Waste-to-Energy Plants: Waste-to-Energy (WtE) plants are specialized facilities designed to generate electricity and/or heat by converting municipal solid waste (MSW), industrial waste, or other types of combustible waste materials into energy. These plants play a dual role in modern waste management: reducing the volume of waste sent to landfills while simultaneously producing usable energy, contributing to a circular economy and lowering reliance on fossil fuels.

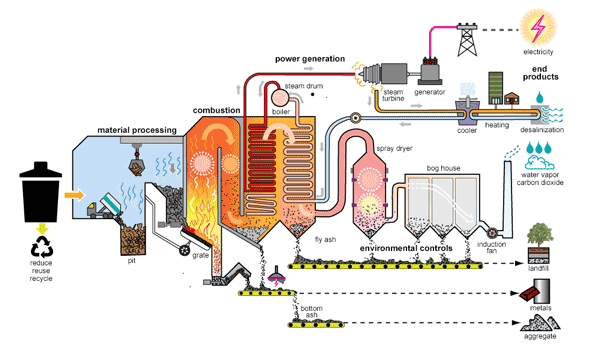

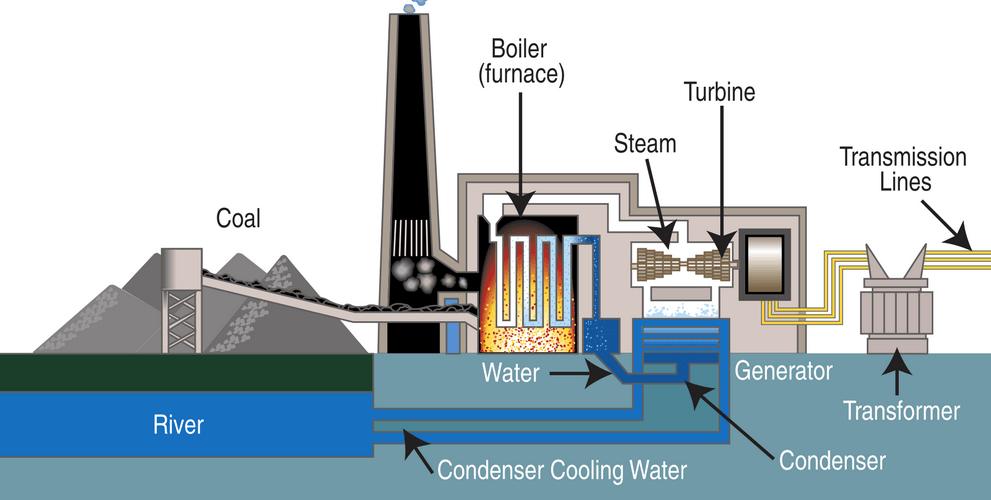

The core process in a typical WtE plant involves the controlled combustion of waste in a boiler or furnace. The heat produced from combustion converts water into high-pressure steam, which then drives a steam turbine connected to an electricity generator. In some cases, combined heat and power (CHP) systems are employed to provide both electricity and district heating to nearby industrial or residential areas, improving overall plant efficiency. Advanced WtE plants often use fluidized bed combustion, grate furnaces, or gasification technologies to optimize energy recovery and reduce emissions.

Waste preprocessing is an essential step to ensure efficient combustion. This may include sorting recyclables, removing metals, shredding, and drying waste to achieve a uniform calorific value. Some plants co-fire biomass or other renewable materials alongside conventional waste to enhance energy output and reduce carbon emissions.

Flue gas cleaning is another critical component, as combustion of waste can release pollutants such as particulate matter, acidic gases, heavy metals, and dioxins. Modern WtE facilities employ sophisticated air pollution control systems, including electrostatic precipitators, fabric filters, scrubbers, and selective catalytic reduction units to meet stringent environmental regulations.

Ash handling is also a key aspect of plant operation. Bottom ash, the non-combustible residue from the furnace, can often be processed and repurposed in construction materials, while fly ash, collected from flue gas treatment, must be stabilized and safely disposed of due to its higher concentration of heavy metals.

Control and monitoring systems ensure safe and efficient operation, providing real-time data on combustion parameters, emissions, and energy output. Automation and advanced control strategies enhance reliability and optimize fuel-to-energy conversion.

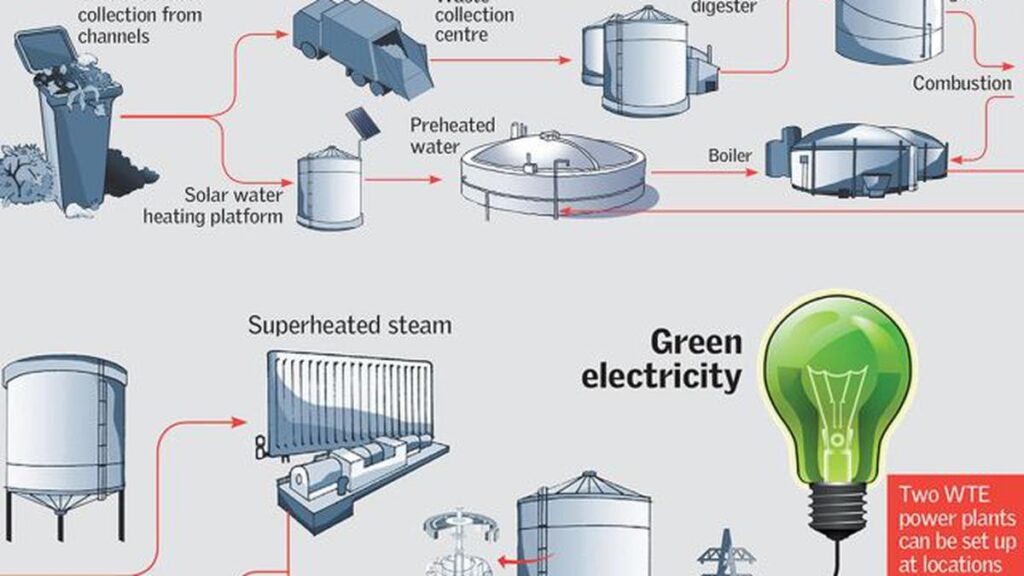

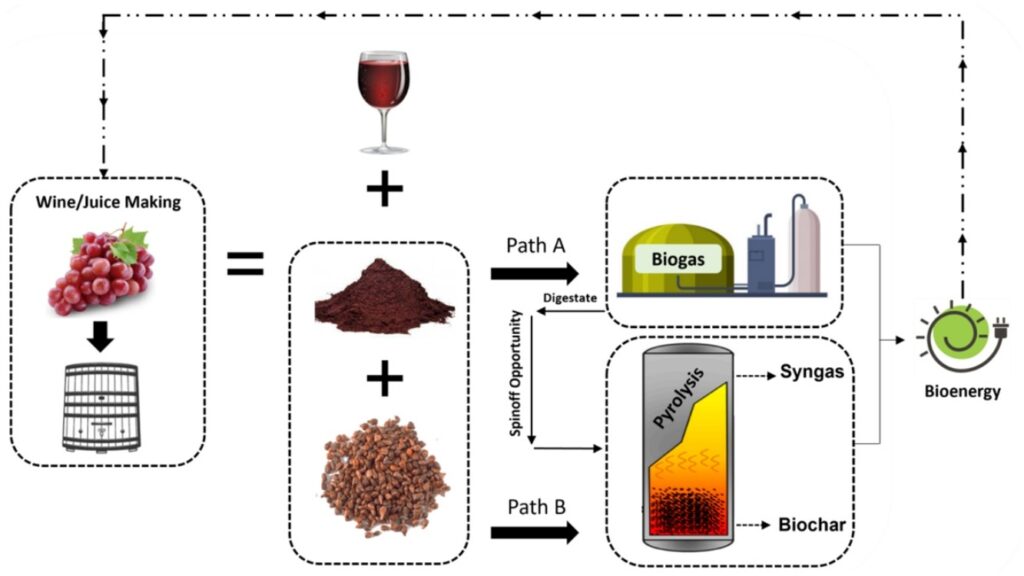

In addition to conventional thermal WtE plants, emerging technologies such as pyrolysis, plasma gasification, and anaerobic digestion are being explored. These methods can further improve energy recovery, reduce emissions, and enable the extraction of valuable byproducts like biochar, synthetic gas, or digestate for agricultural use.

Overall, Waste-to-Energy plants are a crucial component of sustainable waste management infrastructure, offering a practical solution to the growing challenges of urbanization and resource scarcity, while simultaneously generating renewable energy and minimizing environmental impact.

Main Types of Waste-to-Energy Plants

Waste-to-Energy (WtE) plants can be classified into several main types based on the technology used to convert waste into energy. Each type has specific advantages, efficiencies, and applications:

1. Mass Burn Incineration Plants:

This is the most common WtE technology. Municipal solid waste (MSW) is burned directly on a grate in a furnace. The heat generated produces steam to drive a turbine and generate electricity. Mass burn plants are straightforward in design, can handle large volumes of heterogeneous waste, and are equipped with advanced flue gas cleaning systems to minimize emissions.

2. Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) Plants:

In this type, waste is first pretreated—sorted, shredded, and dried—to produce a more uniform fuel called RDF or SRF. This fuel has higher calorific value than raw MSW, allowing for more efficient combustion. RDF can be used in dedicated WtE boilers or co-fired in conventional power plants and cement kilns.

3. Fluidized Bed Combustion Plants:

Fluidized bed WtE plants burn waste on a bed of sand or other inert material that is kept in suspension by a flow of air. This technology allows for more uniform and complete combustion at lower temperatures, reducing the formation of nitrogen oxides (NOx) and dioxins. Fluidized beds are particularly suited for high-moisture or heterogeneous waste streams.

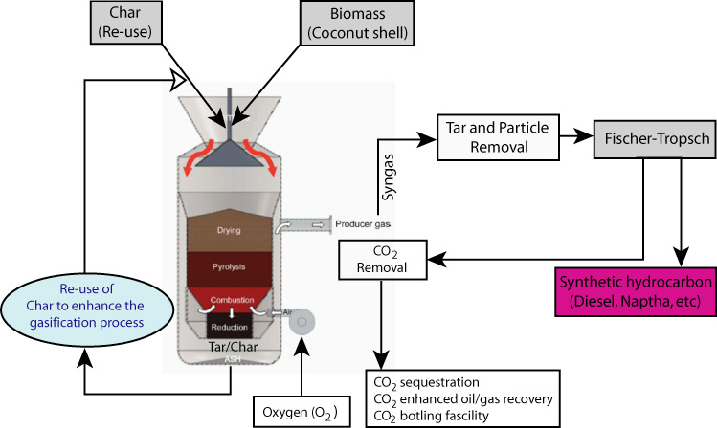

4. Gasification Plants:

Gasification converts waste into a synthetic gas (syngas) under high temperatures in a low-oxygen environment. The syngas, consisting mainly of carbon monoxide, hydrogen, and methane, can be burned to generate electricity or used as a feedstock for chemical production. Gasification produces less ash and can be cleaner than direct combustion if flue gas cleaning is adequate.

5. Pyrolysis Plants:

Pyrolysis is the thermal decomposition of waste in the absence of oxygen, producing syngas, oils, and char. The syngas can be used for electricity generation, while the pyrolysis oil can be refined as a fuel. This method is suitable for plastics and tires, but less common for mixed MSW.

6. Anaerobic Digestion (Biogas Plants):

Organic waste such as food scraps, agricultural residues, and sewage sludge is decomposed by microorganisms in oxygen-free tanks, producing biogas (mainly methane) and digestate. The biogas can be burned in engines or turbines to generate electricity and heat. Anaerobic digestion is especially suitable for wet, high-organic-content waste.

7. Plasma Arc Gasification:

This advanced technology uses extremely high temperatures generated by plasma torches to convert waste into syngas and vitrified slag. It can handle hazardous or medical waste and produces minimal emissions and residue. Plasma arc systems are highly efficient but have higher capital and operational costs.

Each WtE type is chosen based on the waste composition, local energy demands, environmental regulations, and economic considerations. Modern WtE plants often combine technologies, such as mass burn with flue gas energy recovery or RDF co-firing with conventional boilers, to optimize energy efficiency and reduce environmental impact.

Mass Burn Incineration Plants

Mass Burn Incineration Plants are the most widely used type of Waste-to-Energy (WtE) facility and are designed to directly combust municipal solid waste (MSW) without significant preprocessing. In these plants, waste is delivered to a reception and storage area, where it is temporarily held and homogenized to ensure continuous and stable feeding into the furnace. Large cranes or automated conveyors transport the waste onto a moving grate inside the combustion chamber. The grate system is designed to progressively move the waste through different temperature zones, ensuring complete combustion. Primary air is supplied from below the grate to facilitate combustion, while secondary air is injected above the waste to complete the burning of volatile gases.

The heat released during combustion is absorbed by water in boiler tubes surrounding the furnace, generating high-pressure steam. This steam is routed to a steam turbine connected to an electricity generator, producing electrical energy for local grids or industrial use. In many modern mass burn plants, combined heat and power (CHP) systems are integrated to supply district heating or industrial process steam, increasing overall plant efficiency.

Flue gas cleaning is a critical aspect of mass burn operations. Combustion of heterogeneous waste produces pollutants, including particulate matter, acid gases, heavy metals, and dioxins. To address this, mass burn plants use multi-stage flue gas treatment systems, which may include electrostatic precipitators or fabric filters to remove dust, wet or dry scrubbers to neutralize acidic components, and activated carbon injection to capture heavy metals and organic pollutants. Continuous monitoring ensures compliance with stringent environmental standards.

Ash handling is another important component. Bottom ash, which remains on the grate, is collected and can often be processed for use in construction materials, while fly ash from flue gas treatment is treated and stabilized due to its higher concentration of toxic elements. Automated systems transport both types of ash to storage or disposal areas.

Mass burn incineration plants are capable of handling large volumes of mixed waste with relatively low operational complexity compared to other WtE technologies. Their design emphasizes reliability, continuous operation, and efficient energy recovery, making them a cornerstone of modern urban waste management strategies.

Mass Burn Incineration Plants consist of several main parts, each critical to the efficient and safe conversion of municipal solid waste into energy. These components work together to handle waste, generate steam, control emissions, and manage residues:

1. Waste Reception and Storage Area:

This is the entry point for incoming municipal solid waste. Trucks deliver waste to a tipping floor or bunker, where it is temporarily stored. Cranes, grabbers, or conveyors move the waste to the feeding system. The storage area ensures a continuous supply of waste to the furnace and allows for preliminary sorting of oversized or non-combustible items.

2. Waste Feeding System:

The feeding system transports waste from the storage area into the furnace. It typically consists of conveyors, hoppers, and feeding chutes designed to meter waste at a controlled rate to maintain optimal combustion conditions. Automation in feeding ensures continuous operation without overloading the furnace.

3. Combustion Chamber / Furnace with Grate System:

The heart of the mass burn plant is the furnace. Waste is burned on a moving grate, which advances material through different temperature zones to achieve complete combustion. Primary air is supplied beneath the grate to support burning, and secondary air is injected above the waste to oxidize combustible gases. The design of the grate ensures uniform combustion, efficient energy release, and minimal unburned residues.

4. Boiler and Steam Generation System:

Surrounding the furnace, water-filled boiler tubes absorb heat from combustion and convert it into high-pressure steam. This steam is routed to a turbine-generator system to produce electricity. In combined heat and power (CHP) configurations, some of the steam can also be extracted for industrial use or district heating, enhancing overall efficiency.

5. Steam Turbine and Generator:

The high-pressure steam drives a turbine connected to an electricity generator. The turbine converts thermal energy into mechanical energy, which the generator then transforms into electrical energy. Condensers and cooling systems are used to convert exhaust steam back to water for reuse in the boiler.

6. Flue Gas Cleaning System:

Combustion of mixed waste produces pollutants, so flue gas cleaning is essential. Systems may include:

- Electrostatic precipitators or fabric filters for particulate removal

- Wet or dry scrubbers to neutralize acidic gases such as HCl and SO₂

- Activated carbon injection or catalytic systems to capture heavy metals and dioxins

Continuous monitoring ensures compliance with environmental regulations.

7. Ash Handling System:

Mass burn plants generate two types of ash: bottom ash (residue from the grate) and fly ash (captured from flue gas). Bottom ash is collected, cooled, and can be processed for reuse in construction materials. Fly ash, containing higher concentrations of heavy metals and toxins, is stabilized and disposed of safely. Conveyors, hoppers, and storage silos are used to handle both ash types efficiently.

8. Control and Monitoring Systems:

Advanced automation and control systems manage waste feeding, combustion conditions, steam generation, emission treatment, and ash handling. Real-time sensors and feedback loops ensure optimal performance, energy efficiency, and safety.

These main parts form an integrated system that allows mass burn incineration plants to convert heterogeneous municipal waste into usable energy while minimizing environmental impact.

Waste Reception and Storage Area

The Waste Reception and Storage Area is the first and a critical part of a Mass Burn Incineration Plant, serving as the entry point for municipal solid waste (MSW) and ensuring a continuous, controlled supply to the furnace. Incoming waste is typically delivered by trucks to the tipping floor or storage bunker. Here, waste is temporarily held, allowing plant operators to manage fluctuations in delivery rates and maintain steady combustion in the furnace.

The storage area is designed to accommodate large volumes of heterogeneous waste, including household refuse, commercial waste, and non-recyclable materials. It is often equipped with robust concrete bunkers resistant to wear, fire, and corrosive substances. Overhead cranes, hydraulic grabs, or automated conveyors are used to transfer waste from the tipping floor to the feeding system. These handling systems ensure that oversized items, such as furniture or large plastics, can be separated or broken down if necessary, preventing damage to downstream equipment.

Effective storage and reception management also allow for preliminary sorting to remove bulky inerts, metals, or hazardous materials that could interfere with combustion. In some modern facilities, mechanical pre-shredding or homogenization systems are integrated within the storage area to create a more uniform waste feed, improving boiler efficiency and reducing the risk of incomplete combustion.

Additionally, the design of the waste reception area emphasizes safety, ventilation, and odor control. Dust suppression, negative pressure ventilation, and fire detection systems are commonly installed to protect workers and prevent environmental hazards. Automation and monitoring systems track the quantity, composition, and flow of incoming waste, ensuring that the furnace receives a steady, controlled feed rate, which is essential for maintaining stable combustion, maximizing energy recovery, and minimizing emissions.

The Waste Reception and Storage Area, therefore, serves not only as a logistical hub for waste intake but also as a vital first step in optimizing the performance, safety, and environmental compliance of the entire mass burn incineration plant.

Waste Feeding System

The Waste Feeding System is a critical component of a Mass Burn Incineration Plant, responsible for transporting municipal solid waste (MSW) from the reception and storage area into the furnace at a controlled and consistent rate. Its primary function is to ensure that the combustion chamber receives a continuous feed of waste, allowing stable combustion, optimal energy recovery, and efficient operation of the plant.

Typically, the feeding system consists of heavy-duty conveyors, hoppers, chutes, and sometimes ram feeders or pushers. After waste is stored in the bunker or tipping floor, overhead cranes or hydraulic grabs transfer it onto the conveyor system. In some plants, mechanical shredders or homogenizers are integrated before feeding to break down bulky or irregular waste, ensuring a uniform size and composition that improves combustion efficiency.

The feeding system is designed for precision and reliability. Feed rates are carefully controlled through automated systems that monitor the furnace’s temperature, oxygen levels, and steam generation. By adjusting the speed of conveyors, the movement of ram feeders, or the operation of pushers, operators can maintain an optimal fuel-to-air ratio, preventing under- or over-firing, reducing the formation of unburned residues, and minimizing harmful emissions.

Safety and durability are also key considerations. The feeding system must handle abrasive and heterogeneous waste without frequent maintenance. Fire-resistant materials, robust construction, and emergency shutoff mechanisms are standard features. In addition, dust suppression systems and enclosures are often included to reduce airborne particulates, improve operator safety, and maintain environmental compliance.

In modern mass burn plants, the waste feeding system is integrated with the plant’s overall control and monitoring architecture. Sensors track the weight, volume, and moisture content of the incoming waste, allowing automatic adjustments to feed rates. This integration ensures that the furnace operates at steady temperatures, maximizes energy conversion, and supports consistent steam production for electricity or heat generation.

The Waste Feeding System, therefore, serves as the vital link between the storage area and the combustion chamber, ensuring that the plant operates efficiently, safely, and in compliance with environmental standards.

Combustion Chamber / Furnace with Grate System

The Combustion Chamber, or Furnace, with the Grate System is the central component of a Mass Burn Incineration Plant, where the actual conversion of municipal solid waste (MSW) into heat energy occurs. It is engineered to provide complete and efficient combustion of heterogeneous waste while ensuring safety, reliability, and compliance with environmental regulations.

In a mass burn plant, waste delivered from the feeding system is deposited onto a moving grate inside the furnace. The grate is typically segmented and mechanically driven, moving the waste progressively through different temperature zones. This design ensures that combustion occurs in stages: drying, ignition, volatile gas combustion, and final burnout of remaining solids. The moving grate allows uniform air distribution and effective mixing of the waste, optimizing heat release and minimizing unburned residues.

Air supply is a critical element in the combustion process. Primary air is injected from beneath the grate to support combustion of solid waste at the base, while secondary air is introduced above the grate to burn volatile gases released during pyrolysis. Some modern furnaces also include tertiary air injection to reduce emissions and improve the thermal efficiency of the process. By precisely controlling the air-to-fuel ratio, the furnace can maintain high combustion efficiency and reduce the formation of pollutants such as carbon monoxide, dioxins, and particulate matter.

The furnace is surrounded by boiler tubes or water walls that absorb the heat generated during combustion. These tubes convert water into high-pressure steam, which is then used in turbines for electricity generation or in combined heat and power (CHP) systems for district heating or industrial process steam. The design of the furnace ensures even heat distribution and maximum energy recovery while maintaining safe operating temperatures and pressures.

Durability and safety are central to the construction of the combustion chamber. High-temperature-resistant refractory lining protects the furnace walls from thermal stress and corrosion caused by acidic components in the waste. Continuous monitoring systems track temperature, oxygen levels, and combustion efficiency, allowing automated adjustments to air supply, grate speed, and feed rates. Fire detection systems and emergency shut-off mechanisms are also integrated to prevent accidents and ensure operational safety.

In addition, the furnace design facilitates the handling of combustion residues. Bottom ash, collected from the grate, can be cooled and processed for recycling, while fly ash, carried with flue gases, is directed toward the flue gas cleaning system for safe removal and disposal.

The Combustion Chamber with the Grate System is therefore the heart of a mass burn incineration plant, transforming heterogeneous waste into usable energy with controlled emissions, high thermal efficiency, and robust operational reliability.

Boiler and Steam Generation System

The Boiler and Steam Generation System in a Mass Burn Incineration Plant is a critical component that converts the thermal energy produced during combustion into high-pressure steam, which can then be used to generate electricity or supply heat in combined heat and power (CHP) applications. This system surrounds or is integrated with the furnace and is designed to efficiently capture heat while withstanding the harsh conditions of waste combustion.

Water-filled boiler tubes, often referred to as water walls, are positioned along the furnace walls and sometimes above the combustion chamber. As the municipal solid waste burns on the grate, the intense heat—typically ranging from 850°C to 1,100°C—is transferred to the water circulating in these tubes. This heat converts water into high-pressure, high-temperature steam. The design of the boiler maximizes heat absorption by using multiple passes for flue gases, including superheaters, economizers, and reheaters, ensuring that the energy from combustion is efficiently captured before gases exit to the flue gas cleaning system.

Superheaters raise the steam temperature above its saturation point, improving the efficiency of the steam turbine and electricity generation. Economizers preheat the feedwater entering the boiler using residual heat from flue gases, reducing fuel requirements and enhancing overall plant efficiency. Reheaters may be included in larger systems to improve the efficiency and stability of the turbine operation, particularly in CHP plants.

The boiler and steam system are equipped with multiple safety and monitoring mechanisms. Pressure and temperature sensors continuously track operating conditions, ensuring that steam is produced within design limits. Automatic control systems adjust water flow, feed rates, and combustion air supply to maintain stable steam production despite variations in waste composition or calorific value. Safety valves and emergency shutdown protocols protect against overpressure or overheating scenarios, ensuring reliable and safe operation.

In some mass burn plants, the boiler system is integrated with flue gas heat recovery devices, such as economizers or air preheaters, which capture residual heat from gases before they enter the flue gas cleaning system. This further increases overall energy efficiency and reduces fuel consumption.

The generated steam is directed to a steam turbine, where thermal energy is converted into mechanical energy and then into electricity via a generator. In combined heat and power systems, part of the steam can also be extracted at various stages of the turbine to supply district heating or industrial process steam, achieving higher total energy utilization.

Overall, the Boiler and Steam Generation System is the backbone of energy conversion in a mass burn incineration plant, transforming the heat from heterogeneous waste combustion into controlled, high-pressure steam for electricity production and heat supply while ensuring safety, efficiency, and operational stability.

Steam Turbine and Generator

The Steam Turbine and Generator system is a core component of a Mass Burn Incineration Plant, responsible for converting thermal energy from steam into mechanical energy and subsequently into electrical energy for distribution or on-site use. High-pressure, high-temperature steam produced in the boiler is directed into the turbine, where it expands through a series of blades mounted on a rotating shaft. The expansion of steam across the turbine stages causes the shaft to spin, converting thermal energy into mechanical rotational energy.

Turbines are typically designed as multi-stage, condensing units to maximize energy extraction from the steam. In larger installations, back-pressure or extraction-condensing turbines may be used for combined heat and power (CHP) applications, allowing part of the steam to be diverted for industrial processes or district heating while the remaining steam continues through the turbine for electricity generation. The turbine design ensures minimal energy loss while maintaining stable operation under varying steam flows and pressures, which are common in waste combustion due to fluctuations in calorific value and feed rate.

The turbine shaft is mechanically coupled to an electrical generator, usually a synchronous generator, which converts the rotational energy into electricity. The generator produces alternating current (AC), which is then stepped up by transformers for transmission to the electrical grid or supplied directly to industrial consumers. Modern generator systems are equipped with protective relays, monitoring devices, and excitation control systems to maintain voltage stability, frequency regulation, and safe operation under varying load conditions.

Condensers and cooling systems are essential to turbine efficiency. Exhaust steam leaving the turbine is condensed back into water in a condenser, creating a pressure drop that allows the turbine to extract maximum energy from the steam. The condensed water is collected, treated, and pumped back into the boiler for reuse, completing a closed-loop cycle. Cooling may be achieved through air-cooled or water-cooled condensers depending on local environmental conditions and water availability.

The integration of the steam turbine and generator system with the boiler and combustion control systems is critical for maintaining plant efficiency and operational stability. Sensors continuously monitor steam pressure, temperature, flow rate, and turbine vibration, enabling automated adjustments and protective shutdowns if abnormal conditions arise.

In combined heat and power configurations, the turbine system is designed to balance electricity production with heat extraction, optimizing overall energy utilization. This flexibility allows the plant to respond to varying demand profiles for both electricity and process or district heating, improving economic performance and sustainability.

Overall, the Steam Turbine and Generator system transforms the thermal energy from waste combustion into reliable electrical power and usable heat, forming the heart of energy conversion in a Mass Burn Incineration Plant while ensuring safety, efficiency, and operational flexibility.

Flue Gas Cleaning System

The Flue Gas Cleaning System is a vital component of a Mass Burn Incineration Plant, designed to remove pollutants generated during the combustion of municipal solid waste (MSW) and ensure compliance with stringent environmental regulations. Because mass burn plants combust heterogeneous waste, the resulting flue gases contain a mixture of particulate matter, acid gases, heavy metals, dioxins, furans, and other potentially harmful compounds. The cleaning system integrates multiple treatment stages to reduce these emissions to safe levels before discharge through the stack.

The first stage typically involves particulate removal. Electrostatic precipitators (ESPs) or fabric filter baghouses capture fly ash and fine dust particles carried in the flue gas. ESPs use electrical fields to charge and collect particles on metal plates, while baghouses physically filter particles through specialized fabric bags. Efficient particulate removal is critical, as fly ash can contain concentrated heavy metals and unburned carbon.

Next, acid gas neutralization is performed to remove gases such as hydrogen chloride (HCl), sulfur dioxide (SO₂), and hydrogen fluoride (HF). This is often achieved using dry, semi-dry, or wet scrubbers. Dry scrubbers inject alkaline powders, such as hydrated lime or sodium bicarbonate, which react with acidic components to form stable salts. Wet scrubbers pass flue gas through a liquid solution that absorbs acid gases, which are later treated or neutralized.

Heavy metal and dioxin control is another essential function. Activated carbon is commonly injected into the flue gas stream to adsorb mercury, lead, cadmium, and organic pollutants like dioxins and furans. In some systems, catalytic reactors or selective catalytic reduction (SCR) units are also employed to further reduce nitrogen oxides (NOx) and destroy trace organic pollutants.

Continuous monitoring and control systems are integrated into the flue gas cleaning process to ensure compliance with emission limits. Sensors measure concentrations of particulate matter, NOx, SO₂, CO, HCl, heavy metals, and dioxins, providing real-time feedback to optimize reagent injection, airflow, and scrubber operation. Automated systems adjust the treatment process based on gas composition and flow, ensuring consistent performance despite variations in waste type and calorific value.

Finally, treated flue gases are exhausted through the plant stack, with emission parameters continuously recorded to satisfy regulatory reporting requirements. Collected residues, including fly ash and reaction byproducts, are handled separately in the ash handling system, often stabilized or encapsulated before disposal due to their potential toxicity.

The Flue Gas Cleaning System is therefore critical for minimizing the environmental impact of waste-to-energy plants. By effectively removing particulates, acid gases, heavy metals, and organic pollutants, it ensures safe air emissions while allowing mass burn incineration plants to operate efficiently and sustainably.

Ash Handling System

The Ash Handling System is an essential component of a Mass Burn Incineration Plant, responsible for the safe, efficient collection, transport, and management of the solid residues generated during waste combustion. Combustion of municipal solid waste (MSW) produces two primary types of ash: bottom ash, which remains on the grate, and fly ash, which is carried with flue gases and captured in the flue gas cleaning system. Proper handling of both types is crucial for environmental compliance, operational efficiency, and potential resource recovery.

Bottom ash is the coarse, non-combustible residue left on the furnace grate after combustion. It typically contains metals, ceramics, glass, and other inert materials. Bottom ash is collected in a quenching pit or hopper, where it is cooled using water to prevent residual combustion and reduce dust formation. Once cooled, bottom ash is conveyed to storage silos or processing areas. In many modern WtE plants, bottom ash undergoes further treatment to recover ferrous and non-ferrous metals, which are separated using magnets and eddy current separators. The remaining material can be processed and recycled for construction applications, such as road base or concrete aggregate, contributing to circular economy objectives.

Fly ash is the fine particulate matter captured from flue gases during flue gas cleaning. Fly ash contains higher concentrations of heavy metals, salts, and potentially toxic compounds, making it hazardous and requiring careful handling. It is typically collected using fabric filters, electrostatic precipitators, or scrubbers and then stabilized by mixing with binding agents such as cement or lime to reduce leachability. After stabilization, fly ash is transported via sealed conveyors or pneumatic systems to secure storage or disposal facilities that meet regulatory requirements.

The ash handling system is designed for automation, safety, and dust control. Conveyors, screw feeders, hoppers, and silos are enclosed to minimize dust emissions and prevent worker exposure. Water sprays, airlocks, and negative pressure ventilation are often employed to suppress dust and avoid fugitive emissions. Sensors and control systems monitor ash levels, flow rates, and equipment performance, enabling continuous, reliable operation and integration with the overall plant control system.

By efficiently managing both bottom and fly ash, the Ash Handling System ensures that solid residues are safely contained, processed for potential material recovery, or disposed of in compliance with environmental regulations. It is a critical part of maintaining operational continuity, reducing environmental impact, and supporting the sustainability goals of modern mass burn incineration plants.

Control and Monitoring Systems

The Control and Monitoring Systems in a Mass Burn Incineration Plant are the central intelligence of the facility, responsible for ensuring safe, efficient, and environmentally compliant operation of all plant processes. These systems integrate advanced automation, real-time data acquisition, and process control to manage the complex interactions between waste feeding, combustion, steam generation, flue gas cleaning, ash handling, and energy conversion.

At the core of the system is a Supervisory Control and Data Acquisition (SCADA) platform or a Distributed Control System (DCS). This platform continuously collects data from hundreds of sensors placed throughout the plant, monitoring parameters such as furnace temperature, steam pressure and flow, oxygen levels, combustion air rates, feed rate of waste, flue gas composition, and ash handling operations. The SCADA/DCS provides operators with a real-time overview of the plant, enabling quick responses to any deviations from normal operating conditions.

Automation and process control are critical for maintaining combustion efficiency and emission compliance. The system automatically adjusts waste feed rates, grate speed, primary and secondary air flows, and boiler water circulation based on live measurements of temperature, oxygen, and steam production. This ensures stable combustion, optimal energy recovery, and minimal formation of pollutants such as carbon monoxide, nitrogen oxides, and dioxins. In CHP plants, the control system also balances electricity generation with heat extraction to meet variable energy demand.

Safety and alarm management are fully integrated into the control system. Fire detection, pressure and temperature limits, gas leak detection, and emergency shutdown mechanisms are monitored continuously. In case of abnormal conditions, the system can trigger automatic safety protocols, shut off feed systems, adjust airflow, or initiate emergency venting to prevent accidents and protect equipment and personnel.

Flue gas emissions monitoring is a key function of the control system. Continuous Emission Monitoring Systems (CEMS) measure concentrations of particulate matter, NOx, SO₂, HCl, CO, dioxins, and heavy metals in the exhaust gases. The system uses this data to automatically optimize reagent injection, scrubber operation, and other flue gas cleaning processes, ensuring compliance with environmental regulations and reporting requirements.

Advanced control systems may also incorporate predictive maintenance and diagnostics, using historical data and AI-based analytics to predict equipment wear, detect anomalies, and schedule maintenance proactively, reducing downtime and operational costs.

Overall, the Control and Monitoring Systems serve as the operational backbone of a mass burn incineration plant. By integrating real-time monitoring, automation, safety management, and emission control, these systems maximize energy efficiency, ensure environmental compliance, and maintain continuous, reliable operation of the plant.

Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) Plants

Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plants are specialized Waste-to-Energy (WtE) facilities designed to convert municipal solid waste (MSW) or industrial waste into a high-calorific, uniform fuel that can be burned efficiently in dedicated boilers, co-fired in conventional power plants, or used in cement kilns. Unlike mass burn incineration plants, which combust waste directly on a grate, RDF/SRF plants focus on preprocessing and refining waste to produce a controlled, engineered fuel, improving energy recovery and reducing environmental impact.

The process begins in the waste reception and preprocessing area, where incoming MSW is sorted to remove bulky inerts, metals, glass, and non-combustible or hazardous materials. Mechanical shredders reduce the size of the waste, while screens and air classifiers separate lightweight, combustible fractions from heavier materials. Magnetic and eddy current separators remove ferrous and non-ferrous metals, and further drying or homogenization may be applied to achieve a consistent moisture content and particle size. This preprocessing results in a uniform fuel that is easier to handle, store, and burn efficiently.

Once prepared, the RDF or SRF is baled, pelletized, or stored in silos, depending on the plant design and downstream energy use. The high calorific value, reduced moisture content, and uniform composition of RDF/SRF allow it to be fed into specialized combustion systems, such as fluidized bed boilers, grate-fired RDF boilers, or cement kiln burners, with precise control over energy output and emissions. Co-firing RDF/SRF with coal or biomass in existing power plants is also common, providing a sustainable alternative fuel while reducing fossil fuel consumption.

The combustion system in RDF/SRF plants is designed to maximize energy extraction while minimizing pollutant formation. Secondary air injection, staged combustion, and temperature control ensure complete burning of volatiles, while flue gas cleaning systems remove particulate matter, acid gases, heavy metals, and organic pollutants. Continuous monitoring maintains compliance with environmental standards and optimizes combustion efficiency.

Ash handling systems manage the residues from RDF/SRF combustion. Bottom ash can often be recycled for construction materials, while fly ash collected in flue gas cleaning systems is stabilized and safely disposed of due to its higher concentration of heavy metals and toxins.

Advanced control and monitoring systems integrate the preprocessing, combustion, and emissions control processes, ensuring stable operation despite variations in fuel composition, moisture content, or calorific value. Automated systems adjust feed rates, combustion air, boiler conditions, and emission treatment parameters to maintain consistent energy output and regulatory compliance.

RDF/SRF plants offer several advantages over conventional mass burn incineration. By producing a uniform fuel, they improve combustion efficiency, reduce the formation of pollutants, and allow flexible energy recovery through multiple applications. Additionally, preprocessing enables better separation of recyclables and metals, supporting circular economy objectives. These facilities are increasingly used in urban and industrial settings where controlled, high-calorific waste fuel can supplement conventional energy sources while minimizing landfill disposal.

Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plants consist of several main parts, each designed to transform heterogeneous waste into a uniform, high-calorific fuel and to efficiently convert it into energy while minimizing environmental impact. These components work together to ensure proper preprocessing, fuel handling, combustion, and emissions control:

1. Waste Reception and Storage Area:

Incoming municipal solid waste (MSW) or industrial waste is delivered to a reception area, typically a tipping floor or bunker. Waste is temporarily stored here to ensure a continuous and controlled supply to preprocessing systems. Overhead cranes, grabbers, or conveyors transport the waste, and preliminary sorting may remove oversized, hazardous, or non-combustible materials. This area also serves as a buffer to manage fluctuations in waste delivery.

2. Preprocessing and Sorting Systems:

The core of an RDF/SRF plant is the preprocessing stage, where waste is converted into a uniform fuel. Mechanical shredders reduce particle size, while trommel screens, air classifiers, and vibrating screens separate lightweight combustible fractions from heavier inerts. Magnetic and eddy current separators extract ferrous and non-ferrous metals, which can be recycled. Additional drying or homogenization may be applied to achieve consistent moisture content and calorific value. This stage ensures that the produced fuel burns efficiently with predictable energy output.

3. Fuel Production and Storage:

Processed waste is formed into RDF or SRF in various forms such as loose fuel, bales, or pellets. Storage silos, hoppers, or fuel bunkers provide temporary storage and maintain continuous supply to combustion systems. Automated handling ensures controlled feed rates to downstream boilers or co-firing applications.

4. Combustion System:

RDF/SRF is burned in specialized boilers, fluidized bed systems, or co-fired in existing power or cement plants. The combustion system is designed to optimize energy recovery while minimizing emissions. Staged air injection, temperature control, and residence time management ensure complete combustion of volatiles and solid fractions. Steam generation or direct heat output depends on the energy recovery strategy of the facility.

5. Flue Gas Cleaning System:

Combustion of RDF/SRF produces flue gases containing particulate matter, acid gases, heavy metals, and organic pollutants. Multi-stage cleaning systems are employed, including fabric filters or electrostatic precipitators for dust removal, wet or dry scrubbers for acid gases, and activated carbon or catalytic systems for heavy metals and dioxins. Continuous emission monitoring ensures compliance with environmental regulations.

6. Ash Handling System:

Combustion residues are managed via ash handling systems. Bottom ash is collected, cooled, and may undergo processing to recover metals or for use in construction materials. Fly ash captured from flue gas cleaning contains higher concentrations of hazardous elements and is stabilized before secure disposal. Automated conveyors, hoppers, and silos facilitate efficient and safe handling of all residues.

7. Control and Monitoring Systems:

Advanced control systems integrate all plant processes, from preprocessing to combustion and emission treatment. Sensors monitor temperature, moisture, feed rate, air flow, steam production, and flue gas composition. Automated feedback loops adjust system parameters in real time to optimize energy efficiency, maintain safe operation, and ensure regulatory compliance. Predictive maintenance features may also be incorporated to reduce downtime and improve reliability.

These main parts form an integrated system that allows RDF/SRF plants to convert heterogeneous waste into a uniform fuel and subsequently into energy, while maintaining operational efficiency, environmental compliance, and safety.

Waste Reception and Storage Area

The Waste Reception and Storage Area in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant is the first and a crucial part of the facility, serving as the entry point for incoming municipal solid waste (MSW) or industrial waste and ensuring a steady, controlled supply to the preprocessing systems. Waste delivered by trucks is typically unloaded onto a tipping floor or into a storage bunker. This area functions as a buffer, allowing the plant to manage fluctuations in delivery rates and maintain a continuous feed to downstream equipment.

The design of the reception and storage area emphasizes capacity, durability, and safety. Concrete bunkers with high wear and fire resistance are commonly used to withstand the abrasive and potentially reactive nature of waste. Overhead cranes, hydraulic grabs, or automated conveyors transport the waste from the tipping floor into the preprocessing system. This allows for separation of oversized items, hazardous materials, or non-combustible fractions that could damage shredders or disrupt fuel production.

Effective preliminary sorting and homogenization can also occur in the storage area. Large objects such as furniture, metal scrap, or construction debris may be manually or mechanically removed, while initial shredding or blending can help create a more uniform feedstock. This improves the quality and consistency of the RDF/SRF, resulting in higher calorific value and more efficient combustion in the boiler or co-fired system.

Safety, ventilation, and environmental control are essential in the waste reception area. Dust suppression systems, negative-pressure ventilation, and odor control mechanisms protect workers and minimize environmental impact. Fire detection and emergency suppression systems are also integrated due to the combustible nature of stored waste.

Automation and monitoring enhance operational efficiency. Sensors track the quantity, composition, and flow of incoming waste, allowing operators to optimize feed rates to the preprocessing system and ensure consistent fuel quality.

In summary, the Waste Reception and Storage Area is a critical hub in RDF/SRF plants, providing secure, controlled, and continuous handling of incoming waste while supporting preliminary sorting, homogenization, and environmental and operational safety.

Preprocessing and Sorting Systems

The Preprocessing and Sorting Systems are the core of a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant, responsible for transforming heterogeneous municipal solid waste (MSW) or industrial waste into a uniform, high-calorific fuel suitable for efficient combustion. These systems ensure that the final RDF/SRF product has consistent particle size, moisture content, and energy value, which improves boiler performance, reduces emissions, and enables reliable energy production.

After waste is transferred from the reception and storage area, it enters mechanical preprocessing units. Shredders or hammer mills reduce large items and bulky materials into smaller, manageable particles. This size reduction facilitates easier separation of combustible and non-combustible fractions and ensures uniform feeding into the fuel production system.

Sorting systems then separate materials based on weight, size, or magnetic properties. Trommel screens, vibrating screens, and air classifiers are used to remove inerts such as stones, glass, and sand. Magnetic separators extract ferrous metals, while eddy current separators recover non-ferrous metals like aluminum and copper. These recovered metals can be recycled, enhancing the plant’s sustainability and circular economy performance.

Moisture control is a critical aspect of preprocessing. High moisture content reduces the calorific value of the RDF/SRF and can affect combustion efficiency. Drying systems, including mechanical or thermal dryers, are often integrated to achieve a target moisture range, producing a more consistent and energy-dense fuel. In some facilities, homogenization systems blend different waste fractions to further standardize fuel quality.

Advanced preprocessing lines may also include dust suppression and odor control measures to maintain environmental compliance and protect workers. Enclosed conveyors, water sprays, and negative-pressure ventilation prevent fugitive dust and minimize unpleasant odors.

Finally, sensors and monitoring equipment track particle size distribution, moisture content, and calorific value in real time. Automated feedback systems adjust shredding, drying, and sorting parameters to maintain consistent fuel quality, ensuring that the RDF/SRF meets the specifications required for downstream combustion systems.

In summary, the Preprocessing and Sorting Systems convert heterogeneous waste into a predictable, high-calorific fuel. By combining shredding, separation, drying, and homogenization with advanced monitoring, these systems ensure that RDF/SRF plants operate efficiently, safely, and in compliance with environmental standards.

Fuel Production and Storage

The Fuel Production and Storage stage in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant is where preprocessed waste is transformed into a uniform, energy-dense fuel ready for combustion. This stage ensures that the final RDF/SRF product meets the required specifications for particle size, moisture content, density, and calorific value, enabling efficient energy recovery and consistent plant operation.

After preprocessing and sorting, the combustible fraction of waste is directed to fuel formation systems. Depending on plant design and downstream requirements, RDF/SRF may be processed into loose fuel, baled fuel, or pellets. Mechanical compactors and balers compress shredded material into dense bales, which facilitate storage, handling, and transport. Pelletizing systems produce small, uniform cylindrical fuel pellets, improving combustion efficiency and reducing dust and handling issues.

Storage facilities are designed to maintain a continuous supply of fuel to the combustion system while preserving fuel quality. Silos, hoppers, and fuel bunkers store loose, baled, or pelletized RDF/SRF under controlled conditions. Storage areas are often enclosed and equipped with ventilation, dust suppression, and fire detection systems to prevent ignition, reduce fugitive emissions, and maintain safety. Automated conveyors, feeders, or augers move fuel from storage to the boiler or co-firing system at a controlled rate, ensuring steady combustion and stable energy output.

Moisture control and quality monitoring are critical during storage. Excess moisture can reduce calorific value and affect boiler performance, so some plants use aeration, controlled ventilation, or additional drying to maintain fuel within the desired specifications. Sensors and monitoring systems track fuel temperature, moisture content, and flow rates, feeding data into the plant’s control system to adjust feeding rates and maintain consistent combustion conditions.

In addition to operational efficiency, the Fuel Production and Storage stage supports logistics and flexibility. Baled or pelletized RDF/SRF can be transported to external energy facilities, such as cement kilns or power plants, enabling decentralized energy recovery. Storage capacity ensures that the plant can handle fluctuations in waste supply or fuel demand without interrupting operations.

Overall, the Fuel Production and Storage stage is essential for converting preprocessed waste into a high-quality, uniform fuel and maintaining a reliable supply to combustion systems. It combines mechanical processing, quality control, and safe storage practices to optimize energy recovery, reduce emissions, and support sustainable waste-to-energy operations.

Combustion System

The Combustion System in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant is the central unit where the processed fuel is converted into usable thermal energy. Unlike mass burn incineration plants, which burn heterogeneous waste directly, RDF/SRF combustion relies on a uniform, engineered fuel, allowing for more efficient, controlled, and cleaner burning. The combustion system is designed to maximize energy recovery while minimizing emissions and operational issues.

RDF/SRF fuel is fed into the boiler or furnace using automated conveyors, hoppers, or feeding systems that ensure a continuous and controlled supply. Depending on the plant configuration, the fuel may be burned in grate-fired boilers, fluidized bed systems, or rotary kilns. Grate-fired systems move the fuel over a mechanically driven grate, providing staged combustion zones for drying, ignition, volatile gas combustion, and final burnout. Fluidized bed boilers suspend the fuel on a bed of inert particles, allowing uniform heat distribution, efficient combustion of high-moisture fuels, and reduced formation of nitrogen oxides (NOx).

Air supply management is crucial for efficient combustion. Primary air supports the burning of solid fuel at the base of the furnace, while secondary and sometimes tertiary air is injected above the fuel to oxidize volatile gases released during pyrolysis. Proper staging of air prevents incomplete combustion, reduces carbon monoxide emissions, and ensures complete burnout of RDF/SRF. Combustion temperatures are carefully controlled, typically between 850°C and 1,100°C, to optimize energy extraction and minimize pollutant formation.

The heat generated during combustion is absorbed by boiler tubes or water walls, producing high-pressure steam for electricity generation or combined heat and power (CHP) applications. Advanced boiler designs may include superheaters, economizers, and reheaters to maximize energy capture and improve overall efficiency.

Emissions control integration begins in the combustion system itself. Stable and complete combustion reduces the formation of dioxins, furans, and particulate matter, lowering the load on downstream flue gas cleaning systems. Real-time sensors monitor temperature, oxygen levels, and combustion efficiency, feeding data to the control system to automatically adjust fuel feed rates, grate speed, and air supply.

The combustion system is also designed with residue management in mind. Bottom ash from the grate or bed is collected and cooled, while fly ash carried with flue gases is directed to the flue gas cleaning system for capture and safe disposal. Fire-resistant linings and refractory materials protect the furnace structure from high temperatures and corrosive components in RDF/SRF.

Overall, the Combustion System in an RDF/SRF plant is engineered to provide efficient, reliable, and environmentally responsible energy recovery. By combining controlled feeding, staged combustion, temperature management, and integration with steam generation and emissions control, it ensures maximum energy output and regulatory compliance.

Flue Gas Cleaning System

The Flue Gas Cleaning System in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant is a critical component for controlling emissions and ensuring compliance with strict environmental standards. Even though RDF/SRF is a more uniform and energy-dense fuel than raw municipal solid waste, its combustion still produces pollutants such as particulate matter, acid gases, heavy metals, and organic compounds. The flue gas cleaning system removes these contaminants before the exhaust is released into the atmosphere.

The first stage typically involves particulate removal. Fly ash and other solid particles are captured using fabric filter baghouses or electrostatic precipitators (ESPs). Baghouse filters physically trap fine dust particles, while ESPs use electrical fields to collect particles on metal plates. Efficient particulate removal is essential because fly ash can contain concentrated heavy metals and unburned carbon.

Next, acid gas neutralization is performed to eliminate components such as hydrogen chloride (HCl), sulfur dioxide (SO₂), and hydrogen fluoride (HF). This is often accomplished using dry, semi-dry, or wet scrubbing systems. In dry scrubbers, alkaline reagents such as hydrated lime or sodium bicarbonate are injected into the flue gas, chemically neutralizing acids. Wet scrubbers use a liquid solution that absorbs acidic gases, which is later treated or neutralized.

Heavy metal and organic pollutant control is another key function. Activated carbon injection is commonly employed to adsorb mercury, lead, cadmium, and organic compounds such as dioxins and furans. In some RDF/SRF plants, selective catalytic reduction (SCR) or other catalytic processes are used to reduce nitrogen oxides (NOx) and destroy trace organic pollutants.

Continuous monitoring systems are integrated throughout the flue gas cleaning process. Sensors measure concentrations of particulate matter, NOx, SO₂, CO, HCl, heavy metals, and dioxins in real time. Automated feedback loops adjust reagent injection, airflow, and scrubber operation to optimize emission control and ensure compliance with regulatory limits.

After treatment, cleaned flue gases are discharged through the stack, while collected residues, including fly ash and scrubber byproducts, are handled in the ash handling system. Fly ash is stabilized and securely stored or disposed of due to its higher concentration of hazardous elements.

The Flue Gas Cleaning System in RDF/SRF plants is therefore crucial for minimizing environmental impact, reducing toxic emissions, and ensuring safe, compliant operation. By combining particulate filtration, acid gas neutralization, heavy metal capture, and continuous monitoring, it allows RDF/SRF plants to operate efficiently and sustainably.

Ash Handling System

The Ash Handling System in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant is responsible for the safe collection, transport, and management of solid residues generated during combustion. Although RDF/SRF is a more uniform fuel than raw municipal solid waste, its combustion still produces two main types of ash: bottom ash, which remains in the furnace or boiler, and fly ash, which is carried with flue gases and captured in the flue gas cleaning system. Proper handling of both ash types is essential for environmental compliance, operational efficiency, and potential resource recovery.

Bottom ash consists of non-combustible materials, including metals, glass, ceramics, and inert components. It is collected in hoppers or pits beneath the combustion system and is often cooled with water to prevent residual combustion and reduce dust formation. After cooling, bottom ash can be transported via conveyors or screw feeders to storage areas or processing units. Metals can be recovered using magnetic or eddy current separators, while the remaining inert material may be recycled in construction applications such as road base or aggregate.

Fly ash, captured in the flue gas cleaning system, contains higher concentrations of hazardous elements, including heavy metals and salts. It is typically stabilized by mixing with binding agents such as cement or lime to reduce leachability before secure storage or disposal. Fly ash handling systems are fully enclosed, using pneumatic or mechanical transport systems to minimize dust emissions and prevent environmental contamination.

Safety and operational reliability are critical in ash handling. The system is designed with dust suppression, fire detection, and containment measures to protect workers and the environment. Enclosed conveyors, airlocks, and negative-pressure ventilation are commonly used to prevent fugitive emissions. Sensors monitor ash levels, flow rates, and equipment status, allowing automated control of ash transport, storage, and disposal operations.

By efficiently managing both bottom and fly ash, the Ash Handling System ensures that solid residues are safely contained, processed for potential material recovery, or disposed of in accordance with environmental regulations. It supports continuous plant operation, minimizes the environmental footprint of RDF/SRF combustion, and contributes to sustainable waste-to-energy management.

Control and Monitoring Systems

The Control and Monitoring Systems in a Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF) plant form the operational backbone of the facility, ensuring safe, efficient, and environmentally compliant operation across all processes. Given the variability in waste composition, moisture content, and calorific value—even in processed RDF/SRF—the control systems are critical for maintaining stable combustion, optimal energy recovery, and regulatory compliance.

At the core of the system is a Supervisory Control and Data Acquisition (SCADA) platform or a Distributed Control System (DCS). These systems continuously collect data from sensors installed throughout the plant, monitoring parameters such as fuel feed rates, boiler temperature and pressure, air supply, steam generation, flue gas composition, ash levels, and equipment status. The platform provides operators with real-time visualization of plant operation and enables automated responses to maintain optimal performance.

Automation and process control are central to maintaining efficient combustion and energy production. The system adjusts fuel feeding rates, grate or feeder speeds, primary and secondary air flows, and boiler water circulation in real time based on feedback from sensors monitoring oxygen levels, combustion temperature, and steam output. This ensures complete burnout of fuel, reduces the formation of pollutants such as carbon monoxide and nitrogen oxides (NOx), and maintains consistent steam or heat production for electricity or CHP applications.

Emissions monitoring is fully integrated into the control system. Continuous Emission Monitoring Systems (CEMS) measure particulate matter, NOx, SO₂, HCl, CO, dioxins, and heavy metals in the exhaust gases. The system uses this data to automatically optimize reagent injection, scrubber operation, and other flue gas treatment parameters, maintaining compliance with stringent environmental regulations.

Safety and alarm management are also integrated. Fire detection, emergency shutdown mechanisms, overpressure protection, and equipment failure alerts are continuously monitored. In the event of abnormal conditions, the system can initiate automated safety responses, such as stopping fuel feeding, adjusting airflow, or activating fire suppression, ensuring the safety of personnel, equipment, and the facility.

Advanced control systems may incorporate predictive maintenance and diagnostic features, using historical data and real-time monitoring to anticipate equipment wear, detect anomalies, and schedule maintenance proactively. This minimizes downtime, reduces operational costs, and ensures continuous plant availability.

Overall, the Control and Monitoring Systems in an RDF/SRF plant integrate real-time data acquisition, automation, emissions management, and safety protocols to maintain stable, efficient, and environmentally responsible operations. They are essential for maximizing energy recovery, ensuring regulatory compliance, and providing reliable, continuous operation of the facility.

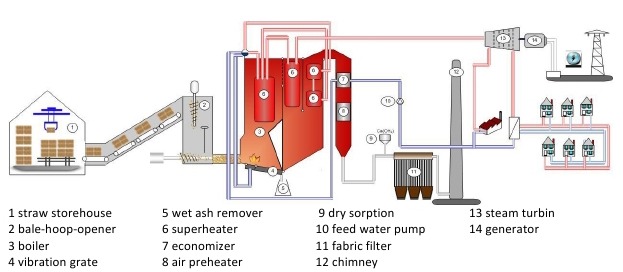

Fluidized Bed Combustion Plants

Fluidized Bed Combustion (FBC) plants are a type of Waste-to-Energy (WtE) or biomass-fired power plant that utilize fluidized bed technology to efficiently combust a wide range of solid fuels, including municipal solid waste (MSW), biomass, refuse-derived fuel (RDF), and other heterogeneous fuels. Unlike conventional grate-fired or mass burn systems, fluidized bed combustion suspends fuel particles in a bed of hot, inert material—usually sand or ash—using a controlled flow of air, creating a fluid-like state. This enables uniform temperature distribution, high combustion efficiency, and reduced pollutant formation.

The main advantages of FBC technology include the ability to burn low-calorific fuels with high moisture content, precise temperature control to reduce nitrogen oxides (NOx) formation, and the capability to co-fire multiple types of fuels simultaneously. Fluidized beds operate at relatively lower combustion temperatures (typically 800–900°C), which reduces thermal stress on boiler components and minimizes the formation of dioxins and furans. The technology also allows in-situ capture of sulfur by injecting lime or limestone directly into the bed, reducing sulfur dioxide (SO₂) emissions without requiring extensive flue gas scrubbing.

Main parts of a Fluidized Bed Combustion Plant:

- Fuel Handling and Storage: Incoming fuels, including biomass, MSW, or RDF, are received and stored in dedicated bunkers or silos. Storage systems ensure a continuous, controlled supply to the fuel feeding system. Preprocessing may include shredding, drying, or homogenization to achieve a uniform particle size and moisture content.

- Fuel Feeding System: Fuel is transported from storage to the combustion chamber using automated conveyors, feeders, or pneumatic systems. Feed rates are controlled to maintain stable bed conditions and combustion efficiency.

- Fluidized Bed Combustion Chamber: The heart of the plant is the fluidized bed furnace. Air is blown from the bottom through a distributor plate, suspending fuel and inert bed material in a turbulent, fluid-like state. This ensures excellent mixing, uniform heat distribution, and complete combustion. Bed temperature is carefully controlled to optimize energy output and minimize pollutant formation. Limestone or other sorbents can be added directly to the bed to capture sulfur during combustion.

- Heat Recovery and Boiler System: The heat released in the combustion chamber is transferred to water-cooled tubes or boiler walls, generating high-pressure steam for electricity generation or combined heat and power (CHP) applications. Superheaters and economizers improve energy conversion efficiency.

- Flue Gas Cleaning System: FBC plants produce flue gases containing particulate matter, acid gases, and trace heavy metals. Multi-stage cleaning systems—including cyclones, fabric filters, scrubbers, and activated carbon injection—are employed to remove pollutants and ensure emissions meet regulatory standards.

- Ash Handling System: The combustion produces two main types of ash: bed ash, which consists of unreacted material and inert bed media, and fly ash, collected from flue gas cleaning. Bed ash may be recycled back into the furnace to maintain bed material or disposed of, while fly ash is stabilized and securely managed due to its potentially hazardous content.

- Control and Monitoring Systems: Advanced distributed control systems (DCS) or SCADA platforms monitor temperature, oxygen, fuel feed, bed fluidization, steam generation, and emissions. Automated adjustments maintain stable combustion, optimal energy production, and safe operation.

Fluidized Bed Combustion plants are especially suited for low-quality fuels with variable moisture content and calorific value, including biomass residues, RDF, and challenging waste streams. Their high efficiency, fuel flexibility, and lower pollutant emissions make them an increasingly preferred choice for sustainable energy recovery from waste and biomass sources.

Fuel Handling and Storage

The Fuel Handling and Storage system in a Fluidized Bed Combustion (FBC) plant is the first stage in the fuel-to-energy conversion process, responsible for receiving, storing, and preparing a continuous supply of fuel for combustion. Because FBC plants are designed to burn a wide variety of fuels—including municipal solid waste (MSW), biomass, refuse-derived fuel (RDF), and other heterogeneous or low-calorific fuels—this system must accommodate differences in size, moisture content, and energy density while ensuring operational efficiency and safety.

Incoming fuel is typically delivered via trucks, railcars, or conveyors and unloaded into reception areas, bunkers, or silos. These storage facilities are designed to act as a buffer, enabling the plant to manage fluctuations in fuel delivery and maintain a continuous feed to the combustion system. Bunkers and silos are constructed from wear-resistant, fire-resistant materials to withstand abrasive and combustible fuels. They often include features for ventilation, odor control, and dust suppression to protect operators and minimize environmental impact.

Preprocessing within the storage area may include mechanical shredding, screening, or blending to achieve uniform particle size, remove oversized or non-combustible materials, and homogenize moisture content. This ensures stable fluidized bed operation and consistent thermal performance in the combustion chamber. Magnetic and eddy current separators may also be installed to extract metals, supporting recycling and minimizing damage to downstream equipment.

The system incorporates automated feeding equipment such as conveyors, screw feeders, or pneumatic transport systems to deliver fuel at controlled rates to the fluidized bed furnace. Feed rate control is critical to maintaining the proper fuel-to-air ratio, bed fluidization, and combustion stability. Sensors continuously monitor fuel levels, flow rates, and temperature, feeding data to the plant’s control system for real-time adjustments.

Safety is a central consideration. Fuel storage areas are equipped with fire detection and suppression systems, temperature monitoring, and ventilation to prevent spontaneous combustion or fire hazards. Enclosures and negative-pressure systems minimize dust emissions, while safety interlocks prevent uncontrolled fuel discharge.

Overall, the Fuel Handling and Storage system ensures that a diverse range of fuels is securely received, properly conditioned, and continuously supplied to the fluidized bed combustion chamber. By combining robust construction, preprocessing, automated feeding, and integrated monitoring, it supports efficient, safe, and environmentally compliant operation of the FBC plant.

Fuel Feeding System

The Fuel Feeding System in a Fluidized Bed Combustion (FBC) plant is a critical link between fuel storage and the combustion chamber, ensuring a consistent, controlled, and precisely measured supply of fuel to the fluidized bed. Proper feeding is essential for maintaining stable bed fluidization, uniform combustion, optimal energy recovery, and reduced pollutant formation.

Fuel from storage silos, bunkers, or hoppers is transported to the combustion chamber using mechanical conveyors, screw feeders, belt feeders, or pneumatic systems, depending on the fuel type, particle size, and plant configuration. These systems are designed to handle a wide variety of fuels—including shredded MSW, biomass residues, refuse-derived fuel (RDF), or low-calorific industrial wastes—while preventing blockages, bridging, or surges that could destabilize the bed.

Feed rate control is a key aspect of the system. Sensors continuously monitor the fuel level in storage, the mass flow, and the temperature of the material. The plant’s control system adjusts feeding rates in real time to match combustion demand, maintain bed temperature, and optimize air-to-fuel ratios. This is especially important in FBC plants, where variations in fuel calorific value or moisture content can affect fluidization and combustion stability.

Advanced feeding systems also include fuel metering and distribution mechanisms to ensure even fuel delivery across the bed. In larger or multi-fuel installations, the system may include multiple feeders to inject different fuel types at precise locations in the bed, enabling co-firing and improving combustion efficiency.

Safety and environmental controls are integral. Enclosed conveyors and pneumatic systems reduce dust emissions, while fire detection sensors and emergency shut-off mechanisms prevent ignition outside the furnace. Anti-bridging devices, vibration feeders, and flow regulators help prevent fuel clogging and ensure continuous operation.

In summary, the Fuel Feeding System is essential for reliable, stable, and efficient operation of a fluidized bed combustion plant. By delivering a controlled and consistent fuel supply, it maintains optimal bed fluidization, maximizes energy recovery, minimizes emissions, and integrates seamlessly with the plant’s advanced control and monitoring systems.

Fluidized Bed Combustion Chamber

The Fluidized Bed Combustion (FBC) Chamber is the heart of a Fluidized Bed Combustion plant, where the thermal conversion of fuel into energy takes place. Unlike conventional grate-fired systems, the FBC chamber suspends fuel particles in a bed of hot, inert material—typically sand, ash, or other refractory granules—using a controlled upward flow of air. This fluidization creates a uniform, turbulent, fluid-like mixture that enables highly efficient combustion, excellent heat transfer, and reduced formation of pollutants.

Fuel is introduced into the bed via the fuel feeding system, while primary air is blown from the bottom through a distributor plate, suspending the bed material and fuel particles. Secondary or tertiary air may be injected above the bed to complete combustion of volatile gases released during pyrolysis. This staged air injection ensures complete oxidation, minimizes carbon monoxide (CO) formation, and reduces nitrogen oxides (NOx) generation by maintaining moderate bed temperatures, typically between 800°C and 900°C.

One of the key advantages of fluidized bed technology is its ability to handle fuels with high moisture content or low calorific value, as the uniform mixing promotes consistent combustion and prevents localized hot or cold spots. Limestone or other sorbents can be added directly to the bed to capture sulfur in-situ, reducing sulfur dioxide (SO₂) emissions without requiring extensive downstream scrubbing.

The bed’s fluidized nature also facilitates excellent heat transfer to boiler tubes or water walls surrounding the chamber, generating high-pressure steam for electricity generation or combined heat and power (CHP) applications. The uniform temperature distribution minimizes thermal stress on boiler components, prolonging equipment life.

FBC chambers are equipped with advanced instrumentation to monitor bed temperature, pressure drop, air flow, and fuel feed rates. These sensors feed real-time data to the plant’s control system, enabling automatic adjustments to fuel input, air flow, or sorbent injection to maintain stable and efficient operation.

Ash management is integrated into the chamber design. Bottom ash, consisting of inert bed material and unburned residues, is continuously or periodically removed from the chamber through cooled hoppers or screw conveyors. This ensures the bed maintains proper fluidization characteristics and allows partial recycling of inert material to optimize bed stability.

In summary, the Fluidized Bed Combustion Chamber is the core energy conversion unit in FBC plants. Its fluidized bed design enables efficient combustion of diverse fuels, uniform heat distribution, in-situ pollutant control, and reliable steam or heat generation, making it particularly suitable for low-quality, high-moisture, or heterogeneous fuels.

Heat Recovery and Boiler System

The Heat Recovery and Boiler System in a Fluidized Bed Combustion (FBC) plant is responsible for capturing the thermal energy produced in the combustion chamber and converting it into high-pressure steam for electricity generation or combined heat and power (CHP) applications. Efficient heat recovery is critical to maximizing energy output, improving plant efficiency, and ensuring stable operation of downstream power generation equipment.

The FBC combustion chamber is surrounded by water-cooled boiler tubes or water walls, which absorb the heat released during fuel combustion. The circulating water inside the tubes is heated to generate steam, which is then routed through superheaters, economizers, and sometimes reheaters to achieve the desired temperature and pressure for the steam turbine or industrial process. Superheaters increase the temperature of the steam beyond its saturation point, improving turbine efficiency and energy conversion. Economizers preheat boiler feedwater using residual flue gas heat, enhancing overall system efficiency.

The system is designed to handle the variable combustion characteristics of heterogeneous fuels, such as RDF, biomass, or waste residues. Sensors continuously monitor steam pressure, temperature, and flow rate, providing real-time feedback to the plant’s control system. Automated adjustments to fuel feed rates, air supply, and combustion parameters ensure consistent steam generation even when fuel moisture content or calorific value fluctuates.

Flue gas flow management is an integral part of the boiler system. The layout ensures that flue gases pass over heat exchange surfaces efficiently before entering the flue gas cleaning system. By extracting as much heat as possible, the system reduces the temperature of exhaust gases, minimizes energy loss, and improves overall thermal efficiency.

Materials and design considerations are critical in FBC boiler systems due to the abrasive nature of bed material and the corrosive components in flue gas, such as sulfur compounds and alkali metals. Boiler tubes are typically made of high-alloy or refractory-lined steel to resist erosion, corrosion, and thermal stress over long-term operation.

The Heat Recovery and Boiler System is closely integrated with control and monitoring systems, which manage steam conditions, fuel feeding, bed temperature, and auxiliary equipment. This integration ensures safe, reliable, and efficient operation, protecting both the boiler and downstream turbines or heat users.

In summary, the Heat Recovery and Boiler System in a Fluidized Bed Combustion plant captures combustion heat, converts it into high-pressure steam, and delivers it for electricity or heat production. Its design accommodates fuel variability, maximizes energy efficiency, protects equipment from abrasive and corrosive conditions, and ensures stable, reliable plant operation.

Flue Gas Cleaning System

The Flue Gas Cleaning System in a Fluidized Bed Combustion (FBC) plant is a critical component designed to remove pollutants from the exhaust gases before they are released into the atmosphere. Even though fluidized bed combustion produces more uniform and cleaner combustion compared to conventional grate-fired systems, flue gases still contain particulate matter, acid gases, nitrogen oxides (NOx), and trace heavy metals that must be controlled to meet environmental regulations.

The first stage is typically particulate removal. Cyclones, fabric filter baghouses, or electrostatic precipitators (ESPs) capture fine ash particles carried in the flue gas. Cyclones separate heavier particles using centrifugal force, while baghouses and ESPs are capable of removing very fine particulates, including fly ash and unburned fuel residues. Effective particulate control prevents air pollution and protects downstream equipment.

Acid gas neutralization is another essential step. Flue gases from FBC contain sulfur dioxide (SO₂), hydrogen chloride (HCl), and other acid gases. Dry, semi-dry, or wet scrubbers are used to remove these pollutants. In dry or semi-dry systems, alkaline powders such as hydrated lime or sodium bicarbonate are injected into the gas stream, chemically neutralizing acids and forming stable salts. Wet scrubbers pass the flue gas through a liquid solution that absorbs acid gases, which are then treated or neutralized.

Nitrogen oxide (NOx) control is typically achieved through staged combustion in the bed, which limits NOx formation during fuel burning. Additional reduction may be performed using selective non-catalytic reduction (SNCR) or selective catalytic reduction (SCR) systems, depending on regulatory requirements.