Small Scale Power Plant for Hotels and Resorts: Power plants utilizing steam turbines play a crucial role in global electricity generation. These plants operate on the principle of thermodynamic cycles, primarily the Rankine cycle, where water is heated to produce steam that drives a turbine connected to a generator. The process begins with a heat source, which can vary depending on the type of power plant. The most common sources include fossil fuels such as coal, natural gas, and oil, as well as nuclear energy, biomass, geothermal heat, and solar thermal energy. Regardless of the heat source, the goal is to convert thermal energy into mechanical energy and ultimately into electrical energy.

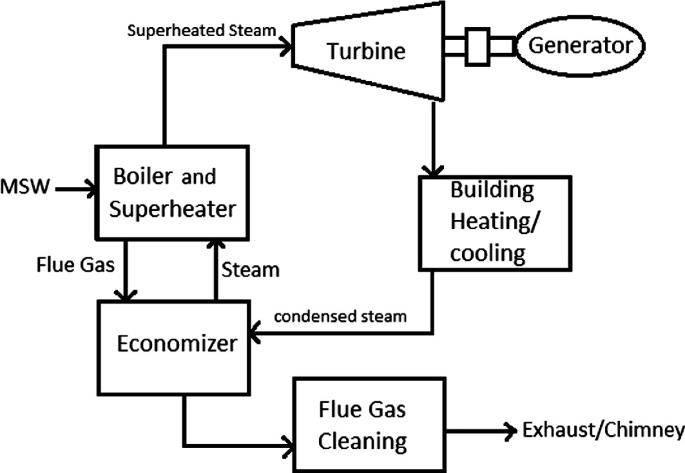

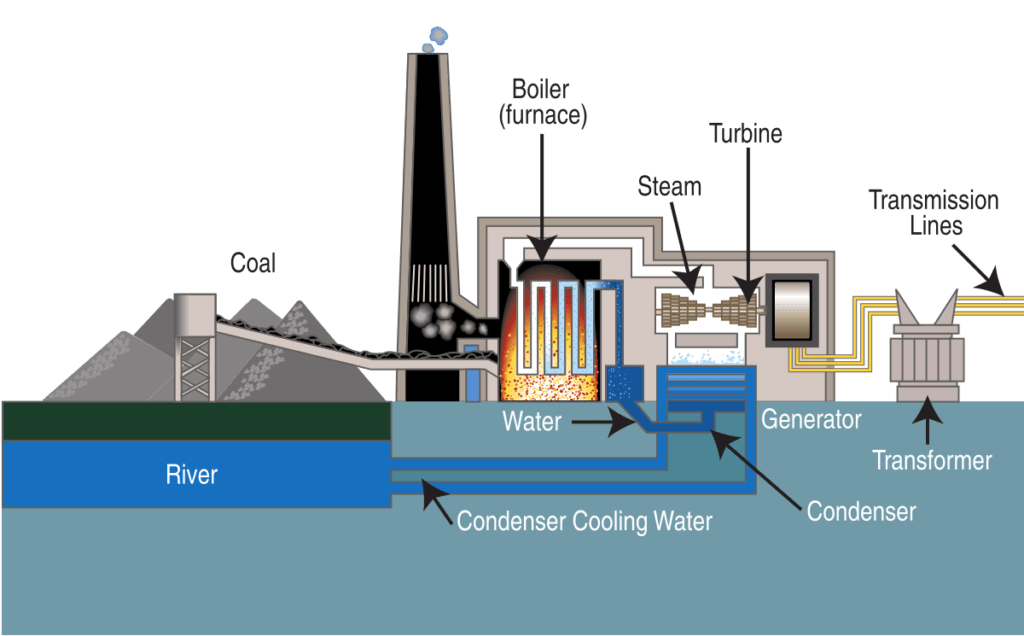

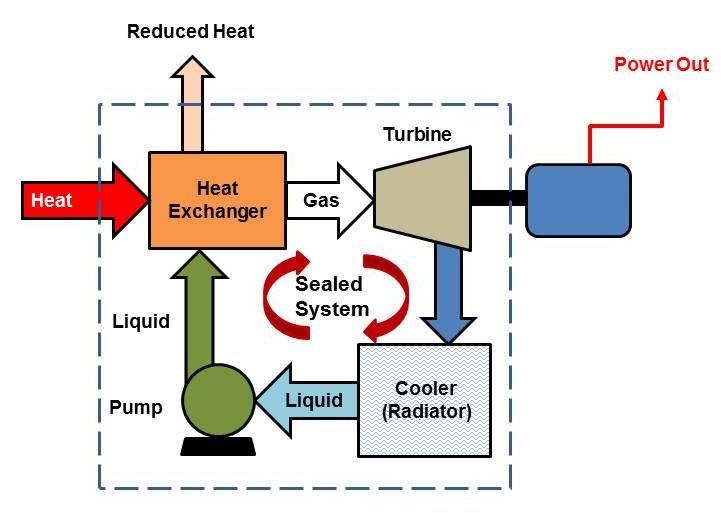

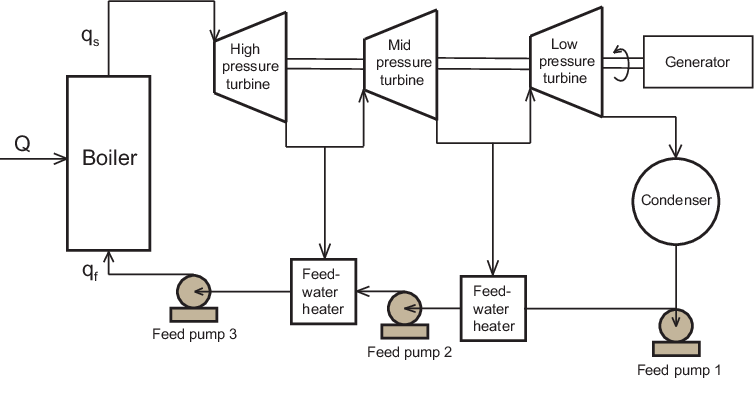

In a typical steam power plant, water is first fed into a boiler or steam generator, where it is heated under high pressure to produce superheated steam. This steam is then directed through a series of high-pressure turbines, where it expands and causes the turbine blades to rotate. The rotational energy is transferred to a generator via a shaft, converting mechanical energy into electrical power. After passing through the high-pressure turbine, the steam moves into intermediate- and low-pressure turbines, further expanding and transferring additional energy before being exhausted into a condenser.

The condenser plays a vital role in maintaining efficiency by cooling and condensing the steam back into liquid form. This condensed water, known as condensate, is then pumped back into the boiler through feedwater heaters that recover residual heat from extracted steam. This regenerative heating process improves overall efficiency by reducing the amount of fuel needed to reheat the water to its boiling point. The cycle continues, maintaining a continuous and efficient process of electricity generation.

Different types of steam power plants exist based on fuel source and operational characteristics. Fossil fuel power plants, including coal-fired and gas-fired plants, rely on burning hydrocarbons to generate heat. Coal-fired plants, though historically dominant, are facing increasing scrutiny due to environmental concerns related to carbon emissions and air pollution. Advanced technologies, such as supercritical and ultra-supercritical steam cycles, have been developed to enhance efficiency and reduce emissions. Natural gas power plants, particularly those using combined cycle technology, integrate steam turbines with gas turbines to maximize energy extraction, significantly increasing efficiency.

Nuclear power plants operate similarly but use nuclear fission to generate heat. In a pressurized water reactor (PWR), the reactor heats water in a primary loop, which then transfers heat to a secondary loop that generates steam to drive the turbine. Boiling water reactors (BWRs) produce steam directly within the reactor vessel. Nuclear plants provide a stable and continuous power supply, making them a key source of baseload electricity. However, they require strict safety measures and long-term solutions for radioactive waste disposal.

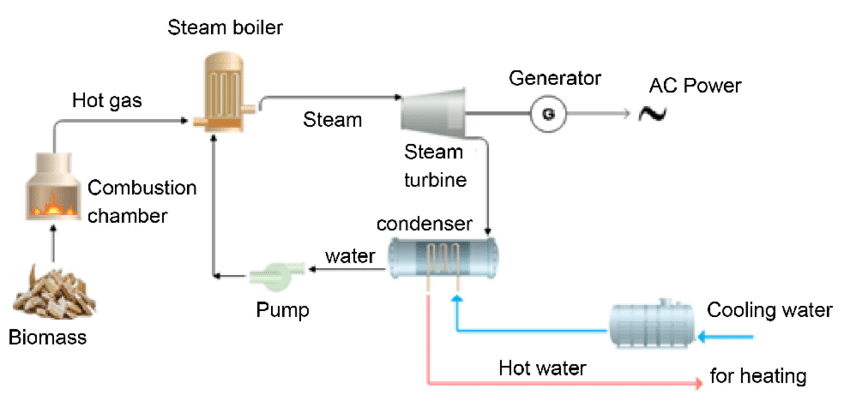

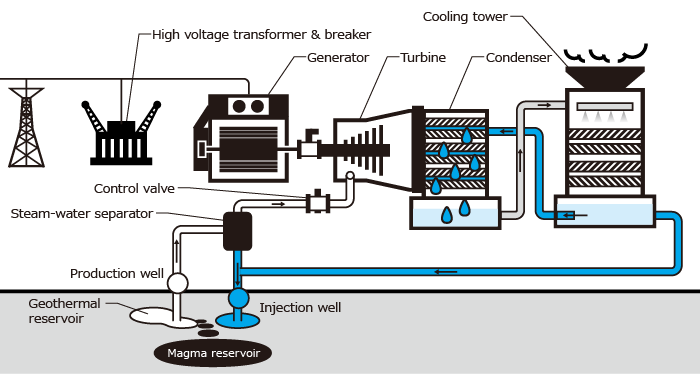

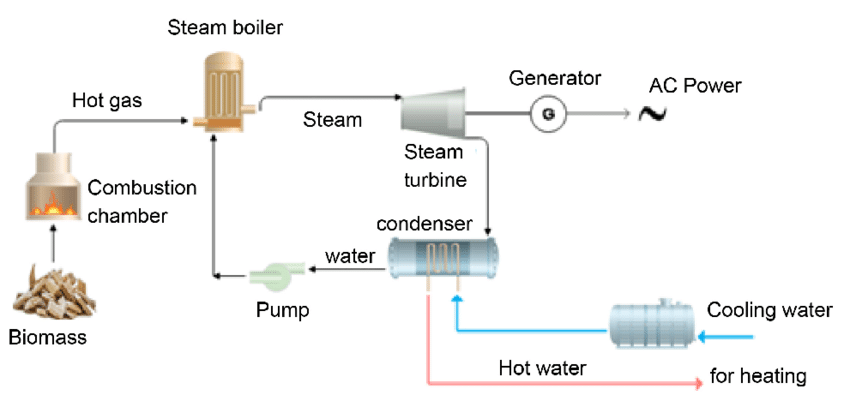

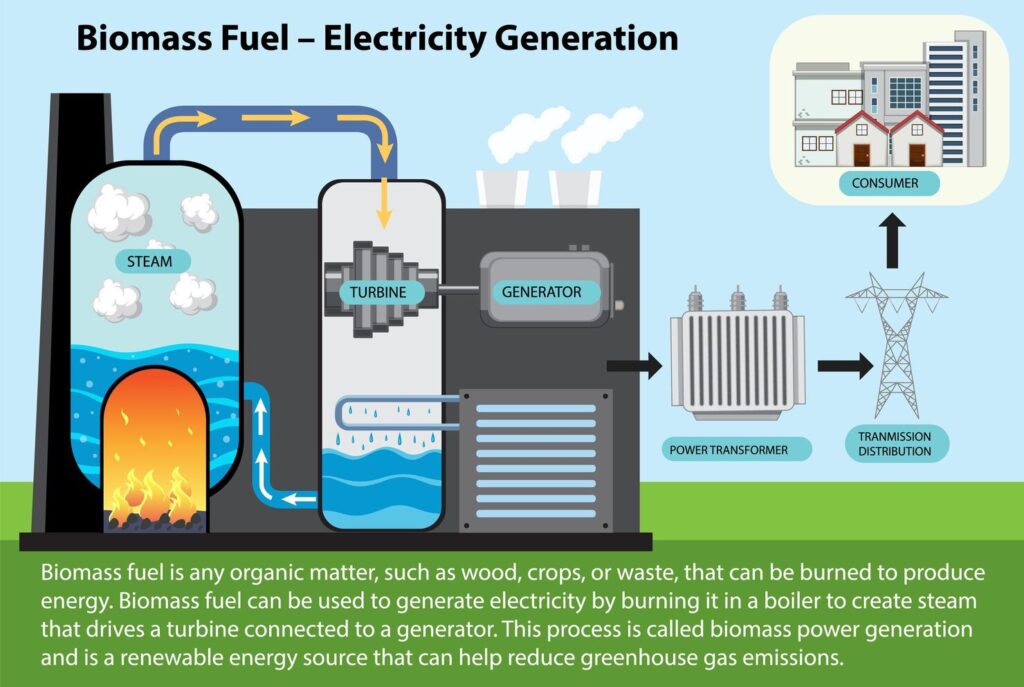

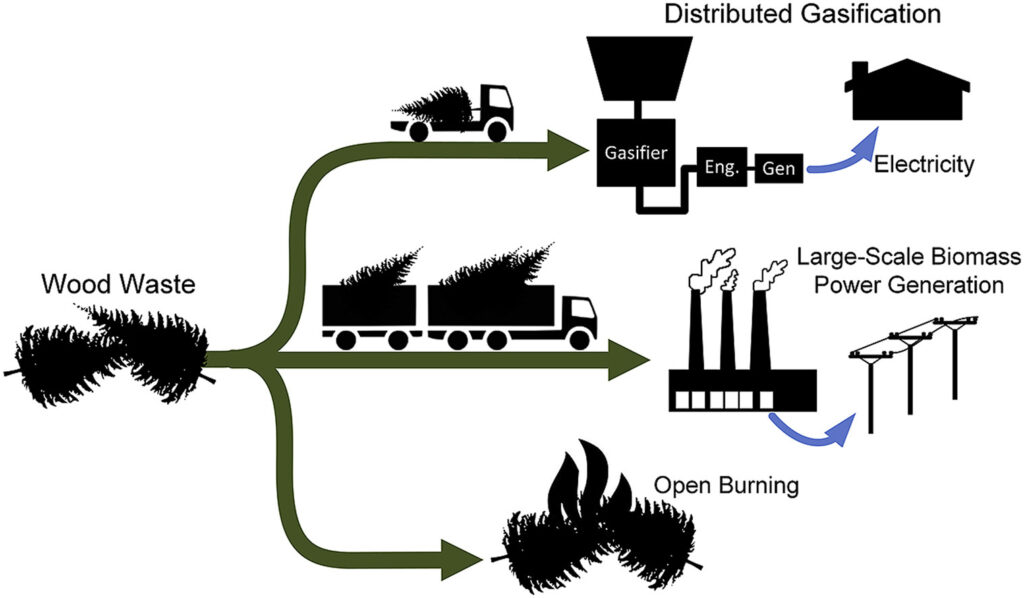

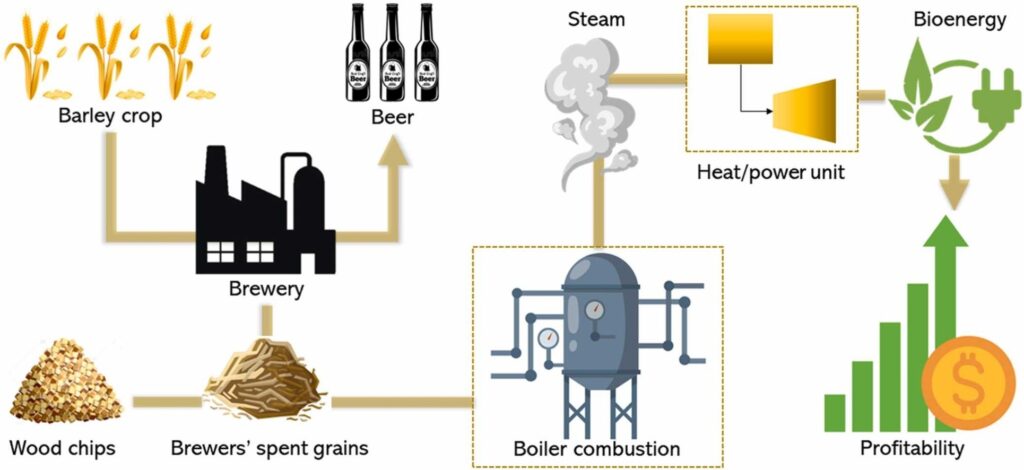

Renewable energy sources such as biomass, geothermal, and solar thermal also employ steam turbines. Biomass plants burn organic materials like wood, agricultural waste, or municipal solid waste to generate steam. Geothermal power plants utilize heat from beneath the Earth’s surface, extracting steam or hot water from underground reservoirs. Flash steam, dry steam, and binary cycle geothermal plants use different methods to harness this heat efficiently. Solar thermal power plants, such as concentrated solar power (CSP) systems, use mirrors to focus sunlight onto a receiver that heats a working fluid, producing steam to drive a turbine.

Efficiency improvements in steam power plants focus on advanced turbine designs, higher steam temperatures and pressures, and integrated heat recovery systems. Technologies such as cogeneration, also known as combined heat and power (CHP), increase efficiency by utilizing waste heat for industrial processes or district heating. Additionally, carbon capture and storage (CCS) is being explored to mitigate emissions from fossil fuel-based plants.

Steam turbine power plants continue to be a backbone of global electricity production due to their reliability and scalability. However, the transition towards cleaner and more sustainable energy sources is shaping the future of steam power technology. Research and development efforts are aimed at improving efficiency, reducing emissions, and integrating renewable energy with conventional steam turbine systems. The continued evolution of steam power plants will play a crucial role in balancing energy demand, environmental responsibility, and economic viability.

Small Scale Power Plants

Further advancements in steam power plant technology have been driven by the need for higher efficiency, reduced environmental impact, and increased reliability. One of the most significant developments has been the transition from subcritical steam cycles to supercritical and ultra-supercritical cycles. In subcritical plants, steam is generated at pressures below the critical point of water, meaning a distinct phase change from water to steam occurs in the boiler. However, supercritical plants operate at pressures above the critical point, eliminating the phase transition and allowing for more efficient thermal energy conversion. Ultra-supercritical plants push these limits further, achieving even higher steam temperatures and pressures, which significantly improve efficiency and reduce fuel consumption.

In addition to improvements in steam parameters, turbine technology itself has evolved. Modern turbines are designed with advanced aerodynamics, optimized blade profiles, and high-strength materials capable of withstanding extreme temperatures and pressures. Many large-scale power plants use multi-stage turbines, where high-pressure, intermediate-pressure, and low-pressure stages work together to extract the maximum amount of energy from the steam. Efficiency enhancements also come from reducing steam leakage, improving blade cooling techniques, and using coatings that prevent corrosion and wear.

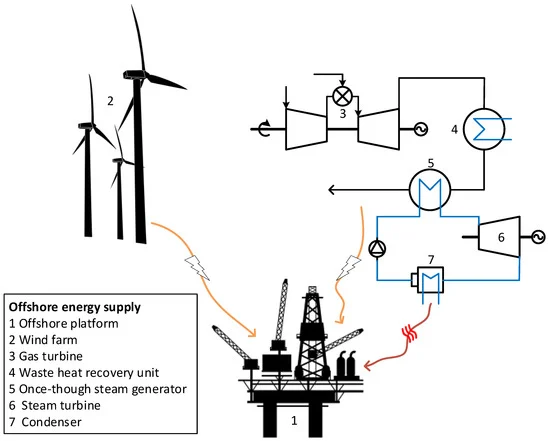

Heat recovery is another crucial aspect of efficiency improvement in steam power plants. The use of regenerative feedwater heating allows for better utilization of extracted steam, reducing the amount of additional heat energy required in the boiler. Condenser efficiency is also vital, as the faster and more effectively steam is condensed back into water, the better the vacuum conditions in the turbine, which enhances power output. In combined cycle power plants, waste heat from a gas turbine is used to generate additional steam for a steam turbine, dramatically improving overall efficiency.

The environmental impact of steam power plants is a major concern, particularly for fossil fuel-based systems. Carbon dioxide (CO₂) emissions from coal and natural gas plants contribute to climate change, leading to increased focus on carbon capture and storage (CCS) technologies. These systems aim to capture CO₂ before it is released into the atmosphere and store it underground or utilize it in industrial applications. Other emission control technologies include flue gas desulfurization (FGD) for removing sulfur dioxide (SO₂), selective catalytic reduction (SCR) for nitrogen oxides (NOx), and particulate matter filters to reduce air pollution.

Water usage is another important factor in steam power plants. Traditional once-through cooling systems withdraw large amounts of water from natural sources, raising concerns about thermal pollution and water scarcity. As a result, many plants now use closed-loop cooling systems with cooling towers or air-cooled condensers to minimize water consumption. In regions with limited water resources, dry cooling technology is being adopted, though it can result in slightly lower plant efficiency due to higher condenser temperatures.

The role of digitalization and automation in modern steam power plants is growing, with advanced monitoring and control systems enhancing performance and reliability. Predictive maintenance using artificial intelligence (AI) and machine learning algorithms helps detect potential failures before they occur, reducing downtime and maintenance costs. Sensors and data analytics provide real-time insights into turbine performance, boiler efficiency, and emissions control, allowing for continuous optimization.

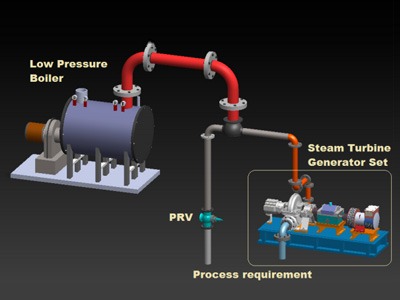

In addition to large centralized power plants, smaller-scale steam turbine systems are being used for industrial applications and distributed energy generation. Combined heat and power (CHP) plants, often found in industrial facilities, universities, and district heating systems, provide both electricity and useful heat, significantly increasing overall energy utilization. Some biomass and waste-to-energy plants use steam turbines to generate power while simultaneously addressing waste disposal and reducing landfill use.

The integration of renewable energy with steam turbine technology is another emerging trend. Hybrid systems that combine solar thermal energy with traditional steam power plants can improve efficiency and reduce fuel consumption. Some geothermal power plants utilize steam turbines to harness Earth’s natural heat, providing a renewable and stable source of electricity. In the long term, advancements in hydrogen combustion and zero-carbon fuels could allow steam power plants to operate sustainably while maintaining their reliability and large-scale energy production capabilities.

As global energy demand continues to grow, steam power plants will remain a key component of the energy mix. While renewable energy sources such as wind and solar are expanding rapidly, steam turbine plants provide a crucial source of baseload and dispatchable power. Future developments will likely focus on improving efficiency, reducing emissions, and integrating cleaner energy sources to ensure that steam power generation remains both viable and sustainable in a rapidly changing energy landscape.

Further improvements in steam turbine technology are focusing on efficiency gains through material advancements, operational optimizations, and alternative fuel sources. One of the key challenges in steam power plants is the thermal efficiency limitation imposed by the Carnot cycle. Since efficiency is directly related to the temperature difference between the heat source and the heat sink, researchers are exploring ways to increase maximum operating temperatures while maintaining the structural integrity of turbine components.

Advanced materials, such as nickel-based superalloys and ceramic matrix composites, are being developed to withstand extreme temperatures and pressures, allowing turbines to operate at higher efficiencies. These materials offer better resistance to thermal stress, oxidation, and corrosion, reducing maintenance needs and extending component lifespan. Additionally, advancements in coatings, such as thermal barrier coatings (TBCs), are helping to protect turbine blades from high-temperature degradation, further improving operational longevity.

Operational optimizations are also playing a crucial role in enhancing steam turbine performance. Digital twin technology, where a virtual model of a steam power plant is continuously updated with real-time data, is being used to optimize performance and predict potential failures. This approach allows operators to test different scenarios in a simulated environment, leading to better decision-making and efficiency improvements. Artificial intelligence (AI) and machine learning are being integrated into plant management systems to analyze vast amounts of operational data and identify opportunities for optimization.

One promising area of research is the development of closed-loop supercritical carbon dioxide (sCO₂) cycles as an alternative to traditional steam-based Rankine cycles. sCO₂ operates at higher efficiencies due to its superior thermodynamic properties, allowing for compact turbine designs and reduced heat losses. These systems have the potential to significantly improve efficiency while reducing water consumption, making them particularly attractive for arid regions where water availability is limited.

Another critical area of innovation is the transition toward alternative fuels in steam power plants. While coal remains a dominant fuel source in some regions, there is a growing push toward cleaner alternatives such as biomass, hydrogen, and ammonia. Biomass co-firing, where biomass is blended with coal, reduces net CO₂ emissions while utilizing existing infrastructure. Hydrogen, when produced using renewable energy sources, presents a zero-carbon alternative for steam generation, though challenges remain in terms of production costs and storage. Ammonia, which can be used as a hydrogen carrier, is also being explored as a potential fuel for steam power plants due to its high energy density and ease of transportation.

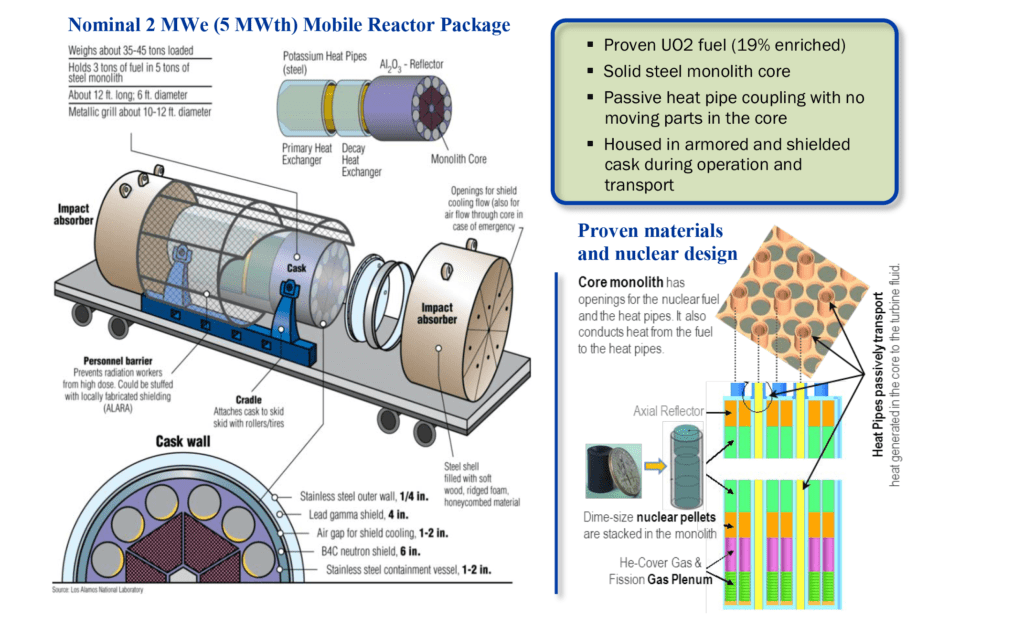

Nuclear steam power is another area of ongoing innovation. Small modular reactors (SMRs) are being developed as a more flexible and scalable alternative to traditional large nuclear power plants. These reactors use steam turbines for power generation but feature enhanced safety mechanisms, simplified designs, and reduced construction times. SMRs are expected to play a significant role in the future energy landscape, providing reliable, low-carbon electricity with improved adaptability to grid demands.

Hybrid power systems that integrate steam turbines with renewable energy sources are also being explored to enhance grid stability and reduce reliance on fossil fuels. Solar thermal plants with molten salt storage can generate steam for turbines even when sunlight is unavailable, providing a continuous power supply. Geothermal power plants utilizing steam turbines can serve as a baseload energy source, complementing intermittent renewables like wind and solar.

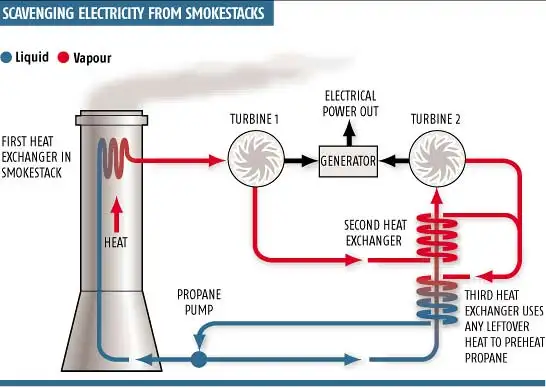

Waste heat recovery systems are further improving the efficiency of industrial processes and power generation. By capturing excess heat from industrial operations or power plants and using it to generate steam, these systems maximize energy utilization and reduce environmental impact. Combined cycle plants, which pair gas turbines with steam turbines, are an example of how waste heat can be effectively repurposed to increase overall efficiency.

As the global energy transition continues, steam turbine power plants will need to adapt to new regulatory requirements, carbon reduction targets, and evolving market demands. The future of steam power lies in greater efficiency, integration with cleaner energy sources, and the adoption of advanced digital technologies. With ongoing research and development, steam turbines will continue to be a vital part of the world’s energy infrastructure, balancing the need for reliability, sustainability, and economic feasibility.

The future of steam power plants is increasingly shaped by the need for sustainability, flexibility, and technological advancements. As global energy systems evolve, steam turbine technology must adapt to integrate with renewable energy, reduce emissions, and enhance efficiency through innovative engineering solutions. The role of steam turbines in power generation is being redefined, particularly as the world shifts toward decarbonization and grid modernization.

One of the most significant trends is the integration of steam turbines with renewable energy sources to create hybrid power systems. Solar thermal power plants, also known as concentrated solar power (CSP) plants, use mirrors to focus sunlight onto a receiver, which heats a working fluid to generate steam. Unlike photovoltaic solar panels that directly convert sunlight into electricity, CSP plants utilize steam turbines to produce power in a manner similar to conventional fossil-fuel plants. The advantage of CSP technology is its ability to incorporate thermal energy storage, such as molten salt systems, which allow for electricity generation even after sunset. This helps address the intermittency issues associated with solar energy and provides a stable, dispatchable power source.

Another promising area of development is geothermal power generation. Geothermal plants rely on heat from the Earth’s core to produce steam, which drives turbines to generate electricity. Unlike fossil fuel-based plants, geothermal energy is a renewable and consistent source of power with minimal carbon emissions. Enhanced geothermal systems (EGS) are being developed to expand the reach of geothermal energy by artificially creating reservoirs in deep rock formations, significantly increasing the potential for steam-based renewable electricity.

The role of steam turbines is also being explored in the hydrogen economy. Hydrogen combustion in steam power plants could provide a zero-emission alternative to natural gas and coal. Hydrogen-fueled boilers and combined-cycle plants are being tested as a means of decarbonizing traditional steam-based power generation. However, large-scale adoption will depend on advancements in hydrogen production, storage, and transportation infrastructure. Ammonia, as a hydrogen carrier, is being investigated as an alternative fuel for steam power plants, offering a potentially viable pathway for carbon-free electricity generation.

In parallel with fuel source diversification, advancements in turbine efficiency and design are pushing the limits of what steam power plants can achieve. Supercritical and ultra-supercritical steam cycles have already improved efficiency by increasing steam temperature and pressure, but new research is focusing on advanced cycles such as supercritical carbon dioxide (sCO₂) power cycles. Unlike traditional steam turbines, sCO₂ turbines operate at higher densities and require smaller components, allowing for more compact and efficient power plant designs. These systems have the potential to revolutionize steam-based power generation by reducing material costs, enhancing thermal efficiency, and minimizing water consumption.

The digital transformation of power plants is another key factor in the evolution of steam turbine technology. Modern plants are increasingly adopting advanced monitoring systems, artificial intelligence (AI), and automation to optimize performance, reduce downtime, and improve predictive maintenance. Digital twins—real-time virtual replicas of physical steam turbines—are being used to simulate operations, predict failures, and test optimization strategies before implementing them in actual power plants. This technology enhances reliability, reduces maintenance costs, and extends the lifespan of critical components.

The role of steam power plants in industrial applications is also expanding beyond traditional electricity generation. Industrial steam turbines are widely used in cogeneration (combined heat and power, or CHP) systems, which provide both electricity and process heat for manufacturing, chemical production, and district heating. These systems significantly increase overall energy efficiency by utilizing waste heat that would otherwise be lost in conventional power plants. Many industries, including pulp and paper, food processing, and petrochemicals, rely on steam turbines to meet their energy demands efficiently.

Despite these advancements, the transition toward a low-carbon future presents challenges for existing steam power plants, particularly those dependent on fossil fuels. Governments and regulatory bodies worldwide are implementing stricter emissions standards, prompting the need for carbon capture and storage (CCS) technologies. CCS systems capture CO₂ emissions from power plants and store them underground or use them for industrial applications, such as enhanced oil recovery or synthetic fuel production. While CCS offers a potential solution for reducing the carbon footprint of steam power plants, high costs and energy penalties associated with the process remain significant hurdles.

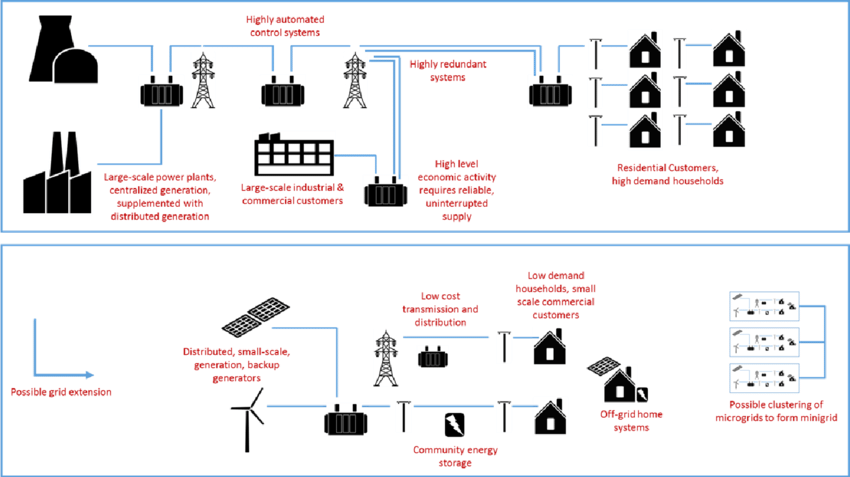

Additionally, the global shift toward decentralized and distributed energy generation is changing the way steam turbines fit into the energy landscape. Traditionally, large central power stations with steam turbines supplied electricity to vast regions, but modern energy grids are moving toward a mix of smaller, localized generation sources. This trend is driven by the expansion of renewable energy, microgrids, and energy storage technologies. To remain competitive, steam power plants must adapt to provide flexible and responsive generation, potentially operating in hybrid configurations with renewables and battery storage.

Ultimately, the future of steam power generation will be defined by a balance between innovation, environmental responsibility, and economic feasibility. While the share of fossil fuel-based steam power is expected to decline, steam turbine technology will continue to play a critical role in providing reliable baseload power, supporting industrial processes, and integrating with new energy systems. Whether through advanced steam cycles, alternative fuels, digital optimization, or hybrid renewable systems, steam turbines are set to remain a cornerstone of global energy infrastructure in the coming decades.

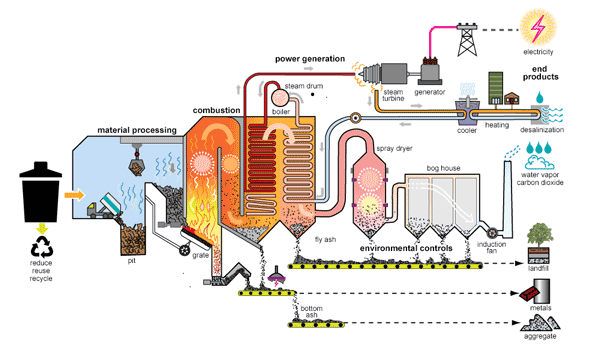

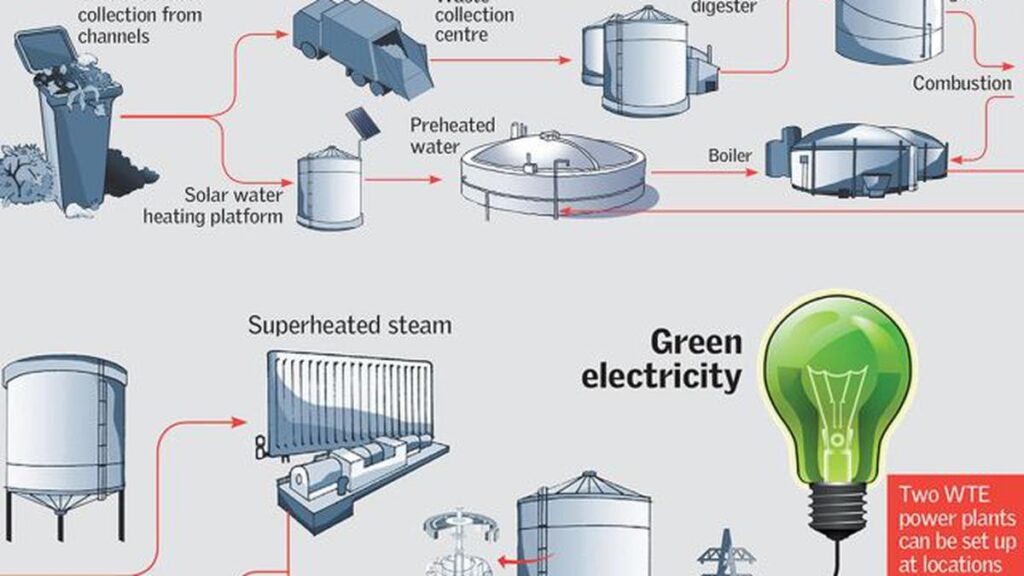

Small-scale power plants for landfill waste-to-energy (WTE) applications provide a sustainable solution for urban districts dealing with waste management and power reliability issues. These plants convert municipal solid waste (MSW) into electricity and heat through various thermal and biological processes, reducing landfill volumes while generating local, decentralized power. By integrating steam turbine technology with waste processing, small-scale landfill WTE plants offer a dual benefit: waste reduction and energy production, making them an attractive solution for cities looking to enhance sustainability and energy security.

Waste-to-Energy Conversion Methods in Small-Scale Plants

Several technologies can be used to convert landfill waste into energy, each with its advantages in terms of efficiency, environmental impact, and feasibility for small-scale applications:

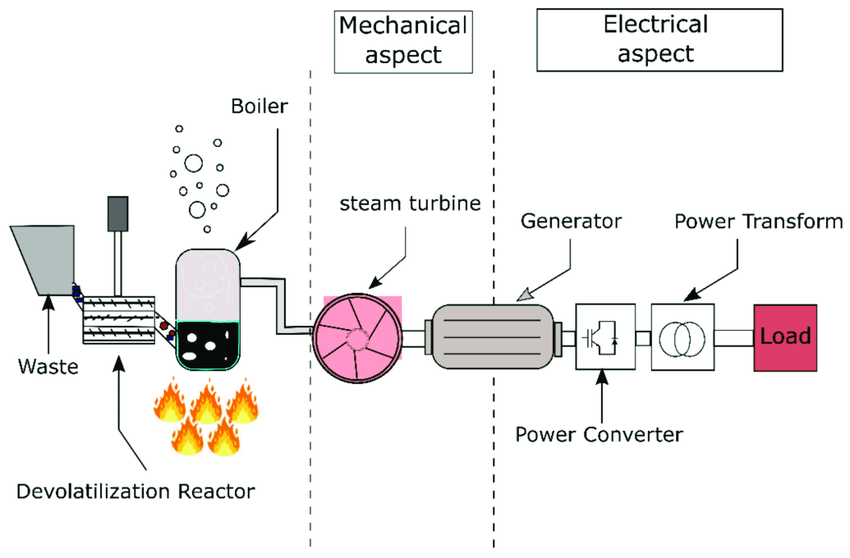

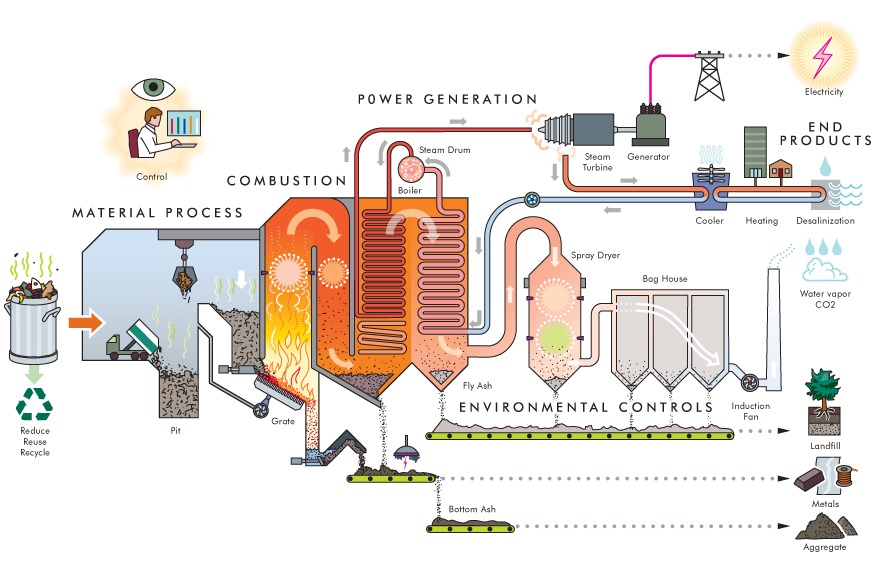

- Incineration with Steam Turbines

- The most common method for landfill WTE plants is mass-burn incineration, where municipal solid waste is combusted in high-temperature furnaces.

- The heat generated from combustion produces steam, which drives a small steam turbine to generate electricity.

- Modern small-scale incineration plants incorporate advanced air pollution control systems (e.g., scrubbers, filters, and catalytic converters) to minimize emissions of particulates, dioxins, and NOx gases.

- These systems can be designed to support Combined Heat and Power (CHP), providing district heating or industrial process heat in addition to electricity.

- Gasification and Pyrolysis

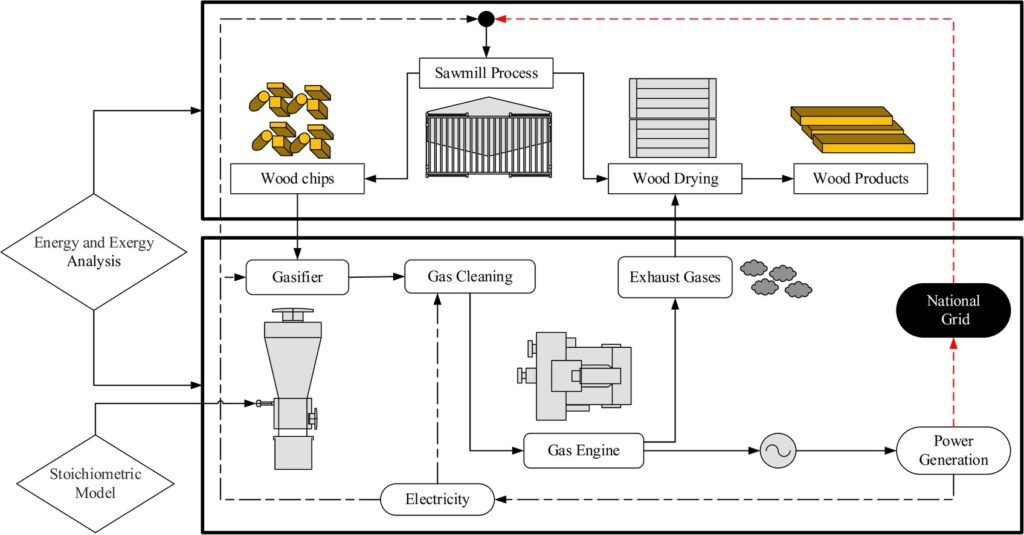

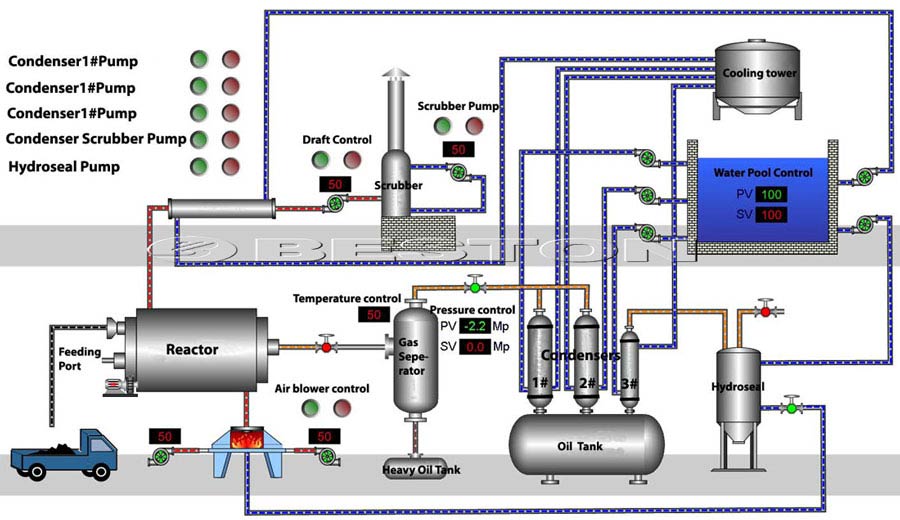

- Gasification and pyrolysis break down waste at high temperatures in a low-oxygen or oxygen-free environment, converting it into syngas (a mixture of hydrogen, carbon monoxide, and methane).

- The syngas can then be combusted in a boiler to produce steam for a turbine or used in gas engines and fuel cells for electricity generation.

- These methods produce fewer emissions compared to direct incineration and allow for greater flexibility in fuel sources, including plastics and organic waste fractions.

- Gasification can also be integrated with carbon capture technologies, further reducing environmental impact.

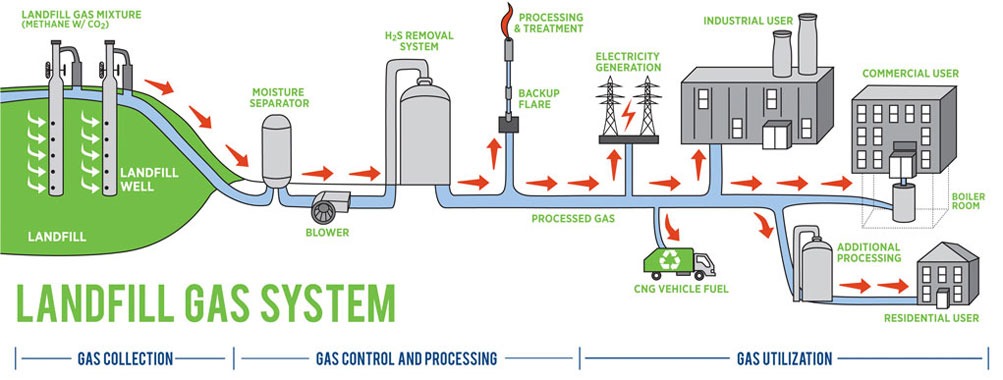

- Landfill Gas (LFG) to Energy

- As organic waste decomposes in landfills, it releases methane, a potent greenhouse gas. Instead of allowing this gas to escape into the atmosphere, small-scale landfill WTE plants can capture it and use it as a fuel source.

- The methane-rich biogas is typically used in internal combustion engines or microturbines to generate electricity, but it can also be burned in a boiler to generate steam for turbines.

- This approach is particularly cost-effective for existing landfills with large amounts of organic waste, as it provides an ongoing energy source without requiring additional feedstock.

Advantages of Small-Scale Landfill WTE Plants

- Localized Energy Generation: By producing electricity and heat close to the point of consumption, small-scale WTE plants reduce transmission losses and enhance grid stability.

- Waste Reduction: Incineration and gasification can reduce landfill volumes by up to 90%, extending landfill lifespans and reducing the need for new waste disposal sites.

- Lower Greenhouse Gas Emissions: Converting landfill gas to energy prevents methane emissions, significantly reducing the carbon footprint of waste management.

- Revenue Generation: In addition to electricity sales, WTE plants can generate revenue from tipping fees, carbon credits, and by-products like ash (which can be used in construction materials).

- Energy Resilience: These plants can operate as microgrids, providing backup power during grid outages and supporting critical infrastructure.

Challenges and Future Innovations

Despite their advantages, small-scale landfill WTE plants face several challenges:

- Public Perception and Environmental Concerns: Incineration and gasification plants must comply with strict emissions regulations and address community concerns about air pollution.

- Feedstock Variability: MSW composition varies significantly, affecting combustion efficiency and energy output. Advanced sorting and preprocessing technologies can help optimize performance.

- Regulatory Barriers: Permitting for WTE plants can be complex due to stringent environmental regulations, requiring compliance with waste management, air quality, and energy policies.

Future innovations aim to enhance the efficiency and sustainability of small-scale landfill WTE plants:

- Plasma Arc Gasification: A next-generation technology that uses extremely high temperatures to break down waste into clean syngas with minimal emissions.

- Carbon Capture and Utilization (CCU): Emerging WTE plants are integrating CO₂ capture systems to reduce emissions and repurpose carbon for industrial applications or synthetic fuels.

- Hybrid Renewable Systems: Pairing WTE plants with solar, wind, or battery storage can improve overall energy reliability and efficiency.

Conclusion

Small-scale landfill waste-to-energy plants represent a practical solution for urban districts struggling with both waste management and power reliability. By converting landfill waste into electricity and heat using steam turbines, gasification, or landfill gas capture, these plants support sustainable energy production while reducing environmental impact. As technology advances and regulatory frameworks evolve, small-scale WTE facilities will play an increasingly important role in the circular economy, transforming urban waste into a valuable energy resource.

Small-scale landfill waste-to-energy (WTE) plants present a sustainable solution to urban waste management challenges while also addressing energy reliability concerns. By converting landfill waste into electricity and heat, these plants not only help reduce waste volumes but also provide a local, dependable power source for communities. With various technologies available, including incineration, gasification, and landfill gas capture, small-scale WTE plants can be tailored to fit the needs of specific urban districts, particularly in areas facing frequent power outages or grid instability.

Incineration is the most widely used method in small-scale WTE plants. The waste is burned in high-temperature furnaces, and the resulting heat is used to produce steam that drives a turbine for electricity generation. These plants can be configured as combined heat and power (CHP) systems, which provide both electricity and useful thermal energy for district heating or industrial applications. To ensure minimal environmental impact, modern WTE plants are equipped with advanced air pollution control systems, which limit harmful emissions such as particulates, nitrogen oxides, and dioxins. These measures make small-scale incineration plants viable even in densely populated urban areas.

Another growing technology for landfill waste-to-energy is gasification. This process involves heating waste in a low-oxygen environment, which causes it to break down into syngas (a mixture of hydrogen, carbon monoxide, and methane) rather than directly combusting it. This syngas can then be used to generate electricity or further processed for other applications. Gasification offers advantages in terms of efficiency and emission reduction, as it produces fewer pollutants compared to traditional incineration. Additionally, gasification can handle a wider variety of waste types, including plastics and organic materials, making it a flexible and attractive option for small-scale plants.

Landfill gas-to-energy (LFG) systems capture methane emissions from landfills, converting this potent greenhouse gas into usable energy. By extracting methane from landfills and burning it in turbines or internal combustion engines, small-scale WTE plants can generate electricity while preventing harmful emissions from escaping into the atmosphere. This method is particularly useful for existing landfills with substantial organic waste decomposition, as it utilizes gas that would otherwise go untapped. The energy generated from landfill gas can be used locally, either for power generation or to supplement heating systems, and it can serve as a reliable source of energy for communities near landfills.

The benefits of small-scale landfill WTE plants are numerous. They offer a dual advantage of waste reduction and energy production, providing a sustainable alternative to traditional waste disposal methods. By reducing the volume of landfill waste by up to 90%, these plants help extend the lifespan of landfills and mitigate the environmental impact of waste accumulation. Furthermore, by harnessing landfill gas and converting waste into electricity and heat, these plants reduce reliance on fossil fuels, contributing to a cleaner, more sustainable energy mix.

From an energy security perspective, small-scale WTE plants provide localized power generation, which reduces dependence on centralized grids. This makes them particularly valuable in urban districts prone to power outages or facing grid instability. These plants can operate as part of microgrids, ensuring that critical infrastructure, such as hospitals, schools, and government buildings, remain operational even during power disruptions. In addition to improving power reliability, small-scale WTE plants contribute to the overall resilience of the energy system by diversifying the energy sources and increasing local self-sufficiency.

Despite their potential, small-scale landfill WTE plants face certain challenges. Public perception of waste-to-energy technologies can be negative due to concerns about air pollution, particularly from incineration. To mitigate these concerns, modern WTE plants use state-of-the-art emissions control technology to minimize their environmental footprint, but they still face regulatory hurdles and community opposition. Another challenge is the variability of waste feedstocks, which can affect plant performance and energy output. Variations in waste composition require advanced sorting and preprocessing systems to ensure that the plant operates efficiently and generates consistent energy.

Looking ahead, several innovations are set to improve the efficiency and sustainability of small-scale landfill WTE plants. Plasma arc gasification, a next-generation waste conversion technology, uses extremely high temperatures to break down waste into clean syngas with minimal emissions, offering a cleaner alternative to traditional methods. Additionally, carbon capture and utilization (CCU) technologies are being integrated into some WTE plants to capture CO2 emissions, reducing their environmental impact while also enabling the reuse of captured carbon for industrial purposes. Hybrid systems that combine waste-to-energy with renewable energy sources, such as solar or wind, are also becoming more common, helping to increase the overall energy reliability and reduce the plant’s carbon footprint.

Ultimately, small-scale landfill waste-to-energy plants offer a valuable solution for urban districts struggling with waste management and power reliability. By transforming landfill waste into a renewable energy resource, these plants support local energy needs while addressing environmental concerns. As technology advances, and as urban areas continue to grapple with the challenges of waste disposal and energy supply, the role of waste-to-energy systems will become increasingly important in creating resilient, sustainable cities.

As small-scale landfill waste-to-energy (WTE) plants evolve, their role in urban energy systems will continue to expand, driven by technological advancements, environmental goals, and the growing need for sustainable waste management solutions. As cities face increased pressure to reduce landfill waste and improve energy reliability, the integration of WTE systems offers a practical, scalable solution for both power generation and waste reduction. These plants not only help mitigate the environmental impact of landfills but also contribute to energy diversification and carbon footprint reduction.

In addition to the key technologies of incineration, gasification, and landfill gas recovery, further improvements in small-scale WTE plants are being driven by a focus on efficiency, fuel flexibility, and environmental impact. Advanced combustion and thermal treatment technologies are being developed to maximize the energy output from waste, increase operational efficiency, and reduce emissions. For instance, fluidized bed combustion systems, which use a bed of sand or other granular material to enhance the combustion process, can handle waste materials with high moisture content, such as food waste or certain industrial by-products, that traditional incinerators struggle with. These systems offer a more flexible, cost-effective solution for small-scale WTE plants in urban districts where waste composition varies widely.

Another innovation gaining traction in WTE technologies is the use of supercritical steam cycles in small-scale plants. In traditional subcritical steam turbines, steam is generated at lower pressure and temperature, limiting overall efficiency. However, supercritical steam cycles operate at higher pressures and temperatures, allowing the steam to have more energy, which is then converted into more electricity. This significantly increases the efficiency of small-scale WTE plants, making them more competitive in the energy market. This technology has historically been used in large, central power plants but is now being scaled down for smaller applications, helping to meet the increasing energy demand from urban districts while reducing operational costs.

Fuel flexibility remains a major focus for small-scale landfill WTE plants. Waste-to-energy systems are typically fueled by municipal solid waste, but there is growing interest in using alternative fuels, including biomass and plastic waste. As cities look to move away from single-use plastics, converting waste plastics into fuel through pyrolysis or gasification could provide a cleaner, more efficient energy source, while also addressing growing concerns over plastic pollution. Additionally, some WTE plants are exploring the use of co-firing with renewable fuels like wood chips or agricultural waste, which helps lower emissions and provide a reliable, continuous fuel supply. This co-firing strategy helps optimize fuel usage and reduce the environmental impact of traditional waste processing methods, especially in urban areas with abundant biomass resources.

The environmental impact of small-scale landfill WTE plants is increasingly being mitigated through the integration of carbon capture, utilization, and storage (CCUS) technologies. As carbon emissions are a key concern for waste-to-energy operations, capturing CO2 produced during the combustion or gasification process can help reduce the overall carbon footprint of these plants. The captured carbon can either be stored underground (carbon sequestration) or utilized in commercial applications, such as creating synthetic fuels, or in manufacturing materials like concrete. Some innovative systems are even working on using the captured CO2 to create value-added products like algae-based biofuels or chemicals, offering a potential revenue stream in addition to the energy produced.

Furthermore, the hybridization of small-scale landfill WTE plants with renewable energy technologies, such as solar, wind, and battery storage, is becoming a growing trend. By pairing waste-to-energy with renewable power generation, these plants can provide a more stable and resilient energy supply to urban districts. For instance, during periods when landfill waste generation is lower or the WTE plant is undergoing maintenance, solar or wind power can help meet electricity demand, while energy storage systems can smooth out fluctuations in supply. This hybrid approach enables the integration of multiple energy sources, creating a more reliable, sustainable, and flexible energy system that is resilient to grid disruptions and increases energy independence for urban districts.

Small-scale WTE plants are also becoming more digitally connected and data-driven, using sensors, artificial intelligence (AI), and predictive analytics to improve operational performance and reduce maintenance costs. These systems enable plant operators to monitor waste composition, optimize combustion or gasification processes, and predict when equipment might need maintenance or repair, improving plant efficiency and reducing downtime. Additionally, data from these systems can be used to inform waste management strategies, helping cities better manage waste streams and optimize resource recovery.

The role of microgrids is becoming increasingly important in urban energy strategies. Small-scale WTE plants integrated into microgrids can operate independently or in coordination with the larger grid, providing reliable electricity during power outages or periods of peak demand. This decentralized model increases energy resilience, as microgrids are less vulnerable to widespread grid failures. By combining WTE technologies with storage, renewable sources, and digital management systems, urban districts can create self-sustaining energy systems that reduce dependency on the central grid and improve energy security for communities.

Despite the many advancements in technology and the growing importance of small-scale WTE plants, regulatory and community acceptance remain critical challenges. Local governments often need to balance waste-to-energy projects with public concerns about air quality and waste management. Effective policy, clear regulatory frameworks, and ongoing community engagement are key to ensuring the success of these projects. Public education and transparent communication about the environmental benefits, safety measures, and technological improvements in WTE facilities can help build trust and support for these systems in urban districts.

In conclusion, small-scale landfill waste-to-energy plants will continue to play an essential role in urban energy systems as cities move toward greater sustainability, waste reduction, and energy resilience. With advances in fuel flexibility, efficiency, hybrid technologies, and carbon capture, these plants offer an attractive solution for turning waste into a valuable energy resource. As technological innovations evolve and regulatory frameworks support their growth, small-scale WTE plants will become an even more integral part of the global transition to cleaner, more resilient urban energy systems.

As the demand for sustainable energy and waste management solutions continues to grow, small-scale landfill waste-to-energy (WTE) plants are positioned to play an increasingly important role in the future energy landscape. These plants provide an effective means to manage municipal solid waste (MSW) while also addressing power reliability challenges faced by urban districts. With the combination of waste reduction, renewable energy generation, and reduced environmental impact, small-scale WTE facilities are emerging as a key component of a circular economy.

Further advancements in technology are likely to refine the efficiency and performance of small-scale landfill WTE plants. For example, advanced combustion technologies such as catalytic combustion or oxygen-enriched combustion are gaining traction in small-scale plants. These technologies help achieve more complete combustion of waste materials at lower temperatures, resulting in fewer pollutants and higher energy output. Oxygen-enriched combustion, in particular, enhances the combustion process by increasing the oxygen content in the furnace, allowing for more efficient energy recovery and reducing the formation of nitrogen oxides (NOx), which are a common pollutant in conventional incineration.

Waste sorting and pre-processing technologies are also evolving to improve feedstock quality and efficiency in small-scale WTE plants. By better sorting waste materials before they enter the processing phase, plants can ensure that only the most suitable materials, such as high-calorific-value waste, are burned or gasified. This can significantly improve energy efficiency while reducing the environmental impact. Advanced sensor systems and AI-powered sorting algorithms can automate this process, increasing the accuracy and speed of waste separation, as well as identifying potentially harmful or hazardous materials before they reach the processing stage.

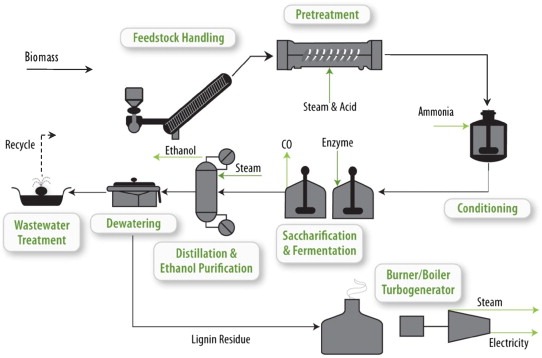

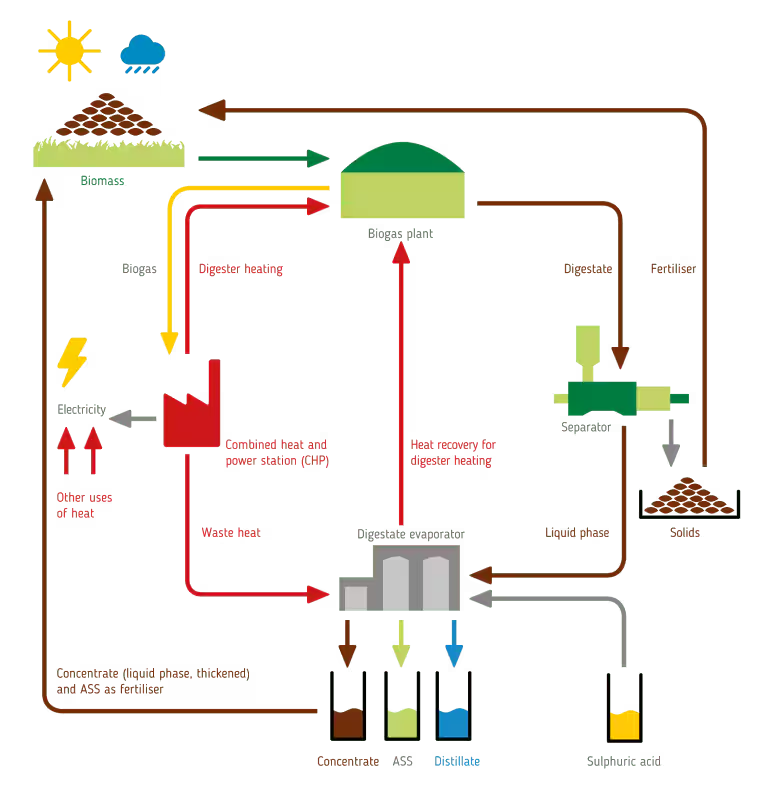

Another emerging trend is the use of biological waste-to-energy (bio-WTE) technologies, which harness the natural decomposition process of organic waste to generate energy. Anaerobic digestion is one of the most well-known methods, in which organic waste is broken down by microorganisms in an oxygen-free environment to produce biogas (primarily composed of methane). This biogas can then be used for electricity generation in gas engines or turbines, providing a cleaner alternative to traditional incineration. The beauty of anaerobic digestion is that it not only produces energy but also produces valuable by-products such as digestate, which can be used as a fertilizer or soil conditioner. Small-scale bio-WTE systems are particularly suited for urban districts with significant organic waste fractions, such as food scraps or yard waste, and could help cities reach their sustainability goals while reducing methane emissions from landfills.

Distributed generation and modular WTE systems are becoming increasingly important as urban energy needs shift toward decentralized, localized power sources. Traditional large-scale WTE plants often face logistical challenges related to waste transportation, land availability, and high initial capital investment. Small-scale, modular WTE systems, however, are more adaptable and can be deployed in urban environments where land is limited and waste streams are more localized. These modular systems can be customized to fit the specific needs of an urban area, taking into account the volume and composition of waste, as well as local energy demand. The flexibility of these systems makes them well-suited for integration into urban microgrids, where multiple small-scale WTE plants work in conjunction with other distributed energy resources, such as solar, wind, and energy storage.

Energy storage technologies will also play a critical role in the future of small-scale landfill WTE plants. These technologies allow excess energy generated by WTE plants to be stored and used when demand is high or when the plant is not producing energy due to fluctuating waste supply. Batteries, pumped hydro storage, and thermal energy storage systems are just some examples of energy storage solutions that can be integrated with small-scale WTE plants to provide greater energy reliability and grid stability. For instance, thermal storage systems could store the excess heat generated during periods of low demand, which can then be used for electricity generation or district heating during peak demand times.

Hybrid systems that combine small-scale landfill WTE plants with other renewable energy technologies such as solar thermal and geothermal are increasingly being explored to provide a continuous, stable energy supply. In a hybrid WTE-solar thermal system, solar energy can supplement the waste-based energy generation by providing additional heat to the steam turbines, improving efficiency. Similarly, geothermal energy can be used to provide a base load supply of energy, supporting the WTE plant when waste generation or availability is low. This combination of renewable energy sources ensures that small-scale WTE systems are capable of delivering a more reliable and consistent power supply while contributing to carbon reduction efforts.

The future of small-scale landfill WTE plants also looks promising in terms of digitalization and smart grid integration. By leveraging Internet of Things (IoT) devices, big data analytics, and artificial intelligence (AI), WTE plants will be able to optimize operations and minimize waste in real-time. IoT sensors can monitor key parameters such as temperature, pressure, and gas composition, sending this data to centralized control systems where AI algorithms analyze it to make predictive adjustments to plant operations. This allows for better decision-making, improved energy efficiency, and reduced operational costs. Moreover, the integration of WTE plants with smart grids enables more dynamic and flexible energy distribution, where the energy generated from WTE systems can be distributed to the grid or used locally as needed, depending on real-time demand and supply conditions.

Policy and regulatory frameworks will continue to shape the development and deployment of small-scale WTE plants. Governments around the world are implementing stricter regulations on waste management, emissions, and carbon reduction. To remain competitive and meet these evolving standards, small-scale WTE plants will need to continually innovate and adopt cleaner, more efficient technologies. Incentive programs, carbon credits, and renewable energy standards may provide financial support to accelerate the deployment of small-scale WTE systems, particularly in regions where waste management is a significant challenge.

In conclusion, small-scale landfill waste-to-energy plants offer a versatile and sustainable solution for urban districts, addressing both waste management and energy reliability issues. With advancements in technology, regulatory support, and integration into the broader energy system, these plants are poised to play a critical role in the transition to cleaner, more resilient urban energy infrastructures. As cities continue to embrace circular economy principles and seek ways to minimize their environmental footprint, the role of small-scale landfill WTE systems will only become more essential, ensuring that urban waste becomes a valuable resource for sustainable energy production.

Small Scale Power Plant for dairy farms

Small-scale power plants for dairy farms are emerging as an innovative solution to address both energy consumption and waste management challenges in the agricultural sector. Dairy farms, like many other agricultural operations, require a substantial amount of energy to run equipment such as milking machines, refrigeration systems, heating systems, and lighting. However, they also produce significant amounts of organic waste, including manure, which presents an opportunity to generate renewable energy locally and reduce operational costs.

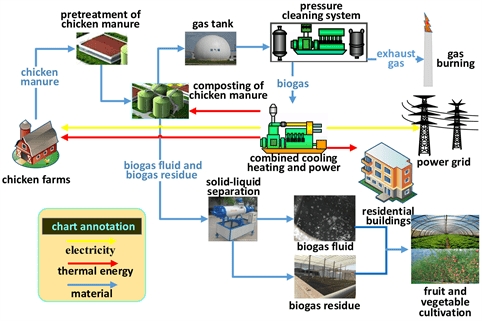

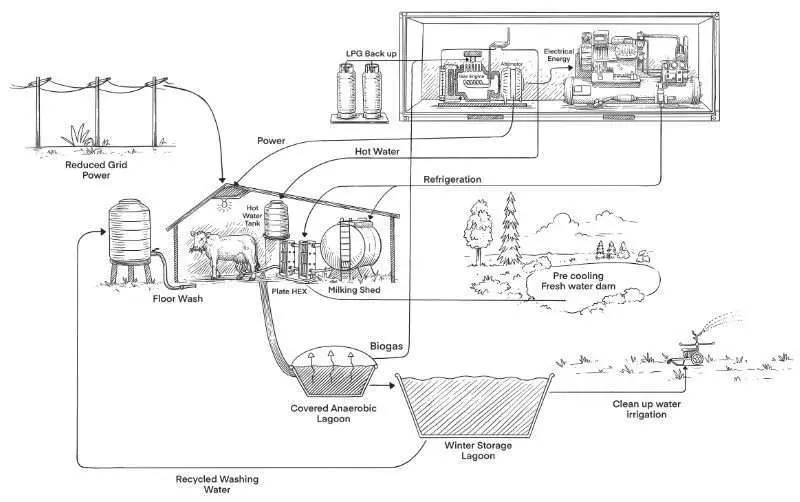

One of the most effective ways small-scale power plants are being integrated into dairy farms is through biogas production from anaerobic digestion of manure and other organic farm waste. In this process, manure is collected and placed in an anaerobic digester, where bacteria break down the organic material in an oxygen-free environment, producing biogas—a mixture of methane and carbon dioxide. This biogas can be used to fuel combined heat and power (CHP) systems, providing both electricity and heat for the farm.

The biogas-powered CHP system typically includes a gas engine or turbine that converts the biogas into electricity, which can either be used on-site to power farm operations or sold back to the local grid. The heat generated during electricity production can be used for various farm needs, such as heating barns or water, thus reducing the need for external energy sources. This approach can help dairy farms become more self-sufficient in terms of energy, significantly lowering their dependence on the grid and providing a reliable, renewable energy source for daily operations.

In addition to biogas, small-scale power plants on dairy farms can also utilize solar energy or wind energy. By installing solar panels on barn roofs or in open areas, dairy farms can capture sunlight and convert it into electricity, which can supplement or even entirely offset their energy needs. Wind turbines, particularly in rural areas with consistent wind patterns, can also provide a viable renewable energy source to power the farm’s operations.

Small-scale biomass power plants can be another useful option for dairy farms, especially when combined with agricultural residues, such as leftover crop material or feedstock. Biomass can be burned or converted into gas to produce heat and electricity, helping dairy farms to manage waste while simultaneously generating power. Some farms also use digestate, the solid byproduct from anaerobic digestion, as a fertilizer or soil amendment, reducing the need for synthetic fertilizers and contributing to sustainable farming practices.

One significant benefit of small-scale power plants on dairy farms is that they can help to mitigate the environmental impact of manure and other waste products. Manure left untreated can release methane—a potent greenhouse gas—into the atmosphere, but by capturing this methane for energy production, dairy farms can reduce their carbon footprint while simultaneously improving waste management. Biogas production also minimizes the risk of water and soil pollution that can result from poorly managed manure disposal practices.

Small-scale power plants on dairy farms can also improve economic resilience. By generating their own renewable energy, dairy farms can lower their energy bills, which often represent a significant portion of operating costs. Additionally, excess energy can be sold back to the grid, providing a potential revenue stream and enhancing the farm’s profitability. In areas with feed-in tariffs or other incentive programs for renewable energy, small-scale power plants can provide dairy farms with a financial boost.

Another important aspect is the role these power plants can play in energy security for rural areas. Many dairy farms are located in regions that may be prone to power outages or unreliable grid access, making a local power generation solution even more critical. A small-scale power plant ensures that the farm can continue operations even during grid disruptions, providing uninterrupted service for milking, refrigeration, and other essential tasks that are time-sensitive and need a continuous power supply.

The integration of renewable energy technologies on dairy farms can also play an important part in enhancing sustainability. These systems reduce the reliance on fossil fuels and external energy sources, which contribute to air pollution and environmental degradation. Additionally, the holistic approach of using organic waste (manure) to produce energy can significantly contribute to a farm’s environmental footprint reduction, improving the overall sustainability of the dairy industry.

Despite the many advantages, there are some challenges and considerations when implementing small-scale power plants on dairy farms. The initial capital investment required for the installation of biogas digesters, solar panels, or wind turbines can be significant. However, various subsidies, grants, and financing options are available to assist farms in making these investments, especially in regions where renewable energy adoption is being actively promoted. Furthermore, the operation and maintenance of the equipment require ongoing effort and cost, including managing the anaerobic digestion process and ensuring that renewable energy systems are functioning efficiently.

The scalability of small-scale power plants is also an important factor to consider. Farms may need a power system that can adapt as their energy needs evolve. The installation of modular systems, where additional biogas or renewable energy capacity can be added as the farm grows, can provide the necessary flexibility to meet future demands.

Additionally, the regulatory environment for renewable energy generation may vary by region, and dairy farms need to ensure they comply with local regulations and permitting requirements when installing and operating their power plants. Regulations related to waste management, energy production, and emissions must all be carefully considered to ensure the farm’s operations remain in compliance.

Looking ahead, the integration of advanced energy storage systems could further enhance the efficiency and reliability of small-scale power plants on dairy farms. By using batteries or thermal energy storage systems, excess energy generated during periods of high production (e.g., sunny days for solar or windy days for wind energy) can be stored for use during periods of lower energy production or higher demand. This would make renewable energy systems even more reliable and reduce the farm’s reliance on the grid.

In conclusion, small-scale power plants on dairy farms present a promising solution to both energy and waste management challenges in the agricultural sector. By utilizing biogas, solar, wind, or biomass energy, dairy farms can improve their sustainability, reduce their environmental footprint, and achieve energy self-sufficiency. With the right support and technological innovations, these systems can provide dairy farms with the resilience and efficiency needed to thrive in a changing energy landscape. The ongoing development of renewable energy technologies, coupled with supportive policies and financial incentives, will continue to make small-scale power plants an attractive and economically viable option for dairy farms seeking to embrace sustainable energy practices.

Small-scale power plants for dairy farms not only offer energy independence but also enhance the economic viability and environmental sustainability of farm operations. These plants provide a practical solution for the growing demand for sustainable practices within agriculture, particularly in dairy farming, where energy costs can constitute a significant portion of the operational expenses. The ability to generate renewable energy on-site helps mitigate the volatility of energy prices, contributing to more stable financial planning and improving overall cost efficiency.

The adoption of biogas systems remains one of the most promising methods for generating energy on dairy farms, as it directly addresses the challenge of managing manure waste while also producing a valuable resource—energy. Anaerobic digestion systems can process manure from dairy cows, along with other organic waste materials such as crop residues or food waste, to produce biogas. This process not only helps manage the environmental issues associated with manure, such as odors and methane emissions but also recycles valuable nutrients back into the farm’s operations. The digestate that remains after the digestion process is rich in organic matter and can be used as a nutrient-rich fertilizer for crops, reducing the need for chemical fertilizers and promoting soil health.

Biogas-powered CHP systems on dairy farms can be configured to meet the farm’s specific energy needs. In addition to producing electricity, the heat generated during electricity production can be captured and used for heating barns, water systems, or milking parlors, making it a dual-purpose energy solution. This heat utilization is particularly valuable in colder climates where dairy operations require constant heating for both animal welfare and operational needs, reducing the demand for additional heating sources and helping to lower utility bills.

Beyond biogas, solar energy continues to be a growing option for dairy farms that have access to ample sunlight. Solar panels can be installed on barn roofs, open fields, or other available land areas to generate electricity during the day. Dairy farms can use this solar energy to meet their daily electricity demand, reducing reliance on the grid. Solar energy can be particularly effective when combined with battery storage systems, allowing the farm to store excess energy produced during sunny periods and use it during the night or cloudy days when solar generation is limited. This combination makes solar energy a flexible and reliable power source for small-scale dairy farms.

Similarly, wind power can play a complementary role, particularly for farms located in areas with consistent wind patterns. Small-scale wind turbines can harness the energy of the wind to generate electricity, contributing to the farm’s energy portfolio and providing a renewable energy source to offset grid reliance. While wind power may not always be as consistent as solar energy, in combination with biogas or solar power, it can contribute to a more diversified and reliable renewable energy solution.

Small-scale power plants for dairy farms also offer a potential avenue for carbon footprint reduction and sustainability. Dairy farms are often under pressure to reduce their greenhouse gas emissions, particularly methane, which is produced during the digestive process of cows and during manure decomposition. The conversion of methane into biogas for energy production reduces its release into the atmosphere and prevents it from contributing to global warming. Furthermore, by relying on renewable energy sources and reducing their dependency on fossil fuels, dairy farms can significantly lower their carbon emissions, meeting both regulatory requirements and environmental stewardship goals.

Moreover, small-scale power plants can enhance the resilience of dairy operations to external shocks such as grid outages, fuel price fluctuations, or extreme weather events. In rural areas, where power outages are more common, having an independent source of energy can ensure that critical operations—such as milking, refrigeration, and animal heating—continue uninterrupted. This resilience is increasingly important as climate change brings more frequent and severe weather events that could affect grid reliability, especially in agricultural areas.

The integration of smart technologies can further optimize the performance of small-scale power plants. IoT devices and smart meters can provide real-time monitoring of energy generation, consumption, and storage, allowing farm managers to adjust operations for maximum efficiency. AI-driven systems can predict energy needs, automatically adjusting energy production or usage to ensure that the farm runs smoothly and that energy is utilized optimally. For example, if the biogas plant produces more energy than needed during a certain period, the excess can be stored or sold back to the grid.

One of the challenges that dairy farms may face when adopting small-scale power plants is the initial investment required for infrastructure. However, with the availability of government incentives, subsidies, and financing options, many farms can offset the upfront costs. Incentive programs for renewable energy adoption, such as feed-in tariffs, tax credits, and low-interest loans, can help make the transition to renewable energy more affordable. Additionally, the operational savings and potential revenue from selling surplus energy back to the grid can offer a return on investment (ROI) that justifies the initial capital expenditure over time.

Another important consideration is the scalability of these systems. Small-scale power plants can be designed to match the energy needs of a farm, but as farms grow or energy demands change, the systems must be flexible enough to scale. The modular nature of many renewable energy technologies—such as biogas digesters, solar panels, and wind turbines—allows for gradual expansion, meaning that farms can increase their energy production capacity over time without needing to invest in entirely new systems. This scalability helps ensure that small-scale power plants remain a viable option as farms evolve.

Finally, community benefits should not be overlooked when considering small-scale power plants on dairy farms. These systems can create local jobs related to the construction, operation, and maintenance of renewable energy systems. Additionally, when farms generate surplus energy, they may have the opportunity to sell it back to the grid, benefiting the local power supply and contributing to the wider adoption of renewable energy in the region. By embracing renewable energy, dairy farms can be seen as leaders in sustainability, promoting a circular economy where waste is transformed into a valuable resource.

In conclusion, small-scale power plants on dairy farms present a comprehensive and sustainable solution to energy and waste management challenges in the agricultural sector. By utilizing renewable energy sources such as biogas, solar, and wind, dairy farms can reduce their energy costs, improve environmental sustainability, and increase resilience. With ongoing technological advancements, supportive policies, and innovative financing options, small-scale power plants will continue to offer dairy farmers a practical and economically viable path toward energy independence and sustainability. As the agricultural industry embraces renewable energy solutions, dairy farms will play a critical role in contributing to a more sustainable and resilient food production system.

As small-scale power plants on dairy farms evolve, the broader agricultural landscape is likely to witness a transformation in energy practices, with farms of all sizes increasingly adopting sustainable energy solutions. The integration of smart grid technologies and advanced renewable energy storage systems will play a critical role in this transformation, further enhancing the operational efficiency and energy security of dairy farms.

One of the next frontiers in optimizing small-scale power plants is the use of energy storage technologies. As mentioned earlier, battery storage systems offer the potential to store excess energy produced during periods of high renewable generation, whether from biogas, solar, or wind. Dairy farms can take advantage of this stored energy during peak demand periods or when energy production drops due to unfavorable weather conditions. In addition to battery storage, thermal energy storage can be utilized, where excess heat from the biogas-powered CHP systems or other renewable technologies can be stored and used for heating purposes, such as warming barns or water used for milking. This ensures that dairy farms can continue to operate efficiently even during periods of low energy generation.

Another development likely to emerge is the rise of hybrid power systems that combine multiple renewable energy sources to optimize energy production and supply. For example, biogas and solar hybrid systems could provide complementary energy. During sunny periods, solar energy can supplement the biogas generation, and during cloudy or nighttime hours, the biogas plant would take over. Similarly, wind and biogas hybrids could be implemented in regions with good wind resources, allowing the farm to diversify its energy mix and reduce dependency on a single renewable source. This hybrid approach improves the reliability and stability of the energy supply and can ensure that the farm has a consistent, renewable power source year-round.

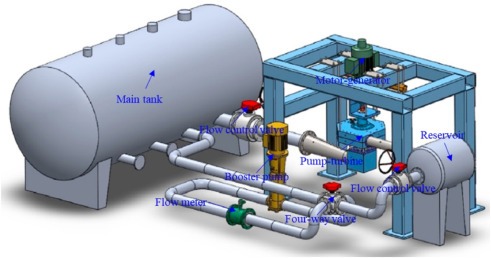

The implementation of energy management systems (EMS) will also become increasingly important. These systems integrate all the farm’s energy resources, including renewable energy, storage, and traditional energy sources, into a centralized control system. The EMS monitors and manages energy flow, ensuring that energy production and consumption are balanced and optimized. For example, if the biogas system is producing excess electricity, the EMS can direct that energy to storage or the grid, or alternatively, use the excess energy to meet non-essential farm needs, such as charging electric vehicles or powering auxiliary equipment. This system helps to avoid wastage, lower energy costs, and ensure that energy is used as efficiently as possible.

In addition to energy systems, sustainable farming practices will continue to evolve in parallel. As the focus on renewable energy increases, there will likely be a greater integration of precision agriculture technologies, such as smart sensors and AI-driven analytics to monitor soil health, water usage, and crop growth. This will complement the energy strategies by ensuring that farms not only generate their own energy but also use resources more efficiently, minimizing water waste, reducing the need for fertilizers, and enhancing crop yields.

Small-scale power plants for dairy farms also align well with the increasing demand for sustainability certification. As consumers become more aware of the environmental impact of food production, many dairy farms are exploring certification programs that recognize sustainable practices. By adopting renewable energy technologies, dairy farms can improve their environmental credentials, enhancing their appeal to environmentally conscious consumers. Eco-labels and sustainability certifications can become a key marketing tool for dairy producers, differentiating their products in the marketplace and increasing consumer trust.

As the technology surrounding renewable energy systems continues to improve, cost reductions are expected across the board. Biogas digesters, solar panels, wind turbines, and energy storage systems are becoming increasingly affordable, allowing more dairy farms to access these technologies. In addition, the ongoing development of more efficient biogas production processes, lower-cost storage options, and innovative financing mechanisms (e.g., pay-as-you-go solar or green bonds) will make small-scale power plants even more economically accessible.

Microgrid systems—which allow a farm to operate independently or in conjunction with the grid—are also likely to become more common. A microgrid enables dairy farms to generate and manage their own electricity, ensuring that they can operate autonomously during power outages or supply disruptions. Microgrids can be equipped with energy storage systems and flexible controls to integrate renewable energy, providing the farm with not only energy security but also greater autonomy and cost savings.

Further advancements in biogas technology are expected to enhance the efficiency of biogas production on dairy farms. New developments in high-temperature anaerobic digestion and the use of co-digestion, where additional organic waste such as food scraps, agricultural residues, or other farm by-products are added to the digester, will improve gas yield and overall system efficiency. These innovations will help dairy farms maximize energy production while also providing enhanced waste management solutions. Furthermore, the growth of biogas-to-grid technologies, where biogas is converted into high-quality biomethane that can be injected into the natural gas grid, could offer dairy farms an additional revenue stream, allowing them to sell excess energy or gas.

On the regulatory front, policy incentives and subsidies for renewable energy adoption will continue to evolve. Governments around the world are increasingly focused on achieving carbon reduction targets, and many have implemented programs designed to support sustainable energy transitions in agriculture. Dairy farms adopting small-scale power plants can take advantage of these programs to help defray the upfront costs of installation. In regions where carbon trading or carbon credit markets are in place, dairy farms may also be eligible to participate, earning credits for reducing methane emissions through biogas systems or contributing to overall greenhouse gas reductions by using renewable energy.

Finally, collaboration between agricultural stakeholders, energy providers, and technology developers will be essential for the continued success of small-scale power plants on dairy farms. Partnerships between local utilities and dairy farmers could facilitate the development of community-based energy networks or energy cooperatives. This approach could help streamline the process of integrating small-scale renewable energy systems, making it easier for farms to access funding, technical expertise, and regulatory support.

In conclusion, the future of small-scale power plants on dairy farms looks increasingly bright as technologies advance, costs decrease, and regulations continue to support renewable energy adoption. The combination of biogas, solar, wind, and energy storage technologies, along with smart grid systems and hybrid solutions, will provide dairy farmers with a reliable, cost-effective, and sustainable way to meet their energy needs. With the right support from policy, financing, and technology, small-scale power plants will not only help dairy farms become more self-sufficient but will also make them leaders in the sustainable agricultural movement, contributing to a cleaner, more resilient energy future.

As small-scale power plants for dairy farms continue to evolve and gain traction, the potential for scalability and replicability will play a crucial role in expanding their adoption beyond individual farms. The concept of decentralized energy production, where energy is generated locally and consumed within the community, is gaining momentum as a model for sustainable farming. This model could transform rural areas, where many dairy farms are located, into energy hubs, supporting the broader adoption of renewable energy technologies and reducing reliance on centralized power grids.

Community-Based Energy Solutions

One of the key aspects of this transformation is the potential for community-based renewable energy projects, where multiple dairy farms and other local agricultural operations share the benefits of small-scale power plants. For instance, a cluster of dairy farms could install a cooperative biogas plant that processes manure and organic waste from several farms, producing biogas that is used to generate electricity and heat. The electricity produced could be distributed among the farms in the cooperative, helping each participant reduce their energy costs and improve their sustainability. The collective approach also spreads the upfront costs of renewable energy infrastructure, making it more affordable for individual farms.

Additionally, these community-based projects could integrate with larger local energy systems, such as microgrids or community-owned power plants. Microgrids are localized energy systems that can operate independently from the main grid or be connected to it, providing increased energy security and reliability. By pooling resources, dairy farms and neighboring farms could take advantage of shared renewable energy generation, storage solutions, and smart grid technologies that improve efficiency and lower costs.

In this scenario, the renewable energy produced could also be sold to local utilities or consumers, creating new economic opportunities for dairy farmers. If the power plant generates more energy than needed for farm operations, the surplus could be exported to the local grid, contributing to the broader renewable energy supply in the region. This not only generates additional income but also promotes the localization of energy markets, reducing transmission losses and enhancing energy resilience at the community level.

Technological Innovation and Integration

Technological innovation will be a driving force in making small-scale power plants even more efficient, cost-effective, and adaptable to the needs of dairy farms. As the demand for renewable energy grows, new breakthroughs in energy storage, energy conversion, and waste-to-energy technologies will further improve the feasibility of small-scale power plants.

For example, biogas production is likely to become more efficient with the development of advanced anaerobic digestion technologies. High-efficiency digesters can process manure and organic waste faster and produce more biogas, while modular biogas systems offer flexibility in scaling up capacity as the energy needs of a farm grow. The integration of AI and machine learning into biogas plants could optimize the anaerobic digestion process by continuously adjusting parameters such as temperature, feedstock composition, and microbial activity to maximize gas production. In addition, biogas purification technologies will enable the conversion of biogas into biomethane, a cleaner and more versatile form of natural gas that can be injected into the national grid or used for vehicle fuel.

Solar panel efficiency is also improving steadily. New technologies, such as bifacial solar panels (which can capture sunlight on both the front and back sides), perovskite solar cells, and thin-film solar modules, are expected to drive down the cost of solar energy production, making it even more accessible for small-scale dairy farms. As solar energy becomes cheaper and more efficient, the return on investment for solar panel installations will improve, allowing farmers to recoup their costs more quickly and invest in other renewable energy technologies.

Wind energy will also benefit from ongoing advancements. Small-scale wind turbines are becoming more efficient and cost-effective, with designs that are better suited to low-wind-speed environments—making wind a viable option for farms that might not have been able to utilize it before. As turbine technology improves, the energy generation capacity of small-scale wind systems will increase, helping to meet the farm’s energy needs and providing another source of renewable power.

Moreover, the integration of energy storage systems, particularly advanced battery technologies, will address one of the major challenges of renewable energy generation—intermittency. Lithium-ion batteries, solid-state batteries, and flow batteries are all advancing rapidly in terms of efficiency, cost, and lifespan. These energy storage systems will allow dairy farms to store excess power produced by solar, wind, or biogas systems, and use it during periods of low generation or high demand, ensuring a continuous and reliable energy supply.

Policy and Regulatory Landscape

The regulatory landscape will be key to accelerating the adoption of small-scale power plants on dairy farms. Government incentives and subsidy programs are already playing a significant role in reducing the financial burden of installing renewable energy systems. However, as renewable energy technologies continue to improve, policymakers must create more comprehensive long-term frameworks that ensure the ongoing viability of these systems.

This could include expanding the availability of financial incentives for renewable energy adoption, such as tax credits, grants, and low-interest loans. Programs that reward farms for reducing emissions—such as carbon credits or participation in carbon markets—could provide additional income streams for farms with biogas or other renewable energy systems. By expanding incentives for renewable energy adoption and waste-to-energy technologies, governments can help dairy farms achieve greater energy independence while also meeting their environmental goals.

Furthermore, regulations that promote energy grid integration will enable dairy farms to connect their small-scale power plants to local grids more easily. This could include simplifying the process for selling excess energy back to the grid through net metering or other compensation programs, and ensuring that the grid can accommodate the distributed generation of renewable energy.

Another important regulatory consideration is the creation of policies that support biogas production and waste management on farms. Regulations that make it easier to capture and utilize methane emissions from dairy farm operations could further incentivize the adoption of biogas systems. By supporting the development of biogas infrastructure and reducing barriers to entry, policymakers can encourage more dairy farms to participate in the renewable energy transition.

Consumer Demand and Market Trends

Increasing consumer demand for sustainably produced food is another powerful force driving the adoption of renewable energy technologies on dairy farms. As awareness of the environmental impact of food production grows, more consumers are seeking products from farms that prioritize sustainable practices. Dairy farms that invest in renewable energy can differentiate themselves in the market by promoting their environmental stewardship and commitment to sustainability. This is especially true for consumers who are willing to pay a premium for eco-friendly products.

In addition, the rise of plant-based alternatives to dairy products may prompt traditional dairy farms to reimagine their operations in order to stay competitive. By incorporating renewable energy systems and other sustainable farming practices, dairy farms can improve their sustainability profile and appeal to both traditional consumers and those seeking greener alternatives. The ability to market energy-efficient operations and environmentally friendly practices can strengthen a farm’s brand and improve its marketability.

The Future of Small-Scale Power Plants on Dairy Farms

In the coming years, small-scale power plants on dairy farms will likely become a common feature across the agricultural landscape. As renewable energy technologies become more affordable, efficient, and scalable, dairy farms will have a greater opportunity to decarbonize their operations, reduce costs, and enhance their resilience to energy disruptions. By embracing renewable energy, dairy farmers will not only benefit economically but will also contribute to a cleaner, more sustainable food production system.