Steam Turbines in Modular Nuclear Units: Electricity generation using nuclear energy is a process that involves harnessing the heat produced by nuclear fission reactions to generate steam, which then drives a turbine connected to an electrical generator. Here’s an overview of the key components and working principles of a nuclear power plant:

Basic Working Principle

- Nuclear Fission:

- Atoms of a fissile material (such as Uranium-235 or Plutonium-239) undergo fission, splitting into smaller nuclei and releasing a large amount of heat.

- This reaction is controlled within a nuclear reactor.

- Heat Transfer:

- The heat from fission is used to produce high-temperature steam by heating a coolant, typically water or gas.

- In pressurized water reactors (PWRs), the water is kept under high pressure to prevent boiling, while in boiling water reactors (BWRs), water turns directly into steam.

- Steam Generation:

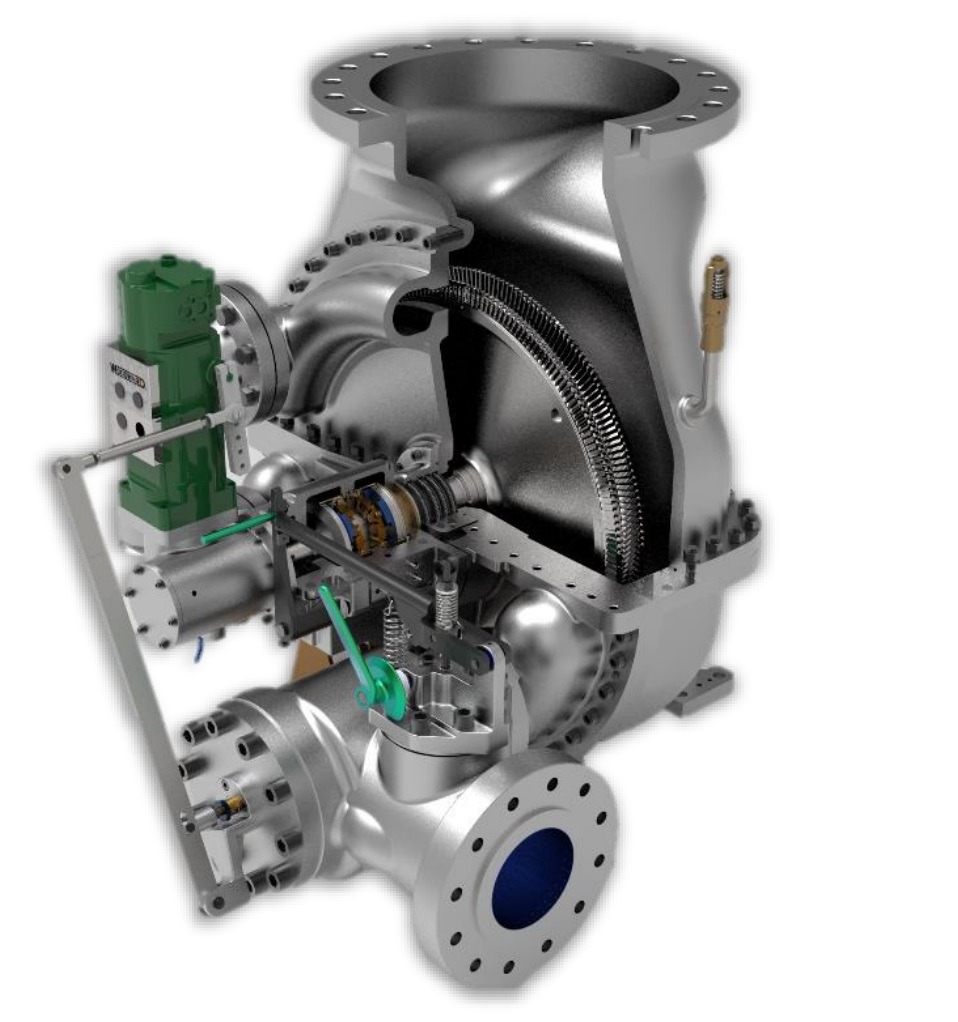

- The steam is directed toward steam turbines, causing them to rotate.

- Electricity Generation:

- The rotating turbine drives a generator, which converts mechanical energy into electricity through electromagnetic induction.

- Cooling & Condensation:

- After passing through the turbine, the steam is cooled down using a condenser, turning it back into liquid water.

- This cooling is often done using a nearby river, lake, or cooling tower.

- Recycling & Reuse:

- The condensed water is pumped back to the reactor to continue the cycle.

Types of Nuclear Reactors

There are several types of reactors used in nuclear power plants:

- Pressurized Water Reactor (PWR) – Uses high-pressure water as a coolant; most common type.

- Boiling Water Reactor (BWR) – Water is boiled directly in the reactor to produce steam.

- Pressurized Heavy Water Reactor (PHWR) – Uses heavy water as both coolant and moderator.

- Gas-cooled Reactor (GCR) – Uses carbon dioxide or helium as a coolant.

- Fast Breeder Reactor (FBR) – Uses fast neutrons and can produce more fissile material than it consumes.

Advantages of Nuclear Power

✔ High Energy Density – A small amount of nuclear fuel generates a large amount of electricity.

✔ Low Carbon Emissions – Unlike fossil fuels, nuclear power does not release CO₂ during operation.

✔ Reliable & Continuous Power Supply – Unlike solar and wind, nuclear plants provide consistent baseload power.

✔ Long Fuel Life – Fuel rods last for several years before requiring replacement.

Challenges & Disadvantages

❌ Radioactive Waste – Spent nuclear fuel remains hazardous for thousands of years and requires safe disposal.

❌ High Initial Cost – Building a nuclear plant requires huge investments in safety and technology.

❌ Nuclear Accidents – Events like Chernobyl (1986) and Fukushima (2011) show the risks of radiation leaks.

❌ Limited Fuel Supply – Uranium reserves are finite, though breeder reactors can extend fuel availability.

Future of Nuclear Energy

- Small Modular Reactors (SMRs) – More compact, safer, and easier to deploy.

- Fusion Power – Future reactors (e.g., ITER) aim to use nuclear fusion, the same process as the Sun, for safer and nearly limitless energy.

- Advanced Reactors – Generation IV reactors focus on higher efficiency, safety, and waste reduction.

Electricity generation with nuclear energy begins with nuclear fission, where atoms of a fissile material such as Uranium-235 split into smaller nuclei, releasing a large amount of heat. This reaction occurs in a nuclear reactor, where the energy is controlled and sustained. The heat generated is used to convert water into steam, which is then directed to a steam turbine. The high-pressure steam causes the turbine blades to rotate, which in turn drives a generator that produces electricity through electromagnetic induction. After passing through the turbine, the steam is cooled and condensed back into liquid form using a condenser, often with the help of cooling water from a nearby river, lake, or cooling tower. The condensed water is then pumped back to the reactor to continue the cycle, ensuring a continuous supply of steam for power generation. This entire process enables nuclear power plants to generate electricity efficiently while producing minimal greenhouse gas emissions.

Electricity generation using nuclear energy relies on the process of nuclear fission, where the nucleus of a heavy atom, such as Uranium-235 or Plutonium-239, splits into smaller nuclei when struck by a neutron. This reaction releases a tremendous amount of heat energy along with additional neutrons, which can sustain a chain reaction when properly controlled within a nuclear reactor. The fission process is carefully managed using control rods, typically made of materials like boron or cadmium, which absorb excess neutrons to regulate the rate of the reaction and prevent overheating or runaway reactions.

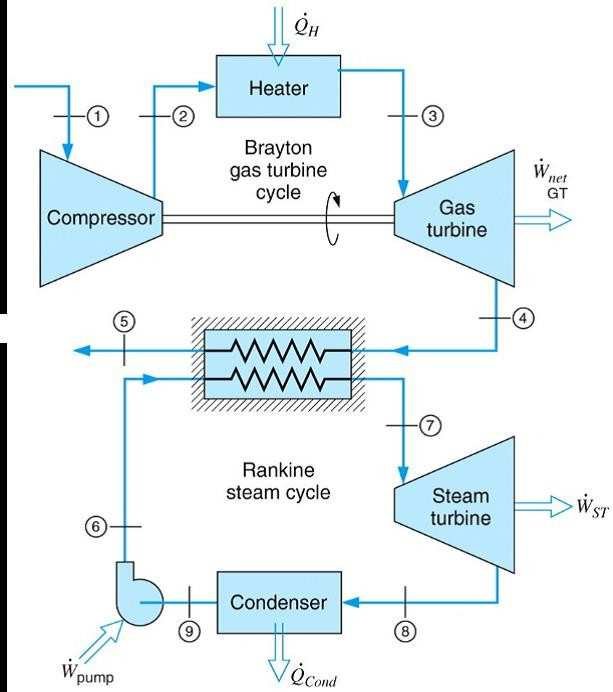

The heat produced in the reactor is transferred to a coolant, which is usually water, gas, or liquid metal, depending on the type of reactor. In the case of pressurized water reactors (PWRs), which are the most common type, water is kept under high pressure to prevent it from boiling inside the reactor. The heated coolant then passes through a heat exchanger or steam generator, where it transfers its thermal energy to a separate water loop, turning the water into high-pressure steam. In boiling water reactors (BWRs), the water is allowed to boil directly within the reactor, producing steam without the need for a heat exchanger.

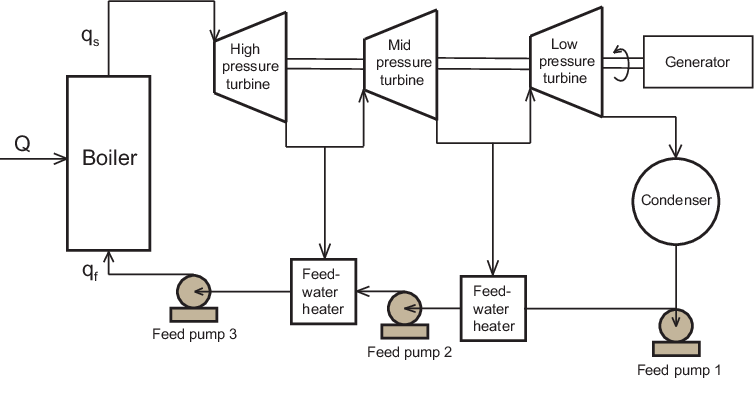

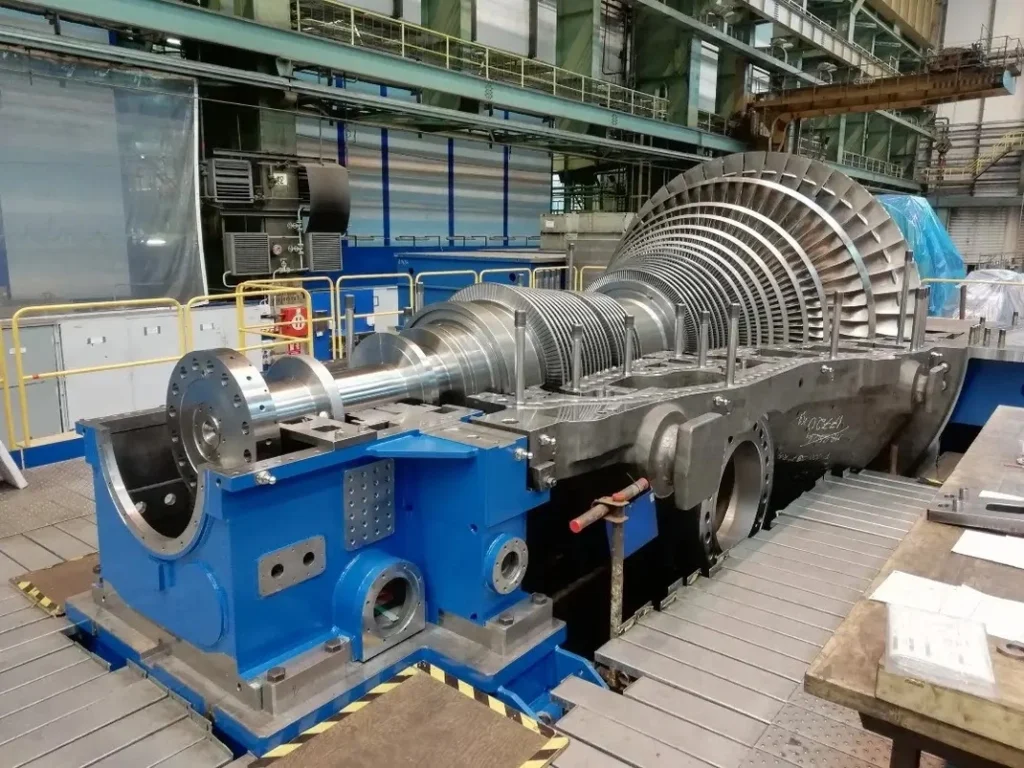

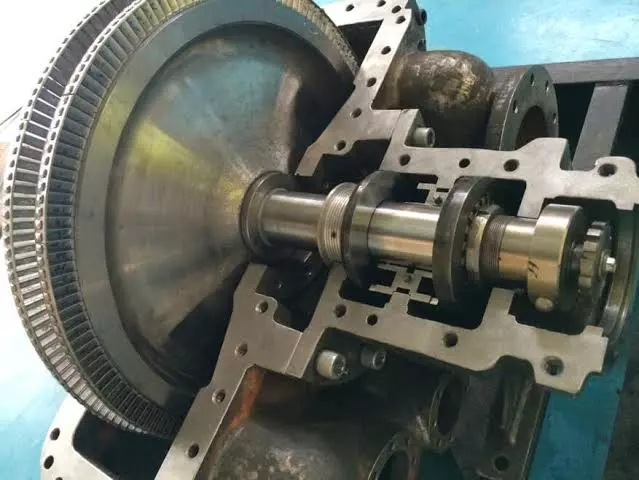

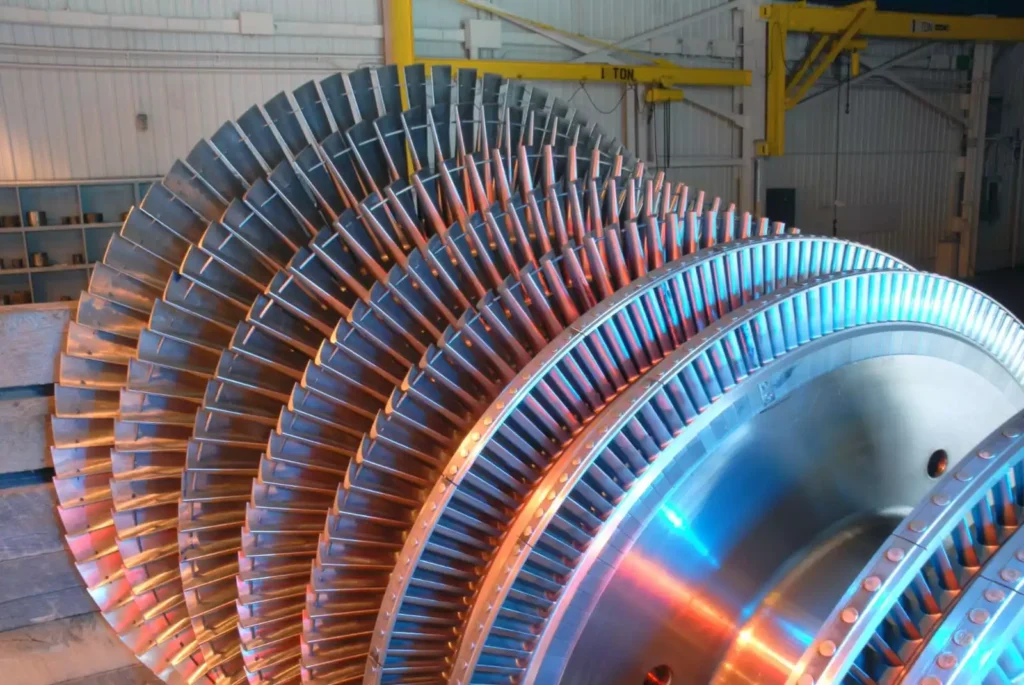

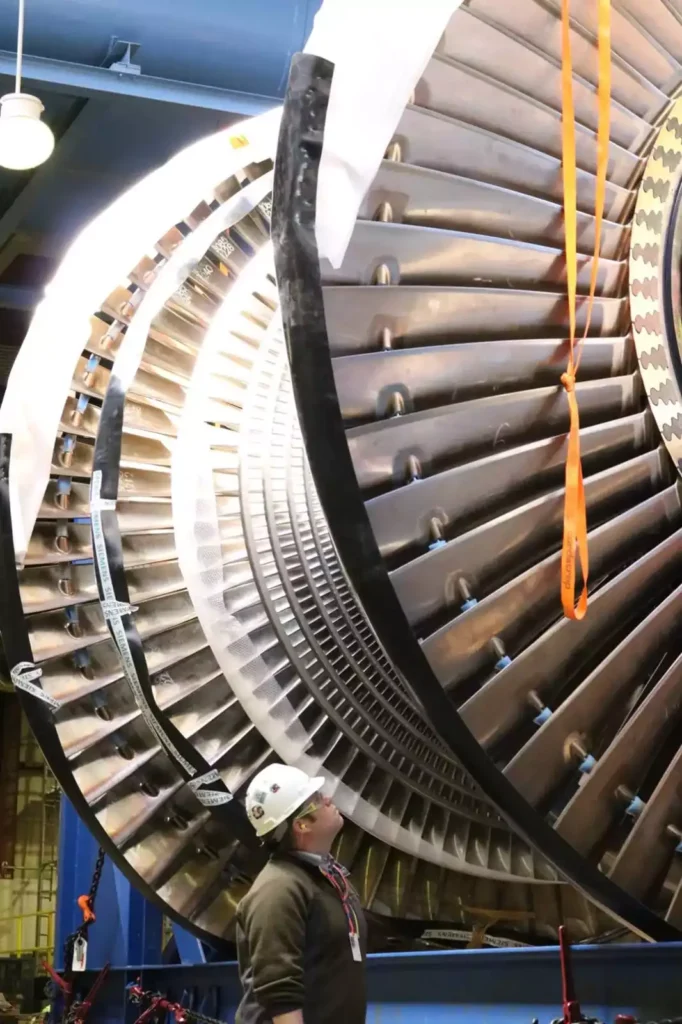

The high-pressure steam is then directed toward a steam turbine, where it expands and pushes the turbine blades, causing them to spin at high speeds. The turbine is mechanically connected to a generator, which consists of a rotating magnet surrounded by a stationary coil of wire. As the turbine spins the generator, it induces an electric current, converting the mechanical energy of the turbine into electrical energy that can be distributed through the power grid.

After passing through the turbine, the steam must be cooled and converted back into liquid form for reuse. This is achieved in a condenser, where the steam is exposed to cool water from an external source, such as a river, lake, or cooling tower. The cooling process allows the steam to condense back into liquid water, which is then pumped back into the system to be reheated in the reactor, ensuring a continuous cycle of energy production. The cooling water itself, after absorbing heat from the steam, is either recirculated or safely released back into the environment at a controlled temperature to minimize ecological impact.

Nuclear power plants are designed to operate with high efficiency and reliability, providing baseload power—a steady and continuous supply of electricity that is not affected by fluctuations in weather or fuel availability. Unlike fossil fuel power plants, nuclear reactors do not produce carbon dioxide or other greenhouse gases during operation, making them a low-emission energy source. However, the process does generate radioactive waste, including spent nuclear fuel, which must be carefully stored and managed to prevent environmental contamination and radiation exposure.

Despite challenges such as high initial construction costs, concerns over nuclear safety, and the need for long-term waste disposal solutions, nuclear energy remains a key part of global electricity generation. Ongoing research into advanced reactor designs, small modular reactors (SMRs), and nuclear fusion technology aims to improve safety, efficiency, and sustainability, making nuclear power a potential long-term solution for clean and reliable energy production.

The role of nuclear energy in electricity generation continues to evolve as advancements in technology aim to improve efficiency, safety, and sustainability. Traditional nuclear power plants primarily use light water reactors (LWRs), including pressurized water reactors (PWRs) and boiling water reactors (BWRs), which have been the dominant technology for decades. However, newer reactor designs, such as Generation IV reactors and small modular reactors (SMRs), are being developed to address challenges such as waste disposal, fuel efficiency, and safety concerns.

One of the key concerns in nuclear energy production is the management of radioactive waste, particularly spent nuclear fuel. After a fuel rod has been used in a reactor, it remains highly radioactive and must be carefully handled. Initially, spent fuel is stored in cooling pools within the power plant, where water acts as both a coolant and a radiation shield. After several years, once heat and radiation levels have decreased, the fuel can be transferred to dry cask storage, where it is sealed in reinforced concrete and steel containers for long-term safekeeping. Some countries, such as France and Russia, use nuclear fuel reprocessing to extract usable fissile material from spent fuel, reducing waste and increasing fuel efficiency. However, reprocessing is expensive and raises proliferation concerns, as it involves the separation of plutonium, which could be used in nuclear weapons.

Another critical aspect of nuclear power generation is safety. While nuclear reactors are designed with multiple layers of safety systems, past accidents—such as Chernobyl (1986), Fukushima (2011), and Three Mile Island (1979)—have highlighted potential risks associated with reactor operation. Modern reactors incorporate advanced passive safety features, which rely on natural physical processes rather than active mechanical systems to maintain cooling and containment in the event of an emergency. For example, some advanced reactors are designed with molten salt coolant or helium gas cooling, which are less likely to lead to catastrophic failures compared to traditional water-based cooling systems.

In addition to traditional nuclear fission, significant research efforts are being directed toward nuclear fusion, which has the potential to provide virtually limitless energy with minimal radioactive waste. Unlike fission, which splits heavy atomic nuclei, fusion involves combining light nuclei—such as hydrogen isotopes (deuterium and tritium)—to form helium, releasing vast amounts of energy in the process. The International Thermonuclear Experimental Reactor (ITER) in France is one of the largest fusion research projects in the world, aiming to demonstrate the feasibility of fusion as a large-scale energy source. If successful, fusion reactors could revolutionize energy production by providing a safer, cleaner, and more abundant alternative to conventional nuclear power.

Despite challenges, nuclear energy remains a crucial part of the global energy mix, providing a stable and low-carbon alternative to fossil fuels. Countries such as France, the United States, China, and Russia continue to invest in nuclear power as a key strategy for reducing greenhouse gas emissions and achieving energy security. The future of nuclear energy will likely be shaped by a combination of advanced fission reactors, small modular reactors (SMRs), and potential breakthroughs in fusion technology, offering cleaner, safer, and more efficient ways to generate electricity.

The continued advancement of nuclear energy technology is shaping its role in the future of global electricity generation. With growing concerns over climate change, energy security, and the need for reliable baseload power, many countries are reassessing and expanding their nuclear energy programs. The development of advanced reactors, improvements in nuclear fuel cycles, and the exploration of alternative reactor designs are all part of a broader effort to make nuclear energy safer, more efficient, and more sustainable.

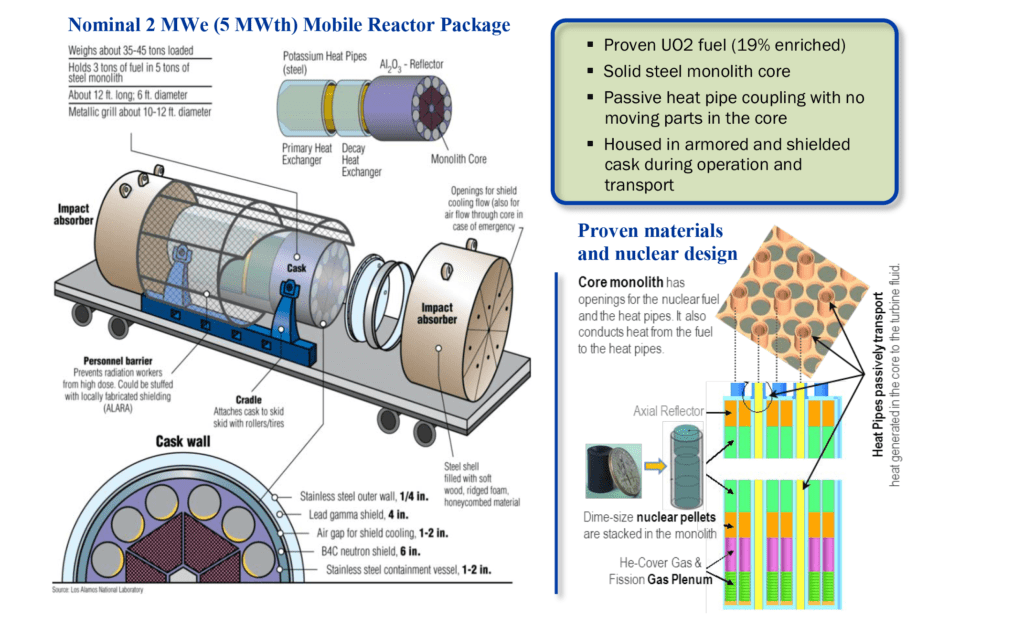

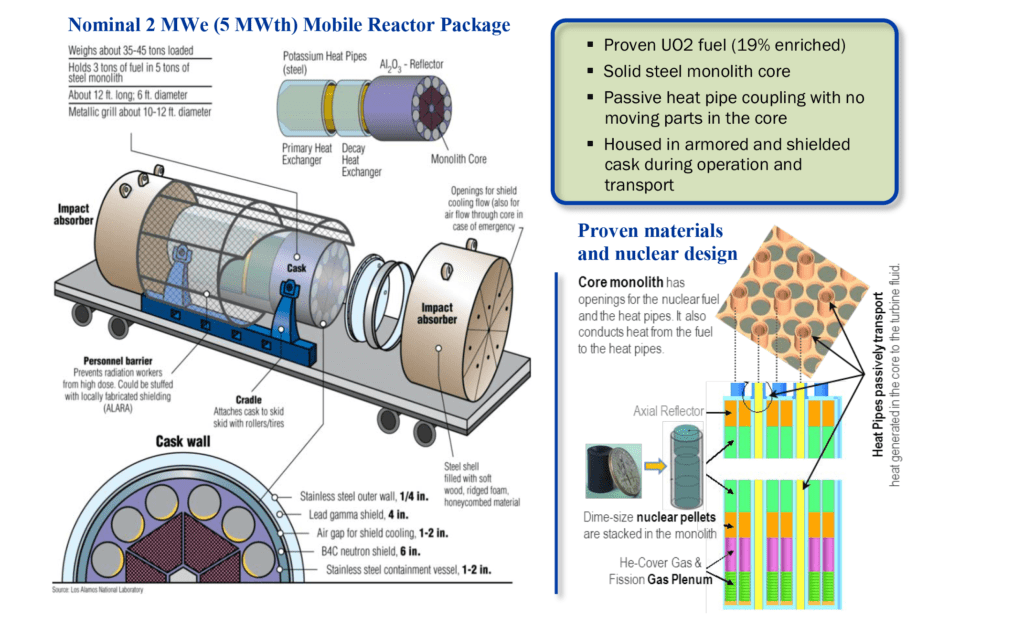

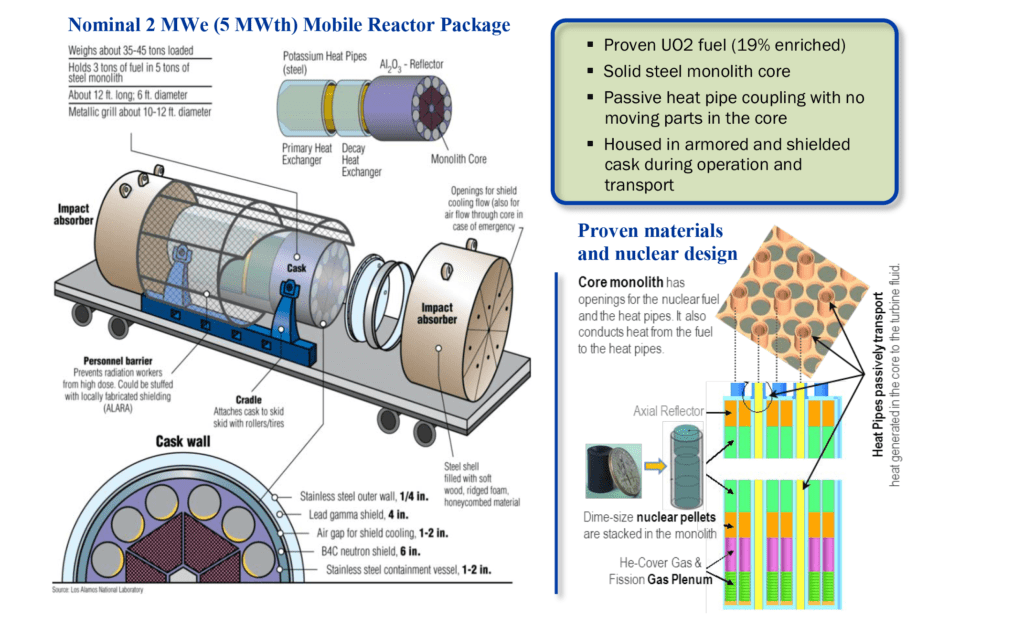

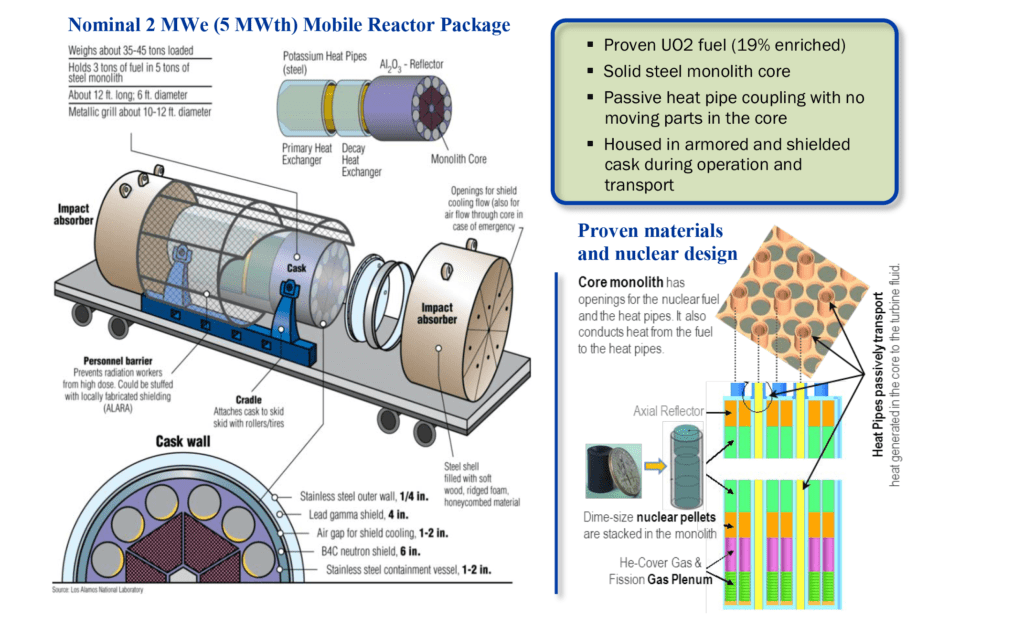

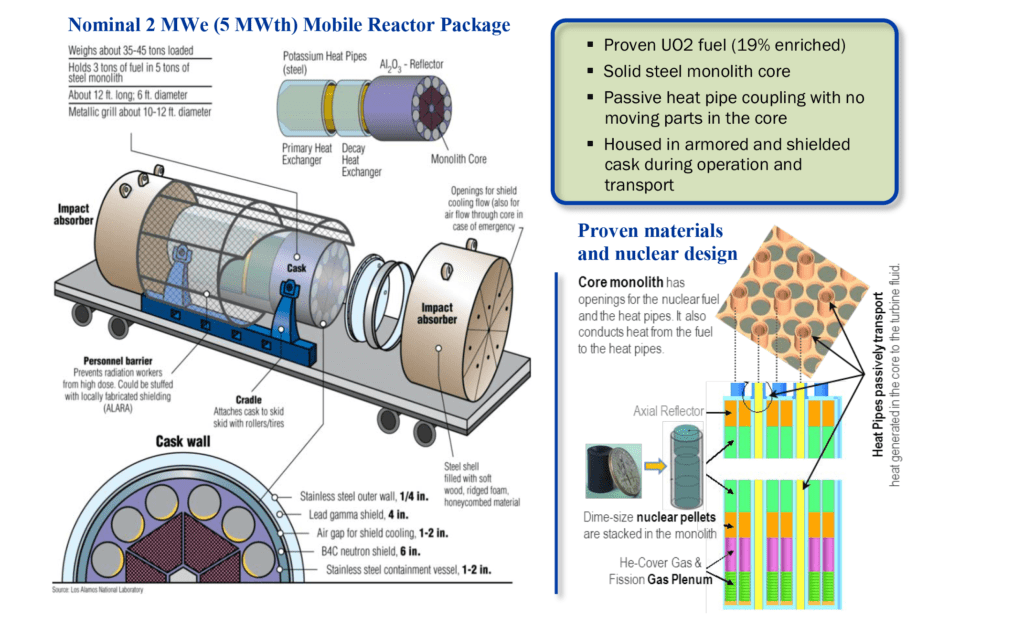

One of the most promising innovations in nuclear energy is the development of Small Modular Reactors (SMRs). Unlike traditional large-scale nuclear power plants, SMRs are designed to be smaller, modular, and more flexible, making them easier to deploy in remote locations, industrial facilities, or areas with smaller energy demands. These reactors typically produce less than 300 megawatts (MW) of electricity, compared to conventional reactors that generate over 1,000 MW. SMRs are also designed with passive safety features, meaning they rely on natural physical processes like gravity, convection, and heat dissipation rather than active mechanical systems, reducing the risk of accidents. Countries like the United States, Canada, Russia, and China are leading efforts to commercialize SMRs, with several designs currently in development and testing.

In parallel with SMRs, Generation IV reactors are being designed to address challenges related to fuel efficiency, safety, and waste management. These next-generation reactors include fast neutron reactors (FNRs), molten salt reactors (MSRs), gas-cooled reactors, and lead-cooled reactors. A key advantage of these reactors is their ability to operate at higher temperatures and utilize breeder reactor technology, which can generate more fissile material than they consume. This process significantly improves fuel utilization and reduces the amount of long-lived nuclear waste. Some Generation IV reactors are also capable of using thorium as a fuel source, an element that is more abundant than uranium and produces less long-lived radioactive waste. Countries such as India and China are actively exploring thorium-based nuclear reactors as a future energy solution.

Beyond traditional fission, the pursuit of nuclear fusion remains one of the most exciting frontiers in energy research. Fusion offers the promise of nearly limitless clean energy without the risks associated with radioactive waste or nuclear accidents. Unlike fission, which splits heavy atoms, fusion joins light atomic nuclei—such as deuterium and tritium—to release energy. The challenge, however, is achieving the extremely high temperatures and pressures required to sustain a controlled fusion reaction. The ITER (International Thermonuclear Experimental Reactor) project, based in France, is currently the world’s largest fusion research effort. It aims to demonstrate the feasibility of fusion power by the 2030s. In addition to ITER, private companies and national research programs are working on alternative fusion approaches, such as magnetic confinement (tokamaks), inertial confinement (laser-based fusion), and magnetized target fusion.

Meanwhile, nuclear policy and public perception continue to influence the expansion of nuclear power worldwide. While some countries, like Germany, have chosen to phase out nuclear energy due to public concerns following the Fukushima disaster, others, including France, China, Russia, and India, are expanding their nuclear power infrastructure. The global shift toward decarbonization and energy security is likely to drive further investment in nuclear technology. Emerging economies are also looking toward nuclear power as a means of supporting industrialization while reducing reliance on fossil fuels.

Looking ahead, nuclear energy is expected to play a critical role in the transition to a carbon-neutral future. Its ability to provide continuous, high-output, low-carbon electricity makes it a strong complement to renewable energy sources such as wind and solar, which are intermittent by nature. The integration of advanced nuclear reactors, SMRs, and fusion technology will likely define the next era of nuclear power, ensuring that it remains a key player in global energy strategies.

Types of Nuclear Reactors

Nuclear reactors are classified based on their design, coolant type, moderator material, and fuel cycle. Each reactor type has unique characteristics that influence its efficiency, safety, and suitability for different applications. The most common classification includes thermal reactors and fast reactors, as well as emerging advanced reactor designs that aim to improve fuel utilization and reduce radioactive waste.

The most widely used nuclear reactors are light water reactors (LWRs), which use ordinary water as both a coolant and a neutron moderator. The two main types of LWRs are pressurized water reactors (PWRs) and boiling water reactors (BWRs). In a PWR, water is maintained under high pressure to prevent it from boiling inside the reactor core. Instead, the heated water is transferred to a secondary loop where it produces steam to drive a turbine. This design provides additional safety by ensuring that radioactive water does not directly interact with the turbine system. BWRs, on the other hand, allow water to boil directly within the reactor vessel, generating steam that is sent directly to the turbine. While simpler in design, BWRs require more radiation shielding in the turbine area due to the direct interaction between steam and reactor water. Both PWRs and BWRs are widely used around the world, with PWRs being the most common type of commercial reactor.

Another class of reactors is the pressurized heavy water reactor (PHWR), which uses heavy water (D₂O) as both a coolant and a moderator. Heavy water is more effective at slowing down neutrons than ordinary water, allowing PHWRs to use natural uranium as fuel without the need for enrichment. The most well-known PHWR design is the CANDU reactor, developed in Canada. These reactors are known for their online refueling capability, meaning they can be refueled without shutting down the reactor. This feature improves fuel efficiency and operational flexibility. PHWRs are used in several countries, including Canada, India, and Argentina.

A variation of heavy water reactors is the boiling heavy water reactor (BHWR), which functions similarly to a BWR but uses heavy water instead of light water. While not as widely used, this design offers the advantage of enhanced neutron economy, allowing for more efficient use of nuclear fuel.

Gas-cooled reactors (GCRs) are another category that uses gases like carbon dioxide or helium as a coolant instead of water. One example is the advanced gas-cooled reactor (AGR), developed in the United Kingdom. AGRs use carbon dioxide as a coolant and graphite as a moderator, operating at higher temperatures than LWRs. This higher temperature improves thermal efficiency, making AGRs more efficient than water-cooled reactors. The high-temperature gas-cooled reactor (HTGR) is a more advanced version that uses helium as a coolant and can achieve even higher operating temperatures, making it suitable for industrial heat applications in addition to electricity generation.

Another important type of reactor is the fast neutron reactor (FNR), which operates without a neutron moderator, relying on fast neutrons to sustain the fission process. Unlike thermal reactors, which use slow (thermal) neutrons, FNRs can efficiently breed new fissile material from fertile isotopes such as Uranium-238 or Thorium-232. This allows them to generate more fuel than they consume, making them a promising long-term energy solution. One notable FNR design is the liquid metal-cooled fast reactor (LMFR), which uses liquid sodium or lead as a coolant. Examples of operational fast reactors include Russia’s BN-600 and BN-800 reactors, which use sodium as a coolant. These reactors offer high fuel efficiency and can reduce nuclear waste by utilizing spent fuel from conventional reactors.

Another advanced type of nuclear reactor is the molten salt reactor (MSR), which uses liquid fuel dissolved in molten salt. This design allows for high-temperature operation and passive safety features, as molten salt remains stable at high temperatures and operates at atmospheric pressure, reducing the risk of pressure-related accidents. MSRs can also be designed to use thorium as a fuel source, which has the potential to be more abundant and produce less long-lived nuclear waste compared to uranium-based fuels. The most well-known molten salt reactor experiment was conducted in the United States at Oak Ridge National Laboratory in the 1960s. Today, several countries and private companies are working on modern MSR designs to commercialize this technology.

A variation of molten salt reactors is the liquid fluoride thorium reactor (LFTR), which specifically uses thorium-232 as its primary fuel. Thorium has the advantage of being more abundant than uranium and can be converted into Uranium-233, a fissile material that sustains the fission reaction. LFTRs are being explored as a cleaner and more sustainable alternative to conventional uranium-based reactors.

Another emerging category is the small modular reactor (SMR), which is not a specific type of reactor but rather a design concept that applies to various reactor types, including PWRs, FNRs, and MSRs. SMRs are designed to be smaller, factory-built, and modular, meaning multiple units can be deployed in different locations based on energy demand. These reactors typically generate less than 300 MW of electricity, compared to the 1,000+ MW output of conventional reactors. Their modular nature makes them easier to transport, install, and scale up, making them an attractive option for remote areas, industrial facilities, and developing countries. Countries such as the United States, Canada, China, and Russia are actively developing SMR technology, with several designs expected to be deployed in the coming years.

In addition to fission-based reactors, research is ongoing in nuclear fusion reactors, which aim to replicate the energy-producing process of the Sun. Unlike fission, which splits heavy atomic nuclei, fusion combines light atomic nuclei, such as deuterium and tritium, to form helium and release vast amounts of energy. The most prominent fusion research project is the International Thermonuclear Experimental Reactor (ITER) in France, which is expected to demonstrate large-scale fusion energy production by the 2030s. Fusion reactors, such as tokamaks and stellarators, require extremely high temperatures and advanced magnetic confinement techniques to sustain a controlled fusion reaction. If successful, fusion technology could provide virtually limitless, clean energy with minimal radioactive waste and no risk of meltdowns.

Overall, the diversity of nuclear reactor designs reflects the continuous evolution of nuclear technology to address challenges related to fuel efficiency, waste management, safety, and sustainability. While traditional reactors like PWRs and BWRs dominate the global nuclear fleet, advanced reactor designs such as fast reactors, molten salt reactors, and thorium reactors hold significant promise for the future. Additionally, the development of SMRs and fusion reactors could revolutionize the nuclear industry by making nuclear energy more accessible, flexible, and environmentally friendly. With ongoing research and investment, nuclear power is expected to play a crucial role in the transition to a low-carbon energy future, complementing renewable energy sources such as solar and wind while providing a reliable and sustainable source of electricity.

The development of nuclear reactors continues to evolve as governments, research institutions, and private companies seek to improve efficiency, safety, and sustainability. One of the key challenges facing nuclear power is the need for better fuel utilization and waste reduction, leading to the advancement of closed fuel cycles, breeder reactors, and thorium-based nuclear systems.

Closed Fuel Cycles and Breeder Reactors

Traditional nuclear reactors operate on an open fuel cycle, meaning that once the fuel is used, it is discarded as spent nuclear fuel and stored as radioactive waste. However, a closed fuel cycle aims to reprocess and recycle spent fuel, reducing the amount of high-level waste and making more efficient use of uranium resources. Some advanced reactor designs, such as fast breeder reactors (FBRs), are specifically designed to convert fertile isotopes (Uranium-238 or Thorium-232) into fissile materials (Plutonium-239 or Uranium-233), effectively breeding new fuel while generating power.

Fast breeder reactors operate using fast neutrons rather than thermal neutrons, eliminating the need for a neutron moderator. These reactors typically use liquid metal coolants, such as sodium or lead-bismuth, which allow for higher operating temperatures and improved thermal efficiency. The ability of breeder reactors to generate more fissile material than they consume makes them an attractive long-term solution for nuclear fuel sustainability. Countries like Russia, France, Japan, and India have been actively researching and developing FBR technology. Russia’s BN-600 and BN-800 reactors, as well as India’s Prototype Fast Breeder Reactor (PFBR), represent significant steps toward commercializing this technology.

Thorium-Based Nuclear Reactors

Thorium has been gaining attention as an alternative nuclear fuel due to its abundance, safety advantages, and waste reduction potential. Unlike uranium, thorium-232 is not directly fissile, meaning it must be converted into Uranium-233 through neutron absorption before it can sustain a nuclear chain reaction. This process occurs naturally in specially designed reactors, such as liquid fluoride thorium reactors (LFTRs) and heavy water reactors (HWRs).

One of the key advantages of thorium-based reactors is their ability to produce less long-lived radioactive waste compared to uranium-based systems. Additionally, thorium does not generate plutonium, which is a key concern for nuclear weapons proliferation. Countries such as India, China, and Norway are leading the development of thorium-based nuclear power due to their large domestic thorium reserves. India, in particular, has an extensive three-stage nuclear power program aimed at transitioning from uranium-fueled reactors to breeder reactors and eventually thorium-fueled reactors.

Molten Salt Reactors (MSRs) and Next-Generation Nuclear Technology

Molten salt reactors (MSRs) represent a major shift in nuclear reactor technology by using liquid fuel dissolved in molten fluoride or chloride salts instead of traditional solid fuel rods. This design offers several key benefits, including higher operating temperatures, improved thermal efficiency, and passive safety features. Because molten salt reactors operate at low pressure, they eliminate the risk of steam explosions or pressure-related accidents, which are concerns in traditional water-cooled reactors.

One of the most promising MSR designs is the liquid fluoride thorium reactor (LFTR), which combines the benefits of thorium fuel with molten salt technology. LFTRs can operate with a continuous fuel reprocessing system, meaning they can extract valuable fissile material from spent fuel and significantly reduce nuclear waste. Several companies and research institutions, including TerraPower, Copenhagen Atomics, and the Chinese Academy of Sciences, are working on commercializing MSR technology.

Small Modular Reactors (SMRs) and Microreactors

In addition to new reactor designs, the nuclear industry is focusing on small modular reactors (SMRs) and microreactors as a way to provide flexible, scalable, and cost-effective nuclear power. Unlike large conventional reactors, which require multi-billion-dollar investments and years of construction, SMRs are designed to be factory-built, transportable, and rapidly deployed.

SMRs typically generate between 10 MW and 300 MW of electricity, making them ideal for remote communities, industrial facilities, military bases, and developing countries. Many SMR designs incorporate passive safety features, such as self-cooling capabilities, which eliminate the need for external power sources in case of an emergency. Some SMRs are based on existing light water reactor technology, while others use advanced reactor designs, such as high-temperature gas-cooled reactors (HTGRs), molten salt reactors (MSRs), and sodium-cooled fast reactors (SFRs).

Several countries are making significant progress in SMR deployment. In the United States, companies like NuScale Power and X-energy are developing SMRs for commercial use, while Canada is supporting SMR development for use in remote regions and mining operations. Russia has already deployed a floating nuclear power plant, the Akademik Lomonosov, which uses two small pressurized water reactors to provide electricity to Arctic regions.

An even smaller category of nuclear reactors, known as microreactors, is being developed to provide ultra-compact nuclear power solutions. These reactors, typically generating 1 MW to 10 MW, are designed to be transportable, self-regulating, and capable of operating autonomously for several years without refueling. Microreactors have potential applications in disaster relief, space exploration, and decentralized energy systems.

Fusion Reactors: The Future of Nuclear Power

While current nuclear power plants rely on fission, in which heavy atomic nuclei split to release energy, scientists are actively researching nuclear fusion, the process that powers the Sun and stars. Fusion offers the promise of limitless, clean, and safe energy, as it generates minimal radioactive waste and poses no risk of meltdowns.

In a fusion reactor, hydrogen isotopes (deuterium and tritium) are combined under extreme temperature and pressure to form helium, releasing massive amounts of energy. The challenge lies in maintaining the necessary conditions for a sustained fusion reaction. The most common approach is the tokamak design, which uses powerful magnetic fields to confine superheated plasma. The International Thermonuclear Experimental Reactor (ITER) in France is the world’s largest fusion research project, aiming to demonstrate the feasibility of large-scale fusion power by the 2030s. Other fusion projects, such as the Stellarator (Wendelstein 7-X in Germany) and inertial confinement fusion (ICF) using laser technology, are also being explored.

Private companies, including Commonwealth Fusion Systems, Helion Energy, and Tokamak Energy, are working on compact fusion reactors, with some claiming that they could achieve commercial fusion power within the next two decades. If successful, fusion energy could revolutionize the world’s electricity supply, providing an almost limitless and clean energy source that could replace fossil fuels entirely.

The Future of Nuclear Energy in a Low-Carbon World

As the world shifts toward clean energy solutions to combat climate change, nuclear power is expected to play a vital role in achieving carbon neutrality. Unlike fossil fuel power plants, nuclear reactors do not produce carbon dioxide (CO₂) emissions, making them a key option for decarbonizing electricity generation.

With advancements in breeder reactors, molten salt reactors, SMRs, and fusion technology, the future of nuclear power looks promising. While challenges remain, including public perception, regulatory hurdles, and long-term waste management, ongoing research and innovation are paving the way for a new generation of nuclear reactors that are safer, more efficient, and more sustainable.

The integration of advanced nuclear energy with renewable sources like solar and wind will be crucial in ensuring a stable and low-carbon energy grid. As governments and industries invest in next-generation nuclear technologies, nuclear power is likely to remain a cornerstone of global energy policy, supporting the transition toward a sustainable and emission-free future.

Innovations in Nuclear Fuel and Waste Management

One of the most critical aspects of nuclear energy development is fuel efficiency and waste management. Traditional nuclear reactors use uranium-based fuel, but advancements in nuclear fuel technology are improving the sustainability and safety of nuclear power.

Advanced Nuclear Fuels

Conventional nuclear reactors primarily use Uranium-235 (U-235) enriched to about 3-5%. However, research is focused on developing advanced nuclear fuels that offer higher efficiency, increased safety, and reduced waste production.

- High-Assay Low-Enriched Uranium (HALEU):

- HALEU fuel is enriched to between 5% and 20% U-235, compared to traditional low-enriched uranium (LEU), which is limited to 5% U-235.

- HALEU is expected to be a key fuel for next-generation reactors, including SMRs and advanced fast reactors.

- Its higher enrichment level allows for greater efficiency, longer fuel cycles, and reduced nuclear waste.

- TRISO (Tristructural-Isotropic) Fuel:

- TRISO fuel consists of tiny, spherical uranium fuel particles encased in multiple layers of ceramic and carbon coatings.

- This fuel is highly resistant to radiation damage and extreme temperatures, making it ideal for high-temperature gas-cooled reactors (HTGRs) and SMRs.

- The structural integrity of TRISO particles prevents meltdowns, enhancing reactor safety.

- The U.S. Department of Energy (DOE) and companies like X-energy are actively developing TRISO-based reactors.

- Metallic Fuels:

- Metallic uranium or uranium-zirconium alloy fuels offer higher thermal conductivity, allowing for better heat dissipation and increased reactor efficiency.

- These fuels are particularly well-suited for fast neutron reactors (FNRs) and liquid metal-cooled reactors.

- Thorium-Based Fuels:

- Thorium (Th-232) is an alternative nuclear fuel that can be converted into Uranium-233 (U-233), a fissile material that sustains nuclear reactions.

- Thorium is three to four times more abundant than uranium, and its use can significantly reduce long-lived nuclear waste.

- India, China, and Norway are leading research in thorium reactor technology.

Nuclear Waste Reduction and Recycling

Spent nuclear fuel from reactors remains radioactive and requires long-term storage. Current methods for managing nuclear waste include geological disposal, reprocessing, and transmutation technologies.

- Nuclear Fuel Reprocessing (Closed Fuel Cycle):

- Traditional reactors use only about 5% of the potential energy in uranium fuel before it is classified as waste.

- Reprocessing spent fuel allows for the extraction of unused uranium and plutonium, which can be recycled into new fuel.

- Countries like France, Russia, and Japan have established fuel reprocessing facilities to reduce waste and improve fuel efficiency.

- The PUREX (Plutonium and Uranium Recovery by Extraction) process is the most widely used method for reprocessing spent fuel.

- Fast Reactors and Actinide Recycling:

- Fast neutron reactors (FNRs) can burn long-lived transuranic elements (e.g., plutonium and minor actinides), reducing the radioactive lifespan of nuclear waste.

- This process is known as transmutation, where highly radioactive isotopes are converted into shorter-lived or non-radioactive elements.

- Russia’s BN-800 reactor and France’s proposed ASTRID reactor are examples of fast reactors designed for waste reduction.

- Deep Geological Repositories (Long-Term Storage):

- For high-level radioactive waste that cannot be reprocessed, deep underground repositories are considered the safest disposal method.

- Countries like Finland, Sweden, and Canada are leading the way in developing permanent geological storage sites.

- Finland’s Onkalo repository is the world’s first permanent nuclear waste disposal facility, expected to begin operations by the 2030s.

- Molten Salt Reactors (MSRs) and Waste Burning:

- MSRs can use spent nuclear fuel as a fuel source, reducing existing nuclear waste.

- Some MSR designs can operate on U-233, plutonium, or minor actinides, helping to eliminate long-lived radioactive materials from spent fuel stockpiles.

Advanced Nuclear Safety and Passive Safety Systems

Nuclear reactor safety has significantly improved with modern designs that incorporate passive safety features to prevent accidents without human intervention.

- Passive Cooling Systems:

- Unlike traditional reactors that require external cooling pumps, passive safety reactors use natural convection, gravity, and heat dissipation to cool the reactor core.

- Examples include NuScale’s SMR design, which can safely shut down and cool itself without external power.

- Inherently Safe Fuel Designs:

- TRISO fuel and molten salt fuels are designed to withstand extreme temperatures without melting or releasing radiation.

- MSRs, for example, have a freeze plug system that automatically drains molten fuel into a safe containment tank if overheating occurs.

- Modular and Underground Reactor Construction:

- SMRs and some advanced reactor designs are being built underground or underwater, reducing the risk of external threats like earthquakes or terrorist attacks.

- Automated Reactor Control and AI Monitoring:

- AI and machine learning are being integrated into nuclear power plants to monitor reactor performance, predict failures, and optimize fuel usage.

Integration of Nuclear Energy with Renewables

As the global energy transition accelerates, nuclear power is being integrated with renewable energy sources like solar and wind to create a stable, low-carbon energy grid.

- Hybrid Nuclear-Renewable Energy Systems:

- Nuclear reactors can provide baseload power to support intermittent renewables.

- Advanced reactors can be used for hydrogen production, desalination, and industrial heat applications, reducing reliance on fossil fuels.

- Nuclear-Powered Hydrogen Production:

- High-temperature reactors (HTGRs and MSRs) can produce hydrogen through thermochemical cycles, enabling clean hydrogen production for transportation and industry.

- Countries like Japan, South Korea, and the United States are investing in nuclear-powered hydrogen plants.

Space Exploration and Nuclear Energy

Nuclear energy is also being explored for space applications, including space propulsion, lunar bases, and deep-space exploration.

- Nuclear Thermal Propulsion (NTP):

- NTP engines, using nuclear reactors to heat propellant, could enable faster travel to Mars and beyond.

- NASA and private companies are developing reactor-based propulsion systems for deep-space missions.

- Kilopower Reactors for Space Colonization:

- Small nuclear reactors, like NASA’s Kilopower project, could provide continuous power for lunar and Martian colonies.

- These compact reactors are designed to operate in extreme environments with minimal maintenance.

Conclusion: The Future of Nuclear Power

As energy demand rises and climate concerns intensify, nuclear power is poised to play a key role in the global transition to clean energy. Advancements in reactor design, fuel technology, waste management, and safety are making nuclear energy more sustainable, efficient, and adaptable.

With the development of small modular reactors, molten salt reactors, fusion technology, and hybrid nuclear-renewable systems, nuclear energy is set to become a cornerstone of the world’s clean energy future. Investment in next-generation nuclear technologies will ensure that nuclear power continues to provide reliable, low-carbon electricity for decades to come.

Public Perception and Policy Challenges in Nuclear Energy

Despite the advancements in reactor safety, fuel technology, and waste management, the nuclear industry faces public perception challenges, regulatory hurdles, and economic factors that impact its expansion. Addressing these issues is critical for the future of nuclear power as a key solution for decarbonization and energy security.

Public Perception and Nuclear Safety Concerns

The perception of nuclear energy has been shaped by historical accidents, misinformation, and public fear regarding radiation and nuclear waste. Events such as Three Mile Island (1979), Chernobyl (1986), and Fukushima (2011) have left lasting concerns about nuclear safety, even as modern reactors incorporate significant safety improvements.

- Radiation Misconceptions:

- Public fears about radiation exposure are often exaggerated, as nuclear power plants emit minimal radiation compared to natural sources like radon, cosmic rays, and medical imaging.

- Education campaigns and transparent communication are essential to counter misinformation and build public trust in nuclear energy.

- Nuclear Accidents and Lessons Learned:

- Chernobyl (1986): Caused by design flaws and operator error, leading to a catastrophic explosion and widespread contamination.

- Fukushima (2011): Triggered by a massive earthquake and tsunami, highlighting the need for improved backup power and passive cooling systems.

- Modern reactors integrate passive safety features, advanced monitoring, and improved containment structures to prevent similar incidents.

- Public Support and Opposition:

- Some countries, like France, Russia, and China, have strong government backing and public acceptance of nuclear power.

- Others, such as Germany, have chosen to phase out nuclear energy due to public pressure, despite its role in reducing carbon emissions.

- Younger generations are increasingly supporting nuclear energy as a climate solution, especially as renewable energy faces challenges related to intermittency and storage.

Regulatory and Economic Challenges

The nuclear industry faces significant regulatory barriers, high capital costs, and lengthy approval processes, which slow down the deployment of new reactors.

- Strict Licensing and Regulatory Approvals:

- Nuclear reactors require extensive safety reviews, environmental impact assessments, and regulatory approvals, leading to delays and cost overruns.

- In some countries, the process of licensing a new reactor can take 10–15 years, making it difficult to compete with faster-deploying renewable energy projects.

- Streamlining regulatory frameworks for advanced reactors could help accelerate nuclear deployment.

- High Construction and Capital Costs:

- Large nuclear plants require billions of dollars in upfront investment, making financing a major barrier.

- Cost overruns and delays have plagued projects like Hinkley Point C (UK) and Vogtle Units 3 & 4 (USA).

- Small Modular Reactors (SMRs) and factory-built reactors aim to reduce costs through standardization and mass production.

- Competition with Renewable Energy and Natural Gas:

- Solar and wind power have seen rapid cost declines, making them attractive alternatives to nuclear energy.

- However, renewables require energy storage solutions, while nuclear provides consistent, baseload power.

- Carbon pricing and government incentives could help level the playing field by accounting for nuclear’s role in reducing greenhouse gas emissions.

- Nuclear Waste Policy and Public Acceptance:

- Long-term disposal of spent nuclear fuel remains a political and technical challenge.

- Some countries, like Finland and Sweden, are leading the way with deep geological repositories, while others rely on temporary storage.

- Public opposition to nuclear waste transport and disposal sites can delay progress.

Government Policies and Global Nuclear Expansion

Despite challenges, many governments are recognizing the importance of nuclear power in achieving climate goals and energy security.

- Pro-Nuclear Policies and Investments:

- Countries like China, Russia, France, and India are heavily investing in nuclear energy, with dozens of new reactors under construction.

- The United States and Canada are supporting advanced reactor development, particularly SMRs, to ensure domestic energy security.

- Phasing Out vs. Expanding Nuclear Power:

- Germany shut down its last nuclear plants in 2023, increasing reliance on coal and natural gas.

- France, Japan, and South Korea have reversed previous plans to phase out nuclear, recognizing its role in reducing carbon emissions.

- International Collaboration on Nuclear Innovation:

- Organizations like the International Atomic Energy Agency (IAEA) and Generation IV International Forum (GIF) promote research on next-generation reactors.

- Russia and China are leading in exporting nuclear technology, including SMRs and floating nuclear plants.

- The U.S.-led Partnership for Global Infrastructure aims to compete with China’s nuclear exports by financing SMRs in developing countries.

The Role of Nuclear Energy in the 21st Century

As the world faces the dual challenges of climate change and energy security, nuclear power remains one of the most reliable and scalable sources of low-carbon electricity.

- Nuclear as a Climate Solution:

- Nuclear power plants prevent over 2 billion tons of CO₂ emissions annually, making them critical for net-zero targets.

- Countries integrating nuclear energy with renewables and hydrogen production will have more resilient energy systems.

- Future Innovations in Nuclear Technology:

- Fusion power could revolutionize energy production if commercial viability is achieved.

- Next-generation reactors (Gen IV), including molten salt, fast neutron, and thorium reactors, promise greater efficiency and sustainability.

- Decentralized and Microreactor Deployment:

- The rise of microreactors could make nuclear energy more accessible for remote areas, military bases, and disaster recovery.

- Companies like Oklo, Westinghouse, and Rolls-Royce are pioneering ultra-compact, portable nuclear power solutions.

Conclusion: A Nuclear Renaissance?

Despite historical setbacks, nuclear energy is experiencing a global resurgence, driven by the urgent need for clean, reliable, and sustainable power. With advancements in safety, modularity, and fuel technology, nuclear energy is poised to complement renewables in the transition to a low-carbon future.

The next decade will determine whether advanced reactors, SMRs, and fusion technology can overcome economic and regulatory barriers, leading to a nuclear renaissance that supports global climate goals and energy security.

Advantages of Nuclear Power

Nuclear power is a crucial component of the global energy mix, offering numerous economic, environmental, and technological benefits. As nations seek reliable, low-carbon energy sources to combat climate change, nuclear energy remains a key contender for sustainable power generation. Below are the primary advantages of nuclear power:

Low Carbon Emissions

One of the most significant benefits of nuclear power is its minimal carbon footprint. Unlike fossil fuels, nuclear power plants do not emit CO₂ or greenhouse gases during electricity generation.

- A single 1,000 MW nuclear plant prevents the emission of 5–8 million tons of CO₂ annually compared to coal-fired power plants.

- According to the International Energy Agency (IEA), nuclear energy has prevented over 60 gigatons of CO₂ emissions globally since 1971.

- Countries striving for net-zero emissions by 2050 recognize nuclear power as a critical component of their decarbonization strategies.

High Energy Density and Efficiency

Nuclear fuel has an extremely high energy density, meaning a small amount of uranium produces a vast amount of energy.

- 1 gram of uranium-235 can generate approximately 24,000 kWh of electricity, compared to only 8 kWh from 1 gram of coal.

- A single nuclear reactor can generate as much power as hundreds of wind turbines or thousands of solar panels.

- This efficiency makes nuclear power a cost-effective solution for supplying large-scale baseload electricity.

Reliable and Continuous Power Supply

Unlike solar and wind power, which are dependent on weather conditions, nuclear power provides stable and continuous electricity 24/7.

- Nuclear plants operate at a capacity factor of over 90%, meaning they generate electricity more than 90% of the time.

- In contrast, solar power has a capacity factor of around 20-30%, and wind power ranges from 30-50%.

- This reliability makes nuclear power essential for maintaining grid stability and energy security.

Reduces Dependence on Fossil Fuels

Nuclear energy reduces reliance on coal, oil, and natural gas, decreasing exposure to volatile fuel prices and geopolitical risks.

- Countries with strong nuclear programs, like France and Canada, have low electricity costs and energy independence.

- Nuclear power allows nations to diversify their energy portfolios, reducing reliance on imported fossil fuels.

Advanced Safety Measures and Low Accident Rate

Despite past accidents, modern nuclear reactors are designed with passive safety features that significantly reduce risks.

- Generation III+ and IV reactors have automatic shutdown systems, improved cooling mechanisms, and containment structures to prevent meltdowns.

- Small Modular Reactors (SMRs) feature self-cooling systems and underground construction, enhancing safety.

- The nuclear industry has one of the lowest accident and fatality rates compared to coal, oil, and hydroelectric power.

Small Land Footprint

Compared to solar farms and wind parks, nuclear plants require far less land per unit of electricity generated.

- A 1,000 MW nuclear plant occupies around 1-4 km², while a solar farm of the same capacity requires 20-50 km².

- This compact footprint makes nuclear power ideal for urbanized regions with limited land availability.

Potential for Advanced Reactors and New Technologies

Future nuclear technologies, such as Small Modular Reactors (SMRs), Molten Salt Reactors (MSRs), and Fast Neutron Reactors (FNRs), promise even greater efficiency, safety, and sustainability.

- SMRs offer flexible deployment, shorter construction times, and lower costs.

- Thorium reactors could provide safer, more abundant fuel alternatives with reduced long-lived waste.

- Fusion energy, if commercialized, could revolutionize power generation by producing virtually limitless clean energy with minimal waste.

Long Fuel Life and Reduced Resource Extraction

Unlike fossil fuels, nuclear fuel is highly efficient and requires less frequent replacement.

- A single nuclear fuel rod can last 3-5 years, whereas coal and gas plants require constant fuel input.

- Advanced reactor designs can reprocess spent fuel, further reducing the need for uranium mining.

Creates High-Paying Jobs and Boosts Economy

Nuclear energy supports high-skilled, long-term jobs across various sectors, including engineering, construction, and research.

- The World Nuclear Association (WNA) estimates that a nuclear power plant employs 400–700 full-time workers, compared to 50-100 for a natural gas plant.

- Countries investing in nuclear energy experience economic growth through innovation, infrastructure development, and energy exports.

Potential for Hydrogen Production and Industrial Use

Nuclear reactors can be used for more than just electricity generation—they can also produce clean hydrogen and supply heat for industrial processes.

- High-temperature gas-cooled reactors (HTGRs) can generate low-carbon hydrogen, reducing dependence on fossil fuels in industries like steelmaking and transportation.

- Nuclear energy could be a key driver in the hydrogen economy, supporting clean fuel production for a wide range of applications.

Conclusion

Nuclear power remains one of the most reliable, efficient, and environmentally friendly energy sources available today. With advancements in reactor safety, fuel technology, and waste management, nuclear energy is poised to play a critical role in the transition to a sustainable, low-carbon future.

While challenges such as high capital costs and regulatory barriers exist, continued investment in next-generation nuclear technologies and public education can help overcome these obstacles. As the world moves towards net-zero emissions, nuclear energy is expected to be a cornerstone of global energy security and decarbonization efforts.

Challenges and Future Prospects of Nuclear Power

Despite its numerous advantages, nuclear power faces economic, political, and technological challenges that impact its growth and acceptance. However, advancements in next-generation reactors, waste management, and public perception strategies could shape the future of nuclear energy in a low-carbon world.

High Initial Costs and Long Construction Times

One of the most significant barriers to nuclear energy expansion is the high capital cost of building new reactors.

- The construction of large-scale nuclear power plants often requires billions of dollars in investment and 10–15 years for completion.

- Projects like Hinkley Point C (UK) and Vogtle Units 3 & 4 (USA) have faced cost overruns and delays, making investors hesitant.

- Modular reactor designs (SMRs) could reduce costs through factory-based manufacturing and faster deployment.

Nuclear Waste Management and Public Concerns

Although nuclear energy produces far less waste than fossil fuels, the disposal of spent nuclear fuel remains a major challenge.

- High-level waste (HLW) remains radioactive for thousands of years and requires secure, long-term storage.

- Countries like Finland and Sweden have developed deep geological repositories, but public opposition often delays their implementation in other nations.

- Advanced fuel recycling and new reactor designs could significantly reduce waste and improve sustainability.

Public Perception and Nuclear Fear

Misinformation and fear surrounding radiation, nuclear accidents, and waste disposal have led to strong opposition in some regions.

- The impact of disasters like Chernobyl (1986) and Fukushima (2011) continues to shape public opinion, even though modern reactors have vastly improved safety measures.

- Educational campaigns and transparent government policies are crucial to building public trust in nuclear energy.

Competition with Renewable Energy and Energy Storage

The rapid growth of solar, wind, and battery storage technologies presents competition for nuclear power.

- Solar and wind energy costs have declined significantly, leading some governments to prioritize these over nuclear.

- However, renewables are intermittent, requiring backup solutions like energy storage, hydrogen, or nuclear baseload power to maintain grid stability.

- Many experts advocate for a balanced mix of renewables and nuclear energy to ensure a stable and clean electricity supply.

Political and Regulatory Barriers

Nuclear energy is heavily regulated due to safety and security concerns, making approvals for new reactors lengthy and expensive.

- In some countries, nuclear projects must undergo complex licensing procedures, delaying development.

- Geopolitical factors, such as uranium supply chains and international nuclear agreements, also influence nuclear expansion.

- Government incentives, carbon pricing, and streamlined regulations could help make nuclear energy more competitive.

Future Innovations and the Nuclear Renaissance

Despite challenges, nuclear technology is evolving, with promising advancements in reactor safety, efficiency, and sustainability.

- Small Modular Reactors (SMRs):

- Can be mass-produced in factories, reducing costs and construction time.

- Ideal for remote areas, industrial applications, and decentralized power grids.

- Countries like Canada, the U.S., Russia, and China are investing in SMR development.

- Advanced Generation IV Reactors:

- Includes Molten Salt, Fast Neutron, and Thorium reactors, offering higher safety and waste reduction.

- Can reuse spent nuclear fuel, making nuclear energy more sustainable.

- Fusion Energy:

- The ultimate goal of nuclear research, offering limitless clean power with no long-lived waste.

- Experimental projects like ITER and private fusion companies are making progress, but commercialization is still decades away.

Conclusion: The Path Forward

Nuclear power remains one of the most promising solutions for a clean, reliable, and sustainable energy future. While challenges like high costs, public perception, and regulatory barriers persist, advancements in reactor technology, waste management, and policy support could lead to a nuclear renaissance in the coming decades.

As nations seek to achieve net-zero emissions, nuclear power is expected to play a crucial role alongside renewables, hydrogen, and energy storage technologies. By investing in next-generation reactors and improving public engagement, the global energy sector can unlock the full potential of nuclear energy for future generations.

The Role of Nuclear Power in a Sustainable Energy Future

As the world transitions to low-carbon energy systems, nuclear power remains one of the most viable options for achieving energy security, grid stability, and carbon neutrality. Its ability to provide reliable, high-density energy makes it a crucial component in global decarbonization efforts.

Nuclear Power and Climate Change Mitigation

One of the primary drivers for nuclear energy expansion is its role in reducing greenhouse gas (GHG) emissions.

- Nuclear power currently provides about 10% of global electricity and nearly 30% of low-carbon electricity.

- Unlike fossil fuels, nuclear reactors do not produce CO₂, sulfur dioxide, or particulate matter, making them a clean alternative to coal and natural gas.

- Studies from the Intergovernmental Panel on Climate Change (IPCC) emphasize that limiting global warming to 1.5°C will require a significant increase in nuclear energy deployment alongside renewables.

Nations with ambitious net-zero targets (e.g., France, China, Canada, and the UK) are investing in nuclear power to maintain baseload electricity generation while integrating renewable sources like wind and solar.

The Integration of Nuclear Energy with Renewable Sources

While renewables are expanding rapidly, they come with challenges related to intermittency and grid stability. Nuclear power can complement renewables by providing consistent, round-the-clock energy that balances fluctuations in solar and wind generation.

- Hybrid Energy Systems: Combining nuclear with renewables and battery storage enhances grid reliability and resilience.

- Load-Following Reactors: Advanced nuclear designs can ramp up or down to adjust for fluctuations in renewable output.

- Hydrogen Production: Nuclear plants can generate low-carbon hydrogen, supporting sectors like transportation and heavy industry.

By integrating nuclear, solar, wind, and storage solutions, countries can create diverse, resilient energy portfolios that ensure long-term sustainability and energy independence.

The Global Expansion of Nuclear Power

Several countries are actively expanding their nuclear power programs, recognizing its strategic importance for energy security and economic growth.

Leading Nuclear Power Nations:

- France: One of the largest nuclear producers, generating over 70% of its electricity from nuclear power. Plans to build new reactors to meet climate goals.

- China: Rapidly expanding its nuclear fleet with over 20 reactors under construction and investments in advanced reactor designs.

- Russia: A major exporter of nuclear technology, with ongoing projects in India, Egypt, Turkey, and Bangladesh.

- United States: While facing economic challenges, the U.S. is developing Small Modular Reactors (SMRs) and extending the lifespans of existing plants.

- India: Expanding its nuclear capacity to support its growing economy while reducing dependence on coal-fired power plants.

Other nations, including Canada, South Korea, Japan, and the UK, are also reinvesting in nuclear energy as part of their long-term climate strategies.

The Future of Nuclear Reactor Technologies

Next-generation nuclear reactors promise to address cost, safety, and waste management issues, making nuclear energy more competitive and sustainable.

Small Modular Reactors (SMRs):

- Scalable and factory-produced, allowing for lower costs and faster deployment.

- Ideal for remote regions, industrial applications, and grid flexibility.

- SMRs are being developed by companies like NuScale (USA), Rolls-Royce (UK), and Rosatom (Russia).

Generation IV Reactors:

- Molten Salt Reactors (MSRs): Use liquid fuel with inherent safety features and minimal waste production.

- Fast Neutron Reactors (FNRs): Can reuse spent fuel, reducing nuclear waste and improving resource efficiency.

- High-Temperature Gas Reactors (HTGRs): Enable efficient hydrogen production for clean fuel applications.

Nuclear Fusion:

- The “Holy Grail” of energy, offering unlimited power with no risk of meltdown and minimal waste.

- Research projects like ITER (France), SPARC (MIT), and private companies like Helion Energy are working towards commercialization.

- While fusion is still decades away, breakthroughs in plasma physics, superconducting magnets, and AI-driven optimization are accelerating progress.

Overcoming Public and Political Barriers

For nuclear power to thrive, governments and energy companies must address public concerns, regulatory challenges, and misinformation.

Key Strategies for Nuclear Advocacy:

- Public Education & Transparency: Clear communication on nuclear safety, radiation risks, and waste disposal can build public trust.

- Regulatory Reform: Streamlining approval processes can reduce costs and accelerate nuclear deployment.

- International Cooperation: Joint research initiatives and technology-sharing agreements can drive global nuclear innovation.

- Investment in Advanced Reactors: Government funding for SMRs, fusion, and waste recycling will enhance nuclear energy’s long-term viability.

With effective policy support, public engagement, and technological innovation, nuclear power can overcome existing barriers and play a leading role in the global clean energy transition.

Conclusion: The Next Era of Nuclear Power

As the world faces increasing energy demands and climate challenges, nuclear power is positioned as a critical solution for low-carbon, high-efficiency energy production. While costs, regulatory issues, and public perception remain obstacles, advancements in reactor design, fuel technology, and waste management are paving the way for a nuclear resurgence.

In the coming decades, nuclear power—alongside renewables, energy storage, and hydrogen production—will be essential for creating a sustainable, resilient, and low-carbon global energy system. If supported by strong policies and continued innovation, nuclear energy could usher in a new era of clean, reliable power for future generations.

The Role of Nuclear Power in a Resilient Energy Future

As global energy systems evolve, nuclear power is expected to play a more dynamic role in ensuring energy resilience, economic stability, and deep decarbonization. While challenges remain, advancements in reactor technologies, fuel cycles, and hybrid energy systems position nuclear as a cornerstone of future energy strategies.

Enhancing Energy Security with Nuclear Power

Nuclear energy provides nations with a stable, domestically controlled power source, reducing dependence on imported fossil fuels and insulating economies from volatile energy markets.

- Reducing Reliance on Gas and Coal Imports:

- Countries like France, Canada, and South Korea have successfully reduced their dependence on coal and natural gas by prioritizing nuclear energy.

- The Russia-Ukraine conflict has highlighted the risks of overreliance on imported fossil fuels, prompting European nations to reconsider nuclear energy expansion.

- Diversified Energy Mix for Stability:

- Nuclear can operate as a baseload power source, supporting grid reliability as solar and wind capacity expands.

- Countries with a high share of nuclear power, such as Sweden and Finland, experience lower electricity price volatility than those heavily reliant on fossil fuel imports.

With energy markets experiencing frequent supply chain disruptions, nuclear power offers a long-term, strategic energy asset that enhances national security.

Innovations in Nuclear Fuel and Waste Management

The long-term sustainability of nuclear energy depends on its ability to maximize fuel efficiency and minimize waste production. Advanced technologies are addressing these challenges.

a. Recycling and Reprocessing Spent Fuel

- Traditional once-through fuel cycles leave behind high-level waste with long-lived isotopes.

- New reprocessing techniques, such as those used in France, Russia, and Japan, extract usable uranium and plutonium from spent fuel.

- Fast Neutron Reactors (FNRs) can utilize recycled fuel, reducing the volume and toxicity of nuclear waste.

b. Deep Geological Repositories for Safe Storage

- Countries like Finland (Onkalo Project) and Sweden are pioneering geological disposal sites for high-level waste.

- These sites provide permanent, passive containment, eliminating risks associated with above-ground storage pools.

c. Advanced Fuel Types for Next-Generation Reactors

- Thorium-Based Fuel: Offers enhanced proliferation resistance and abundant global reserves.

- TRISO Fuel (Tri-Structural Isotropic Particles):

- Used in High-Temperature Gas Reactors (HTGRs) and Molten Salt Reactors (MSRs).

- Highly resistant to meltdown scenarios, making reactors inherently safer.

- Metallic and Accident-Tolerant Fuels (ATFs):

- Improve heat dissipation and enhance reactor performance under extreme conditions.

Efforts in fuel innovation and waste reduction are crucial to ensuring the long-term viability of nuclear power.

Small Modular Reactors (SMRs) and Their Potential Impact

SMRs are emerging as a transformative technology that could make nuclear power more flexible, affordable, and accessible.

Key Advantages of SMRs:

- Lower Initial Costs and Shorter Construction Times:

- Factory-based manufacturing reduces construction risks and delays.

- Countries like Canada, the U.S., and the UK are investing in SMR deployment.

- Scalability and Regional Deployment:

- Ideal for off-grid locations, industrial sites, and disaster recovery zones.

- Countries with remote communities, such as Canada and Russia, are testing SMRs to replace diesel generators.

- Enhanced Safety Features:

- Passive cooling systems prevent overheating without external power sources.

- Many SMRs are designed for underground or underwater installation, reducing risks of sabotage or attacks.

Notable SMR Projects Worldwide:

- NuScale Power (USA): First SMR design approved by the U.S. Nuclear Regulatory Commission (NRC).

- Rolls-Royce SMRs (UK): Focused on rapid deployment and mass production.

- Russia’s Floating SMR (Akademik Lomonosov): Operates in the Arctic, supplying power to remote regions.

- China’s HTR-PM: A high-temperature gas-cooled SMR designed for hydrogen production.

SMRs could revolutionize nuclear power by making it more cost-effective, adaptable, and widely available.

Nuclear Fusion: The Future of Unlimited Clean Energy

While still in the research phase, nuclear fusion could eliminate many of the concerns associated with traditional nuclear fission.

Why Fusion Is Considered the Ultimate Energy Source:

- Virtually Unlimited Fuel Supply:

- Uses isotopes like deuterium and tritium, which are abundant in seawater.

- No Long-Lived Radioactive Waste:

- Unlike fission, fusion does not produce high-level radioactive waste requiring geological storage.

- Inherently Safe Reaction:

- Fusion cannot trigger a runaway reaction or meltdown—if disrupted, the reaction stops automatically.

Ongoing Fusion Research and Key Players:

- ITER (France): The world’s largest fusion experiment, expected to demonstrate net energy gain in the 2030s.

- SPARC (MIT) & Commonwealth Fusion Systems: Using high-temperature superconducting magnets to accelerate fusion breakthroughs.

- Private Companies (Helion Energy, Tokamak Energy): Pursuing compact, commercial-scale fusion reactors by the 2040s.

Although fusion energy remains decades away, continued investment and research could lead to commercial fusion power within the 21st century.

Policy and Investment Strategies for Nuclear Expansion

For nuclear energy to reach its full potential, governments, industries, and international organizations must implement policies that facilitate nuclear deployment.

Key Policy Measures for Supporting Nuclear Energy:

- Carbon Pricing and Incentives for Low-Carbon Energy:

- Establishing carbon taxes or cap-and-trade programs makes nuclear more economically competitive with fossil fuels.

- Streamlined Regulatory Approvals:

- Reducing excessive licensing delays and bureaucratic hurdles can accelerate reactor deployment.

- Public-Private Partnerships for Nuclear Innovation:

- Collaboration between government agencies and private firms can advance SMR and fusion technology commercialization.

- Global Nuclear Cooperation and Non-Proliferation Agreements:

- Ensuring international collaboration in reactor development, uranium enrichment, and nuclear security.

Governments that prioritize nuclear-friendly policies will gain a competitive advantage in the global clean energy market.

Conclusion: A Nuclear-Powered Future

As the world moves toward net-zero emissions and energy resilience, nuclear power will be a key pillar of the clean energy transition.

Key Takeaways:

- Nuclear energy provides stable, low-carbon electricity that complements renewables like solar and wind.

- Advancements in fuel recycling, SMRs, and fusion technology are making nuclear power safer and more cost-effective.

- Global investment in next-generation reactors and supportive policies will determine the future scale and impact of nuclear energy.

The next few decades will be crucial for shaping nuclear’s role in the global energy landscape. If technological innovation, public support, and political commitment align, nuclear power could drive a clean, reliable, and sustainable energy future for generations to come.

The Future of Nuclear Energy: Innovations, Challenges, and Global Prospects

Nuclear energy is at a pivotal moment in history, as climate change, energy security, and technological advancements drive a renewed focus on its potential. While traditional nuclear power has been a reliable source of electricity for decades, the next generation of reactors, fusion energy breakthroughs, and advanced fuel cycles are set to redefine its role in global energy systems.

The Shift Towards Advanced Nuclear Technologies

The future of nuclear energy depends on safer, more efficient, and more cost-effective reactors. Several advanced technologies are currently being developed to address the challenges faced by conventional nuclear power.

a. Small Modular Reactors (SMRs): The Next Evolution in Nuclear Power

SMRs are gaining traction as a flexible and scalable alternative to large traditional nuclear plants.

- Smaller Size, Faster Deployment:

- SMRs are factory-built and modular, allowing for reduced construction times and costs.

- Can be installed in remote areas, industrial sites, or regions with smaller electricity demands.

- Enhanced Safety Features:

- Many SMR designs include passive cooling systems, reducing the risk of meltdowns.

- Underground or submerged installations improve security and resistance to natural disasters.

- Leading SMR Projects:

- NuScale (USA): First SMR design approved by the U.S. Nuclear Regulatory Commission.

- Rolls-Royce SMRs (UK): Focused on mass production and exportability.

- China’s HTR-PM: A high-temperature gas-cooled SMR designed for hydrogen production.

b. Generation IV Reactors: Safer, More Efficient, and Sustainable

Next-generation reactors aim to improve upon traditional nuclear power with better fuel utilization, reduced waste, and passive safety systems.

- Molten Salt Reactors (MSRs):

- Operate at lower pressure with liquid fuel, reducing meltdown risks.

- Can use thorium as a fuel source, offering higher fuel availability and minimal waste production.

- Fast Neutron Reactors (FNRs):

- Can burn existing nuclear waste, making nuclear energy more sustainable.

- Allow for closed fuel cycles, where spent fuel is reprocessed and reused.

- High-Temperature Gas Reactors (HTGRs):

- Operate at extremely high temperatures, enabling hydrogen production and industrial applications.

c. Nuclear Fusion: The Ultimate Clean Energy Source

While still in development, nuclear fusion promises unlimited, clean, and inherently safe energy.

- Key Advantages of Fusion:

- No risk of meltdown—if the reaction is disrupted, it simply stops.

- No long-lived radioactive waste.

- Virtually unlimited fuel supply from isotopes like deuterium and tritium.

- Major Fusion Projects:

- ITER (France): The world’s largest fusion experiment, expected to demonstrate net energy gain in the 2030s.

- SPARC (MIT) & Commonwealth Fusion Systems: Developing compact, commercially viable fusion reactors.

- Helion Energy & Tokamak Energy: Private companies racing to bring fusion power to market within decades.

While commercial fusion power remains at least two to three decades away, rapid advances in superconducting magnets, AI-driven plasma control, and materials science could accelerate its arrival.

Nuclear Energy and the Clean Energy Transition

As countries work towards net-zero carbon emissions, nuclear energy is expected to play a crucial role in decarbonizing electricity grids and supporting renewable energy integration.

a. Nuclear’s Role in a Renewable Energy-Dominated Future

- Stabilizing the Grid:

- Wind and solar energy are intermittent—nuclear provides constant, reliable baseload power.

- Hydrogen Production with Nuclear Reactors:

- Advanced reactors like HTGRs can efficiently produce green hydrogen, an essential fuel for heavy industry and transportation.

- Hybrid Energy Systems:

- Future power grids may integrate nuclear, solar, wind, and energy storage for maximum efficiency.

b. Reducing Dependence on Fossil Fuels

- Countries reliant on coal (e.g., India, China, Poland) are investing in nuclear to transition away from carbon-intensive power.

- Advanced nuclear fuels and waste recycling will make nuclear a long-term, low-carbon solution for energy security.

Challenges and Barriers to Nuclear Expansion

Despite its advantages, nuclear energy still faces economic, political, and societal challenges that must be addressed.

a. High Upfront Costs & Financing Challenges

- Traditional nuclear plants require billions of dollars and over a decade to construct, leading to financial risks.

- New financing models, such as government-backed investments, loan guarantees, and private-public partnerships, are needed to accelerate nuclear deployment.

b. Public Perception and Safety Concerns

- Accidents like Chernobyl (1986) and Fukushima (2011) have left lasting public fears about nuclear safety.

- Improved safety designs, stronger regulations, and transparent communication are essential to rebuilding trust in nuclear energy.

c. Nuclear Waste Management

- High-level nuclear waste remains radioactive for thousands of years, requiring long-term storage solutions.

- Innovations in fuel recycling, deep geological repositories, and advanced reactor designs are helping to reduce nuclear waste concerns.

d. Geopolitical and Regulatory Barriers

- Nuclear energy is often tied to political and non-proliferation concerns, requiring strict international oversight.

- Regulatory frameworks need modernization to support faster deployment of SMRs and next-generation reactors.

Global Trends in Nuclear Energy Expansion

a. Countries Leading Nuclear Growth

Several nations are investing heavily in nuclear energy as part of their long-term energy strategies.

- China:

- Has the fastest-growing nuclear program, with over 20 reactors under construction.

- Developing advanced reactors, including fast breeder and thorium-based designs.

- France:

- Reaffirmed commitment to nuclear power with plans to build new EPR reactors.

- Aims to maintain its high percentage (over 70%) of electricity from nuclear.

- Russia:

- A global leader in exporting nuclear technology, with projects in India, Turkey, Egypt, and Bangladesh.

- United States:

- While facing economic challenges, the U.S. is investing in SMRs and extending reactor lifetimes.

- DOE funding for fusion research and next-generation reactors is increasing.

- India:

- Expanding its nuclear capacity to meet rising energy demands.

- Developing indigenous fast breeder reactors and thorium-based reactors.

b. Countries Reviving or Considering Nuclear Power

- Japan: Restarting nuclear reactors after safety upgrades post-Fukushima.

- Germany: Phasing out nuclear, but facing energy security challenges due to fossil fuel dependency.

- UK, Canada, Poland, and South Korea: Investing in new SMRs and next-gen nuclear plants.

The Next 50 Years of Nuclear Energy

Short-Term (2025-2035):

- Expansion of SMRs and Generation IV reactors.

- Increased focus on nuclear-renewable hybrid grids.

- Fusion experiments (ITER, SPARC) reach net energy gain milestones.

Medium-Term (2035-2050):

- Commercial deployment of fusion power becomes feasible.

- Large-scale nuclear-hydrogen production for industry and transportation.

- Nuclear-powered desalination plants address global water shortages.

Long-Term (2050 and Beyond):

- Fusion becomes the dominant clean energy source.

- Advanced AI-driven reactor management systems make nuclear operations safer and more efficient.

- Global decarbonization is largely achieved, with nuclear playing a key role.

Conclusion: A Nuclear Renaissance?