized.

When selecting a steam turbine for mechanical drive applications, engineers consider factors such as steam pressure and temperature, required power output, efficiency requirements, and site-specific conditions. Customization is often necessary to ensure that the turbine meets the exact needs of the process it will be integrated with. Manufacturers offer a range of designs, from compact, single-stage turbines for low-power applications to large, multi-stage turbines capable of delivering thousands of horsepower.

Future developments in steam turbine technology continue to focus on improving efficiency, reducing emissions, and enhancing operational flexibility. The incorporation of advanced materials, such as ceramics and high-temperature alloys, is expected to further extend the performance limits of steam turbines. Additionally, hybrid systems that integrate steam turbines with other energy sources, such as gas turbines or renewable energy, are gaining interest as industries seek to optimize energy use and reduce environmental impact.

In summary, steam turbines for mechanical drive applications play a vital role in numerous industrial processes, providing reliable and efficient mechanical power for pumps, compressors, and other rotating equipment. Their ability to operate independently of the electrical grid, handle variable loads, and integrate with complex process systems makes them an indispensable component of modern industry. With ongoing advancements in materials, design, and control systems, steam turbines will continue to be a key technology in industrial operations, offering high efficiency, durability, and sustainability for years to come.

Straight Back-pressure Turbines

Straight back-pressure turbines are a specific type of steam turbine designed for industrial applications where steam is required for both mechanical work and process heating. Unlike condensing turbines, which maximize energy extraction by exhausting steam at a vacuum pressure, back-pressure turbines exhaust steam at an intermediate or high pressure, making them well-suited for combined heat and power (CHP) applications. These turbines are widely used in industries such as chemical processing, paper manufacturing, food production, and district heating systems, where steam is needed for both mechanical power and thermal energy.

The fundamental operation of a straight back-pressure turbine is based on the controlled expansion of high-pressure steam through a series of blades, which convert thermal energy into mechanical work. The steam exits the turbine at a predetermined pressure, which is then used directly in industrial processes. This approach ensures that the energy contained in the steam is fully utilized, improving overall efficiency and reducing fuel consumption compared to systems that generate mechanical power and process steam separately.

Straight back-pressure turbines are typically selected in applications where a steady supply of process steam is required. Since these turbines do not condense steam into water, they eliminate the need for a condenser, reducing the complexity and capital cost of the system. Instead, the steam exhausted from the turbine is directed to process heaters, heat exchangers, or other steam-using equipment, making them an integral part of cogeneration and industrial heat recovery systems.

The design of a straight back-pressure turbine is influenced by the pressure and temperature requirements of the downstream process. The turbine must be sized to ensure that it provides the necessary power output while maintaining the correct exhaust pressure. In many cases, multiple extraction points can be incorporated to supply steam at different pressure levels, allowing for greater flexibility in industrial applications. However, in the case of a strict straight back-pressure turbine, the steam is exhausted at a single defined pressure without intermediate extractions.

One of the primary advantages of straight back-pressure turbines is their high energy efficiency in cogeneration systems. By using the steam for both power generation and heating, these turbines maximize fuel utilization, reducing overall energy costs and environmental impact. This makes them particularly attractive in industries that require large amounts of process heat, such as sugar mills, breweries, and refineries. In these facilities, steam is often produced from boilers fueled by biomass, natural gas, or waste heat, further enhancing the sustainability of the system.

The operational reliability of straight back-pressure turbines is another key benefit. These turbines are designed for continuous operation, with robust construction and minimal moving parts to reduce wear and maintenance requirements. The absence of a condenser and associated cooling systems simplifies maintenance and reduces water consumption, making them more suitable for areas with limited water resources. Additionally, because they operate at relatively high exhaust pressures, they are less prone to the moisture-related blade erosion that can affect condensing turbines.

Control and regulation of straight back-pressure turbines are critical to ensuring stable operation and process efficiency. Modern turbines are equipped with automated governing systems that adjust steam flow based on load demand while maintaining the required exhaust pressure. This ensures a consistent supply of process steam, even when mechanical power demand fluctuates. In some cases, pressure control valves are used in conjunction with the turbine to maintain stable downstream steam conditions.

Material selection and turbine blade design play a crucial role in the efficiency and longevity of straight back-pressure turbines. High-temperature alloys and coatings are used to withstand the stresses of steam expansion and minimize thermal degradation. Advanced computational fluid dynamics (CFD) techniques are employed to optimize steam flow through the turbine, reducing aerodynamic losses and enhancing performance. Bearings and lubrication systems are designed to provide smooth operation and minimize mechanical losses.

Industries that rely on straight back-pressure turbines benefit from their adaptability to different steam conditions and energy demands. In paper mills, for example, these turbines drive mechanical equipment such as dryers and refiners while supplying steam to the paper drying process. In chemical plants, they power pumps and compressors while providing heat for chemical reactions. In district heating applications, they generate electricity while supplying steam for building heating systems, improving overall energy efficiency.

From an environmental perspective, straight back-pressure turbines contribute to reduced greenhouse gas emissions by maximizing fuel efficiency in CHP systems. By integrating power generation with process heat utilization, they minimize waste energy, leading to lower fuel consumption compared to conventional separate heat and power systems. Many industrial facilities use renewable or waste-derived fuels, such as biomass or waste heat recovery, to further reduce their carbon footprint.

Future advancements in straight back-pressure turbine technology are expected to focus on improving efficiency, durability, and integration with modern industrial energy systems. The development of high-performance blade materials, enhanced steam sealing techniques, and digital monitoring systems will contribute to greater operational efficiency and reliability. Additionally, the increasing adoption of hybrid energy systems, which combine steam turbines with other power generation technologies, may expand the role of back-pressure turbines in sustainable industrial energy solutions.

In conclusion, straight back-pressure turbines play a crucial role in industrial energy systems by providing both mechanical power and process steam. Their ability to maximize energy efficiency, reduce operational costs, and simplify plant design makes them an ideal choice for industries that require both power and heat. With ongoing advancements in technology and increasing emphasis on energy sustainability, straight back-pressure turbines will continue to be a key component of industrial cogeneration and process heating applications.

One of the key considerations when designing and implementing a straight back-pressure turbine system is the balance between mechanical power generation and process steam requirements. Since the exhaust steam from these turbines is used directly in industrial processes, the turbine’s operation must align with the steam consumption of the facility. If the process steam demand decreases, adjustments must be made to the turbine’s operation to maintain stable pressure and avoid disruptions. This is often managed through bypass systems or steam venting, though these methods can reduce overall efficiency. An optimal system design carefully matches steam supply with demand to minimize energy losses.

Straight back-pressure turbines are commonly used in industries with a continuous demand for both power and process steam. In sugar mills, for example, these turbines drive cane crushers while supplying steam for sugar refining and crystallization. In petrochemical plants, they power compressors while providing steam for distillation and reaction processes. In district heating systems, they generate electricity while delivering steam to heat buildings and provide hot water. The ability to integrate both mechanical and thermal energy makes them highly valuable in such applications.

Another important aspect of straight back-pressure turbine operation is steam quality. Poor steam quality, particularly the presence of excessive moisture or impurities, can lead to blade erosion and scaling, reducing efficiency and increasing maintenance costs. To mitigate these risks, steam conditioning systems such as moisture separators and superheaters are often used to ensure that steam entering the turbine remains dry and at the correct temperature. Proper boiler operation and water treatment also play a crucial role in maintaining steam quality and prolonging turbine life.

The absence of a condenser in straight back-pressure turbine systems simplifies plant design and reduces infrastructure costs. However, this also means that the energy contained in the exhaust steam is not fully recovered as it would be in a condensing system. The trade-off between efficiency and process integration depends on the specific requirements of the facility. In many cases, the benefits of having readily available process steam outweigh the potential efficiency losses associated with not fully expanding the steam to a vacuum.

The efficiency of a straight back-pressure turbine depends on several factors, including steam inlet conditions, turbine blade design, and load variations. Higher inlet steam pressures and temperatures generally result in greater energy extraction per unit of steam, improving overall efficiency. Advanced blade profiles, optimized for aerodynamic performance, help reduce steam flow losses and maximize power output. In addition, maintaining a stable load and operating the turbine within its optimal efficiency range can significantly impact overall performance.

Automation and control systems have greatly improved the reliability and flexibility of straight back-pressure turbines. Modern turbines are equipped with digital governors, pressure sensors, and steam flow controllers that allow for precise adjustments in response to changing process demands. These systems ensure that the turbine operates within safe limits while maintaining the required steam pressure for downstream applications. In some cases, integration with plant-wide energy management systems allows for real-time optimization of turbine performance based on overall energy usage and production goals.

Maintenance of straight back-pressure turbines is relatively straightforward compared to condensing turbines, but it remains critical for ensuring long-term reliability. Routine inspections of turbine blades, seals, and bearings help detect wear and tear before it leads to significant downtime. Lubrication systems must be carefully maintained to prevent excessive friction and overheating. Additionally, steam leaks and insulation issues should be promptly addressed to prevent energy losses and maintain efficiency.

From an economic perspective, straight back-pressure turbines offer significant cost savings over the long term due to their high efficiency and reduced fuel consumption in cogeneration systems. Industries that implement these turbines can achieve lower energy costs by utilizing waste steam effectively rather than requiring separate energy sources for power generation and process heating. Government incentives and policies promoting energy efficiency and carbon reduction further enhance the financial attractiveness of these systems.

Environmental benefits also play a role in the increasing adoption of straight back-pressure turbines. By maximizing fuel utilization and reducing waste energy, these turbines contribute to lower greenhouse gas emissions compared to separate power and steam generation systems. Many facilities use biomass, waste heat, or other renewable energy sources to generate steam, further reducing their environmental impact. As industries continue to seek sustainable energy solutions, back-pressure turbines will remain a key component of integrated energy systems.

Looking ahead, advancements in materials science, digital control systems, and steam turbine design will further improve the efficiency and performance of straight back-pressure turbines. The development of high-performance coatings and erosion-resistant materials will extend blade life and reduce maintenance costs. Enhanced steam sealing technologies and improved rotor dynamics will contribute to greater reliability and efficiency. Additionally, the integration of artificial intelligence and machine learning into turbine monitoring systems will enable predictive maintenance and real-time optimization, minimizing downtime and improving overall operational efficiency.

In summary, straight back-pressure turbines are a crucial component of industrial energy systems, providing both mechanical power and process steam in an efficient and cost-effective manner. Their ability to maximize energy utilization, reduce fuel consumption, and integrate seamlessly with various industrial processes makes them a preferred choice for many industries. With ongoing advancements in technology and a growing emphasis on energy sustainability, these turbines will continue to play a vital role in industrial operations, supporting economic and environmental goals while ensuring reliable energy supply.

Straight Condensing Turbines

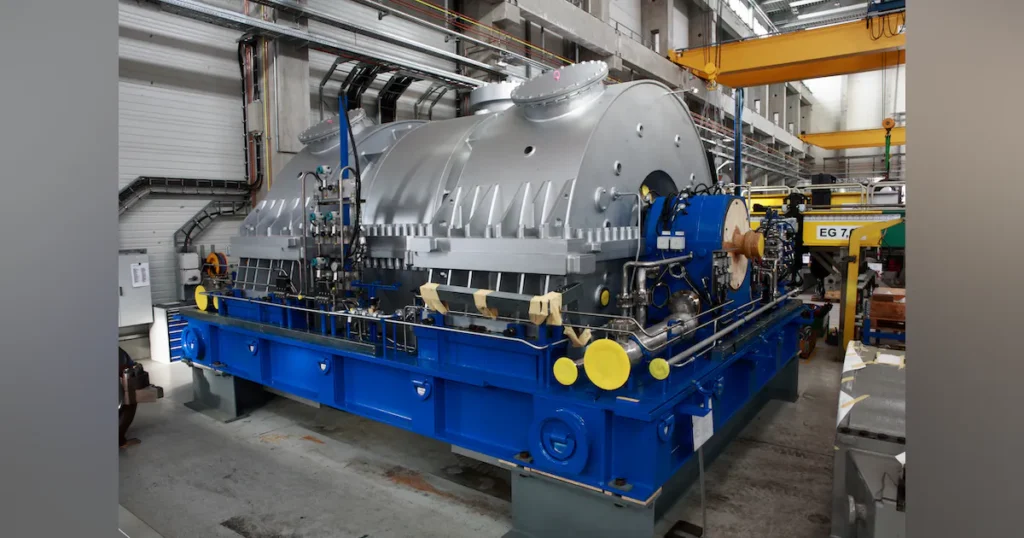

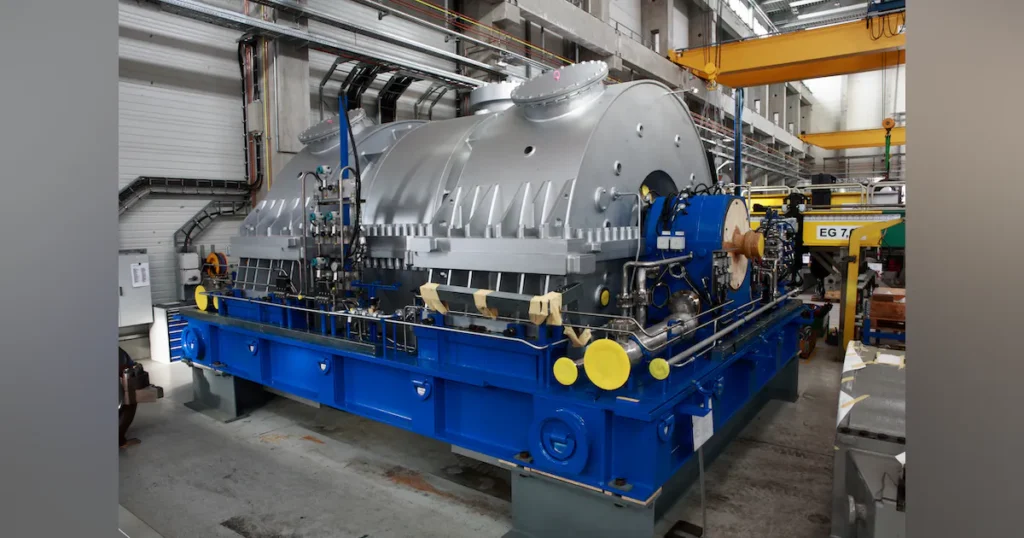

Straight condensing turbines are a type of steam turbine designed for maximum energy extraction by expanding steam to a low-pressure state, typically below atmospheric pressure. Unlike back-pressure turbines, which exhaust steam at an intermediate pressure for use in industrial processes, straight condensing turbines direct the exhausted steam into a condenser, where it is converted back into liquid water. This design maximizes the efficiency of energy conversion, making these turbines ideal for applications where mechanical or electrical power generation is the primary objective rather than process steam supply. These turbines are widely used in power plants, industrial facilities, and marine propulsion systems, where maximizing power output per unit of steam is essential.

The operation of a straight condensing turbine begins with high-pressure, high-temperature steam entering the turbine’s first stage, where it expands through a series of stationary and rotating blades. This expansion process converts the steam’s thermal energy into mechanical energy, which rotates the turbine shaft. The steam continues to expand through multiple stages, losing pressure and temperature as it transfers its energy to the turbine blades. By the time the steam reaches the final stages of the turbine, it has been expanded to a very low pressure, often near vacuum conditions.

The exhaust steam from the turbine is then directed into a condenser, where it is cooled by a circulating water system. The cooling process condenses the steam back into liquid water, creating a pressure drop that enhances the efficiency of steam expansion within the turbine. The condensed water, or condensate, is then pumped back into the boiler to be reheated and converted into steam again, completing the Rankine cycle. This closed-loop system ensures minimal water loss and efficient thermal energy utilization.

One of the primary advantages of straight condensing turbines is their ability to achieve high thermal efficiency. Because these turbines expand steam to the lowest possible pressure, they extract the maximum amount of energy per unit of steam, resulting in higher power output compared to other types of steam turbines. This makes them particularly suitable for power generation applications, where efficiency and fuel economy are critical.

Condensing turbines are commonly found in large-scale power plants, including coal-fired, natural gas, nuclear, and biomass power plants, where they drive electrical generators. In these applications, the turbines are designed for long-term, continuous operation at optimal efficiency levels. The integration of reheat and superheat cycles further improves their performance by increasing steam temperatures and reducing moisture content in the later stages of expansion, which helps protect turbine blades from erosion.

In industrial settings, straight condensing turbines are used in facilities where the primary goal is power generation rather than process steam supply. For example, they are used in cogeneration plants where excess steam is not needed for heating or manufacturing processes. Some large manufacturing plants, such as steel mills and chemical refineries, use condensing turbines to generate in-house power, reducing reliance on external electricity sources and improving energy independence.

Marine propulsion systems also utilize straight condensing turbines, particularly in naval vessels and some commercial ships. In these applications, the turbines drive the ship’s propellers through a reduction gear system, providing efficient and reliable propulsion. The condenser plays a critical role in maintaining performance by ensuring a continuous supply of low-pressure steam, which allows for sustained high-power output.

The design of straight condensing turbines involves careful consideration of steam conditions, blade geometry, and condenser performance. The turbine blades must be designed to optimize steam flow while minimizing aerodynamic losses. In addition, last-stage blades are typically larger and designed to handle high steam velocities at low pressures. The efficiency of the condenser is equally important, as its ability to maintain a vacuum directly impacts turbine performance. Cooling systems for the condenser may use seawater, river water, or closed-loop cooling towers, depending on the plant’s location and environmental considerations.

One of the main challenges in operating straight condensing turbines is maintaining condenser vacuum conditions. Any leakage of air or non-condensable gases into the condenser can reduce efficiency by increasing back pressure, leading to lower power output. To mitigate this, vacuum pumps or air ejectors are used to remove unwanted gases and maintain optimal pressure conditions. Regular monitoring and maintenance of the condenser, including cleaning of heat exchanger tubes and inspection for leaks, are necessary to ensure reliable operation.

Material selection is another critical factor in the longevity and efficiency of condensing turbines. High-pressure and high-temperature components must be made from materials capable of withstanding thermal stresses and corrosion. Special coatings and advanced alloys are used for turbine blades and rotors to resist erosion caused by moisture and impurities in the steam. Proper water treatment and boiler chemistry control are also essential to prevent scaling and deposits that could reduce efficiency.

Advancements in steam turbine technology continue to improve the performance of straight condensing turbines. Computational fluid dynamics (CFD) and finite element analysis (FEA) are used to optimize blade designs, reduce energy losses, and enhance durability. Digital control systems allow for real-time monitoring and adaptive optimization of turbine operation, improving efficiency and reliability. Additionally, the integration of combined cycle power plants (CCPP), where steam turbines work alongside gas turbines, has further enhanced the overall efficiency of power generation.

From an environmental perspective, condensing turbines contribute to lower emissions by improving fuel efficiency in power generation. Many power plants that use condensing turbines incorporate waste heat recovery systems, such as regenerative feedwater heating, to further optimize energy use. In addition, renewable energy sources such as biomass and geothermal power are increasingly being used in conjunction with condensing turbines to produce sustainable electricity.

In terms of economics, the high efficiency of straight condensing turbines translates into lower operating costs and improved return on investment, particularly for large-scale power plants. While the initial capital investment for a condensing turbine system, including the condenser and cooling infrastructure, can be significant, the long-term energy savings and reliability of these systems make them a cost-effective choice for power producers.

Future developments in straight condensing turbines will likely focus on increasing efficiency, reducing emissions, and integrating with renewable energy sources. Advances in high-temperature materials, improved blade aerodynamics, and enhanced cooling technologies will continue to push the limits of turbine performance. Additionally, the adoption of digital twins and AI-driven predictive maintenance will further enhance reliability and operational efficiency.

In conclusion, straight condensing turbines play a crucial role in power generation and high-efficiency energy conversion applications. Their ability to maximize power output by fully expanding steam to low-pressure conditions makes them an essential technology for utilities, industrial power generation, and marine propulsion. With ongoing advancements in materials, digital controls, and thermodynamic optimization, straight condensing turbines will remain a cornerstone of efficient energy production, supporting the transition toward more sustainable and cost-effective power solutions.

The continued evolution of straight condensing turbines is driven by the need for greater efficiency, reliability, and sustainability in power generation. These turbines are at the core of large-scale energy production, and their design and operational parameters directly impact overall plant performance. Modern developments in turbine technology, materials science, and digital control systems are enhancing their capabilities, making them more efficient and adaptable to evolving energy demands.

One of the key areas of improvement in straight condensing turbines is the development of advanced steam path designs. Computational Fluid Dynamics (CFD) simulations have enabled engineers to optimize steam flow, reduce energy losses, and increase power output. New blade profiles with enhanced aerodynamics and reduced surface friction allow for better steam expansion and energy extraction. Additionally, improved sealing mechanisms, such as brush seals and advanced labyrinth seals, help minimize steam leakage and improve overall efficiency.

The materials used in turbine construction also play a crucial role in performance and longevity. High-temperature superalloys, ceramic coatings, and corrosion-resistant materials are increasingly being used to withstand the extreme conditions inside a condensing turbine. In the final stages of the turbine, where the steam is at its lowest pressure and highest velocity, moisture content increases, leading to potential blade erosion. To mitigate this, last-stage blades are made from specially treated erosion-resistant alloys, and moisture removal techniques, such as drainage slots and steam extraction, are incorporated into the design.

The efficiency of a straight condensing turbine is also heavily dependent on the performance of its condenser. The condenser must maintain a low-pressure environment to maximize the energy extracted from steam expansion. Different cooling methods are used depending on the location and water availability. Once-through cooling systems use large volumes of water from natural sources, such as rivers or oceans, while recirculating cooling towers minimize water consumption by reusing cooled water. Air-cooled condensers (ACC) are an alternative used in water-scarce areas, though they tend to be less efficient than water-cooled systems.

Operational strategies also influence the performance of straight condensing turbines. Load following and cycling operations, common in modern power grids with high renewable energy penetration, require turbines to be flexible and responsive to changes in demand. While traditional steam turbines were designed for continuous base-load operation, modern condensing turbines are being adapted for more dynamic operation. Fast-start capabilities, improved thermal cycling resistance, and automated control systems enable turbines to ramp up and down efficiently, complementing the intermittent nature of wind and solar energy sources.

Another critical factor in the efficiency of straight condensing turbines is heat recovery and regeneration. Many power plants incorporate feedwater heaters that use extracted steam from intermediate turbine stages to preheat the boiler feedwater. This reduces the amount of fuel needed to generate steam, increasing overall cycle efficiency. Regenerative cycles, such as those used in supercritical and ultra-supercritical steam plants, further enhance energy efficiency by operating at higher temperatures and pressures, achieving thermal efficiencies exceeding 45%.

Digitalization and automation are revolutionizing the operation and maintenance of straight condensing turbines. Advanced monitoring systems equipped with IoT (Internet of Things) sensors continuously track turbine parameters, including temperature, pressure, vibration, and efficiency. AI-driven predictive maintenance systems analyze this data to detect anomalies, predict potential failures, and optimize maintenance schedules. This reduces downtime, extends the lifespan of critical components, and lowers operational costs. Digital twins—virtual models of turbines that simulate real-time conditions—are being used to improve performance analysis, streamline troubleshooting, and refine operational strategies.

The integration of straight condensing turbines with renewable energy sources is another area of ongoing development. Hybrid power plants that combine solar thermal energy with steam turbines use concentrated solar power (CSP) systems to generate high-temperature steam, which can be expanded through a condensing turbine to produce electricity. Similarly, geothermal power plants utilize naturally occurring steam or hot water from underground reservoirs to drive condensing turbines. Biomass power plants also employ condensing turbines to generate electricity from organic waste materials, contributing to carbon-neutral energy production.

Environmental regulations and sustainability goals are shaping the future of straight condensing turbines. Power plants are increasingly required to reduce greenhouse gas emissions, water consumption, and waste heat discharge. Advanced emission control technologies, such as carbon capture and storage (CCS), are being integrated with steam power plants to reduce CO₂ emissions. Additionally, research into supercritical carbon dioxide (sCO₂) power cycles, which use CO₂ as a working fluid instead of steam, promises higher efficiencies and reduced environmental impact.

Economic considerations also play a significant role in the deployment of straight condensing turbines. While the initial investment in high-efficiency turbine systems can be substantial, the long-term savings from reduced fuel consumption and improved reliability make them cost-effective. Energy producers analyze factors such as fuel costs, electricity market prices, and regulatory incentives when determining the viability of turbine upgrades or new installations. Advances in modular turbine designs and standardized components are helping reduce manufacturing and installation costs, making condensing turbines more accessible to a broader range of applications.

Looking ahead, the future of straight condensing turbines will be shaped by continued advancements in efficiency, digitalization, and sustainability. Next-generation turbine designs will incorporate even higher steam temperatures and pressures, reaching beyond ultra-supercritical conditions to achieve unprecedented efficiency levels. AI-driven automation will further optimize performance and maintenance, while integration with renewable and hybrid energy systems will enhance their role in a cleaner, more resilient energy landscape.

In summary, straight condensing turbines remain a cornerstone of efficient power generation, providing reliable and high-efficiency energy conversion for large-scale electricity production. Their ability to extract maximum energy from steam expansion makes them indispensable in power plants, industrial applications, and marine propulsion. With ongoing technological innovations, enhanced digital controls, and increasing integration with renewable energy, these turbines will continue to play a crucial role in the global energy transition, supporting sustainability goals while maintaining economic viability.

As the global energy landscape evolves, straight condensing turbines continue to play a critical role in balancing efficiency, reliability, and sustainability. These turbines, which maximize energy extraction by expanding steam to the lowest possible pressure, remain a key component of large-scale power generation. Ongoing advancements in materials, digitalization, and system integration are further improving their performance, reducing emissions, and enabling their adaptation to modern energy challenges.

Enhancing Efficiency Through Advanced Steam Conditions

One of the most significant trends in condensing turbine development is the push toward higher steam temperatures and pressures. Ultra-supercritical (USC) and advanced ultra-supercritical (AUSC) steam cycles operate at temperatures exceeding 600°C and pressures above 30 MPa, dramatically improving thermal efficiency. By reducing the specific fuel consumption per unit of electricity generated, these high-efficiency turbines lower greenhouse gas emissions while increasing power output. The adoption of nickel-based superalloys and advanced thermal barrier coatings enables turbine components to withstand extreme operating conditions, ensuring durability and reliability.

A key challenge in high-temperature turbine operation is managing oxidation and thermal fatigue. Advanced cooling techniques, such as internal steam cooling and optimized airfoils, help maintain blade integrity while minimizing heat-related degradation. Research into ceramic matrix composites (CMCs) is also opening new possibilities for high-temperature turbine components that offer superior thermal resistance compared to traditional metal alloys.

Digitalization and Smart Monitoring for Optimized Performance

The integration of digital twin technology, artificial intelligence (AI), and real-time monitoring is transforming the operation and maintenance of straight condensing turbines. Sensors embedded throughout the turbine system continuously collect data on temperature, pressure, vibration, and efficiency. AI-driven analytics process this data to detect early signs of wear, optimize load distribution, and predict maintenance needs.

Predictive maintenance reduces unplanned downtime by allowing operators to address potential issues before they lead to costly failures. Automated control systems also enable dynamic turbine operation, adjusting steam flow, valve positions, and blade angles in response to grid demand fluctuations. This flexibility is particularly valuable in modern energy grids that incorporate intermittent renewable sources, such as wind and solar, requiring thermal power plants to ramp up and down efficiently.

Cybersecurity is another growing concern as turbines become increasingly digitalized. Power plants must implement robust security measures to protect control systems from cyber threats and ensure uninterrupted operation. Blockchain-based energy tracking and AI-enhanced anomaly detection are emerging as potential solutions to enhance security in turbine monitoring systems.

Innovations in Condensation and Heat Recovery

The performance of a straight condensing turbine is closely linked to the efficiency of its condenser. Advanced condenser designs are being developed to maximize heat transfer and minimize cooling water usage. Hybrid cooling systems, which combine wet and dry cooling techniques, offer improved efficiency while reducing environmental impact.

Waste heat recovery is also playing a larger role in modern condensing turbine systems. In combined-cycle power plants (CCPP), exhaust steam from a condensing turbine can be used to drive a secondary power cycle, such as an organic Rankine cycle (ORC) or a supercritical CO₂ cycle. These additional cycles capture residual thermal energy, further improving overall plant efficiency.

Another promising development is the use of district heating systems in conjunction with condensing turbines. In some power plants, a portion of the extracted low-pressure steam is redirected to provide heating for residential and industrial areas, reducing the need for separate heating systems. This approach, known as combined heat and power (CHP) or cogeneration, significantly improves energy utilization and lowers carbon emissions.

Reducing Environmental Impact and Integrating with Renewables

Environmental regulations are driving the adoption of cleaner and more efficient turbine technologies. Carbon capture and storage (CCS) is being integrated with condensing turbines to reduce CO₂ emissions in fossil fuel-based power plants. Post-combustion carbon capture techniques, such as chemical absorption using amines, can remove up to 90% of CO₂ emissions before they are released into the atmosphere.

Additionally, there is growing interest in integrating straight condensing turbines with renewable energy sources. Geothermal power plants, for example, use naturally occurring steam from underground reservoirs to drive condensing turbines. Concentrated solar power (CSP) plants employ large arrays of mirrors to generate high-temperature steam, which can then be expanded through condensing turbines to produce electricity. Biomass-fired power plants also rely on condensing turbines to convert steam energy into power while utilizing organic waste materials as a fuel source.

Hydrogen-fired turbines are another emerging technology with the potential to revolutionize power generation. Research is underway to adapt existing steam turbine designs to operate with hydrogen combustion, offering a zero-emission alternative to fossil fuels. The ability to retrofit condensing turbines for hydrogen compatibility could make them a critical component of future green energy systems.

Economic and Market Considerations

Despite the growing emphasis on renewable energy, straight condensing turbines continue to be a cost-effective solution for baseload power generation. Their high efficiency and reliability make them an attractive investment for utilities and industrial facilities looking to secure stable energy supplies. However, the economic viability of new turbine installations depends on factors such as fuel prices, carbon taxation, and government incentives for clean energy adoption.

In regions where electricity demand is growing rapidly, new high-efficiency condensing turbine installations remain a priority. Countries with aging power infrastructure are also investing in turbine upgrades and repowering projects to extend the lifespan of existing plants. Retrofitting older turbines with modern blade designs, improved sealing systems, and digital controls can significantly enhance performance while reducing emissions.

Meanwhile, emerging markets are seeing increased adoption of modular and small-scale condensing turbines. These compact systems provide decentralized power generation for industrial zones, remote areas, and microgrid applications. The ability to operate independently of large power grids makes them valuable in regions with limited energy infrastructure.

Future Prospects and the Path Forward

Looking to the future, straight condensing turbines will continue to evolve as efficiency and sustainability remain top priorities. Breakthroughs in materials, aerodynamics, and digital optimization will drive further performance improvements. The development of supercritical CO₂ (sCO₂) turbines, which operate at higher thermal efficiencies than traditional steam turbines, could eventually replace or complement existing condensing turbine designs.

Hybrid power plants that combine multiple energy sources, such as gas turbines, renewables, and condensing turbines, will become more prevalent, creating more resilient and adaptable energy systems. The ability to integrate with carbon-neutral fuels, such as ammonia and hydrogen, will further enhance the role of condensing turbines in a low-carbon energy future.

In conclusion, straight condensing turbines remain a cornerstone of global power generation, delivering high-efficiency energy conversion in a wide range of applications. Advances in materials, digitalization, and integration with renewable energy will ensure their continued relevance in the evolving energy landscape. By embracing innovation and sustainability, these turbines will contribute to a cleaner, more efficient, and more reliable energy future.

Steam Turbines with Dry Steam

Steam turbines with dry steam are designed to operate with steam that contains minimal moisture, ensuring efficient energy conversion and reduced wear on turbine components. These turbines are commonly used in geothermal power plants, industrial applications, and traditional fossil fuel power generation, where maintaining steam quality is crucial for optimal performance. Unlike turbines that handle wet steam, which contains a mixture of vapor and liquid droplets, dry steam turbines are engineered to maximize energy extraction while minimizing the risks associated with moisture erosion and deposition.

Principles of Operation

Dry steam turbines function by expanding high-temperature, low-moisture steam through a series of stationary and rotating blades. The steam’s thermal energy is converted into mechanical energy, which drives the turbine shaft and, in most cases, an electrical generator. Since dry steam carries no significant liquid content, it reduces the potential for blade erosion and improves efficiency by ensuring consistent aerodynamic performance throughout the turbine stages.

The steam used in these turbines can originate from various sources, including superheated steam generated in boilers, direct geothermal steam from underground reservoirs, or reheated steam from an intermediate extraction point in a thermal power cycle. Regardless of the source, the primary objective is to maintain steam quality to prevent condensation and ensure efficient energy transfer.

Applications in Power Generation

One of the most common applications of dry steam turbines is in geothermal power plants, particularly in areas where high-quality geothermal steam is naturally available. In these plants, steam is extracted directly from geothermal wells and fed into the turbine without requiring a separate boiler system. The dry nature of the steam makes it ideal for direct expansion through the turbine blades, eliminating the need for extensive steam drying or reheating processes.

Fossil fuel and biomass power plants also utilize dry steam turbines by ensuring that the steam generated in boilers is superheated before entering the turbine. This approach enhances efficiency by preventing early condensation within the turbine, reducing maintenance costs and prolonging the lifespan of turbine components. Combined-cycle power plants (CCPP) also employ dry steam turbines in their bottoming cycle, where steam generated from waste heat is used to drive additional power generation.

Geothermal Steam Turbine Considerations

Geothermal power plants that use dry steam turbines have unique design considerations compared to conventional thermal plants. Since geothermal steam often contains dissolved gases and impurities, special filtration and separation techniques are employed to remove non-condensable gases and particulate matter before the steam enters the turbine. Silica scaling, a common issue in geothermal steam systems, is managed through proper chemical treatment and steam conditioning.

In some geothermal fields, the steam may not be entirely dry at the extraction point, requiring separators to remove excess moisture. This ensures that only high-quality steam reaches the turbine, preventing blade erosion and deposits that could reduce efficiency.

Design and Performance Optimization

To maximize efficiency, dry steam turbines are designed with advanced blade profiles, optimized steam paths, and enhanced sealing mechanisms. The following design elements contribute to their performance:

- Superheated Steam Expansion: By ensuring the steam remains in a dry state throughout the expansion process, efficiency is improved, and blade erosion is minimized. Superheating the steam before entering the turbine helps maintain this condition.

- Optimized Blade Geometry: Modern dry steam turbines feature high-efficiency blade profiles that reduce aerodynamic losses and improve energy extraction. Computational fluid dynamics (CFD) is used to refine blade designs for optimal steam flow.

- Advanced Sealing Systems: Minimizing steam leakage between turbine stages is critical for maintaining efficiency. Labyrinth seals, brush seals, and active clearance control systems are used to enhance sealing performance.

- Moisture Management Strategies: While dry steam turbines are designed to handle low-moisture steam, minor condensation may still occur in later stages. Drainage slots and steam extraction ports help remove excess moisture before it can impact performance.

Efficiency and Operational Advantages

Dry steam turbines offer several operational benefits over their wet steam counterparts:

- Higher Efficiency: Since dry steam eliminates moisture-related losses, the turbine can achieve higher energy conversion rates. The absence of liquid droplets reduces drag forces on the blades, improving overall performance.

- Reduced Blade Erosion: Moisture droplets in wet steam turbines cause impact erosion, shortening the lifespan of turbine blades. Dry steam turbines avoid this issue, leading to lower maintenance costs and extended operational life.

- Lower Condensation Losses: By maintaining steam quality, dry steam turbines prevent early condensation that could reduce efficiency and increase back pressure in the condenser.

- Simplified Maintenance: Without moisture-related damage, turbine components experience less wear and require less frequent maintenance, improving reliability and reducing downtime.

- Optimized for High-Temperature Applications: Dry steam turbines are particularly well-suited for applications where steam temperatures exceed 400°C, ensuring stable operation in high-energy environments.

Challenges and Limitations

Despite their advantages, dry steam turbines also face certain challenges:

- Steam Source Dependence: The availability of dry steam is limited to certain geothermal fields and power plant configurations that support superheated steam generation. In locations where wet steam is more prevalent, additional drying or superheating processes may be required.

- Material Considerations: The high temperatures associated with dry steam require turbine components to be made from heat-resistant alloys and coatings. Materials such as stainless steel, nickel-based superalloys, and ceramic coatings are used to ensure durability.

- Geothermal Impurities: In geothermal applications, non-condensable gases such as CO₂ and H₂S must be managed to prevent corrosion and efficiency losses. Special gas extraction systems and corrosion-resistant materials are necessary.

- Load Variation Sensitivity: Dry steam turbines perform best under stable load conditions. Rapid load changes can impact steam quality and turbine efficiency, requiring advanced control systems for optimal operation.

Future Developments and Innovations

Advancements in dry steam turbine technology continue to enhance efficiency and adaptability in power generation. Several key developments are shaping the future of these turbines:

- Advanced Steam Drying Techniques: Innovations in steam separation and conditioning are improving the ability to maintain dry steam in a wider range of operating conditions. Enhanced moisture separators and steam reheaters are being integrated into turbine systems to optimize performance.

- Hybrid Geothermal Systems: Combining dry steam turbines with other renewable energy sources, such as solar thermal or waste heat recovery, is expanding the applicability of geothermal power plants. These hybrid systems improve energy utilization and provide more consistent power output.

- Digital Twin and AI Integration: Real-time monitoring and predictive analytics are revolutionizing turbine maintenance and operation. Digital twin models simulate turbine behavior under different conditions, allowing operators to optimize performance and predict potential issues before they occur.

- Supercritical and Ultra-Supercritical Steam Cycles: Research into supercritical steam conditions is leading to turbines capable of operating at even higher temperatures and pressures, pushing efficiency limits beyond current standards. These developments promise further reductions in fuel consumption and emissions.

- Carbon Capture and Storage (CCS) Integration: In fossil fuel-based power plants, dry steam turbines are being adapted to work alongside carbon capture technologies, reducing greenhouse gas emissions while maintaining high efficiency.

Conclusion

Steam turbines with dry steam play a crucial role in efficient and reliable power generation across various industries. Their ability to minimize moisture-related losses, reduce maintenance costs, and operate at high efficiencies makes them a preferred choice in geothermal power plants, superheated steam cycles, and advanced energy systems. As technology continues to evolve, innovations in steam drying, digital optimization, and hybrid power systems will further enhance the performance and sustainability of dry steam turbines. Their continued development ensures that they remain a cornerstone of modern energy production, supporting the global transition to cleaner and more efficient power generation solutions.

Integration with Renewable Energy and Sustainable Development

As the energy sector moves toward greater sustainability, steam turbines with dry steam are playing an increasingly important role in renewable power generation. Geothermal energy, in particular, benefits significantly from the efficiency and reliability of dry steam turbines, offering a clean, baseload power source that operates independently of weather conditions. In hybrid renewable systems, dry steam turbines are being integrated with other energy sources, such as concentrated solar power (CSP) and biomass, to maximize efficiency and reduce reliance on fossil fuels.

Geothermal Power Expansion and Innovations

Geothermal power plants utilizing dry steam turbines have traditionally been limited to high-temperature geothermal fields where naturally occurring dry steam is available. However, technological advancements are expanding the potential of geothermal energy to new locations. Enhanced geothermal systems (EGS) are now being developed to extract geothermal heat from deeper and less accessible rock formations, significantly increasing the number of viable sites for geothermal power generation.

- Deep Drilling Technologies: Modern drilling techniques, such as directional drilling and plasma-based drilling systems, allow for access to deeper geothermal reservoirs where dry steam can be produced at higher pressures and temperatures.

- Supercritical Geothermal Steam: Some geothermal reservoirs contain supercritical steam—a state between liquid and gas that offers even greater energy potential. Research into utilizing supercritical geothermal steam with advanced turbine designs could lead to groundbreaking improvements in efficiency and power output.

- Modular Geothermal Power Plants: Smaller, scalable dry steam turbines are being developed for distributed geothermal energy applications, allowing communities and industries to generate their own clean power.

Hybrid Power Plants and Waste Heat Recovery

Dry steam turbines are also being increasingly used in hybrid power plants, where they operate alongside other renewable and waste heat recovery systems to improve energy efficiency.

- Solar-Geothermal Hybrid Systems: Concentrated solar power (CSP) plants generate high-temperature steam by focusing sunlight on heat-absorbing materials. When combined with geothermal dry steam turbines, CSP can provide additional energy during peak sunlight hours, enhancing overall power output.

- Biomass and Waste Heat Utilization: Industrial processes and biomass power plants produce high-temperature waste heat, which can be converted into dry steam for turbine operation. Utilizing waste heat recovery with dry steam turbines maximizes energy efficiency and reduces environmental impact.

- Supercritical CO₂ Cycles: Future hybrid systems may incorporate supercritical CO₂ (sCO₂) turbines, which operate at higher efficiencies than conventional steam turbines. These systems could work alongside dry steam turbines to further improve performance.

Environmental Impact and Sustainability

One of the main advantages of steam turbines with dry steam is their potential for sustainability and low environmental impact. Unlike fossil fuel-based power generation, geothermal and waste heat recovery systems using dry steam turbines produce little to no greenhouse gas emissions. However, there are still challenges and environmental considerations that must be addressed.

- Reducing Geothermal Emissions: While geothermal energy is considered a clean source, some geothermal reservoirs contain non-condensable gases such as CO₂ and hydrogen sulfide (H₂S). Advanced gas extraction and reinjection techniques help minimize these emissions.

- Water Conservation Strategies: Many dry steam turbine systems use cooling water in condensers, which can be a concern in water-scarce regions. Air-cooled condensers and hybrid cooling systems reduce water consumption while maintaining efficiency.

- Geothermal Resource Management: Overextraction of geothermal steam can lead to reservoir depletion over time. Sustainable geothermal management practices, including reinjecting used steam condensate into the reservoir, help maintain long-term viability.

Future Trends and Research Directions

As steam turbine technology continues to evolve, several key research areas are expected to drive the future development of dry steam turbines:

- High-Temperature Turbine Materials: Research into ceramic matrix composites (CMCs) and nickel-based superalloys is improving turbine durability and efficiency at higher operating temperatures.

- Digital Optimization and AI Control Systems: Machine learning and AI-driven controls enable real-time performance optimization, predictive maintenance, and adaptive steam flow management.

- Decentralized Power Generation: With the rise of microgrids and distributed energy systems, small-scale dry steam turbines are becoming more viable for localized power generation.

- Hydrogen-Ready Steam Cycles: As hydrogen production from renewable sources grows, there is potential for integrating hydrogen-fueled steam cycles with dry steam turbines, further reducing carbon emissions.

- Advanced Condensation Technologies: Improved condenser designs and direct-contact heat exchangers enhance heat rejection efficiency, reducing energy losses in steam turbine systems.

Conclusion

Steam turbines with dry steam remain a cornerstone of efficient, high-performance power generation, particularly in geothermal, waste heat recovery, and hybrid renewable applications. Their ability to operate with minimal moisture-related losses, reduce maintenance costs, and integrate with advanced energy systems ensures their continued relevance in the evolving global energy landscape. As new materials, digital optimization tools, and hybrid power plant configurations emerge, dry steam turbines will play an essential role in delivering sustainable and reliable energy for future generations.

Steam Turbines with Wet Steam

Steam turbines designed to operate with wet steam are engineered to handle steam that contains a mixture of water vapor and liquid droplets. Unlike turbines designed for dry steam, which are optimized for high-temperature and low-moisture steam, wet steam turbines are typically used in lower-pressure stages of steam cycles, where condensation naturally occurs. These turbines are integral to traditional power plants, where the steam is generated in a boiler and undergoes expansion and cooling during the power generation process. Wet steam turbines are also commonly used in combined-cycle and cogeneration plants. Despite the potential for moisture-related challenges, such as erosion and efficiency loss, wet steam turbines remain a critical technology due to their flexibility and widespread applicability.

Principles of Operation

Wet steam turbines operate by expanding steam through multiple stages of blades, converting thermal energy into mechanical energy. Wet steam, which contains water droplets, is introduced to the turbine at lower stages of the steam cycle, where the steam’s pressure and temperature are lower compared to the higher-pressure stages of dry steam turbines. In these systems, the steam typically undergoes partial condensation as it loses heat and energy while expanding through the turbine stages.

In wet steam turbines, moisture content is a key factor. The presence of liquid droplets in the steam can significantly affect turbine performance, especially by introducing additional mechanical stress on turbine blades, reducing aerodynamic efficiency, and causing erosion over time. Therefore, wet steam turbines are designed with specialized blade profiles, drainage systems, and material coatings to mitigate these risks and ensure reliable operation.

Applications in Power Generation

Wet steam turbines are commonly found in traditional fossil-fuel and biomass power plants, particularly in the intermediate and low-pressure sections of the steam cycle. These turbines are also a crucial component in combined-cycle power plants (CCPP), where waste heat from a gas turbine is used to generate steam, which is then expanded through the steam turbine to produce additional power. Wet steam turbines can be effectively integrated into the bottoming cycle of CCPP, enhancing overall efficiency by recovering waste heat from the gas turbine exhaust.

In these plants, steam is often generated at high pressure and temperature, and as it travels through the turbine stages, it gradually loses energy, which results in condensation. This process leads to the formation of wet steam, which is then directed into the lower pressure stages of the turbine. These turbines are also used in cogeneration applications, where they provide both electricity and thermal energy for industrial processes or district heating.

Challenges with Wet Steam and Design Considerations

While wet steam turbines can offer high performance and efficiency in certain applications, there are several design challenges that must be addressed due to the nature of wet steam. The presence of water droplets in the steam can lead to a variety of issues that require specialized engineering solutions.

- Moisture-Induced Erosion: One of the most significant challenges with wet steam turbines is the erosion of turbine blades caused by the impact of water droplets. These droplets can strike turbine blades at high velocity, leading to gradual wear and tear. Over time, this erosion can decrease the turbine’s efficiency and reduce its lifespan. To combat this, wet steam turbines are often equipped with advanced materials, such as high-alloy steel or coatings, that offer resistance to erosion. Additionally, blades may be designed with special profiles that minimize droplet impact.

- Reduced Efficiency: The presence of moisture in the steam increases the entropy of the system, which can reduce the efficiency of the turbine. Wet steam turbines are typically less efficient than dry steam turbines due to the added energy loss from condensation and moisture content. This issue is addressed by optimizing turbine design, including better steam path management and ensuring that moisture is removed or controlled during the expansion process.

- Droplet Separation Systems: Modern wet steam turbines often include droplet separation systems to minimize moisture content at the turbine inlet. These systems can include cyclonic separators or moisture-removal devices designed to trap water droplets before they enter the turbine blades. By reducing the moisture content, these systems help mitigate the erosion issue and improve efficiency.

- Dealing with Wet Steam at Low Pressure: Wet steam is more likely to occur at the lower-pressure stages of the turbine, where the steam expands and loses heat. To maximize efficiency in these stages, turbine designs must focus on reducing the risks associated with moisture buildup. This is often achieved by maintaining appropriate pressure and temperature gradients throughout the turbine cycle and ensuring that excess moisture is removed before entering the final stages of the turbine.

Efficiency and Performance Optimization

Despite the challenges presented by wet steam, there are several strategies employed to optimize the performance of wet steam turbines and ensure they continue to deliver efficient power generation. These optimization techniques are particularly important in systems where the use of dry steam is not feasible due to cost, fuel, or operational constraints.

- Optimizing Expansion Stages: Wet steam turbines are often designed with multiple expansion stages that help manage the moisture content and energy transfer more efficiently. In each stage, the pressure and temperature of the steam are reduced progressively, allowing for better energy extraction while minimizing the impact of moisture on the blades.

- Advanced Blade Materials and Coatings: The erosion caused by water droplets can be minimized with advanced materials and protective coatings. High-strength alloys, ceramic coatings, and thermal barrier coatings are commonly used to enhance blade durability and reduce wear.

- Moisture-Resistant Blade Designs: Wet steam turbines are equipped with blades designed to cope with the presence of water droplets. Blades may have a specific profile and curvature that helps divert or reduce the impact of droplets, limiting damage and improving aerodynamic efficiency.

- Improved Condenser Designs: To enhance overall turbine performance, improved condenser designs are employed to effectively deal with wet steam. These condensers help separate steam from excess water by maintaining an optimal pressure differential, ensuring that only the correct steam quality is supplied to the turbine. In some systems, vacuum condensers or cooling towers may be used to help reduce moisture content and manage the thermal load.

Environmental Considerations and Sustainability

Wet steam turbines, like dry steam turbines, play a crucial role in reducing carbon emissions when integrated with low-carbon technologies such as combined-cycle power plants or cogeneration systems. While fossil fuel-based plants often rely on wet steam turbines, the efficiency gains from combined-cycle designs can help offset carbon emissions by improving the overall efficiency of the power plant.

Additionally, wet steam turbines are being adapted for use in renewable energy plants, particularly in hybrid systems that combine biomass or waste-to-energy technologies with steam turbines. These systems provide a means to generate power while simultaneously reducing waste, offering a cleaner alternative to conventional power generation methods.

Water usage remains a concern in regions with limited freshwater resources, as steam turbine systems require significant water for cooling. However, innovations in dry cooling systems and air-cooled condensers help reduce water consumption, making wet steam turbines more environmentally friendly in water-scarce regions.

Future Trends and Innovations

The future of wet steam turbine technology will be shaped by advancements in materials, digital optimization, and integration with renewable and hybrid energy systems. Some of the promising trends and innovations include:

- Supercritical Steam Turbines: Research into supercritical steam cycles is leading to turbines that can operate at higher efficiencies, even with wet steam. Supercritical steam cycles achieve higher thermal efficiency by operating at higher pressures and temperatures, offering potential improvements in both wet and dry steam systems.

- Digital Monitoring and Predictive Maintenance: Advances in digital monitoring and predictive maintenance technologies are revolutionizing the operation of wet steam turbines. Sensors and digital twin models allow for real-time performance tracking, enabling operators to detect inefficiencies or potential failures before they occur. This leads to more reliable operation and reduced downtime.

- Hybrid and Integrated Power Systems: The integration of wet steam turbines with renewable energy sources, such as biomass, solar thermal, or waste heat recovery, will continue to expand. These hybrid systems allow for more sustainable power generation by leveraging different energy sources, reducing carbon emissions and improving efficiency.

- Alternative Fuels: The development of alternative fuels, such as hydrogen and ammonia, may lead to the adaptation of wet steam turbines to operate with these fuels. Hydrogen combustion, for example, produces no carbon emissions, and its use in power plants, including wet steam turbines, could contribute to a cleaner energy future.

Conclusion