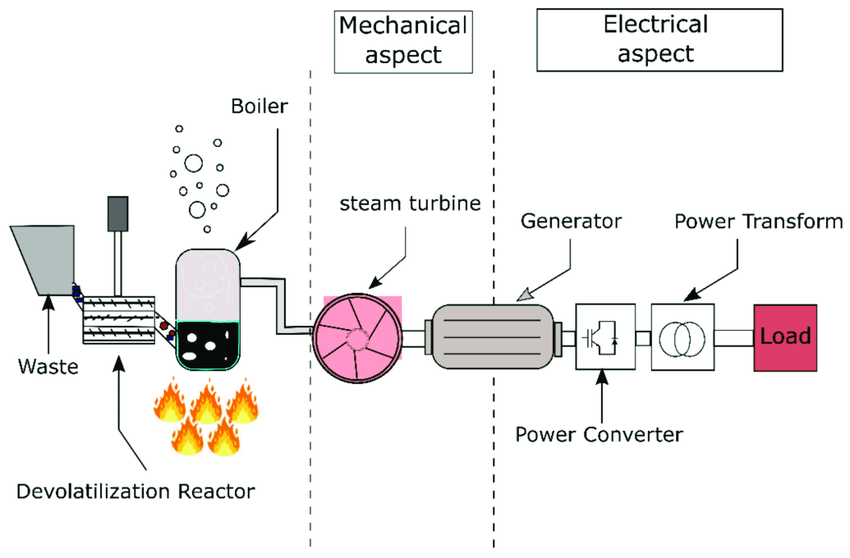

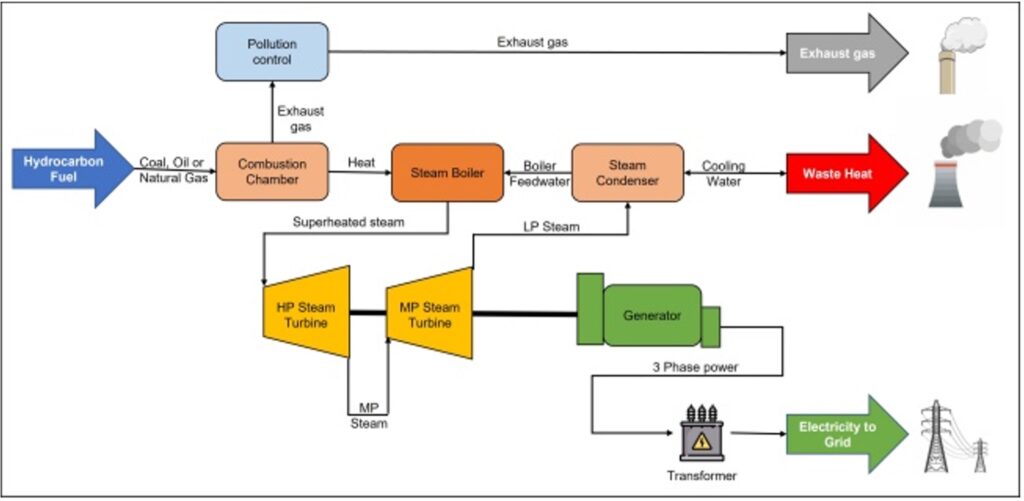

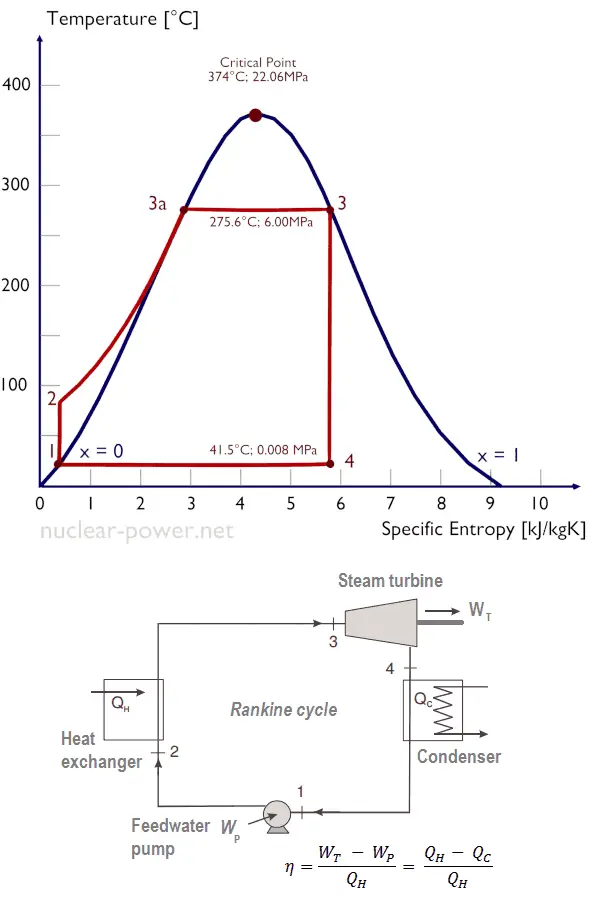

Steam Turbine Price in India: A steam-powered generator is a device that converts thermal energy from steam into electrical energy. It operates on the principle of the Rankine cycle, which involves the generation of steam by heating water, expanding the steam through a turbine to produce mechanical work, and then converting this mechanical energy into electricity using a generator. The process begins with a heat source, which could be fossil fuels like coal, natural gas, or oil, nuclear reactions, or renewable sources like geothermal heat or solar thermal energy. This heat source is used to convert water into high-pressure steam in a boiler. The high-pressure steam is then directed towards a steam turbine, where it rapidly expands and cools. As the steam expands, it pushes against the blades of the turbine, causing the turbine shaft to rotate. This rotational mechanical energy is then transferred to a generator, which produces electricity through electromagnetic induction.

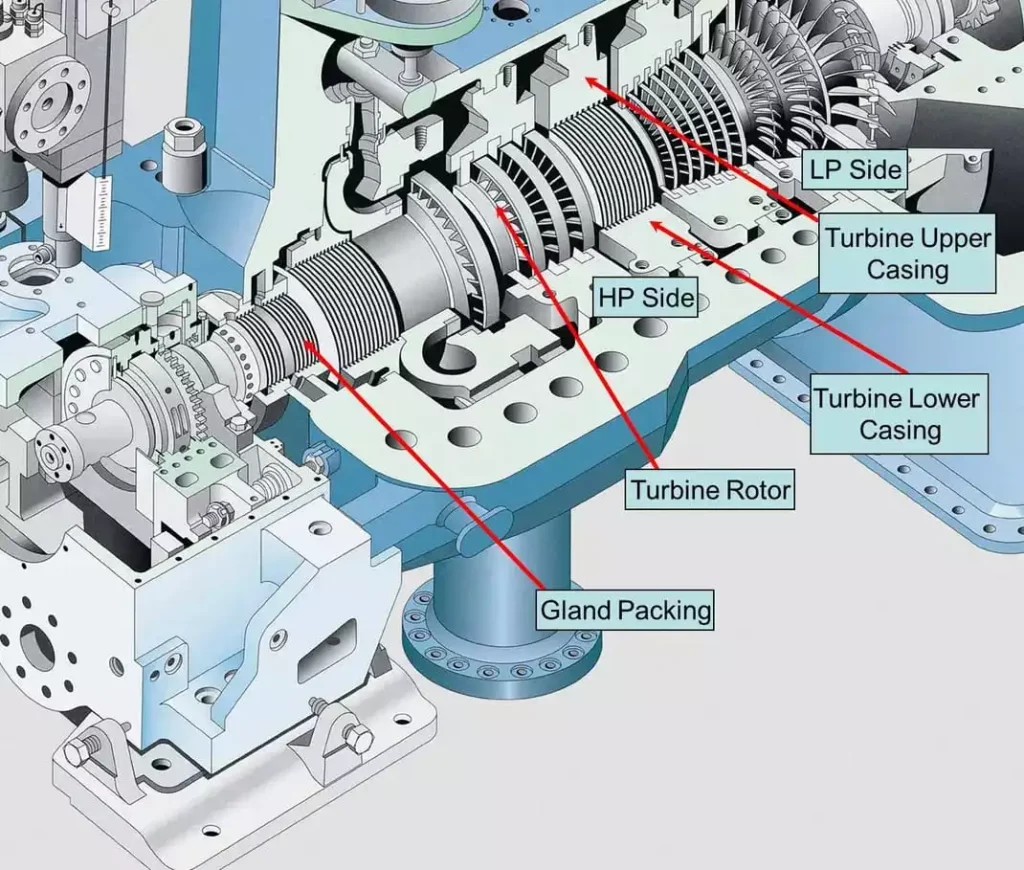

The efficiency and performance of a steam-powered generator depend on various factors, including steam temperature and pressure, turbine design, and the effectiveness of the condenser. Higher steam temperatures and pressures generally result in higher thermal efficiency, as they allow more energy to be extracted from the steam. Advanced systems use superheated steam, which is steam heated beyond its saturation point to prevent condensation within the turbine, thereby increasing efficiency and minimizing turbine blade erosion. The steam turbine is a crucial component, typically designed with multiple stages to maximize energy extraction. In multi-stage turbines, high-pressure steam first passes through high-pressure turbine stages, then medium-pressure, and finally low-pressure stages before being exhausted. This staged expansion allows for a more efficient energy conversion process.

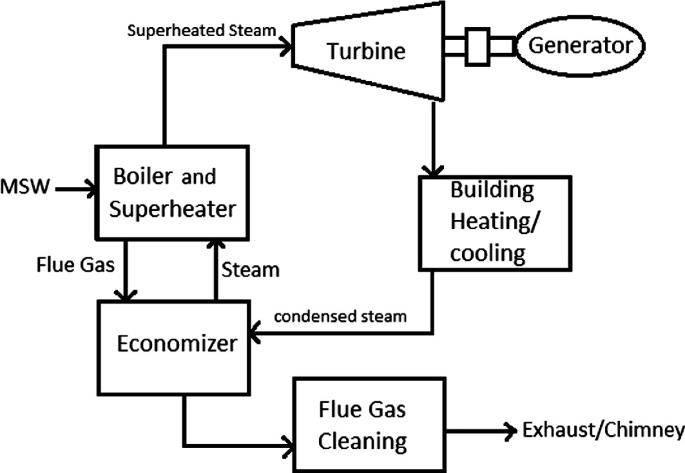

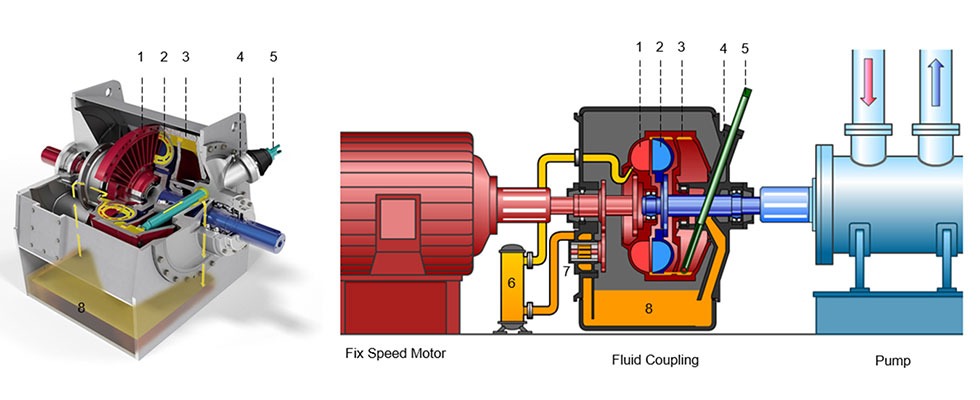

After passing through the turbine, the low-pressure steam enters a condenser, where it is cooled and condensed back into water. This condensate is then pumped back to the boiler to be reheated and turned into steam again, completing the closed-loop cycle. The condenser is a vital component as it maintains low pressure at the turbine exhaust, ensuring a significant pressure drop across the turbine stages for maximum energy extraction. In some configurations, especially in back-pressure turbines, the exhaust steam is not condensed but utilized for industrial processes or heating, enhancing overall energy efficiency through cogeneration. The generator connected to the turbine converts mechanical energy into electrical energy using the principle of electromagnetic induction. As the turbine rotates the generator rotor within a magnetic field, an electric current is induced in the stator windings. The generated electricity is then conditioned to the required voltage and frequency before being distributed to the power grid or end users.

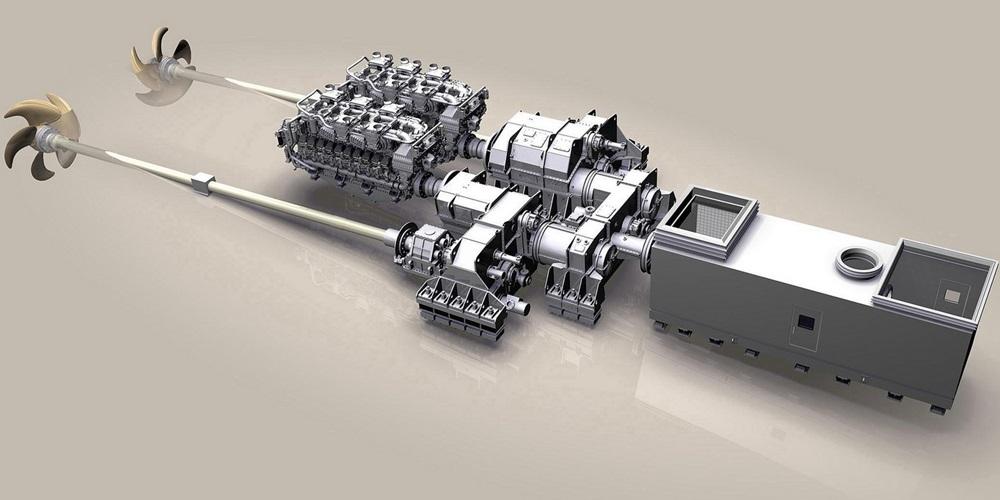

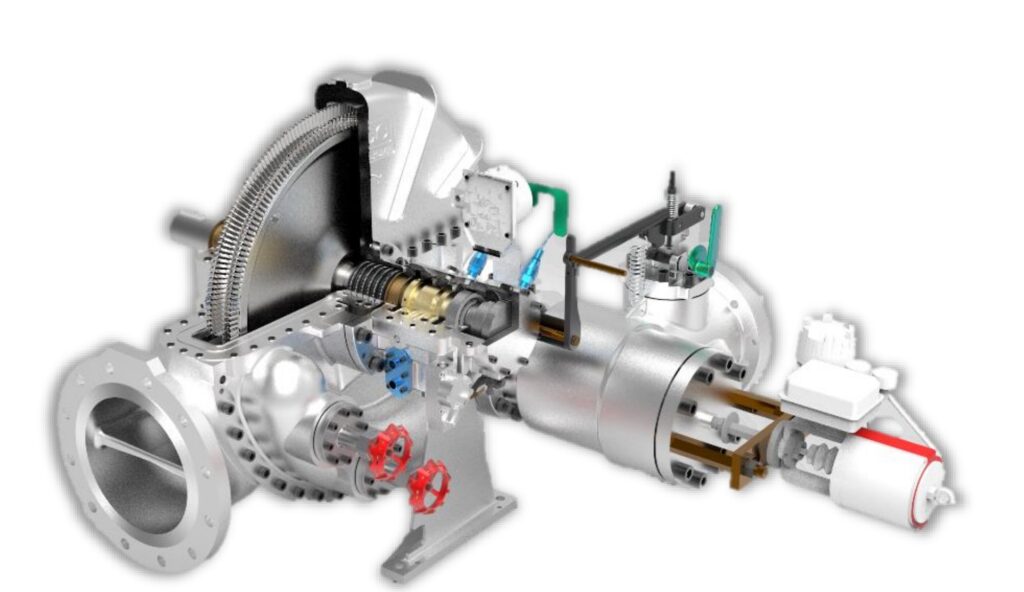

Steam Powered Generator

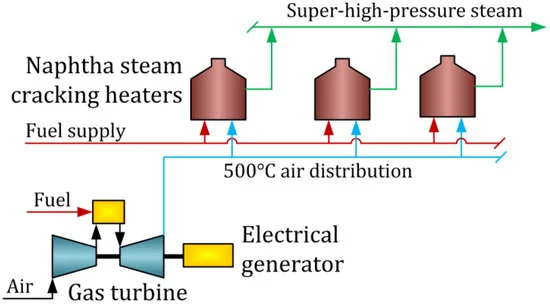

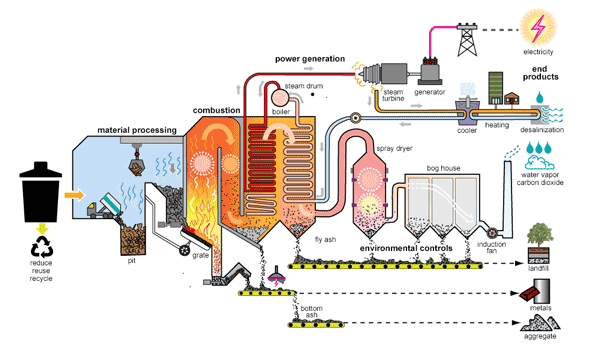

Steam-powered generators have been widely used in power plants due to their reliability, efficiency, and ability to use a variety of fuel sources. They are commonly found in coal-fired power plants, nuclear power plants, and concentrated solar power systems. In recent years, combined-cycle power plants have gained popularity, where a steam-powered generator is used in conjunction with a gas turbine generator to maximize efficiency. In such systems, the exhaust heat from the gas turbine is used to generate steam for the steam turbine, thereby increasing overall energy conversion efficiency. However, steam-powered generators also face challenges, including high capital costs, maintenance requirements, and environmental concerns related to emissions from fossil fuel combustion. To address these challenges, modern power plants are increasingly adopting advanced technologies such as supercritical and ultra-supercritical steam cycles, which operate at much higher temperatures and pressures to achieve greater efficiency and lower emissions.

Overall, steam-powered generators remain a cornerstone of global electricity generation, playing a crucial role in providing reliable base-load power. Their adaptability to various heat sources, including renewable energy, makes them a viable option in the transition towards cleaner and more sustainable energy systems. With ongoing advancements in materials, turbine design, and waste heat recovery, steam-powered generators are expected to continue evolving, offering enhanced performance and efficiency for decades to come.

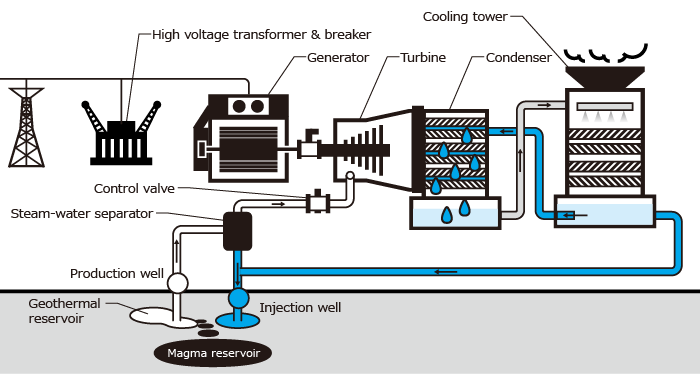

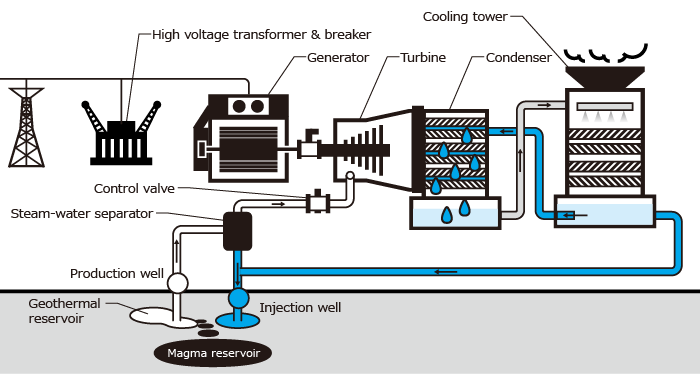

Steam-powered generators are deeply rooted in the history of industrialization, having played a pivotal role in powering factories, ships, and electricity grids since the 19th century. Their fundamental operating principle, based on the Rankine cycle, remains unchanged, but technological advancements have significantly enhanced their efficiency, reliability, and environmental performance. In traditional systems, steam is generated by burning fossil fuels, but modern steam power plants are increasingly adopting alternative heat sources, including nuclear reactors, biomass, and concentrated solar power, reflecting a shift towards sustainable energy solutions. Nuclear power plants, for example, utilize the heat generated from nuclear fission to produce steam, which then drives turbines to generate electricity. In geothermal power plants, naturally occurring steam or hot water from beneath the Earth’s surface is used directly or flashed into steam to drive turbines. Concentrated solar power plants use mirrors to focus sunlight onto a receiver, heating a fluid to produce steam for electricity generation. This versatility in heat sources makes steam-powered generators adaptable to a wide range of energy contexts, ensuring their continued relevance in modern power systems.

The efficiency of steam-powered generators has steadily improved over the years, largely due to advances in materials science and engineering. High-temperature materials, such as advanced alloys and ceramics, are now used to build turbines that can operate at supercritical and ultra-supercritical steam conditions. These conditions involve extremely high temperatures and pressures, often exceeding 600°C and 250 bar, allowing for much higher thermal efficiencies compared to subcritical systems. Supercritical and ultra-supercritical steam cycles minimize energy losses, reduce fuel consumption, and lower greenhouse gas emissions, making them a preferred choice for new coal and biomass power plants. Additionally, the use of reheat cycles, where steam is returned to the boiler for reheating between turbine stages, further enhances efficiency by maintaining higher average steam temperatures throughout the expansion process. Advanced sealing technologies, optimized blade designs, and improved aerodynamic profiles also contribute to minimizing energy losses and maximizing power output.

One of the significant challenges faced by steam-powered generators is the management of condensate and exhaust steam. In conventional condensing steam turbines, the low-pressure exhaust steam is condensed back into water using a condenser, which is typically cooled by a large volume of water sourced from rivers, lakes, or cooling towers. This process not only maintains the pressure differential required for efficient turbine operation but also recycles water back to the boiler. In regions where water resources are scarce, air-cooled condensers are used, although they are generally less efficient due to lower heat transfer rates. An alternative approach is the use of back-pressure turbines, which exhaust steam at higher pressures for industrial processes or district heating. This cogeneration or combined heat and power (CHP) approach significantly improves overall energy utilization, as the thermal energy of the exhaust steam is not wasted but put to productive use. Such systems are commonly found in industrial facilities, chemical plants, and paper mills, where continuous heat demand complements electricity generation.

The integration of steam-powered generators with other power generation systems has also evolved, leading to the development of combined-cycle power plants. In a combined-cycle configuration, a gas turbine generator produces electricity and its hot exhaust gases are used to generate steam for a steam turbine. This cascading use of energy achieves thermal efficiencies of over 60%, far surpassing the efficiency of standalone gas or steam turbines. Combined-cycle power plants are predominantly powered by natural gas, which is not only abundant but also emits lower carbon dioxide compared to coal or oil, contributing to cleaner energy production. Furthermore, these plants offer operational flexibility, as gas turbines can be quickly ramped up to meet peak power demands, while steam turbines provide stable base-load power. The combined-cycle design exemplifies how steam-powered generators continue to adapt and integrate with emerging technologies to meet modern energy needs efficiently.

Environmental concerns have significantly influenced the design and operation of steam-powered generators, especially those using fossil fuels. Regulatory requirements for emission control have led to the widespread adoption of flue gas desulfurization, selective catalytic reduction systems, and electrostatic precipitators to reduce pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter. Carbon capture and storage (CCS) technologies are also being developed and implemented to capture carbon dioxide emissions before they are released into the atmosphere. In addition to emission controls, steam power plants are focusing on improving water usage efficiency, as water is a critical resource for steam generation and cooling. Advanced cooling technologies, such as dry cooling and hybrid cooling systems, are being deployed to minimize water consumption, particularly in arid regions.

The future of steam-powered generators is closely linked to advancements in digitalization and automation. Smart sensors, data analytics, and predictive maintenance systems are increasingly being used to monitor equipment health, optimize operational parameters, and reduce unplanned downtime. Digital twins, which are virtual replicas of physical power plant systems, allow operators to simulate different operational scenarios and maintenance strategies, enhancing decision-making and reducing costs. Furthermore, the integration of steam-powered generators with renewable energy sources, such as solar thermal and biomass, supports the transition towards a more sustainable and decarbonized energy grid. In hybrid systems, steam turbines are paired with solar concentrators or biomass boilers, leveraging renewable heat sources while maintaining reliable power output. This adaptability underscores the versatility and resilience of steam-powered generators in an evolving energy landscape.

In conclusion, steam-powered generators are a vital component of global electricity generation, demonstrating remarkable adaptability and efficiency improvements over the decades. Their ability to utilize a variety of heat sources, from fossil fuels to nuclear and renewable energy, highlights their versatility and importance in achieving energy security and sustainability. As environmental regulations become more stringent and the need for cleaner energy grows, steam-powered generators are evolving with advanced technologies, including supercritical steam cycles, carbon capture, and hybrid renewable integration. Digitalization and automation are further enhancing their operational efficiency and reliability, paving the way for their continued relevance in the power industry. With ongoing research and innovation, steam-powered generators are set to remain a cornerstone of global power systems, contributing to a balanced and resilient energy future.

The evolution of steam-powered generators has been driven by the continuous quest for greater efficiency, reliability, and environmental sustainability. One of the most significant advancements in this field is the development of supercritical and ultra-supercritical steam cycles. These systems operate at temperatures and pressures above the critical point of water, where there is no distinction between liquid and gas phases. Supercritical steam cycles typically operate at pressures around 240 bar and temperatures exceeding 565°C, while ultra-supercritical systems push these boundaries even further, with temperatures above 600°C and pressures beyond 300 bar. By operating at such high temperatures and pressures, these systems achieve much higher thermal efficiencies, often exceeding 45%, compared to conventional subcritical plants that typically operate at around 35-38% efficiency. This improvement in efficiency not only reduces fuel consumption but also significantly lowers carbon dioxide emissions per unit of electricity generated, making them an attractive choice for modern power plants.

The materials used in steam turbines and boilers have had to evolve to withstand the extreme conditions of supercritical and ultra-supercritical cycles. Advanced alloys and composites with high creep resistance, thermal stability, and corrosion resistance are now employed to ensure the durability and reliability of these systems. Nickel-based superalloys, for instance, are used in turbine blades and boiler tubes due to their ability to maintain mechanical strength at high temperatures. Additionally, research is ongoing into ceramic matrix composites and other advanced materials that could further enhance the performance and longevity of steam turbine components. These material advancements not only enable higher operating temperatures but also improve maintenance intervals and reduce the overall lifecycle costs of steam-powered generators.

The efficiency and effectiveness of steam-powered generators are also greatly influenced by turbine design and configuration. Modern steam turbines are designed with multiple stages to maximize energy extraction from the steam. In a typical multi-stage turbine, high-pressure steam first passes through a high-pressure turbine section, where it expands and cools slightly while imparting rotational energy to the turbine blades. The partially expanded steam is then reheated in the boiler before entering an intermediate-pressure turbine stage, followed by a low-pressure stage, where the steam undergoes further expansion. This sequential expansion across multiple stages maximizes the extraction of thermal energy, increasing overall efficiency. Reheat cycles, in which steam is reheated between stages, maintain higher average temperatures throughout the expansion process, further enhancing efficiency and preventing moisture formation within the turbine. This is particularly important in ultra-supercritical systems, where high efficiency and turbine blade protection are paramount.

Another critical aspect of steam-powered generators is the condenser, which plays a vital role in maintaining low exhaust pressure for efficient turbine operation. In traditional condensing steam turbines, the exhaust steam is condensed back into water using a water-cooled condenser, typically sourced from natural water bodies or cooling towers. This creates a low-pressure region at the turbine outlet, maximizing the pressure drop across the turbine stages and thus the energy extracted. However, water-cooled condensers require significant water resources, posing challenges in water-scarce regions. To address this, air-cooled condensers are used in some power plants, especially in arid areas. Although less efficient due to lower heat transfer rates, air-cooled systems eliminate the need for large water supplies, providing a sustainable alternative. Hybrid cooling systems that combine both water and air cooling are also being developed to optimize efficiency and water usage.

Cogeneration or combined heat and power (CHP) systems represent another significant development in steam-powered generator technology. In a cogeneration setup, back-pressure turbines are used instead of condensing turbines. These turbines exhaust steam at higher pressures, which can be directly used for industrial processes, district heating, or other thermal applications. By utilizing the thermal energy of the exhaust steam, cogeneration systems achieve overall energy utilization efficiencies of up to 80%, compared to 30-40% for conventional power plants. This integrated approach is highly efficient and economically advantageous, particularly in industries with substantial heat and power demands, such as chemical manufacturing, paper production, and food processing. In district heating applications, back-pressure turbines provide electricity while simultaneously supplying hot water or steam for residential and commercial heating, significantly reducing fuel consumption and emissions compared to separate heat and power production systems.

The integration of steam-powered generators with renewable energy sources is becoming increasingly important in the transition to sustainable power systems. Hybrid power plants that combine steam turbines with solar thermal, biomass, or geothermal energy are emerging as effective solutions for reducing carbon emissions. In concentrated solar power (CSP) systems, solar energy is focused onto a receiver to produce high-temperature steam, which drives a steam turbine. The ability to store thermal energy in molten salt or other heat storage media allows CSP systems to generate electricity even during cloudy periods or after sunset, providing a reliable renewable energy source. Biomass power plants use organic materials such as agricultural waste, wood pellets, or dedicated energy crops as a fuel source to produce steam. These systems are considered carbon-neutral because the carbon dioxide released during combustion is offset by the carbon absorbed during the growth of the biomass feedstock. Geothermal power plants, on the other hand, use steam directly from underground reservoirs or generate steam by flashing hot geothermal water. These renewable integrations highlight the adaptability of steam-powered generators to diverse energy sources, supporting the global shift towards cleaner and more sustainable power generation.

Digitalization and automation are revolutionizing the operation and maintenance of steam-powered generators. The implementation of smart sensors and advanced data analytics allows for real-time monitoring of critical parameters, such as temperature, pressure, vibration, and efficiency. Predictive maintenance systems analyze historical and real-time data to predict equipment failures before they occur, reducing unplanned downtime and maintenance costs. Digital twins, which are virtual models of physical power plant systems, enable operators to simulate operational scenarios, optimize performance, and test new strategies without impacting actual plant operations. These digital advancements not only enhance operational efficiency and reliability but also improve safety by providing early warning of potential issues.

In conclusion, steam-powered generators continue to play a crucial role in global electricity generation due to their high efficiency, reliability, and adaptability to various fuel sources. Technological advancements, such as supercritical and ultra-supercritical cycles, cogeneration systems, renewable integration, and digitalization, have significantly enhanced their performance and environmental sustainability. As the world moves towards decarbonization and cleaner energy solutions, steam-powered generators will remain essential, especially in hybrid systems that combine renewable and conventional power sources. Their ability to provide stable base-load power, combined with ongoing innovations in efficiency and emission reduction, ensures their continued relevance in the evolving energy landscape. With further advancements in materials science, digital technology, and hybrid configurations, steam-powered generators are poised to contribute to a more sustainable and resilient energy future.

The future of steam-powered generators is shaped by a combination of technological advancements, environmental regulations, and the growing demand for sustainable energy solutions. One of the most exciting areas of development is the ongoing enhancement of supercritical and ultra-supercritical steam cycles. Researchers are exploring advanced ultra-supercritical systems that operate at temperatures above 700°C and pressures exceeding 350 bar. These extreme operating conditions require cutting-edge materials capable of maintaining structural integrity under high thermal and mechanical stress. Innovations in materials science, such as the use of nickel-based superalloys, ceramic matrix composites, and advanced coatings, are crucial for enabling these high-efficiency systems. These materials offer superior resistance to creep, oxidation, and corrosion, significantly extending the lifespan of turbines and boilers while maximizing efficiency. By achieving thermal efficiencies above 50%, advanced ultra-supercritical steam cycles dramatically reduce fuel consumption and carbon dioxide emissions, making them a cornerstone of next-generation power plants.

In addition to material advancements, significant progress is being made in turbine design and aerodynamics. Modern steam turbines feature optimized blade geometries, advanced sealing technologies, and high-precision manufacturing techniques that minimize aerodynamic losses and maximize energy extraction from steam. Computational fluid dynamics (CFD) simulations are extensively used to analyze steam flow patterns and optimize blade shapes, ensuring minimal turbulence and maximum efficiency. Furthermore, variable-speed turbine designs are being developed to improve operational flexibility and efficiency under varying load conditions. These innovations allow steam-powered generators to adapt to the fluctuating power demands of modern grids, which are increasingly influenced by intermittent renewable energy sources such as wind and solar power.

The integration of steam-powered generators with renewable energy sources is also driving significant change in the power generation landscape. Hybrid systems that combine steam turbines with solar thermal, biomass, or geothermal energy offer flexible and sustainable solutions for electricity production. Concentrated solar power (CSP) plants, for instance, use mirrors to focus sunlight onto a receiver that heats a working fluid to produce steam. By incorporating thermal energy storage systems, such as molten salt, CSP plants can generate electricity even after sunset, providing a reliable and dispatchable renewable power source. Similarly, biomass power plants use organic waste materials or dedicated energy crops as fuel to produce steam, offering a carbon-neutral alternative to fossil fuels. In geothermal power plants, steam is extracted directly from underground reservoirs or generated by flashing hot geothermal brine, leveraging Earth’s natural heat to drive turbines. These renewable integrations highlight the versatility of steam-powered generators in supporting the transition to low-carbon energy systems.

Another transformative trend in steam-powered generator technology is the implementation of carbon capture, utilization, and storage (CCUS) solutions. As environmental regulations become more stringent, power plants are increasingly required to reduce their carbon dioxide emissions. CCUS technologies capture CO₂ from the exhaust gases of steam-powered generators and either store it underground or utilize it in industrial processes, such as enhanced oil recovery or the production of synthetic fuels. Advanced post-combustion capture systems use chemical solvents to selectively absorb CO₂ from flue gases, while pre-combustion and oxy-fuel combustion methods offer alternative approaches to reduce emissions. These technologies are particularly relevant for coal and natural gas-fired power plants, enabling them to achieve near-zero emissions and comply with international climate agreements.

Cogeneration and combined heat and power (CHP) systems continue to gain traction due to their exceptional energy efficiency and economic benefits. By utilizing the thermal energy of exhaust steam for industrial processes or district heating, cogeneration systems achieve overall energy efficiencies of up to 80%. This integrated approach significantly reduces fuel consumption and emissions compared to separate heat and power generation systems. In industrial settings, back-pressure turbines are widely used to provide both electricity and process steam, optimizing energy use and lowering operational costs. District heating applications are also expanding, particularly in urban areas and colder climates, where waste heat from power plants is used to heat residential and commercial buildings. This efficient use of energy resources not only enhances sustainability but also provides energy security by reducing dependency on external heating fuels.

Digitalization and automation are revolutionizing the operation and maintenance of steam-powered generators. Advanced sensors, data analytics, and artificial intelligence are being deployed to monitor critical parameters, optimize performance, and predict maintenance needs. Predictive maintenance systems analyze real-time data from sensors to identify potential equipment failures before they occur, minimizing unplanned downtime and reducing maintenance costs. Digital twins—virtual replicas of physical power plant systems—allow operators to simulate different operational scenarios, optimize turbine performance, and test new strategies without disrupting actual plant operations. These digital tools enhance operational efficiency, reliability, and safety, ensuring optimal performance throughout the lifecycle of steam-powered generators.

The role of steam-powered generators is also evolving within modern power grids, which are increasingly characterized by distributed generation and the integration of renewable energy sources. In this context, steam turbines provide critical base-load power, ensuring grid stability and reliability. Their operational flexibility allows them to complement intermittent renewable sources, such as wind and solar power, by adjusting output to match demand fluctuations. This capability is particularly important for grid balancing and frequency regulation in regions with high penetration of renewable energy. Additionally, steam-powered generators are being integrated into microgrids and distributed energy systems, providing reliable power supply for remote areas, industrial facilities, and data centers.

Looking ahead, ongoing research and development in steam-powered generators are focused on enhancing efficiency, sustainability, and operational flexibility. Innovations in high-temperature superconducting generators, advanced thermal energy storage, and hydrogen-fueled boilers are being explored to further improve performance and reduce environmental impact. Hydrogen, in particular, holds great potential as a zero-emission fuel for steam generation, offering a clean alternative to fossil fuels. By integrating hydrogen combustion systems with steam turbines, power plants can achieve carbon-free electricity generation while leveraging existing infrastructure. This approach supports the global transition towards a hydrogen economy, facilitating decarbonization across the power sector.

In conclusion, steam-powered generators continue to be a cornerstone of global electricity generation, demonstrating remarkable adaptability and efficiency improvements. Technological advancements, including advanced ultra-supercritical cycles, renewable integration, CCUS solutions, digitalization, and hydrogen utilization, are driving their evolution towards cleaner and more sustainable energy systems. As the world accelerates its transition to low-carbon energy, steam-powered generators will play a crucial role in ensuring grid stability, energy security, and operational efficiency. Their ability to provide reliable base-load power, combined with ongoing innovations in efficiency, emission reduction, and renewable integration, guarantees their continued relevance in the power industry. With further advancements in materials science, digital technology, and hybrid configurations, steam-powered generators are poised to lead the way towards a more sustainable, flexible, and resilient energy future.

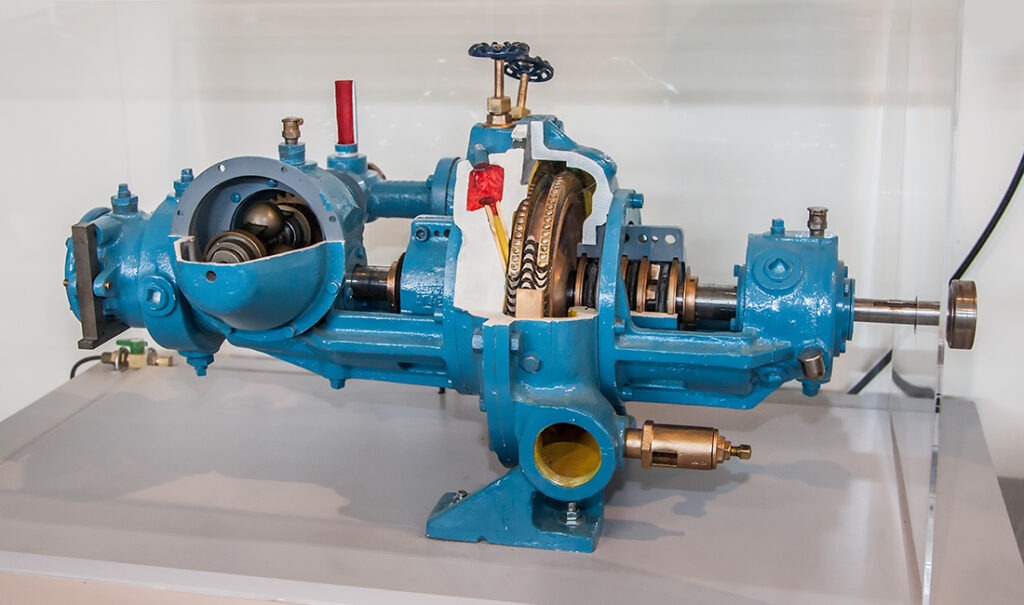

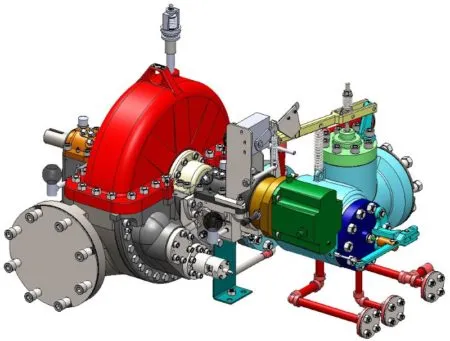

Delaval Steam Turbine

The De Laval steam turbine, named after its inventor Gustaf de Laval, is one of the pioneering designs in the field of steam turbine technology. Introduced in the late 19th century, this impulse-type turbine was revolutionary for its time and laid the groundwork for modern high-speed turbines. Unlike reaction turbines, which rely on pressure differences across the blades, the De Laval turbine operates on the impulse principle, where high-velocity steam jets impact the turbine blades, causing them to rotate. This design was particularly effective for applications requiring high rotational speeds, such as driving centrifugal pumps, electrical generators, and even early marine propulsion systems.

One of the most notable features of the De Laval turbine is its use of a converging-diverging nozzle, also known as a Laval nozzle. This nozzle design accelerates steam to supersonic speeds before directing it onto the turbine blades. In the nozzle, steam expands and accelerates due to a drop in pressure, converting thermal energy into kinetic energy. The high-velocity steam jet then strikes the turbine blades, imparting momentum and causing the rotor to spin at extremely high speeds, often exceeding 30,000 revolutions per minute. This approach maximizes energy transfer efficiency by concentrating the kinetic energy of steam into a high-speed jet, which directly impacts the blades.

A key challenge faced by early designers of the De Laval turbine was the management of high rotational speeds, which posed significant issues related to centrifugal forces and mechanical stress on the rotor. Gustaf de Laval addressed this problem by pioneering the use of a flexible shaft, which could bend slightly under high rotational speeds without breaking. This design allowed the rotor to pass through its critical speed safely, avoiding destructive resonant vibrations. The use of a flexible shaft was a remarkable engineering achievement that enabled the turbine to operate reliably at high speeds, paving the way for the development of high-speed rotating machinery in various industrial applications.

Another significant innovation introduced by de Laval was the use of a single-stage impulse design. In this configuration, all the pressure drop and acceleration of steam occur in the nozzle rather than across the turbine blades. The blades merely change the direction of the high-velocity steam jet without experiencing a pressure drop. This design simplifies the construction of the turbine and minimizes energy losses associated with blade friction and turbulence. However, the single-stage design also limits the efficiency of the De Laval turbine compared to multi-stage turbines, which expand steam gradually through multiple sets of nozzles and blades. Consequently, De Laval turbines are most efficient at handling relatively small power outputs and high-speed applications.

Despite its limitations in efficiency, the simplicity, reliability, and high-speed capability of the De Laval turbine made it extremely popular in various industrial and marine applications during the early 20th century. It was widely used to drive centrifugal pumps, air compressors, electric generators, and even small ship propellers. Its compact size and high rotational speed also made it suitable for applications requiring direct coupling to high-speed machinery, reducing the need for complex gear systems. In addition to industrial applications, the De Laval turbine found success in early power generation systems, particularly in small-scale power plants and auxiliary generators.

The influence of the De Laval steam turbine extends beyond its own design, as it significantly impacted the development of modern steam and gas turbines. The impulse principle demonstrated by de Laval was further refined and expanded by other engineers, including Sir Charles Parsons and Aegidius Elling, leading to the creation of multi-stage impulse turbines with higher efficiencies. Today, the basic impulse design concept pioneered by De Laval is still used in high-pressure stages of modern steam turbines, as well as in gas turbines and rocket engines, where supersonic jet velocities are essential for efficient operation.

Modern versions of the De Laval turbine have evolved significantly, incorporating advanced materials, precision manufacturing techniques, and digital control systems. High-strength alloys and composite materials are used to withstand extreme centrifugal forces and thermal stresses. Computer-aided design and computational fluid dynamics (CFD) simulations optimize nozzle shapes and blade geometries for maximum efficiency and reliability. Digital monitoring systems provide real-time data on temperature, pressure, vibration, and rotational speed, enabling predictive maintenance and operational optimization.

In contemporary power systems, De Laval turbines are primarily used in niche applications where high rotational speeds and compact design are required. They are commonly found in turboexpanders, cryogenic systems, and small-scale power generation units. Turboexpanders, which are used in natural gas processing and refrigeration systems, utilize the impulse principle to extract energy from high-pressure gases while cooling them through expansion. This application demonstrates the continued relevance of the De Laval turbine’s impulse design in modern industrial processes.

In conclusion, the De Laval steam turbine represents a landmark achievement in the history of steam power and high-speed rotating machinery. Its innovative use of the impulse principle, converging-diverging nozzles, and flexible shaft technology revolutionized the design and operation of early turbines. Although surpassed in efficiency by multi-stage reaction and impulse turbines, the simplicity, reliability, and high-speed capability of the De Laval turbine ensured its widespread use in industrial and marine applications. Its legacy lives on in modern turbine designs, particularly in high-speed applications such as turboexpanders and cryogenic systems. As an engineering pioneer, Gustaf de Laval’s contributions laid the foundation for the development of high-speed turbines and advanced rotating machinery, influencing generations of engineers and inventors.

The legacy of the De Laval steam turbine extends far beyond its initial invention, influencing not only the development of steam turbines but also the broader field of high-speed rotating machinery. Gustaf de Laval’s innovative approach to managing high rotational speeds and his mastery of fluid dynamics set the stage for advancements in centrifugal pumps, compressors, and even modern jet engines. One of the key breakthroughs introduced by de Laval was his understanding and application of supersonic flow dynamics through the converging-diverging nozzle, which has since become a fundamental principle in aerospace propulsion and rocket engine design. The Laval nozzle’s ability to accelerate fluids to supersonic velocities by carefully controlling pressure and area changes is a concept still widely used in modern engineering, particularly in jet propulsion and space exploration technologies.

In addition to his work on steam turbines, Gustaf de Laval made significant contributions to other fields of mechanical engineering and industrial machinery. He invented the first continuous centrifugal separator, revolutionizing the dairy industry by enabling the rapid separation of cream from milk. This invention was based on the same high-speed rotational principles that governed his steam turbine design, demonstrating his ability to apply core engineering concepts to diverse applications. De Laval’s centrifugal separator not only transformed dairy processing but also laid the foundation for the development of centrifugal pumps and compressors used in countless industrial processes today. His pioneering work on high-speed shafts and bearings directly influenced the design of modern turbomachinery, including gas turbines, jet engines, and cryogenic expanders.

The single-stage impulse design of the De Laval turbine, while simple and robust, had limitations in terms of efficiency, particularly for large-scale power generation. In a single-stage impulse turbine, all the steam expansion occurs in one set of nozzles, and the steam velocity is extremely high when it strikes the blades. This high velocity results in significant kinetic energy losses as the steam exits the blades, limiting the overall efficiency of energy conversion. Additionally, the high-speed rotation required to match the steam jet velocity posed challenges in terms of mechanical stress, vibration, and wear. To address these limitations, multi-stage impulse turbines were developed, building on De Laval’s impulse principle but distributing the steam expansion across multiple stages, thereby reducing exit velocity losses and increasing efficiency.

One of the engineers who expanded on De Laval’s concepts was Sir Charles Parsons, who developed the reaction turbine, where steam expands gradually over multiple stages of rotating and stationary blades. Unlike the impulse design, which relies solely on the kinetic energy of steam jets, the reaction turbine extracts energy from both pressure drop and velocity change across the blades. This design achieves higher efficiency, particularly for large power plants, by maintaining lower steam velocities at each stage and reducing aerodynamic losses. However, Parsons’ reaction turbine was more complex and required more precise manufacturing and alignment compared to the simpler De Laval impulse design. This trade-off between simplicity and efficiency illustrates the different engineering approaches taken to optimize steam turbine performance.

Despite the emergence of more efficient multi-stage turbines, the De Laval impulse turbine found enduring success in specialized applications that demanded high rotational speeds, compact size, and robust construction. One of the most notable applications was in the propulsion of torpedoes and small naval vessels. The high-speed, direct-drive capability of the De Laval turbine made it ideal for powering propellers without the need for complex gearboxes. This simplicity and reliability were critical in military applications, where maintenance was challenging, and operational demands were severe. During the early 20th century, several navies around the world adopted De Laval turbines for their torpedoes and small fast-attack craft, leveraging the turbine’s ability to provide rapid acceleration and high top speeds.

The De Laval turbine also played a significant role in the early development of electrical power generation. Its compact design and high rotational speed made it suitable for driving small electrical generators, particularly in industrial plants and remote locations. In the early days of electricity generation, small-scale power plants used De Laval turbines to provide localized power for factories, mills, and isolated communities. This decentralized approach to power generation was highly effective before the widespread development of electrical grids. The simplicity of the De Laval turbine allowed for easy maintenance and reliable operation, which were crucial advantages in remote or industrial environments.

With the advent of larger power plants and more efficient multi-stage turbines, the role of the De Laval turbine in large-scale power generation diminished. However, its influence persisted in other high-speed applications. Turboexpanders, which are widely used in cryogenic processes, natural gas liquefaction, and chemical processing, utilize the impulse principle to extract work from high-pressure gases while simultaneously cooling them through expansion. The design and operation of modern turboexpanders owe much to De Laval’s original impulse turbine concept, demonstrating the enduring relevance of his ideas in advanced industrial applications.

Today, De Laval turbines continue to be used in niche applications requiring high-speed rotation, simplicity, and durability. In addition to turboexpanders, they are found in small steam-powered generators, centrifugal compressors, and specialized propulsion systems. The principles of impulse staging, supersonic nozzles, and high-speed rotor dynamics developed by Gustaf de Laval remain integral to modern turbine engineering and fluid dynamics research. Furthermore, advancements in computational fluid dynamics (CFD) and materials science have enabled engineers to optimize De Laval turbine designs for even greater efficiency and reliability in contemporary applications.

The legacy of Gustaf de Laval extends beyond his inventions to his contributions as an industrialist and entrepreneur. He founded several companies to manufacture his turbines and centrifugal separators, including AB Separator, which later became Alfa Laval—a global leader in fluid handling and separation technologies. His visionary approach to industrial innovation and his commitment to practical engineering solutions established him as one of the most influential figures in mechanical engineering history. His emphasis on high-speed machinery, fluid dynamics, and robust mechanical design continues to inspire modern engineers and researchers.

In conclusion, the De Laval steam turbine represents a groundbreaking achievement in the history of turbine technology, influencing the design and development of high-speed rotating machinery across multiple industries. Its impulse principle, supersonic nozzle design, and flexible shaft technology were revolutionary for their time and remain relevant in modern engineering applications. Although surpassed by more efficient multi-stage turbines for large-scale power generation, the De Laval turbine’s simplicity, reliability, and high-speed capabilities have ensured its continued use in specialized applications such as turboexpanders and cryogenic systems. Gustaf de Laval’s pioneering spirit and innovative approach to engineering laid the foundation for modern turbomachinery, inspiring future generations of engineers to explore new frontiers in high-speed fluid dynamics and mechanical design. His legacy endures not only through the continued use of his turbines but also through the impact of his ideas on the broader field of engineering and industrial innovation.

The impact of the De Laval steam turbine on modern engineering cannot be overstated. Its innovative use of the impulse principle and high-speed rotation paved the way for advancements in not only steam turbines but also gas turbines and rocket propulsion systems. The converging-diverging nozzle, a fundamental component of the De Laval turbine, became the cornerstone of supersonic fluid dynamics. This design efficiently accelerates gases to supersonic speeds by exploiting the thermodynamic relationships between pressure, velocity, and temperature. Today, the Laval nozzle is a critical element in jet engines and rocket motors, where controlled expansion and acceleration of exhaust gases are essential for thrust generation. In fact, nearly all modern rocket engines use variations of the Laval nozzle to achieve the high exit velocities required for space propulsion, demonstrating the enduring influence of Gustaf de Laval’s pioneering work.

In addition to its applications in aerospace, the impulse principle demonstrated by the De Laval turbine has been adapted and refined in advanced gas turbines used in power generation and aviation. In modern gas turbines, high-pressure combustion gases are expanded through impulse stages to drive rotors at extremely high speeds. These turbines benefit from the same principles of kinetic energy transfer and supersonic flow that were first realized in the De Laval steam turbine. By optimizing the design of nozzles and blades using computational fluid dynamics (CFD), engineers have been able to achieve exceptional efficiencies and power outputs. These advancements highlight how foundational concepts developed by Gustaf de Laval continue to shape cutting-edge technologies in energy and propulsion systems.

The legacy of the De Laval turbine also extends to its influence on centrifugal compressors and pumps. The high-speed rotational principles and aerodynamic designs first explored by de Laval became fundamental to the development of centrifugal machinery. By using high-velocity fluid jets and impulse-driven rotors, centrifugal compressors achieve rapid pressure increases, enabling efficient compression of gases for industrial applications, refrigeration, and jet engines. Similarly, centrifugal pumps leverage high rotational speeds to create centrifugal force, efficiently moving fluids through piping systems. The success of these designs owes much to the pioneering work on high-speed shafts, impulse stages, and aerodynamic flow patterns established by Gustaf de Laval.

The engineering principles demonstrated by the De Laval turbine have also been applied in cryogenic expanders, which are used to produce ultra-low temperatures for liquefying gases such as oxygen, nitrogen, and natural gas. In these applications, high-pressure gas is expanded through impulse stages, performing work on the turbine rotor and cooling the gas through the Joule-Thomson effect. This method of energy extraction and cooling relies on the efficient conversion of kinetic energy from high-velocity gas jets, a concept directly derived from De Laval’s impulse turbine design. Modern cryogenic expanders utilize advanced materials and precision manufacturing to operate at extremely low temperatures and high rotational speeds, ensuring reliable performance in critical industrial processes.

In power generation, the De Laval turbine played an important role in the early development of distributed power systems. Its compact size, simplicity, and high-speed capability made it ideal for small-scale power plants, especially in remote locations or industrial facilities where localized electricity generation was required. These early power systems laid the groundwork for modern distributed energy solutions, including microgrids and cogeneration plants. By providing reliable and efficient power in decentralized settings, De Laval turbines contributed to the growth of industrialization and urban development during the late 19th and early 20th centuries.

The design principles of the De Laval turbine have also found applications in hybrid renewable energy systems. In concentrated solar power (CSP) plants, for instance, steam turbines are used to convert solar thermal energy into electricity. The impulse principle is particularly effective in high-temperature CSP systems, where superheated steam is expanded through impulse stages to drive generators at high speeds. By integrating thermal energy storage, such as molten salt, CSP plants can continue generating electricity after sunset, providing a reliable and sustainable power source. This application demonstrates the versatility of the De Laval turbine’s impulse design in adapting to modern renewable energy technologies.

In marine propulsion, the simplicity and high-speed capability of the De Laval turbine made it ideal for powering small naval vessels and torpedoes. Its direct-drive configuration, which eliminated the need for complex reduction gears, provided high efficiency and rapid acceleration. This design was particularly advantageous in military applications, where reliability and speed were critical. During the early 20th century, De Laval turbines were widely adopted by navies around the world for fast attack craft and submarine propulsion. Their robust construction and operational simplicity ensured reliable performance under harsh marine conditions, influencing naval engineering for decades.

The continued relevance of the De Laval turbine in modern engineering is also supported by advancements in digitalization and automation. Today, high-speed turbines are equipped with advanced sensors and digital monitoring systems that provide real-time data on temperature, pressure, vibration, and rotational speed. These systems enable predictive maintenance, minimizing unplanned downtime and extending equipment lifespan. Digital twins, which are virtual replicas of physical systems, allow engineers to simulate turbine performance, optimize designs, and test operational scenarios. These digital tools enhance the efficiency, safety, and reliability of high-speed turbines, ensuring their continued success in industrial applications.

Furthermore, research into advanced materials has significantly enhanced the performance and durability of De Laval turbines. High-strength alloys, ceramic matrix composites, and advanced coatings are used to withstand extreme centrifugal forces and thermal stresses, allowing for higher rotational speeds and improved efficiency. These materials provide excellent resistance to creep, oxidation, and corrosion, ensuring reliable operation in harsh environments. The integration of advanced materials with precise manufacturing techniques has resulted in modern De Laval turbines that are more efficient, durable, and capable of operating under extreme conditions.

In conclusion, the De Laval steam turbine stands as a testament to the power of innovation and engineering ingenuity. Its pioneering use of the impulse principle, high-speed rotation, and supersonic nozzles revolutionized the design of steam turbines and laid the foundation for modern turbomachinery. From rocket engines to gas turbines, centrifugal compressors to cryogenic expanders, the influence of the De Laval turbine is evident across a wide range of engineering fields. Its simplicity, reliability, and high-speed capability continue to inspire new generations of engineers and researchers. By integrating advanced materials, digital monitoring, and hybrid renewable systems, the legacy of Gustaf de Laval lives on, driving progress in energy, propulsion, and industrial machinery. As technology continues to evolve, the fundamental principles established by the De Laval turbine will remain relevant, ensuring its place in the history of engineering excellence.

The influence of the De Laval steam turbine continues to shape modern engineering, particularly in the realm of high-speed turbomachinery and energy systems. One of the most significant contributions of the De Laval design is its role in advancing the efficiency and reliability of turboexpanders. These devices are crucial in a wide range of industrial applications, including natural gas processing, air separation, and cryogenic refrigeration. Turboexpanders work by expanding high-pressure gases through impulse stages, extracting mechanical work while simultaneously reducing the gas temperature. This process is essential for liquefying gases such as nitrogen and natural gas, which require extremely low temperatures to transition into a liquid state. The impulse principle first demonstrated by the De Laval turbine is ideally suited for this application, as it efficiently converts the kinetic energy of high-velocity gas jets into mechanical work, ensuring high efficiency and reliability even at cryogenic temperatures.

Modern turboexpanders have evolved significantly from the original De Laval design, benefiting from advancements in computational fluid dynamics (CFD) and materials science. CFD simulations enable engineers to optimize nozzle shapes, blade profiles, and flow paths for maximum efficiency and minimal energy losses. Advanced materials such as titanium alloys and ceramic composites provide the necessary strength, durability, and resistance to extreme temperatures and pressures. These innovations have allowed turboexpanders to achieve remarkable levels of efficiency and operational stability, making them indispensable in the energy and chemical processing industries. The fundamental impulse principle established by Gustaf de Laval remains at the core of these advanced designs, underscoring his enduring impact on modern turbomachinery.

In addition to its industrial applications, the De Laval turbine’s high-speed capability has influenced the development of modern aerospace propulsion systems. The converging-diverging nozzle, a key feature of the De Laval turbine, is widely used in rocket engines to accelerate exhaust gases to supersonic speeds, generating the thrust required for spaceflight. This design concept is fundamental to all modern rocket propulsion systems, from chemical rockets to advanced ion thrusters. The precise control of pressure and velocity in the nozzle allows for optimal expansion of exhaust gases, maximizing thrust and efficiency. This principle, first demonstrated in the De Laval turbine, has enabled humanity’s exploration of space, from launching satellites into orbit to sending probes to distant planets.

The legacy of the De Laval turbine extends to aviation as well, particularly in the design of jet engines. Modern turbojet and turbofan engines utilize impulse stages in the high-pressure turbine section to extract energy from hot, high-velocity exhaust gases produced by combustion. These turbines operate at extremely high rotational speeds, driving the compressor stages that maintain the engine’s air intake and fuel mixture. The impulse principle allows for efficient energy transfer and high-speed operation, ensuring optimal performance and fuel efficiency. By refining nozzle and blade designs using CFD and advanced manufacturing techniques, modern jet engines achieve exceptional thrust-to-weight ratios and operational reliability. The high-speed rotational principles pioneered by Gustaf de Laval remain integral to the performance of modern aerospace propulsion systems.

The De Laval turbine’s influence is also evident in renewable energy systems, particularly in concentrated solar power (CSP) and geothermal plants. In CSP plants, sunlight is concentrated using mirrors or lenses to generate high-temperature steam, which is then expanded through steam turbines to produce electricity. The impulse principle is highly effective in these high-temperature environments, where superheated steam can be expanded through impulse stages to achieve high rotational speeds and power output. By integrating advanced thermal storage systems, such as molten salt, CSP plants can continue generating electricity even after sunset, providing a reliable and sustainable power source. The efficiency and simplicity of the De Laval impulse turbine make it a practical choice for these renewable energy applications, highlighting its continued relevance in modern power systems.

Geothermal power plants also benefit from the impulse principle, as high-pressure steam from underground reservoirs is expanded through impulse stages to drive electrical generators. The high-speed capability and robust design of the De Laval turbine are particularly suited to geothermal applications, where steam conditions can vary significantly depending on the geothermal reservoir. Advanced materials and coatings are used to withstand the corrosive and abrasive properties of geothermal steam, ensuring reliable long-term operation. The simplicity and durability of the impulse turbine design contribute to the economic viability of geothermal power, supporting the transition to clean and renewable energy sources.

The continued development of the De Laval turbine is supported by advancements in digital technology and smart manufacturing. Today, high-speed turbines are equipped with sophisticated digital monitoring systems that provide real-time data on pressure, temperature, vibration, and rotational speed. These systems enable predictive maintenance, optimizing operational performance and reducing downtime. Digital twins, which are virtual replicas of physical turbines, allow engineers to simulate performance under various conditions, identify potential issues, and test new designs without the need for physical prototypes. This integration of digital technology enhances the efficiency, safety, and reliability of modern De Laval turbines, ensuring their continued success in industrial and energy applications.

In terms of manufacturing, precision machining and additive manufacturing techniques have significantly improved the performance and reliability of De Laval turbines. Advanced computer numerical control (CNC) machines are used to produce complex nozzle and blade geometries with exceptional accuracy, minimizing aerodynamic losses and maximizing efficiency. Additive manufacturing, or 3D printing, enables the production of lightweight yet robust components, reducing material costs and increasing design flexibility. These manufacturing advancements allow engineers to optimize turbine designs for specific applications, from small-scale power generation to high-speed aerospace propulsion, ensuring maximum performance and durability.

Looking to the future, the De Laval turbine is poised to play a key role in emerging energy technologies, including hydrogen power systems. Hydrogen, as a clean and renewable fuel, requires efficient compression and expansion technologies for storage, transportation, and power generation. The impulse principle is well-suited to hydrogen applications, as it allows for high-speed, efficient energy transfer with minimal energy losses. Turboexpanders based on the De Laval design are already being adapted for hydrogen liquefaction and regasification processes, supporting the growth of the hydrogen economy. As hydrogen power systems continue to develop, the simplicity, efficiency, and high-speed capability of the De Laval turbine will be crucial in enabling clean energy solutions for the future.

In conclusion, the De Laval steam turbine is more than just an historical invention—it is a foundational technology that continues to shape modern engineering and energy systems. From turboexpanders and aerospace propulsion to renewable energy and hydrogen power, the principles of impulse staging, high-speed rotation, and supersonic flow dynamics remain central to cutting-edge technologies. Gustaf de Laval’s vision and ingenuity laid the groundwork for high-speed turbomachinery, influencing generations of engineers and inventors. By integrating digital monitoring, advanced materials, and precision manufacturing, the De Laval turbine has evolved into a versatile and efficient solution for modern industrial challenges. Its legacy endures not only in its continued use but also in its influence on the future of energy, propulsion, and sustainable technology.

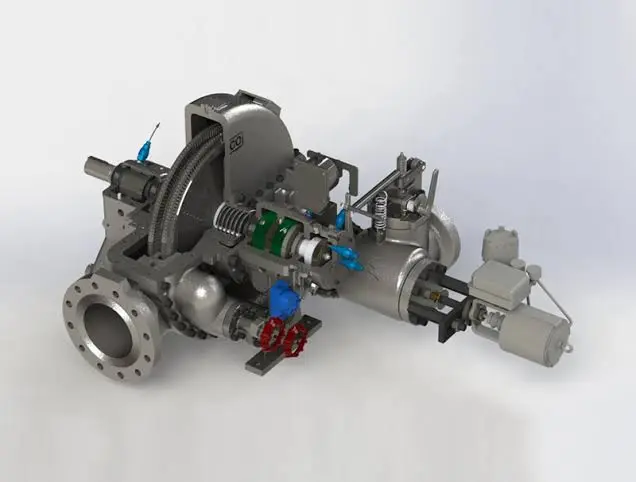

Reaction Type Condensing Turbine

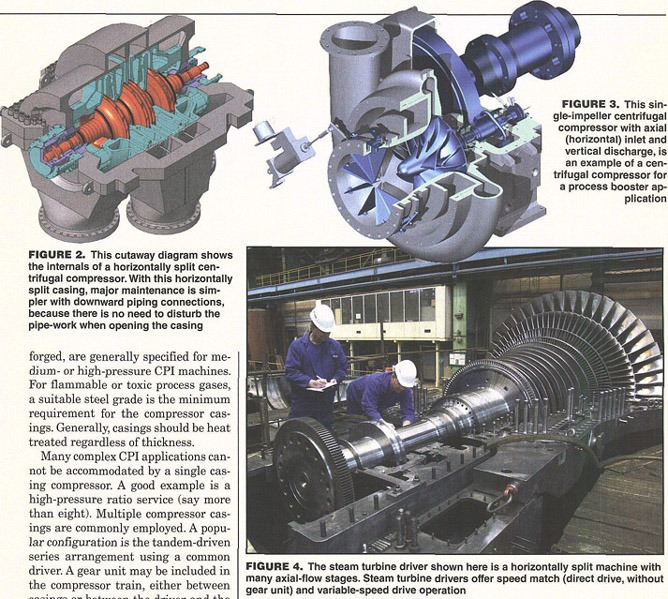

The Reaction Type Condensing Turbine is one of the most widely used configurations in modern steam power generation, known for its high efficiency and adaptability to varying load conditions. This type of steam turbine operates on the principle of reaction, where steam expansion and acceleration occur both in the stationary nozzles and the rotating blades. Unlike impulse turbines, where steam is directed at high velocity onto the rotor blades, reaction turbines utilize the pressure drop across both fixed and moving blades, creating a continuous flow that enhances efficiency and power output. This design was pioneered by Sir Charles Parsons in the late 19th century and remains the backbone of large-scale power plants worldwide, particularly in thermal and nuclear power generation.

The fundamental operating principle of a reaction turbine relies on Newton’s third law of motion—every action has an equal and opposite reaction. In this context, steam expands as it passes through the fixed nozzles, gaining velocity while its pressure decreases. As the high-velocity steam enters the rotating blades, it continues to expand and accelerate, producing a reactive force that drives the rotor. This continuous pressure drop and velocity change through both stationary and moving blades create a smooth and efficient energy conversion process, maximizing the extraction of thermal energy from the steam.

The design of reaction turbines is characterized by the use of both stationary and moving blades, arranged in multiple stages to maximize energy extraction. In each stage, the fixed blades act as nozzles, guiding and accelerating the steam flow towards the rotating blades. The rotating blades, in turn, extract kinetic energy from the steam and convert it into mechanical work to drive the rotor. This staged expansion allows for gradual pressure and temperature drops across the turbine, reducing thermal stresses and improving efficiency. The number of stages in a reaction turbine depends on the steam inlet pressure and temperature, as well as the required power output, with larger turbines featuring several hundred stages to optimize performance.

One of the key advantages of reaction turbines is their high efficiency, particularly at part-load conditions. Unlike impulse turbines, which rely solely on velocity changes for energy conversion, reaction turbines utilize both pressure and velocity changes across each stage. This dual energy extraction mechanism enhances efficiency across a wide range of operating conditions, making reaction turbines highly adaptable to varying power demands. This is particularly beneficial in grid power applications, where load fluctuations are common, and maintaining efficiency at partial loads is crucial for economic and environmental sustainability.

In addition to their high efficiency, reaction turbines are known for their smooth and continuous flow characteristics, resulting in reduced vibration and mechanical stress. This is because the steam flow remains continuous and uniform throughout the turbine, minimizing turbulence and pressure fluctuations. The balanced pressure distribution across the fixed and moving blades reduces axial thrust, enhancing the stability and reliability of the rotor system. This smooth operation not only extends the lifespan of the turbine components but also minimizes maintenance requirements, contributing to lower operational costs and improved power plant availability.

Reaction type condensing turbines are commonly used in large-scale power generation applications, including thermal power plants, nuclear power plants, and combined-cycle power plants. In these applications, high-pressure, high-temperature steam is expanded through multiple reaction stages to drive electrical generators. In a condensing configuration, the exhaust steam is directed into a condenser, where it is cooled and condensed back into water at a pressure below atmospheric pressure. This condensation process creates a significant pressure drop at the turbine exhaust, enhancing the efficiency of the energy conversion process by maximizing the expansion ratio of the steam.

The condensing configuration is particularly advantageous in large power plants, as it allows for maximum energy extraction from the steam. By condensing the exhaust steam at low pressure, the turbine can achieve a high thermodynamic efficiency, typically ranging from 35% to 45% in modern power plants. This is because the low exhaust pressure increases the enthalpy drop across the turbine, allowing for more mechanical work to be extracted from the steam. The condensed water is then pumped back to the boiler as feedwater, completing the Rankine cycle and ensuring a continuous and efficient power generation process.

The condenser in a reaction type condensing turbine plays a crucial role in maintaining low exhaust pressure and maximizing efficiency. It typically uses a water-cooled or air-cooled heat exchanger to condense the exhaust steam, with water-cooled condensers being more common in large power plants due to their higher cooling efficiency. The condenser also acts as a vacuum chamber, maintaining sub-atmospheric pressure at the turbine exhaust to maximize the expansion ratio. This vacuum condition is achieved using steam ejectors or vacuum pumps, which continuously remove non-condensable gases from the condenser to maintain optimal performance.

The performance and efficiency of reaction type condensing turbines are significantly influenced by the condenser cooling method and the cooling water temperature. In water-cooled condensers, the cooling water is typically sourced from rivers, lakes, or seawater, depending on the power plant’s location. The temperature of the cooling water directly affects the condenser pressure and, consequently, the turbine efficiency. Cooler water temperatures result in lower condenser pressures, enhancing the expansion ratio and increasing the overall efficiency of the power cycle. Conversely, higher cooling water temperatures reduce efficiency, which is why power plants located near cold water sources often achieve superior performance.

In addition to water-cooled condensers, air-cooled condensers are used in power plants located in arid regions or areas with limited water resources. Air-cooled condensers use large fans to circulate ambient air over finned heat exchangers, condensing the exhaust steam without the need for cooling water. While air-cooled condensers are less efficient than water-cooled systems due to the lower heat transfer capacity of air, they provide an environmentally sustainable solution for power generation in water-scarce regions. The choice between water-cooled and air-cooled condensers depends on the availability of cooling resources, environmental regulations, and economic considerations.

Modern reaction type condensing turbines are designed with advanced materials and cooling technologies to enhance performance and durability. High-strength alloys, corrosion-resistant coatings, and precision-engineered blade profiles ensure reliable operation under high temperatures and pressures. In addition, advanced sealing systems and high-efficiency vacuum pumps minimize steam leakage and maintain optimal condenser performance. Digital monitoring systems provide real-time data on temperature, pressure, and vibration, enabling predictive maintenance and optimizing operational efficiency. These innovations have significantly improved the efficiency, reliability, and longevity of reaction type condensing turbines, making them a cornerstone of modern power generation.

In conclusion, the Reaction Type Condensing Turbine represents a pinnacle of steam turbine technology, offering high efficiency, reliability, and adaptability to varying power demands. Its unique design, utilizing both pressure and velocity changes for energy conversion, ensures efficient power generation across a wide range of operating conditions. With advanced materials, digital monitoring, and efficient cooling systems, modern reaction turbines continue to play a vital role in thermal and nuclear power plants worldwide. As the energy industry transitions to cleaner and more sustainable solutions, reaction type condensing turbines will remain essential for grid stability and efficient power generation, showcasing the enduring legacy of Charles Parsons’ pioneering design.

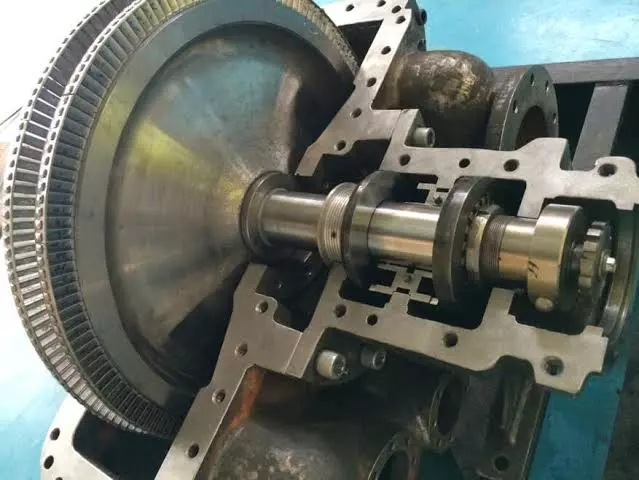

The continued evolution of the Reaction Type Condensing Turbine is driven by advancements in materials science, digital technology, and thermodynamic optimization, ensuring its relevance in modern power generation systems. One of the most significant developments in recent years is the use of advanced materials to enhance performance and durability under extreme operating conditions. Modern reaction turbines operate at high temperatures and pressures to maximize thermal efficiency, necessitating materials that can withstand thermal stress, creep, and corrosion. Superalloys, such as nickel-based and cobalt-based alloys, are widely used in high-pressure and high-temperature sections of the turbine due to their exceptional mechanical strength and resistance to oxidation. These materials maintain structural integrity at temperatures exceeding 600°C, enabling higher steam temperatures and pressures, which in turn improve the overall efficiency of the Rankine cycle.

In addition to superalloys, ceramic matrix composites (CMCs) are gaining prominence in advanced reaction turbine designs. CMCs offer high temperature resistance, low density, and superior thermal insulation properties, making them ideal for applications in high-pressure stages and rotating blades. Their lightweight nature reduces centrifugal forces on the rotor, allowing for higher rotational speeds and improved aerodynamic efficiency. This results in increased power output and reduced fuel consumption, contributing to the overall efficiency and sustainability of power generation. Furthermore, the use of advanced coatings, such as thermal barrier coatings (TBCs), protects turbine blades from high-temperature corrosion and erosion, extending component life and reducing maintenance costs.

The aerodynamic design of reaction turbines has also seen significant improvements, thanks to computational fluid dynamics (CFD) and advanced manufacturing techniques. CFD simulations allow engineers to analyze and optimize steam flow patterns, minimizing aerodynamic losses and maximizing energy extraction in each stage. By refining blade profiles, minimizing tip leakage, and optimizing flow angles, modern reaction turbines achieve higher isentropic efficiencies and improved power output. In particular, the use of three-dimensional blade designs, which account for secondary flows and boundary layer effects, enhances aerodynamic performance and reduces turbulence, further increasing efficiency.

Advanced manufacturing technologies, such as precision casting and additive manufacturing, play a crucial role in realizing complex blade geometries and high-efficiency nozzle shapes. Precision casting techniques, including investment casting and directional solidification, allow for the production of blades with intricate cooling passages and optimized internal structures. These cooling passages enable efficient heat transfer, maintaining blade temperatures within safe limits even under extreme operating conditions. Additive manufacturing, commonly known as 3D printing, offers even greater design flexibility, enabling the production of lightweight yet robust components with complex geometries that are difficult to achieve using traditional manufacturing methods. These innovations contribute to the aerodynamic efficiency, mechanical strength, and durability of modern reaction turbines.

Digitalization is another key driver of innovation in reaction type condensing turbines, enhancing operational efficiency, reliability, and maintenance strategies. Modern turbines are equipped with sophisticated sensors and digital monitoring systems that provide real-time data on temperature, pressure, vibration, and rotational speed. This data is analyzed using advanced algorithms and artificial intelligence (AI) to optimize performance, predict maintenance needs, and prevent potential failures. Predictive maintenance strategies, powered by machine learning models, enable operators to schedule maintenance activities based on actual equipment conditions, reducing unplanned downtime and maintenance costs. Digital twins, which are virtual replicas of physical turbines, allow engineers to simulate performance under various operating conditions, optimize control strategies, and test new designs without the need for physical prototypes.

Automation and advanced control systems further enhance the efficiency and reliability of reaction type condensing turbines. Automated control systems continuously adjust steam flow, pressure, and temperature to maintain optimal operating conditions, ensuring maximum efficiency and power output. These systems also respond dynamically to load fluctuations, grid demands, and environmental conditions, providing flexible and reliable power generation. In combined-cycle power plants, advanced control systems synchronize the operation of gas turbines and steam turbines, optimizing overall plant efficiency and minimizing emissions. This level of automation and digitalization enables modern reaction turbines to achieve high operational efficiency, grid stability, and economic viability.

The integration of renewable energy sources and the transition to low-carbon power generation present new opportunities and challenges for reaction type condensing turbines. As renewable energy sources, such as wind and solar, are inherently intermittent, grid stability requires flexible and reliable backup power generation. Reaction turbines, with their high efficiency and rapid load-following capability, are ideally suited to complement renewable energy sources, ensuring grid stability and reliable power supply. In hybrid power plants, reaction turbines operate in conjunction with renewable energy systems, balancing power output and optimizing energy storage. By adapting to variable renewable energy inputs, reaction type condensing turbines play a crucial role in the transition to sustainable and decarbonized energy systems.

One promising application of reaction type condensing turbines is in concentrated solar power (CSP) plants, where high-temperature steam generated from solar energy is expanded through multi-stage reaction turbines to produce electricity. The high efficiency and flexibility of reaction turbines make them well-suited for CSP applications, particularly when integrated with advanced thermal storage systems. These thermal storage systems, such as molten salt, enable CSP plants to generate electricity even during periods of low sunlight, providing a reliable and sustainable power source. The ability to operate efficiently at partial loads further enhances the viability of CSP plants as a renewable energy solution.

Hydrogen power systems also present significant potential for reaction type condensing turbines, as hydrogen combustion produces high-temperature steam without carbon emissions. In hydrogen-fired power plants, high-temperature steam is expanded through multi-stage reaction turbines to generate electricity, achieving high efficiency and zero carbon emissions. The adaptability of reaction turbines to high-temperature and high-pressure steam conditions makes them ideal for hydrogen applications. Furthermore, existing natural gas power plants can be retrofitted with reaction turbines capable of burning hydrogen or hydrogen-natural gas blends, facilitating the transition to a hydrogen economy and supporting decarbonization efforts.

In nuclear power plants, reaction type condensing turbines continue to play a vital role, particularly in advanced reactor designs such as Generation IV and small modular reactors (SMRs). These advanced reactors operate at higher temperatures and pressures than conventional nuclear reactors, requiring efficient and reliable steam turbines for power generation. The robust design and high efficiency of reaction turbines ensure optimal performance under these demanding conditions. In SMRs, which are designed for flexible deployment and smaller power outputs, compact reaction turbines provide reliable and efficient power generation, supporting grid stability and energy security.

In conclusion, the Reaction Type Condensing Turbine remains at the forefront of power generation technology, driven by continuous advancements in materials, digitalization, and aerodynamic design. Its high efficiency, reliability, and adaptability make it indispensable in thermal, nuclear, and renewable energy applications. As the energy industry transitions to low-carbon solutions and integrates renewable energy sources, reaction type condensing turbines will play a crucial role in ensuring grid stability, efficiency, and sustainability. With ongoing research and innovation, including hydrogen power systems, advanced materials, and digital twins, the future of reaction type condensing turbines is poised for even greater efficiency and environmental sustainability. The legacy of Sir Charles Parsons endures in the continued evolution and impact of this remarkable technology, powering the world towards a cleaner and more sustainable energy future.

As we look towards the future, the evolution of Reaction Type Condensing Turbines will increasingly align with the global push towards more sustainable, flexible, and decentralized power systems. Technological advancements in turbine design, coupled with the growing importance of energy efficiency and reduced carbon emissions, will guide the next generation of turbines. The ongoing integration of renewable energy, particularly from wind, solar, and hydropower, into the grid will create new demands for turbines that can not only operate efficiently across a wide range of conditions but also provide grid stability as these variable energy sources fluctuate. Reaction turbines, with their adaptability and efficiency at both full-load and part-load operation, are positioned to meet these challenges head-on.

One key development will be the improvement in the integration of energy storage solutions with steam turbines. Thermal energy storage systems, such as molten salt and phase change materials, are being enhanced to store excess energy produced by solar or wind sources. These stored thermal energies can be converted back into steam to drive reaction turbines during periods of low renewable output or peak demand. By optimizing reaction turbines for such cycles, power plants can achieve greater flexibility, ensuring that energy is available when needed most, regardless of weather or time of day. The role of reaction turbines in balancing the grid in such hybrid setups is vital, as they can help manage the intermittency of renewables while providing reliable power in the absence of sun or wind.

The role of digital technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, will also become more prominent in the optimization and monitoring of reaction turbines. Advanced predictive maintenance, facilitated by data-driven insights, will help operators avoid unscheduled outages by forecasting component wear and potential failures. This allows for proactive repairs or component replacements, significantly improving the turbine’s operational uptime and extending its service life. The analysis of vast amounts of operational data will also enable real-time optimization, adjusting turbine settings for maximum performance based on changing load conditions and fuel quality. These innovations will be especially important as the demand for flexible and responsive power generation grows in line with increasing shares of renewable energy in the global power mix.