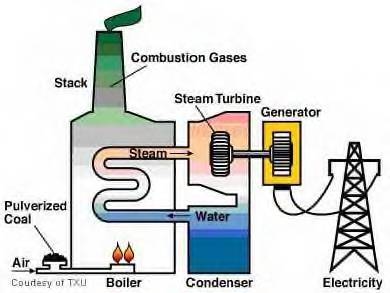

Generating Electricity using Heat from Oil Refining Processes: Generating electricity from steam involves a process called thermodynamic power generation, often using steam turbines as the primary mechanism. This process converts the energy in steam, usually created by boiling water using heat from burning fuel, nuclear reactions, or geothermal energy, into mechanical energy, which is then transformed into electrical energy.

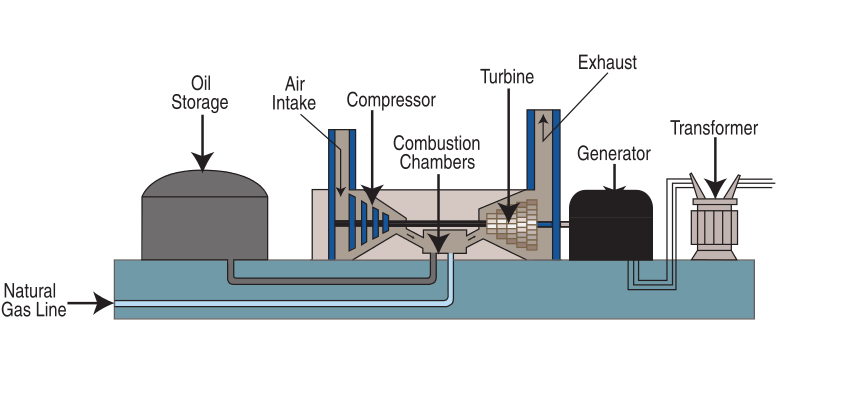

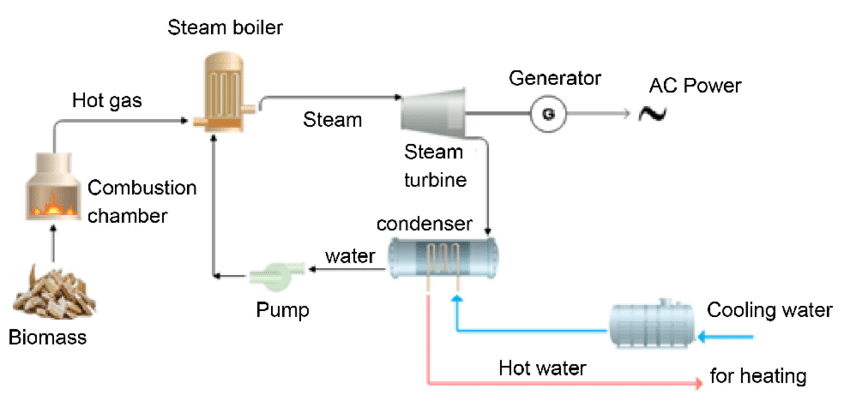

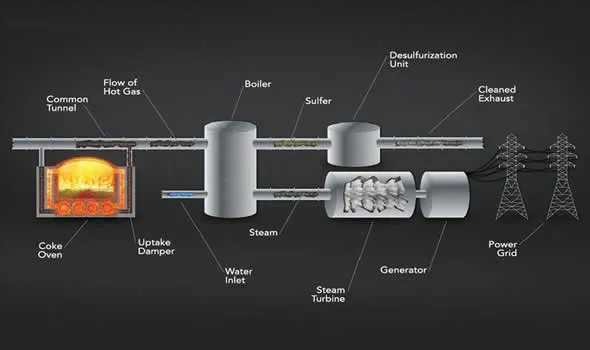

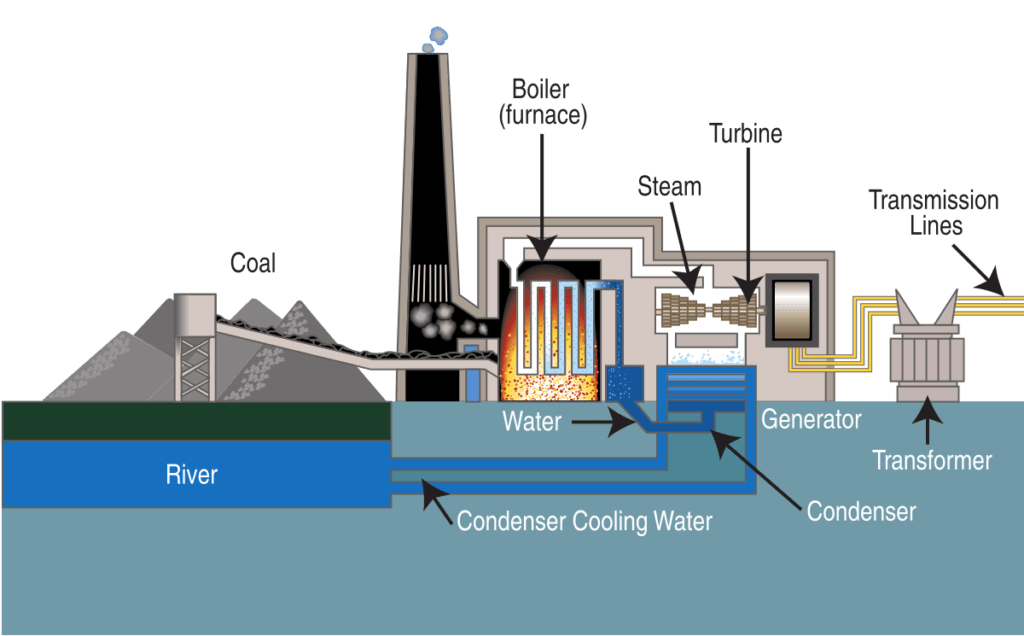

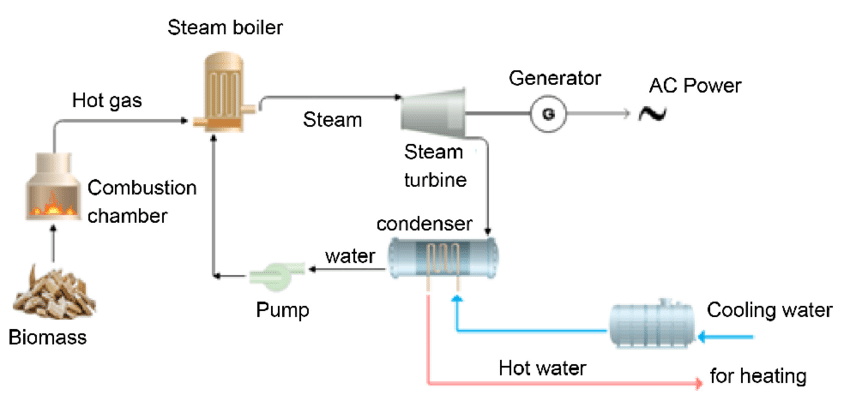

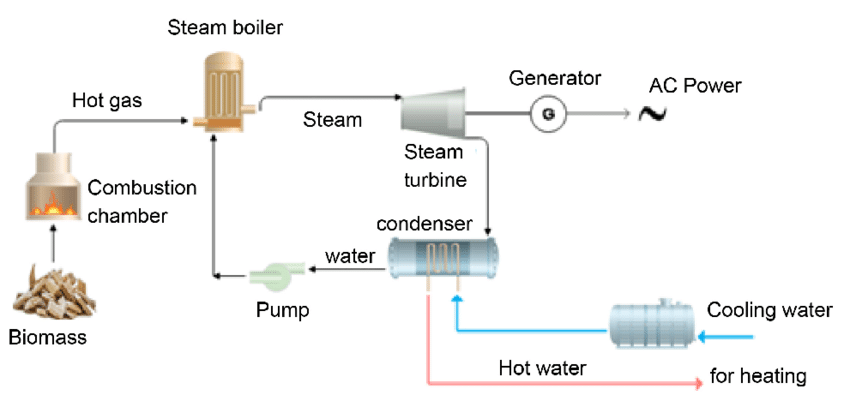

The basic steps to generate electricity from steam start with the heating of water to produce steam. This can be done in a boiler or a heat exchanger, depending on the system’s design. In a boiler, fuel such as coal, natural gas, oil, or even biomass is burned to generate heat. In a nuclear power plant, heat is produced from nuclear fission reactions. Alternatively, in geothermal power plants, heat from the Earth’s natural reservoirs is used to convert water into steam.

Once steam is produced, it is directed into a steam turbine. The turbine consists of blades mounted on a shaft. As steam flows over the blades, the force of the steam causes the blades to spin. This mechanical energy of the rotating turbine blades is then transferred to a generator connected to the turbine. The generator uses the mechanical energy to rotate a magnetic field within a set of coils, inducing an electrical current through electromagnetic induction.

The steam turbine operates based on the principles of thermodynamics, particularly the Rankine cycle. In the Rankine cycle, steam is generated at high pressure and temperature, expanded in the turbine, and then condensed back into water in a condenser. This process of expansion and condensation allows for a continuous cycle of energy conversion. The condenser cools the steam, usually by passing it through cooling towers or heat exchangers, and converts it back into liquid water, which is then pumped back into the boiler to be reheated and turned back into steam.

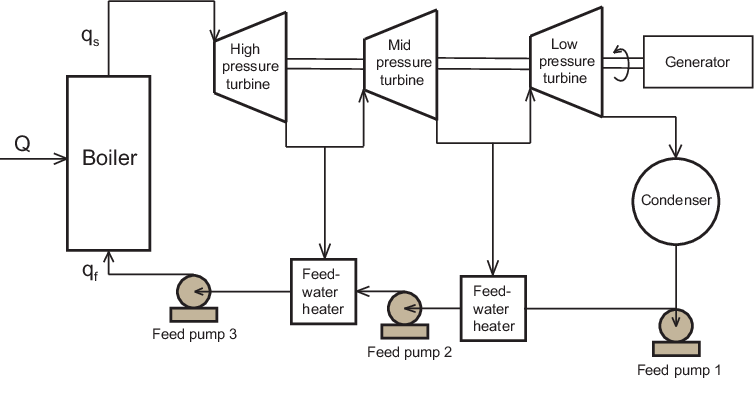

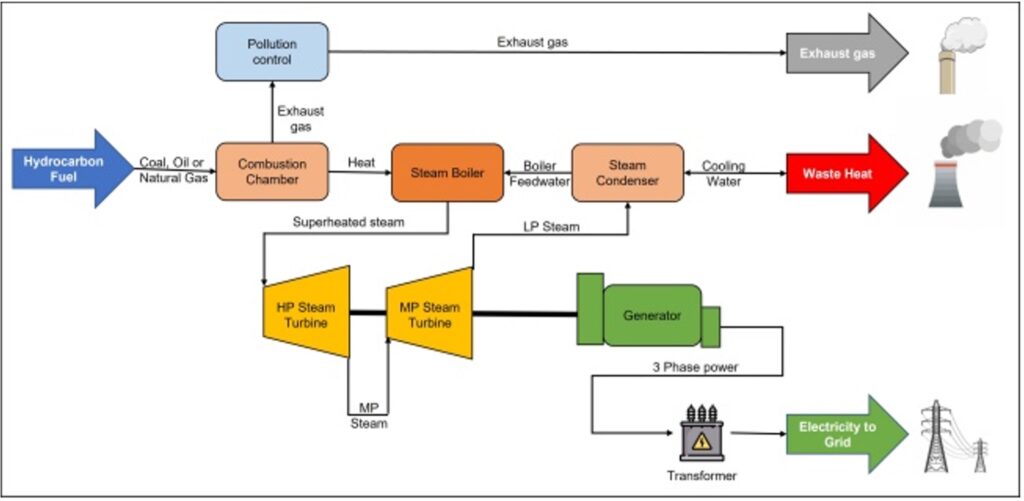

In larger power plants, multiple stages of turbines are often used to maximize efficiency. This is known as a multi-stage turbine system, where steam passes through several turbines at different pressure levels. The steam’s pressure is gradually reduced as it moves through each turbine, extracting more energy. In many systems, the steam is also reheated between stages to maintain its energy content and prevent too much pressure drop in the turbines.

The efficiency of a steam power plant is largely determined by how well it can maintain the pressure and temperature of the steam as it moves through the system, as well as the efficiency of the turbine and the generator. Steam turbines are capable of converting a large percentage of the heat energy into mechanical work, but some energy is always lost in the process, primarily due to heat dissipation in the condenser and the inevitable frictional losses in the turbine and other moving parts.

To improve the efficiency of electricity generation, some plants incorporate regenerative systems, where part of the steam or exhaust gases are used to preheat incoming water before it enters the boiler. This reduces the amount of fuel needed to heat the water to the required steam temperature, leading to a more energy-efficient process.

Once the electrical energy is generated, it is transmitted through power lines and distributed to homes and businesses. The voltage of the generated electricity is stepped up by a transformer for long-distance transmission, reducing energy loss during transport. At the point of use, the voltage is stepped down again to a level suitable for household or industrial applications.

In addition to conventional coal, oil, and natural gas power plants, steam turbines are also widely used in renewable energy sources. Geothermal power plants use naturally occurring steam from deep within the Earth to generate electricity, while solar thermal plants use mirrors or lenses to concentrate sunlight and heat a fluid that produces steam. These renewable methods of generating steam offer a more sustainable way to generate electricity without burning fossil fuels.

Overall, generating electricity from steam is a well-established and versatile technology that continues to be used in power plants around the world, with ongoing research focused on improving its efficiency, reducing emissions, and expanding its use in renewable energy systems.

In the process of steam-based electricity generation, one of the key elements that influence performance is the design and operation of the steam turbine itself. The turbine is designed to convert the thermal energy from steam into mechanical energy efficiently. This is achieved by careful engineering of the turbine blades, which are shaped to extract the maximum amount of energy from the steam as it flows over them. The steam enters the turbine under high pressure and high temperature, and as it expands and loses pressure, it passes through different stages of turbines with progressively smaller blades. These stages allow for a more gradual and efficient transfer of energy.

After passing through the turbines, the steam exits at lower pressure and temperature. To complete the cycle, the steam must be condensed back into water in a process that typically occurs in a condenser. The condenser cools the steam, causing it to lose its heat and turn back into liquid form. In most systems, water from nearby rivers, lakes, or cooling towers is used to absorb the excess heat from the steam, often at a temperature below 40°C to 50°C, depending on the local climate and environmental regulations.

The condensed water, now in liquid form, is collected and pumped back into the boiler to be reheated and transformed into steam once again. This closed-loop system helps to conserve water and reduce environmental impacts, though some plants may use once-through cooling systems where water is used only once before being returned to its source.

As part of the overall power plant system, the generator that is coupled to the turbine plays a critical role in converting the mechanical energy into electrical energy. The generator consists of a rotating shaft and a set of stationary coils or magnets. As the turbine shaft rotates, it turns the generator’s rotor, creating a changing magnetic field within the coils, which induces an electrical current through the wires by the principle of electromagnetic induction. This electrical current is then transferred through transformers, where its voltage is adjusted to be suitable for transmission over long distances. Once the electricity reaches its destination, transformers step down the voltage again for distribution to households or businesses.

Generating Electricity using Heat

A significant part of the energy generated by the steam turbine system is often lost as heat due to the second law of thermodynamics, which states that some energy is always lost to the surroundings. Efficiency improvements, such as the integration of combined-cycle power plants, aim to capture and utilize some of this waste heat. In combined-cycle systems, the exhaust gases from the gas turbine are used to heat water, which then produces additional steam to drive a steam turbine. This significantly increases the overall efficiency of the plant, sometimes by as much as 50% or more compared to a simple steam turbine system.

Another emerging trend in steam-based electricity generation is the implementation of supercritical and ultra-supercritical steam cycles. These systems use steam at higher pressures and temperatures than conventional methods, resulting in higher thermodynamic efficiency and lower emissions. By using steam at supercritical pressures (above 22.1 MPa) and ultra-supercritical pressures (above 30 MPa), the thermal efficiency of power plants can be greatly improved, allowing them to generate more electricity from the same amount of fuel. These advanced steam turbines are typically found in modern coal-fired power plants, as well as some nuclear and combined-cycle plants.

Environmental concerns have led to the development of cleaner technologies for generating electricity from steam. The burning of fossil fuels in traditional steam plants releases carbon dioxide (CO₂) and other greenhouse gases into the atmosphere, contributing to climate change. To mitigate these effects, power plants have started implementing carbon capture and storage (CCS) technologies, which capture CO₂ emissions from the exhaust gases and store them underground or use them in industrial processes. Additionally, the growing adoption of renewable energy sources such as geothermal, solar thermal, and biomass for generating steam offers a way to produce electricity with fewer environmental impacts.

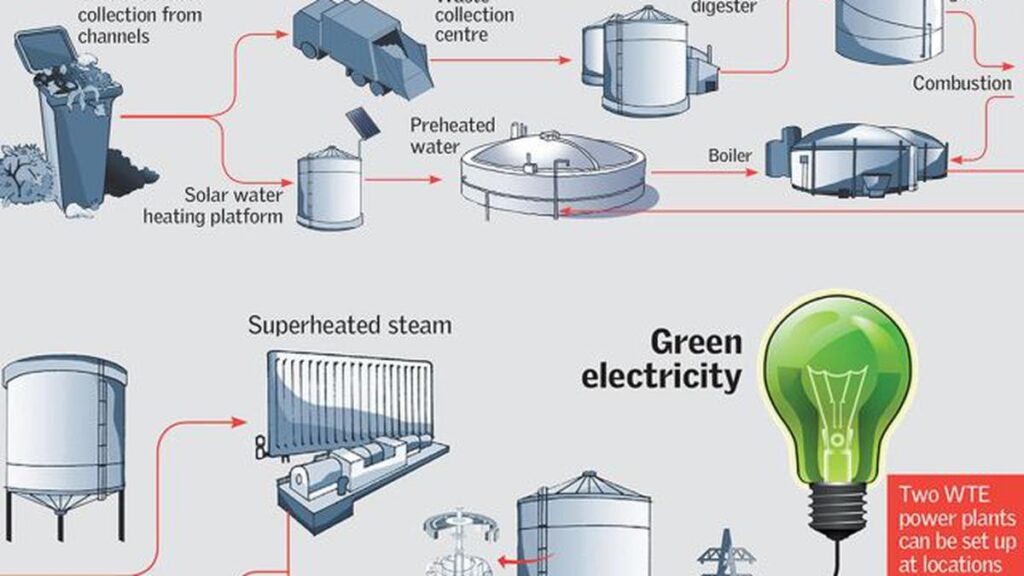

While fossil fuels continue to dominate global electricity generation from steam, the trend toward cleaner energy solutions is growing. Geothermal plants, for example, utilize steam sourced from the Earth’s natural heat, which is renewable and produces no direct emissions. Solar thermal power plants use mirrors or lenses to concentrate sunlight, heating a fluid that can generate steam. In some regions, biomass and waste-to-energy plants are being developed to convert organic materials into steam, contributing to reducing waste while generating power.

In summary, the generation of electricity from steam is a well-established and essential method of power generation, with significant advancements in turbine technology, heat recovery systems, and renewable energy integration. The efficiency of the process has been continuously improved over the years, and innovations such as combined-cycle plants and ultra-supercritical steam systems are pushing the boundaries of what is possible. As global energy demands rise and environmental concerns increase, the role of steam-based power generation in providing a reliable and cleaner energy supply will continue to evolve.

As the world moves towards more sustainable energy practices, the role of steam-based electricity generation remains pivotal, albeit with shifts in how it is implemented and integrated with renewable energy sources. Traditional steam-based systems, which rely heavily on burning fossil fuels such as coal, natural gas, or oil, face increasing scrutiny due to their environmental impact, particularly in terms of carbon emissions. As a result, there has been a substantial push to modernize steam power plants, incorporating new technologies and improving the overall energy efficiency of the process.

One of the primary areas of focus in advancing steam-based electricity generation is the development and implementation of carbon capture, utilization, and storage (CCUS) technologies. These systems capture CO₂ emissions produced during the combustion of fossil fuels, preventing them from entering the atmosphere and contributing to climate change. In some systems, the captured CO₂ can be used in industrial processes, such as enhancing oil recovery or producing synthetic fuels, making the technology potentially economically viable in certain contexts. CCUS is seen as a critical part of reducing emissions from traditional fossil-fuel-based power plants, including steam turbines, and is a focal point of research for improving the environmental footprint of steam-based electricity generation.

Moreover, the energy transition is driving a renewed interest in hybrid systems that combine steam-based power generation with renewable energy sources. One notable example is the integration of solar thermal energy into steam power plants. Solar thermal plants use mirrors or lenses to concentrate sunlight and heat a working fluid, often oil or molten salt, which can then be used to produce steam. This process mirrors traditional steam generation, but the heat source is clean and renewable. In some cases, solar thermal plants are combined with conventional steam turbines in hybrid systems, where the steam turbine can operate using both solar heat and the backup from fossil fuels or other energy sources when sunlight is insufficient.

Geothermal energy, another renewable energy source, has long been a significant contributor to steam-based power generation. In geothermal power plants, steam is extracted from the Earth’s natural geothermal reservoirs and used to turn turbines. Geothermal plants operate efficiently in regions with significant geothermal activity, such as Iceland, parts of the United States (e.g., California), and the Philippines. These plants offer the advantage of being able to provide a constant, baseload supply of electricity, since the Earth’s heat is inexhaustible on human timescales. Unlike solar and wind power, which can be intermittent, geothermal energy is available 24/7, making it a reliable renewable energy source.

In addition to integrating renewable sources, there has been a push to utilize advanced materials and design innovations to increase the efficiency of steam turbines and reduce energy losses. High-efficiency materials are being developed to withstand the extreme pressures and temperatures encountered in modern steam turbines, allowing for more efficient power generation. For example, advanced alloys and coatings can improve the turbine’s resistance to corrosion and thermal degradation, extending the lifespan of the turbine and maintaining high levels of efficiency throughout its operation.

The ongoing trend toward supercritical and ultra-supercritical steam cycles is also helping to push the boundaries of steam-based power generation efficiency. By operating at pressures and temperatures beyond the traditional limits of the steam cycle, these advanced turbines extract more energy from the same amount of fuel. Supercritical plants are typically used in newer coal-fired power plants and some nuclear plants, allowing them to operate more efficiently while reducing emissions. However, the high cost of building and maintaining these advanced systems remains a challenge, which is why their adoption has been somewhat limited in many regions.

A promising area of development is the application of advanced digital technologies to monitor and optimize steam turbine performance. Through the use of sensors, data analytics, and artificial intelligence (AI), power plant operators can gain real-time insights into turbine performance, detect inefficiencies or anomalies, and adjust operational parameters to optimize efficiency and reduce downtime. Predictive maintenance tools are also being used to forecast when components of the turbine or other systems might fail, allowing for proactive maintenance to prevent costly failures and extend the operational life of the plant.

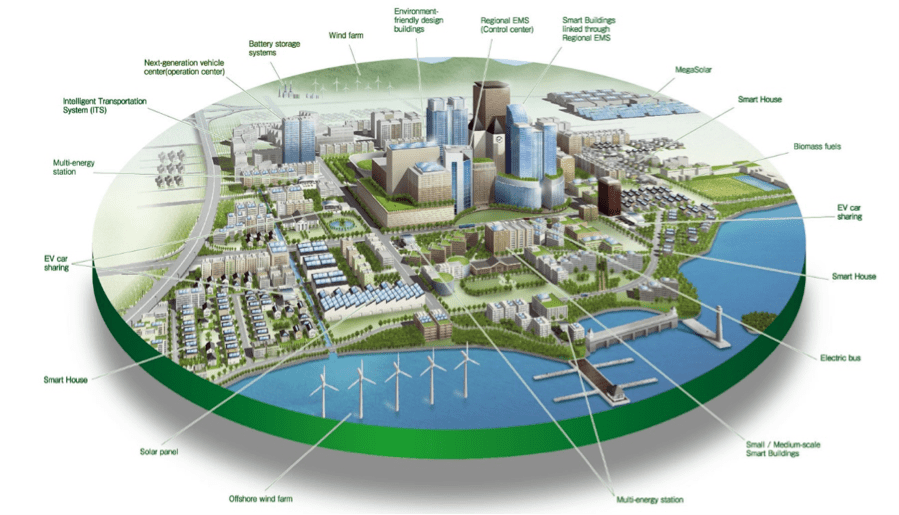

Alongside these technological advancements, there is growing interest in decentralized power generation models that use smaller, modular steam systems to provide local or regional electricity. Microgrids, which can be powered by small-scale steam turbines or other distributed energy sources, offer the potential for localized generation with lower transmission losses and enhanced grid resilience. For example, biomass plants, which use organic materials such as wood pellets or agricultural waste to generate steam, can be deployed in rural or remote areas to provide power. These systems are particularly attractive in regions with abundant biomass resources, where the steam can be produced locally and used to provide electricity with a minimal carbon footprint.

The global energy transition is also influencing the development of new energy systems that combine steam turbines with energy storage technologies. For example, some power plants are integrating steam turbines with large-scale battery storage systems or pumped hydro storage, which can store excess energy produced during periods of high demand or when renewable sources like solar and wind are producing more electricity than is needed. This stored energy can then be used to produce steam when demand is high or when renewable energy generation is low, providing grid stability and ensuring a constant supply of power.

In the future, steam turbines may also play a role in the hydrogen economy. Hydrogen, particularly green hydrogen produced through electrolysis powered by renewable electricity, is gaining attention as a potential clean energy source. Steam turbines could be used in combined systems that generate hydrogen through high-temperature electrolysis or other processes, and then use the hydrogen to generate power or heat in various applications. Additionally, steam turbines might be used in plants that convert hydrogen into electricity, acting as an efficient and flexible component in a hydrogen-powered energy system.

As the world continues to seek solutions to the challenges of climate change and energy security, steam-based electricity generation remains a cornerstone of the global energy mix. By evolving alongside advances in technology, renewable energy integration, and emission reduction strategies, the steam turbine continues to serve as a vital tool in the transition to a cleaner, more sustainable energy future.

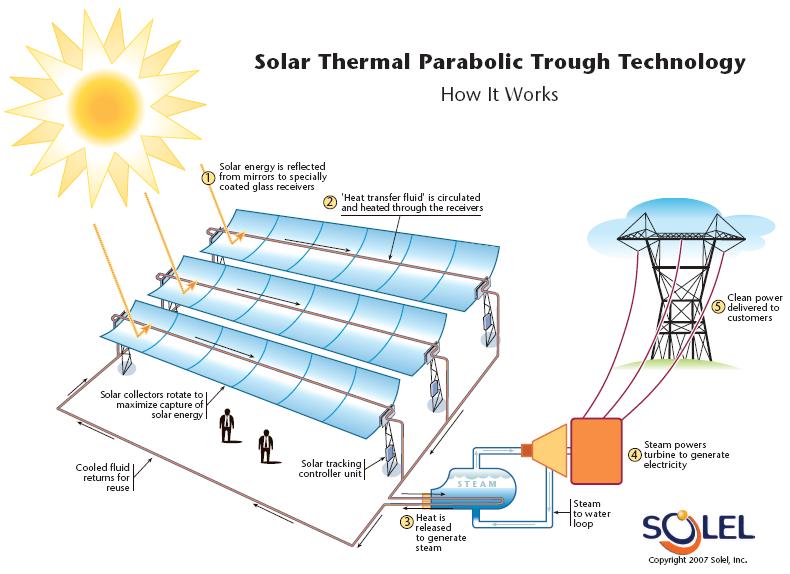

Solar thermal energy systems harness the heat of the sun to generate electricity through a series of processes that convert solar radiation into thermal energy, which is then used to drive a power generation cycle. Unlike photovoltaic systems, which directly convert sunlight into electricity using semiconductor materials, solar thermal energy systems focus sunlight onto a working fluid, which is then used to produce high-temperature steam or gas to turn a turbine and generate power.

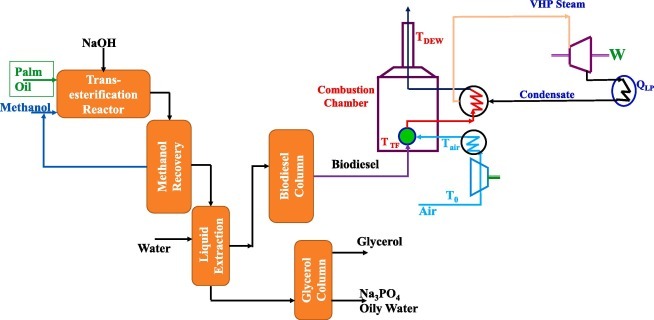

The core principle behind solar thermal energy systems is the concentration of sunlight to achieve the necessary high temperatures for electricity generation. This is typically accomplished through the use of mirrors or lenses that focus sunlight onto a small area. The concentrated solar energy is then transferred to a heat transfer fluid, often a type of molten salt, synthetic oil, or water, which absorbs and retains the thermal energy. The heated fluid is then used to produce steam, which drives a steam turbine connected to an electrical generator, converting the thermal energy into mechanical energy and ultimately into electrical energy.

There are several types of solar thermal power plants, each employing different methods to concentrate and utilize solar heat. One of the most common designs is the parabolic trough system, which consists of long, curved mirrors that focus sunlight onto a receiver pipe running along the focal line of the trough. A heat transfer fluid flows through the receiver pipe, absorbing the concentrated sunlight and reaching high temperatures, often exceeding 300°C. The hot fluid then passes through a heat exchanger, where it generates steam to drive a turbine. Another widely used design is the power tower system, which employs a field of heliostats—large, flat mirrors that track the sun—to reflect and concentrate sunlight onto a central receiver mounted on top of a tower. This receiver collects the solar heat and transfers it to a working fluid, which then generates steam for electricity production. Power tower systems can reach much higher temperatures than parabolic troughs, often exceeding 500°C, increasing their efficiency and allowing for improved energy storage.

Another approach to solar thermal power generation is the use of dish Stirling systems. These systems consist of a parabolic dish that focuses sunlight onto a receiver attached to a Stirling engine. The Stirling engine operates by cyclically expanding and contracting a working gas due to the absorbed heat, which drives a piston and produces mechanical energy that is directly converted into electricity. While dish Stirling systems offer high efficiency and modularity, they are typically used for small-scale applications rather than large power plants.

One of the key advantages of solar thermal energy systems over other renewable energy sources is their ability to store thermal energy for use when the sun is not shining. Thermal energy storage is commonly achieved using molten salt storage tanks, which can retain heat for several hours or even overnight, enabling continuous electricity generation even after sunset. This capability makes solar thermal power plants more reliable compared to photovoltaic systems, which are directly dependent on sunlight and require battery storage for energy continuity.

Despite the benefits, solar thermal energy systems also face several challenges. The initial capital costs for constructing large-scale solar thermal power plants are significant, requiring substantial investment in infrastructure, land, and materials. The efficiency of solar thermal power plants is also affected by atmospheric conditions, such as cloud cover, dust, and humidity, which can reduce the effectiveness of sunlight concentration. Additionally, water consumption in steam-based solar thermal plants can be high, making them less suitable for arid regions where water scarcity is a concern. To address this, some systems employ dry cooling technologies that use air instead of water for condensation, though this may result in lower efficiency.

Recent advancements in solar thermal technology have focused on improving efficiency, reducing costs, and enhancing thermal energy storage capabilities. Innovations such as supercritical carbon dioxide cycles, improved selective coatings for absorbers, and hybridization with other renewable energy sources have contributed to making solar thermal power more viable. In particular, integrating solar thermal plants with fossil fuel or biomass power plants has been explored as a means of increasing overall energy efficiency while reducing carbon emissions.

Solar thermal energy systems represent a promising solution for large-scale renewable energy generation, particularly in regions with high solar insolation, such as deserts and sunny coastal areas. As research and development continue to improve the efficiency and cost-effectiveness of these systems, they are likely to play an increasingly significant role in the transition to sustainable and clean energy sources. The ability to provide dispatchable power through thermal energy storage further strengthens their potential as a reliable alternative to conventional fossil fuel-based power generation.

Further advancements in solar thermal energy systems continue to push the boundaries of efficiency and cost-effectiveness, making them an increasingly attractive option for large-scale electricity generation. One of the key areas of improvement is the development of advanced heat transfer fluids that can operate at higher temperatures while maintaining stability. Traditional fluids such as synthetic oils are limited by thermal degradation at high temperatures, but newer alternatives, such as molten salts and liquid metals, can sustain much higher temperatures, significantly enhancing system efficiency. By operating at temperatures above 600°C, these fluids allow for higher thermal-to-electric conversion efficiencies, reducing energy losses and improving the overall performance of solar thermal plants.

Another promising avenue is the implementation of supercritical carbon dioxide (sCO₂) power cycles in solar thermal plants. Unlike traditional steam-based Rankine cycles, which have limitations in efficiency, sCO₂ cycles operate at much higher pressures and temperatures, allowing for a more compact and efficient power generation process. These systems require smaller turbines and heat exchangers, reducing capital costs while improving energy conversion rates. Research into sCO₂ technology is ongoing, with pilot projects demonstrating its potential to revolutionize solar thermal electricity generation.

Hybridization of solar thermal plants with other energy sources is also gaining traction as a means of improving reliability and dispatchability. By integrating solar thermal systems with biomass, natural gas, or geothermal energy, power plants can maintain stable electricity output even during periods of low solar radiation. Hybrid plants can use solar energy during the day and switch to alternative energy sources when solar input is insufficient, making them more competitive with traditional fossil fuel plants in terms of availability and grid stability.

The geographic placement of solar thermal power plants plays a crucial role in their efficiency and economic viability. Regions with high direct normal irradiance (DNI), such as the southwestern United States, North Africa, the Middle East, and Australia, offer ideal conditions for solar thermal deployment. Large-scale projects, such as the Noor Complex in Morocco and the Ivanpah Solar Power Facility in California, demonstrate the potential of concentrated solar power (CSP) technology to generate significant amounts of electricity with minimal carbon emissions. These plants provide valuable case studies on the feasibility of scaling up solar thermal technology to meet growing energy demands.

Energy storage remains a cornerstone of solar thermal energy’s future viability. While molten salt storage has become the industry standard, ongoing research is exploring alternative materials and phase-change technologies to enhance thermal storage capacity. Innovations such as solid-state heat storage using ceramic or graphite-based materials and thermochemical storage methods that store energy in reversible chemical reactions could further improve the efficiency and cost-effectiveness of solar thermal storage. Enhanced storage solutions enable longer periods of electricity generation without sunlight, reducing the need for backup fossil fuel power and increasing the competitiveness of CSP in global energy markets.

Economic and policy factors also influence the adoption of solar thermal power. While CSP technology has historically been more expensive than photovoltaic solar power, its ability to provide stable, dispatchable electricity gives it a distinct advantage. Government incentives, feed-in tariffs, and renewable energy mandates in various countries have played a crucial role in encouraging investment in solar thermal projects. As production scales up and technological advancements drive down costs, CSP is expected to become increasingly competitive with other forms of renewable energy.

Environmental considerations are another important aspect of solar thermal power development. Unlike photovoltaic systems, which rely on semiconductor materials that can have resource extraction and recycling challenges, solar thermal plants use largely conventional materials such as glass, steel, and concrete. However, land use and water consumption remain key concerns, particularly in desert environments where these plants are often located. Dry cooling systems and improved land-use planning strategies are being developed to mitigate these issues and make solar thermal energy more sustainable.

Looking ahead, the role of artificial intelligence (AI) and automation in solar thermal energy is expected to grow. Advanced control systems that optimize mirror alignment, heat transfer fluid circulation, and turbine operation can enhance efficiency and reduce operational costs. Machine learning algorithms can be used to predict weather patterns and adjust energy storage and dispatch accordingly, further improving the reliability of solar thermal power plants.

As global energy demand continues to rise and the urgency to transition away from fossil fuels intensifies, solar thermal energy stands as a critical component of the renewable energy landscape. With ongoing technological advancements, cost reductions, and policy support, solar thermal power has the potential to become a major contributor to the world’s energy mix. The combination of high-efficiency power generation, effective energy storage, and scalability makes it a strong candidate for meeting future electricity needs in a sustainable and environmentally friendly manner.

The continued evolution of solar thermal energy systems is driven by the need for more efficient, reliable, and cost-effective solutions to meet global energy demands. One of the most significant areas of development is in the enhancement of energy storage technologies. While molten salt storage is currently the most widely used method, research is underway to explore phase-change materials (PCMs) and thermochemical storage systems that can store and release energy more efficiently. PCMs absorb and release large amounts of heat during phase transitions, such as melting and solidifying, making them a promising alternative to molten salts. Thermochemical storage, on the other hand, involves reversible chemical reactions that can store heat for extended periods with minimal loss, potentially revolutionizing how solar thermal plants manage energy dispatch.

Another major focus of research and innovation is improving the efficiency of concentrator designs. Traditional parabolic trough and power tower systems have proven effective, but next-generation designs are aiming for higher solar concentration ratios and reduced optical losses. Multi-faceted heliostats with adaptive control algorithms are being developed to improve sunlight reflection accuracy, while new receiver coatings and materials are enhancing heat absorption and reducing thermal losses. Some researchers are also exploring advanced optics, such as beam-down concentrators, which use secondary mirrors to direct sunlight to ground-based receivers, simplifying maintenance and reducing tower height costs.

The integration of solar thermal energy with industrial processes is another emerging trend that could expand its applications beyond electricity generation. High-temperature solar heat can be used in industries such as metal smelting, cement production, and chemical synthesis, which currently rely heavily on fossil fuels. Solar-driven hydrogen production is particularly promising, as concentrated solar energy can be used to split water molecules into hydrogen and oxygen through thermochemical cycles. This approach could provide a renewable source of hydrogen for fuel cells, transportation, and industrial applications, reducing dependence on fossil fuels and lowering greenhouse gas emissions.

Economic and policy considerations continue to play a crucial role in shaping the future of solar thermal energy. While the cost of photovoltaic (PV) solar has dropped significantly, making it the dominant solar technology in many markets, solar thermal power offers advantages in dispatchability and grid stability. Governments and utilities are recognizing the value of CSP plants with energy storage as a means to provide round-the-clock renewable power, reducing the need for fossil fuel backup. Countries with high solar potential, such as Spain, Chile, and the United Arab Emirates, have implemented policies and incentives to encourage investment in large-scale CSP projects. In some cases, hybrid systems combining PV with CSP are being explored to leverage the benefits of both technologies—PV for daytime electricity generation and CSP for nighttime power supply.

One of the persistent challenges facing solar thermal energy is the need for extensive land and infrastructure. Large solar thermal plants require significant land area for mirror fields, which can create environmental and logistical challenges. Efforts are being made to optimize land use through dual-purpose installations, such as agrivoltaics, where CSP plants are integrated with agricultural activities. Additionally, floating solar thermal systems, similar to floating PV farms, are being investigated as a way to utilize water surfaces for energy generation while reducing evaporation losses in reservoirs.

Advancements in materials science are also contributing to improved performance and longevity of solar thermal components. High-temperature-resistant coatings, corrosion-resistant materials for heat exchangers, and self-cleaning mirror surfaces are all being developed to reduce maintenance costs and extend the lifespan of CSP plants. These innovations help address operational challenges, particularly in harsh desert environments where dust accumulation and extreme temperatures can impact efficiency.

Looking to the future, the role of artificial intelligence and digital twin technology in solar thermal operations is expected to grow. AI-driven monitoring and predictive maintenance systems can optimize plant performance by analyzing real-time data and forecasting potential failures before they occur. Digital twins—virtual replicas of physical CSP plants—allow operators to simulate different scenarios and optimize energy dispatch strategies, improving overall efficiency and profitability.

As the global energy transition accelerates, solar thermal energy is poised to become a key player in the renewable energy landscape. With continued technological advancements, cost reductions, and supportive policies, CSP has the potential to provide a stable and sustainable source of electricity while complementing other renewables such as wind and PV. The integration of CSP with emerging technologies, such as green hydrogen production and industrial heat applications, further expands its potential, making it a valuable asset in the push toward a decarbonized future

The future of solar thermal energy is deeply intertwined with advancements in global energy infrastructure, policy frameworks, and emerging technologies that aim to optimize efficiency, storage, and integration with existing energy systems. One of the most promising directions is the increasing role of hybrid renewable energy systems, where solar thermal power is combined with other energy sources such as photovoltaics, wind, and battery storage. These hybrid configurations help balance energy generation throughout the day and night, improving grid stability and reducing reliance on fossil fuel backup.

One particularly effective hybrid approach is the combination of solar thermal energy with photovoltaic (PV) systems. While PV generates electricity directly from sunlight and is most effective during peak daylight hours, solar thermal systems with energy storage can continue producing power after sunset. By integrating the two, hybrid plants can achieve higher capacity factors, ensuring a steady supply of renewable electricity. Some large-scale projects are already exploring this model, such as the Noor Energy 1 project in the United Arab Emirates, which combines CSP with PV and molten salt storage to provide reliable power day and night.

Beyond electricity generation, solar thermal energy is gaining traction as a solution for industrial heat applications. Many industries, such as steel, cement, and chemical production, require high-temperature heat, which is currently generated primarily by burning fossil fuels. Concentrated solar power (CSP) can replace these traditional methods by providing high-temperature process heat, significantly reducing carbon emissions in these hard-to-decarbonize sectors. For example, solar thermal energy is being explored for use in desalination plants, where concentrated solar heat can drive the evaporation and condensation processes required for freshwater production, offering a sustainable solution for water-scarce regions.

One of the most exciting applications of solar thermal technology is in the production of green hydrogen. Using high-temperature solar heat, thermochemical water-splitting processes can produce hydrogen with minimal environmental impact. This method is more energy-efficient than traditional electrolysis powered by electricity and has the potential to provide a large-scale, renewable source of hydrogen for fuel cells, transportation, and industrial applications. Research in this area is accelerating, with pilot projects demonstrating the feasibility of solar-driven hydrogen production as a future clean fuel alternative.

Advances in energy storage remain a critical factor in the long-term success of solar thermal power. While molten salt storage is the current industry standard, new approaches are being developed to improve efficiency and lower costs. One promising alternative is solid-state thermal storage, which uses materials such as ceramic, graphite, or concrete to store heat for extended periods with minimal losses. Thermochemical energy storage, which involves reversible chemical reactions to store and release heat, is another area of intense research. These innovations could significantly enhance the dispatchability of solar thermal power, making it even more competitive with conventional fossil-fuel-based electricity generation.

The economic viability of solar thermal energy is also improving due to ongoing cost reductions and economies of scale. As manufacturing techniques for mirrors, receivers, and heat transfer fluids advance, the capital costs of CSP plants are gradually decreasing. Additionally, digitalization and automation are streamlining plant operations, reducing maintenance costs, and improving overall efficiency. Artificial intelligence (AI) is being used to optimize mirror alignment, predict maintenance needs, and enhance thermal storage management, further increasing the reliability and cost-effectiveness of solar thermal power.

Policy support and international collaboration play a crucial role in the expansion of solar thermal energy. Governments in sun-rich regions are increasingly recognizing the benefits of CSP as a dispatchable renewable energy source and are implementing incentives, subsidies, and mandates to encourage investment. Countries such as Spain, China, Morocco, and Australia are leading the way with large-scale CSP installations, demonstrating the technology’s potential to contribute significantly to national and regional energy mixes. International organizations and research institutions are also fostering collaboration on CSP advancements, sharing knowledge and best practices to accelerate deployment worldwide.

Looking forward, the role of solar thermal energy in a global clean energy transition is expected to grow. With continued advancements in storage, hybridization, and industrial applications, CSP is poised to become a key player in providing reliable, sustainable, and scalable energy solutions. The integration of CSP with emerging technologies such as green hydrogen, AI-driven plant management, and advanced energy storage will further solidify its place in the future energy landscape. As the world moves toward decarbonization, solar thermal power stands as a vital component of the renewable energy portfolio, offering a sustainable and flexible solution to meet the increasing demand for clean electricity and industrial heat.

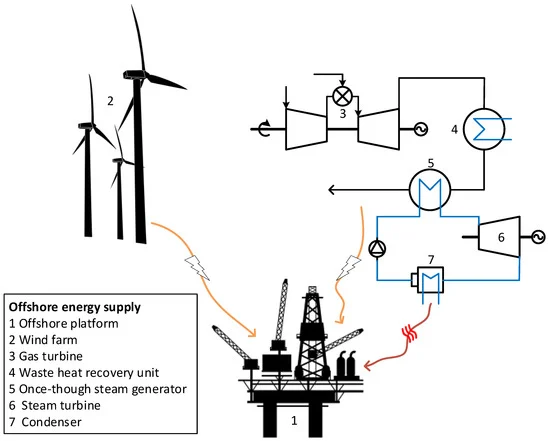

Generating Electricity using waste heat from gas turbines in power plants

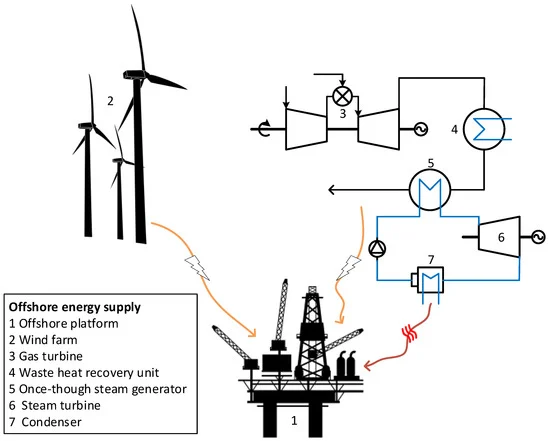

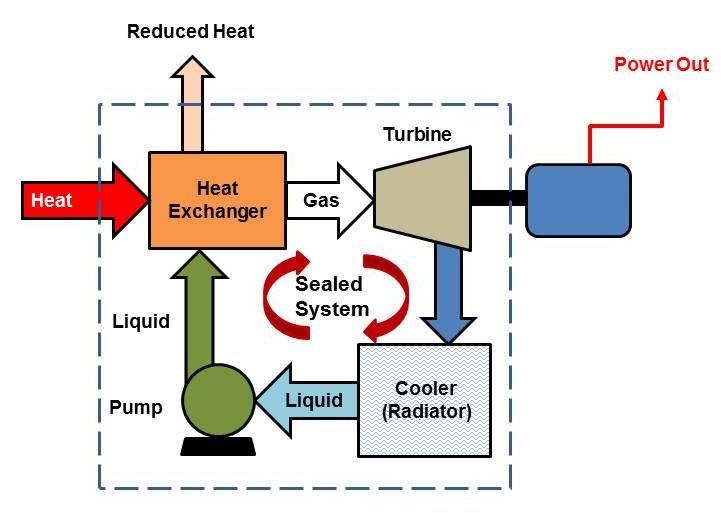

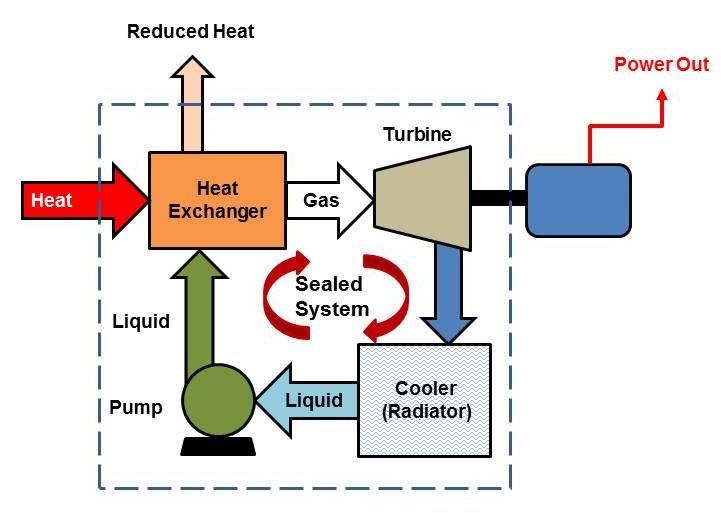

Generating electricity using waste heat from gas turbines in power plants is an essential strategy for improving overall energy efficiency and reducing fuel consumption. Gas turbines are widely used in power generation due to their high efficiency, reliability, and ability to quickly respond to fluctuations in electricity demand. However, a significant portion of the energy produced by gas turbines is lost as waste heat through the exhaust gases. Capturing and utilizing this waste heat can significantly enhance the overall efficiency of a power plant, reducing fuel consumption and lowering greenhouse gas emissions.

One of the most common methods of utilizing waste heat from gas turbines is through combined cycle power plants (CCPPs). In a combined cycle system, a gas turbine generates electricity by burning natural gas or another fuel, and the hot exhaust gases, which would otherwise be wasted, are directed to a heat recovery steam generator (HRSG). The HRSG extracts thermal energy from the exhaust gases to produce steam, which then drives a steam turbine to generate additional electricity. This process effectively increases the total power output without requiring additional fuel, improving the overall efficiency of the plant from around 35–40% in a simple gas turbine system to 55–60% or more in a combined cycle configuration.

Another approach to utilizing waste heat from gas turbines is through cogeneration, or combined heat and power (CHP) systems. In a CHP system, the waste heat is used not only for additional electricity generation but also for industrial processes, district heating, or other thermal applications. Cogeneration systems can achieve overall efficiencies of 70–90% by making use of both the electrical and thermal energy produced. This makes them particularly useful in industrial facilities, refineries, and commercial buildings where both power and heat are needed.

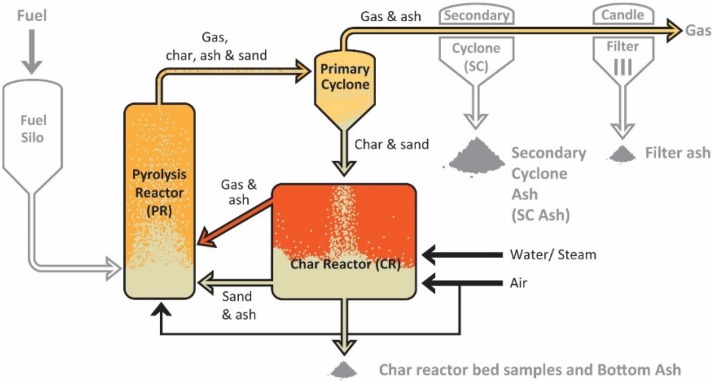

Organic Rankine Cycle (ORC) technology is another promising method for utilizing waste heat from gas turbines. In an ORC system, the waste heat is used to vaporize an organic working fluid with a lower boiling point than water, allowing power generation at lower temperatures. The vaporized fluid expands through a turbine, generating electricity before being condensed back into a liquid and recirculated. ORC systems are particularly useful in situations where the exhaust temperature of the gas turbine is not high enough for conventional steam-based power generation.

Advancements in waste heat recovery technologies continue to improve the efficiency and viability of these systems. High-efficiency heat exchangers, advanced materials for heat recovery steam generators, and improved thermodynamic cycle designs are all contributing to better performance. Some modern power plants are exploring supercritical and ultra-supercritical steam cycles, which operate at higher pressures and temperatures to further increase efficiency. Additionally, closed-loop carbon dioxide (CO₂) power cycles, such as the supercritical CO₂ Brayton cycle, are being investigated as potential alternatives to conventional steam cycles due to their higher efficiency and compact design.

Economic and environmental benefits are key drivers behind the adoption of waste heat recovery systems in gas turbine power plants. By capturing and utilizing waste heat, power plants can reduce their fuel consumption, leading to lower operating costs and reduced dependency on fossil fuels. This also translates to lower greenhouse gas emissions and improved sustainability. Many countries and regulatory bodies are encouraging or mandating the use of waste heat recovery through incentives, subsidies, and efficiency standards, making it an attractive option for power plant operators.

Despite its advantages, waste heat recovery in gas turbine power plants does present some challenges. The initial capital investment for heat recovery equipment, such as HRSGs and steam turbines, can be substantial, requiring careful financial planning and long-term commitment. The design and implementation of waste heat recovery systems must also consider factors such as space constraints, integration with existing infrastructure, and operational flexibility. Additionally, in smaller-scale gas turbine installations, the amount of waste heat available may not justify the cost of recovery systems, making it more suitable for larger power plants or industrial applications with high heat demand.

Looking ahead, continued advancements in waste heat recovery technologies, integration with renewable energy sources, and innovative cycle designs will further improve the feasibility and efficiency of generating electricity from waste heat in gas turbine power plants. The use of artificial intelligence and data analytics for optimizing waste heat recovery operations is also expected to enhance performance and reduce maintenance costs. As the global energy sector moves toward greater sustainability and efficiency, waste heat recovery from gas turbines will remain a crucial strategy for maximizing energy utilization, reducing emissions, and improving the overall economics of power generation.

The continuous advancement of waste heat recovery technologies in gas turbine power plants is playing a critical role in improving energy efficiency and reducing emissions. One of the most significant areas of development is the optimization of heat recovery steam generators (HRSGs), which are essential for capturing and utilizing the waste heat from gas turbine exhaust gases. Modern HRSG designs incorporate advanced materials and improved heat exchanger configurations to maximize heat transfer efficiency and minimize energy losses. Multi-pressure HRSGs, which operate at different steam pressure levels, are increasingly being used in combined cycle power plants to extract as much energy as possible from the exhaust gases before they are released into the atmosphere.

Another promising area of innovation is the use of advanced thermodynamic cycles beyond the traditional Rankine cycle. The supercritical carbon dioxide (sCO₂) Brayton cycle, for example, has been gaining attention for its potential to significantly enhance efficiency in waste heat recovery applications. Unlike conventional steam-based systems, sCO₂ cycles operate at high pressures and densities, enabling more compact and efficient power generation. The closed-loop nature of these systems allows for better heat utilization and reduces energy losses, making them particularly attractive for integration with gas turbines.

Hybrid power generation is also emerging as a key strategy for improving the effectiveness of waste heat recovery in gas turbine power plants. By integrating renewable energy sources, such as solar thermal or biomass, with waste heat recovery systems, power plants can achieve higher overall efficiency and reduce their reliance on fossil fuels. For instance, a hybrid system combining concentrated solar power (CSP) with a gas turbine and waste heat recovery can provide additional thermal energy to enhance steam production in the HRSG, increasing the total power output while maintaining low emissions. Similarly, biomass can be used as an auxiliary heat source to improve waste heat utilization in combined cycle plants, further diversifying the energy mix and enhancing sustainability.

Energy storage technologies are also being explored to enhance the flexibility and reliability of waste heat recovery systems. Thermal energy storage (TES) solutions, such as molten salts or phase-change materials, can store excess heat generated by waste heat recovery systems for later use, enabling power generation even when the gas turbine is not running at full capacity. This approach helps improve grid stability and allows operators to optimize electricity production based on demand fluctuations.

The use of organic Rankine cycle (ORC) technology continues to expand, particularly in applications where gas turbine exhaust temperatures are relatively low. ORC systems use organic working fluids with lower boiling points than water, allowing them to effectively convert lower-grade waste heat into electricity. This technology is particularly well-suited for small- and medium-scale gas turbine installations, where conventional steam cycles may not be economically viable due to their higher complexity and cost.

Economic and policy considerations are driving the wider adoption of waste heat recovery systems in gas turbine power plants. Governments and regulatory agencies are implementing energy efficiency standards and carbon reduction targets, incentivizing power plant operators to invest in waste heat recovery technologies. Carbon pricing mechanisms, tax credits, and government grants for energy efficiency improvements further encourage the deployment of these systems. Additionally, corporate sustainability goals and environmental regulations are pushing industries to adopt cleaner and more efficient energy practices, making waste heat recovery a crucial strategy for reducing emissions and improving overall sustainability.

One of the key challenges associated with waste heat recovery in gas turbine power plants is the variability of waste heat availability. The efficiency of heat recovery systems depends on factors such as turbine load fluctuations, ambient temperature conditions, and operational constraints. To address this challenge, intelligent control systems and artificial intelligence (AI)-driven optimization techniques are being developed to dynamically adjust heat recovery operations in real-time. These systems use predictive analytics and machine learning algorithms to optimize heat exchanger performance, steam production, and energy dispatch, ensuring that the maximum amount of waste heat is utilized effectively.

Looking to the future, the integration of digital twin technology in waste heat recovery systems is expected to further enhance efficiency and reliability. Digital twins—virtual replicas of physical power plant systems—allow operators to simulate different operating scenarios, optimize system configurations, and predict maintenance needs before issues arise. By leveraging real-time data and advanced simulations, digital twins can help improve decision-making and maximize the economic and environmental benefits of waste heat recovery.

As the global energy sector continues its transition toward cleaner and more efficient power generation, waste heat recovery from gas turbines will remain a key strategy for improving sustainability and reducing emissions. The combination of advanced HRSG designs, innovative thermodynamic cycles, hybrid energy systems, and AI-driven optimization will further enhance the viability of waste heat recovery technologies, making them an integral part of the future energy landscape.

The role of waste heat recovery in gas turbine power plants is expected to grow as technological advancements continue to drive improvements in efficiency, cost-effectiveness, and environmental benefits. One of the most promising developments in this field is the enhancement of materials used in heat exchangers and other critical components of waste heat recovery systems. High-temperature alloys, advanced ceramics, and coatings designed to withstand extreme heat and corrosive environments are being developed to increase the longevity and performance of heat recovery steam generators (HRSGs) and other heat recovery equipment. These advancements reduce maintenance costs and downtime while improving the overall efficiency of energy conversion.

Another key innovation is the ongoing refinement of advanced combined cycle configurations. Traditionally, combined cycle power plants rely on a single HRSG and steam turbine, but newer designs are exploring the use of multiple pressure levels, reheating cycles, and even alternative working fluids to maximize energy extraction. Some next-generation combined cycle systems integrate reheating stages, where partially expanded steam is reheated using additional waste heat before entering the next stage of expansion in the steam turbine. This approach improves thermal efficiency and increases power output while maintaining low emissions.

The integration of artificial intelligence (AI) and machine learning in waste heat recovery systems is also playing a significant role in improving performance. AI-driven analytics platforms can continuously monitor and optimize the operation of HRSGs, steam turbines, and heat exchangers, ensuring that the system operates at peak efficiency under varying load conditions. Predictive maintenance algorithms can also identify potential issues before they lead to equipment failures, reducing downtime and maintenance costs. These smart automation solutions enhance the reliability of waste heat recovery systems and contribute to more stable and efficient power plant operations.

Waste heat utilization beyond electricity generation is becoming an important focus for industries seeking to maximize energy efficiency. In addition to power generation, recovered waste heat from gas turbines can be used for district heating, desalination, and industrial process heating. In colder regions, combined heat and power (CHP) systems can supply waste heat to district heating networks, providing a sustainable source of thermal energy for residential and commercial buildings. In coastal areas and arid regions, waste heat can be used to power desalination plants, improving access to freshwater while reducing the energy demand of traditional desalination methods.

Another innovative application of waste heat recovery is in carbon capture and utilization (CCU) technologies. Gas turbine power plants equipped with carbon capture systems require significant amounts of thermal energy to separate and process CO₂ from flue gases. Instead of using additional fuel to generate this energy, waste heat from the gas turbine exhaust can be repurposed to drive carbon capture processes, reducing the overall energy penalty associated with CO₂ removal. This integration helps make carbon capture more economically viable and environmentally sustainable, aligning with global decarbonization goals.

Hybrid power plants that combine waste heat recovery with renewable energy sources are also gaining traction. For instance, solar thermal energy can be used to supplement steam production in HRSGs, allowing for greater flexibility and improved efficiency. Similarly, biomass-fired boilers can work alongside waste heat recovery systems to provide additional thermal energy, reducing reliance on fossil fuels. These hybrid configurations enhance the resilience of power plants while lowering their carbon footprint.

As global energy policies continue to emphasize sustainability and energy efficiency, financial incentives and regulatory frameworks are evolving to support the adoption of waste heat recovery technologies. Many governments are implementing tax credits, grants, and emissions reduction targets that encourage industries to invest in energy efficiency improvements. Carbon pricing mechanisms, which place a financial value on greenhouse gas emissions, further incentivize the implementation of waste heat recovery solutions as a cost-effective way to reduce overall carbon output.

One of the remaining challenges in widespread waste heat recovery adoption is the variability of waste heat availability due to fluctuating turbine loads and operational constraints. Advanced thermal energy storage (TES) solutions are being developed to address this issue, allowing excess waste heat to be stored and used when needed. Technologies such as molten salt storage, phase-change materials, and high-efficiency thermal batteries are being explored as ways to smooth out energy supply and demand mismatches, making waste heat recovery systems more adaptable to changing power plant conditions.

Looking ahead, the continued evolution of waste heat recovery systems in gas turbine power plants will be driven by innovations in materials science, thermodynamic cycle optimization, AI-driven control systems, and hybrid renewable energy integration. The ability to efficiently harness and utilize waste heat will play a crucial role in improving overall power plant efficiency, reducing fuel consumption, and lowering greenhouse gas emissions. As energy demands increase and environmental regulations become more stringent, waste heat recovery will remain a fundamental strategy for enhancing the sustainability and economic viability of power generation.

The future of waste heat recovery in gas turbine power plants is closely tied to global energy trends, technological advancements, and the increasing focus on sustainability. As the world transitions toward more efficient and lower-emission energy systems, waste heat recovery will play a crucial role in optimizing power generation and reducing fuel consumption. Emerging innovations in heat recovery technology, energy storage, and digitalization are set to further enhance the efficiency, reliability, and economic viability of these systems.

One of the most significant developments in waste heat recovery is the advancement of supercritical carbon dioxide (sCO₂) power cycles. Unlike traditional steam-based Rankine cycles, sCO₂ cycles operate at higher pressures and efficiencies, allowing for more compact and cost-effective waste heat recovery systems. These cycles utilize CO₂ in a closed-loop system as the working fluid, which requires less energy to compress than steam, resulting in improved thermodynamic performance. Research and pilot projects in sCO₂ technology are paving the way for its integration into gas turbine power plants, potentially increasing overall plant efficiency beyond current combined cycle capabilities.

Another emerging innovation is the development of high-performance thermal energy storage (TES) systems. Traditional waste heat recovery relies on immediate use of the captured thermal energy, but TES allows for heat to be stored and dispatched when needed, enhancing flexibility and reliability. Molten salts, phase-change materials, and ceramic-based storage systems are being explored as viable solutions for integrating TES with gas turbine waste heat recovery. These storage systems can be particularly useful in hybrid power plants that combine waste heat utilization with renewable energy sources, enabling a more stable and dispatchable power supply.

The integration of artificial intelligence (AI) and machine learning in waste heat recovery is also revolutionizing the way power plants operate. AI-driven control systems can continuously optimize heat exchanger performance, adjust operating conditions in real-time, and predict maintenance needs before failures occur. Predictive analytics allow for better decision-making in plant operations, reducing downtime and improving overall efficiency. Additionally, digital twin technology is being increasingly used to create real-time virtual models of waste heat recovery systems, enabling operators to simulate different operating conditions, optimize configurations, and plan maintenance schedules more effectively.

Hybrid energy systems that combine waste heat recovery with renewable sources such as solar, wind, or biomass are gaining attention as a way to enhance power plant sustainability. In particular, concentrated solar power (CSP) can be used in conjunction with waste heat recovery systems to provide additional thermal energy for steam production, further improving plant efficiency. Biomass can also be co-fired with gas turbines in a combined cycle plant, using waste heat recovery to maximize energy extraction from the fuel source while reducing overall carbon emissions. These hybrid configurations offer a pathway to cleaner and more resilient power generation.

Another promising application of waste heat recovery is in hydrogen production. As the global push for green hydrogen accelerates, utilizing waste heat to improve the efficiency of hydrogen production processes can make a significant impact. High-temperature electrolysis and thermochemical water-splitting processes require substantial amounts of heat, which can be supplied by waste heat recovery systems in gas turbine power plants. By repurposing waste heat for hydrogen production, power plants can contribute to the growing hydrogen economy while improving their overall energy efficiency.

Regulatory policies and economic incentives continue to drive the adoption of waste heat recovery technologies. Many governments and energy agencies have introduced policies that promote energy efficiency, carbon reduction, and waste heat utilization. Incentives such as tax credits, low-interest financing, and mandatory efficiency standards encourage power plant operators to invest in waste heat recovery systems. Carbon pricing mechanisms, which place a financial value on CO₂ emissions, further increase the economic attractiveness of these technologies by making energy-efficient power generation more cost-competitive.

Despite these advancements, challenges remain in scaling up waste heat recovery solutions. The upfront capital costs of installing heat recovery equipment, integrating storage systems, and upgrading plant infrastructure can be significant. Additionally, technical complexities such as optimizing heat exchanger designs, managing fluctuating turbine loads, and ensuring seamless integration with existing plant operations require careful planning and engineering expertise. However, as technology continues to improve and costs decline, waste heat recovery is becoming an increasingly viable and attractive option for power generation.

Looking to the future, waste heat recovery in gas turbine power plants will continue to evolve as part of a broader effort to create more sustainable and efficient energy systems. Advances in thermodynamic cycle design, energy storage, digitalization, and hybrid energy integration will further enhance the role of waste heat recovery in reducing emissions and improving power plant performance. As the energy sector moves toward greater sustainability, waste heat recovery will remain a fundamental strategy for maximizing energy utilization and minimizing environmental impact, making it a key component of the global clean energy transition.

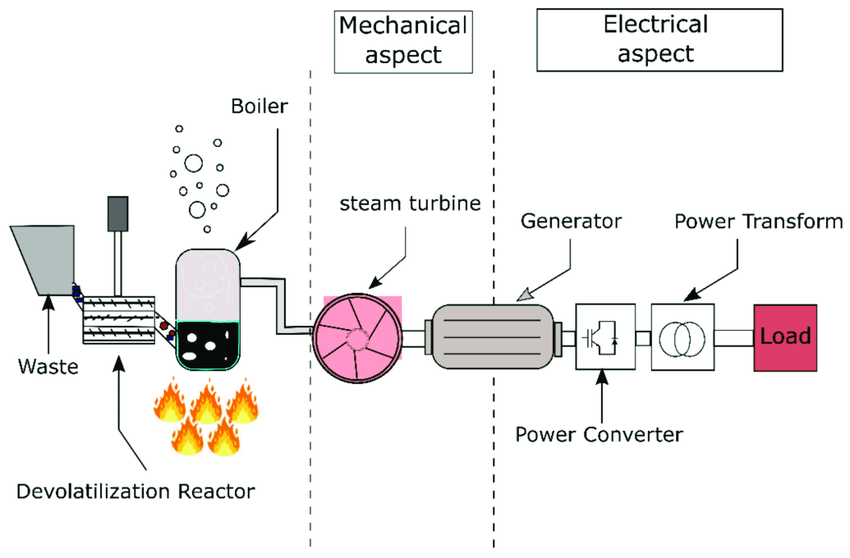

Generating Electricity using Heat from Distillery Operations

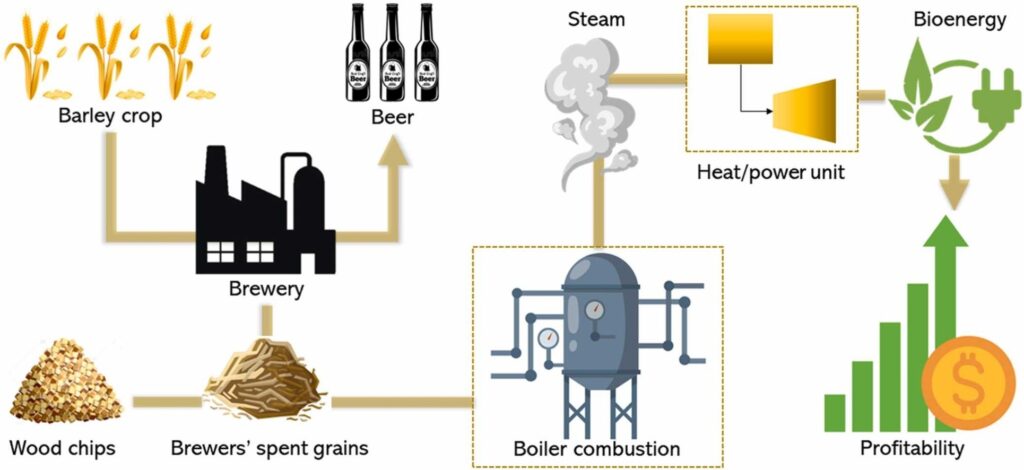

Generating electricity using heat from distillery operations is an effective way to improve energy efficiency, reduce operational costs, and lower environmental impact. Distilleries generate significant amounts of waste heat through processes such as fermentation, distillation, and evaporation. Traditionally, much of this heat is lost to the atmosphere, but with the implementation of waste heat recovery systems, this energy can be captured and converted into electricity, providing a more sustainable and cost-effective energy solution for the industry.

One of the most common methods of generating electricity from distillery waste heat is through cogeneration, also known as combined heat and power (CHP). In a cogeneration system, waste heat from distillation and boiler operations is recovered and used to produce steam, which drives a steam turbine to generate electricity. The same steam can also be used for heating purposes within the distillery, maximizing energy efficiency. By using CHP, distilleries can achieve overall efficiencies of 70–90%, significantly reducing their reliance on external electricity sources and lowering greenhouse gas emissions.

Another efficient technology for converting waste heat into electricity in distilleries is the Organic Rankine Cycle (ORC). ORC systems operate similarly to traditional steam-based power generation but use an organic working fluid with a lower boiling point than water. This allows ORC systems to effectively generate electricity from lower-temperature waste heat, such as that produced by distillation and fermentation processes. ORC technology is particularly useful in distilleries where waste heat temperatures are insufficient for conventional steam turbines but still contain enough thermal energy to be converted into electricity.

Biogas production from distillery waste can also play a crucial role in energy generation. Many distilleries produce significant quantities of organic waste, such as spent wash and stillage, which can be processed in anaerobic digesters to produce biogas. This biogas can then be used as a fuel source for gas engines or microturbines, which generate electricity while producing additional waste heat. The heat from these engines can be recovered and used in the distillation process or further converted into electricity, creating a highly efficient closed-loop energy system.

The integration of waste heat recovery systems in distilleries not only improves energy efficiency but also contributes to sustainability goals. By utilizing waste heat to generate electricity, distilleries can reduce their carbon footprint, lower fuel consumption, and minimize the environmental impact of their operations. Many governments and regulatory bodies are promoting energy efficiency initiatives through incentives, tax benefits, and carbon credit programs, encouraging distilleries to adopt waste heat recovery technologies.

Despite its benefits, waste heat recovery in distillery operations does present some challenges. The initial capital investment for heat recovery equipment, such as ORC units, steam turbines, and heat exchangers, can be substantial. Additionally, the design and implementation of these systems require careful consideration of factors such as waste heat availability, temperature levels, and plant layout. However, advancements in waste heat recovery technology, along with increasing regulatory pressure to improve energy efficiency and reduce emissions, are making these solutions more accessible and economically viable.

As the global focus on sustainable energy grows, distilleries will continue to explore innovative ways to optimize energy use and reduce environmental impact. Future advancements in thermodynamic cycles, heat exchanger technology, and energy storage will further enhance the feasibility of waste heat recovery in distillery operations. The adoption of digital monitoring and AI-driven optimization can also improve system performance by ensuring that waste heat is utilized effectively. By integrating these technologies, distilleries can significantly reduce energy costs, improve operational efficiency, and contribute to a cleaner, more sustainable energy future.

The growing emphasis on sustainability and energy efficiency in the distillery industry is driving the adoption of advanced waste heat recovery technologies. Distilleries, particularly those involved in large-scale alcohol production, consume substantial amounts of thermal energy for processes such as distillation, evaporation, and drying. Without proper recovery systems, a significant portion of this energy is lost as waste heat. However, with the implementation of innovative energy recovery solutions, distilleries can harness this excess thermal energy to generate electricity and improve overall operational efficiency.

One of the most effective ways to convert waste heat from distillery operations into electricity is by optimizing cogeneration (combined heat and power, or CHP) systems. CHP units capture heat from boilers, fermenters, and stills and use it to produce steam, which drives a steam turbine to generate electricity. This approach significantly reduces the amount of external energy required, making the distillery more self-sufficient and reducing dependency on fossil fuel-based power. Additionally, the steam generated in this process can be reused for heating applications, enhancing the overall energy efficiency of the plant.

In distilleries where waste heat is available at lower temperatures, the Organic Rankine Cycle (ORC) is increasingly being employed as a viable solution for power generation. Unlike traditional steam turbines, which require high-temperature steam, ORC systems use organic working fluids that can evaporate at lower temperatures. This makes ORC an ideal choice for capturing and converting waste heat from distillation columns, condensers, and other thermal processes. ORC-based power generation enables distilleries to extract useful energy from heat sources that would otherwise be too low-grade for conventional steam turbines.

Beyond ORC and CHP, another method for utilizing waste heat in distillery operations is through thermoelectric generators (TEGs). These devices use the Seebeck effect to directly convert temperature gradients into electricity. While still in the early stages of commercial application, TEG technology has the potential to provide supplementary power by harnessing small amounts of residual heat from various equipment surfaces, such as boiler flues, exhaust stacks, and heat exchangers.

The integration of biogas generation with waste heat recovery is also gaining popularity in distillery energy systems. Distillery spent wash and organic byproducts can be processed in anaerobic digesters to produce biogas, which can be burned in a gas engine or microturbine to generate electricity. The waste heat from the engine’s exhaust gases and cooling systems can then be captured using heat exchangers and fed into either an ORC system or directly used in the distillery’s thermal processes. This approach not only provides an additional renewable energy source but also contributes to waste management and emissions reduction efforts.

Energy storage solutions are being increasingly explored to enhance the efficiency of waste heat recovery in distilleries. Thermal energy storage (TES) systems, such as molten salts or phase-change materials, can store excess heat during peak production hours and release it when needed, ensuring a more stable and continuous supply of electricity. This is particularly useful in distilleries with variable production schedules or fluctuating energy demands.

Digitalization and automation are playing a crucial role in optimizing waste heat recovery systems in distilleries. The use of artificial intelligence (AI) and machine learning algorithms allows real-time monitoring and predictive control of energy flows within the plant. Smart sensors and IoT-enabled devices can continuously track temperature variations, heat exchanger performance, and steam flow rates, ensuring that waste heat is utilized in the most efficient manner possible. Additionally, digital twin technology, which creates a virtual model of the distillery’s energy system, can help operators simulate different heat recovery configurations and identify the most effective strategies for power generation.

As distilleries strive to become more sustainable, regulatory frameworks and government incentives are encouraging the adoption of waste heat recovery technologies. Carbon credits, tax breaks, and subsidies for energy efficiency projects are making it more financially viable for distilleries to invest in heat-to-power conversion systems. In some regions, distilleries that generate surplus electricity from waste heat can even sell excess power back to the grid, creating an additional revenue stream.

Looking ahead, the continued advancement of waste heat recovery technologies will further transform the energy landscape of distillery operations. Emerging developments in high-efficiency heat exchangers, improved working fluids for ORC systems, and next-generation energy storage solutions will enhance the feasibility and economic benefits of on-site power generation. As distilleries increasingly integrate these solutions into their operations, they will not only reduce energy costs but also contribute to the global transition toward cleaner and more sustainable industrial practices.

As the distillery industry continues to evolve toward more sustainable practices, the adoption of waste heat recovery technologies is becoming increasingly sophisticated. The integration of energy-efficient solutions and renewable energy sources is driving both environmental benefits and cost savings for distilleries worldwide. Looking forward, several key trends and innovations will shape the future of electricity generation from distillery waste heat.

One of the most promising developments is the use of hybrid systems that combine multiple energy sources. In particular, combining waste heat recovery with renewable energy technologies such as solar thermal, biomass, and wind power can greatly enhance the efficiency and sustainability of distillery operations. For instance, solar thermal collectors can be used to pre-heat water or air, reducing the energy required for distillation. This pre-heating process not only lowers the operating costs of distilleries but also reduces the load on the waste heat recovery systems, allowing them to focus on generating electricity or providing heating for other processes.

Biomass energy also offers a complementary solution to waste heat recovery. Distilleries can use agricultural waste products, wood chips, or other biomass fuels to generate additional heat, which can be integrated into the waste heat recovery system. Biomass-based combined heat and power (CHP) units, when paired with waste heat recovery technologies, can help distilleries become energy self-sufficient, reducing their reliance on external grid power and fossil fuels. Furthermore, the utilization of biomass in this context can further reduce the carbon footprint of distillery operations, contributing to the achievement of climate goals.

Microgrids and decentralized energy systems are another area of innovation in distillery power generation. By creating microgrids that incorporate waste heat recovery, renewable energy, and energy storage systems, distilleries can become more resilient to power outages and price fluctuations from the main grid. Microgrids can also enable distilleries to optimize energy distribution based on real-time demand, allowing them to balance the energy produced from waste heat, renewable sources, and stored energy to maximize efficiency and reduce costs. This approach enhances energy security, promotes sustainability, and gives distilleries more control over their energy consumption and production.

As digital technologies continue to advance, the role of artificial intelligence (AI) and data analytics in optimizing waste heat recovery systems will become even more significant. AI can help distilleries analyze vast amounts of operational data in real-time, making it easier to identify inefficiencies, predict maintenance needs, and adjust system operations dynamically. Machine learning algorithms can optimize energy use by learning from historical performance data and predicting energy demand patterns, allowing for more efficient allocation of recovered heat and generated electricity. Moreover, predictive maintenance systems powered by AI can detect issues before they lead to equipment failure, improving system reliability and reducing downtime.

The role of thermal energy storage (TES) systems will continue to expand as distilleries look to optimize waste heat recovery and power generation. These systems store excess thermal energy generated during periods of high activity and release it when needed, smoothing out fluctuations in energy demand. High-temperature TES technologies, such as molten salts or ceramics, are becoming more efficient and cost-effective, making them an attractive option for distilleries looking to store heat generated from both waste heat recovery and renewable sources. In addition, coupling TES with battery storage systems allows distilleries to store electricity generated from both waste heat and renewable sources, providing an additional layer of flexibility and stability to the energy supply.

Government policies and incentives will continue to drive the adoption of waste heat recovery technologies in distilleries. As countries strengthen their commitment to reducing carbon emissions and improving energy efficiency, distilleries will benefit from a wide range of financial incentives, such as tax credits, rebates, and grants. For example, policies that encourage the use of renewable energy and waste-to-energy technologies will make it easier for distilleries to adopt these systems and improve their profitability. Additionally, carbon pricing schemes and emissions reduction targets will provide further economic motivation to implement waste heat recovery solutions as a way to lower carbon footprints and offset operational costs.

The market for waste heat recovery technologies in distilleries is also being shaped by increasing consumer demand for sustainable products. Distilleries that incorporate energy-efficient technologies and reduce their environmental impact are likely to see greater consumer interest and loyalty, particularly as sustainability becomes a key differentiator in the marketplace. As more consumers prioritize environmentally responsible brands, distilleries that invest in waste heat recovery and other sustainable practices will be able to appeal to this growing demographic while meeting regulatory and environmental standards.

Looking to the future, the distillery industry will continue to benefit from breakthroughs in materials science, energy storage, and thermodynamic cycles. New, high-efficiency heat exchangers and advanced working fluids for Organic Rankine Cycle (ORC) systems will make it easier for distilleries to generate electricity from lower-temperature waste heat, further expanding the range of waste heat recovery applications. As research in thermoelectrics and advanced heat-to-power conversion technologies progresses, distilleries may also have access to new tools for generating electricity from residual heat that was previously difficult to utilize.

In conclusion, the generation of electricity using heat from distillery operations represents an exciting opportunity to improve energy efficiency, reduce costs, and contribute to a cleaner, more sustainable future. With ongoing advancements in waste heat recovery systems, renewable energy integration, and digital optimization, distilleries can continue to harness their waste heat to generate electricity while reducing their environmental impact. As the industry continues to innovate and adopt new technologies, it will become increasingly possible for distilleries to operate more sustainably, reduce operational expenses, and meet the growing demand for green and energy-efficient products.

As distilleries increasingly integrate waste heat recovery systems to generate electricity, the future of energy efficiency within the industry will be shaped by several emerging trends and technological breakthroughs. Distilleries have significant potential to reduce energy consumption, lower emissions, and improve the overall sustainability of their operations by further developing and optimizing heat-to-power systems.

One key area of development is the expansion of waste heat recovery systems that operate at a wider range of temperatures. Distillery operations, such as distillation, fermentation, and drying, produce waste heat across a spectrum of temperatures, often varying significantly depending on production levels and equipment design. To maximize the potential for electricity generation, distilleries are increasingly adopting systems capable of capturing heat from low, medium, and high-temperature sources. This may include advanced Organic Rankine Cycle (ORC) systems that can operate efficiently across varying temperatures or thermoelectric generators (TEGs) that directly convert waste heat into electricity even from low-grade sources. These systems will enhance the flexibility of waste heat recovery, enabling distilleries to capture and convert as much of their available waste heat as possible.