A small wood gasifier is a device that converts wood or other biomass into a combustible gas mixture known as wood gas. Wood gas consists mainly of carbon monoxide, hydrogen, and methane, and it can be used as a fuel for various applications, such as cooking, heating, or powering internal combustion engines.

Small Wood Gasifier

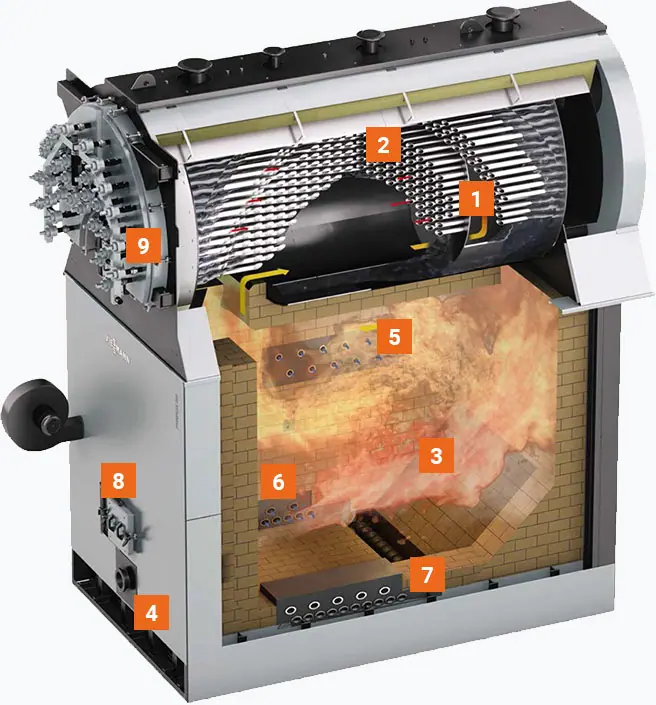

Here are the basic components and working principles of a small wood gasifier:

- Fuel Hopper: This is where you load the wood or biomass fuel. It’s typically a container located at the top of the gasifier.

- Pyrolysis Zone: Below the fuel hopper, there is a pyrolysis zone where the wood is heated in the absence of oxygen. This process, known as pyrolysis, causes the wood to break down into volatile gases, liquids, and charcoal.

- Combustion Zone: The volatile gases produced during pyrolysis move downward into the combustion zone, where they react with a limited amount of oxygen to produce carbon monoxide, hydrogen, and other combustible gases. The heat generated here helps sustain the overall gasification process.

- Reduction Zone: The gases produced in the combustion zone then move into the reduction zone, where any remaining oxygen is removed through further chemical reactions, leaving a clean, combustible gas mixture.

- Output: The wood gas, now consisting of carbon monoxide, hydrogen, methane, and other gases, is collected and can be used for various applications. It can be piped to a burner for cooking, heating, or used to power an internal combustion engine for electricity generation or mechanical work.

Small wood gasifiers are often used in off-grid or rural settings where traditional fuel sources may be limited. They offer a sustainable and renewable energy option by utilizing locally available biomass. Keep in mind that safety precautions should be taken when operating a wood gasifier, as carbon monoxide is a byproduct of the process and can be harmful if not handled properly.

Wood Gasification:

Wood gasification is a process that transforms wood or other biomass into a valuable fuel known as wood gas. This advanced thermal conversion technique involves the controlled heating of wood in a low-oxygen environment, resulting in the production of combustible gases. Wood gas, primarily composed of carbon monoxide, hydrogen, and methane, serves as a versatile and sustainable energy source. The process begins in a fuel hopper, where biomass is loaded, and progresses through pyrolysis, combustion, and reduction zones within the gasifier.

During pyrolysis, the wood breaks down into volatile gases, liquids, and charcoal in the absence of sufficient oxygen. In the combustion zone, these volatile gases react with a limited supply of oxygen, generating heat and producing a gas mixture rich in carbon monoxide and hydrogen. The reduction zone further refines the gas, removing any remaining oxygen, and resulting in a clean and combustible gas. Wood gasifiers find applications in off-grid settings, providing a renewable and locally sourced alternative to traditional fuels. The technology contributes to sustainable energy practices and reduces reliance on non-renewable resources, offering an environmentally friendly solution for both domestic and industrial energy needs.

Biomass Energy:

Biomass energy encompasses the utilization of organic materials, such as wood, agricultural residues, and other plant or animal matter, to generate heat, electricity, or fuel. One significant aspect of biomass energy is the production of wood gas through gasification. Unlike fossil fuels, biomass is considered renewable as it relies on the continuous growth of organic materials. The biomass energy cycle involves extracting energy from plants or waste, burning or converting it into biofuels, and ultimately using the resulting energy for various applications.

Wood gasifiers play a crucial role in biomass energy systems, particularly in the production of a clean and combustible gas mixture from wood or other plant-based feedstocks. This sustainable approach aids in reducing greenhouse gas emissions and dependence on finite fossil fuels. Biomass energy is versatile and can be harnessed on both small and large scales, making it suitable for decentralized energy production in rural areas or as a supplement to conventional power sources. As societies strive for cleaner and more sustainable energy solutions, biomass energy, facilitated by technologies like wood gasification, emerges as a vital component in the transition towards greener and more eco-friendly energy alternatives.

Renewable Fuel:

Renewable fuel refers to fuels derived from sources that are continually replenished, offering a sustainable and environmentally friendly alternative to traditional fossil fuels. Wood gas, produced through the gasification of wood or biomass, is a prime example of a renewable fuel. Unlike finite fossil fuels, renewable fuels are derived from sources such as solar, wind, geothermal, and biomass, ensuring a continuous and sustainable supply.

Wood gas as a renewable fuel holds promise for reducing dependence on non-renewable resources and mitigating the environmental impact associated with fossil fuel combustion. The process of wood gasification, wherein biomass is converted into a combustible gas mixture, exemplifies the utilization of renewable resources for energy production. This clean-burning fuel not only contributes to a more sustainable energy landscape but also aids in addressing climate change concerns by minimizing carbon emissions.

The development and widespread adoption of renewable fuels, including wood gas, represent a crucial step towards achieving energy security, reducing environmental impact, and fostering a more sustainable and resilient energy future. As technology advances and awareness grows, renewable fuels continue to play a pivotal role in diversifying energy sources and promoting a cleaner, greener energy ecosystem.

Pyrolysis:

Pyrolysis is a thermochemical process that involves the decomposition of organic materials, such as wood or biomass, at elevated temperatures in the absence of oxygen. In the context of wood gasification, pyrolysis is a fundamental stage where biomass undergoes transformation into volatile gases, liquids, and solid char. This process occurs in the pyrolysis zone of a gasifier and is a key step in the production of wood gas.

During pyrolysis, heat is applied to the biomass, causing it to break down without combustion. The lack of oxygen prevents the material from burning completely, leading to the release of volatile compounds. These volatile gases, including methane, ethane, propane, and hydrogen, are crucial precursors for the subsequent stages of wood gasification. The remaining solid char, often referred to as biochar, can be used as a soil amendment or for other applications.

Pyrolysis is an essential and intricate aspect of wood gasification technology, providing a controlled means of converting biomass into valuable fuel components. The efficiency of this stage influences the overall performance of the gasifier, impacting the quality and quantity of the produced wood gas. Understanding and optimizing the pyrolysis process contribute to the development of efficient and sustainable energy solutions that harness the potential of biomass resources.

Combustible Gases:

Combustible gases, in the context of wood gasification, refer to the mix of gases produced through the controlled thermal conversion of wood or biomass. These gases, primarily composed of carbon monoxide (CO), hydrogen (H2), methane (CH4), and other hydrocarbons, form the core of the wood gas and serve as a valuable renewable fuel. The production of combustible gases occurs during the combustion stage within the gasifier.

In the combustion zone, the volatile gases generated during pyrolysis react with a limited supply of oxygen, producing heat and combustible gases. Carbon monoxide, in particular, plays a crucial role as a major component of wood gas, contributing to its energy content. Hydrogen and methane further enhance the combustibility of the gas mixture. The controlled conditions in the gasifier ensure the efficient conversion of biomass into a clean-burning fuel suitable for various applications.

Combustible gases derived from wood gasification offer a sustainable alternative to traditional fossil fuels, with the added benefit of reduced environmental impact. These gases can be utilized for cooking, heating, or powering internal combustion engines, contributing to energy self-sufficiency and promoting a more eco-friendly approach to energy production. As the demand for cleaner and renewable energy sources grows, the development and optimization of wood gasifiers continue to enhance the efficient generation of these valuable combustible gases.

Carbon Monoxide:

Carbon monoxide (CO) is a key component of the combustible gas produced through wood gasification. In the gasification process, carbon monoxide is formed during the combustion stage when volatile gases generated in the pyrolysis zone react with a limited supply of oxygen. This controlled reaction results in the production of a gas mixture rich in carbon monoxide, hydrogen, methane, and other combustible gases.

As a combustible gas, carbon monoxide contributes significantly to the energy content of wood gas. It is a colorless, odorless gas that, when burned, releases heat energy. Carbon monoxide has a high energy density, making it a valuable fuel for various applications. While it is crucial for energy production, it’s important to note that carbon monoxide is also a poisonous gas. Proper safety measures must be in place to prevent exposure, and wood gasifiers typically include systems to minimize the release of carbon monoxide into the environment.

The utilization of carbon monoxide from wood gas offers a sustainable and renewable energy source, contributing to the transition away from conventional fossil fuels. It finds applications in off-grid settings, providing a clean-burning fuel for cooking, heating, and power generation while emphasizing the importance of safety precautions to ensure responsible and efficient use.

Hydrogen Production:

Hydrogen (H2) is a significant component of the gas produced during wood gasification, contributing to its combustible and renewable nature. In the gasification process, hydrogen is formed as a result of the controlled thermal conversion of biomass in the presence of a limited oxygen supply. This occurs during the combustion stage within the gasifier, where volatile gases released during pyrolysis react to produce a gas mixture rich in hydrogen, carbon monoxide, methane, and other hydrocarbons.

Hydrogen is a clean-burning fuel that releases energy when combusted with oxygen, producing water vapor as the primary byproduct. As a renewable energy carrier, hydrogen holds promise for various applications, including powering internal combustion engines, fuel cells, and acting as a versatile energy storage medium. Wood gasifiers play a crucial role in facilitating the sustainable production of hydrogen by harnessing the energy stored in biomass and converting it into a usable and environmentally friendly fuel.

The production of hydrogen through wood gasification aligns with the growing interest in clean energy technologies and the transition toward a low-carbon future. It highlights the potential of biomass as a renewable resource for hydrogen production, offering a sustainable and eco-friendly alternative to conventional fossil fuels.

Gasification Technology:

Gasification technology involves the conversion of solid carbonaceous materials, such as wood or biomass, into a combustible gas mixture through a controlled thermochemical process. This process, facilitated by gasifiers, transforms the organic material into valuable gases like carbon monoxide, hydrogen, and methane. Gasification is a versatile and efficient technology with applications ranging from energy production to waste management.

Wood gasification is a specific application of this technology where wood, a renewable biomass resource, serves as the feedstock. Gasifiers are designed with various zones, including the pyrolysis zone, combustion zone, and reduction zone, each contributing to the transformation of biomass into a clean and usable gas. Gasification technology enables the extraction of energy from biomass in a controlled and efficient manner, offering an alternative to traditional combustion processes.

The benefits of gasification technology include the ability to use a variety of feedstocks, including agricultural residues and waste materials, promoting resource efficiency and waste reduction. Moreover, the produced gas can be utilized for decentralized energy generation, providing a sustainable and renewable energy solution, especially in off-grid or remote areas. As technology advances, gasification continues to play a crucial role in developing cleaner and more efficient energy systems.

Sustainable Energy:

Sustainable energy refers to energy sources and practices that meet current needs without compromising the ability of future generations to meet their own needs. Wood gasification contributes to sustainable energy by utilizing renewable biomass resources to produce clean-burning gases for various applications. This approach aligns with principles of environmental responsibility, social equity, and economic viability.

Wood gas, generated through sustainable practices like gasification, offers an eco-friendly alternative to conventional fossil fuels. Biomass, being a renewable resource, ensures a continuous and replenishable supply, reducing dependence on finite and environmentally harmful energy sources. Sustainable energy systems, such as those employing wood gasifiers, contribute to mitigating climate change, preserving biodiversity, and promoting community resilience.

The adoption of wood gasification for sustainable energy production also aligns with global efforts to transition away from fossil fuels and reduce greenhouse gas emissions. By harnessing the energy stored in biomass, wood gasification supports the development of a more sustainable and resilient energy infrastructure, addressing both present and future energy needs in an environmentally conscious manner.

Off-Grid Power:

Off-grid power refers to the generation of electricity independently of the traditional utility grid. Wood gasification plays a crucial role in providing off-grid power solutions, especially in remote or rural areas where access to centralized electricity infrastructure may be limited. The compact nature of small wood gasifiers makes them well-suited for off-grid applications, offering a sustainable and decentralized energy source.

In off-grid scenarios, a wood gasifier can be used to convert locally available biomass, such as wood chips or agricultural residues, into a combustible gas. This gas can then be utilized to power electrical generators or internal combustion engines, providing electricity for various needs, including lighting, appliances, and other electrical devices. Off-grid power solutions based on wood gasification enhance energy self-sufficiency, reducing reliance on external power grids.

The use of wood gasifiers for off-grid power is particularly advantageous in areas where traditional energy sources are impractical or unavailable. It fosters independence, resilience, and sustainability by tapping into local biomass resources, promoting community development, and minimizing the environmental impact associated with transporting and burning traditional fuels. As technology advances, off-grid power solutions based on wood gasification continue to play a vital role in meeting the energy needs of remote and off-grid communities.

Small-Scale Gasifier:

A small-scale gasifier is a compact and efficient device designed for the controlled conversion of biomass, such as wood or agricultural residues, into combustible gases. The term “small-scale” denotes the size and capacity of the gasifier, making it suitable for decentralized and localized applications. These gasifiers are often used in off-grid settings, providing sustainable and renewable energy solutions for various purposes.

The design of a small-scale gasifier typically includes features such as a fuel hopper, pyrolysis zone, combustion zone, and reduction zone. Despite their compact size, these gasifiers maintain the key principles of larger gasification systems, efficiently transforming biomass into clean-burning gases like carbon monoxide, hydrogen, and methane.

Small-scale gasifiers are versatile and can be employed for tasks such as cooking, heating, and generating electricity in remote or rural areas. Their adaptability makes them valuable tools for achieving energy self-sufficiency and reducing dependence on traditional fuels. Additionally, the decentralized nature of small-scale gasification aligns with sustainable development goals, offering a practical and environmentally friendly solution for localized energy needs. As technology advances, improvements in small-scale gasifier design continue to enhance their efficiency and applicability in diverse settings.

Alternative Cooking Fuel:

Wood gasification provides an alternative cooking fuel that addresses both environmental and energy sustainability concerns. In many parts of the world, traditional cooking methods involve burning solid biomass such as wood or charcoal, contributing to deforestation, indoor air pollution, and respiratory health issues. Wood gasifiers offer a cleaner and more sustainable alternative for cooking purposes.

Using wood gas as a cooking fuel involves the combustion of gases produced through the gasification of wood or biomass. This approach significantly reduces the emission of particulate matter and harmful pollutants associated with traditional solid fuel combustion. The combustible gases, including carbon monoxide and hydrogen, generated by the wood gasifier can be channeled to a burner for cooking, providing a reliable and cleaner source of energy.

Adopting wood gasification as an alternative cooking fuel not only reduces the environmental impact but also promotes sustainable forestry practices. It offers an eco-friendly solution for communities relying on biomass for cooking, contributing to improved indoor air quality and overall health. As the need for sustainable cooking solutions grows, wood gasifiers play a vital role in providing a cleaner and renewable energy source for households and communities.

Internal Combustion Engine:

Wood gasification finds practical application in powering internal combustion engines, presenting an innovative and sustainable alternative to conventional liquid fuels. Internal combustion engines are commonly used in vehicles, generators, and machinery, and wood gas can be employed as a renewable and locally sourced fuel for these engines.

In the context of internal combustion engines, wood gas serves as a versatile fuel, capable of powering both spark-ignition (SI) and compression-ignition (CI) engines. The combustible gases produced through the gasification process, including carbon monoxide, hydrogen, and methane, are fed into the engine where they combust with air to generate mechanical energy.

Using wood gas to fuel internal combustion engines is particularly relevant in off-grid or remote areas where traditional liquid fuels may be scarce or expensive. This application allows for the utilization of locally available biomass resources, reducing the reliance on imported fossil fuels. Additionally, the combustion of wood gas in internal combustion engines can be a more sustainable and environmentally friendly option, contributing to the reduction of greenhouse gas emissions and promoting cleaner energy practices.

Energy Self-Sufficiency:

Energy self-sufficiency refers to the ability of a system, community, or individual to meet their energy needs independently, without relying on external or centralized energy sources. Wood gasification plays a crucial role in achieving energy self-sufficiency, especially in off-grid or decentralized settings where access to traditional energy infrastructure may be limited.

By utilizing local biomass resources, such as wood or agricultural residues, wood gasifiers provide a sustainable and renewable energy source. The gas produced through the gasification process can be used for cooking, heating, powering internal combustion engines, or generating electricity. This decentralized approach empowers communities or individuals to harness their local resources, reducing dependence on external energy grids and contributing to resilience in the face of energy supply challenges.

Energy self-sufficiency through wood gasification not only addresses energy security concerns but also promotes environmental sustainability. It minimizes the need for long-distance transport of traditional fuels, reduces carbon emissions, and fosters a more resilient and independent energy infrastructure. As communities seek ways to enhance their sustainability and reduce their carbon footprint, the adoption of wood gasification for energy self-sufficiency becomes an integral part of the solution.

Clean Energy Solution:

Wood gasification stands as a clean energy solution, offering an environmentally friendly and sustainable alternative to traditional fossil fuels. The gas produced through this process, comprising carbon monoxide, hydrogen, methane, and other combustible gases, serves as a clean-burning fuel with lower environmental impact compared to conventional energy sources.

One of the primary advantages of wood gas as a clean energy solution is its renewable nature. Utilizing biomass, a readily available and replenishable resource, contributes to reducing reliance on non-renewable fossil fuels. The controlled gasification process minimizes emissions of particulate matter and pollutants, addressing air quality concerns associated with traditional solid fuel combustion.

Wood gasifiers provide a decentralized and versatile solution for various energy needs, including cooking, heating, and power generation. The adoption of wood gasification technologies supports sustainable development goals by promoting cleaner energy practices, mitigating climate change impacts, and fostering resilience in energy supply. As the world seeks cleaner and greener alternatives, wood gasification stands out as a promising clean energy solution with the potential to create a more sustainable and environmentally conscious energy landscape.

EMS Power Machines

We design, manufacture and assembly Power Machines such as – diesel generators, electric motors, vibration motors, pumps, steam engines and steam turbines

EMS Power Machines is a global power engineering company, one of the five world leaders in the industry in terms of installed equipment. The companies included in the company have been operating in the energy market for more than 60 years.

EMS Power Machines manufactures steam turbines, gas turbines, hydroelectric turbines, generators, and other power equipment for thermal, nuclear, and hydroelectric power plants, as well as for various industries, transport, and marine energy.

EMS Power Machines is a major player in the global power industry, and its equipment is used in power plants all over the world. The company has a strong track record of innovation, and it is constantly developing new and improved technologies.

Here are some examples of Power Machines’ products and services:

- Steam turbines for thermal and nuclear power plants

- Gas turbines for combined cycle power plants and industrial applications

- Hydroelectric turbines for hydroelectric power plants

- Generators for all types of power plants

- Boilers for thermal power plants

- Condensers for thermal power plants

- Reheaters for thermal power plants

- Air preheaters for thermal power plants

- Feedwater pumps for thermal power plants

- Control systems for power plants

- Maintenance and repair services for power plants

EMS Power Machines is committed to providing its customers with high-quality products and services. The company has a strong reputation for reliability and innovation. Power Machines is a leading provider of power equipment and services, and it plays a vital role in the global power industry.

EMS Power Machines, which began in 1961 as a small factory of electric motors, has become a leading global supplier of electronic products for different segments. The search for excellence has resulted in the diversification of the business, adding to the electric motors products which provide from power generation to more efficient means of use.