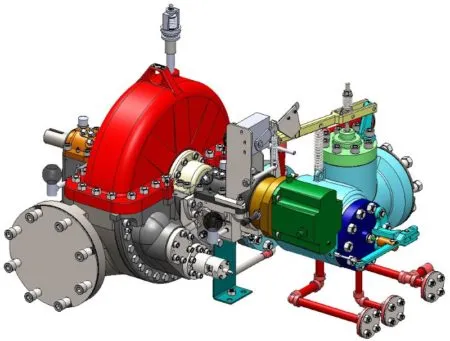

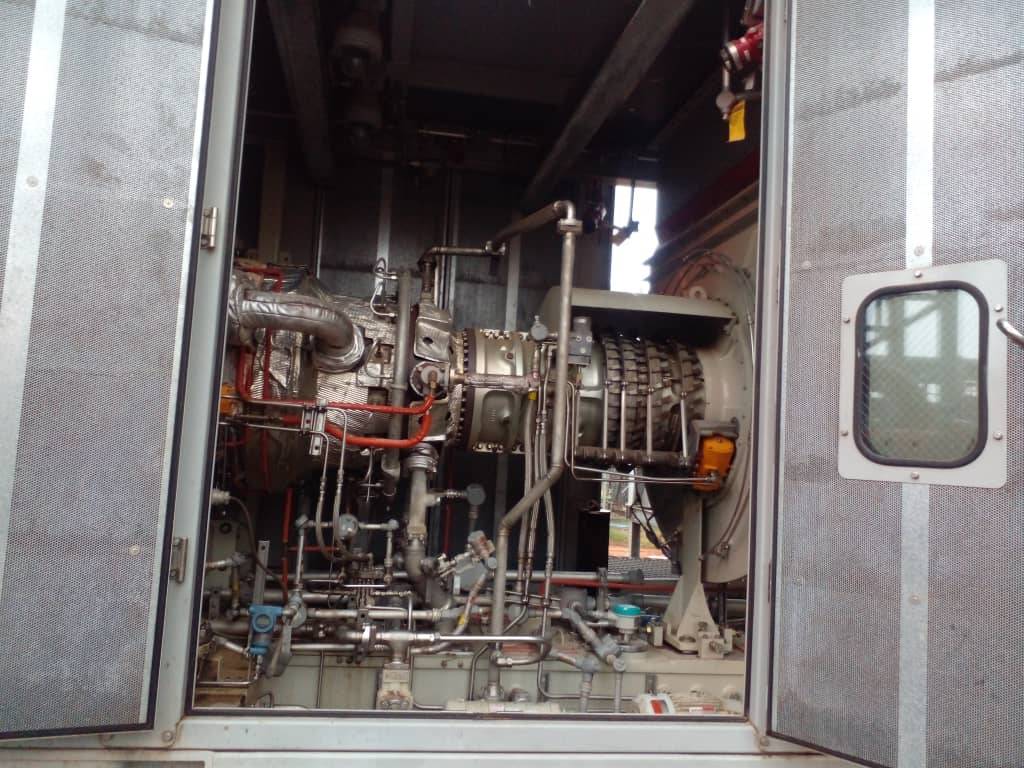

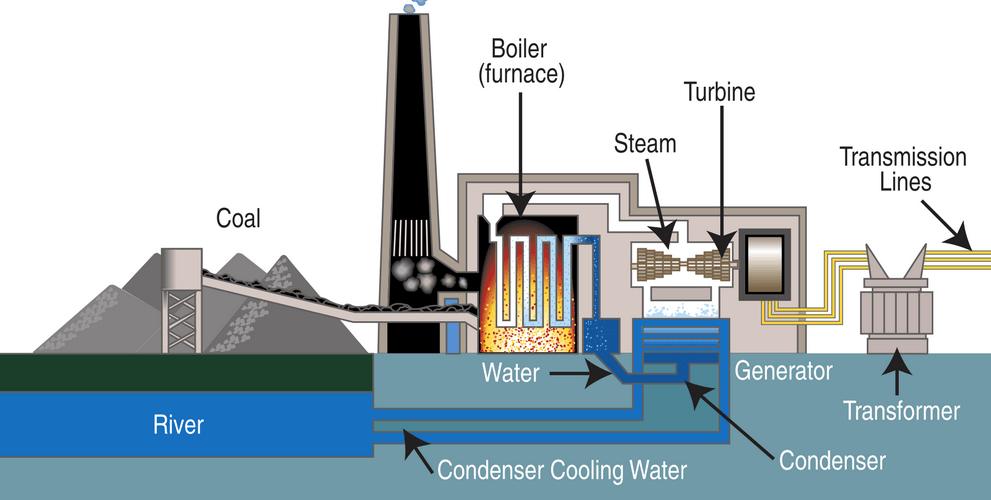

Steam Turbine for Electricity Generation with Synthetic Natural Gas (SNG): A steam turbine generator is a device that converts thermal energy from steam into mechanical energy and then into electrical energy. This process involves the expansion of high-pressure steam through a turbine, which rotates a shaft connected to an electrical generator. Steam turbine generators are widely used in power plants, industrial facilities, and various energy applications due to their efficiency, reliability, and ability to operate on various heat sources, including fossil fuels, nuclear energy, and renewable sources like biomass and geothermal energy.

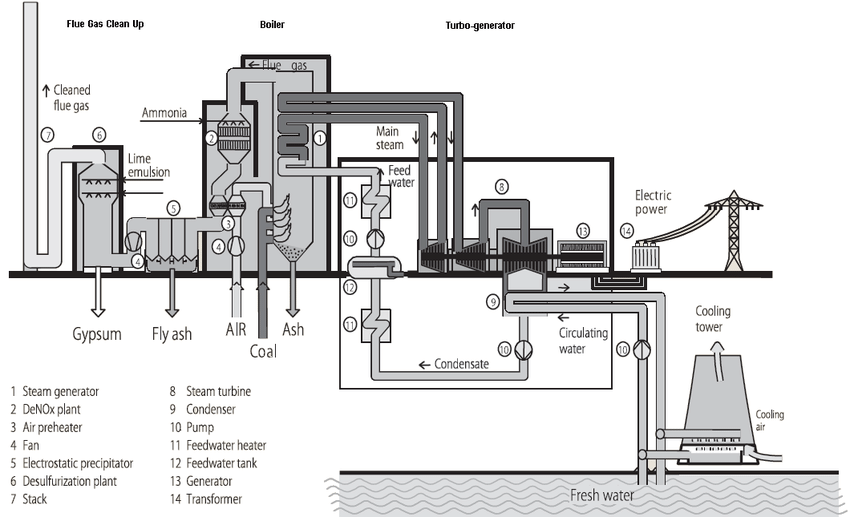

The operation of a steam turbine generator begins with a heat source, typically a boiler, that heats water to generate steam. This steam is then directed at high pressure onto the turbine blades, causing the rotor to spin. The turbine is designed to maximize energy extraction from the steam through stages of expansion, where pressure and temperature gradually decrease while mechanical energy increases. The rotating turbine shaft is mechanically coupled to an electrical generator, which uses electromagnetic induction to convert rotational energy into electrical power.

Steam turbines come in different configurations, such as condensing and back-pressure types. Condensing steam turbines exhaust steam into a condenser, where it is cooled and converted back into liquid water for reuse in the cycle, increasing efficiency and enabling large-scale power generation. In contrast, back-pressure turbines discharge steam at higher pressures for industrial processes that require steam heating. The choice between these types depends on the application and energy requirements.

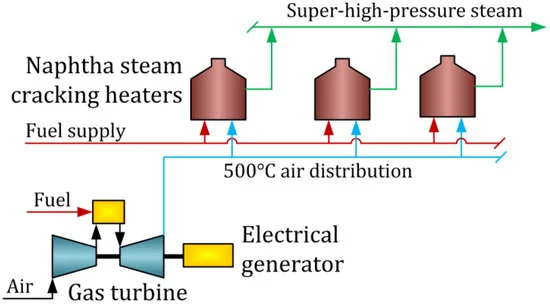

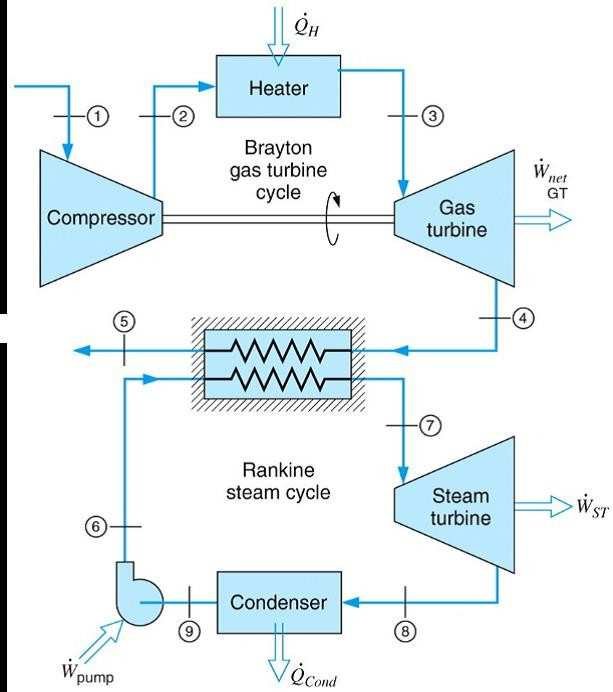

Efficiency is a key factor in steam turbine generator operation, and various technologies are used to optimize performance. Reheating and regenerative feedwater heating are two common techniques. Reheating involves routing partially expanded steam back to the boiler for further heating before returning it to the turbine, reducing moisture content and improving efficiency. Regenerative feedwater heating preheats water using extracted steam from intermediate turbine stages, reducing the fuel needed to reach boiling temperatures. Combined cycle power plants further enhance efficiency by utilizing a gas turbine along with a steam turbine, making use of waste heat from the gas turbine exhaust to generate additional steam.

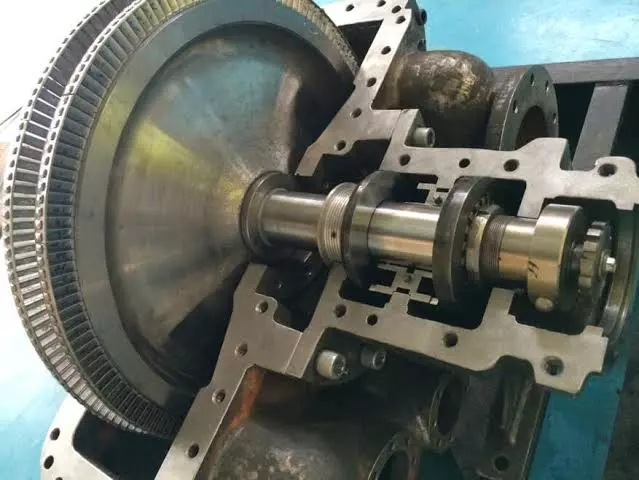

Steam turbines must withstand high temperatures, pressures, and rotational speeds, necessitating the use of high-strength alloys and advanced manufacturing techniques. Materials like stainless steel and nickel-based superalloys are commonly used to handle the extreme conditions inside a steam turbine. Bearings and lubrication systems are critical to maintaining smooth operation, while precision machining and balancing ensure minimal vibration and mechanical stress.

Control systems play a vital role in steam turbine generators, ensuring stable operation, safety, and efficiency. Modern turbines incorporate digital control systems that monitor parameters such as temperature, pressure, and rotational speed. Automatic regulation of steam flow and turbine speed helps maintain optimal performance and prevents damage due to fluctuations in load demand. Protection systems, including overspeed protection and emergency shutdown mechanisms, safeguard the turbine from potential failures.

Maintenance and reliability are essential considerations in steam turbine operation. Regular inspections, lubrication, and monitoring of critical components help prevent breakdowns and extend equipment life. Major maintenance activities include turbine blade inspection, bearing replacement, and steam path cleaning to remove deposits that could affect performance. Advanced diagnostic techniques such as vibration analysis and thermal imaging are used to detect early signs of wear or damage.

Environmental considerations are increasingly shaping the development of steam turbine technology. Efforts to improve efficiency and reduce emissions have led to innovations such as ultra-supercritical steam turbines, which operate at extremely high temperatures and pressures to maximize thermal efficiency. The integration of steam turbines with renewable energy sources, such as concentrated solar power and biomass, contributes to sustainable energy generation. Waste heat recovery systems further enhance energy utilization by capturing excess heat from industrial processes and converting it into useful power.

The versatility of steam turbine generators makes them a cornerstone of global energy production. Whether used in traditional coal-fired power plants, nuclear facilities, or emerging renewable applications, these machines provide reliable and efficient power generation. Continued advancements in materials, design, and control technologies are expected to further enhance their performance, making steam turbine generators a vital component of the modern energy landscape.

Steam Turbine

Steam turbine generators continue to evolve as advancements in technology improve their efficiency, reliability, and environmental sustainability. One major area of development focuses on increasing cycle efficiency through higher operating temperatures and pressures. Ultra-supercritical and advanced ultra-supercritical steam turbines operate at temperatures exceeding 600°C and pressures above 30 MPa, significantly boosting thermal efficiency compared to conventional subcritical designs. These high-efficiency turbines reduce fuel consumption per unit of electricity generated, thereby lowering greenhouse gas emissions and operational costs.

Another innovation in steam turbine technology involves the use of advanced materials and manufacturing techniques. Traditional turbine components are made from high-strength steels and nickel-based alloys, but newer designs incorporate ceramic matrix composites and additive manufacturing (3D printing) to enhance performance and durability. These materials provide superior heat resistance, corrosion protection, and reduced component weight, leading to increased operational efficiency and extended service life.

Steam turbine generators also benefit from improved control and monitoring systems. Modern turbines are equipped with digital twin technology, which creates a real-time virtual model of the turbine to simulate its performance under various operating conditions. This enables predictive maintenance, allowing operators to detect potential failures before they occur and optimize operational parameters for maximum efficiency. Artificial intelligence (AI) and machine learning further enhance turbine management by analyzing vast amounts of operational data to identify patterns and recommend efficiency improvements.

Cogeneration, or combined heat and power (CHP), is another area where steam turbine generators play a crucial role. In industrial settings, CHP systems use back-pressure or extraction turbines to generate electricity while simultaneously supplying process steam for heating or cooling applications. This dual-use of steam increases overall energy efficiency and reduces waste, making cogeneration an attractive solution for industries such as chemical processing, pulp and paper, and district heating networks.

The integration of steam turbines with renewable energy sources has also gained attention. In biomass power plants, steam turbines convert heat from burning organic materials into electricity, offering a sustainable alternative to fossil fuels. Similarly, concentrated solar power (CSP) plants use mirrors to focus sunlight onto a heat transfer fluid, producing steam to drive a turbine. Geothermal power plants rely on underground heat sources to generate steam, providing a constant and renewable energy supply with minimal environmental impact.

Hybrid power generation, which combines steam turbines with other technologies, further enhances energy efficiency. Combined cycle power plants integrate gas turbines with steam turbines, utilizing exhaust heat from the gas turbine to generate additional steam. This approach achieves efficiencies of over 60%, making it one of the most effective methods of fossil fuel-based power generation. Some hybrid systems also incorporate energy storage solutions, such as molten salt storage in CSP plants, to ensure continuous electricity generation even when sunlight is unavailable.

As the energy sector transitions toward decarbonization, steam turbine generators are being adapted to support hydrogen-based power generation. Hydrogen-fired boilers and turbines can produce steam without carbon emissions, offering a clean alternative to coal and natural gas. Additionally, existing steam turbines can be retrofitted to operate with hydrogen-enriched fuels, providing a pathway toward lower-carbon power generation without requiring entirely new infrastructure.

Environmental regulations and sustainability goals are driving improvements in emissions reduction technologies for steam turbine power plants. Flue gas desulfurization, selective catalytic reduction, and carbon capture and storage (CCS) systems help reduce pollutants associated with coal-fired steam turbines. CCS technology captures CO₂ emissions from power plants and stores them underground or repurposes them for industrial applications, contributing to carbon neutrality efforts.

The future of steam turbine generators is shaped by ongoing research and development focused on enhancing efficiency, reducing environmental impact, and integrating with emerging energy technologies. As global energy demand continues to rise, steam turbines will remain a critical component of the power generation landscape, evolving to meet the needs of a cleaner and more sustainable energy future.

As the role of steam turbine generators expands to meet the growing global energy demand, there are numerous factors shaping their future trajectory. Innovations are not only focused on improving their mechanical and operational performance but also on integrating them seamlessly into modern energy systems that emphasize sustainability, grid flexibility, and resilience.

One of the key developments in this direction is the integration of steam turbines with advanced grid systems, particularly in the context of renewable energy integration. As the proportion of intermittent energy sources like wind and solar power increase, maintaining grid stability becomes a challenge. Steam turbine generators, especially in combined-cycle plants, are being designed to offer faster ramp-up and ramp-down times to help stabilize the grid when renewable generation fluctuates. This means that steam turbines can act as a flexible, responsive backup, quickly adjusting their output to match demand or compensate for shortfalls in renewable generation.

In addition to their use in large-scale power generation, steam turbines are being adapted for smaller-scale and distributed energy applications. Microgrids and localized power generation, which often rely on renewable energy sources combined with backup systems, can benefit from steam turbines that efficiently convert biomass, geothermal, or even waste heat into electricity. This shift toward smaller, more decentralized power systems allows for greater energy security and resilience in remote or off-grid locations. Furthermore, steam turbines in such settings can support communities by providing both electricity and useful thermal energy for heating, desalination, or industrial applications, boosting overall energy efficiency.

Another important aspect of steam turbine technology’s future involves its ability to be part of the circular economy. Industrial processes that generate significant waste heat—such as steel production, cement manufacturing, and petrochemical operations—can repurpose this waste heat by converting it into steam to drive turbines and generate power. The integration of steam turbines into waste heat recovery systems not only increases the overall energy efficiency of these industries but also helps reduce their carbon footprints by generating clean power from processes that would otherwise release excess heat into the environment.

Advancements in computational fluid dynamics (CFD) and digital modeling are further enhancing the design and operation of steam turbines. These technologies allow engineers to simulate and optimize the flow of steam through the turbine, ensuring maximum energy extraction while minimizing mechanical wear. CFD modeling also helps identify potential problem areas in turbine design and operation, improving both performance and longevity. As computational power increases, these tools will continue to provide increasingly accurate simulations, reducing the time and cost associated with turbine development and enabling more customized solutions for different industries and energy applications.

The role of steam turbines in hybrid and multigeneration systems is also gaining attention. For example, some modern power plants are exploring the potential of integrating steam turbines with energy storage systems, such as lithium-ion or flow batteries, to smooth out fluctuations in power generation. By utilizing energy storage, these plants can store excess energy generated during periods of high renewable output and release it during times of high demand or low renewable generation, ensuring a continuous and stable power supply. This approach not only enhances grid reliability but also maximizes the efficiency of renewable energy sources, reducing reliance on fossil-fuel-based power generation.

Furthermore, advances in hydrogen technology are pushing the boundaries of what steam turbines can achieve. In the long term, the decarbonization of the power sector hinges on the use of hydrogen as a clean fuel source. Steam turbines, traditionally powered by fossil fuels, are now being tested with hydrogen to determine their viability for clean power generation. Hydrogen combustion produces water vapor instead of CO₂, which offers a path to zero-emission power generation when used in conjunction with a steam turbine. This shift could play a pivotal role in decarbonizing sectors that are difficult to electrify, such as heavy industry and long-haul transportation. Research is ongoing to determine the best materials and designs for turbines that can safely and efficiently operate with hydrogen at scale.

In parallel, the concept of “smart” steam turbines is emerging, where artificial intelligence (AI) and machine learning are integrated into turbine control systems. These systems can predict performance trends, identify potential faults before they occur, and automatically adjust operating conditions to optimize efficiency. For instance, AI algorithms might analyze real-time data from sensors embedded in turbine components, such as temperature, vibration, and pressure, to detect signs of wear and suggest maintenance schedules that minimize downtime. This predictive maintenance model will allow for less invasive, more cost-effective upkeep, and could ultimately extend the turbine’s service life while reducing the risk of catastrophic failure.

Lastly, the growing global focus on reducing the environmental impact of all industrial processes is leading to the development of greener steam turbine technologies. In addition to efficiency improvements, these innovations include advanced coatings and surface treatments that prevent corrosion and erosion, particularly in the turbine’s high-pressure sections. These coatings extend the life of the turbine blades and reduce the frequency of overhauls, improving the economics of power generation.

As the energy sector continues its transition to renewable and low-carbon technologies, steam turbine generators will remain a cornerstone of electricity generation. Their ability to integrate with emerging energy solutions, such as hydrogen, renewables, and storage, positions them as adaptable, long-term players in the global energy mix. With advancements in materials science, computational modeling, and control systems, steam turbines will continue to evolve, offering more efficient, reliable, and sustainable power generation for decades to come.

As the development of steam turbine technology continues to progress, there are several important trends and challenges that will shape the future of these machines, particularly in terms of their role in the global energy transition, energy security, and environmental sustainability. These trends not only focus on technical advancements but also on their integration into emerging energy systems and evolving market dynamics.

One of the most significant areas of focus is the ongoing development of steam turbines for hybrid energy systems. Hybrid plants, combining steam turbines with gas turbines, solar power, wind power, or energy storage systems, are becoming increasingly popular due to their ability to offer flexibility, efficiency, and reduced emissions. In a hybrid setup, steam turbines can provide base-load power, while renewable sources like solar or wind fill in the gaps when demand spikes or during periods of low renewable generation. The hybridization of energy systems is particularly valuable in the context of the push toward reducing carbon emissions while maintaining the reliability of power grids. By combining the versatility of steam turbines with renewables, plants can better balance load and minimize fossil fuel consumption, making steam turbines a key component in clean energy solutions.

An area of immense potential lies in the use of steam turbines for offshore wind energy systems. Offshore wind farms are typically located in regions with higher and more consistent wind speeds than onshore turbines, which makes them an attractive option for large-scale renewable energy production. By using steam turbines to convert the electricity generated by these wind farms into more flexible, usable energy, offshore wind systems could further enhance the stability and availability of renewable power. Steam turbines can be integrated into offshore platforms, where they would help provide a more stable and dependable power supply by converting wind power into electricity, alongside other renewable or backup technologies, to maintain grid stability.

In addition to hybrid systems, the potential role of steam turbines in the decarbonization of industrial sectors is also an important area of focus. Many heavy industries, including cement, steel, and chemical production, require vast amounts of energy, primarily in the form of heat and steam. By utilizing steam turbines to generate electricity or provide combined heat and power (CHP), these industries can significantly reduce their reliance on fossil fuels. Furthermore, by integrating renewable or low-carbon heat sources such as solar, geothermal, or waste heat recovery into these processes, steam turbines can help reduce carbon emissions from some of the hardest-to-decarbonize industries. In this regard, steam turbines have the potential to play a significant role in helping to meet global climate goals, particularly in sectors where electrification may not be a viable alternative.

In parallel, the importance of integrating steam turbines into district heating systems is rising. District heating refers to the practice of generating heat in a central location and distributing it to multiple buildings or facilities through insulated pipes. Steam turbines can be used to generate both electricity and heat in combined heat and power (CHP) plants that serve entire communities, particularly in urban or industrial areas. These plants can optimize fuel use by generating electricity when demand is high and providing heat during colder months. With the growing focus on reducing heating costs and improving energy efficiency in cities, district heating systems utilizing steam turbines are becoming increasingly attractive due to their ability to generate low-carbon energy and reduce the environmental footprint of heating infrastructure.

Another notable trend is the increasing focus on integrating steam turbines into grid-scale energy storage systems. As more renewable energy sources are added to the grid, the challenge of energy storage becomes even more pressing. Steam turbines, when used in combination with energy storage systems such as pumped hydro storage, compressed air energy storage (CAES), or molten salt storage, can help provide stability and backup power. For example, excess renewable energy during periods of low demand can be used to pump water to an elevated reservoir in a pumped hydro storage system, and when demand peaks, this water can be released to drive turbines and generate power. In systems that incorporate steam turbines with large-scale thermal storage, the energy generated can be dispatched when needed most, ensuring grid reliability while maximizing the use of renewable energy.

Looking forward, steam turbine manufacturers are also developing advanced turbine designs that incorporate digitalization and smart technologies. The use of Internet of Things (IoT) sensors and data analytics tools enables real-time monitoring and management of turbine operations, improving efficiency and providing advanced diagnostics. These sensors allow operators to track performance indicators such as vibration, temperature, and steam flow, detecting potential issues before they develop into major faults. Through the use of predictive maintenance algorithms, maintenance can be optimized, reducing downtime and extending the lifespan of the turbine. This smart, data-driven approach is helping to reduce the operational costs of steam turbines while ensuring the continued optimization of their performance.

Moreover, the global trend toward increasing electrification and the digitalization of energy systems will also affect how steam turbines are deployed. In regions transitioning from fossil-fuel-powered grids to renewable energy-dominated grids, steam turbines are increasingly being used in a supportive, backup, and balancing role rather than as the primary source of electricity generation. In these systems, steam turbines must be capable of fast ramp-up and ramp-down times to adapt to fluctuating renewable energy supplies. This is critical for grid stability, as the variability of solar and wind power necessitates a backup solution that can step in when renewable generation is low. Steam turbines, particularly those in combined-cycle plants, have the flexibility to ramp up quickly and provide reliable backup power as needed.

With the increasing global demand for electricity and a push for lower-carbon energy systems, there is also a growing need for steam turbine generators to operate in remote or off-grid locations. This is particularly relevant for developing countries or regions with unreliable power grids, where steam turbines can be used in off-grid power plants to provide both electricity and process heat. This decentralized approach to energy generation can help improve energy access and security, particularly in remote or isolated communities. By utilizing locally available resources like biomass, geothermal, or waste heat, steam turbines can generate clean and sustainable energy where it is most needed.

As the energy transition accelerates and as steam turbine technology continues to evolve, these machines will remain at the heart of the global power generation landscape. Their adaptability to a wide range of energy sources, their potential for integration with emerging energy storage and hybrid systems, and their critical role in supporting energy security and resilience ensure that steam turbines will continue to be vital players in meeting the world’s growing energy demands in an increasingly sustainable and low-carbon future.

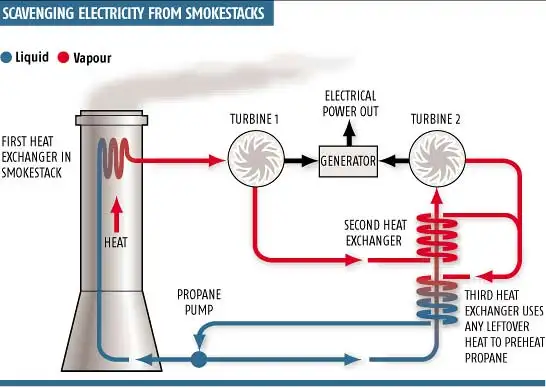

Steam turbines are widely used for electricity generation, offering high efficiency and reliability in converting thermal energy into mechanical power. One of the most effective applications of steam turbines is in waste heat recovery from industrial processes. This approach enhances energy efficiency and reduces fuel consumption by utilizing heat that would otherwise be lost to the environment. Various industrial operations, such as metal processing, cement production, and chemical manufacturing, generate significant amounts of waste heat, typically in the form of high-temperature exhaust gases or hot liquids. Instead of letting this energy dissipate, it can be harnessed through a waste heat recovery system that produces steam to drive a turbine and generate electricity.

The process begins with capturing waste heat from industrial sources using heat exchangers or waste heat boilers. The selection of the appropriate heat recovery equipment depends on factors such as temperature, pressure, and composition of the waste heat stream. In many cases, a heat recovery steam generator (HRSG) is employed, particularly in cogeneration or combined heat and power (CHP) systems. The HRSG converts the thermal energy into steam, which is then directed to a steam turbine. Depending on the specific application and requirements, either a back-pressure or a condensing steam turbine can be used. Back-pressure turbines discharge steam at a pressure suitable for industrial use, enabling simultaneous electricity generation and process heat supply. In contrast, condensing turbines maximize power output by expanding the steam to the lowest possible pressure, typically exhausting into a condenser where the steam is converted back into water for reuse.

The efficiency of steam turbines in waste heat recovery depends on several factors, including steam parameters, turbine design, and system integration. High-temperature and high-pressure steam improves energy conversion efficiency and power output. Advanced blade designs and optimized flow paths within the turbine further enhance performance by minimizing energy losses. Proper integration with industrial processes is crucial to ensure a stable and continuous supply of waste heat. Industries with fluctuating heat output may require thermal storage solutions or supplementary fuel firing to maintain consistent steam production and power generation.

One of the key advantages of using steam turbines for waste heat recovery is their ability to reduce overall energy costs and carbon emissions. By generating electricity on-site, industries can lower their dependence on grid power and mitigate the impact of volatile electricity prices. Additionally, using waste heat reduces fuel consumption, leading to lower greenhouse gas emissions and improved environmental sustainability. Many industries implement steam turbine-based waste heat recovery as part of their sustainability initiatives and energy efficiency programs, often benefiting from government incentives and regulatory support for clean energy projects.

Despite these benefits, certain challenges must be addressed when implementing steam turbines for waste heat recovery. The initial investment cost can be significant, requiring careful feasibility studies to assess economic viability. Space constraints in existing industrial facilities may also limit the feasibility of installing large heat recovery systems. Furthermore, waste heat availability and quality can vary, impacting system efficiency and reliability. Advances in technology, such as compact heat exchangers, modular HRSGs, and hybrid systems combining steam turbines with organic Rankine cycle (ORC) turbines, are helping to overcome these challenges and expand the applicability of waste heat recovery solutions.

In conclusion, steam turbines play a crucial role in utilizing waste heat from industrial processes for electricity generation, offering economic and environmental advantages. By capturing and repurposing heat that would otherwise be wasted, industries can improve their energy efficiency, lower costs, and contribute to sustainability efforts. As technology continues to evolve, steam turbine-based waste heat recovery systems are expected to become even more efficient and widely adopted across various industrial sectors.

Another significant factor influencing the performance and adoption of steam turbines for electricity generation with waste heat recovery is the evolving regulatory landscape and energy policies. Many governments and energy agencies around the world are encouraging industrial facilities to implement waste heat recovery solutions as part of broader decarbonization and energy efficiency strategies. Policies such as feed-in tariffs, tax incentives, and grants for combined heat and power (CHP) systems or cogeneration projects are making steam turbine installations more financially attractive. Carbon pricing mechanisms and emissions reduction targets also push industries to adopt cleaner energy solutions, with waste heat recovery offering a practical and cost-effective means of reducing their carbon footprint.

In addition to regulatory support, advancements in digitalization and automation are improving the efficiency and reliability of steam turbine-based waste heat recovery systems. Modern control systems, equipped with real-time monitoring and predictive maintenance capabilities, optimize turbine operation to match fluctuating heat availability and electricity demand. Internet of Things (IoT) sensors and advanced analytics allow operators to detect potential issues before they lead to costly downtime, ensuring consistent performance and extended equipment lifespan. The integration of smart grids further enhances the value of on-site electricity generation by enabling industries to supply excess power to the grid or dynamically adjust their energy usage based on market conditions.

The economic viability of steam turbine-based waste heat recovery depends on multiple variables, including the cost of electricity, fuel prices, and the scale of waste heat availability. Large-scale industrial plants, such as steel mills, petrochemical refineries, and paper manufacturing facilities, tend to benefit the most due to the continuous and substantial heat output. However, even medium-sized enterprises can take advantage of modular and scalable waste heat recovery solutions tailored to their specific needs. Companies are increasingly recognizing waste heat as a valuable asset rather than a byproduct, leading to greater investments in energy efficiency and sustainability initiatives.

Material advancements and engineering innovations are also expanding the possibilities for steam turbine applications in waste heat recovery. High-temperature-resistant alloys, improved steam seals, and advanced coatings enhance turbine durability and efficiency under harsh operating conditions. Additionally, developments in supercritical and ultra-supercritical steam cycles allow for higher efficiency in power generation, pushing the boundaries of what is achievable with waste heat recovery. Hybrid systems that combine steam turbines with alternative technologies, such as the Organic Rankine Cycle (ORC) and thermoelectric generators, are being explored to maximize energy extraction from low-grade waste heat sources that were previously considered unsuitable for steam-based recovery.

As industries continue to prioritize energy efficiency and sustainability, the role of steam turbines in waste heat recovery is expected to grow. Future advancements in energy storage, heat recovery system integration, and turbine technology will further enhance the feasibility and attractiveness of these systems. With increasing global efforts to reduce carbon emissions and improve energy utilization, steam turbines will remain a key technology in the transition toward more sustainable and cost-effective industrial energy solutions.

The continued evolution of steam turbine technology for waste heat recovery is also closely linked to broader developments in energy infrastructure and industrial decarbonization strategies. As industries aim to reduce their reliance on fossil fuels and increase overall efficiency, waste heat recovery systems with steam turbines are being integrated into larger energy management frameworks. These frameworks often include renewable energy sources such as biomass, solar thermal, and geothermal energy, creating hybrid energy solutions that maximize efficiency and sustainability. By combining waste heat recovery with renewable energy integration, industrial facilities can further reduce their carbon footprint while maintaining a stable and reliable energy supply.

Another key area of development is the role of steam turbines in industrial symbiosis, where multiple industries collaborate to utilize each other’s waste heat and byproducts. For example, a steel plant generating large amounts of waste heat could supply steam to a nearby chemical processing facility, which in turn provides waste gases that can be used as an energy source. Such interconnected energy ecosystems not only improve efficiency but also create economic benefits by reducing fuel costs and increasing overall productivity. Industrial clusters and eco-industrial parks are increasingly adopting this approach, supported by policy incentives and technological advancements that enable effective waste heat sharing.

The application of steam turbines in waste heat recovery is also becoming more prevalent in decentralized and distributed energy systems. With the growing trend of microgrids and localized power generation, industries are leveraging steam turbines to create self-sufficient energy networks that enhance resilience and reduce dependence on external power grids. This is particularly important in regions with unstable electricity supply or high energy costs, where on-site generation through waste heat recovery can provide a reliable and cost-effective alternative. Advanced microgrid control systems, enabled by artificial intelligence (AI) and machine learning, allow for real-time optimization of energy flows, ensuring maximum efficiency in the utilization of waste heat and electricity generation.

A critical consideration in expanding the use of steam turbines for waste heat recovery is the improvement of steam cycle efficiency and system flexibility. Innovations in variable-speed turbines, adjustable steam extraction, and advanced superheating techniques allow for better adaptability to fluctuating industrial conditions. Additionally, the development of compact and modular turbine designs enables easier retrofitting into existing industrial facilities, reducing capital investment requirements and expanding the feasibility of waste heat recovery projects across different sectors.

Looking ahead, research and development efforts continue to focus on increasing the efficiency and economic viability of steam turbines in waste heat recovery applications. Emerging technologies such as supercritical CO₂ power cycles, which operate at higher efficiencies than traditional steam cycles, are being explored as potential alternatives or complementary solutions. Moreover, advances in thermal energy storage, such as molten salt or phase-change materials, offer new possibilities for storing recovered heat and optimizing turbine operation even when waste heat availability fluctuates.

In summary, the future of steam turbines in electricity generation with waste heat recovery from industrial processes is highly promising. As industries and policymakers increasingly prioritize energy efficiency, sustainability, and cost reduction, steam turbine technology will remain at the forefront of waste heat utilization strategies. The integration of digital solutions, hybrid energy systems, and innovative turbine designs will further enhance the efficiency and applicability of these systems. With ongoing advancements in materials science, thermodynamics, and industrial integration, steam turbines will continue to play a crucial role in transforming waste heat into a valuable resource, driving both economic and environmental benefits for industries worldwide.

Steam Turbine for Electricity Generation with Wind Energy (through Heat Conversion)

Steam turbines are traditionally associated with fossil fuel and waste heat recovery applications, but an emerging and innovative approach involves integrating them with wind energy through heat conversion. This method seeks to address some of the inherent challenges of wind power, such as intermittency and variability, by converting surplus wind energy into thermal energy that can later be used to generate steam for electricity production. By coupling wind power with thermal energy storage and steam turbine technology, a more stable and controllable power output can be achieved, making renewable energy sources more reliable and dispatchable.

The fundamental concept behind this approach involves using excess electricity generated by wind turbines during periods of high wind availability to power resistive heating elements, heat pumps, or other thermal storage mechanisms. These systems convert the electrical energy into heat, which is then stored in high-temperature thermal storage media such as molten salts, phase-change materials, or even solid ceramic blocks. When electricity demand rises or wind conditions weaken, the stored heat is used to generate steam in a boiler or heat exchanger, which then drives a steam turbine to produce electricity. This method effectively decouples wind energy generation from immediate grid demand, providing a buffer that enhances grid stability and reliability.

One of the key advantages of this approach is its ability to mitigate the intermittency of wind power, which is a major challenge in integrating wind energy into electrical grids. Unlike conventional wind turbines, which generate electricity directly and are subject to fluctuations in wind speed, steam turbines powered by stored thermal energy can operate continuously, ensuring a more stable power output. This is particularly beneficial for maintaining grid frequency and reducing reliance on backup fossil fuel generators, which are often required to compensate for wind energy variability.

The efficiency and feasibility of integrating steam turbines with wind energy depend on several factors, including the thermal storage medium, heat transfer efficiency, and steam cycle optimization. High-efficiency thermal storage materials with minimal heat loss over time are crucial for maintaining energy efficiency and economic viability. Advanced superheating techniques and optimized turbine designs further improve the conversion efficiency of stored thermal energy into electricity. Additionally, hybrid configurations that combine steam turbines with other renewable sources, such as solar thermal energy, can enhance overall system performance and resilience.

Economic and environmental benefits further support the adoption of this technology. By utilizing surplus wind power for thermal energy storage, curtailment of wind energy—where turbines are shut down due to excess generation or grid constraints—can be minimized. This leads to better utilization of renewable resources and a reduction in wasted energy. Additionally, integrating thermal storage with steam turbines helps reduce dependency on fossil fuel-based power plants, lowering carbon emissions and contributing to long-term sustainability goals. Governments and energy regulators are increasingly incentivizing energy storage solutions, and steam turbine systems with wind energy integration could benefit from policy support and financial incentives for renewable energy projects.

Despite these advantages, challenges remain in scaling up and commercializing this approach. The efficiency of energy conversion from electricity to heat and back to electricity introduces losses, making overall round-trip efficiency a critical factor. Research and development efforts are focused on improving thermal storage efficiency, reducing system costs, and enhancing turbine flexibility to handle variable operating conditions. Additionally, integrating these systems with existing grid infrastructure requires careful planning to ensure seamless operation and optimal dispatch of stored energy.

Looking ahead, steam turbine integration with wind energy through heat conversion represents a promising avenue for enhancing renewable energy reliability and efficiency. Advances in thermal energy storage, materials science, and turbine technology will play a key role in improving the feasibility and competitiveness of this approach. As the energy transition progresses, innovative solutions like this will contribute to a more resilient and sustainable power generation landscape, maximizing the potential of renewable energy sources while maintaining grid stability and reliability.

The integration of steam turbines with wind energy through heat conversion is an innovative approach that aligns with the global transition toward sustainable and flexible power generation. As the share of wind energy continues to grow in power grids worldwide, the need for effective energy storage and dispatchable generation solutions becomes increasingly critical. By leveraging thermal energy storage and steam turbines, this system offers a pathway to address wind power’s variability while maintaining a high level of energy efficiency and grid reliability.

A major component of this approach is the selection and optimization of thermal energy storage (TES) systems. Various TES technologies can be employed, each with its advantages and challenges. Sensible heat storage, which involves heating solid or liquid materials such as molten salts, concrete, or ceramic bricks, is among the most widely used due to its relatively low cost and proven reliability. Latent heat storage, which uses phase-change materials (PCMs) that store and release energy during phase transitions (e.g., solid to liquid), offers higher energy density and improved efficiency. Emerging thermochemical storage methods, which involve reversible chemical reactions to store and release heat, promise even greater energy density and long-duration storage capabilities, though they are still in the experimental stage.

The efficiency of converting stored heat back into electricity through a steam turbine is another crucial factor in determining the feasibility of this system. Traditional Rankine cycle steam turbines can achieve efficiencies of around 30-40%, with advanced supercritical and ultra-supercritical cycles reaching even higher efficiencies. However, the round-trip efficiency of the entire system, from wind energy conversion to heat storage and finally to electricity generation, must be optimized to ensure economic viability. This involves minimizing heat losses, improving turbine performance, and integrating smart control systems to ensure seamless operation based on grid demand and wind energy availability.

The flexibility of this approach also extends to its potential for hybridization with other renewable energy sources. For instance, combining wind-powered thermal energy storage with solar thermal power plants can create a highly resilient and diversified renewable energy system. During periods of high solar radiation, solar thermal collectors can contribute additional heat to the storage system, reducing reliance on wind energy for charging the TES. Similarly, biomass or geothermal heat sources can serve as auxiliary inputs, ensuring a continuous supply of thermal energy for the steam turbine even when wind conditions are unfavorable. Such multi-source hybrid systems enhance overall reliability and increase the utilization factor of the steam turbine, making the investment more economically attractive.

The economic and policy landscape for such systems is evolving as governments and energy regulators recognize the importance of long-duration energy storage. Many countries are implementing policies that incentivize energy storage solutions to complement variable renewable energy sources. Financial mechanisms such as capacity payments, tax incentives, and research grants for thermal storage technologies are supporting the development of innovative energy storage methods, including steam turbine integration with wind power. In addition, carbon pricing and emissions reduction mandates are driving industries and utilities to explore cleaner alternatives to fossil fuel-based backup generation, making thermal storage with steam turbines an increasingly attractive solution.

However, despite the promising potential, several challenges must be addressed to accelerate the adoption of this technology. The capital investment required for setting up large-scale thermal storage and steam turbine systems can be significant, necessitating favorable financing options and long-term policy support. The efficiency losses associated with multiple energy conversion steps (electricity to heat, heat to steam, and steam to electricity) need to be minimized through advanced materials, insulation techniques, and optimized turbine designs. Moreover, the integration of such systems into existing power grids must be carefully planned to ensure their effective operation within broader energy networks.

Looking forward, continuous advancements in materials science, turbine engineering, and digital control systems will drive improvements in efficiency and cost-effectiveness. As the energy sector increasingly shifts toward renewables, the role of flexible and dispatchable power generation solutions such as wind-powered thermal storage with steam turbines will become more significant. By addressing the intermittency challenge of wind energy while leveraging the proven efficiency of steam turbines, this approach has the potential to play a crucial role in shaping the future of sustainable energy generation.

The long-term viability of integrating steam turbines with wind energy through heat conversion will depend on further advancements in key technological areas, as well as strategic deployment in regions where wind energy resources are abundant but grid stability remains a challenge. The scalability of thermal energy storage systems is a crucial factor, as larger storage capacities enable longer-duration energy dispatchability, making renewable power more consistent and reliable. Research and development efforts are increasingly focused on high-temperature thermal storage materials that minimize heat loss over extended periods, ensuring that energy stored from wind power can be efficiently converted into electricity when needed.

One of the most promising developments in this space is the use of supercritical steam cycles, which operate at extremely high temperatures and pressures to improve the efficiency of power generation. Supercritical and ultra-supercritical steam turbines can achieve thermal efficiencies above 45%, significantly reducing energy losses compared to traditional subcritical steam cycles. In addition, the use of advanced coatings and materials, such as nickel-based alloys and ceramic composites, enhances turbine durability and resistance to high-temperature conditions, making them better suited for frequent cycling based on wind energy availability.

Beyond technical improvements, another key aspect of successful implementation is the integration of artificial intelligence (AI) and machine learning for optimal energy management. AI-driven predictive analytics can improve the efficiency of steam turbine operations by forecasting wind energy production, grid demand, and thermal storage levels in real time. Smart control systems can dynamically adjust heat transfer rates, turbine loading, and dispatch strategies to maximize overall system performance. For example, during periods of low electricity prices, excess wind energy can be stored as heat instead of being sold at low or negative market rates, allowing it to be dispatched later when demand and prices are higher.

The economic benefits of this approach are particularly notable in energy markets with high penetration of renewables, where curtailment of wind energy remains a persistent issue. In many wind-rich regions, turbines are frequently shut down due to grid congestion or oversupply, resulting in wasted energy potential. By redirecting excess wind power into thermal storage for later electricity generation via steam turbines, these systems provide an effective solution to curtailment while improving the overall utilization of wind assets. This is especially valuable in remote or off-grid applications, where reliable energy storage and dispatchable power generation are crucial for industrial and community energy needs.

Additionally, hybrid renewable power plants that combine wind energy with thermal storage and steam turbines can offer a more stable and predictable power supply, making them attractive for industrial users and grid operators alike. Industries with high heat and power demands, such as steel production, cement manufacturing, and chemical processing, can integrate these systems to achieve energy self-sufficiency while reducing dependence on fossil fuels. By using surplus wind energy to generate process heat and electricity simultaneously, these industries can lower operational costs and contribute to carbon reduction efforts.

Despite these advantages, challenges remain in making this technology cost-competitive with other energy storage solutions, such as lithium-ion batteries and pumped hydro storage. While thermal energy storage has the advantage of long-duration storage capabilities and lower degradation rates, the efficiency losses associated with the multiple conversion steps (wind to electricity, electricity to heat, heat to steam, steam to electricity) can limit overall performance. Ongoing research into improving heat exchanger efficiency, reducing standby heat losses, and enhancing steam turbine responsiveness will be critical to making these systems more competitive in the energy market.

Looking ahead, continued investment in demonstration projects and pilot plants will be essential to validating the economic and technical feasibility of integrating steam turbines with wind energy through heat conversion. Collaborative efforts between renewable energy developers, turbine manufacturers, and research institutions can accelerate the development of scalable, cost-effective solutions. As energy policies increasingly prioritize long-duration energy storage and grid reliability, this approach has the potential to play a significant role in the future energy mix, complementing other renewable and storage technologies to create a more resilient and sustainable power system.

Steam Turbine for Electricity Generation with Hydroelectric Power (with Pumped Storage)

The integration of steam turbines with hydroelectric power through pumped storage presents an innovative approach to enhancing grid stability, increasing renewable energy utilization, and improving overall energy efficiency. Pumped storage hydro (PSH) is already a well-established method of energy storage, using excess electricity to pump water to an elevated reservoir, which can later be released to generate hydroelectric power when needed. By incorporating steam turbines into this system, additional flexibility and efficiency gains can be achieved, creating a hybrid energy storage and generation solution that leverages both thermal and hydropower resources.

The fundamental concept behind this integration is to use surplus electricity, whether from renewable sources like wind or solar, or from off-peak grid supply, to generate heat that is stored in thermal energy storage (TES) systems. This stored heat can later be used to produce steam, which drives a steam turbine to generate electricity when demand rises. By combining this thermal storage with pumped hydro storage, a dual-buffer energy system is created, ensuring that energy can be dispatched in multiple ways based on grid needs. The hydro component provides rapid-response power generation, while the steam turbine offers sustained power output over longer durations, making the system highly adaptable to fluctuating electricity demand.

One of the major benefits of this approach is its ability to enhance the efficiency and utilization of both pumped storage hydro and steam turbine technologies. Traditional pumped storage plants are limited by the availability of water and the elevation difference between reservoirs, while steam turbines require a consistent heat source to maintain efficient operation. By integrating these two technologies, surplus energy can be efficiently stored in both thermal and gravitational potential forms, allowing for a more flexible and robust energy management strategy. This is particularly beneficial in regions where water availability fluctuates, as stored heat can serve as an alternative energy source when hydropower generation is constrained.

Thermal energy storage plays a crucial role in this system, determining the efficiency and feasibility of the steam turbine component. Various TES technologies can be used, including molten salts, phase-change materials (PCMs), and high-temperature ceramics, each offering different advantages in terms of energy density, heat retention, and operational lifetime. When energy demand increases, the stored heat is used to produce steam, which drives a turbine in a conventional Rankine cycle, generating electricity in a controllable and dispatchable manner. The ability to store energy as heat rather than relying solely on water levels ensures that power generation can continue even during dry seasons or periods of low water availability.

From an economic perspective, integrating steam turbines with pumped storage hydro can improve the financial viability of both technologies. Pumped storage plants are capital-intensive projects that require significant infrastructure investment, but they offer one of the highest energy storage capacities among existing technologies. The addition of steam turbines provides an additional revenue stream by allowing stored heat to be converted into electricity when market prices are high, increasing overall system profitability. Furthermore, by reducing the reliance on fossil fuel-based peaking plants, this hybrid approach can contribute to lower electricity costs and reduced carbon emissions, aligning with global decarbonization goals.

Another key advantage of this system is its potential to enhance grid stability and reliability. Pumped storage hydro is already known for its rapid response capabilities, making it ideal for frequency regulation and grid balancing. By adding a steam turbine component, the system gains the ability to provide longer-duration energy supply, complementing the short-duration, fast-response nature of hydroelectric power. This is particularly useful in grids with high penetration of variable renewable energy sources, where the need for both short-term and long-term energy storage solutions is critical. Additionally, the use of digital control systems and artificial intelligence (AI) can optimize the dispatch strategy, ensuring that the most efficient energy source is used at any given time.

Despite its advantages, there are challenges to be addressed before large-scale implementation of this approach becomes widespread. The overall efficiency of the system depends on minimizing energy losses during the multiple conversion steps—electricity to heat, heat to steam, steam to electricity, and water pumping to hydroelectric generation. Research into high-efficiency thermal storage materials, advanced steam turbine designs, and optimized pumped storage configurations will be crucial for improving system performance. Additionally, site selection plays an important role, as suitable locations for pumped storage plants must have access to both elevated terrain and water resources, while also being near industrial facilities or power grids that can benefit from thermal energy integration.

Looking ahead, the combination of steam turbines with pumped storage hydro has the potential to become a key solution in the evolving energy landscape. As energy markets shift toward greater reliance on renewables, the need for reliable, large-scale energy storage will continue to grow. Hybrid systems that integrate multiple storage and generation technologies will be critical for ensuring a stable and efficient power supply. With ongoing advancements in thermal energy storage, turbine efficiency, and grid management technologies, this innovative approach could play a vital role in shaping the future of sustainable energy generation and storage.

The continued advancement of integrating steam turbines with pumped storage hydro presents numerous opportunities for improving the efficiency, flexibility, and resilience of energy systems. As the share of renewable energy sources such as wind and solar increases, the need for hybrid storage solutions that can provide both short-term rapid response and long-duration energy dispatch becomes more critical. By combining pumped hydro storage with thermal energy storage for steam turbine operation, a multi-layered energy buffering system is created, ensuring that stored energy can be used in the most efficient way depending on grid conditions and market demand.

One of the key technical areas of focus is improving the efficiency of thermal energy storage (TES) to maximize the effectiveness of the steam turbine component. High-temperature TES systems, such as molten salts or solid-state heat storage using ceramic or refractory materials, have demonstrated high thermal retention and efficient heat-to-steam conversion. These systems are designed to minimize heat loss over time, ensuring that stored energy remains available for extended periods without significant degradation. Advanced insulation techniques and vacuum-sealed storage tanks further enhance the efficiency of TES, making them a viable complement to pumped storage hydro.

The operational flexibility of this hybrid approach is another crucial advantage. Pumped storage hydro is well-known for its rapid ramp-up capabilities, making it ideal for balancing short-term fluctuations in electricity demand and supply. However, once the upper reservoir is depleted, the system’s ability to generate power is limited until water is pumped back up. In contrast, the steam turbine component, powered by stored thermal energy, can provide continuous and controlled power generation over longer durations, complementing the rapid-response function of hydroelectric turbines. This synergy ensures a stable power output across different timescales, improving grid reliability and reducing the need for fossil fuel-based backup generation.

From a system design perspective, integrating TES and steam turbines into pumped storage hydro facilities requires careful planning to optimize energy flow and minimize conversion losses. Smart control systems, powered by artificial intelligence (AI) and machine learning, can be deployed to dynamically manage energy dispatch. These systems analyze real-time grid conditions, weather forecasts, and electricity market prices to determine the optimal use of stored energy. For instance, when electricity prices are low or surplus renewable energy is available, excess power can be used to both pump water to the upper reservoir and charge the thermal storage system. When electricity prices rise, the system can selectively deploy either hydroelectric or steam turbine generation based on availability and efficiency considerations.

A significant advantage of this integration is its potential to enhance the resilience of power grids, particularly in regions that experience seasonal variations in water availability. While traditional pumped storage hydro relies on an adequate supply of water, the addition of a steam turbine powered by thermal storage ensures that electricity generation can continue even when hydropower output is constrained. This is especially relevant in areas affected by droughts or changing precipitation patterns, where hydroelectric plants may face reduced capacity during dry seasons. By providing an alternative dispatchable power source, this hybrid system increases energy security and grid stability.

Economically, integrating steam turbines with pumped storage hydro can improve the return on investment for both technologies. Pumped storage hydro facilities often require large capital expenditures for infrastructure development, including dams, tunnels, and reservoirs. By incorporating a steam turbine system with TES, additional revenue streams can be created by allowing stored thermal energy to be sold as electricity during peak pricing periods. This makes the overall energy storage and generation system more financially viable, particularly in markets with variable electricity pricing structures where the ability to store and dispatch energy at optimal times provides a competitive advantage.

Looking forward, ongoing research and innovation in thermal storage materials, steam turbine efficiency, and energy market integration will play a crucial role in scaling up this technology. Demonstration projects and pilot plants will be essential for validating the technical and economic feasibility of these hybrid systems, allowing for real-world performance assessment and further refinements. As energy storage becomes an increasingly important part of global electricity grids, hybrid approaches that combine pumped storage hydro with thermal energy storage and steam turbines will play a key role in ensuring a stable, reliable, and sustainable energy future.

As the energy transition accelerates, the need for more advanced and flexible energy storage solutions grows. Hybrid systems combining pumped storage hydro with thermal energy storage and steam turbines represent a promising approach to addressing the challenges associated with intermittent renewable energy sources like wind and solar. In particular, the versatility of such hybrid systems enables them to meet the dual goals of maintaining grid stability while reducing greenhouse gas emissions by decreasing reliance on fossil fuel-powered peaking plants.

The integration of steam turbines in pumped storage hydro facilities could be expanded further by incorporating advanced thermal storage technologies. For example, phase-change materials (PCMs) have shown considerable promise in enhancing thermal storage efficiency. These materials store and release large amounts of energy during phase transitions (e.g., from solid to liquid), providing a highly energy-dense and efficient means of storing heat. The high energy density of PCMs allows for the storage of greater amounts of heat in smaller volumes, making them ideal for large-scale energy storage systems. As PCMs become more commercially viable, their use in hybrid pumped storage and steam turbine systems could further optimize both the size and cost-effectiveness of the energy storage solution.

Another key area of development is in steam turbine efficiency. Modern steam turbines, especially those used in advanced thermal power plants, have evolved to operate at much higher efficiencies due to improvements in materials, coatings, and turbine design. For instance, ultra-supercritical steam turbines, which operate at extremely high pressures and temperatures, can achieve thermal efficiencies of over 45%. These high-efficiency turbines, when integrated into a pumped storage system, could dramatically increase the overall energy conversion efficiency from thermal storage to electricity. By improving steam cycle efficiency and reducing mechanical losses in the turbine system, the energy output per unit of stored heat could be maximized, leading to more economical energy generation over longer periods.

Moreover, hybrid systems that combine pumped storage with thermal energy generation are increasingly supported by developments in grid-scale energy management and storage optimization technologies. With the implementation of advanced monitoring systems and artificial intelligence (AI), grid operators can optimize the dispatch of both hydro and thermal storage resources based on real-time market prices and grid requirements. AI algorithms can predict energy demand and generation patterns, allowing for optimal decision-making on when to release stored thermal energy from steam turbines and when to pump water to the upper reservoir. These technologies improve the efficiency of energy dispatch and reduce the overall costs of energy storage systems.

In addition, integrating steam turbines with pumped storage hydro systems offers the opportunity to contribute significantly to decarbonization goals. With increased pressure on utilities to meet stricter emissions standards, hybrid energy systems that combine renewable energy with dispatchable storage solutions are becoming more attractive. These hybrid systems provide a cleaner alternative to traditional fossil fuel-fired peaking plants, which are often used to meet spikes in electricity demand. By shifting the focus from fossil fuel reliance to flexible, renewable-powered systems, countries and regions can make significant strides toward achieving net-zero emissions targets.

The potential to integrate such hybrid systems into the existing energy infrastructure further enhances their appeal. In regions where pumped storage hydro facilities are already in operation, retrofitting these plants with thermal energy storage and steam turbine components can provide a cost-effective way to expand storage and generation capacity. This is particularly valuable in areas where the development of new pumped storage projects is constrained by geographical or environmental factors. Retrofitting existing plants is a faster and more efficient way to enhance energy storage capabilities without the need for extensive new infrastructure, making it an attractive option for grid operators and utility companies.

Looking further into the future, the combination of pumped storage hydro and steam turbines could evolve alongside other emerging storage technologies, such as hydrogen storage and next-generation batteries. While hydrogen storage remains in the early stages of development, it holds promise as a complement to both pumped storage and thermal storage systems. By using excess renewable energy to produce hydrogen through electrolysis, it could serve as a long-duration storage solution that is converted back into electricity or heat when needed. The potential for hybrid systems that incorporate pumped storage, thermal storage, and hydrogen could further improve the dispatchability and resilience of renewable energy systems.

Ultimately, the hybridization of pumped storage hydro with thermal energy storage and steam turbines offers a multifaceted solution to energy storage and generation. By addressing the challenges of energy intermittency, grid stability, and sustainability, these systems present a powerful tool for transforming the future of energy generation. As research and development continue to advance and new technologies are integrated, hybrid energy storage systems will play an increasingly vital role in the global energy transition, enabling the transition to a more sustainable, resilient, and efficient energy grid.

Steam Turbine for Electricity Generation with Solar Thermal Energy

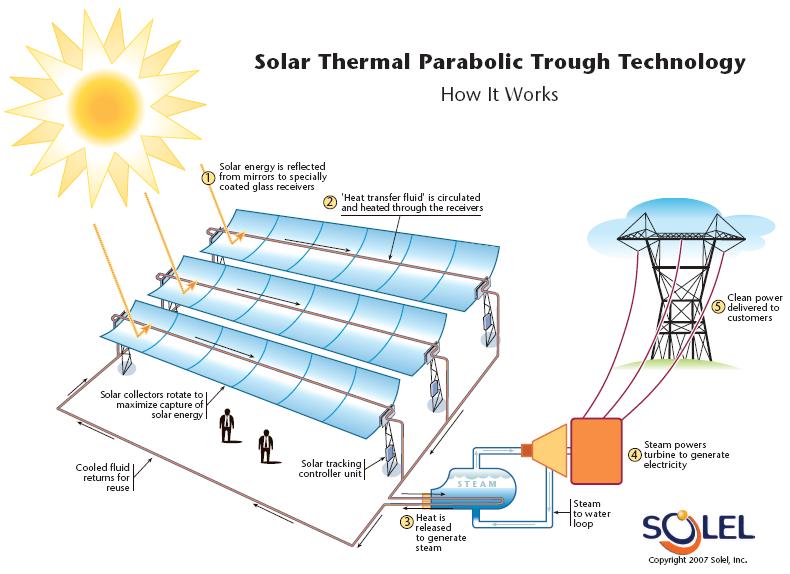

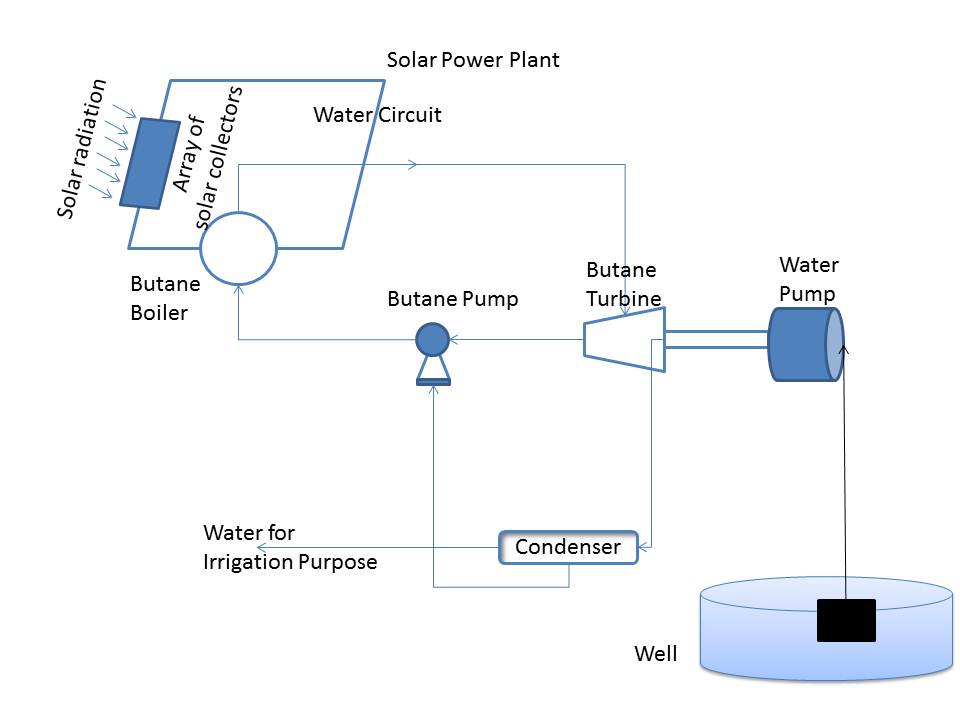

The integration of steam turbines with solar thermal energy for electricity generation offers an effective solution to both the challenges of renewable energy intermittency and the need for dispatchable power sources. Solar thermal power plants, which use concentrated solar power (CSP) to generate heat, can be paired with steam turbines to produce electricity. Unlike photovoltaic (PV) solar, which generates electricity directly from sunlight, CSP systems capture solar energy through mirrors or lenses to concentrate sunlight onto a fluid that absorbs the heat. This heat is then used to produce steam, which drives a steam turbine to generate electricity. By combining this process with thermal energy storage, solar thermal power plants can offer a highly reliable and dispatchable form of renewable power, capable of providing electricity even when the sun is not shining.

One of the key advantages of using steam turbines with solar thermal energy is the ability to store energy in the form of heat. Thermal energy storage systems (TES) are integral to solar thermal power plants, enabling them to store the heat generated during sunny periods for later use. Materials like molten salts, which have a high heat retention capacity, are often used in these systems. By using molten salt or other thermal storage mediums, solar thermal plants can continue to generate electricity from stored heat even after the sun has set or when cloud cover reduces solar radiation. The use of steam turbines with these systems enhances the overall efficiency of the plant, as steam can be generated from stored heat and used to produce electricity as demand arises.

Solar thermal plants that use steam turbines can also operate at higher efficiencies than conventional photovoltaic (PV) systems. The efficiency of PV systems is typically limited by the amount of sunlight captured, and their performance can drop significantly in cloudy weather or at night. In contrast, CSP systems can generate electricity at higher temperatures, typically between 300 and 500 degrees Celsius, which increases the thermodynamic efficiency of the steam cycle. The Rankine cycle, commonly used in steam turbines, converts heat into mechanical energy, and the higher the temperature of the heat source, the more efficiently the turbine can operate. Advanced supercritical steam turbines, which operate at even higher pressures and temperatures, can push the efficiency of solar thermal systems to levels comparable to or even exceeding those of fossil fuel plants.

In addition to improving efficiency, the integration of steam turbines with solar thermal energy offers a significant benefit in terms of scalability. Solar thermal plants can be scaled up to meet large industrial demands for electricity, as well as to serve entire grid systems. When combined with large-scale thermal storage, these plants can generate electricity around the clock, providing a reliable source of power that can complement other renewable energy sources such as wind or hydropower. The ability to store thermal energy and dispatch it as needed also addresses the issue of solar energy’s intermittency, which can create challenges for grid operators who need to balance supply and demand. By allowing solar thermal plants to generate electricity even during periods when sunlight is unavailable, steam turbines enhance grid reliability and reduce dependence on fossil fuels for peak power generation.

Economically, solar thermal power plants with steam turbines and thermal energy storage can offer a competitive alternative to other renewable energy sources and even conventional fossil fuel plants. The capital cost of CSP systems can be higher than that of PV systems, but the addition of thermal energy storage enables them to provide firm, reliable power, which is highly valuable for grid operators. In regions with high solar irradiation, the cost per kilowatt-hour of electricity generated by CSP plants has been steadily declining, making them more cost-competitive with other forms of renewable energy. Furthermore, by reducing reliance on fossil fuel peaking plants, solar thermal systems can help to lower overall electricity prices, reduce fuel costs, and contribute to long-term sustainability goals.

A critical factor in the successful integration of steam turbines with solar thermal energy is the continued advancement of materials and technology. High-temperature materials, such as advanced alloys and ceramics, are necessary to ensure that steam turbines can operate efficiently at the elevated temperatures typical of CSP systems. Ongoing research into improving the durability of materials, as well as developing more efficient heat exchangers and thermal storage systems, will be crucial for maximizing the performance of these plants. Advances in digital control systems and AI-driven energy management can also play a significant role in optimizing the dispatch of stored thermal energy, ensuring that power is generated when demand is highest.

In the long term, combining solar thermal energy with steam turbines could also play a critical role in hybrid energy systems, where multiple renewable sources are integrated into a single, flexible energy solution. For example, hybrid systems that combine CSP with wind or geothermal energy could provide even greater reliability and energy security by utilizing multiple renewable energy resources in a complementary manner. In such systems, solar thermal plants could provide baseload power with steam turbines, while wind and geothermal energy could contribute to meeting peak demand and ensuring grid stability.

From an environmental perspective, the integration of steam turbines with solar thermal energy offers a highly sustainable and low-carbon alternative to traditional fossil fuel-based power generation. The ability to generate electricity from renewable solar energy, even during non-sunny periods, drastically reduces the need for coal or gas-fired power plants. This integration helps in decarbonizing the electricity sector, which is a key strategy in mitigating climate change and reducing global greenhouse gas emissions. Additionally, since CSP systems generally use water more efficiently than traditional steam turbines in fossil fuel plants, they are a viable option in arid regions where water resources are scarce.

As the global energy landscape evolves and the need for clean, reliable, and dispatchable renewable energy becomes more pressing, steam turbines integrated with solar thermal energy will play a critical role in the energy mix. Continued technological advancements, cost reductions, and supportive policy frameworks will be essential to realizing the full potential of this approach. By providing a reliable and efficient way to store and convert solar energy into electricity, solar thermal systems with steam turbines offer a sustainable solution for meeting the world’s growing energy demands in an environmentally responsible manner.

As the demand for clean, renewable energy continues to rise, the integration of steam turbines with solar thermal energy represents a promising strategy for meeting both electricity generation and grid stability needs. One of the most compelling features of this approach is its ability to provide firm, dispatchable power, which is increasingly important in a world transitioning to renewable energy sources. While technologies like wind and solar photovoltaics (PV) are intermittent by nature, solar thermal plants with thermal energy storage offer a solution that can operate continuously, even when the sun isn’t shining, thanks to the ability to store energy in the form of heat. This makes solar thermal power, combined with steam turbines, particularly suitable for use in regions with high solar irradiation and for providing electricity during peak demand times when other renewable sources may be unavailable.

Thermal energy storage (TES) systems, like molten salt or solid-state materials, enable solar thermal plants to store excess heat generated during sunny periods, which can then be converted to steam to generate electricity later. This long-duration storage capability is critical to enhancing the stability of the power grid by smoothing out the fluctuations caused by daily solar variations. For example, while solar PV systems typically generate power only during daylight hours, solar thermal plants equipped with TES systems can continue to generate electricity after sunset, making them a more reliable and consistent power source. Additionally, when combined with steam turbines, which have the ability to generate electricity over extended periods, these systems can act as a steady base load power source, complementing intermittent renewable generation and reducing reliance on fossil fuel peaking plants.

The integration of steam turbines with solar thermal energy systems also allows for high thermal efficiency in converting solar energy into usable electricity. As previously mentioned, CSP systems can operate at higher temperatures than photovoltaic systems, which boosts the efficiency of the steam turbines. Higher temperatures lead to a larger thermodynamic gradient, allowing the Rankine cycle (used in steam turbines) to convert more heat energy into mechanical power. Advanced steam turbines, especially those operating in supercritical conditions (higher pressures and temperatures), can achieve efficiencies of up to 45% or higher, which is a significant improvement over traditional subcritical steam turbines typically used in fossil fuel plants.

Furthermore, the combination of steam turbines with solar thermal energy systems presents a significant opportunity for industrial applications. Many industries, such as chemicals, cement, and steel, require both heat and electricity. Solar thermal systems, with their ability to generate high-temperature heat, can serve as a direct source of thermal energy for industrial processes while also providing electricity through steam turbines. This dual-use capability could greatly enhance energy efficiency and reduce industrial dependence on fossil fuels, supporting both decarbonization goals and cost savings for industries in the long run. In some cases, industries located in sunny regions may even be able to become energy self-sufficient by integrating solar thermal energy systems with steam turbine generation and thermal storage.

From an environmental perspective, solar thermal energy with steam turbines can significantly contribute to reducing greenhouse gas emissions, especially in regions where electricity generation still heavily relies on coal, natural gas, or other fossil fuels. By replacing fossil fuel-based power plants with solar thermal power, carbon emissions are reduced, helping countries meet their renewable energy targets and climate goals. Additionally, solar thermal power plants typically require less water for cooling than conventional fossil fuel plants, making them an ideal solution for arid and water-scarce regions.

One of the next challenges for the widespread adoption of solar thermal energy systems with steam turbines is the cost competitiveness of these systems. While the cost of CSP plants has been decreasing steadily over the past decade, it remains higher than other forms of renewable energy like wind and PV. However, the long-term benefits of solar thermal systems, particularly in terms of grid reliability and their ability to provide energy around the clock, could make them an attractive investment in regions where power reliability is a critical concern. Further research into reducing the capital costs of thermal storage materials, improving turbine efficiency, and enhancing the performance of the heat transfer fluids will continue to make these systems more economical.