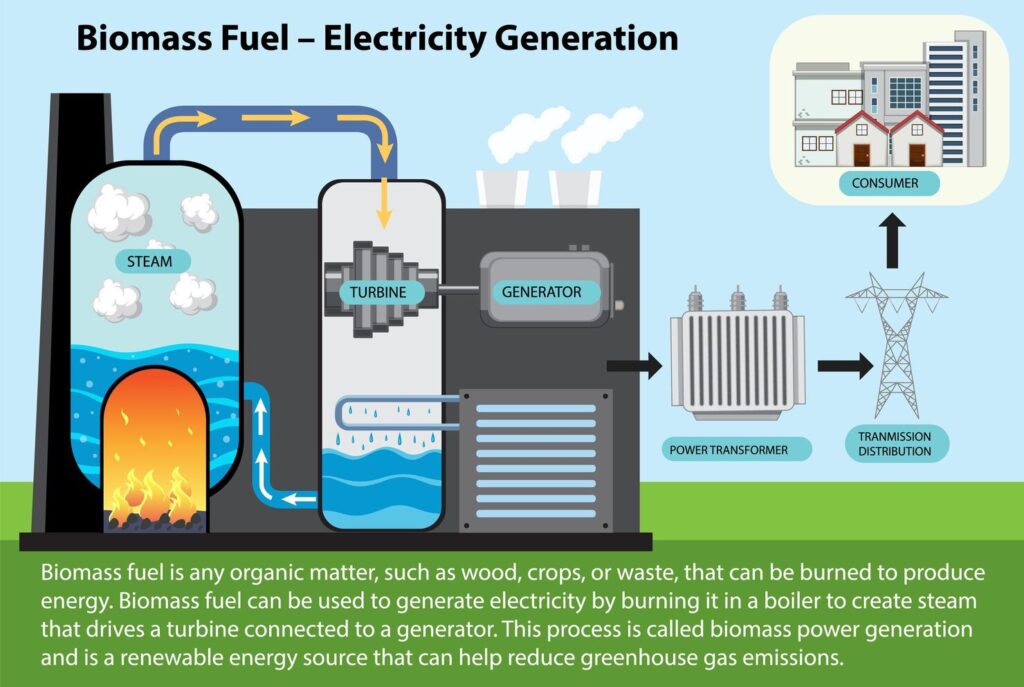

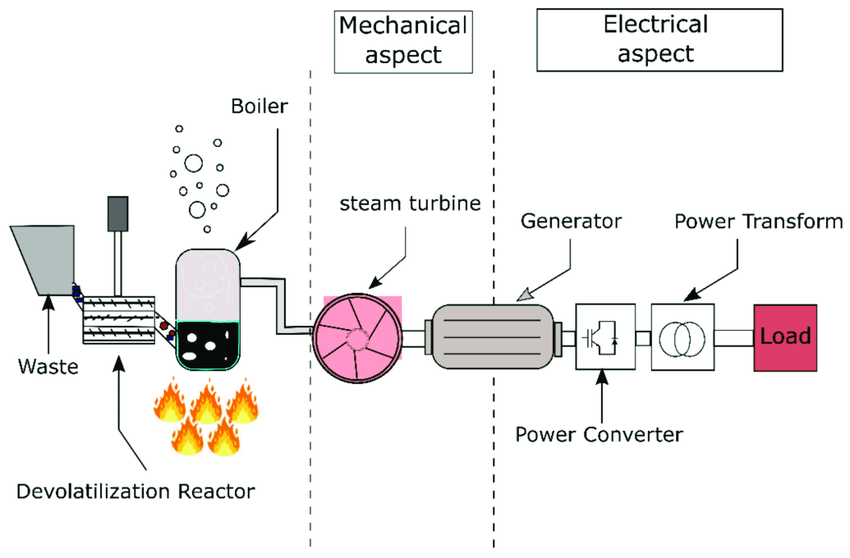

Small Scale Power Plant for Gas Production Facilities: Power plants utilizing steam turbines play a crucial role in global electricity generation. These plants operate on the principle of thermodynamic cycles, primarily the Rankine cycle, where water is heated to produce steam that drives a turbine connected to a generator. The process begins with a heat source, which can vary depending on the type of power plant. The most common sources include fossil fuels such as coal, natural gas, and oil, as well as nuclear energy, biomass, geothermal heat, and solar thermal energy. Regardless of the heat source, the goal is to convert thermal energy into mechanical energy and ultimately into electrical energy.

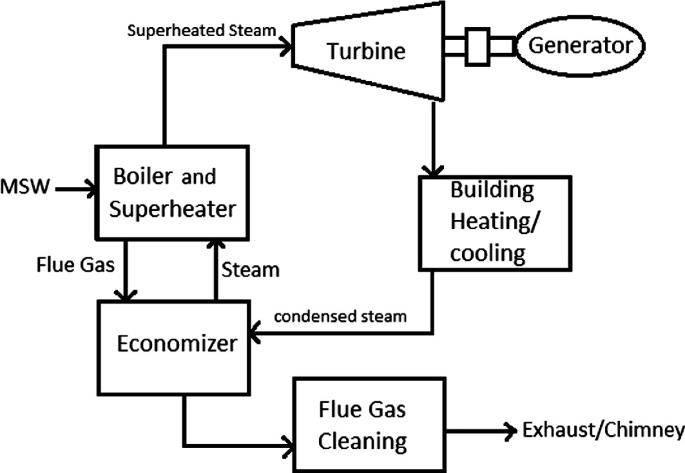

In a typical steam power plant, water is first fed into a boiler or steam generator, where it is heated under high pressure to produce superheated steam. This steam is then directed through a series of high-pressure turbines, where it expands and causes the turbine blades to rotate. The rotational energy is transferred to a generator via a shaft, converting mechanical energy into electrical power. After passing through the high-pressure turbine, the steam moves into intermediate- and low-pressure turbines, further expanding and transferring additional energy before being exhausted into a condenser.

The condenser plays a vital role in maintaining efficiency by cooling and condensing the steam back into liquid form. This condensed water, known as condensate, is then pumped back into the boiler through feedwater heaters that recover residual heat from extracted steam. This regenerative heating process improves overall efficiency by reducing the amount of fuel needed to reheat the water to its boiling point. The cycle continues, maintaining a continuous and efficient process of electricity generation.

Different types of steam power plants exist based on fuel source and operational characteristics. Fossil fuel power plants, including coal-fired and gas-fired plants, rely on burning hydrocarbons to generate heat. Coal-fired plants, though historically dominant, are facing increasing scrutiny due to environmental concerns related to carbon emissions and air pollution. Advanced technologies, such as supercritical and ultra-supercritical steam cycles, have been developed to enhance efficiency and reduce emissions. Natural gas power plants, particularly those using combined cycle technology, integrate steam turbines with gas turbines to maximize energy extraction, significantly increasing efficiency.

Nuclear power plants operate similarly but use nuclear fission to generate heat. In a pressurized water reactor (PWR), the reactor heats water in a primary loop, which then transfers heat to a secondary loop that generates steam to drive the turbine. Boiling water reactors (BWRs) produce steam directly within the reactor vessel. Nuclear plants provide a stable and continuous power supply, making them a key source of baseload electricity. However, they require strict safety measures and long-term solutions for radioactive waste disposal.

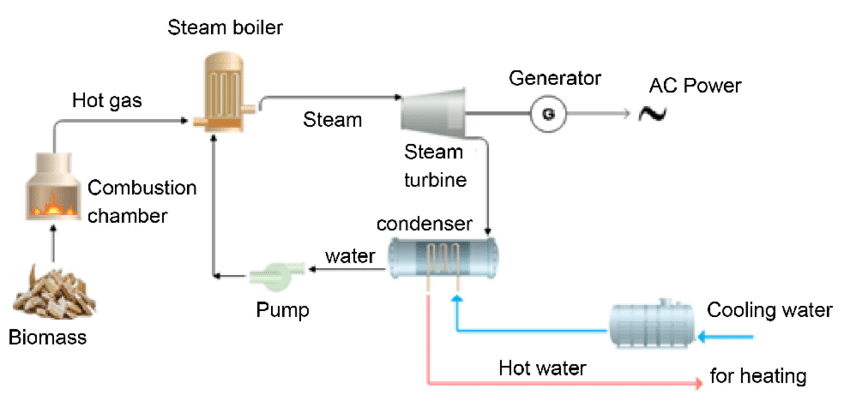

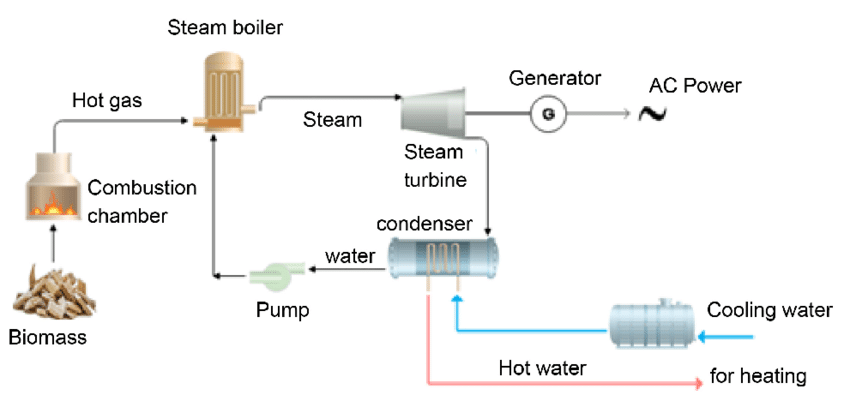

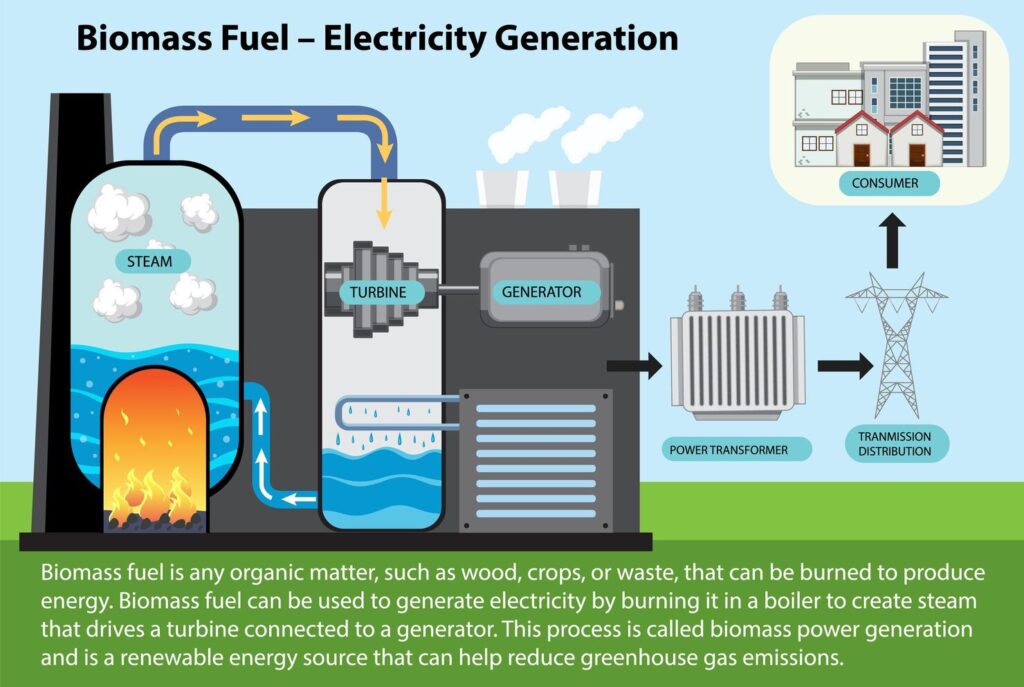

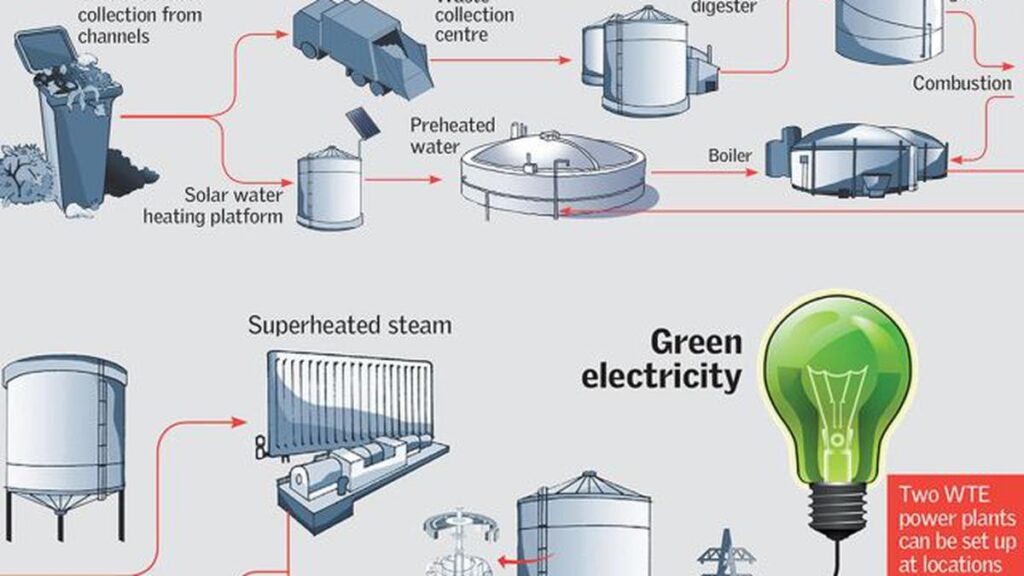

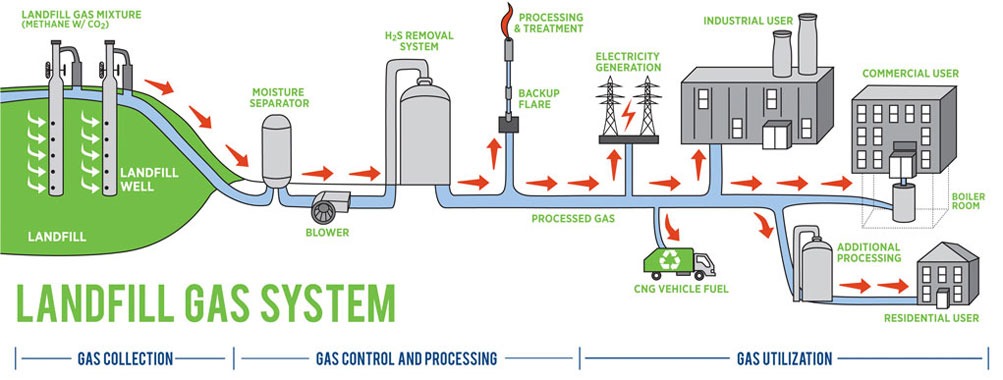

Renewable energy sources such as biomass, geothermal, and solar thermal also employ steam turbines. Biomass plants burn organic materials like wood, agricultural waste, or municipal solid waste to generate steam. Geothermal power plants utilize heat from beneath the Earth’s surface, extracting steam or hot water from underground reservoirs. Flash steam, dry steam, and binary cycle geothermal plants use different methods to harness this heat efficiently. Solar thermal power plants, such as concentrated solar power (CSP) systems, use mirrors to focus sunlight onto a receiver that heats a working fluid, producing steam to drive a turbine.

Efficiency improvements in steam power plants focus on advanced turbine designs, higher steam temperatures and pressures, and integrated heat recovery systems. Technologies such as cogeneration, also known as combined heat and power (CHP), increase efficiency by utilizing waste heat for industrial processes or district heating. Additionally, carbon capture and storage (CCS) is being explored to mitigate emissions from fossil fuel-based plants.

Steam turbine power plants continue to be a backbone of global electricity production due to their reliability and scalability. However, the transition towards cleaner and more sustainable energy sources is shaping the future of steam power technology. Research and development efforts are aimed at improving efficiency, reducing emissions, and integrating renewable energy with conventional steam turbine systems. The continued evolution of steam power plants will play a crucial role in balancing energy demand, environmental responsibility, and economic viability.

Small Scale Power Plant

Further advancements in steam power plant technology have been driven by the need for higher efficiency, reduced environmental impact, and increased reliability. One of the most significant developments has been the transition from subcritical steam cycles to supercritical and ultra-supercritical cycles. In subcritical plants, steam is generated at pressures below the critical point of water, meaning a distinct phase change from water to steam occurs in the boiler. However, supercritical plants operate at pressures above the critical point, eliminating the phase transition and allowing for more efficient thermal energy conversion. Ultra-supercritical plants push these limits further, achieving even higher steam temperatures and pressures, which significantly improve efficiency and reduce fuel consumption.

In addition to improvements in steam parameters, turbine technology itself has evolved. Modern turbines are designed with advanced aerodynamics, optimized blade profiles, and high-strength materials capable of withstanding extreme temperatures and pressures. Many large-scale power plants use multi-stage turbines, where high-pressure, intermediate-pressure, and low-pressure stages work together to extract the maximum amount of energy from the steam. Efficiency enhancements also come from reducing steam leakage, improving blade cooling techniques, and using coatings that prevent corrosion and wear.

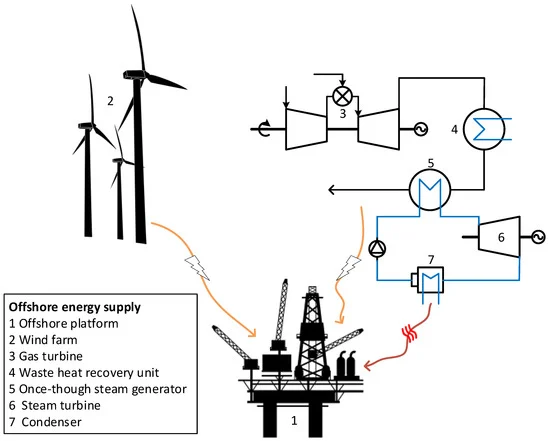

Heat recovery is another crucial aspect of efficiency improvement in steam power plants. The use of regenerative feedwater heating allows for better utilization of extracted steam, reducing the amount of additional heat energy required in the boiler. Condenser efficiency is also vital, as the faster and more effectively steam is condensed back into water, the better the vacuum conditions in the turbine, which enhances power output. In combined cycle power plants, waste heat from a gas turbine is used to generate additional steam for a steam turbine, dramatically improving overall efficiency.

The environmental impact of steam power plants is a major concern, particularly for fossil fuel-based systems. Carbon dioxide (CO₂) emissions from coal and natural gas plants contribute to climate change, leading to increased focus on carbon capture and storage (CCS) technologies. These systems aim to capture CO₂ before it is released into the atmosphere and store it underground or utilize it in industrial applications. Other emission control technologies include flue gas desulfurization (FGD) for removing sulfur dioxide (SO₂), selective catalytic reduction (SCR) for nitrogen oxides (NOx), and particulate matter filters to reduce air pollution.

Water usage is another important factor in steam power plants. Traditional once-through cooling systems withdraw large amounts of water from natural sources, raising concerns about thermal pollution and water scarcity. As a result, many plants now use closed-loop cooling systems with cooling towers or air-cooled condensers to minimize water consumption. In regions with limited water resources, dry cooling technology is being adopted, though it can result in slightly lower plant efficiency due to higher condenser temperatures.

The role of digitalization and automation in modern steam power plants is growing, with advanced monitoring and control systems enhancing performance and reliability. Predictive maintenance using artificial intelligence (AI) and machine learning algorithms helps detect potential failures before they occur, reducing downtime and maintenance costs. Sensors and data analytics provide real-time insights into turbine performance, boiler efficiency, and emissions control, allowing for continuous optimization.

In addition to large centralized power plants, smaller-scale steam turbine systems are being used for industrial applications and distributed energy generation. Combined heat and power (CHP) plants, often found in industrial facilities, universities, and district heating systems, provide both electricity and useful heat, significantly increasing overall energy utilization. Some biomass and waste-to-energy plants use steam turbines to generate power while simultaneously addressing waste disposal and reducing landfill use.

The integration of renewable energy with steam turbine technology is another emerging trend. Hybrid systems that combine solar thermal energy with traditional steam power plants can improve efficiency and reduce fuel consumption. Some geothermal power plants utilize steam turbines to harness Earth’s natural heat, providing a renewable and stable source of electricity. In the long term, advancements in hydrogen combustion and zero-carbon fuels could allow steam power plants to operate sustainably while maintaining their reliability and large-scale energy production capabilities.

As global energy demand continues to grow, steam power plants will remain a key component of the energy mix. While renewable energy sources such as wind and solar are expanding rapidly, steam turbine plants provide a crucial source of baseload and dispatchable power. Future developments will likely focus on improving efficiency, reducing emissions, and integrating cleaner energy sources to ensure that steam power generation remains both viable and sustainable in a rapidly changing energy landscape.

Further improvements in steam turbine technology are focusing on efficiency gains through material advancements, operational optimizations, and alternative fuel sources. One of the key challenges in steam power plants is the thermal efficiency limitation imposed by the Carnot cycle. Since efficiency is directly related to the temperature difference between the heat source and the heat sink, researchers are exploring ways to increase maximum operating temperatures while maintaining the structural integrity of turbine components.

Advanced materials, such as nickel-based superalloys and ceramic matrix composites, are being developed to withstand extreme temperatures and pressures, allowing turbines to operate at higher efficiencies. These materials offer better resistance to thermal stress, oxidation, and corrosion, reducing maintenance needs and extending component lifespan. Additionally, advancements in coatings, such as thermal barrier coatings (TBCs), are helping to protect turbine blades from high-temperature degradation, further improving operational longevity.

Operational optimizations are also playing a crucial role in enhancing steam turbine performance. Digital twin technology, where a virtual model of a steam power plant is continuously updated with real-time data, is being used to optimize performance and predict potential failures. This approach allows operators to test different scenarios in a simulated environment, leading to better decision-making and efficiency improvements. Artificial intelligence (AI) and machine learning are being integrated into plant management systems to analyze vast amounts of operational data and identify opportunities for optimization.

One promising area of research is the development of closed-loop supercritical carbon dioxide (sCO₂) cycles as an alternative to traditional steam-based Rankine cycles. sCO₂ operates at higher efficiencies due to its superior thermodynamic properties, allowing for compact turbine designs and reduced heat losses. These systems have the potential to significantly improve efficiency while reducing water consumption, making them particularly attractive for arid regions where water availability is limited.

Another critical area of innovation is the transition toward alternative fuels in steam power plants. While coal remains a dominant fuel source in some regions, there is a growing push toward cleaner alternatives such as biomass, hydrogen, and ammonia. Biomass co-firing, where biomass is blended with coal, reduces net CO₂ emissions while utilizing existing infrastructure. Hydrogen, when produced using renewable energy sources, presents a zero-carbon alternative for steam generation, though challenges remain in terms of production costs and storage. Ammonia, which can be used as a hydrogen carrier, is also being explored as a potential fuel for steam power plants due to its high energy density and ease of transportation.

Nuclear steam power is another area of ongoing innovation. Small modular reactors (SMRs) are being developed as a more flexible and scalable alternative to traditional large nuclear power plants. These reactors use steam turbines for power generation but feature enhanced safety mechanisms, simplified designs, and reduced construction times. SMRs are expected to play a significant role in the future energy landscape, providing reliable, low-carbon electricity with improved adaptability to grid demands.

Hybrid power systems that integrate steam turbines with renewable energy sources are also being explored to enhance grid stability and reduce reliance on fossil fuels. Solar thermal plants with molten salt storage can generate steam for turbines even when sunlight is unavailable, providing a continuous power supply. Geothermal power plants utilizing steam turbines can serve as a baseload energy source, complementing intermittent renewables like wind and solar.

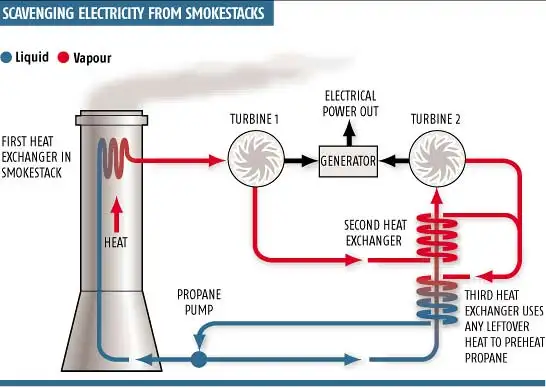

Waste heat recovery systems are further improving the efficiency of industrial processes and power generation. By capturing excess heat from industrial operations or power plants and using it to generate steam, these systems maximize energy utilization and reduce environmental impact. Combined cycle plants, which pair gas turbines with steam turbines, are an example of how waste heat can be effectively repurposed to increase overall efficiency.

As the global energy transition continues, steam turbine power plants will need to adapt to new regulatory requirements, carbon reduction targets, and evolving market demands. The future of steam power lies in greater efficiency, integration with cleaner energy sources, and the adoption of advanced digital technologies. With ongoing research and development, steam turbines will continue to be a vital part of the world’s energy infrastructure, balancing the need for reliability, sustainability, and economic feasibility.

The future of steam power plants is increasingly shaped by the need for sustainability, flexibility, and technological advancements. As global energy systems evolve, steam turbine technology must adapt to integrate with renewable energy, reduce emissions, and enhance efficiency through innovative engineering solutions. The role of steam turbines in power generation is being redefined, particularly as the world shifts toward decarbonization and grid modernization.

One of the most significant trends is the integration of steam turbines with renewable energy sources to create hybrid power systems. Solar thermal power plants, also known as concentrated solar power (CSP) plants, use mirrors to focus sunlight onto a receiver, which heats a working fluid to generate steam. Unlike photovoltaic solar panels that directly convert sunlight into electricity, CSP plants utilize steam turbines to produce power in a manner similar to conventional fossil-fuel plants. The advantage of CSP technology is its ability to incorporate thermal energy storage, such as molten salt systems, which allow for electricity generation even after sunset. This helps address the intermittency issues associated with solar energy and provides a stable, dispatchable power source.

Another promising area of development is geothermal power generation. Geothermal plants rely on heat from the Earth’s core to produce steam, which drives turbines to generate electricity. Unlike fossil fuel-based plants, geothermal energy is a renewable and consistent source of power with minimal carbon emissions. Enhanced geothermal systems (EGS) are being developed to expand the reach of geothermal energy by artificially creating reservoirs in deep rock formations, significantly increasing the potential for steam-based renewable electricity.

The role of steam turbines is also being explored in the hydrogen economy. Hydrogen combustion in steam power plants could provide a zero-emission alternative to natural gas and coal. Hydrogen-fueled boilers and combined-cycle plants are being tested as a means of decarbonizing traditional steam-based power generation. However, large-scale adoption will depend on advancements in hydrogen production, storage, and transportation infrastructure. Ammonia, as a hydrogen carrier, is being investigated as an alternative fuel for steam power plants, offering a potentially viable pathway for carbon-free electricity generation.

In parallel with fuel source diversification, advancements in turbine efficiency and design are pushing the limits of what steam power plants can achieve. Supercritical and ultra-supercritical steam cycles have already improved efficiency by increasing steam temperature and pressure, but new research is focusing on advanced cycles such as supercritical carbon dioxide (sCO₂) power cycles. Unlike traditional steam turbines, sCO₂ turbines operate at higher densities and require smaller components, allowing for more compact and efficient power plant designs. These systems have the potential to revolutionize steam-based power generation by reducing material costs, enhancing thermal efficiency, and minimizing water consumption.

The digital transformation of power plants is another key factor in the evolution of steam turbine technology. Modern plants are increasingly adopting advanced monitoring systems, artificial intelligence (AI), and automation to optimize performance, reduce downtime, and improve predictive maintenance. Digital twins—real-time virtual replicas of physical steam turbines—are being used to simulate operations, predict failures, and test optimization strategies before implementing them in actual power plants. This technology enhances reliability, reduces maintenance costs, and extends the lifespan of critical components.

The role of steam power plants in industrial applications is also expanding beyond traditional electricity generation. Industrial steam turbines are widely used in cogeneration (combined heat and power, or CHP) systems, which provide both electricity and process heat for manufacturing, chemical production, and district heating. These systems significantly increase overall energy efficiency by utilizing waste heat that would otherwise be lost in conventional power plants. Many industries, including pulp and paper, food processing, and petrochemicals, rely on steam turbines to meet their energy demands efficiently.

Despite these advancements, the transition toward a low-carbon future presents challenges for existing steam power plants, particularly those dependent on fossil fuels. Governments and regulatory bodies worldwide are implementing stricter emissions standards, prompting the need for carbon capture and storage (CCS) technologies. CCS systems capture CO₂ emissions from power plants and store them underground or use them for industrial applications, such as enhanced oil recovery or synthetic fuel production. While CCS offers a potential solution for reducing the carbon footprint of steam power plants, high costs and energy penalties associated with the process remain significant hurdles.

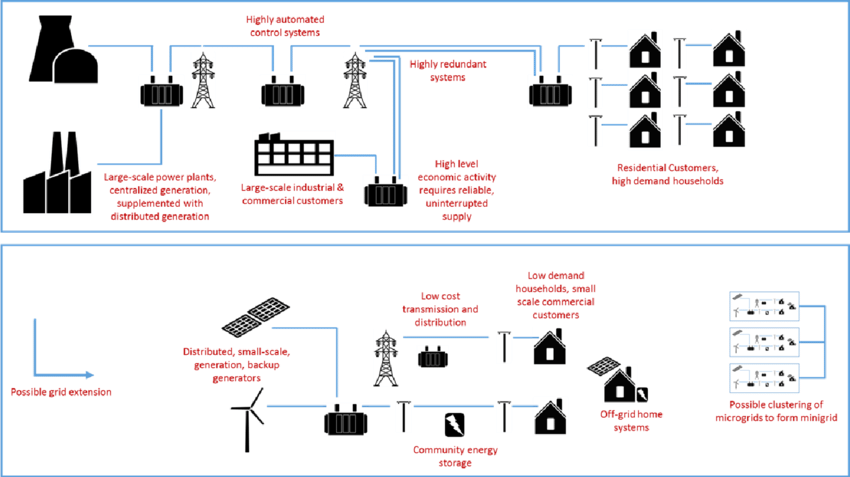

Additionally, the global shift toward decentralized and distributed energy generation is changing the way steam turbines fit into the energy landscape. Traditionally, large central power stations with steam turbines supplied electricity to vast regions, but modern energy grids are moving toward a mix of smaller, localized generation sources. This trend is driven by the expansion of renewable energy, microgrids, and energy storage technologies. To remain competitive, steam power plants must adapt to provide flexible and responsive generation, potentially operating in hybrid configurations with renewables and battery storage.

Ultimately, the future of steam power generation will be defined by a balance between innovation, environmental responsibility, and economic feasibility. While the share of fossil fuel-based steam power is expected to decline, steam turbine technology will continue to play a critical role in providing reliable baseload power, supporting industrial processes, and integrating with new energy systems. Whether through advanced steam cycles, alternative fuels, digital optimization, or hybrid renewable systems, steam turbines are set to remain a cornerstone of global energy infrastructure in the coming decades.

Small-scale power plants for biodiesel production plants play a crucial role in ensuring energy self-sufficiency and sustainability. These power plants are designed to meet the energy demands of biodiesel production facilities, which require electricity and heat for various processes such as oil extraction, transesterification, and refining. By integrating small-scale power plants with biodiesel production, manufacturers can reduce operational costs, minimize reliance on external energy sources, and enhance the overall efficiency of their production systems.

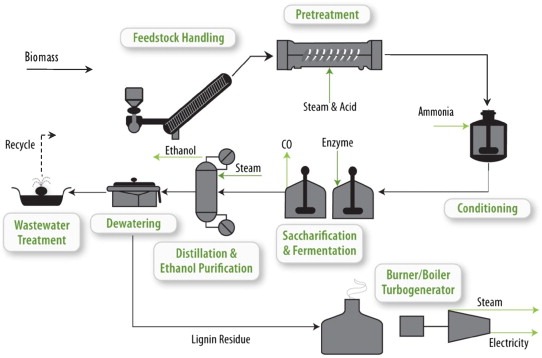

Small-scale power plants used in biodiesel facilities typically utilize renewable energy sources such as biomass, biogas, and biodiesel itself as fuels. Biomass gasification systems can convert agricultural residues, wood chips, or other organic waste into syngas, which can then be used to generate electricity. Biogas, produced through anaerobic digestion of organic waste, can be used in gas engines or microturbines to produce both heat and power. Additionally, biodiesel-powered generators provide a direct application of the fuel being produced, creating a closed-loop energy system that enhances sustainability.

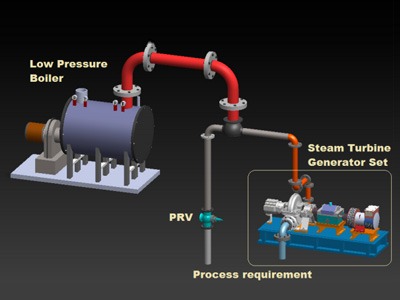

The selection of power generation technology for a small-scale biodiesel plant depends on factors such as feedstock availability, energy demand, and economic feasibility. Internal combustion engines, steam turbines, and microturbines are commonly employed for power generation. Internal combustion engines, especially diesel engines modified to run on biodiesel, offer a flexible and cost-effective solution. Steam turbines, when integrated with biomass boilers, provide a continuous and efficient power supply, particularly for larger small-scale operations. Microturbines, though relatively expensive, offer high efficiency and low emissions, making them a suitable option for facilities prioritizing environmental performance.

The integration of cogeneration, or combined heat and power (CHP) systems, in small-scale biodiesel plants enhances overall energy efficiency. CHP systems utilize waste heat from power generation for heating processes such as transesterification, distillation, and drying. This significantly reduces energy waste and improves the economic viability of the biodiesel plant. The use of CHP also contributes to lower greenhouse gas emissions by maximizing fuel utilization and reducing the need for fossil fuel-based energy sources.

Economic considerations play a significant role in the deployment of small-scale power plants for biodiesel production. Capital investment, fuel costs, maintenance, and operational efficiency must be carefully assessed to ensure financial viability. Government incentives, feed-in tariffs, and renewable energy policies can influence the feasibility of implementing these systems. In regions where electricity costs are high or grid reliability is poor, small-scale power plants offer a compelling solution for energy security and cost savings.

Environmental benefits are another critical aspect of integrating small-scale power plants with biodiesel production. By utilizing renewable fuels and reducing dependence on fossil fuels, these systems contribute to lower carbon emissions and improved sustainability. The use of locally available biomass or waste-derived biogas reduces transportation-related emissions and promotes circular economy principles by valorizing waste materials.

Advancements in power generation technology, automation, and energy management systems further enhance the performance of small-scale power plants for biodiesel facilities. Smart grid integration, real-time monitoring, and predictive maintenance technologies improve reliability and efficiency. The adoption of modular and scalable designs allows biodiesel producers to expand their power generation capacity as their production scales up.

Overall, small-scale power plants serve as a key enabler of sustainable and cost-effective biodiesel production. By leveraging renewable energy sources, employing efficient power generation technologies, and integrating CHP systems, biodiesel plants can achieve energy independence and environmental benefits. The continued development and adoption of innovative energy solutions will further strengthen the role of small-scale power plants in the transition to a cleaner and more resilient energy future.

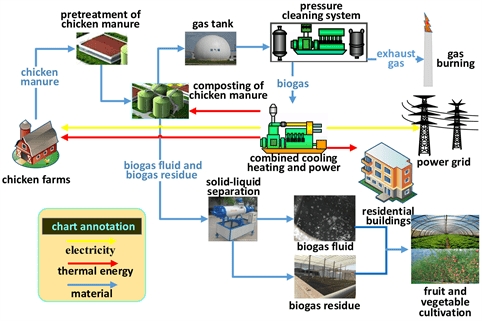

Small-scale power plants for biogas plants are another crucial component of sustainable energy production. Biogas plants generate energy from organic waste materials through anaerobic digestion, producing methane-rich biogas that can be utilized for power generation. These small-scale power plants help maximize the efficiency of biogas utilization while providing reliable electricity and heat for industrial, agricultural, and residential applications.

Biogas-fueled power plants typically employ gas engines, microturbines, or fuel cells to convert biogas into usable energy. Internal combustion engines are the most commonly used technology, offering a proven and cost-effective method for biogas power generation. Microturbines provide a compact and efficient alternative, especially in locations where space is limited. Fuel cells, although still in development for widespread use, offer high efficiency and minimal emissions, making them an attractive option for future applications.

The integration of CHP systems in small-scale biogas power plants further enhances energy efficiency by capturing and utilizing waste heat. This makes biogas plants more self-sufficient and economically viable, as they can generate power for internal operations while also supplying excess electricity to local grids or nearby consumers. The use of biogas for power generation significantly reduces reliance on fossil fuels and contributes to carbon neutrality by utilizing waste-derived methane that would otherwise be released into the atmosphere.

Economic and environmental benefits drive the adoption of small-scale power plants in biogas facilities. The ability to generate power on-site lowers energy costs, while the use of organic waste feedstocks reduces landfill disposal and greenhouse gas emissions. Government incentives, carbon credit programs, and renewable energy subsidies further support the deployment of biogas-based power plants, making them an attractive investment for businesses and communities seeking sustainable energy solutions.

Advancements in biogas upgrading and purification technologies continue to improve the efficiency and scalability of small-scale biogas power plants. Technologies such as membrane separation, water scrubbing, and pressure swing adsorption enhance biogas quality by removing impurities, allowing for cleaner and more efficient combustion in power generation systems. As energy storage and smart grid integration evolve, biogas power plants will play an increasingly important role in decentralized and renewable energy networks.

In summary, small-scale power plants for biogas production offer an effective means of utilizing organic waste for sustainable energy generation. By employing efficient conversion technologies, integrating CHP systems, and leveraging supportive policies, biogas facilities can achieve energy independence and contribute to a low-carbon economy. As advancements in biogas technology and energy management continue, small-scale biogas power plants will become an essential part of the global transition toward renewable energy solutions.

Small-scale power plants for geothermal plants offer a promising solution for harnessing geothermal energy in locations with moderate heat resources. These plants utilize geothermal heat to generate electricity on a smaller scale, making them suitable for decentralized energy production, remote communities, and industrial applications. Unlike large geothermal power plants that require extensive infrastructure, small-scale geothermal power plants can be deployed with relatively lower investment costs while still providing a sustainable and continuous energy source.

Geothermal power generation technologies for small-scale applications include binary cycle power plants, organic Rankine cycle (ORC) systems, and Kalina cycle systems. Binary cycle power plants use low-temperature geothermal fluids to heat a secondary working fluid with a lower boiling point, such as isobutane or pentane, which then drives a turbine to generate electricity. ORC systems are a widely used variation of this technology, offering high efficiency and compatibility with low-to-moderate temperature geothermal resources. Kalina cycle systems, which use a mixture of water and ammonia as the working fluid, provide further efficiency gains by optimizing heat exchange processes.

The integration of small-scale geothermal power plants with district heating, greenhouse agriculture, and industrial processes enhances overall energy utilization and economic viability. These plants can provide both electricity and thermal energy, reducing dependency on fossil fuels and supporting local industries. Government incentives, feed-in tariffs, and advances in drilling and exploration technologies continue to drive the adoption of small-scale geothermal power plants, making them a viable and sustainable solution for clean energy generation in various regions worldwide.

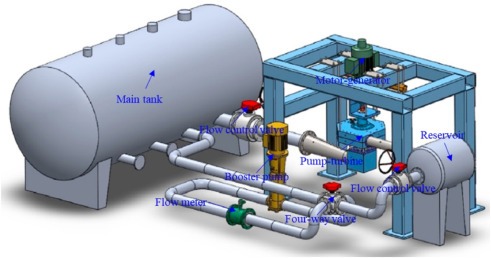

Another crucial factor in the design and operation of small-scale power plants for biodiesel production is energy storage and distribution. Since biodiesel plants may experience fluctuating energy demands depending on production cycles, incorporating an energy storage system can help balance supply and demand. Battery storage, flywheels, or thermal storage can be used to store excess energy generated during low-demand periods and release it when production requires additional power. This approach enhances reliability, reduces energy waste, and ensures a consistent power supply even during maintenance or unexpected power fluctuations.

Grid integration is another consideration for small-scale power plants. Some biodiesel facilities may be connected to the local electrical grid, allowing them to sell excess electricity back to the grid under feed-in tariff programs or net metering schemes. This can provide an additional revenue stream while also contributing to local renewable energy supplies. However, grid integration requires compliance with regulations and standards, including voltage stability, synchronization, and safety protocols. In cases where grid connectivity is unreliable or unavailable, off-grid power solutions using biodiesel-fueled generators, solar hybrid systems, or microgrids can ensure uninterrupted plant operation.

Automation and digital monitoring play an increasingly important role in optimizing power plant efficiency. Modern small-scale power plants benefit from smart control systems that monitor energy consumption, adjust power output based on real-time demand, and optimize fuel usage. Internet of Things (IoT) technology and cloud-based analytics enable remote monitoring, predictive maintenance, and fault detection, reducing downtime and improving overall performance. Automated control systems can also integrate multiple power sources, such as biodiesel generators, solar PV, and biomass gasifiers, to ensure seamless operation with minimal human intervention.

Sustainability and circular economy principles further enhance the value of integrating power plants with biodiesel production. Beyond using biodiesel as a fuel source, facilities can explore additional waste-to-energy opportunities, such as utilizing spent biomass residues, waste oils, or glycerol byproducts for heat and power generation. The use of modular and scalable power plant designs allows facilities to expand capacity as production increases without significant infrastructure changes. Moreover, adopting life-cycle assessment (LCA) methodologies helps biodiesel producers evaluate the environmental footprint of their energy systems and identify areas for improvement.

Research and innovation continue to drive advancements in small-scale power generation for biodiesel plants. Emerging technologies such as hydrogen fuel cells, advanced biofuels, and hybrid renewable energy systems hold promise for further improving efficiency and reducing emissions. Policymakers and industry stakeholders are also exploring financing mechanisms, such as green bonds and carbon credits, to support the development of decentralized renewable energy solutions tailored for small biodiesel producers.

Ultimately, the integration of small-scale power plants with biodiesel production represents a strategic move toward energy independence, cost reduction, and environmental responsibility. By leveraging renewable energy sources, optimizing energy use, and embracing technological innovations, biodiesel facilities can achieve long-term sustainability while contributing to the broader transition toward a cleaner energy future.

Another important aspect of small-scale power plants for biodiesel production is the role of hybrid energy systems in enhancing efficiency and resilience. While biodiesel generators serve as a reliable energy source, integrating renewable energy technologies such as solar photovoltaics (PV), wind turbines, and biomass gasifiers can create a more sustainable and cost-effective energy mix. Hybrid systems reduce reliance on a single energy source, optimizing fuel consumption and lowering operational costs. For instance, solar panels can provide electricity during the daytime, reducing the load on biodiesel-powered generators and extending their lifespan by minimizing wear and tear. Similarly, wind turbines can contribute power when wind conditions are favorable, ensuring continuous energy generation without excessive fuel usage.

Microgrid technology further supports the development of resilient energy systems for biodiesel plants. A microgrid is a localized power network that can operate independently or in conjunction with the main electrical grid. It enables biodiesel producers to manage their energy production, storage, and distribution efficiently. In remote areas or regions with unreliable grid access, microgrids offer a decentralized solution, ensuring continuous operations without interruptions caused by external power failures. Advanced microgrid controllers can balance multiple energy sources, prioritize renewable inputs, and optimize power flow to critical plant processes.

The economic feasibility of small-scale power plants for biodiesel production is heavily influenced by fuel supply chain logistics. The cost and availability of feedstocks, transportation infrastructure, and local energy market conditions all impact the viability of an on-site power generation system. In regions where biodiesel feedstocks are abundant and affordable, on-site power generation using biodiesel-fueled generators can be a cost-effective solution. However, in areas where biodiesel production costs are high, hybrid energy systems that incorporate solar or wind power can help offset expenses and improve overall financial sustainability.

Additionally, the policy landscape plays a vital role in supporting or hindering the adoption of small-scale power plants in biodiesel production. Governments and regulatory bodies often provide incentives, tax benefits, and grants for renewable energy projects, making investment in on-site power generation more attractive. Policies promoting decentralized energy production, such as net metering, power purchase agreements (PPAs), and feed-in tariffs, can further enhance the financial viability of biodiesel plant power systems. Compliance with environmental regulations, emissions standards, and safety requirements must also be factored into the planning and implementation of power plants.

Technological advancements in energy storage solutions continue to improve the efficiency and reliability of small-scale power plants. Battery storage systems allow biodiesel plants to store excess electricity generated during periods of low demand and deploy it when energy needs peak. Lithium-ion batteries, flow batteries, and emerging solid-state battery technologies provide flexible storage options that can complement hybrid power systems. Thermal energy storage, where excess heat from power generation is stored and later used for biodiesel processing, offers another avenue for maximizing energy utilization.

Community-scale biodiesel projects can also benefit from shared power generation infrastructure. In rural or cooperative farming communities where multiple small biodiesel producers operate, a centralized small-scale power plant can supply energy to multiple facilities. This approach enhances economies of scale, reduces investment costs per facility, and fosters energy-sharing models that strengthen local resilience. Shared power systems can also integrate additional renewable energy sources, such as small hydro or geothermal, depending on the local resource availability.

Looking to the future, ongoing research in bioenergy and small-scale power generation is expected to yield even more efficient and sustainable solutions. Innovations in biodiesel refining processes, enzyme-based catalysts, and waste-to-energy conversion technologies will contribute to more integrated and self-sufficient production systems. Digitalization and artificial intelligence (AI) will further optimize power plant performance, predicting energy demand patterns, automating system maintenance, and enhancing decision-making for biodiesel producers.

In conclusion, small-scale power plants are a vital component of sustainable biodiesel production, offering energy security, cost savings, and environmental benefits. By leveraging hybrid energy systems, microgrids, advanced storage solutions, and smart technologies, biodiesel facilities can enhance efficiency and resilience. As renewable energy adoption continues to grow, small biodiesel producers will increasingly benefit from innovations that improve sustainability, reduce operational costs, and contribute to a cleaner, decentralized energy future.

Another significant factor in the development of small-scale power plants for biodiesel production is the role of decentralized energy networks in supporting local economies and enhancing energy security. Decentralized energy systems allow biodiesel producers to generate power independently, reducing reliance on national grids, which can be unreliable or expensive in some regions. This is particularly beneficial for rural and remote areas where access to consistent electricity is limited. By producing their own energy, biodiesel facilities not only achieve operational stability but also contribute to local energy resilience, enabling nearby businesses and households to benefit from surplus power through community microgrids or local distribution networks.

One of the key advantages of integrating small-scale power plants with biodiesel production is the potential for energy cost savings. Electricity prices fluctuate based on demand, fuel supply, and geopolitical factors, making energy expenditures a major concern for industrial operations. On-site power generation using biodiesel, biomass, or hybrid renewable systems provides cost predictability, shielding producers from market volatility. Additionally, government incentives, such as tax credits for renewable energy projects, carbon trading schemes, and subsidies for decentralized energy production, further enhance the economic viability of biodiesel-powered generation systems.

From an environmental perspective, the integration of energy-efficient technologies into small-scale power plants significantly reduces emissions and waste. Carbon capture and utilization (CCU) technologies are being explored to capture CO₂ from biodiesel combustion processes, converting it into useful byproducts such as biochar or synthetic fuels. Additionally, the implementation of low-emission combustion systems, exhaust treatment mechanisms, and energy recovery processes helps biodiesel plants meet stringent environmental regulations while minimizing their carbon footprint.

Advanced automation and smart grid technologies are also transforming the efficiency and effectiveness of small-scale biodiesel power plants. Artificial intelligence (AI) and machine learning (ML) algorithms can analyze energy consumption patterns, optimize fuel use, and predict maintenance needs, reducing downtime and operational costs. Smart meters and digital monitoring platforms provide real-time data on energy production, allowing biodiesel producers to make informed decisions on load management, storage, and distribution. Furthermore, blockchain technology is emerging as a potential tool for enabling transparent energy transactions, allowing biodiesel plants to participate in peer-to-peer energy trading networks.

The global push for energy diversification and climate change mitigation is driving innovations in next-generation biofuels and power generation methods. Research in algal biodiesel, waste-derived biofuels, and synthetic fuel production is expanding the range of viable feedstocks for small-scale biodiesel plants. When coupled with next-generation power technologies such as hydrogen fuel cells, supercritical CO₂ turbines, and thermoelectric generators, biodiesel production facilities can become even more energy-efficient and environmentally friendly.

Collaboration between policymakers, industry stakeholders, and research institutions is essential to further advance small-scale biodiesel power plants. Supportive regulatory frameworks, investment in research and development, and knowledge-sharing initiatives will accelerate the adoption of cleaner and more efficient energy systems. International partnerships and technology transfer programs can help developing countries implement sustainable energy solutions tailored to their unique challenges and resources.

In summary, small-scale power plants are crucial enablers of sustainable and cost-effective biodiesel production. By leveraging decentralized energy systems, hybrid renewable technologies, and advanced automation, biodiesel facilities can enhance energy security, improve economic resilience, and minimize environmental impact. Continued innovation in bioenergy and power generation will further strengthen the role of biodiesel plants in the global transition toward cleaner, more sustainable energy solutions.

Small Scale Power Plant for Biogas Plants

Another critical aspect of small-scale power plants for biogas production is the optimization of biogas utilization to maximize energy output and system efficiency. Since biogas primarily consists of methane and carbon dioxide, upgrading its quality through purification processes enhances its usability in power generation. Technologies such as pressure swing adsorption (PSA), water scrubbing, and membrane separation help remove impurities, ensuring a higher methane concentration for combustion. This results in improved engine performance, reduced emissions, and greater overall efficiency in electricity and heat production.

The integration of energy storage solutions with small-scale biogas power plants further enhances operational stability. Since biogas production can fluctuate due to variations in feedstock availability and digestion rates, incorporating battery storage or thermal energy storage systems allows for better management of energy supply and demand. Excess electricity generated during peak production periods can be stored and used during periods of lower biogas output, ensuring continuous power availability. This is particularly beneficial for off-grid or remote installations that rely solely on biogas for energy needs.

Hybrid power systems that combine biogas with other renewable energy sources, such as solar or wind, further improve efficiency and resilience. A hybrid system allows for more stable energy production by utilizing solar or wind energy when biogas production is low, thereby reducing dependence on fossil fuel-based backup power. Advanced microgrid solutions, incorporating smart control systems, enable seamless integration of multiple energy sources, optimizing power distribution based on real-time energy demand and resource availability.

Economic feasibility remains a key factor in the successful deployment of small-scale biogas power plants. Capital investment in digester infrastructure, purification systems, and power generation equipment must be balanced with potential cost savings from on-site energy generation and revenue from excess electricity sales. Governments and international organizations often provide financial incentives, subsidies, or low-interest loans to encourage the adoption of biogas technology, making small-scale power plants more accessible to agricultural enterprises, municipalities, and industrial facilities.

Environmental sustainability is a driving force behind the growth of small-scale biogas power plants. By capturing methane emissions from organic waste decomposition, biogas systems prevent a potent greenhouse gas from being released into the atmosphere. The digestate byproduct from anaerobic digestion can also be used as a nutrient-rich organic fertilizer, closing the loop in sustainable waste management. Moreover, by replacing conventional fossil fuels with renewable biogas, these power plants contribute to reducing overall carbon emissions, supporting climate change mitigation efforts.

Technological advancements in automation and digital monitoring further enhance the efficiency of biogas power plants. IoT-based sensors and cloud-based data analytics provide real-time insights into digester performance, gas composition, and power generation metrics. Automated control systems adjust operational parameters dynamically, ensuring optimal energy output while minimizing maintenance requirements. Predictive maintenance algorithms help identify potential issues before they lead to system failures, reducing downtime and operational costs.

Looking ahead, the role of small-scale biogas power plants will continue to expand as demand for decentralized, renewable energy solutions grows. Innovations in gasification, microbial fuel cells, and bioelectrochemical systems are expected to further improve energy conversion efficiency and broaden the applicability of biogas technology. The integration of biogas with green hydrogen production and carbon capture technologies presents new opportunities for advancing sustainable energy systems.

In conclusion, small-scale biogas power plants are an essential component of the transition toward a cleaner and more resilient energy future. By leveraging purification technologies, hybrid energy systems, economic incentives, and digital innovations, biogas facilities can optimize their energy production, reduce environmental impact, and enhance long-term sustainability. As research and development in biogas technology progress, small-scale power plants will play an increasingly vital role in achieving energy independence and reducing carbon emissions on a global scale.

Another key factor in the advancement of small-scale biogas power plants is the diversification of feedstocks used for biogas production. Traditional biogas plants primarily rely on agricultural residues, manure, and food waste; however, emerging technologies are enabling the use of alternative organic materials such as algae, industrial wastewater sludge, and lignocellulosic biomass. Expanding the range of feedstocks not only enhances biogas yield but also improves waste management efficiency, turning previously underutilized resources into valuable energy sources.

Feedstock pre-treatment techniques are also playing an increasingly important role in optimizing biogas production. Methods such as hydrothermal processing, enzymatic hydrolysis, and mechanical disintegration help break down complex organic compounds, increasing the availability of digestible material for microbial activity. This leads to higher methane yields and more efficient energy conversion, making small-scale biogas plants more productive and economically viable.

The role of community-scale biogas power plants is also gaining attention, particularly in rural and agricultural regions where decentralized energy solutions are crucial. Cooperative biogas projects allow multiple farms, food processing facilities, and households to contribute organic waste to a shared digester, collectively generating electricity and heat. This collaborative model helps distribute costs, maximize feedstock availability, and provide a stable energy supply for the participating community. In some cases, excess biogas can be upgraded to biomethane and injected into local gas grids or used as a renewable vehicle fuel.

Another promising development is the use of bioelectrochemical systems, such as microbial fuel cells and microbial electrolysis cells, to enhance biogas production efficiency. These systems leverage the metabolic activities of bacteria to generate additional electrical power or produce hydrogen gas alongside methane. Although still in the research and pilot phase, these technologies have the potential to further improve the energy balance of biogas plants, making them even more efficient and sustainable.

The application of artificial intelligence (AI) and machine learning in small-scale biogas power plants is revolutionizing plant operations. AI-driven models can analyze large datasets on feedstock composition, digestion rates, and environmental conditions to optimize biogas production in real time. These predictive analytics tools help biogas plant operators make data-driven decisions on feedstock blending, retention times, and maintenance schedules, leading to increased efficiency and reduced operational costs.

Grid integration strategies for small-scale biogas power plants are also evolving. Many countries are implementing policies that enable biogas power plants to participate in decentralized energy markets, allowing them to sell excess electricity to the grid or engage in demand response programs. This provides additional revenue streams for biogas plant operators while contributing to overall grid stability. The use of smart inverters and virtual power plant (VPP) technology further enhances the ability of small-scale biogas plants to integrate seamlessly with existing energy infrastructure.

As the transition to renewable energy continues, there is growing interest in coupling small-scale biogas power plants with hydrogen production systems. Excess biogas can be used to generate green hydrogen through steam reforming or electrolysis processes, creating a valuable energy carrier for fuel cells, industrial applications, and transport. This synergy between biogas and hydrogen aligns with global efforts to develop low-carbon energy solutions and establish sustainable fuel supply chains.

In summary, the continued evolution of small-scale biogas power plants is being driven by advancements in feedstock utilization, pre-treatment technologies, AI-based optimization, and grid integration. The expansion of community-scale biogas projects, the development of bioelectrochemical systems, and the emerging role of biogas in hydrogen production all contribute to the increasing importance of biogas as a key component of the renewable energy transition. As innovation progresses, small-scale biogas power plants will become more efficient, economically viable, and environmentally beneficial, playing a crucial role in sustainable energy systems worldwide.

The future of small-scale biogas power plants is closely linked to advancements in energy storage and utilization, as well as the development of circular economy models that maximize resource efficiency. One of the primary challenges of biogas power generation is managing fluctuations in biogas production, which can be influenced by feedstock variability, seasonal changes, and digestion efficiency. To address this, hybrid energy storage systems, including batteries and thermal energy storage, are being integrated into small-scale biogas plants to ensure a steady and reliable energy supply. By storing excess electricity generated during peak biogas production periods, these systems enable continuous power availability, improving plant efficiency and resilience.

Additionally, innovations in power-to-gas (P2G) technology are enhancing the potential of small-scale biogas plants. P2G systems allow surplus renewable electricity—such as excess solar or wind energy—to be used for electrolysis, producing hydrogen that can be combined with biogenic CO₂ from biogas upgrading to generate synthetic methane. This approach not only maximizes the use of biogas plant byproducts but also creates a renewable gas that can be injected into natural gas networks or used as a clean fuel for transportation and industrial applications.

Another emerging trend is the development of modular and scalable biogas power plants that can be easily adapted to different operational scales. Containerized biogas systems, for example, offer a plug-and-play solution for small-scale energy projects, enabling rapid deployment in rural areas, farms, and off-grid communities. These prefabricated units come equipped with digesters, gas engines, and power management systems, allowing for easy installation and scalability based on energy demand.

The role of small-scale biogas power plants in sustainable agriculture is also expanding. Many farms are adopting integrated biogas systems that utilize livestock manure, crop residues, and organic waste to produce energy for irrigation, grain drying, and on-farm processing activities. These systems not only reduce dependency on fossil fuel-based energy but also help manage agricultural waste more effectively, reducing methane emissions and improving soil health through the use of digestate as an organic fertilizer.

Policy and regulatory support play a crucial role in the long-term success of small-scale biogas power plants. Governments around the world are introducing incentives such as feed-in tariffs, carbon credits, and investment grants to encourage the adoption of biogas technology. In some regions, decentralized energy policies are facilitating the development of community-owned biogas projects, enabling local stakeholders to participate in renewable energy production and benefit from shared economic and environmental advantages.

Looking ahead, the digitalization of biogas power plants is expected to further optimize their efficiency and operational performance. Advanced sensor networks, real-time monitoring platforms, and automated control systems are allowing operators to track key performance indicators, detect inefficiencies, and implement corrective measures remotely. Blockchain technology is also being explored for transparent tracking of biogas production, carbon savings, and energy transactions, increasing trust and efficiency in decentralized energy markets.

In conclusion, small-scale biogas power plants are poised to play an increasingly significant role in the global transition to sustainable energy. Through the integration of energy storage solutions, modular designs, digital technologies, and policy-driven incentives, these plants are becoming more efficient, flexible, and accessible. As advancements in power-to-gas technology, hybrid renewable energy systems, and circular economy practices continue to emerge, small-scale biogas power plants will contribute not only to energy security but also to environmental protection and economic development. Their growing importance in rural electrification, sustainable agriculture, and decentralized energy networks underscores their potential as a key component of a resilient, low-carbon energy future.

Small-scale geothermal power plants are often used in locations where there is moderate geothermal activity, or for situations where larger-scale plants are not viable due to space, budget, or infrastructure constraints. These plants can produce electricity using the heat from the Earth, typically from hot water or steam reservoirs. Here’s a breakdown of the key features and considerations for small-scale geothermal power plants:

Types of Small-Scale Geothermal Power Plants:

- Binary Cycle Power Plants:

- These are often used in areas with lower temperature geothermal resources (below 400°F or 200°C). The hot water or steam from the geothermal reservoir is passed through a heat exchanger where it heats a secondary fluid with a lower boiling point (like isobutane or pentane).

- The secondary fluid evaporates and drives a turbine, generating electricity. Afterward, the secondary fluid is condensed and recycled.

- These systems are more compact and can operate at lower temperatures compared to flash or dry steam plants.

- Flash Steam Power Plants:

- Suitable for higher-temperature geothermal resources (above 400°F or 200°C).

- The geothermal fluid is extracted, and its pressure is reduced (flashed), causing part of the fluid to vaporize. The steam is then used to drive a turbine for electricity generation, while the remaining water is reinjected into the ground.

- Flash plants are typically larger, but there are smaller-scale versions with reduced turbine capacities.

- Dry Steam Power Plants:

- These are used when there is a direct source of steam from the geothermal reservoir, which can be sent directly to the turbine without needing to convert water into steam.

- These systems are less common for small-scale applications due to the specific and high-quality geothermal resources needed.

Key Advantages of Small-Scale Geothermal Power Plants:

- Sustainability:

- Geothermal energy is a renewable resource, and small-scale plants help reduce dependence on fossil fuels. They provide a clean energy solution with minimal carbon emissions.

- Reduced Environmental Impact:

- The environmental footprint of small geothermal plants is relatively low compared to larger facilities or other forms of power generation. The land use is smaller, and the impacts on local ecosystems are typically minimal.

- Low Operating Costs:

- Geothermal plants generally have low operating and maintenance costs once built, as geothermal energy is a free resource. Small plants benefit from a reduced initial capital investment and have lower overhead compared to large-scale facilities.

- Energy Security:

- Small-scale geothermal plants can provide localized, stable, and independent energy production, reducing reliance on external energy sources.

Challenges of Small-Scale Geothermal Power Plants:

- Initial Capital Investment:

- While operating costs are low, the initial costs of drilling and establishing a geothermal plant can be significant. The drilling phase, in particular, can be expensive, as it requires deep wells to access geothermal resources.

- Resource Availability:

- Small-scale geothermal power plants depend heavily on the availability of geothermal resources in a given area. Without adequate geothermal potential, these plants may not be feasible or efficient.

- Site Selection:

- Identifying suitable sites for geothermal development is crucial. Not all regions have access to the geothermal heat needed for power generation, and poor site selection can result in reduced efficiency or the inability to operate a plant.

- Grid Connection and Energy Storage:

- Depending on the location and size of the plant, integrating small geothermal plants into the power grid can present challenges. In some cases, energy storage systems might be needed to manage the intermittent nature of the grid demand.

Technology and Innovations:

- Enhanced Geothermal Systems (EGS): A newer approach that involves stimulating geothermal reservoirs by creating fractures in hot dry rock to allow water to flow through, thus creating a more accessible heat source. Small-scale plants using EGS are a potential breakthrough, especially for areas with no natural geothermal resources.

- Modular Power Plants: There are also innovations in modular systems that can be scaled up or down depending on the resource potential and demand, making it easier to adapt to various market sizes.

Applications:

- Remote Locations: Small geothermal power plants are especially useful in remote or off-grid locations where connecting to a national grid is not feasible.

- Industrial or Agricultural Use: Geothermal power can be used directly for heating or in cogeneration (combined heat and power systems) to serve industrial processes, aquaculture, or agricultural needs.

Conclusion:

Small-scale geothermal power plants offer a promising solution for sustainable energy production, particularly in areas with access to geothermal resources. While they face challenges like high upfront costs and resource location issues, they provide a clean, reliable, and cost-effective power source with low environmental impact. Advances in technology and modular plant designs are making these systems increasingly viable for small and remote communities.

Small-scale Geothermal Power Plants

Small-scale geothermal power plants are typically used in areas where the geothermal resource is moderate or where space, budget, or infrastructure limits larger installations. They work by harnessing the heat from beneath the Earth’s surface to generate electricity, with several technologies available for conversion.

The primary advantages of small-scale geothermal plants are sustainability and low environmental impact. Geothermal energy is renewable and generates minimal carbon emissions. These plants also have reduced land use and ecosystem disruption, making them an attractive option for environmentally conscious power generation. Once constructed, the operating costs for geothermal plants are relatively low, as the geothermal resource itself is free. The low overhead costs and efficiency of geothermal energy also help make these systems economically viable.

Another significant advantage is energy security. Small-scale plants provide localized, stable power that is independent of external sources, reducing reliance on imported or grid-based electricity. For remote areas or regions that are difficult to connect to the main grid, small-scale geothermal plants can be particularly useful. Additionally, geothermal systems can be integrated into other systems for heating purposes, serving industrial, agricultural, or residential needs.

However, there are some challenges to consider. The initial capital investment required to build these plants can be high, especially when it comes to drilling wells to access the geothermal resource. Site selection is crucial because the success of the plant depends on having access to enough geothermal heat to make power generation feasible. Not all regions have viable geothermal resources, and poor site selection can lead to a loss of efficiency or even render a project unworkable.

There are also technical hurdles in connecting small-scale geothermal plants to the power grid. While some plants may function independently, others may need to address the challenge of intermittency and storage to align with grid demand. To manage this, some plants incorporate energy storage systems, but this can add another layer of complexity and cost.

Technological advancements are making small-scale geothermal plants more efficient and adaptable. The development of enhanced geothermal systems (EGS) has opened up the potential for creating geothermal reservoirs in areas that don’t have natural geothermal resources. EGS involves stimulating hot dry rock formations to create fractures through which water can flow, improving heat extraction. Furthermore, the modular nature of some geothermal systems means that power plants can be scaled up or down based on the specific geothermal resource and demand of the location.

Despite the challenges, small-scale geothermal plants are gaining traction, particularly for communities looking to reduce their dependence on fossil fuels and stabilize their energy supply. Whether used for local grid integration, off-grid power, or industrial heating, these plants are proving to be an effective and sustainable energy solution in the right conditions.

Building on the previous points, small-scale geothermal power plants continue to gain attention due to their growing potential to address energy needs while reducing environmental impacts.

Expanding Applications and Potential

Small-scale geothermal power plants can be particularly beneficial in various settings. For instance, in remote or isolated locations where access to the national grid is limited or unavailable, geothermal energy offers an effective way to generate reliable power. This can be vital for rural communities, islands, or mining operations that require a steady energy supply but may struggle to connect to large-scale energy infrastructure. In these scenarios, small-scale geothermal plants can provide long-term, sustainable power.

Moreover, the versatility of geothermal energy extends beyond just electricity generation. Cogeneration systems, where both electricity and useful heat are produced, are increasingly popular. These plants can serve industrial processes that require both power and heat, such as in food processing, paper mills, and district heating systems. For agricultural sectors, geothermal heat can be used for greenhouse heating, aquaculture, or drying crops. In regions with both geothermal resources and strong agricultural or industrial sectors, the ability to provide multiple forms of energy (electricity and heat) can make geothermal plants an even more attractive solution.

Technological Developments in Geothermal Energy

One area of development is the growing interest in modular geothermal systems. These are smaller, more flexible plants that can be scaled up or down depending on the resource available and the power demand. Instead of large, centralized plants, modular units can be deployed to meet specific community needs, with potential for expansion as demand grows. These smaller systems are more adaptable to various geographies and may reduce the need for large, upfront investments. The modular approach can also help mitigate risks by allowing developers to test and optimize smaller-scale operations before committing to larger-scale geothermal projects.

Another emerging technology is the enhanced geothermal systems (EGS) approach. EGS techniques allow for the stimulation of geothermal resources in areas that might not have sufficient natural geothermal activity. By creating artificial reservoirs in hot dry rock, water can be introduced to create steam for power generation. Although EGS is still in the early stages of commercialization, it holds tremendous promise in unlocking geothermal resources in regions that were previously considered unsuitable. For smaller-scale applications, this could enable a broader geographic range of geothermal power plants, especially in areas where traditional geothermal resources are not present.

Additionally, direct use geothermal energy (as opposed to generating electricity) is gaining popularity in some areas. In this system, geothermal energy is used directly for heating purposes in homes, buildings, or even for spa-like applications in tourism areas. Small-scale geothermal plants that focus on direct use rather than electricity generation can offer an alternative that reduces the need for complex power plant infrastructures, while still utilizing the Earth’s heat efficiently. This approach can also be combined with district heating systems, where geothermal heat is used to warm multiple buildings or facilities within a specific geographic area.

Challenges and Future Directions

Despite the potential, there are ongoing challenges that need to be addressed for small-scale geothermal power plants to thrive. One such challenge is the geothermal resource management. While geothermal energy is renewable, it is important to manage the resources carefully to avoid depleting them. This requires efficient monitoring and reinjection of used geothermal fluids into the reservoir. Failure to properly manage resources can lead to a decline in plant efficiency over time. Small-scale geothermal plants may face more difficulty in maintaining an adequate supply of geothermal fluid compared to large-scale operations, as smaller reservoirs may be more sensitive to overuse.

In addition, while the modular nature of smaller plants can offer flexibility, initial capital costs remain a barrier. Although the operating costs of geothermal plants are generally low, drilling and resource exploration can be costly, especially in regions where the resource depth is significant. Financing mechanisms and government support for renewable energy projects, such as grants, subsidies, or tax incentives, can help offset some of these initial costs, but the economic viability of small-scale geothermal plants depends largely on the availability of these financial resources.

Finally, the integration of small-scale geothermal plants into national or local grids remains an important consideration. In regions where geothermal energy is part of the broader energy mix, small plants may need to interact with the grid and potentially balance energy fluctuations. Geothermal energy itself can be quite stable, but depending on the plant’s size and resource availability, it may need to be complemented by other sources of renewable energy or battery storage systems to ensure a consistent supply.

Conclusion

In summary, small-scale geothermal power plants offer significant opportunities for renewable energy generation, especially in areas with geothermal potential. They have a minimal environmental footprint, provide reliable power, and can be versatile in their applications—serving both electricity and heat needs. Technological innovations such as modular systems and enhanced geothermal systems are expanding the possibilities for these plants to be more efficient and adaptable. However, challenges like initial costs, resource management, and grid integration still need to be addressed for these plants to achieve their full potential. With continued development and investment in geothermal technologies, small-scale geothermal power plants could play an increasingly important role in sustainable energy generation worldwide.

As we continue exploring the development and potential of small-scale geothermal power plants, there are a few additional considerations and strategies that can help overcome the challenges and maximize the benefits of these systems.

1. Policy and Regulatory Support

Government policies and incentives play a critical role in the development and success of small-scale geothermal power plants. Regulatory frameworks that encourage renewable energy development, offer financial incentives (such as tax credits or subsidies), and streamline permitting processes can significantly reduce the initial investment burden and accelerate project timelines.

- Feed-in Tariffs (FiTs) and Power Purchase Agreements (PPAs): Governments can establish financial mechanisms like FiTs, which guarantee a fixed price for the electricity produced from renewable sources like geothermal, giving developers a predictable return on investment. Similarly, PPAs between the plant operators and utilities or other large consumers can ensure a stable revenue stream.

- Research and Development Support: Continued support for R&D initiatives can foster innovation in geothermal technologies, including drilling techniques, resource management, and system efficiency. Governments and private entities can work together to fund demonstration projects and pilot programs that explore new applications of small-scale geothermal systems.

- Geothermal Resource Mapping and Data Sharing: One of the major barriers to geothermal plant development is the upfront cost and risk associated with exploration and resource assessment. Governments can aid this process by investing in detailed geothermal resource mapping and sharing data with developers, which reduces uncertainty and encourages investment.

2. Improved Drilling Techniques and Cost Reductions

A significant portion of the cost of building a geothermal power plant comes from drilling wells to access geothermal reservoirs. As drilling technology improves, these costs are expected to decrease, making geothermal energy more competitive.

- Directional Drilling: New techniques, such as horizontal or directional drilling, can help access geothermal resources more efficiently, especially in locations where deep drilling is required. These methods allow operators to reach geothermal resources without having to drill as many wells, lowering costs and reducing surface impact.

- Deep Drilling Innovations: Advances in high-temperature and high-pressure drilling technologies could open up new geothermal fields and make the resource accessible even in regions that were previously considered economically unfeasible. More efficient drilling also allows for deeper reservoirs to be tapped, which could significantly extend the life of geothermal plants.

3. Hybrid and Integrated Systems

Small-scale geothermal plants do not have to operate in isolation. One promising strategy for overcoming intermittency or optimizing energy output is integrating geothermal with other renewable energy sources or storage solutions.

- Hybrid Systems: Small-scale geothermal power plants can be combined with solar or wind energy systems to create hybrid power plants. These systems can leverage the strengths of both geothermal (which provides a steady, base-load supply of power) and solar or wind (which offer peak generation during specific times). By pairing these resources, the overall system can provide more reliable, 24-hour power.

- Energy Storage: While geothermal energy is relatively constant, there may be instances when demand exceeds the plant’s generation capacity or when grid instability occurs. By integrating energy storage systems, such as batteries or thermal storage, small-scale geothermal plants can store excess energy during periods of low demand and discharge it when needed. This makes geothermal systems more flexible and better integrated into the broader energy market.

4. Microgrids and Decentralized Energy Systems

Microgrids, which are localized energy networks that can operate independently of the central grid, are becoming increasingly popular in remote or off-grid areas. Small-scale geothermal plants can be an ideal component of such systems. A microgrid with a geothermal energy source can provide stable, reliable power to a community, even if the larger grid is unavailable or unreliable. These decentralized systems are particularly useful for areas prone to natural disasters or in remote regions that are difficult to connect to centralized infrastructure.

- Resilient Energy Systems: In disaster-prone areas, microgrids powered by geothermal energy can provide greater resilience, ensuring that essential services like hospitals, water treatment plants, and communication systems continue to function even during grid outages. Geothermal microgrids can also support critical industries that require uninterrupted power supply.

5. Environmental and Social Considerations

While geothermal energy is widely regarded as one of the cleanest energy sources, its development still needs to consider environmental and social impacts.

- Resource Management: Sustainable management of geothermal resources is essential to prevent depletion and ensure long-term viability. Effective reinjection practices (where the cooled water is reintroduced into the geothermal reservoir) can help maintain pressure in the system and extend the life of the resource. Developing effective monitoring systems for resource management can prevent overuse and optimize plant efficiency.

- Local Community Engagement: The social impact of geothermal development should not be overlooked. In many cases, local communities can benefit directly from geothermal power plants through job creation, infrastructure development, and increased access to energy. However, there may also be concerns about the environmental impact, including land use and the risk of induced seismicity (small earthquakes caused by fluid injection or extraction). Engaging local communities early in the planning process and addressing their concerns through transparency and collaboration can help build support for the project and ensure that it meets both energy and social needs.

- Ecosystem Impact: While geothermal plants generally have a lower environmental impact compared to fossil fuel-based power generation, it’s important to consider the specific context of each site. The use of chemicals in geothermal fluids, for example, needs to be managed carefully to prevent contamination of local water supplies. In addition, the construction and operation of geothermal plants should minimize disruption to wildlife habitats and ecosystems.

6. Global Expansion and Future Outlook

The potential for small-scale geothermal power plants extends far beyond traditional geothermal hotspots. As technology improves and costs decrease, geothermal energy could become more accessible in regions that were once considered non-viable for geothermal development. Enhanced geothermal systems, modular technologies, and hybrid solutions are all expected to play a significant role in making geothermal power a key player in the global renewable energy landscape.