Best Electric Motor. High quality & low price and long service life. AC electric motor producer. Free Consultation

EMS Motors is a subsidiary of the EMS Group, a privately held Turkish conglomerate with interests in real estate development, tooling and molding, pharmaceuticals, mining, and low-voltage industrial motor manufacturing.

Best Electric Motor

We manufacture the highest quality electric motors, designed and produced in a modern facility utilizing highly trained personnel and the latest manufacturing equipment. We not only operate cost-efficiently but also in an environmentally responsible manner. Our recent expansion into international markets has led to a new management philosophy based on international standards in administration and customer support.

Our new International Development Strategy fosters an environment of not only quality and service but also the international perspective and professionalism necessary to support our partners worldwide. This approach has led to successful partnerships with several large OEMs and distributors in the Middle East and Europe and was the strategy behind the establishment of EMS Electric Motors B.V. in The Netherlands with warehouse, sales, and the technical support capacity required in the European market.

Characteristics of the Best Electric Motor

Our motors are manufactured according to the IEC 60034-5 standard, protecting them against dust and squirting liquids. Our standard motors are manufactured in IP 55 protection class. IP56, IP65, and IP66 are available upon request.

As shown in Table 4, the first digit in the IP (Ingress Progress) diagram describes the protection against solid materials. The second digit shows the protection against liquid materials.

Cooling aims to transfer the heat from the motor to the ambient. The objective is to keep the temperature of isolation materials under limited values. The cooling type in Electrical Machines is determined with numbers between “1-9” that come after ‘IC’ (International Cooling), code letters according to the IEC 60034-6 standard.

Cooling air is supplied by a plastic fan which is connected to the motor shaft and operates inside a holed steel sheet protection cover; cooling is performed outside of the completely closed surface of the motor. Since EMS Electric motors are cooled with a fan from a completely closed outside surface, their cooling type is IC 411. IC 418 cooling type can also be manufactured upon special requests. Commonly used cooling examples for IEC 60034-6 standard are given in following Figure 18.

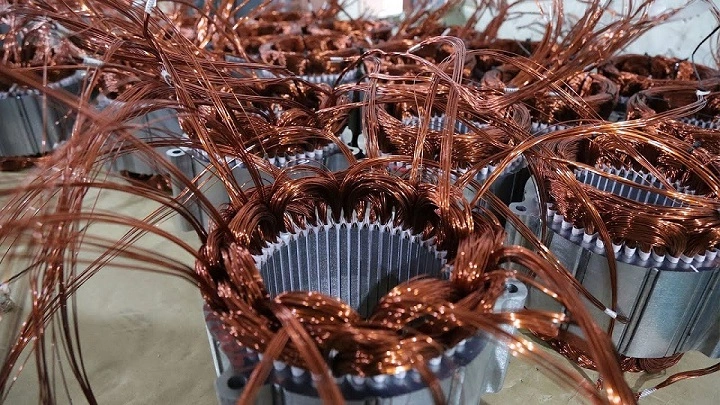

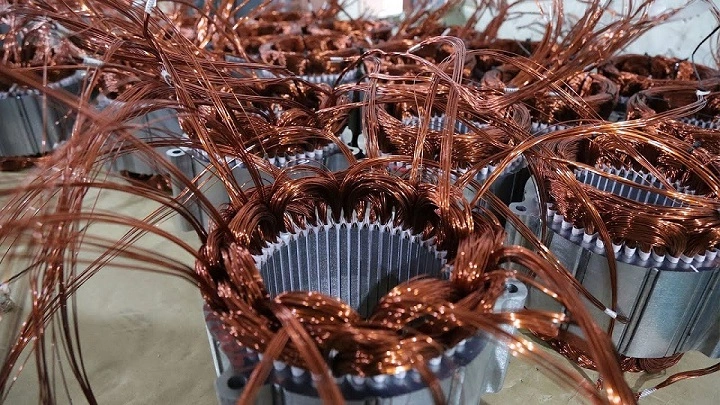

The temperature rise limit of EMS Electric motors is in class B. Stator windings are composed of copper conductors which are plated by double-layered enamel in class H. In phase windings (in each channel and in each winding start) and winding heads, complete isolation is provided by the Lacquer absorption method which is highly qualified and in class H (total 180 °C ). Other isolation materials are also in class H. This enables a winding construction to stand up to 155 °C.

Classification of Isolation

The classification of isolation materials based on their standing temperature is shown in Table 10. There are also Y, 200, 220, and 250 isolation classes according to IEC 60085. Y class defines a 90 °C temperature limit, the 200 class defines a 200 °C limit, the 220 class defines a 220 °C limit and the 250 class defines a 250 °C temperature limit.

Permitted vibration densities are determined in IEC 60034- 14 standards and these values which are given in Table 11 are recommended as upper limit values for motor producers. Three separate vibration density levels are determined according to this standard. Vibration levels of EMS Electric motors are within normal limits and meet the standard provisions. All our rotors are dynamically balanced by half key

EMS Electric Motors are manufactured to operate continuously at rated power in S1 duty type at 40°C ambient temperature and at an altitude up to 1000 m. Since motor performance will decrease at values that exceed these temperature and altitude values, the motor-rated power should be decreased. Temperature-Controlled Protection Equipment: Motor protection is achieved with fuse thermal relays, thermal magnetic circuit breakers, and thermistors.

Fuses protect motors, cables, relay circuit breakers and soft starters, and speed-controlling devices as well as; against short circuits however they cannot protect motors against overloading and over warming. Thermal relays and thermal-magnetic circuit breakers are adjusted according to the rated current of the motor they protect the motor by cutting the circuit against overloading and overcurrent.

However, other factors out of overloading and current can cause damage to the motor. Operation at two-phase; decreasing or stopping at cooling air; exceeding the ambient temperature and unstable ambient conditions (e.g. environment where the thermal relay exists can be cool and the environment where the motor exists can be hot) to operate at high altitudes; over start/stop; longer starting; and braking and similar situations; can cause the winding temperature to increase up to permitted temperatures and thermal relays may not provide protection.

Protection

In explained and similar situations increase in temperature more than set forth values should not be permitted. The most reliable protection for these cases is temperature-controlled protection.

Generally, two types of protective equipment are used in

temperature-controlled protection:

- Bi-metal circuit breakers (Micro thermostats)

- Semiconductor temperature sensors (PTC Thermistors)

Micro Thermostats: They are serial-connected bi-metal circuit breakers that include two or three elements. They open the circuit during over-limit temperatures and are closed during under-limit temperatures. They have NC (Normally Closed) and NO (Normally Opened) types. Micro thermostats are selected according to motor insulation class and maximum

temperature limits which are permitted for windings and are placed inside stator phase windings.

Thermostat terminals are brought into the motor terminal table and one type of thermostat is used for motors for all power classes. Micro thermostat protection thermals are serially connected to the contactor coil circuit, which controls the motor energy contactor. If the temperature in the motor windings exceeds the limit value the bi-metal circuit breaker is opened. Since the thermostat circuit is serially connected to motor energy, the contactor coil circuit energy contactor opens and the motor will stop. EMS Electric installs micro thermostat equipment into motor windings upon the request of customers.

Types of the Electric Motors

These types of motors are ready for temperature-controlled protection. PTC (Positive Temperature Coefficient) Thermistor and Relay: PTC thermistors are sets with serially-connected, three components, and a relay. They are semi-conductor temperature-sensitive equipment. Their electrical resistances increase according to certain temperature values. The temperature value where their resistance suddenly increases is called Nominal Response Temperature (NAT).

The nominal Response Temperature should be selected according to the motor’s insulation class and the permitted temperature value of the motor being protected. There is one type of thermistor and relay for all kinds of motors at all power, which is efficient for motors with greater power. PTC thermistor elements assets are installed into the motor’s stator windings. The PTC relay is installed in the motor control cabinet. Relay connections can be different according to producers.

Relay controls motor energy contactor. Thermistor elements provide an alarm signal for the relay when the temperature is close to the limit temperature as well as the trip signal at the permitted limit temperature. The relay operates when it receives a trip signal and opens the energy contactor. Therefore they protect windings from blowing out during situations such as sudden over-current increases and sudden over-voltage changes. EMS Electric uses a total of 3 PTC thermistors in each of the three-phase stator windings, one-by-one, in motor frame sizes 180 and up. PTC thermistors and bi-metal thermostats can be used in smaller size frames according to customer requests.

Electric motors are devices that convert electrical energy into mechanical energy. They play a crucial role in various applications and are widely used in industries, transportation, household appliances, and more. Here are some key points about electric motors:

- Basic Principle: Electric motors operate on the principle of electromagnetic induction, discovered by Michael Faraday. When an electric current flows through a coil placed in a magnetic field, a force is exerted on the coil, causing it to rotate. This rotation is then used to perform mechanical work.

- Components:

- Stator: The stationary part of the motor that produces a magnetic field.

- Rotor (Armature): The rotating part of the motor, usually a coil or a set of coils, which experiences the magnetic field and rotates.

- Types of Electric Motors:

- DC Motors: Direct current motors operate on a constant voltage and are commonly used in applications where precise speed control is required.

- AC Motors: Alternating current motors are more common and come in various types, including:

- Induction Motors: Widely used in household appliances and industrial applications.

- Synchronous Motors: Maintain synchrony with the frequency of the applied AC voltage.

- Brushless DC Motors: Similar to traditional DC motors but use electronic controllers instead of brushes for commutation.

- Applications:

- Industrial Applications: Electric motors power machinery, pumps, fans, compressors, and various manufacturing processes.

- Transportation: Electric motors are used in electric vehicles (EVs), trains, and other forms of electric transportation.

- Household Appliances: They power everything from kitchen appliances like blenders and mixers to HVAC systems and vacuum cleaners.

- Renewable Energy: Electric motors are used in wind turbines and hydropower generators to convert rotational energy into electricity.

- Efficiency and Sustainability: Electric motors are generally more energy-efficient than traditional internal combustion engines, making them a key component in the transition to more sustainable and environmentally friendly technologies.

- Control Systems: Advanced control systems, such as variable frequency drives (VFDs) and programmable logic controllers (PLCs), are often used with electric motors to regulate speed, torque, and direction.

- Maintenance: Electric motors require maintenance to ensure optimal performance. This includes lubrication, checking for worn-out parts, and monitoring electrical components.

The choice of the type of electric motor depends on the specific application’s requirements, such as power output, speed, and efficiency. Advances in motor technology continue to contribute to increased efficiency, reduced environmental impact, and broader applications for electric motors.

Basic Principle

The basic principle behind the operation of electric motors is electromagnetic induction, a phenomenon discovered by Michael Faraday in the early 19th century. Faraday’s law of electromagnetic induction states that a change in magnetic field within a closed loop of wire induces an electromotive force (EMF) or voltage in the wire. This principle is fundamental to the operation of electric motors.

Here’s a simplified explanation of the basic principle:

- Magnetic Field: An electric motor consists of a stationary part called the stator, which produces a magnetic field. This magnetic field can be created by a permanent magnet or by passing an electric current through coils of wire.

- Moving Coil (Armature or Rotor): Inside the magnetic field, there is a moving part called the rotor or armature. The rotor typically consists of a coil of wire or a set of coils.

- Electrical Current: When an electric current is passed through the coil in the rotor, it generates its own magnetic field. This magnetic field interacts with the magnetic field produced by the stator.

- Force and Rotation: According to the laws of electromagnetism, when a current-carrying conductor (the coil in the rotor) is placed in a magnetic field, a force is exerted on it. This force causes the rotor to rotate.

- Continuous Rotation: The rotation of the rotor continues as long as there is a flow of electric current through the coil and the magnetic field is present. The direction of rotation can be reversed by reversing the direction of the current.

In summary, the basic principle of electric motors involves the interaction of magnetic fields and electric currents, resulting in the generation of mechanical motion. This principle is fundamental to various types of electric motors, including DC motors and AC motors, and it forms the basis for the conversion of electrical energy into mechanical work.

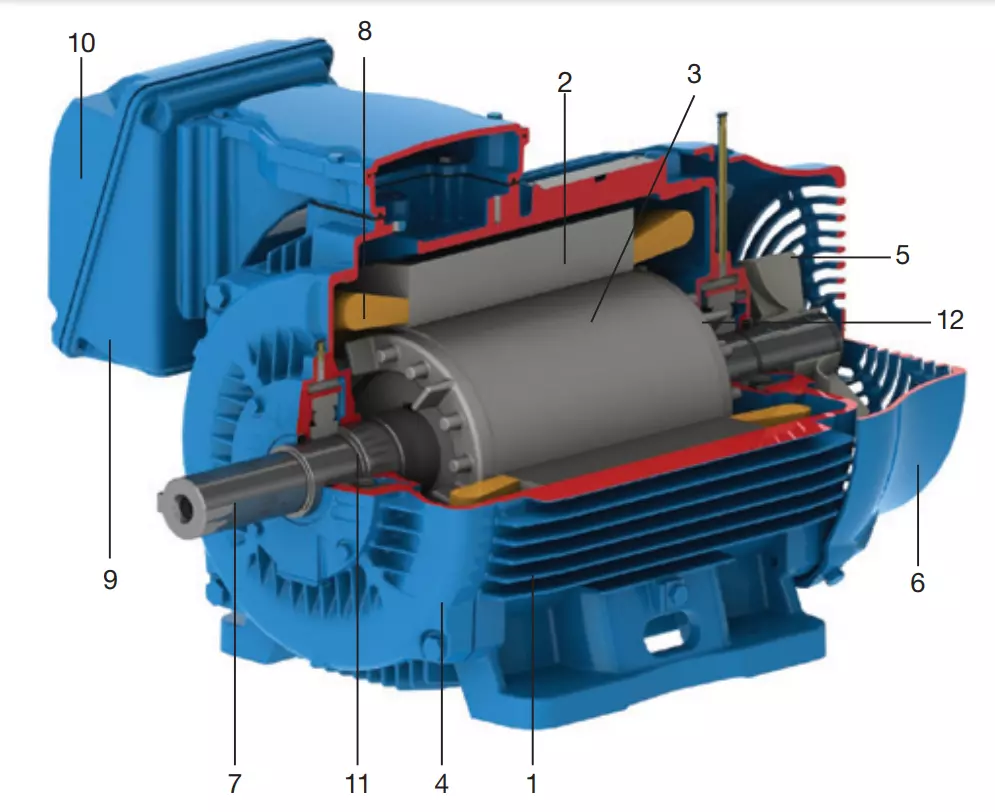

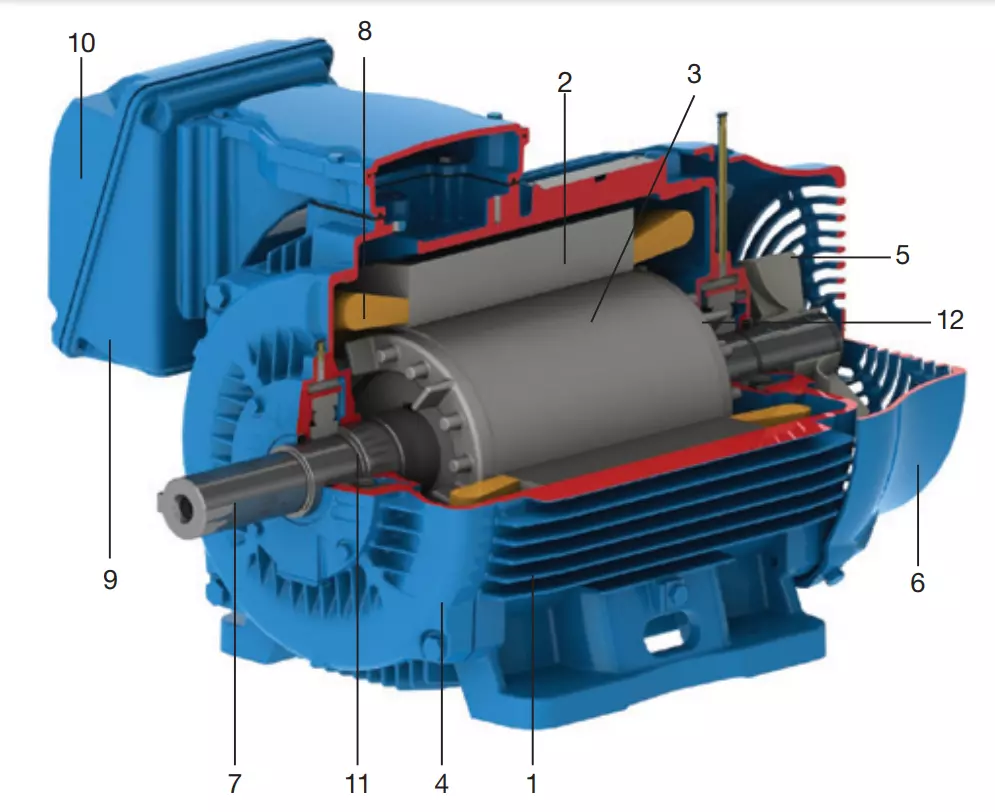

Components of an Electric Motor

Electric motors consist of several key components that work together to convert electrical energy into mechanical motion. The specific components may vary depending on the type of motor, but the fundamental parts are common to many motor designs. Here are the main components of an electric motor:

- Stator:

- The stator is the stationary part of the motor.

- It typically consists of a core made of laminated iron or steel sheets to minimize eddy current losses.

- Coils or windings are wound around the stator to produce a magnetic field when an electric current flows through them.

- In AC motors, the stator windings are connected to the power supply, creating a rotating magnetic field.

- Rotor (Armature):

- The rotor is the rotating part of the motor.

- It is usually located inside the stator.

- In DC motors, the rotor typically consists of a coil or coils of wire mounted on a shaft.

- In AC motors, the rotor can take different forms, such as a squirrel-cage rotor in induction motors or a wound rotor in some types of synchronous motors.

- Coil or Windings:

- Coils or windings are conductive wires wound around the stator and/or rotor.

- When an electric current flows through these coils, they generate a magnetic field.

- The interaction between the magnetic fields of the stator and rotor is what produces the mechanical motion.

- Communator (in DC Motors) or Slip Rings (in Some AC Motors):

- In DC motors, the commutator is a rotary switch that reverses the direction of the current in the rotor windings, ensuring a continuous rotation.

- In some AC motors, slip rings are used instead of a commutator to transfer electrical power to the rotor.

- Bearings:

- Bearings support the rotor and allow it to rotate smoothly within the stator.

- They reduce friction and wear between moving parts.

- Brushes (in Some DC Motors):

- In DC motors with a commutator, brushes are used to maintain electrical contact with the rotating commutator.

- The brushes carry current to the rotor windings, allowing the motor to continue rotating.

- Housing or Frame:

- The housing or frame encloses and protects the internal components of the motor.

- It provides structural support and helps dissipate heat generated during operation.

- Cooling Mechanism:

- Many motors include a cooling mechanism, such as a fan, to dissipate heat generated during operation.

- Efficient cooling is crucial for maintaining optimal motor performance and preventing overheating.

These components work together to enable the motor to convert electrical energy into mechanical motion, serving various industrial, commercial, and residential applications. The specific design and arrangement of these components can vary depending on the type and purpose of the motor.

Types of Electric Motors

There are various types of electric motors, each designed for specific applications and operating on different principles. Here are some common types of electric motors:

- DC Motors:

- Brushed DC Motors: These motors use brushes and a commutator to switch the direction of the current in the rotor windings, causing the rotor to rotate.

- Brushless DC Motors (BLDC): Instead of brushes and a commutator, BLDC motors use electronic controllers to switch the direction of current in the stator windings. They are more efficient and have a longer lifespan compared to brushed DC motors.

- AC Motors:

- Induction Motors:

- Single-Phase Induction Motors: Commonly used in household appliances.

- Three-Phase Induction Motors: Widely used in industrial applications due to their efficiency and reliability.

- Synchronous Motors:

- Permanent Magnet Synchronous Motors (PMSM): Use permanent magnets in the rotor, providing better efficiency and power factor.

- Wound Rotor Synchronous Motors: Have windings on the rotor connected to external resistors, allowing for controlled torque.

- Induction Motors:

- Linear Motors:

- Instead of rotational motion, linear motors produce linear motion along a straight path.

- Linear induction motors and linear synchronous motors are examples of linear motor types.

- Servo Motors:

- Servo motors are designed for precise control of position, velocity, and acceleration.

- They are often used in robotics, CNC machines, and other applications requiring high precision.

- Stepper Motors:

- Stepper motors move in discrete steps, making them suitable for applications where precise positioning is essential.

- They are commonly used in 3D printers, CNC machines, and various automation systems.

- Hollow Shaft Motors:

- These motors have a central opening in the rotor, allowing for the passage of cables, fluids, or other mechanical components through the center of the motor.

- Hermetic Motors:

- Sealed and designed to operate in environments where they are exposed to liquids or gases. Commonly used in refrigeration and air conditioning.

- Universal Motors:

- These motors can run on both AC and DC power.

- Commonly used in small household appliances like vacuum cleaners and power tools.

- Fractional Horsepower Motors:

- Motors with a power rating less than one horsepower.

- Widely used in applications where a small and economical motor is sufficient, such as fans and pumps.

- Gear Motors:

- Combines an electric motor with a gearbox to provide increased torque and lower speed.

- Used in applications where high torque is required, such as in automotive windshield wipers.

The choice of electric motor depends on factors such as the application requirements, power efficiency, size, speed, and cost considerations. Each type of motor has its advantages and disadvantages, making them suitable for specific tasks and industries.

DC Motors

DC motors, short for direct current motors, are devices that convert electrical energy into mechanical energy through the interaction of magnetic fields. They operate on the principle of electromagnetism and find applications in various industries due to their simplicity and controllability. Here are some key aspects of DC motors:

Basic Structure:

- Stator: The stationary part of a DC motor, usually consisting of permanent magnets or electromagnets that create a magnetic field.

- Rotor: The rotating part of the motor, typically made up of a coil of wire or multiple coils (armature) wound around a core. The rotor is placed within the stator’s magnetic field.

- Commutator: Found in brushed DC motors, the commutator is a segmented metal ring that ensures the direction of current in the rotor windings changes as the rotor turns, allowing for continuous rotation.

- Brushes: In brushed DC motors, brushes are conductive components that maintain contact with the commutator, supplying electric current to the rotor windings.

Types of DC Motors:

- Brushed DC Motors: These motors use brushes and a commutator for current reversal in the rotor windings. They are relatively simple but may require more maintenance due to the brushes.

- Brushless DC Motors (BLDC): BLDC motors use electronic controllers instead of brushes and a commutator. They are more efficient, produce less noise, and require less maintenance compared to brushed DC motors.

Working Principle:

- When a direct current flows through the coils of the rotor, an electromagnetic field is generated around the rotor.

- The interaction between the magnetic fields of the stator and rotor causes a torque, resulting in the rotation of the rotor.

- In brushed DC motors, the commutator and brushes ensure that the direction of the current in the rotor windings changes as the rotor turns, maintaining the rotation.

Applications:

- Automotive: DC motors power various components in vehicles, such as power windows, windshield wipers, and seat adjustment mechanisms.

- Industrial Machinery: They’re used in conveyors, pumps, compressors, and other equipment requiring variable speed control.

- Household Appliances: Found in appliances like electric razors, mixers, and some types of fans.

Advantages:

- Controllability: DC motors offer precise speed control and torque adjustments.

- Simple Design: Particularly brushed DC motors have a relatively straightforward design, making them easy to understand and maintain.

Limitations:

- Brush Wear: In brushed DC motors, the brushes can wear out over time, requiring periodic replacement and maintenance.

- Electromagnetic Interference: In some cases, DC motors can produce electromagnetic interference that might affect nearby electronic devices.

DC motors remain a vital part of various industries despite the rise of other motor types, thanks to their simplicity, controllability, and suitability for specific applications.

Applications

Electric motors find applications in a wide range of industries and everyday devices due to their ability to convert electrical energy into mechanical motion efficiently. Here are some common applications of electric motors:

- Industrial Machinery:

- Electric motors power various industrial machines, including conveyor systems, pumps, compressors, fans, and manufacturing equipment.

- Transportation:

- Electric Vehicles (EVs): Electric motors drive the wheels in electric cars, buses, and bikes, contributing to the shift towards more sustainable transportation.

- Trains and Light Rail: Electric motors are used in electric trains and light rail systems for propulsion.

- Household Appliances:

- Electric motors are integral to many household appliances, such as washing machines, refrigerators, air conditioners, vacuum cleaners, blenders, and electric fans.

- HVAC Systems:

- Heating, ventilation, and air conditioning (HVAC) systems use electric motors in fans, compressors, and pumps to circulate air and control temperature.

- Pumps and Water Systems:

- Electric motors power water pumps for domestic water supply, irrigation, and industrial processes.

- Power Tools:

- Many power tools, including drills, saws, and grinders, are powered by electric motors for various applications.

- Renewable Energy:

- Electric motors are used in renewable energy systems, such as wind turbines and hydropower generators, to convert rotational energy into electricity.

- Robotics:

- Servo motors and stepper motors play a crucial role in robotics, providing precise control of movement in robotic arms, drones, and other automated systems.

- Aerospace:

- Electric motors are used in various aircraft systems, including landing gear, pumps, and auxiliary power units.

- Medical Devices:

- Electric motors are used in medical equipment such as ventilators, infusion pumps, and diagnostic devices.

- Consumer Electronics:

- Electric motors are present in devices like electric toothbrushes, cameras, and computer hard drives.

- Elevators and Escalators:

- Electric motors power the movement of elevators and escalators in buildings.

- Gaming and Entertainment:

- Electric motors are used in gaming consoles, virtual reality devices, and amusement park rides.

- Automotive Systems:

- Besides electric vehicles, electric motors are used in various automotive applications, including power windows, windshield wipers, and cooling fans.

- Oil and Gas Industry:

- Electric motors are employed in pumps, compressors, and other equipment used in the extraction and processing of oil and gas.

- Mining:

- Electric motors power equipment such as crushers, conveyors, and drills in the mining industry.

These examples highlight the versatility and widespread use of electric motors in modern society, contributing to increased efficiency, automation, and the transition to more sustainable energy sources.

AC Motors

AC motors, or alternating current motors, are devices that convert electrical energy from an alternating current power source into mechanical energy. These motors are widely used in various applications due to their reliability, efficiency, and adaptability to different power systems. Here are key aspects of AC motors:

Types of AC Motors:

- Induction Motors:

- Single-Phase Induction Motors: Commonly used in residential applications and small industrial equipment.

- Three-Phase Induction Motors: Widely used in industrial applications due to their efficiency, reliability, and ability to handle higher power loads.

- Synchronous Motors:

- Permanent Magnet Synchronous Motors (PMSM): Use permanent magnets in the rotor, providing efficiency benefits.

- Wound Rotor Synchronous Motors: Feature windings on the rotor connected to external resistors, allowing for controlled torque.

Basic Structure:

- Stator:

- The stator contains coils or windings that are connected to the AC power supply.

- When AC voltage is applied, it induces a rotating magnetic field in the stator.

- Rotor:

- The rotor is placed inside the stator and can take different forms depending on the motor type.

- In induction motors, the rotor is typically a squirrel-cage rotor consisting of conductive bars.

- Working Principle:

- In induction motors, the rotating magnetic field in the stator induces a current in the rotor, creating a secondary magnetic field.

- The interaction between the stator’s rotating magnetic field and the rotor’s magnetic field generates torque, causing the rotor to turn.

Applications:

- Industrial Machinery:

- AC induction motors are used in a wide range of industrial equipment, including pumps, fans, compressors, conveyors, and manufacturing machinery.

- HVAC Systems:

- AC motors power the fans and compressors in heating, ventilation, and air conditioning (HVAC) systems.

- Electric Appliances:

- Many household appliances, such as washing machines, refrigerators, and air conditioners, use AC motors.

- Power Tools:

- AC motors are employed in various power tools, such as drills, saws, and grinders.

- Transportation:

- AC motors are used in electric trains, trolleys, and some types of electric vehicles.

- Renewable Energy:

- AC motors are integral components in wind turbines, converting wind energy into electrical power.

Advantages:

- Efficiency: AC motors are known for their high efficiency, especially in larger industrial applications.

- Low Maintenance: Induction motors, in particular, have fewer moving parts, resulting in lower maintenance requirements.

Limitations:

- Control Complexity: Compared to DC motors, AC motors can be more complex to control, especially in terms of speed regulation.

- Starting Torque: Induction motors may have lower starting torque compared to some DC motors, although this can be addressed with additional components.

AC motors are a cornerstone of modern industrial and commercial applications, providing reliable and efficient means of converting electrical energy into mechanical motion. The specific type of AC motor chosen depends on the requirements of the application.

Electric Motors

Electric motors are devices that convert electrical energy into mechanical energy. They are commonly used in a wide range of applications, from household appliances to industrial machinery, and are essential components in many modern technologies.

The basic principle behind an electric motor is simple. It consists of a magnetic field and a conductor. When a current is passed through the conductor, it experiences a force due to the interaction between the magnetic field and the electric charge. The direction of the force depends on the direction of the current and the orientation of the magnetic field.

There are two main types of electric motors: AC (alternating current) motors and DC (direct current) motors. AC motors are typically used in applications where constant speed is required, while DC motors are used in applications where variable speed is required.

AC motors operate by changing the direction of the current flowing through the windings of the motor, causing the magnetic field to rotate. This rotation creates a torque on the rotor, which causes it to turn. AC motors are typically used in household appliances, such as fans and refrigerators, as well as in industrial applications, such as pumps and compressors.

DC motors operate by applying a voltage to the motor, causing the current to flow through the windings of the motor. This creates a magnetic field, which interacts with the permanent magnets on the rotor, causing it to turn. DC motors are typically used in applications where variable speed is required, such as in electric vehicles and power tools.

Electric motors come in a wide range of sizes and power ratings, from small motors used in household appliances to large motors used in industrial machinery. They are also used in a variety of applications, including robotics, automation, and renewable energy systems.

In recent years, electric motors have become increasingly important due to their role in the transition to clean energy. Electric motors are used in electric vehicles, wind turbines, and solar panels, making them key components in the transition to a low-carbon economy. As technology continues to improve, electric motors are expected to become even more efficient and versatile, driving innovation and growth in a wide range of industries.

Electric Motors

An electric motor is a machine capable of converting electrical energy into mechanical energy. The induction motor is the most widely used type of motor because it combines all the advantages offered by electrical energy such as low cost, ease of supply and distribution, clean handling, and simple controls – together with those of simple construction and its great versatility to be adapted to wide ranges of loads and improved efficiencies. The most common types of electric motors are:

- Direct current motors: These motors are quite expensive requiring a direct current source or a converting device to convert normal alternating current into direct current. They are capable of operating with adjustable speeds over a wide range and are perfectly suited for accurate and flexible speed control. Therefore, their use is restricted to special applications where these requirements compensate for the much higher installation and maintenance costs.

- Alternating current motors: These are the most frequently used motors because electrical power is normally supplied as alternating current. The most common types are:

- Synchronous motors: synchronous motors are three-phase AC motors that run at a fixed speed, without slip, and are generally applied for large outputs (due to their relatively high costs in smaller frame sizes).

- Induction motor: these motors generally run at a constant speed which changes slightly when mechanical loads are applied to the motor shaft. Due to its simplicity, robustness, and low cost, this type of motor is the most widely used and, in practical terms, is quite suitable for almost all types of machines. Currently, it is possible to control the speed of induction motors with frequency inverters.

Electric motors are so much a part of everyday life that we seldom give them a second thought. When we switch on an electric drill, for example, we confidently expect it to run rapidly up to the correct speed and we do not question how it knows what pace to run, or how it is that once enough energy has been drawn from the supply to bring it up to speed, the power drawn falls to a very low level.

When we put the drill to work it draws more power, and when we finish the power drawn from the mains reduces automatically, without intervention on our part.

The humble motor, consisting of nothing more than an arrangement

of copper coils and steel laminations, is rather a clever energy converter, which warrants serious consideration. By gaining a basic understanding of how the motor works, we will be able to appreciate its potential and its limitations, and (in later chapters) see how the addition of external electronic controls can further enhance its already remarkable performance.

Mechanism of Electric Motors

This chapter deals with the basic mechanisms of motor operation, so

readers familiar with magnetic Xux, magnetic and electric circuits, torque, and motional e.m.f can probably afford to skim over much of it. In the course of the discussion, however, several very important general principles and guidelines emerge.

Nearly all motors exploit the force which is exerted on a current-carrying conductor placed in a magnetic Weld. The force can be demonstrated by placing a bar magnet near a wire carrying current, but anyone trying the experiment will probably be disappointed to discover how feeble the force is, and will doubtless be left wondering how such an unpromising effect can be used to make effective motors.

We will see that in order to make the most of the mechanism, we need

to arrange a very strong magnetic Weld, and make it interact with many

conductors, each carrying as much current as possible. We will also see

later that although the magnetic Weld (or ‘excitation’) is essential to the

working of the motor, it acts only as a catalyst and all of the mechanical

output power comes from the electrical supply to the conductors on

which the force is developed.

Energy in Electric Motor Works

It will emerge later that in some motors the parts of the machine responsible for the excitation and the energy-converting functions are distinct and self-evident. In the d.c. motor, for example, the excitation is provided either by permanent magnets or by Weld coils wrapped around clearly defined projecting Weld poles on the stationary part, while the conductors on which force is developed are on the rotor and supplied with current via sliding brushes.

In many motors, however, there is no such clear-cut physical distinction between the ‘excitation’ and the ‘energy-converting’ parts of the machine, and a single stationary winding serves both purposes. Nevertheless, we will find that identifying and separating the excitation and energy-converting functions are always helpful in understanding how motors of all types operate.

Operation Principle of Electric Motors

A large percentage of AC motors are induction motors. This implies that there is no current supplied to the rotating coils (rotor windings). These coils are closed loops that have large currents induced in them. Three-phase currents flowing in the stator windings lead to establishing a rotating magnetic field in the air gap. This magnetic field continuously pulsates across the air gap and into the rotor. This is a single-phase representation of windings and current flow.

As magnetic flux cuts across the rotor bars, a voltage is induced in them, much as a voltage is induced in the secondary winding of a transformer. Because the rotor bars are part of a closed circuit (including the end rings), a current circulates in them. The rotor current in turn produces a

magnetic field that interacts with the magnetic field of the stator. Since this field is rotating and magnetically interlocked with the rotor, the rotor is dragged around with the stator field.

Wound Rotor Electric Motor Types

Wound-rotor motors — Although the squirrel-cage induction motor is relatively inflexible about speed and torque characteristics, a special wound-rotor version has controllable speed and torque. The application of wound-rotor motors is markedly different from squirrel-cage motors because of the accessibility of the rotor circuit. Various performance characteristics can be obtained by inserting different values of resistance in the rotor circuit.

Wound rotor motors are generally started with secondary resistance in the rotor circuit. This resistance is sequentially reduced to permit the motor to come up to speed. Thus the motor can develop substantial torque while limiting the locked rotor current.

The secondary resistance can be designed for continuous service to dissipate heat produced by continuous operation at reduced speed, frequent acceleration, or acceleration with a large inertia load. External resistance gives the motor a characteristic that results in a large drop in rpm for a fairly small change in load. Reduced speed is provided down to about 50%, rated speed, but efficiency is low.

EMS Power Machines

We design, manufacture and assembly Power Machines such as – diesel generators, electric motors, vibration motors, pumps, steam engines and steam turbines

EMS Power Machines is a global power engineering company, one of the five world leaders in the industry in terms of installed equipment. The companies included in the company have been operating in the energy market for more than 60 years.

EMS Power Machines manufactures steam turbines, gas turbines, hydroelectric turbines, generators, and other power equipment for thermal, nuclear, and hydroelectric power plants, as well as for various industries, transport, and marine energy.

EMS Power Machines is a major player in the global power industry, and its equipment is used in power plants all over the world. The company has a strong track record of innovation, and it is constantly developing new and improved technologies.

Here are some examples of Power Machines’ products and services:

- Steam turbines for thermal and nuclear power plants

- Gas turbines for combined cycle power plants and industrial applications

- Hydroelectric turbines for hydroelectric power plants

- Generators for all types of power plants

- Boilers for thermal power plants

- Condensers for thermal power plants

- Reheaters for thermal power plants

- Air preheaters for thermal power plants

- Feedwater pumps for thermal power plants

- Control systems for power plants

- Maintenance and repair services for power plants

EMS Power Machines is committed to providing its customers with high-quality products and services. The company has a strong reputation for reliability and innovation. Power Machines is a leading provider of power equipment and services, and it plays a vital role in the global power industry.

EMS Power Machines, which began in 1961 as a small factory of electric motors, has become a leading global supplier of electronic products for different segments. The search for excellence has resulted in the diversification of the business, adding to the electric motors products which provide from power generation to more efficient means of use.