Driving Cargo Pumps with Steam Turbines: Steam turbines play a crucial role in industrial applications by providing mechanical power to drive a wide range of equipment, from pumps and compressors to generators and process machinery. These turbines convert thermal energy from steam into mechanical energy through a series of high-speed rotating blades. The use of steam turbines for driving industrial equipment is widespread due to their efficiency, reliability, and ability to operate under a variety of conditions. One of the key advantages of steam turbines is their ability to handle large power loads while maintaining operational stability. Unlike reciprocating engines, steam turbines operate with continuous rotary motion, resulting in smoother operation, lower vibration, and reduced maintenance requirements. This characteristic makes them particularly suitable for applications where consistent and reliable power is essential.

Steam turbines are often categorized based on their design and operational characteristics. Condensing steam turbines are used when maximum energy extraction from steam is required. These turbines expand steam to a very low pressure, often creating a vacuum in the condenser to maximize efficiency. The extracted energy is then used to drive industrial equipment such as power generators or heavy-duty compressors. On the other hand, back-pressure turbines operate by exhausting steam at a higher pressure, which can then be used for heating or other process requirements in industrial plants. This makes them particularly useful in cogeneration systems, where both mechanical power and thermal energy are needed.

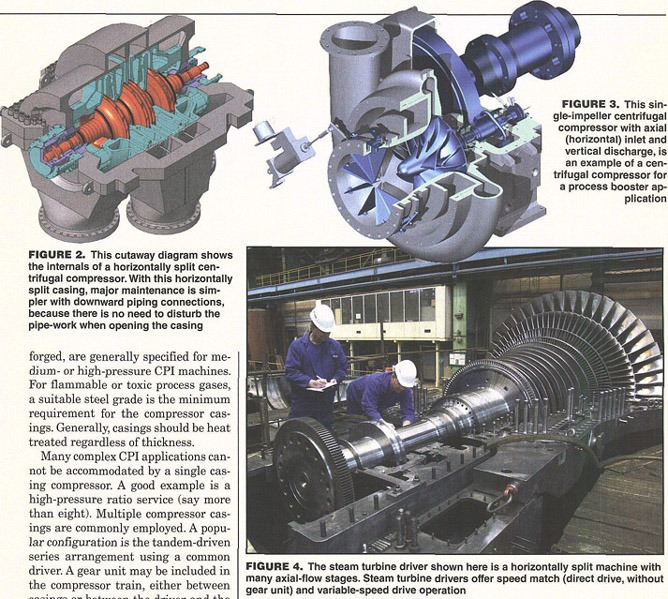

The efficiency of a steam turbine depends on several factors, including steam inlet conditions, blade design, and the effectiveness of steam expansion within the turbine. High-pressure and high-temperature steam results in better efficiency, as it allows for greater energy conversion. Modern steam turbines often incorporate advanced materials and precision-engineered blades to withstand the extreme conditions of industrial applications. Additionally, the use of reheat cycles, extraction points, and controlled steam flow can further enhance efficiency and adaptability to different industrial needs.

Steam turbines are widely employed in industries such as petrochemical, power generation, pulp and paper, and food processing. In oil refineries, they are used to drive large compressors that aid in refining crude oil. In the pulp and paper industry, steam turbines power machinery used for wood processing and paper production. Many industrial plants integrate steam turbines with boilers and heat recovery systems to optimize energy usage and minimize waste. The ability to harness excess steam from industrial processes and convert it into mechanical power is one of the key benefits of using steam turbines in industrial applications.

Maintenance and operational considerations play a significant role in ensuring the reliability and longevity of steam turbines. Regular inspections, lubrication, and monitoring of steam conditions help prevent unexpected failures. Common issues such as blade erosion, steam leakage, and bearing wear must be addressed to maintain peak performance. Advanced diagnostic tools, such as vibration analysis and thermal imaging, are often used to detect early signs of wear or misalignment. With proper maintenance, steam turbines can operate efficiently for decades, providing a reliable source of mechanical power in industrial settings.

The choice between steam turbines and other power sources, such as electric motors or internal combustion engines, depends on factors like fuel availability, efficiency requirements, and process integration. While electric motors are often preferred for smaller loads due to their simplicity and lower upfront costs, steam turbines become more attractive when waste steam or excess thermal energy is available. Their ability to utilize a variety of steam sources, including waste heat recovery and cogeneration systems, makes them an energy-efficient solution for many industrial applications.

Overall, the use of steam turbines for driving industrial equipment remains an essential aspect of modern industry. Their ability to deliver continuous power, handle high loads, and integrate with thermal energy systems makes them a preferred choice in many sectors. With ongoing advancements in turbine design and efficiency improvements, steam turbines continue to play a vital role in sustainable and efficient industrial operations.

Another significant advantage of steam turbines in industrial applications is their adaptability to different operational demands. Unlike internal combustion engines, which have a fixed power output dependent on fuel combustion, steam turbines can be controlled more flexibly by adjusting steam flow and pressure. This allows industries to optimize energy consumption based on real-time demand, reducing fuel wastage and operational costs. Many modern steam turbine systems are equipped with automated control systems that regulate steam supply, monitor performance parameters, and adjust turbine operation for optimal efficiency. These intelligent control mechanisms ensure that turbines operate within safe and efficient limits while minimizing downtime and maintenance requirements.

In industrial settings where continuous operation is required, such as in chemical plants, power stations, and steel mills, steam turbines offer unmatched reliability. Their robust construction and relatively simple mechanical design contribute to long operational lifespans, often exceeding several decades with proper maintenance. Many steam turbines operate 24/7 without significant interruptions, making them an ideal choice for critical industrial processes. Their ability to use various steam sources, including waste heat from other processes, further enhances their practicality and energy efficiency. This is particularly valuable in combined heat and power (CHP) systems, where the turbine not only drives equipment but also helps generate steam for heating or other industrial processes.

Another important aspect of steam turbine-driven industrial equipment is its scalability. Steam turbines can be designed to handle small-scale applications, such as driving a single pump, or large-scale industrial systems that require megawatts of power. This scalability makes them a viable choice for industries of all sizes, from small manufacturing plants to large petrochemical complexes. Additionally, steam turbines can be integrated with multiple process units within a plant, allowing for centralized power generation and distribution. This approach enhances overall plant efficiency, as a single steam turbine system can supply power to multiple machines and processes, reducing the need for separate power sources.

One of the critical considerations when using steam turbines in industrial applications is steam quality. The presence of impurities, excessive moisture, or variations in pressure can significantly impact turbine performance and longevity. Poor steam quality can lead to erosion of turbine blades, scaling on internal components, and reduced efficiency. Therefore, industries must implement proper water treatment and steam conditioning processes to maintain the integrity of their steam supply. Superheating steam before it enters the turbine is a common practice to prevent condensation and improve efficiency. Additionally, steam separators, filters, and desuperheaters may be used to ensure consistent steam conditions.

Environmental considerations also play a role in the continued development of steam turbine technology. As industries strive to reduce carbon emissions and improve energy efficiency, steam turbines are being optimized for cleaner and more sustainable operation. Many industries are investing in waste heat recovery systems, which capture excess heat from industrial processes and use it to generate steam for turbine operation. This not only reduces fuel consumption but also minimizes greenhouse gas emissions. Additionally, advances in materials science are leading to the development of high-temperature, corrosion-resistant turbine components, further improving efficiency and reducing maintenance needs.

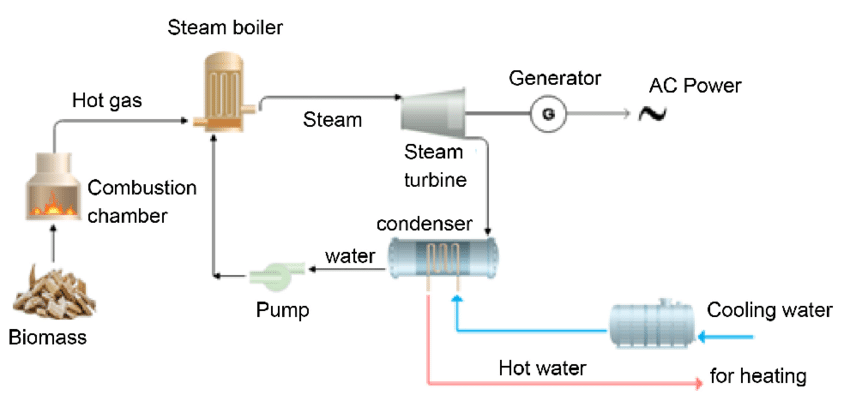

Another emerging trend in steam turbine applications is their integration with renewable energy sources. Biomass and concentrated solar power (CSP) plants use steam turbines to convert thermal energy from organic materials or solar collectors into mechanical and electrical power. These renewable energy systems rely on the same fundamental principles as traditional steam turbine applications but utilize sustainable fuel sources. In some cases, hybrid systems combine conventional fossil fuel-based steam generation with renewable sources to create more flexible and environmentally friendly energy solutions.

Steam turbines also play a crucial role in the expansion of industrial automation and digitalization. Modern steam turbine systems often include sensors, predictive maintenance algorithms, and remote monitoring capabilities. These advancements allow operators to track performance in real time, detect potential issues before they escalate, and optimize turbine operation based on changing process demands. The use of digital twins—virtual models that simulate real-world turbine performance—enables engineers to analyze different operating scenarios, predict maintenance needs, and enhance overall system efficiency.

Despite their many advantages, steam turbines do have some limitations. The initial capital investment for a steam turbine system can be high, particularly when considering the need for boilers, condensers, and other auxiliary equipment. Additionally, steam turbines require a reliable steam source, which means industries must invest in efficient steam generation systems. However, for operations where steam is already a byproduct of other processes, the use of steam turbines can significantly improve overall energy efficiency and reduce operational costs.

Looking ahead, the role of steam turbines in driving industrial equipment is expected to evolve with advancements in energy efficiency, sustainability, and digitalization. Industries will continue to seek ways to maximize the use of available thermal energy, reduce emissions, and enhance operational flexibility. Steam turbines, with their proven track record of reliability and efficiency, will remain a cornerstone of industrial power generation and mechanical drive applications for years to come.

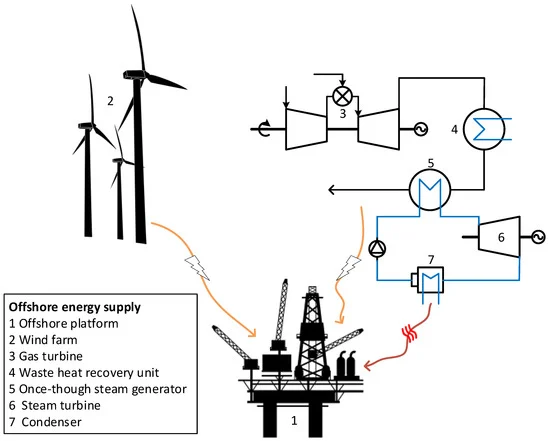

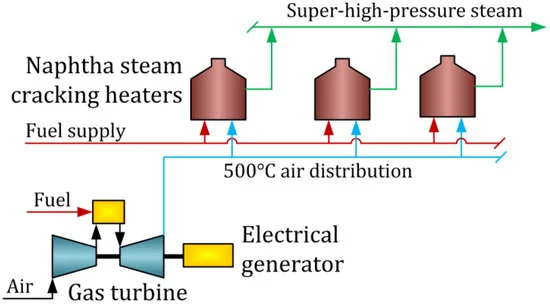

Another critical aspect of steam turbine-driven industrial systems is their integration with advanced heat recovery technologies. In many industrial settings, steam turbines are part of a larger system that includes boilers, heat exchangers, and condensers designed to maximize energy utilization. Waste heat from industrial processes, such as steel production, chemical refining, and cement manufacturing, can be captured and repurposed to generate steam. This approach enhances overall energy efficiency and reduces reliance on external fuel sources, leading to lower operating costs and improved sustainability. In cogeneration and combined-cycle power plants, steam turbines work in conjunction with gas turbines to extract maximum energy from fuel combustion. These integrated systems contribute to reducing greenhouse gas emissions by utilizing fuel more effectively and minimizing waste heat dissipation into the environment.

In applications requiring variable power output, steam turbines offer a level of flexibility that is advantageous for fluctuating industrial demands. Unlike conventional reciprocating engines, steam turbines can operate efficiently across a range of loads by adjusting steam flow rates, regulating extraction points, or incorporating reheating stages. This adaptability is particularly useful in industries such as pulp and paper, where process steam requirements may change throughout the production cycle. By modifying operating parameters in real time, steam turbine systems can maintain optimal performance while ensuring that both power generation and process steam demands are met efficiently.

Another key consideration when deploying steam turbines for industrial applications is lubrication and bearing technology. Steam turbines operate at high rotational speeds, necessitating precision-engineered bearings and lubrication systems to minimize friction and wear. Hydrodynamic and tilt-pad bearings are commonly used in industrial steam turbines to provide stability, reduce vibrations, and extend service life. Proper lubrication systems ensure consistent oil supply to bearings, preventing overheating and reducing mechanical losses. Advanced condition monitoring techniques, such as oil analysis and thermography, are employed to detect early signs of bearing degradation, allowing for predictive maintenance and minimizing unexpected shutdowns.

The development of advanced steam turbine blade materials and coatings has also contributed to improved efficiency and durability. Modern turbine blades are designed to withstand extreme temperatures and pressures while minimizing erosion caused by high-velocity steam. Coatings such as thermal barrier layers and erosion-resistant materials help mitigate wear and extend turbine lifespan. Computational fluid dynamics (CFD) simulations are widely used in blade design to optimize aerodynamic performance and enhance energy conversion efficiency. As a result, newer steam turbine models achieve higher efficiency rates and lower operating costs compared to earlier generations.

Steam turbines continue to play a crucial role in industries that require large-scale mechanical drive applications. For example, in the oil and gas sector, steam turbines are used to drive large compressors for natural gas processing, pipeline transportation, and petrochemical refining. Their ability to provide continuous, high-power output makes them ideal for heavy-duty industrial processes that demand reliability and operational stability. Similarly, in fertilizer production, steam turbines power ammonia and urea synthesis compressors, ensuring efficient chemical processing and production scalability.

As industries transition toward more sustainable energy solutions, the role of steam turbines in decarbonization efforts is becoming increasingly important. One promising development is the integration of steam turbines with carbon capture and utilization (CCU) systems. By utilizing waste heat from carbon capture processes, steam turbines can generate additional power while simultaneously reducing carbon emissions. In green hydrogen production, where electrolysis requires significant energy input, steam turbines can provide an efficient and low-emission power source when integrated with renewable energy-based steam generation.

Future advancements in steam turbine technology will likely focus on enhancing efficiency through digitalization, automation, and smart grid integration. The incorporation of artificial intelligence (AI) and machine learning in turbine control systems will enable real-time performance optimization, predictive maintenance scheduling, and autonomous fault detection. These innovations will not only improve reliability but also extend the operational lifespan of steam turbines in industrial applications. Additionally, ongoing research into supercritical and ultra-supercritical steam turbine designs aims to further increase efficiency by operating at higher temperatures and pressures, reducing fuel consumption and emissions.

Ultimately, the continued evolution of steam turbines in industrial applications will be driven by the need for greater efficiency, sustainability, and operational flexibility. As global industries seek to optimize energy use and reduce environmental impact, steam turbines will remain a cornerstone of mechanical power generation, playing a vital role in shaping the future of industrial energy systems.

Another crucial factor in the widespread adoption of steam turbines for driving industrial equipment is their compatibility with diverse fuel sources. Unlike internal combustion engines, which rely on specific fuels such as diesel or natural gas, steam turbines can utilize steam generated from a wide range of sources. This includes conventional fossil fuels such as coal, oil, and natural gas, as well as renewable and alternative sources like biomass, geothermal energy, and concentrated solar power. This versatility allows industries to choose fuel sources based on availability, cost, and environmental considerations, making steam turbines a flexible and future-proof option for industrial applications.

In industries with high-temperature waste heat, steam turbines provide an effective means of energy recovery. Waste heat boilers, also known as heat recovery steam generators (HRSGs), capture thermal energy from exhaust gases, process heat, or combustion byproducts and use it to produce steam for turbines. This approach significantly improves overall plant efficiency and reduces the amount of energy lost to the environment. Industries such as steel manufacturing, cement production, and chemical processing often implement waste heat recovery steam turbines to maximize energy efficiency and lower operational costs. The ability to repurpose otherwise wasted heat into usable mechanical power further strengthens the economic and environmental case for steam turbine adoption.

Another key advantage of steam turbines is their ability to operate under extreme conditions while maintaining high reliability. Many industrial settings expose equipment to harsh environments, including high temperatures, corrosive chemicals, and heavy mechanical loads. Steam turbines, with their robust construction and minimal moving parts, are well-suited for such conditions. Special coatings and alloy materials are used to enhance resistance to high-temperature corrosion and oxidation, particularly in applications where aggressive steam conditions are present. This durability ensures that steam turbines can operate for decades with minimal degradation, making them a cost-effective long-term investment.

The integration of steam turbines with advanced automation and control technologies has further improved their efficiency and operational stability. Modern steam turbines are equipped with digital control systems that optimize steam flow, pressure, and temperature based on real-time process requirements. Automated valve control, predictive maintenance algorithms, and remote monitoring capabilities help reduce human intervention and minimize the risk of unexpected failures. Advanced sensors continuously monitor turbine performance parameters such as vibration levels, thermal expansion, and lubrication quality, allowing operators to detect anomalies before they lead to costly breakdowns.

A critical factor in steam turbine efficiency is the management of steam expansion and extraction. Many industrial turbines feature multiple extraction points where steam can be withdrawn at specific pressures for use in other process applications. This allows plants to balance power generation with process steam needs, improving overall system efficiency. In cogeneration systems, extracted steam can be used for district heating, desalination, or chemical processing, providing additional value beyond mechanical power generation. The ability to integrate power and process steam requirements into a single system is a key reason why many industries favor steam turbines over other prime movers.

Another emerging application for steam turbines is their role in hybrid energy systems. As industries seek to reduce their carbon footprint, hybrid solutions combining steam turbines with renewable energy sources are gaining traction. For instance, concentrated solar power (CSP) plants use mirrors to focus sunlight onto a central receiver, generating high-temperature steam that drives a turbine. Similarly, geothermal power plants harness underground heat to produce steam, which is then expanded through a turbine to generate electricity or mechanical power. These applications demonstrate how steam turbines can seamlessly integrate with low-carbon energy sources to enhance sustainability.

Despite their many advantages, steam turbines also present certain challenges that industries must consider. One of the primary limitations is the need for an efficient steam supply system, including high-performance boilers, condensers, and piping infrastructure. The initial capital investment for a steam turbine system can be substantial, particularly for small-scale operations where alternative power sources such as electric motors or reciprocating engines may be more cost-effective. However, for larger industrial applications, the long-term efficiency and durability of steam turbines often offset the higher upfront costs.

Another challenge is the potential for efficiency losses due to steam leakage, turbine fouling, and mechanical wear. Over time, deposits can form on turbine blades, reducing aerodynamic efficiency and increasing energy losses. Regular maintenance, including steam purity management and periodic blade cleaning, is essential to maintaining peak performance. Advances in material science and surface coatings continue to improve resistance to fouling and erosion, helping extend turbine life and reduce maintenance costs.

As industries move toward decarbonization and energy efficiency improvements, steam turbines are expected to remain a key technology in the transition to a more sustainable future. Ongoing research into supercritical and ultra-supercritical steam cycles aims to push efficiency levels even higher, reducing fuel consumption and emissions. Additionally, the integration of digital twins—virtual models that simulate real-time turbine performance—will enhance predictive maintenance and operational optimization. These advancements will further solidify the role of steam turbines in modern industrial energy systems, ensuring their continued relevance in an evolving energy landscape.

Looking ahead, steam turbines will continue to be an indispensable part of industrial power generation and mechanical drive applications. Their ability to deliver high efficiency, reliability, and fuel flexibility makes them an ideal choice for industries seeking long-term energy solutions. With ongoing technological improvements and increasing integration with renewable energy sources, steam turbines will play a pivotal role in driving industrial processes while supporting global efforts to enhance sustainability and reduce carbon emissions.

Driving Electric Generators with Steam Turbines

Driving electric generators with steam turbines is one of the most widespread and efficient methods of electricity generation. Steam turbines convert thermal energy from steam into mechanical energy, which then drives an electric generator to produce electricity. This principle is the foundation of power generation in fossil fuel power plants, nuclear power stations, and renewable energy facilities such as biomass and geothermal plants. The efficiency, reliability, and scalability of steam turbines make them an essential component in both large-scale and distributed power generation systems.

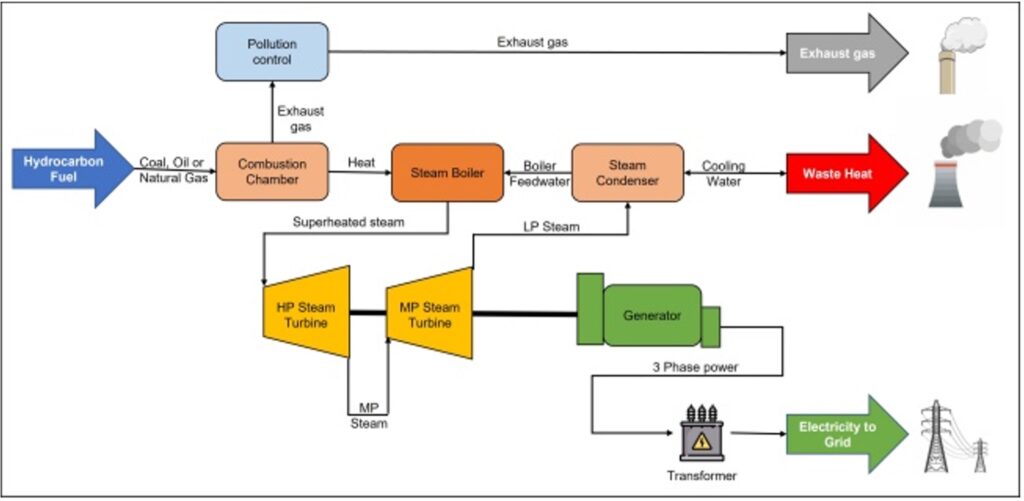

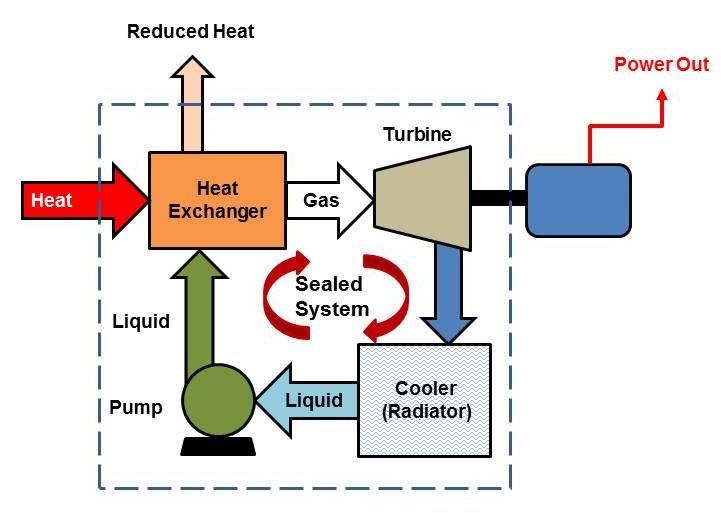

The fundamental process begins with a heat source, which generates high-pressure steam in a boiler or heat recovery system. This steam is directed into the turbine, where it expands across multiple stages of blades, causing the rotor to spin at high speeds. The kinetic energy from the spinning turbine shaft is transferred to an electrical generator through a coupling mechanism. Inside the generator, electromagnetic induction occurs as the rotating shaft turns a rotor within a stator, converting mechanical energy into electrical energy. The generated electricity is then conditioned, transformed to appropriate voltage levels, and distributed to the power grid or industrial consumers.

The efficiency of a steam turbine-driven generator depends on various factors, including steam pressure, temperature, turbine design, and generator characteristics. Higher steam temperatures and pressures generally improve efficiency by allowing more energy to be extracted from the steam before it is exhausted or condensed. Modern power plants employ superheated and reheated steam cycles to maximize energy conversion, reducing fuel consumption and lowering emissions. Ultra-supercritical steam turbines operate at extremely high temperatures and pressures, further enhancing efficiency and minimizing environmental impact.

There are different types of steam turbines used for driving electric generators, each suited to specific applications. Condensing steam turbines are the most common in large-scale power generation, as they extract maximum energy from the steam before it is condensed back into water in a vacuum-operated condenser. This design increases thermal efficiency and allows for greater power output. In contrast, back-pressure steam turbines exhaust steam at higher pressures for use in industrial processes, such as heating or manufacturing, making them ideal for combined heat and power (CHP) systems. Extraction steam turbines, which allow controlled steam extraction at intermediate pressures, offer additional flexibility in balancing electricity production with process steam demands.

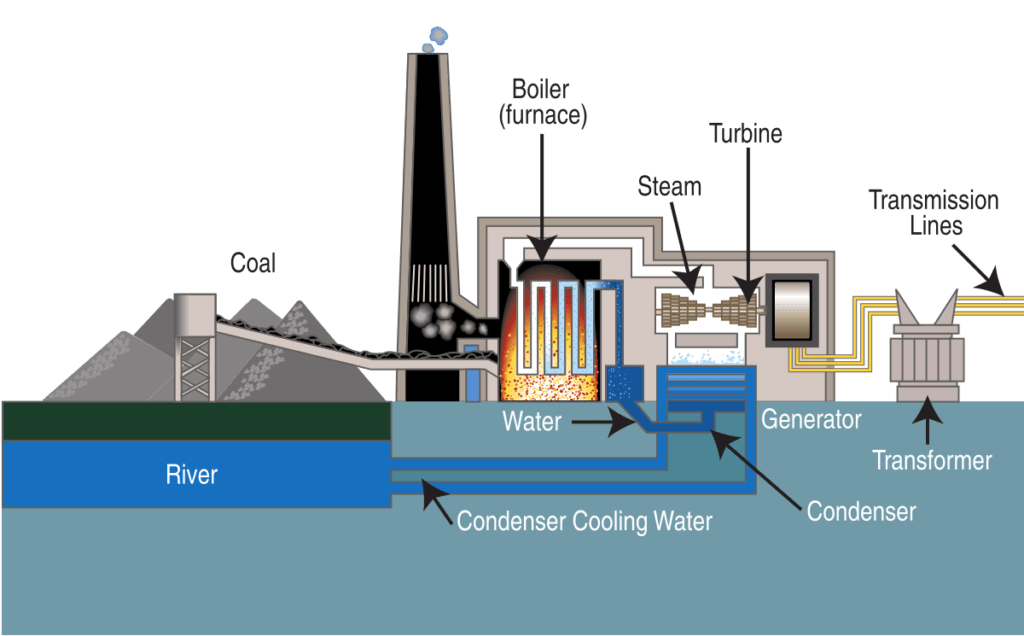

Steam turbine-driven generators are widely used in fossil fuel power plants, where coal, natural gas, or oil is burned in boilers to produce steam. In coal-fired power plants, pulverized coal is combusted to generate high-temperature steam, which then powers the turbine. Similarly, in gas-fired plants, heat from gas combustion produces steam either directly (in steam boilers) or as part of a combined-cycle configuration, where a gas turbine generates initial power and a steam turbine utilizes waste heat for additional generation. This combined-cycle approach significantly improves overall plant efficiency, reaching levels above 60% in modern installations.

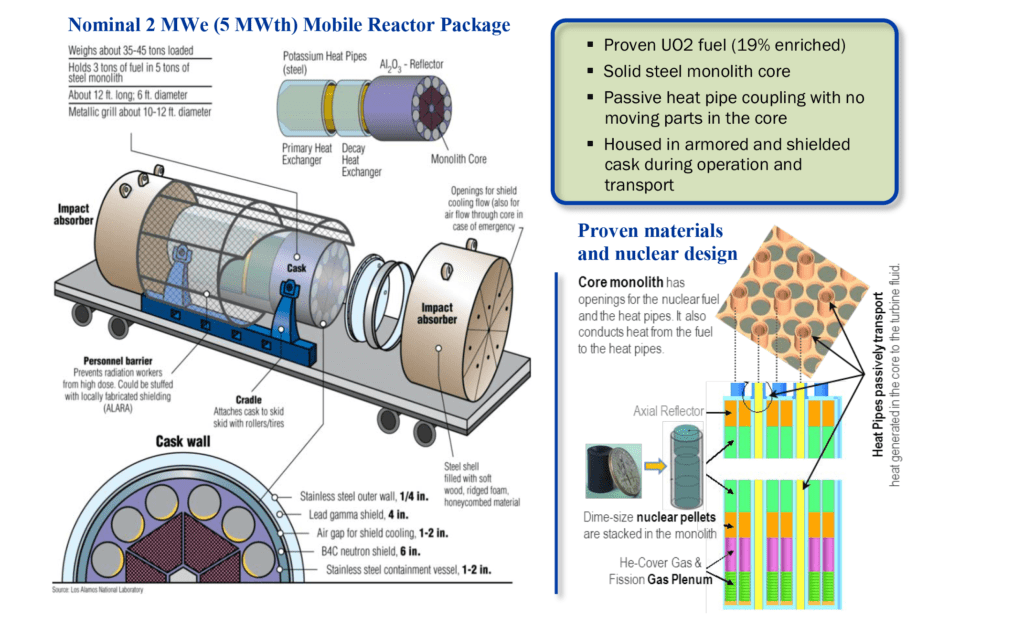

Nuclear power plants also rely on steam turbines for electricity generation, but instead of burning fossil fuels, they use nuclear fission to heat water and create steam. Pressurized water reactors (PWRs) and boiling water reactors (BWRs) are the two primary types of nuclear reactors used in steam turbine power generation. In a PWR, heat from the nuclear core is transferred to a secondary loop that produces steam, while in a BWR, steam is generated directly within the reactor vessel and fed to the turbine. The ability of steam turbines to operate under high-load conditions with minimal mechanical wear makes them particularly suitable for the constant power output required by nuclear power plants.

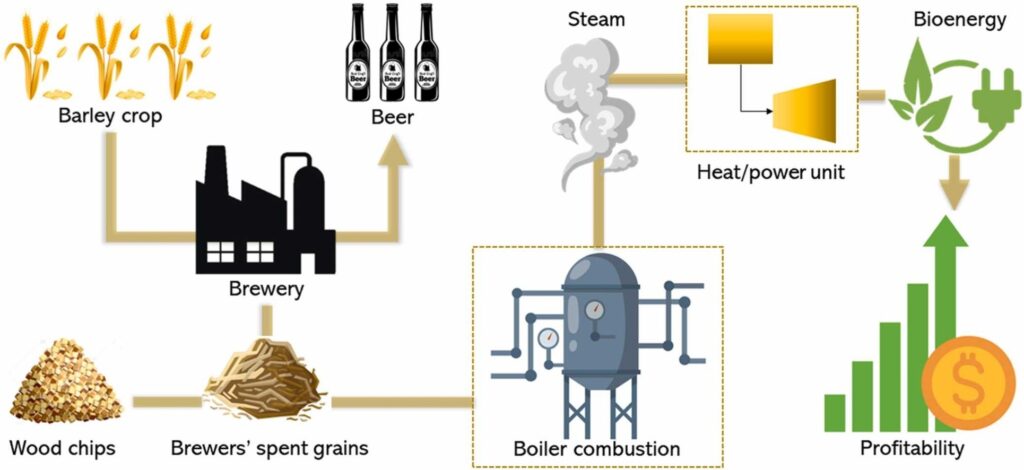

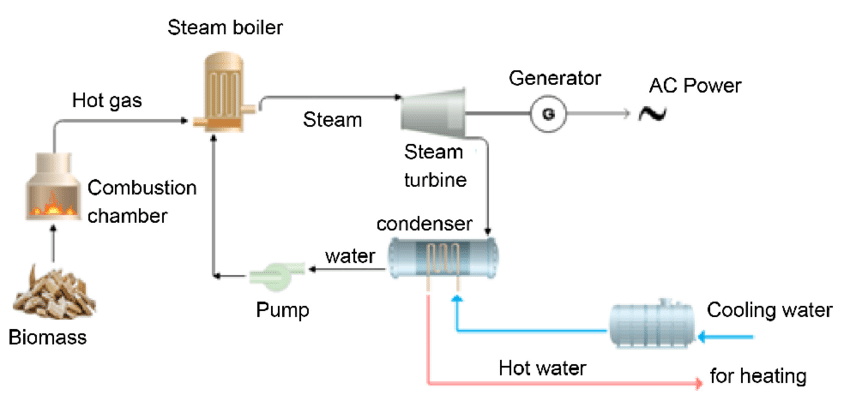

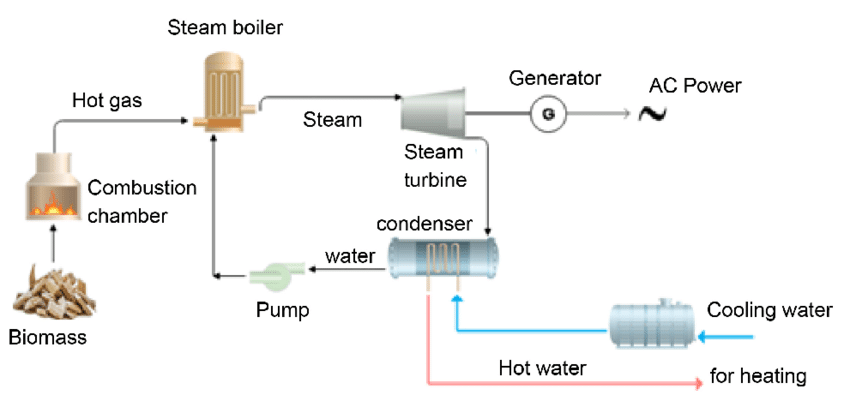

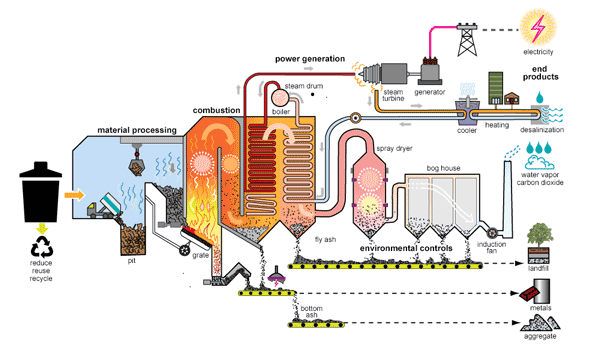

Beyond fossil and nuclear power, steam turbine generators play a crucial role in renewable energy systems. Biomass power plants burn organic materials such as wood chips, agricultural waste, or municipal solid waste to generate steam for turbine-driven electricity production. Geothermal power plants extract naturally occurring steam or hot water from underground reservoirs, using it to drive turbines and generate electricity with minimal carbon emissions. Additionally, concentrated solar power (CSP) plants use mirrors to focus sunlight onto a receiver, heating a fluid that generates steam for turbine operation. These renewable applications highlight the versatility and adaptability of steam turbines in various energy production contexts.

The design and operation of the electrical generator coupled with the steam turbine are also critical to overall efficiency and reliability. Most power plants use synchronous generators, which operate at a constant speed synchronized with the grid frequency (e.g., 50 Hz or 60 Hz, depending on the region). The generator’s rotor, typically equipped with electromagnets or permanent magnets, induces an alternating current (AC) in the stator windings as it spins. Large power plants often employ hydrogen-cooled or water-cooled generators to manage heat dissipation and enhance performance. Advanced excitation and voltage regulation systems ensure stable output and efficient integration into the power grid.

Efficiency improvements in steam turbine power generation continue to be a focus of research and development. Technologies such as supercritical carbon dioxide (sCO₂) cycles, which use CO₂ instead of steam as the working fluid, promise higher efficiency and reduced environmental impact. Additionally, digital monitoring systems and predictive maintenance using artificial intelligence (AI) help optimize turbine performance, detect potential issues, and extend operational lifespans. The integration of steam turbines with smart grids and energy storage solutions further enhances their role in modern power systems, ensuring reliable electricity supply even in fluctuating demand scenarios.

Despite their many advantages, steam turbine-driven generators also present challenges. The initial capital investment for steam-based power plants is high, requiring significant infrastructure such as boilers, condensers, cooling towers, and extensive piping networks. The thermal efficiency of a steam turbine system is also limited by the second law of thermodynamics, meaning that some energy loss is inevitable. Additionally, water usage for steam generation and cooling can be a concern, particularly in regions with limited freshwater availability. To address this, many power plants implement dry cooling or hybrid cooling systems to reduce water consumption while maintaining efficiency.

Looking ahead, steam turbines will remain a cornerstone of electricity generation worldwide. As industries transition toward cleaner energy sources, steam turbine technology will continue to evolve to support decarbonization efforts. The expansion of hybrid power systems, integration with renewable energy, and advancements in high-efficiency turbine designs will shape the future of steam-based power generation. With their proven reliability, adaptability, and efficiency, steam turbine-driven generators will continue to play a vital role in meeting global energy demands for decades to come.

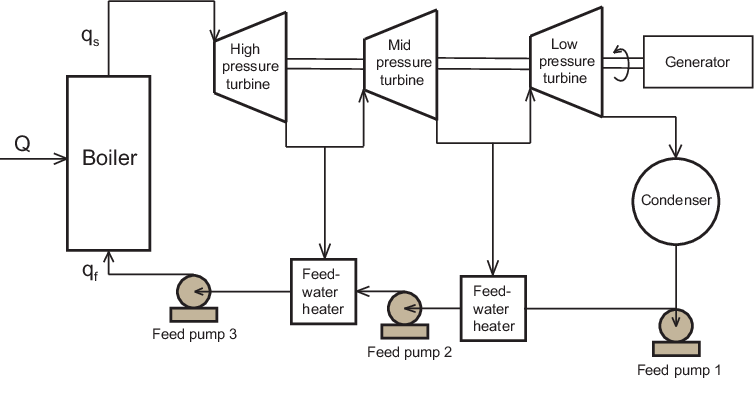

One of the most significant factors influencing the efficiency of steam turbine-driven generators is the thermodynamic cycle used in the power generation process. The Rankine cycle, which forms the foundation of steam turbine operation, consists of four key stages: heat addition in a boiler, expansion in a turbine, heat rejection in a condenser, and pressurization of the working fluid in a pump. Enhancing each stage of this cycle can lead to considerable improvements in power plant efficiency. For example, increasing the steam temperature and pressure before it enters the turbine reduces the amount of fuel required per unit of electricity generated, leading to better thermal efficiency and lower emissions.

To achieve higher efficiencies, modern power plants utilize variations of the Rankine cycle, such as the regenerative Rankine cycle and the reheat cycle. In the regenerative cycle, a portion of the steam is extracted from the turbine at intermediate pressures and used to preheat the feedwater before it enters the boiler. This process reduces the heat input required, thereby improving overall efficiency. Similarly, the reheat cycle involves expanding steam in a high-pressure turbine stage, reheating it in the boiler, and then expanding it further in a low-pressure turbine stage. Reheating prevents excessive moisture content in the later turbine stages, which can cause erosion of turbine blades and reduce efficiency.

Another critical aspect of steam turbine performance is the design of turbine blades and the optimization of steam flow paths. Steam turbines consist of multiple stages of rotating and stationary blades, with each stage responsible for extracting energy from the steam as it expands. The shape, length, and material composition of these blades directly affect the turbine’s efficiency and durability. Advanced computational fluid dynamics (CFD) modeling is used to optimize blade aerodynamics, ensuring that steam flows smoothly through the turbine with minimal turbulence and energy loss. Additionally, modern blade coatings and materials, such as nickel-based superalloys and ceramic composites, enhance resistance to high temperatures and corrosion, extending turbine lifespan and reducing maintenance requirements.

The condenser plays a vital role in the steam turbine power generation process by converting low-energy exhaust steam back into water for reuse in the boiler. The efficiency of this heat rejection process influences overall power plant performance. Most large power plants use water-cooled condensers, where cooling water absorbs heat from the steam and carries it away, enabling rapid condensation. In coastal areas, seawater cooling is commonly employed, while inland plants rely on freshwater cooling towers or air-cooled condensers. Improving condenser performance through enhanced heat exchanger designs, optimized cooling water flow rates, and advanced materials can lead to significant gains in efficiency and reduced operating costs.

In addition to thermodynamic optimizations, modern steam turbine power plants incorporate advanced control and automation systems to improve operational efficiency. Digital monitoring tools, such as condition-based maintenance (CBM) and predictive analytics, enable plant operators to detect potential issues before they lead to equipment failures. Sensors installed throughout the turbine, generator, and auxiliary systems continuously collect data on temperature, pressure, vibration, and other critical parameters. Artificial intelligence (AI) and machine learning algorithms analyze this data in real-time, providing insights that help operators optimize steam flow rates, adjust turbine load conditions, and schedule maintenance more effectively. This proactive approach minimizes downtime, reduces maintenance costs, and enhances overall reliability.

Another important consideration in steam turbine power generation is grid integration and load-following capability. While steam turbines are traditionally associated with baseload power generation, modern plants are increasingly designed to accommodate fluctuations in electricity demand. Variable steam flow control, rapid startup and shutdown procedures, and flexible operational modes allow steam turbine plants to complement intermittent renewable energy sources such as wind and solar. For example, hybrid power plants combine steam turbines with battery storage systems or gas turbines to provide grid stability and ensure a consistent electricity supply.

The environmental impact of steam turbine power generation is also a major focus of research and innovation. Although fossil fuel-based steam power plants produce greenhouse gas emissions, advanced carbon capture and storage (CCS) technologies can significantly reduce their environmental footprint. CCS systems capture CO₂ from power plant emissions and either store it underground or utilize it for industrial applications such as enhanced oil recovery or synthetic fuel production. Additionally, integrating steam turbines with renewable energy sources—such as biomass and geothermal—can provide cleaner alternatives to conventional fossil fuel power generation.

Furthermore, the transition to hydrogen as a fuel source presents new opportunities for steam turbine technology. Hydrogen can be burned in boilers to generate steam or used in fuel cells to produce electricity with zero emissions. Some power plants are exploring the co-firing of hydrogen with natural gas to reduce carbon intensity while maintaining the reliability and efficiency of steam turbines. Research into high-temperature electrolysis and thermochemical water-splitting methods aims to produce hydrogen more efficiently using excess heat from steam turbine power plants, creating a pathway for deeper decarbonization.

Looking to the future, continued advancements in steam turbine design, materials, and control systems will further enhance the efficiency, flexibility, and sustainability of steam-driven power generation. Supercritical and ultra-supercritical steam cycles will push efficiency levels even higher, reducing fuel consumption and emissions. Digitalization and automation will enable smarter, more responsive power plants that adapt to changing energy demands in real time. As global energy systems evolve, steam turbines will remain a cornerstone of reliable electricity generation, playing a crucial role in meeting energy needs while supporting the transition to a low-carbon future.

Another key factor in the continued advancement of steam turbine-driven generators is the role of emerging technologies that enhance efficiency and operational flexibility. One such innovation is the use of advanced heat recovery systems, particularly in combined-cycle power plants. In these systems, steam turbines operate in conjunction with gas turbines to maximize energy extraction from fuel. The gas turbine generates electricity by burning natural gas, and its high-temperature exhaust gases are used to produce steam in a heat recovery steam generator (HRSG), which then powers a steam turbine for additional electricity generation. This combined-cycle configuration significantly increases overall efficiency, often exceeding 60%, making it one of the most effective methods for fossil fuel-based electricity production.

Additionally, steam turbine performance is being further enhanced through improvements in steam cycle conditions. The development of advanced ultra-supercritical (A-USC) steam plants is pushing operational temperatures beyond 700°C (1,292°F) and pressures above 35 MPa, allowing for even greater efficiency gains. These high-performance conditions require advanced materials capable of withstanding extreme heat and pressure while maintaining long-term durability. Nickel-based superalloys, ceramic matrix composites, and advanced coatings are being incorporated into turbine components to ensure reliability under these harsh conditions. As a result, A-USC power plants achieve higher energy conversion efficiency while reducing CO₂ emissions per unit of electricity generated.

Furthermore, increasing the adaptability of steam turbines for grid balancing applications is becoming a major focus. Traditionally, steam turbines have been optimized for baseload power generation, operating at a steady output over long periods. However, the growing share of intermittent renewable energy sources, such as wind and solar, requires greater flexibility in power plant operations. To address this challenge, modern steam turbines are designed to ramp up and down more quickly, allowing them to complement fluctuations in renewable energy generation. Faster startup times, advanced steam bypass systems, and variable pressure operation help steam turbines support grid stability, reducing the risk of supply disruptions.

A significant breakthrough in steam turbine control systems has been the integration of artificial intelligence (AI) and machine learning for predictive maintenance and optimization. AI-driven monitoring systems continuously collect and analyze data from turbines, generators, and auxiliary equipment, identifying patterns that indicate potential failures or inefficiencies. By leveraging this data, operators can implement condition-based maintenance strategies, reducing unplanned downtime and extending the lifespan of critical components. This proactive approach not only lowers maintenance costs but also improves overall power plant availability and reliability.

The role of steam turbines in industrial cogeneration and district heating applications is also expanding. In cogeneration (also known as combined heat and power, or CHP) systems, steam turbines generate electricity while simultaneously providing process steam or hot water for industrial facilities, commercial buildings, or residential districts. This dual-use approach enhances energy efficiency, as it utilizes heat that would otherwise be wasted in traditional power plants. Industrial sectors such as chemical processing, refining, and pulp and paper manufacturing particularly benefit from CHP systems, as they require both electricity and process heat for production. District heating networks, commonly used in colder regions, distribute steam or hot water from central power plants to multiple buildings, further improving energy efficiency and reducing reliance on fossil fuels.

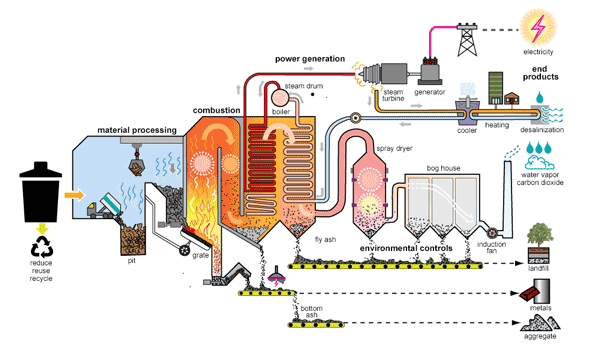

The transition to low-carbon energy sources is also influencing the design and operation of steam turbines. Biomass-fired power plants, which use organic materials such as wood pellets, agricultural residues, or municipal waste to generate steam, are gaining traction as a renewable alternative to coal. Co-firing biomass with coal in existing steam turbine power plants is an effective strategy to reduce carbon emissions without requiring significant modifications to infrastructure. Additionally, waste-to-energy plants, which convert municipal solid waste into steam for power generation, provide an environmentally friendly solution for reducing landfill waste while producing electricity.

Geothermal power generation is another area where steam turbines play a crucial role. In geothermal plants, steam or high-temperature fluids extracted from underground reservoirs drive turbines to generate electricity. Dry steam and flash steam geothermal systems directly use natural steam, while binary cycle geothermal plants transfer heat from geothermal fluids to a secondary working fluid with a lower boiling point, which then vaporizes to drive the turbine. Because geothermal energy provides a stable and continuous source of power, it serves as an important complement to intermittent renewable energy sources like wind and solar.

The potential for hydrogen to become a major fuel source in steam turbine power generation is also being explored. Hydrogen can be combusted in boilers to produce steam or used in gas turbines as part of a hydrogen-natural gas blend. Hydrogen-fired steam cycles have the potential to offer carbon-free electricity generation, particularly if the hydrogen is produced through electrolysis using renewable energy. Research is ongoing to develop efficient methods for integrating hydrogen into existing steam turbine infrastructure, with the goal of achieving zero-emission power generation.

In the future, hybrid energy systems that combine steam turbines with other emerging technologies will likely play a larger role in power generation. For example, integrating steam turbines with molten salt energy storage allows excess electricity from renewable sources to be stored as thermal energy and later converted back into steam for electricity production during periods of high demand. Similarly, supercritical carbon dioxide (sCO₂) power cycles, which replace steam with high-pressure CO₂ as the working fluid, are being developed to achieve higher efficiency and reduced environmental impact. These innovations will further improve the viability of steam turbines in an evolving energy landscape.

Despite the advancements in steam turbine technology, challenges remain. The high capital costs associated with constructing new steam turbine power plants can be a barrier, particularly as some regions prioritize decentralized and renewable energy solutions. Additionally, water consumption for cooling and steam production is a concern in water-scarce areas, prompting research into dry cooling techniques and alternative working fluids. Nevertheless, the long-term benefits of steam turbine power generation, including reliability, efficiency, and fuel flexibility, ensure that they will continue to play a vital role in meeting global electricity demand.

As energy systems transition toward a more sustainable future, steam turbines will remain a key technology in power generation. Their ability to integrate with renewable energy sources, provide grid stability, and adapt to new fuel types will ensure their continued relevance. Whether through ultra-efficient supercritical steam cycles, hydrogen-powered systems, or hybrid renewable energy configurations, steam turbines will play a crucial role in delivering clean, reliable, and cost-effective electricity in the decades to come.

Another significant area of development in steam turbine-driven power generation is the ongoing refinement of energy storage integration and load management strategies. As electrical grids incorporate more variable renewable energy sources, steam turbines must operate with greater flexibility to balance supply and demand. Advanced thermal energy storage (TES) solutions are being integrated with steam turbines to store excess energy generated during periods of low demand and release it when electricity consumption peaks. Technologies such as molten salt storage, phase change materials (PCMs), and high-temperature steam accumulators are being explored to improve grid reliability and efficiency while reducing the reliance on fossil fuel peaking plants.

Molten salt storage, widely used in concentrated solar power (CSP) plants, enables steam turbines to generate electricity even after the sun has set. In this system, solar energy heats molten salt, which retains thermal energy for extended periods. When electricity is needed, the stored heat is transferred to a working fluid to produce steam that drives a turbine. This method significantly enhances the dispatchability of renewable power plants, allowing them to function more like conventional baseload power sources. Similar storage solutions are being tested in hybrid fossil-renewable plants to improve efficiency and reduce emissions.

Another promising development is the use of supercritical carbon dioxide (sCO₂) power cycles as an alternative to traditional steam turbines. Instead of water and steam, these systems use high-pressure CO₂ as the working fluid in a closed-loop cycle. Because sCO₂ has superior thermodynamic properties, it allows for higher energy conversion efficiency at lower operating temperatures and pressures. Additionally, sCO₂ turbines are much smaller than steam turbines of equivalent power output, reducing capital and maintenance costs. Research is ongoing to scale up sCO₂ power systems for commercial deployment, with applications ranging from fossil and nuclear power plants to concentrated solar and waste heat recovery.

Advancements in steam turbine materials and manufacturing processes are also improving performance, longevity, and cost-effectiveness. Additive manufacturing (AM), or 3D printing, is being increasingly used to produce complex turbine components with enhanced durability and efficiency. This technique allows for the creation of intricate blade designs that optimize aerodynamics while reducing weight and material waste. Additionally, AM enables the rapid production of replacement parts, minimizing downtime and maintenance costs. High-temperature-resistant materials, such as ceramic matrix composites and nickel-based superalloys, are being developed to withstand extreme operating conditions, further improving turbine efficiency and service life.

One of the key challenges in steam turbine-driven power generation is water usage, particularly in arid regions where freshwater resources are scarce. Traditional steam power plants rely on large amounts of water for cooling and steam generation, which can pose environmental and economic challenges. To address this issue, researchers are developing advanced dry cooling systems that reduce water consumption while maintaining high efficiency. Air-cooled condensers (ACCs) and hybrid cooling solutions that combine wet and dry cooling methods are being adopted in power plants to minimize water use without compromising performance. Additionally, innovative water recovery technologies, such as membrane-based steam condensation and advanced desiccant cooling systems, are being explored to further enhance sustainability.

In industrial settings, the role of steam turbines is evolving beyond traditional power generation. Industries that require large amounts of heat and electricity, such as petrochemicals, food processing, and paper manufacturing, are increasingly turning to steam turbine-based cogeneration systems to improve efficiency and reduce operating costs. In these systems, steam turbines generate both electricity and process steam, optimizing fuel usage and reducing emissions. The integration of waste heat recovery systems further enhances efficiency by capturing and reusing thermal energy that would otherwise be lost. In some cases, excess steam from industrial processes is supplied to nearby district heating networks, providing residential and commercial buildings with efficient heating solutions.

Another frontier in steam turbine technology is the exploration of fusion energy as a long-term power generation solution. Fusion reactors, such as those being developed by ITER and other research institutions, aim to harness the energy produced by nuclear fusion reactions to generate electricity. In these systems, the extreme heat from the fusion process is used to produce steam, which drives turbines in a manner similar to conventional nuclear power plants. While commercial fusion power is still in the experimental stage, successful implementation could provide a nearly limitless source of clean electricity, with steam turbines playing a central role in energy conversion.

As steam turbines continue to evolve, their integration with smart grid technology is becoming increasingly important. Digital twins—virtual replicas of physical turbine systems—are being used to simulate performance under different operating conditions, enabling predictive maintenance and real-time optimization. These digital models, combined with Internet of Things (IoT) sensors and big data analytics, allow power plant operators to monitor turbine efficiency, detect early signs of wear or failure, and implement corrective measures before problems escalate. This approach improves reliability, extends equipment lifespan, and reduces unplanned outages.

Looking to the future, the role of steam turbines in global energy systems will continue to adapt in response to technological advances, environmental concerns, and economic pressures. Whether through hybrid renewable-fossil configurations, hydrogen-fired steam cycles, or next-generation materials and cooling technologies, steam turbines will remain a key component of large-scale power generation. Their ability to provide stable, high-efficiency electricity generation ensures that they will continue to be a critical part of the transition to a cleaner, more resilient energy future.

Driving Feedwater Pumps with Steam Turbines

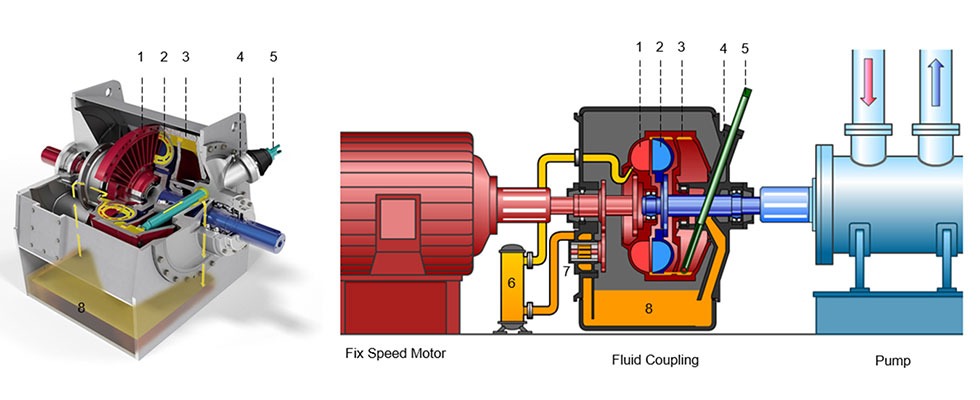

Driving feedwater pumps with steam turbines is a common practice in large-scale steam power plants, particularly in nuclear and fossil fuel plants, to ensure the continuous flow of water to the boiler. Feedwater pumps are essential for maintaining the steam generation process, as they supply water to the boiler at high pressure, allowing for the production of steam that drives the turbine. These pumps typically operate under very high pressures to overcome the resistance from the boiler and ensure an uninterrupted supply of water. Steam turbines provide a reliable and efficient method of driving these pumps by using the energy from steam to drive the mechanical rotation of the pump.

The principle behind driving feedwater pumps with steam turbines is straightforward. Steam turbines, in this case, are used to harness the energy in high-pressure steam, converting it into mechanical energy that turns the pump’s shaft. The mechanical energy is transferred through a shaft or coupling to the feedwater pump, which then pressurizes and feeds water into the boiler. In this process, steam turbines act as a mechanical power source for the pump, ensuring that the water is pumped to the desired pressure for steam generation.

In large power plants, there are typically two or more feedwater pumps in operation to ensure reliability and meet the demands of the plant. These pumps are often driven by dedicated steam turbines, though smaller pumps may be driven by electric motors. The steam turbines that drive feedwater pumps are usually low-pressure or auxiliary turbines, meaning they operate at lower pressures than the main turbine used for electricity generation. The steam used for the feedwater pump is typically extracted from the main turbine after it has passed through the high-pressure and intermediate stages. This process of steam extraction is efficient because it utilizes steam that would otherwise be at a lower pressure and temperature, which still contains a significant amount of energy.

In a typical steam cycle, the feedwater pump is located after the condenser and before the steam generator. The water that enters the pump is cooled, condensed, and demineralized to remove impurities. The feedwater pump then increases the pressure of this water, which is eventually heated in the boiler to generate steam. Once the water is pressurized, it enters the boiler at a controlled rate, where it is heated by the burning of fossil fuels, nuclear reactions, or concentrated solar power. The high-pressure steam produced in the boiler is sent to the turbine, which drives the generator to produce electricity.

Using steam turbines to drive feedwater pumps is advantageous for several reasons. First, it is a highly reliable and proven method of providing mechanical power to pumps. Since steam turbines are already integrated into the power generation cycle, they can efficiently share steam with the feedwater pumps, reducing the need for separate motor-driven systems. This integration reduces equipment complexity and improves overall system reliability.

Another benefit of using steam turbines for feedwater pumps is the potential for energy recovery. In some systems, the low-pressure steam extracted from the main turbine can be utilized effectively for pump operation without significantly reducing the power available for electricity generation. By carefully controlling the amount of steam extracted and ensuring efficient steam usage, power plants can optimize the performance of both the turbine and the feedwater pump, maximizing energy conversion efficiency.

Steam-driven feedwater pumps also help ensure that there is enough pressure in the boiler to sustain the steam generation process. Maintaining the correct feedwater pressure is essential for optimizing the efficiency of the boiler and ensuring safe operation. If the pressure of the water entering the boiler is too low, it can cause fluctuations in steam production, leading to inefficiencies or potentially dangerous conditions. On the other hand, having the proper pressure ensures that the water is efficiently heated to generate steam, which is then used to drive the turbine and produce electricity.

In some plants, particularly in combined-cycle or cogeneration systems, steam turbines that drive feedwater pumps may be part of a broader system of interconnected turbines that also provide mechanical power to other equipment, such as condensate pumps, air compressors, and cooling water pumps. These systems allow for optimized energy usage, as steam from the turbine is used efficiently for multiple purposes within the plant, reducing waste and improving overall performance.

While steam turbines are generally efficient for driving feedwater pumps, their performance must be carefully managed to prevent mechanical wear and ensure long-term reliability. For instance, the steam turbine must be operated within its optimal pressure and temperature ranges to avoid damage from overheating or excessive pressure buildup. Additionally, regular maintenance and monitoring are necessary to ensure that the feedwater pump, turbine, and related components remain in good working condition. Modern digital monitoring and predictive maintenance technologies, which use sensors to collect data on temperature, vibration, and pressure, can help detect potential issues before they lead to mechanical failure, reducing downtime and maintenance costs.

Another important consideration is the control of steam flow to the feedwater pump turbines. The amount of steam used for this purpose can vary depending on the load demand and operational conditions of the power plant. Control valves and regulation systems are typically employed to adjust steam flow to the turbines, maintaining the correct pressure and ensuring optimal pump operation. This dynamic adjustment ensures that the feedwater pump is always operating efficiently without using excessive steam, which could reduce the overall power plant efficiency.

In some power plants, multiple feedwater pumps may be operated in parallel, each driven by its own steam turbine or by a shared turbine, depending on the plant design. This configuration improves reliability by providing redundancy; if one pump or turbine fails, the others can continue to operate. In such cases, the control system can automatically adjust steam flow to ensure that the remaining pumps continue to function as needed. This level of automation and adaptability ensures that the feedwater system is always operating efficiently, even in the event of component failures.

In conclusion, driving feedwater pumps with steam turbines remains a critical component of the operation in many large-scale power plants. This method of providing mechanical energy offers a reliable, efficient, and cost-effective solution that integrates seamlessly with the rest of the steam cycle. By utilizing steam from the turbine, feedwater pumps ensure that the boiler receives a continuous supply of water at the correct pressure, enabling the plant to generate steam for electricity production. With advancements in control systems, maintenance technologies, and steam cycle optimization, steam turbines will continue to play an essential role in driving feedwater pumps and improving the overall efficiency and reliability of steam power plants.

To further enhance the efficiency and performance of feedwater pumps driven by steam turbines, power plants are increasingly incorporating advanced technologies and system optimizations that aim to improve both operational flexibility and energy efficiency. One such advancement is the use of variable-speed drives (VSDs) on steam turbines that drive feedwater pumps. In systems where variable load conditions are common, VSDs allow for better control of pump speed and, consequently, the feedwater pressure. This reduces the need for throttling, which is often used to regulate pump flow and pressure, thereby minimizing energy losses and improving overall system efficiency.

Additionally, the integration of advanced turbine and pump controls through digital systems has made it easier to optimize performance in real-time. Modern plant control systems use data from various sensors located throughout the steam cycle to continuously monitor the operation of the steam turbine, feedwater pump, and related components. These systems can make immediate adjustments to steam flow, pump speed, and other operating parameters to ensure that the system operates within the most efficient parameters. The ability to predict when a turbine or pump is likely to experience wear or degradation allows operators to plan maintenance more effectively, reducing downtime and extending the lifespan of critical components.

Moreover, the integration of artificial intelligence (AI) and machine learning (ML) into plant operations offers significant potential for optimizing the performance of steam turbines driving feedwater pumps. AI algorithms can analyze vast amounts of operational data, identifying patterns and trends that humans may overlook. For example, predictive analytics can forecast changes in the performance of feedwater pumps based on past behavior and operating conditions. The system can then adjust operational parameters proactively, avoiding unnecessary wear on the turbine or pump and ensuring that energy is used efficiently. This type of advanced data analysis and predictive maintenance reduces the likelihood of unexpected failures, ensuring that the plant operates smoothly and minimizes unplanned maintenance costs.

In terms of materials and component design, steam turbines driving feedwater pumps are benefitting from innovations that improve efficiency and reduce wear over time. For instance, advanced turbine blades and seals made from corrosion-resistant and high-temperature materials are becoming more common. These materials ensure that steam turbines can handle the harsh conditions of high-pressure steam while maintaining their efficiency. In addition, advanced coatings applied to critical components, such as the blades, reduce friction and prevent material degradation, allowing for longer service intervals and greater reliability. These improvements in material science are particularly important as the operational pressures and temperatures in modern steam cycles continue to increase, pushing the limits of traditional turbine technology.

As power plants continue to integrate renewable energy sources such as wind and solar, the role of steam turbines in driving feedwater pumps will evolve further. In hybrid systems, where steam turbines complement renewable sources, the ability to quickly adjust steam generation to match fluctuations in renewable output will be essential. In these cases, steam turbines driving feedwater pumps may need to operate more dynamically, ramping up or down in response to changes in available renewable energy. This capability allows the plant to maintain a stable supply of steam to the turbine for power generation while still supporting the fluctuating output of solar or wind power.

Additionally, with the push for more sustainable energy solutions, the potential to use alternative fuels to generate steam is becoming more prominent. Biomass, hydrogen, and waste-to-energy systems are being explored as viable sources of steam generation. Biomass, in particular, offers a renewable fuel option that can be integrated into existing steam cycles, driving the steam turbines that feed water into the boiler. Hydrogen, when used as a clean fuel source, can provide zero-emission power generation, reducing the environmental impact of steam-based electricity production. Incorporating these renewable fuels into steam turbine operations will allow plants to reduce their carbon footprints while still maintaining the efficiency and reliability required for power generation.

Furthermore, advances in the use of combined heat and power (CHP) systems are influencing the way steam turbines are used to drive feedwater pumps. In CHP applications, the steam produced for electricity generation is also used to provide heat for industrial processes, district heating, or commercial facilities. This process of cogeneration allows plants to use both the electrical and thermal energy produced in a more efficient manner. By utilizing waste heat from the turbine exhaust or other parts of the system, these plants can reduce their fuel consumption and environmental impact while driving feedwater pumps to maintain a consistent and efficient steam cycle.

In some plants, the integration of steam turbines with advanced heat recovery systems, such as organic Rankine cycle (ORC) or Kalina cycle technology, is being explored to further increase overall system efficiency. These cycles allow for additional heat recovery from the turbine exhaust, which can be used to preheat the feedwater before it enters the boiler. Preheating the feedwater reduces the amount of fuel required to reach the desired steam temperature, improving the overall thermal efficiency of the power plant. In this way, steam turbines that drive feedwater pumps can be further optimized for energy recovery and reduced fuel consumption.

Finally, improving the integration of steam turbines into the overall plant design through modularity and flexible configurations is another avenue being explored. Modular systems allow power plants to scale up or down more easily based on energy demand and grid requirements. This flexibility is especially useful in systems that need to accommodate large variations in electricity demand or integrate with a mix of renewable and conventional generation sources. Steam turbines that drive feedwater pumps in these systems can be adjusted to match the varying load conditions, ensuring that feedwater pressure and steam generation remain consistent and efficient.

In summary, while the role of steam turbines in driving feedwater pumps is well-established, ongoing advancements in technology, materials, and control systems continue to improve efficiency, flexibility, and sustainability. From digital optimization and predictive maintenance to renewable fuel integration and modular plant design, the future of steam turbine-powered feedwater pumps looks promising. These innovations will allow for more reliable, cost-effective, and environmentally friendly power generation, ensuring that steam turbines remain an integral part of modern energy systems for years to come.

In addition to the technological advancements and operational optimizations discussed, there are several emerging trends and strategic shifts that could influence the future of driving feedwater pumps with steam turbines. These developments are closely tied to the broader energy transition, where the focus is increasingly on decarbonization, flexibility, and enhancing the efficiency of both new and existing power plants.

Hybrid and Integrated Systems

One notable trend is the continued development of hybrid systems that combine steam turbines with renewable energy sources or advanced thermal storage. In a hybrid setup, steam turbines still play a crucial role in driving feedwater pumps and maintaining boiler pressure, but they do so in conjunction with renewable technologies such as solar thermal, geothermal, or waste heat recovery systems. The integration of these renewable energy sources into the steam cycle helps reduce the overall carbon footprint of the plant by displacing fossil fuel-based steam generation.

For example, in a hybrid solar-steam system, concentrated solar power (CSP) plants use mirrors or lenses to focus sunlight on a fluid, often molten salt, which is then used to generate steam. This steam is fed into a steam turbine, which drives a generator and also powers feedwater pumps. By supplementing steam generation with solar energy, the overall fuel consumption can be reduced, which not only lowers emissions but also optimizes the operation of steam turbines, especially during times when solar output is high.

Similarly, integrated geothermal systems use the earth’s natural heat to generate steam. When paired with steam turbines, this allows plants to operate with minimal external fuel input, significantly improving efficiency. Geothermal systems can also reduce the operational load on steam turbines since they provide a constant source of heat, helping to ensure a stable and reliable supply of steam for driving feedwater pumps.

Focus on Sustainability and Emissions Reduction

As part of global efforts to decarbonize the energy sector, there is an increasing emphasis on reducing emissions from fossil fuel-based power plants. For plants that still rely on coal or natural gas for steam generation, carbon capture and storage (CCS) technology is being explored as a way to reduce the environmental impact. In such plants, steam turbines driving feedwater pumps could be part of an integrated CCS system where the captured CO2 is compressed and transported to storage sites.

These plants could also benefit from an optimization of steam turbine and feedwater pump systems that allows for the efficient capture and utilization of waste heat. For instance, the integration of combined heat and power (CHP) systems in industrial facilities or district heating applications can reduce overall fuel consumption by making use of heat that would otherwise be wasted in conventional power generation cycles. By reusing this waste heat to preheat feedwater, plants can decrease the amount of energy required to bring the water to the appropriate pressure and temperature levels, lowering both operational costs and environmental impact.

Additionally, more sustainable feedwater pump systems could be achieved by using biofuels and hydrogen as alternative sources of heat for steam generation. These fuels produce significantly fewer greenhouse gas emissions than traditional fossil fuels, and their use could further align power plants with global sustainability goals. For example, using hydrogen in place of natural gas for generating steam can potentially eliminate carbon emissions, contributing to the decarbonization of the steam cycle.

Advanced Control Systems for Improved Efficiency

Another area of focus for the future of steam turbine-driven feedwater pumps is the continued advancement of control systems. As steam cycles become more complex with the integration of various energy sources and technologies, the need for sophisticated control and optimization strategies grows. The use of digital control systems, coupled with artificial intelligence (AI) and machine learning (ML), allows operators to optimize the performance of steam turbines and feedwater pumps in real-time.

These systems can predict and adjust for fluctuating operating conditions, ensuring that the steam turbine operates at its peak efficiency, whether the plant is running at full capacity or at part load. For instance, during periods of low electricity demand, it may be necessary to reduce steam generation or adjust the feedwater pump speed to ensure that the plant does not consume more fuel than necessary. Advanced algorithms can detect patterns in system performance and adjust settings to prevent overuse of steam, optimizing the turbine’s mechanical output while ensuring sufficient feedwater supply.

AI-driven predictive maintenance tools also enhance the reliability of steam turbines. These tools can anticipate when a feedwater pump turbine may require servicing, based on data such as vibration levels, steam pressure, and temperature fluctuations. This proactive approach to maintenance helps to prevent costly breakdowns and unplanned shutdowns, ensuring that the plant continues to operate smoothly and efficiently over its lifespan.

Decentralized and Modular Power Systems

Another future trend is the shift towards decentralized, modular power generation systems that use smaller, more flexible steam turbines. These systems can be deployed in a variety of locations, from industrial plants to remote areas, reducing the need for long-distance transmission and improving overall grid resilience. In such systems, steam turbines that drive feedwater pumps can be scaled to match the output of smaller plants while still maintaining high levels of efficiency.

Modular systems also offer the benefit of faster deployment, allowing plants to be quickly expanded or adapted to meet changing energy demands. With increasing flexibility, these plants can respond to the variable generation of renewable energy sources, providing backup power when renewable generation dips or smoothing out fluctuations in demand. This shift toward decentralization is also aligned with the ongoing trends in microgrids, where smaller-scale, independent energy systems operate in conjunction with the larger grid, improving resilience and energy security.

In some cases, smaller-scale, renewable-driven systems could rely on steam turbines to drive feedwater pumps, especially in geothermal or waste heat recovery applications. These decentralized plants could provide localized power and heating, helping reduce reliance on centralized fossil fuel-based generation.

Conclusion

As the global energy landscape evolves toward a cleaner, more sustainable future, steam turbines driving feedwater pumps will continue to play an essential role in maintaining the efficiency, reliability, and flexibility of power generation. Innovations such as hybrid systems, advanced control technologies, and the integration of renewable energy sources are driving new levels of optimization. These advancements enable power plants to reduce emissions, operate more efficiently, and provide cleaner energy solutions. The integration of renewable energy, along with improvements in turbine technology and materials, will further enhance the role of steam turbines in the global transition to sustainable energy, ensuring that they remain integral to the future of both power generation and industrial processes.

As the global energy transition accelerates, steam turbines driving feedwater pumps will increasingly need to adapt to evolving demands for greater flexibility, decarbonization, and resilience in energy systems. The future of these systems will involve several cutting-edge trends and innovations aimed at improving performance, minimizing environmental impact, and integrating renewable energy sources. This section will focus on some of the emerging technologies and strategies that will shape the future of steam turbine-driven feedwater pumps in both large-scale and decentralized energy systems.

Integration with Energy Storage Systems

One of the most promising developments in the future of steam turbines driving feedwater pumps is the integration of energy storage systems. As power grids increasingly rely on intermittent renewable energy sources such as wind and solar, energy storage solutions will play a critical role in ensuring grid stability. In many cases, excess electricity generated by renewable sources can be used to store energy, which can later be converted into steam or thermal energy to drive turbines, including those used for feedwater pumping.

For example, concentrating solar power (CSP) plants with thermal storage systems can use surplus solar energy to heat a storage medium, such as molten salt, which retains heat over extended periods. This stored thermal energy can then be used to generate steam when the sun is not shining, providing a steady source of steam to drive turbines and feedwater pumps. Similarly, other thermal energy storage technologies, such as phase-change materials or heat storage tanks, are being researched to provide continuous energy to steam turbines, enabling them to maintain steady operations even when renewable sources are unavailable.

Energy storage systems combined with steam turbines can help balance the fluctuations between renewable generation and grid demand, ensuring that feedwater pumps continue to operate optimally regardless of the variability of energy supply. This will be particularly valuable in regions that rely heavily on renewable energy but still need reliable steam-powered systems for industrial processes or electricity generation. By using stored energy, these plants can achieve higher levels of efficiency and sustainability without sacrificing reliability.

Digital Twins and Advanced Simulation

In recent years, the use of “digital twins” has gained significant traction across the energy sector, including in the context of steam turbines and feedwater pump systems. A digital twin is a virtual representation of a physical system, created by integrating real-time data with advanced simulations. This technology allows operators to simulate various operational conditions and predict the behavior of turbines and pumps before any physical changes are made. By analyzing performance data in the context of a digital twin, operators can optimize system parameters, perform risk assessments, and even plan maintenance schedules with greater accuracy.

For example, digital twins can simulate the impact of different steam flow rates, pump speeds, and operating pressures on the overall efficiency of the turbine and feedwater pump system. By running these simulations continuously, digital twins help identify potential inefficiencies or points of failure, allowing for preemptive action to correct them before they affect the performance of the plant. The use of digital twins in combination with predictive analytics enables better decision-making, ensuring that turbines and pumps operate at their highest possible efficiency while extending the lifespan of critical components.

Additionally, digital twins can play a crucial role in the design phase of steam turbine and feedwater pump systems. By creating highly accurate virtual models, engineers can test different configurations and optimize designs before any physical systems are built. This helps ensure that new installations are optimized for performance, cost, and sustainability from the start, reducing the need for costly adjustments during the commissioning phase.

Hydrogen as a Fuel Source for Steam Generation

The growing interest in hydrogen as a clean alternative to fossil fuels is poised to reshape many aspects of the energy industry, including steam turbine-driven systems. Hydrogen can be used as a fuel to generate steam in boilers, providing an environmentally friendly way to produce the necessary steam to drive turbines and feedwater pumps.

One of the main advantages of using hydrogen is that it produces no carbon emissions when burned. This makes it a promising solution for decarbonizing steam generation in industrial and power plant settings. Hydrogen can be produced from renewable sources, such as wind, solar, and biomass, making it a sustainable fuel option for the future.

However, there are challenges to overcome before hydrogen can be widely adopted as a steam generation fuel. These include the production, storage, and transportation of hydrogen, which require significant infrastructure investment and technological advancements. In addition, hydrogen combustion in steam boilers needs to be optimized to ensure efficiency and avoid issues such as corrosion, especially when used in large-scale power plants. Nevertheless, as technologies for hydrogen production and distribution improve, hydrogen-driven steam generation systems could play an increasingly important role in driving feedwater pumps and other essential equipment in the energy sector.

Advanced Materials and Turbine Efficiency

The ongoing development of advanced materials will continue to enhance the efficiency and durability of steam turbines, including those used to drive feedwater pumps. As steam turbine systems operate under extreme conditions of high pressure and temperature, materials that are resistant to corrosion, erosion, and thermal fatigue are essential for long-term performance.