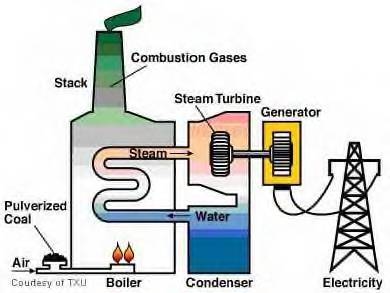

Generating Electricity using Heat from Food and Beverage Pasteurization: Generating electricity from steam involves a process called thermodynamic power generation, often using steam turbines as the primary mechanism. This process converts the energy in steam, usually created by boiling water using heat from burning fuel, nuclear reactions, or geothermal energy, into mechanical energy, which is then transformed into electrical energy.

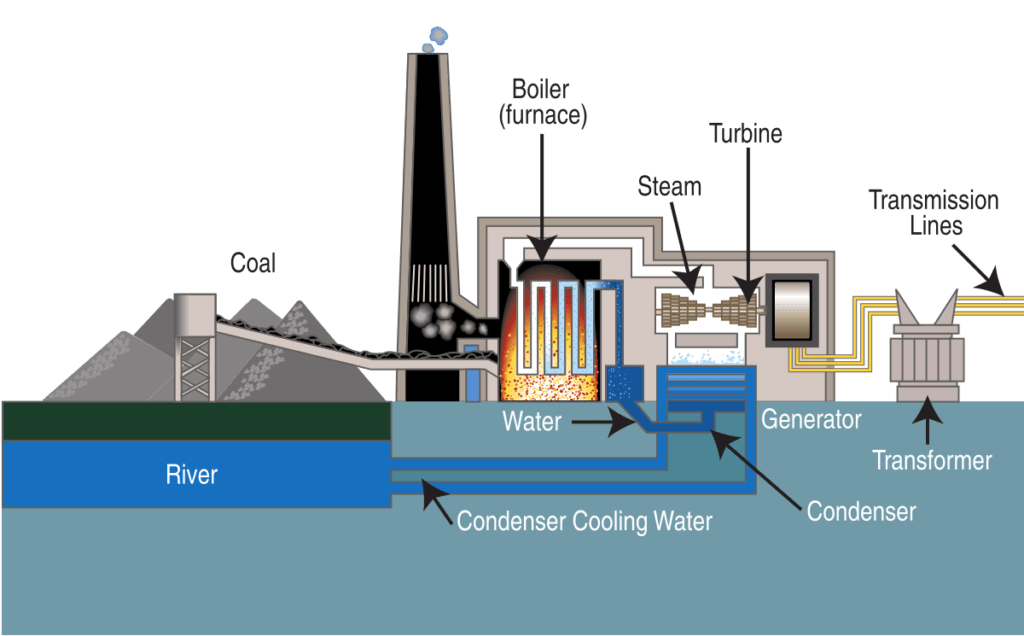

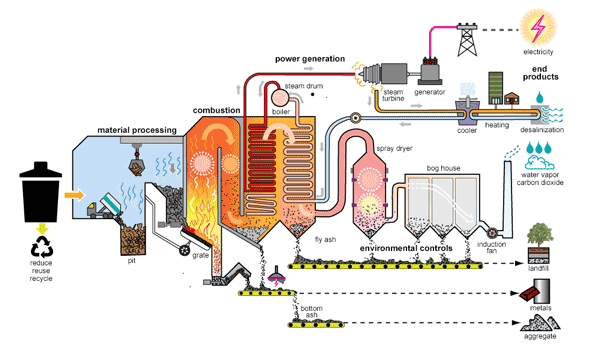

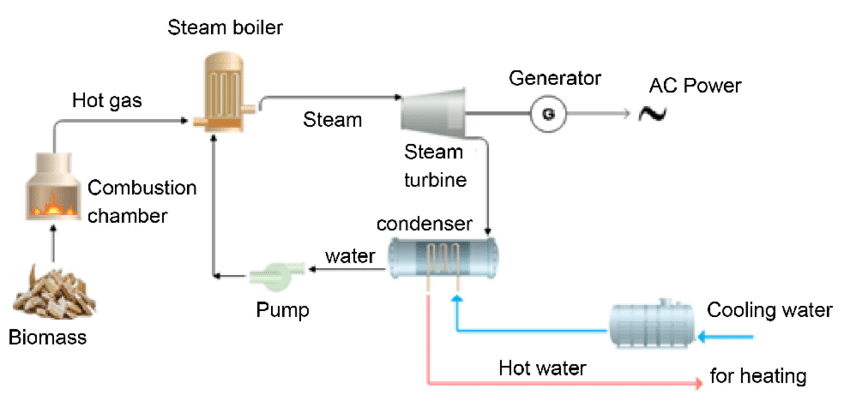

The basic steps to generate electricity from steam start with the heating of water to produce steam. This can be done in a boiler or a heat exchanger, depending on the system’s design. In a boiler, fuel such as coal, natural gas, oil, or even biomass is burned to generate heat. In a nuclear power plant, heat is produced from nuclear fission reactions. Alternatively, in geothermal power plants, heat from the Earth’s natural reservoirs is used to convert water into steam.

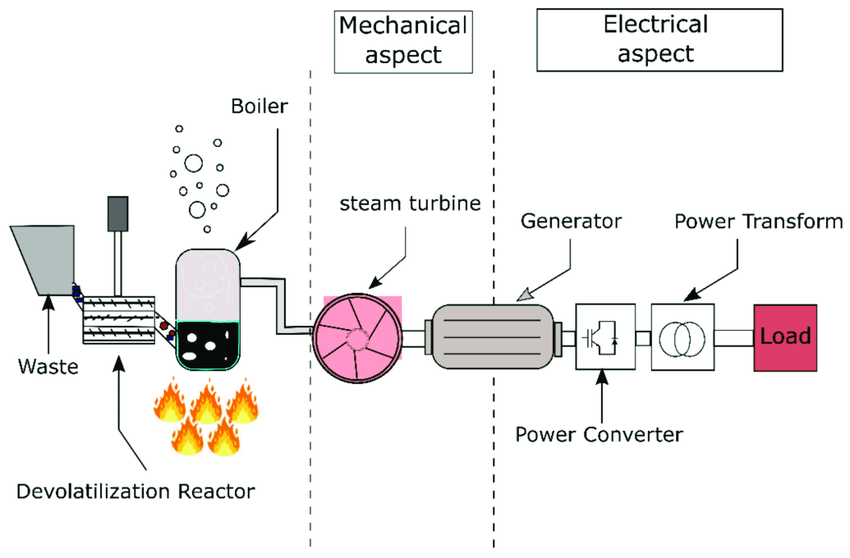

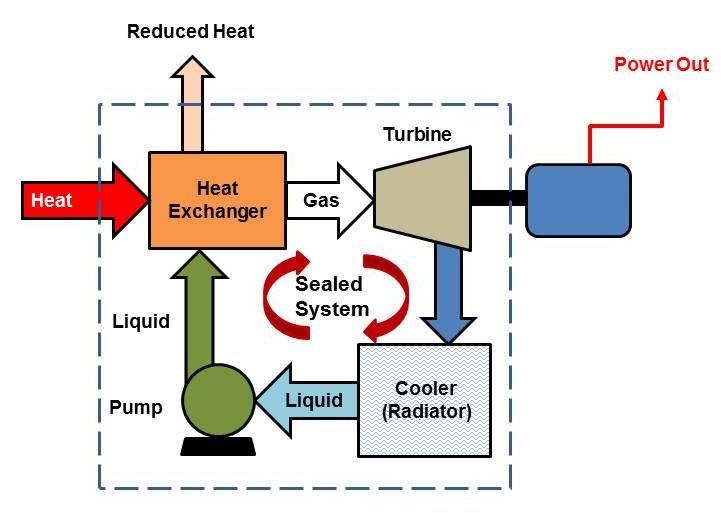

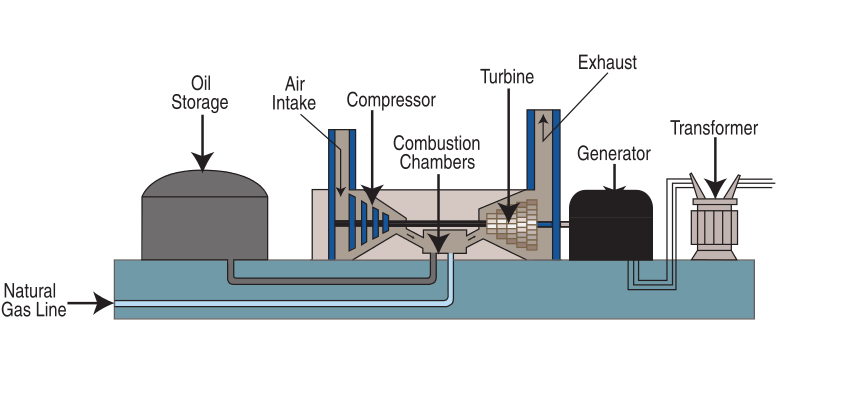

Once steam is produced, it is directed into a steam turbine. The turbine consists of blades mounted on a shaft. As steam flows over the blades, the force of the steam causes the blades to spin. This mechanical energy of the rotating turbine blades is then transferred to a generator connected to the turbine. The generator uses the mechanical energy to rotate a magnetic field within a set of coils, inducing an electrical current through electromagnetic induction.

The steam turbine operates based on the principles of thermodynamics, particularly the Rankine cycle. In the Rankine cycle, steam is generated at high pressure and temperature, expanded in the turbine, and then condensed back into water in a condenser. This process of expansion and condensation allows for a continuous cycle of energy conversion. The condenser cools the steam, usually by passing it through cooling towers or heat exchangers, and converts it back into liquid water, which is then pumped back into the boiler to be reheated and turned back into steam.

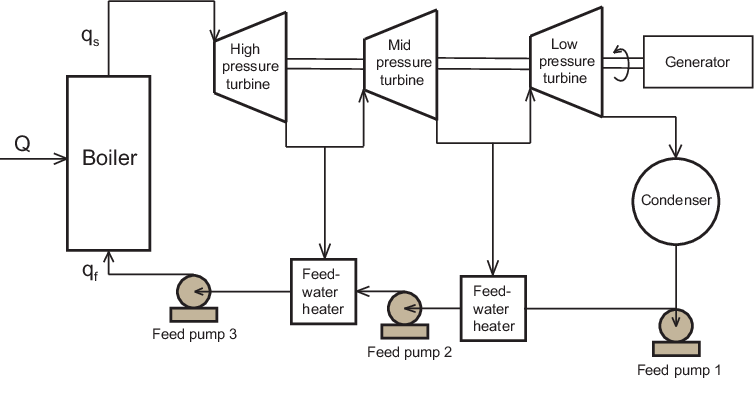

In larger power plants, multiple stages of turbines are often used to maximize efficiency. This is known as a multi-stage turbine system, where steam passes through several turbines at different pressure levels. The steam’s pressure is gradually reduced as it moves through each turbine, extracting more energy. In many systems, the steam is also reheated between stages to maintain its energy content and prevent too much pressure drop in the turbines.

The efficiency of a steam power plant is largely determined by how well it can maintain the pressure and temperature of the steam as it moves through the system, as well as the efficiency of the turbine and the generator. Steam turbines are capable of converting a large percentage of the heat energy into mechanical work, but some energy is always lost in the process, primarily due to heat dissipation in the condenser and the inevitable frictional losses in the turbine and other moving parts.

To improve the efficiency of electricity generation, some plants incorporate regenerative systems, where part of the steam or exhaust gases are used to preheat incoming water before it enters the boiler. This reduces the amount of fuel needed to heat the water to the required steam temperature, leading to a more energy-efficient process.

Once the electrical energy is generated, it is transmitted through power lines and distributed to homes and businesses. The voltage of the generated electricity is stepped up by a transformer for long-distance transmission, reducing energy loss during transport. At the point of use, the voltage is stepped down again to a level suitable for household or industrial applications.

In addition to conventional coal, oil, and natural gas power plants, steam turbines are also widely used in renewable energy sources. Geothermal power plants use naturally occurring steam from deep within the Earth to generate electricity, while solar thermal plants use mirrors or lenses to concentrate sunlight and heat a fluid that produces steam. These renewable methods of generating steam offer a more sustainable way to generate electricity without burning fossil fuels.

Overall, generating electricity from steam is a well-established and versatile technology that continues to be used in power plants around the world, with ongoing research focused on improving its efficiency, reducing emissions, and expanding its use in renewable energy systems.

In the process of steam-based electricity generation, one of the key elements that influence performance is the design and operation of the steam turbine itself. The turbine is designed to convert the thermal energy from steam into mechanical energy efficiently. This is achieved by careful engineering of the turbine blades, which are shaped to extract the maximum amount of energy from the steam as it flows over them. The steam enters the turbine under high pressure and high temperature, and as it expands and loses pressure, it passes through different stages of turbines with progressively smaller blades. These stages allow for a more gradual and efficient transfer of energy.

After passing through the turbines, the steam exits at lower pressure and temperature. To complete the cycle, the steam must be condensed back into water in a process that typically occurs in a condenser. The condenser cools the steam, causing it to lose its heat and turn back into liquid form. In most systems, water from nearby rivers, lakes, or cooling towers is used to absorb the excess heat from the steam, often at a temperature below 40°C to 50°C, depending on the local climate and environmental regulations.

The condensed water, now in liquid form, is collected and pumped back into the boiler to be reheated and transformed into steam once again. This closed-loop system helps to conserve water and reduce environmental impacts, though some plants may use once-through cooling systems where water is used only once before being returned to its source.

As part of the overall power plant system, the generator that is coupled to the turbine plays a critical role in converting the mechanical energy into electrical energy. The generator consists of a rotating shaft and a set of stationary coils or magnets. As the turbine shaft rotates, it turns the generator’s rotor, creating a changing magnetic field within the coils, which induces an electrical current through the wires by the principle of electromagnetic induction. This electrical current is then transferred through transformers, where its voltage is adjusted to be suitable for transmission over long distances. Once the electricity reaches its destination, transformers step down the voltage again for distribution to households or businesses.

A significant part of the energy generated by the steam turbine system is often lost as heat due to the second law of thermodynamics, which states that some energy is always lost to the surroundings. Efficiency improvements, such as the integration of combined-cycle power plants, aim to capture and utilize some of this waste heat. In combined-cycle systems, the exhaust gases from the gas turbine are used to heat water, which then produces additional steam to drive a steam turbine. This significantly increases the overall efficiency of the plant, sometimes by as much as 50% or more compared to a simple steam turbine system.

Another emerging trend in steam-based electricity generation is the implementation of supercritical and ultra-supercritical steam cycles. These systems use steam at higher pressures and temperatures than conventional methods, resulting in higher thermodynamic efficiency and lower emissions. By using steam at supercritical pressures (above 22.1 MPa) and ultra-supercritical pressures (above 30 MPa), the thermal efficiency of power plants can be greatly improved, allowing them to generate more electricity from the same amount of fuel. These advanced steam turbines are typically found in modern coal-fired power plants, as well as some nuclear and combined-cycle plants.

Environmental concerns have led to the development of cleaner technologies for generating electricity from steam. The burning of fossil fuels in traditional steam plants releases carbon dioxide (CO₂) and other greenhouse gases into the atmosphere, contributing to climate change. To mitigate these effects, power plants have started implementing carbon capture and storage (CCS) technologies, which capture CO₂ emissions from the exhaust gases and store them underground or use them in industrial processes. Additionally, the growing adoption of renewable energy sources such as geothermal, solar thermal, and biomass for generating steam offers a way to produce electricity with fewer environmental impacts.

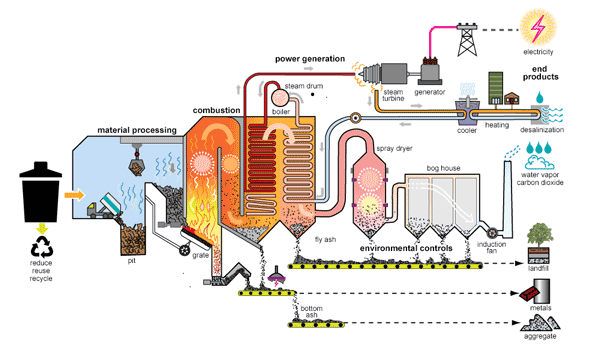

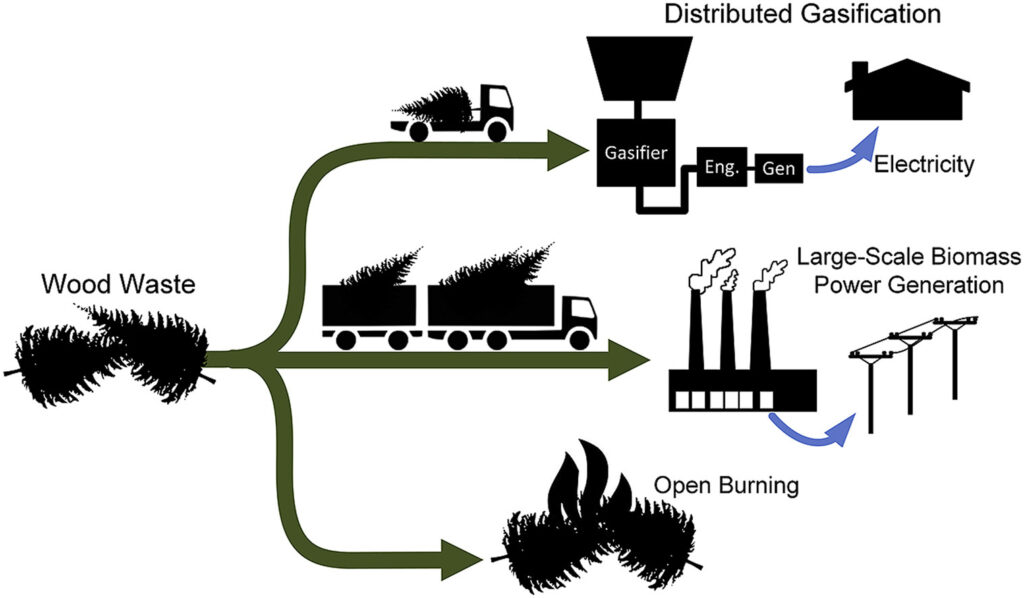

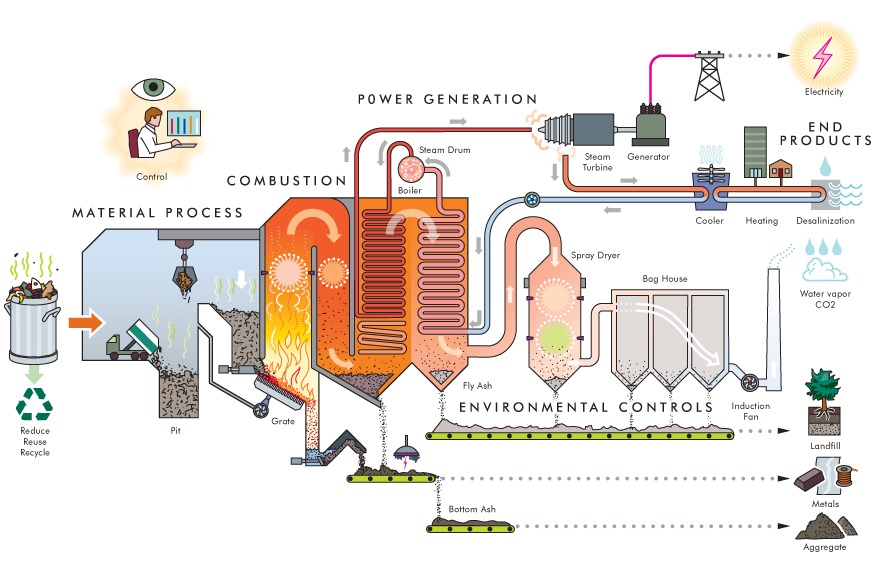

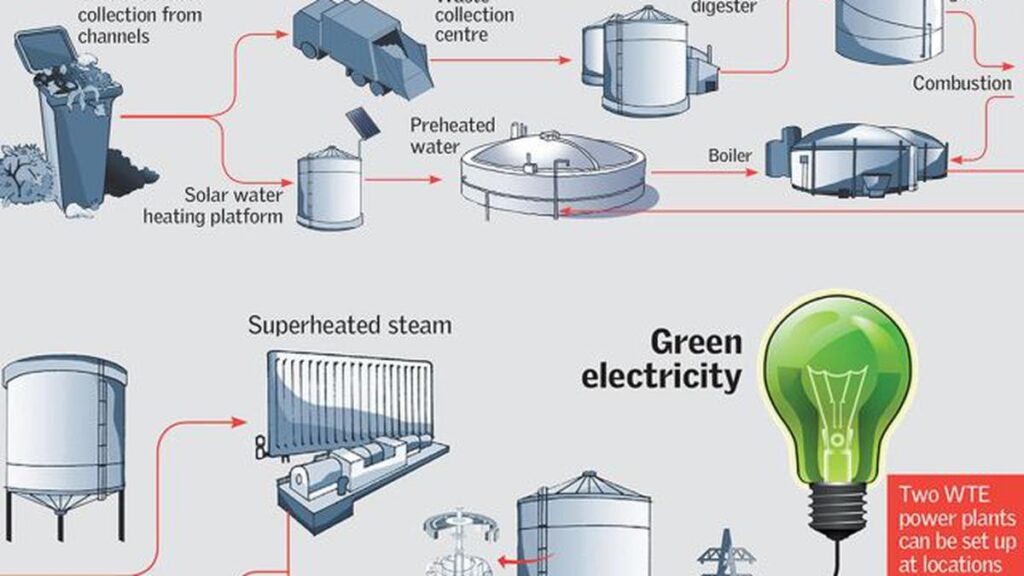

While fossil fuels continue to dominate global electricity generation from steam, the trend toward cleaner energy solutions is growing. Geothermal plants, for example, utilize steam sourced from the Earth’s natural heat, which is renewable and produces no direct emissions. Solar thermal power plants use mirrors or lenses to concentrate sunlight, heating a fluid that can generate steam. In some regions, biomass and waste-to-energy plants are being developed to convert organic materials into steam, contributing to reducing waste while generating power.

In summary, the generation of electricity from steam is a well-established and essential method of power generation, with significant advancements in turbine technology, heat recovery systems, and renewable energy integration. The efficiency of the process has been continuously improved over the years, and innovations such as combined-cycle plants and ultra-supercritical steam systems are pushing the boundaries of what is possible. As global energy demands rise and environmental concerns increase, the role of steam-based power generation in providing a reliable and cleaner energy supply will continue to evolve.

How to Generate Electricity from Steam?

As the world moves towards more sustainable energy practices, the role of steam-based electricity generation remains pivotal, albeit with shifts in how it is implemented and integrated with renewable energy sources. Traditional steam-based systems, which rely heavily on burning fossil fuels such as coal, natural gas, or oil, face increasing scrutiny due to their environmental impact, particularly in terms of carbon emissions. As a result, there has been a substantial push to modernize steam power plants, incorporating new technologies and improving the overall energy efficiency of the process.

One of the primary areas of focus in advancing steam-based electricity generation is the development and implementation of carbon capture, utilization, and storage (CCUS) technologies. These systems capture CO₂ emissions produced during the combustion of fossil fuels, preventing them from entering the atmosphere and contributing to climate change. In some systems, the captured CO₂ can be used in industrial processes, such as enhancing oil recovery or producing synthetic fuels, making the technology potentially economically viable in certain contexts. CCUS is seen as a critical part of reducing emissions from traditional fossil-fuel-based power plants, including steam turbines, and is a focal point of research for improving the environmental footprint of steam-based electricity generation.

Moreover, the energy transition is driving a renewed interest in hybrid systems that combine steam-based power generation with renewable energy sources. One notable example is the integration of solar thermal energy into steam power plants. Solar thermal plants use mirrors or lenses to concentrate sunlight and heat a working fluid, often oil or molten salt, which can then be used to produce steam. This process mirrors traditional steam generation, but the heat source is clean and renewable. In some cases, solar thermal plants are combined with conventional steam turbines in hybrid systems, where the steam turbine can operate using both solar heat and the backup from fossil fuels or other energy sources when sunlight is insufficient.

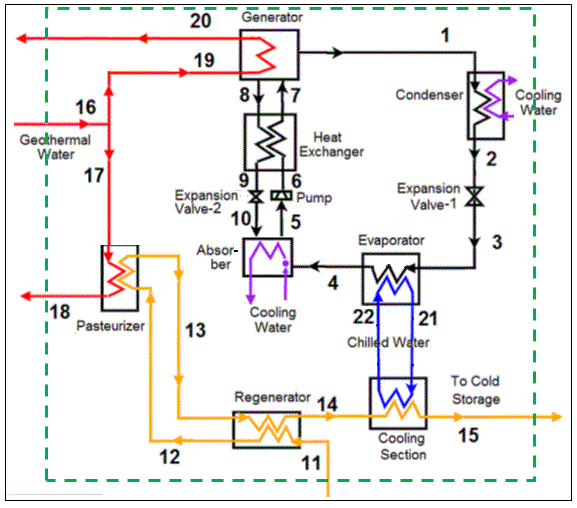

Geothermal energy, another renewable energy source, has long been a significant contributor to steam-based power generation. In geothermal power plants, steam is extracted from the Earth’s natural geothermal reservoirs and used to turn turbines. Geothermal plants operate efficiently in regions with significant geothermal activity, such as Iceland, parts of the United States (e.g., California), and the Philippines. These plants offer the advantage of being able to provide a constant, baseload supply of electricity, since the Earth’s heat is inexhaustible on human timescales. Unlike solar and wind power, which can be intermittent, geothermal energy is available 24/7, making it a reliable renewable energy source.

In addition to integrating renewable sources, there has been a push to utilize advanced materials and design innovations to increase the efficiency of steam turbines and reduce energy losses. High-efficiency materials are being developed to withstand the extreme pressures and temperatures encountered in modern steam turbines, allowing for more efficient power generation. For example, advanced alloys and coatings can improve the turbine’s resistance to corrosion and thermal degradation, extending the lifespan of the turbine and maintaining high levels of efficiency throughout its operation.

The ongoing trend toward supercritical and ultra-supercritical steam cycles is also helping to push the boundaries of steam-based power generation efficiency. By operating at pressures and temperatures beyond the traditional limits of the steam cycle, these advanced turbines extract more energy from the same amount of fuel. Supercritical plants are typically used in newer coal-fired power plants and some nuclear plants, allowing them to operate more efficiently while reducing emissions. However, the high cost of building and maintaining these advanced systems remains a challenge, which is why their adoption has been somewhat limited in many regions.

A promising area of development is the application of advanced digital technologies to monitor and optimize steam turbine performance. Through the use of sensors, data analytics, and artificial intelligence (AI), power plant operators can gain real-time insights into turbine performance, detect inefficiencies or anomalies, and adjust operational parameters to optimize efficiency and reduce downtime. Predictive maintenance tools are also being used to forecast when components of the turbine or other systems might fail, allowing for proactive maintenance to prevent costly failures and extend the operational life of the plant.

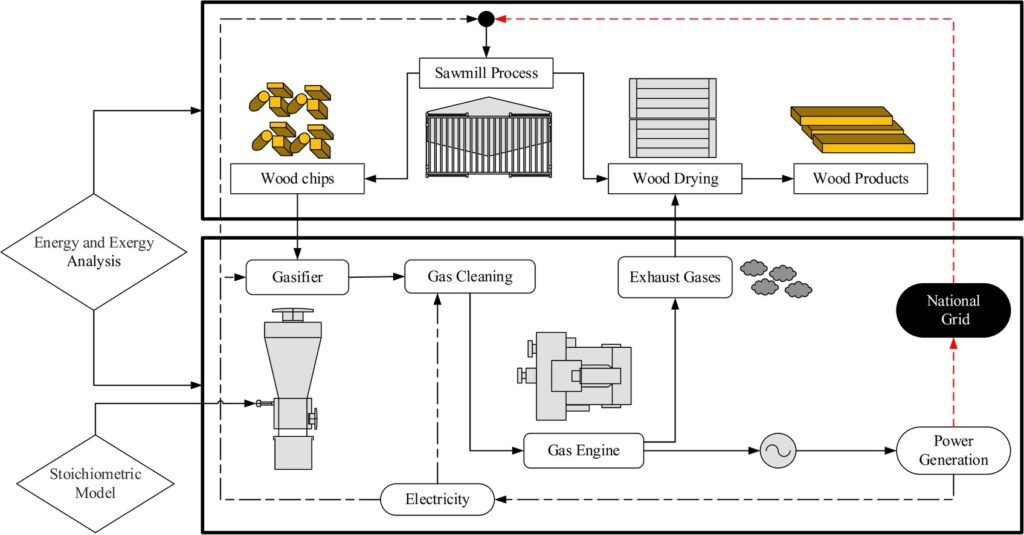

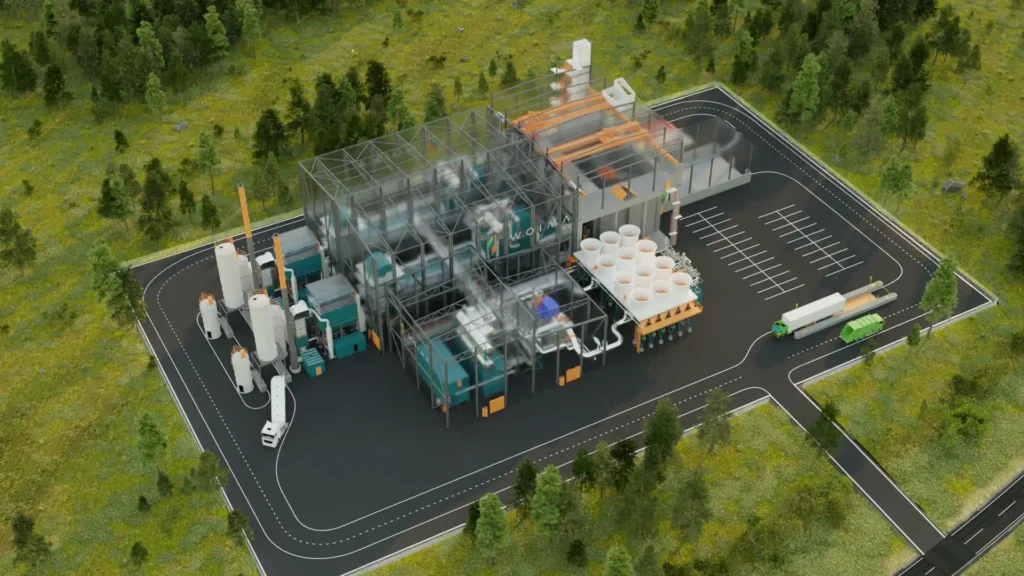

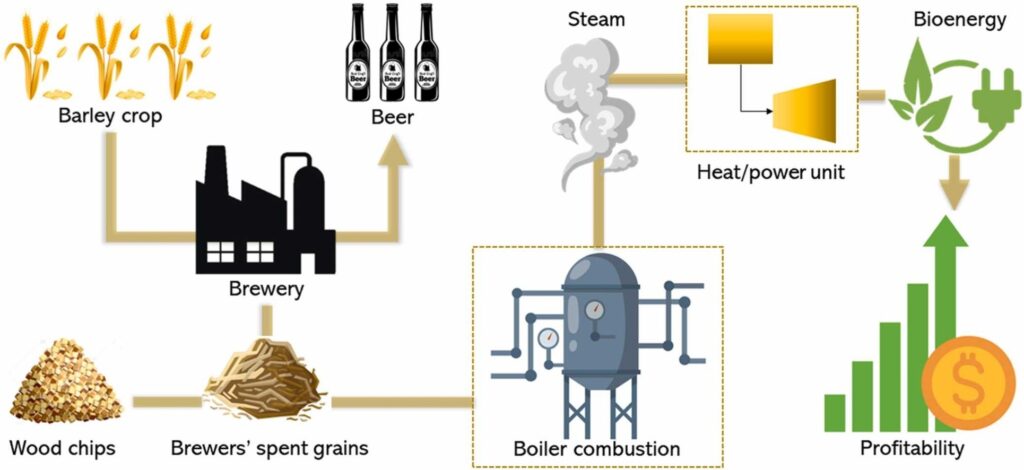

Alongside these technological advancements, there is growing interest in decentralized power generation models that use smaller, modular steam systems to provide local or regional electricity. Microgrids, which can be powered by small-scale steam turbines or other distributed energy sources, offer the potential for localized generation with lower transmission losses and enhanced grid resilience. For example, biomass plants, which use organic materials such as wood pellets or agricultural waste to generate steam, can be deployed in rural or remote areas to provide power. These systems are particularly attractive in regions with abundant biomass resources, where the steam can be produced locally and used to provide electricity with a minimal carbon footprint.

The global energy transition is also influencing the development of new energy systems that combine steam turbines with energy storage technologies. For example, some power plants are integrating steam turbines with large-scale battery storage systems or pumped hydro storage, which can store excess energy produced during periods of high demand or when renewable sources like solar and wind are producing more electricity than is needed. This stored energy can then be used to produce steam when demand is high or when renewable energy generation is low, providing grid stability and ensuring a constant supply of power.

In the future, steam turbines may also play a role in the hydrogen economy. Hydrogen, particularly green hydrogen produced through electrolysis powered by renewable electricity, is gaining attention as a potential clean energy source. Steam turbines could be used in combined systems that generate hydrogen through high-temperature electrolysis or other processes, and then use the hydrogen to generate power or heat in various applications. Additionally, steam turbines might be used in plants that convert hydrogen into electricity, acting as an efficient and flexible component in a hydrogen-powered energy system.

As the world continues to seek solutions to the challenges of climate change and energy security, steam-based electricity generation remains a cornerstone of the global energy mix. By evolving alongside advances in technology, renewable energy integration, and emission reduction strategies, the steam turbine continues to serve as a vital tool in the transition to a cleaner, more sustainable energy future.

Generating Electricity using waste heat from rotary kilns

Generating electricity using waste heat from rotary kilns is an innovative approach that aims to capture the excess thermal energy generated during industrial processes, typically in cement, lime, and other heavy industries, and convert it into electrical energy. Rotary kilns, which are large, cylindrical furnaces used for high-temperature processes such as calcination (in cement production), smelting, or chemical manufacturing, are notorious for producing a significant amount of waste heat. This waste heat can be harnessed through various methods to produce electricity, providing an energy-efficient solution and reducing the overall environmental impact of industrial operations.

Waste Heat Recovery Process

The process of generating electricity from waste heat in rotary kilns typically involves several key steps:

- Heat Recovery System (HRS): The first step is to capture the heat from the rotary kiln. This is often achieved through the installation of heat recovery systems, such as waste heat boilers or heat exchangers. The hot gases that exit the kiln, typically at temperatures of 300–400°C (or higher), pass through these systems, where the heat is transferred to a working fluid, usually water or air.

- Heat Transfer to Fluid: In many systems, waste heat is transferred to water in a waste heat boiler. The water absorbs the heat, turning it into steam. In other systems, air can be heated directly in heat exchangers and sent to other parts of the plant for use in various processes or in a thermal energy storage system.

- Steam Generation: When water is used, the waste heat from the rotary kiln boils the water, creating steam. This steam is then fed into a steam turbine generator system. The high-pressure steam drives the turbine, converting thermal energy into mechanical energy.

- Power Generation via Steam Turbine: The steam turbine is connected to a generator, and as the turbine spins, it drives the generator to produce electricity. The mechanical energy of the rotating turbine is converted into electrical energy via electromagnetic induction in the generator. The process is similar to traditional steam-based power generation but utilizes waste heat as the energy source instead of burning additional fuel.

- Condensation and Recirculation: After the steam passes through the turbine, it is condensed back into water in a condenser. The condensed water is then pumped back into the waste heat recovery system to be reheated, and the cycle continues, creating a closed-loop system.

- Supplementary Use of Exhaust Gases: In some cases, excess exhaust gases can be used for additional heat recovery. Instead of allowing these gases to escape into the atmosphere, they can be directed through secondary heat exchangers to further preheat incoming combustion air or to generate additional power, improving the overall energy efficiency of the system.

Efficiency Considerations

The efficiency of generating electricity using waste heat from rotary kilns depends on several factors, including the temperature of the exhaust gases, the design of the heat recovery system, and the efficiency of the steam turbine and generator. Generally, the higher the temperature of the waste gases, the more effective the heat recovery process will be, as it allows for greater amounts of thermal energy to be captured and converted into electricity.

The efficiency of waste heat recovery is also influenced by the system’s design. For example, in some modern systems, the waste heat boiler is designed to maximize the transfer of heat from the exhaust gases to the water, increasing the overall efficiency. Additionally, using multi-stage turbines or combining different waste heat recovery systems, such as using hot air and water-based heat exchangers, can help improve energy recovery.

Furthermore, the effectiveness of the steam turbine plays a significant role in the overall efficiency. Advanced turbines designed to operate at higher pressures and temperatures can extract more energy from the steam, increasing the amount of electricity generated. Similarly, the generator’s efficiency in converting mechanical energy into electrical energy affects the overall performance of the system.

Types of Systems for Generating Electricity from Waste Heat

There are several different systems designed to recover and convert waste heat from rotary kilns into electricity, each with its own advantages and applications:

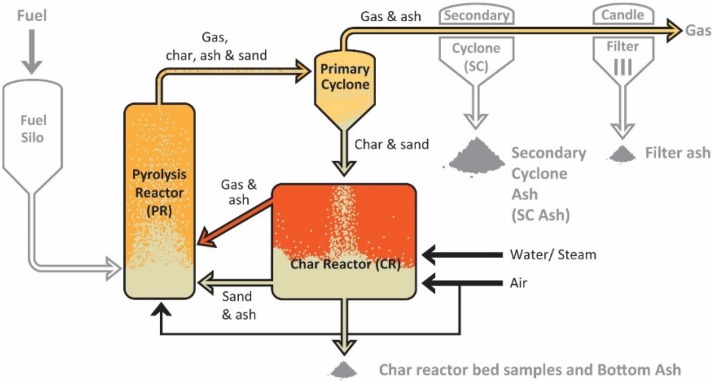

- Rankine Cycle System (Steam Cycle): The Rankine cycle is the most common method for generating electricity from waste heat in rotary kilns. This system uses the waste heat to produce steam, which drives a steam turbine connected to a generator. The Rankine cycle is widely used in industries where a significant amount of waste heat is generated at relatively high temperatures.

- Organic Rankine Cycle (ORC) System: The Organic Rankine Cycle (ORC) is a variation of the traditional Rankine cycle that uses an organic fluid, such as refrigerants, instead of water to drive the turbine. The organic fluid has a lower boiling point than water, which allows it to be used for lower-temperature waste heat recovery (typically in the range of 100–300°C). This makes ORC systems particularly well-suited for applications where the waste heat from rotary kilns is not high enough to generate steam in a traditional Rankine cycle.

- Thermoelectric Generators (TEGs): Another emerging technology for generating electricity from waste heat is the use of thermoelectric generators (TEGs). These devices work based on the Seebeck effect, where a temperature difference across two different materials creates an electrical voltage. While TEGs have lower efficiencies compared to steam turbine-based systems, they are compact and can be used in specific applications where small-scale electricity generation is needed.

- Kalina Cycle: The Kalina cycle is an advanced thermodynamic cycle that uses a mixture of water and ammonia as the working fluid. The advantage of the Kalina cycle is that it can achieve higher thermal efficiency than the traditional Rankine cycle, especially when dealing with waste heat at moderate temperatures. The Kalina cycle can be used in applications where the temperature of the waste heat is not high enough for conventional steam turbines to operate efficiently.

- Gas Turbine Systems: For rotary kilns that produce waste heat in the form of hot gases, a gas turbine can be used to generate electricity. In this system, the exhaust gases from the kiln are passed through the gas turbine, which converts the thermal energy into mechanical energy. The rotating turbine then drives a generator to produce electricity. While this system is more commonly used in industries that burn natural gas, it can also be applied to rotary kilns with high-temperature exhaust gases.

Benefits of Waste Heat Recovery for Power Generation

- Energy Efficiency: Capturing and using waste heat from rotary kilns improves the overall energy efficiency of the industrial process. By converting waste heat into electricity, industries can reduce their reliance on external power sources, leading to cost savings and a smaller carbon footprint.

- Reduced Environmental Impact: Using waste heat reduces the amount of energy that must be generated from conventional sources, such as fossil fuels, which in turn lowers greenhouse gas emissions. It also helps to reduce the need for cooling systems that consume additional energy.

- Cost Savings: By harnessing waste heat for power generation, industrial facilities can reduce their energy costs. The electricity generated can be used internally to power equipment or sold back to the grid, providing a potential source of revenue.

- Sustainability: Waste heat recovery contributes to the sustainability goals of industries by promoting the use of renewable energy (in the form of recovered waste heat) and reducing the overall consumption of fossil fuels.

Challenges

While the potential benefits of generating electricity from waste heat are significant, there are also some challenges. The initial capital cost of installing waste heat recovery systems can be high, and the return on investment may take several years to materialize. Furthermore, the system’s efficiency depends heavily on the temperature and volume of waste heat available, which can vary depending on the type of rotary kiln and the process conditions. Finally, the integration of these systems into existing industrial operations can be complex, requiring careful planning and potentially significant modifications to the plant’s infrastructure.

In conclusion, generating electricity from waste heat in rotary kilns offers a promising method to improve energy efficiency, reduce costs, and decrease the environmental impact of industrial processes. By capturing the waste heat produced during high-temperature operations and converting it into electrical energy, industries can make more sustainable use of the resources at their disposal, while contributing to a greener, more energy-efficient industrial landscape.

As industries continue to look for ways to improve energy efficiency and reduce environmental impacts, the integration of waste heat recovery systems for power generation in rotary kilns becomes an increasingly attractive solution. This process not only helps businesses lower operational costs but also supports the broader goals of sustainability and reducing carbon emissions. As we explore further, it’s important to dive deeper into the challenges, innovations, and potential applications of these systems.

Advanced Technological Innovations in Waste Heat Recovery

The ongoing development of waste heat recovery systems is focused on improving both efficiency and cost-effectiveness. Some of the most notable innovations include:

- Advanced Heat Exchangers: Modern heat exchangers are designed to transfer heat more efficiently, improving the overall performance of waste heat recovery systems. High-efficiency heat exchangers, such as plate heat exchangers or spiral heat exchangers, can capture heat from exhaust gases at higher temperatures and transfer it to the working fluid more effectively. These systems can be tailored to suit the specific characteristics of the rotary kiln’s exhaust, whether it’s in the form of hot gases, molten materials, or particulates.

- Modular and Scalable Systems: For industries that operate on a smaller scale or cannot afford large capital expenditures upfront, modular waste heat recovery systems are becoming more popular. These systems can be tailored to specific needs and installed incrementally, reducing the initial investment required. Over time, companies can expand the system as needed, improving its efficiency and power output without significant disruptions to existing operations.

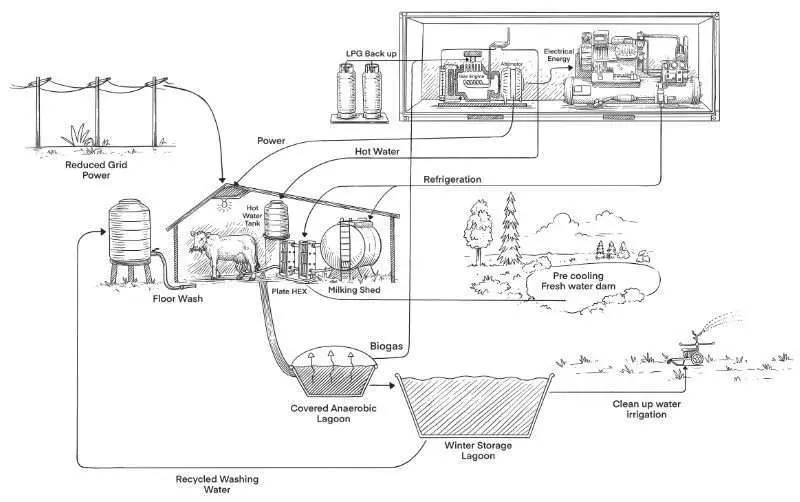

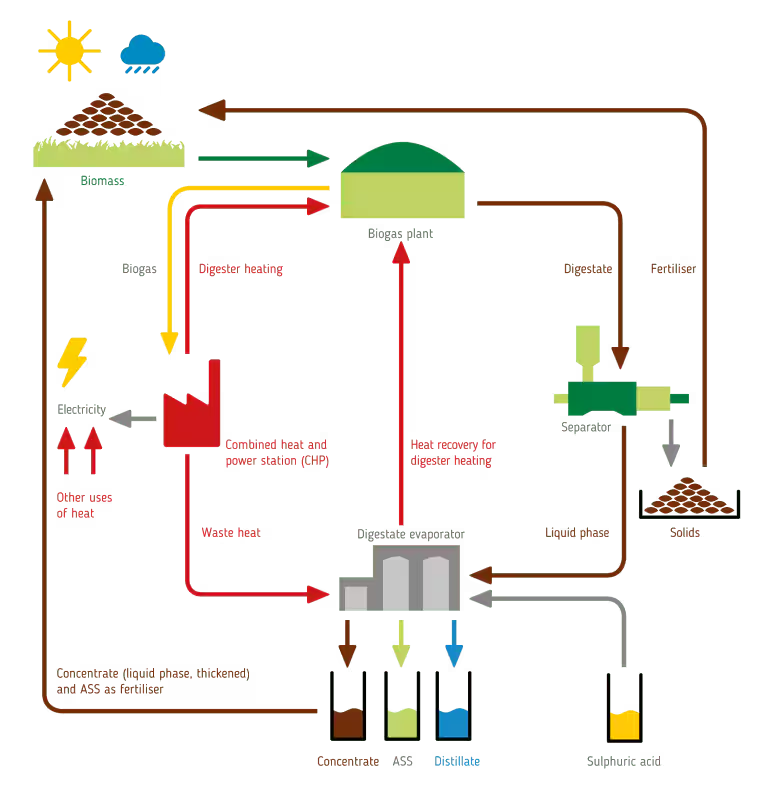

- Integrated Combined Heat and Power (CHP) Systems: Many waste heat recovery systems are now being integrated with Combined Heat and Power (CHP) systems, also known as cogeneration. These systems simultaneously produce electricity and useful heat from the same energy source, optimizing overall energy use. In a rotary kiln setup, CHP can use the recovered heat not only to generate electricity but also to provide steam or hot water for other parts of the process, such as drying, heating, or chemical reactions, thus improving overall energy efficiency.

- Thermal Energy Storage: One of the limitations of waste heat recovery systems is that the heat generated by the rotary kiln is often intermittent, depending on production cycles or fluctuations in kiln operation. To address this, some systems are incorporating thermal energy storage solutions, such as molten salt or phase-change materials, to store excess heat when it is available. This stored energy can then be released and used later, improving system flexibility and ensuring a more consistent supply of power.

- Hybrid Systems: Hybrid systems that combine multiple forms of waste heat recovery technology are also gaining traction. For instance, integrating both organic Rankine cycle (ORC) and steam Rankine cycle systems can allow for the efficient recovery of waste heat at varying temperatures. The lower-temperature heat can be used with an ORC system, while the higher-temperature heat can be used with a traditional steam Rankine cycle. This approach maximizes energy recovery across a broader range of temperatures.

Industry-Specific Applications and Benefits

- Cement Industry: The cement industry is one of the largest consumers of energy in the industrial sector, largely due to the high temperatures required in rotary kilns for the production of clinker. Cement plants are ideal candidates for waste heat recovery systems because they produce significant amounts of waste heat that can be harnessed. Using waste heat to generate electricity in cement plants can drastically reduce electricity costs, often offsetting the need for external power sources, while also improving the overall energy efficiency of the plant.

- Steel and Metal Industries: Steel manufacturing, especially the production of iron and steel in blast furnaces and rotary kilns, generates enormous amounts of waste heat. This heat can be recovered and used to generate electricity, providing a more sustainable energy source for steel plants. Additionally, the use of waste heat can reduce reliance on coal, helping industries meet increasingly stringent emissions regulations.

- Lime and Other Chemical Manufacturing: Similar to cement production, the lime industry also uses rotary kilns to produce lime from limestone. These kilns operate at high temperatures and release significant amounts of waste heat that can be captured and used for electricity generation. Other chemical manufacturing processes, such as those used in glass, ceramics, and brick production, also generate heat that can be recovered to produce power, improving energy efficiency and reducing environmental footprints.

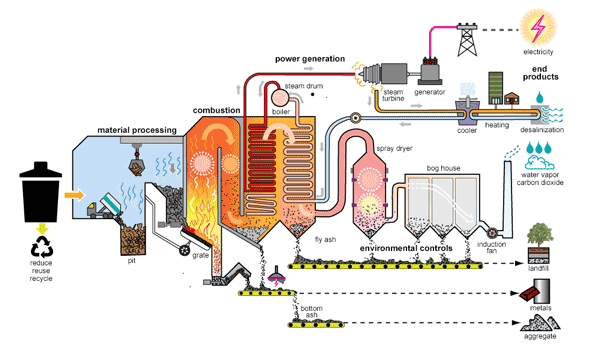

- Waste-to-Energy Plants: In waste-to-energy plants that burn municipal solid waste (MSW) or biomass, rotary kilns are used to combust the waste, often at very high temperatures. These plants can incorporate waste heat recovery systems to generate electricity. The captured energy not only helps power the plant but can also be fed into the grid, providing additional energy for surrounding communities.

Economic and Environmental Impacts

The adoption of waste heat recovery systems can lead to significant economic and environmental benefits:

- Cost Savings: By recovering waste heat and converting it into electricity, industries can drastically reduce their reliance on purchased energy. In some cases, the electricity generated can be used internally to power the plant, reducing operational costs. In other cases, excess electricity can be sold back to the grid, creating a potential new revenue stream for the business.

- Reduced Carbon Footprint: Utilizing waste heat for power generation reduces the need for additional fossil fuel consumption, which in turn reduces greenhouse gas emissions. This is a key benefit for companies aiming to reduce their environmental footprint and comply with environmental regulations, such as emissions limits or carbon tax initiatives.

- Improved Energy Security: Waste heat recovery systems help industrial facilities become more energy independent. By reducing reliance on external power suppliers, companies can better control their energy supply, particularly in areas where energy prices are volatile or unreliable. This increased energy security is especially important for energy-intensive industries, such as cement and steel manufacturing.

- Compliance with Regulations: As governments around the world implement stricter environmental regulations, industries that generate large amounts of waste heat face increasing pressure to improve energy efficiency and reduce emissions. Waste heat recovery systems can help these industries comply with regulations related to energy efficiency, emissions reduction, and sustainability goals.

Challenges and Future Prospects

While the benefits of waste heat recovery are clear, there are several challenges to widespread adoption:

- Initial Capital Costs: The installation of waste heat recovery systems requires significant upfront investment in equipment, engineering, and integration with existing industrial processes. This can be a barrier for small and medium-sized businesses or those with tight capital budgets. However, as technologies improve and economies of scale are realized, the costs of such systems are expected to decrease over time.

- System Integration: Integrating waste heat recovery systems with existing rotary kiln setups can be complex. Modifications to the kiln or surrounding infrastructure may be needed, which can disrupt operations and increase costs. A thorough analysis of the plant’s waste heat potential, process requirements, and system design is essential for ensuring successful implementation.

- Operational Challenges: Waste heat recovery systems require careful monitoring and maintenance to ensure optimal performance. Factors such as fluctuations in kiln operation, variations in waste heat temperature, and wear and tear on components can affect system efficiency. Advanced monitoring systems and predictive maintenance technologies are being developed to address these challenges and improve system reliability.

Conclusion

Generating electricity from waste heat in rotary kilns offers a powerful solution to improve energy efficiency, reduce operational costs, and decrease environmental impacts. As industries continue to embrace sustainability and move toward cleaner energy practices, the integration of waste heat recovery technologies will play a crucial role in advancing energy efficiency in energy-intensive sectors. The ongoing development of advanced systems, such as modular units, hybrid systems, and integrated CHP solutions, is making these technologies more accessible and cost-effective, paving the way for a more sustainable and energy-efficient industrial future.

As the push for energy efficiency and sustainability in industrial sectors intensifies, the utilization of waste heat recovery systems continues to evolve. The integration of such systems into rotary kiln operations is not only a way to cut energy costs but also a vital step toward reducing greenhouse gas emissions and enhancing overall plant performance. As we continue to explore the potential of these systems, it’s important to examine emerging trends, policy incentives, and future technologies that will drive their further adoption.

Emerging Trends in Waste Heat Recovery Systems

- Digitalization and Smart Systems: The integration of digital technologies into waste heat recovery systems is one of the key trends shaping the future of industrial energy efficiency. Advanced sensors, Internet of Things (IoT) devices, and cloud-based data platforms are being deployed to monitor real-time performance of waste heat recovery systems. These technologies allow for continuous performance tracking, predictive maintenance, and optimization, ensuring that systems operate at peak efficiency. AI-driven analytics can also predict fluctuations in waste heat production and optimize system operations to minimize energy waste and maximize power generation.

- Integration with Renewable Energy: As industries aim to reduce their carbon footprints and transition to cleaner energy sources, there is growing interest in integrating waste heat recovery systems with renewable energy technologies. For example, waste heat recovery can be combined with solar thermal or geothermal energy systems to create hybrid power plants. Solar thermal energy can provide additional heat to supplement the energy produced from rotary kiln waste heat, enhancing overall system efficiency. Similarly, waste heat could be stored in thermal energy storage systems to be used in conjunction with wind or solar power, providing a stable and continuous energy supply.

- Advanced Materials for Heat Transfer: Advances in material science are also making waste heat recovery more efficient. New heat transfer materials, including advanced alloys, ceramics, and coatings, are being developed to withstand higher temperatures and corrosive environments. These materials can significantly improve the efficiency of heat exchangers, making it easier to capture heat from rotary kilns and other high-temperature industrial processes. In addition, research into thermoelectric materials is exploring their potential to convert heat directly into electricity, further enhancing waste heat recovery.

- Waste Heat for District Heating: Instead of generating electricity directly from waste heat, some industrial facilities are focusing on using waste heat for district heating systems, especially in regions where large-scale industrial complexes are located near residential or commercial areas. Waste heat captured from rotary kilns can be used to supply hot water or steam to nearby buildings, reducing the need for fossil-fuel-powered heating systems. This approach not only benefits the industrial facility by increasing its overall energy efficiency but also provides a low-cost, low-emission energy source to local communities.

- Energy-as-a-Service (EaaS) Models: As the energy landscape shifts, some companies are moving away from traditional ownership of energy generation systems toward energy-as-a-service (EaaS) models. In this model, waste heat recovery and other energy systems are provided as a service, where third-party providers install, operate, and maintain the systems while the industrial facility pays for the electricity generated or energy saved. This model reduces the capital investment burden for businesses and makes advanced waste heat recovery systems more accessible to smaller enterprises. Over time, such partnerships can lead to increased adoption of waste heat recovery technologies across various industries.

Policy Incentives and Regulatory Support

Governments around the world are introducing policies to incentivize the adoption of waste heat recovery systems. These policies include financial incentives, tax credits, and regulatory mandates that encourage companies to invest in energy-efficient technologies. Some of the key policy drivers include:

- Carbon Emissions Reduction Targets: As global efforts to mitigate climate change intensify, industries are being pressured to reduce their carbon emissions. Waste heat recovery systems play a crucial role in this by helping companies minimize the amount of energy consumed from fossil fuels. Many countries, particularly in Europe and North America, have set ambitious targets for carbon reduction, and industries that invest in waste heat recovery can help meet these targets while benefiting from government incentives.

- Energy Efficiency Regulations: In addition to carbon emission reduction targets, many regions have enacted energy efficiency regulations that require industrial plants to reduce energy consumption. In some jurisdictions, energy-intensive industries like cement, steel, and chemicals are required to adopt energy-saving technologies and reduce their energy intensity. Waste heat recovery systems can help meet these requirements by enabling industries to reuse their own waste energy, thus lowering overall energy demand.

- Subsidies and Grants: Several governments offer financial incentives, such as grants or subsidies, to companies that invest in energy-saving technologies like waste heat recovery. These incentives help offset the high upfront costs of installation and integration, making the transition to waste heat recovery more financially viable for industrial operators. In some cases, grants are provided for research and development to advance the technology and improve its performance, further driving innovation in the field.

- International Climate Agreements: As part of international climate agreements, such as the Paris Agreement, countries are increasingly committed to transitioning to cleaner, more sustainable energy systems. Industrial sectors in these countries are expected to contribute to national climate goals. Waste heat recovery, which reduces dependence on fossil fuels and enhances energy efficiency, aligns with these goals, prompting governments to offer support and recognition for companies that adopt these technologies.

Future Technologies in Waste Heat Recovery

Looking ahead, several emerging technologies have the potential to revolutionize the way waste heat is captured and converted into usable energy:

- Direct Thermoelectric Conversion: Thermoelectric materials have the potential to directly convert heat into electricity without the need for a mechanical engine (like a steam turbine). These materials generate electricity through the Seebeck effect, which occurs when there is a temperature difference between two different conductive materials. Though current thermoelectric systems are less efficient than traditional methods like steam turbines, ongoing research is focused on improving the efficiency of thermoelectric generators, potentially making them viable for small-scale waste heat recovery systems in rotary kilns and other industrial applications.

- Heat-Driven Absorption Refrigeration: Absorption refrigeration is a cooling method that uses heat to drive the refrigeration cycle, rather than mechanical compressors. In industries like cement production, where rotary kilns generate significant waste heat, absorption refrigeration can be used for cooling purposes within the plant or for nearby district cooling applications. By utilizing waste heat for refrigeration, companies can increase the overall efficiency of their energy systems and reduce the need for electricity-intensive cooling technologies.

- Low-Grade Waste Heat Recovery: Another area of innovation is the recovery of low-grade waste heat (i.e., heat generated at lower temperatures, typically below 100°C) that has historically been difficult to utilize effectively. Technologies such as the Organic Rankine Cycle (ORC) are being adapted to capture this low-grade heat and convert it into electricity. This opens up opportunities for industries that produce large volumes of low-temperature waste heat, like food processing or textiles, to generate electricity and improve their energy efficiency.

- Hybrid Thermoelectric and Rankine Cycle Systems: Combining thermoelectric generators with traditional Rankine cycle systems could enhance waste heat recovery by addressing a broader temperature range. The thermoelectric system could handle low-temperature waste heat, while the Rankine cycle system could capture higher-temperature waste heat. This hybrid approach could maximize overall energy recovery and improve efficiency for a wide range of industrial applications.

Conclusion: The Future of Waste Heat Recovery

The future of generating electricity from waste heat in rotary kilns is bright, driven by technological innovations, supportive policies, and a global push toward sustainability. By harnessing the significant amounts of waste heat produced in energy-intensive industrial processes, businesses can reduce their environmental impact, improve energy efficiency, and cut operational costs. As the technology continues to evolve, especially with the integration of digitalization, renewable energy sources, and new materials, the potential for waste heat recovery will only continue to grow. Ultimately, industries that invest in these systems will not only benefit from improved performance but will also play a critical role in the global transition to a more sustainable and low-carbon energy future.

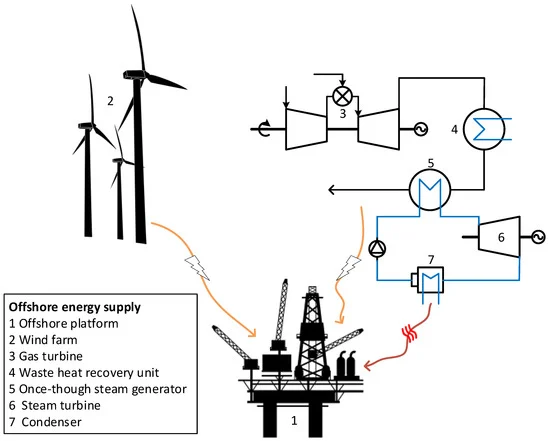

The oil and gas industry is a significant player in global energy markets, but it also generates large amounts of waste heat as a byproduct of exploration, extraction, refining, and transportation processes. This waste heat, often released through exhaust gases, flared gas, or thermal processes, represents a substantial, untapped resource that can be harnessed for power generation. The recovery and utilization of this waste heat can enhance energy efficiency, lower operational costs, and reduce the carbon footprint of the industry.

Overview of Heat Generation in the Oil and Gas Industry

In the oil and gas sector, heat is generated through a variety of activities, including:

- Upstream Processes (Exploration and Extraction): Exploration and extraction of oil and natural gas often involve drilling, well stimulation, and production processes that generate significant amounts of waste heat. During hydraulic fracturing (fracking) or oil extraction from offshore platforms, for example, large amounts of energy are required to operate pumps, compressors, and other equipment, and a significant portion of this energy is released as waste heat.

- Refining and Processing: Oil refining processes such as distillation, cracking, and hydroprocessing involve high temperatures. These processes generate substantial waste heat in the form of hot gases or heated fluids, which, if not recovered, are vented into the atmosphere. Refinery operations are particularly energy-intensive and present a prime opportunity for waste heat recovery.

- Natural Gas Compression and Transportation: The transportation and compression of natural gas, both onshore and offshore, require substantial amounts of energy. Compressors, pipelines, and LNG (liquefied natural gas) facilities are often sources of waste heat, as compressors in particular can operate at high temperatures. This heat is typically vented and wasted unless captured for recovery.

- Flaring and Venting: Flaring is a common practice in the oil and gas industry, where natural gas that cannot be captured or processed is burned off, typically in remote drilling operations. This process generates significant amounts of heat and carbon emissions, but the potential to capture and convert this heat into electricity through waste heat recovery systems could significantly reduce emissions and generate value.

Methods of Harnessing Waste Heat for Electricity Generation

There are several established and emerging technologies that can capture and convert waste heat from the oil and gas industry into electricity. The choice of technology depends on the temperature and nature of the waste heat, as well as the specific needs of the facility. These technologies include:

1. Organic Rankine Cycle (ORC)

The Organic Rankine Cycle (ORC) is a well-established technology for converting low- to medium-temperature waste heat into electricity. The ORC works similarly to a traditional steam Rankine cycle but uses an organic working fluid with a lower boiling point than water. This allows ORC systems to operate efficiently at lower temperatures, making them ideal for recovering heat from sources like natural gas compressors, flare stacks, or waste heat in refinery processes.

The ORC system is composed of several key components:

- Heat Exchanger: Captures the waste heat from the industrial process and transfers it to the organic working fluid.

- Turbine: The heated fluid expands, driving a turbine connected to a generator to produce electricity.

- Condenser: The expanded fluid is cooled and condensed back into a liquid before being recirculated.

Advantages of ORC systems include their ability to operate efficiently at lower temperatures and their scalability, making them suitable for a variety of oil and gas operations. However, their efficiency tends to decrease with very low-temperature waste heat sources, so they are best used with heat sources in the range of 150-400°C.

2. Steam Rankine Cycle (SRC)

For high-temperature waste heat recovery, particularly in refining and extraction processes, the Steam Rankine Cycle (SRC) remains one of the most effective methods for electricity generation. Similar to ORC, SRC utilizes a working fluid (in this case, water) that is heated by the waste heat and converted into steam. The steam expands through a turbine, which drives a generator to produce electricity.

SRC systems are highly efficient when capturing heat from sources with temperatures greater than 400°C, such as combustion exhaust gases or high-temperature refinery processes. However, they are typically more complex and require significant infrastructure for steam generation, cooling, and condensation.

3. Thermoelectric Generators (TEGs)

Thermoelectric generators are solid-state devices that directly convert heat into electricity using the Seebeck effect. When there is a temperature difference between two materials, a voltage is generated, which can be used to drive an electric current. TEGs can be used to recover waste heat from a variety of sources in the oil and gas industry, including exhaust gases, flare stacks, and even equipment surfaces.

While TEGs are not yet as widely used in large-scale applications as ORC or SRC, they offer several benefits:

- Compact and scalable: TEGs are relatively small and can be integrated into existing equipment without the need for large mechanical systems.

- Low maintenance: Because they have no moving parts, TEGs are less prone to wear and tear compared to traditional heat recovery systems.

- Efficiency improvements: Research into advanced thermoelectric materials is improving the efficiency of these devices, potentially making them more viable for industrial applications.

However, the efficiency of TEGs is currently lower than that of traditional Rankine systems, and the cost of high-performance materials can be a limiting factor. Ongoing research into new materials and nanotechnology is expected to improve the performance of thermoelectric systems over time.

4. Heat Recovery Steam Generators (HRSG)

Heat Recovery Steam Generators (HRSG) are commonly used in combined heat and power (CHP) systems to recover waste heat from flue gases. In the oil and gas industry, HRSGs are particularly useful in power generation facilities and combined-cycle plants, where high-temperature waste heat from gas turbines can be used to generate steam. This steam can then drive a steam turbine to generate additional electricity, significantly improving the overall efficiency of the power generation system.

HRSGs typically consist of:

- Heat exchangers: These transfer heat from exhaust gases to water or another fluid, generating steam.

- Steam turbine: The generated steam is used to drive a turbine and generate electricity.

- Cooling system: After passing through the turbine, the steam is cooled and condensed before being recirculated.

This technology is widely used in large-scale power plants and offers a high level of efficiency. However, it is typically most suitable for facilities with continuous high-temperature waste heat, such as gas turbines or large-scale oil and gas processing plants.

5. Flare Gas Recovery Systems

Flaring is a major source of wasted energy in the oil and gas industry, especially in remote areas where infrastructure for capturing and transporting natural gas is not available. Flare gas recovery systems can capture the flared gas and use it to generate electricity.

These systems use combustion engines or turbines to burn the captured flare gas, converting its energy into mechanical power that drives a generator. This process not only reduces the need for flaring but also provides a useful power source for remote oil and gas operations. Additionally, the recovered energy can be used for internal consumption, such as powering equipment or providing heat for other industrial processes.

Flare gas recovery systems are typically employed in offshore oil platforms, gas gathering stations, and remote production sites, where they help minimize the environmental impact of gas flaring while providing a reliable and cost-effective source of electricity.

Economic and Environmental Benefits

The recovery of waste heat in the oil and gas industry provides both economic and environmental benefits:

1. Cost Savings

- Reduced Energy Consumption: By recovering waste heat and converting it into electricity, oil and gas companies can reduce their dependence on external power sources, lowering energy bills.

- Flare Gas Utilization: By recovering flare gas and converting it to electricity, companies can reduce or eliminate the need for expensive natural gas imports or diesel generators, especially in remote locations.

2. Reduced Carbon Emissions

- Lower Carbon Footprint: By capturing and converting waste heat instead of relying on fossil fuels for electricity generation, the carbon emissions of oil and gas operations are reduced. This can help companies meet emissions reduction targets and align with global sustainability goals.

- Flaring Reduction: Recovering flare gas for power generation reduces the amount of gas flared into the atmosphere, helping to mitigate harmful greenhouse gas emissions.

3. Improved Sustainability

- Waste heat recovery supports the oil and gas industry’s transition toward more sustainable operations. It makes use of otherwise wasted energy, reducing resource consumption and improving the overall energy efficiency of operations.

Conclusion

Generating electricity from waste heat in the oil and gas industry is a growing opportunity for improving energy efficiency, reducing operational costs, and minimizing environmental impacts. The implementation of technologies like the Organic Rankine Cycle, Thermoelectric Generators, Steam Rankine Cycles, and flare gas recovery systems can help companies convert waste heat into usable energy, enabling them to reduce reliance on external energy sources, improve sustainability, and meet regulatory demands. As the industry continues to prioritize energy efficiency and environmental responsibility, the adoption of waste heat recovery technologies will play a crucial role in shaping a more sustainable future for the oil and gas sector.

As the demand for energy efficiency and sustainability continues to rise, the oil and gas industry is increasingly focused on reducing its carbon footprint and optimizing energy consumption. The recovery and use of waste heat represent one of the most practical and impactful strategies to achieve these objectives. To further elaborate, there are several key aspects to consider as the industry moves forward in harnessing waste heat for electricity generation.

1. Technological Advancements and Innovations in Heat Recovery

While traditional methods for waste heat recovery like ORC, SRC, and HRSG systems are well-established, new and emerging technologies are helping to further optimize the process and increase energy generation. Advancements in materials, system integration, and efficiency improvements are continuously enhancing the potential for oil and gas companies to generate electricity from waste heat. Some notable innovations include:

a. High-Temperature Materials

One of the challenges in waste heat recovery is the need for materials that can withstand the extremely high temperatures found in oil and gas operations, particularly in refinery and extraction processes. Research into advanced heat-resistant materials, including high-temperature alloys and ceramics, is improving the longevity and efficiency of heat exchangers and turbines. These materials can handle higher temperatures more effectively, leading to greater energy capture and efficiency in heat recovery systems.

b. Hybrid Systems

Hybrid systems that combine different methods of waste heat recovery—such as pairing ORC with traditional steam turbines or thermoelectric generators—are gaining attention as they can maximize electricity generation across a wider range of temperatures. Hybrid systems have the potential to capture both low- and high-temperature heat from various sources in an oil or gas facility, increasing overall efficiency and reducing waste heat loss.

c. Closed-Loop Heat Recovery

Closed-loop systems are gaining popularity in situations where waste heat cannot be directly used for power generation due to environmental or operational concerns. In a closed-loop system, heat is captured and stored in a secondary fluid, which is then used to power a turbine or generate electricity through other means. These systems have the advantage of preventing waste heat from escaping into the environment and can be designed to integrate seamlessly into existing infrastructure without significant modifications.

d. Energy Storage Integration

Integrating energy storage systems with waste heat recovery technologies is another area of development. Thermal energy storage (TES) can store excess heat generated during peak demand periods, which can then be converted into electricity when needed. This integration helps smooth out fluctuations in power generation and improves the reliability of electricity produced from waste heat.

2. Operational Efficiency and Cost Optimization

The recovery of waste heat does not just generate electricity—it also enhances the overall operational efficiency of oil and gas facilities. By reducing energy consumption and reliance on external power sources, companies can significantly lower operational costs.

a. Fuel Savings

In remote oil and gas operations, where access to grid electricity is limited or nonexistent, waste heat recovery systems can replace or reduce the need for diesel generators and other expensive power sources. These generators are typically used for backup power or to meet the electricity demand of facilities, and their fuel costs can be a major expense. By utilizing waste heat to generate electricity on-site, companies can save fuel and reduce logistical costs associated with fuel transportation.

b. Efficiency Gains in Production

Energy efficiency is a critical factor in maximizing production output and minimizing costs in the oil and gas sector. By recovering waste heat from processes such as compression, refining, and fracking, oil and gas operators can reduce the energy required to maintain operations, leading to better overall efficiency. Additionally, recovered energy can be used to power other processes within the plant, such as heating, cooling, or even the operation of electrical equipment, further optimizing energy consumption.

c. Lifecycle Cost Benefits

While the initial investment in waste heat recovery systems can be substantial, the long-term financial benefits typically outweigh the upfront costs. By reducing the reliance on purchased electricity or fuel, companies can recover their investment over time through energy savings. Moreover, waste heat recovery systems have a relatively low operational and maintenance cost, especially when compared to traditional power generation methods, further enhancing their economic feasibility.

3. Environmental and Regulatory Compliance

As the global regulatory landscape becomes more stringent in terms of emissions reduction, waste heat recovery systems offer a clear path for oil and gas companies to meet both local and international environmental standards.

a. Carbon Emissions Reduction

The oil and gas industry is one of the largest contributors to global greenhouse gas emissions. Flare gas, in particular, is a significant source of methane emissions, a potent greenhouse gas. By capturing flare gas and converting it into electricity, the industry can mitigate the harmful environmental impacts of flaring and reduce carbon emissions.

Furthermore, using waste heat to generate electricity instead of relying on fossil fuel-powered generators or grid electricity can significantly lower the overall carbon footprint of operations. Companies can achieve carbon reduction goals set by international climate agreements, such as the Paris Agreement, and demonstrate their commitment to sustainability.

b. Compliance with Emission Standards

Governments worldwide are tightening regulations around emissions from industrial facilities, including the oil and gas sector. In many regions, companies are required to reduce their emissions by a certain percentage each year. The installation of waste heat recovery systems provides a cost-effective way to comply with these regulations by decreasing the need for fuel combustion and reducing greenhouse gas emissions.

Many oil and gas companies are also being incentivized through tax credits, subsidies, and regulatory exemptions for investing in cleaner energy technologies. Waste heat recovery falls within the category of low-carbon technologies and can qualify companies for such incentives, further improving the financial viability of these systems.

c. Reputation and Corporate Responsibility

As public awareness about climate change and sustainability grows, the reputation of oil and gas companies is increasingly tied to their environmental practices. Companies that invest in waste heat recovery and other energy-efficient technologies demonstrate a commitment to reducing their environmental impact, which can strengthen their brand image and appeal to environmentally-conscious investors, stakeholders, and customers.

4. Challenges and Barriers to Adoption

While the potential for waste heat recovery in the oil and gas industry is significant, there are several challenges that can hinder the widespread adoption of these technologies.

a. High Initial Costs

One of the main barriers to the implementation of waste heat recovery systems is the high capital expenditure required for their installation. Although the long-term benefits of reduced energy costs and lower carbon emissions are clear, the initial cost can be prohibitive for some companies, particularly in smaller operations or in regions where energy prices are relatively low.

b. Technical Complexity

Integrating waste heat recovery systems into existing oil and gas infrastructure can be technically complex. The systems often require specialized components, such as heat exchangers, turbines, and generators, which need to be customized to fit the specific operating conditions of the facility. This can increase both the cost and the time required for installation.

c. Operational Variability

Waste heat recovery systems are dependent on the availability of consistent and adequate heat. In some oil and gas operations, the amount of waste heat produced can fluctuate due to changes in production processes, maintenance schedules, or seasonal variations. This variability can make it difficult to design waste heat recovery systems that operate efficiently at all times. Additionally, in situations where waste heat is intermittent or low-grade, the economics of recovery may not justify the investment.

d. Regulatory and Policy Uncertainty

In some regions, the regulatory environment surrounding waste heat recovery technologies is still developing, which can create uncertainty for companies considering these investments. Clear and stable policies, as well as government incentives for waste heat recovery, are essential for encouraging wider adoption of these systems across the oil and gas sector.

5. Looking Ahead: The Future of Waste Heat Recovery in the Oil and Gas Industry

The future of waste heat recovery in the oil and gas industry looks promising, with continued advancements in technology, growing regulatory pressures, and a greater emphasis on sustainability. As waste heat recovery technologies become more efficient and cost-effective, their adoption is likely to increase, helping the industry meet its energy needs while also reducing its environmental impact.

Further innovations in material science, system integration, and digital monitoring technologies will continue to improve the performance and economics of waste heat recovery. In particular, hybrid systems that combine multiple technologies to capture and utilize waste heat will offer new opportunities for maximizing energy efficiency.

Ultimately, the integration of waste heat recovery systems will play a crucial role in the oil and gas industry’s efforts to reduce emissions, increase energy efficiency, and contribute to a more sustainable energy future.

6. The Role of Digitalization and Smart Technologies in Waste Heat Recovery

Digital technologies are revolutionizing the way industries manage energy, and the oil and gas sector is no exception. In the context of waste heat recovery, smart technologies can enhance system performance, improve efficiency, and provide real-time data for optimization. The integration of digital tools is making waste heat recovery more intelligent, adaptive, and cost-effective.

a. Advanced Sensors and IoT

The use of advanced sensors and Internet of Things (IoT) devices allows for continuous monitoring of temperature, pressure, and flow rates in waste heat recovery systems. These sensors collect real-time data from various parts of the system, providing operators with actionable insights on system performance. By identifying inefficiencies, such as heat loss or suboptimal operation, the system can be adjusted dynamically to maximize energy recovery.

For example, sensors in heat exchangers can detect temperature fluctuations that may indicate fouling or other operational issues, prompting immediate maintenance actions. This predictive capability ensures that waste heat recovery systems operate at peak efficiency, avoiding costly downtime and reducing maintenance costs.

b. Data Analytics and Artificial Intelligence (AI)

Data analytics and AI are increasingly being applied to optimize waste heat recovery systems. By processing large volumes of data from sensors, AI algorithms can identify patterns, predict system performance under different conditions, and make real-time adjustments to improve energy capture. For instance, AI can predict fluctuations in waste heat availability and adjust recovery strategies accordingly, ensuring maximum power generation even in variable operational conditions.

Moreover, machine learning algorithms can enhance predictive maintenance by identifying trends that indicate impending equipment failure. This proactive approach to maintenance helps avoid unplanned shutdowns and reduces the risk of costly repairs, extending the lifespan of equipment and optimizing the system’s return on investment.

c. Digital Twins

A digital twin is a virtual replica of a physical asset or system that can simulate real-time conditions and performance. In the case of waste heat recovery systems, digital twins can model the entire heat recovery process, from heat capture to electricity generation. By creating a virtual model of the system, operators can simulate different scenarios, test system configurations, and optimize performance before implementing changes in the real-world system.

Digital twins can also be used to predict the performance of waste heat recovery systems under varying operational conditions, such as changes in the production process or environmental factors. This capability enables better decision-making, more accurate system design, and improved maintenance planning.

7. Industry Case Studies and Applications

Several companies and oil and gas operations have already implemented waste heat recovery technologies, demonstrating the practical benefits and value of these systems. Some notable examples include:

a. BP’s Waste Heat Recovery Project in the North Sea

BP has successfully implemented a waste heat recovery system on one of its North Sea platforms. The project uses a combination of ORC and other heat recovery technologies to capture waste heat from gas turbines and other equipment on the platform. The recovered heat is then converted into electricity, providing a significant portion of the platform’s power needs. This project has resulted in reduced fuel consumption, lower emissions, and a more reliable power supply.

b. Shell’s Motiva Refinery in the U.S.

Shell’s Motiva refinery in the United States is another example of successful waste heat recovery in the oil and gas sector. The refinery utilizes an HRSG system to recover heat from flue gases generated during refining operations. The recovered heat is used to generate steam, which drives a steam turbine to produce electricity. This system has helped the refinery reduce its reliance on external power sources and improve energy efficiency, while also reducing greenhouse gas emissions from the facility.

c. Statoil’s Waste Heat Recovery System in Offshore Platforms

Statoil (now Equinor) has implemented a waste heat recovery system on one of its offshore platforms in the North Sea. The system captures heat from gas turbines and uses it to generate electricity through an ORC system. This project has not only reduced fuel consumption and operational costs but has also provided a blueprint for similar projects on other offshore platforms. The successful implementation of waste heat recovery on offshore platforms shows the potential for these systems in harsh, remote environments.

8. The Future of Waste Heat Recovery: Challenges and Opportunities

Despite the progress made in waste heat recovery, there are still some challenges that the oil and gas industry must overcome to fully unlock the potential of this technology.

a. Overcoming Economic Barriers

The primary barrier to widespread adoption of waste heat recovery systems remains the initial capital investment. While the long-term financial benefits are evident, the upfront costs of purchasing and installing waste heat recovery systems can be significant. Many companies are hesitant to invest in these systems, especially when the return on investment may take several years to materialize.

However, as technologies improve and become more cost-effective, it is likely that the economic barriers will continue to decrease. Additionally, government incentives, subsidies, and carbon credit systems aimed at reducing emissions may provide financial support for the implementation of waste heat recovery technologies.

b. Expanding the Use of Hybrid and Integrated Systems

As the oil and gas industry continues to explore ways to enhance energy efficiency, hybrid and integrated systems will play a larger role in waste heat recovery. These systems combine multiple technologies to capture and utilize heat from various sources within a facility. For example, a hybrid system may combine an ORC unit with a conventional steam turbine to maximize electricity generation from both high and low-temperature waste heat.

The integration of waste heat recovery systems with renewable energy sources, such as solar or wind power, could also help companies create more sustainable and resilient energy systems. For example, excess heat captured from a flare stack could be stored or used to power a solar energy system, creating a hybrid solution that reduces both waste heat and emissions.

c. Regulatory Pressure and the Push Toward Carbon Neutrality

As global demand for cleaner energy continues to rise, oil and gas companies will face increasing pressure to reduce their carbon footprint. The adoption of waste heat recovery technologies will become more critical as regulatory bodies introduce stricter emissions regulations and governments implement carbon pricing mechanisms. To meet these regulatory pressures, companies must not only focus on reducing emissions through waste heat recovery but also work on improving the overall energy efficiency of their operations.

The growing push for carbon neutrality will drive investment in waste heat recovery technologies and other energy-efficient solutions, creating new opportunities for innovation and growth. Companies that invest in these technologies now will be better positioned to comply with future regulatory requirements and capitalize on the demand for cleaner energy.

Conclusion: A Sustainable and Efficient Future for the Oil and Gas Industry

The oil and gas industry faces a significant challenge in balancing energy production with environmental responsibility. Waste heat recovery provides a unique opportunity to reduce the industry’s carbon footprint while simultaneously improving energy efficiency and reducing operational costs. The continued development and adoption of waste heat recovery technologies, driven by advancements in digitalization, material science, and system integration, will play a pivotal role in shaping the future of the industry.

As oil and gas companies increasingly recognize the financial and environmental benefits of waste heat recovery, the industry is poised to make significant strides toward sustainability. By leveraging existing technologies and pursuing innovative solutions, companies can reduce emissions, increase energy security, and move closer to a more sustainable energy future.

Generating Electricity Using Waste Heat from the Mining of Minerals

The mining industry, particularly the extraction of minerals, is an energy-intensive process. With the need for heavy machinery, high temperatures, and constant operation in mining facilities, vast amounts of waste heat are produced at various stages of the mining process. Capturing and converting this waste heat into electricity is becoming a key strategy for improving energy efficiency, reducing operational costs, and lowering the environmental impact of mining operations. This practice not only helps in the efficient use of resources but also contributes to sustainable mining practices.

1. Sources of Waste Heat in the Mining Industry

Mining operations generate waste heat at various stages, primarily during the following activities:

a. Ore Processing

Ore processing, such as crushing, grinding, flotation, and smelting, involves high temperatures that lead to the production of significant amounts of waste heat. During the smelting process, for example, the heat from furnaces or kilns used to melt ore can be substantial. Often, this heat is vented into the atmosphere or dissipated without being utilized.

b. Diesel and Electricity-Driven Equipment

Mining facilities, especially those operating in remote locations, rely heavily on diesel-powered generators and heavy equipment to power their operations. These machines, such as trucks, drills, and excavation equipment, release a large amount of waste heat through their engines. In addition, electricity used for the mine’s operational activities often comes from external sources, and the production and distribution of this electricity may result in thermal losses, which can be recovered.

c. Geothermal Heat

In some mining operations, especially those that mine in geologically active regions, natural geothermal heat from the earth can be tapped. This waste heat can come from the ground itself or be generated as part of geothermal energy extraction for processes like heating water used in ore processing.

d. Ventilation Systems

In underground mining operations, ventilation systems are necessary to ensure that miners have access to fresh air and to regulate the temperature and humidity in tunnels. These ventilation systems often release warm air from deep underground, which is a valuable source of waste heat.

2. Technologies for Capturing and Converting Waste Heat

The conversion of waste heat into electricity in the mining industry requires specialized technology to capture, store, and convert the heat into usable electrical power. Several technologies are currently in use or under development for this purpose:

a. Organic Rankine Cycle (ORC) Systems

The ORC system is one of the most commonly used methods for converting low-grade waste heat into electricity. The system works by using an organic fluid with a low boiling point, which allows it to vaporize at relatively low temperatures. The organic fluid is heated by the waste heat from mining operations, causing it to vaporize and drive a turbine connected to a generator, thus producing electricity. ORC systems are well-suited for mining operations because they can efficiently operate at low to medium temperatures, typically between 80°C and 350°C, which is common in many mining waste heat sources.

ORC technology is particularly effective in scenarios where the waste heat is not hot enough for traditional steam turbines but is still significant enough to be utilized for power generation. In addition, the compact nature of ORC systems makes them ideal for installation in remote or space-constrained mining environments.

b. Steam Rankine Cycle (SRC) Systems

For mining operations where higher temperature waste heat is available (typically above 300°C), the Steam Rankine Cycle (SRC) system can be used. In this system, waste heat is used to produce steam, which drives a steam turbine connected to a generator. SRC systems are capable of generating electricity from higher temperature waste heat, making them suitable for operations such as ore smelting, where the heat produced can exceed 600°C.

One of the key benefits of SRC systems is their ability to produce larger quantities of electricity compared to ORC systems. However, they require more complex and expensive infrastructure, including a boiler to produce steam, which can increase the initial capital cost of the project.

c. Thermoelectric Generators (TEGs)

Thermoelectric generators (TEGs) are devices that directly convert heat into electricity through the Seebeck effect, where a temperature difference across a material leads to the generation of an electrical voltage. While still in the early stages of commercialization, TEGs have the potential to be used in mining operations where waste heat is abundant but difficult to capture using traditional methods.