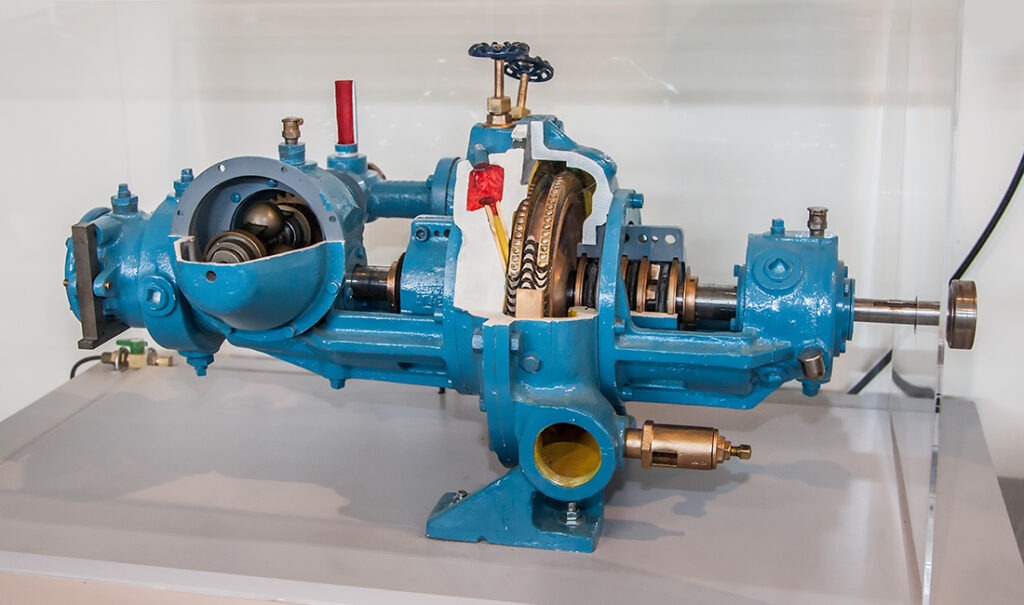

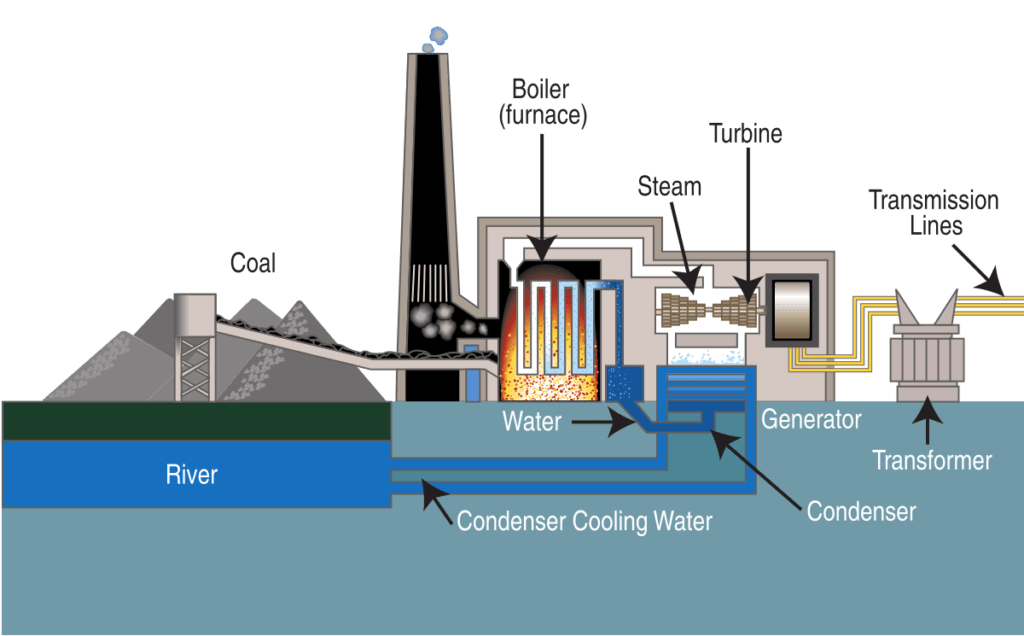

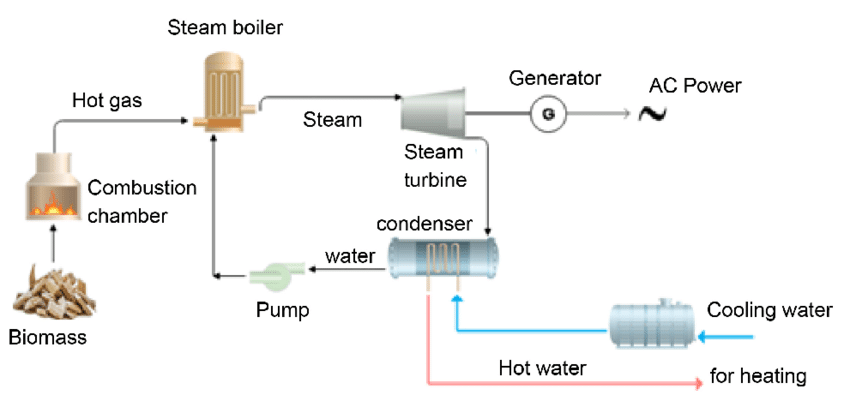

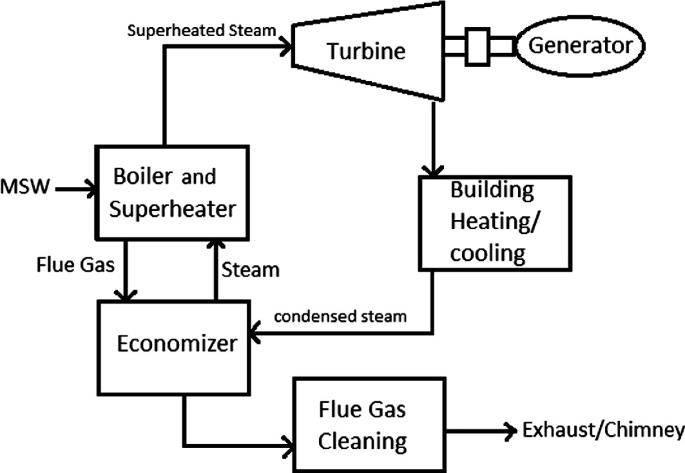

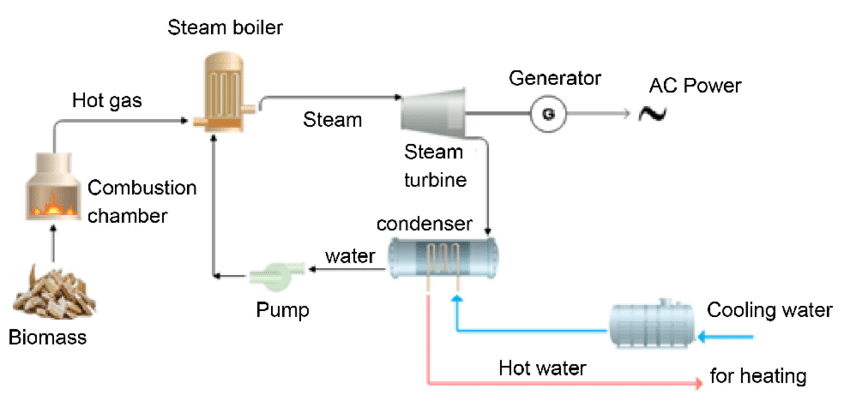

Factories Harness Waste Heat for Power: A steam turbine generator is a critical component in power generation, converting thermal energy from steam into mechanical energy and then into electrical energy. The process begins with high-pressure steam produced in a boiler, where water is heated using a fuel source such as coal, natural gas, nuclear energy, or renewable biomass. The high-pressure steam is directed onto the blades of a steam turbine, causing the rotor to spin. This rotation is transferred to an electrical generator, where electromagnetic induction generates electricity. The efficiency of a steam turbine generator depends on several factors, including steam pressure, temperature, turbine blade design, and the effectiveness of the condenser system that recycles steam into water for reuse.

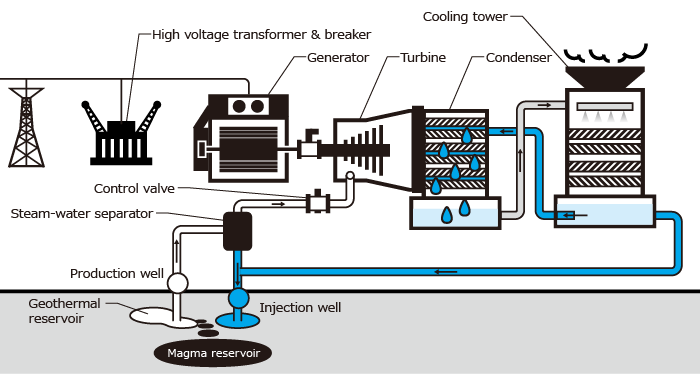

Steam turbine generators are widely used in various types of power plants, including fossil fuel, nuclear, geothermal, and solar thermal plants. In coal-fired and natural gas power plants, steam turbines operate using high-temperature steam produced by burning fuel. In nuclear power plants, the heat from nuclear reactions generates steam to drive the turbine. Geothermal power plants use naturally occurring steam or high-temperature water from beneath the Earth’s surface, while solar thermal power plants concentrate sunlight to produce steam. The versatility and efficiency of steam turbines make them a preferred choice for large-scale electricity generation, as they can operate continuously with minimal downtime.

There are two main types of steam turbines based on their exhaust conditions: condensing and back-pressure turbines. Condensing turbines are used primarily for electricity generation in power plants. They exhaust steam at very low pressure, often close to a vacuum, to maximize energy extraction before the steam is condensed back into water in a condenser. This process ensures maximum efficiency and energy output. In contrast, back-pressure turbines exhaust steam at a higher pressure, which can be used for industrial applications such as heating, drying, or mechanical drive systems. These turbines are often used in cogeneration, where both electricity and thermal energy are utilized, improving overall energy efficiency.

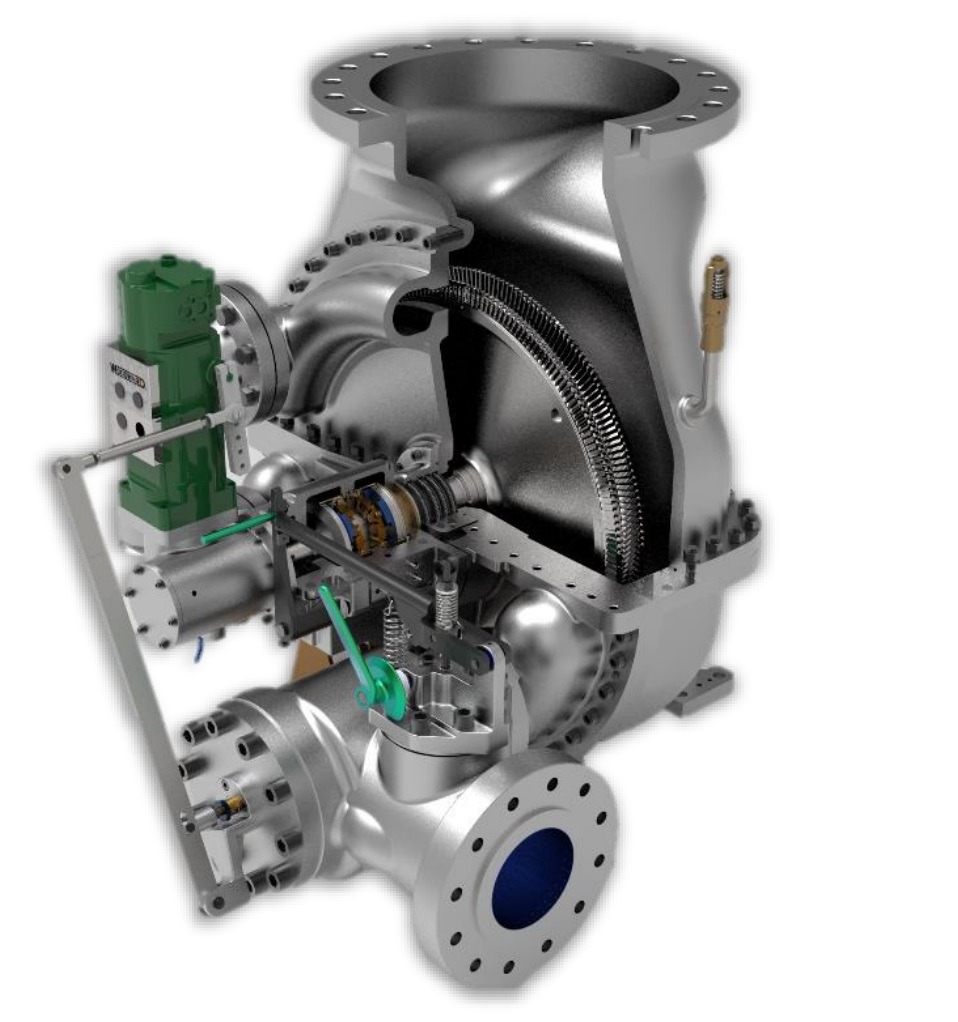

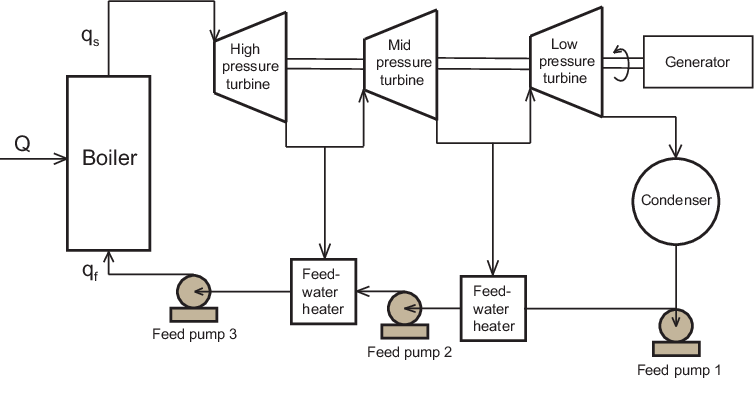

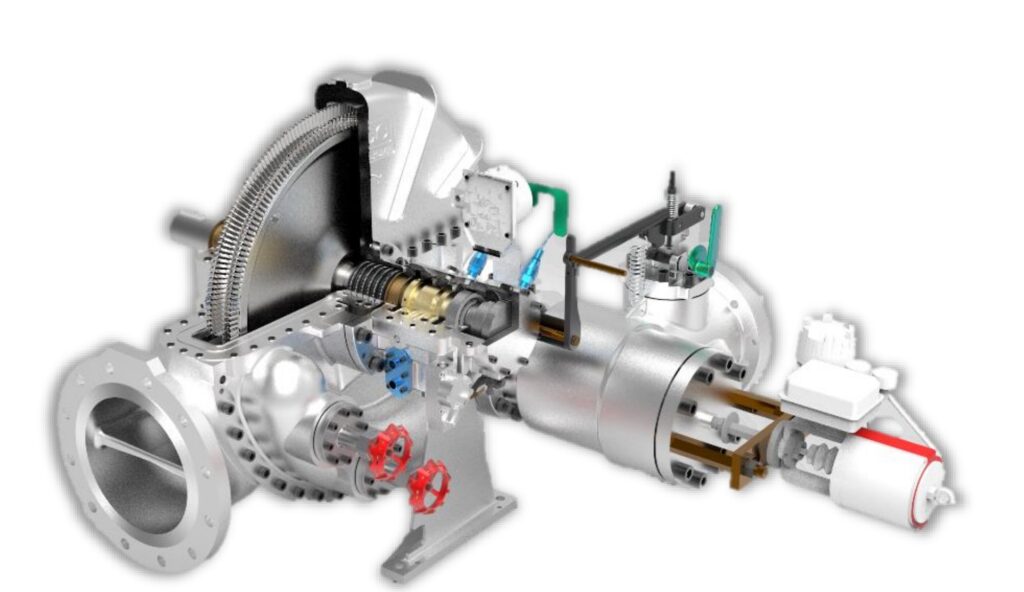

A key factor in the performance of a steam turbine generator is its design and the materials used in its construction. The turbine consists of multiple stages of blades, each designed to extract energy from the expanding steam efficiently. High-pressure turbines handle steam at extreme conditions, while intermediate- and low-pressure turbines extract additional energy as the steam expands. The materials used in turbine blades and casings must withstand high temperatures, pressures, and corrosive environments. Advanced alloys and coatings are employed to improve durability and efficiency.

Steam Turbine Generator

The generator connected to the steam turbine operates on the principle of electromagnetic induction. It consists of a rotor and a stator. The rotor is attached to the turbine shaft and spins within the stator, a stationary set of coils that generate electricity when the rotor’s magnetic field induces an electrical current. The generated electricity is then transmitted to the power grid for distribution. The efficiency of this conversion process is critical to optimizing energy output and minimizing losses.

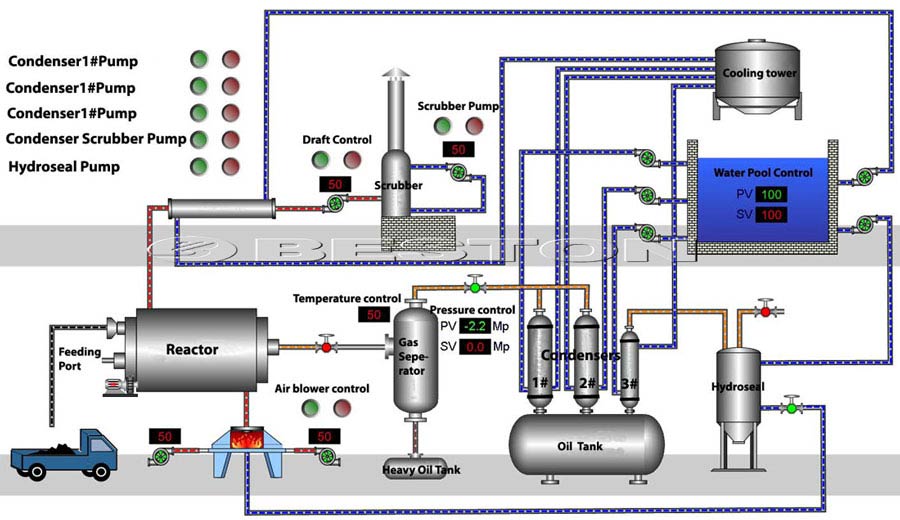

Cooling and condensate systems play a vital role in the operation of steam turbine generators. Once the steam has passed through the turbine, it must be condensed back into water to maintain a continuous cycle. This is typically done in a condenser, where cooling water absorbs heat from the exhaust steam. The condensed water, known as condensate, is then pumped back to the boiler for reuse. Various cooling methods, such as once-through cooling, cooling towers, and air-cooled condensers, are used depending on the availability of water and environmental considerations.

Advanced control systems and monitoring technologies enhance the performance and reliability of steam turbine generators. Digital control systems allow operators to monitor parameters such as temperature, pressure, rotational speed, and power output in real-time. Predictive maintenance techniques, utilizing sensors and data analytics, help identify potential issues before they lead to failures. The implementation of automation and artificial intelligence further optimizes turbine efficiency, reduces emissions, and extends the lifespan of components.

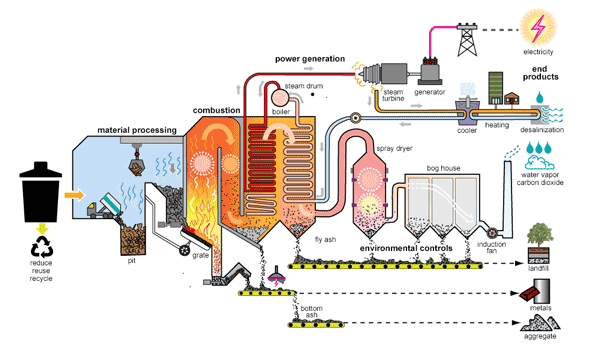

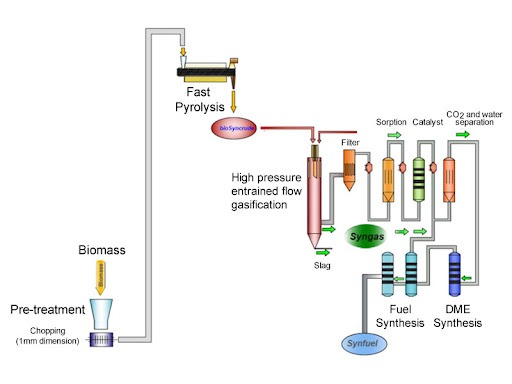

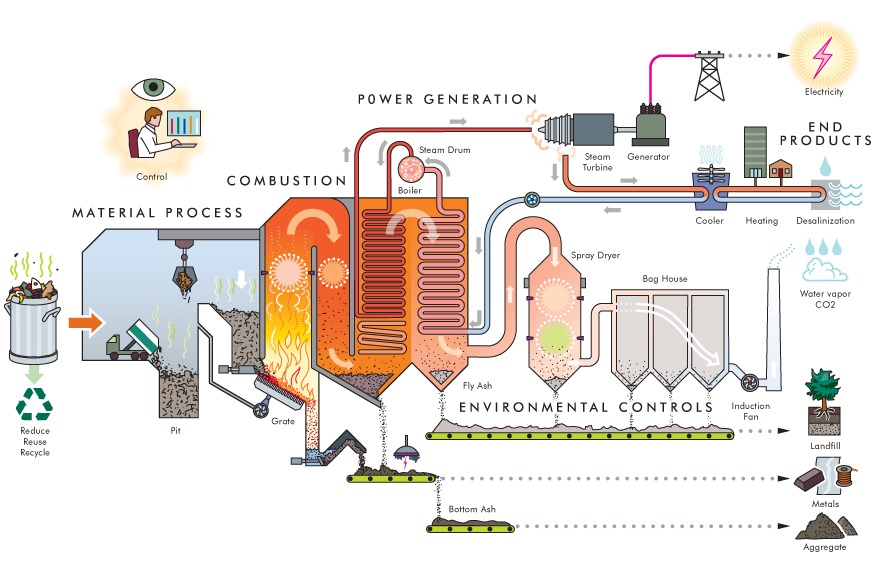

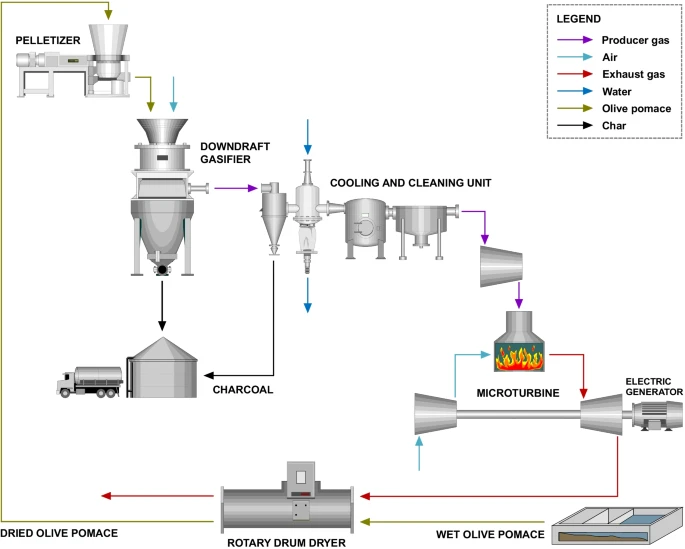

The integration of steam turbine generators with renewable energy sources is gaining attention in modern power generation. Hybrid systems combining solar thermal energy with steam turbines can enhance efficiency and provide stable power output. Similarly, biomass-fueled steam turbines offer a sustainable alternative to fossil fuels by utilizing organic materials such as wood, agricultural waste, and municipal solid waste. These advancements contribute to reducing greenhouse gas emissions and promoting cleaner energy solutions.

As energy demand continues to grow, steam turbine technology is evolving to improve efficiency, reliability, and environmental sustainability. Research and development efforts focus on higher steam temperatures and pressures, advanced materials, and improved blade designs to increase power output while minimizing energy losses. The adoption of supercritical and ultra-supercritical steam cycles, which operate at higher temperatures and pressures, significantly enhances efficiency and reduces fuel consumption.

Steam turbine generators remain an essential part of global power generation, providing reliable and efficient electricity production. Their widespread use across various industries and energy sectors highlights their importance in meeting energy demands. With continued advancements in turbine design, materials, and control systems, steam turbine technology will play a crucial role in shaping the future of sustainable and efficient power generation.

Another critical aspect of steam turbine generator operation is the efficiency of the thermodynamic cycle it follows. Most modern steam turbines operate on the Rankine cycle, which consists of four key processes: heat addition in the boiler, expansion in the turbine, heat rejection in the condenser, and compression in the feedwater pump. The efficiency of this cycle depends on factors such as steam temperature and pressure, as well as the effectiveness of heat recovery systems.

Supercritical and ultra-supercritical steam turbines represent a significant advancement in efficiency. Unlike conventional subcritical steam cycles, supercritical steam turbines operate at pressures above the critical point of water (approximately 22.1 MPa), where there is no distinction between liquid and gas phases. This allows for greater thermal efficiency, reducing fuel consumption and emissions. Ultra-supercritical turbines push these limits further by operating at even higher temperatures and pressures, often exceeding 600°C. These technologies have been widely adopted in modern power plants to improve performance and sustainability.

Another area of development in steam turbine technology is the use of reheating and regenerative cycles. Reheating involves passing partially expanded steam through a secondary heat exchanger before reintroducing it into the turbine for further expansion. This reduces moisture content in the low-pressure stages and improves overall efficiency. Regenerative feedwater heating, on the other hand, uses extracted steam from intermediate turbine stages to preheat the feedwater before it enters the boiler. This process reduces the amount of fuel required to reach operating temperatures, further improving efficiency and reducing emissions.

The maintenance and reliability of steam turbine generators are crucial for their long-term performance. Regular inspections, lubrication, and monitoring of critical components such as bearings, blades, and seals help prevent failures and ensure smooth operation. Condition-based monitoring (CBM) and predictive maintenance strategies use real-time data and machine learning algorithms to detect anomalies and predict potential failures before they occur. This reduces unplanned downtime and extends the lifespan of the equipment.

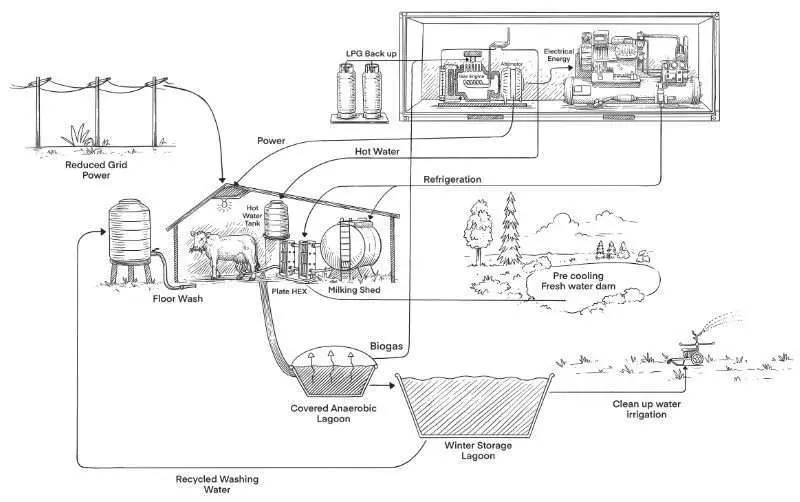

Steam turbines also play an essential role in industrial applications beyond electricity generation. Many industries, including chemical processing, paper manufacturing, food production, and district heating, utilize steam turbines for mechanical drive applications or cogeneration. In cogeneration systems, also known as combined heat and power (CHP) plants, steam turbines generate both electricity and useful thermal energy from the same fuel source. This improves overall energy efficiency, often reaching levels above 80%, compared to conventional power plants that typically operate at efficiencies of 30-40%.

The environmental impact of steam turbine generators depends on the fuel source used for steam production. Fossil-fuel-powered steam turbines contribute to greenhouse gas emissions, but advancements in carbon capture and storage (CCS) technology aim to mitigate their environmental impact. By capturing carbon dioxide emissions before they reach the atmosphere, CCS systems help reduce the carbon footprint of traditional power plants. Additionally, the integration of steam turbines with renewable energy sources such as biomass, geothermal, and solar thermal energy further enhances sustainability.

Another emerging technology is the use of hydrogen as a clean fuel for steam generation. Hydrogen-fired boilers can produce steam without carbon emissions, offering a potential pathway for decarbonizing steam turbine power plants. Research and development efforts are focused on improving hydrogen production methods, such as electrolysis powered by renewable energy, to make hydrogen-based steam generation more viable on a large scale.

With ongoing advancements in digitalization, automation, and energy storage, the future of steam turbine generators looks promising. Smart grids and demand-response systems are enabling more flexible operation, allowing steam turbines to complement variable renewable energy sources like wind and solar. By integrating with energy storage technologies such as molten salt thermal storage and battery systems, steam turbines can provide stable and reliable power even when renewable energy generation fluctuates.

As global energy demand continues to grow, steam turbines will remain a cornerstone of power generation. Their ability to operate efficiently at large scales, adapt to various fuel sources, and integrate with modern energy management technologies ensures their relevance in the evolving energy landscape. Ongoing research in materials science, thermodynamics, and digital optimization will further enhance the efficiency, reliability, and sustainability of steam turbine generators, securing their role in the future of power generation.

Another important aspect of steam turbine generators is their adaptability to different operational needs and load conditions. In modern power grids, demand for electricity fluctuates throughout the day, requiring power plants to adjust their output accordingly. Steam turbine generators can operate in base-load, intermediate-load, and peaking-load conditions, depending on the plant’s design and the requirements of the grid. Base-load power plants, such as nuclear and large coal-fired plants, run continuously at a steady output to provide a stable electricity supply. Intermediate-load plants adjust their output based on demand variations, while peaking plants operate during high-demand periods.

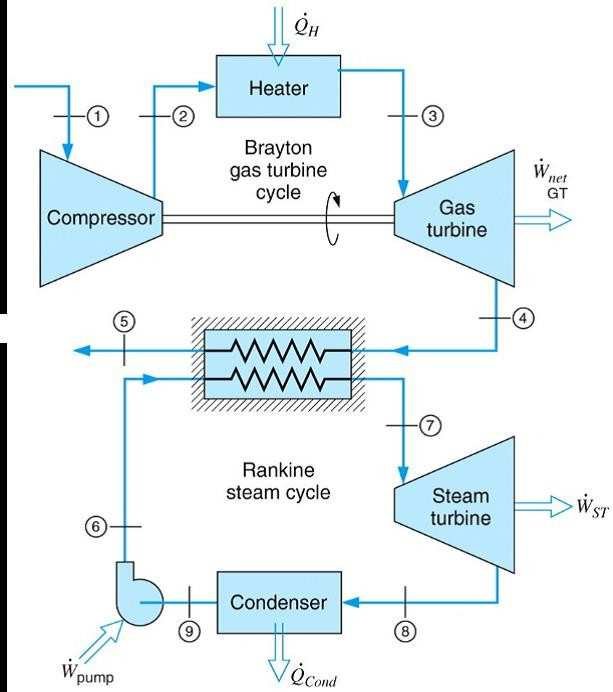

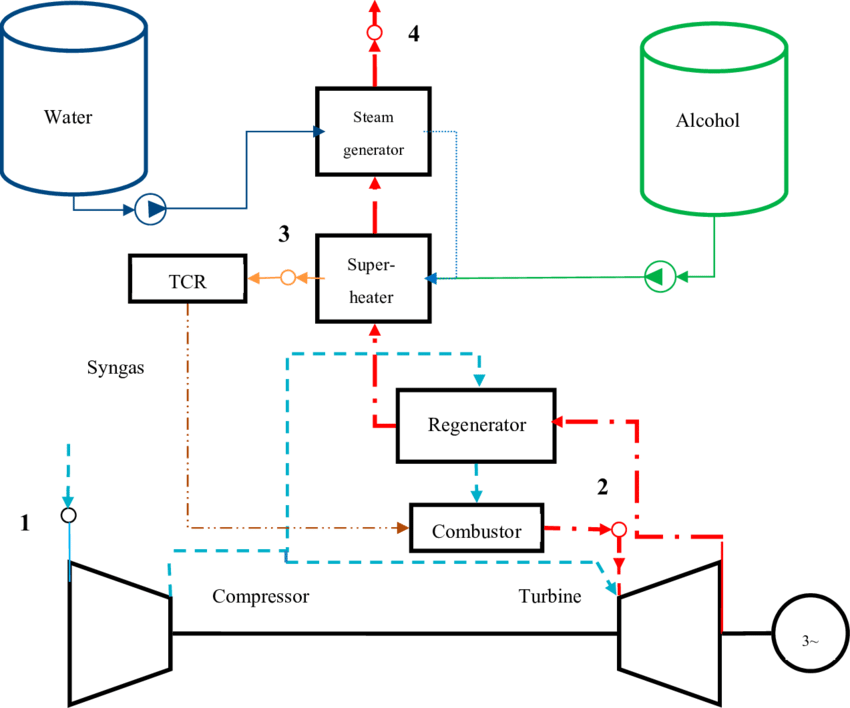

To improve flexibility, advanced steam turbines incorporate fast-start and load-following capabilities. These features allow the turbine to ramp up or down more quickly, reducing startup times and improving responsiveness to grid fluctuations. Combined cycle power plants (CCPPs), which integrate steam turbines with gas turbines, enhance efficiency and operational flexibility. In a CCPP, a gas turbine generates electricity while its exhaust heat is used to produce steam, which drives a steam turbine. This combined system increases efficiency, reduces fuel consumption, and allows for quicker adjustments to power demand.

Steam turbine performance is also influenced by steam quality, particularly in the low-pressure stages. As steam expands through the turbine, it can become wet, leading to moisture-related erosion and efficiency losses. To mitigate this, moisture separators and reheaters are used to improve steam conditions before it enters the later turbine stages. Blade coatings and advanced materials also help protect components from erosion, corrosion, and thermal stress.

The choice of turbine configuration depends on the specific application. Impulse turbines and reaction turbines are the two primary types used in steam power generation. Impulse turbines rely on high-velocity steam jets to strike the turbine blades, causing them to rotate. The steam expands in nozzles before impacting the blades, leading to efficient energy conversion in high-pressure stages. Reaction turbines, on the other hand, extract energy through a combination of steam pressure drop and reactive force, providing a more gradual expansion and energy transfer. Many modern steam turbines use a combination of both impulse and reaction stages to optimize efficiency across different operating conditions.

In addition to power generation, steam turbines play a critical role in industrial processes that require mechanical power. Industries such as petrochemical refining, pulp and paper production, and desalination use steam turbines to drive pumps, compressors, and other machinery. These applications benefit from the efficiency and reliability of steam turbines, especially when integrated with cogeneration systems. By using extracted steam for heating or other industrial purposes, facilities can significantly improve their overall energy efficiency and reduce waste heat losses.

The future of steam turbine generators is closely tied to advancements in energy efficiency, emissions reduction, and digitalization. Digital twins—virtual models of physical turbines—are increasingly used for real-time monitoring, performance optimization, and predictive maintenance. By simulating different operating conditions and analyzing historical data, digital twin technology helps operators maximize efficiency and minimize downtime. The integration of artificial intelligence and machine learning further enhances turbine performance by identifying patterns and optimizing control strategies.

Another area of innovation is supercritical CO₂ (sCO₂) power cycles, which use supercritical carbon dioxide as a working fluid instead of steam. These systems operate at higher efficiencies and require smaller, more compact turbines. sCO₂ power cycles have the potential to revolutionize power generation by reducing plant size, increasing operational flexibility, and improving efficiency beyond conventional steam Rankine cycles. Research and pilot projects are underway to develop commercial-scale sCO₂ power plants, which could complement or even replace traditional steam turbines in the future.

With global efforts to transition to cleaner energy sources, steam turbines will continue to play a role in bridging the gap between conventional and renewable power generation. The adaptation of steam turbine technology to biomass, hydrogen, and waste-to-energy applications will ensure their continued relevance in a decarbonizing energy landscape. Additionally, the integration of energy storage solutions and hybrid systems will enhance the efficiency and reliability of steam-based power plants, making them more competitive in the evolving energy market.

As technological advancements continue, steam turbine generators will remain a cornerstone of industrial and power generation infrastructure. With improvements in materials, thermodynamics, and digital control systems, they will achieve even greater levels of efficiency, reliability, and sustainability. The ongoing evolution of steam turbines will contribute to a more resilient and adaptable global energy system, ensuring their role in power generation for decades to come.

The ongoing advancements in steam turbine generator technology are driven by the need for increased efficiency, reduced environmental impact, and enhanced operational flexibility. One of the primary research areas is improving turbine blade design. Modern steam turbines use aerodynamically optimized blades with advanced materials such as nickel-based superalloys and ceramic coatings. These materials can withstand extreme temperatures and pressures, reducing wear and improving longevity. Additionally, 3D printing and additive manufacturing are being explored to create complex blade geometries that enhance efficiency and reduce turbulence losses.

Another key area of development is the use of advanced steam cycles to extract more energy from the steam before it is condensed back into water. The ultra-supercritical (USC) steam cycle operates at temperatures above 600°C and pressures exceeding 30 MPa, significantly improving thermal efficiency compared to conventional subcritical systems. These high-efficiency cycles reduce fuel consumption and lower carbon dioxide emissions per unit of electricity generated. Many modern coal-fired power plants are being upgraded to ultra-supercritical status to meet stricter environmental regulations while maintaining economic viability.

Cogeneration, also known as combined heat and power (CHP), continues to gain importance in industrial applications where both electricity and heat are needed. In a cogeneration system, steam turbines generate electricity while capturing waste heat for industrial processes, district heating, or desalination. This dual-purpose use of energy improves overall system efficiency and reduces fuel costs. Many industries, including chemical processing, food production, and pharmaceuticals, are adopting cogeneration to enhance their energy efficiency and sustainability.

The integration of steam turbine generators with renewable energy sources is another promising trend. Concentrated solar power (CSP) plants use mirrors or lenses to focus sunlight onto a receiver, generating high-temperature steam to drive a steam turbine. Unlike photovoltaic solar panels, CSP plants can incorporate thermal energy storage, such as molten salt storage, to provide electricity even when the sun is not shining. Geothermal power plants also use steam turbines, harnessing naturally occurring steam from underground reservoirs to generate electricity with minimal environmental impact.

To further reduce emissions from conventional power plants, carbon capture and storage (CCS) technologies are being integrated with steam turbine generators. In a CCS-equipped power plant, carbon dioxide emissions are captured before being released into the atmosphere and then stored underground or utilized in industrial applications. This technology enables steam turbine power plants to operate with significantly lower greenhouse gas emissions, making them a viable option in a low-carbon energy future. Ongoing research focuses on improving the efficiency and cost-effectiveness of carbon capture systems to facilitate wider adoption.

Digitalization is also transforming steam turbine operations. The use of Internet of Things (IoT) sensors, big data analytics, and machine learning algorithms allows for real-time performance monitoring and predictive maintenance. By continuously analyzing operational data, power plant operators can detect early signs of wear, optimize performance, and extend the lifespan of critical components. Digital twin technology, which creates a virtual replica of a steam turbine generator, enables simulations and testing without disrupting actual plant operations. These innovations contribute to higher reliability, reduced downtime, and lower maintenance costs.

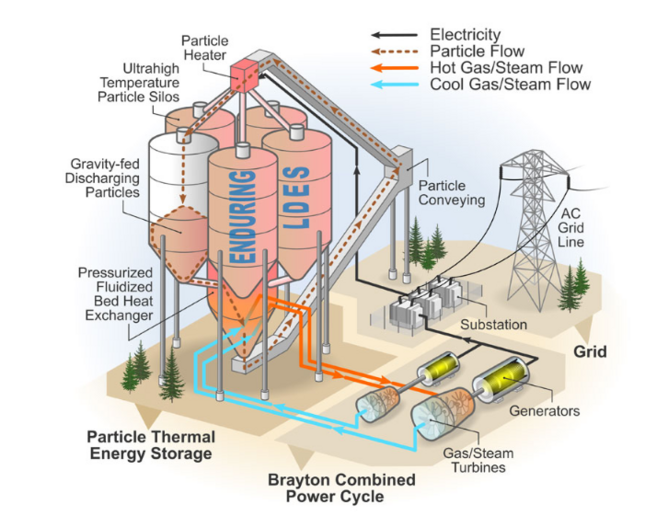

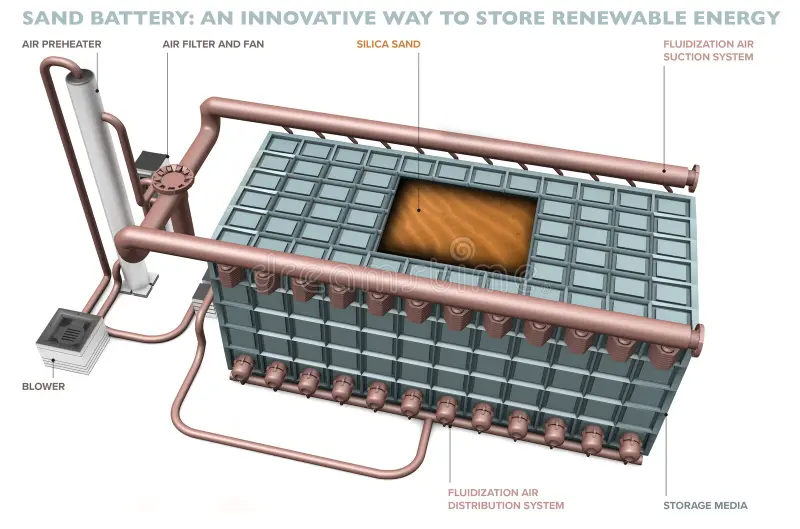

Energy storage solutions are also being explored to complement steam turbine generators. While steam turbines provide steady baseload power, energy storage can help balance supply and demand fluctuations. Technologies such as molten salt thermal storage, compressed air energy storage (CAES), and advanced battery systems allow excess energy generated during low-demand periods to be stored and released when needed. Hybrid power plants that combine steam turbines with energy storage can improve grid stability and increase the flexibility of thermal power generation.

Looking ahead, the role of steam turbine generators in a rapidly evolving energy landscape remains crucial. As global energy demand continues to grow, steam turbine technology will adapt to meet the challenges of efficiency, sustainability, and integration with renewable energy sources. Innovations in materials, digital control systems, and advanced steam cycles will drive further improvements in performance and environmental impact. Whether in large-scale power generation, industrial applications, or hybrid energy systems, steam turbines will continue to play a fundamental role in delivering reliable and efficient energy for decades to come.

An Economic Steam Turbine Generator (ESTG) is designed to provide efficient and cost-effective power generation while minimizing operational and maintenance costs. These turbines are optimized for industries and power plants that require reliable energy production with a strong emphasis on affordability, fuel efficiency, and long-term sustainability. Economic steam turbine generators are used in various applications, including industrial power generation, cogeneration (combined heat and power), and renewable energy integration.

Key Features of an Economic Steam Turbine Generator

- High Efficiency with Lower Fuel Consumption

Economic steam turbines are engineered to maximize energy conversion from steam while minimizing fuel consumption. This is achieved through optimized turbine blade design, advanced materials, and improved thermodynamic cycles such as superheated and reheated steam processes. These enhancements reduce waste energy and improve overall plant efficiency. - Cost-Effective Construction and Operation

The design of economic steam turbine generators prioritizes cost-effective materials and streamlined manufacturing processes to reduce initial capital investment. Modern manufacturing techniques, such as 3D printing and precision machining, contribute to lower production costs while maintaining high performance and durability. - Flexibility in Fuel and Steam Sources

Economic steam turbines can operate using various heat sources, including fossil fuels (coal, natural gas, oil), biomass, geothermal energy, and solar thermal power. This adaptability allows industries and power plants to choose the most cost-effective and locally available fuel sources, reducing dependence on expensive imports. - Compact and Modular Design

Many economic steam turbine generators are designed with modular components that enable easy installation, expansion, and maintenance. This modular approach allows power plants to scale their operations based on demand, reducing initial capital costs and improving long-term economic viability. - Low Maintenance and Extended Lifespan

Economic steam turbines are designed for durability and minimal maintenance requirements. By using high-quality materials, advanced coatings, and self-lubricating components, manufacturers can reduce wear and tear, extending the lifespan of the turbine. Condition-based monitoring systems also help operators detect potential issues early, preventing costly breakdowns. - Integration with Waste Heat Recovery Systems

Many economic steam turbine generators are integrated into waste heat recovery systems (WHRS), allowing them to utilize excess heat from industrial processes. This approach significantly improves efficiency and reduces fuel costs, making them ideal for industries such as cement manufacturing, steel production, and chemical processing. - Suitability for Cogeneration (CHP) Systems

In combined heat and power (CHP) applications, economic steam turbines maximize energy use by simultaneously generating electricity and useful heat. This significantly increases overall system efficiency (often above 80%) and reduces operational costs for industries that require both power and steam for processes. - Environmental and Regulatory Compliance

Economic steam turbines are designed to meet stringent environmental regulations by reducing emissions and optimizing fuel usage. Modern designs incorporate low-emission combustion technologies, carbon capture integration, and improved steam cycle efficiency to comply with global sustainability goals.

Applications of Economic Steam Turbine Generators

- Industrial Power Generation: Factories and manufacturing plants use economic steam turbines to power their operations, reducing dependence on expensive grid electricity.

- Cogeneration Plants: Economic turbines are widely used in CHP plants to provide both power and heat for district heating, food processing, and chemical industries.

- Renewable Energy Projects: Geothermal and solar thermal power plants utilize economic steam turbines to convert heat into electricity efficiently.

- Waste-to-Energy Systems: Economic turbines play a crucial role in converting industrial waste heat into usable electricity, promoting sustainable energy practices.

Future Trends in Economic Steam Turbine Generators

With ongoing advancements in materials science, automation, and digital monitoring, economic steam turbines continue to evolve. Innovations such as artificial intelligence (AI)-driven predictive maintenance, supercritical CO₂ cycles, and hydrogen-based steam generation are shaping the future of economic power generation. These improvements aim to make steam turbine technology even more affordable, efficient, and environmentally friendly.

As global energy markets shift toward sustainability and cost-effectiveness, Economic Steam Turbine Generators will remain a vital component of industrial and power generation systems, ensuring reliable and economical electricity production for years to come.

The increasing demand for cost-effective and sustainable energy solutions continues to drive innovations in Economic Steam Turbine Generators (ESTGs). These turbines are not only essential for industrial power generation but also play a significant role in supporting decentralized energy systems, improving grid stability, and integrating renewable energy sources. Their ability to operate efficiently under varying loads and fuel conditions makes them an attractive choice for both large-scale and small-scale power generation.

Optimization of Economic Steam Turbine Generators

- Enhanced Thermodynamic Cycles for Better Efficiency

Advancements in steam turbine cycles have significantly improved the efficiency of ESTGs. The use of superheated and reheated steam cycles ensures that steam expands through the turbine stages at optimal conditions, reducing moisture content and enhancing energy conversion. Additionally, regenerative feedwater heating is employed to preheat the boiler feedwater using extracted steam, which reduces the energy required for steam generation and improves overall thermal efficiency. - Innovations in Blade Design and Materials

Economic steam turbines utilize aerodynamically optimized blade profiles to minimize energy losses due to turbulence and steam leakage. High-performance alloys, such as nickel-based superalloys and titanium composites, enhance the durability of turbine blades, allowing them to withstand high temperatures and pressures while maintaining efficiency. The use of coatings and erosion-resistant materials further extends turbine lifespan and reduces maintenance costs. - Compact and Lightweight Configurations

To make ESTGs more adaptable for industrial and decentralized power applications, manufacturers are designing compact, modular, and lightweight turbines. These designs reduce installation and transportation costs, making them ideal for industries with limited space or remote locations where logistics are a challenge. - Advanced Control and Monitoring Systems

The integration of digital control systems, IoT-based sensors, and AI-driven analytics has transformed steam turbine operations. These technologies enable real-time monitoring of turbine performance, detecting potential failures before they occur and optimizing operation for maximum efficiency. Predictive maintenance systems reduce downtime and operational costs by ensuring that maintenance is performed only when necessary, rather than on fixed schedules. - Waste Heat Recovery and Combined Cycle Integration

One of the most significant economic advantages of steam turbine generators is their ability to utilize waste heat from industrial processes. Many industries, such as steel production, cement manufacturing, and chemical processing, generate large amounts of waste heat that can be harnessed to produce steam. This steam can then be used to drive turbines, generating electricity at minimal additional cost. Furthermore, ESTGs are increasingly being integrated into combined cycle power plants (CCPPs), where they work in conjunction with gas turbines to maximize fuel efficiency and minimize emissions. - Hybrid Energy Systems and Renewable Energy Integration

Economic steam turbines are becoming a key component of hybrid energy systems, where they operate alongside solar thermal, geothermal, and biomass energy sources. In concentrated solar power (CSP) plants, steam turbines convert solar heat into electricity, providing a stable power output even when solar radiation fluctuates. In geothermal plants, steam turbines use naturally occurring steam from underground reservoirs, offering a low-carbon and cost-effective energy solution. These integrations help reduce reliance on fossil fuels and support the transition to cleaner energy sources.

Cost-Effectiveness and Financial Viability of ESTGs

- Lower Capital and Operational Costs

Economic steam turbines are designed with cost optimization in mind, ensuring that initial investment and long-term operational costs remain low. The use of standardized components, automated manufacturing, and modular construction reduces production expenses. Additionally, longer service intervals and low-maintenance designs further contribute to cost savings over the turbine’s lifespan. - Fuel Flexibility for Economic Operation

The ability of ESTGs to operate on a wide range of fuels, including coal, natural gas, biomass, and waste heat, provides industries with the flexibility to choose the most affordable and locally available energy source. This reduces dependency on expensive imported fuels and stabilizes long-term energy costs. - Government Incentives and Regulatory Support

Many governments are encouraging the adoption of efficient and sustainable energy solutions by offering financial incentives, tax credits, and grants for industries that invest in energy-efficient steam turbines. Policies supporting combined heat and power (CHP) systems, waste heat recovery, and carbon reduction strategies make ESTGs an even more attractive investment for businesses seeking to improve their energy efficiency while complying with environmental regulations.

Future Prospects of Economic Steam Turbine Generators

- Advancements in Supercritical and Ultra-Supercritical Technology

Future developments in supercritical and ultra-supercritical steam cycles will enable steam turbines to operate at even higher temperatures and pressures, further increasing efficiency and reducing fuel consumption. These improvements will be particularly beneficial for large-scale power plants aiming to enhance economic and environmental performance. - Hydrogen-Powered Steam Turbines

With the growing focus on decarbonization, research is underway to develop hydrogen-fueled steam turbines. Hydrogen-fired boilers can generate steam without producing carbon emissions, making steam turbine generators an integral part of future clean energy systems. As hydrogen production technologies become more cost-effective, green hydrogen-based steam power generation will become a viable and sustainable option. - AI and Machine Learning for Smart Operations

The application of AI and machine learning in steam turbine operations is set to revolutionize the industry. Advanced algorithms will continuously analyze operational data, adjusting turbine parameters for optimal performance under varying loads and environmental conditions. Autonomous and self-optimizing turbines will further reduce human intervention and improve overall economic efficiency. - Decentralized Power Generation and Microgrids

The rise of microgrids and decentralized energy systems is creating new opportunities for economic steam turbine generators. Small-scale industries, commercial buildings, and rural communities can deploy compact steam turbines in CHP or waste-to-energy applications, reducing reliance on traditional power grids and enhancing energy security.

Conclusion

Economic Steam Turbine Generators are a cornerstone of cost-effective and efficient power generation. Their adaptability to various fuels, ability to integrate with renewable energy sources, and continuous advancements in efficiency and digitalization make them an essential component of modern energy systems. As industries seek affordable, sustainable, and resilient energy solutions, ESTGs will continue to play a pivotal role in driving global energy efficiency and reducing carbon footprints.

By embracing emerging technologies such as supercritical steam cycles, AI-driven maintenance, hydrogen integration, and hybrid renewable systems, economic steam turbine generators will remain a key player in the evolving energy landscape, ensuring low-cost, reliable, and sustainable power generation for decades to come.

The Role of Economic Steam Turbine Generators in Global Energy Transition

As the world transitions toward cleaner and more sustainable energy sources, Economic Steam Turbine Generators (ESTGs) remain a key component of the power sector. Despite the rise of renewable energy technologies such as wind and solar, steam turbines continue to provide baseload power, ensuring grid stability and reliability. The integration of advanced steam cycles, fuel flexibility, and hybrid energy solutions has further enhanced their economic and environmental viability.

Integration with Modern Energy Systems

- Hybrid Power Plants with Renewable Energy

ESTGs are increasingly being integrated into hybrid power plants, where they complement solar thermal, geothermal, and biomass energy sources. These hybrid configurations improve overall efficiency and ensure continuous power generation, even when renewable sources experience fluctuations. For example:- Concentrated Solar Power (CSP) Plants use steam turbines to generate electricity from stored solar heat, ensuring a steady power supply even after sunset.

- Geothermal Power Plants utilize naturally occurring underground steam to drive turbines, offering a low-cost, sustainable energy solution.

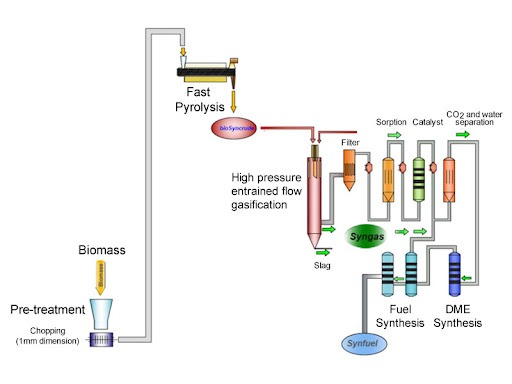

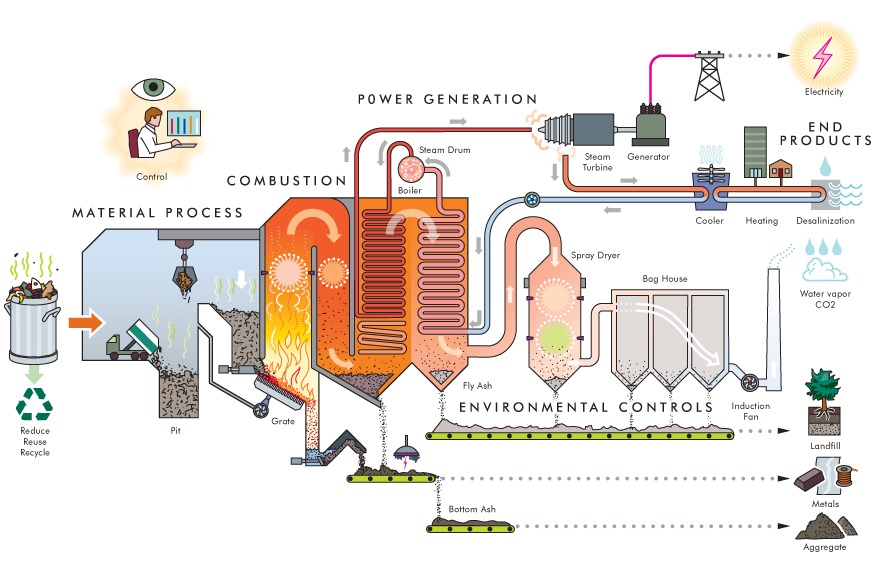

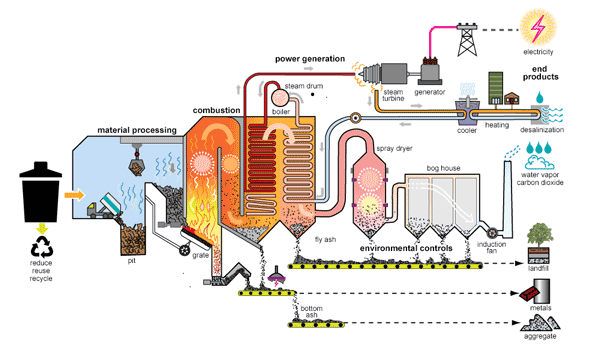

- Biomass and Waste-to-Energy Systems convert agricultural, municipal, and industrial waste into steam, reducing landfill waste while generating electricity.

- Decentralized Energy and Microgrid Applications

As energy distribution models evolve, ESTGs are becoming crucial in microgrids and decentralized energy systems. In remote locations or industrial zones, small-scale steam turbines provide a reliable and cost-effective alternative to grid dependence. These systems:- Reduce transmission and distribution losses.

- Enhance energy security by ensuring on-site power generation for critical industries.

- Support industrial self-sufficiency, lowering electricity costs for manufacturing plants, food processing units, and district heating systems.

- Grid Stability and Load Balancing

With the increasing penetration of intermittent renewable sources such as wind and solar, economic steam turbines play a stabilizing role in power grids. Their ability to rapidly adjust power output makes them an ideal partner for renewable energy by:- Compensating for fluctuations in solar and wind generation.

- Providing inertia and frequency regulation, maintaining grid reliability.

- Operating in flexible load conditions, making them compatible with modern smart grids.

Economic and Environmental Considerations

- Cost-Effective Power Generation

The affordability of ESTGs is a major reason for their widespread adoption in industrial and power generation applications. Compared to gas turbines and diesel generators, steam turbines:- Have lower operating costs due to fuel efficiency and minimal moving parts.

- Offer a longer lifespan, often exceeding 30 years of operation with proper maintenance.

- Utilize a variety of fuels, ensuring adaptability to fluctuating fuel prices and availability.

- Environmental Sustainability and Emission Reduction

Modern ESTGs are designed to meet strict environmental regulations by incorporating low-emission combustion technologies and carbon capture solutions. Some of the key environmental benefits include:- High efficiency, reducing fuel consumption and lowering CO₂ emissions.

- Integration with carbon capture and storage (CCS) technology, making fossil-fuel-based power plants more sustainable.

- Utilization of waste heat recovery, maximizing energy output and reducing overall emissions.

- Government Policies and Incentives

Many governments are supporting the adoption of efficient and clean energy technologies, providing:- Subsidies and tax credits for industries implementing steam turbines in CHP and waste-to-energy applications.

- Carbon pricing mechanisms that encourage the use of high-efficiency turbines with lower emissions.

- Regulatory frameworks promoting renewable-based steam power, such as solar thermal and geothermal projects.

Future Technological Innovations

- Supercritical and Ultra-Supercritical Steam Cycles

The next generation of economic steam turbines will feature supercritical (SC) and ultra-supercritical (USC) technologies, operating at higher temperatures and pressures to increase efficiency. These advancements:- Improve thermal efficiency, reducing fuel consumption by up to 45%.

- Enable lower carbon emissions per megawatt-hour of electricity generated.

- Reduce operational costs over the long term by improving fuel economy.

- AI-Driven Optimization and Digital Twin Technology

Artificial intelligence and machine learning are transforming steam turbine operations through:- Predictive maintenance, using real-time sensor data to detect wear and optimize maintenance schedules.

- Digital twin technology, creating a virtual replica of the turbine to simulate performance and test improvements.

- Automated control systems, dynamically adjusting steam flow, temperature, and load to enhance efficiency.

- Hydrogen-Based Steam Power Generation

As hydrogen production technologies improve, hydrogen-fired steam turbines will become a zero-emission power solution. Hydrogen-based systems:- Reduce reliance on fossil fuels by using green hydrogen from renewable sources.

- Provide long-term energy storage, ensuring reliability in hybrid renewable grids.

- Align with global carbon-neutrality targets, supporting cleaner industrial power generation.

Conclusion

Economic Steam Turbine Generators will continue to evolve and adapt in response to shifting energy demands and sustainability goals. By embracing technological innovations, digitalization, and hybrid energy integration, these turbines will remain a cost-effective, efficient, and environmentally friendly solution for industrial and utility-scale power generation.

As energy markets move toward decarbonization and resilience, ESTGs will play a critical role in ensuring reliable and affordable electricity while supporting the transition to a cleaner energy future. Whether in conventional power plants, industrial cogeneration, or renewable hybrid systems, economic steam turbines will remain a cornerstone of global power infrastructure for decades to come.

Advanced Engineering and Future Developments in Economic Steam Turbine Generators

The continuous evolution of Economic Steam Turbine Generators (ESTGs) is driven by the need for higher efficiency, lower costs, and improved sustainability. Innovations in materials, thermodynamic cycles, digitalization, and integration with renewable energy systems are shaping the next generation of steam turbines. These advancements ensure that steam turbines remain a competitive and essential part of the global energy mix.

Innovations in Steam Turbine Design and Manufacturing

- Next-Generation High-Performance Materials

- The development of high-temperature alloys, such as nickel-based superalloys and ceramic matrix composites, allows steam turbines to operate at higher temperatures and pressures without degradation.

- Coatings and surface treatments improve corrosion resistance, reducing the impact of steam impurities and extending turbine lifespan.

- Advanced 3D printing techniques enable the precise manufacturing of complex turbine components, reducing production costs and material waste.

- Improved Aerodynamics and Blade Efficiency

- Computational fluid dynamics (CFD) simulations are used to optimize turbine blade design, reducing aerodynamic losses and improving efficiency.

- Active clearance control (ACC) systems adjust blade-tip clearances dynamically, minimizing steam leakage and enhancing power output.

- Last-stage blade extensions allow turbines to capture more energy from low-pressure steam, increasing total energy conversion.

- Compact, Modular, and Scalable Designs

- Small and mid-sized steam turbines are being designed with modular components, making them ideal for distributed power generation and microgrid applications.

- Factory-assembled turbine modules reduce installation time and costs, making ESTGs more accessible to industries with limited infrastructure.

- Scalable turbine systems allow businesses to expand their power generation capacity in stages, optimizing capital investment.

Digitalization and Smart Monitoring in ESTGs

- AI-Powered Predictive Maintenance

- Machine learning algorithms analyze sensor data to predict potential failures before they occur, reducing unplanned downtime.

- Automated diagnostics improve turbine reliability by continuously assessing component wear and efficiency.

- Remote monitoring and cloud-based analytics allow operators to manage multiple turbines from a centralized location.

- Digital Twin Technology for Performance Optimization

- Virtual models (digital twins) simulate real-world operating conditions to test new configurations and improve turbine performance.

- Real-time adjustments based on digital twin analysis enhance efficiency, reduce maintenance costs, and extend turbine lifespan.

- Adaptive control systems automatically adjust turbine settings to optimize steam flow and thermal performance.

- Integration with Smart Grids and IoT Networks

- Internet of Things (IoT)-enabled turbines communicate with energy management systems, improving grid stability and demand response.

- Dynamic load balancing allows steam turbines to adjust power output in real-time, supporting fluctuating renewable energy inputs.

- Cybersecurity advancements ensure the protection of digital control systems against cyber threats and operational disruptions.

Sustainability and Environmental Impact

- Carbon Capture and Utilization (CCU) Technologies

- Integrated carbon capture systems allow steam power plants to reduce CO₂ emissions by capturing exhaust gases for storage or reuse.

- CO₂ utilization processes convert captured emissions into industrial products such as synthetic fuels, chemicals, and building materials.

- Enhanced efficiency designs reduce greenhouse gas emissions per megawatt-hour of electricity generated.

- Hydrogen-Ready Steam Turbines

- Hydrogen-fueled steam boilers provide a carbon-neutral alternative to conventional fossil fuel combustion.

- Dual-fuel capability enables steam turbines to operate on a mix of natural gas, biomass, and hydrogen, offering flexibility during the transition to cleaner energy sources.

- Hydrogen-based combined cycle plants integrate gas and steam turbines for near-zero emissions power generation.

- Waste Heat Recovery and Industrial Symbiosis

- Heat recovery steam generators (HRSGs) capture waste heat from industrial processes, converting it into useful power.

- Industrial symbiosis allows multiple industries to share excess heat and steam resources, improving overall energy efficiency.

- Low-temperature steam cycles optimize power production from previously untapped waste heat sources, such as data centers and chemical plants.

Economic and Market Trends for ESTGs

- Cost Reduction Strategies

- Economies of scale in turbine manufacturing lower costs, making ESTGs more accessible to small and mid-sized industries.

- Longer service intervals reduce maintenance expenses, improving the overall return on investment.

- Government incentives for efficient power generation encourage the adoption of high-efficiency steam turbines.

- Rise of Distributed Energy Systems

- More businesses are investing in on-site power generation, reducing dependence on external electricity providers.

- Industrial CHP systems continue to gain traction, offering combined power and heat solutions for manufacturing and processing industries.

- Microgrid applications allow communities and commercial complexes to maintain energy independence with steam turbine-based power generation.

- Growth in Renewable and Hybrid Energy Markets

- Solar-thermal and biomass power plants are expanding their use of steam turbines for sustainable and dispatchable power generation.

- Hybrid energy projects combining wind, solar, and steam turbines provide reliable power with reduced carbon footprints.

- Geothermal energy expansion continues to drive demand for specialized low- and medium-pressure steam turbines.

The Future of Economic Steam Turbine Generators

As global energy demands shift toward efficiency, sustainability, and resilience, ESTGs will remain a vital part of the energy infrastructure. The next generation of steam turbines will integrate advanced materials, digital intelligence, and low-carbon technologies to offer cleaner and more economical power generation. With continuous improvements in automation, fuel flexibility, and hybridization, economic steam turbines will continue to provide reliable, cost-effective, and environmentally responsible power for industries worldwide.

In the coming decades, Economic Steam Turbine Generators will play a key role in supporting industrial growth, enhancing grid stability, and accelerating the transition toward a carbon-neutral energy future.

Self-Sustaining Industrial Power Solutions: A Path to Energy Independence and Efficiency

As industries worldwide seek cost-effective, reliable, and sustainable energy solutions, the concept of self-sustaining industrial power has gained significant traction. By integrating on-site power generation, waste heat recovery, renewable energy sources, and advanced energy storage, industries can achieve energy independence, reduced operational costs, and lower environmental impact.

Key Components of Self-Sustaining Industrial Power Solutions

- On-Site Power Generation: The Foundation of Energy Independence

- Cogeneration (CHP – Combined Heat and Power): Utilizing steam turbines or gas turbines to simultaneously produce electricity and useful heat, improving fuel efficiency by up to 80%.

- Industrial Steam Turbines: Powering factories with steam from biomass, waste-to-energy, or geothermal sources, ensuring continuous and reliable energy.

- Microgrids and Distributed Energy Systems: Independent energy networks that allow industries to function off-grid, reducing dependence on unstable external power supplies.

- Waste Heat Recovery: Maximizing Efficiency

- Heat Recovery Steam Generators (HRSGs): Capturing excess heat from industrial processes (e.g., cement, steel, and chemical manufacturing) to produce additional power.

- Organic Rankine Cycle (ORC) Systems: Converting low-temperature waste heat into electricity, improving overall energy efficiency.

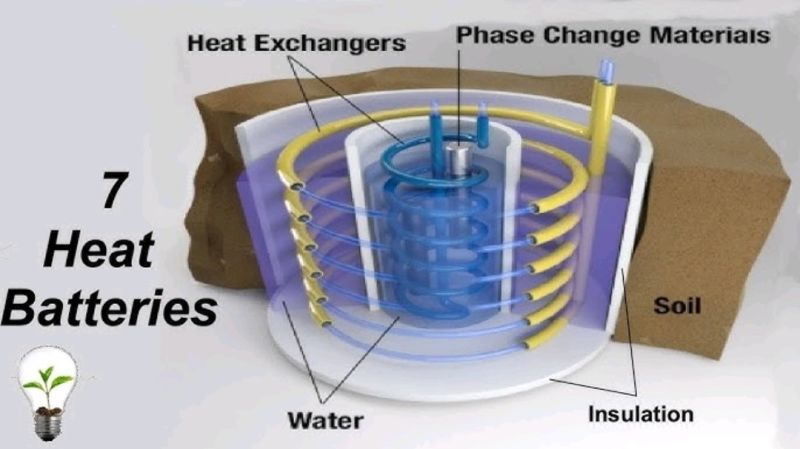

- Thermal Energy Storage (TES): Storing surplus heat for later use, ensuring optimal energy utilization.

- Renewable and Alternative Energy Integration

- Biomass and Waste-to-Energy Plants: Converting industrial byproducts, agricultural residues, and municipal waste into sustainable energy.

- Solar Industrial Heating and Power: Using concentrated solar power (CSP) to generate steam for turbine-based electricity production.

- Geothermal Energy: Harnessing underground heat sources for continuous power and process heating in industrial operations.

- Energy Storage and Smart Grid Integration

- Battery Energy Storage Systems (BESS): Storing excess electricity for peak demand periods, reducing reliance on external power grids.

- Hydrogen Storage: Producing and storing green hydrogen for later use in hydrogen-fired steam turbines or fuel cells.

- AI-Powered Energy Management Systems: Using real-time analytics and automation to optimize energy production, consumption, and storage.

Benefits of Self-Sustaining Industrial Power Solutions

- Energy Cost Reduction: By generating electricity on-site, industries avoid transmission costs and peak grid pricing.

- Operational Resilience: Protection against grid failures, blackouts, and fluctuating fuel prices.

- Carbon Emission Reduction: Lower dependence on fossil fuels through renewables, CHP, and waste heat utilization.

- Regulatory Compliance: Meeting sustainability goals and avoiding carbon taxes through cleaner energy practices.

Industries Leading the Shift to Self-Sustaining Power

- Manufacturing and Heavy Industry: Using CHP and waste heat recovery to power operations.

- Chemical and Refining Plants: Deploying steam turbines and hydrogen-based power solutions.

- Food Processing and Agriculture: Utilizing biogas and biomass-fired power plants for energy self-sufficiency.

- Data Centers and Tech Infrastructure: Implementing microgrids and backup storage solutions for uninterrupted operations.

Conclusion

Self-sustaining industrial power solutions are transforming the way industries approach energy security, cost-efficiency, and sustainability. By leveraging a combination of on-site power generation, waste heat recovery, renewables, and energy storage, businesses can achieve true energy independence while reducing their environmental footprint. With advancements in digitalization, hydrogen power, and hybrid energy systems, the future of industrial energy is increasingly resilient, sustainable, and self-sufficient.

Advanced Technologies Driving Self-Sustaining Industrial Power Solutions

Industries are increasingly adopting self-sustaining power solutions to ensure operational continuity, reduce dependence on external energy suppliers, and enhance efficiency. The integration of next-generation energy technologies, automation, and digitalization is transforming industrial power systems into highly efficient, resilient, and cost-effective solutions.

1. Next-Generation Cogeneration and Combined Heat & Power (CHP) Systems

Cogeneration, or Combined Heat and Power (CHP), remains a cornerstone of self-sustaining industrial power solutions by maximizing energy efficiency and minimizing waste. The latest advancements in CHP technology include:

- High-Efficiency Steam Turbines: Modern steam turbines operate at higher temperatures and pressures, increasing fuel utilization efficiency to over 80%.

- Supercritical and Ultra-Supercritical Steam Systems: These technologies allow for greater energy conversion efficiency and lower emissions.

- Hybrid CHP Systems: Integrating renewable sources such as solar thermal and biomass into cogeneration plants to reduce reliance on fossil fuels.

- District Heating and Cooling (DHC) Networks: Utilizing industrial waste heat for heating and cooling urban areas, increasing overall system efficiency.

2. Decentralized Microgrid Solutions for Industrial Independence

Microgrids are revolutionizing industrial power by allowing facilities to operate autonomously from national grids. These self-contained energy systems enhance energy security, optimize load management, and improve resilience against power outages. Key advancements include:

- Smart Microgrid Controllers: AI-driven systems optimize energy flow, balancing power generation, storage, and consumption.

- Peer-to-Peer (P2P) Energy Trading: Blockchain technology enables industries to trade excess power with neighboring facilities, improving economic viability.

- Multi-Source Integration: Advanced microgrids seamlessly integrate power from steam turbines, solar PV, wind, and battery storage, ensuring uninterrupted operation.

3. Digitalization and AI-Driven Power Optimization

Artificial intelligence and machine learning are transforming industrial power systems by providing real-time analytics, predictive maintenance, and automated control mechanisms. Digital technologies improving self-sustaining industrial power include:

- Digital Twin Technology: Virtual models of power systems simulate operations, predict failures, and optimize performance.

- AI-Based Load Forecasting: Predicts energy demand patterns, allowing industries to optimize power production and reduce waste.

- Automated Energy Efficiency Systems: Smart sensors and IoT-enabled controls dynamically adjust energy consumption based on real-time requirements.

4. Waste Heat Recovery and Industrial Symbiosis

Industries generate vast amounts of waste heat, which, if captured and reused, can significantly improve energy efficiency. Innovations in waste heat recovery include:

- Thermoelectric Generators (TEGs): Convert low-grade industrial waste heat into electricity using advanced thermoelectric materials.

- Supercritical CO₂ Cycles: More efficient than traditional steam cycles, enabling better heat recovery from industrial processes.

- Cross-Industry Energy Exchange: Industrial symbiosis systems enable multiple facilities to share excess heat and steam, improving collective efficiency.

5. Hydrogen as a Game-Changer for Industrial Power

As industries move toward decarbonization, hydrogen is emerging as a key component of self-sustaining energy systems. The development of hydrogen-fired steam turbines and fuel cells allows industries to achieve zero-carbon power generation. Key advancements include:

- Hydrogen-Ready Steam Turbines: Designed to operate on a blend of natural gas and hydrogen, reducing carbon emissions.

- Green Hydrogen Production: Electrolyzers powered by renewable energy sources produce hydrogen for on-site energy use.

- Hydrogen Fuel Cells for Backup Power: Providing a clean, long-duration energy storage solution for industrial applications.

Conclusion

With the adoption of advanced cogeneration systems, intelligent microgrids, digital optimization tools, waste heat recovery solutions, and hydrogen-based technologies, industries are transforming into self-sustaining power hubs. These innovations ensure operational efficiency, cost savings, and environmental sustainability, making energy independence a reality for industrial facilities worldwide.

6. Energy Storage Solutions for Industrial Self-Sufficiency

Energy storage is a critical component of self-sustaining industrial power solutions, ensuring continuous power availability, grid stability, and peak demand management. Industries are increasingly integrating advanced storage technologies to optimize power usage and enhance resilience. Key energy storage solutions include:

Battery Energy Storage Systems (BESS)

- Lithium-Ion Batteries: Widely used for short-term energy storage, allowing industries to store excess power and discharge it during peak demand.

- Solid-State Batteries: An emerging technology that offers higher energy density, longer lifespan, and improved safety compared to conventional lithium-ion batteries.

- Flow Batteries (Vanadium Redox and Zinc-Bromine): Suitable for long-duration energy storage, these batteries store energy in liquid electrolytes and can discharge power for extended periods.

Thermal Energy Storage (TES)

- Molten Salt Storage: Used in concentrated solar power (CSP) plants, molten salt can retain heat for hours or even days, enabling continuous steam turbine operation even when sunlight is unavailable.

- Phase Change Materials (PCMs): Advanced PCMs absorb and release thermal energy efficiently, optimizing heat utilization in industrial processes.

- Cryogenic Energy Storage (CES): Utilizes liquefied air or nitrogen to store excess energy, which is then released as power when needed.

Hydrogen Energy Storage

- Green Hydrogen Production: Excess electricity from industrial power systems is used to produce hydrogen through electrolysis, which can be stored and converted back to power when required.

- Hydrogen Fuel Cells: Provide clean backup power for industrial operations, reducing reliance on diesel generators.

- Underground Hydrogen Storage: Large-scale hydrogen storage in salt caverns or depleted gas fields enables long-term energy security for industrial sites.

7. Hybrid and Multi-Source Power Generation

To achieve complete self-sufficiency, industries are adopting hybrid power generation systems that combine multiple energy sources. These systems offer improved reliability, efficiency, and cost savings.

Hybrid Steam Turbine Systems

- Solar-Steam Hybrid Plants: Integrating solar thermal energy with steam turbines enhances efficiency and reduces fuel consumption.

- Biomass-Steam CHP Systems: Utilizing agricultural waste, wood pellets, or municipal waste to generate steam for industrial power and heat applications.

- Geothermal-Steam Power Plants: Industries located near geothermal resources can use low-enthalpy steam cycles to generate clean, continuous power.

Wind and Solar Hybrid Integration

- Wind-Steam Hybrid Systems: Utilizing excess wind energy to preheat boiler feedwater, improving the efficiency of steam turbines.

- Solar PV and Steam Turbine Integration: Solar photovoltaic (PV) panels supply electricity for auxiliary equipment, reducing overall grid dependency.

- Hydro-Steam Power Generation: Utilizing hydropower alongside steam turbines to balance load fluctuations and ensure stable power supply.

8. Smart Grid and Demand-Side Management for Industrial Optimization

Digitalization and AI-driven demand-side management (DSM) are transforming industrial power systems, allowing real-time optimization of energy consumption, storage, and distribution. These smart technologies include:

- AI-Based Predictive Load Management: AI algorithms forecast energy demand, ensuring optimized power generation and reduced energy waste.

- Industrial Demand Response Programs: Industries adjust power consumption in response to grid fluctuations, earning financial incentives while improving overall grid stability.

- Blockchain-Enabled Energy Transactions: Smart contracts enable secure peer-to-peer (P2P) energy trading, allowing industries to buy and sell excess power in real-time.

- Automated Power Dispatch Systems: Intelligent software directs power flow between storage units, turbines, and industrial loads based on real-time needs.

9. Circular Economy and Industrial Sustainability Initiatives

To enhance long-term sustainability, industries are increasingly adopting circular economy principles in power generation and energy use. These initiatives promote waste reduction, resource efficiency, and environmental responsibility.

- Carbon Capture, Utilization, and Storage (CCUS): Capturing CO₂ emissions from industrial power plants and repurposing them for fuel production, chemical processes, or underground storage.

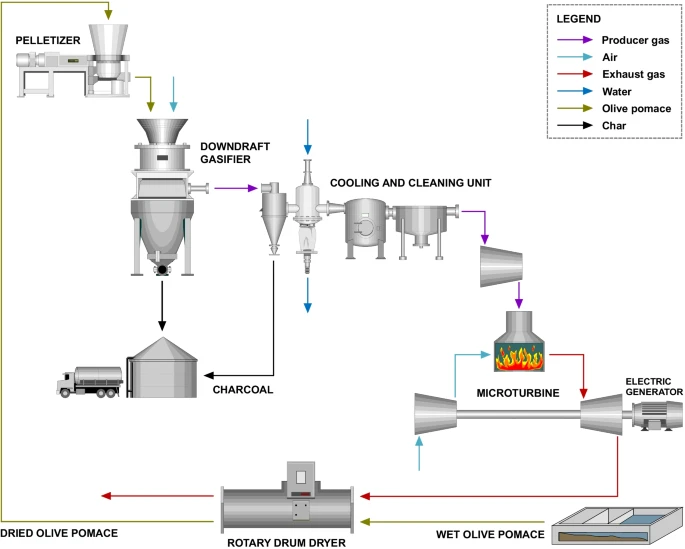

- Industrial Waste-to-Energy Plants: Converting plastic waste, sludge, and agricultural residues into power and heat through advanced gasification and pyrolysis.

- Closed-Loop Water Recycling: Steam power plants implement advanced water treatment and recycling systems, minimizing water usage and environmental impact.

- Green Industrial Parks: Facilities cluster together to share power, heat, and resources, forming a self-sustaining industrial ecosystem.

Conclusion

By integrating energy storage, hybrid power generation, smart grid solutions, and circular economy principles, industries can achieve true energy self-sufficiency while minimizing environmental impact. These innovative, scalable, and cost-effective solutions provide industries with resilience against power disruptions, long-term economic savings, and a path toward carbon neutrality.

With continuous advancements in hydrogen storage, AI-driven energy management, and sustainable waste-to-energy technologies, self-sustaining industrial power solutions will continue to redefine the future of energy independence.

10. Future Trends in Self-Sustaining Industrial Power Solutions

As technology evolves, self-sustaining industrial power systems are set to become even more efficient, reliable, and environmentally friendly. Several emerging trends and innovations are shaping the future of industrial energy independence.

Advanced AI and Machine Learning for Energy Optimization

- AI-Powered Predictive Maintenance: Machine learning models analyze data from turbines, boilers, and storage units to detect anomalies and predict equipment failures before they occur.

- Energy Forecasting and Automated Control: AI-driven systems dynamically adjust power generation, storage, and consumption based on real-time data and weather forecasts.

- Autonomous Power Plants: Future industrial power systems will leverage AI for self-regulation, load balancing, and seamless integration of multiple energy sources.

Decentralized Energy Networks and Industrial Energy Sharing

- Blockchain-Based Energy Trading: Secure, decentralized platforms will allow industries to trade surplus energy with nearby facilities, creating a more flexible and resilient power infrastructure.

- Virtual Power Plants (VPPs): Aggregated industrial power systems will act as a single controllable entity, optimizing power distribution between factories, microgrids, and storage units.

- Collaborative Industrial Energy Hubs: Large-scale industrial zones will integrate shared CHP plants, hydrogen hubs, and waste-to-energy facilities, minimizing energy waste and improving sustainability.

Next-Generation Hydrogen and Ammonia Energy Systems

- Hydrogen-Based Gas Turbines: Industries will transition from natural gas-powered turbines to hydrogen-ready turbines, reducing carbon emissions while maintaining high efficiency.

- Ammonia as an Energy Carrier: Green ammonia (NH₃) will be used for long-term hydrogen storage and direct fuel combustion in industrial turbines.

- On-Site Hydrogen Production: Industries will deploy modular electrolyzers powered by renewables to produce hydrogen for internal energy needs.

Supercritical CO₂ Power Cycles for Higher Efficiency

- Next-Gen Power Conversion: Supercritical CO₂ (sCO₂) turbines will replace traditional steam turbines in high-temperature industrial applications, offering higher efficiency and compact design.

- Low-Carbon Industrial Heat: sCO₂ cycles will enable industries to recover more waste heat, improving overall energy efficiency.

Nuclear Microreactors for Industrial Applications

- Compact, Modular Nuclear Reactors (SMRs): These small, self-contained reactors provide industries with continuous, carbon-free power for decades without refueling.

- Molten Salt and High-Temperature Gas Reactors: Advanced reactor designs will support industrial heat applications, such as hydrogen production and chemical processing.

11. Policy, Investment, and Global Adoption

Governments and industries are investing heavily in self-sustaining power technologies, driven by energy security concerns, economic incentives, and environmental regulations.

Government Policies and Incentives

- Carbon Pricing and Emission Reduction Targets: Industries are being incentivized to transition to low-carbon and energy-efficient technologies.

- Tax Credits and Subsidies: Governments worldwide are offering grants, tax breaks, and subsidies for industries investing in CHP, hydrogen, and renewable energy systems.

- Mandates for Industrial Microgrids: Some regions are requiring critical industries to deploy microgrid solutions to enhance resilience against grid failures.

Corporate Investments and Industrial Adoption

- Major Industrial Companies Going Off-Grid: Large manufacturing and tech companies are investing in self-sustaining energy projects to reduce costs and improve reliability.

- Green Industry Certification Programs: International organizations are launching standards for industries implementing sustainable and self-sufficient energy practices.

- Collaborative Research and Innovation: Joint ventures between governments, research institutions, and private companies are accelerating the development of next-gen power solutions.

Conclusion: The Future of Self-Sustaining Industrial Power

The shift toward self-sustaining industrial power solutions is revolutionizing global energy systems. With advancements in AI-driven optimization, hydrogen storage, decentralized microgrids, and next-generation power cycles, industries are moving closer to achieving energy independence, cost efficiency, and environmental sustainability.

As policies, technologies, and investments align, self-sustaining industrial power is poised to become the new standard for reliable, resilient, and sustainable energy systems. The industries that embrace these innovations will not only gain a competitive edge but also contribute to a cleaner, smarter, and more sustainable future.

Industrial Steam Turbines: Driving Production and Efficiency

Industrial steam turbines play a crucial role in power generation and mechanical drive applications, enabling industries to achieve high efficiency, reliability, and cost-effective energy utilization. These turbines convert thermal energy from steam into mechanical power, which can be used to generate electricity or directly drive industrial machinery. Their versatility makes them essential across industries such as manufacturing, refining, petrochemicals, pulp & paper, and food processing.

How Industrial Steam Turbines Drive Production

- Power Generation for Industrial Facilities

- Industrial steam turbines are widely used in cogeneration (CHP) and combined cycle power plants to provide electricity and process heat simultaneously.

- Industries with access to biomass, waste heat, or geothermal energy use steam turbines to generate low-cost, on-site power, reducing reliance on external grids.

- Back-pressure turbines supply direct steam for industrial heating and production processes, improving overall efficiency.

- Mechanical Drive Applications

- Many industries use steam turbines to drive pumps, compressors, blowers, and fans, ensuring continuous and stable production.

- Oil refineries and chemical plants use steam turbines to power high-pressure compressors, which are essential for process operations.

- Steam-driven mechanical systems are more robust, long-lasting, and efficient compared to electric motors in high-power applications.

- Waste Heat Recovery for Sustainable Production

- Industries with high-temperature processes, such as cement, steel, and glass manufacturing, recover waste heat to generate steam for turbine operation.

- Steam turbines integrated with Heat Recovery Steam Generators (HRSGs) improve overall energy efficiency by capturing excess heat from industrial processes.

- Organic Rankine Cycle (ORC) systems enable turbines to operate using low-grade waste heat, enhancing sustainability.

- Flexible Operation for Various Industries

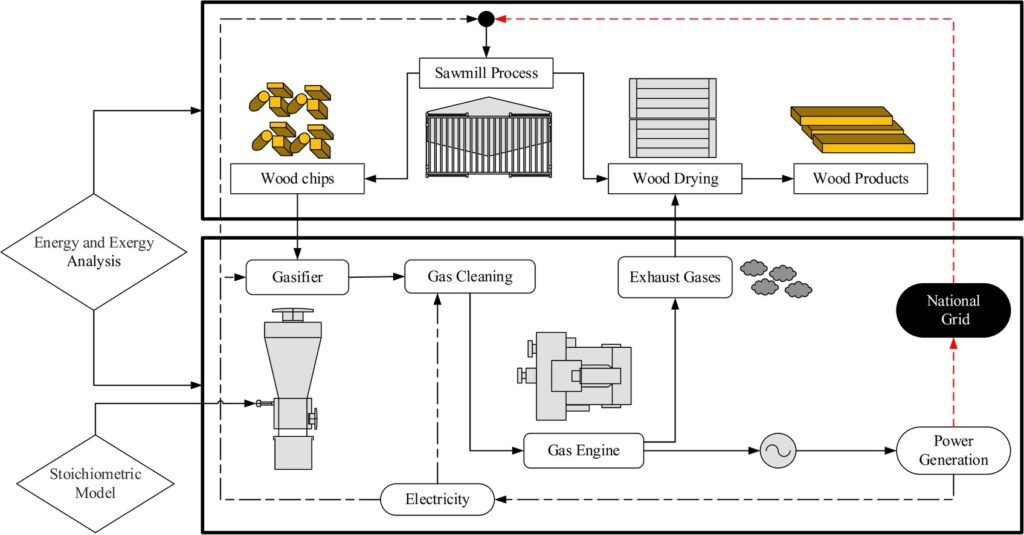

- Pulp & paper mills use steam turbines to generate power from biomass or black liquor recovery boilers.

- Food processing plants rely on steam turbines for sterilization, drying, and mechanical drive applications.

- Pharmaceutical and chemical industries use steam turbines for precision heat and power generation, ensuring production consistency.

Advantages of Industrial Steam Turbines in Production

- High Efficiency: Steam turbines convert a high percentage of thermal energy into mechanical work, optimizing fuel usage.

- Long-Term Reliability: With fewer moving parts compared to internal combustion engines, steam turbines offer extended operational life with lower maintenance.

- Fuel Flexibility: They can run on steam produced from coal, natural gas, biomass, geothermal energy, and waste heat, making them adaptable to various industries.

- Reduced Carbon Footprint: When integrated with renewables and waste heat recovery, steam turbines contribute to lower CO₂ emissions and improved sustainability.

Conclusion

Industrial steam turbines are at the heart of modern production facilities, providing efficient, reliable, and sustainable power and mechanical drive solutions. As industries continue to seek cost-effective and environmentally friendly energy sources, steam turbines will remain a cornerstone of industrial efficiency and productivity, driving manufacturing, refining, and processing operations worldwide.

Industrial steam turbines are essential to modern production, providing efficient and reliable power generation and mechanical drive capabilities across various industries. These turbines convert thermal energy from steam into mechanical work, which can then be used to generate electricity or directly drive equipment such as pumps, compressors, and fans. Their ability to operate on various steam sources, including high-pressure boilers, waste heat recovery systems, and renewable biomass, makes them an indispensable solution for industries seeking energy efficiency and sustainability.

Steam turbines are widely used in cogeneration and combined heat and power (CHP) plants, where they simultaneously produce electricity and process steam, optimizing fuel utilization and reducing energy costs. Their applications extend to refineries, petrochemical plants, pulp and paper mills, food processing facilities, and manufacturing plants, where they ensure continuous and stable production. Unlike internal combustion engines, steam turbines have fewer moving parts and experience less wear, resulting in longer operational life and lower maintenance costs. Many industries leverage steam turbines for their flexibility in handling varying loads, making them ideal for fluctuating energy demands. Additionally, their integration with waste heat recovery systems allows facilities to utilize excess thermal energy that would otherwise be lost, further improving efficiency and sustainability.

With advancements in materials, digital monitoring, and automation, modern steam turbines offer even greater performance, reliability, and adaptability to different industrial needs. As industries continue to focus on reducing carbon emissions and improving energy security, steam turbines remain a key technology in the transition toward cleaner and more efficient power generation. Their ability to integrate with renewable energy sources such as biomass and geothermal power further enhances their role in sustainable industrial operations. By driving production with high efficiency and reliability, industrial steam turbines continue to be a cornerstone of global manufacturing, processing, and energy generation, ensuring optimized performance and economic benefits for industries worldwide.

As industries evolve, steam turbines are increasingly integrated with advanced energy management systems and digital technologies to enhance efficiency and operational control. The introduction of smart sensors and real-time monitoring systems allows operators to track turbine performance, optimize steam flow, and predict maintenance needs before failures occur, minimizing downtime and reducing operational costs. AI-driven analytics and machine learning models are being applied to turbine operations, enabling dynamic adjustments to load demand and steam conditions, which improve overall efficiency and extend equipment lifespan.

Hybrid power solutions combining steam turbines with renewable energy sources such as solar thermal, biomass, and geothermal systems are becoming more prevalent, allowing industries to diversify their energy mix and reduce dependence on fossil fuels. In addition to power generation, steam turbines continue to play a vital role in mechanical drive applications where high power output and long-term reliability are required, such as in large-scale chemical processing and oil refining. The ability of steam turbines to operate in harsh environments and under extreme conditions makes them an ideal choice for heavy industrial applications where durability and efficiency are paramount. Furthermore, advancements in turbine blade design and steam path optimization have led to increased thermal efficiency, allowing industries to extract more energy from each unit of steam.

The shift toward sustainable industrial practices has also driven innovations in carbon capture and waste heat recovery systems, enabling steam turbines to contribute to lower emissions and improved energy conservation. Governments and industries are investing in research and development to further enhance steam turbine efficiency, with a focus on supercritical and ultra-supercritical steam cycles that offer even higher energy conversion rates. As regulatory frameworks tighten around energy consumption and carbon footprints, industries are increasingly turning to steam turbines as a proven solution to meet sustainability goals while maintaining high productivity and cost-effectiveness. The continued evolution of steam turbine technology ensures that these systems will remain at the core of industrial power generation and mechanical drive applications, reinforcing their role as a critical component in the global energy landscape.

With the growing emphasis on energy efficiency and decarbonization, steam turbine technology is undergoing continuous improvements to meet the evolving demands of industrial power generation. Advanced materials, including high-temperature alloys and ceramic coatings, are being developed to enhance turbine durability and performance in extreme operating conditions, allowing for greater thermal efficiency and prolonged operational life. Innovations in steam cycle configurations, such as reheat and regenerative cycles, further optimize energy extraction from steam, reducing fuel consumption and lowering greenhouse gas emissions. The integration of steam turbines into industrial microgrids and distributed energy systems is also gaining traction, providing localized, self-sufficient power generation that enhances grid stability and resilience.

Industries with high thermal energy requirements, such as steel production, cement manufacturing, and chemical processing, are increasingly adopting combined heat and power (CHP) systems with steam turbines to maximize energy utilization and improve overall sustainability. Waste heat recovery steam generators (HRSGs) are playing a crucial role in utilizing excess heat from industrial processes to produce additional steam for power generation, further increasing efficiency and reducing environmental impact. The transition toward hydrogen-based energy solutions is also influencing steam turbine applications, with ongoing research exploring hydrogen combustion in boilers and hybrid hydrogen-steam cycles to support low-carbon industrial power generation.

Digital twin technology, which creates virtual models of steam turbines, is revolutionizing maintenance and performance optimization by allowing engineers to simulate different operating conditions, predict potential failures, and implement preventive measures without disrupting real-world operations. The combination of automation, artificial intelligence, and predictive analytics is transforming how steam turbines are monitored and controlled, leading to smarter, more responsive energy systems that adjust dynamically to fluctuating industrial demands. As industries continue to navigate the challenges of energy security, cost efficiency, and environmental responsibility, steam turbines remain a cornerstone technology that provides scalable, flexible, and highly efficient power solutions. Their ability to adapt to emerging energy trends, integrate with renewable sources, and support industrial decarbonization ensures that steam turbines will continue to drive global production for decades to come.

Factories harness waste heat for power

Factories are increasingly turning to waste heat recovery systems to improve energy efficiency, reduce operating costs, and lower environmental impact. In industrial processes, a significant amount of energy is lost as heat, often vented into the atmosphere. By capturing and repurposing this waste heat, factories can generate additional power, improving overall energy utilization and reducing reliance on external electricity sources. One of the most effective ways to harness waste heat is through Heat Recovery Steam Generators (HRSGs), which capture high-temperature exhaust gases from industrial furnaces, kilns, or gas turbines and use them to produce steam. This steam can then drive a steam turbine to generate electricity or be used for direct heating applications in manufacturing processes.